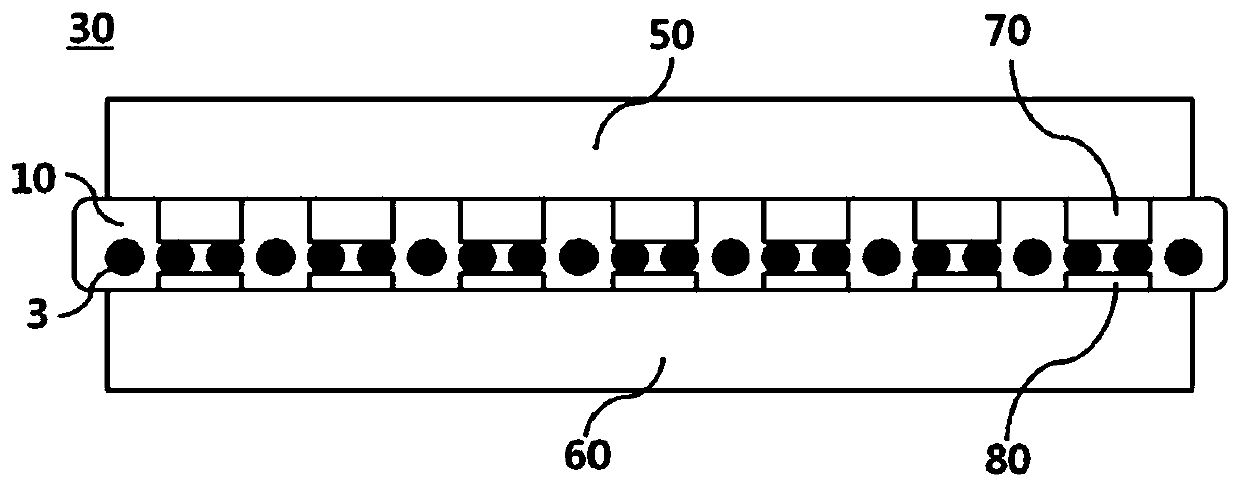

Anisotropic conductive film and display device using same

An anisotropic, conductive film technology, applied in the direction of conductive adhesives, film/sheet adhesives, conductors, etc., to achieve the effects of low DSC heat change rate, good storage stability, and high particle capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

