High strength Al-Mg-Si aluminium alloy and preparation method thereof

An al-mg-si, aluminum alloy technology, applied in the field of aluminum material manufacturing, can solve the problems of reducing the production efficiency of aluminum alloys, time-consuming aging treatment, etc., and achieve the effect of shortening production time, improving various properties, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

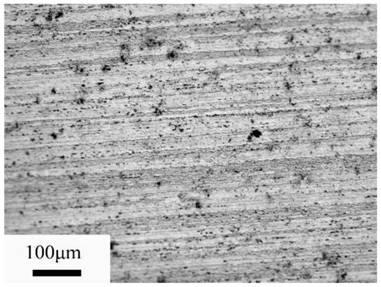

Image

Examples

preparation example Construction

[0040] The invention discloses a method for preparing a high-strength Al-Mg-Si aluminum alloy, which comprises:

[0041] (1) preparing cast aluminum rods;

[0042] Specifically include:

[0043] (1) Put the aluminum ingot into the melting furnace, raise the temperature to 720-750°C, add the recycled waste after complete melting, and melt to obtain the first alloy liquid;

[0044] Among them, in the preparation process, the source of raw materials for aluminum includes aluminum ingots and furnace waste; the furnace waste includes extrusion head and tail, overpressure, rod head and rod tail, spraying waste, casting waste slag, electrophoretic material, etc. Preferably, the ratio of recycled waste to the whole aluminum raw material is ≤30%.

[0045] (2) adding silicon ingot, copper-aluminum alloy, chromium-aluminum alloy, manganese-aluminum alloy in sequence to the first alloy liquid, melting and mixing uniformly to obtain the second alloy liquid;

[0046] Among them, the allo...

Embodiment 1

[0076] alloy composition:

[0077] Si 0.98%, Mg 1.1%, Cu 0.42%, Mn 0.45%, Cr 0.1%, and the balance is Al.

[0078] Preparation:

[0079] (1) Put the aluminum ingot into the melting furnace, raise the temperature to 720°C, add the recycled waste after complete melting, and melt to obtain the first alloy liquid;

[0080] (2) Add high-purity silicon, Al-50Cu master alloy, Al-20Mn master alloy, and Al-10Cr master alloy in sequence in the first alloy liquid, add slag breaking agent after melting and mixing evenly, and remove scum , to obtain the second alloy liquid;

[0081] (3) adding magnesium ingots to the second alloy liquid and homogenizing to obtain the third alloy liquid;

[0082] (4) adding a slagging agent to the third alloy liquid, and removing the scum to obtain the fourth alloy liquid; wherein, the slag removal temperature is 750°C;

[0083] (5) Refining the fourth alloy liquid at 710° C. for 20 minutes; feeding high-purity argon during the refining process;

[008...

Embodiment 2

[0093] alloy composition

[0094] Si 0.95%, Mg 1.2%, Cu 0.35%, Mn 0.4%, Cr 0.2%, and the balance is Al.

[0095] Preparation:

[0096] (1) Put the aluminum ingot into the melting furnace, raise the temperature to 725°C, add the recycled waste after complete melting, and melt to obtain the first alloy liquid;

[0097] (2) Add high-purity silicon, Al-50Cu master alloy, Al-20Mn master alloy, and Al-10Cr master alloy in sequence in the first alloy liquid, add slag breaking agent after melting and mixing evenly, and remove scum , to obtain the second alloy liquid;

[0098] (3) adding magnesium ingots to the second alloy liquid and homogenizing to obtain the third alloy liquid;

[0099] (4) Adding a slagging agent to the third alloy liquid, and removing the scum to obtain the fourth alloy liquid; wherein, the slag removal temperature is 730°C;

[0100] (5) Refining the fourth alloy liquid at 715° C. for 20 minutes; feeding high-purity argon gas during the refining process;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com