Patents

Literature

121 results about "Aluminium casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

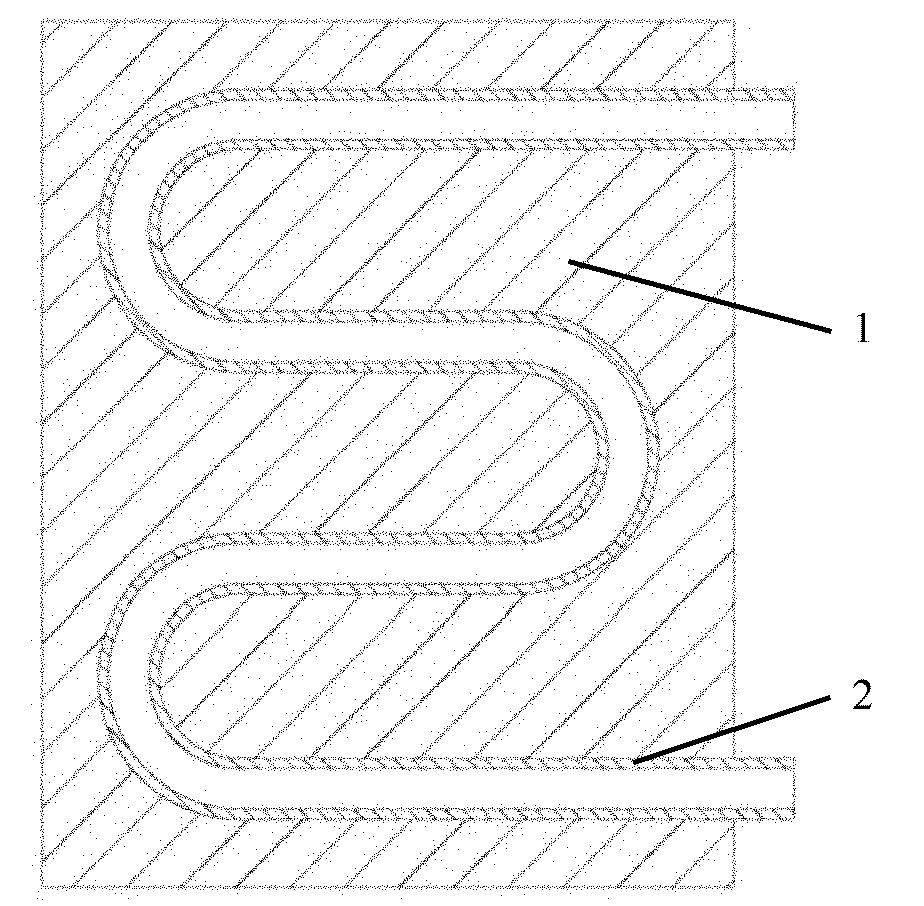

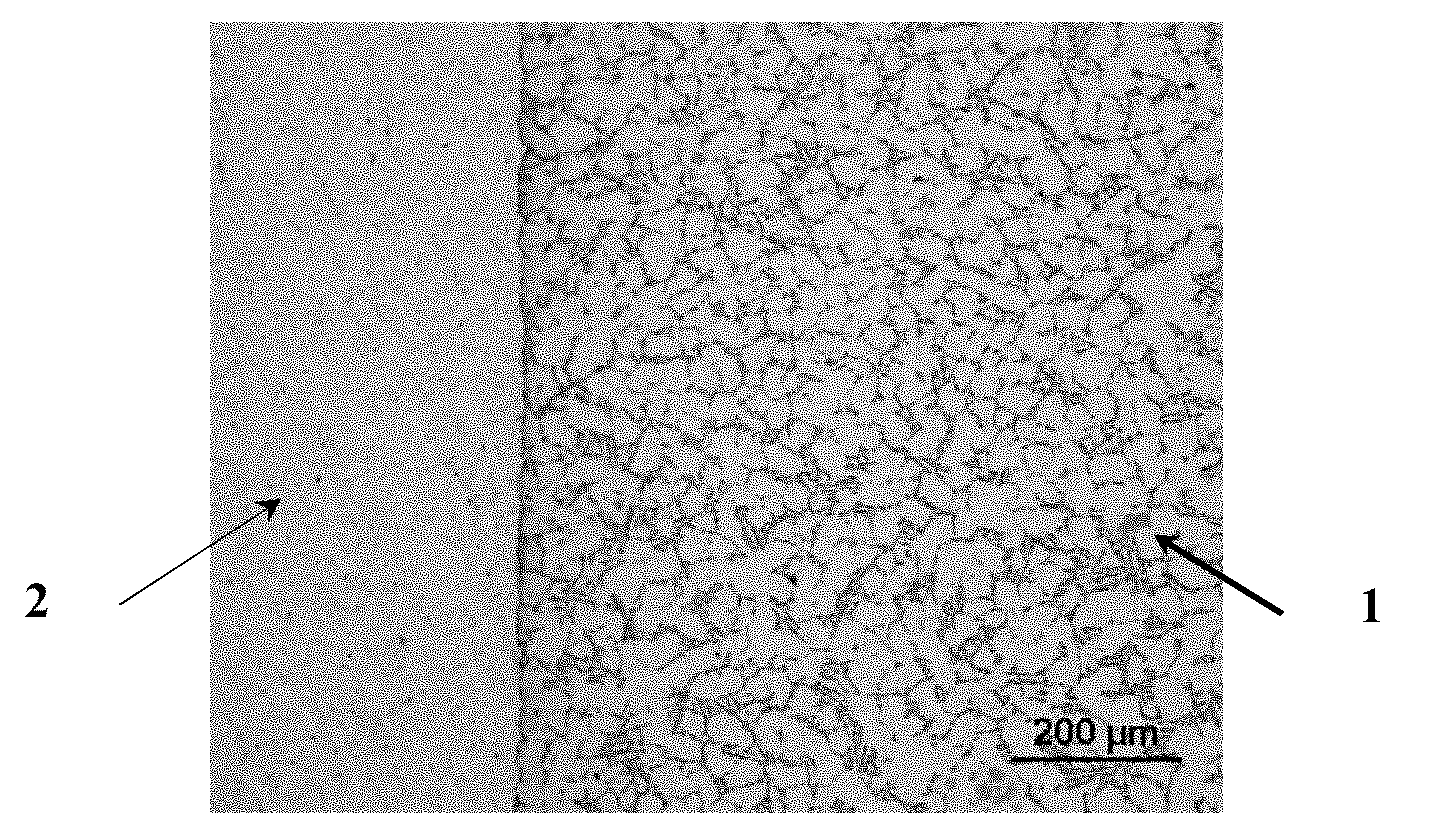

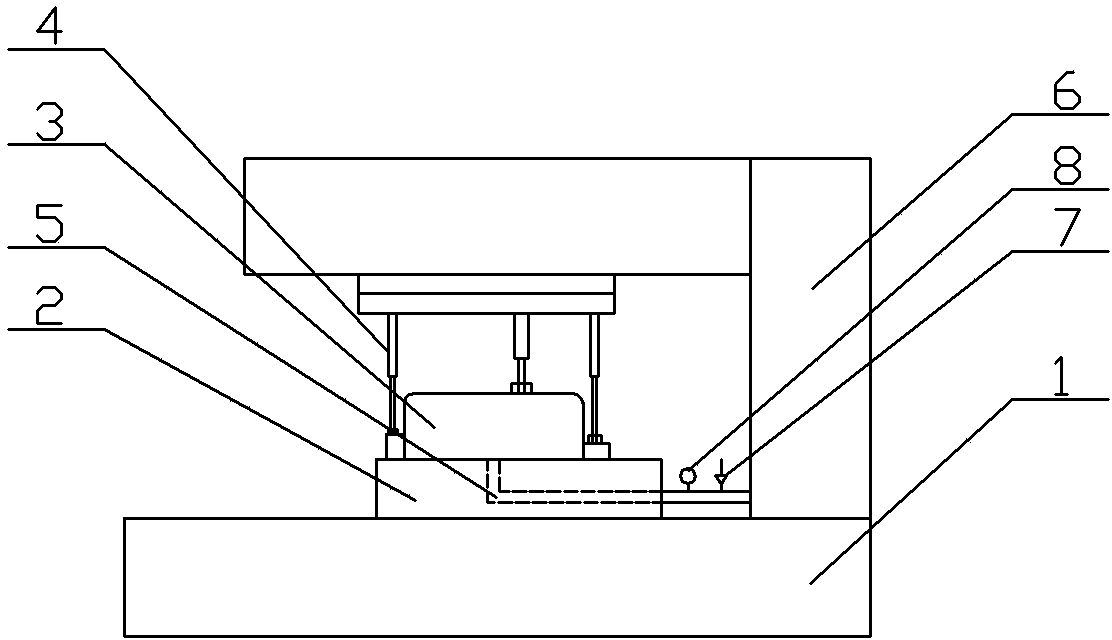

Composite casting method of aluminum cooling plate

InactiveCN102069172AAchieve near net shapeReduce consumptionSemiconductor/solid-state device detailsSolid-state devicesAviationMetallic materials

The invention relates to a composite casting method of an aluminum cooling plate, belonging to the field of metal materials. The composite casting method comprises the following steps: fixing industrial pure aluminum or an aluminum alloy pipe which is used as a cooling liquid passageway in a mold cavity; and then fully filling liquid or semi-solid aluminum alloy melt in the mold cavity and coagulating, so as to prepare the aluminum cooling plate. By using the composite casting method, the problem that when the aluminum alloy is casted in an aluminum tube, a casting is wasted because the aluminum tube is melted and deformed is solved, thereby achieving the near-net forming of the aluminum cooling plate, reducing the consumption of materials for subsequent processing procedures and improving the production efficiency. Because the aluminum tube and an aluminum cooling plate substrate are made of aluminum materials, thereby eliminating an electrochemical corrosion phenomenon; and the aluminum cooling plate can be integrally retrained or recycled, thereby reducing the waste of the material and lowering the production cost. The total density of the casting is the same as that of an aluminum casting, thus the casting can be applied to the fields of aviation, ships and the like which have strict requirements on the weights of parts.

Owner:UNIV OF SCI & TECH BEIJING

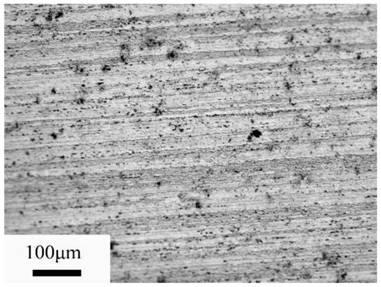

Preparation method for silicon carbide/aluminium alloy composite material for brake disc

The invention relates to the technical field of a brake disc and particularly relates to a preparation method for a silicon carbide / aluminium alloy composite material for a brake disc. The technical scheme of the preparation method is as follows: aluminium casting alloy ZAlSi8MgBe is selected and used as matrix alloy, alpha-SiC particles are selected and used as silicon carbide, and the preparation method comprises the following specific steps of: (1) reshaping of the SiC particles; (2) chlorohydric acid pickling; (3) high-temperature oxidation; (4) nitrate sensitization; (5) stir casting; and (6) T6 thermal treatment. The silicon carbide / aluminium alloy composite material prepared by the invention has the advantages of light weight, high specific strength and specific stiffness, low coefficient of thermal expansion, good thermal conductivity and wear-resistant abrasive resistance, more easiness in preparation and low cost; and the reinforced phases of the silicon carbide / aluminium alloy composite material are dispersively distributed in the matrix and have isotropy so that the silicon carbide / aluminium alloy composite material is suitable for various complex stress states.

Owner:SHANDONG ZHENGNUO GRP

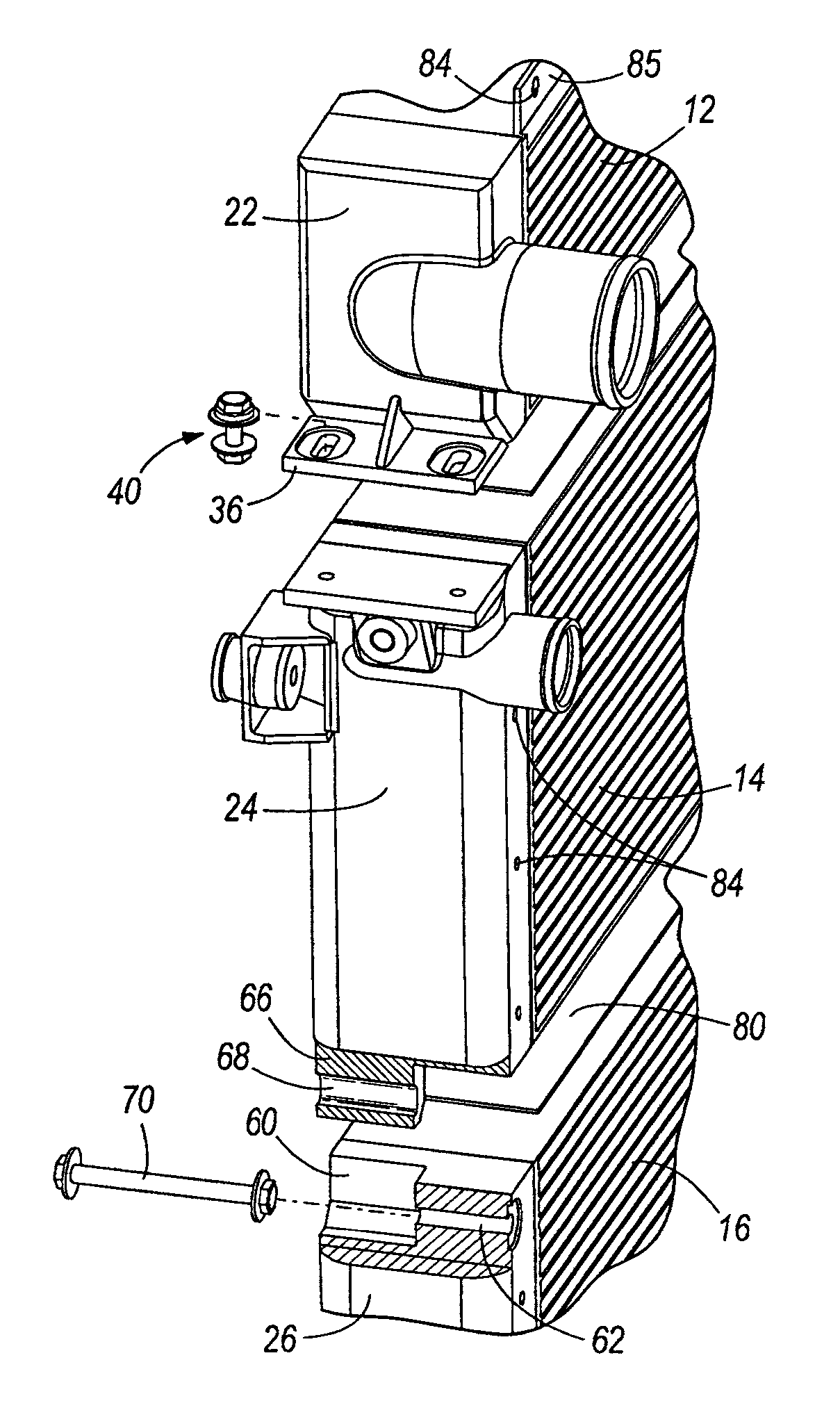

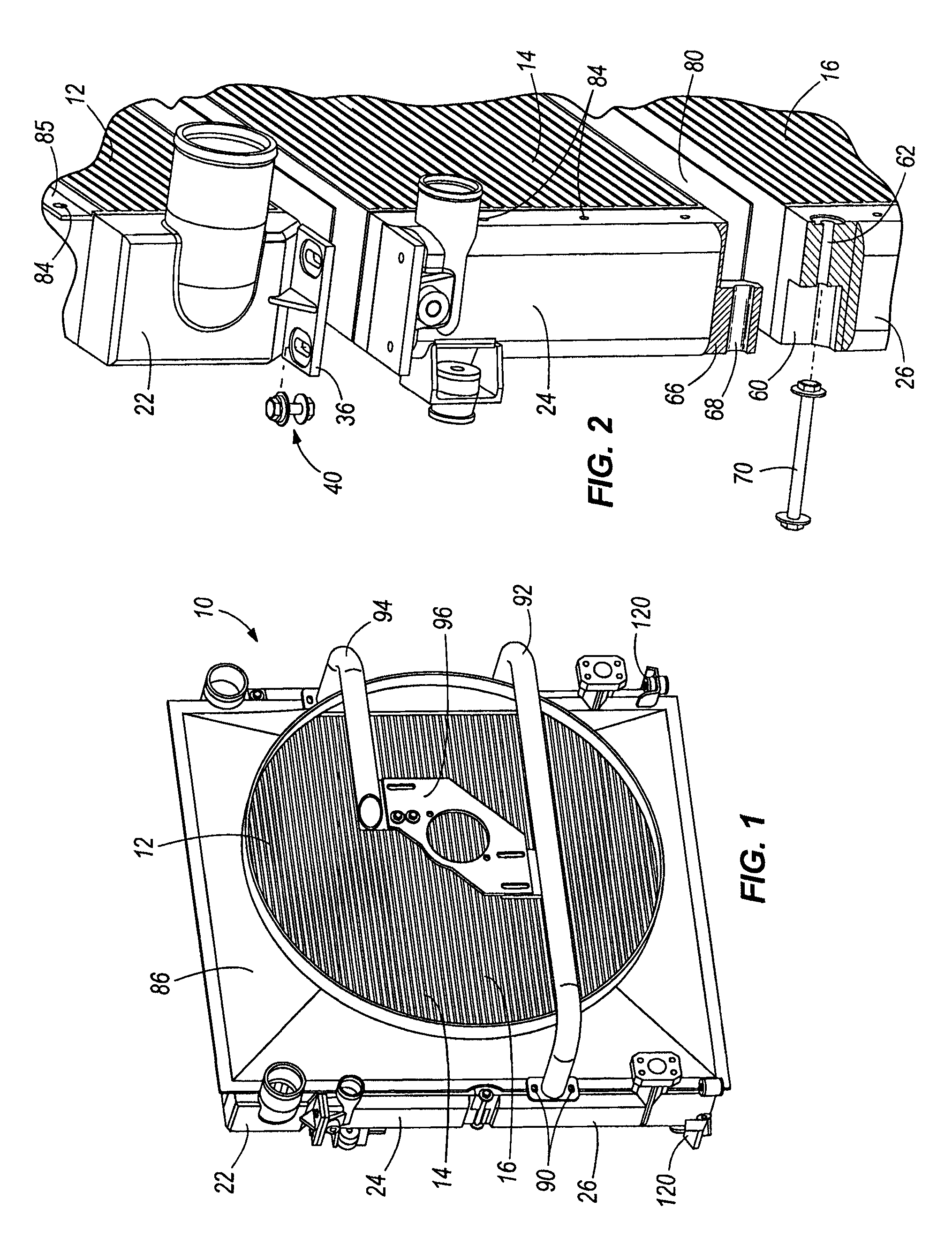

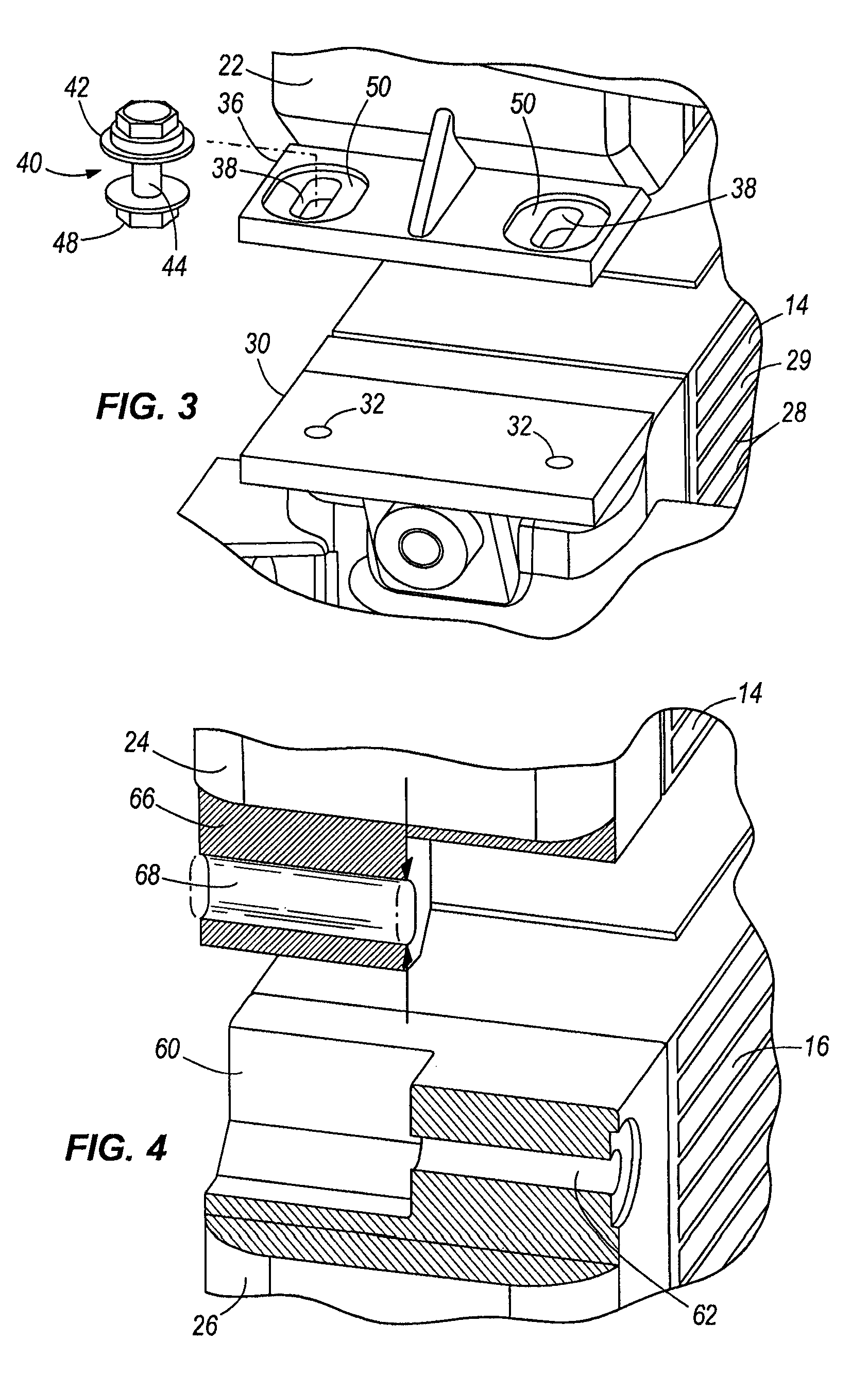

Heat exchanger block

ActiveUS8061410B2Low thermal conductivityAir-treating devicesVehicle heating/cooling devicesAluminium castingFlange

A heat exchanger block including at least two heat exchangers each including a pair of longitudinal headers with tubes extending between the headers, at least some of which are aluminum cast parts. Adjacent heat exchangers are detachably connected at adjacent ends of their headers wherein one of the adjacent headers includes a recessed portion in the adjacent end and the other of the adjacent headers includes a flange receivable in the recess of the one header. Matching holes extend through the flange and the one header end, and a fastener extends through the matching holes in the ends of at least one set of adjacent headers. Shroud attachments are along a longitudinal wall of at least one of the longitudinal headers.

