Casting riser machining machine and operating method thereof

A processing machine and riser technology, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high labor intensity, uneven section, uneven margin, etc., and achieve high cutting efficiency and positioning Convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

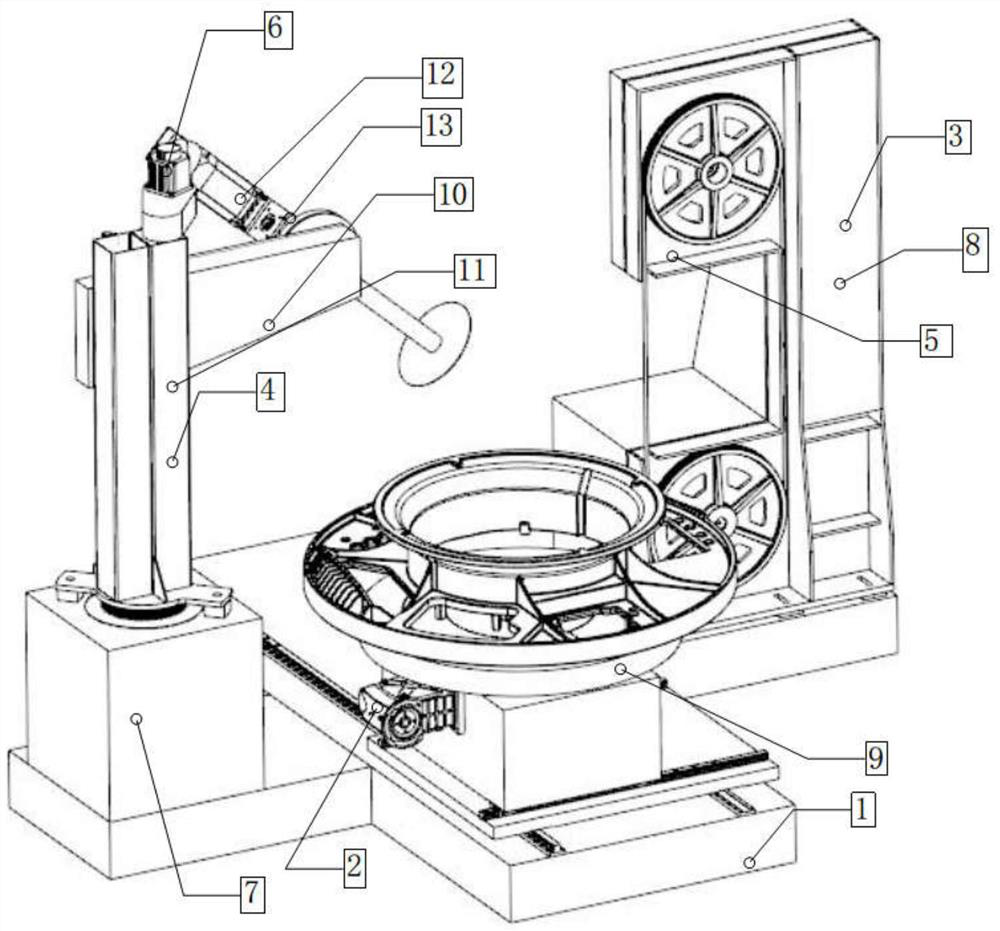

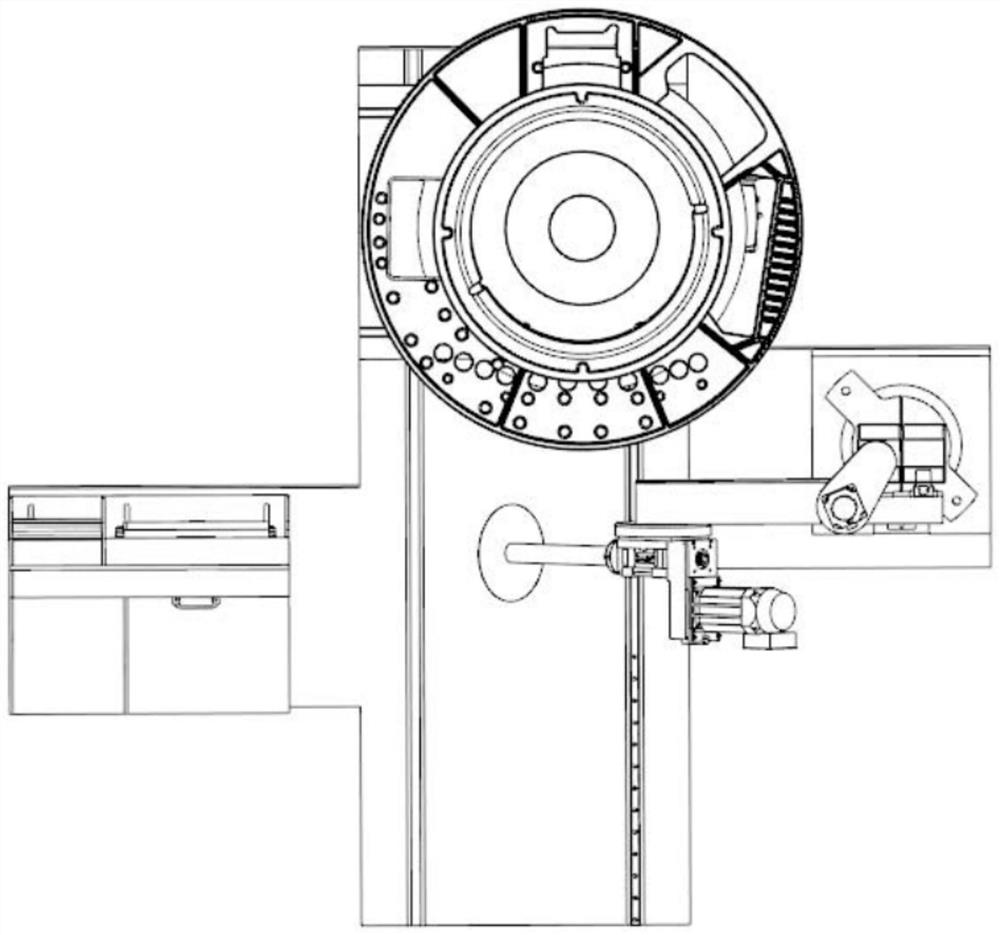

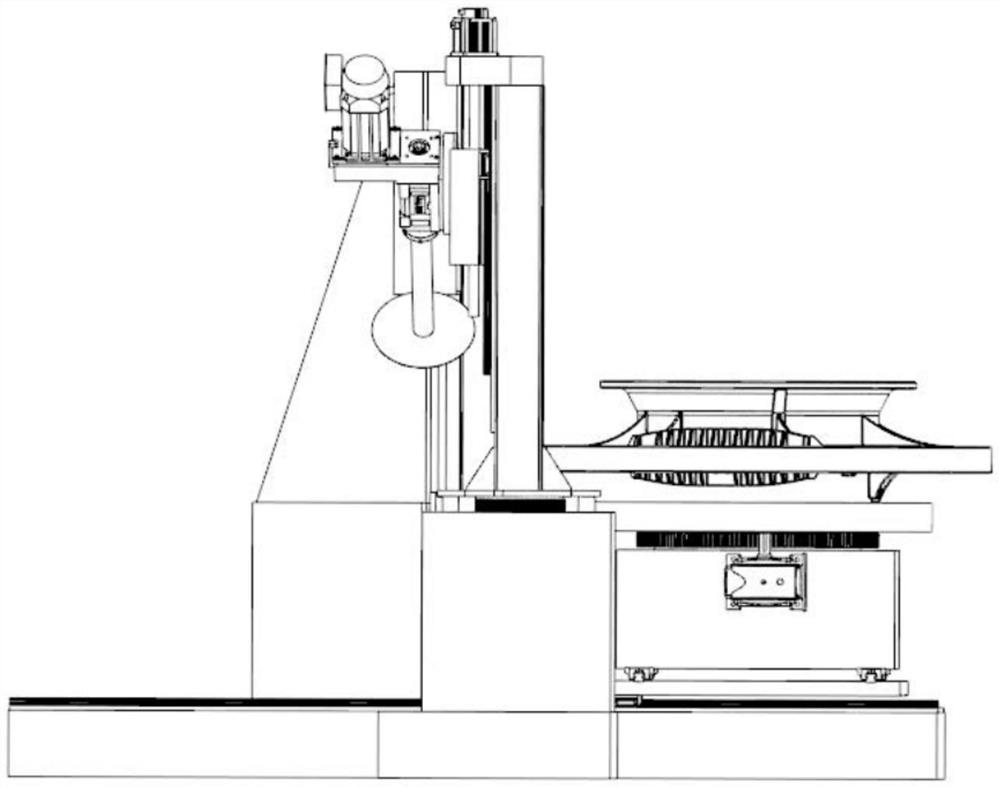

[0030] Such as Figure 1-6 As shown, a casting riser processing machine includes a base 1, a main transmission system 2, a saw frame 3, a guide device 4, a saw blade tensioning device 5, a cooling system 6, a hydraulic system 7, an electrical control system 8, and a workbench 9 , rocking arm 10, rocking arm lifting mechanism 11, power head 12 and power head rotating mechanism 13.

[0031] The base 1 is welded with high-quality steel plates and reasonable reinforcing ribs. After vibration aging treatment, the welding deformation is small. It is mainly used to install various parts of the machine tool. The water tank, oil tank and electric box are all installed in the inner cavity of the base. It is used for circulating cooling during sawing.

[0032] A workbench 9 is installed in the middle of the base 1; the workbench 9 adopts a cast iron structure and is provided with reasonable reinforcing ribs, and after tempering and aging, the casting stress is redistributed and eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com