Patents

Literature

41 results about "Noxious fumes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dressed in his gray suit, he sat in stillness as the noxious fumes billowed into the cabin of his blue Chevy Chevelle. The Professor and the Doomsday Clock: ‘A Confederacy of Dunces’ & Signs of John Kennedy Toole’s Suicide. Cory MacLauchlin. December 17, 2012.

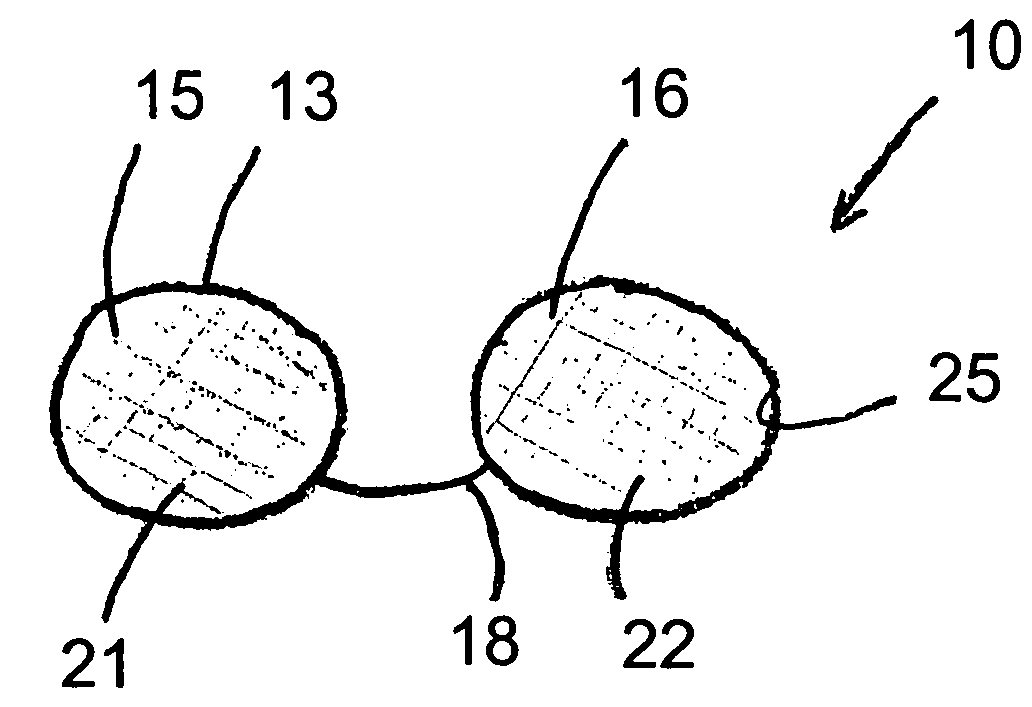

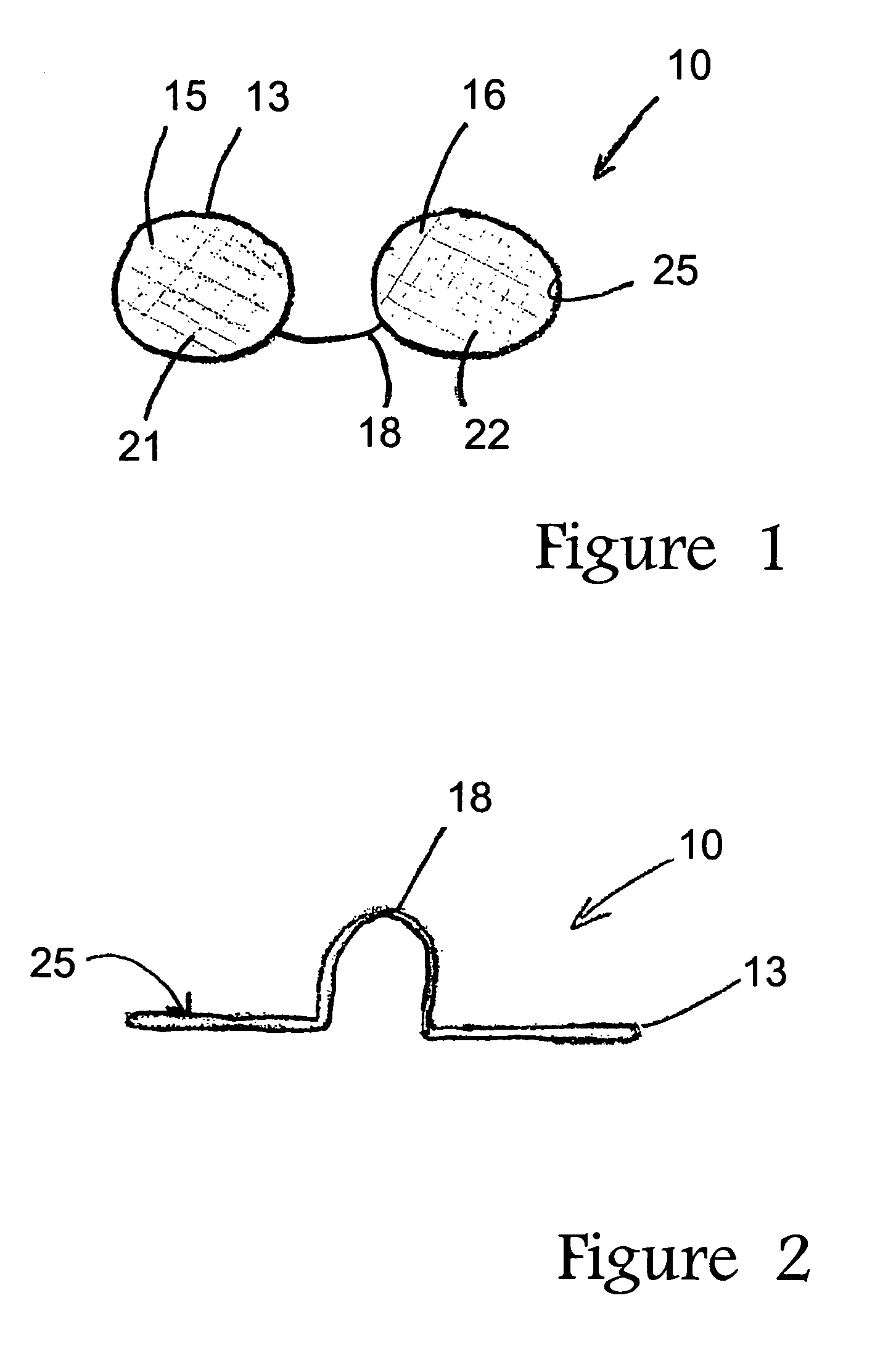

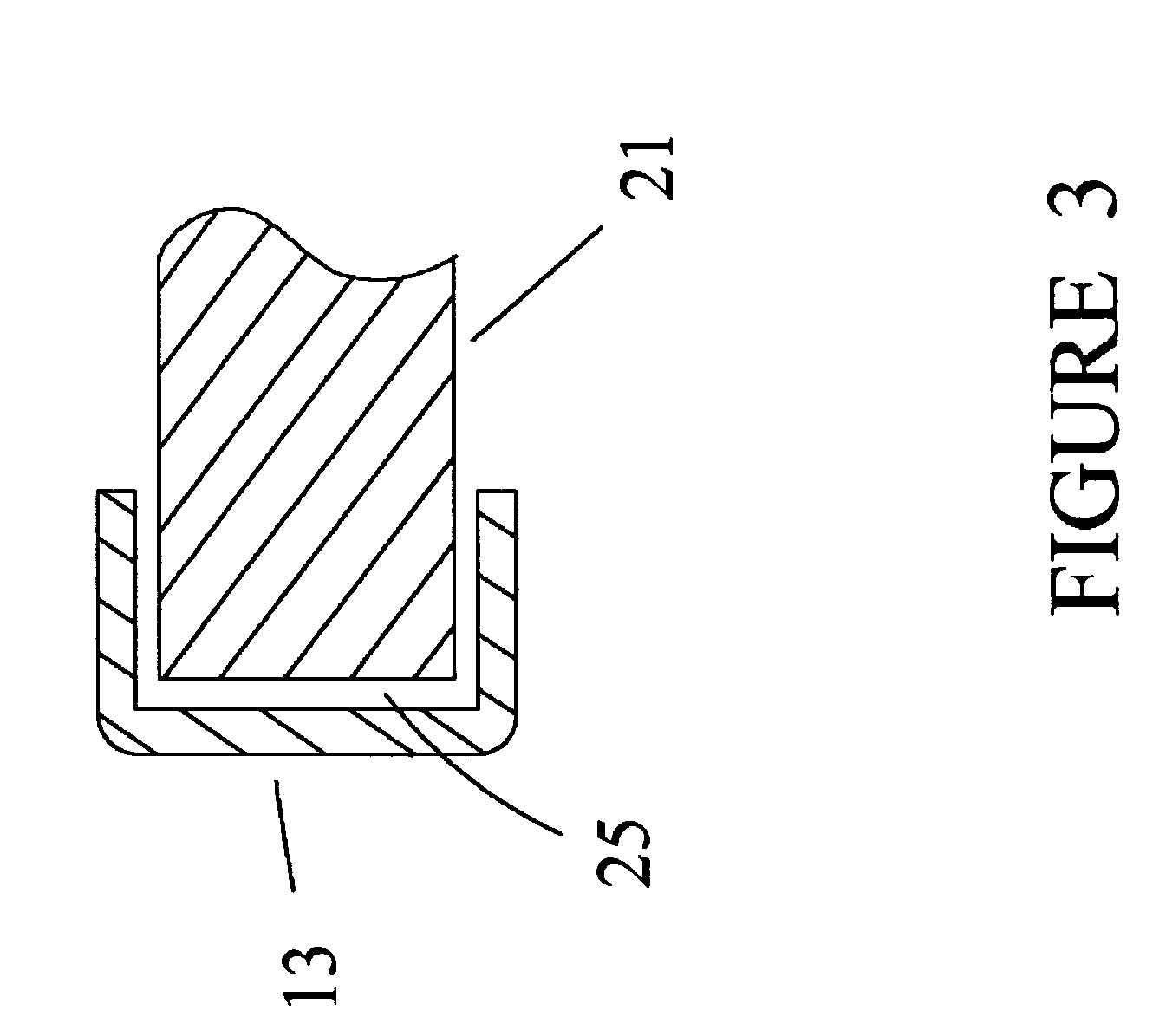

Nostril filtering system

InactiveUS7156099B1Effective resistanceEasy to useRespiratorsBreathing filtersNostrilActivated carbon filtration

A nostril filtering system is described for providing clean, filtered air for breathing in through the nose. The filtering system includes a soft, pliable filter material held in a flexible frame that can be inserted into each nostril of a user. In the case of foul odors or noxious fumes, for example, the filter can include an activated charcoal filter portion. The device can be offered in several sizes to accommodate adults and children.

Owner:JENKINS CLOYTILLIA M

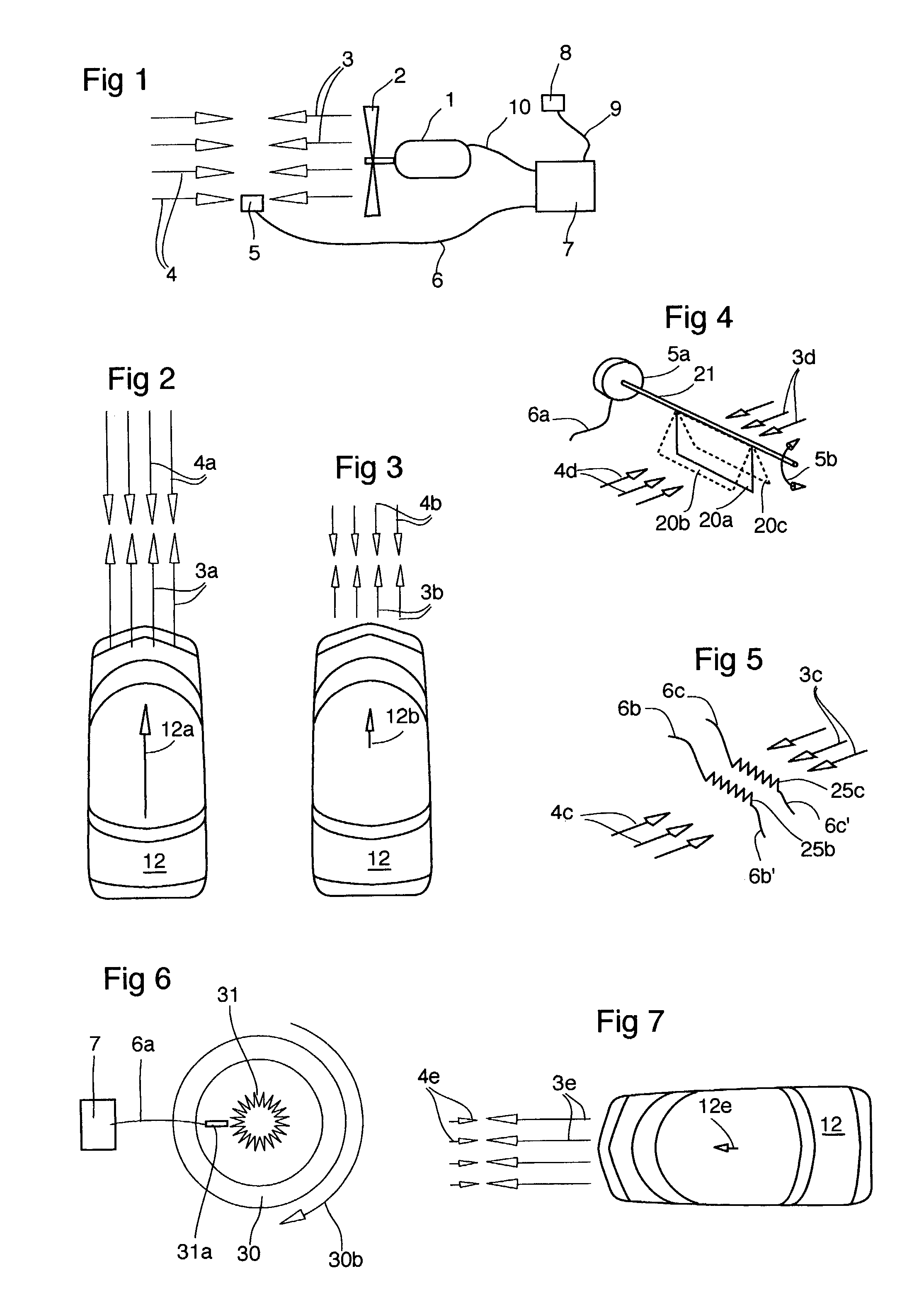

Bi-directional automotive cooling fan

InactiveUS7121368B2Adequate engine coolingMaximize air flow dynamicCoolant flow controlPump componentsCylinder blockTraffic conditions

The instant invention pertains to a road vehicle's axial flow cooling fan which normally draws cooling air from in front of the vehicle and blows it into the engine bay. The instant invention includes a control circuit for the fan motor that provides variable speed and bi-directional, or reverse and normal, fan operation. Reverse fan operation blows air from the engine bay through the radiator and out the front of the vehicle, and normal fan operation blows into the engine bay. Two input sensors feed the control circuit, one for road speed of the vehicle and other for engine temperature. When the engine is below its operating temperature and the vehicle is moving, the fan is made to blows in reverse at a speed proportional to road speed so as to block cold ram air from entering and blasting onto a warming engine. This speeds engine warm-up to reduce emissions, improve fuel economy, and speed windshield defogging. The fan may also be made to blow in reverse when the engine is cold and the vehicle is stopped, in order that exhaust-heated air from the exhaust manifold behind the engine, may be drawn forward over the engine block to speed its warming. When the engine is above its operating temperature and the vehicle is idling or moving slowly, as in traffic, then the control circuit causes the fan to again blow in reverse cooling both the radiator and the engine bay components and preventing hot, noxious fumes from vehicles in front from being drawn into the vehicle. Blowing in reverse in traffic conditions also eliminates hot air looping back to the front of the car and drawn in through the radiator. As vehicle speed increases, the fan is made to revert to normal operation augmenting ram air flow through the radiator.