Owner:MODINE MFG CO

Manufacture method of high electric superalloy conductor and product thereof

ActiveCN1924053AImprove heat resistanceImprove conductivityMetal/alloy conductorsHeat resistanceTitanium

The invention discloses a preparing method of high-conductive thermal tolerance aluminum alloy wire, which comprises the following steps: 1. adding Zr and Fe in the electric aluminium liquid (0.3-0.6% Zr, 0.10-0.25 Fe, not more than 0.08% Si, not more than 0.01% element sum of Ti, V, Mn and Cr); 2. manufacturing thermal tolerance aluminium alloy rod material through continuous aluminium casting manufacturing line; 3. setting the heading temperature at 400-430 deg.c for 50h; 4. drawing and stranding to manufacture high-conductive thermal tolerance alloy wire.

Owner:QINGDAO HANHE CABLE

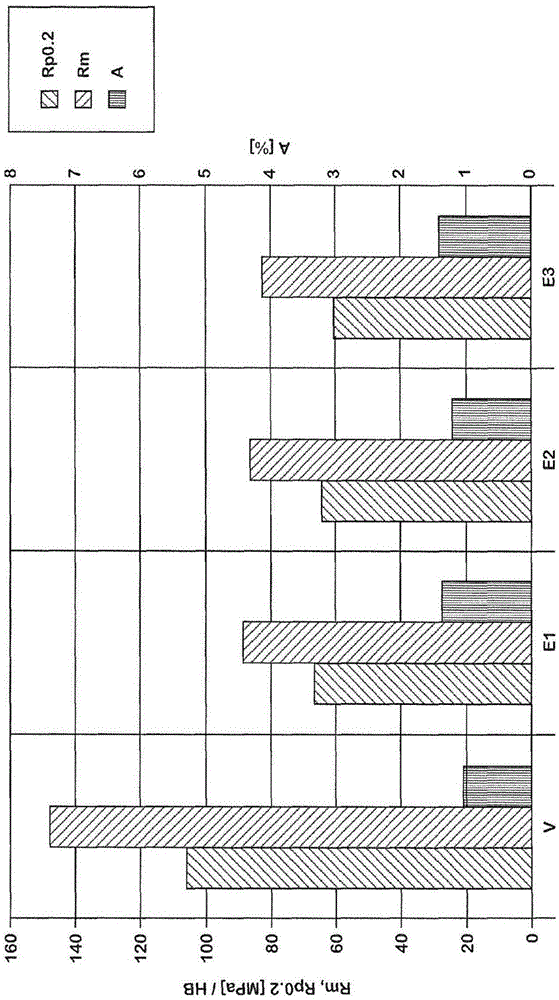

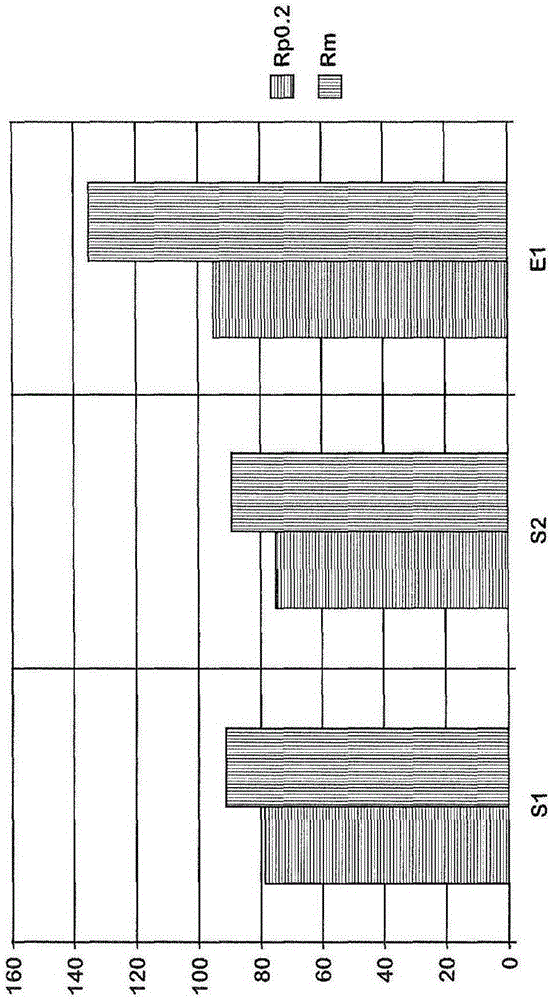

High strength Al-Mg-Si aluminium alloy and preparation method thereof

The invention belongs to the field of aluminium alloys and particularly discloses a preparation method of a high strength Al-Mg-Si aluminium alloy. The preparation method includes the steps that an aluminium casting rod is prepared; two-stage homogenizing treatment is conducted; extruding is conducted; and artificial aging is conducted, wherein the aluminium casting rod is prepared from the components in percentage by weight: 0.95%-1.1% of Si, 0.8-1.2% of Mg, 0.35-0.45% of Cu, 0.4-0.5% of Mn, 0.1-0.2% of Cr and the balance of Al. The high strength Al-Mg-Si aluminium alloy has the characteristics that the intensity is high, and the elongation rate is high, the high intensity can be achieved through short time aging, the applied range is wide, and the production efficiency of the preparationmethod is high.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

Recycling method of waste hydrochloric acid containing aluminum

The invention discloses a recycling method of waste hydrochloric acid containing aluminum and belongs to the technical field of recycling of waste acid containing aluminum. The method comprises the following steps of: (A) carrying out sand filtration on a waste hydrochloric acid washing liquid of an aluminum casting to remove suspended matters; (B) passing the waste hydrochloric acid washing liquid without the suspended matters through a fixed bed adsorption tower which is filled with strong-alkali anion exchange resin and provided with a heat insulation jacket under the conditions that the temperature is 5-45 DEG C and the work flow is 0.5-3.0BV / h; C) adding industrial hydrochloric acid in the processed effluent liquid so that the concentration of HCl is increased to 8mol / L, and then returning the effluent liquid back to a production process to be used as an aluminum casting hydrochloric acid washing liquid for circulating use; and D) passing distilled water or deionized water which is used as a regenerating agent through a resin bed to exchange and elute aluminum complex anions on a strong-alkali anion exchange resin, so as to form an aqueous solution containing aluminum trichloride, wherein the aqueous solution containing aluminum trichloride can be directly used as a purifying agent byproduct. According to the invention, the strong-alkali anion exchange resin is applied to the treatment and resource recovery of the waste hydrochloric acid washing liquid of the aluminum casting, thereby achieving the zero emission of the waste hydrochloric acid washing liquid of the aluminum casting and realizing the complete recycling of hydrochloric acid.

Owner:张炜铭 +3

Aluminium casting alloy

A method of forming a hypoeutectic aluminium silicon alloy including the steps of: forming an aluminium melt including greater than zero and less than about 12 wt % silicon, adding 20-3000 ppm of a eutectic modifying element selected from the group consisting of strontium, sodium, antimony, barium, calcium, yttrium, lithium, potassium, ytterbium, europium and mischmetal; and either adding nucleant particles and / or causing nucleant particles to be formed in the melt, the nucleant particles being selected from the group of TiSix, MnCx, AlP, AlBx and CrBx wherein x is an integer of 1 or 2.

Owner:CAST CENT PTY LTD

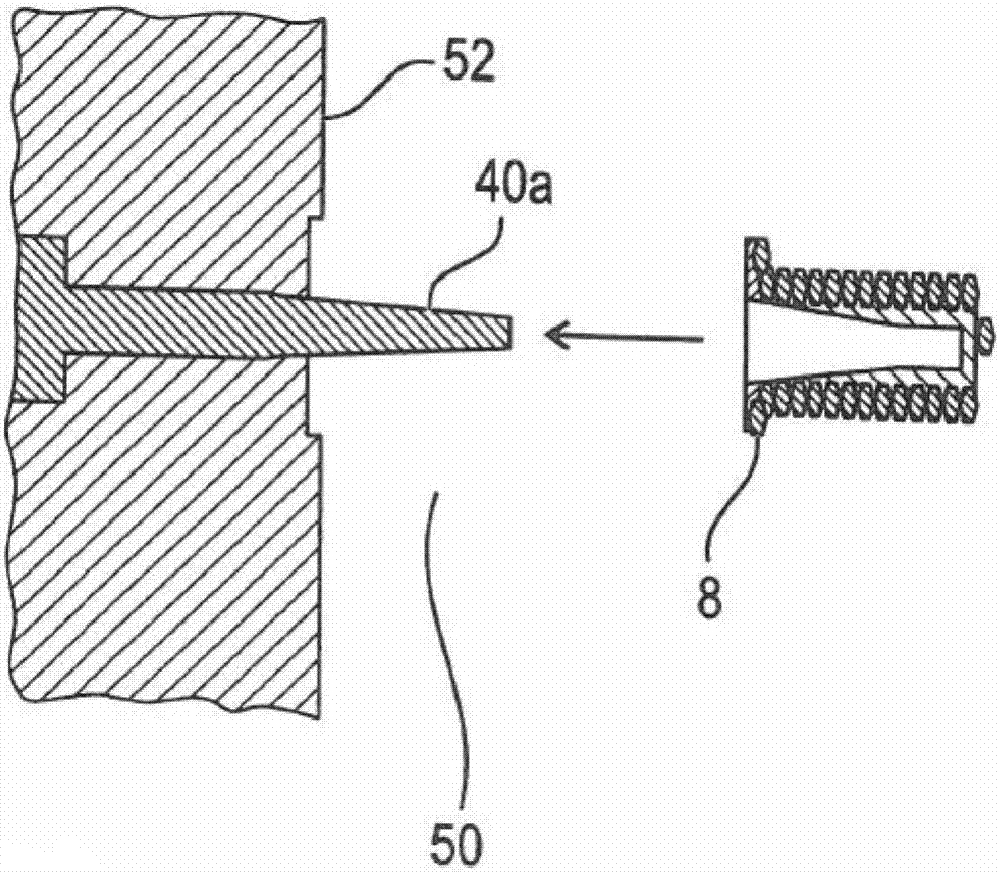

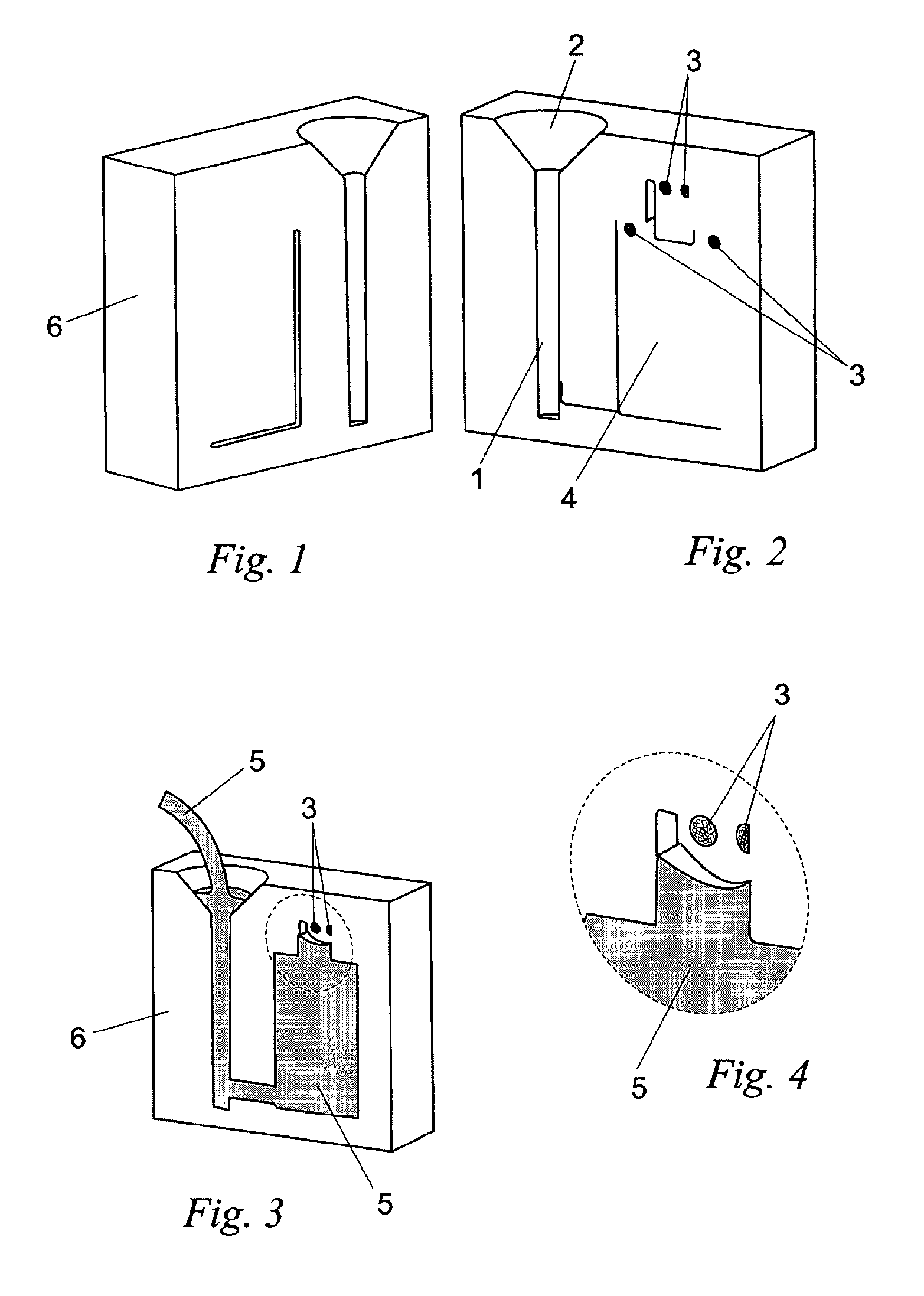

Casting mold, insert for a casting mold, a cast part and a casting method therefor

The present invention describes a metal casting method and a plastics injection molding method in which a material melt is cast around an insert in such a way that the material melt does not penetrate into the interior of the insert. The use of a wire thread insert as the insert has the advantage that threaded holes can be produced for example in a cast aluminum part already during the casting process. For this purpose, the present invention discloses the corresponding casting mold, the insert and the casting method.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH +1

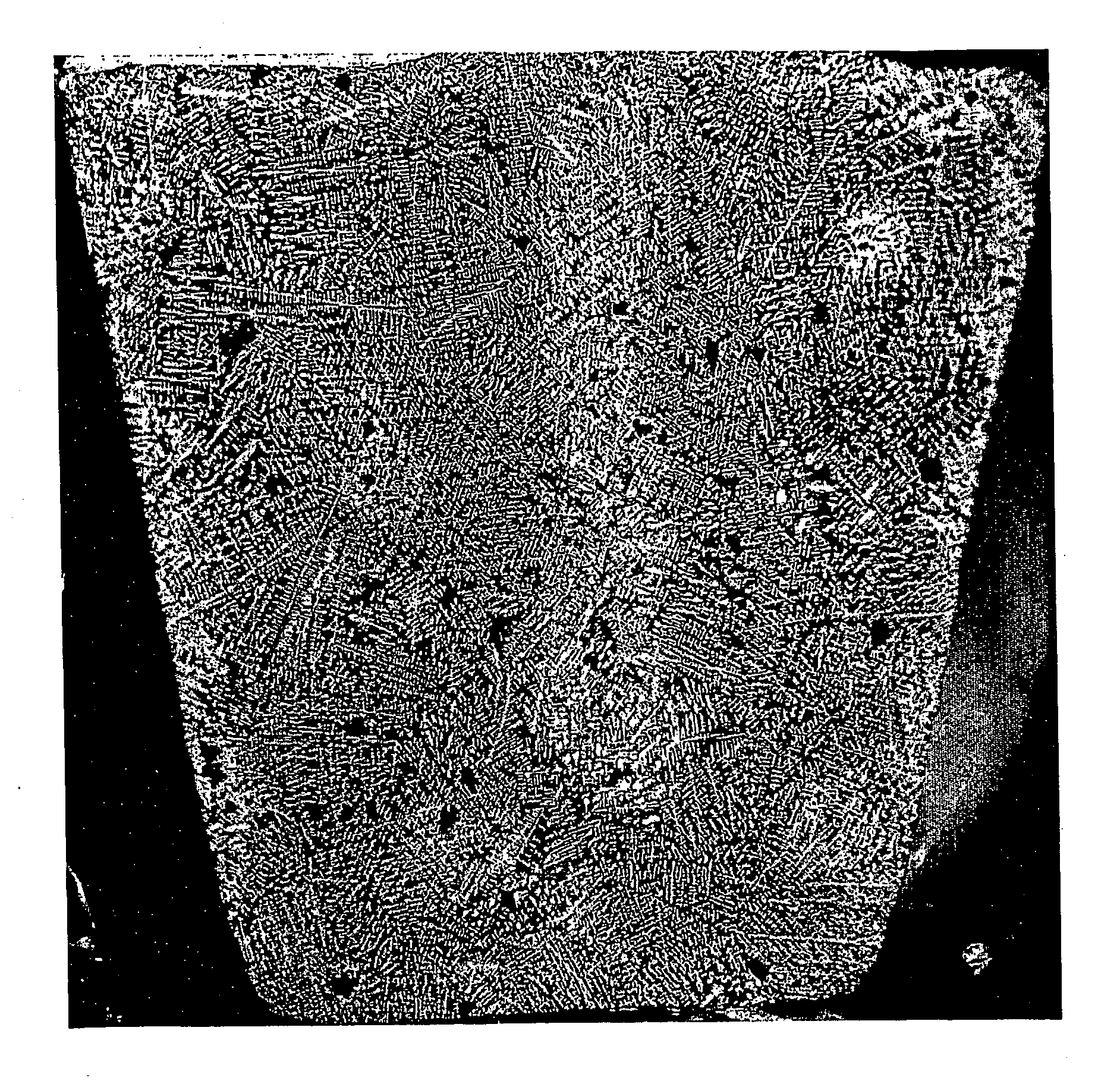

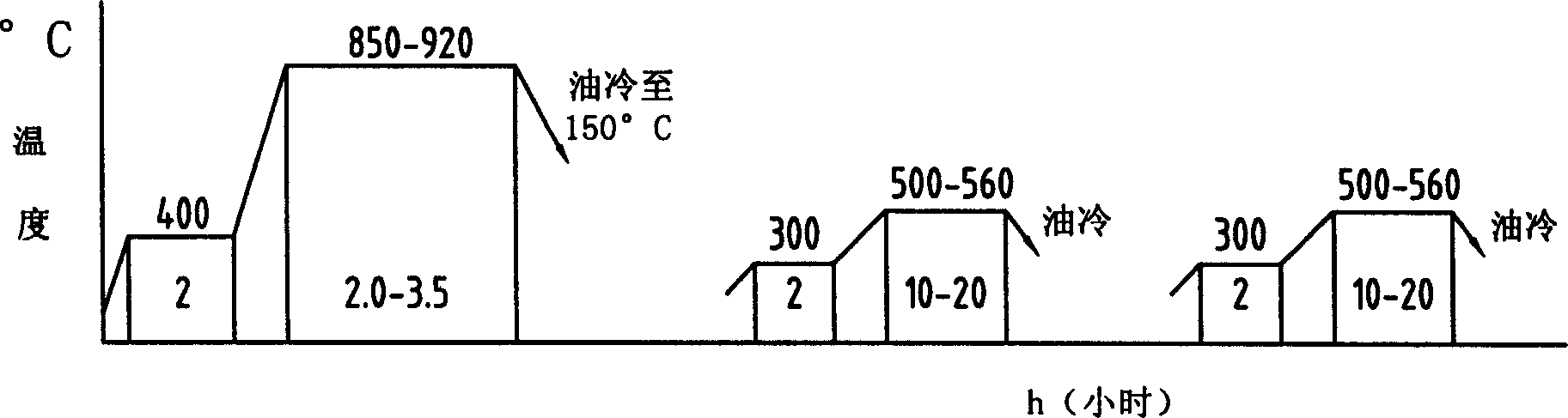

Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

InactiveCN1594636AImproved resistance to thermal fatigue cracksExtended service lifeFurnace typesHeat treatment furnacesStrip millAluminium casting

The invention relates to a roll ring steel for aluminum casting rolling mill and its heat treatment method. Chemical ingredient weight percentage of roll ring steel for aluminum casting rolling mill are : C 0.30-0.45, Mn 0.60-0.80, Si 0.20-0.40, P <=0.025, S <=0.025, Cr 2.00-3.00, Ni 0.50-1.00, Mo 0.80-1.20, V 0.10-0.20, Al <=0.012, surplus being ferrum and other impurity. The final heat treatment method of roll ring steel adopt second tempering after quenching. Quenching temperature is 850-920 DEG C , and proceeding in engine oil after heat preservation. In first tempering, roll ring is heated to 500-560 DEG C , insulated 10-20 hours, cooled in engine oil. The second tempering parameters are same with that of first tempering. The invention promotes anti heat fatigue crack capability of roll ring, so promotes the life of roll ring.

Owner:李春治

Molding material mixtures containing barium sulfate

The invention relates to molding material mixtures containing barium sulfate in combination with refractory basic molding materials and a waterglass-based binder system for producing casting molds and cores for the foundry industry in order to obtain cast pieces, in particular aluminum ones, which have an improved cast surface.

