Patents

Literature

63results about How to "Stable heat source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

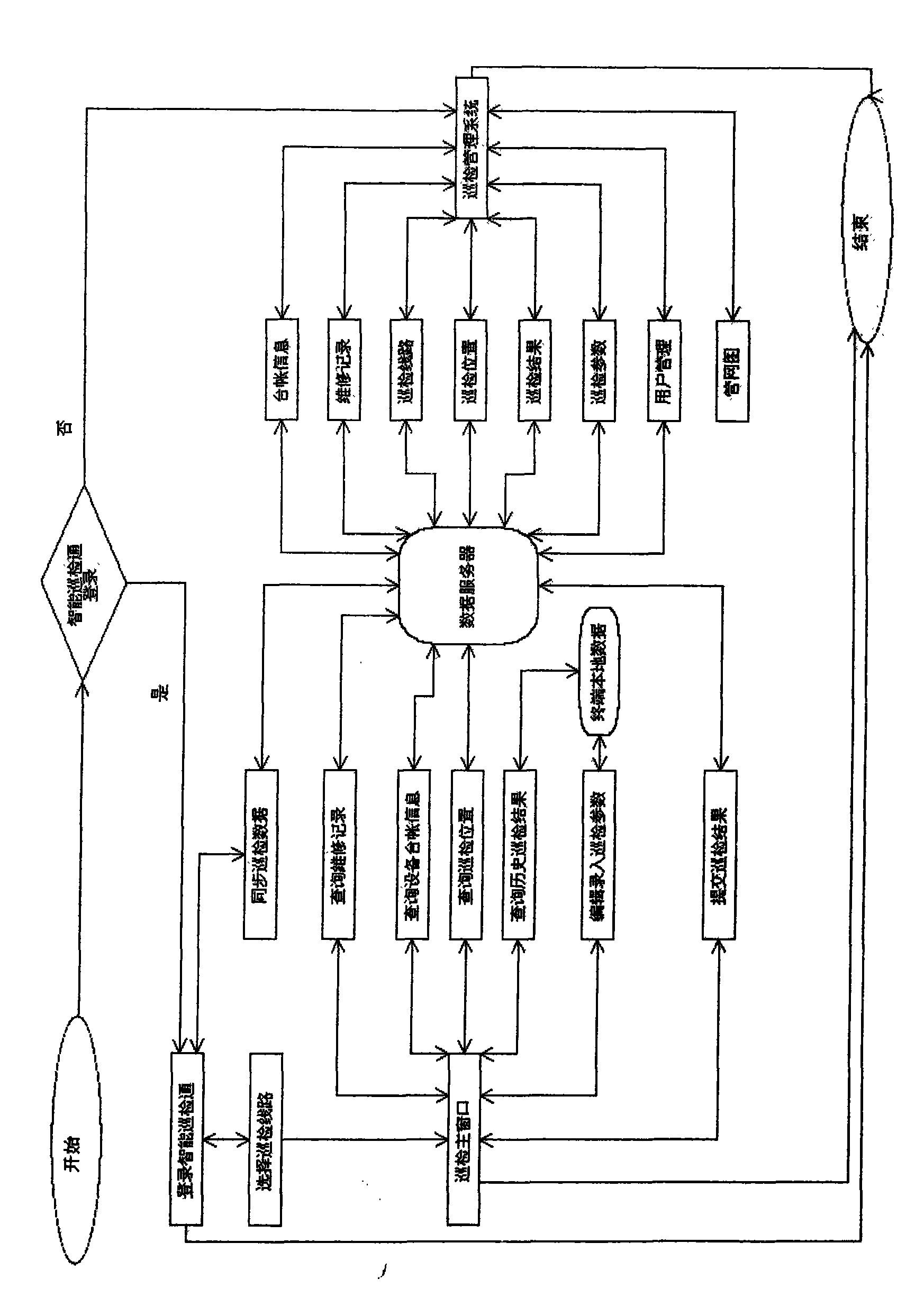

Method for examining and managing thermodynamic system

InactiveCN101540069ADiscover hidden dangers in timePrevent breakdowns and even accidentsChecking time patrolsChecking apparatusReverse orderJob number

The invention relates to a method for examining and managing a thermodynamic system, which comprises the following main steps: scanning information of an examiner, inquiring records of an examining spot, inquiring an examining route, inquiring an examining position and equipment and recording data. Firstly, the information of a job number or a bar code of a working card of the examiner is scanned by a bar code scanner; secondly, the history records of the examining spot are inquired, if no examining spot is found, a prompting message is given, and if the examining spot is found, parameter details are displayed according to a reverse order mode of examining time; thirdly, the examining route is inquired, and the examined examining position is displayed on a display screen; fourthly, the examining position and the equipment are inquired; and finally, a bar code of the examining position is scanned by the bar code scanner to record the data. The invention has simple principle, safe and reliable operation, high degree of automation and wide application range.

Owner:青岛能源热电集团有限公司 +1

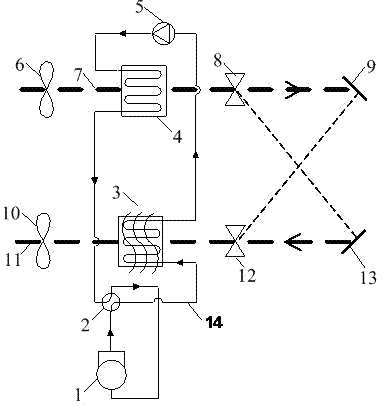

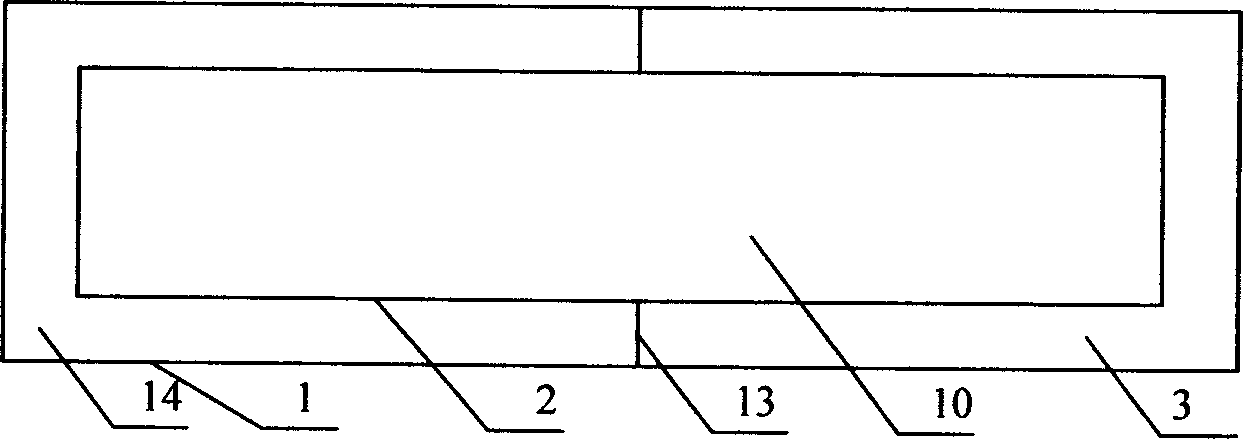

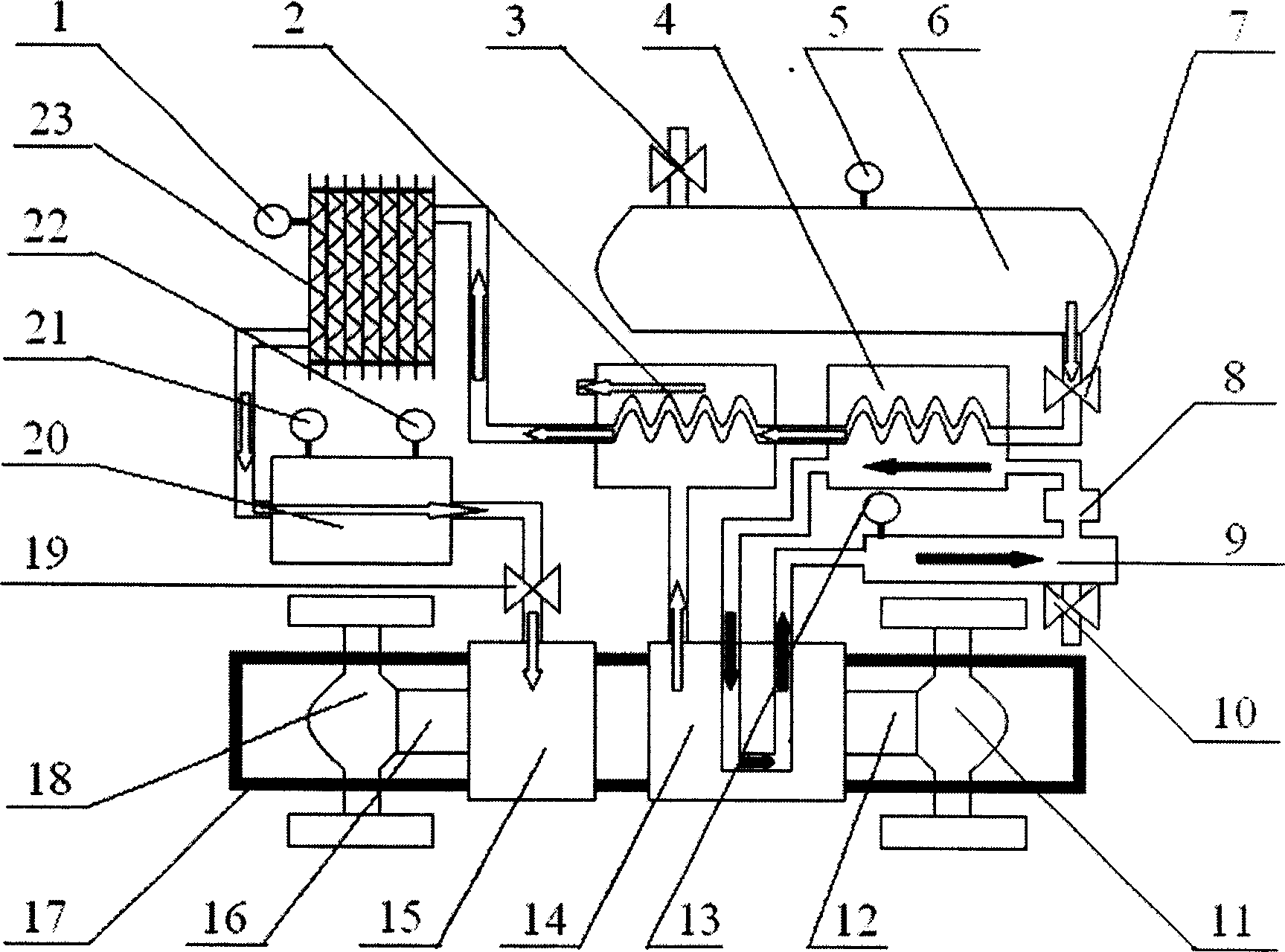

Heat pump system of heat humidity independent control driven by condensation waste heat and based on solid dehumidification

InactiveCN102506475AAchieving processing powerAchieve independent controlEnergy recovery in ventilation and heatingLighting and heating apparatusProcess engineeringRefrigerant

The invention provides a heat pump system of heat humidity independent control driven by condensation waste heat and based on solid dehumidification. The heat pump system provided by the invention comprises a first fan, a second fan, a first dehumidification heat exchanger, a second dehumidification heat exchanger, a first air regulating valve, a second air regulating valve, a compressor, an expansion valve, a bidirectional four-way valve, a first air duct, a second air duct and a refrigerant circulation pipeline, wherein the surfaces of the first dehumidification heat exchanger and the second dehumidification heat exchanger are provided with solid dehumidification materials. According to the invention, the humidity load in air is processed by the solid dehumidification materials arranged on the surfaces of the dehumidification heat exchangers, the processing of air heat load is realized through the cooling mode of the traditional evaporator; and the separation processing and independent control of the heat humidity load are realized only by adopting one device according to the invention, compared with the traditional composite heat humidity independent control heat pump air-conditioning system, the heat pump system provided by the invention has the obvious advantages of simple structure and low manufacturing cost.

Owner:SHANGHAI JIAO TONG UNIV

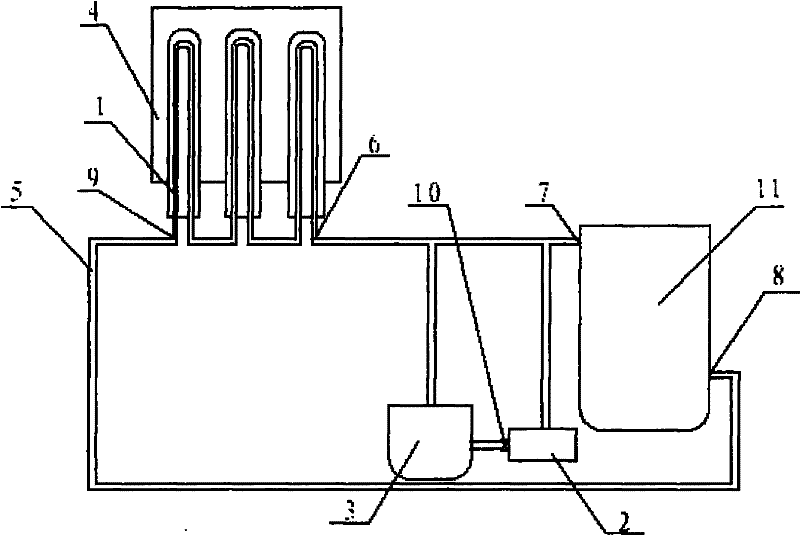

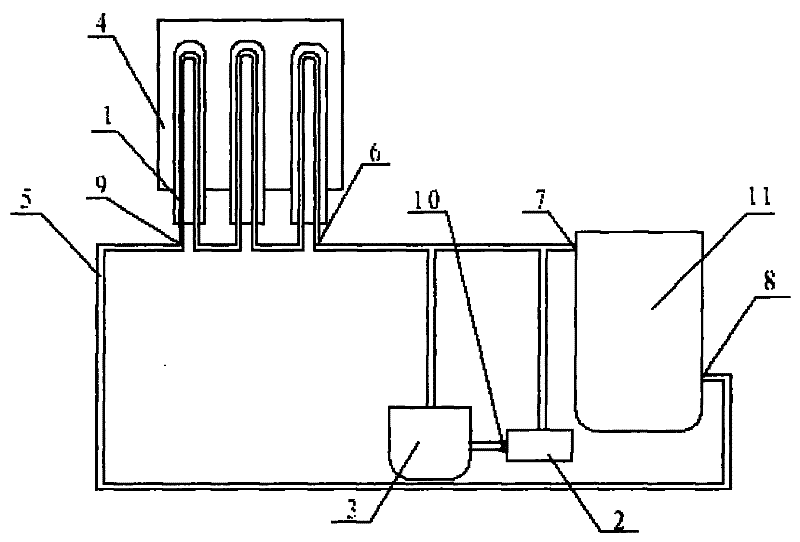

Solar steam power device

InactiveCN102252303ALow costNovel structureSteam generation heating methodsSolar heat devicesElectricityHeat conducting

The invention relates to a solar steam power device. The solar steam power device mainly consists of a solar heat collector, an electric heating apparatus, a heat storage tank and a steam generator, wherein solar heat collecting plates, or U-shaped metal heat collecting tubes serially connected inside a solar vacuum tube, form the solar heat collector, the solar heat collector is internally provided with a heat conducting liquid, the heat conducting liquid outlet of the solar heat collector is connected with the inlet of the heat storage tank, the outlet of the heat storage tank is connected with the solar steam generator, the heat conducting liquid outlet of the solar steam generator is connected with the inlet of the solar heat collector to form a loop, and the electric heating apparatus and a high-temperature circulating pump are connected between the heat storage tank and the solar heat collector. The invention provides brand-new high-efficiency and low-cost solar technical equipment for energy saving and emission reduction as well as clean energy application in China.

Owner:李泽明 +1

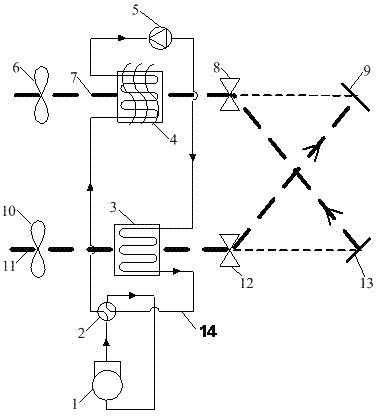

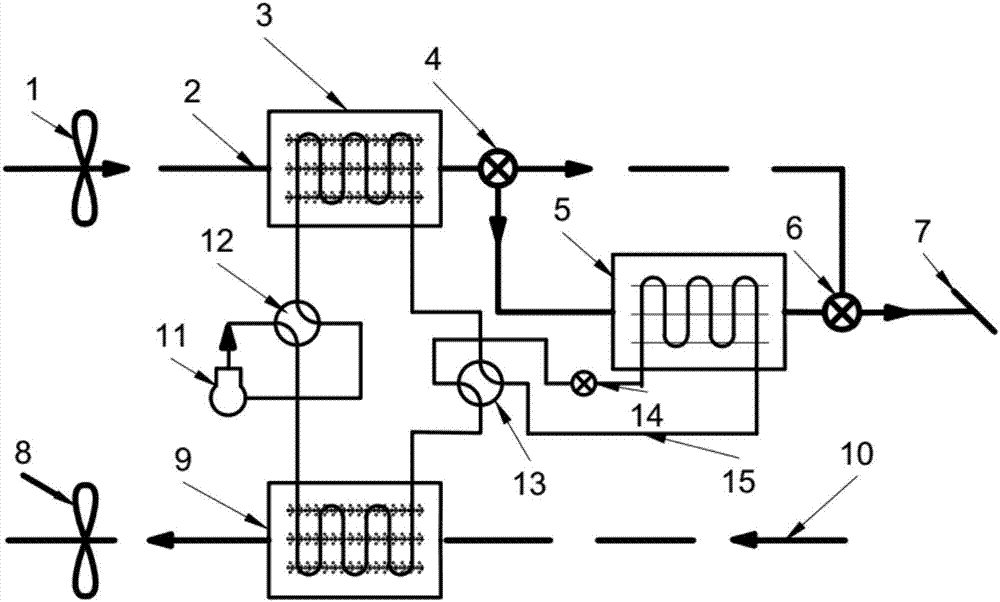

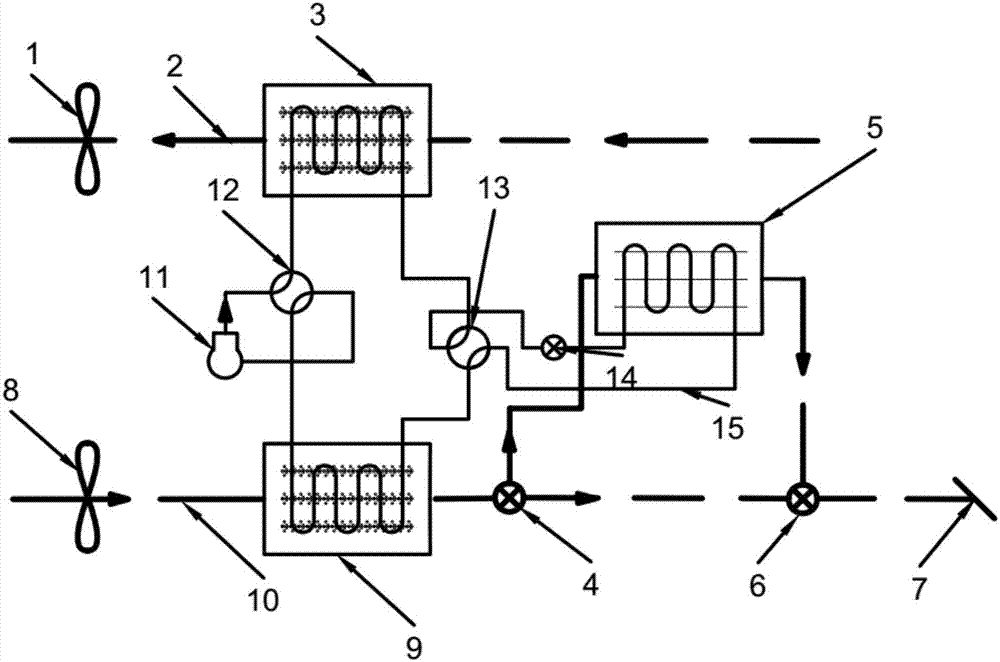

Semi-decoupled cooling dehumidification and graded cooling dehumidification heat pump system and method

InactiveCN107166583ARealize the thermal process of cooling and dehumidificationDecrease the equilibrium adsorption temperatureSpace heating and ventilation safety systemsLighting and heating apparatusEvaporatorEngineering

The invention provides a semi-decoupled cooling dehumidification and graded cooling dehumidification heat pump system. The system comprises a closed refrigerant system and two open air channels operated in parallel. The invention further provides a cooling dehumidification and graded cooling method. A dehumidifying evaporator and an evaporator serially connected are adopted to replace an evaporator in a compressive cycle and a dehumidifying evaporator in a traditional dehumidifying heat pump cycle; a circular condensation side is formed by another dehumidifying heat exchanger; and thermal circulation of continuous heat and moisture load treatment is realized through switching of a four-way reversing valve and an air way. Compared with the prior art, the system is compact in structure and lower in cost, and can realize efficient treatment and flexible matching of heat and moisture loads.

Owner:SHANGHAI JIAO TONG UNIV

Production method of formed coke using coking powder as row-material and special formed coke furnace

The invention is a section coke produced by using braize as main raw material, adding in a proper amount of coking coats and adopting pitch and coke tar as binding agent and then making pressure molding process. It has advantages of low production cost and short coking time. A special section coke furnace for producing the section coke, includes an outer furnace body, there is an inner furnace body in the outer furnace body and they form an interlayer between them. The lower part of the inner furnace body has a tilted furnace bottom and there is a reduced-oxygen combustion chamber and a heat storage chamber between the bottom of the tilted furnace bottom and the bottom plane of the furnace body, the reduced oxygen chamber is connected with the heat storage chamber through a top fire mouth and the interlayer, and the interlayer is connected with a flue through a bottom fire mouth.