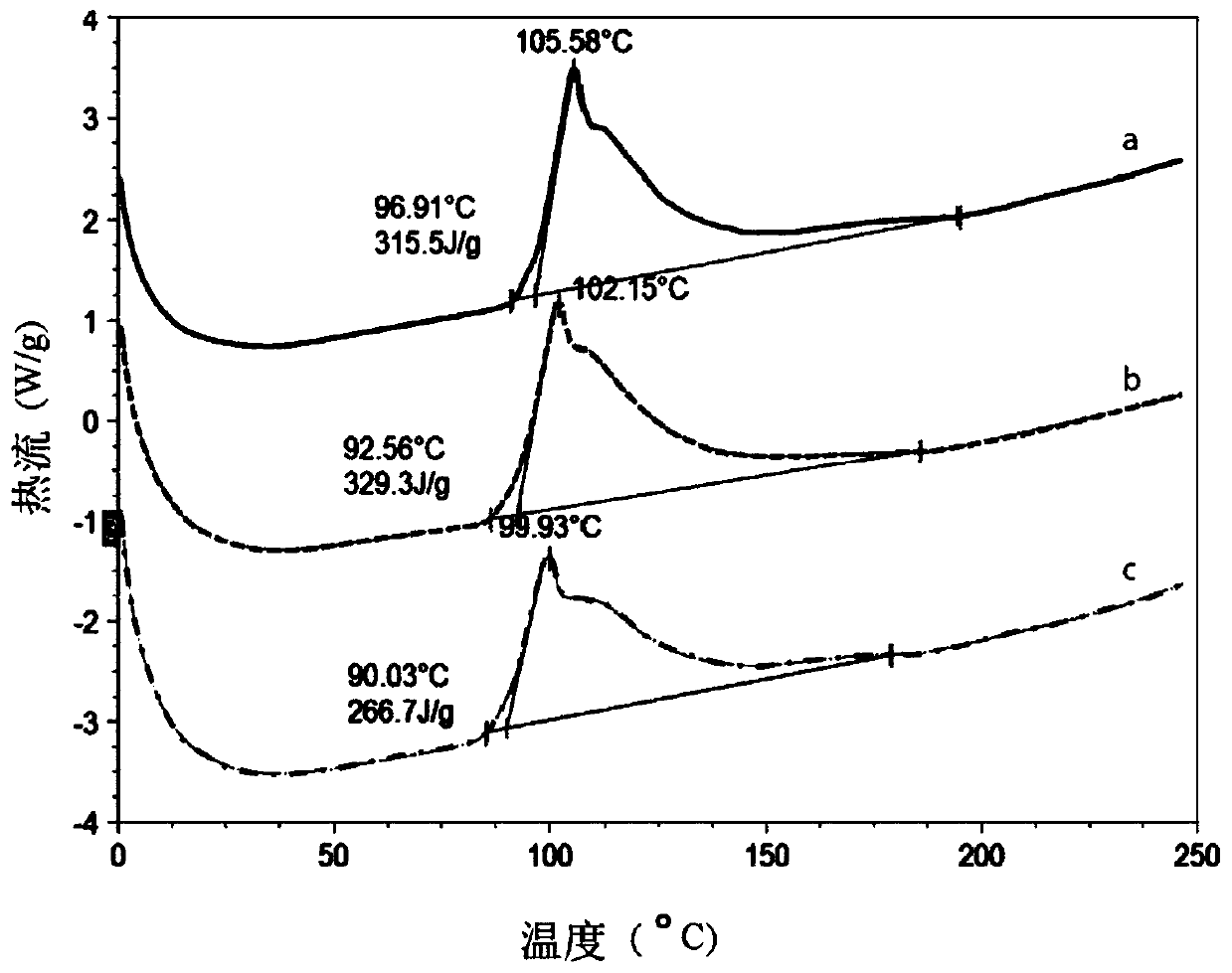

[0157] Example 1: Preparation of anisotropic conductive film

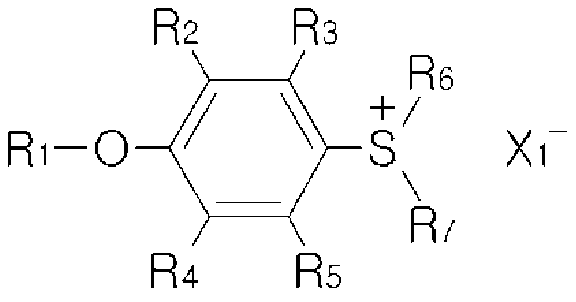

[0158] By mixing 35 wt% of biphenyl fluoride type binder resin (FX-293, Japan Steel Corporation), 35.95 wt% of alicyclic epoxy resin having an epoxy equivalent of 130g / eq (hereinafter referred to as epoxy resin 1 , Celloxide2021P, Daicel Corporation), 5% by weight of oxetane group-containing silsesquioxane compound (TX-100, Toagosei Co., Ltd.), 0.05% by weight of the compound of Chemical Formula 1-1 (SI- S, Sanxin Chemical Co., Ltd., Japan), 4% by weight of cationic curing agent (SI-B3A, Sanxin Chemical Co., Ltd., Japan) and 20% by weight of conductive particles subjected to insulation treatment (AUL-704F, average particle diameter of 4μm, Sekisui Co., Ltd., Japan) to prepare a composition for anisotropic conductive film.

[0159] [Chemical formula 1-1]

[0160]

[0161] The composition for the anisotropic conductive film was coated on the release film and dried in a drying machine at 60°C for 5 minutes to volatilize th...

example 2

[0162] Example 2: Preparation of anisotropic conductive film

[0163] The anisotropic conductive film of Example 2 (Tg: 198°C) was prepared in the same manner as in Example 1, except that the epoxy resin and the oxetane group-containing silsesquioxane compound were changed as listed in Table 1. And the amount of the compound of formula 1-1.

example 3

[0165] The anisotropic conductive film (Tg: 195°C) of Example 3 was prepared in the same manner as in Example 1, except that YX4000 (hereinafter epoxy resin 2, Mitsukoshi Chemical, Japan) was used as the epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com