Ventilated dissection table

a dissection table and ventilated technology, applied in the field of dissection tables, can solve the problems of increasing the risk of students being exposed to elevated levels of noxious fumes from the cadaver, and achieve the effects of convenient movement of the table, convenient bending, cutting and welding, and portable or mobile dissection tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

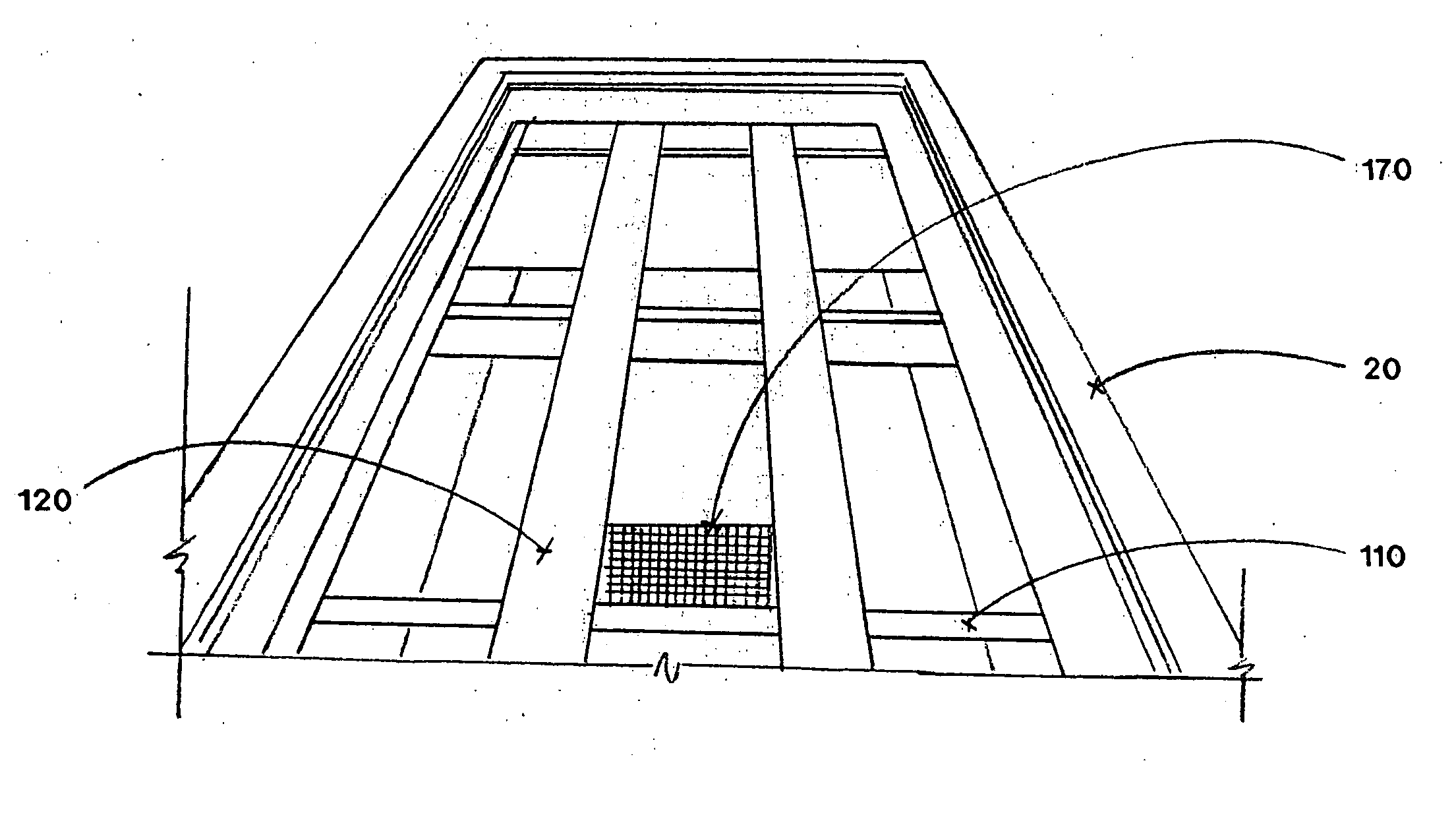

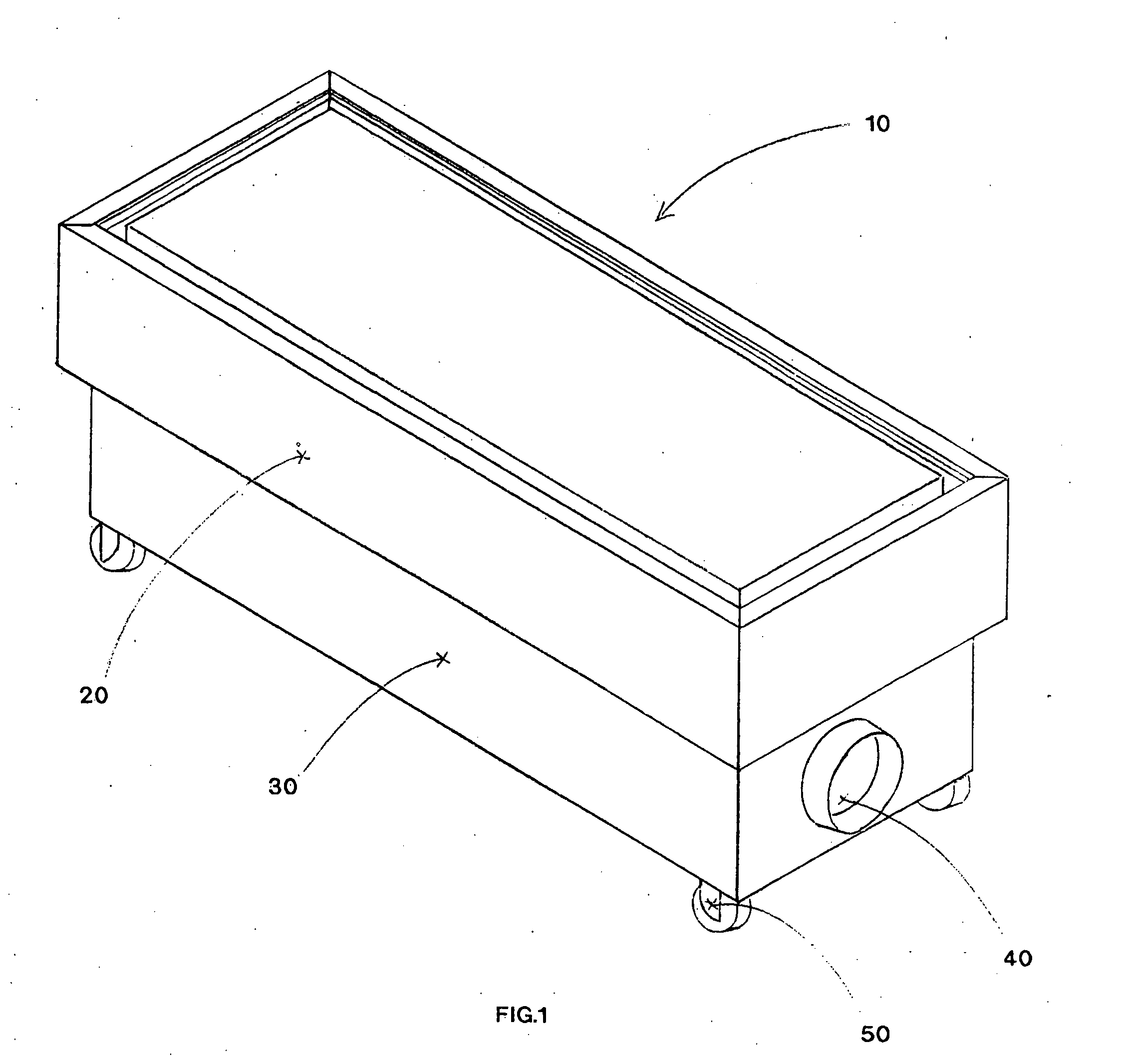

[0023]FIG. 1 shows the preferred embodiment of applicant's invention, dissection table 10. Also readily shown are air chamber 20 sitting atop pedestal 30. Exhaust duct 40 is provided at one end of pedestal 30, and casters 50 are provided at the bottom of pedestal 30 to allow ease of mobility. Pedestal 30 is provided with a close-off plate at its top, which supports air chamber 20. The basic structure is fabricated from 304 stainless steel or equivalent. As stated above, in the preferred embodiment, air chamber 20 and pedestal 30 are fabricated from 16 gage stainless which has the advantage of being easily formed by bending, has strength, may be welded, and is still relatively light in weight.