Owner:李玉林 +1

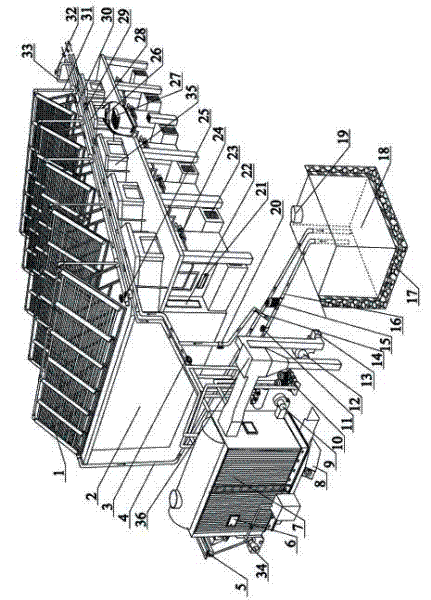

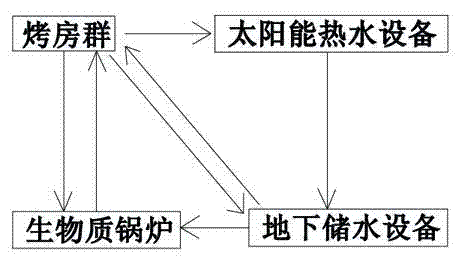

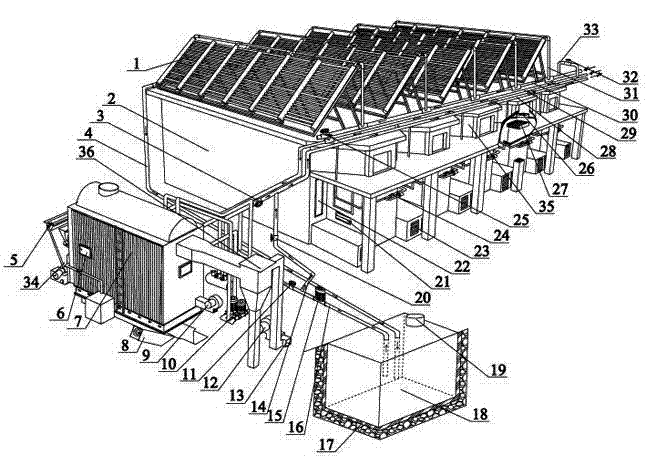

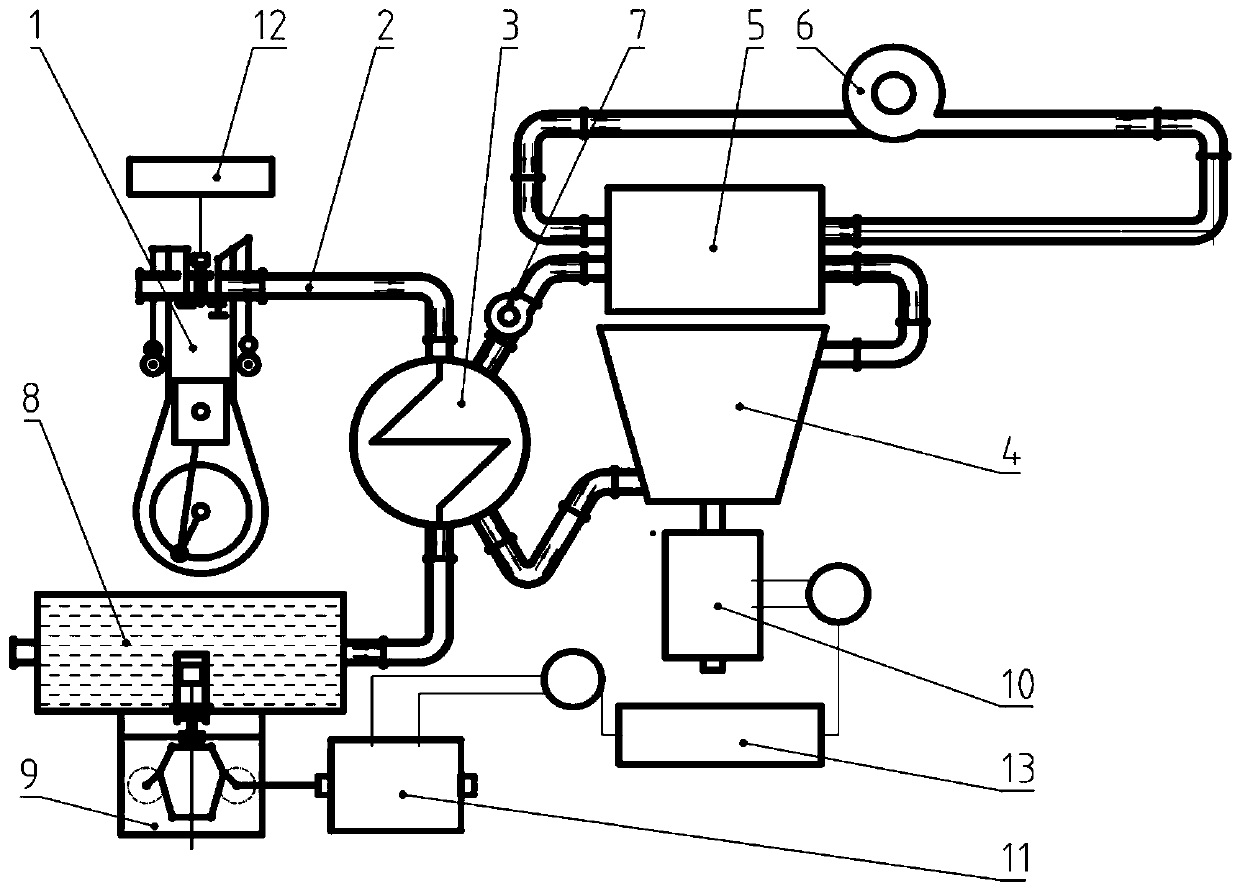

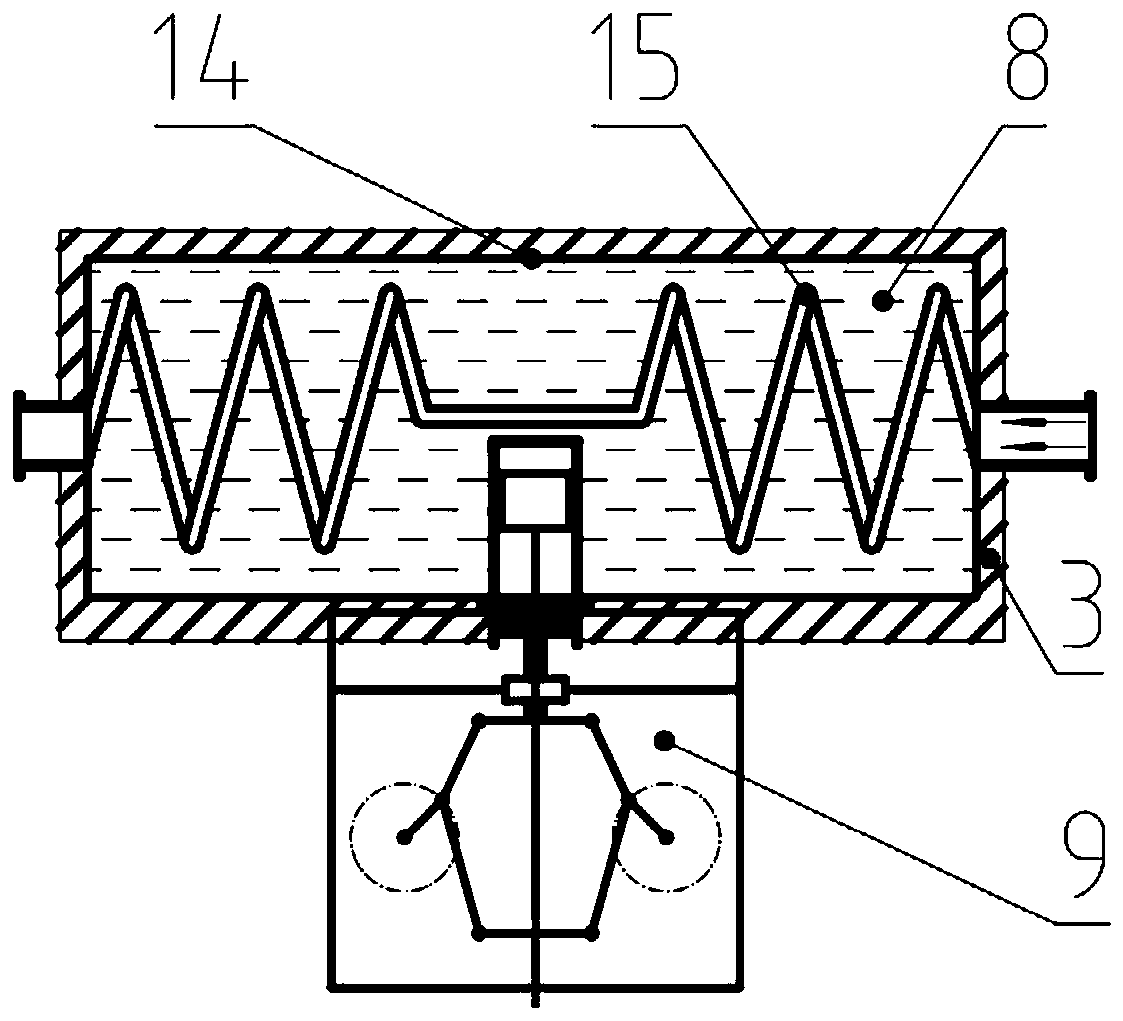

Hot-water centralized heating tobacco flue-curing device adopting combination of solar energy and biomass fuels

InactiveCN102160681ATo achieve the purpose of curing tobacco leavesSave energyTobacco preparationThermodynamicsSolar water

Owner:HENAN AGRICULTURAL UNIVERSITY

A compressed air or liquid nitrogen-fuel/combustion gas mixed powered automobile

InactiveCN1843797AImprove energy utilizationStable heat sourceHybrid vehiclesGas pressure propulsion mountingNitrogenExhaust fumes

The invention relates to a compress air, liquid nitrogen-fuel, or fuel gas mixed power vehicle, which comprises a internal-combustion engine cooling-heating exchange system, a internal-combustion engine waste gas heat exchanger, a energy supplier of compress-air or nitrogen engine, and a vehicle chassis which can driven by internal-combustion engine or / and compressed air or nitrogen engine; when the environment temperature is lower, or needing high driving power, the internal-combustion engine can power vehicle, and the internal-combustion cooling-heating exchange system and the waste gas heat exchanger can supply energy to the energy supply system of compressed air or nitrogen engine; the internal-combustion cooling-heating exchange system can store energy to be supplied to the energy supply system when the internal-combustion engine is not working. The invention can improve the energy utilization and avoid polluting environment.

Owner:JIANGSU UNIV

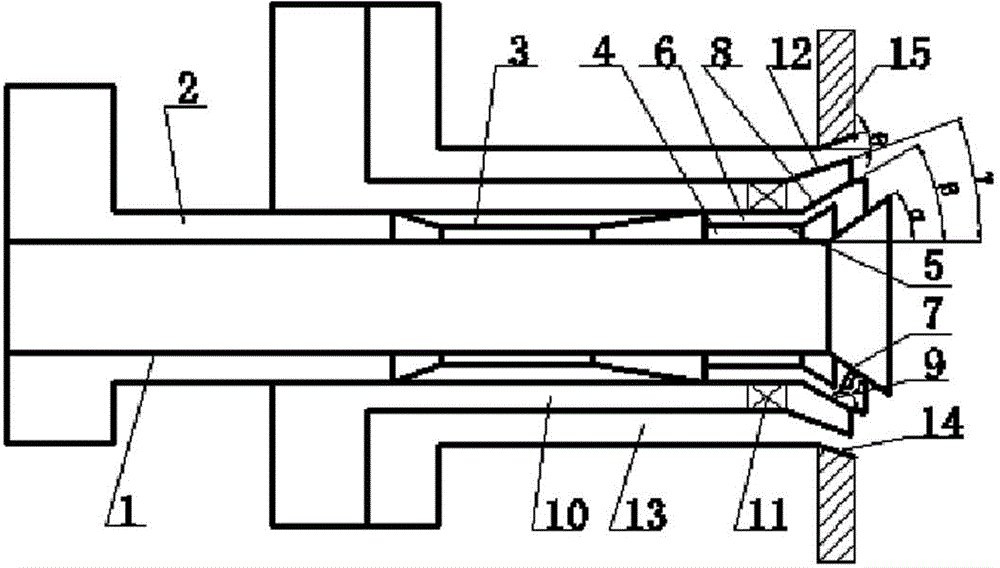

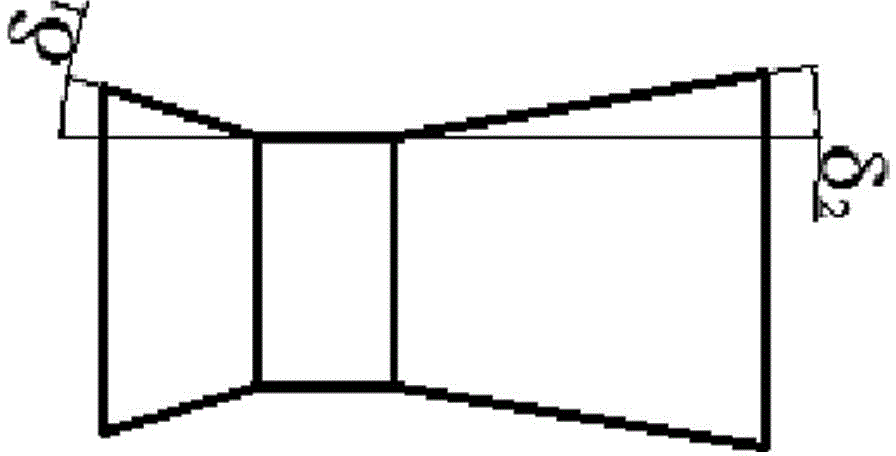

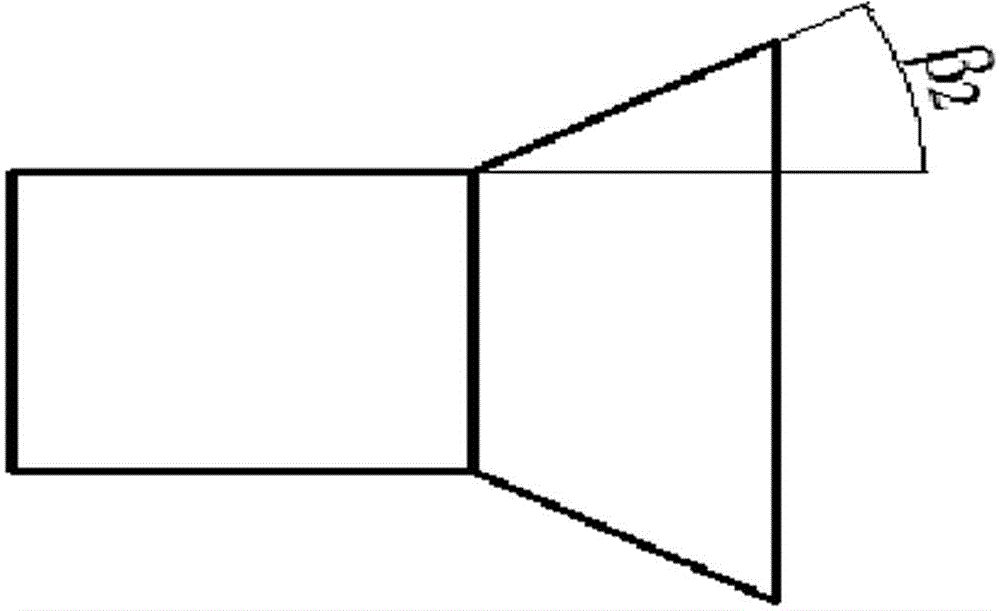

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

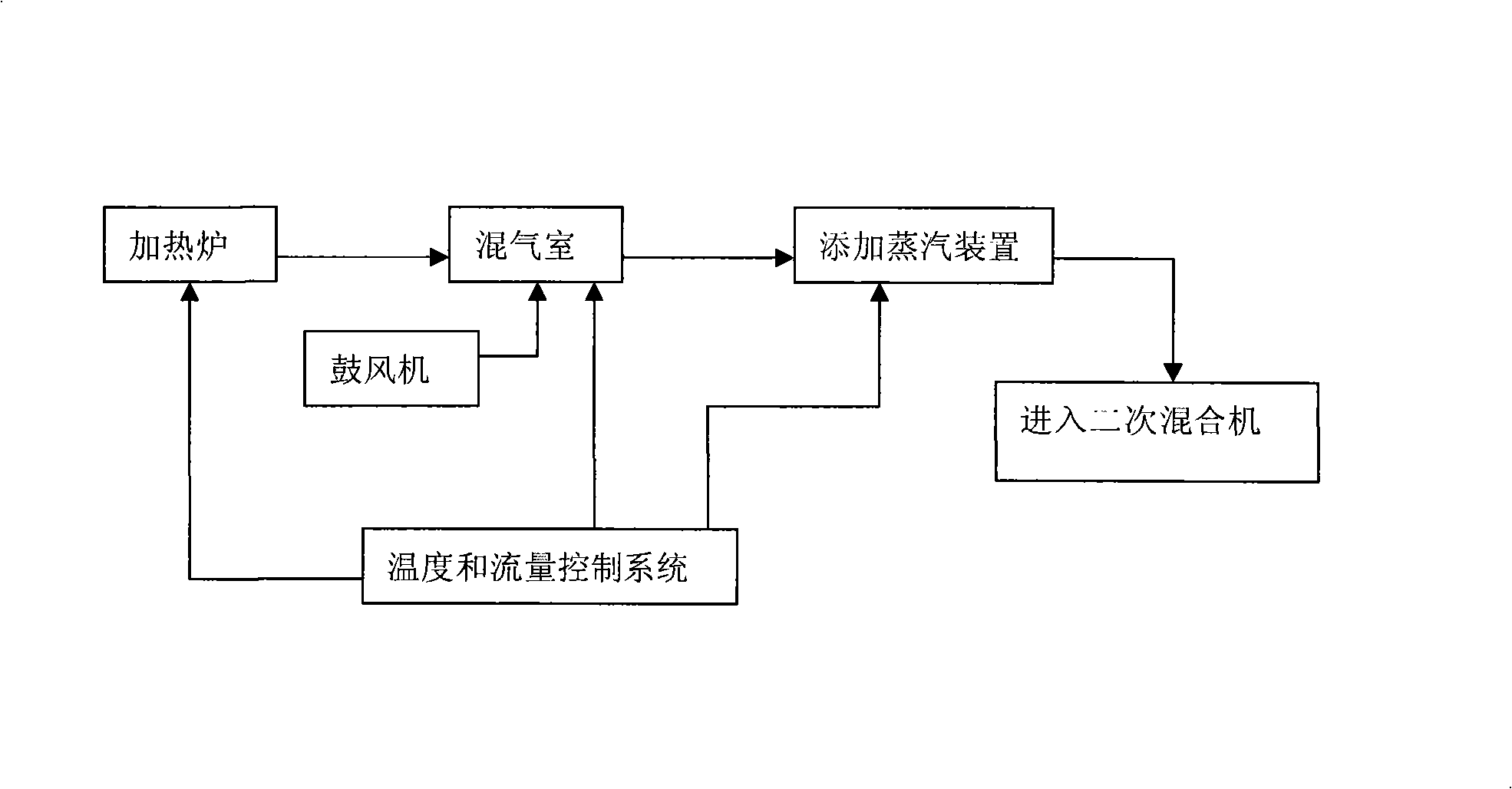

Preheating sintered mixture process utilizing heating furnace hot waste gas

InactiveCN101349509AReduce the temperatureIncrease temperatureIncreasing energy efficiencyPreheating chargesCold airControl system

The invention discloses a process for preheating sintered mixed material through utilizing hot waste gas of a heating furnace, wherein an add-on steam device, a gas mixing chamber and a gas-fired furnace are connected on a secondary mixing machine of a sintering device in turn, wherein the gas-fired furnace, the gas mixing chamber and the add-on steam device are all provided with temperature and flow sensors inside, wherein each temperature and flow sensor is connected with a temperature and flow control system through wires. High temperature hot waste gas which is generated by burning coal gas in the gas-fired furnace enters into the gas mixing chamber which is provided with a blower, and blower can blow a certain amount of cold air into the gas mixing chamber to appropriately regulate the temperature of hot waste gas, hot waste gas which is mixed in the gas mixing chamber is further added into the steam device to mix and humidify with steam to the saturation, then the hot waste gas which is humidified enters into the secondary mixing machine, and is blown to the mixed material along the opposite direction to the material flow of the sintered mixed material. The invention not only has simple technology flow, but also can effectively increase the temperature of sintered mixed material, and has high sintered yield.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

