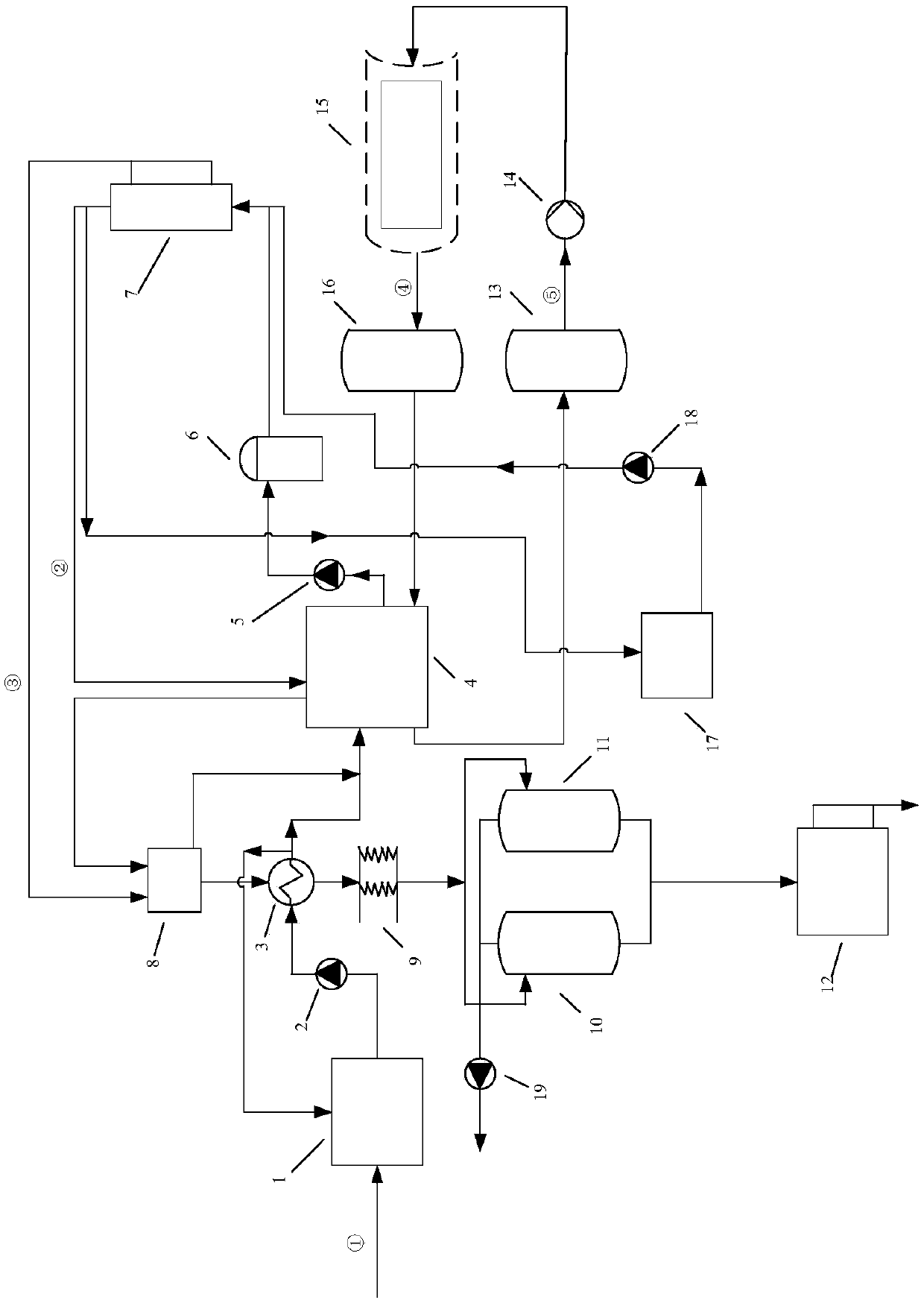

Solar energy and heat pump membrane distillation system

A solar heat pump and solar collector technology, applied in the field of membrane separation, can solve problems such as unstable operation, large heat loss, and low membrane flux, and achieve the effects of reduced operating costs, efficient recycling, and high system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067]In a city in my country’s Type 3 sunshine area, under typical sunny weather conditions in summer, the outdoor ambient temperature is 29-36°C during the day and 25-29°C at night, and high salt water with a conductivity of 50,000μs / cm in a petrochemical enterprise is used as raw water , using the solar heat pump membrane distillation system of the present application for processing. Before starting the operation, the raw water is indirectly heated by the solar heat collector 15, and the solar heat pump membrane distillation system starts to operate when the raw water is heated to a temperature of 70°C. During operation, the heat pump is used to recover the latent heat of steam discharged from the steam of the membrane distillation unit and the heat source provided by the solar collector 15 is used to supplement the heat of the waste water to be treated in the constant temperature water tank 4, so that the temperature of the waste water to be treated is maintained at a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com