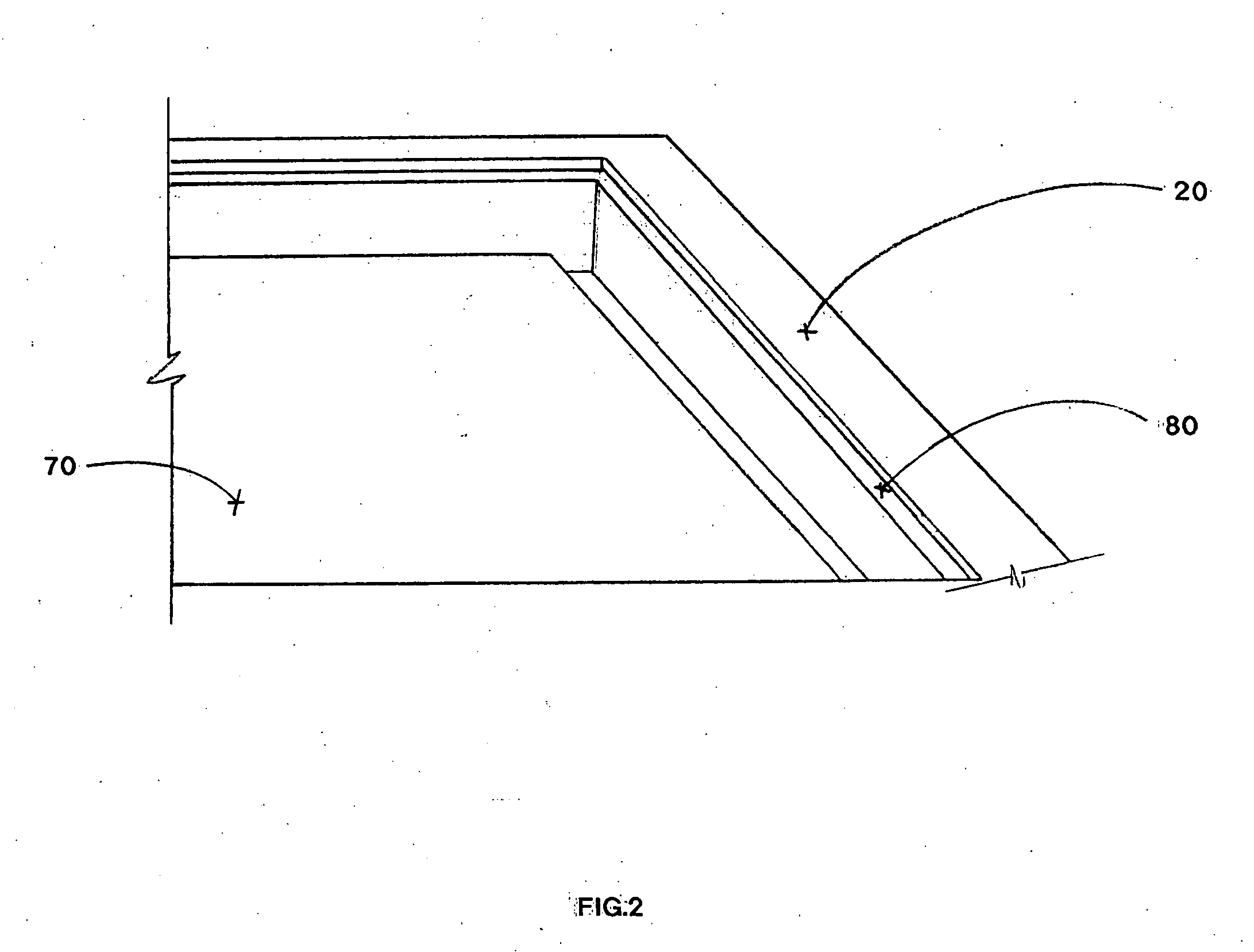

[0024]FIG. 2 depicts the basic configuration of removable work surface 70 proximate to air chamber 20. An inlet 80, proximate to said work surface provides a negative pressure, drawing whatever noxious fumes are attendant to the specimen being dissected down into the chamber for exhausting thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com