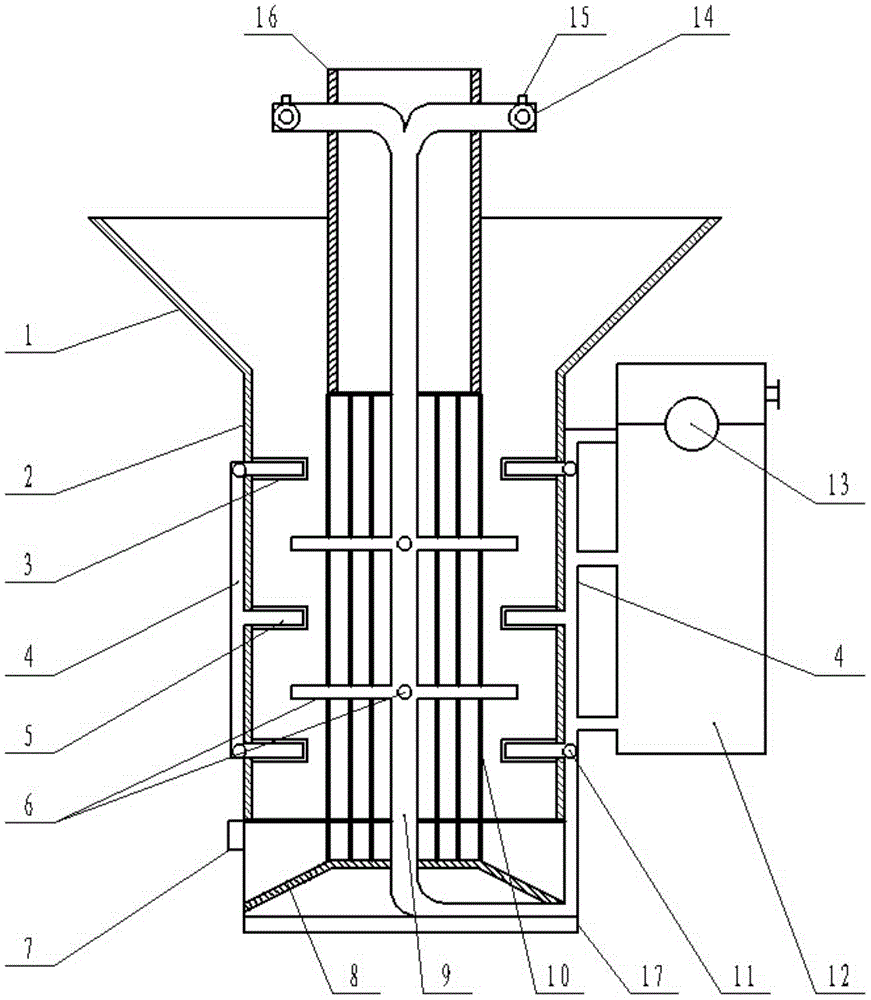

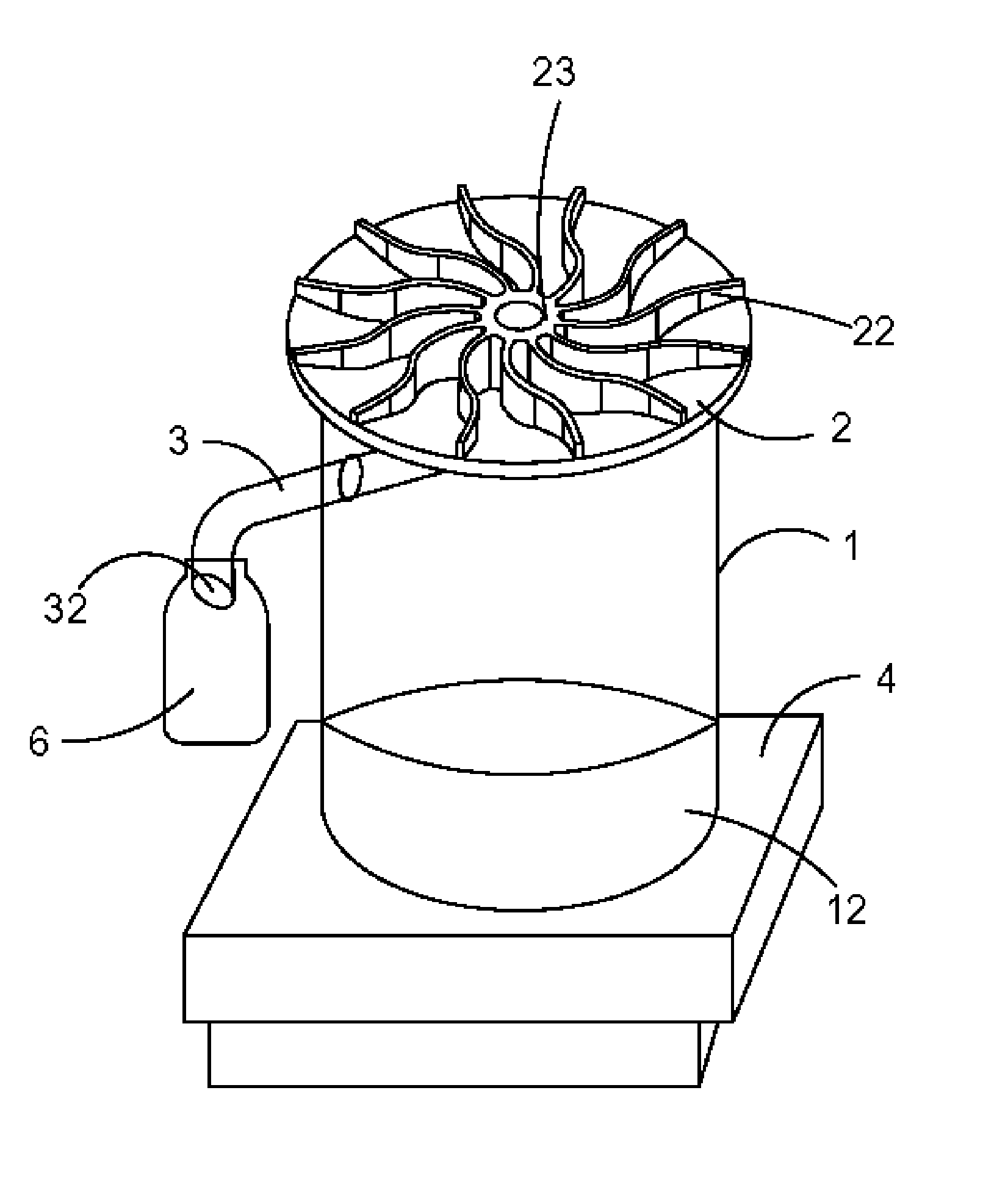

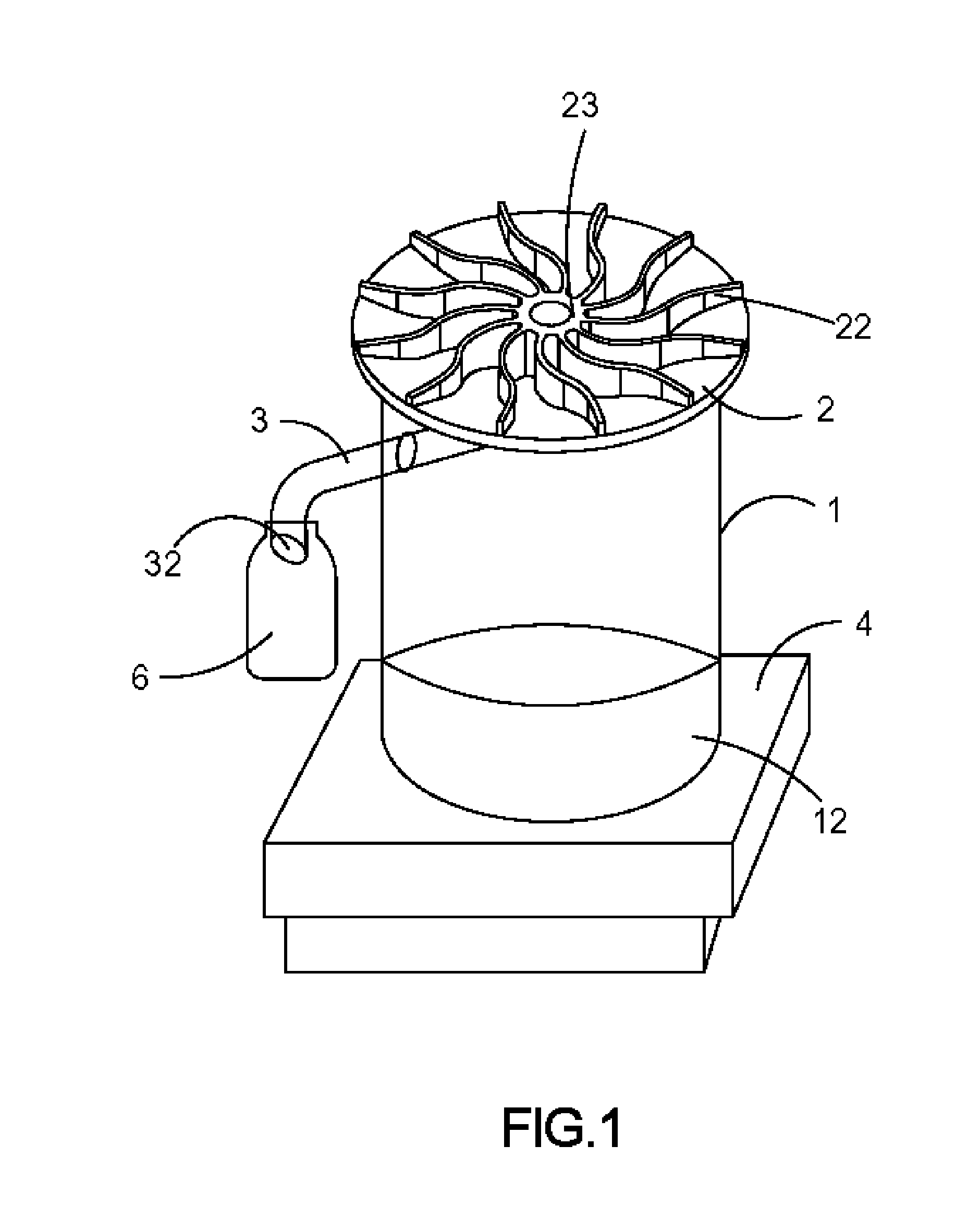

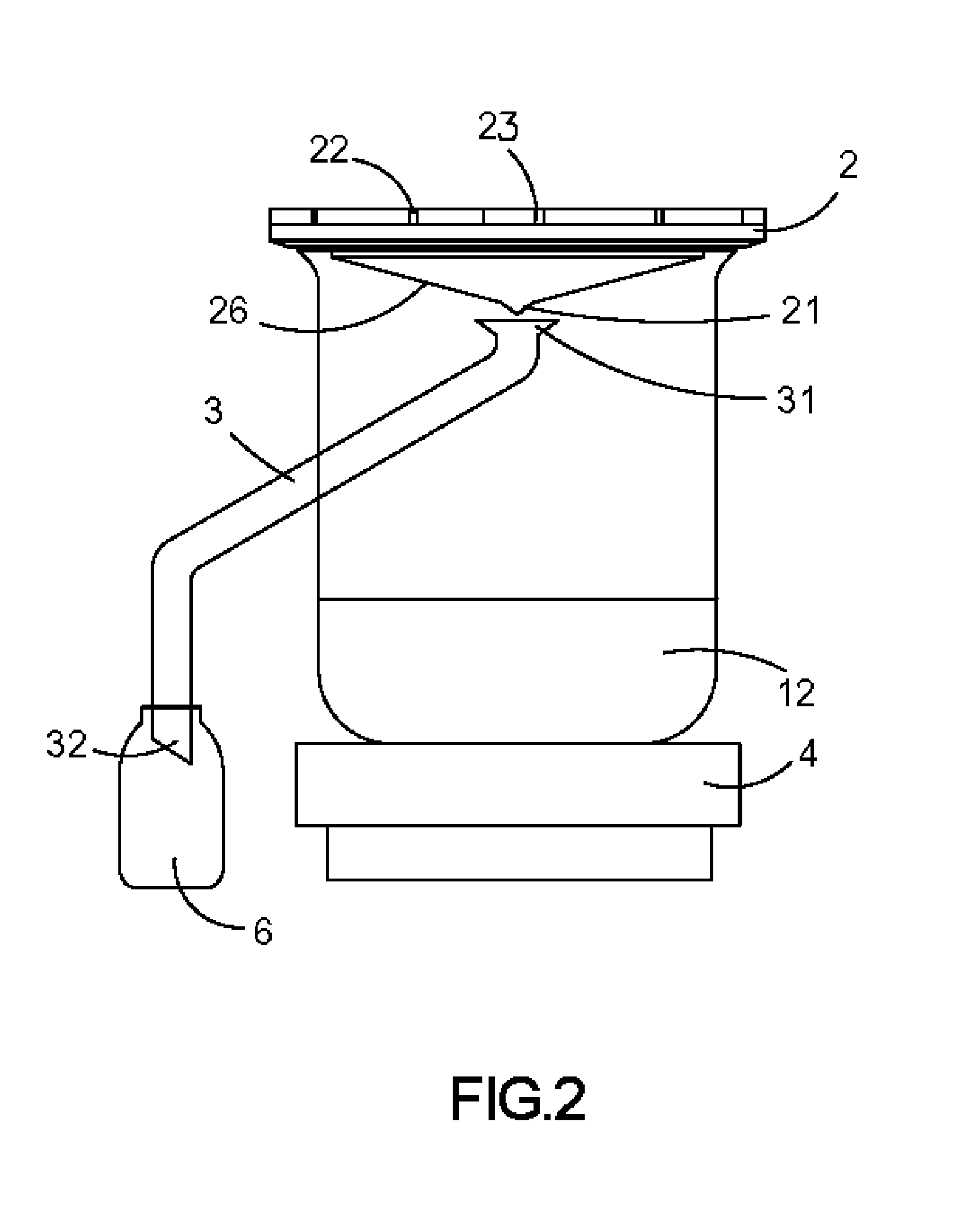

Tritium distillation device

InactiveUS7927463B2Simple structureEasy to assembleAuxillariesEvaporators/condensersWater sourceReactive distillation

