Method for examining and managing thermodynamic system

A technology of thermal system and inspection communication, which is applied in the direction of inspection devices, inspection time patrols, instruments, etc., and can solve problems such as missing inspection points, inspection content and inspection plans without special detailed regulations, and inspections that are not in place. , to achieve the effect of preventing failures and even accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

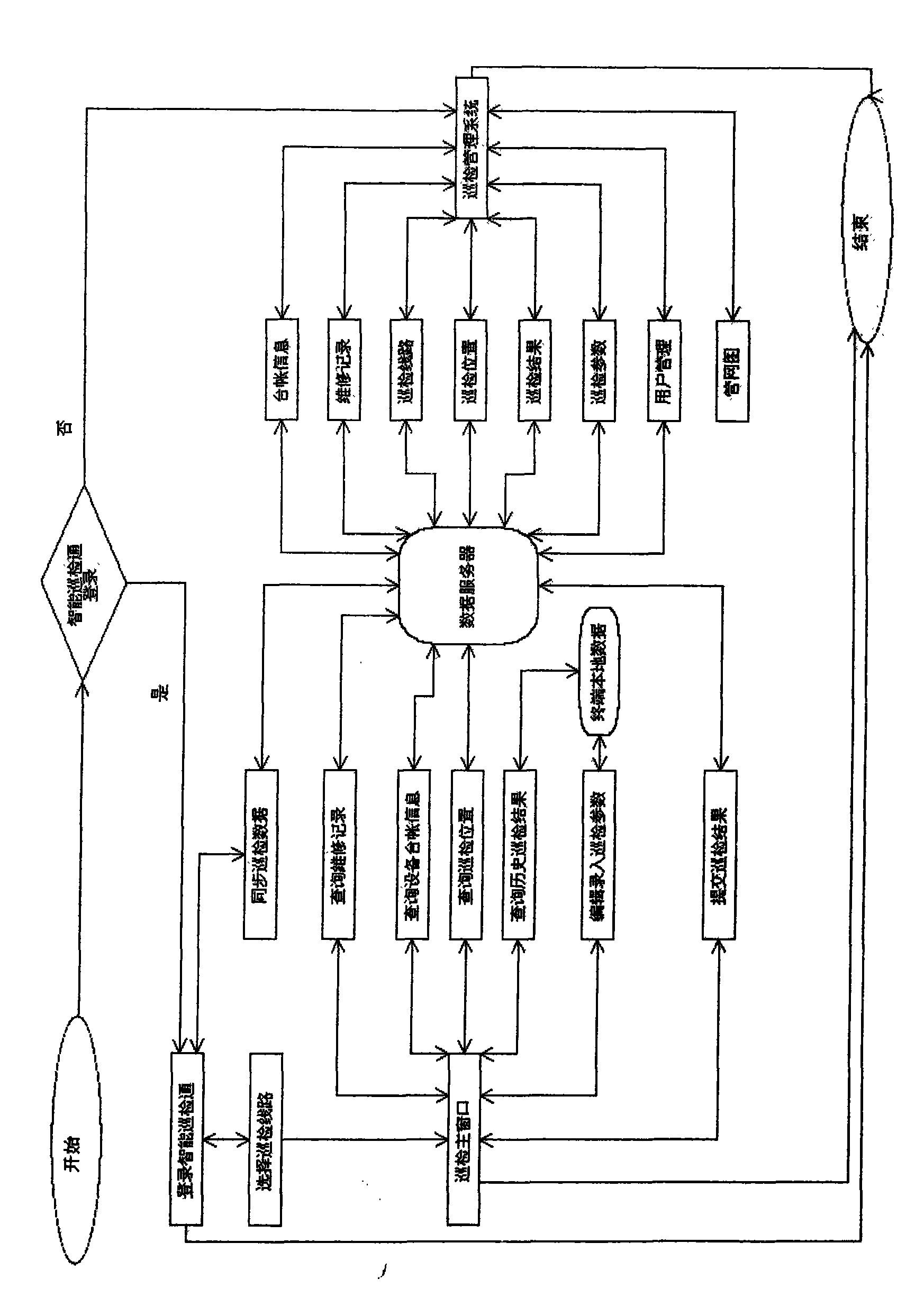

Image

Examples

Embodiment 1

[0039] This embodiment is an inspection and management system for a heating pipe network. The main steps include scan-in of inspector information, inspection point record query, inspection route query, inspection location and equipment query, and data entry. First use a barcode scanner to scan the inspector's job number information or work permit barcode, including login job number, login name, login time, inspection line, and inspection location. After the inspector enters the current inspection line and current inspection location, he scans the barcode of the inspection point, and if he cannot find the inspection point, he will give a prompt message; if he finds the inspection point, he will enter the inspection parameter input interface According to the on-site operation situation, enter relevant data in "Intelligent Patrol", and then query the historical maintenance records and equipment parameters of the inspection point, click the "Submit" button after the input is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com