Owner:MACKELVIE WINSTON

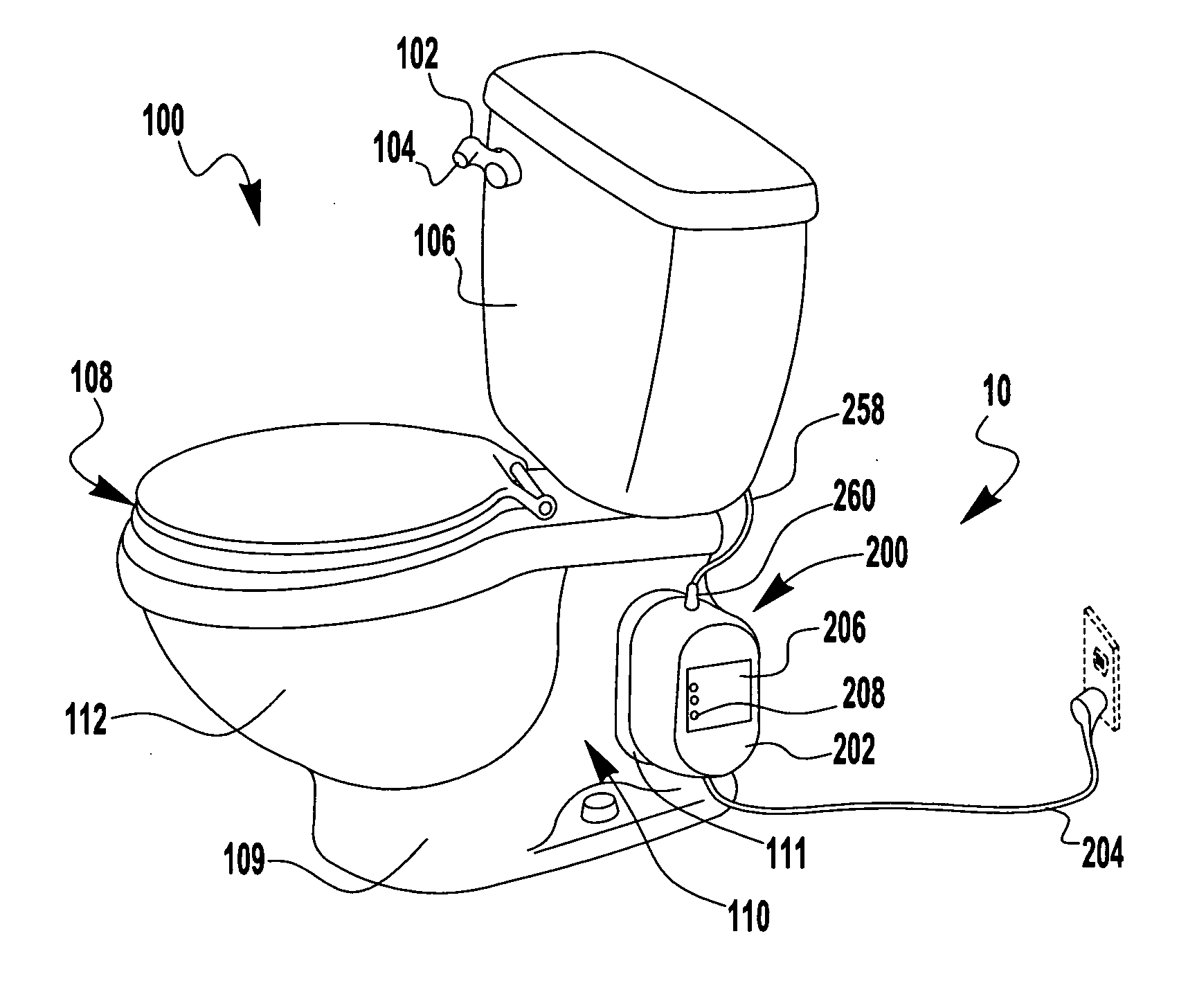

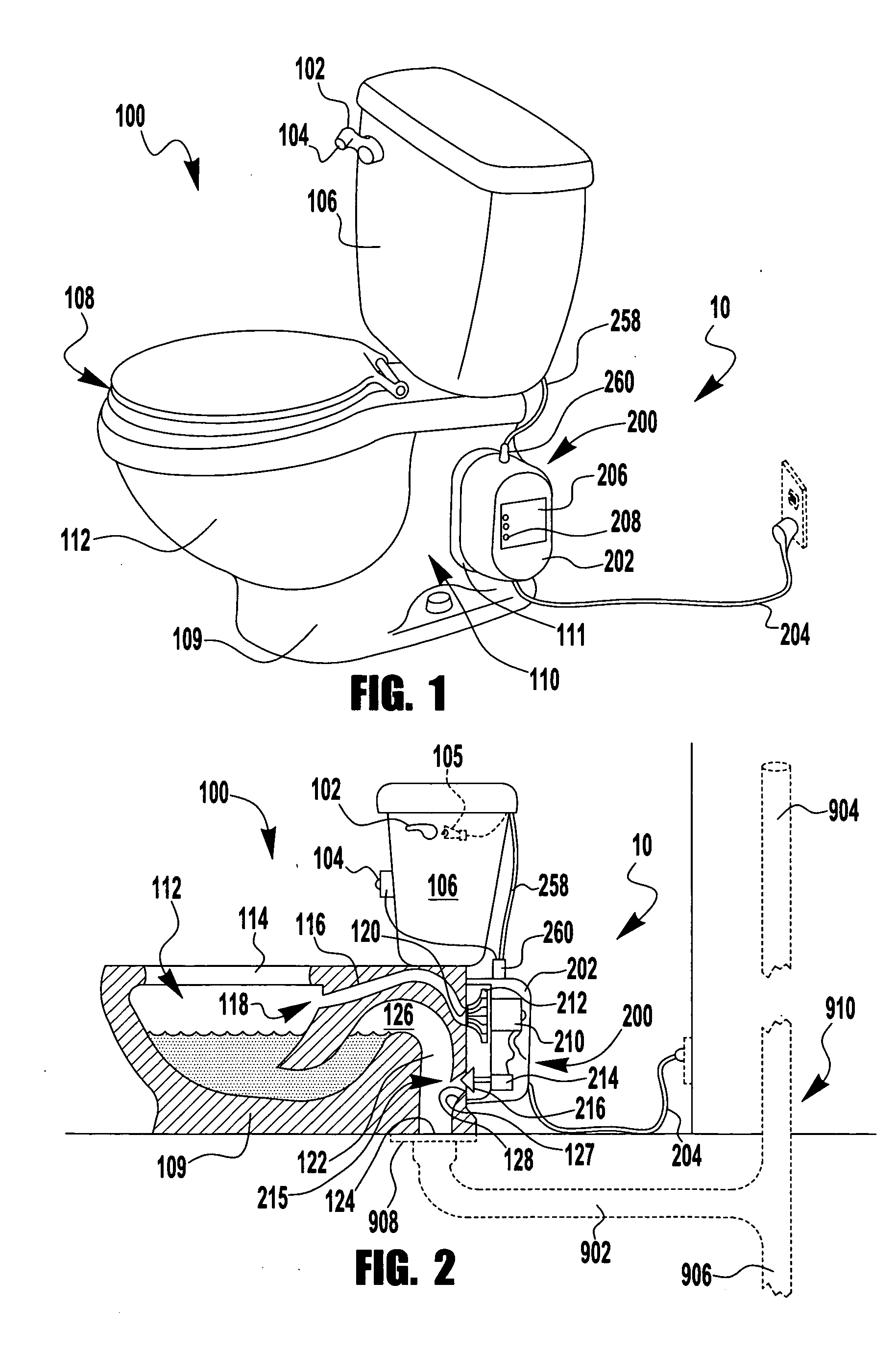

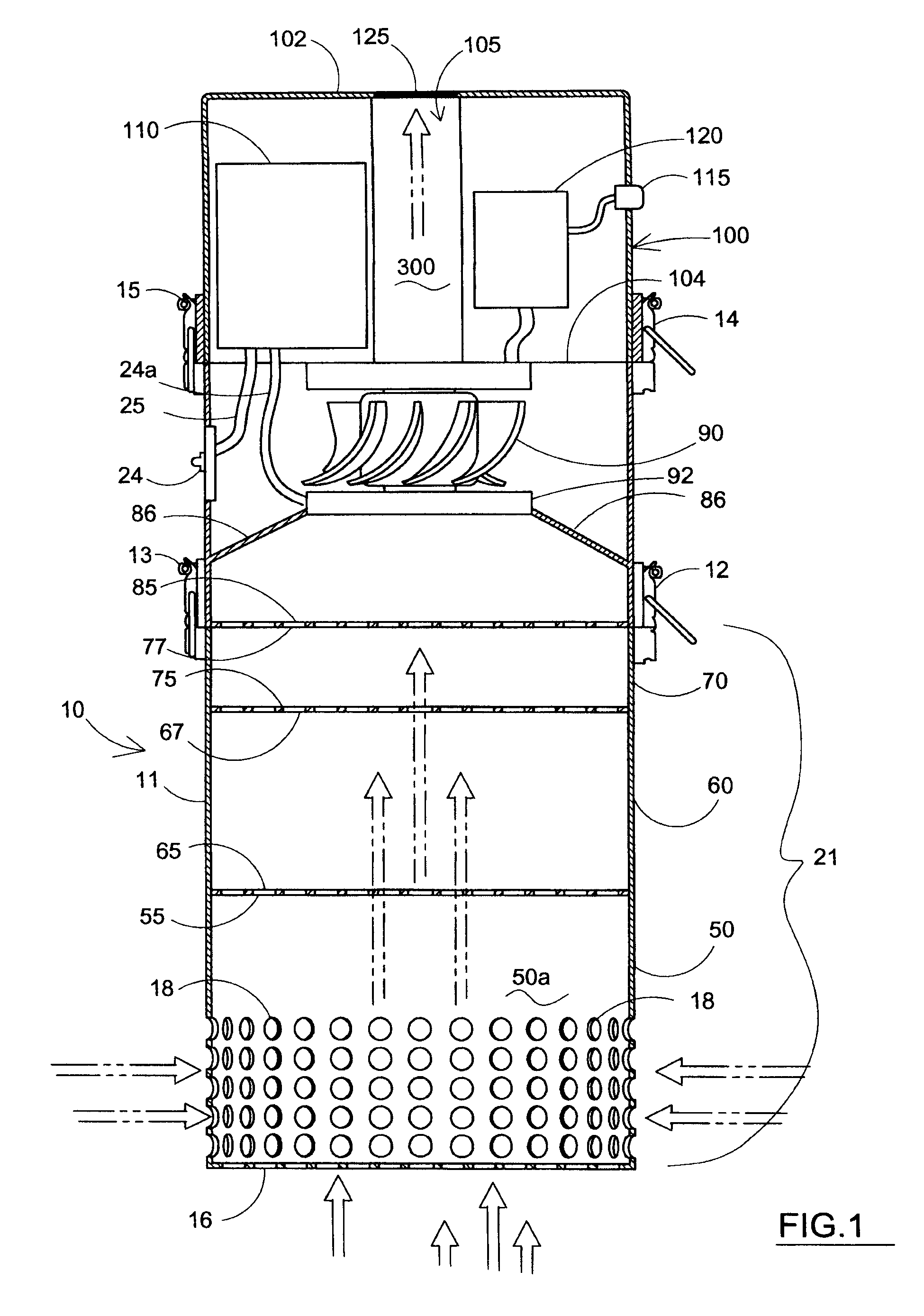

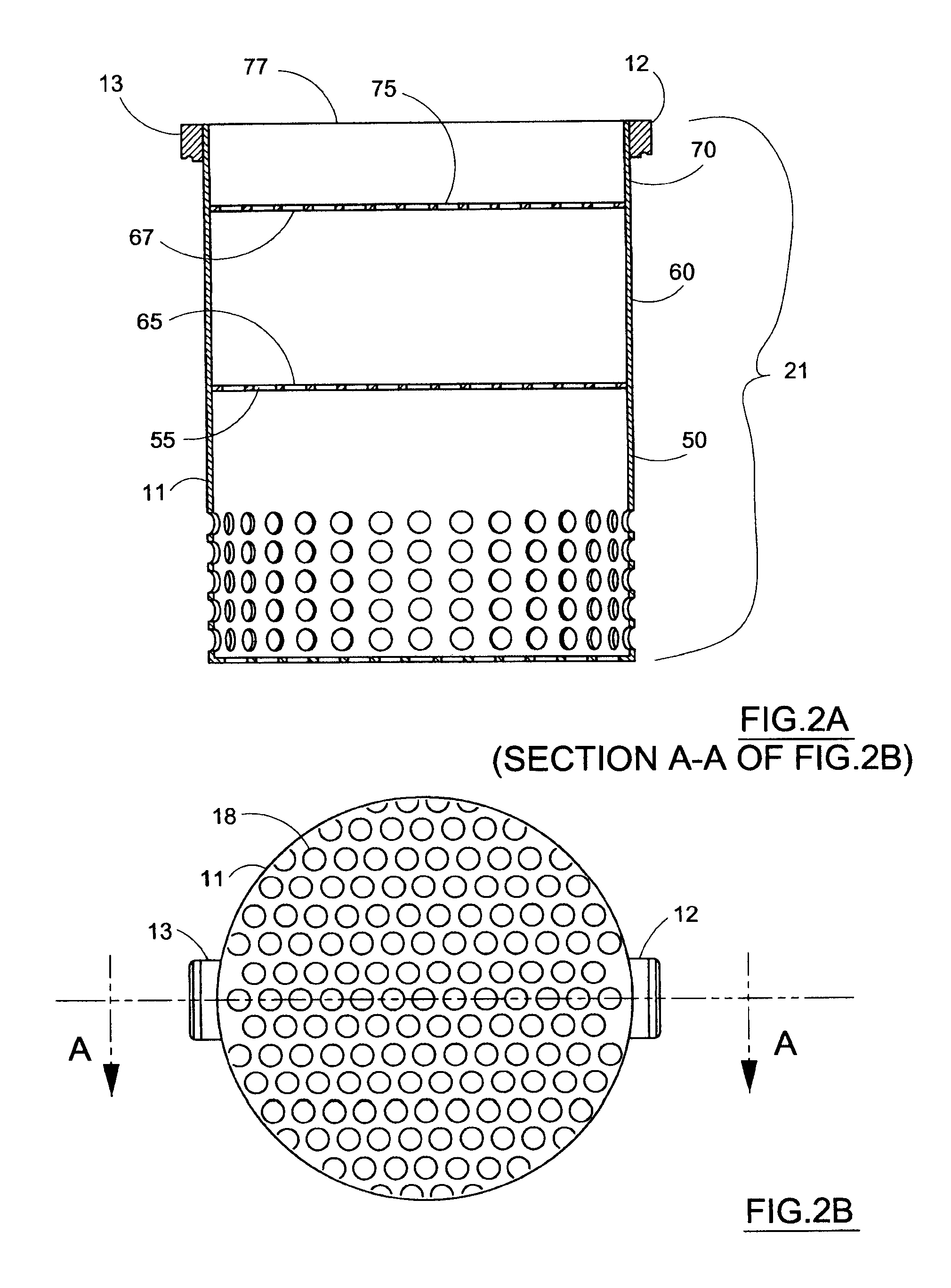

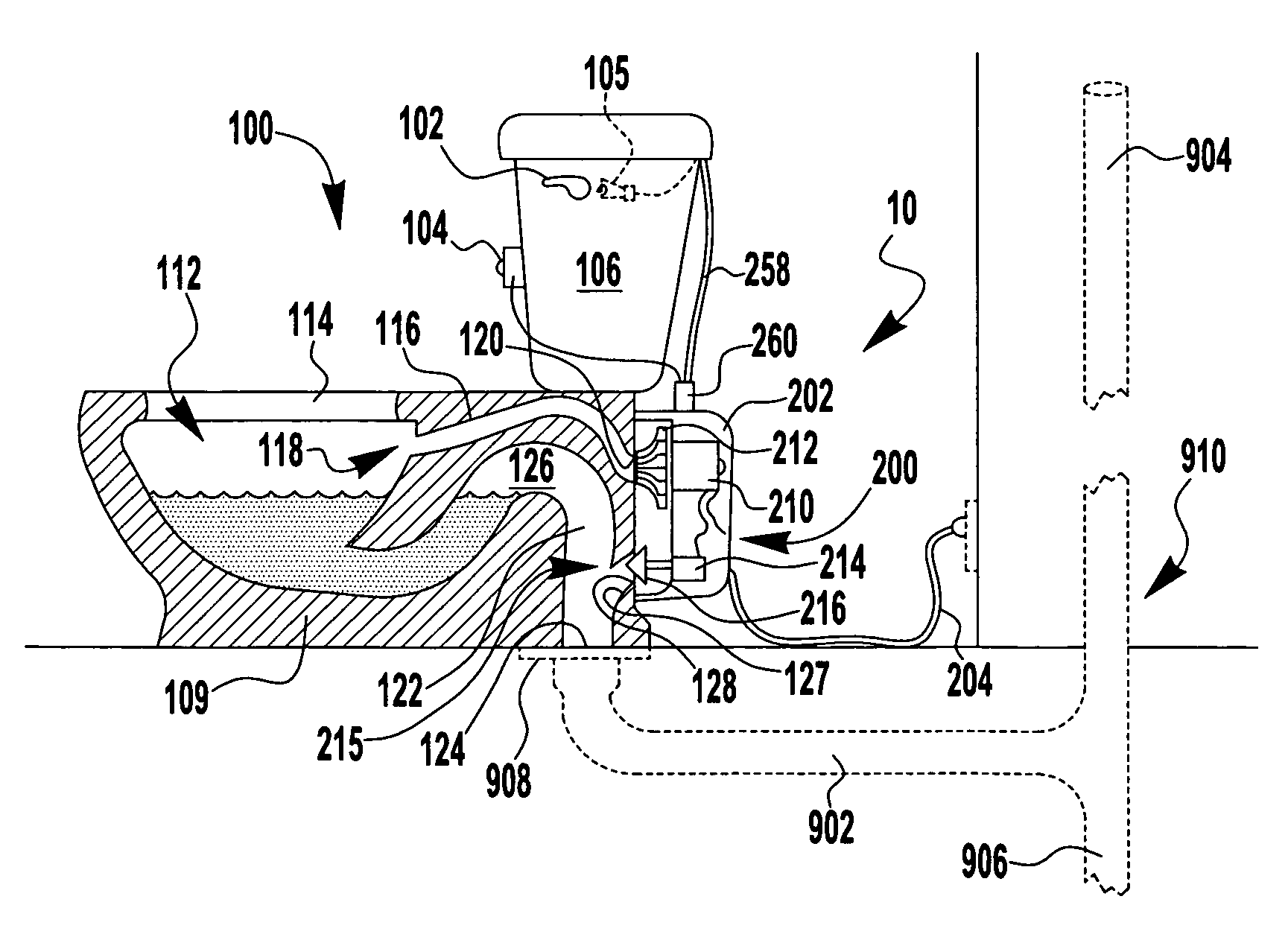

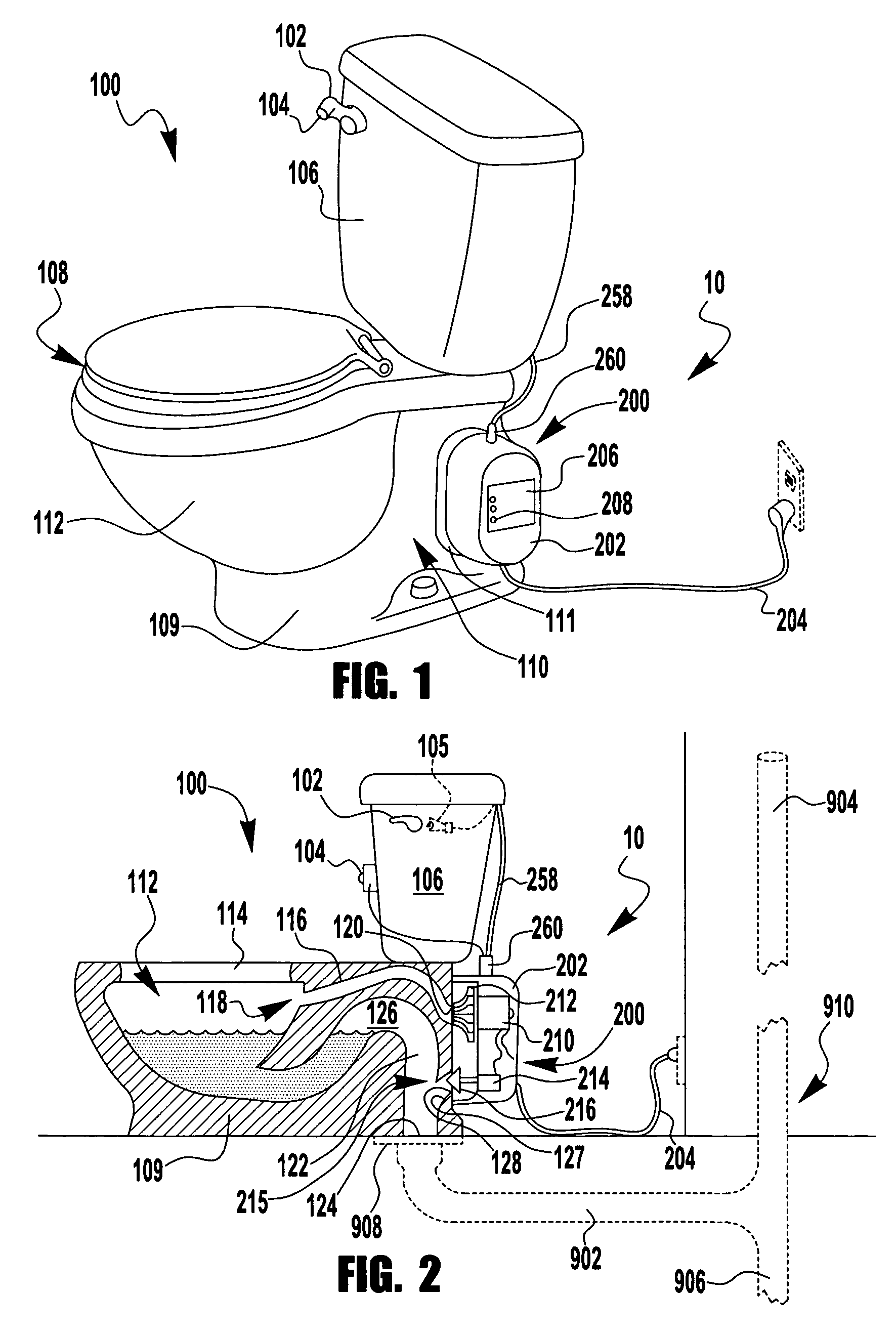

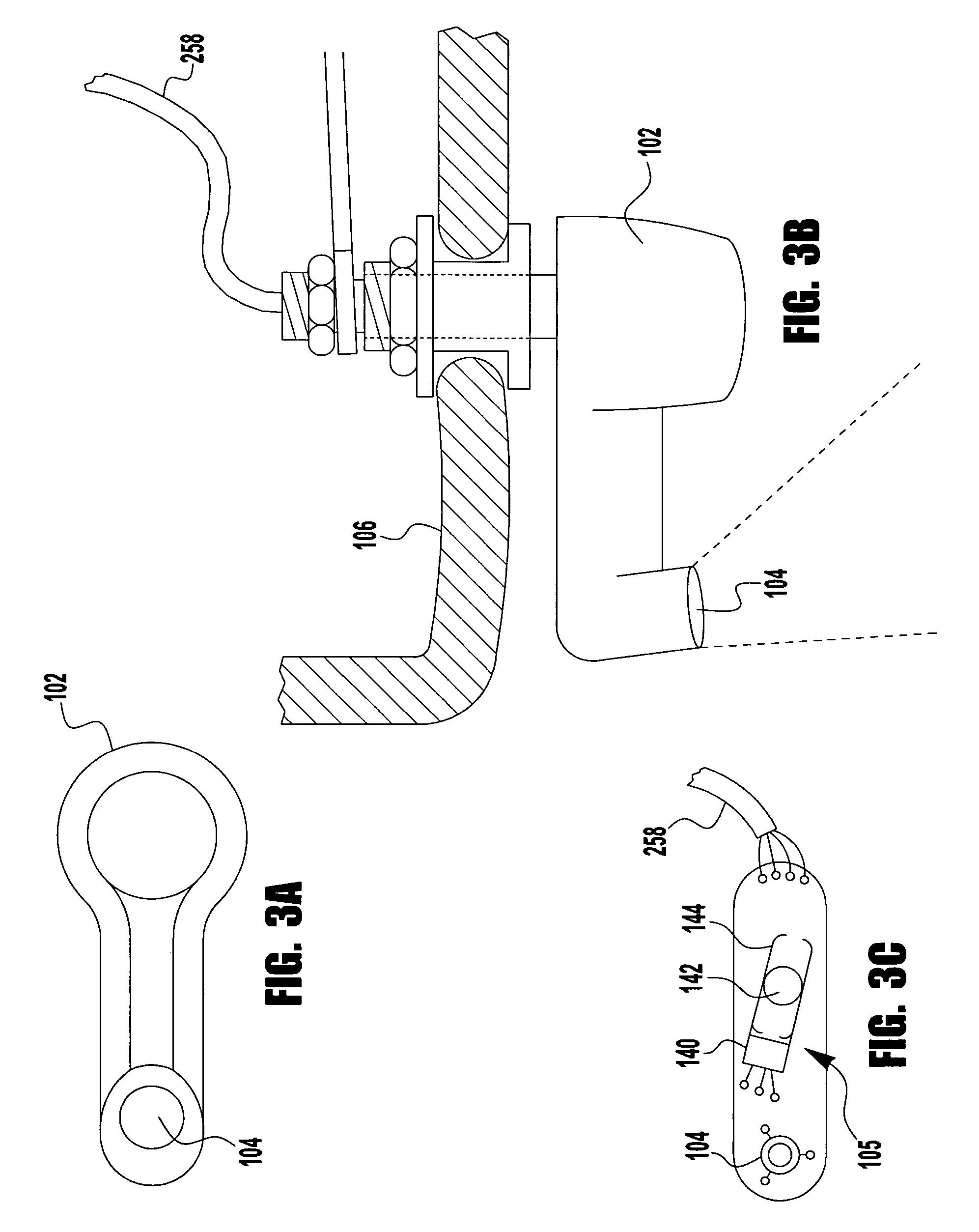

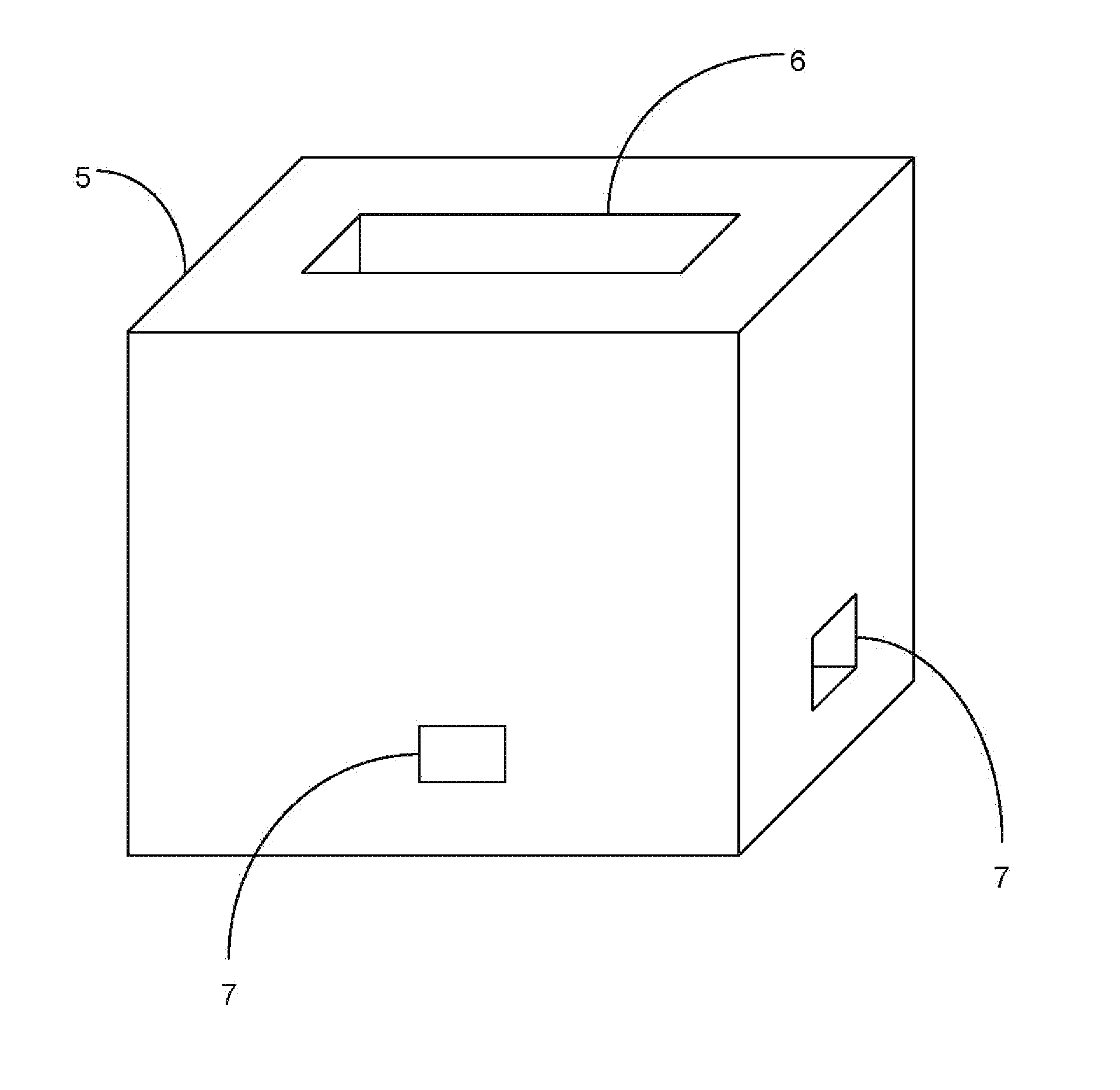

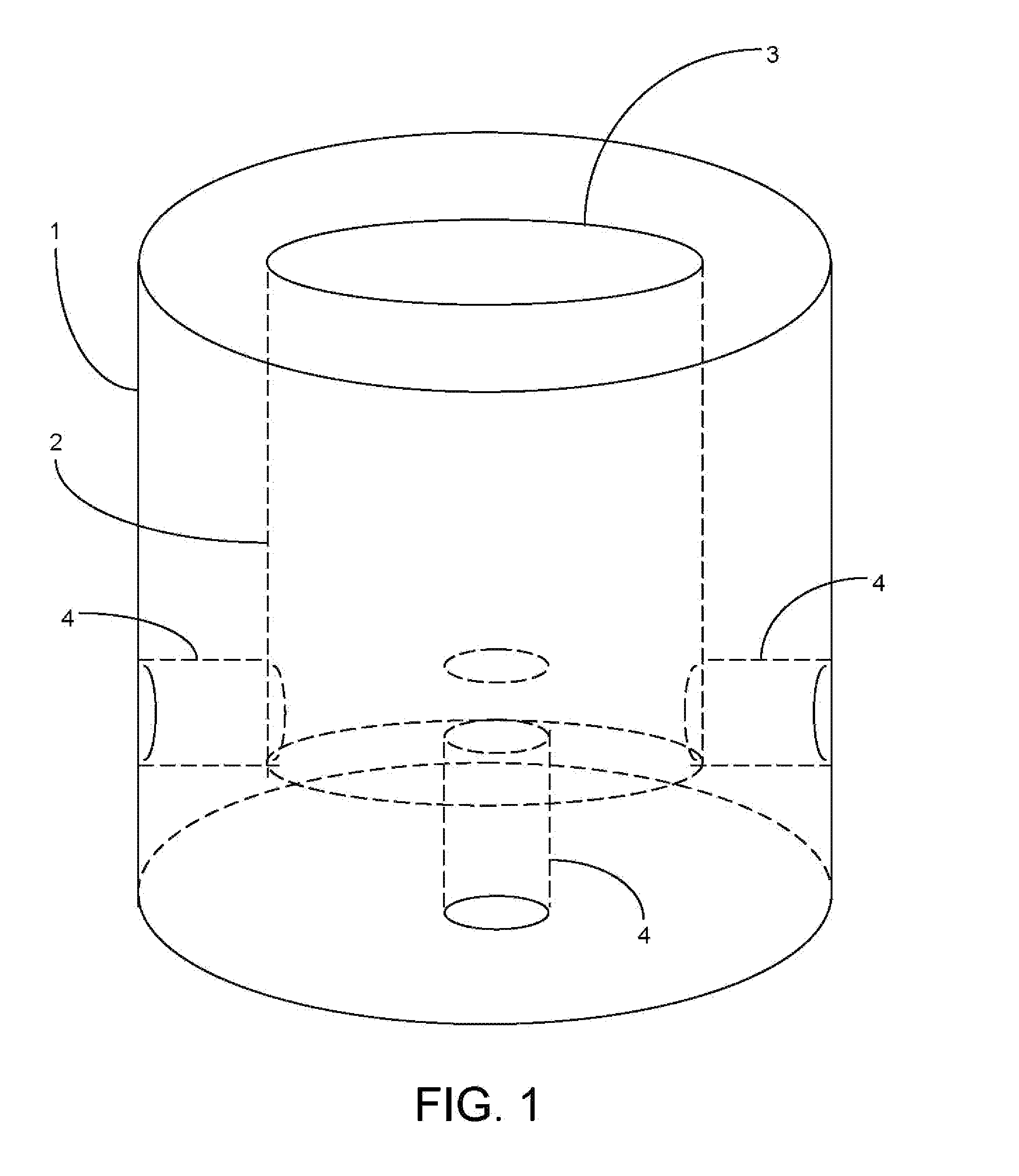

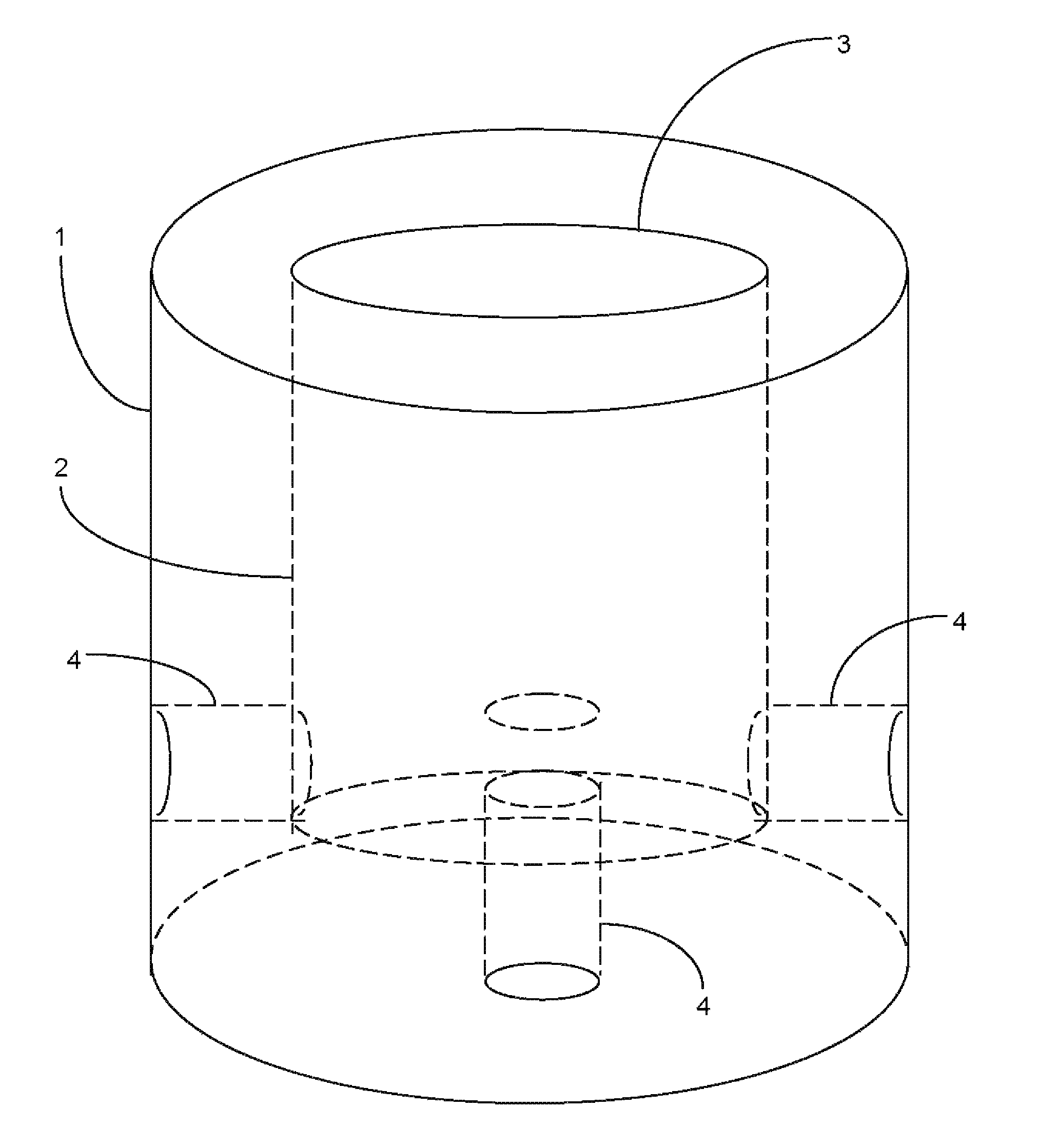

Toilet ventilation system

A premium ventilated toilet having an automated toilet ventilation system for removing noxious fumes from a bowl area of the toilet is disclosed. The ventilation system is mostly built-in to the toilet (e.g., ventilation ducts, and sensors) so that it is unobtrusive and attractive looking, however the active parts (e.g., a blower unit containing a blower impeller, a backflow shutoff valve, and electronic control circuitry) are contained in an simple housing that is unobtrusively and removably attached to the surface (preferably on the side) of the toilet base for simplified installation, maintenance, and replacement as needed. Automated operation is enabled by a non-contact occupancy (proximity) sensor and a flush sensor, both preferably built into a flush handle of the toilet. Detection of occupancy causes the ventilation system to operate and flushing turns it off.

Owner:LAPOSSY KENNETH A

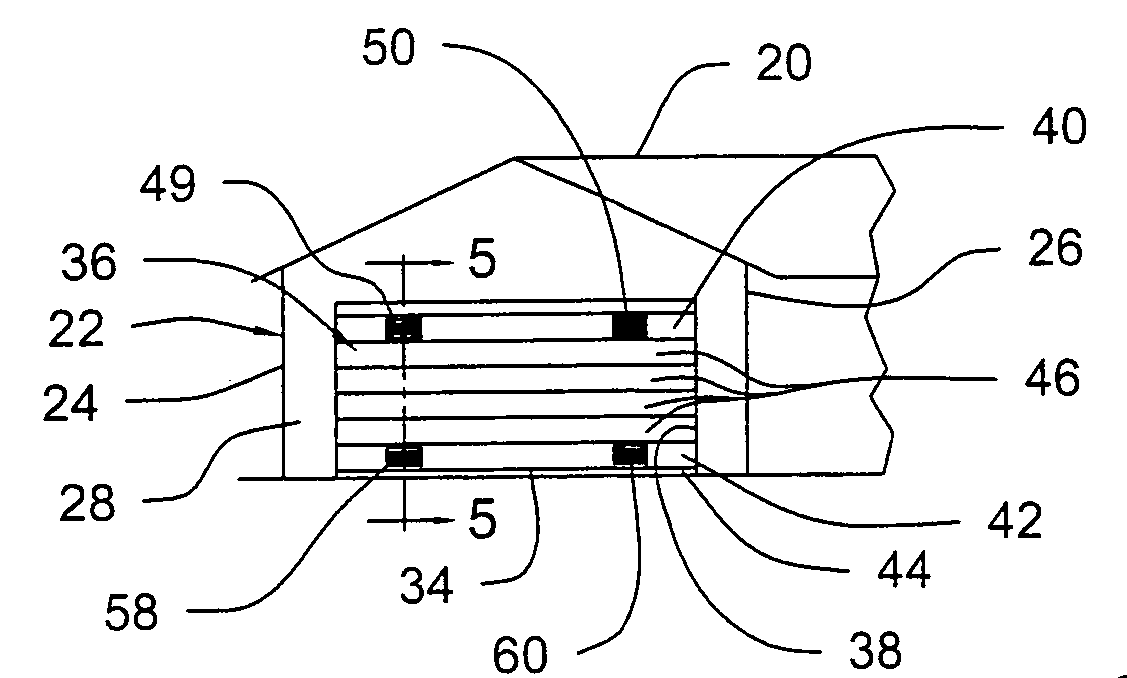

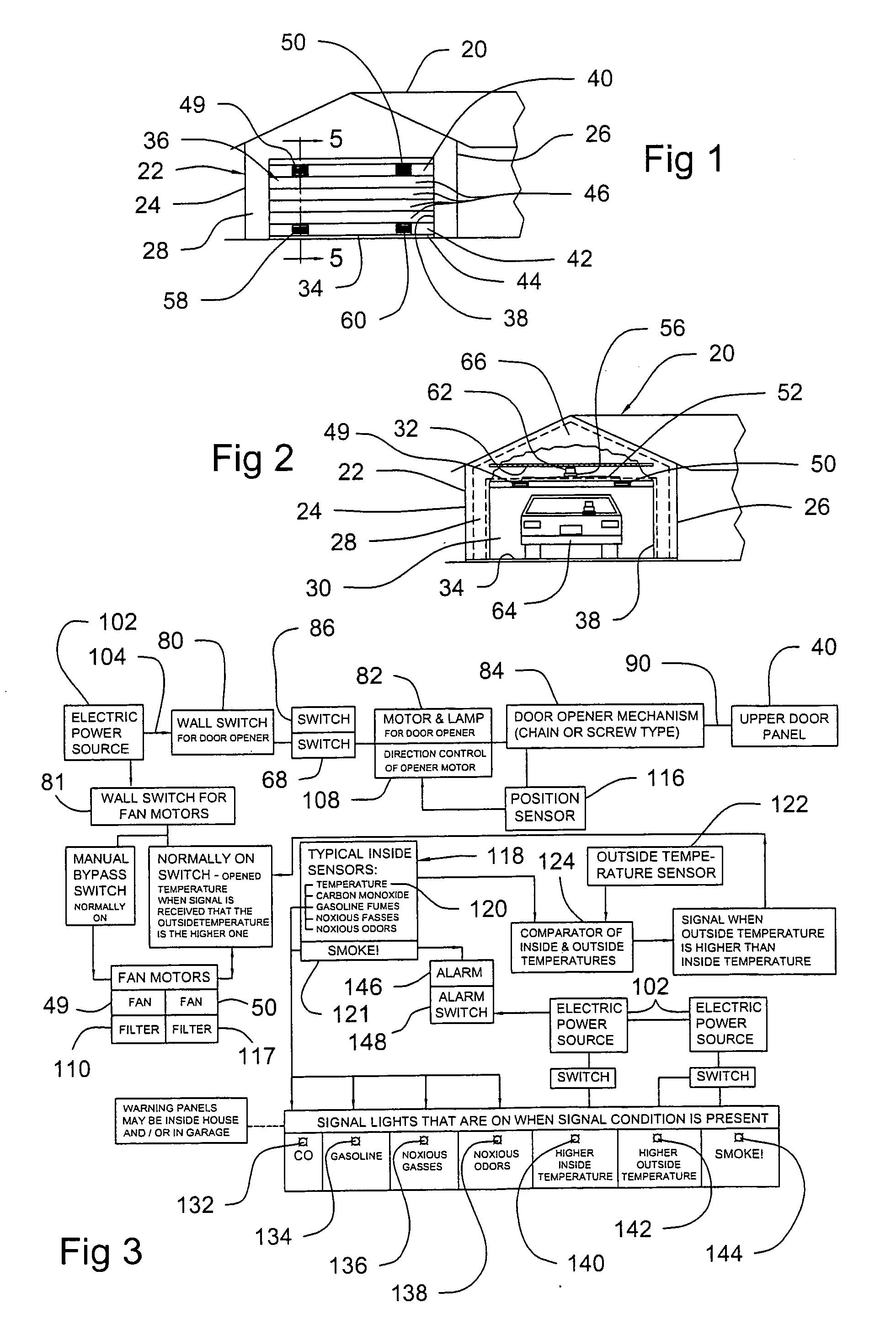

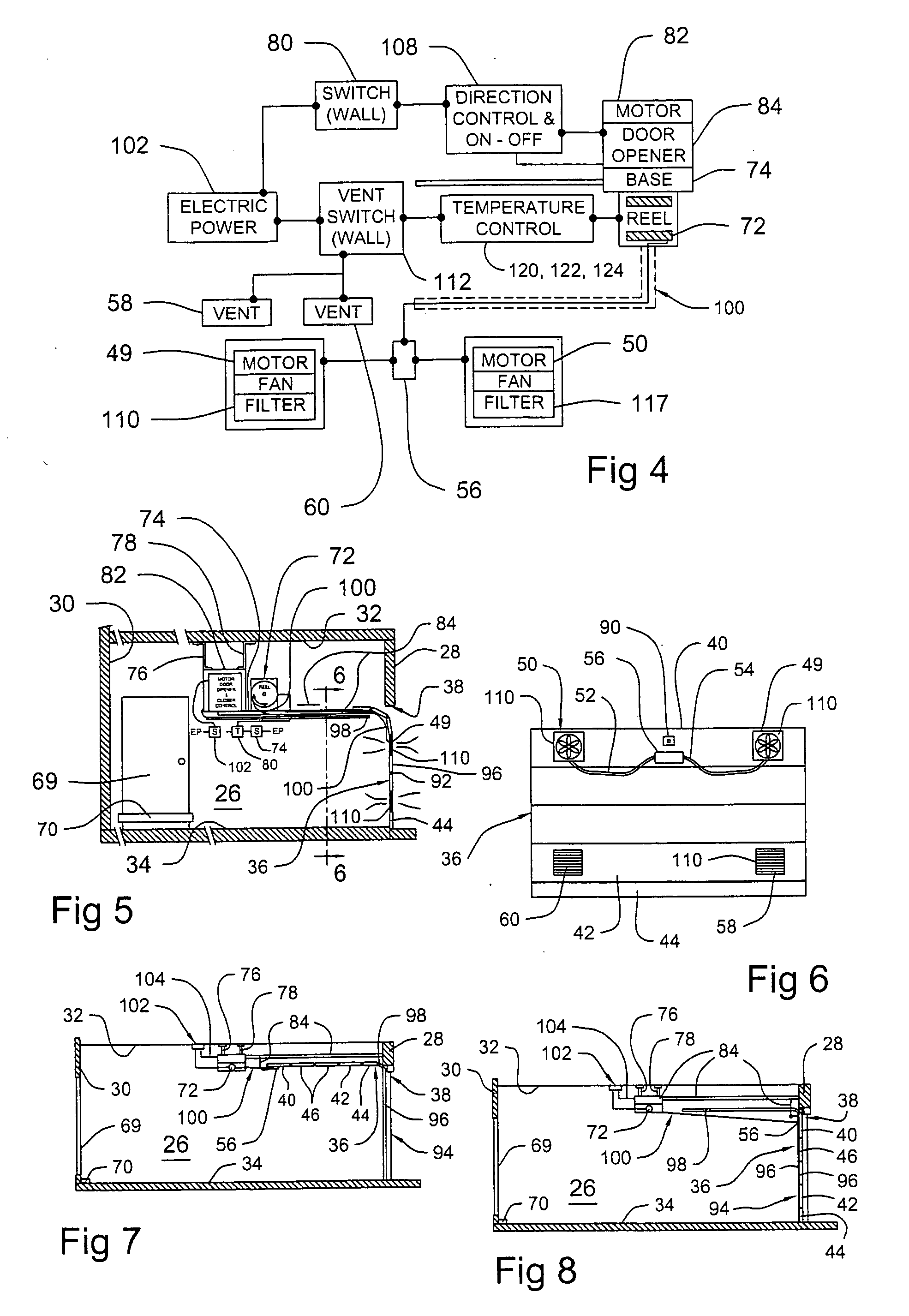

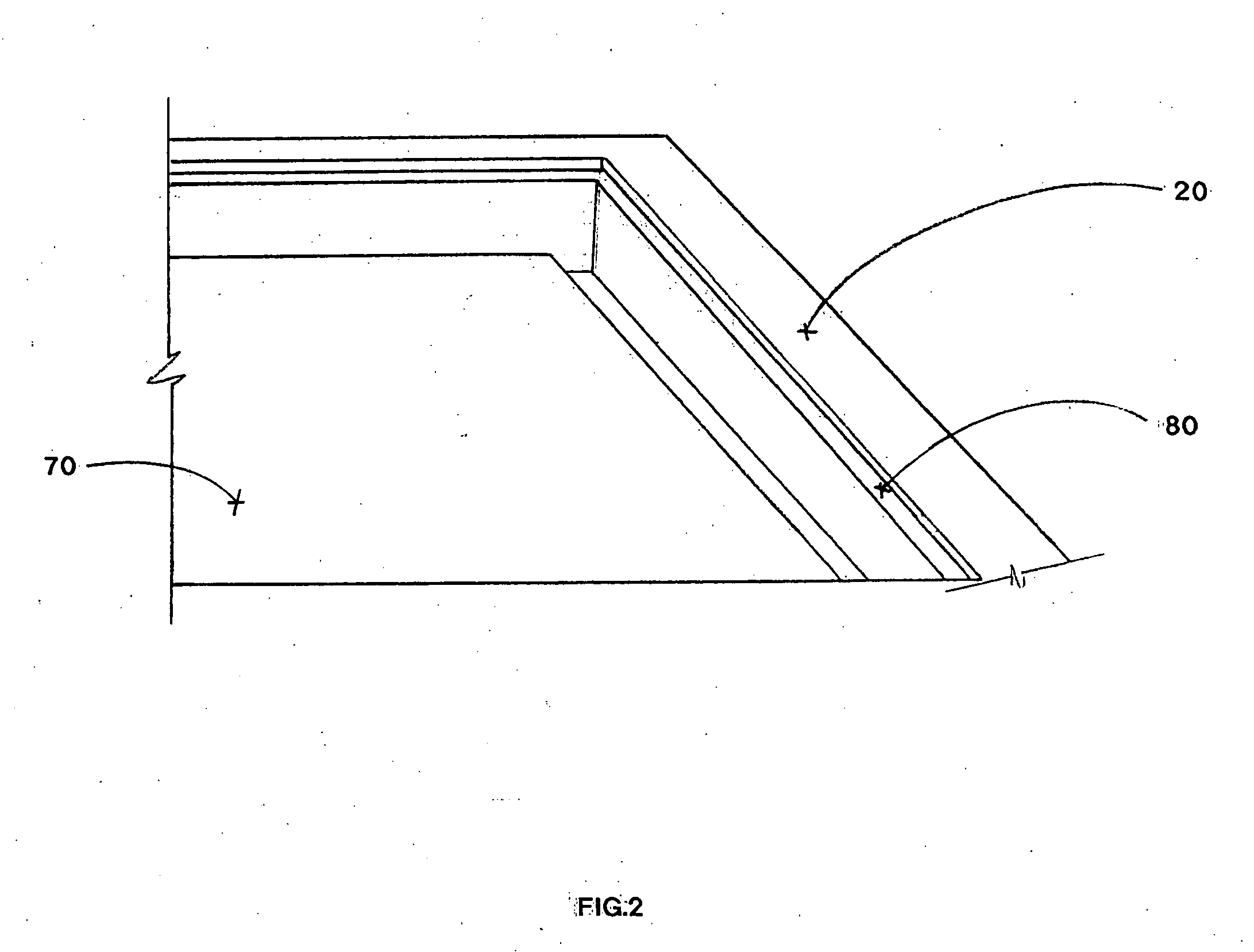

Ventilating system for garages and similar enclosed spaces

InactiveUS20090124189A1Cool interiorSafe removalDucting arrangementsSpace heating and ventilation safety systemsEngineeringFixed position

The system embodying the invention is employed to cool the interior of a normally closed area such as a garage or storage area, and / or to remove any noxious fumes or undesirable odors from inside the garage by moving outside air into the garage and providing means for that inside air and the fumes or odors in it, if any, to be removed to the outside ambient atmosphere. The system includes one or more fans installed in the upper section of the garage door, and the garage door is opened or closed by moving it in any well-known manner either by rolling it's hinged panels upward to a horizontal position from its normally-closed vertical position, or, when it is a solid door, tilting the entire garage door so that it is substantially horizontal instead of vertical and is located above the garage floor a sufficient distance to drive vehicles that will fit into the garage though the door opening. Those fans have a power cord that extends from a power supply position generally near the garage door opener that is secured to the garage ceiling and powers the garage door from its closed position to its open position, and vice versa, and that power cord is also secured to the garage door in the vicinity of the fan or fans used to move air into and out of the garage when the garage door is closed. The power cord is spring-urged to minimize its relatively free section between the power source and the place where it is secured to the garage door in the vicinity of the fan or fans where it provides power to the fan motor or motors when desired and appropriate. In the preferred embodiment the power cord is wound on a reel that is spring loaded to urge the reel in the rotational direction to wind the part of the power cord that is between the reel and the fan motor or motors, keeping the relatively free section of the power cord in tension so that it does not form any dangerous hanging loops when the garage door is moving from its open position to its closed position. There are also lesser desirable alternatives to apply a spring-loading to the power cord to keep it sufficient tension that it does not form such loops when the garage door is being opened.