Owner:INST NUCLEAR ENERGY RES ROCAEC

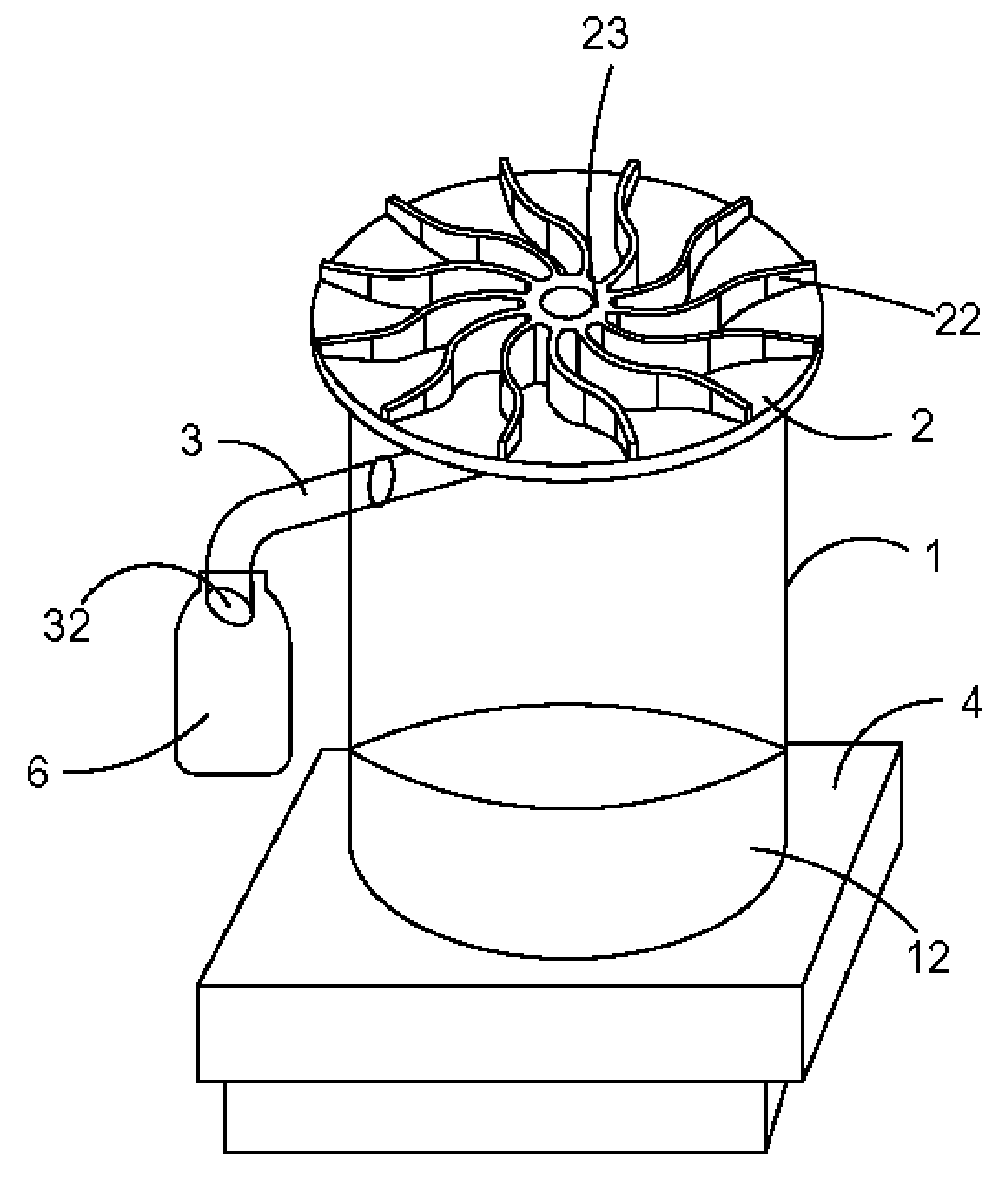

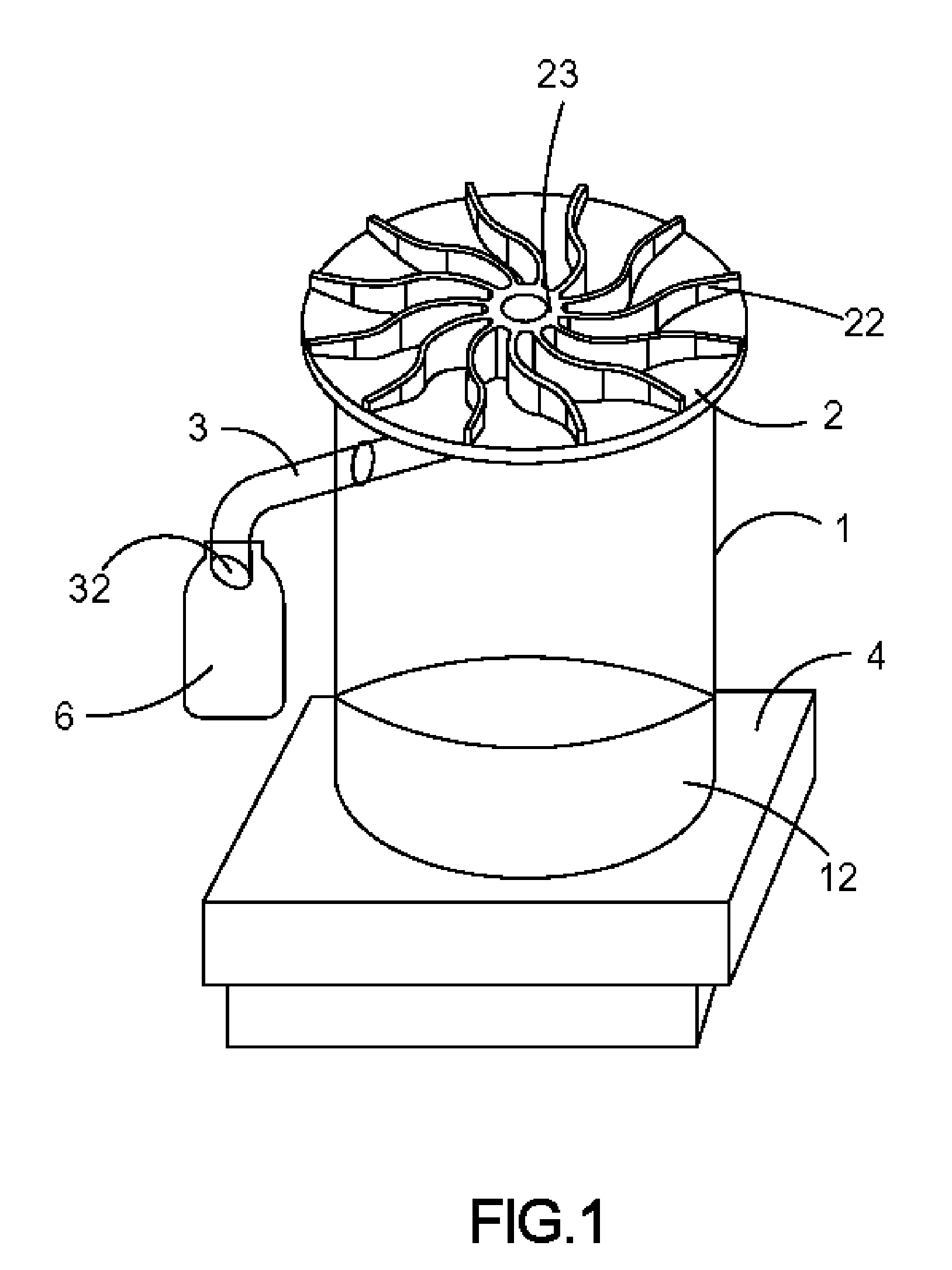

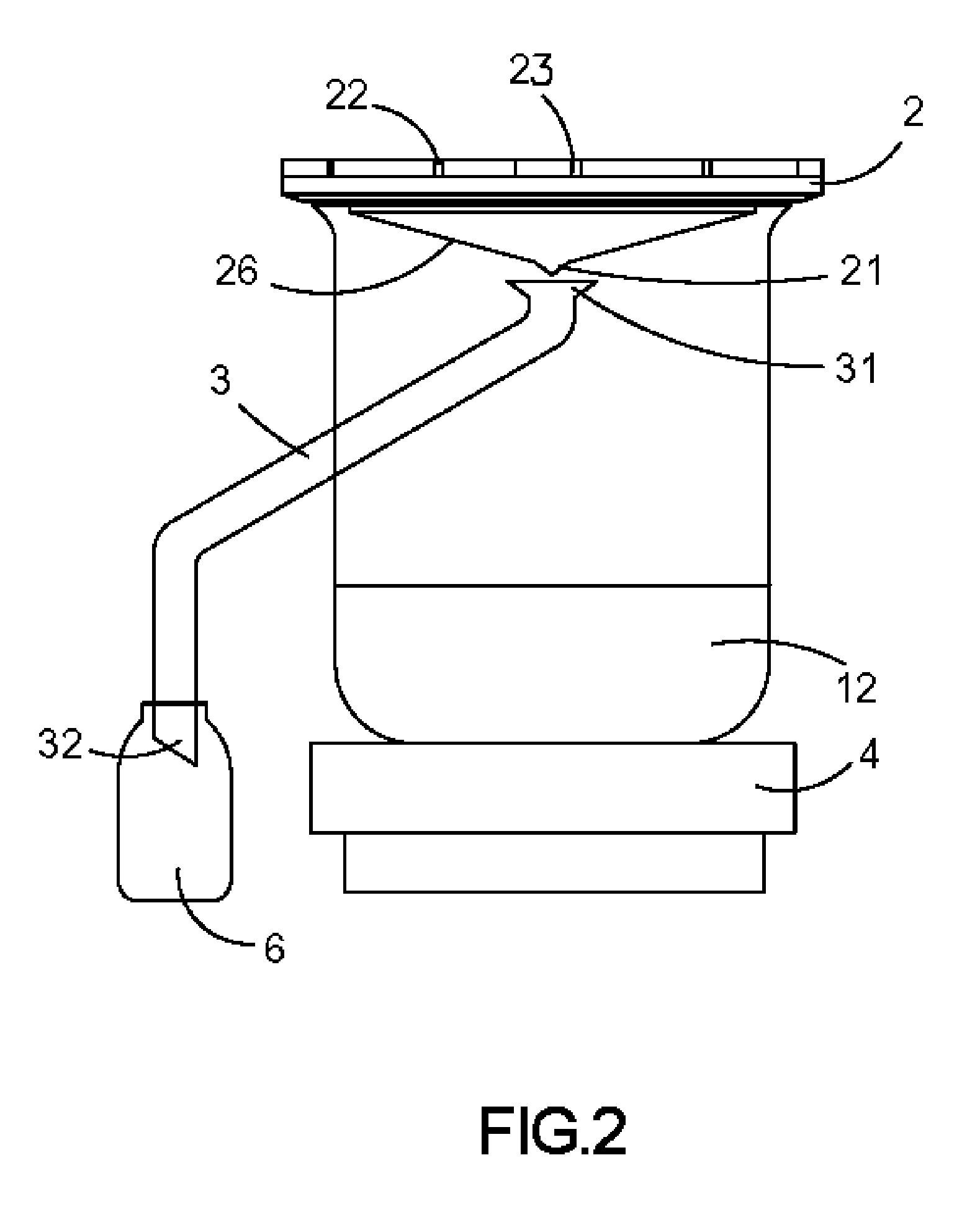

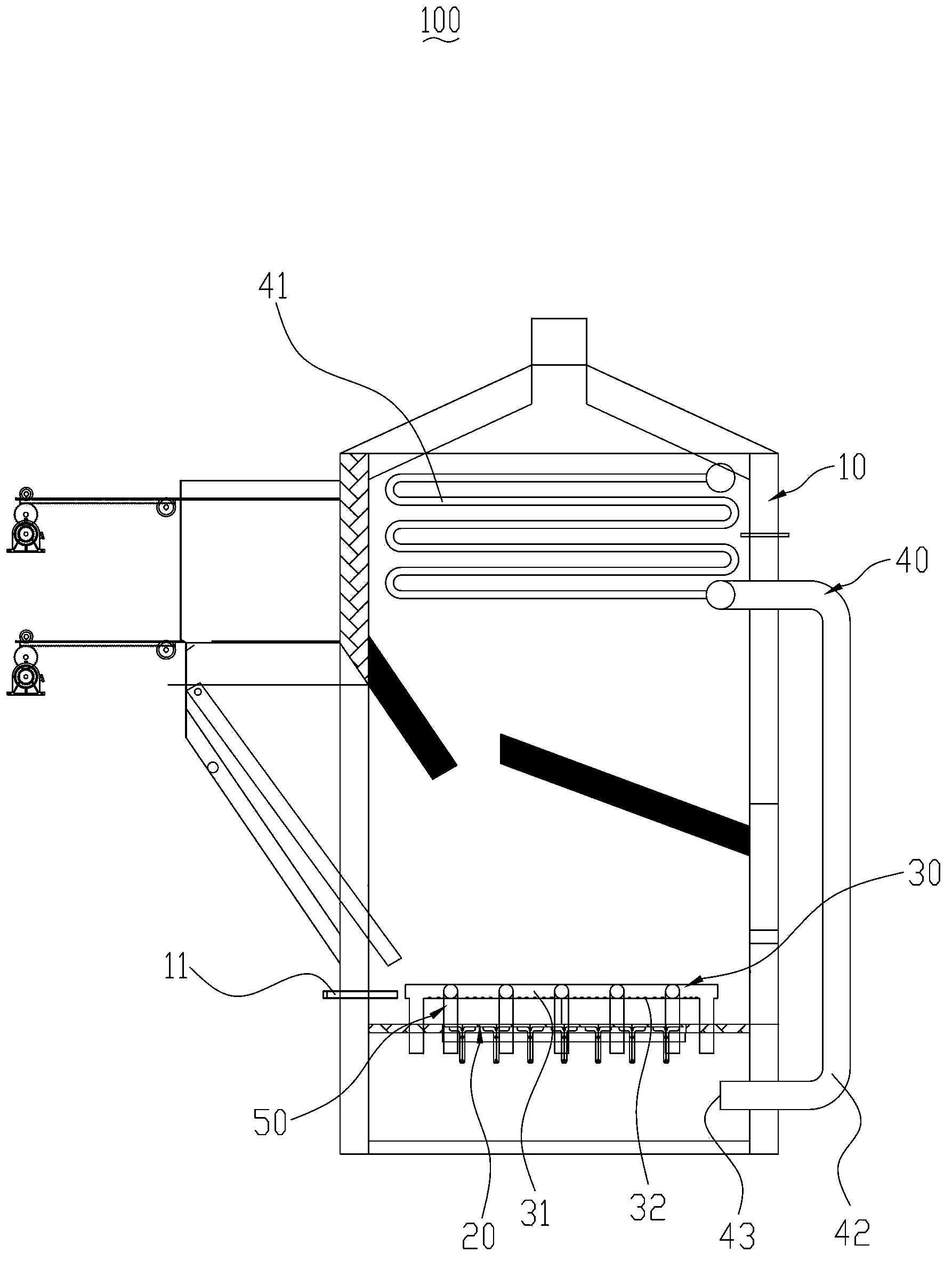

Garbage incinerator with built-in chimney

ActiveCN104456572AIncrease temperatureStable heat sourceIncinerator apparatusPipingCombustion chamber

The invention discloses a garbage incinerator with a built-in chimney. The garbage incinerator comprises an incinerator body, a combustion chamber, a feed hopper, a bracket and a chimney, wherein the feed hopper is arranged above the incinerator body; the bracket is arranged in the middle of the incinerator body; the incinerator body and the bracket form the combustion chamber; the chimney is arranged at the top part of the bracket; the lower end of the chimney is arranged inside the feed hopper and the upper end is higher than the feed hopper; the incinerator body further comprises an automatic water supply tank, an external water pipe and a main water pipe; the automatic water supply tank is arranged on the external side of the incinerator body; the main water pipe is arranged in the middle of each of the bracket and the chimney; the bottom end of the main water pipe is communicated with the automatic water supply tank through the external water pipe; the top end of the main water pipe is communicated with an exhaust annular pipe. The garbage incinerator is provided with the main water pipe and an internal water pipe, which are communicated with the automatic water supply tank outside; and in the combustion process of garbage, a large amount of steam is formed and mist is formed above the incinerator body to settle the dust discharged from the chimney into the incinerator body, so that the pollution from the dust to the environment is reduced; moreover, the garbage incinerator gains a better economic benefit and social benefit.

Owner:都安通达环保设备制造厂(普通合伙)

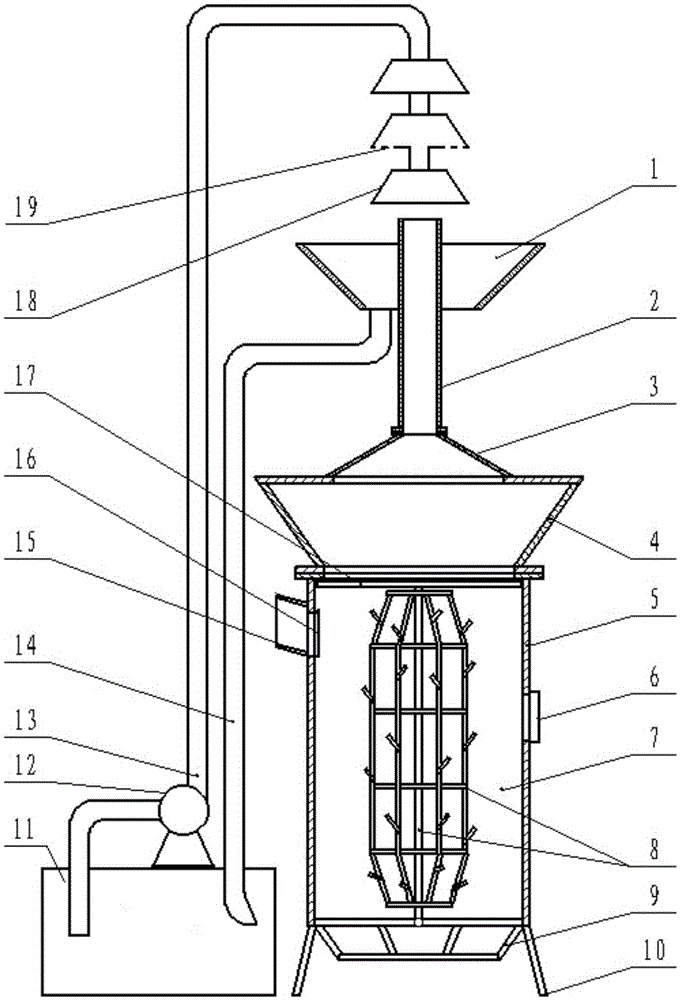

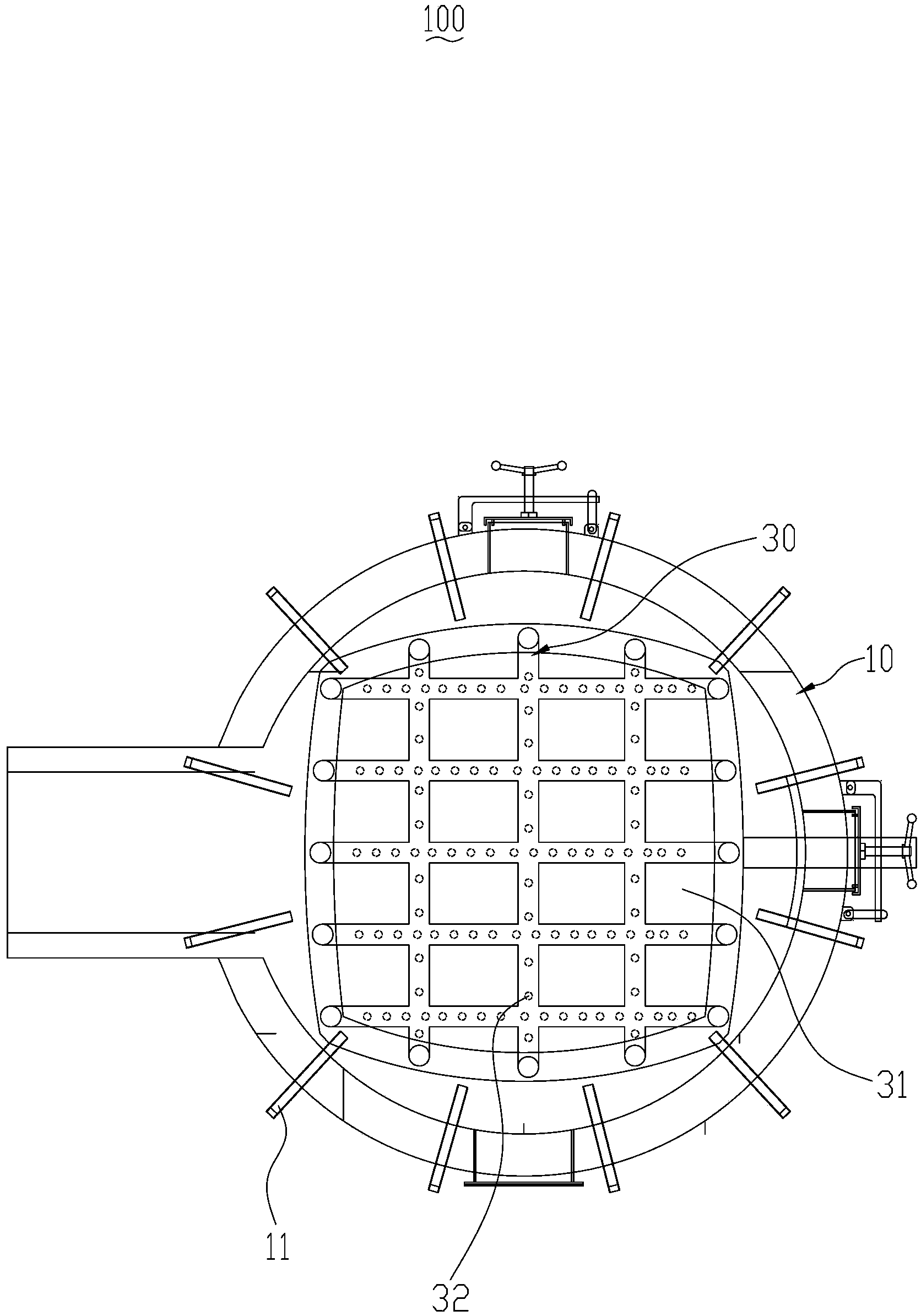

Environment-friendly waste incinerator

ActiveCN105258126AIncrease temperatureStable heat sourceIncinerator apparatusBrickCombustion chamber

The invention discloses an environment-friendly waste incinerator. The environment-friendly waste incinerator comprises an incinerator body, a combustion chamber, a high-position feed inlet, an incinerator grate and incinerator legs. Refractory bricks are arranged on the inner wall of the incinerator body. The incinerator body is hollow, so that the combustion chamber is formed. The high-position feed inlet is formed in the upper portion of the incinerator body. The incinerator grate is arranged at the bottom of the incinerator body. The bottom end of the incinerator body is open, so that an ash outlet is formed. The incinerator legs are arranged at the bottom end of the incinerator body. The environment-friendly waste incinerator further comprises a dust hopper, a chimney, a water collection tank, a water pool, a water pump, a water inlet pipe and a water outlet pipe. The lower end of the dust hopper is connected with the upper end of the incinerator body through a flange. The upper end of the dust hopper is welded to a reversed hopper. The chimney is connected with the reversed hopper through a flange. The water collection tank is fixed to the upper portion of the chimney in a surrounding mode. The water pool is arranged at one side of the incinerator body. The water pump is installed above the water pool. One end of the water inlet pipe is connected with the water pump. The other end of the water inlet pipe is arranged above the chimney. One end of the water outlet pipe is connected into the water pool, and the other end of the water outlet pie is installed at the bottom of the water collection tank. According to the environment-friendly waste incinerator, smoke generated after waste combustion can be cleaned, emission of harmful smoke is reduced, and pollution to air caused by waste combustion is reduced.

Owner:都安瑶族自治县计量检定测试所

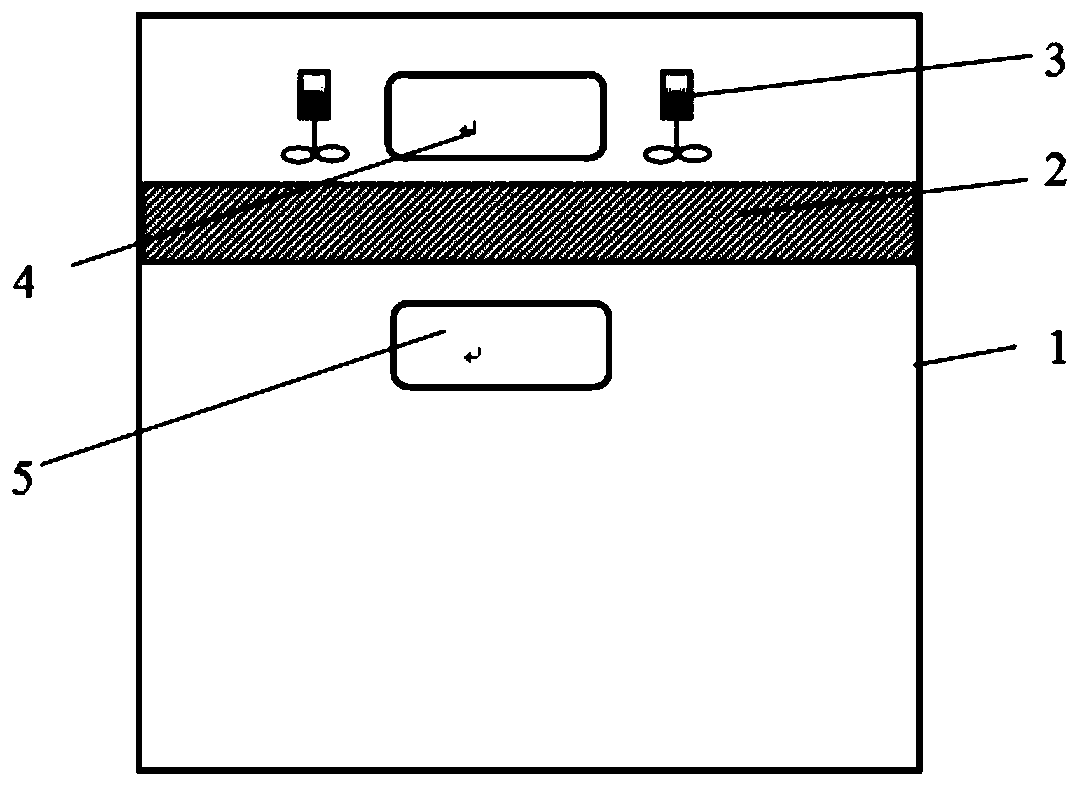

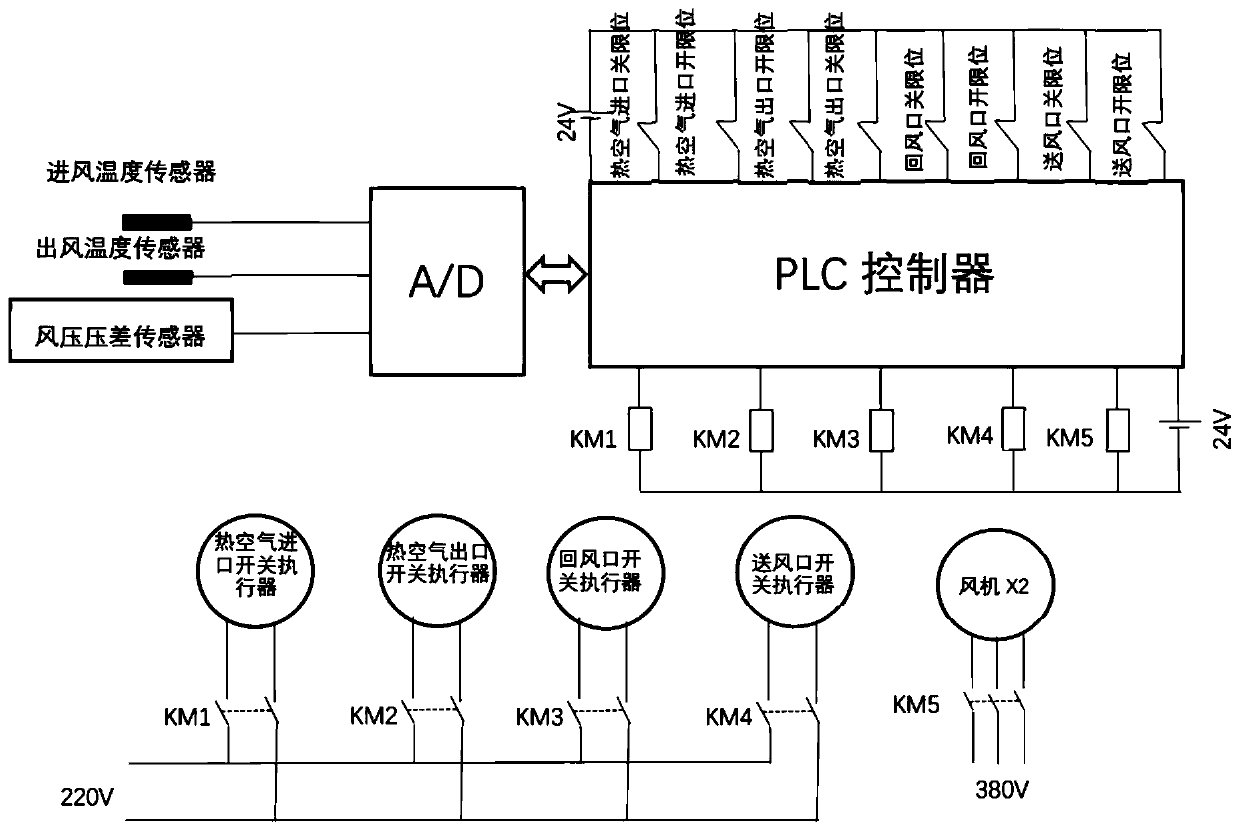

Refrigeration container defrosting system and defrosting method

PendingCN111412710AReduce energy consumption for defrostingStable heat sourceLighting and heating apparatusCooling fluid circulationAutomotive engineeringCool storage

The invention belongs to the field of refrigeration container defrosting, and relates to a refrigeration container defrosting system and a defrosting method. The refrigerated container defrost systemcomprises a box, an evaporator, a hot air inlet, a hot air outlet, an in-box air supply port, an in-box air return port, a control system and a switch execution element. The evaporator is arranged onthe inner wall of the top of the box and provided with a fan. The hot air inlet and the hot air outlet are formed in the upper and lower parts of the rear wall of the box respectively and located on the two sides of the evaporator respectively. The in-box air supply port and the in-box air return port are formed in the upper and lower portions of the front wall of the box respectively and locatedon the two sides of the evaporator respectively. The control system starts or releases a defrosting mode by controlling the switch execution element. The air defrosting technology is utilized, so thatthe defrosting efficiency can be improved, the energy consumption for defrosting is reduced, and temperature fluctuation in a refrigerating container is reduced.

