Electrical heater

An electric heater and electric heating technology, applied in water heaters, air heaters, fluid heaters, etc., can solve the problems of overheating of electric heating tubes, damage to electric heaters, and inability to dissipate heat, and achieve a small temperature gradient, The effect of power reduction, ease of manufacture and difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

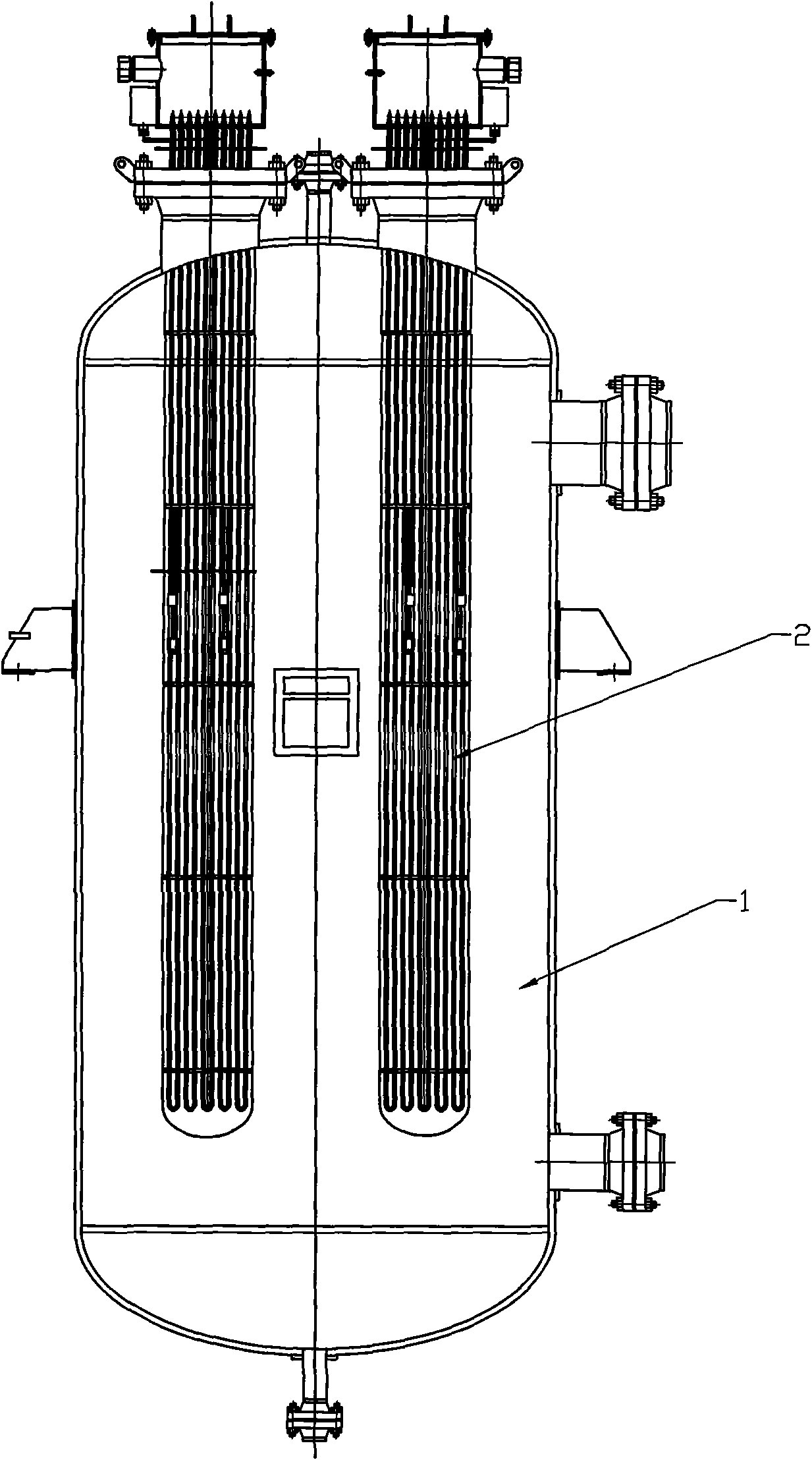

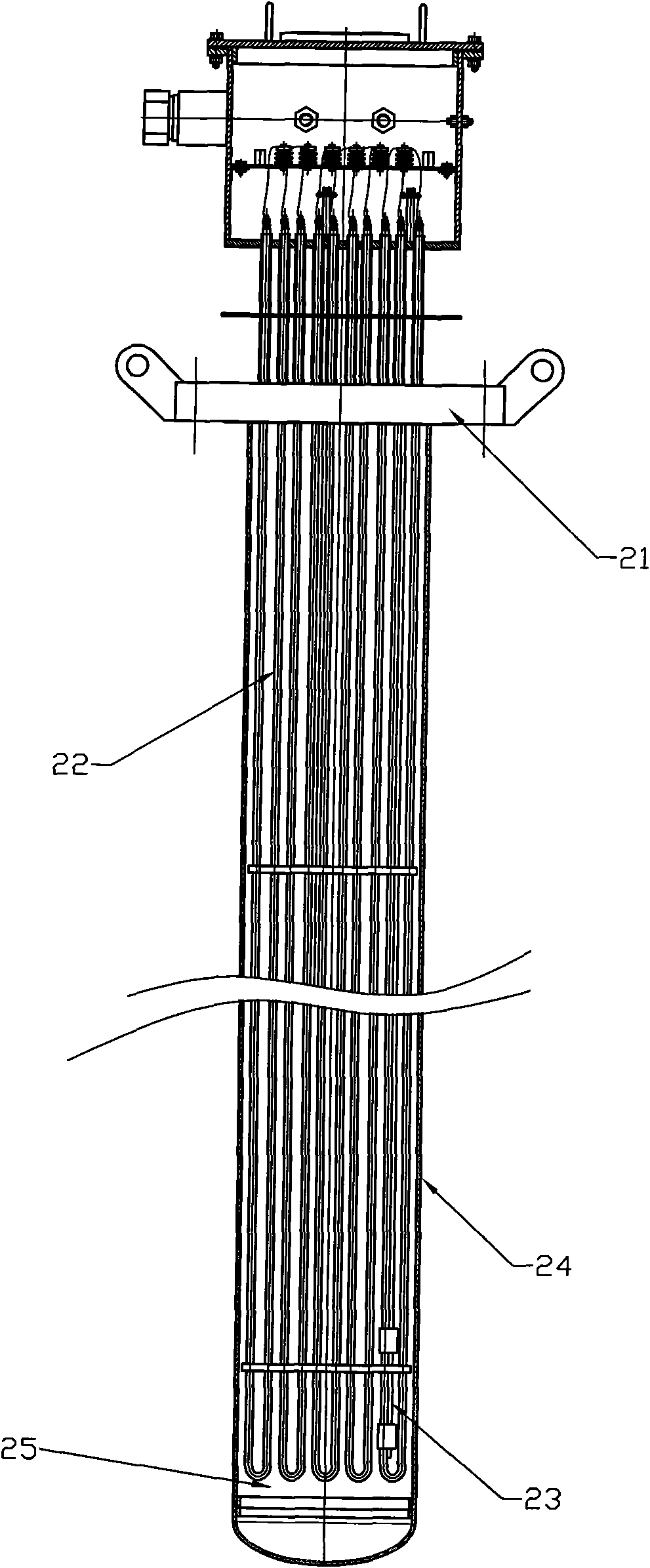

[0013] As shown in the figure, the electric return device includes a medium heating working chamber 1 and at least one electric heating core 2 inserted in the medium heating working chamber. A plurality of electric heating tubes 22 and several temperature measuring tubes 23 connected to the over-temperature protection circuit distributed in the heating range of the electric heating tubes, all the electric heating tubes 22 and the temperature measuring tubes 23 are contained in a metal cylinder 24, and the metal cylinder One end is sealingly connected with the flange cover 21 , the other end of the metal cylinder is closed, and the gap between the inner wall of the metal cylinder, the electric heating tube and the temperature measuring tube is filled with the cast aluminum body 25 .

[0014] There are multiple electric heating cores 2, and the multiple electric heating cores are connected in parallel through their respective connecting terminals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com