Owner:BARBER DAVID J

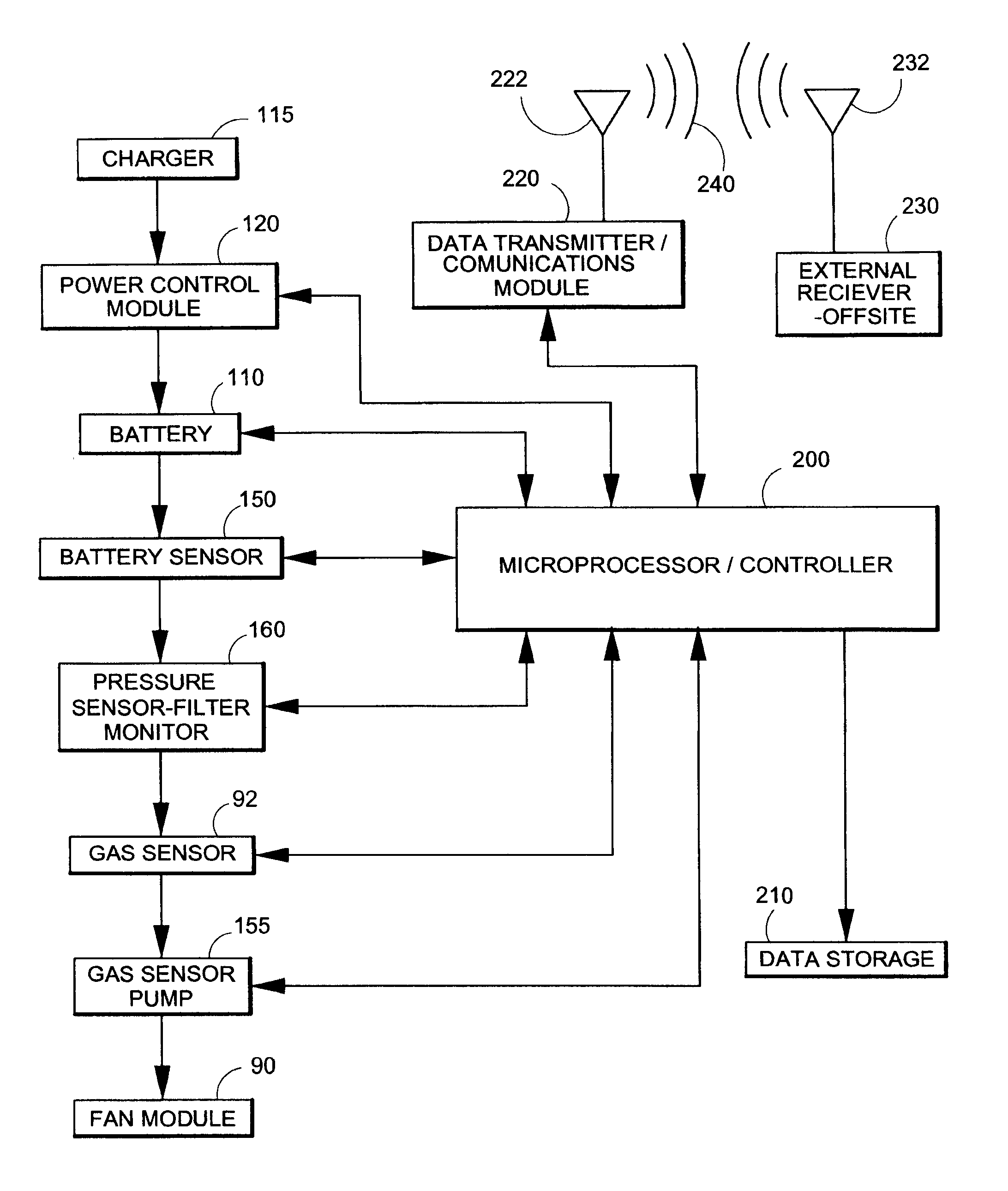

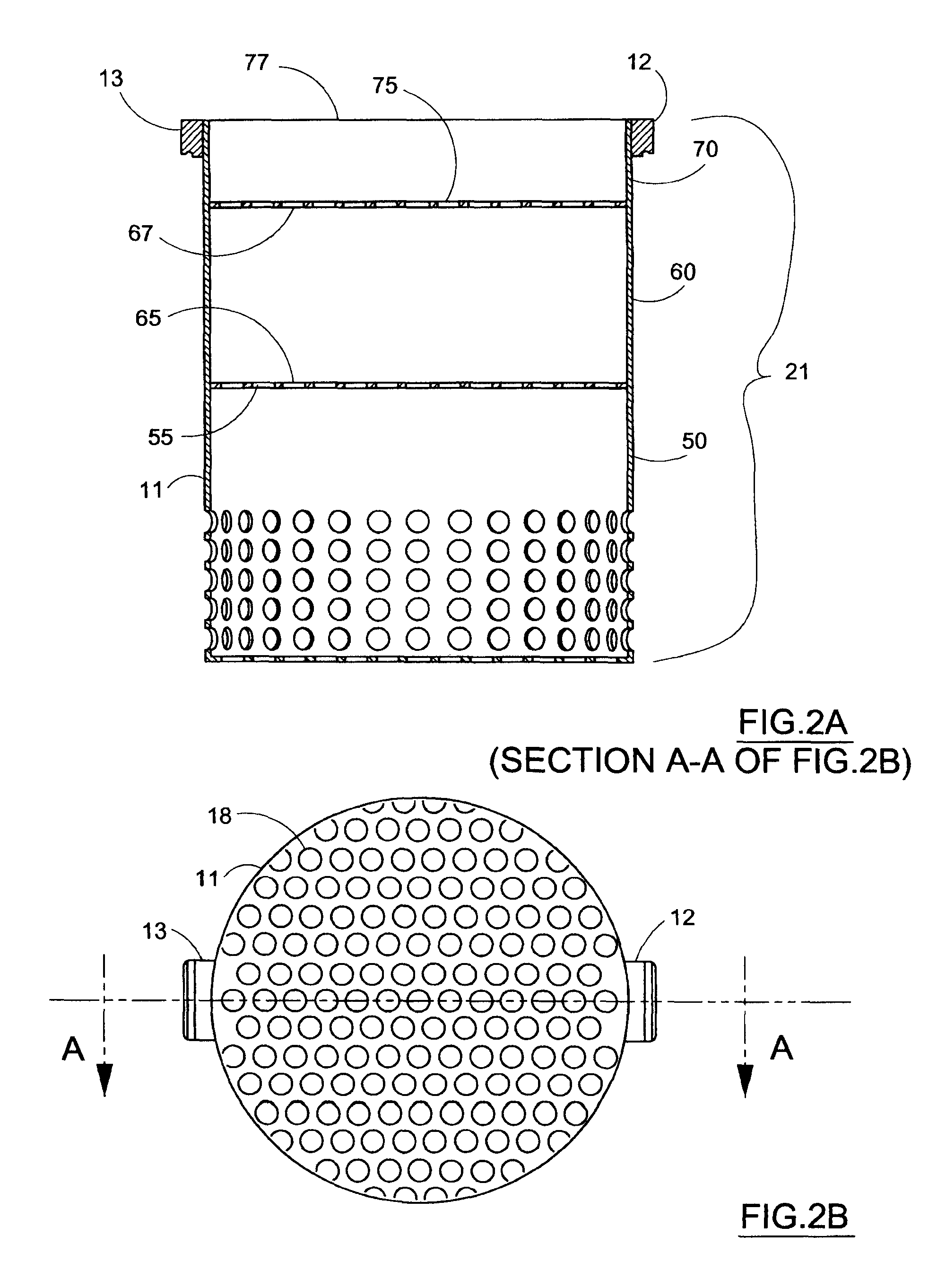

Portable Gas Scrubber With Sensor

InactiveUS20130092029A1Less frequent replacementExtended service lifeGas treatmentSewerage structuresData informationProduct gas

This invention relates to a portable odor scrubber system that is inserted into a sewer manhole or lift station where vaporous odors are prone to escape into the external environment. The invention controls such odors which may be caused by hydrogen sulfide, ammonia, mercaptan and other vapors which smell bad and can pose a severe health hazard. The invention has an automatic gas sensor trigger mechanism to control a fan to pull the noxious fumes through a series of scrubbers and to discharge treated air into the environment. Scrubber units may be easily replaced as well as designated to treat different environmental conditions. The invention can also store and transmit gas data information to an offsite location to monitor conditions where the portable odor scrubber system is located.

Owner:MORGAN GARY +2

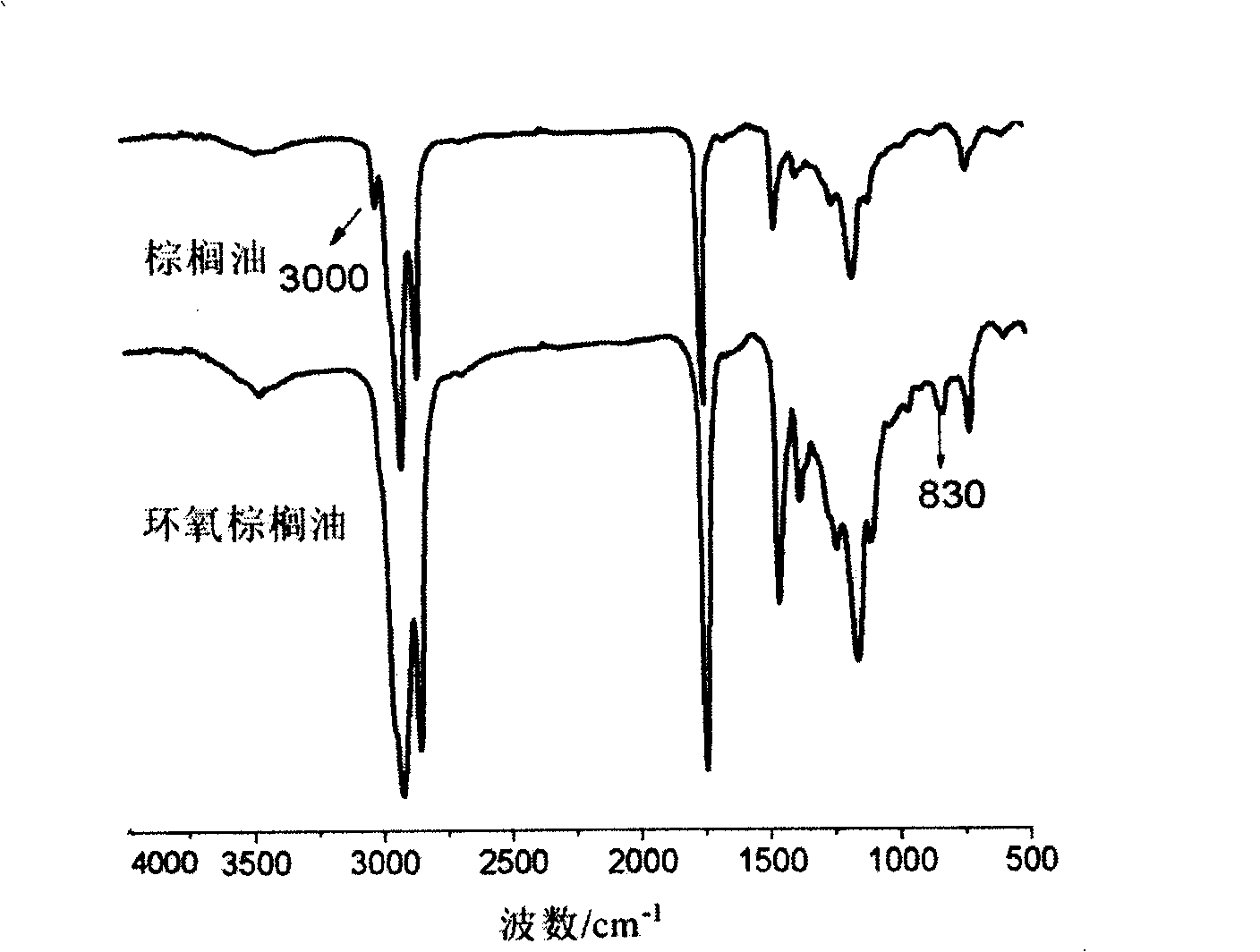

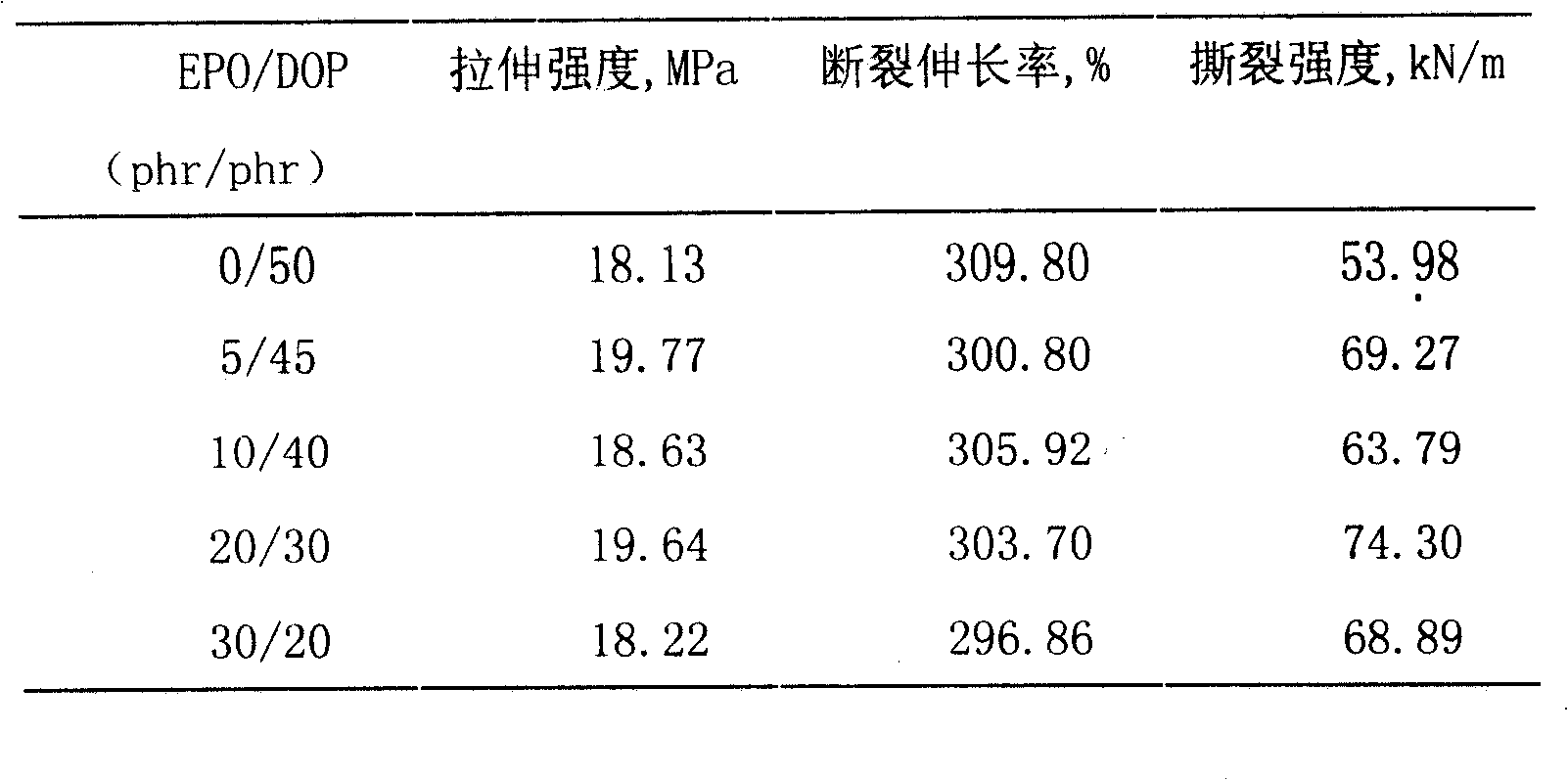

Production method of epoxy palm oil plasticizer

InactiveCN101255143AImprove conversion rateSimple post-processingOrganic chemistryEpoxyOrganic solvent

The invention provides a process for preparing an epoxy palm oil plasticizer, wherein the method, free from any dissolvent, uses palm oil as raw material and synthesizes the epoxy palm oil plasticiser by being reacted with epoxidizing agent on the catalytic action of concentrated sulphuric acid and / or phosphoric acid, under a certain temperature, time and proportioning. The epoxy palm oil plasticiser is used in the fields of plastics, paint industry, novel high molecular material, rubber, etc. wherein the working process does not bring in organic solvent waste liquid and noxious fumes to pollute the environment and harm the human body.

Owner:广东彩艳股份有限公司

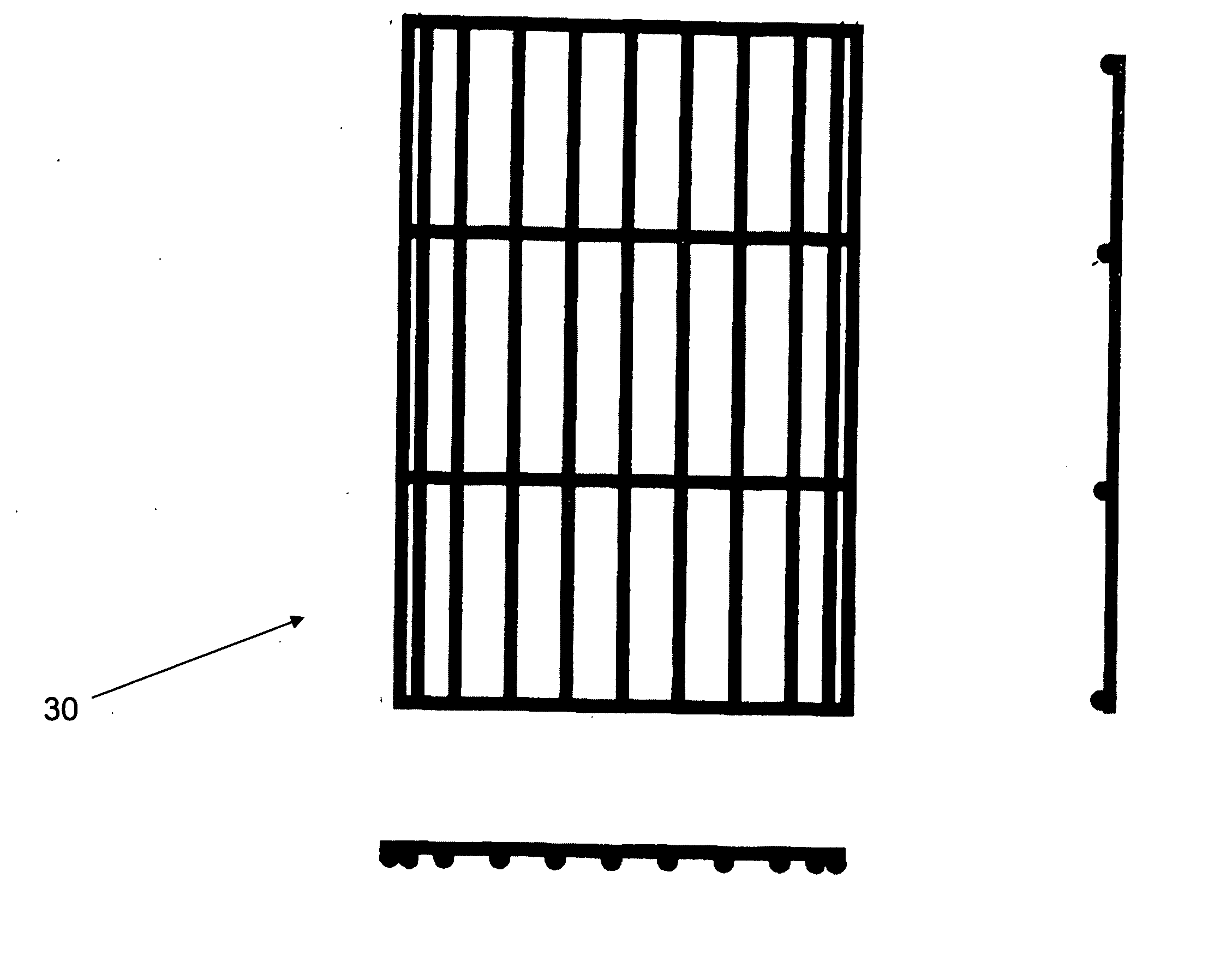

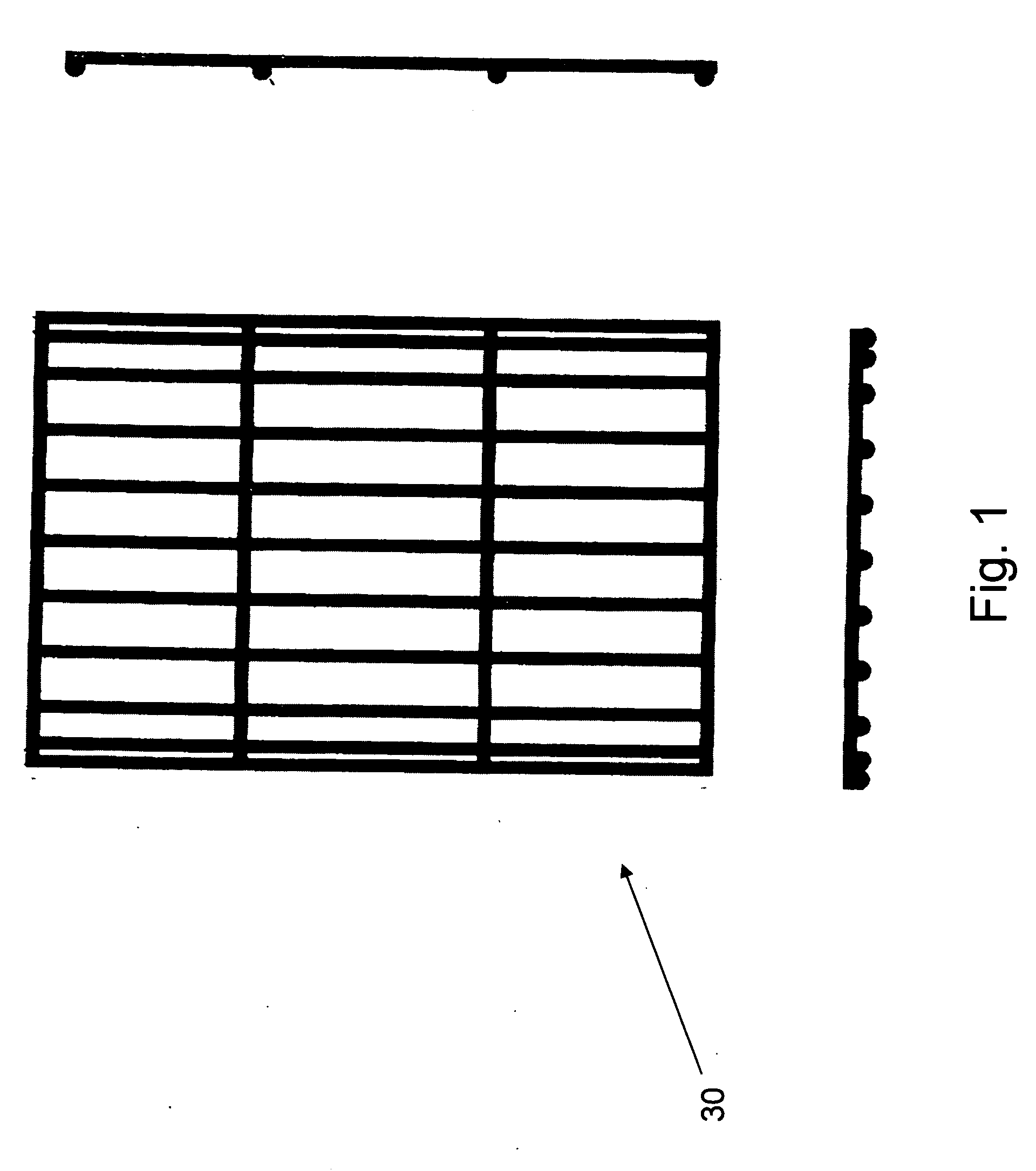

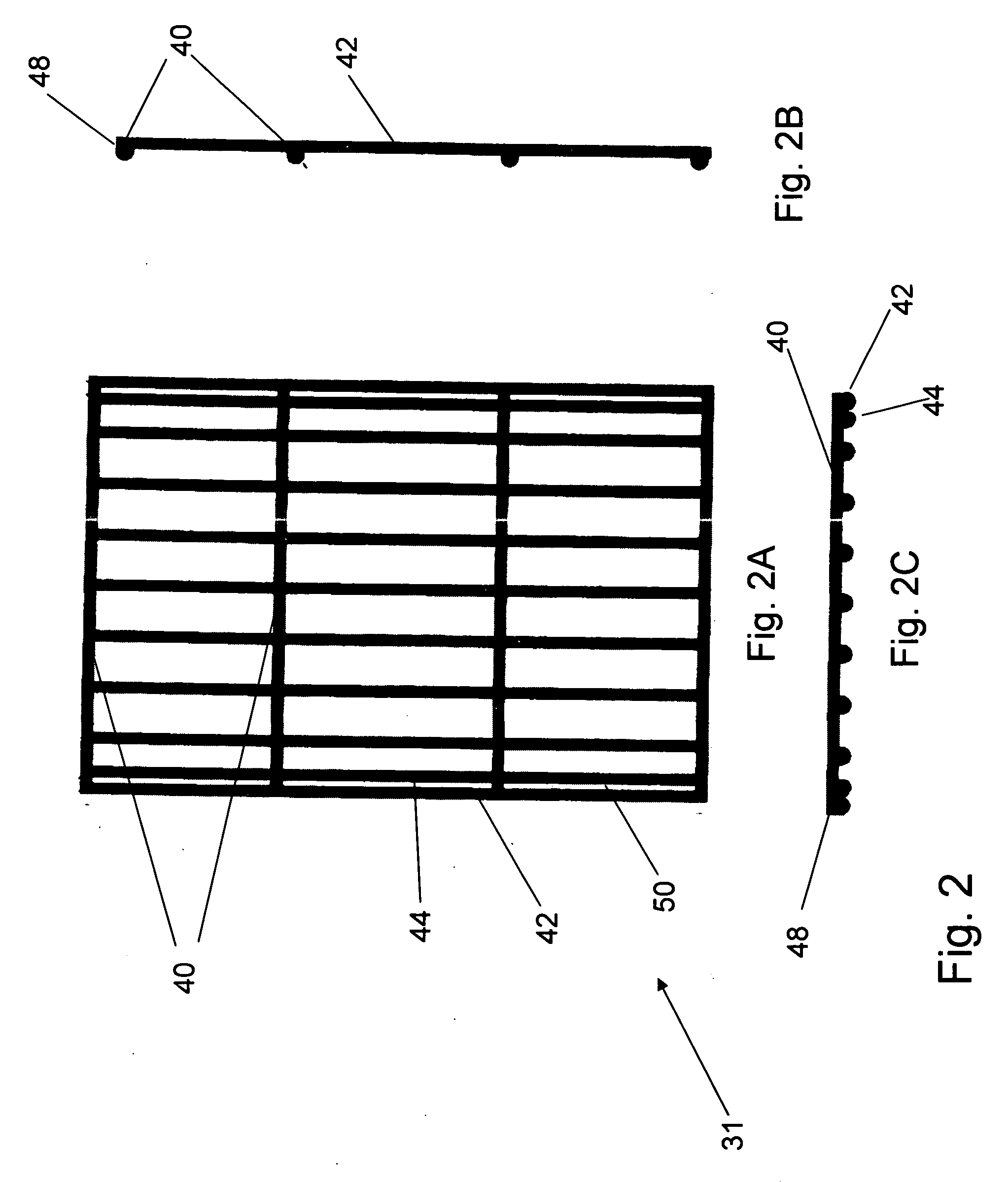

Attic floor joist grid system for weight bearing storage

InactiveUS20060075711A1Extensive complexityExtensive limitationCeilingsTreadsEngineeringFire resistance

An Attic Floor Joist Grid System for Weight Bearing Storage called an Attic Grid System. This system features low profile, flat, open and high strength grid panels that are supported by a joist system. The panels install directly onto the ceiling joists in an attic or storage area for residential and commercial applications. The panels are nominal widths that extend essentially to the center points of supporting joists. The system provides a simple and strong support surfaces which only requires simple, easy to use tools for installation. The panels are easily trimmed to size for non-standard operations and for encircling mechanical and electrical objects. The system is “see-through” and permits full air movement. Hence it does not contribute to moisture entrapment, mold and mildew. The materials are fire resistant and do not collapse or emit toxic fumes in the presence of a flame.

Owner:LANDEY ARLAN H

Toilet ventilation system

A premium ventilated toilet having an automated toilet ventilation system for removing noxious fumes from a bowl area of the toilet is disclosed. The ventilation system is mostly built-in to the toilet (e.g., ventilation ducts, and sensors) so that it is unobtrusive and attractive looking, however the active parts (e.g., a blower unit containing a blower impeller, a backflow shutoff valve, and electronic control circuitry) are contained in an simple housing that is unobtrusively and removably attached to the surface (preferably on the side) of the toilet base for simplified installation, maintenance, and replacement as needed. Automated operation is enabled by a non-contact occupancy (proximity) sensor and a flush sensor, both preferably built into a flush handle of the toilet. Detection of occupancy causes the ventilation system to operate and flushing turns it off.

Owner:LAPOSSY KENNETH A

Portable gas scrubber with sensor

This invention relates to a portable odor scrubber system that is inserted into a sewer manhole or lift station where vaporous odors are prone to escape into the external environment. The invention controls such odors which may be caused by hydrogen sulfide, ammonia, mercaptan and other vapors which smell bad and can pose a severe health hazard. The invention has an automatic gas sensor trigger mechanism to control a fan to pull the noxious fumes through a series of scrubbers and to discharge treated air into the environment. Scrubber units may be easily replaced as well as designated to treat different environmental conditions. The invention can also store and transmit gas data information to an offsite location to monitor conditions where the portable odor scrubber system is located.