Owner:湖南现代物流职业技术学院

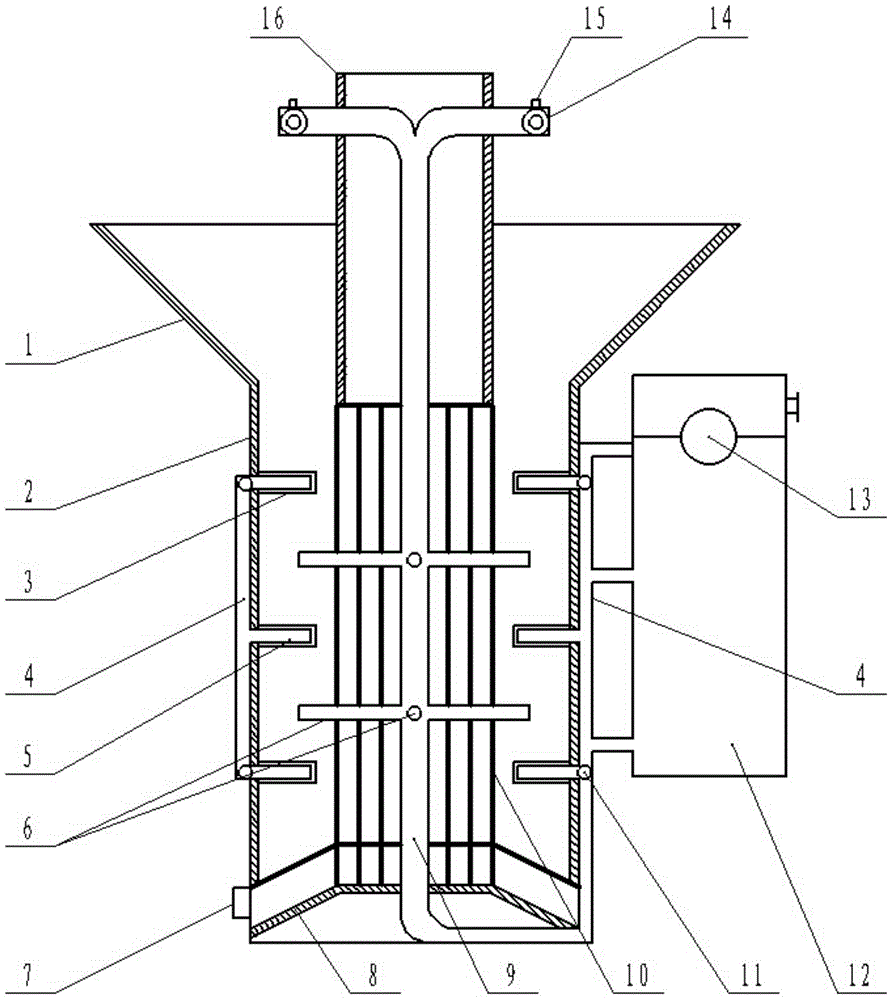

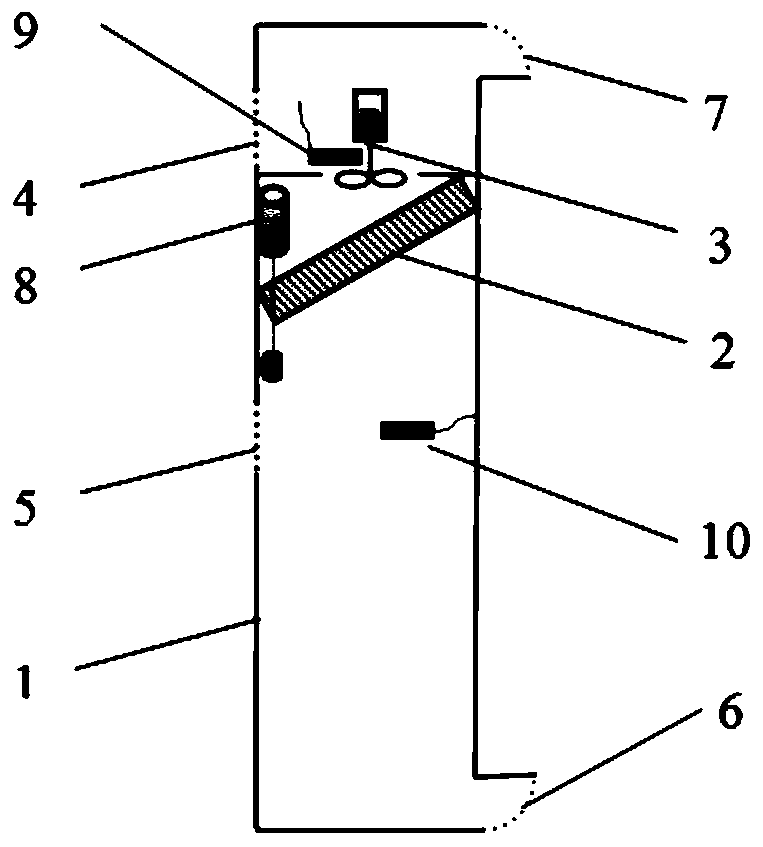

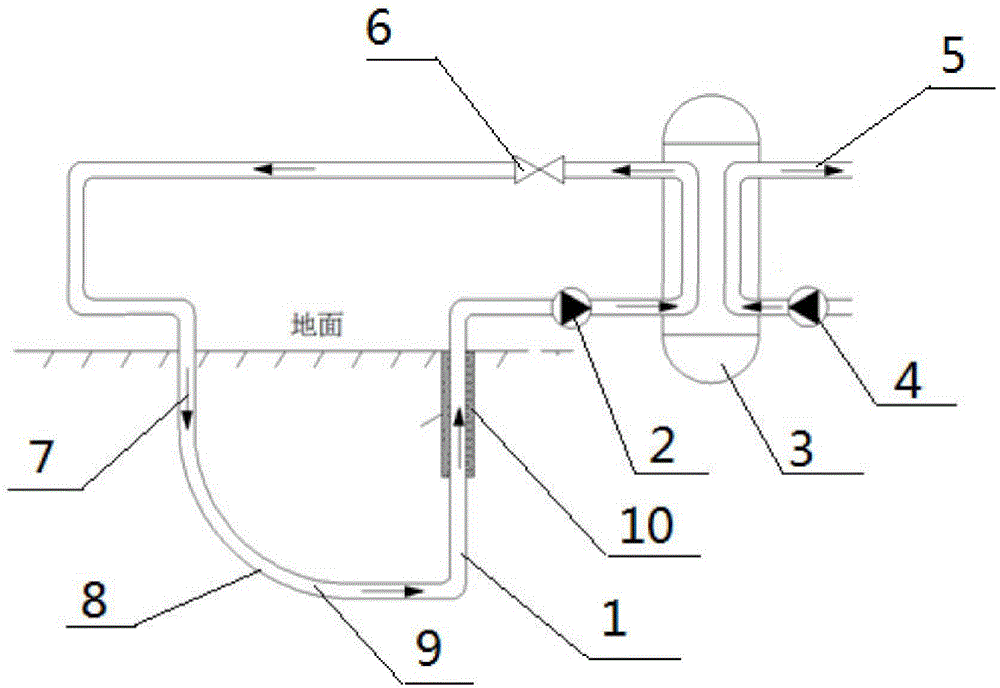

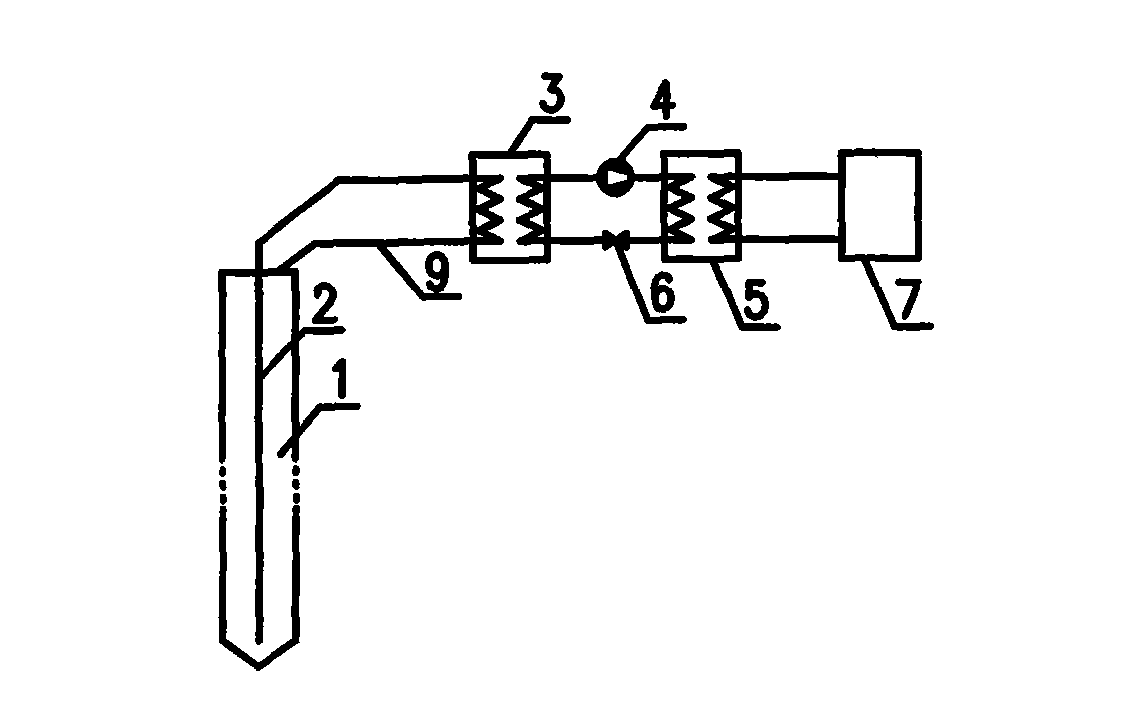

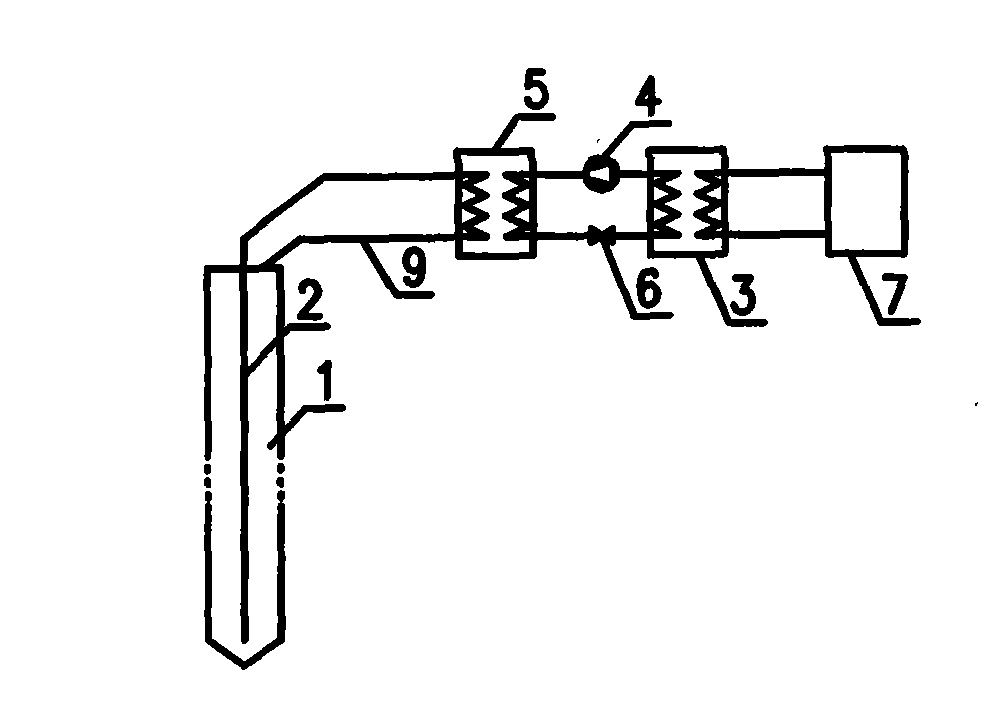

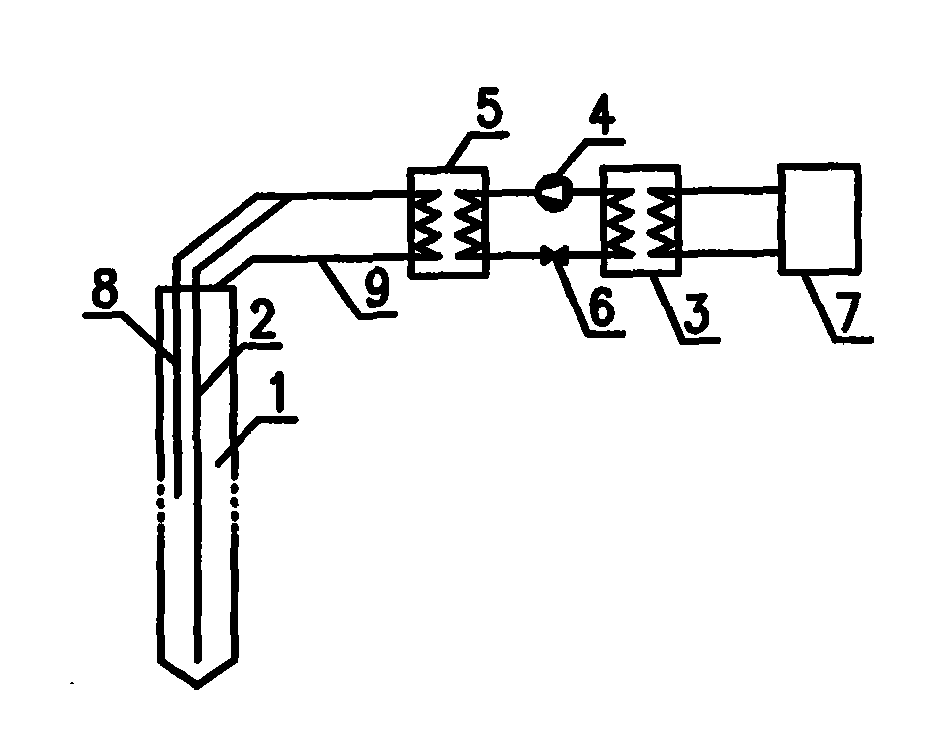

Intermediate-depth part geothermal energy heating system

InactiveCN106196233ARich reservesGreat potential for developmentOther heat production devicesGeothermal energy generationButt jointFresh water

An intermediate-depth part geothermal energy heating system comprises a vertical well vertically extending to the underground part by 2,000 m, and a butt joint well communicating with the vertical well, wherein the vertical well and the butt joint well are the same in depth. After the butt joint well is vertically downwards dug by 1,700 m, an arc deflection section is arranged to be connected with the part, at the underground position of 2,000 m, of the vertical well. Communicating casing pipes are laid in the vertical well and the butt joint well. The casing pipe at an outlet of the vertical well is connected with the heat absorbing side of a ground source heat pump through a water pump. An outlet in the heat absorbing side of the ground source heat pump communicates with the casing pipe in the butt joint well to form a closed circulation loop, and the heat exchange side of the ground source heat pump is connected with a tail end user. The vertical depth of the casing pipes is increased to 2,000 m from the conventional depth of 100 m, the vertical well and the butt joint well are effectively connected in the deep soil, a horizontal heat exchange pipeline is established at the underground position of 2,000 m, a closed circulation system is adopted, softened fresh water efficiently exchanges heat with deep rock soil, and the deep geothermal energy is extracted to be used for building heat supply.

Owner:XI AN JIAOTONG UNIV

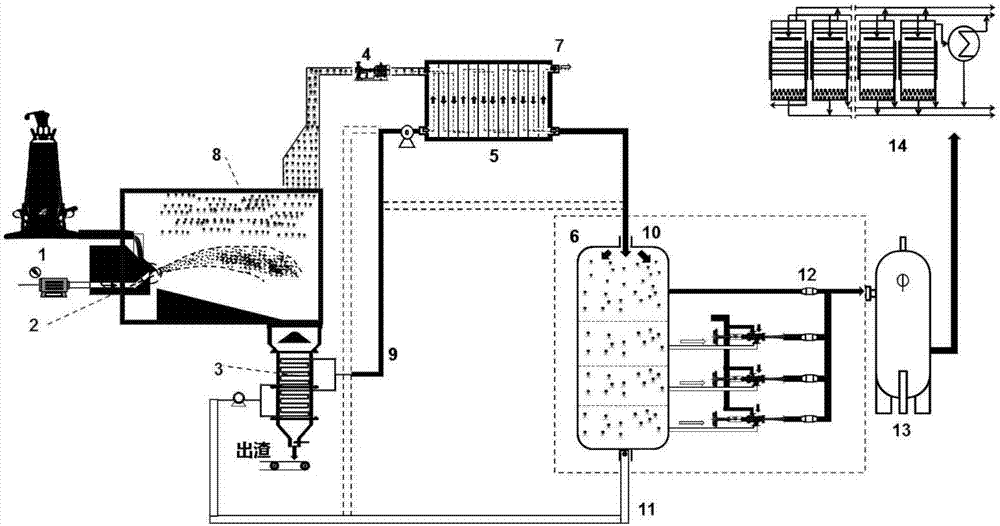

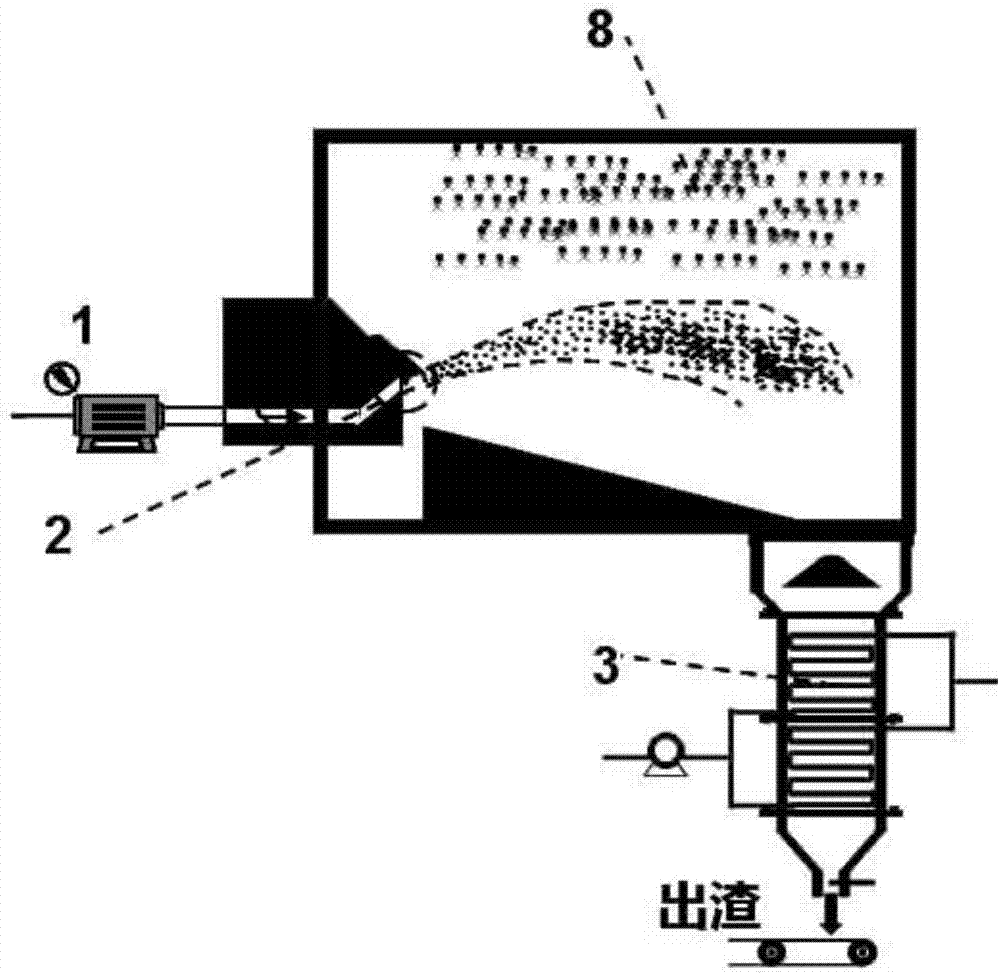

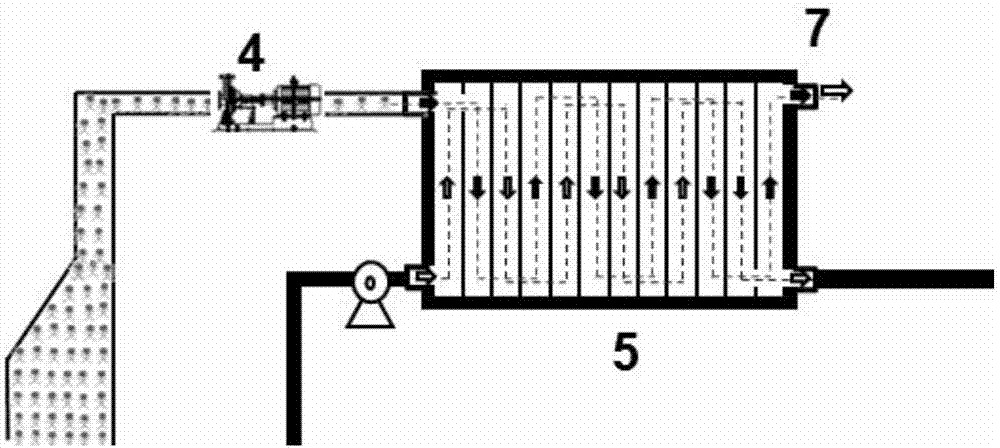

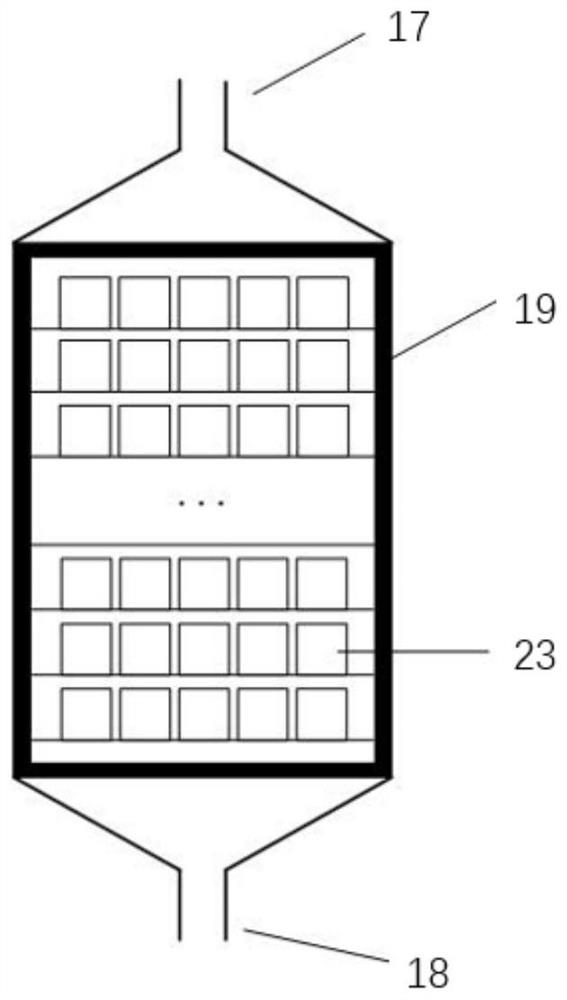

Equipment capable of supplying heat by using blast furnace slag air-quenching granulated particle waste heat based on flash evaporation technology

ActiveCN107990740AAvoid wastingAvoid pollutionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure

The invention provides equipment capable of supplying heat by using blast furnace slag air-quenching granulated particle waste heat based on a flash evaporation technology and belongs to the field ofenergy-saving technologies. The equipment comprises an air-quenching granulated waste heat recovery device, a high-temperature clean water temperature-increasing upgrading device and a deep negative-pressure multistage flash evaporation device. The air-quenching granulated waste heat recovery device comprises a Laval nozzle array and a self-flow bed type heat exchanger. The high-temperature cleanwater temperature-increasing upgrading device comprises a booster pump, a gas-water heat exchanger and a flue gas outlet. The deep negative-pressure multistage flash evaporation device is connected with a booster. According to the equipment, the high-temperature slag flow generated in the metallurgical process is subjected to high-pressure air-quenching granulation and changed into high-temperature particles, high-temperature particles exchange heat with clean water, and waste heat recovery is achieved; and after high-temperature clean water is subjected to heat exchange upgrading, the deep negative-pressure multistage flash evaporation device is introduced, and low-pressure steam obtained after flash evaporation provides a continuous stable heat source for seawater desalination equipment.By the adoption of the equipment capable of supplying the heat by using the blast furnace slag air-quenching granulated particle waste heat based on the flash evaporation technology, the blast furnace slag waste heat is used as the seawater desalination heat source, the better economical efficiency is achieved, and the operating cost of the seawater desalination equipment can be lowered.