Owner:ASK CHEM LP

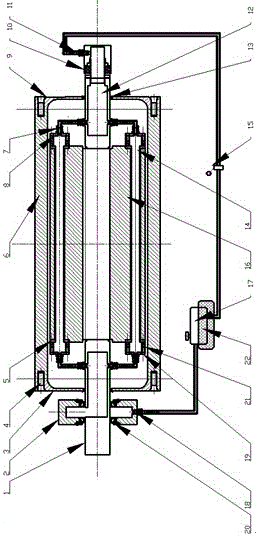

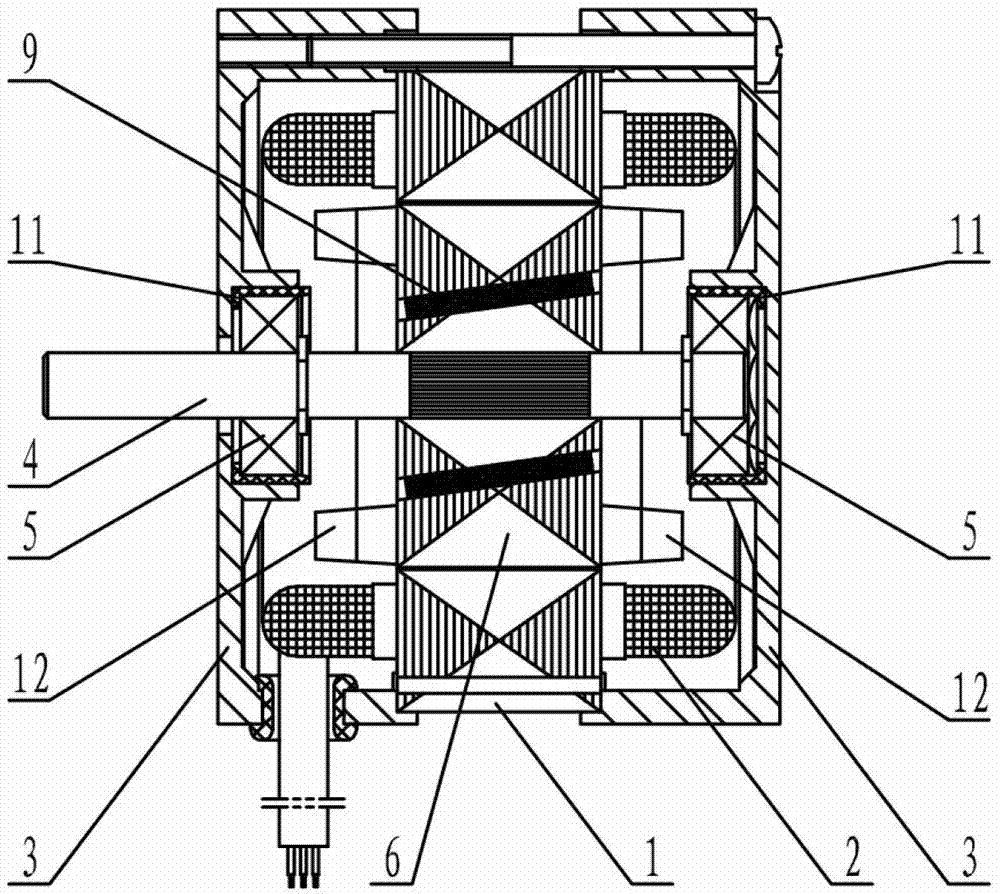

Motor rotor cooling structure

PendingCN106451863AReduce the possibility of burn-inStable mechanical propertiesMagnetic circuit rotating partsCooling/ventillation arrangementWhole bodyEngineering

The invention provides a rotor cooling structure which belongs to the field of motor cooling. A motor rotor is cooled as a whole by circulating pressed cooling oil fluid in the motor rotor. The motor rotor cooling structure comprises a high speed rotary joint, a ferrule-type pipe joint, a motor rotor body, a partially trepanned rotor shaft and the like. The high speed rotary joint comprises a bearing, a sealing ring and an external interface. The ferrule-type pipe joint comprises a ferrule, a nut, a joint body, a combined washer and the like. When aluminium casting is carried out at the corresponding position of the motor rotor body, a dummy shaft is used to cast an aluminum tube at the corresponding position of the rotor body, and a short circuit ring and the aluminum tube cast in the rotor body are cast into a whole body. A blind hole and a screw hole which fixes the ferrule-type pipe joint are arranged in the corresponding position of the partially trepanned rotor shaft. An oil collector comprises an oil collecting tank and a skeleton seal. According to the invention, the overall rotor body is cooled by the cooling oil fluid; the possibility of burning is reduced; the hidden danger of cooling fluid leakage is avoided; the vibration noise of a motor is reduced; and the service life of the motor is prolonged.

Owner:CHANGCHUN UNIV OF TECH

Centrifugal aluminium casting method of cage type rotor of motor

InactiveCN102430734AAvoid air holesPrevent shrinkageManufacturing stator/rotor bodiesElectric machineAluminium casting

The invention provides a centrifugal aluminum casting method of a cage type rotor of a motor. The centrifugal aluminum casting method comprises the following steps of: 1, preheating a rotor iron core; 2, preheating an aluminum casting die; 3, melting aluminum; 4, centrifugally casting: clamping the rotor iron core and the aluminum casting die which reach preheating requirement onto a centrifugal machine, starting the centrifugal machine to stably rotate according to a set initial rotating speed, rapidly injecting aluminum liquid from an upper die sprue of the aluminum casting die at the time, starting a centrifugal machine accelerating button when a die cavity is filled with the aluminum liquid, so that the centrifugal machine rotates according to the set full speed; and 5, dismantling the die after the centrifugal machine naturally stops and the aluminum liquid is solidified. The centrifugal aluminum casting method disclosed by the invention gives different centrifugal machine rotating speeds according to rotors of different diameter sections and effectively avoids castings from generating object quality defects, such as air pores, shrinkage cavities, tissue loosening and the like.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Aluminium casting alloy cylinder cap

InactiveCN101644203AImprove fatigue strengthReduce wearCylinder headsCylindersSolution treatmentChemical composition

The invention relates to an aluminium casting alloy cap, comprising the following chemical components by weight percent: 8-10% of Si, 2-3% of Cu, 0.15-0.35% of Mg, less than 0.3% of Mn, less than 0.45% of Fe, the balance Al. The hardness of the cylinder cap is 100-130HBS. The material adopted by the aluminium casting alloy cap of the invention is on the basis of aluminium-silicon alloy, micro elements of Fe, Cu, Mg and the like are added to form more Mg2Si, Al3Mg2, CuAl2 and the like, so that strengthening phase is formed in the alloy, and grain structure is refined by solution treatment, thusimproving comprehensive mechanical property of material and meeting requirement of high boost high performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

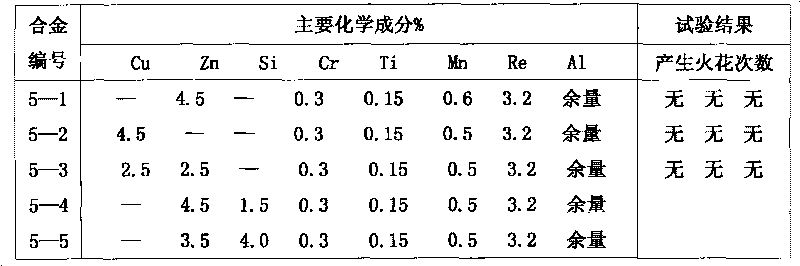

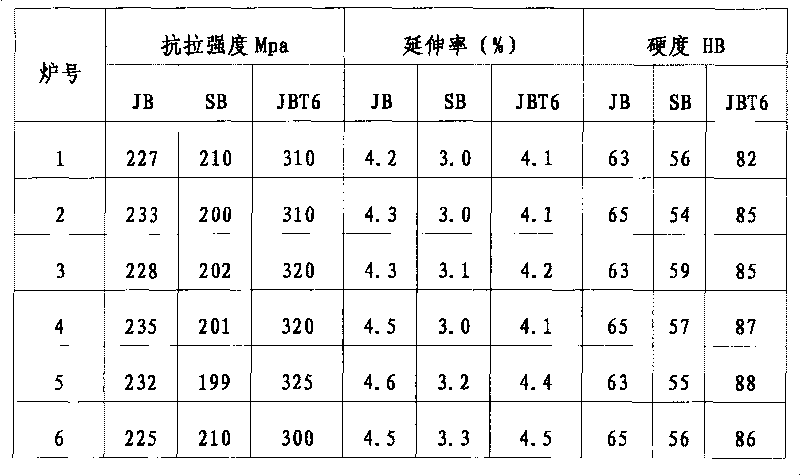

Friction no-spark aluminium casting alloy for mine fanparts

The invention discloses friction no-spark aluminium casting alloy for mine fan parts, relating to aluminium casting alloy materials. The friction no-spark casting aluminium alloy comprises the following components in percentage by weight: 1.0-2.5 percent of Zn, 2.5-6.0 percent of Cu, 0.1-0.3 percent of Cr, 0.1-0.15 percent of Ti, 0.3-0.8 percent of Mn, 2.5-4.5 percent of Re (rare earth elements), not more than 1.5 percent of Si, not more than 0.5 percent of Mg, not more than 0.5 percent of Fe, and the balance of Al. The invention solves the problems of difficult smelting operation, high cost, hard realization in traditional technology, and has the advantages of favorable safety of friction sparks, little material components, low cost, simple batching and convenient implementation.

Owner:山西省运城安瑞节能风机有限公司

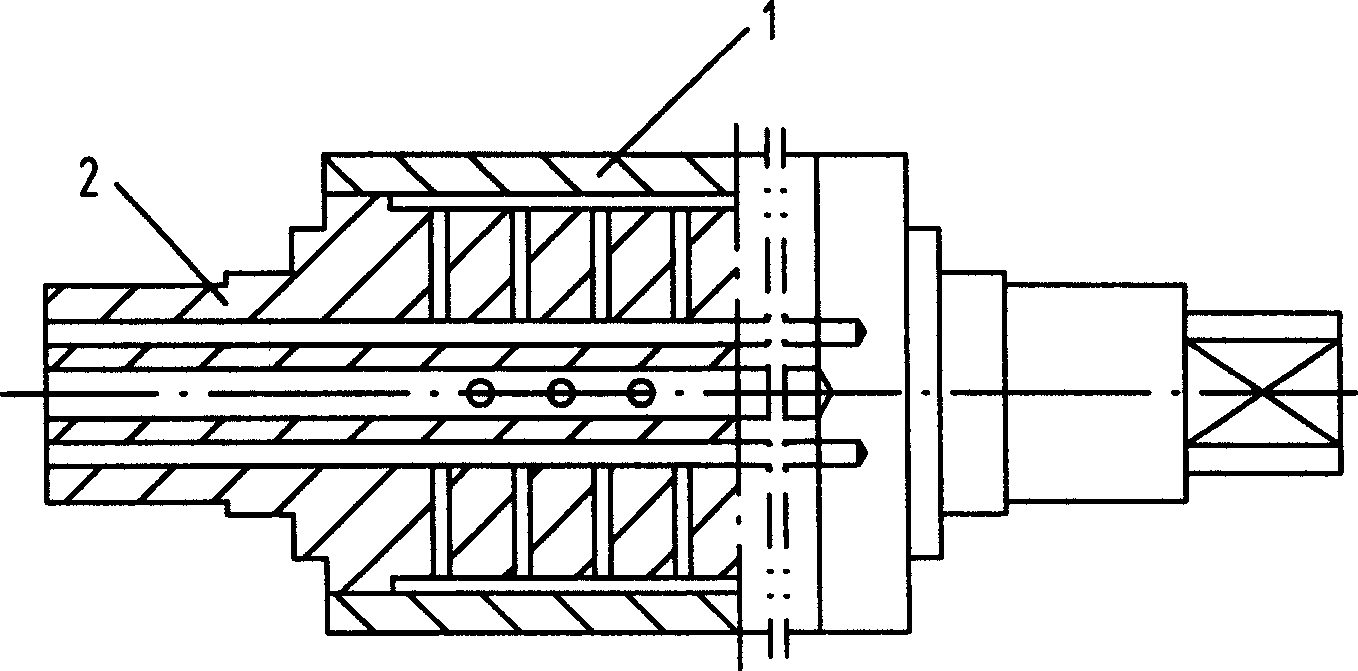

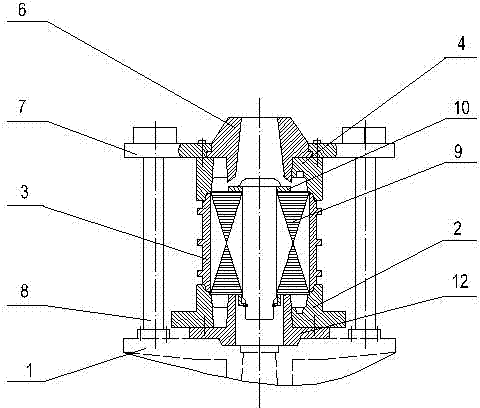

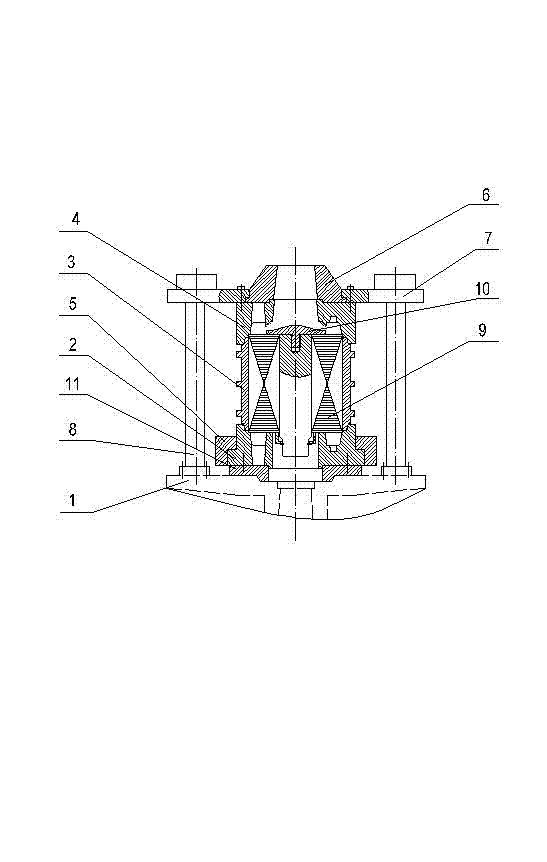

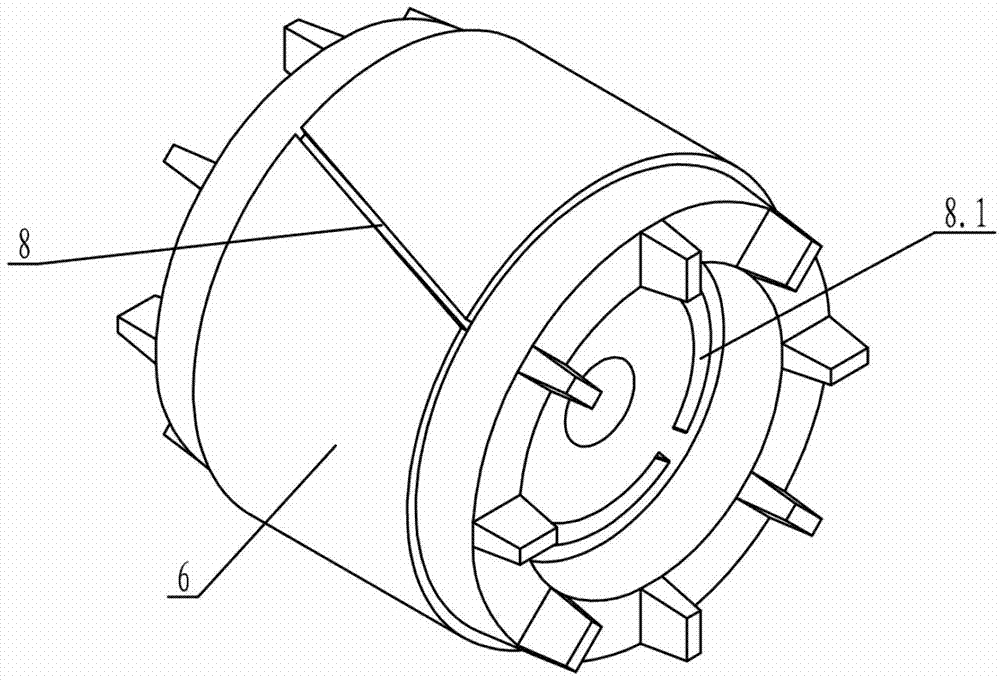

Centrifugal aluminum casting die for shaftless rotor of motor

InactiveCN103192049AQuality improvementSimple structureManufacturing stator/rotor bodiesElectric machineAluminum can

The invention relates to a die, and aims to solve the technical problem in a conventional die for centrifugally casting aluminium to a shaftless rotor of a motor. The practical scheme is that a centrifugal aluminium casting die for a shaftless rotor of a motor is provided, and comprises a low die, a lower die bearing plate, a middle die and an upper die, wherein the lower die and the lower die bearing plate are arranged on a turntable; the middle die is arranged on the lower die; the upper die is arranged on the middle die; a sprue bushing is mounted on the upper die; a rotor core is mounted in the middle die; and a ventilation hole cover plate is mounted at the top of an aluminum casting shaft of the rotor core. The centrifugal aluminum casting die is characterized in that the lower die and the lower die bearing plate are matched and connected through a spigot; the upper die and the sprue bushing are matched and connected through a spigot; and the ventilation hole cover plate at the top of the aluminum casting shaft is in threaded connection with the aluminum casting shaft. The centrifugal aluminum casting die has a simple structure, is low in cost, reasonable in process, and higher in production efficiency and practical efficiency, ensures the aluminum cannot enter into the ventilation hole, improves the shaftless rotor quality, and reduces the production cost.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

