Motor rotor for refrigerator compressor

A technology for a refrigerator compressor and a motor is applied in the field of refrigeration compressors, which can solve the problems of increasing the number of rotor manufacturing molds, increasing the manufacturing cost, low strength of aluminum materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

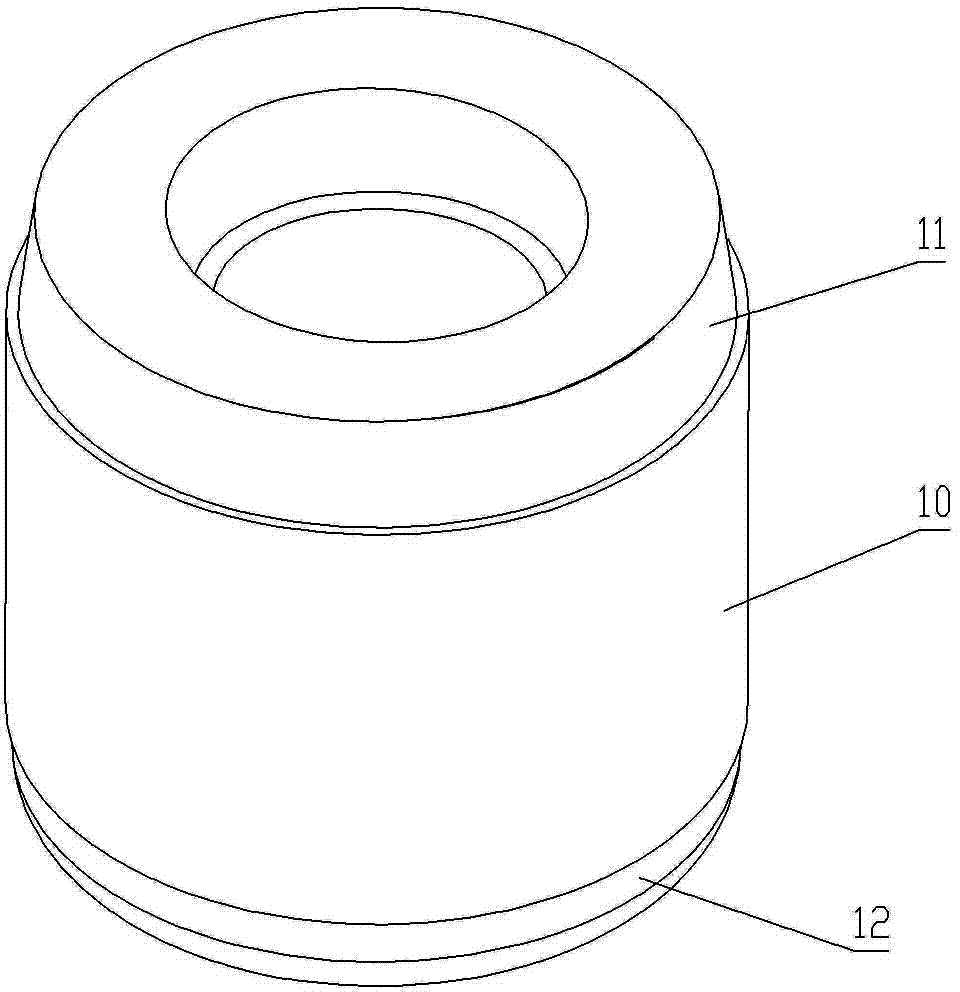

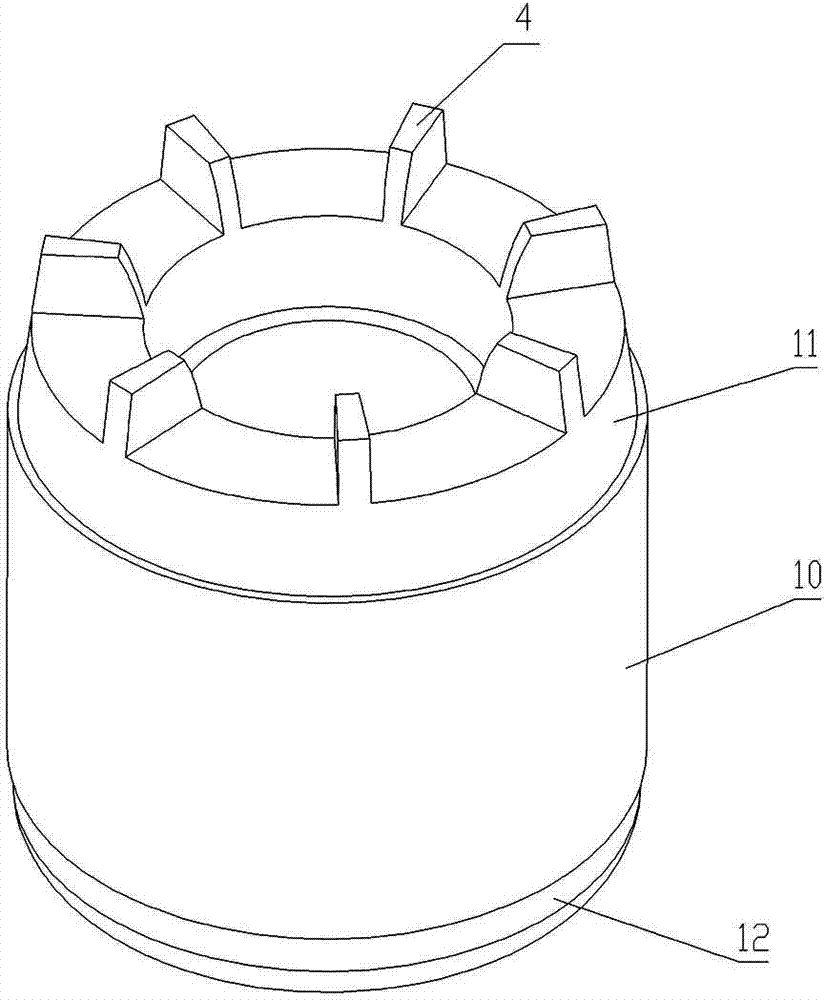

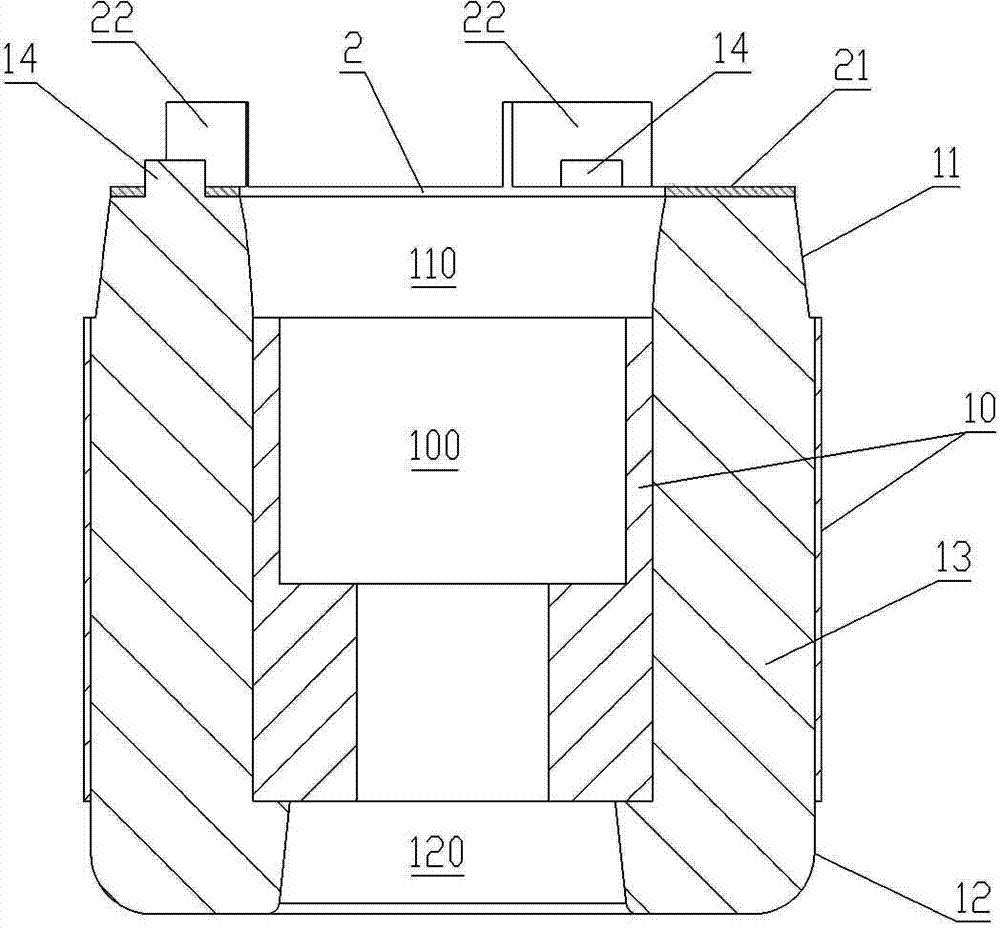

[0026] refer to Figure 3 to Figure 5 , a motor rotor for a refrigerator compressor, comprising a rotor main body, the rotor main body is formed by combining a rotor iron core 10, an aluminum cast upper end ring 11, an aluminum cast lower end ring 12 and a secondary conductor aluminum 13, the rotor iron core 10 It is formed by laminating several silicon steel sheets. The rotor core 10 has an aluminum injection hole. The aluminum cast upper end ring 11 and the aluminum cast lower end ring 12 are respectively located at both ends of the rotor core 10. The secondary conductor aluminum 13 fills the rotor core 10. The aluminum injection hole connects the aluminum casting upper end ring 11, the rotor iron core 10 and the aluminum casting lower end ring 12 into an integral structure, and the rotor iron core 10, the aluminum casting upper end ring 11 and the aluminum casting lower end ring 12 respectively have coaxial inner cores The hole 100, the inner hole 110 of the upper end ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com