Owner:UNIV OF SCI & TECH BEIJING

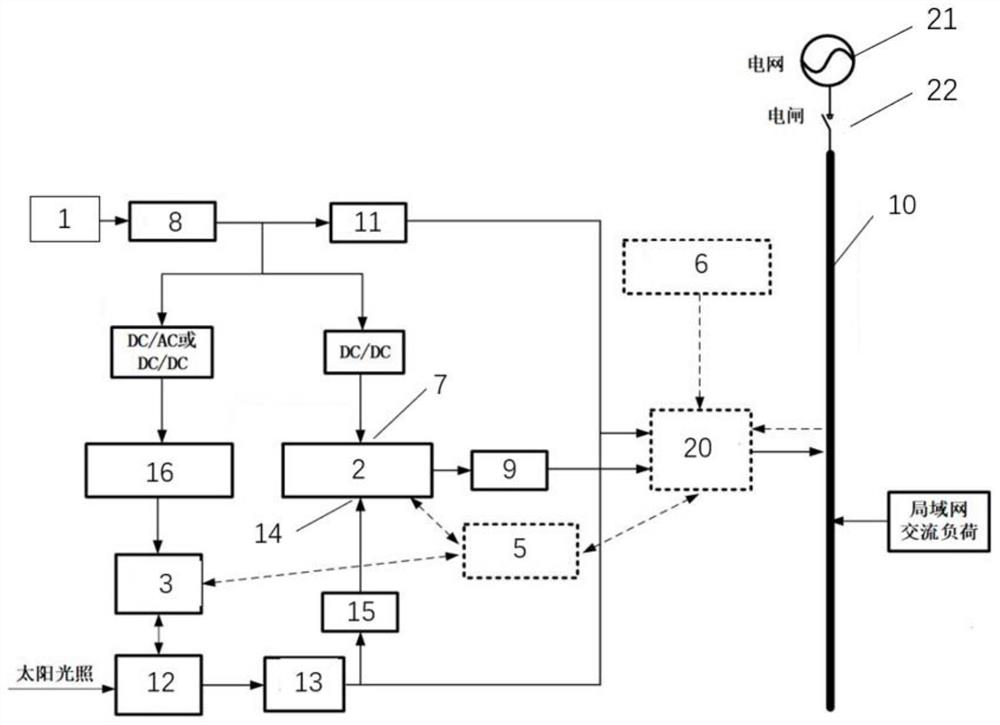

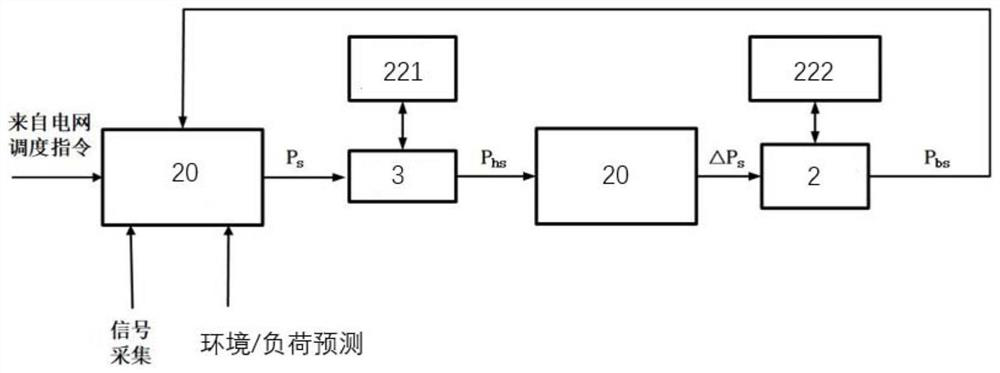

Composite energy storage power supply system for peak regulation and frequency modulation of power grid and regulation and control method thereof

PendingCN113612241AQuick responseLarge capacityHeat storage plantsEnergy storageConvertersElectrical battery

The invention provides a composite energy storage power supply system for peak regulation and frequency modulation of a power grid. The system comprises a renewable energy power generation device; a battery energy storage device, wherein a first input end of the battery energy storage device is connected with a power supply output end of the renewable energy power generation device through a DC / DC converter; a first DC / AC converter, wherein the power supply output end of the battery energy storage device is connected with the common alternating current bus through the first DC / AC converter; a second DC / AC converter, wherein the power supply output end of the renewable energy power generation device is connected with the common alternating current bus through the second DC / AC converter; a solar thermal power generation device, wherein the power supply output end of the solar thermal power generation device is connected with the public alternating current bus through an AC / AC converter; and a heat storage device which is connected with the solar thermal power generation device, wherein heat storage and heat release can be carried out between the heat storage device and the solar thermal power generation device. The composite energy storage power supply system provided by the invention can give consideration to stability, reliability, economy and environmental protection when being used for peak regulation and frequency modulation of a power grid.

Owner:ZHEJIANG UNIV

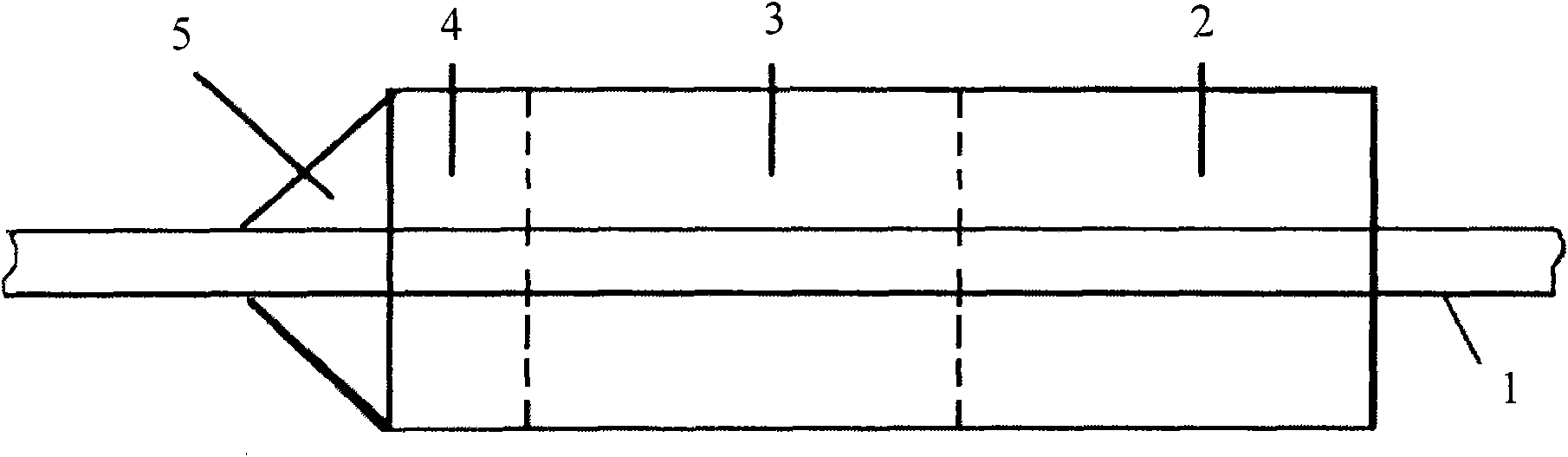

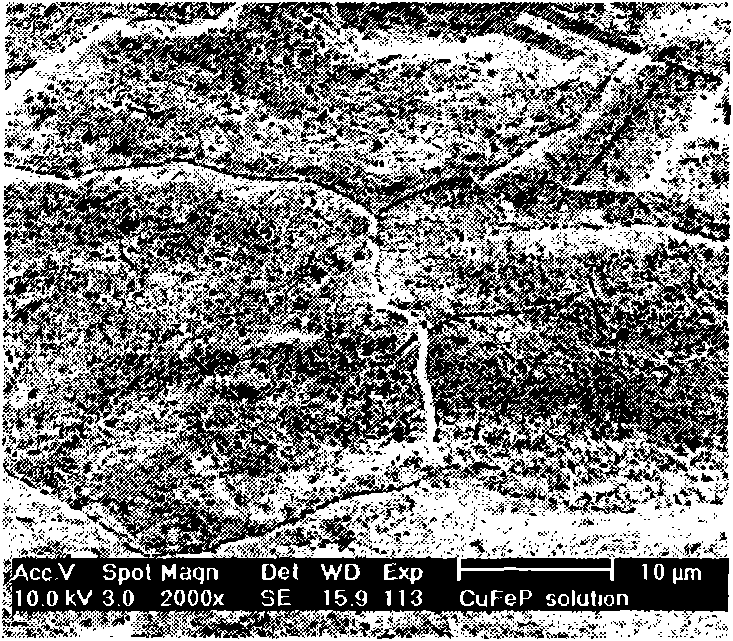

On-line solid solution treatment method for copper alloy used for lead frame

The invention provides an on-line solid solution treatment method for a copper alloy used for a lead frame, which comprises the following steps: (1) carrying out horizontal continuous casting on casing blanks, firstly passing a heating region, and controlling the temperature between 750 and 950 DEG C and the region length between 0.5 and 1.5 m; (2) entering a heat insulation region, and controlling the temperature between 750 and 950 DEG C and the region length between 2 and 10 m; (3) subsequently, entering a temperature compensation region which compensates the temperature loss at an outlet caused in the final water cooling stage because of the heat transfer, and controlling the temperature between 800 and 1200 DEG C and the region length between 0.1 and 1 m; and (4) finally, entering a water cooling region for solid solution treatment to reach the goal of solid solution treatment, and controlling the water cooling intensity between the cooling water pressure of 50 and 150 KPa. The production method is simple, has low cost, and can realize the industrialization easily. The alloy treated by the on-line solid solution treatment method developed by the invention has sufficient solid solution, and is particularly suitable for producing sediment reinforced copper alloy lead frame materials by adopting a horizontal continuous casting method in the actual production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

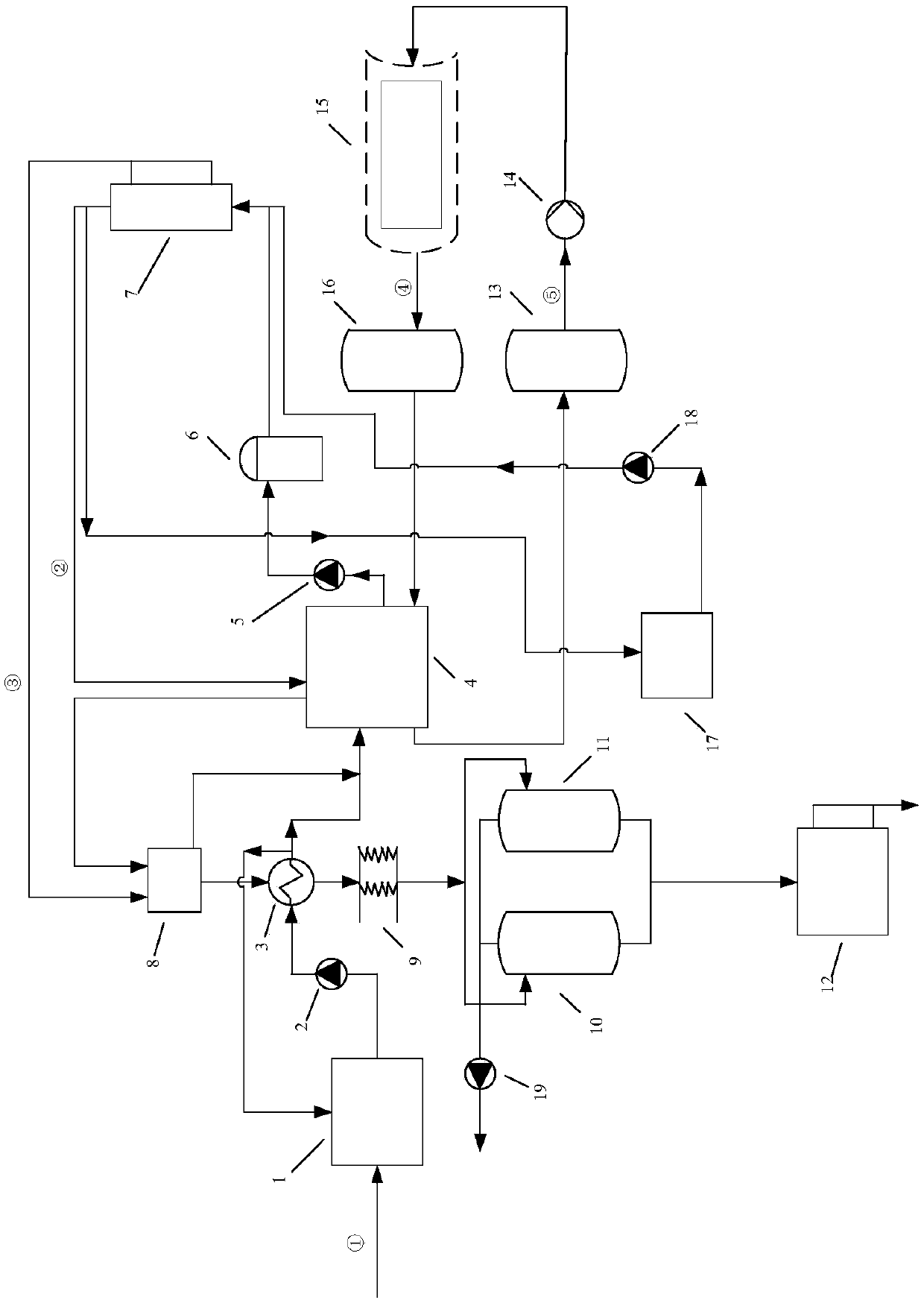

Method for recycling heat energy from returned cooling water in production of polysilicon

InactiveCN101762174AReduce cooling water consumptionSave waterSteam generationIncreasing energy efficiencyLithium bromideEngineering

The invention relates to a method for recycling heat energy from returned cooling water in the production of polysilicon, belonging to the production field of polysilicon. In order to solve technical problem, the invention provides a method for recycling heat energy from returned cooling water in the production of polysilicon, which has high utilization rate of recycling heat energy from the returned cooling water. The method for recycling heat energy from returned cooling water in the production of polysilicon comprises the following steps: a, transfer of heat energy: the returned cooling water is adopted to concentrate lithium bromide dilute solution; b, release of heat energy: the concentrated lithium bromide solution is sprayed by water and the heat discharged therefrom is used to heat water to result in superheated water from 138 to 145 DEG C; and c, preparation of high temperature saturated steam: the superheated water is added to a flash device in order to instantaneously gasify the superheated water to the saturated steam from 128 to 132 DEG C. The method according to the invention has the advantages of: reducing the large use amount of cooling water for plate heat exchange, saving water resource, providing stable and excellent heat source for polysilicon, lowering the use amount of steam, economizing on energy and being favourable for environmental protection.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

