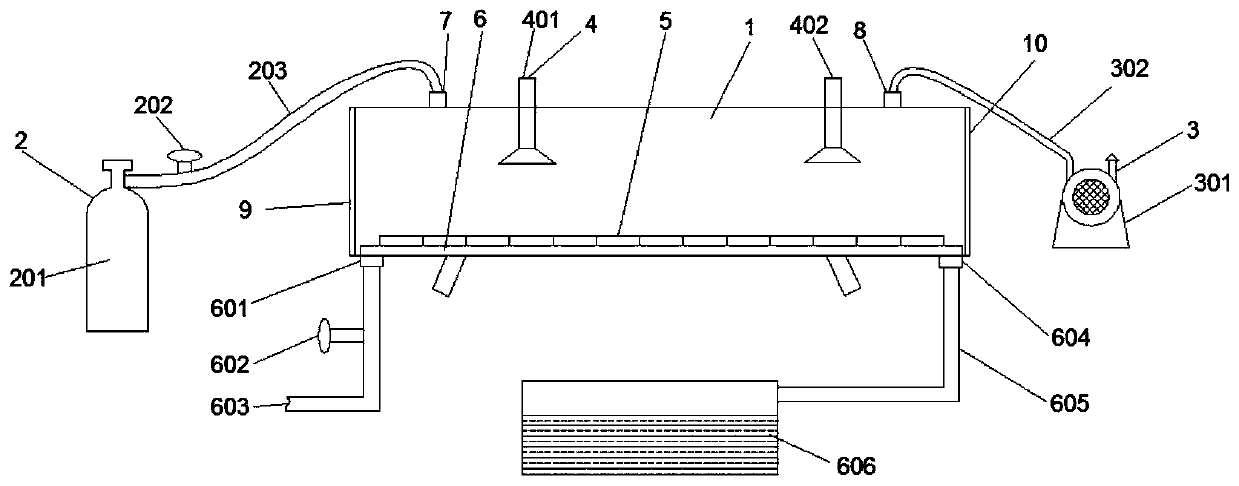

Metal powder semi-automatic drying device

A semi-automated, drying device technology, applied in the direction of heating devices, drying solid materials, drying chambers/containers, etc., can solve the problems of flammability, non-continuous production, oxygen increase, etc., and achieve stable heat source, low labor intensity and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, the iron-based matrix powder used in the diamond product industry is used. The production process is cooling in nitrogen atomized water, the main element is Fe-P-Cu-C alloy powder, and the drying is carried out according to the usual actual production process; Put six trays of powder into the oven, and set the control temperature within 130°C. During the drying process, the materials in the trays are turned manually. During this process, some trays are dried first, and some trays are dried later, indicating that the temperature in the furnace is uneven. It took three hours and forty-five minutes to dry completely, but the color of the powder has changed with the naked eye.

[0036] The drying step that above-mentioned powder is carried out using device of the present invention is:

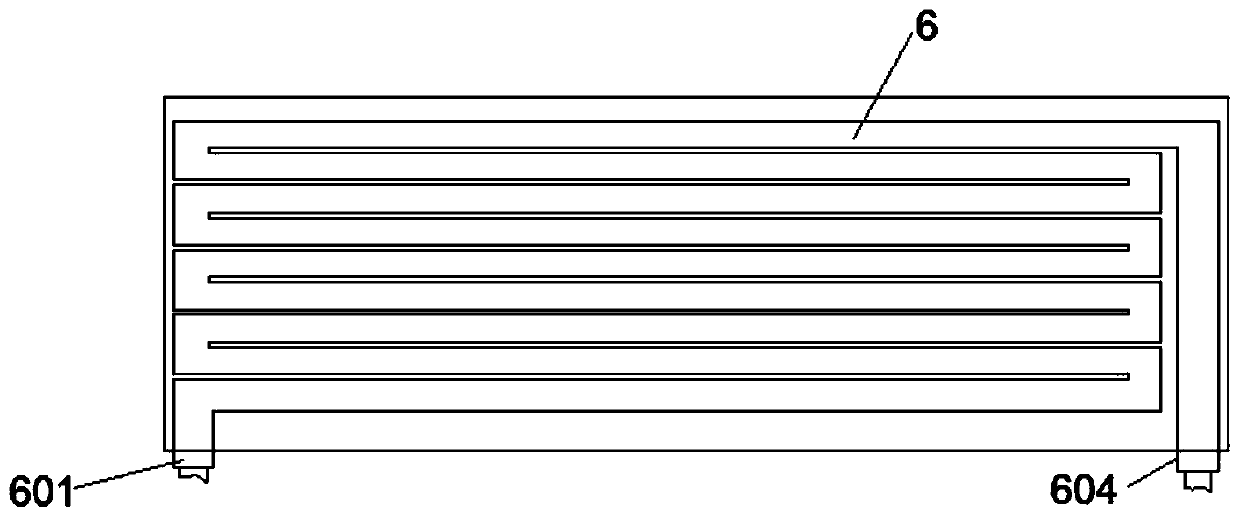

[0037] ① Open the water inlet valve 602 to let the residual hot water fill the U-shaped pipe 6;

[0038] ②Open the feed furnace door 9, put in two trays of materials and cl...

Embodiment 2

[0042] Use device of the present invention to carry out dry treatment to Fe-Cr-B-Si-C thermal spray welding alloy powder, and processing technology still carries out by the production technology of embodiment 1; Send 50 kg of Fe-Cr-B-Si-C powder and Fe-P-Cu-C powder to an external unit, and dry them in a vacuum oven. The drying temperature is set within 150°C, and it takes five hours to complete the drying fifty minutes.

[0043] Carry out oxygen content analysis to powder at last, the result is: the dry Fe-Cr-B-Si-C powder O of device of the present invention 2 Content 0.826%, vacuum-dried Fe-Cr-B-Si-C powder O 2 O content of 0.83%, vacuum-dried Fe-P-Cu-C powder 2 The content is 0.195%.

[0044] It can be seen that when the content of active metals in the powder is high, drying under vacuum will also increase oxygen. The reason is that ① the powder cannot be turned under vacuum, which prolongs the drying time. ② The temperature of vacuum drying is high and the time is long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com