Owner:MORGAN GARY +2

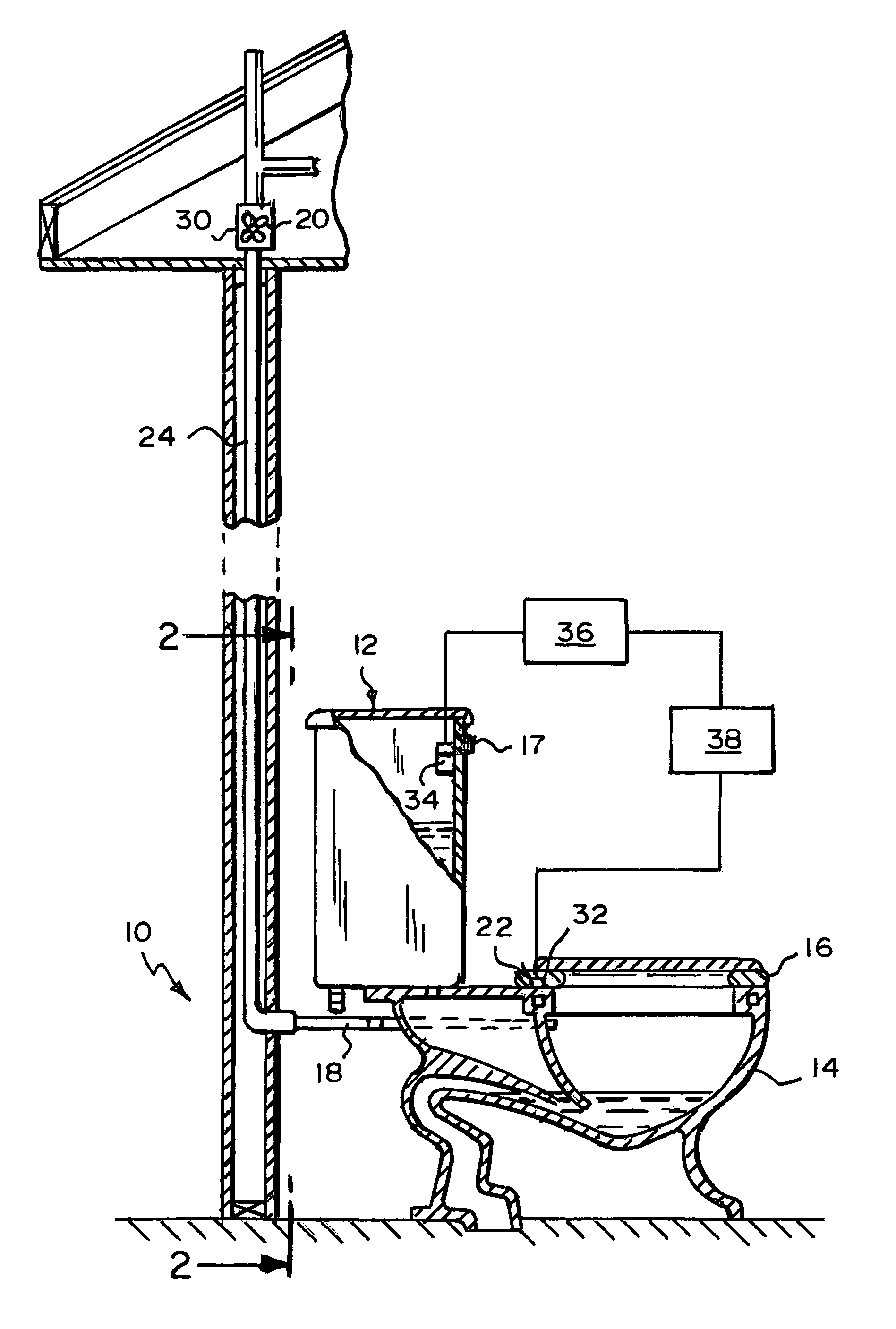

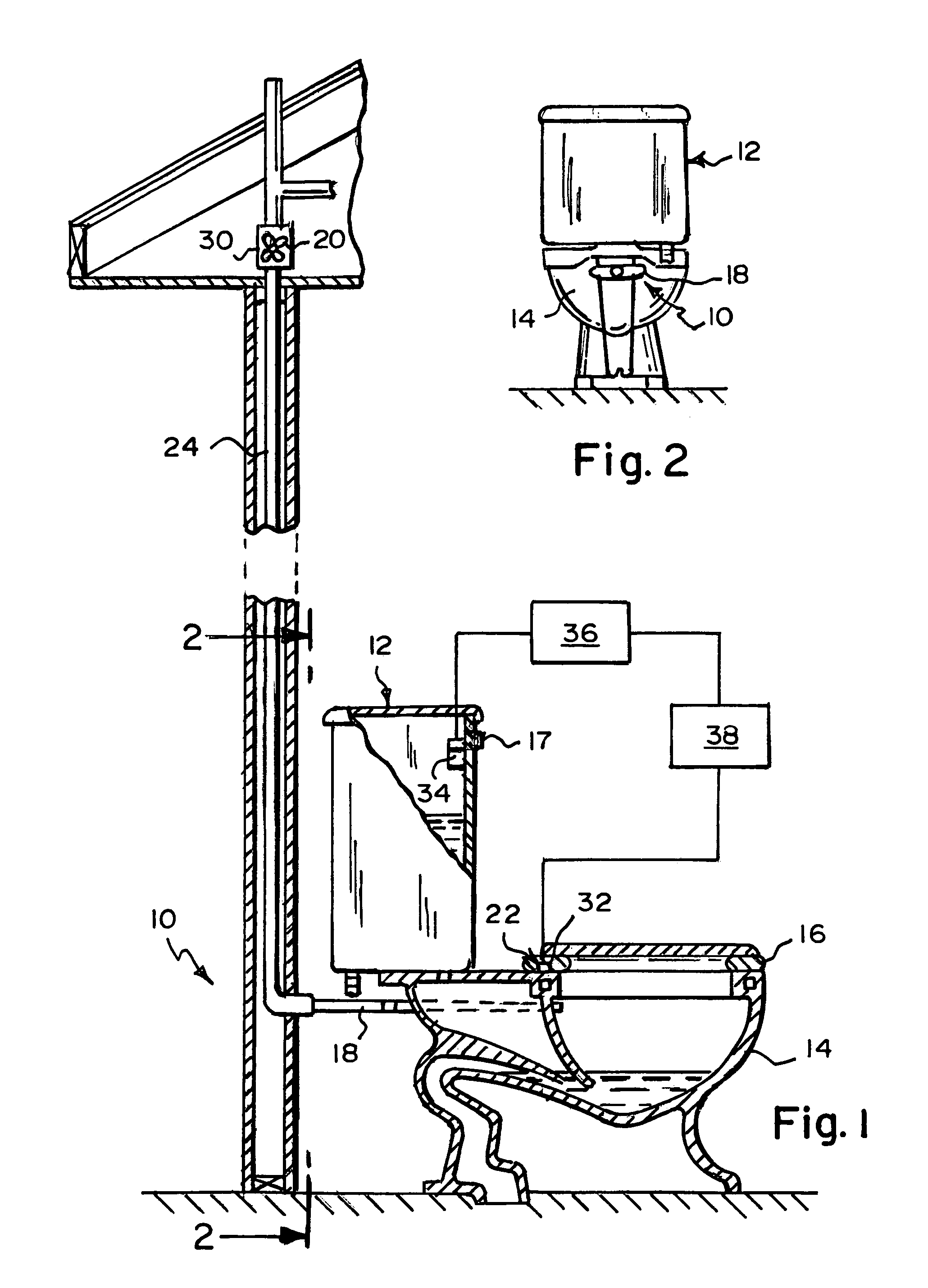

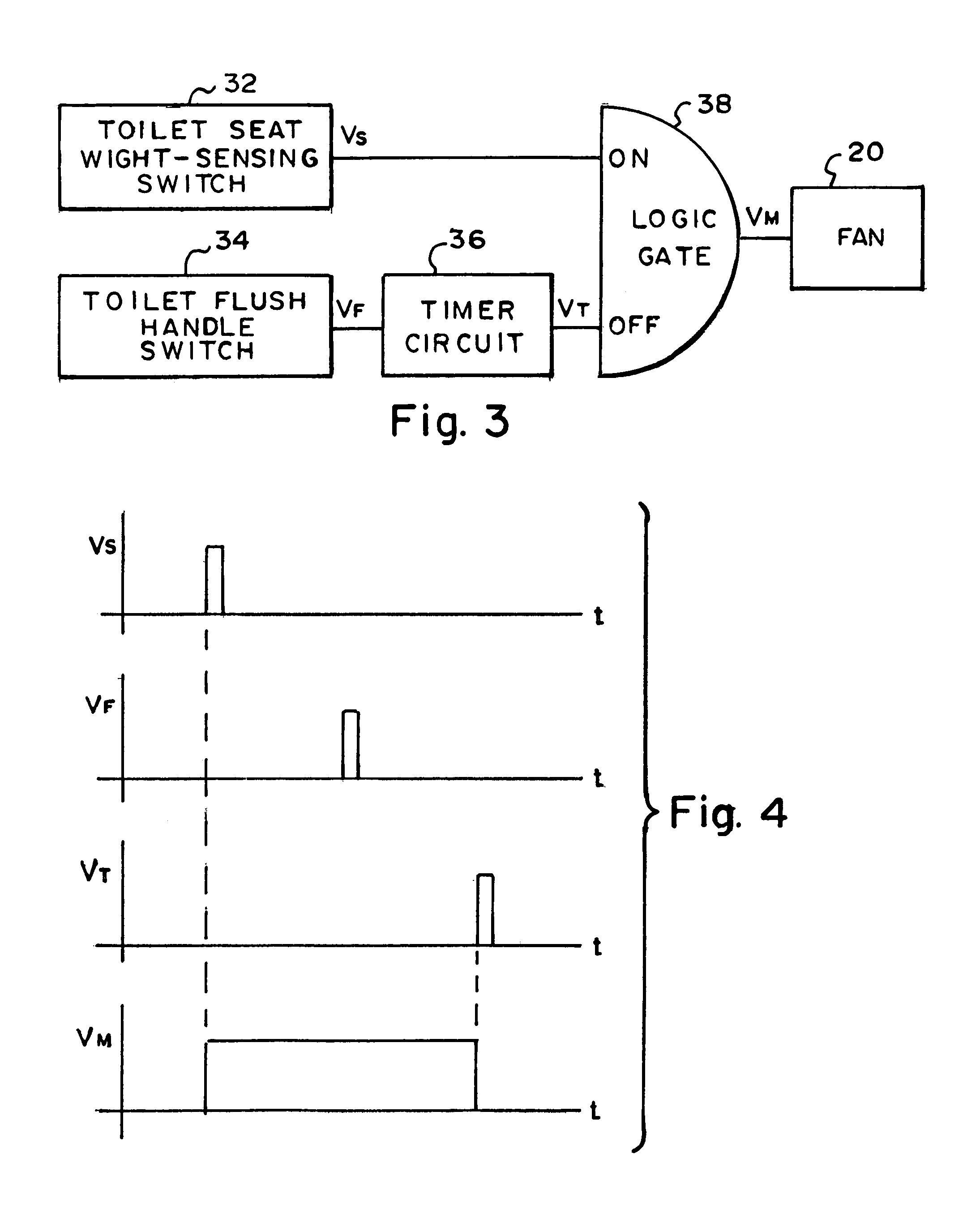

System for venting noxious fumes from a toilet

A system for venting noxious fumes from a toilet. A toilet seat weight-sensing switch operatively connects to a fan and activates when the seat of the toilet is sat upon. A toilet flush handle switch activates when the flush handle of the toilet activates. A timer circuit activates when the toilet flush handle switch is activated. A logic gate operatively connects to the toilet seat weight-sensing switch, the timer circuit, and the fan. When the seat of the toilet is sat upon, the toilet seat weight-sensing switch generates a pulse turning on the logic gate which generates a pulse which turns on the fan. When the flush handle of the toilet activates, the toilet flush handle switch generates a pulse turning on the timer circuit which after a predetermined time generates a pulse which turns off the logic gate which turns off the fan.

Owner:CANALES JR AMADOR

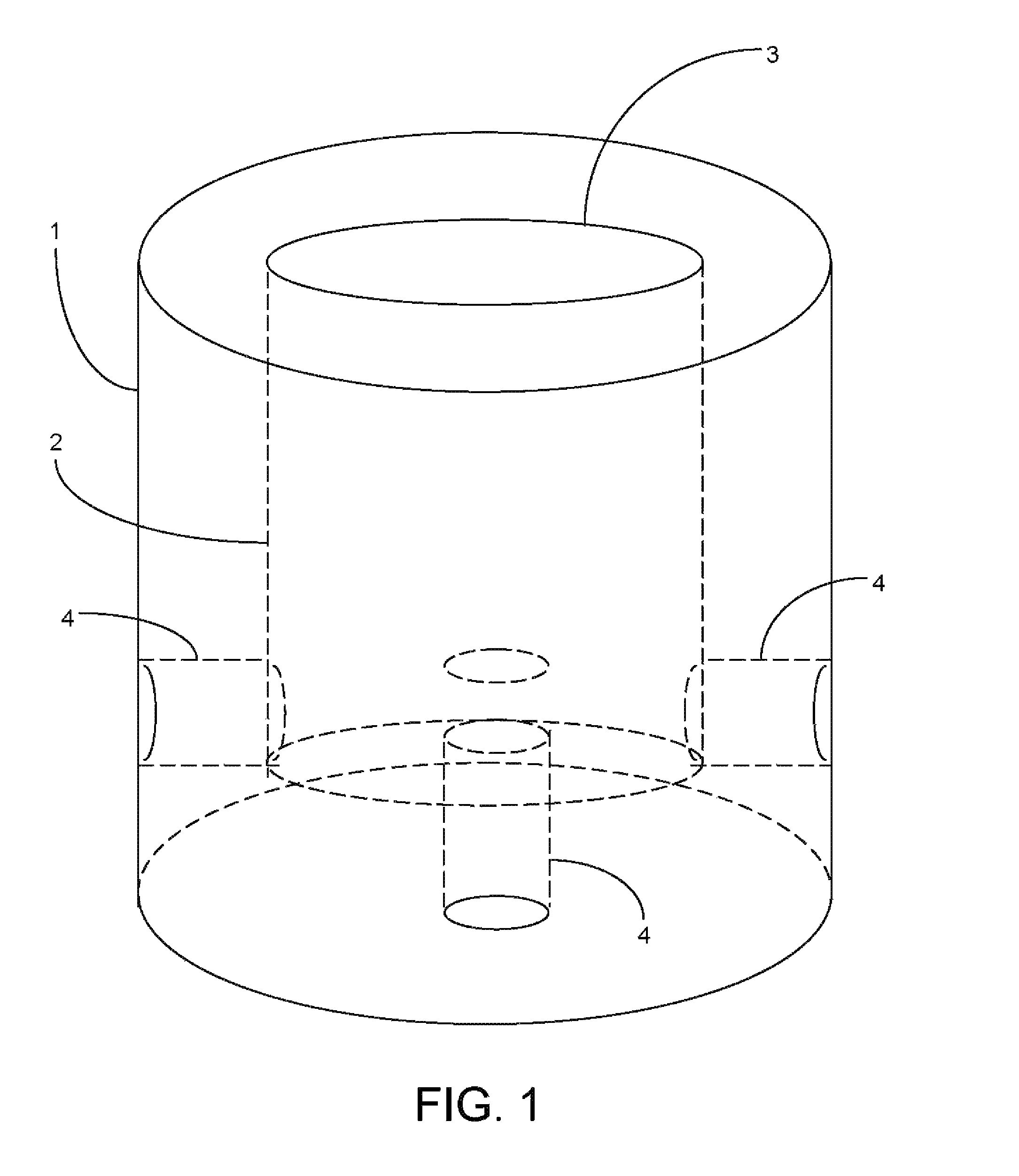

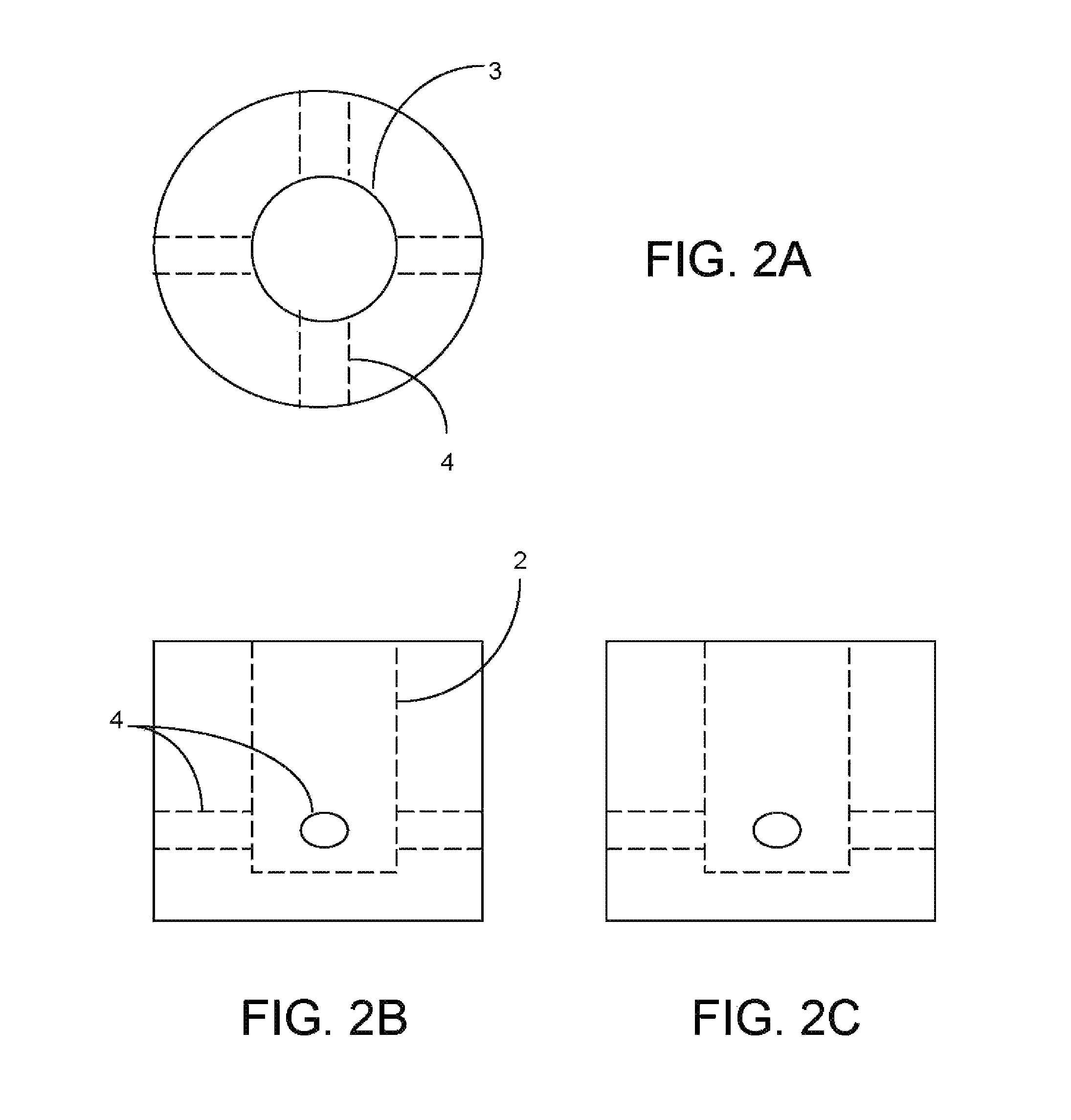

Fire starter

The Present Invention is a fire starting device for use as kindling manufactured from pine straw, as the primary component, a vegetable oil, natural resins, and an herbal component. The composition of the device differs from prior art devices that burn petroleum hydrocarbons. The device is hollow, having at least one vertical channel and at least one horizontal channel drilled from the outer wall of the device to the inner vertical channel. The fire starter device is ignited from the top, and it burns to produce a high, intense flame that ignites other flammable materials having a much greater kindling temperature. The height of the flame and the burn duration are controlled by the overall size of the device and the sizes of the channels. The device burns clean with a minimum of smoke and harmful or noxious fumes. Burning the device minimally creates air pollution. It burns completely with a minimum of ash residue.

Owner:APPTEC

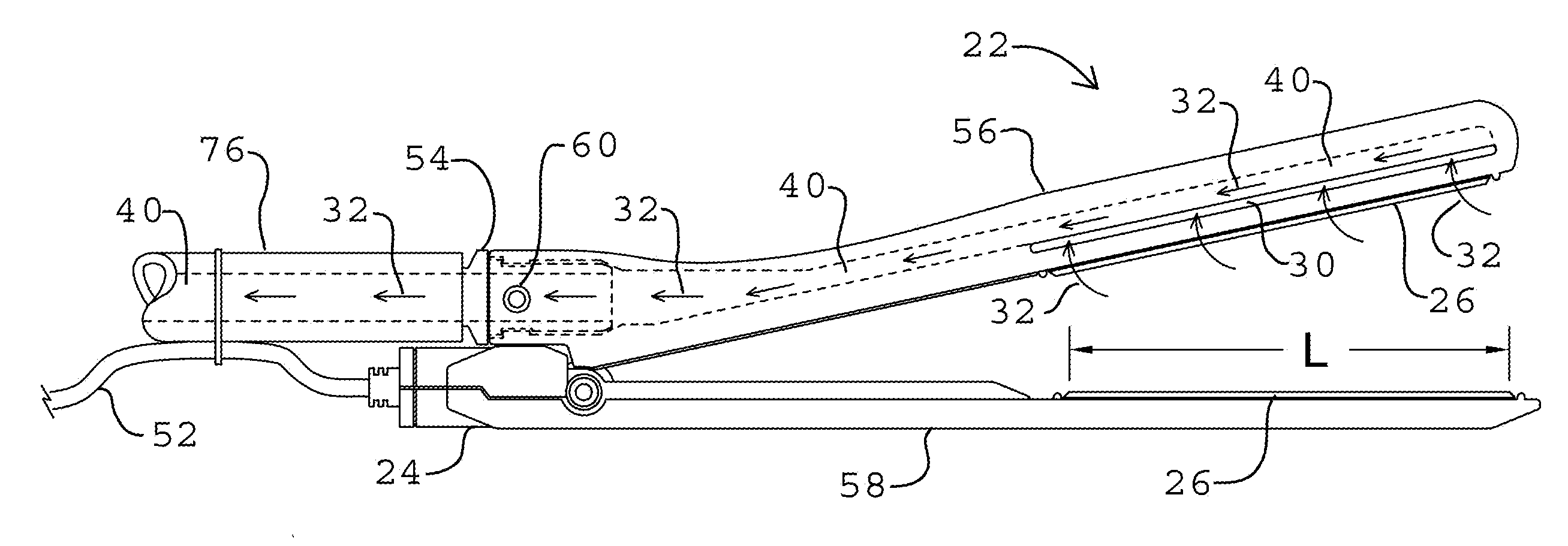

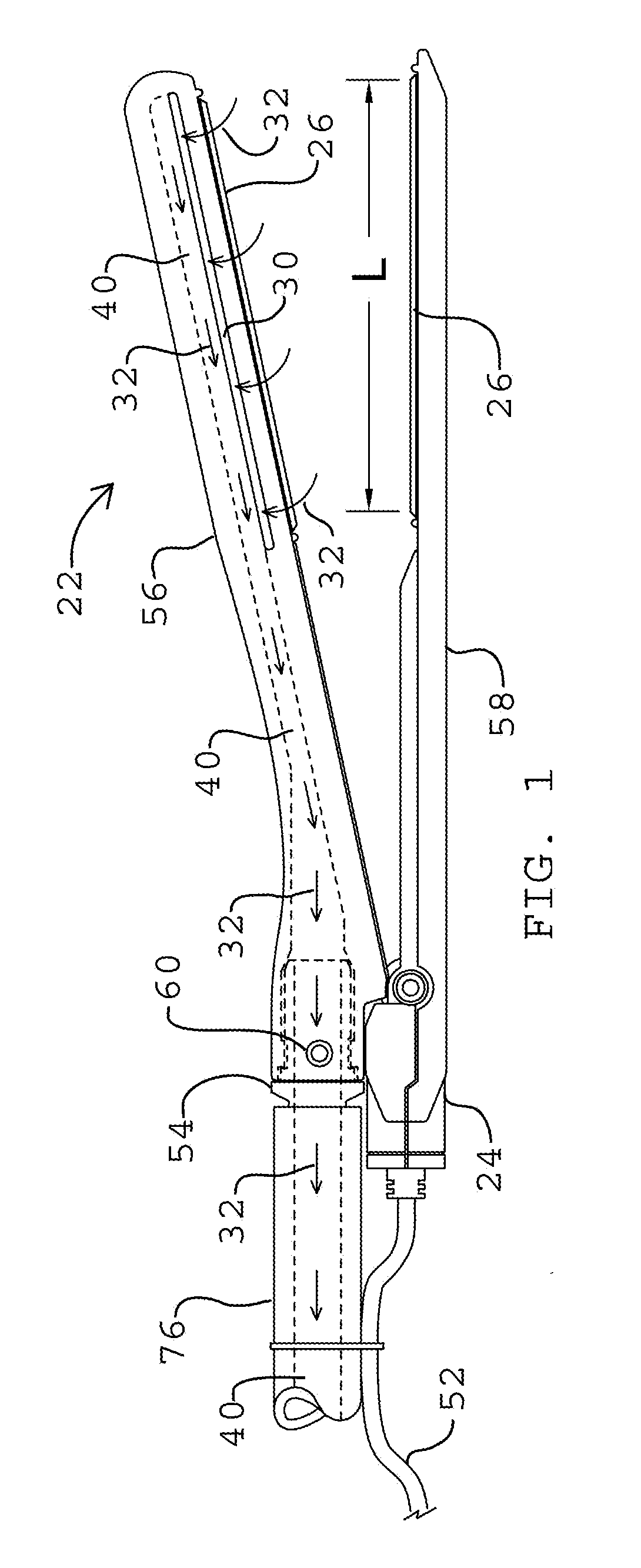

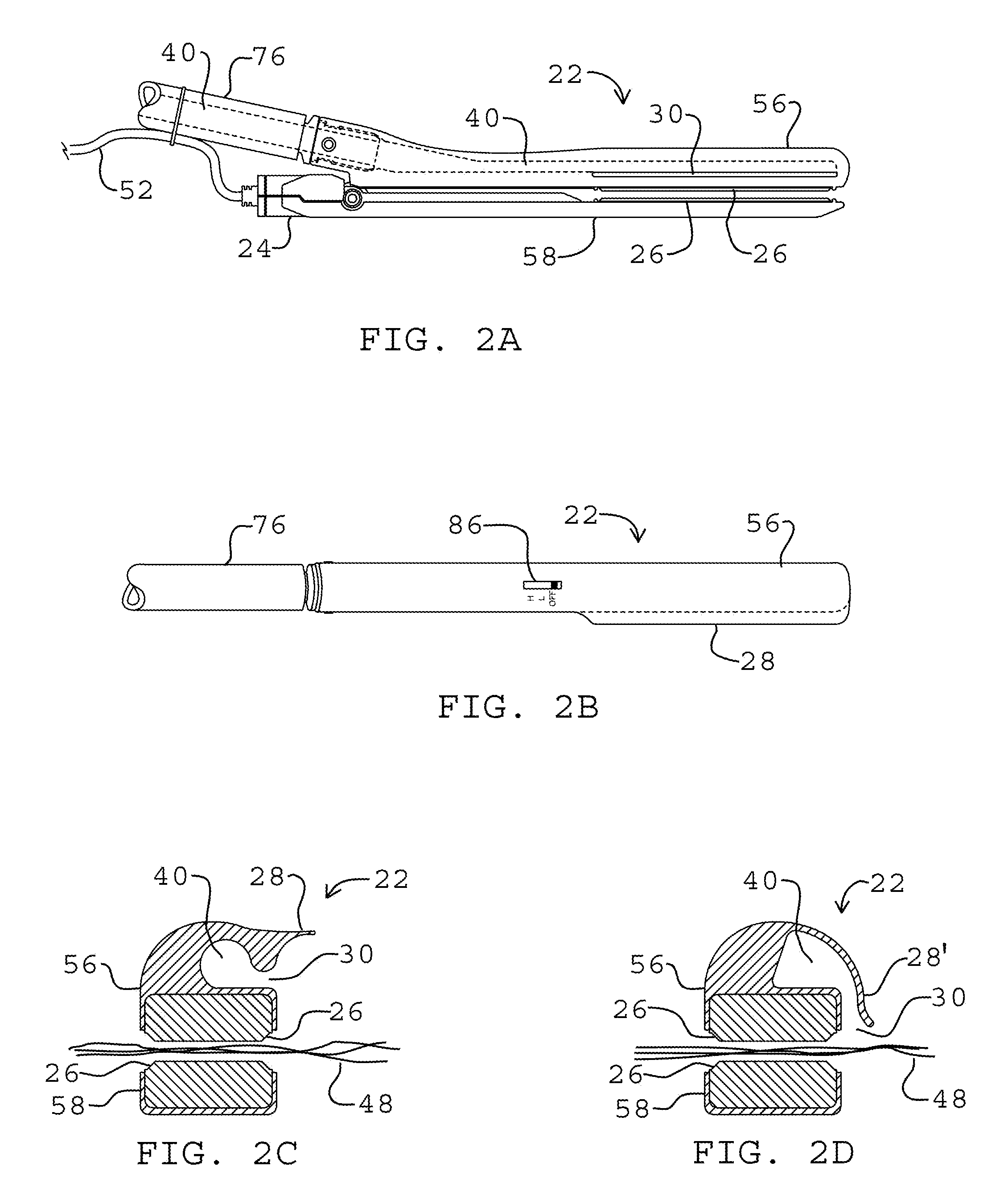

Hair Iron Fume Removal Device

InactiveUS20110036822A1Efficient removalAvoid spreadingCurling-ironsCurling-tongsChemical treatmentFiltration

The problem of noxious fume generation during chemical treatment of hair using a hair iron is solved by providing a fume intake on the hair iron near the point of fume generation, preferably near the iron's heating elements. The fume intake receives the fumes and delivers them to the fume removal passage under vacuum flow generated by a vacuum source, then transported to a filtration system or exhausted to the outside environment. Optionally, the fume intake may extend along the length of the heating element and may be directed downward, towards the hair. Optionally, the fume removal device may be attachable as a retrofit to a standard hair iron. The present invention advantageously prevents the spread of the noxious fumes to the rest of the salon and protects both the stylist and client from discomfort and irritation, thus permitting the more widespread use of these beneficial hair treatments.