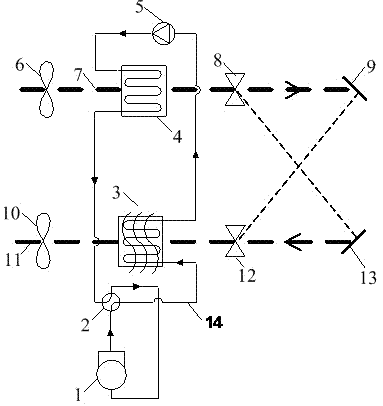

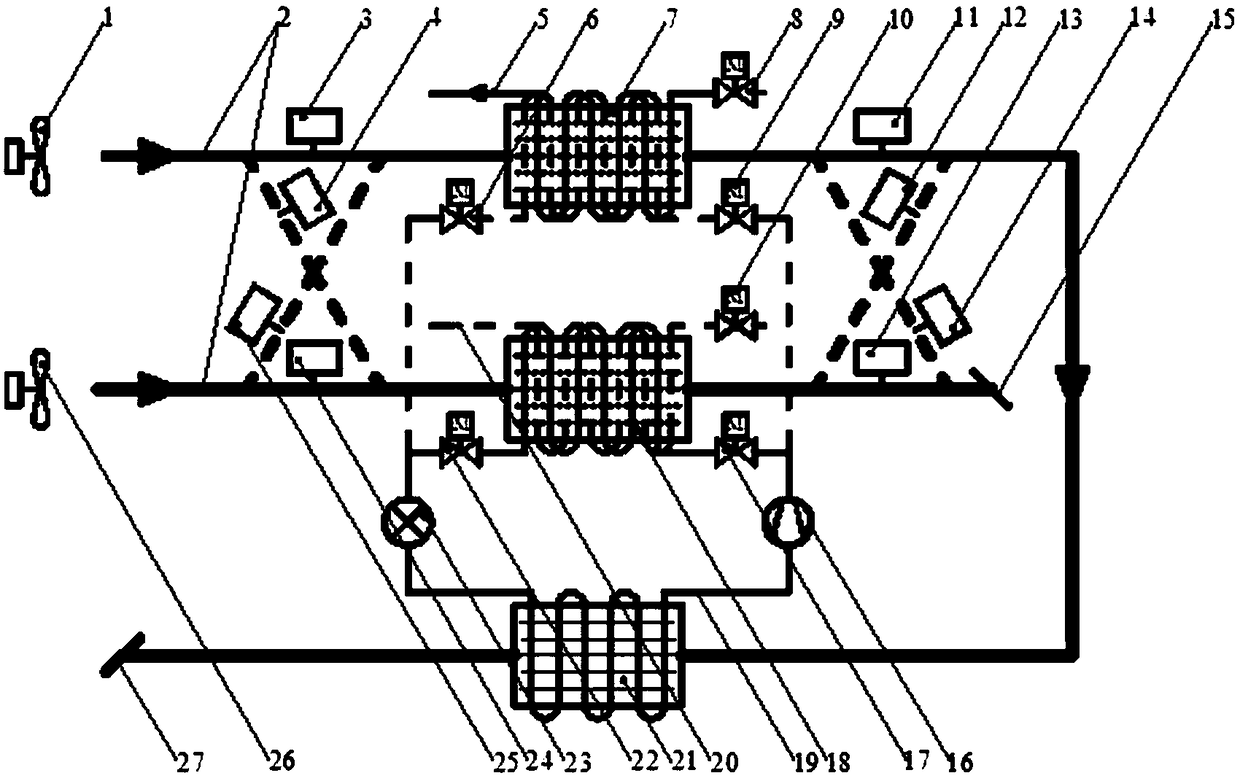

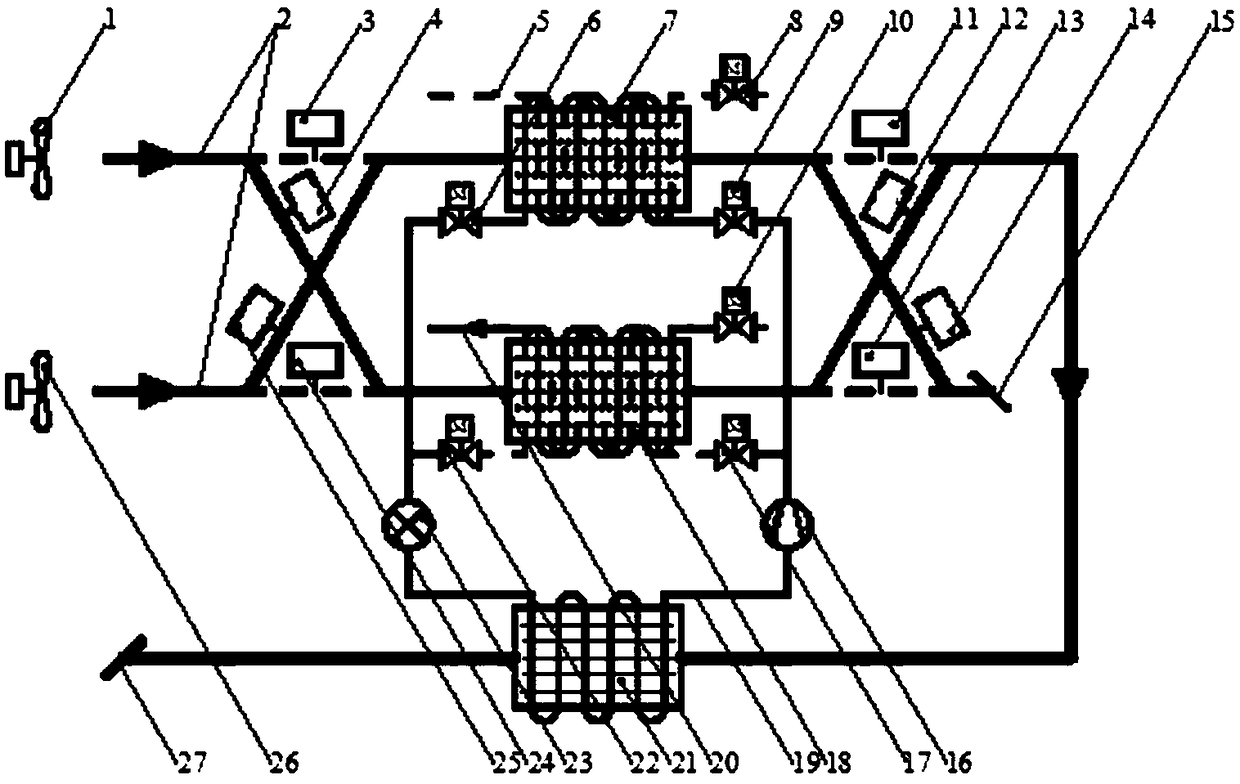

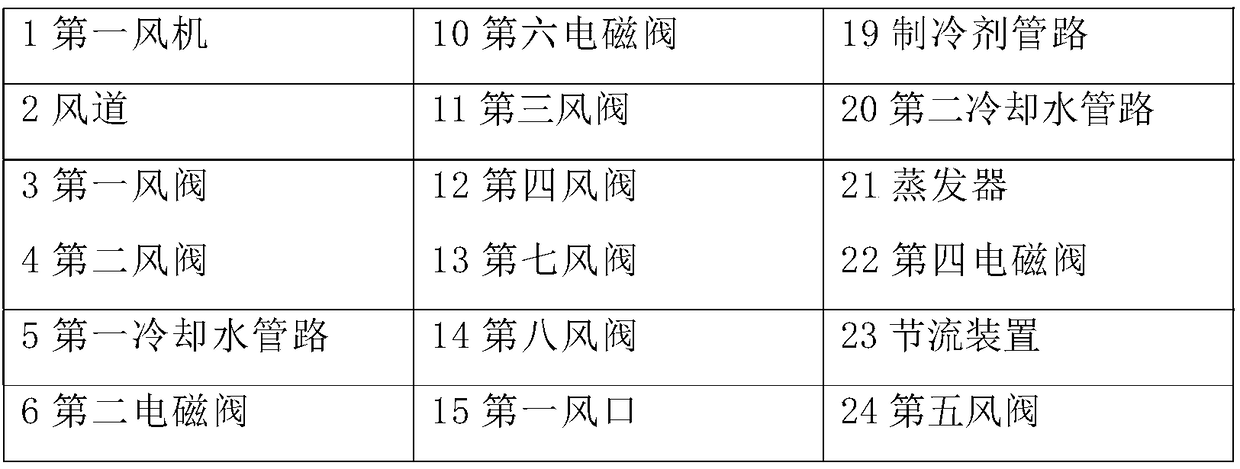

Double-inner-cold-source two-stage cooling dehumidification heat pump system

ActiveCN108644929AAchieve independent controlEfficient use ofMechanical apparatusFluid circulation arrangementEngineeringRecuperator

The invention provides a double-inner-cold-source two-stage cooling dehumidification heat pump system comprising a refrigerant system, a cooling water system and an air system. The refrigerant systemcomprises a compressor, a dehumidification heat exchanger (a refrigerant pipeline), a throttling device and an electromagnetic valve. The cooling water system comprises a dehumidification heat exchanger (a cooling water pipeline) and an electromagnetic valve. The air system comprises a fan, an air valve, an air channel and an air opening. In the double-inner-cold-source two-stage cooling dehumidification heat pump system, the two same dehumidification heat exchangers with double runners are adopted, one dehumidification heat exchanger operates as a dehumidification condenser, the other dehumidification heat exchanger operates as a water cooling dehumidification heat exchanger, and the work modes of the two dehumidification heat exchangers are switched periodically. One stream of air sequentially flows through the dehumidification heat exchanger and an evaporator to be cooled and dehumidified, and meanwhile the other stream of air flows through the dehumidification condenser to be heated and humidified. Continuous thermal and moisture load treatment can be achieved through switching of the electromagnetic valves and the air channel. Compared with the prior art, the double-inner-cold-source two-stage cooling dehumidification heat pump system can achieve stable and efficient treatment of thermal and moisture loads.

Owner:SHANGHAI JIAO TONG UNIV

Cascade recovery system for multi-quality waste heat of internal combustion engine exhaust

InactiveCN109989848AIncrease profitAchieve recyclingInternal combustion piston enginesEngine componentsExternal combustion engineHigh energy

The invention aims to provide a cascade recovery system for multi-quality waste heat of internal combustion engine exhaust. The cascade recovery system comprises a two-stage waste heat recovery loop;the two-stage waste heat recovery loop comprises a primary loop and a secondary loop; the primary loop comprises an evaporator, a steam turbine, a condenser and the like; and the secondary loop includes an energy storage pool and a low temperature difference Stirling engine. In the working process, the primary loop is based on the Rankine cycle principle, and working medium water is heated by high-quality exhaust energy, generates phase change, and expands to do work to push the steam turbine to rotate; and the secondary loop is based on the generality Carnot cycle principle, and residual energy in secondary exhaust gas discharged by the steam turbine is stored in the energy storage pool to provide a stable heat source for the low temperature difference Stirling engine to work continuously. A control unit manages operation of the system, and an energy evaluation unit calculates system parameters and the efficiency. The system realizes cascade recovery and utilization of energy, has high energy conversion efficiency and works reliably.

Owner:HARBIN ENG UNIV

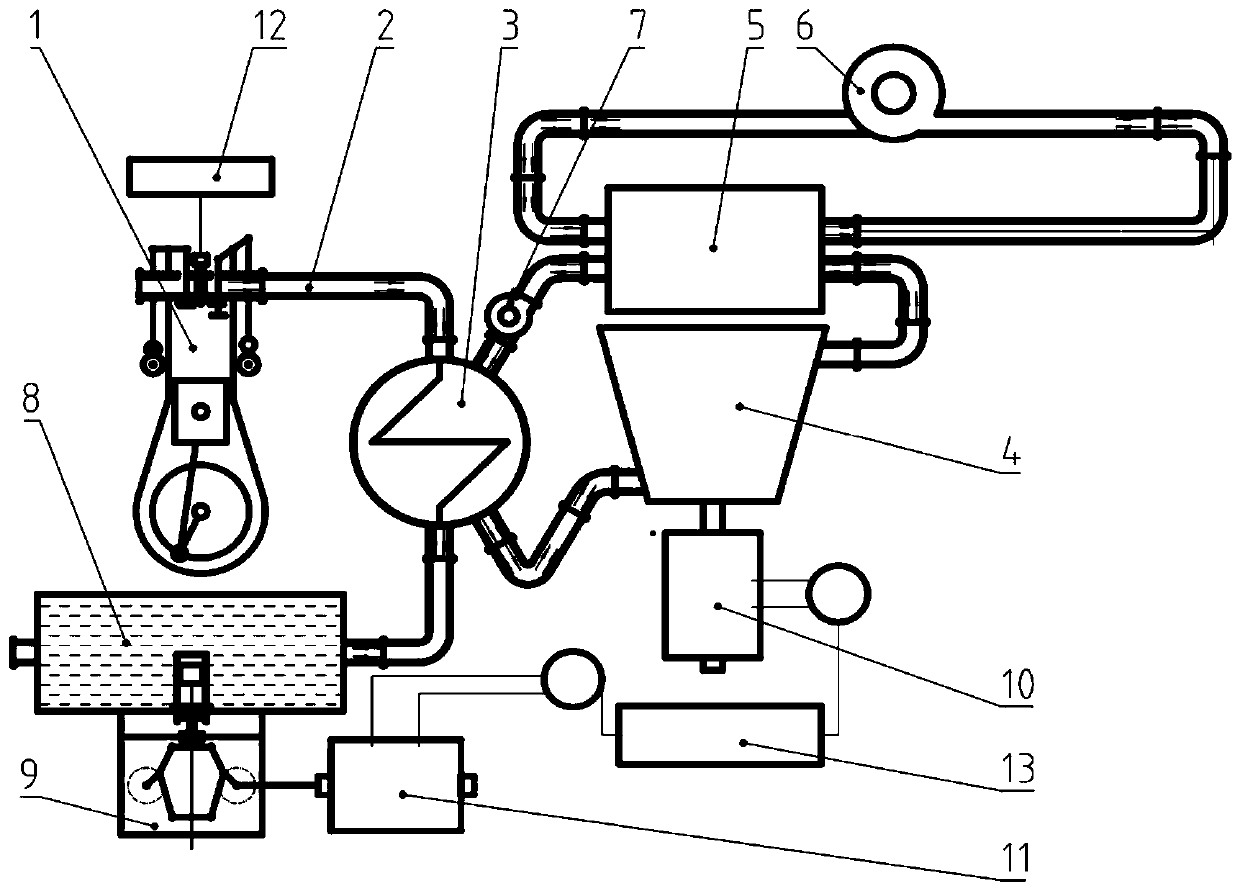

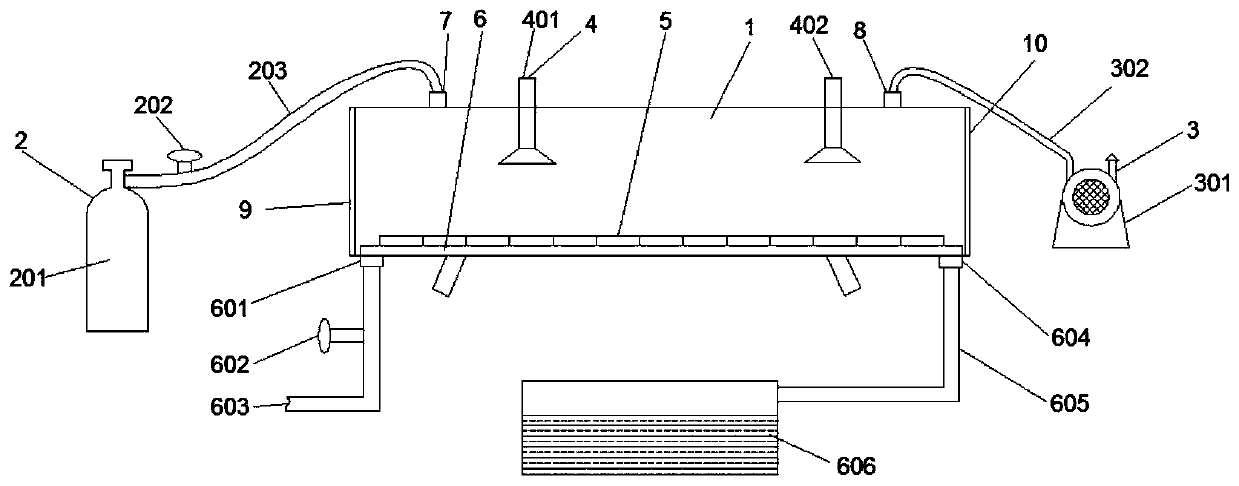

Solar energy and heat pump membrane distillation system

InactiveCN110496537AReduce energy consumptionEfficient recyclingSolar heating energySolar heat storageThermal energyHeat losses

The invention discloses a solar energy and heat pump membrane distillation system. The system comprises a constant-temperature water tank 4, a heat pump heat exchange unit, a solar energy heating unit, a membrane distillation unit, a produced water collection unit, and a chemical clean unit, wherein the solar energy heating unit heats a raw material liquid in the constant-temperature water tank 4by indirect heating. The solar energy and heat pump membrane distillation system provided by the invention improves the thermal energy utilization efficiency of membrane distillation, and has small heat loss, a small amount of cooling water, a higher membrane flux, stable operation and low operating costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat pump device with freezing pipe as ground heat exchanger

InactiveCN101581519AEfficient heat exchangeStable air conditioner cold sourceHeat pumpsOther heat production devicesGround-coupled heat exchangerWater flow

The invention relates to a heat pump device with a freezing pipe as a ground heat exchanger so as to provide stable heat sources and cold sources for the heat pump. During running in winter and summer, the heat pump device can reach the optimal heat exchange effect by changing the direction of water flow in the ground heat exchanger. The final heat source or cold source of the heat pump is soil and groundwater; the water outlet end of the heat pump is connected with a user; the heat pump device provides heat sources for heating and bathing in winter and provides cold sources for air conditioners in summer.

Owner:BEIJING ZHONGKUANG DAYU ENERGY SAVING TECH

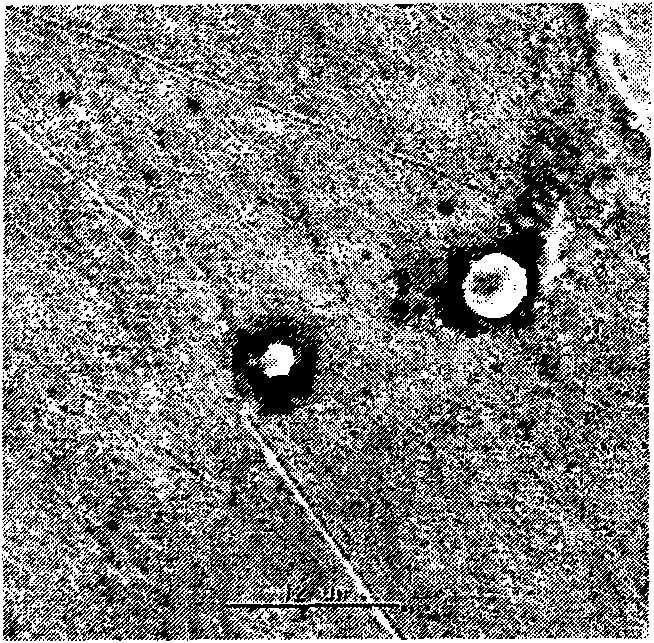

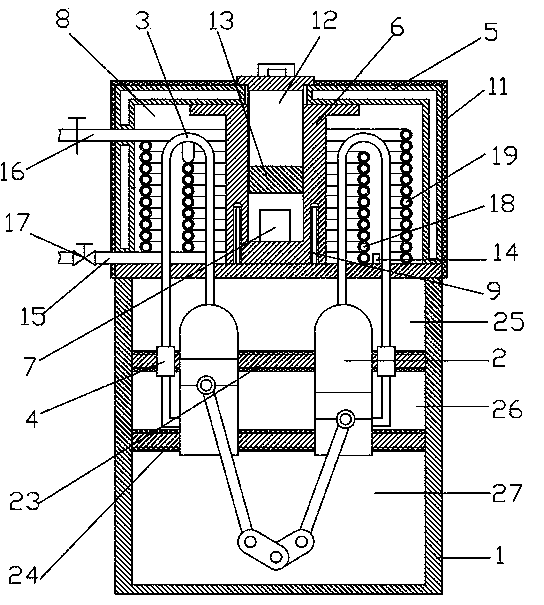

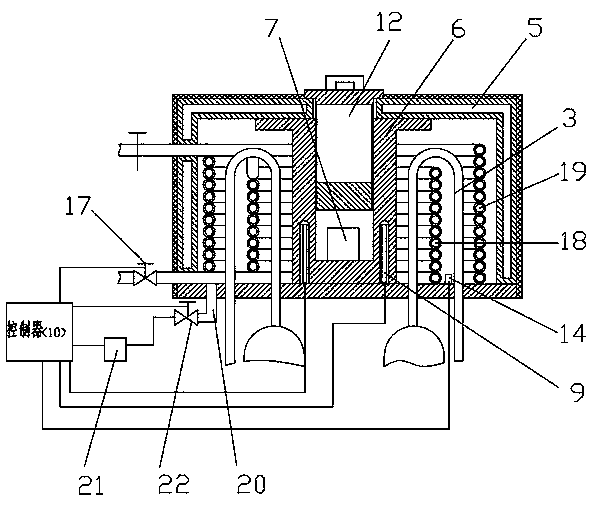

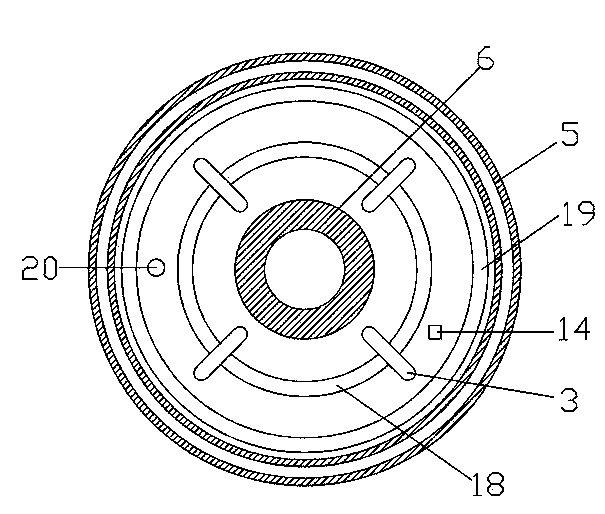

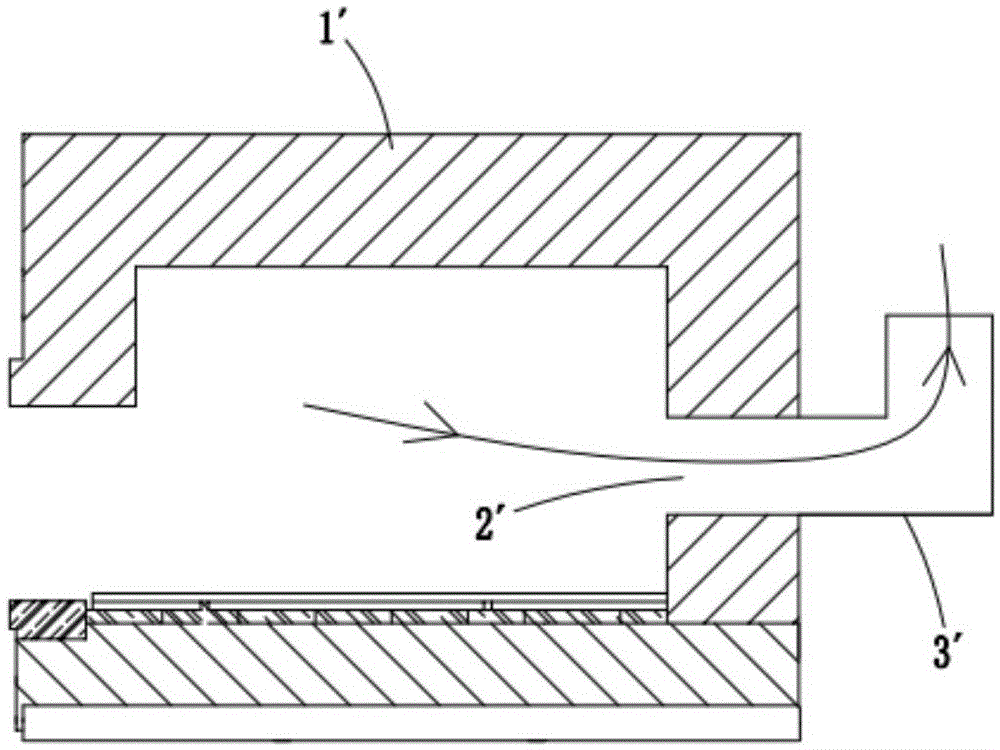

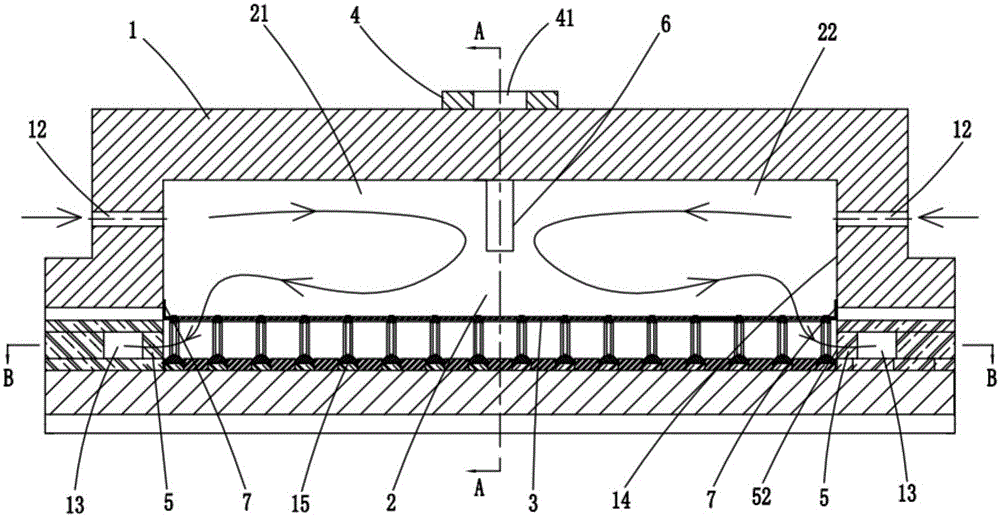

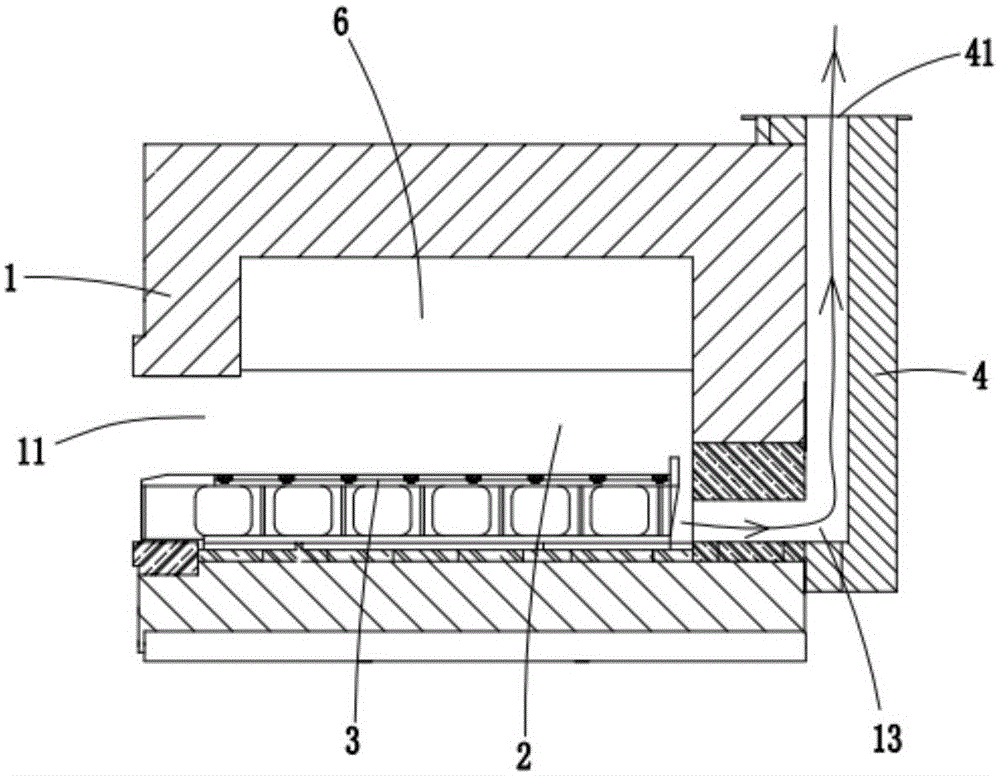

Stirling heat engine based on liquid radioactive waste concentrates

ActiveCN103629009AStable heat sourceImprove work performanceHot gas positive displacement engine plantsWork performancePlate heat exchanger

