Method for producing aluminium trichloride by carbochlorination

An aluminum trichloride, carbonaceous technology, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of high economic cost, high technical difficulty, influence of reaction in the furnace, etc., and achieve the effect of low production cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

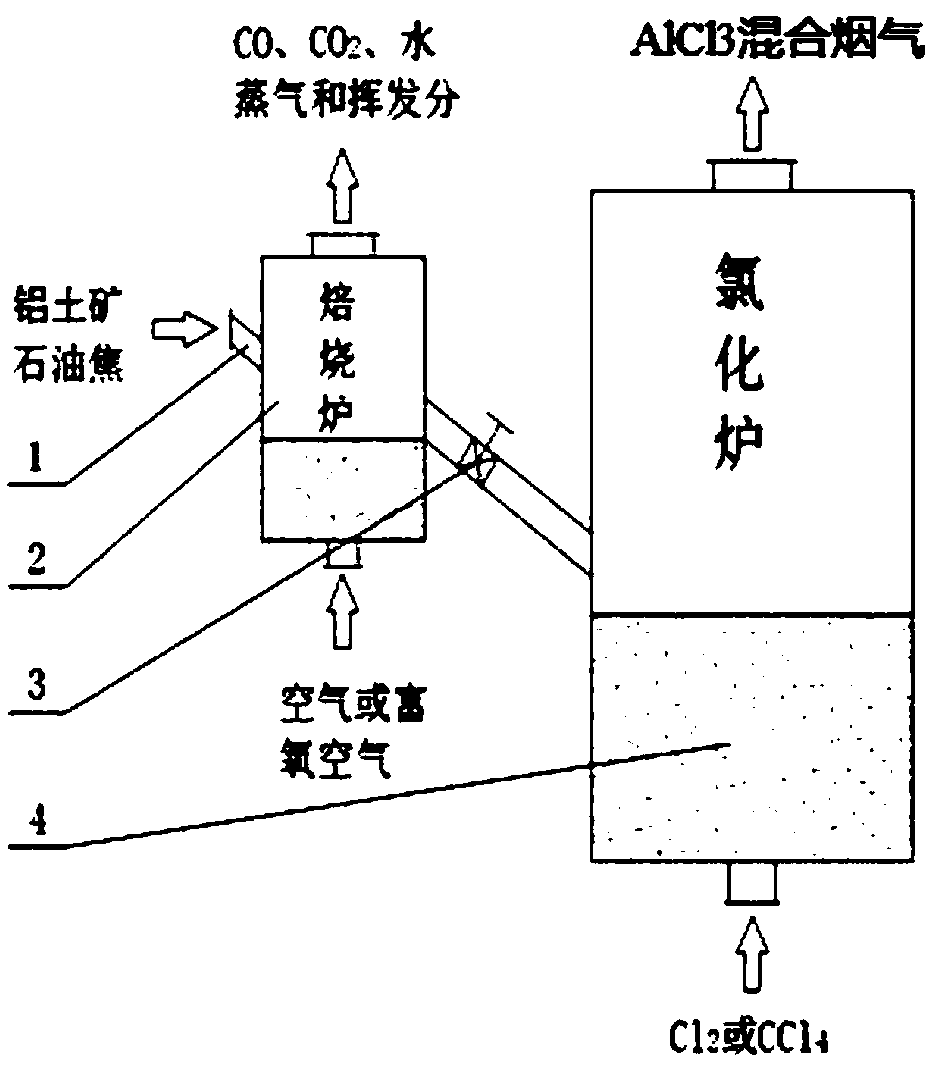

Image

Examples

Embodiment 1

[0026] 1) Mix 100 parts by weight of bauxite and 50 parts by weight of carbonaceous reducing agent as mixed raw materials, and add them to a roasting furnace; wherein the particle size of bauxite is 100-240 mesh; the particle size of carbonaceous reducing agent is 100-160 mesh.

[0027] 2) Air is introduced into the roasting furnace, and the gas velocity is controlled at 0.1m / s. The average residence time of the mixed raw materials in the roasting furnace is 60 minutes. The hot roasting material is continuously introduced into the chlorination furnace, and the smoke from the roasting furnace enters the tail gas system after treatment. emission;

[0028] 3) Chlorine gas is introduced into the chlorination furnace, the operating gas velocity is controlled at 0.2m / s, and the fluidized chlorination contact reaction is carried out with the hot roasting material. The chlorination reaction temperature is controlled at 1200°C, and the average residence time of solid materials is 3h. A...

Embodiment 2

[0030] 1) Mix 100 parts by weight of bauxite and 50 parts by weight of carbonaceous reducing agent as mixed raw materials, and add them to a roasting furnace; wherein the particle size of bauxite is 100-240 mesh; the particle size of carbonaceous reducing agent is 100-160 mesh.

[0031] 2) Air is introduced into the roasting furnace, and the gas velocity is controlled at 0.1m / s. The average residence time of the mixed raw materials in the roasting furnace is 60 minutes. The hot roasting material is continuously introduced into the chlorination furnace, and the smoke from the roasting furnace enters the tail gas system after treatment. emission;

[0032] 3) Carbon tetrachloride gas is passed into the chlorination furnace, the operating gas velocity is controlled at 0.2m / s, and the fluidized chlorination contact reaction is carried out with the hot roasting material. The chlorination reaction temperature is controlled at 1200°C, and the average solid material The residence time ...

Embodiment 3

[0034] 1) Mix 100 parts by weight of bauxite and 45 parts by weight of carbonaceous reducing agent as mixed raw materials, and add them to a roasting furnace; wherein the particle size of bauxite is 160-400 mesh; the particle size of carbonaceous reducing agent is 100-200 mesh.

[0035] 2) Air is introduced into the roasting furnace, and the gas velocity is controlled at 0.1m / s. The average residence time of the mixed raw materials in the roasting furnace is 30 minutes. The hot roasting material is continuously introduced into the chlorination furnace, and the smoke from the roasting furnace enters the tail gas system after treatment. emission;

[0036] 3) Chlorine gas is introduced into the chlorination furnace, the operating gas velocity is controlled at 0.15m / s, and the fluidized chlorination contact reaction is carried out with the hot roasting material. The chlorination reaction temperature is controlled to be 1200°C, and the average residence time of solid materials is 4h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com