Equipment capable of supplying heat by using blast furnace slag air-quenching granulated particle waste heat based on flash evaporation technology

A technology of blast furnace slag and air quenching, which is applied in the field of equipment based on flash evaporation technology to use the waste heat of blast furnace slag air quenching granulation particles to provide heat, which can solve the problems of energy consumption, water resource pollution, environmental pollution, etc., and achieve the effect of stabilizing the heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

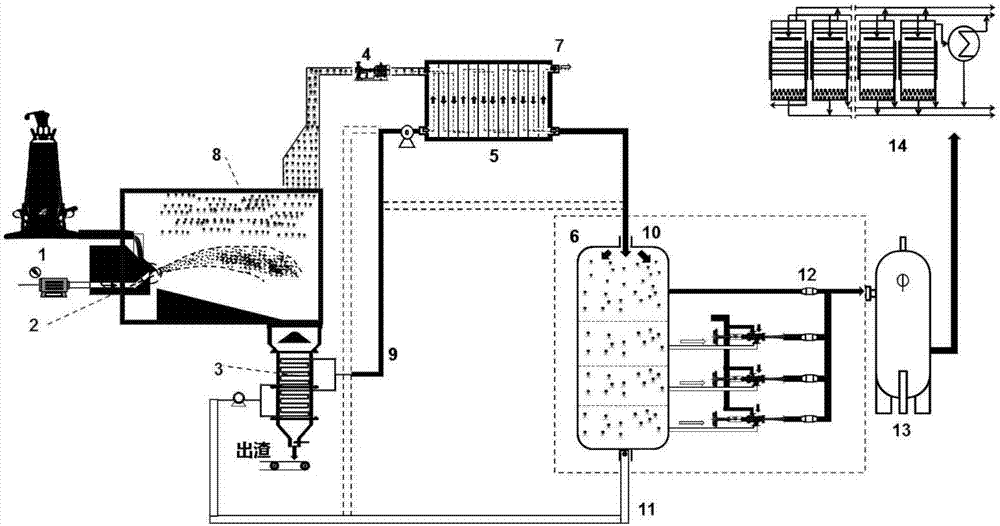

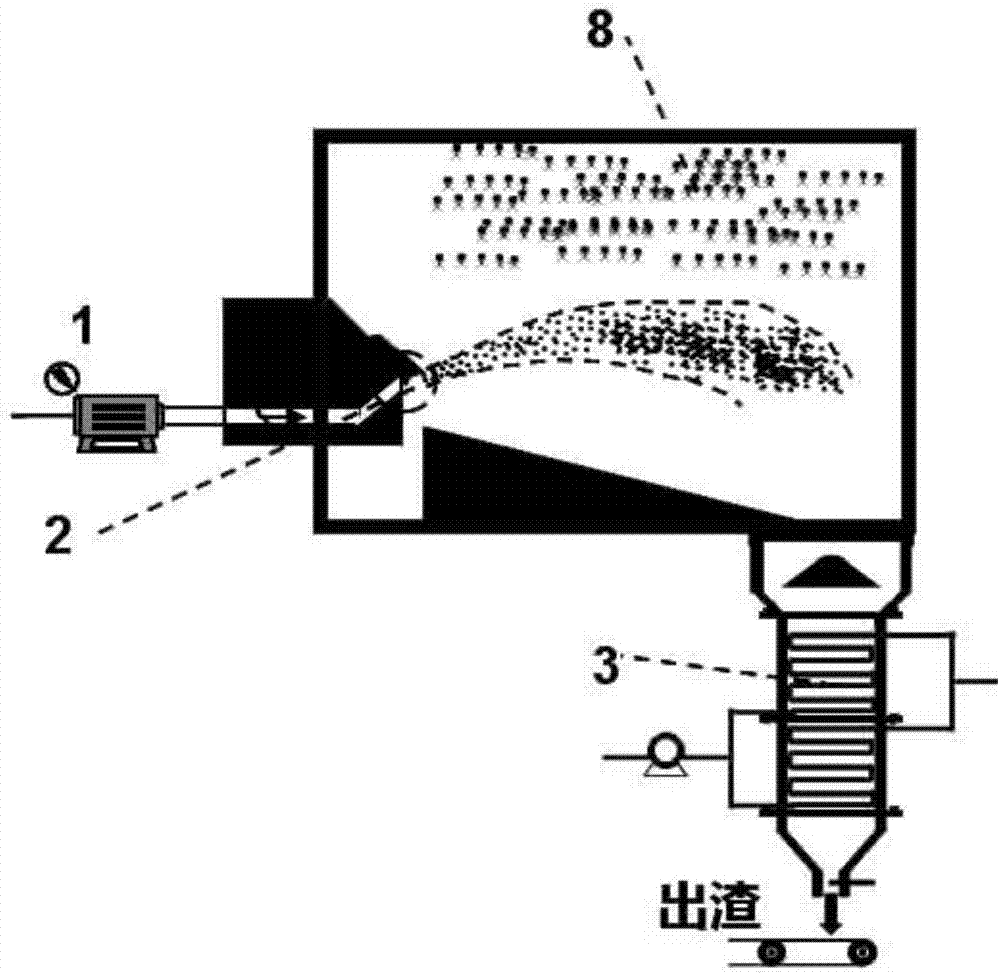

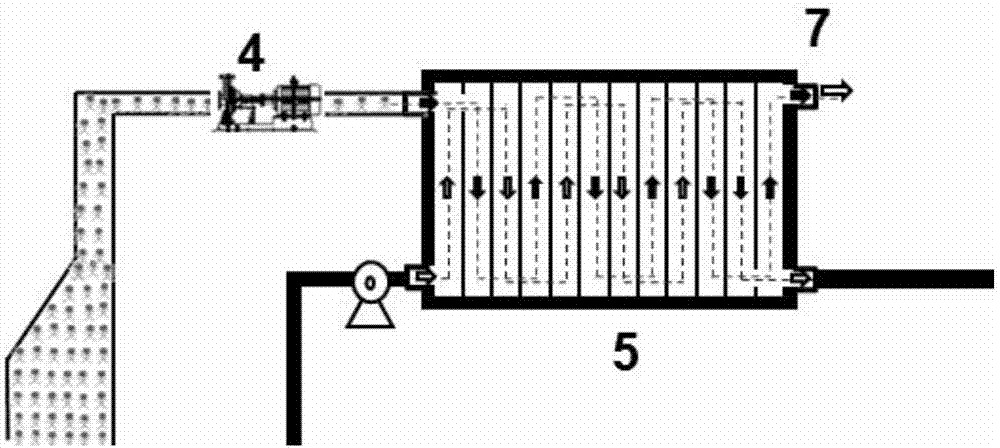

[0018] The invention provides a kind of equipment based on the flash technology to use the residual heat of blast furnace slag air-quenched granulated particles to supply heat, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the equipment includes an air-quenching granulation waste heat recovery device, a high-temperature clean water heating and upgrading device, and a deep negative pressure multi-stage flash evaporation device 6, and the air-quenching granulation waste heat recovery device includes a Laval nozzle array 2 and an artesian bed exchanger Heater 3, high-temperature clean water heating constitution device includes booster pump 4, air-water heat exchanger 5 and flue gas outlet 7; blast furnace 1 is connected to Laval nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com