Owner:JOHNSON NICHOLAS

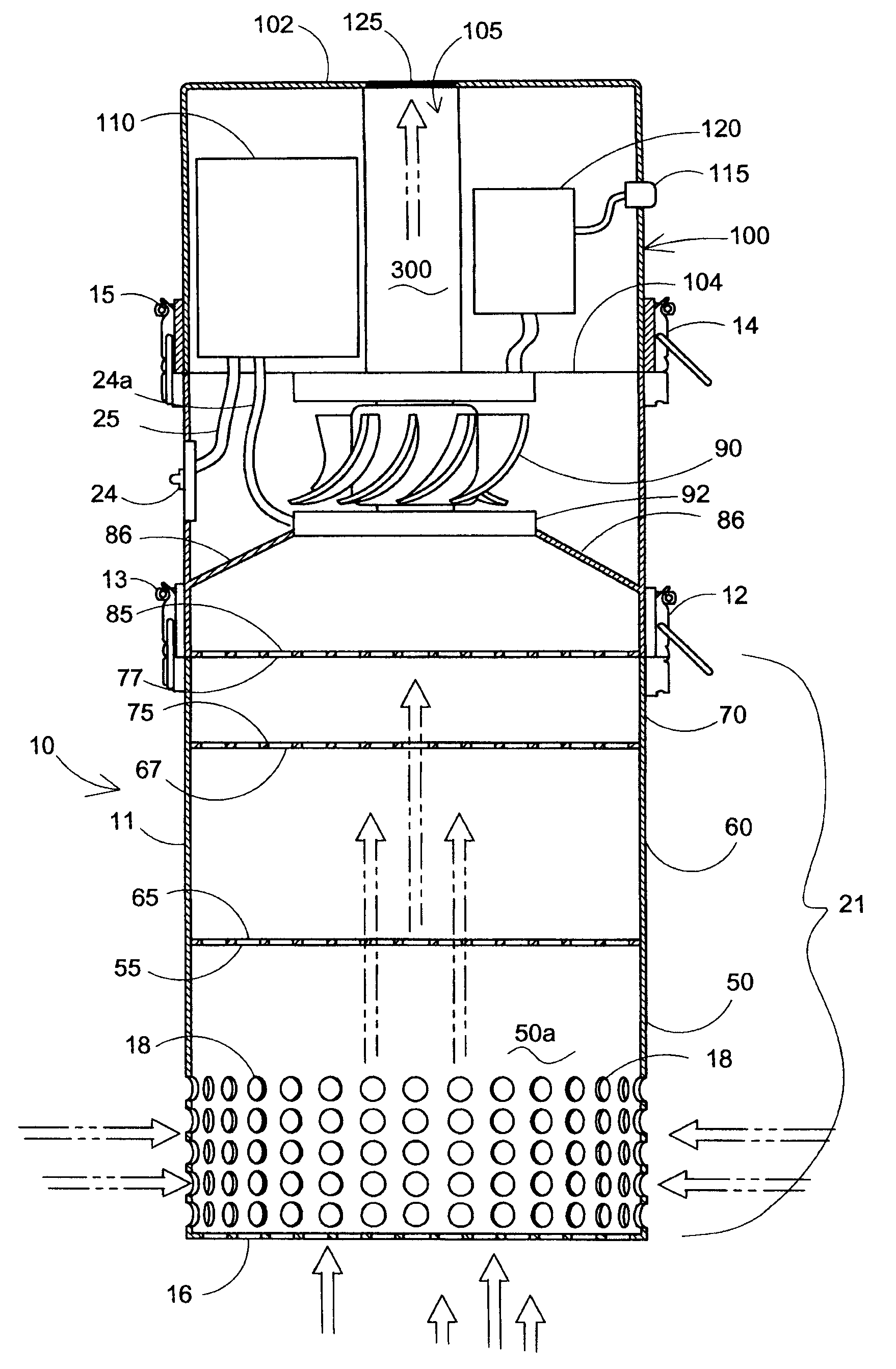

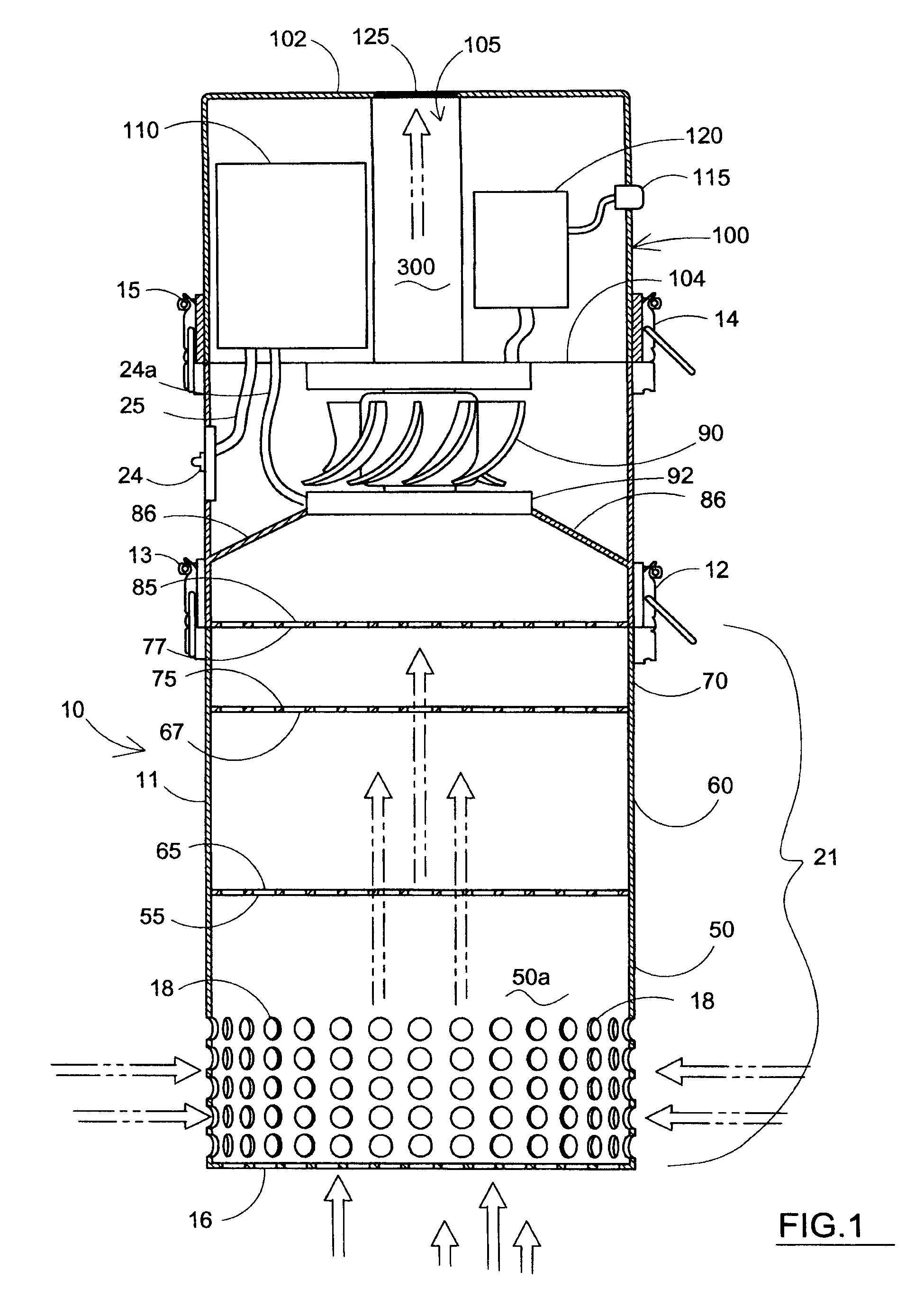

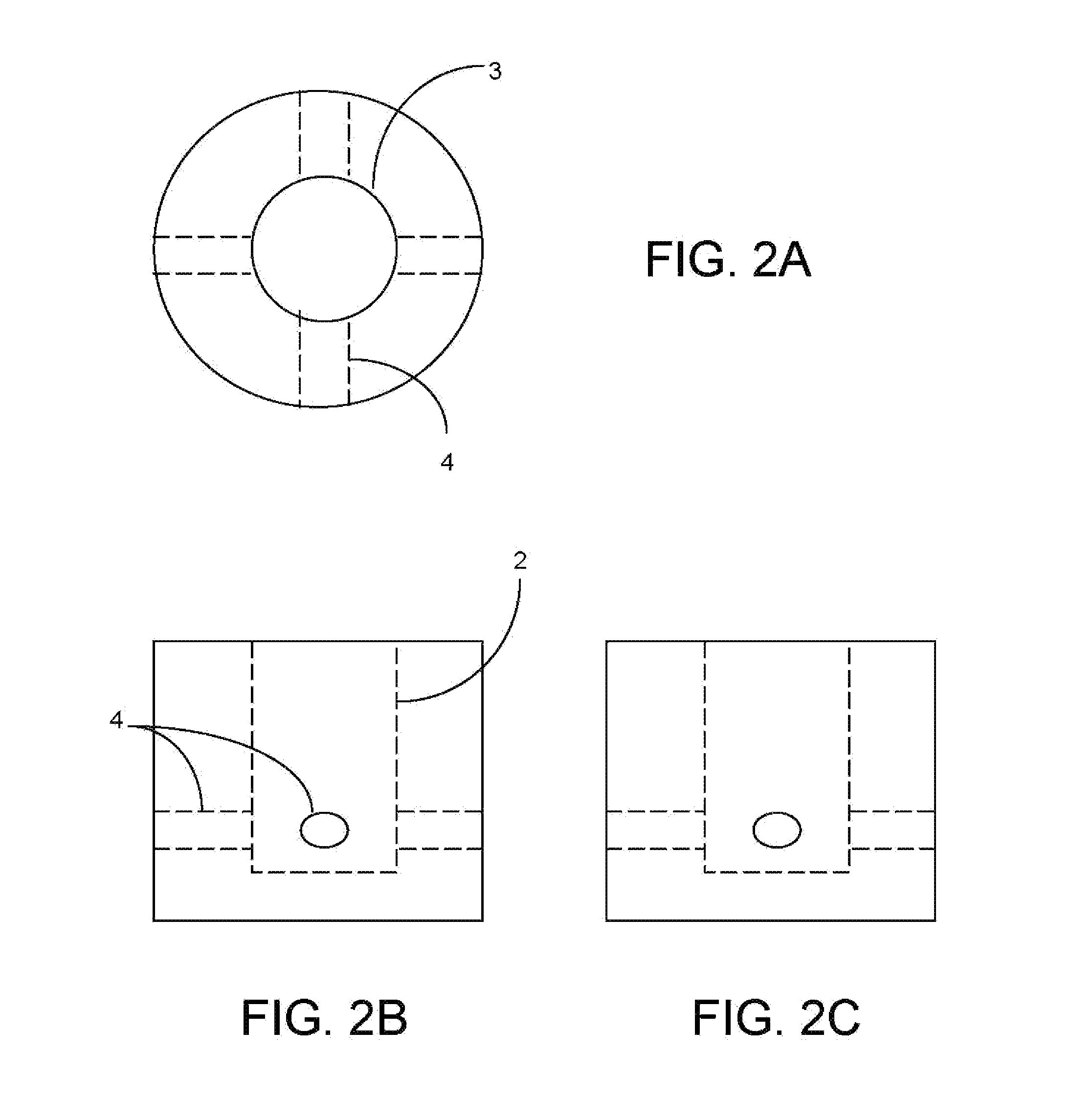

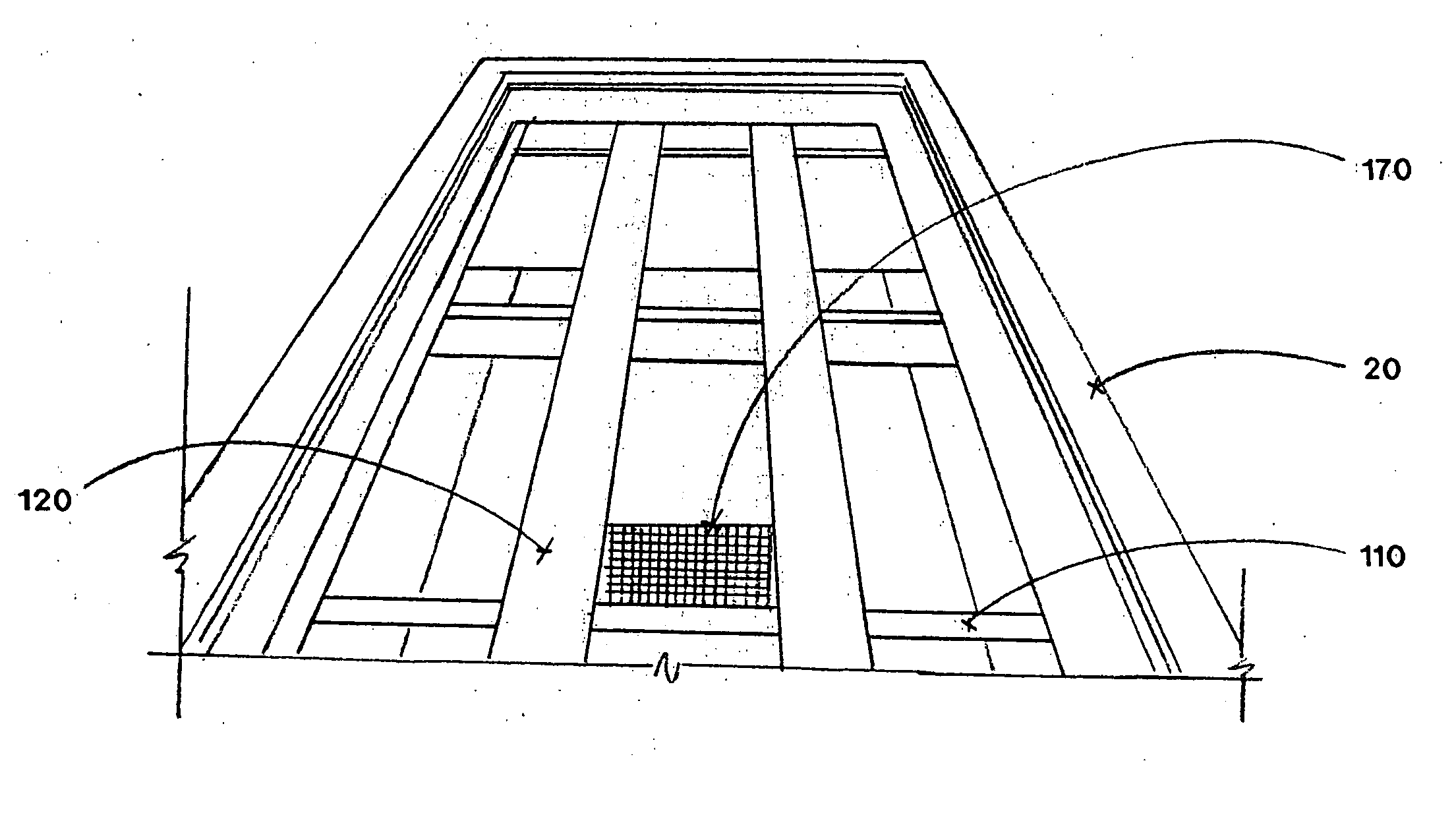

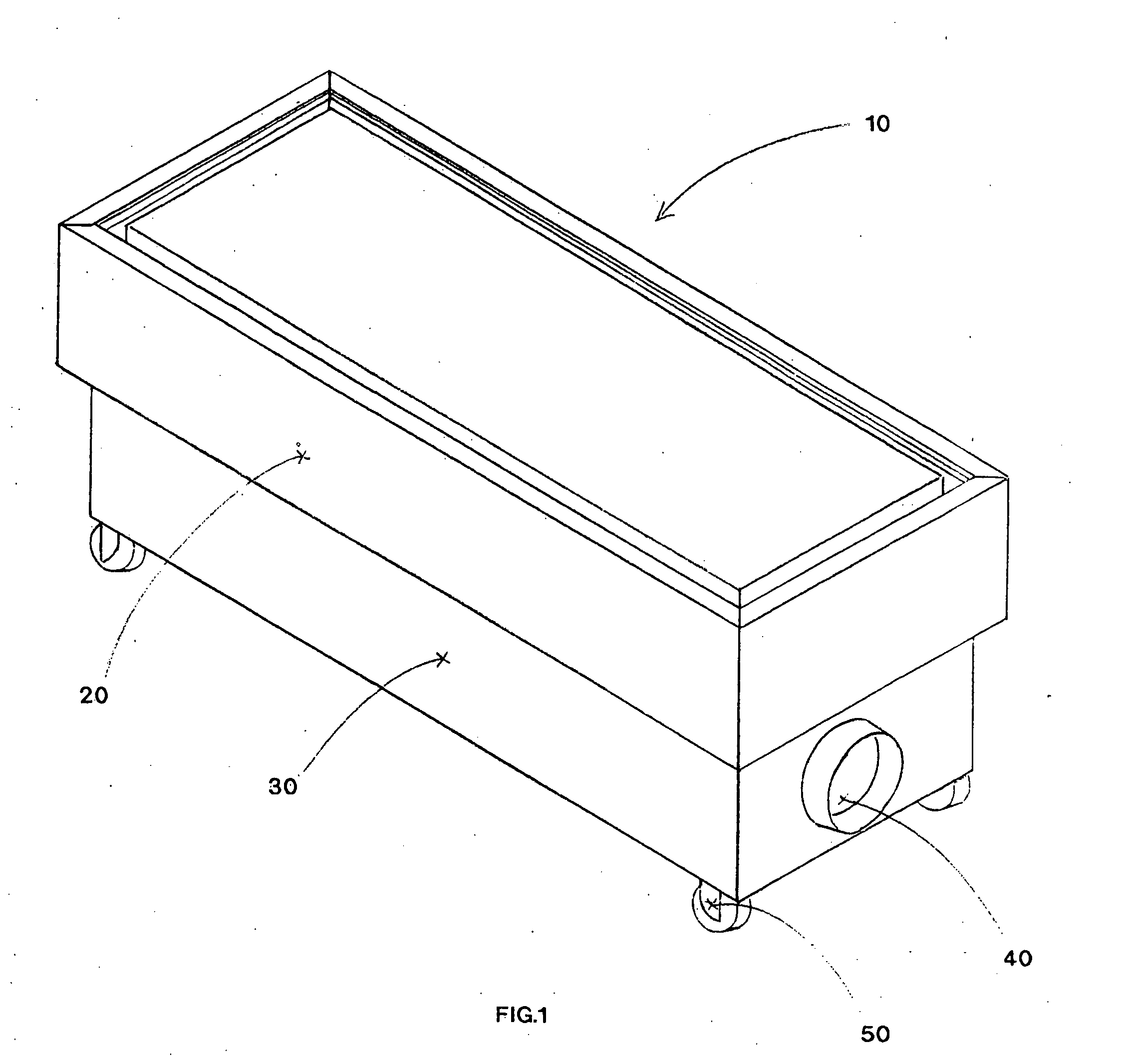

Ventilated dissection table

InactiveUS20050160948A1Improved “ capture rate ”Adequate capture performanceOperating tablesConvertible furnitureDissection tableEngineering

Applicant's invention defines a ventilated dissection table having an air chamber atop a pedestal. Said air chamber comprises a support structure for a removable stainless steel work surface positioned at an optimal distance below an air inlet, said air inlet having a negative pressure created by a blower attached to an exhaust duct which draws undesirable noxious fumes from said air inlet through said chamber past a screen into a plenum and out the exhaust. The positioning of said work surface to air inlet provides improved capture performance. Primary and secondary drains are provided for the removal of fluids generated by the dissection process, as well as the facilitation of basic cleaning. The table is made of stainless steel to aid cleaning and is sized for ease of transfer and mobility via size and weight.

Owner:IRWIN PAUL

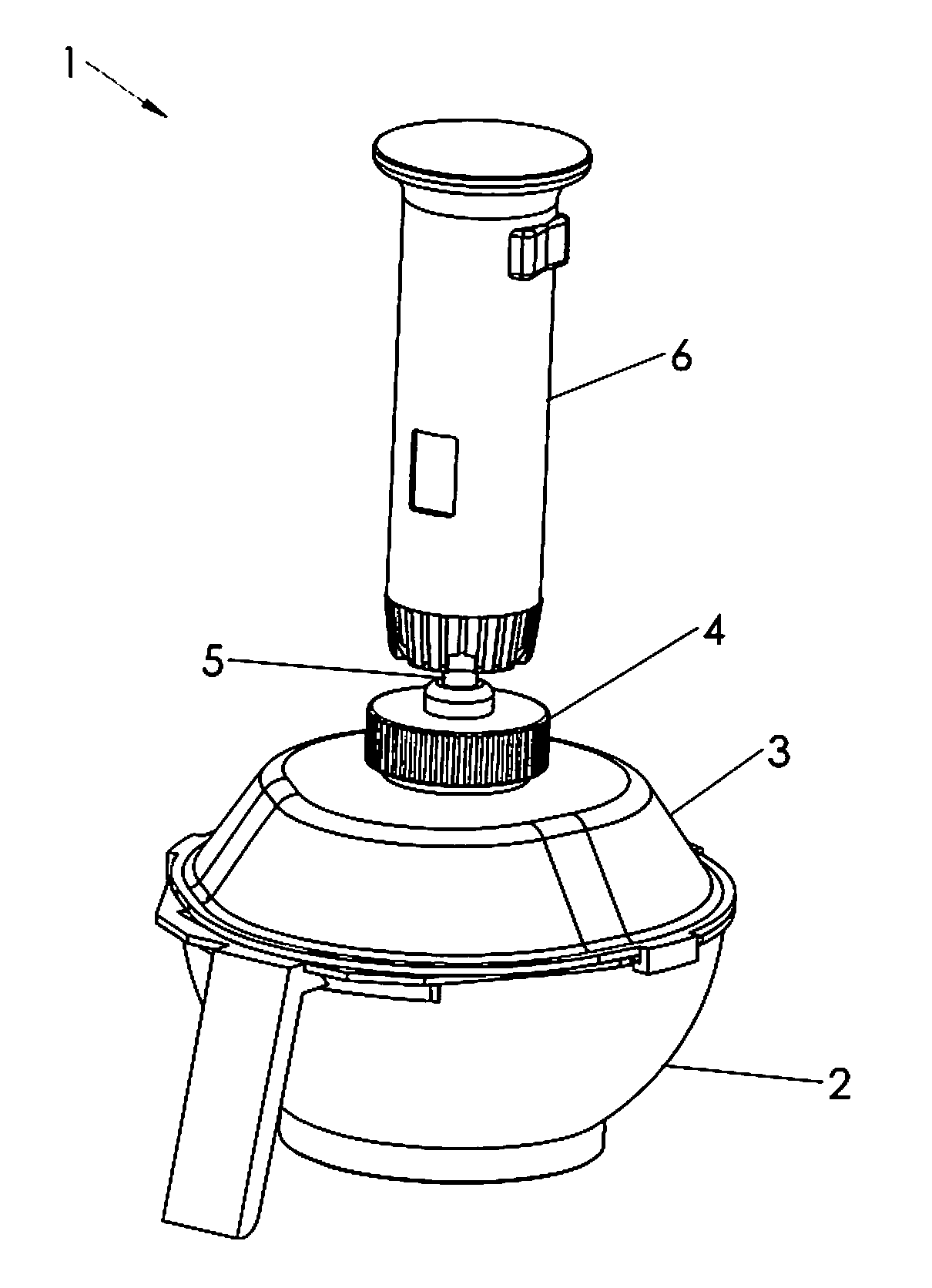

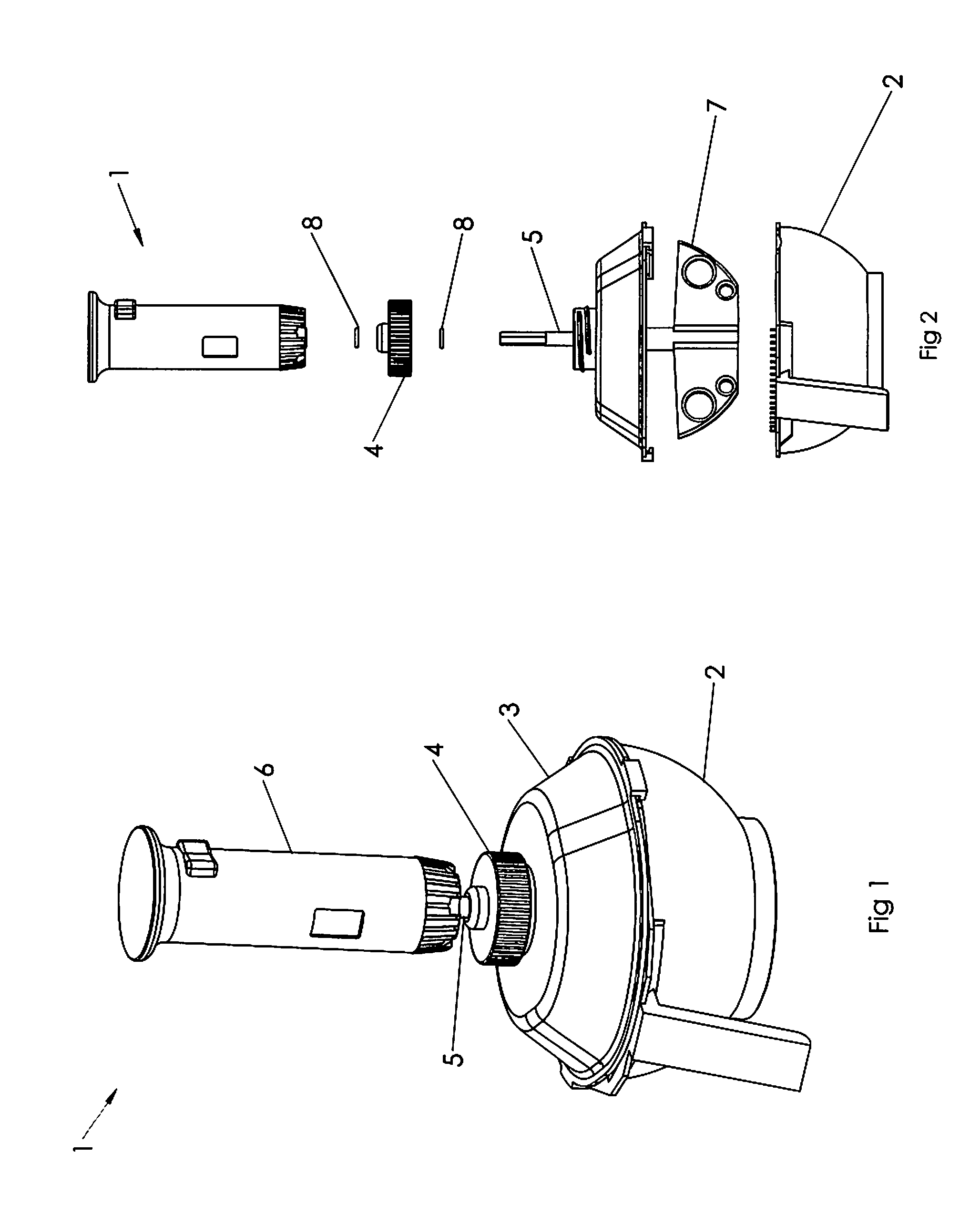

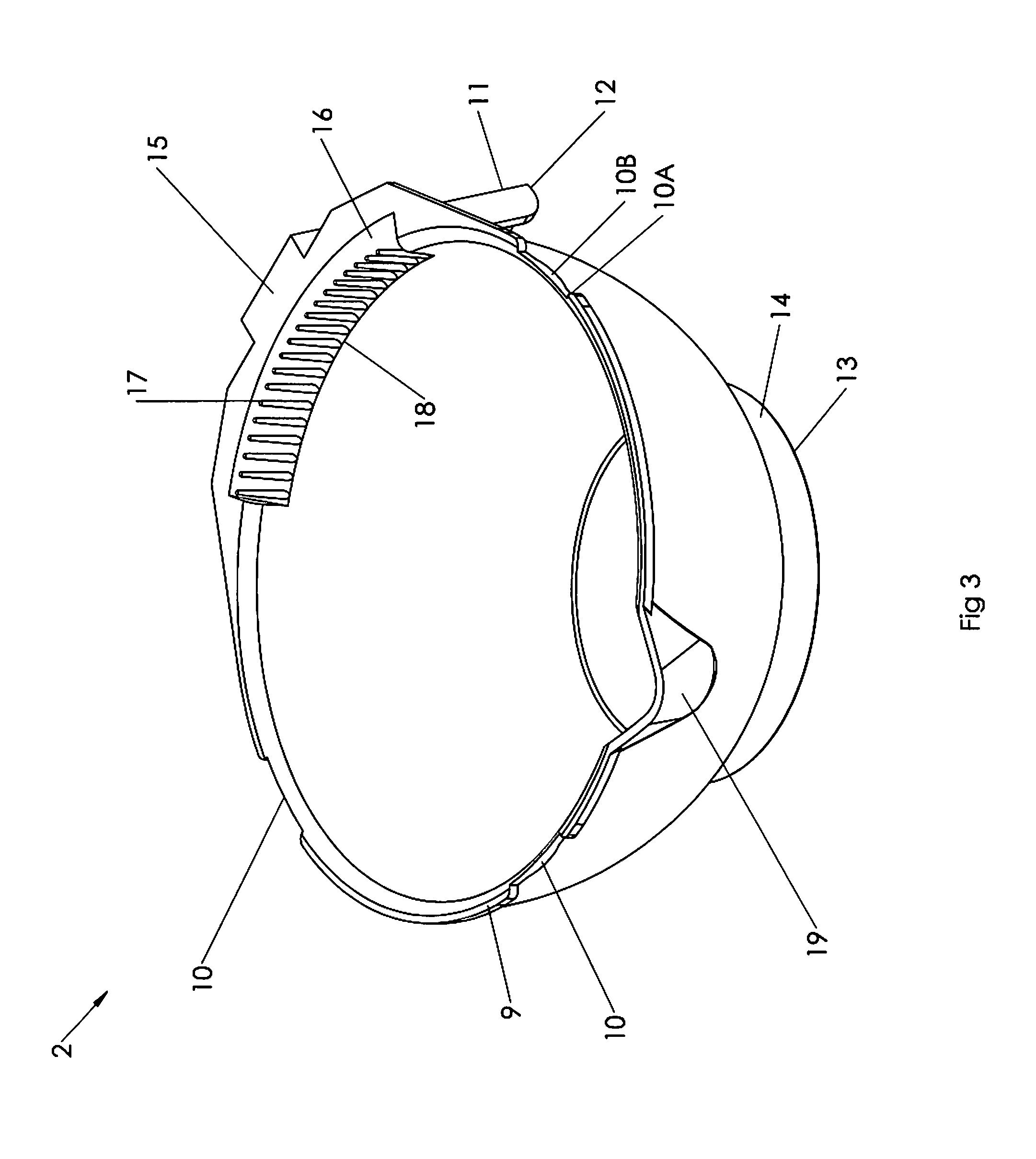

Apparatus for mixing hair colorant chemicals

InactiveUS20110317511A1Easily and efficiently and reliably and thoroughly blend/mix hair colorant chemicalMinimizing exposure to noxious fumeRotary stirring mixersTransportation and packagingHair ColorantsAdditive ingredient

An apparatus is provided which can easily, efficiently, reliably and thoroughly blend or mix hair colorant chemicals while minimizing stylist exposure to noxious fumes. The apparatus may include a mixing bowl molded from a polymeric material, an interlocking lid molded from the same or similar polymer, a specially designed top lid, a motorized handle, and a stiffing paddle or whisk having a rotatable shaft which passes through a sealing means removably affixed to the specially designed top lid and thence engaging a driving end of the motorized handle. The top lid incorporates interlocking means at its outer edge such that it can be easily twist-locked into intimate contact with the bowl which is provided with mating lock surfaces. When engaged, mating surfaces of the top lid and bowl form a seal which prevents or minimizes escape of mixture ingredients and odors from the enclosed volume defined by and between the lid and the bowl.