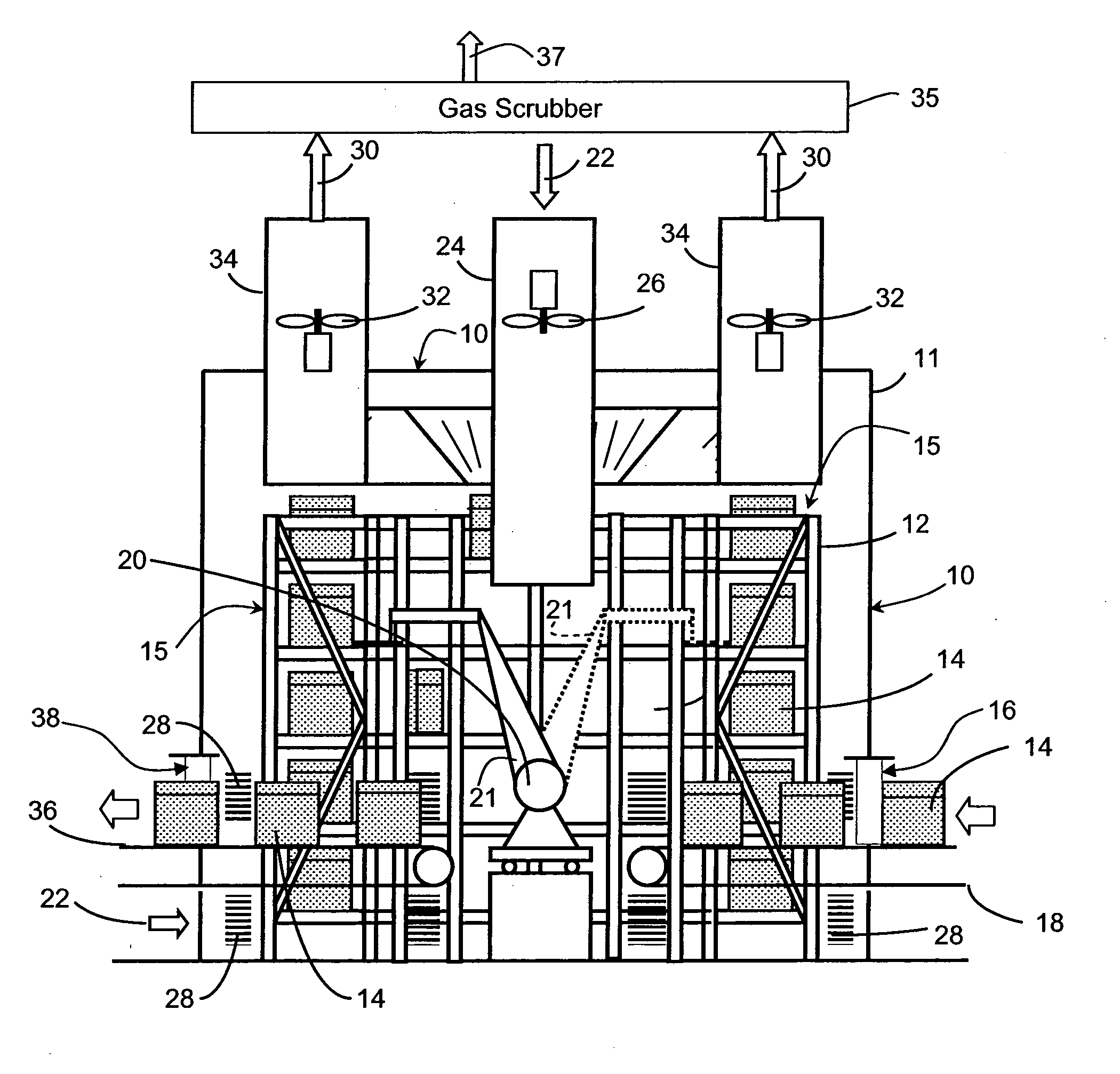

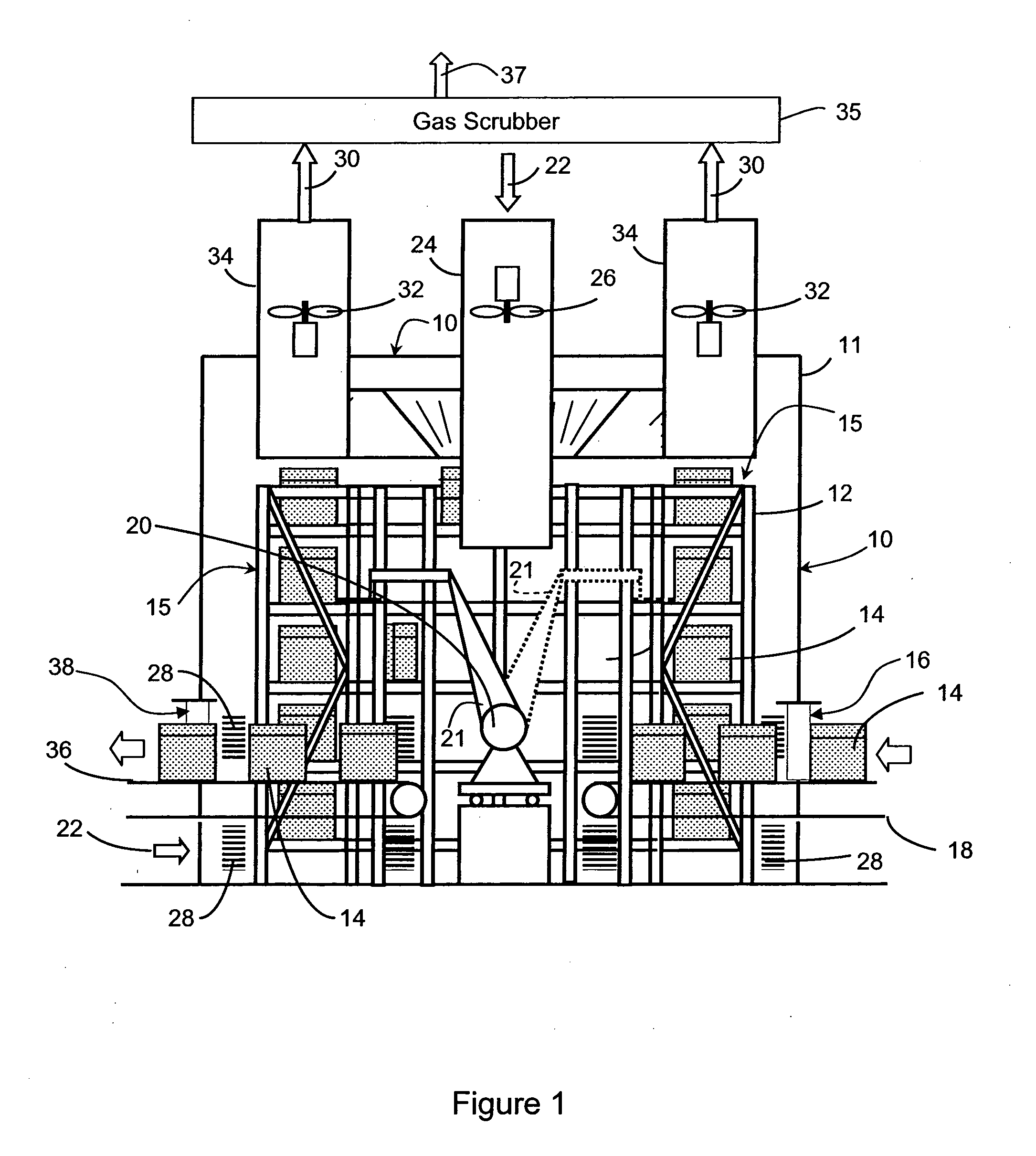

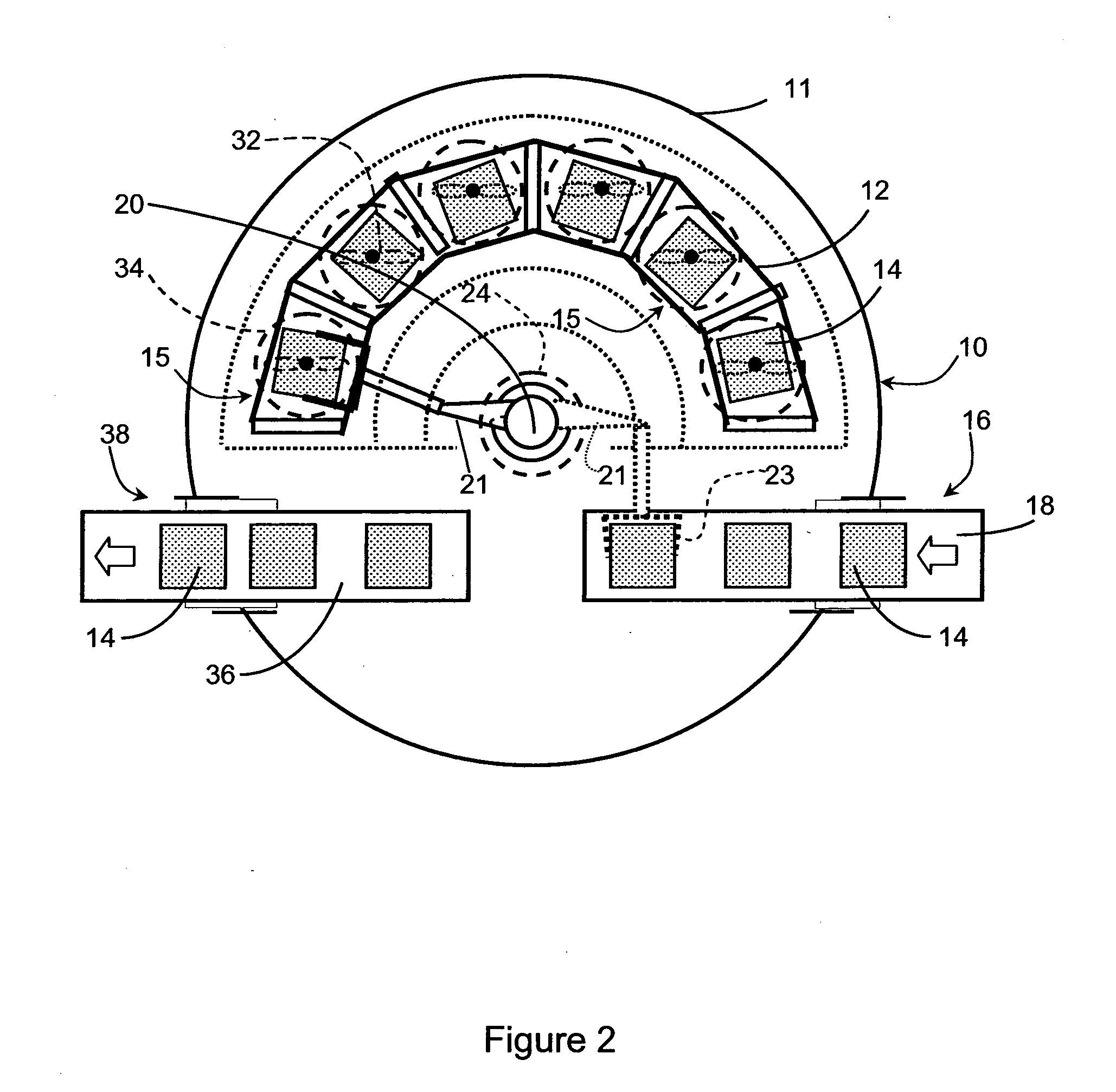

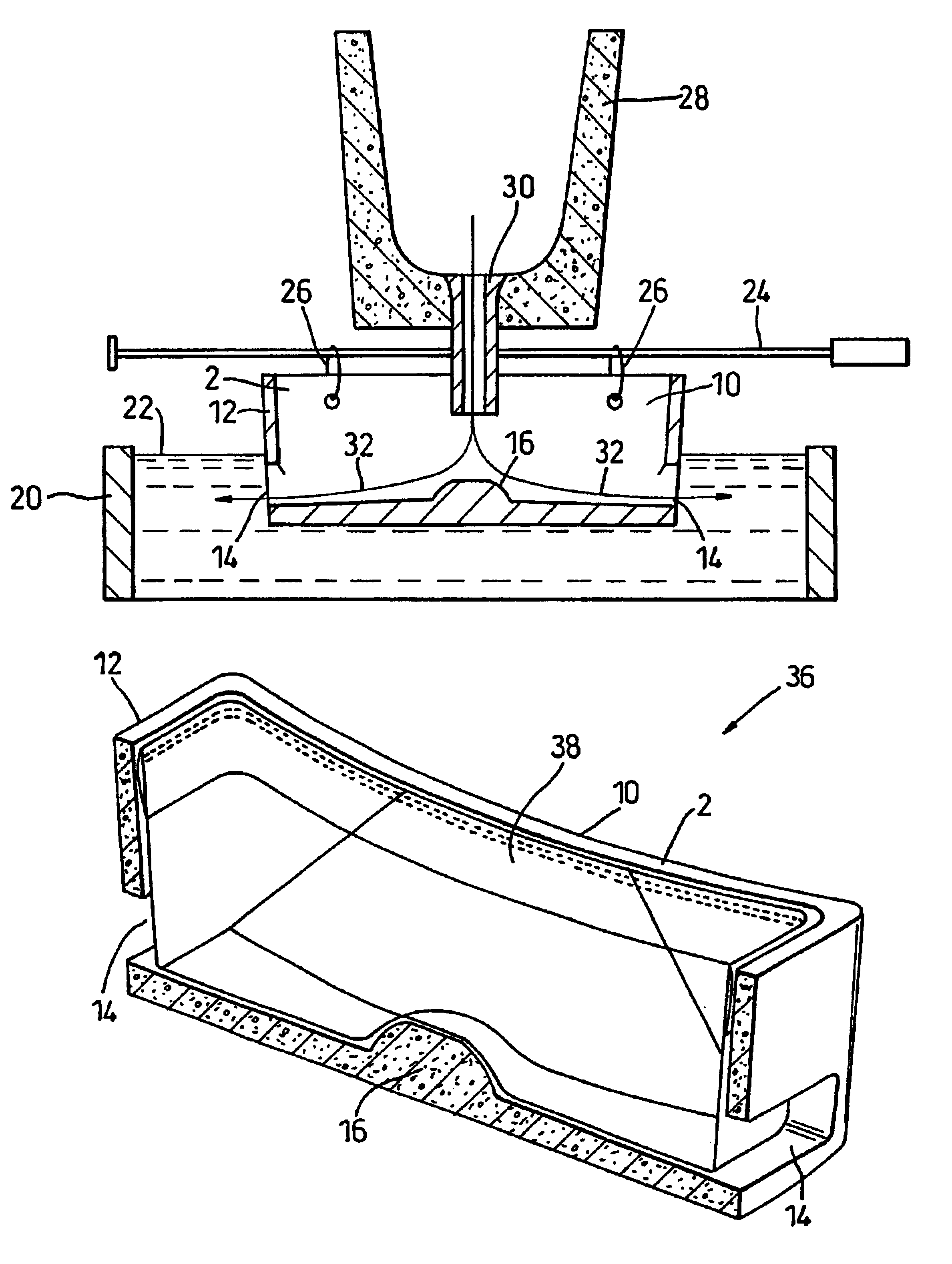

Automated system for improved cooling of aluminum castings in sand molds

InactiveUS20110303385A1Cleaner ambient atmosphereSave spaceMelt-holding vesselsCasting plantsPhysical propertyMolten metal

An improved and efficient method and apparatus for convective cooling of cast sand molds containing molten metal, utilizing vertically-arrayed cooling stations (preferably arranged on a plurality of shelves inside a housing enclosure for temporarily storing said sand molds during their cooling from a molten temperature level to a lower solidification temperature. A draft of cooling air is circulated through said stations in said housing whereby the time for solidifying the molten metal in said cast sand molds is reduced as compared with passive air cooling of said molds. Robot means are provided for moving hot sand molds from a feeding port in said housing to said shelves and for moving cooled sand molds from said shelves to a delivery port in said housing. The robot means is programmed so that the time period of each mold is maintained within said housing according to the individual time required for the solidification of the metal in such individual mold (based on empirical data for typical solidification required for the given individual cast sand mold package or based on other appropriate discernible physical property attributable to achieved solidification).

Owner:TENEDORA NEMAK SA DE CV

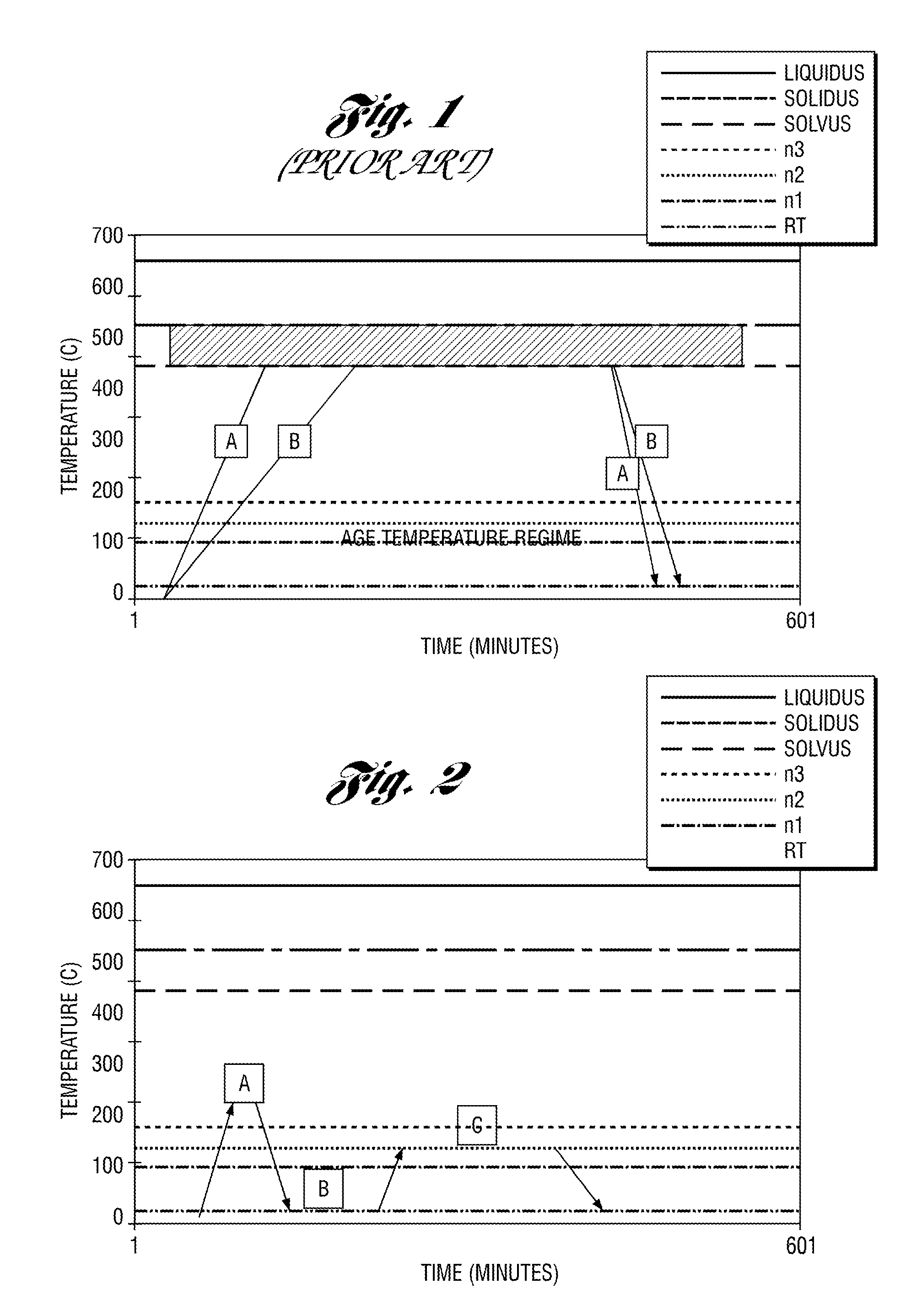

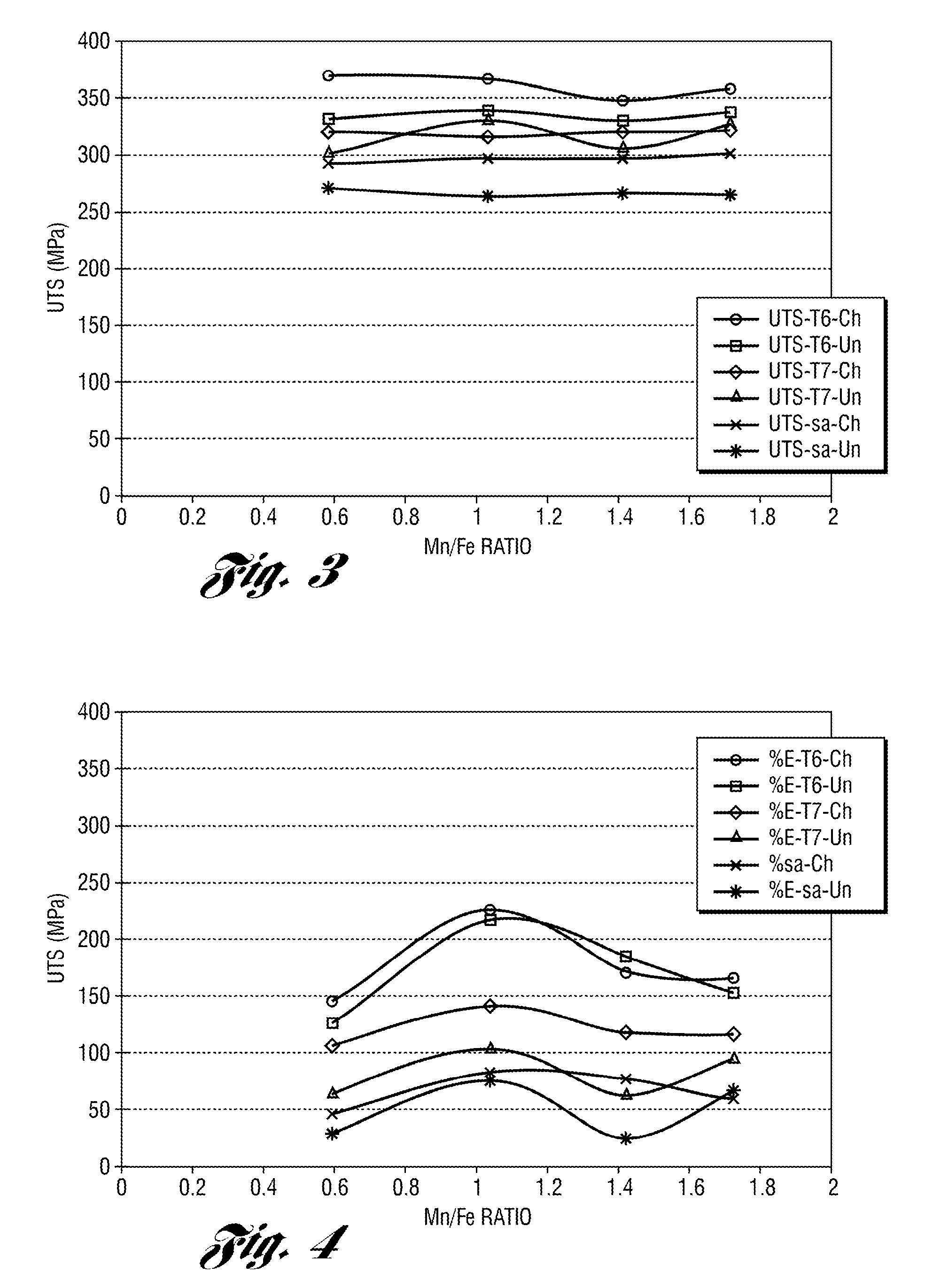

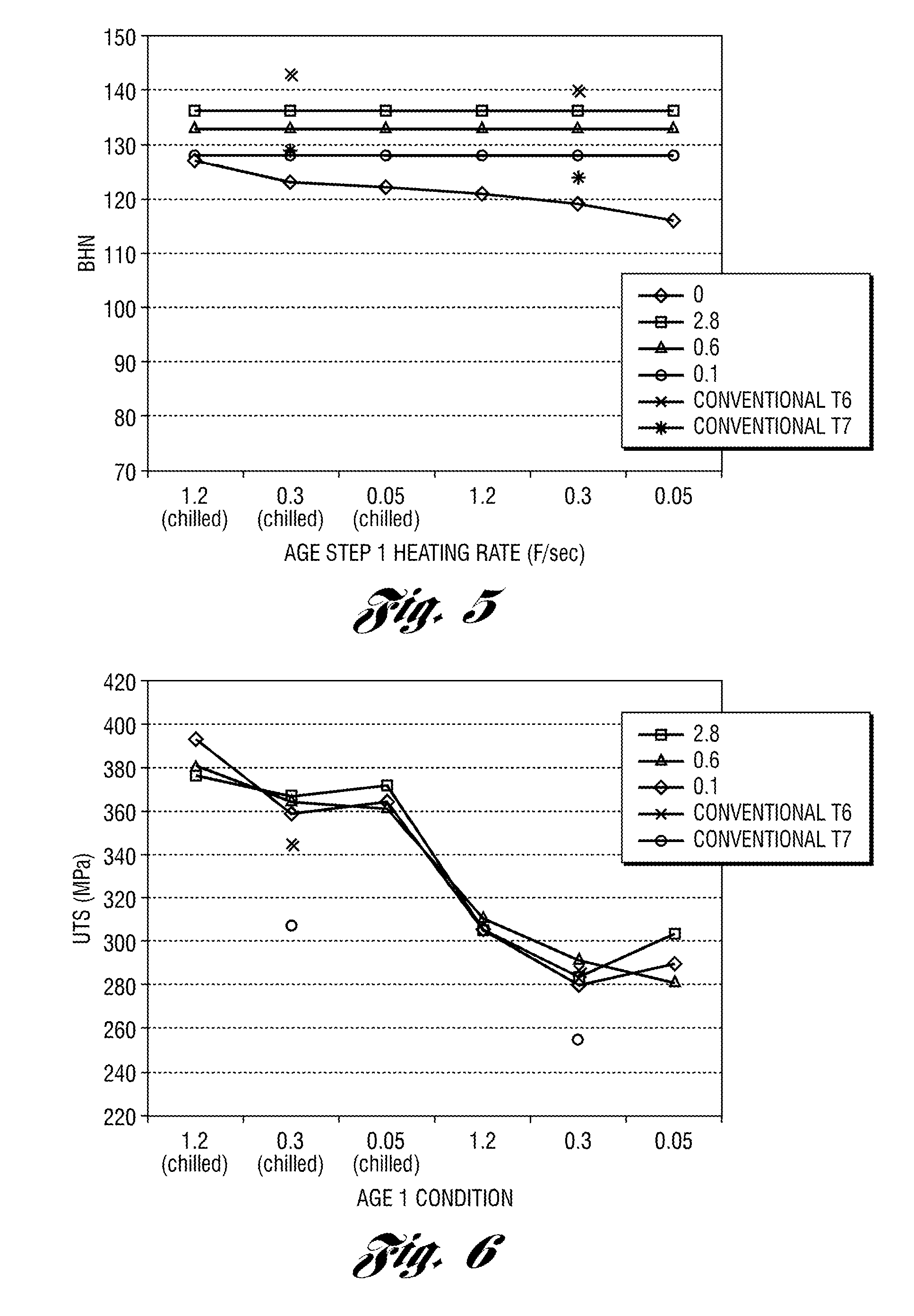

Sequential aging of aluminum silicon casting alloys

Aluminum castings having increased elongation and tensile strength are obtained by sequential aging a solutionized casting followed by rapid heating to nucleation temperature followed by rapid cooling, then reheating to precipitate growth temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

