Automated system for improved cooling of aluminum castings in sand molds

a technology of automatic cooling and aluminum castings, which is applied in the field of aluminum castings and metal castings, can solve the problems of odor and contamination of the plant area, sand molds require a longer cooling time, and need for cooling down, so as to improve the overall quality and mechanical properties of the castings, save space, and improve the overall quality of the castings. the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]A preferred embodiment of the invention will be described as applied to the cooling of sand molds containing aluminum alloys for manufacturing automotive motor parts, e.g. cylinder engine blocks and engine cylinder heads.

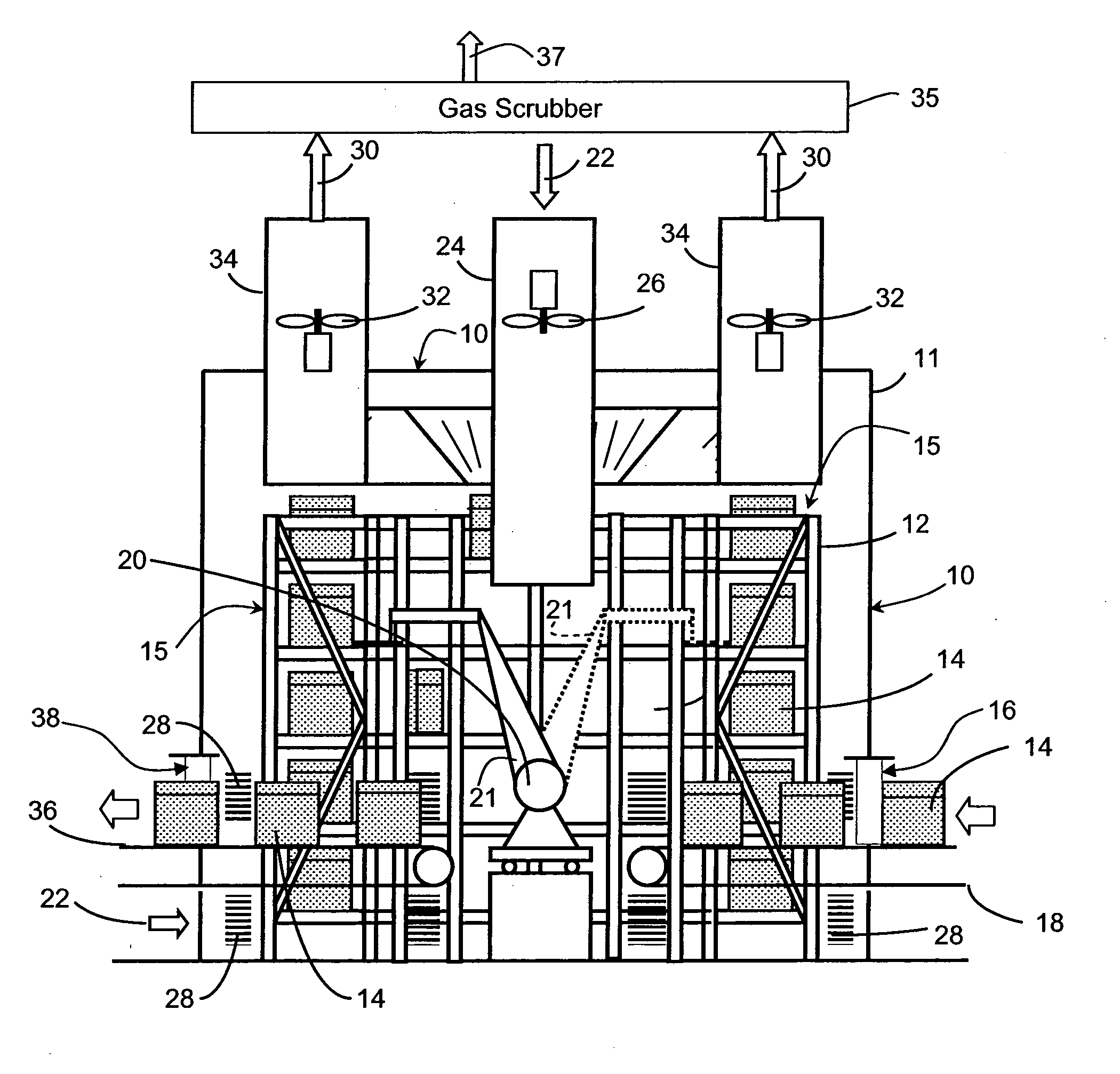

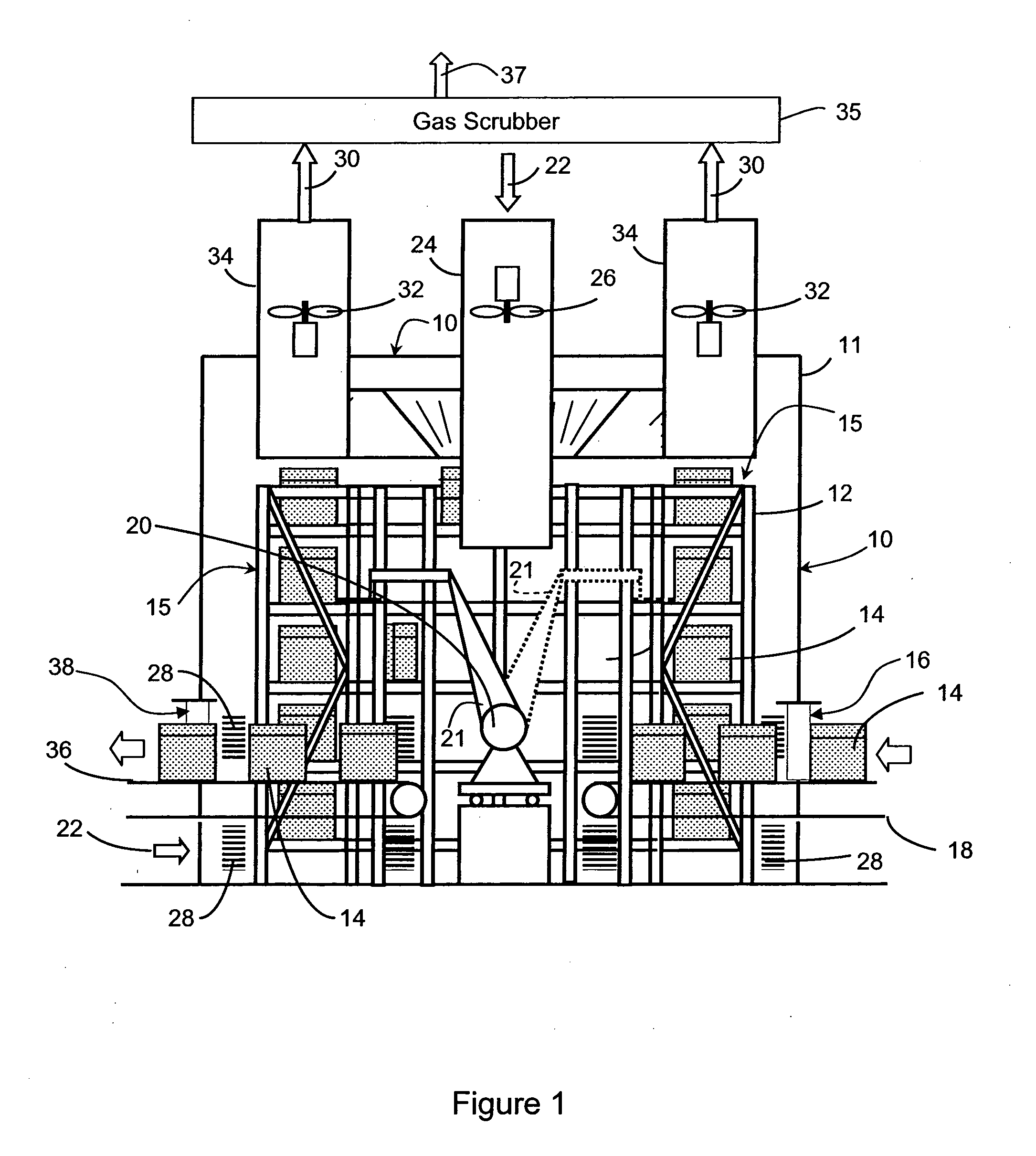

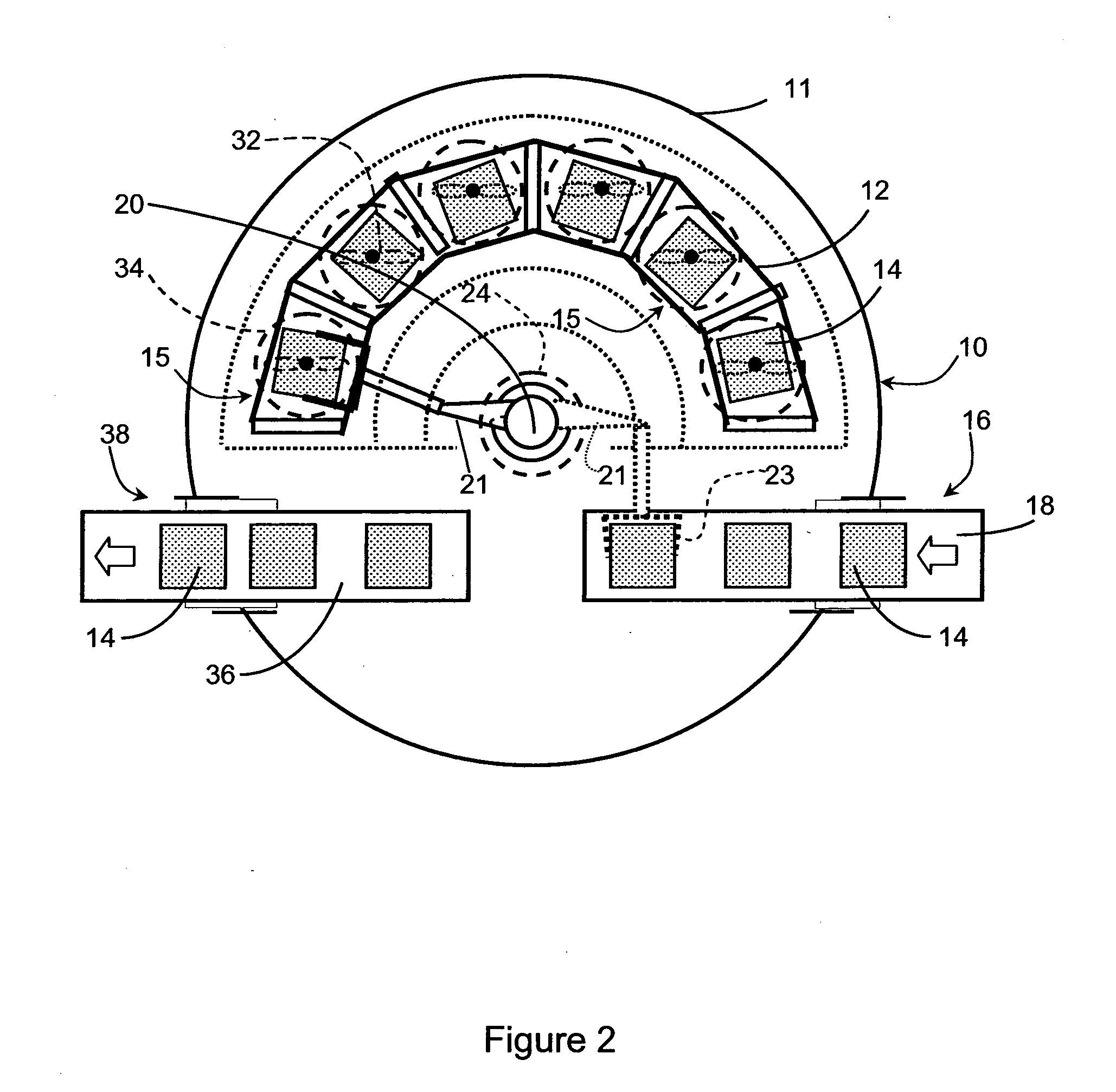

[0025]Referring to FIGS. 1 and 2, there is shown an apparatus for improved cooling of aluminum castings in sand molds comprising a cylindrical housing 10 containing a plurality of vertical shelves 12 which are distributed around at least a portion of the inside of the circular side wall 11 wall of said housing 10 for the purpose of storing sand molds 14 in a cooling environment, while the castings are solidifying. In the illustrated embodiment, each shelf in each unit of the vertical shelving 12 constitutes a single cooling station 15.

[0026]The hot newly cast sand molds containing molten metal 14 are introduced through a sand mold inlet port 16 via conveying feed means 18. From there, the robot 20 uses its arm 21 with clamp 23 (shown in dotted outline in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com