Owner:SALON SOLUTIONS

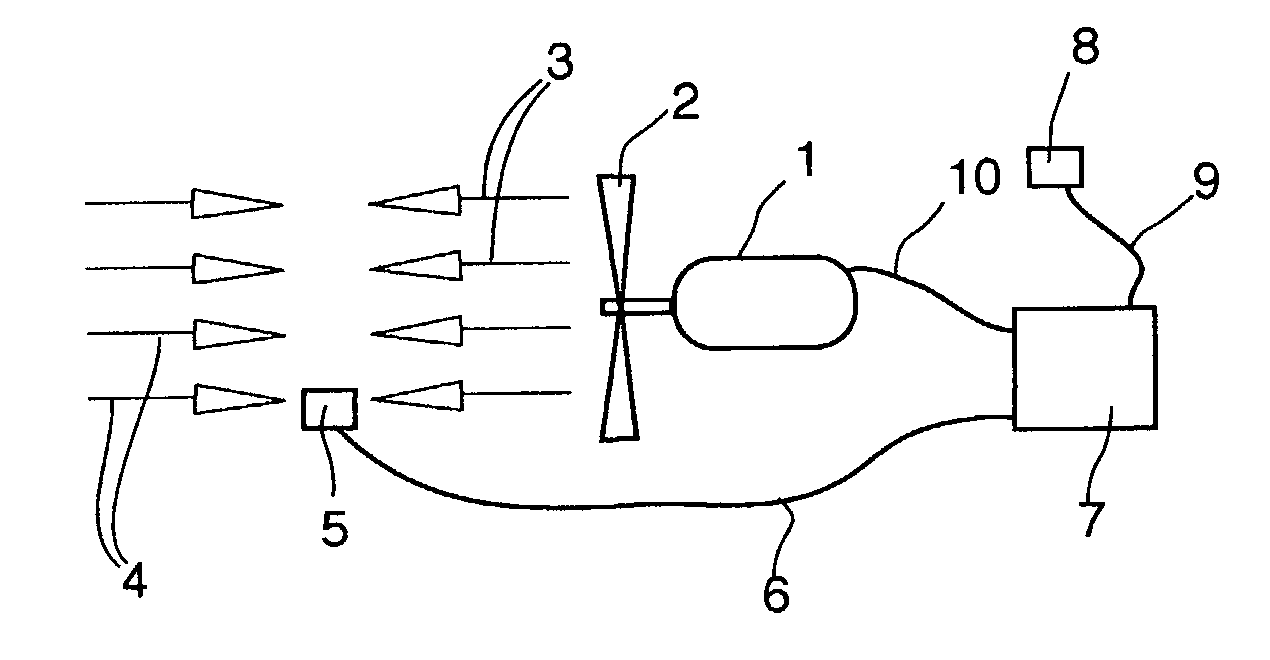

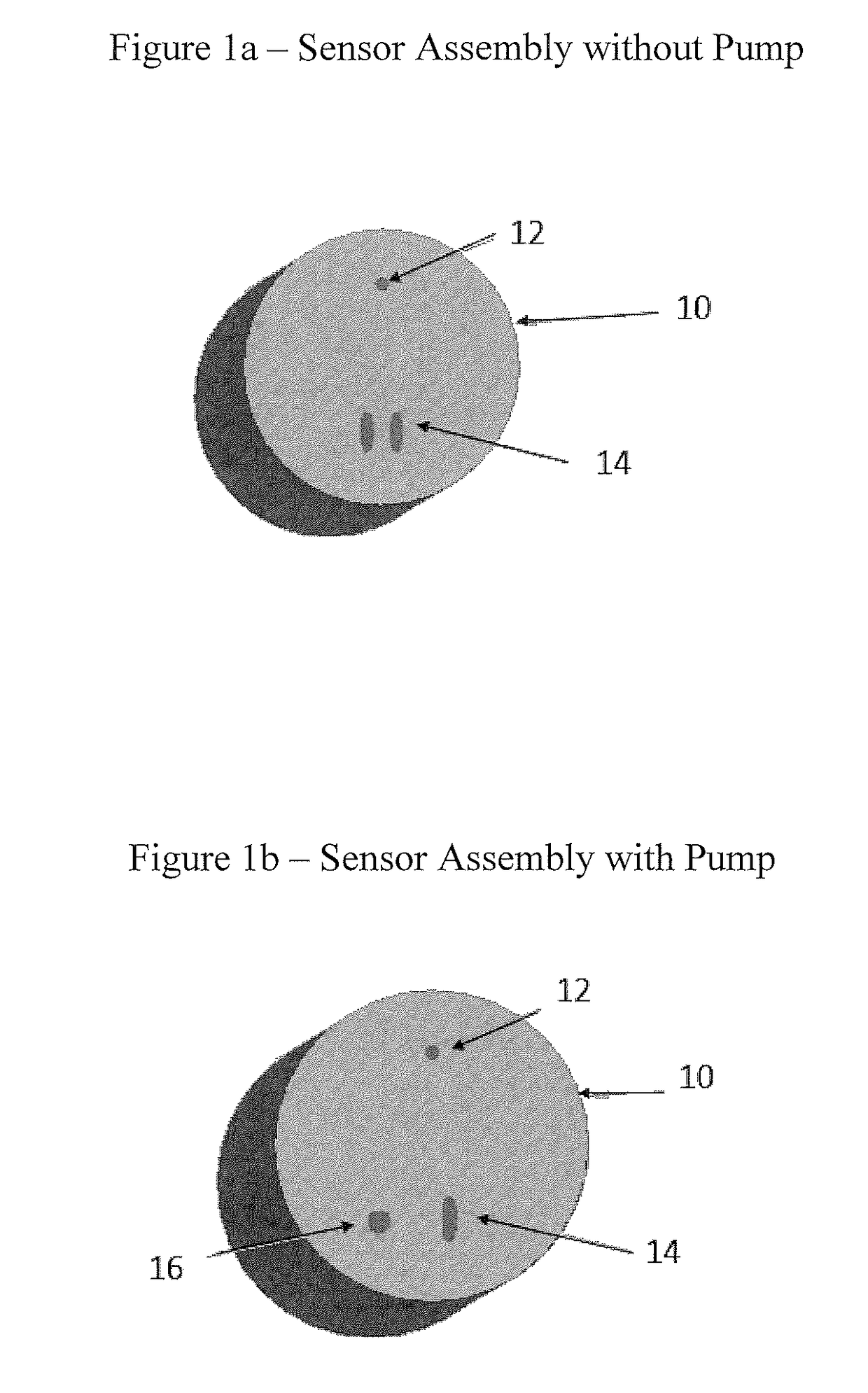

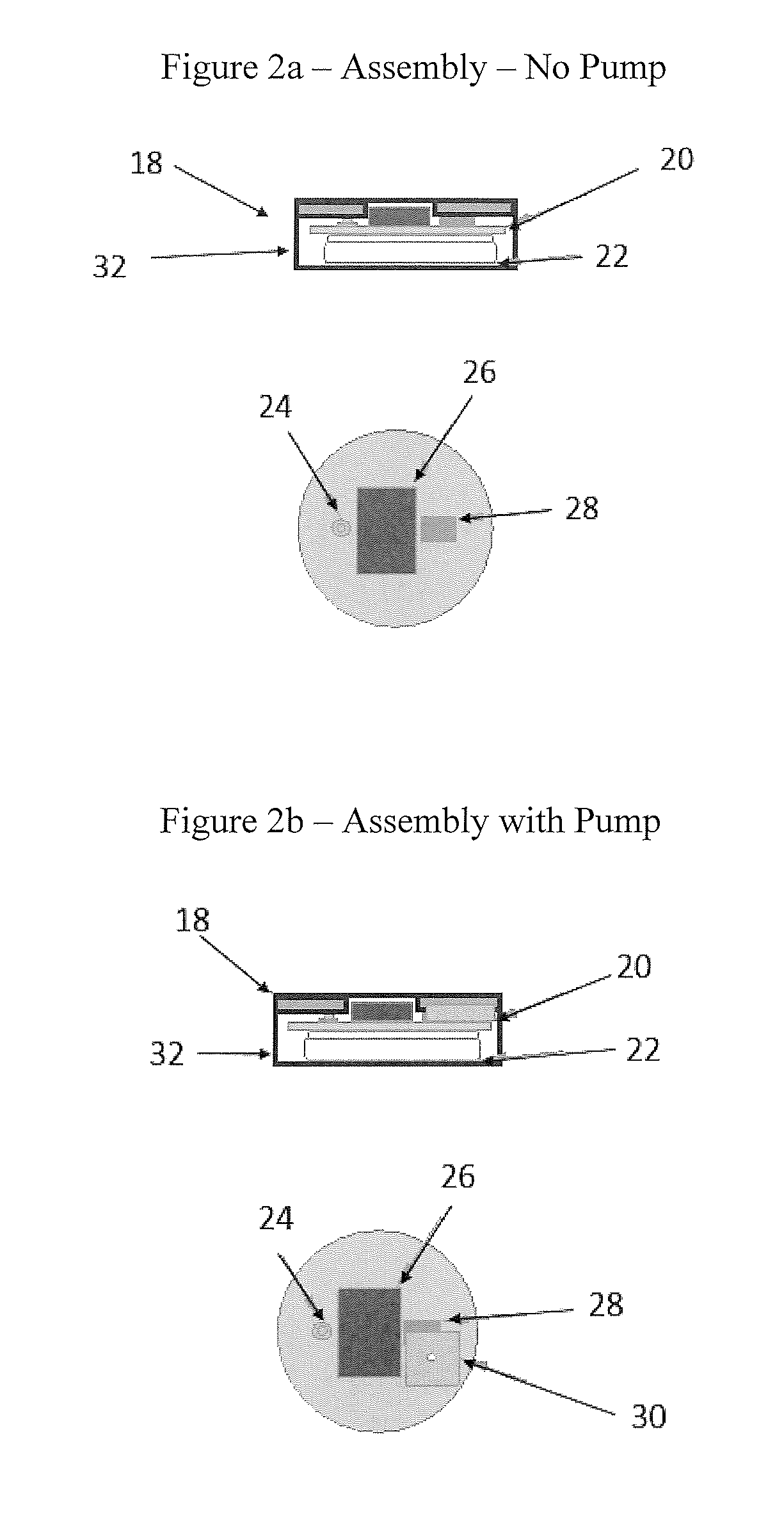

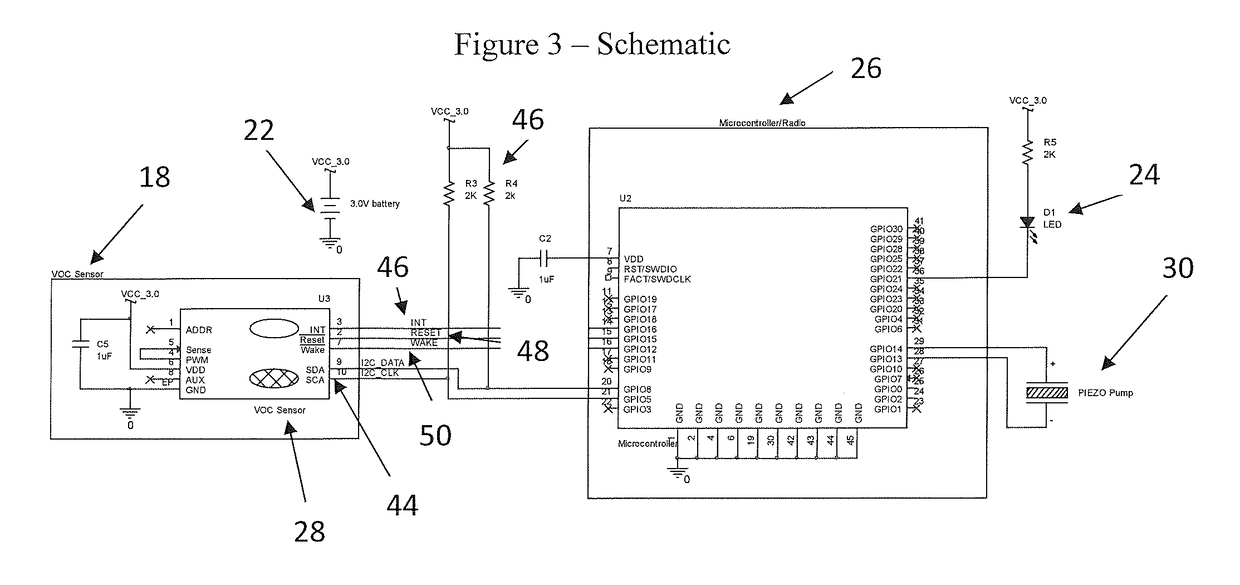

Cockpit and Crew Rest Air Quality Sensor

InactiveUS20180346130A1Understand riskAir-treatment apparatus arrangementsEnergy efficient board measuresAircrewOn board

Disclosed is an area sensor for air quality in the cockpit, crew rest or other area of an aircraft. Noxious fumes, fuel vapors, carbon monoxide and other vapors can cause significant risks to the flight crew of an aircraft. Fumes may cause drowsiness, inattentiveness or confusion to the pilot of an aircraft placing all persons on board an aircraft in danger. There exists a need to monitor and warn the cabin crew of such an event so that measures can be taken, such as donning an oxygen mask, to mitigate the fumes. Many of the vapors encountered that can cause this issue are colorless and / or odorless and therefore not always detected by the flight crew especially if they are in sufficient quantities and exposure is long enough to compromise the pilots cognitive skills.

Owner:ASTRONICS ADVANCED ELECTRONICS SYST

Catalyst precursor particles, their preparation and use

A method for preparing a catalyst precursor for an olefin polymerization catalyst involves the use of aqueous or alcoholic solutions of a chromium salt and of boric acid and aluminium carboxylate for deposition onto an inorganic support material, such as a silica xerogel. The chromium salt, aluminium carboxylate and boric acid are sufficiently soluble for deposition from a single solution to be effective. The catalyst precursor can be activated by calcination to form a catalyst for homo- or co-polymerisation of alpha-olefins which has productivity and melt flow index for the resulting polymeror copolymer which is comparable to results obtained with catalysts prepared by prior art organometallic routes. The activation of the catalyst precursor gives reduced levels of toxic or noxious fumes during activation compared to use of organometallic sources of chromium or aluminium.

Owner:英国埃科维斯特催化剂技术有限公司

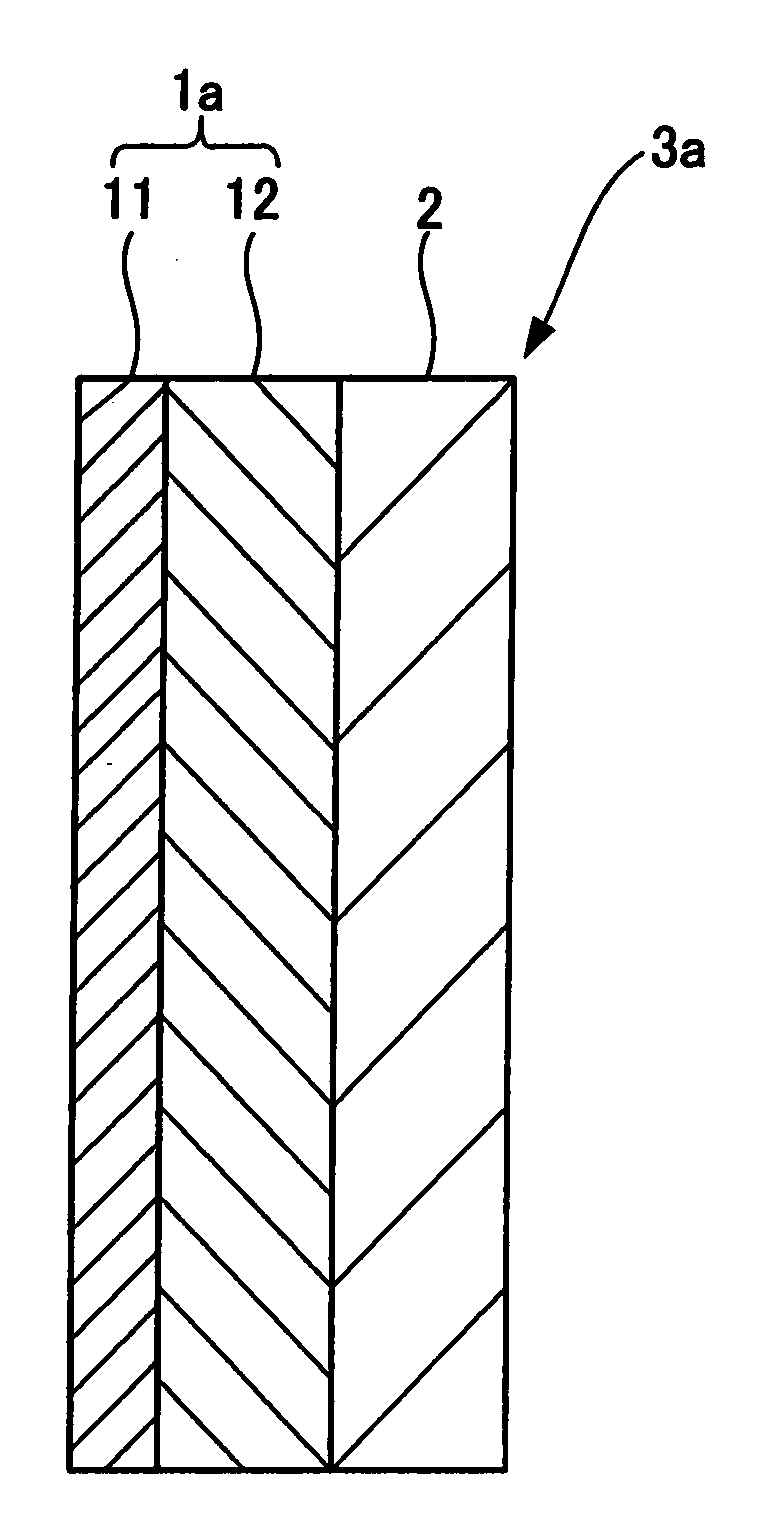

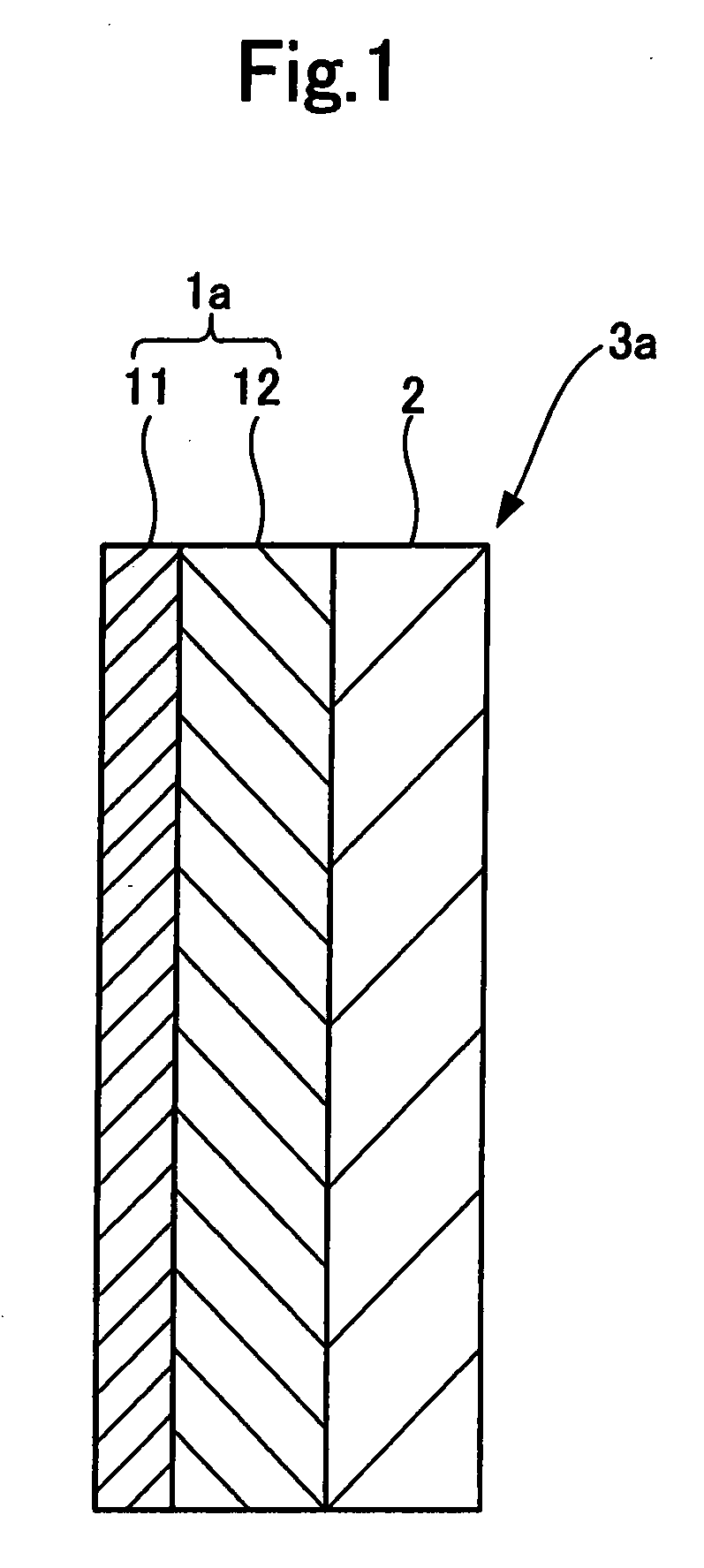

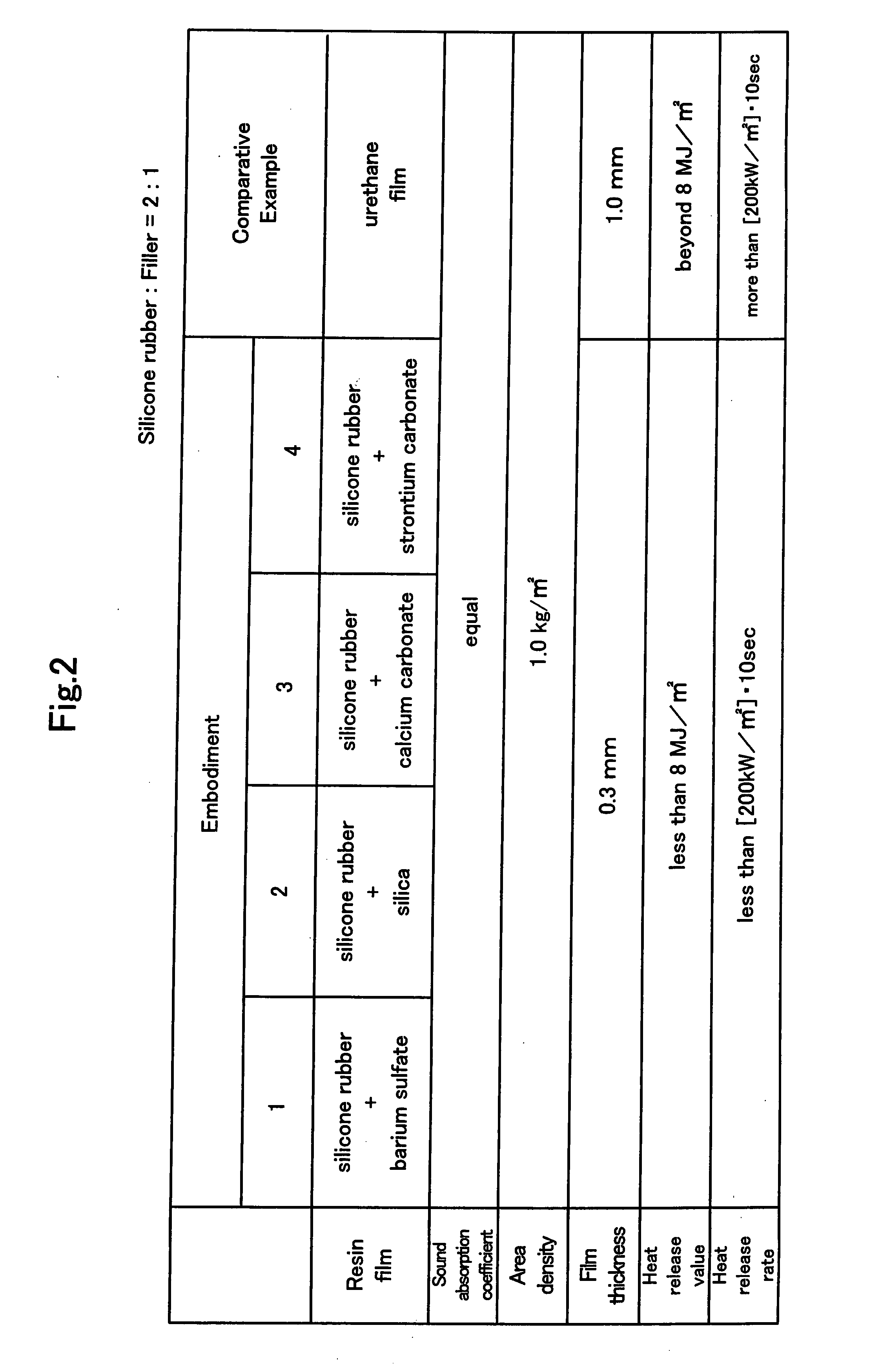

Sound Absorbing Material and Structure Using the Same

InactiveUS20080164093A1Effective absorptionWallsNoise reduction constructionPolymer scienceRigid wall

A sound absorbing material (1a) comprising a film (11) composed of a silicone rubber and a porous layer (12) (i.e., a first porous layer) laminated on the back surface of the film (11). The film (11) is made of a material which has flame retardancy and generates no noxious fume during combustion, such as a silicone rubber comprising only polysiloxane. The film (11) used is preferably one which has an oxygen index of 25 or higher, which exhibits a heat release value of combustion per unit volume of 8 MJ / m or less and which exhibits a heat release rate of combustion of [200 kW / m2]·10 sec or less. The first porous layer (12) is formed from a material having flame retardancy, such as glass wool, rock wool or a mixture thereof. A structure (3a) can be formed by providing the sound absorbing material (1a) having the construction described above on a rigid wall (2) in parallel, with the first porous layer (12) facing to the rigid wall (2).

Owner:SWCC SHOWA DEVICE TECHNOLOGY CO LTD

Chemical incinerator for conveniently treating combustion waste gas and waste slag

InactiveCN107883382AEasy to collect and arrangeReasonable structureEmission preventionBlast-producing apparatusCombustion chamberSlag

The invention relates to a chemical incinerator which is convenient for treating combustion waste gas and waste slag. It includes a furnace body which is divided into a combustion chamber, a slag collection chamber, a waste gas recirculation chamber and a waste gas treatment chamber by a partition inside. The waste gas reflow chamber is respectively connected with the slag collection chamber and The exhaust gas treatment chamber is connected through the air holes on the corresponding partitions. The exhaust gas return chamber is equipped with a first exhaust fan, and the bottom of the exhaust gas treatment chamber is equipped with a second exhaust fan. The air inlet of the first exhaust fan is located in the combustion chamber, and the outlet of the second exhaust fan is The tuyere is connected with the outside; the bottom of the combustion chamber is connected with the slag collection chamber, and the bottom of the combustion chamber is provided with a downward-sloping deflector. There are first and second filter screens, and the mesh holes of the first filter screen are larger than the mesh holes of the second filter screen. The invention can process the harmful flue gas generated in the incineration process on the basis of fully incinerating the waste, prevent the gas from leaking out as much as possible, and also easily collect and discharge the waste slag generated by the combustion.

Owner:登封市绿奥农林科技有限公司

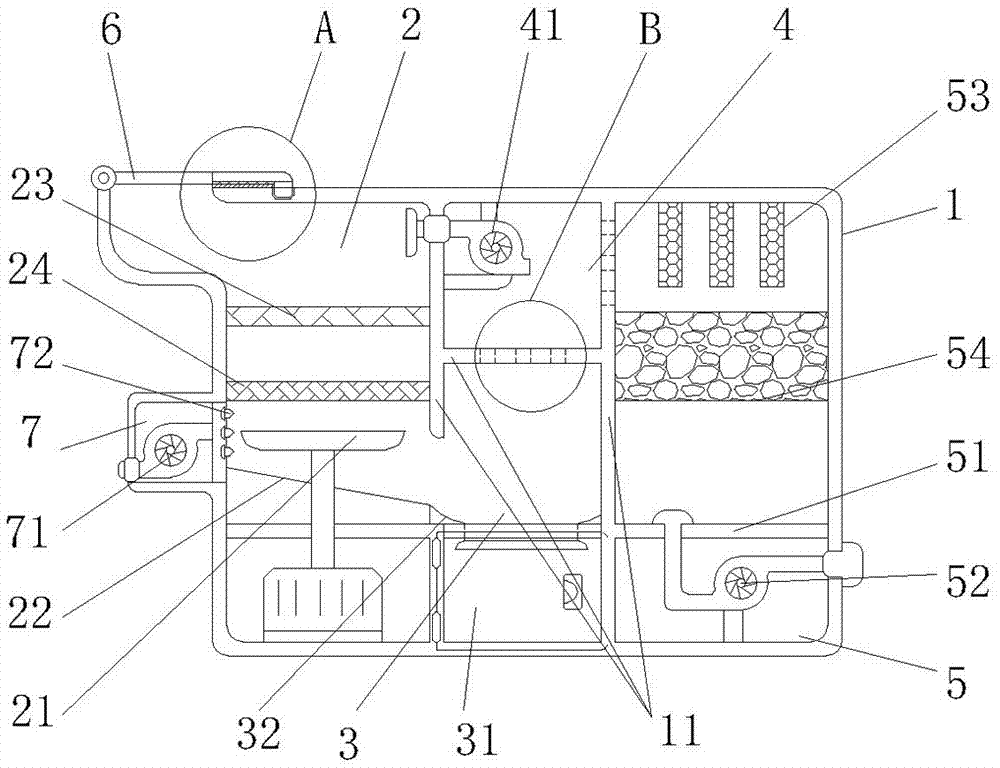

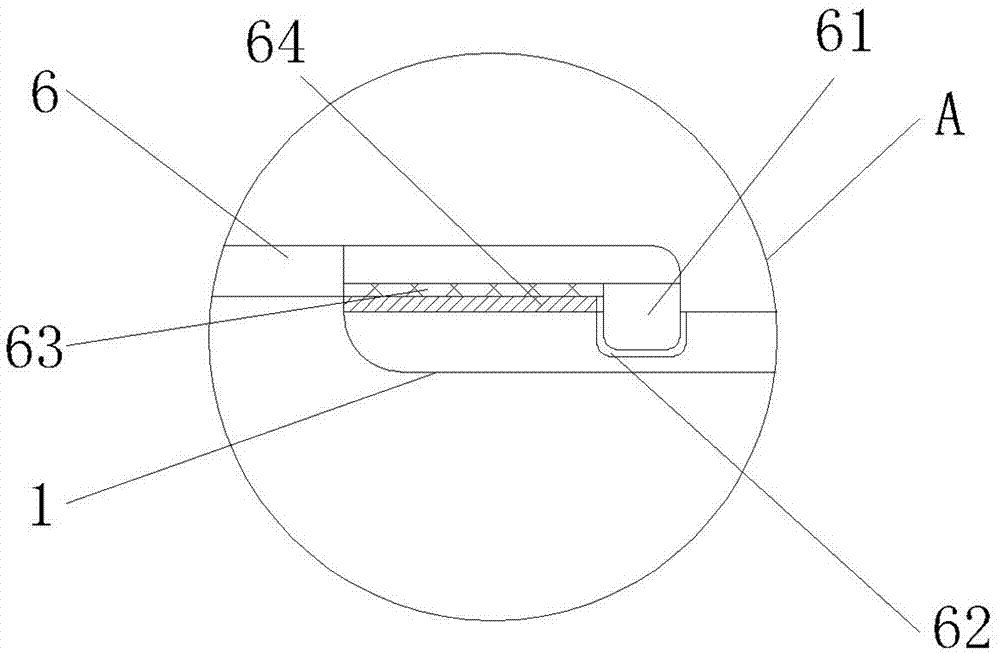

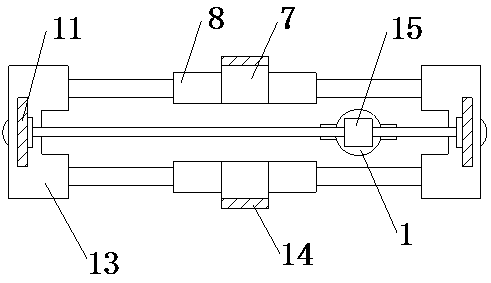

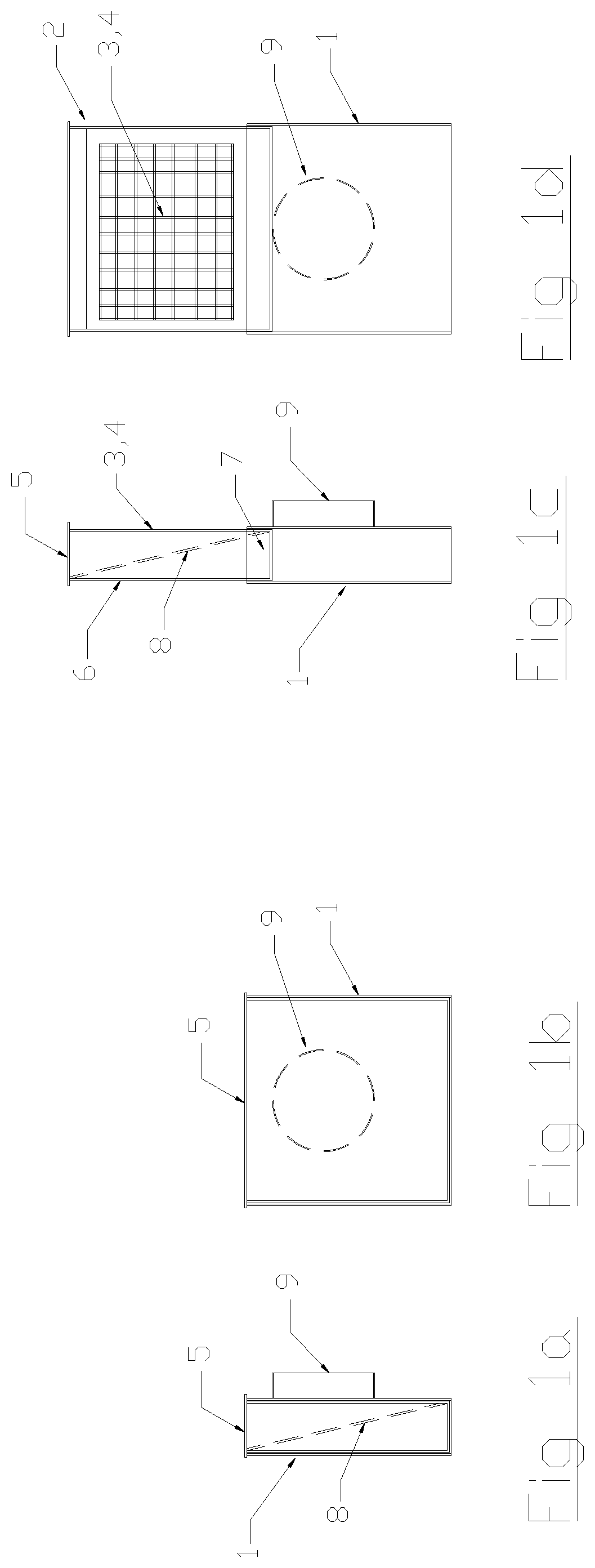

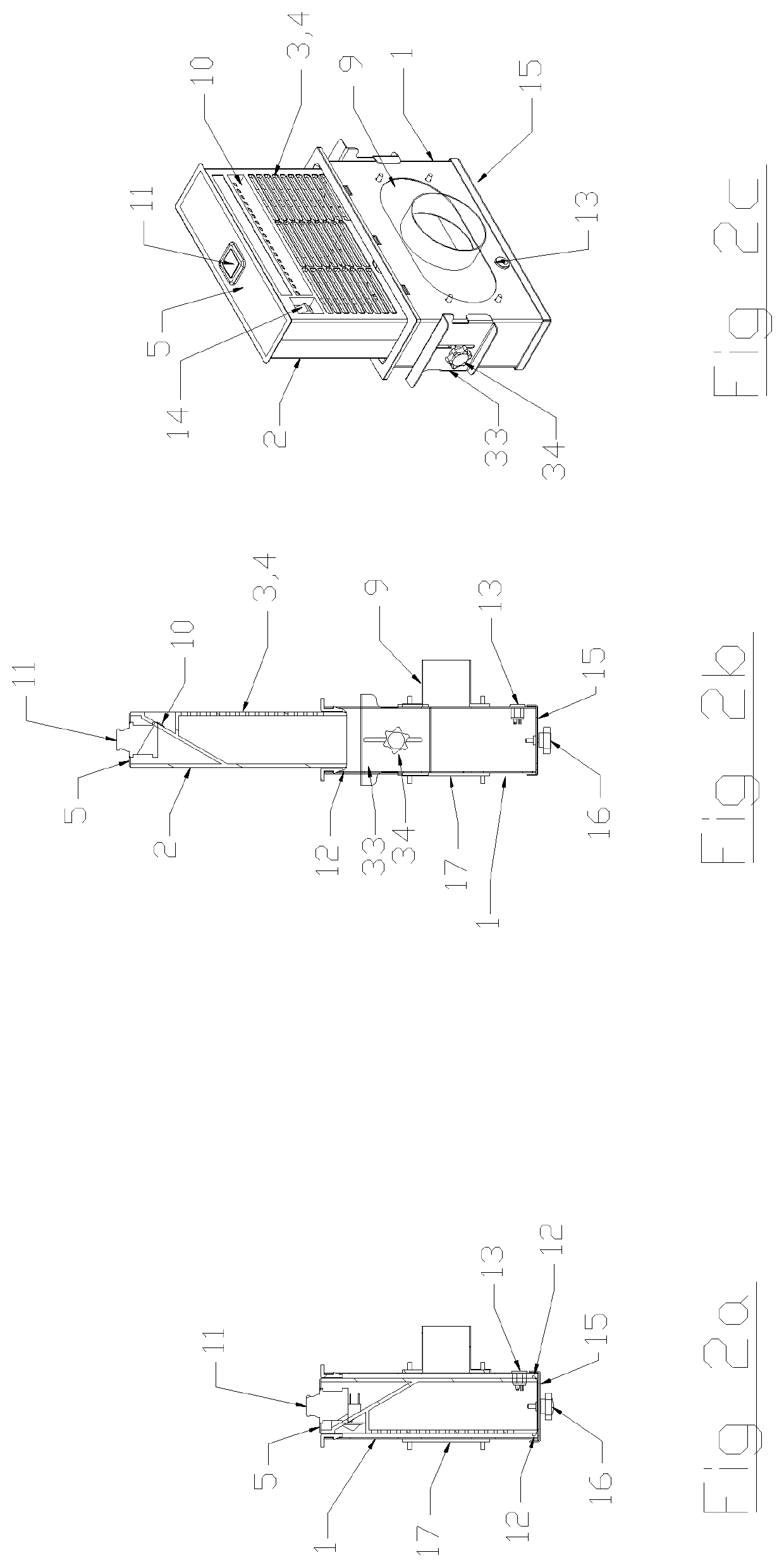

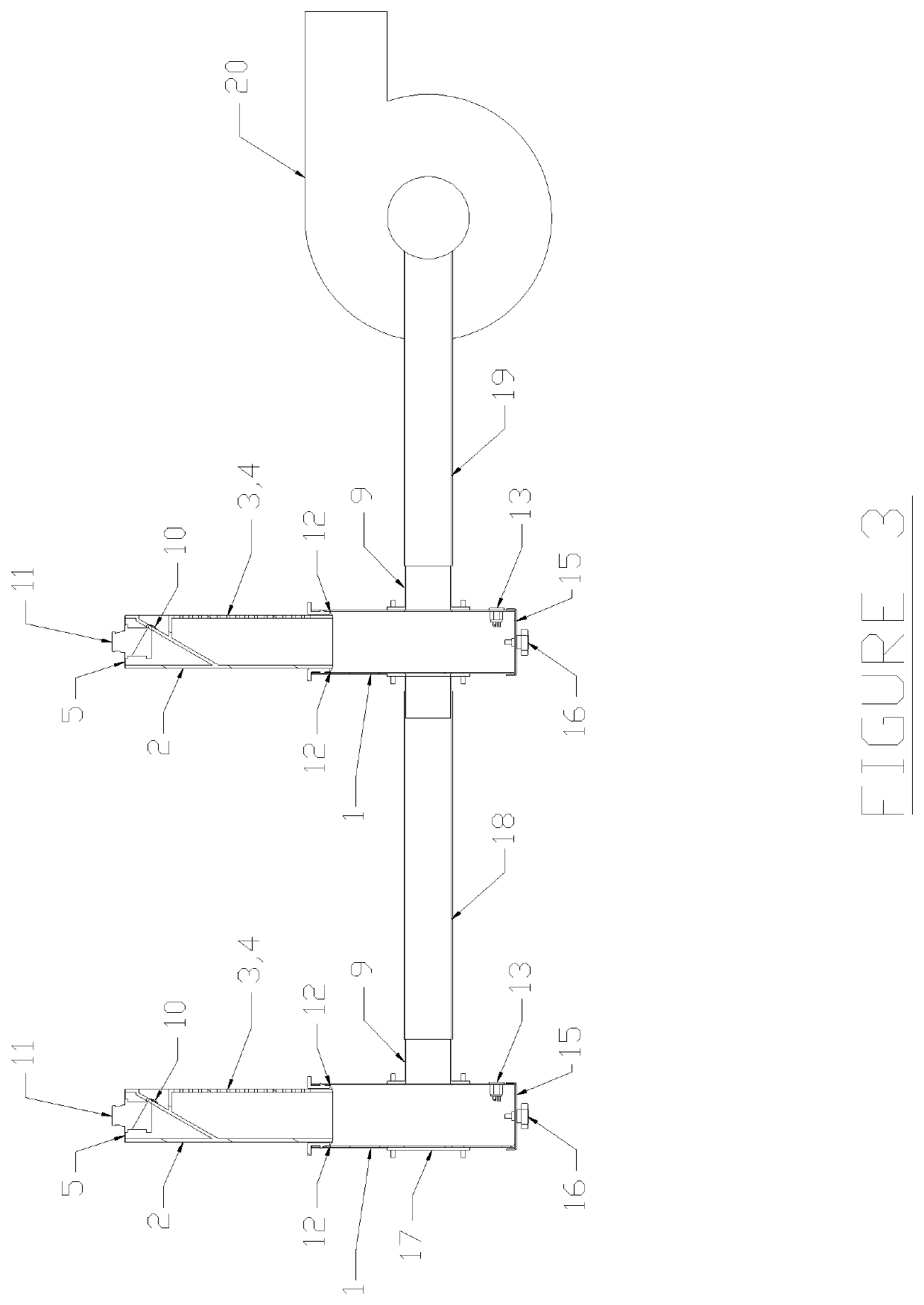

The muffler filter

ActiveUS20190277173A1Reduce conversionInternal combustion piston enginesExhaust apparatusActivated carbon filtrationAbsorbent material