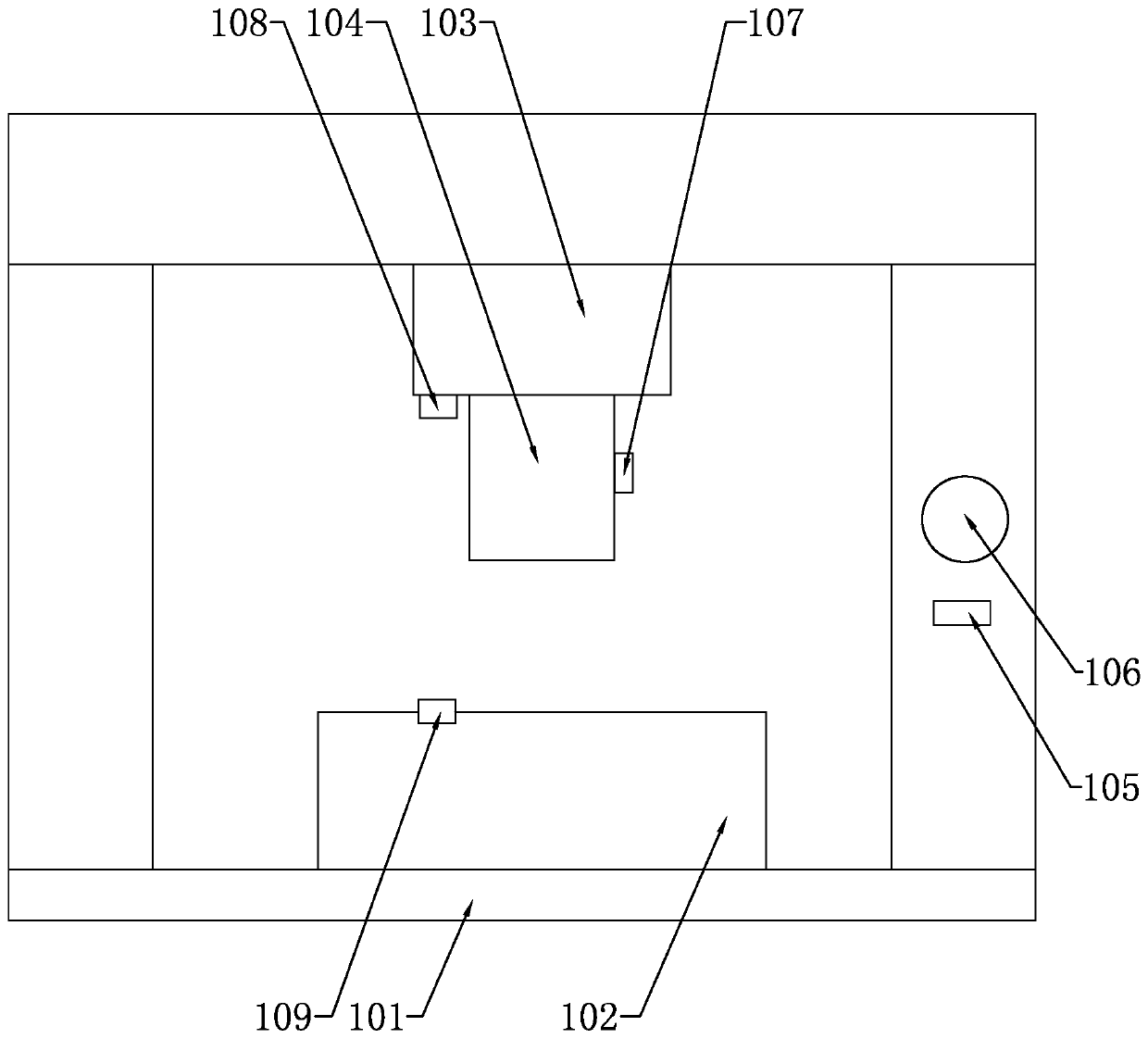

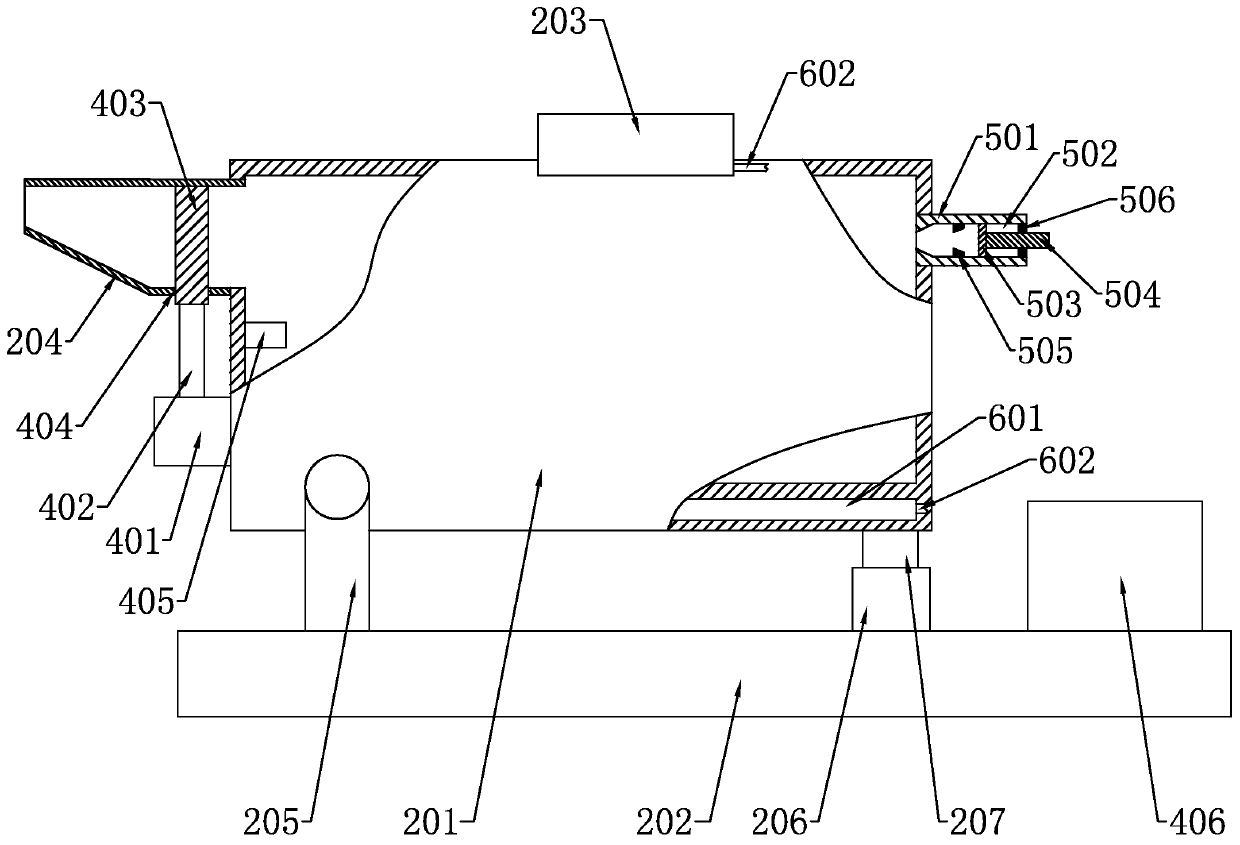

Aluminium casting air tightness detector

InactiveCN103630305AAir tightness judgmentExtended service lifeMeasurement of fluid loss/gain rateSolenoid valveEngineering

The invention relates to a part air tightness detector, in particular to an aluminium casting air tightness detector which comprises a detecting set and a base arranged on the detecting set, wherein the upper surface of the base is provided with a matching surface matched with a sealing connection surface of an aluminium casting, a hydraulic ejector rod for extruding an aluminium casting connecting screw hole is arranged above the base, the base is provided with a vent which corresponds to the cavity of the aluminium casting, and the vent is connected to a compressor by a vent pipe on which a solenoid valve and a barometer are connected in series. By adopting the air tightness detector disclosed by the technical scheme of the invention, the detection speed is fast, and seal levels can be detected quantitatively.

Owner:重庆顺多利机车有限责任公司

Motor rotor for refrigerator compressor

InactiveCN102957234AGuaranteed uptimeAvoid temperature riseMagnetic circuit rotating partsCooling/ventillation arrangementElectrical conductorEngineering

The invention provides a motor rotor for a refrigerator compressor, comprising a rotor main body, wherein the rotor main body is formed by combination of a rotor iron core, an aluminium-casting upper-end ring, an aluminium-casting lower-end ring and secondary conductor aluminium; the rotor iron core is formed by lamination of a plurality of silicon steel pieces; the rotor iron core is provided with an aluminium filling hole; the aluminium-casting upper-end ring and the aluminium-casting lower-end ring are respectively positioned at the two ends of the rotor iron core; the secondary conductor aluminium is filled into the aluminium filling hole to connect the aluminium-casting upper-end ring, the rotor iron core and the aluminium-casting lower-end ring into a whole structure; the rotor iron core, the aluminium-casting upper-end ring and the aluminium-casting lower-end ring are respectively provided with an iron core inner hole, an upper-end ring inner hole and a lower-end ring inner hole which are coaxial; the end surface of the aluminium-casting upper-end ring is provided with at least two riveting columns; a radiating fan is provided with an installing ring piece and at least two blades which are connected and uniformly arranged on the installing ring piece; the installing ring piece is provided with installing-ring-piece penetrating holes corresponding to the riveting columns and is provided with an equal-diameter middle hole corresponding to the upper-end ring inner hole; and the radiating fan is fixed on the aluminium-casting upper-end ring by the ring-piece penetrating holes and the riveting columns. The motor rotor provided by the invention has the advantages of strong popularity, good radiating effect and easiness in manufacture.

Owner:WANBAO GROUP COMPRESSOR CO LTD

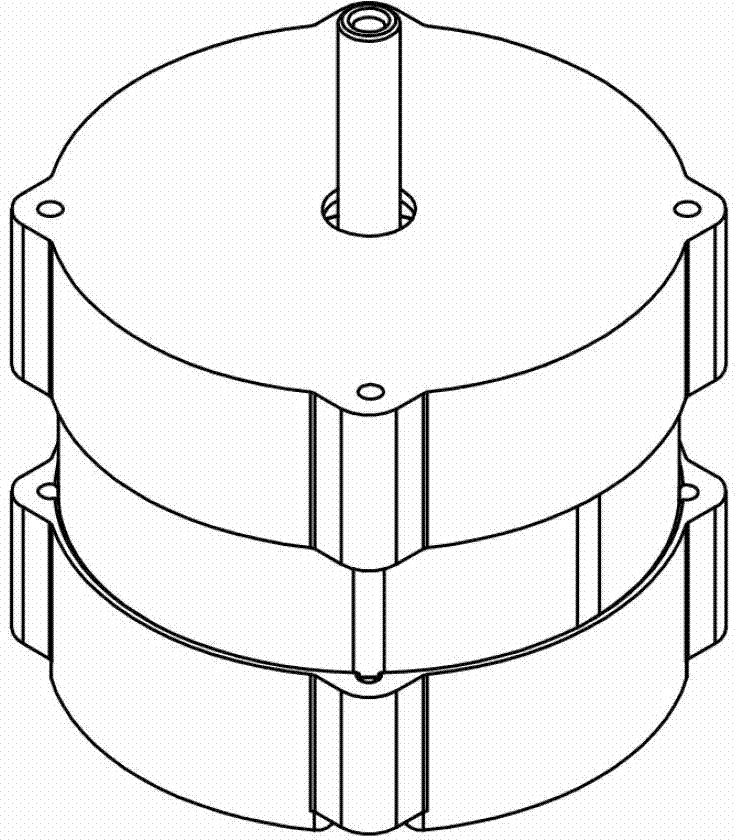

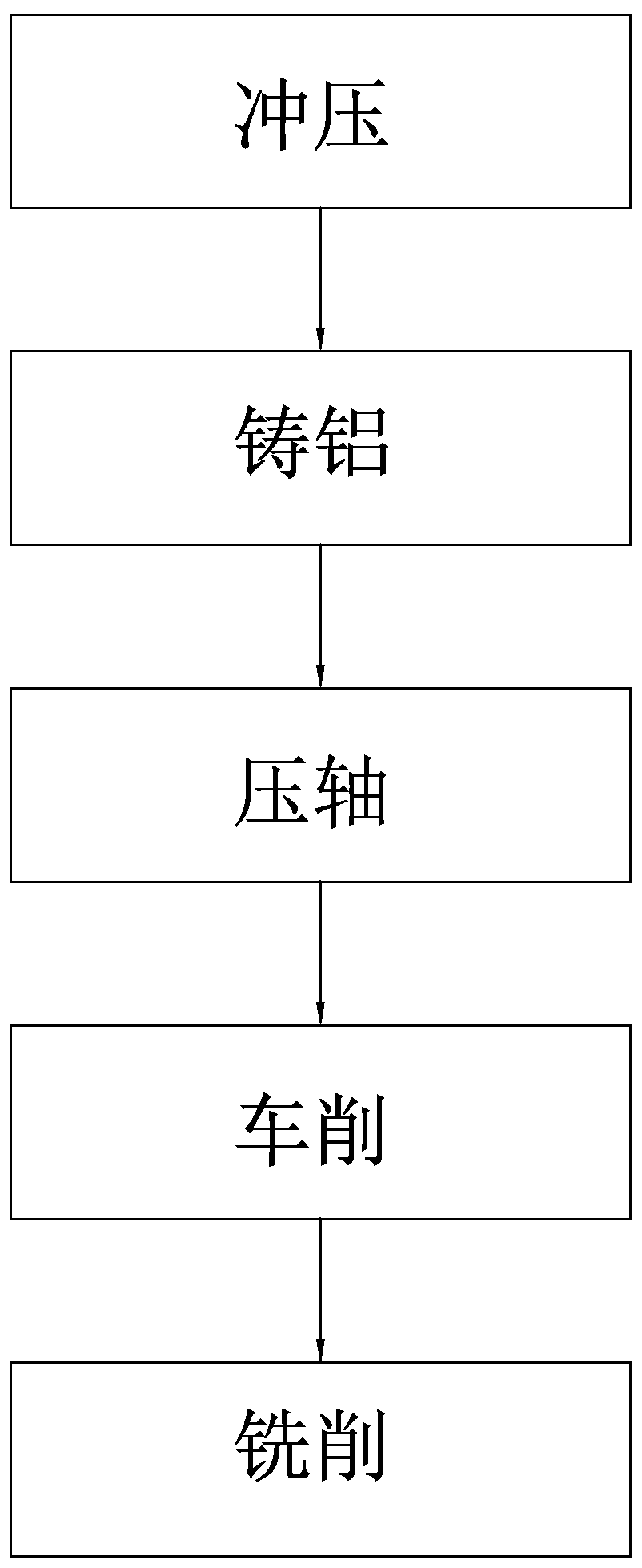

Production process for motor rotor of washing machine

InactiveCN106026548ASimple production processClear processManufacturing stator/rotor bodiesCasting moldAluminium casting

The invention discloses a washing machine motor rotor production process, comprising the following steps: S1: stamping; S2: casting aluminum, setting the temperature of a resistance melting aluminum furnace, and preheating, then adding pure aluminum into the resistance melting aluminum furnace, Put the stamped rotor into the cast aluminum mold, start the cast aluminum hydraulic press, and carry out the cast aluminum operation of the rotor. After the end, inspect the cast aluminum rotor to determine whether it meets the requirements; S3: Finale, press the shaft into the cast aluminum rotor ;S4: Turning, place the rotor on a lathe, and perform turning operation. After the turning operation is completed, perform surface runout detection, and clean up the burrs and aluminum cutting flashes of the rotor; S4: Perform surface processing, and complete the entire Rotor production process. The motor rotor proposed by the invention has a perfect production process, a clear process, high detection accuracy of key procedures, accurate evaluation of the quality of the motor rotor, and ensures that the produced rotor has good quality, stable performance and long service life.

Owner:ANHUI JINSHUAI WASHING MACHINE

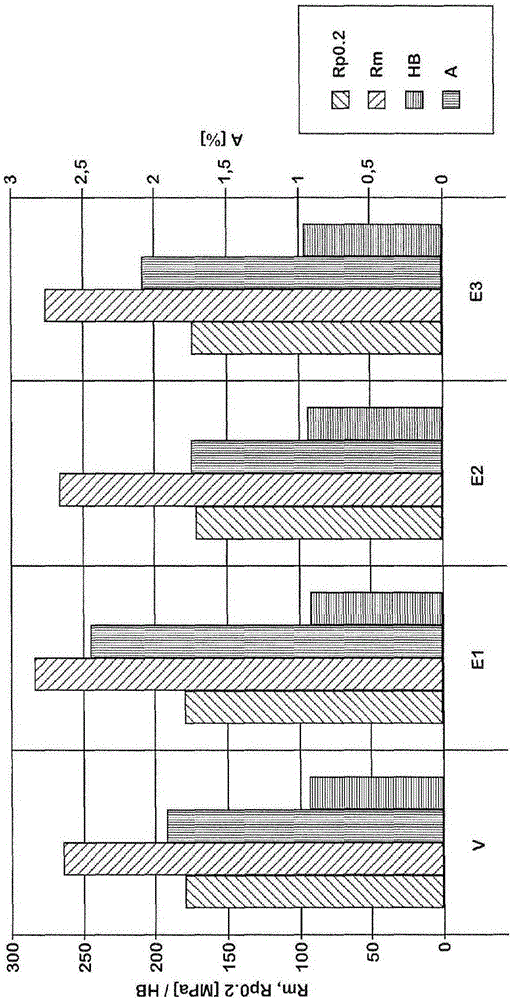

High-temperature-resistant aluminium casting alloy and cast part for internal combustion engines cast from such an alloy

The present invention relates to an aluminium casting alloy containing (in % by weight) Cu: 6.0 - 8.0 %, Mn: 0.3 - 0.55 %, Zr: 0.18 - 0.25 %, Si: 3.0 - 7.0 %, Ti: 0.05 - 0.2 %, Sr: up to 0.03 %, V: up to 0.04 %, Fe: up to 0.25 %, remainder aluminium and unavoidable impurities, and to a cast part for an internal combustion engine. The aluminium casting alloy according to the invention still has good mechanical properties at high temperatures even after a relatively long period of use and can at the same time be cast easily. The cast part according to the invention also has optimised mechanical properties when used at high temperatures and can at the same time be produced in an operationally reliable manner in terms of casting.

Owner:NEMAK LINZ

Structure of rotor of three-phase permanent-magnet synchronous motor

InactiveCN102882298AEasy to processImprove efficiencyMagnetic circuit rotating partsSynchronous motorLoop control

The invention discloses a structure of the rotor of a three-phase permanent-magnet synchronous motor. The rotor is formed by casting aluminium on a silicon steel sheet axially slantwise in an overlaying way, wherein an aluminium casting slot is punched on the outer circumference of the silicon steel sheet, and an arc-shaped magnetic steel slot is punched in the silicon steel sheet; rotor slantwise slots and an arc-shaped slantwise slots are formed on the rotor; the magnetic steel is arranged in each arc-shaped slantwise slot of the rotor; and the magnetic steel is made of the adhesive rare-earth permanent-magnet material and is in the shape of an inclined tile. Because the rotor slantwise slots are adopted, the magnetic vibration and the noise are reduced greatly, the loss is reduced, and the efficiency is improved. When the magnetic steel in the shape of the inclined tile is arranged in the rotor slantwise slots, the fit clearance of the magnetic steel in the circumferential direction isolates magnetism naturally, thus the strength of the punched sheet is improved effectively, and the rotor can be processed conveniently by adopting the mature asynchronous motor rotor aluminum casting process. The three-phase permanent-magnet synchronous motor is simple in structure, can operate stably and reliably, has high efficiency and a wide range of speed regulation and outputs at constant torque. A simple and effective open-loop control system with constant rotation speed requirements can be formed, and the cost spent constructing a control system is saved.

