Garbage incinerator

A technology of waste incinerator and furnace body, applied in incinerator, combustion method, combustion type and other directions, can solve the problems of flame extinguishing, insufficient combustion, affecting combustion efficiency and effect, etc., to prevent harmful gases, improve temperature, structure and so on. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

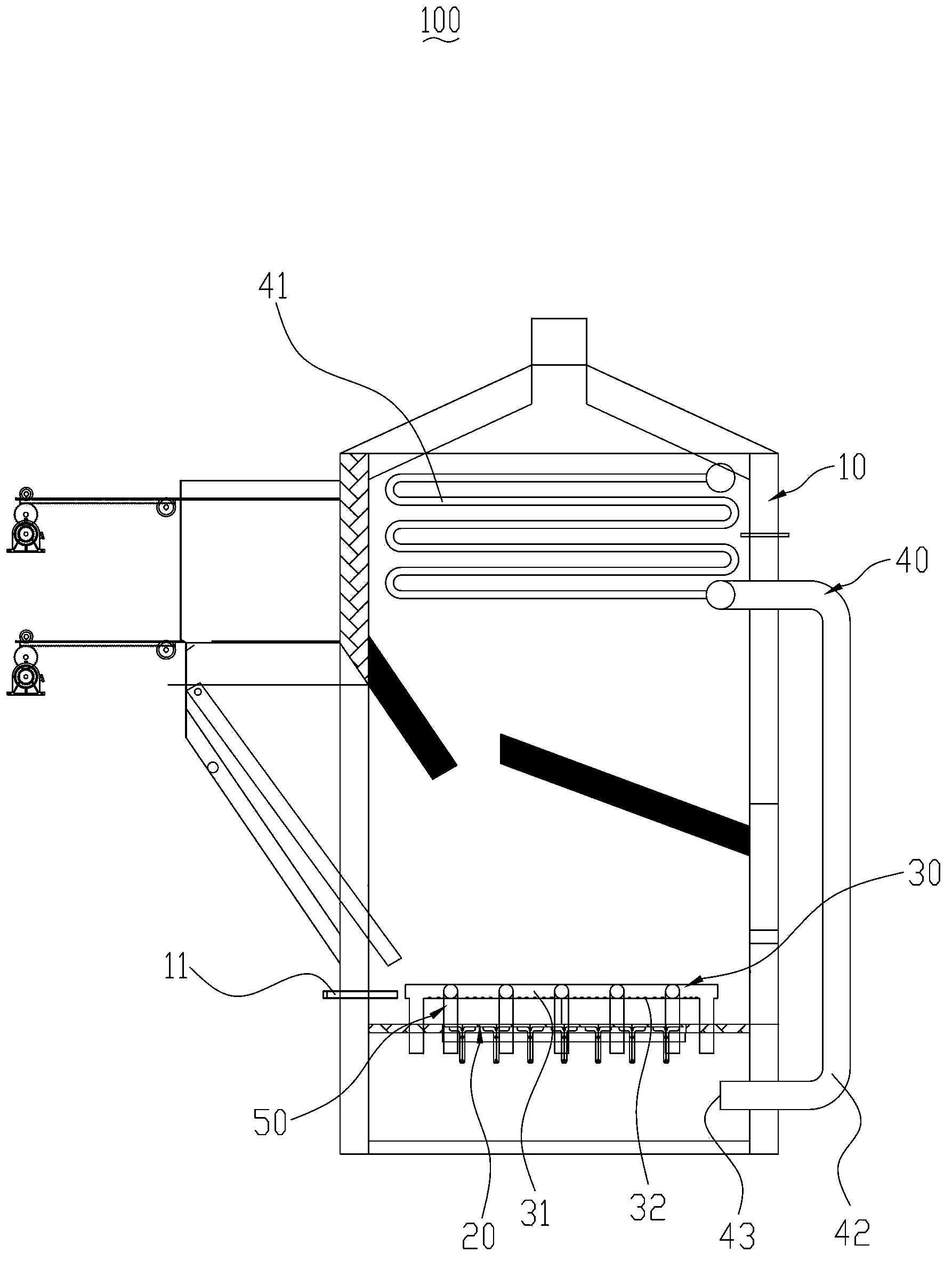

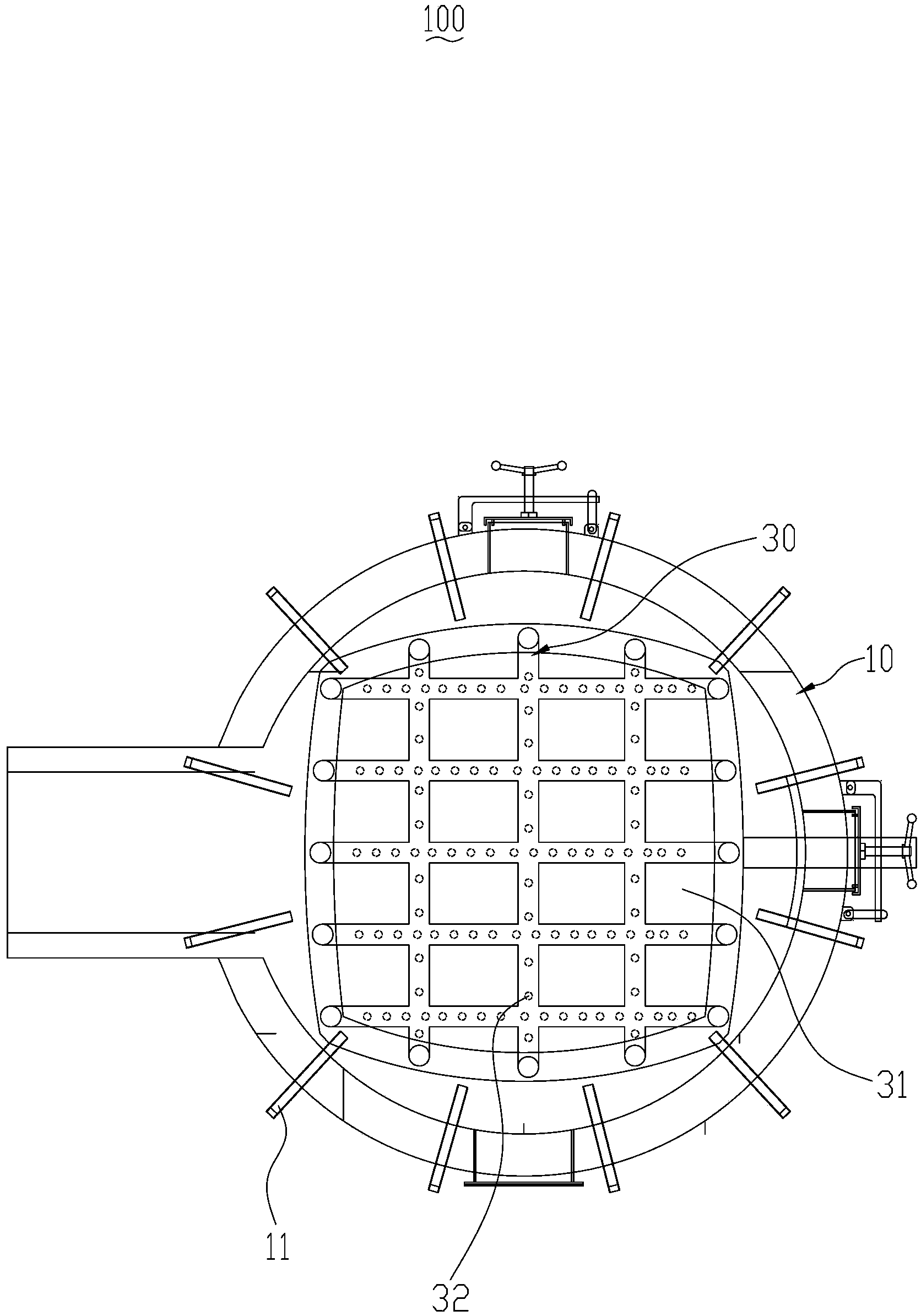

[0029] Please refer to figure 1 and figure 2 , a waste incinerator 100 of the present invention includes a furnace body 10 , a fire grate 20 , a support layer 30 , at least one air duct 40 and at least one connecting pipe 50 .

[0030] Twelve air inlets 11 are arranged on the side wall of the furnace body 10 . Because the pressure inside the furnace body 10 is lower than the outside pressure, the outside air will automatically run into the furnace body 10 through the air inlet ports 11 under the action of the pressure difference. The number and position of the air inlet ports 11 are not fixed.

[0031] The support layer 30 is used to support the garbage, preventing the garbage thrown from a high place from falling directly onto the fire grate 20 to extinguish the flame. Preferably, the support layer 30 is in an arch shape with a high middle part and a low surrounding area. The support layer 30 has a grid shape. The support layer 30 is provided with a number of fire gaps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com