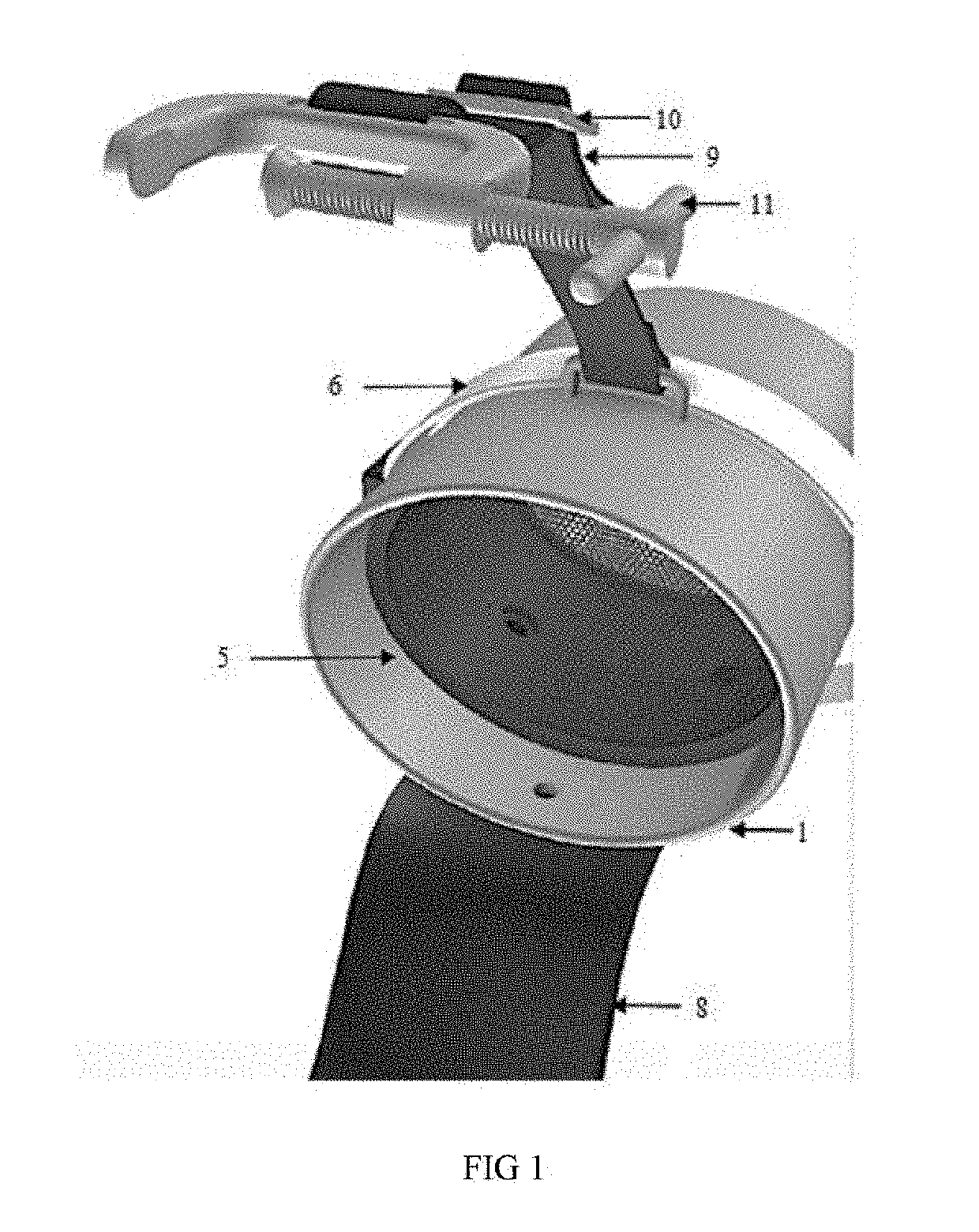

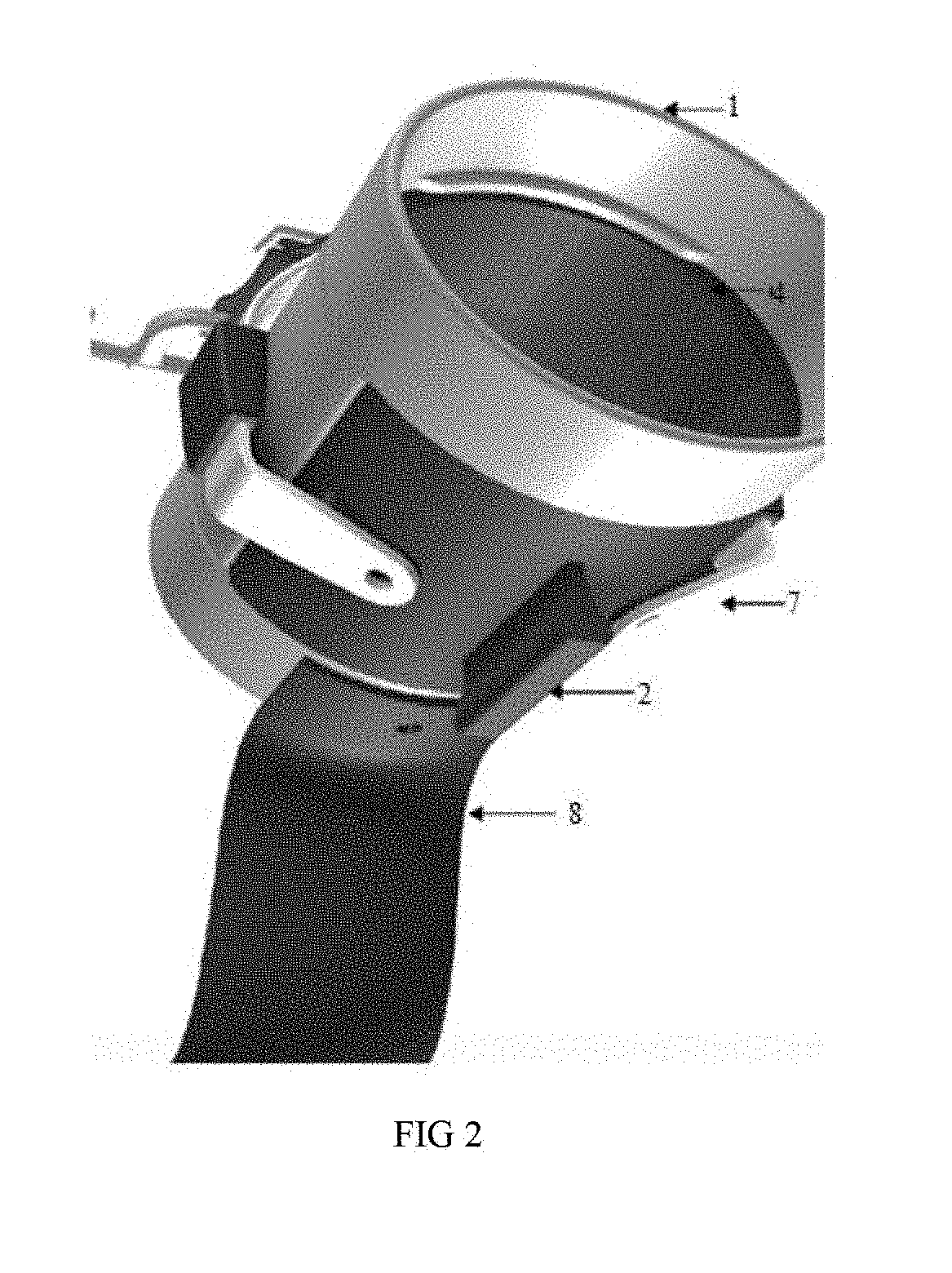

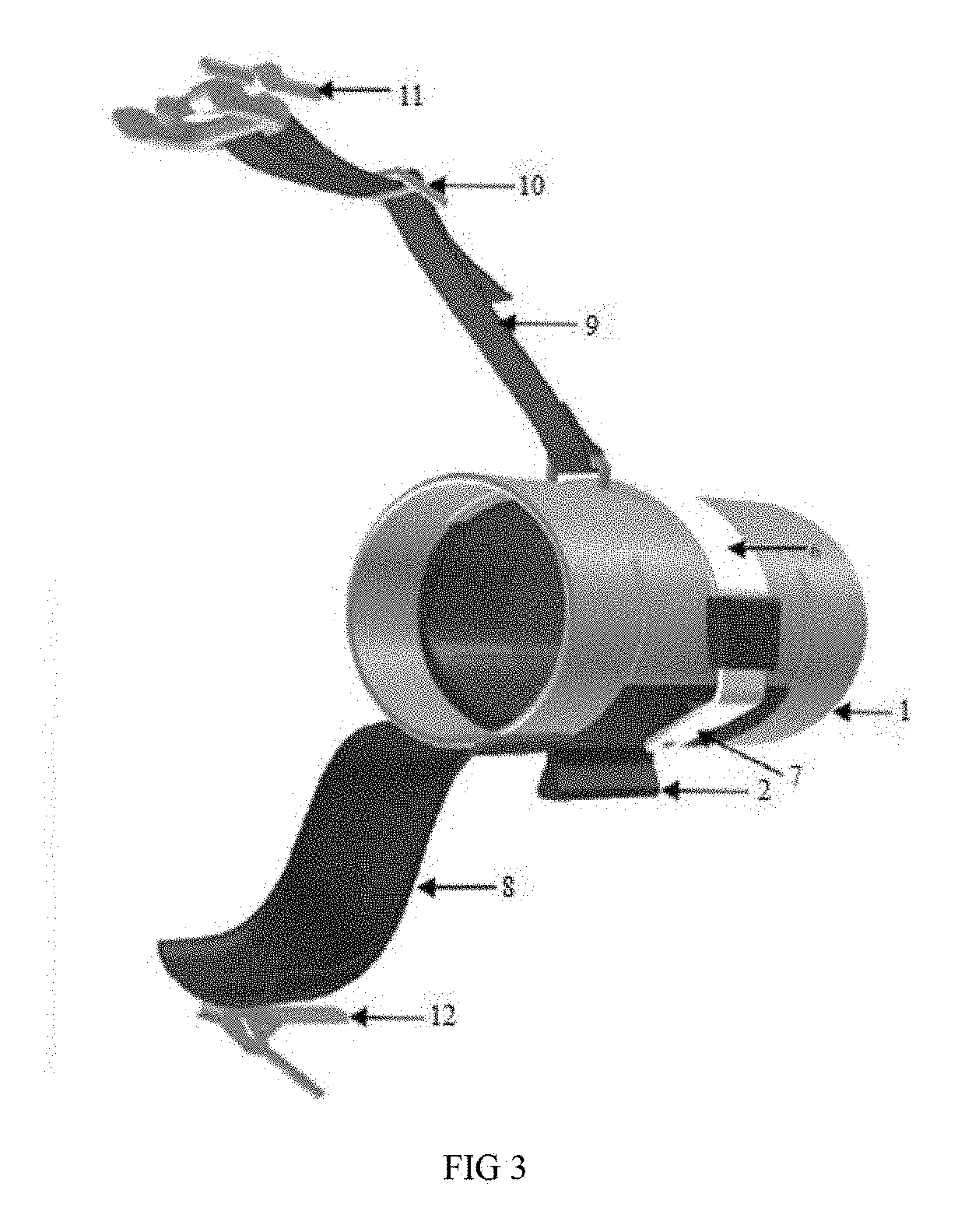

A muffler filter within a housing (1) is disclosed, which is capable of being secured to an automobile rear bumper adjacent the exhaust of an automobile. The filter housing (1) is attached to vehicle with top (11) and bottom (12) clamps. The filters (3, 4) are attached to removable cartridge holder (2). The fireproof band (6) and filter interlocks (7) are attached over housing (1) for locking the filter. The movable slide (8) is attached to housing (1) for connecting filter to bottom of bumper. Fire proof strap (9) for connecting filter to top of bumper is located on top of housing (1). The filters (3, 4) are mainly activated charcoal filters combined with ionic transport membrane system and comprises absorbent material in a matrix capable of absorbing a plurality of noxious fumes emitted from the exhaust the automobile. The filters are capable of being replaced.

Owner:DEAN CHRISTOPHER

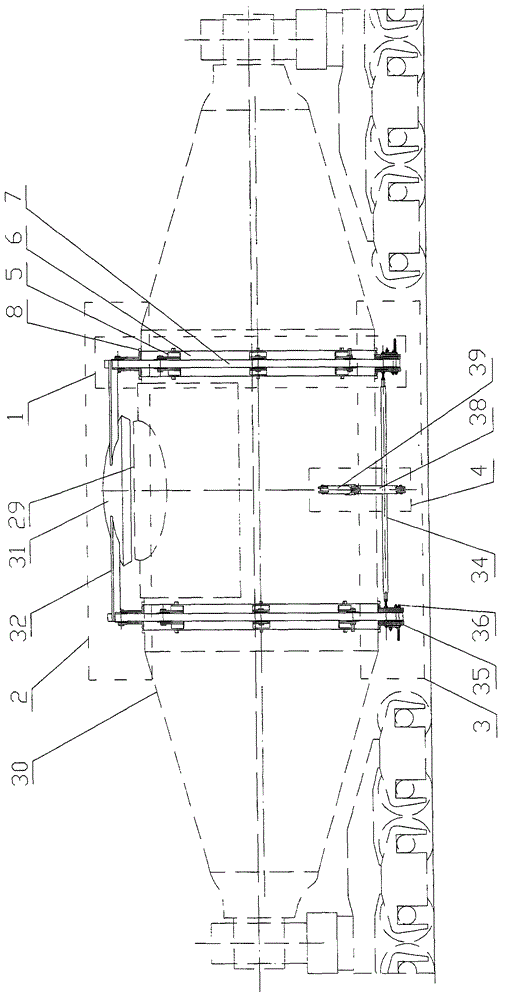

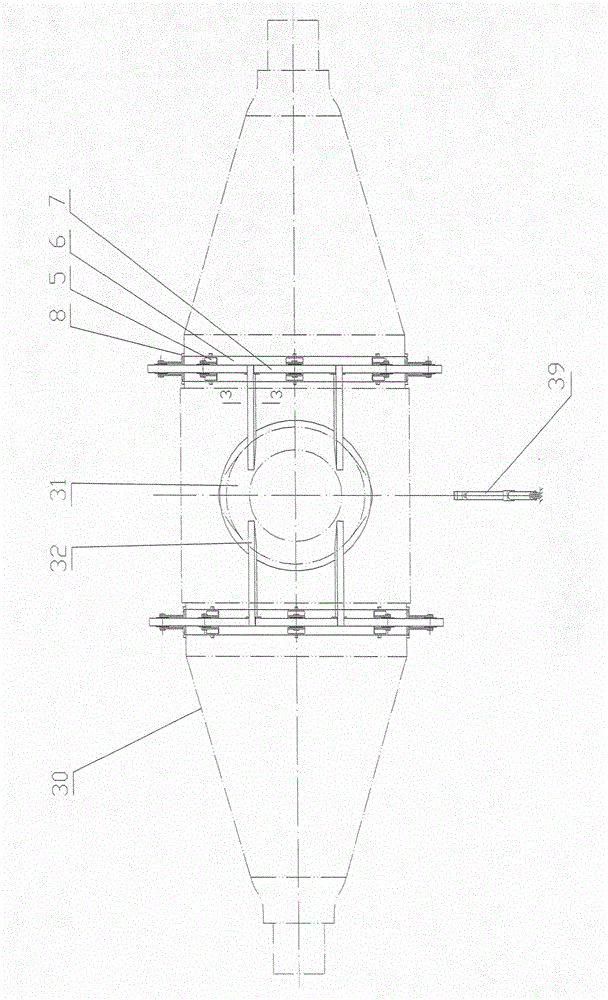

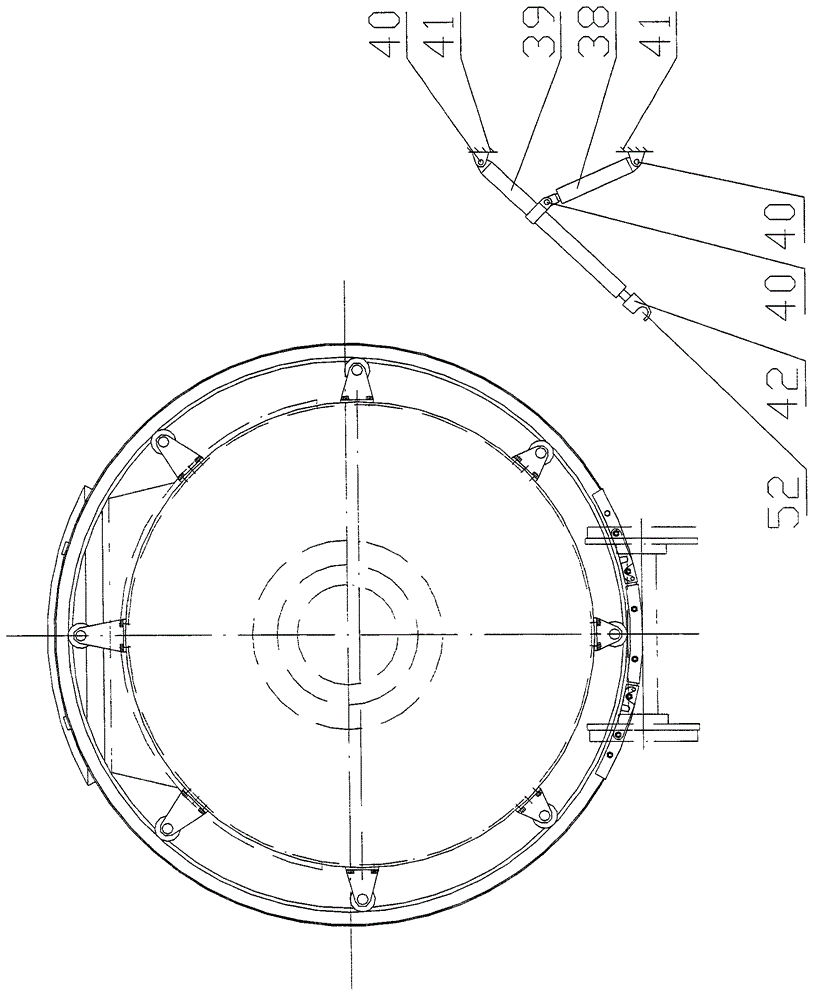

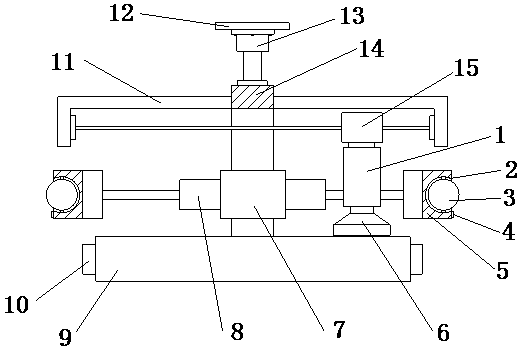

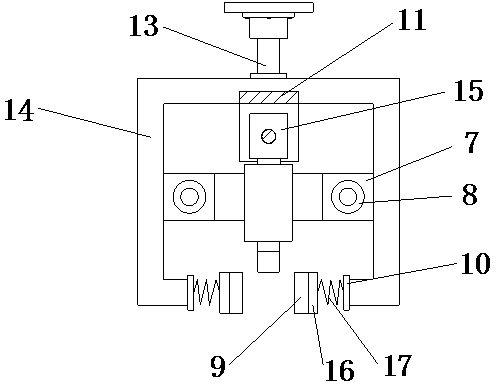

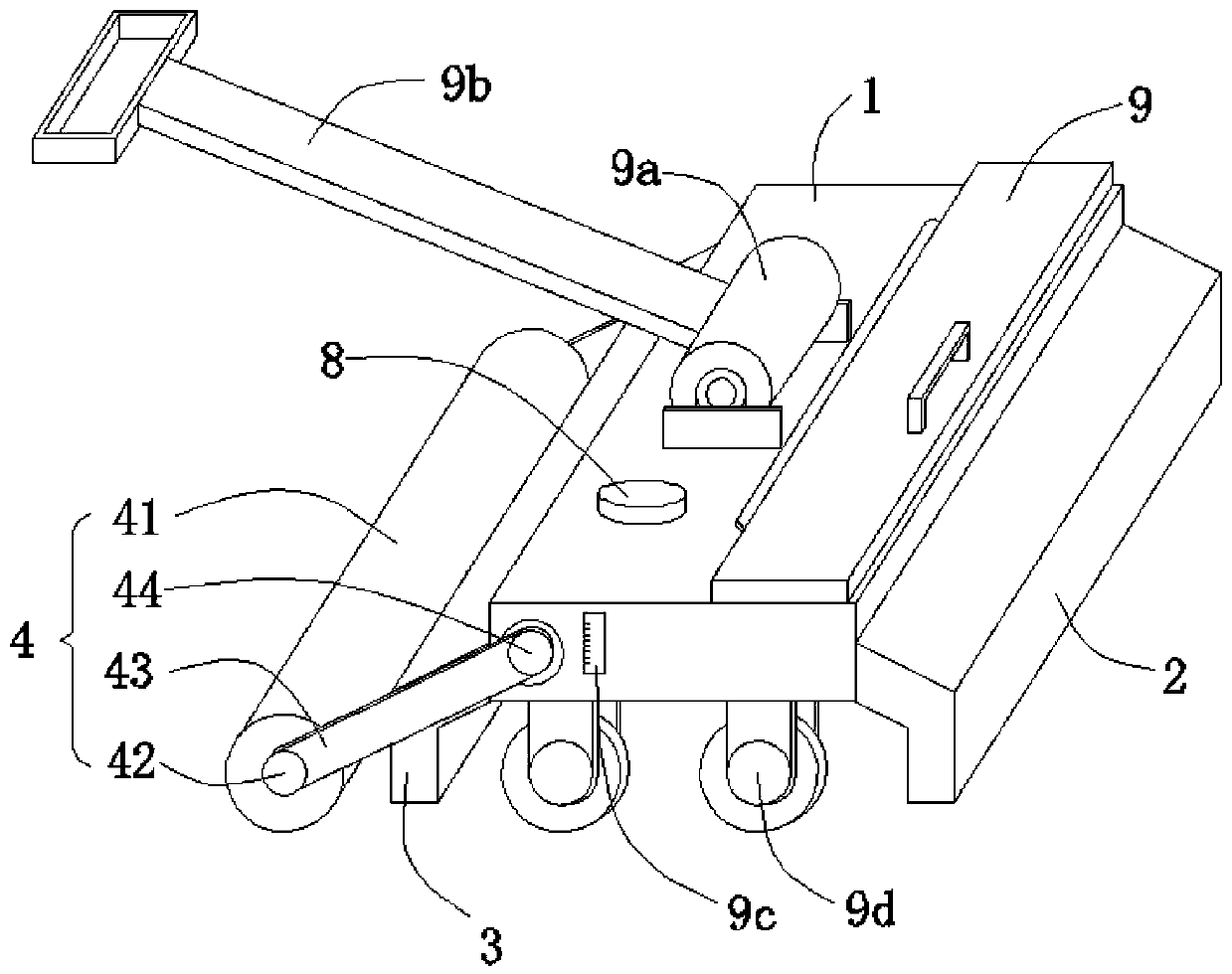

Torpedo tank car molten iron opening protection cover device

The invention relates to the field of ironmaking engineering, in particular to a torpedo tank car molten iron opening protection cover device. The device comprises a sliding conveying mechanism (1), a protection cover (2), a counter weight mechanism (3) and an opening and closing mechanism (4). The protection cover (2) and the counter weight mechanism (3) are connected with two annular sliding rails (7) of the sliding conveying mechanism (1) into an integral unit surrounding a torpedo tank car body (30) and rotating in the circumferential direction. Under the action of gravity of a counter weight plate (35), a cover cap (31) is automatically located on a molten iron opening (29). The cover cap (31) is automatically opened and closed through the opening and closing mechanism (4) before and after the torpedo tank car body (30) receives molten iron. When the torpedo tank car body (30) dumps the molten iron in a rotating mode, the cover cap (31) is opened and closed in a following mode. The independently arranged opening and closing mechanism (4) can be shared by multiple torpedo tank car bodies (30). In the molten iron conveying process of the torpedo tank car body (30), the cover cap (31) is in a covering protection state for the molten iron opening (29) so that emission of noxious fume and heat loss of the molten iron can be reduced, and the service life of lining refractory is prolonged. The device has the advantages of being simple in structure, high in automation degree and worth applying and popularizing.

Owner:浙江西塘实业有限公司

Fire starter

The Present Invention is a fire starting device for use as kindling manufactured from pine straw, as the primary component, a vegetable oil, natural resins, and an herbal component. The device is hollow, having at least one vertical channel and at least one horizontal channel drilled from the outer wall of the device to the inner vertical channel. The fire starter device is ignited from the top, and it burns to produce a high, intense flame that ignites other flammable materials having a much greater kindling temperature. The height of the flame and the burn duration are controlled by the overall size of the device and the sizes of the channels. The device burns clean with a minimum of smoke and harmful or noxious fumes. Burning the device minimally creates air pollution. It burns completely with a minimum of ash residue.

Owner:APPTEC

Sealing device for plastic bag containing chemical powder

PendingCN107826334AReasonable designOperational securityWrapper twisting/gatheringEngineeringSpherical recess

The invention discloses a plastic bag sealing device for chemical powder, comprising an automatic glue applicator, a spherical groove, a ball, a pressure switch, a moving plate, a flat applicator head, a mounting seat, an electric push rod, and a strip electromagnet , strip plate, L-shaped plate, connecting fixed seat, lifter, U-shaped frame, linear motor, load-bearing strip and return spring. The invention is reasonable in design and safe in operation, changes the traditional way of sealing plastic bags with hot-melt plastics, avoids the accidental heating and melting of chemical powder at the mouth of the bag during hot-melting and emits harmful gases, and facilitates sealing of the bag mouth Stretching and flattening are conducive to the next step of glue coating and sealing. By starting the linear motor, the automatic glue applicator is driven to move in a straight line, so that the flat mouth applicator with glue moves slowly at the bag mouth until the bag mouth is completely coated with glue , through glue bonding and solidification, to achieve the effect of sealing the bag mouth.

Owner:洛阳乐森石化新材料有限公司

Source capture apparatus for manicure tables

ActiveUS20190343264A1Efficient extractionEfficient removalGas treatmentDispersed particle filtrationFiltrationComputer science

The invention is a table top filtration device designed to filter noxious fumes on or near the table. In one embodiment, the tables are manicure and pedicure tables.

Owner:HEALTHY AIR INC

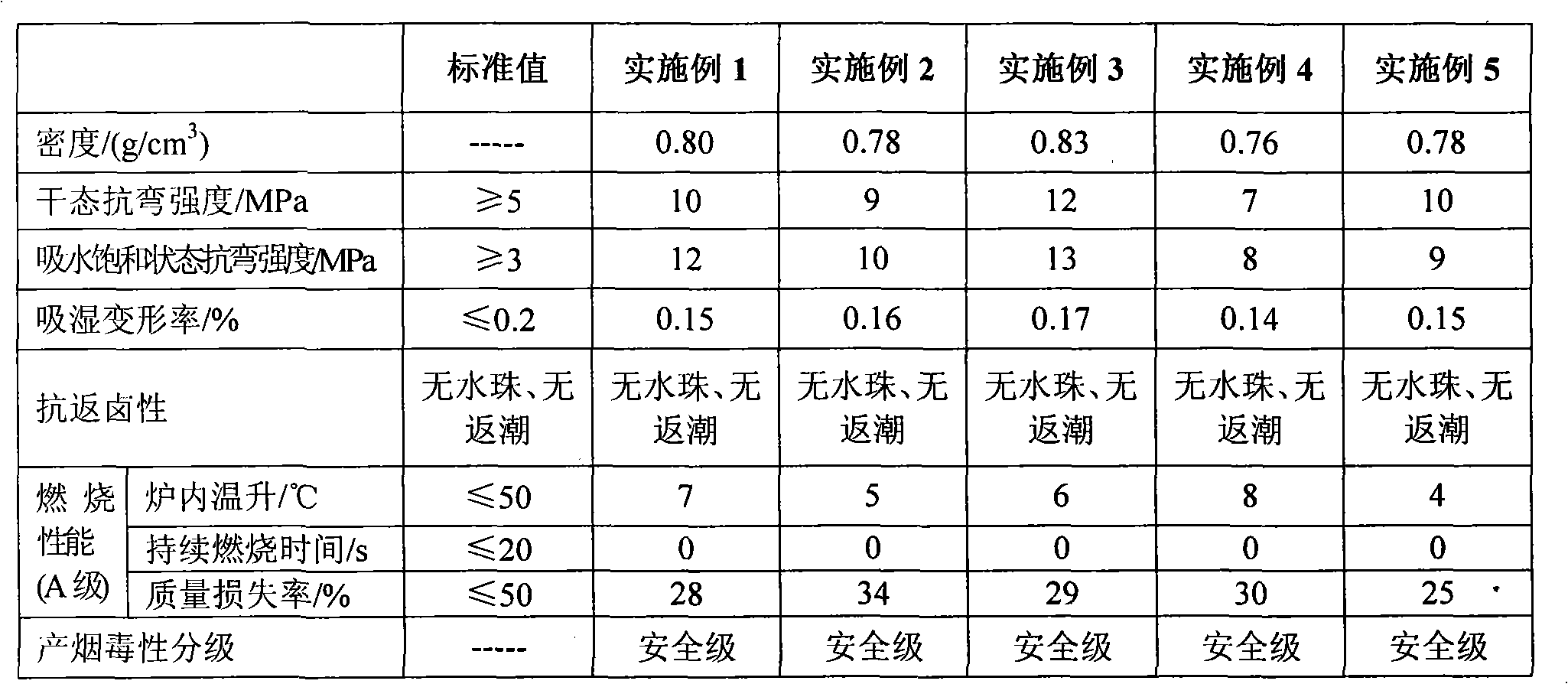

Fireproof plate for heritage building and preparation method thereof

The invention relates to a fire-proof board used for antique buildings and a production method thereof, belongs to the field of refractory materials, and aims to solve the technical problems of the prior art, such as large density, poor fire resistance, low strength and release of noxious fumes during fire. The fire-proof board used for antique buildings contains the following components in weight part: calcined magnesium oxide 18-24, industrial magnesium chloride 7-15, glass fibers 3-6, light-weight fillers 35-60, modifiers 1-2 and water 20-35. The production method of the fire-proof board comprises the following steps: (1) mixing calcined magnesium oxide, light-weight fillers and glass fibers at the give ratio to obtain a mixture; (2) mixing industrial magnesium chloride with water to form solution, adding the solution into the mixture under stirring; 3 adding the modifiers during the stirring procedure; 4 stirring for 1-5 min and discharging; and 5 molding to obtain boards, drying and curing. The fire-proof board is suitable for fire protection of antique buildings.