Owner:WUXI XISHAN SPECIAL FAN

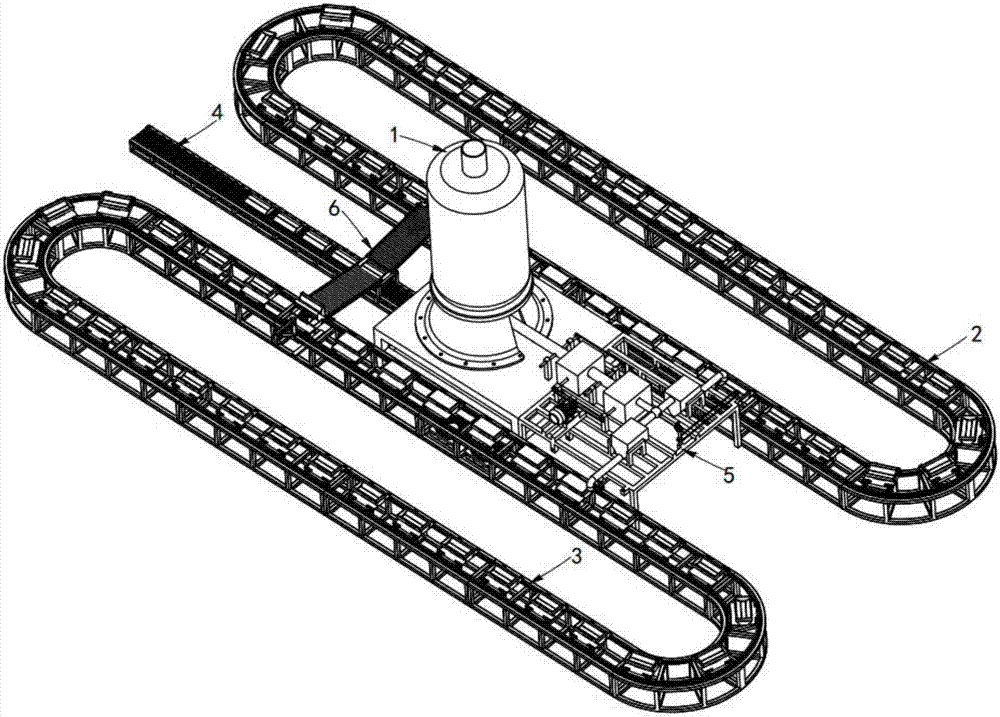

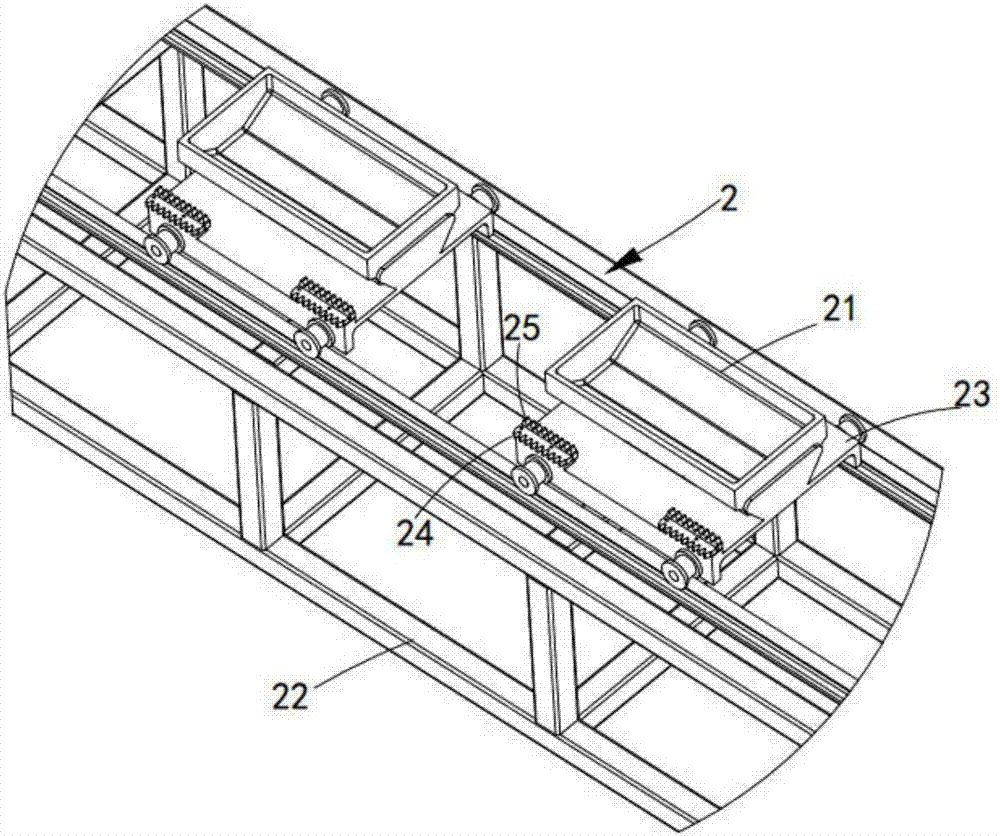

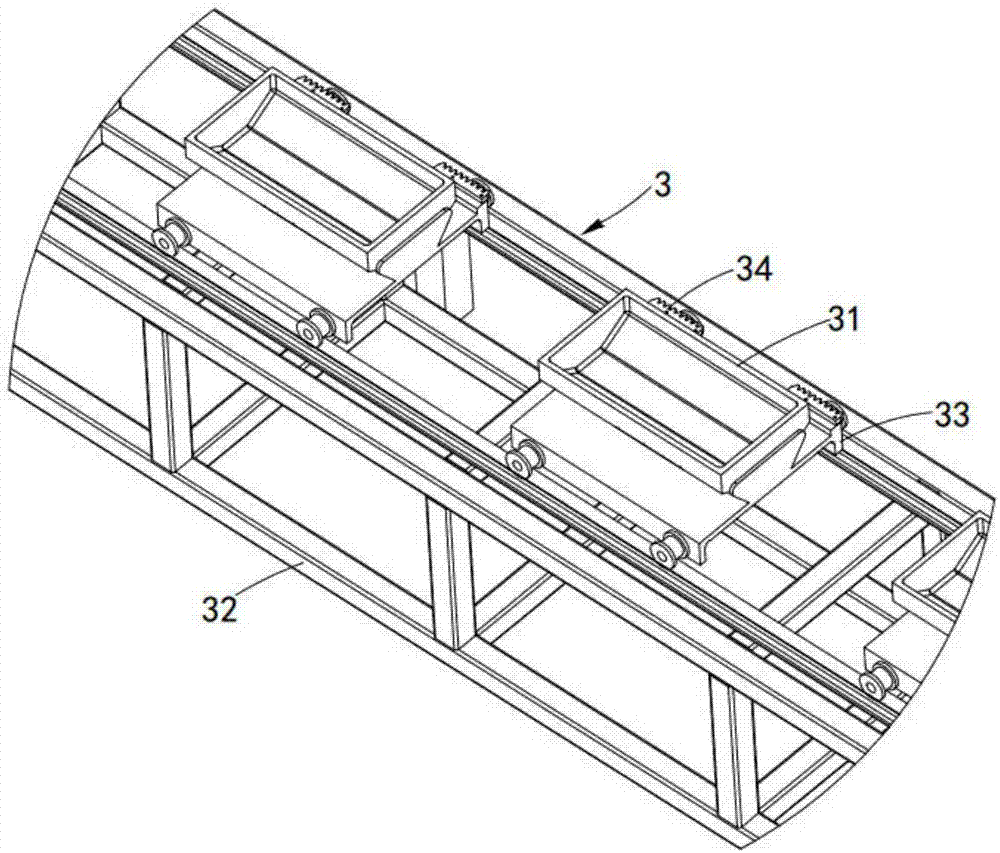

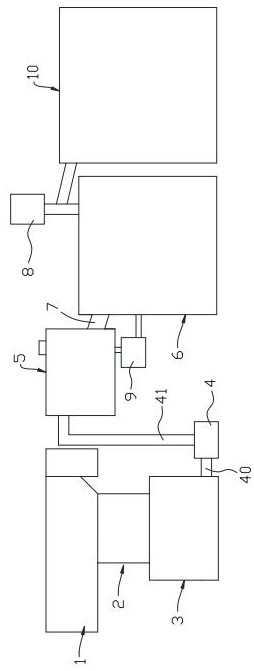

Continuous casting production line of foamed aluminium

InactiveCN107052311AImprove product qualityIncrease production speedPig casting plantsIngot casting plantsProduction lineIngot casting

Owner:长兴鼎盛机械有限公司

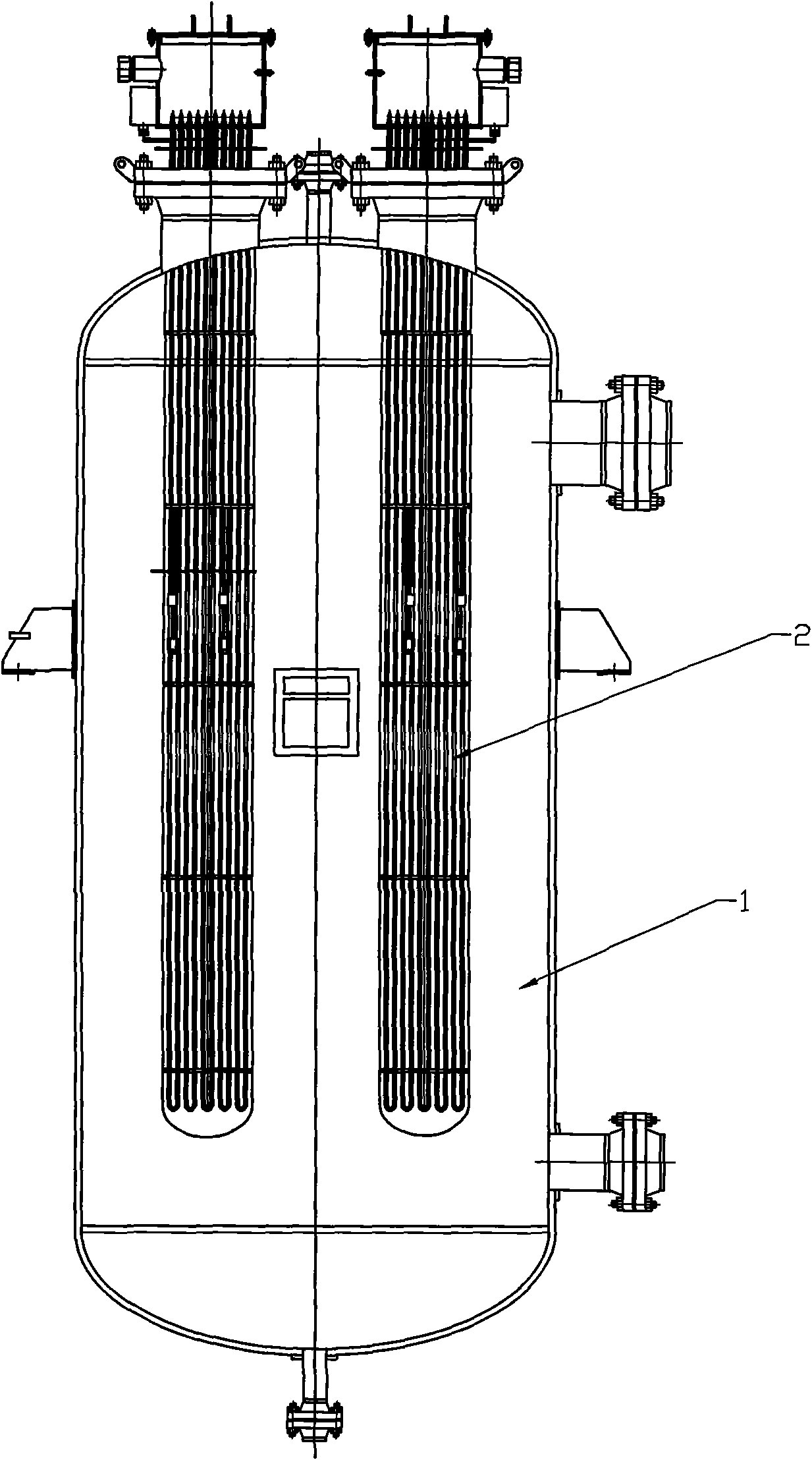

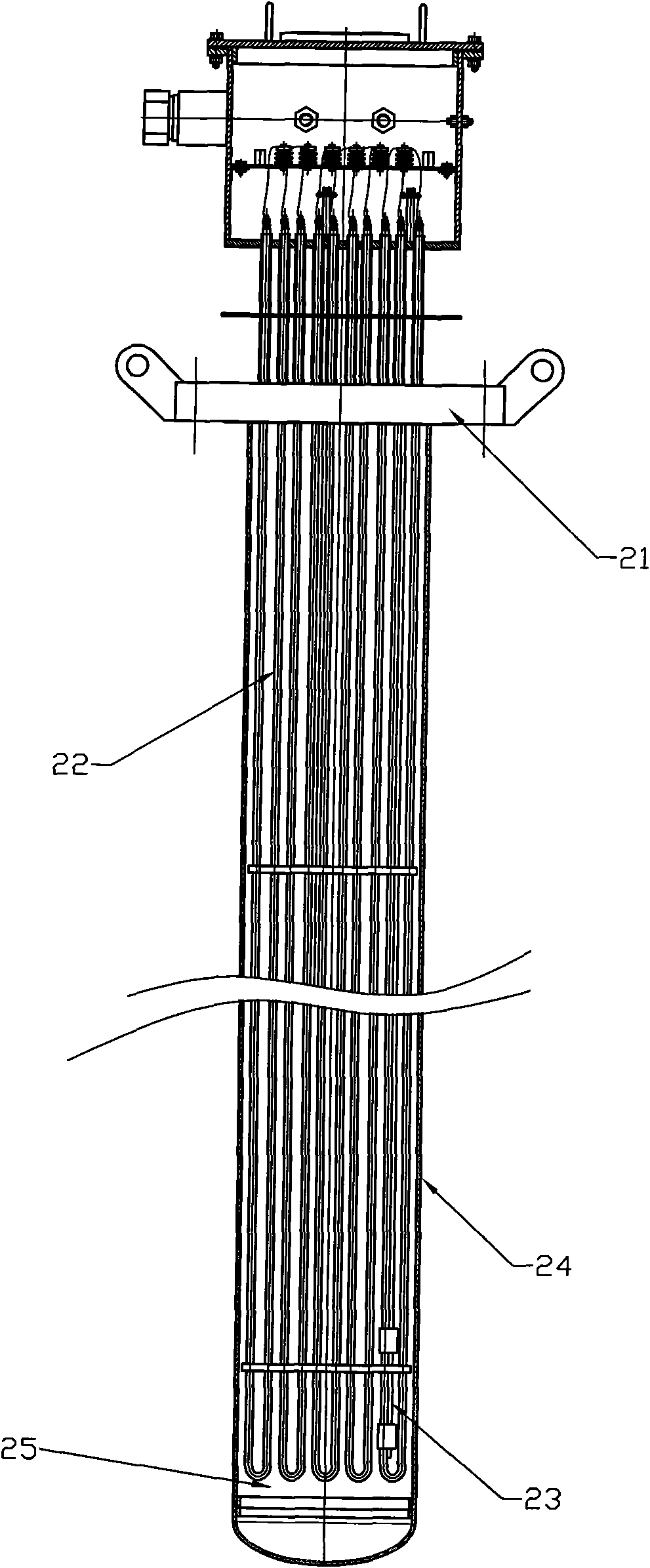

Electrical heater

ActiveCN101634486AReduce temperature gradientImprove thermal conductivityAir heatersWater heatersElectricityLiquid state

The invention relates to an electrical heater for heating a gas state or liquid state medium containing solid particle matters, belonging to the field of electrical heating device and comprising a medium heating work room and at least one electrical heating core, wherein the electrical heating core is inserted into the medium heating work room and comprises a plurality of electrical heating pipes which are arrayed on a flange cover in a clustering way and fixedly arranged on the flange cover and a plurality of temperature measuring pipes which are distributed within a heating range of the electrical heating pipes and connected with an overtemperature protection circuit. The electrical heater is characterized in that the electrical heating pipes and the temperature measuring pipes are accommodated in a thin-walled metal drum, one end of the thin-walled metal drum is hermetically connected with the flange cover, the other end of the thin-walled metal drum is closed, and gaps between the inner wall of the thin-walled metal drum and the electrical heating pipes and between the inner wall of the thin-walled metal drum and the temperature measuring pipes are filled with cast aluminium casting bodies. The electrical heater can heat the gas state or liquid state medium containing the solid particle matters, and a temperature measuring point of the overtemperature protection of the electrical heater can accurately feed back the temperature state of the integral electrical heating core, thereby preventing damage because of the partial overheating of a part of the electrical heating pipes.

Owner:ZHENJIANG DONGFANG ELECTRIC HEATER +1

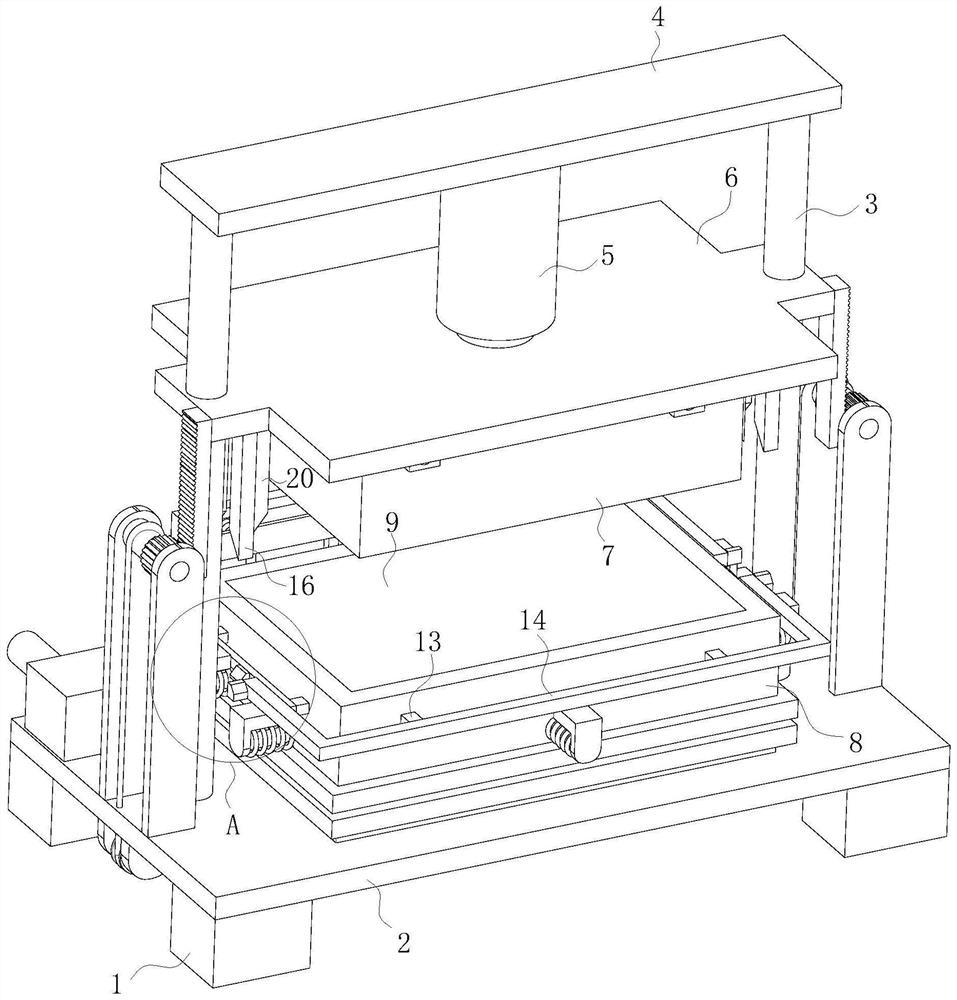

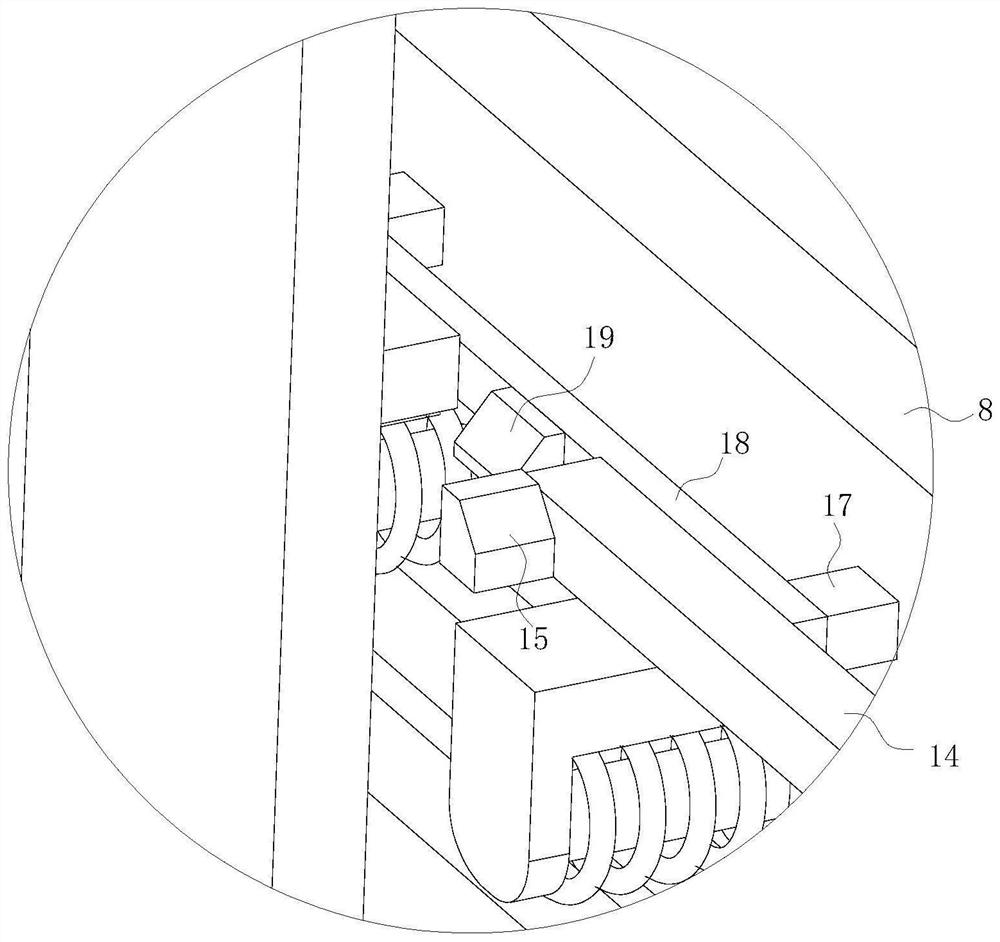

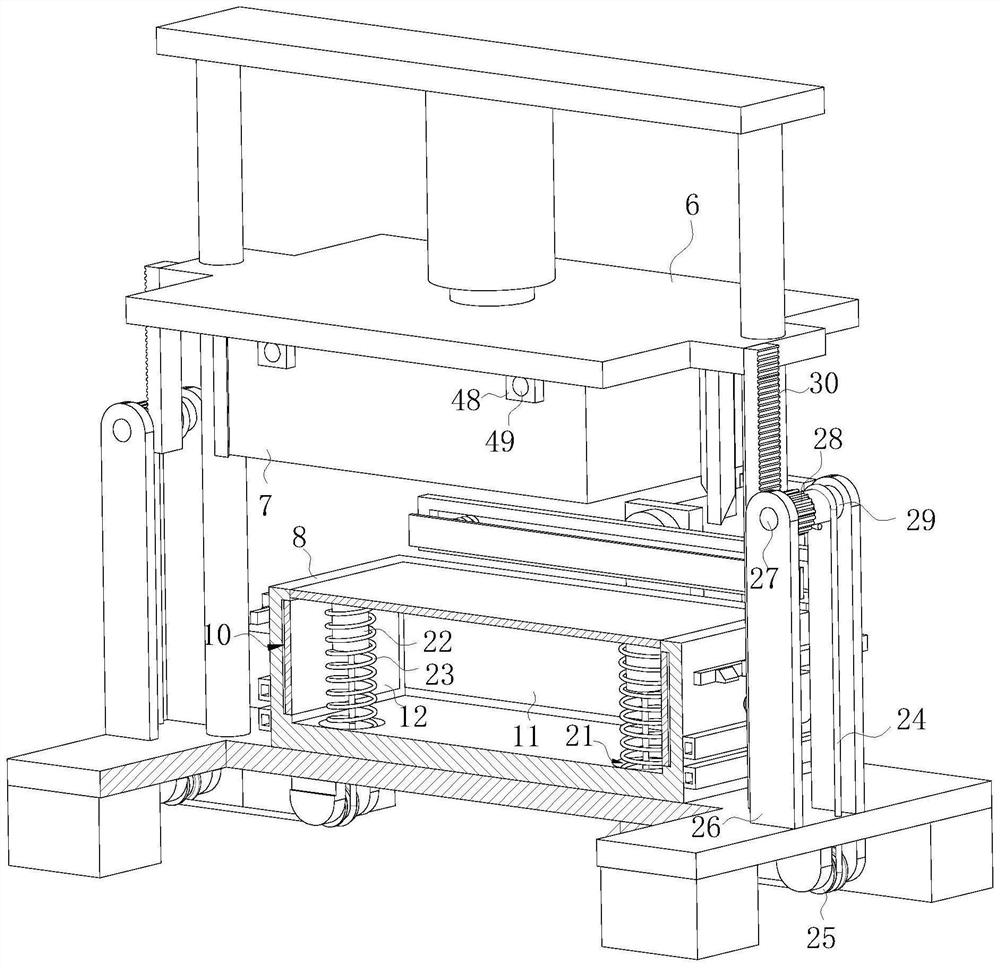

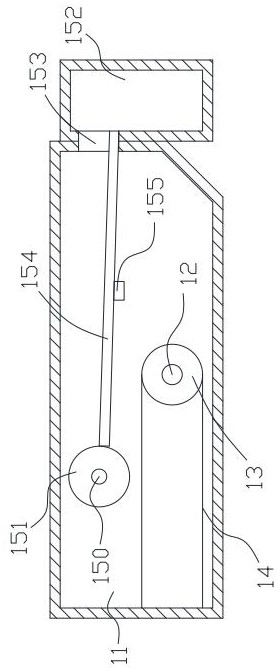

Production technology and production equipment for motor rotor of UAV camera

InactiveCN111558667AEvaluation is objective and accurateQuality assuranceShaping toolsNon-rotating vibration suppressionElectric machineryAluminium casting

The invention relates to a production technology and production equipment for a motor rotor of a UAV camera. The motor rotor meeting the using requirement is obtained through stamping of a punch, melting of pure aluminium by a dump-type aluminium smelting furnace, aluminium casting by an aluminium casting hydraulic machine, shaft pressing by an oil press, turning by a lathe and milling by a milling machine. Compared with the prior art, the production technology is perfected and clear in flow path, can lower the labor intensity of a worker, and is safe, high in obtained product quality and production efficiency.