The invention discloses a Stirling heat engine based on liquid radioactive waste concentrates. The Stirling heat engine based on liquid radioactive waste concentrates comprises a Stirling heat engine base. Multiple sealed air cylinders are arranged in the Stirling heat engine base. The outer ends of piston rods in the air cylinders are connected with a crank-link mechanism. U-shaped air pipes are connected to the air cylinders and heat exchangers are arranged on the U-shaped air pipes. One ends of the U-shaped air pipes are communicated with the hot ends of the upper ends of the air cylinders. The other ends of the U-shaped air pipes are communicated with the cold ends of the lower ends of the air cylinders. A sealed box body is arranged at the upper end of the Stirling heat engine base. A material storage tank is arranged in the middle of the box body and liquid radioactive waste concentrates are contained in the material storage tank. The material storage tank and the inner wall of the box body form an annular cavity. The bottoms of the U-shaped air pipes penetrate into the annular cavity and a pair of electronic poles is arranged on the two sides of the material storage tank. A controller is arranged outside the box body and the electronic poles are connected with the controller through guide wires. Thus, the Stirling heat engine based on liquid radioactive waste concentrates has the advantages of being stable in heat source, stable in working performance and high in working efficiency.

Owner:斯特林威索AB

Box-type fuel gas thermal treatment furnace

The invention relates to a box-type fuel gas thermal treatment furnace. The box-type fuel gas thermal treatment furnace comprises a furnace shell and a furnace hearth. The furnace shell is a rectangular box body. The furnace shell is provided with a material inlet and a material outlet. The furnace hearth is internally provided with a storage rack. The furnace shell is provided with a high-temperature flue gas inlet. The furnace shell is internally provided with an annular flue gas channel. The left side and the right side of the flue gas channel are communicated with the furnace hearth. A vertical flue communicated with the flue gas channel is arranged on the outer portion of the furnace shell. The storage rack is arranged below the high-temperature flue gas inlet and communicated with the flue gas channel. The two ends of the storage rack are in airtight connection with the inner wall of the furnace shell. According to the box-type fuel gas thermal treatment furnace, a plurality of flue gas exhaust pipelines arranged on a traditional thermal treatment furnace are omitted, the flue gas channel is directly and additionally arranged in the furnace shell, and the vertical flue communicated with the flue gas channel is arranged on the outer portion of the furnace shell, so that flue gas subjected to heat exchange in the furnace hearth enters the flue gas channel and centralized and output through the vertical flue; pipeline configuration is simplified, the production cost is lowered, circulation pressure of the flue gas in the furnace is uniform, the thermal utilization rate is high, and heat loss is less.

Owner:海盐凯鑫五金有限公司

Garbage incinerator

The invention discloses a garbage incinerator, comprising an incinerator body, a fire grate and a support layer, wherein the fire grate is arranged inside the incinerator body; the support layer is used for supporting garbage which is thrown in the incinerator body and is arranged inside the incinerator body and above the fire grate; fire channel gaps are formed in the support layer; flame on the fire grate passes through the fire channel gaps and burns the garbage on the support layer; the size of the garbage on the support layer is reduced after combustion; the garbage falls from the fire channel gaps and is burned out on the fire grate. The garbage is supported on the support layer and cannot fall on the fire grate to extinguish flame on the fire grate, so that higher temperature can be kept in the incinerator body, a stable heat source is formed in the incinerator body; as a large amount of water exists in the garbage, the garbage is supported by the support layer, is dried firstly by the flame on the fire grate and the temperature in the incinerator body and then is burned, and combustion is sufficient.

Owner:郑维明

Oven dry process for nature rubber

The invention discloses a drying process of natural rubber, and relates to the deep-processing technical filed of natural rubber, in particular to a natural rubber drying process which dries by steam and can reduce cost, potential safety hazard and pollution. The drying process of the natural rubber comprises procedures of dehumidifying, drying by a two-stage drying system and cooling to dry the natural rubber, and the process is characterized in that the two-stage drying system dries the natural rubber by heat exchange of saturated steam. The natural rubber dried by the process has greatly enhanced heat source utilization rate. Compared with the fuel drying process and equipment in the present natural rubber processing field, the process can better control temperature stability, fully protect and enhance physical and chemical property indexes of the natural rubber, reduce rubber drying cost, and reduce fire risk.

Owner:ISHUANGBANNA PROFOUND RUBBER IND

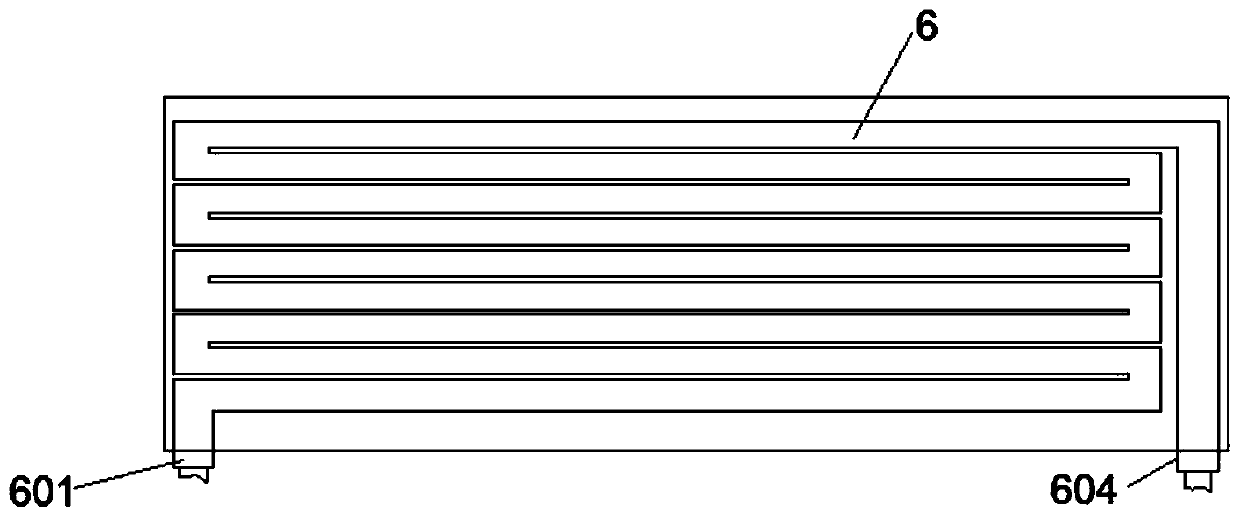

Metal powder semi-automatic drying device

PendingCN111288765AStable heat sourceEasy to makeDrying solid materials without heatIncreasing energy efficiencyWater vaporOxygen enhanced

The invention discloses a metal powder semi-automatic drying device. The metal powder semi-automatic drying device comprises a furnace body, a nitrogen input device and an air draft device, so that gas in a furnace is smooth, water vapor is favorably taken away, a manipulator is arranged, powder caking is eliminated, the powder drying speed is increased, waste heat of low-temperature circulating cooling water flowing out of the medium-frequency smelting furnace is used for drying powder, the oxygenation behavior in the powder drying process is eliminated, and the metal powder semi-automatic drying device is a novel device which is environment-friendly and energy-saving and realizes line production.

Owner:湖南瑞华新材料有限公司

Tritium distillation device

InactiveUS20090057127A1Simple structureEasy to assembleAuxillariesEvaporators/condensersWater sourceDistillation

The present invention provides a novel tritium distillation device, which comprises a container, a radiator covered on top of the container with a protrusion at the bottom, a conduit penetrating the container with an inlet and an outlet, the inlet being arranged in correspondence with the protrusion, and a heating device fixed below the container. The method of operating the tritium distillation includes the steps of adding environmental tritium in the container, covering the radiator on top of the container closely, heating environmental tritium to cause tritium steam to be condensed to the bottom of the radiator, and collecting the tritium condensation dropped from the protrusion with conduit. The present invention uses a simple structure to ease assembly and reduce the cost of cooling water source.

Owner:INST NUCLEAR ENERGY RES ROCAEC

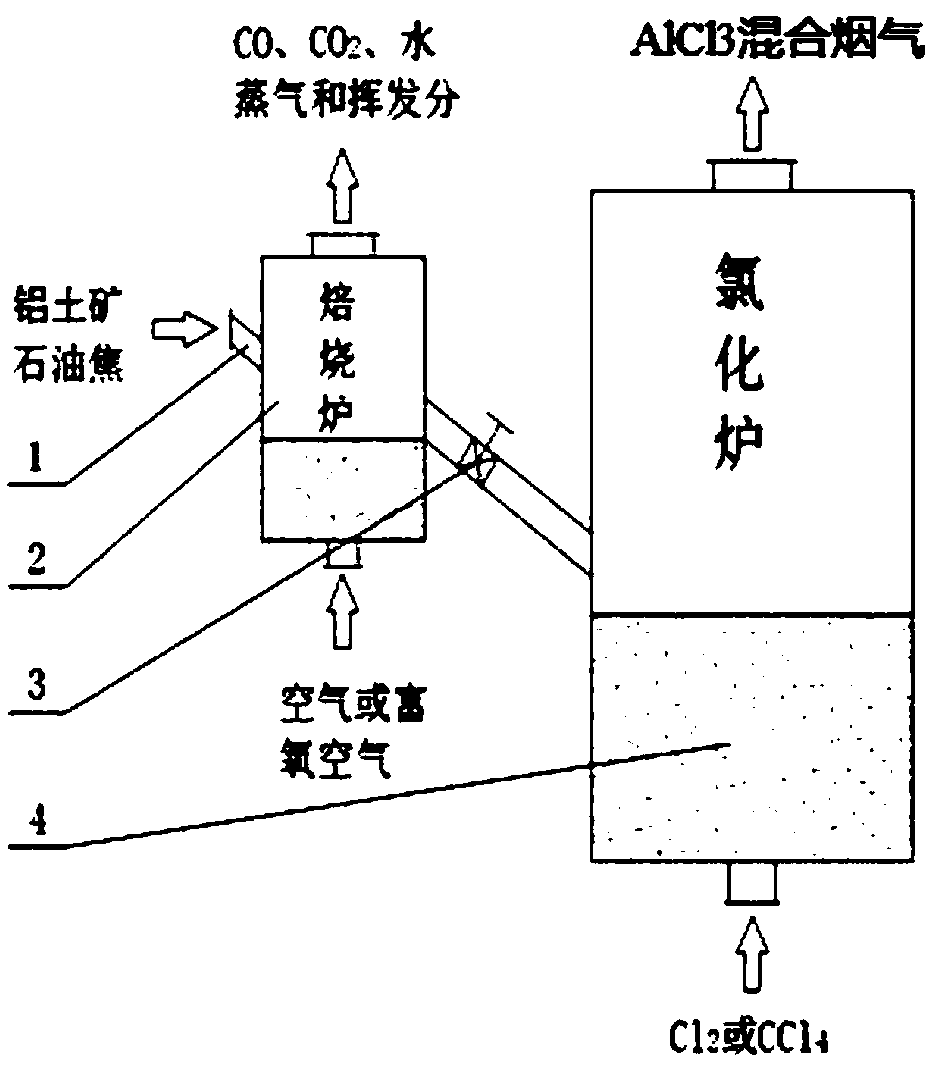

Method for producing aluminium trichloride by carbochlorination

InactiveCN109231248AStable heat sourceAvoid enteringAluminium chloridesCarbon tetrachlorideOxygen rich

The invention belongs to the technical field of fluidization, and particularly relates to a method for producing aluminium trichloride by carbochlorination. Aiming at solving the technical problem, the invention provides the method for producing aluminium trichloride by carbochlorination, which comprises the following steps: (a) roasting: after 100 parts by weight of bauxite and 30 to 55 parts byweight of carbonaceous reducing agent are mixed, air or oxygen-rich air is injected to carry out roasting, and the roasting temperature is controlled at 800 DEG C to 1,000 DEG C; (b) chlorination: chlorine or carbon tetrachloride is injected into the hot-state roasted material obtained after roasting in step (a) to carry out chlorination, the chlorination temperature is controlled at 1,050 DEG C to 1,300 DEG C, and thereby a reaction product containing aluminium trichloride is obtained. The method disclosed by the invention has lower cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

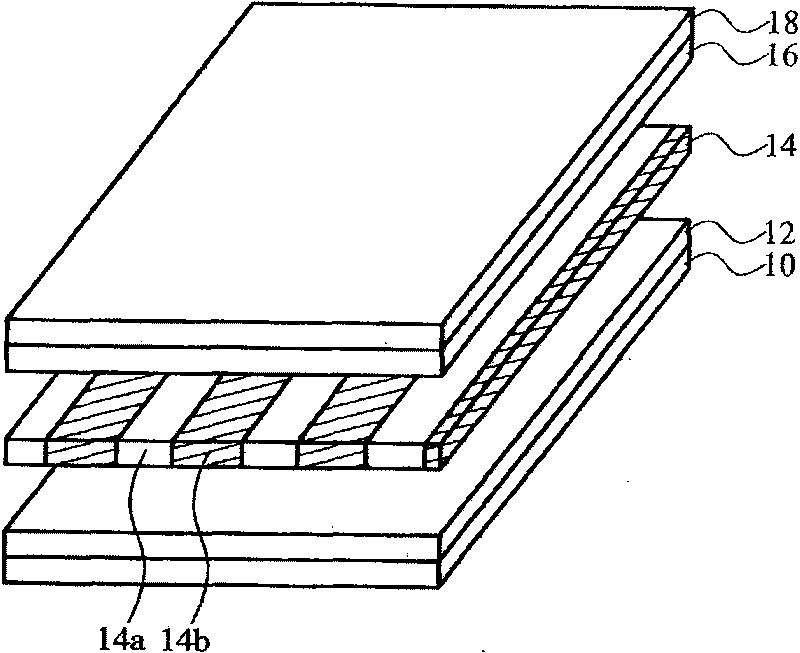

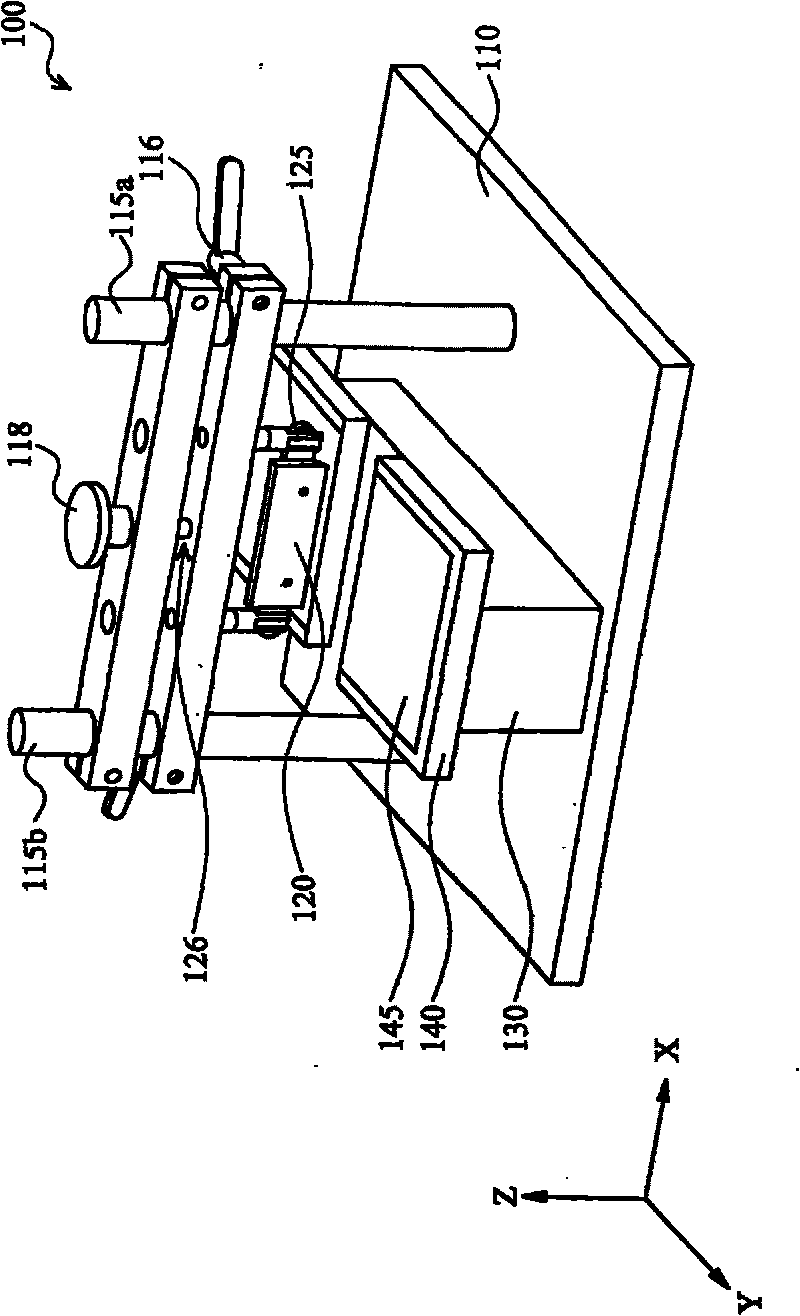

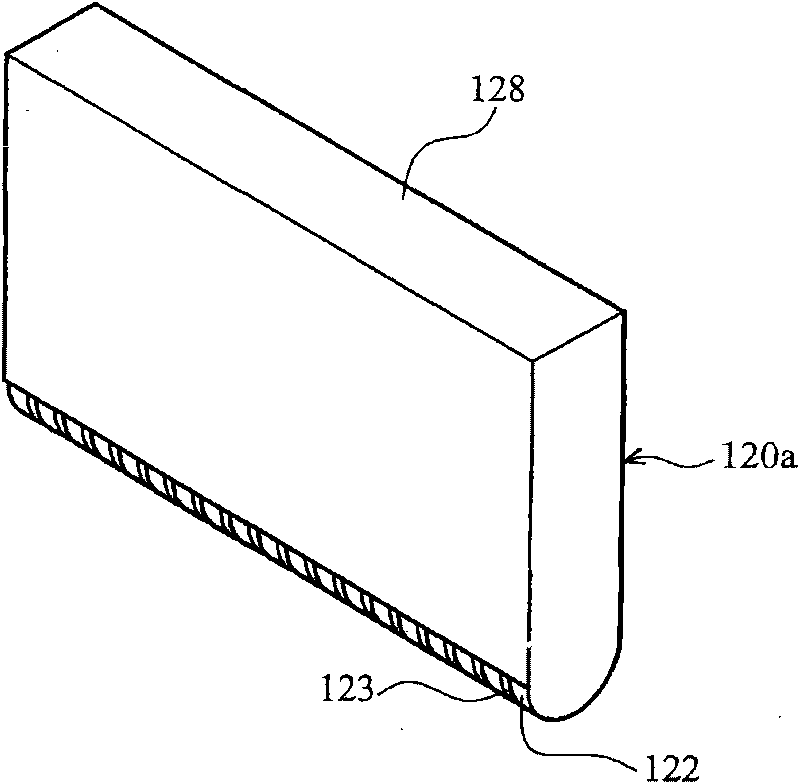

Heat-writing system

The invention relates to a heat-writing system, comprising a heat-writing head module configured with at least one heater, an elasticity adjusting device for adjusting the flatness of the heat-writing head module, and a rotating control device for controlling the heat-writing head module to rotate a certain angle.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com