Warm-mixed modified asphalt and preparation method therefor

A modified asphalt and warm mix technology, which is applied in the field of warm mix modified asphalt and its preparation, can solve the problems of large physical and mental injury to construction workers, large energy consumption, and high working intensity, so as to reduce energy consumption, ensure road performance, and reduce The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0033] A preparation method of warm-mix modified asphalt, comprising the following steps:

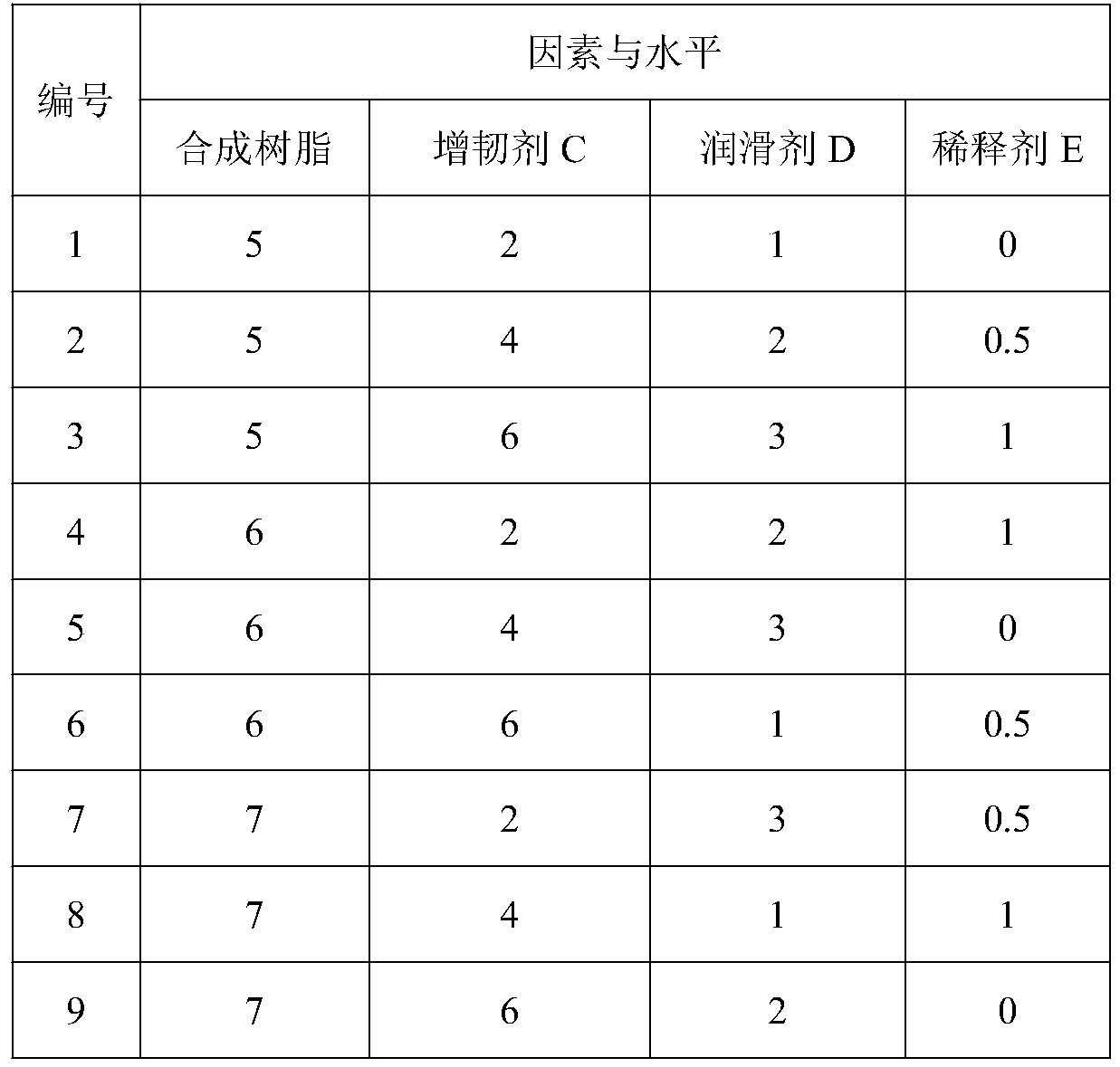

[0034] A1. The waste tires are crushed to remove stray filaments, cracked at a temperature of 360°C to 380°C, and then fractionated at a temperature of 300°C to 350°C to obtain light low-molecular oil required for warm mixing modification;

[0035] A2. The waste plastics mainly made of polypropylene are crushed to remove impurities, and cracked at a temperature of 370°C to 390°C to obtain polypropylene polymer wax;

[0036] A3. Stir and mix the light low-molecular oil obtained in A1 and the polypropylene polymer wax obtained in A2 at a heating temperature of 60°C to 80°C to obtain a special modified resin;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| residual stability | aaaaa | aaaaa |

| freeze-thaw splitting strength ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com