Owner:衢州市迈德电子有限公司

Aluminum pressing casting

The invention discloses an aluminum pressing casting in the technical field of aluminum pressing castings. The aluminum pressing casting comprises four supporting legs, the tops of the four supportinglegs are jointly and fixedly connected with a supporting plate, the left side and the right side of the top of the supporting plate are both fixedly connected with guide rods, and the tops of the twoguide rods are jointly and fixedly connected with a rectangular fixing plate. According to the aluminum pressing casting, a first forming plate and a second forming plate extrude to form a die cavitywhen an upper die descends, the upper die is lifted for die opening after an aluminum pressing casting is formed in a die-casting mode, the first forming plate and the second forming plate are automatically opened, when a lifting mounting plate drives a rack to ascend, a gear is driven to slowly rotate reversely, a first spring extrudes an ejection sliding plate to enable the ejection sliding plate to slowly and stably slide out upwards along the inner wall of a lower die, an aluminum casting is ejected out, the surface of the aluminum casting is not shielded, thus people do not need to stretch into a die-casting cavity for a long time to take the casting, and the possibility of damage caused by taking inconvenience is reduced; and the top of the ejection sliding plate completely bears the aluminum casting, when the aluminum casting is ejected out, the aluminum casting cannot be damaged.

Owner:宁波豪业精密科技有限公司

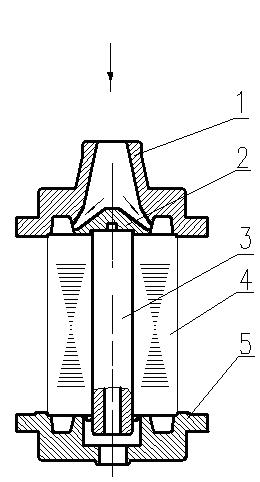

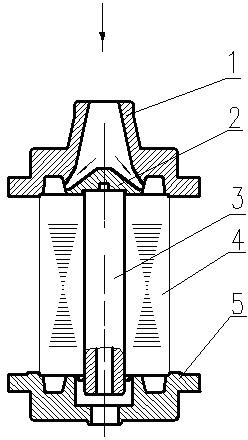

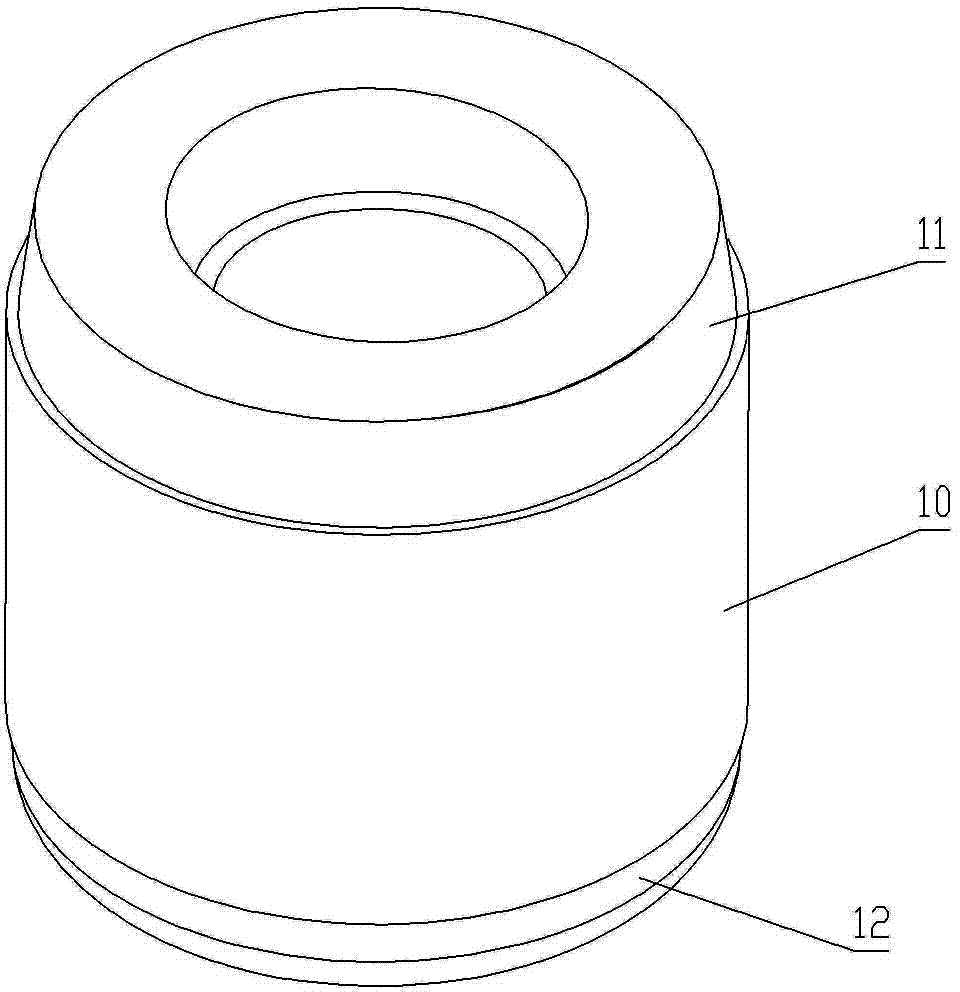

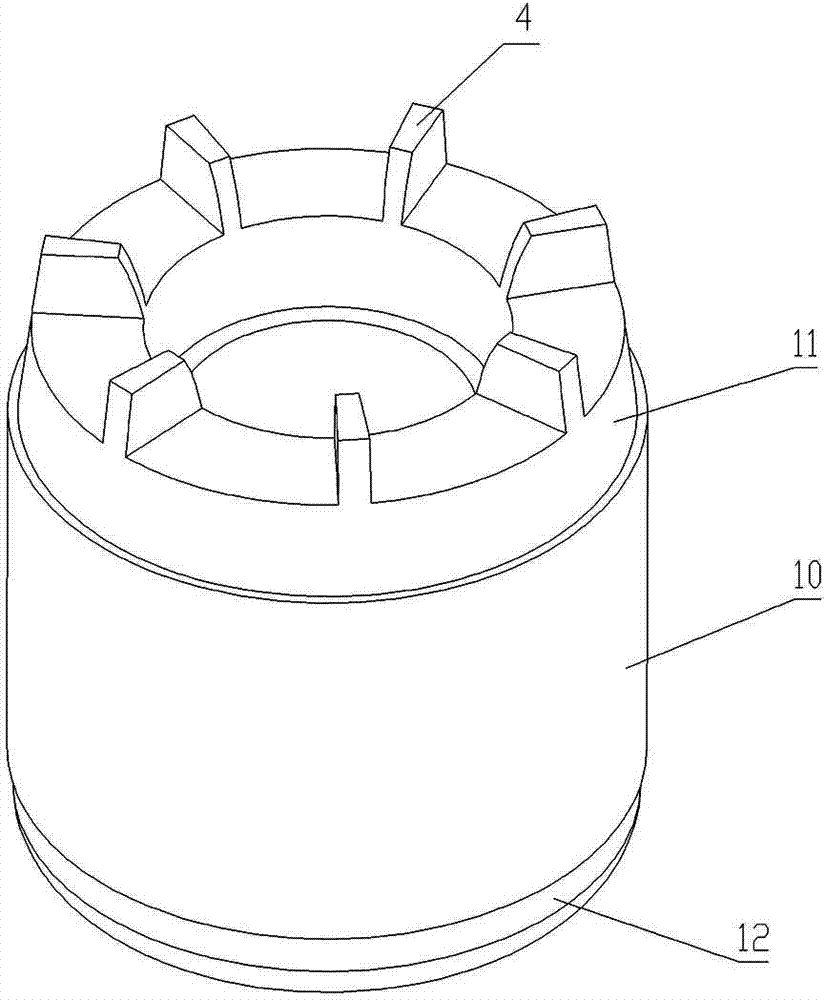

Breather for permanent aluminium-casting mould

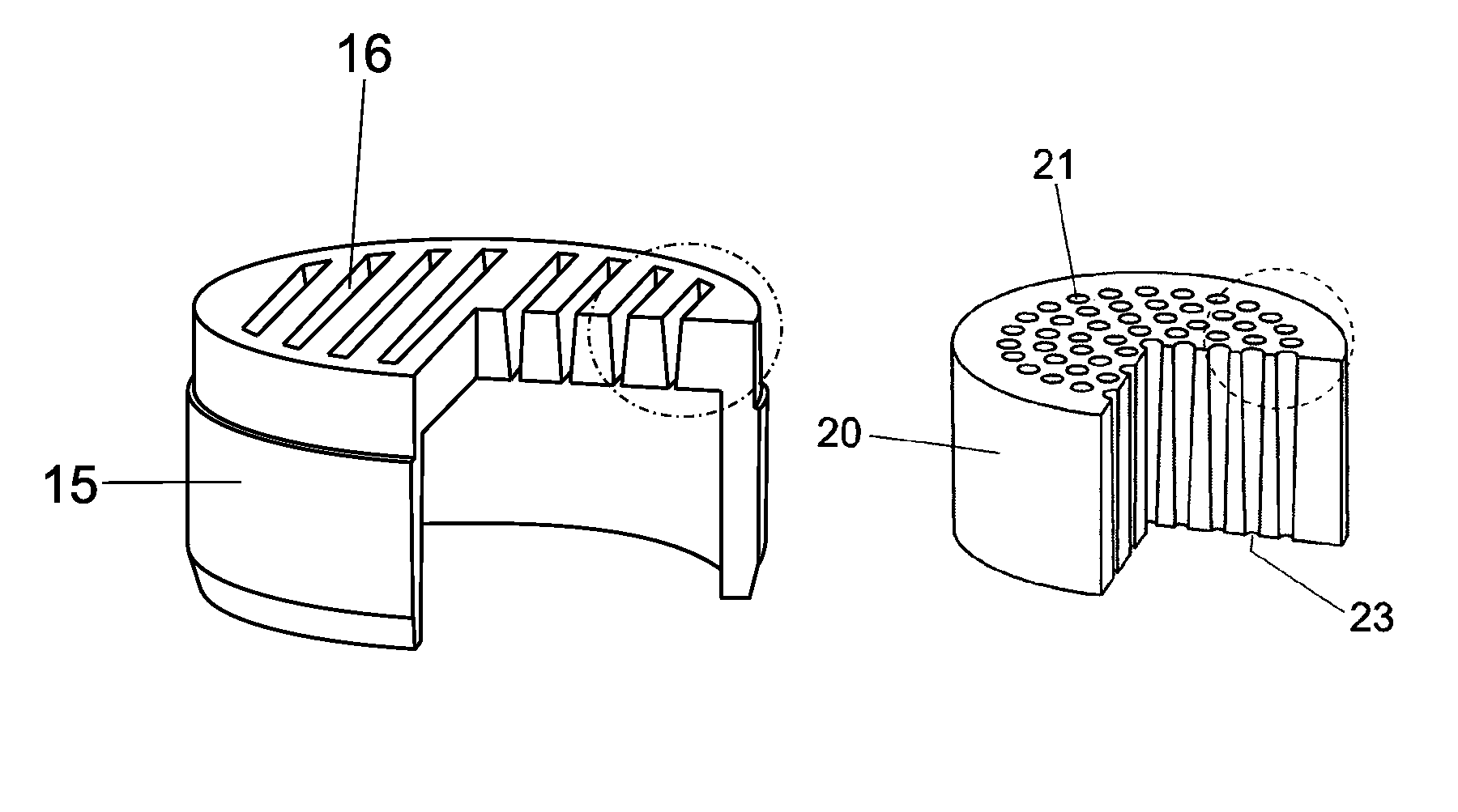

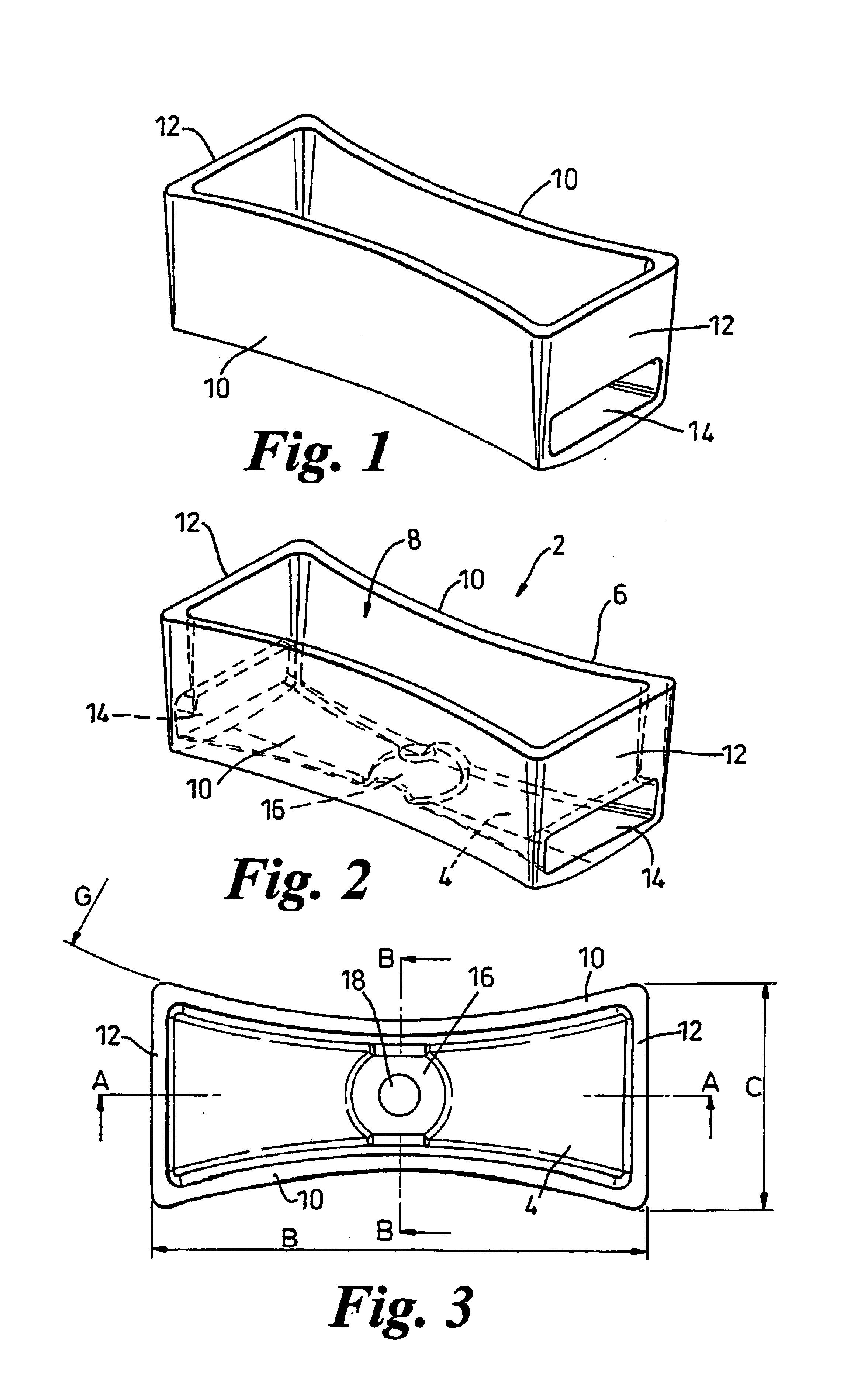

ActiveUS8820391B2Resistance to cloggingImprove casting qualityMoulding toolsFoundry mouldsAluminium castingMaterials science

The patent relates to the field of metallurgical products and comprises a cylindrical body (15) provided with a plurality of slots (16), with a taper “A” designed such that the larger opening (18) is at the outer surface of the breather (15) and the smaller opening (19) is located internally with respect to the breather (15), so that the aluminum component (5), when removed from the mold (6), brings with it the burr (17), leaving the slots (16) of the breather (15) always free, and also a breather (20) comprising a cylindrical body constituted from a plurality of holes (21), with a conicity “A” designed such that the larger opening (22) is at the outer surface of the breather (20) and the smaller opening (23) is located internally with respect to the breather (20).