Owner:应急管理部四川消防研究所

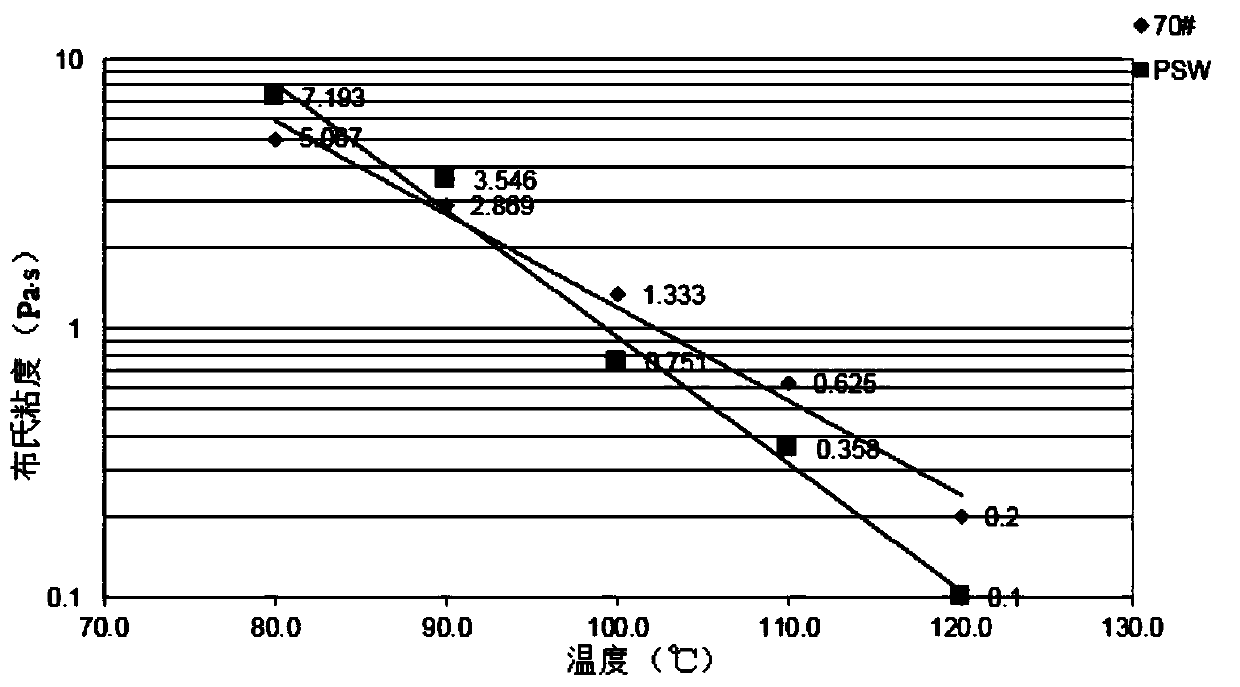

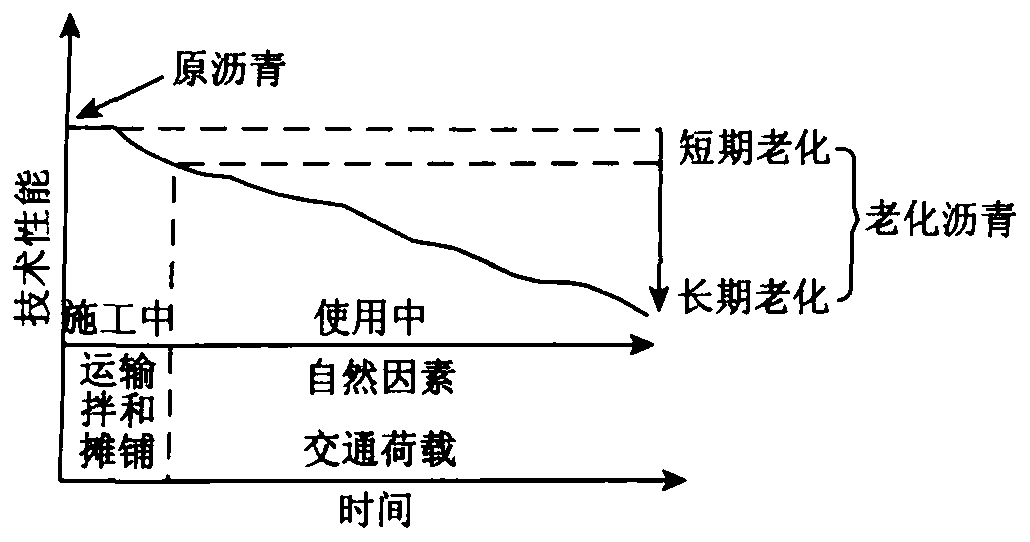

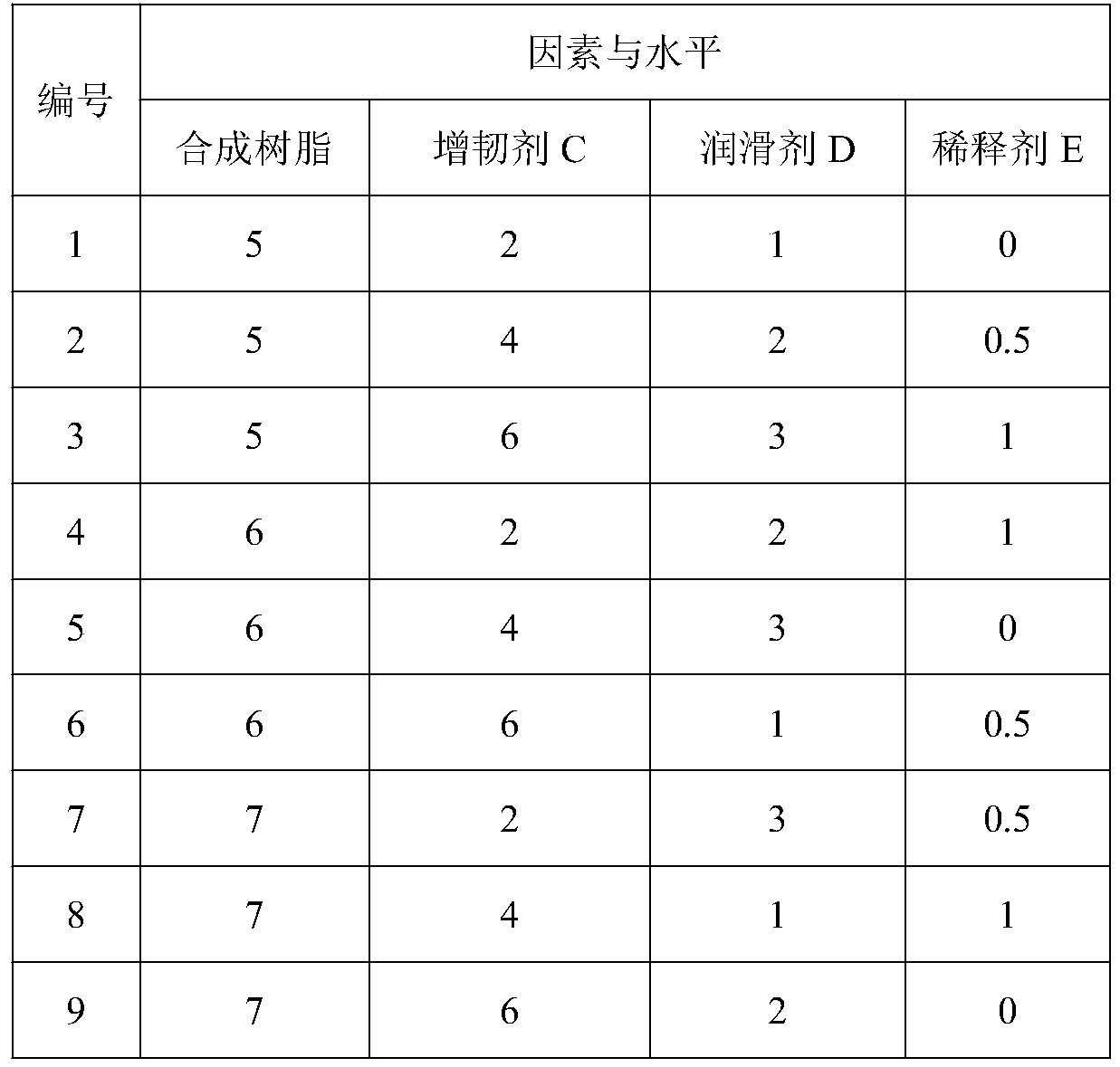

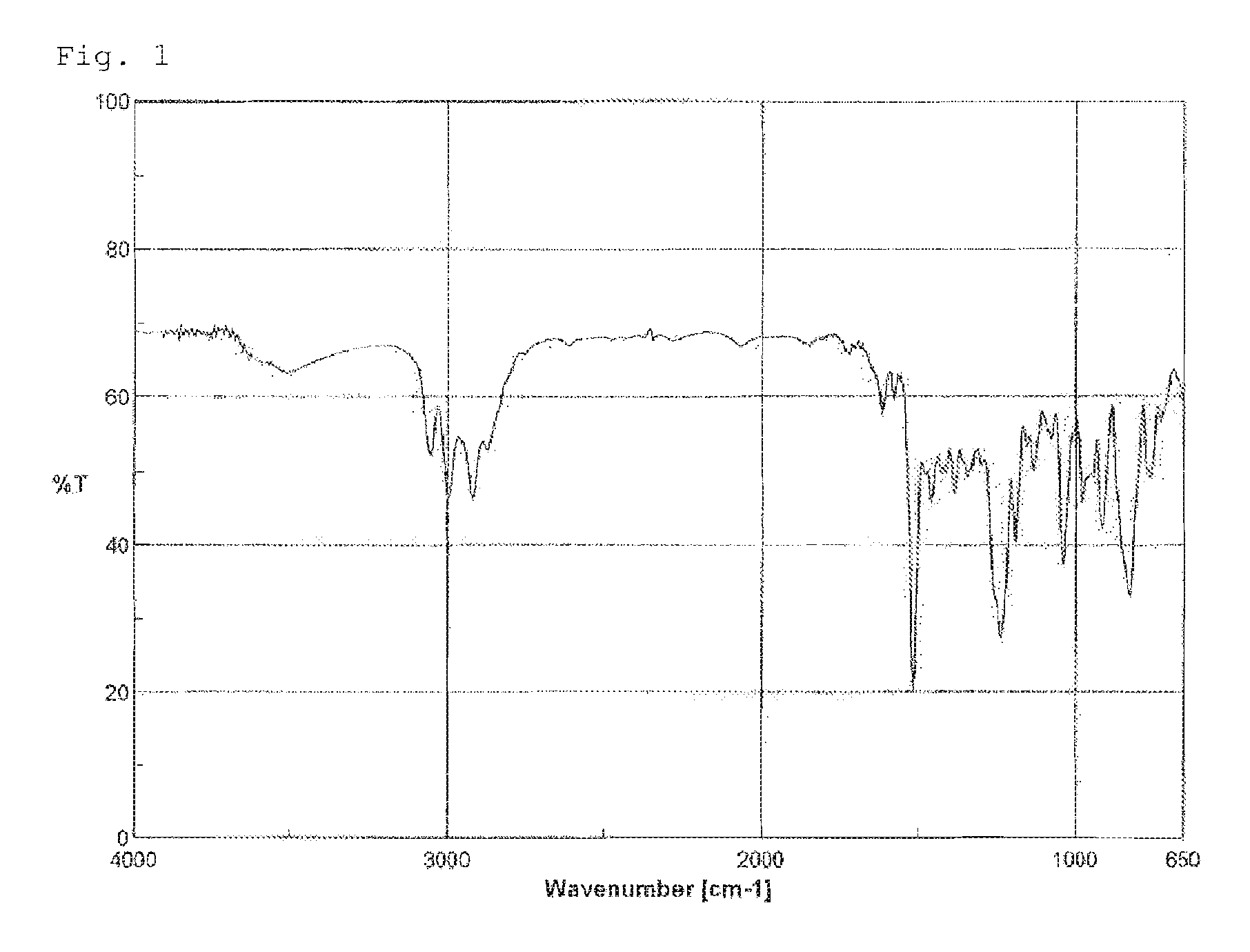

Warm-mixed modified asphalt and preparation method therefor

InactiveCN110396301AGuaranteed performanceEmission reductionIn situ pavingsClimate change adaptationRoad surfacePolypropylene

The invention discloses warm-mixed modified asphalt and a preparation method therefor. Modified asphalt is prepared through mixing lightweight low-molecular-weight oil resulting from scrap tire cracking and polypropylene macromolecular wax resulting from waste plastic cracking with a curing agent and a coupling agent, pavement paving is carried out through subjecting the modified asphalt with an asphalt mixture bitumen aggregate ratio of 3.5% to 4.5%, cement with a weight ratio of 3% to 5% and coarse and fine aggregates to stirring and mixing at a temperature of 110 DEG C to 120 DEG C, then, the about 100 DEG C mixing, 100 DEG C paving and fast curing forming of an asphalt mixture can be achieved, the difficulty of construction is lowered, and pavement performance is guaranteed while the construction cycle is shortened; energy consumption is lowered, the emission of noxious fumes is reduced, the emission of greenhouse gases and smoke dust is reduced, and the injury to construction personnel is reduced; compared with a hot-mixing technology, the warm-mixed modified asphalt is lower in requirements and wider in adaptability; and furthermore, waste tires and waste plastics are reprocessed and reutilized, so that resources can be saved, and an environment-friendly development idea is conformed.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +1

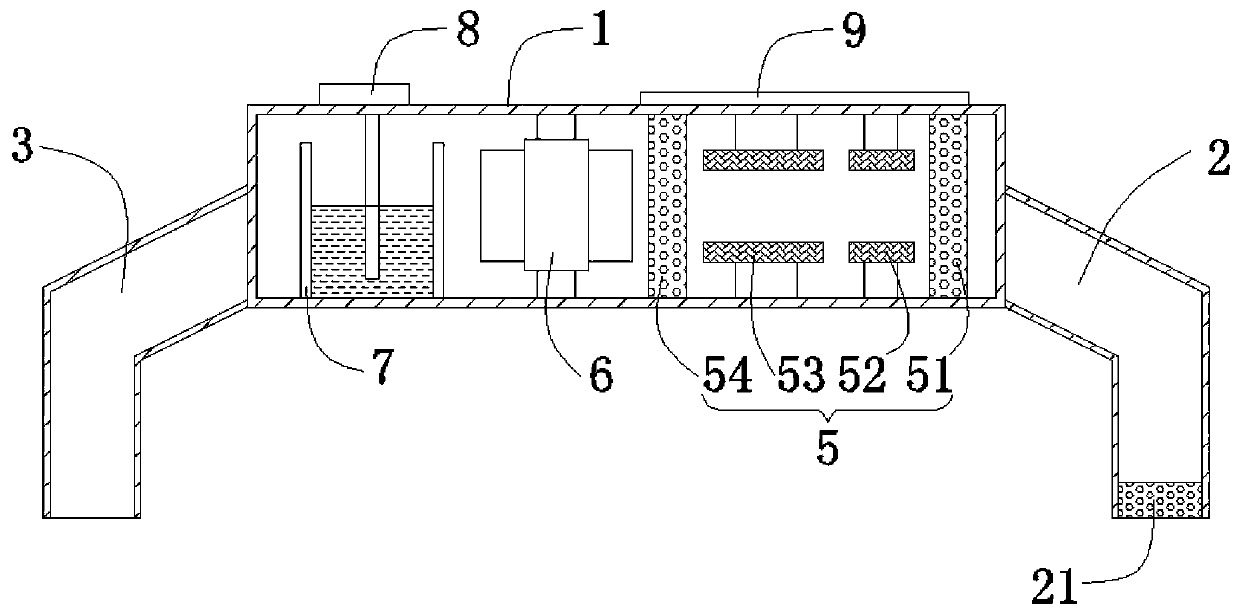

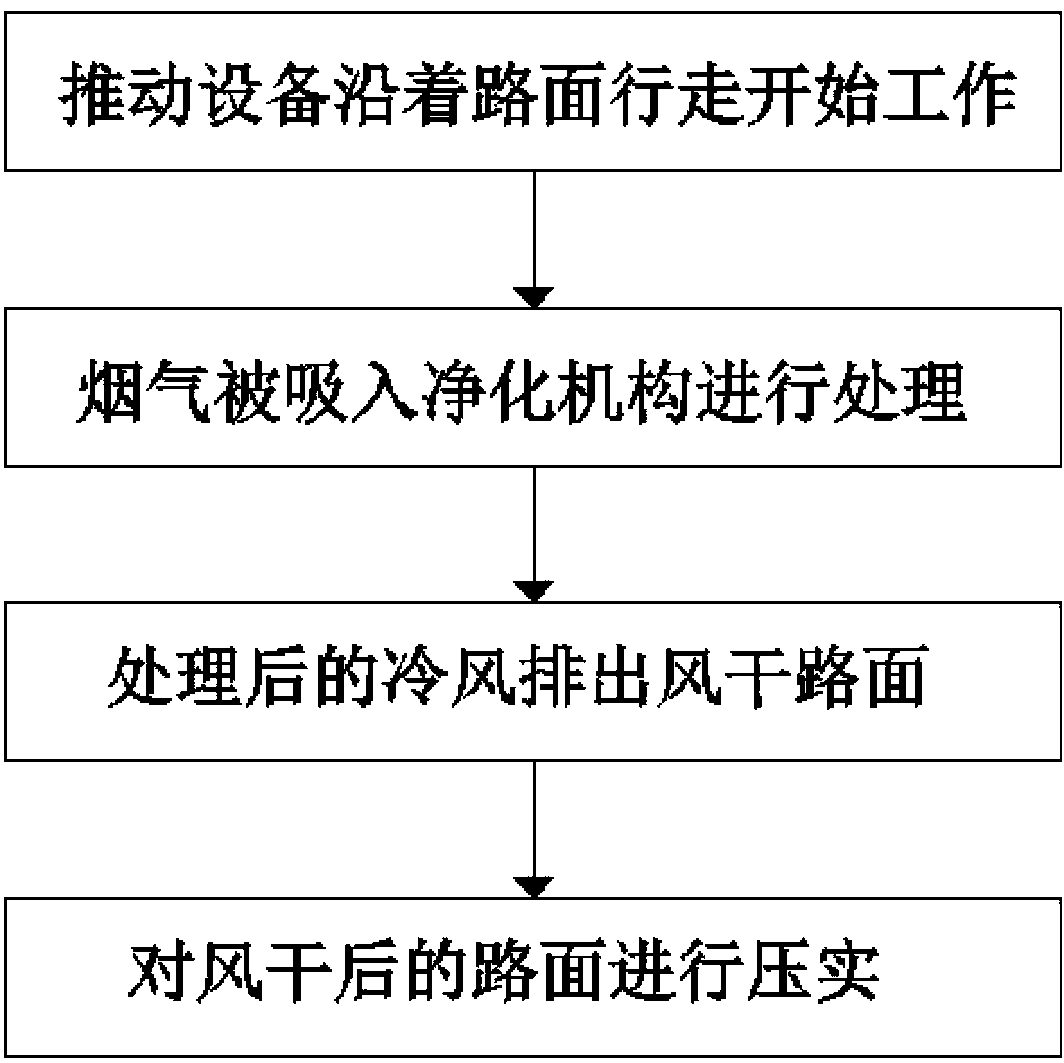

Bituminous pavement purifying device for building industry

InactiveCN107803086AIncrease the speed of solidificationEffective filteringCombination devicesRoad surfaceSecond screen

The invention provides an asphalt pavement purification device for construction industry. The asphalt pavement purification device for the construction industry includes a box; rollers; an air inlet pipe; a first filter screen is installed at the entrance of the air inlet pipe; an air outlet pipe; a flue gas treatment mechanism, which includes A second filter screen, an ionization plate, an electrostatic adsorption plate and a third filter screen, and the second filter screen is arranged at the outlet of the air inlet pipe; one side of the second filter screen is provided with the ionization plate , and one side of the ionization plate is provided with the electrostatic adsorption plate; one side of the electrostatic adsorption plate is provided with the third filter screen; an exhaust fan; a water tank, the water tank is installed on the side of the box Inside, and the water tank is arranged at the entrance of the air outlet pipe. The asphalt pavement purification device for construction industry provided by the invention can quickly and efficiently process harmful smoke and improve the air quality in the working environment of construction personnel.

Owner:长沙翼希网络科技有限公司

Method for regulating and controlling water quality and reducing air pollution in recirculated water acidulous operation condition

ActiveCN101172685AImprove water qualityChemical absorption inhibitionWater/sewage treatment by flocculation/precipitationWash waterWater quality

The invention provides a method for regulating water quality and reducing air pollution under weakly acidic operating conditions of circulating water. Precipitation, removal of suspended solids and sulfides. The organic polymer flocculant adopts Qiba Refining Chemical 1011, and the input amount is 0.4~0.8mg / l. The dosage of ferrous sulfate deacidification flocculant is 9~14mg / l. The invention has good purifying effect of suspended matter and certain desulfurization effect, and can also form calcium sulfate precipitation on the surface of metal components of circulating water facilities to prevent metal corrosion. It is suitable for water quality control of gas washing and cooling circulating water in metallurgy, coal chemical industry and petrochemical industry, to maintain the quality of circulating water and greatly reduce air pollution caused by volatilization of harmful gases in washing and circulating water.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

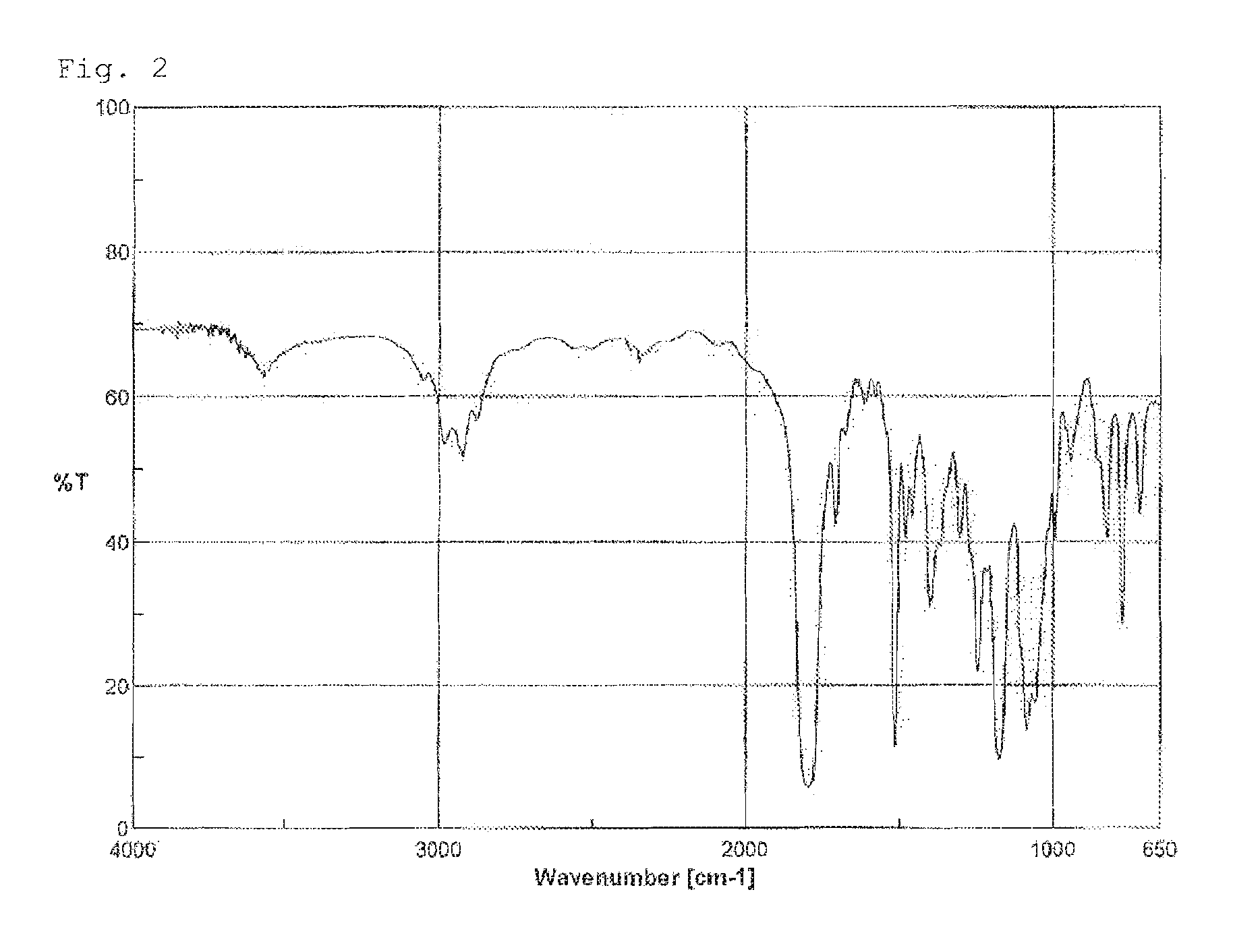

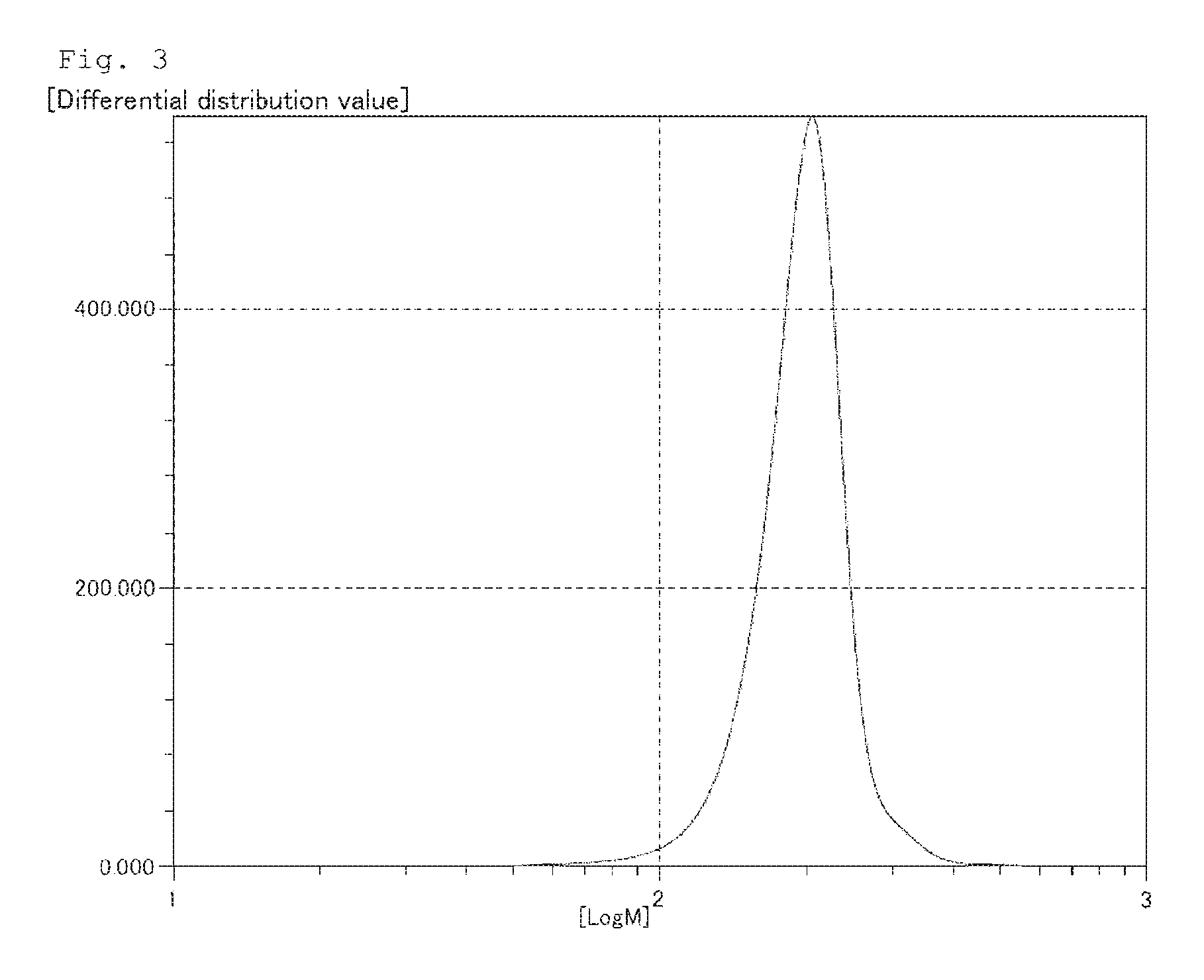

Coating composition for forming gas barrier layer, gas barrier film, and method for producing gas barrier film

ActiveUS9540537B2Improve barrier propertiesSimple forming methodOrganic chemistrySynthetic resin layered productsChemical structureForming gas

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

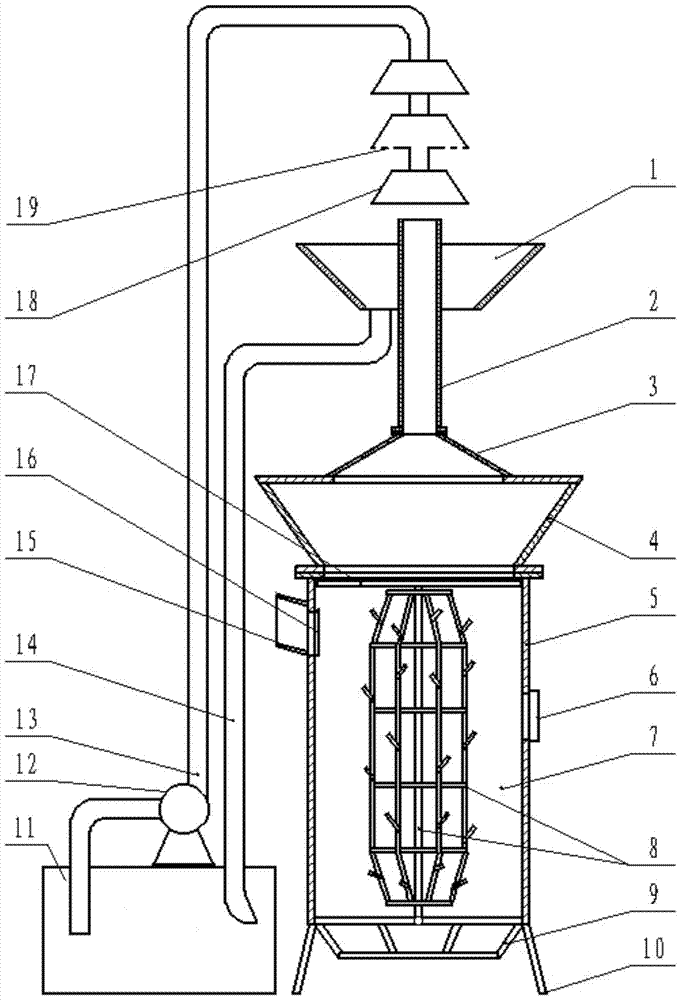

An environmentally friendly waste incinerator

ActiveCN105258126BIncrease temperatureStable heat sourceIncinerator apparatusCombustion chamberBrick

An environment-friendly waste incinerator, comprising a furnace body, a combustion chamber, a high-level feed port, a grate bar and a furnace foot, the inner wall of the furnace body is provided with refractory bricks, the furnace body is hollow to form a combustion chamber, and the upper portion of the furnace body is provided with a high-level feed port The bottom of the furnace body is provided with a furnace bar, and the bottom end of the furnace body is open to form an ash outlet; the bottom end of the furnace body is provided with a furnace foot; Water pipe; the lower end of the dust collecting hopper is connected with the upper end of the furnace body through the flange, and the upper end of the dust collecting hopper is welded with the inverted hopper; the chimney and the inverted hopper are connected by the flange; On one side of the furnace body, a water pump is installed above the reservoir; one end of the water inlet pipe is connected to the water pump, and the other end is arranged above the chimney; one end of the water outlet pipe is connected to the reservoir, and the other end is installed at the bottom of the water collection tank. The invention can clean the flue gas generated after the garbage burning, reduce the emission of harmful flue gas, and reduce the air pollution caused by the garbage incineration.

Owner:都安瑶族自治县计量检定测试所

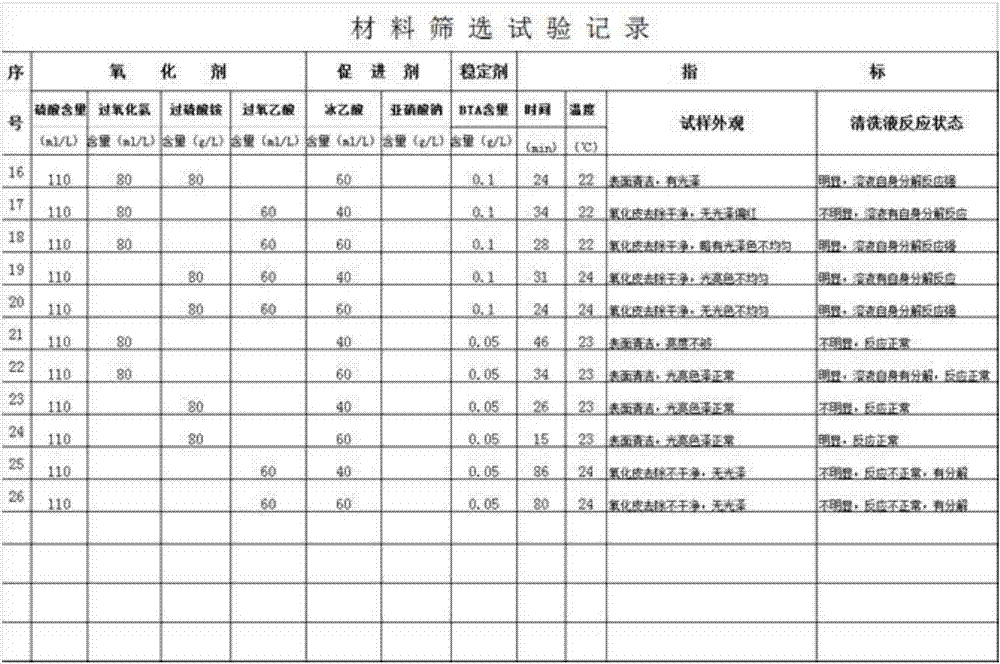

Washing agent and method for treating copper and copper alloy surface oxidation layer

The invention relates to a lotion for treating the oxidized layer on the surface of copper and copper alloy, which is made of the following raw materials in parts by weight: 90-220 parts of sulfuric acid, 40-90 parts of ammonium persulfate, 40-65 parts of glacial acetic acid, and benzene Azole 0.05‑0.2 part. The invention removes the oxide skin of copper and copper alloy products at one time, the inner and outer surfaces of the products and accessories are clean, the color is bright, uniform and shows the normal color of copper and copper alloys, there is no over-corrosion phenomenon, and the threads and accessories are free of any corrosion. damage; the process temperature range is wide, no heating is required in winter, and the natural environment can be produced; the operation is simple, the process parameters are easy to control, no need for frequent adjustments, high production efficiency, and low cost; copper and copper alloy product parts can be used in the same tank Liquid cleaning at the same time; no harmful gas volatilization, no need to add environmental protection equipment.

Owner:祝国忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com