Owner:ZANATTA JEANLIS BRITO

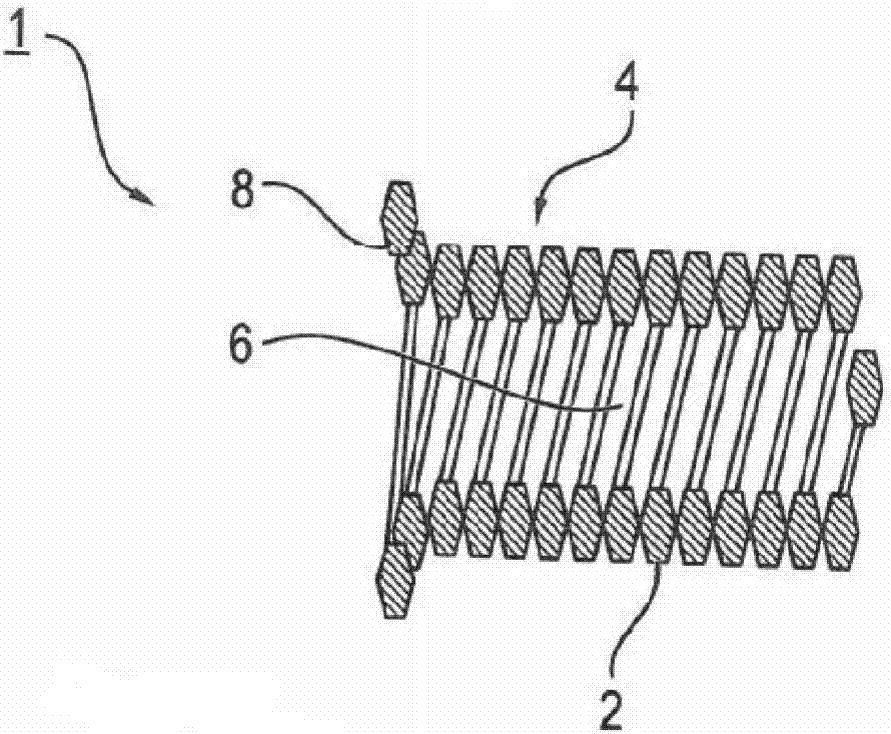

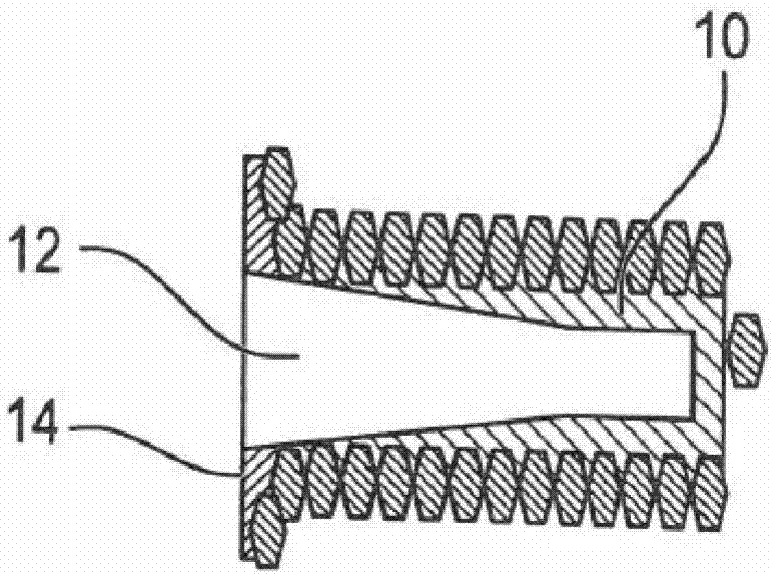

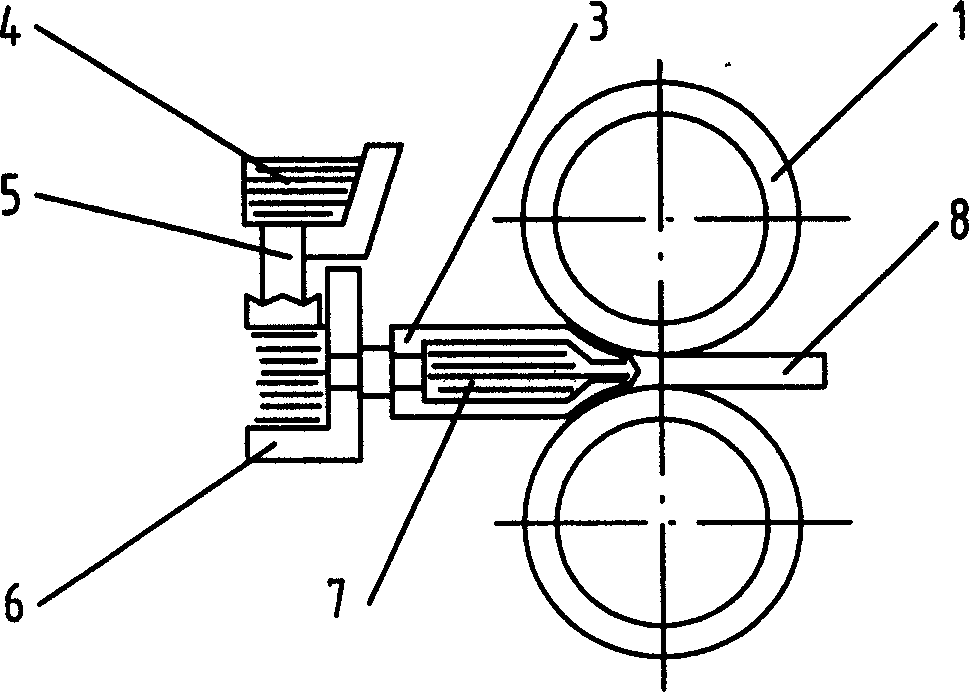

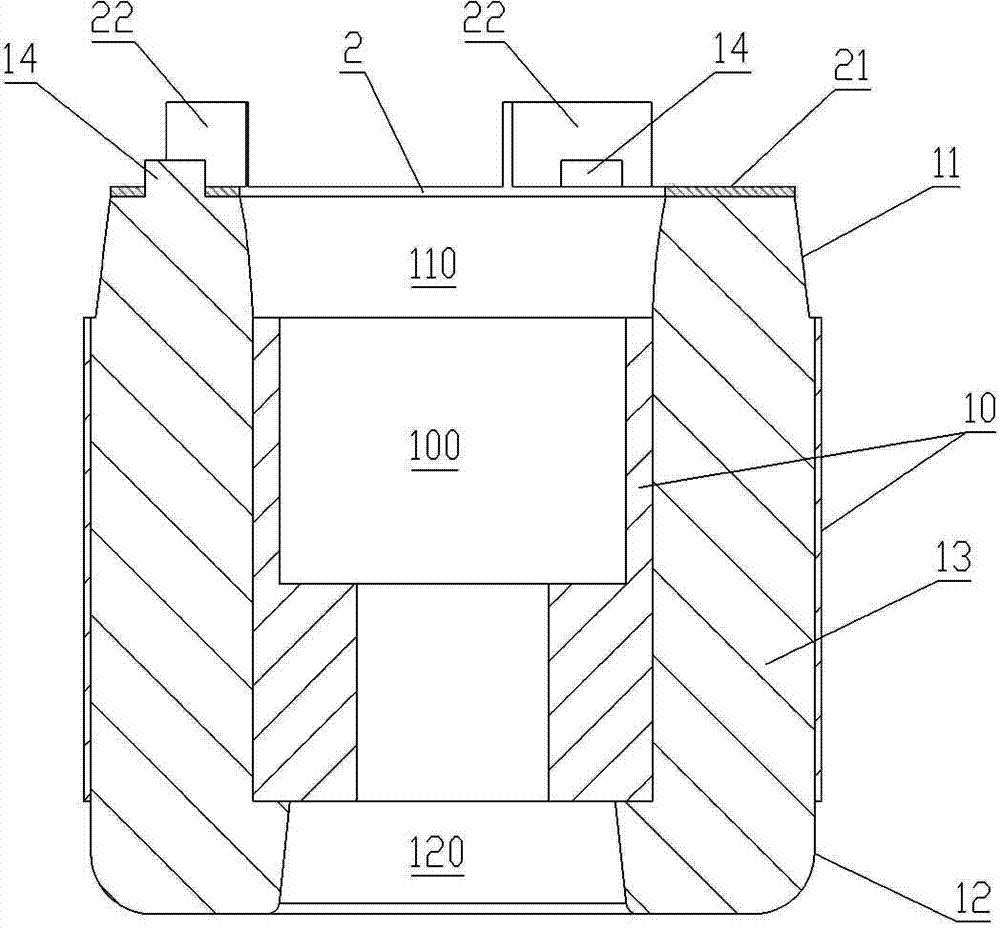

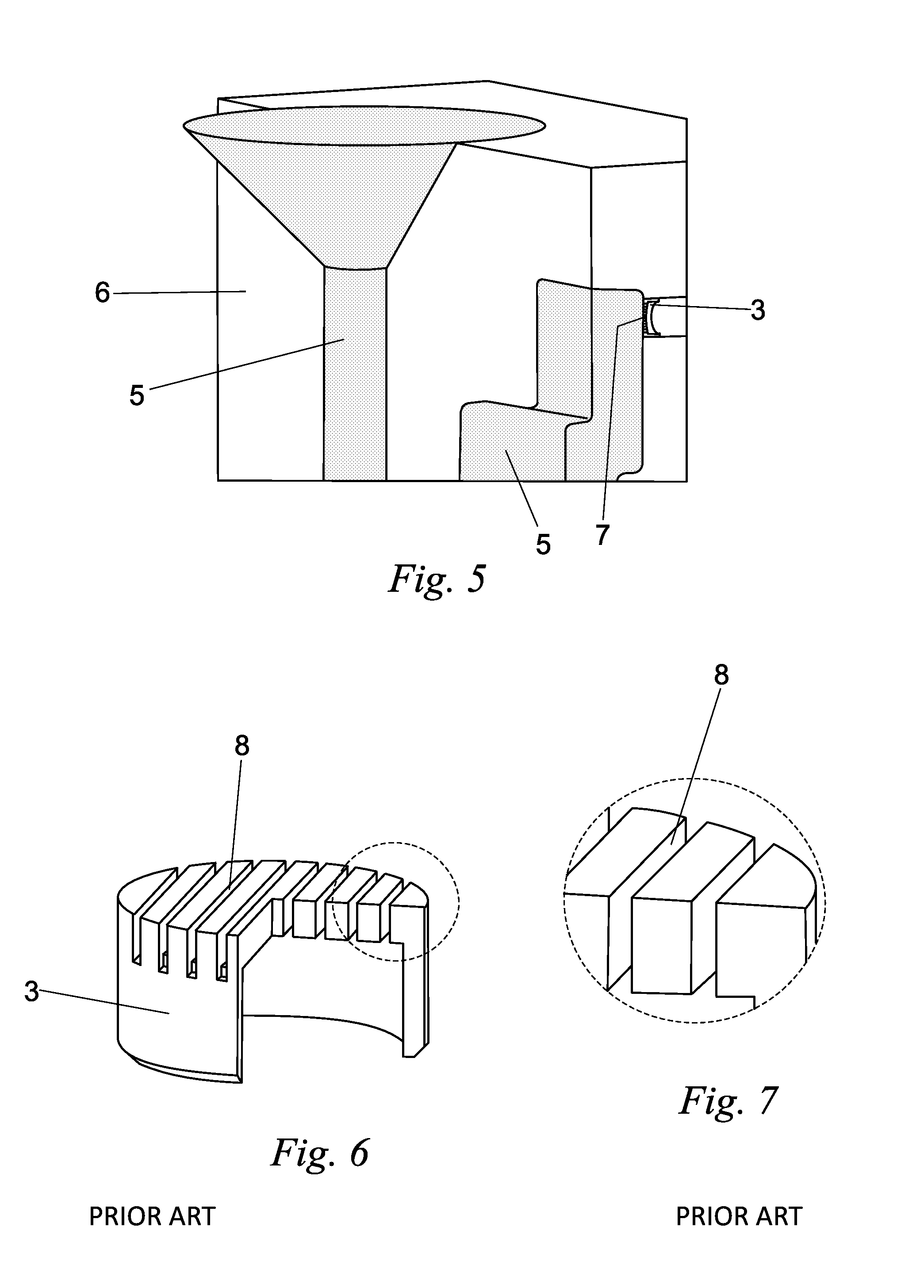

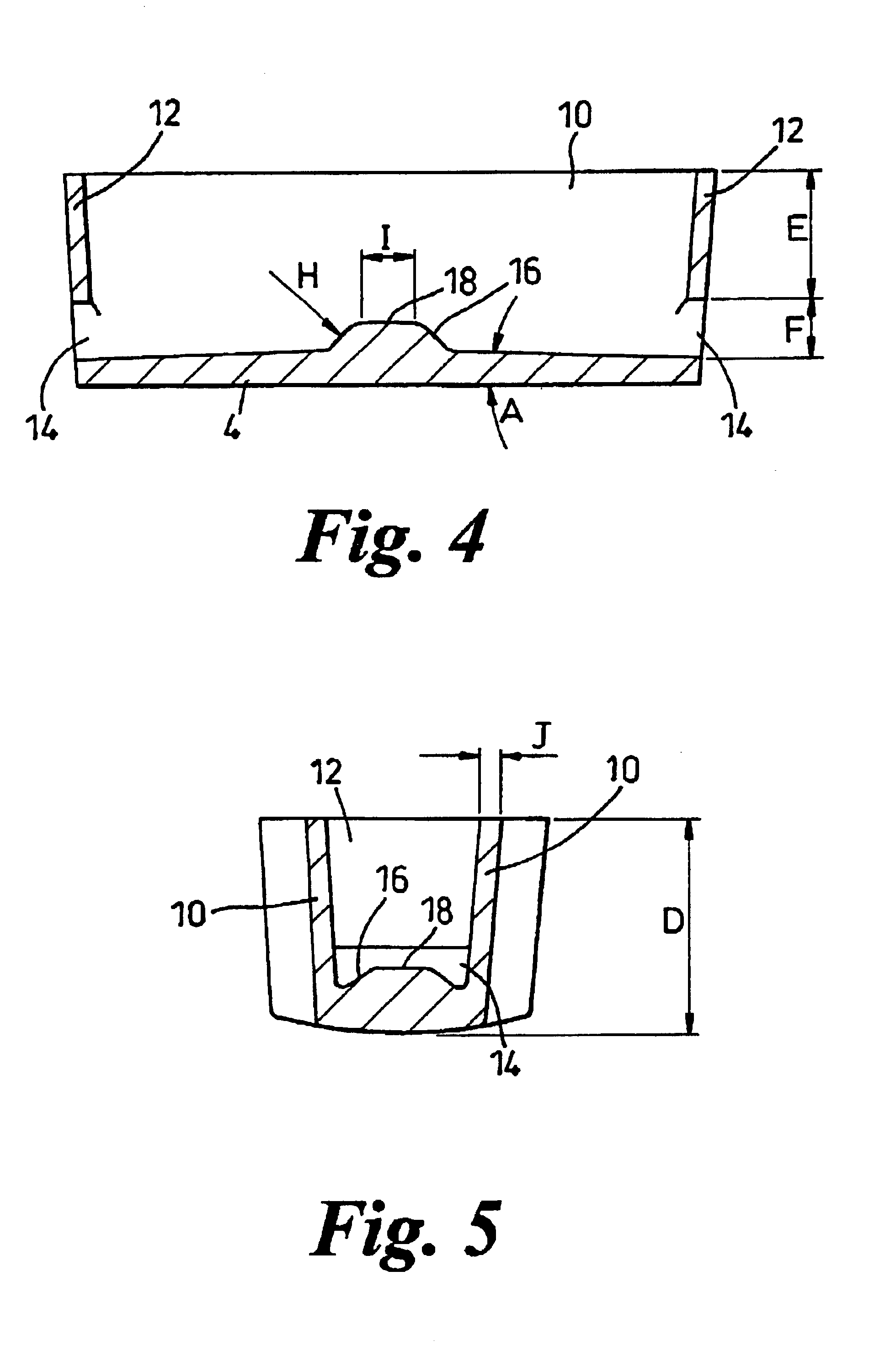

Distributor device for use in metal casting

InactiveUS7036555B1Reduce decreaseMelt-holding vesselsMolten metal pouring equipmentsRefractoryEngineering

A distributor device for use in aluminium casting includes a rigid, substantially bowl-shaped receptacle (2) of a refractory material having a base member (4) and a peripheral wall (6) that extends upwards from the base. The receptacle has an inlet opening (8) towards the upper end thereof and a pair of outlet openings (14) towards the base thereof. The device is constructed and arranged such that, in use, molten aluminium poured into the distributor device through the inlet opening (8) is redirected by the distributor device and flows outwards into the mould through the outlet openings (14).

Owner:PYROTEK ENG MATERIALS

Device and method for manufacturing aluminum casting by recycling waste aluminum material

ActiveCN113416845AReduce entryImprove qualityStirring devicesPreheating chargesAluminium castingMelting furnace

The invention provides a device and a method for manufacturing an aluminum casting by recycling a waste aluminum material, and aims to solve the technical problems that the quality of the casting is influenced by excessive impurities in the existing waste aluminum material and the smelting efficiency is low. The device comprises a conveying mechanism, an impurity removal and crushing device, a dehydration and oil removal mechanism, a preheating furnace, a melting furnace and a column pressing device. The method for manufacturing the aluminum casting by recycling the waste aluminum material comprises the following steps: (1) preliminarily removing impurities; (2) secondarily removing the impurities; (3) performing dehydration and oil removal; (4) performing preheating; (5) performing smelting; and (6) performing pouring. In a waste aluminum material conveying process, the waste aluminum material is subjected to pretreatment preliminary impurity removal firstly and then subjected to secondary deep impurity removal after being crushed, so that iron-containing substances entering the melting furnace are greatly reduced, and the quality of aluminum casting is effectively improved. Meanwhile, before the impurity-removed aluminum material enters the melting furnace, the aluminum material is preheated and heated by the preheating furnace, so that the heating speed of the aluminum material in the melting furnace is shortened, and therefore, the melting efficiency is further improved.

Owner:GUANGYUAN LINFENG ALUMINUM ELECTRIC CO LTD

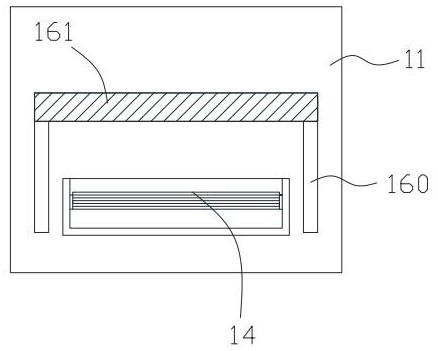

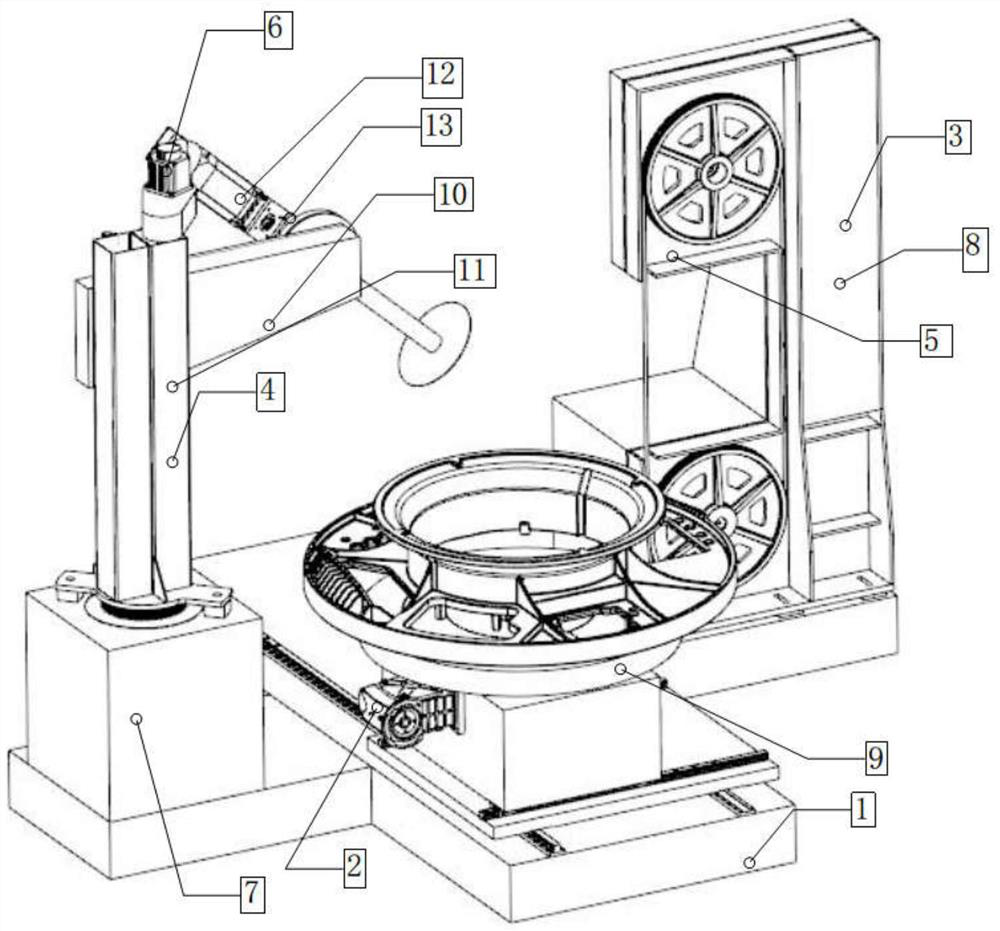

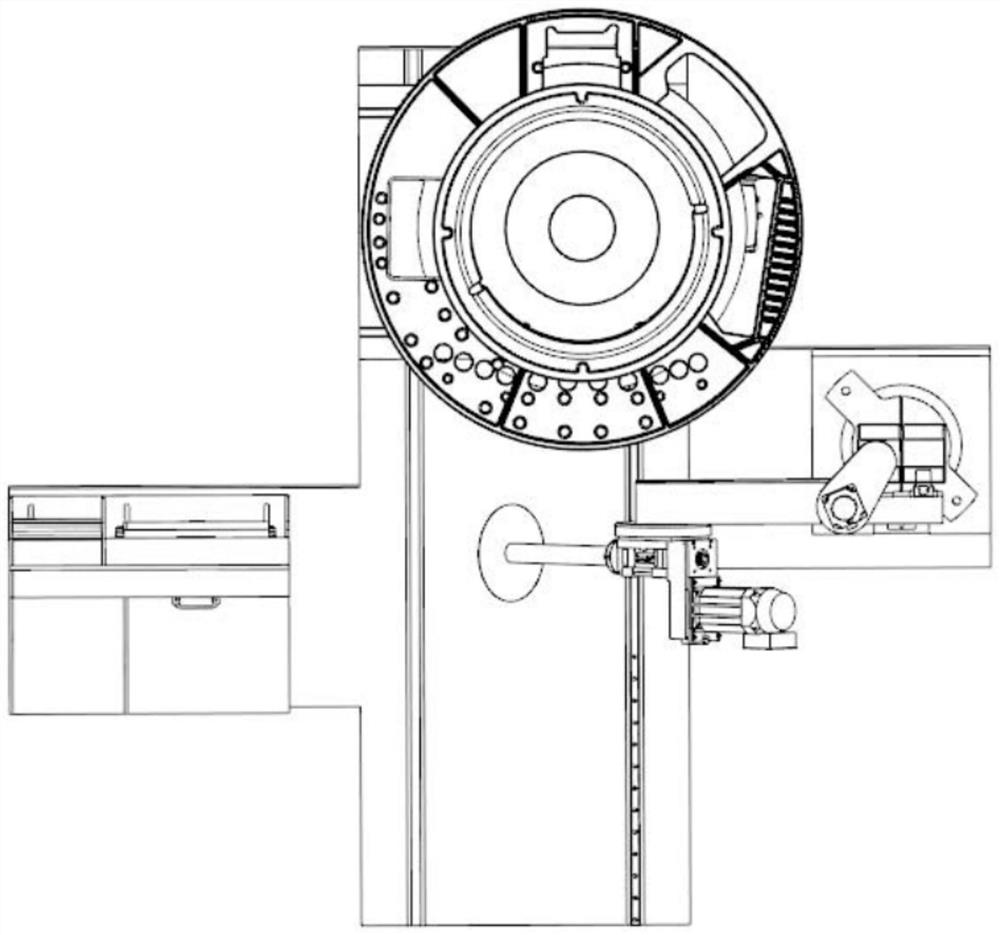

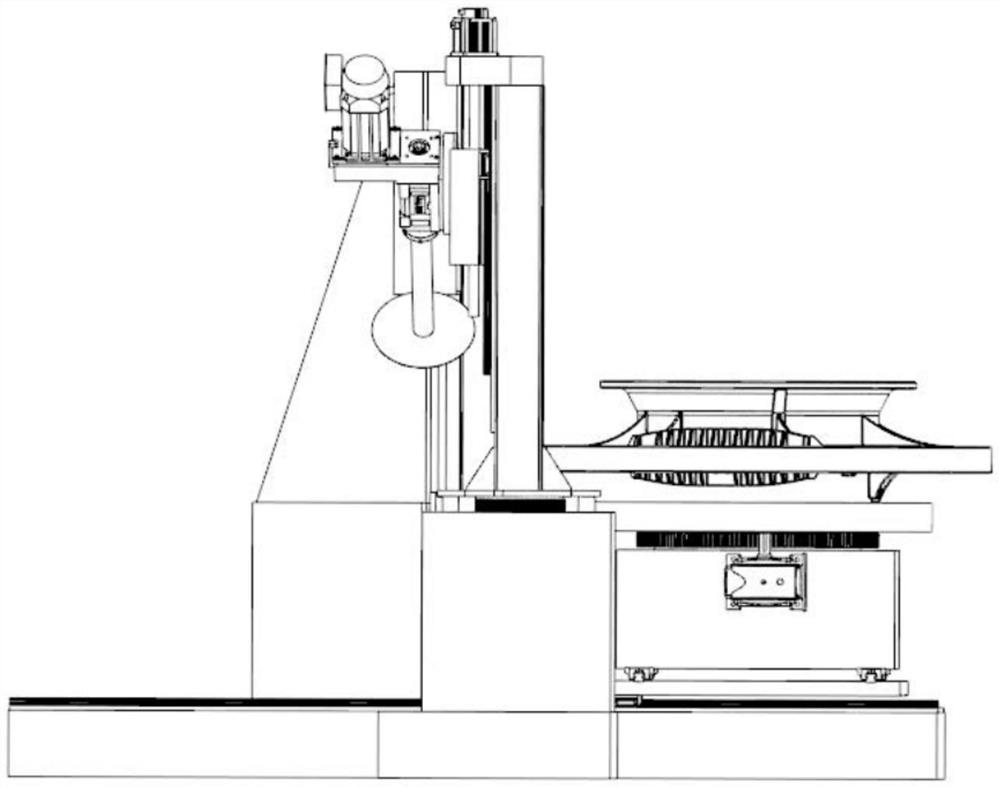

Casting riser machining machine and operating method thereof

ActiveCN111975111AImprove cutting efficiencyPrecise positioningMetal sawing devicesOther manufacturing equipments/toolsCircular discControl system

The invention discloses a casting riser machining machine and an operating method thereof. The machine comprises a base, a main transmission system, a saw frame, a guiding device, a saw blade tensioning device, a cooling system, a hydraulic system, an electrical control system, a work table, a rocker arm, a rocker arm lifting mechanism, a power head, and a power head rotating mechanism. The casting riser machining machine is used for aluminum casting riser sawing, and has the characteristics of high cutting efficiency, convenient positioning, narrow saw mouth, energy saving, simple operation and the like. The machine adopts a vertical crosscutting structure and a disk saw composite structure, which is ideal equipment for batch sawing.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com