On-line solid solution treatment method for copper alloy used for lead frame

A solid solution treatment and lead frame technology, applied in the field of alloy materials, can solve problems such as difficulty in achieving results, increasing investment, and difficult processing, and achieve low cost, energy saving, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

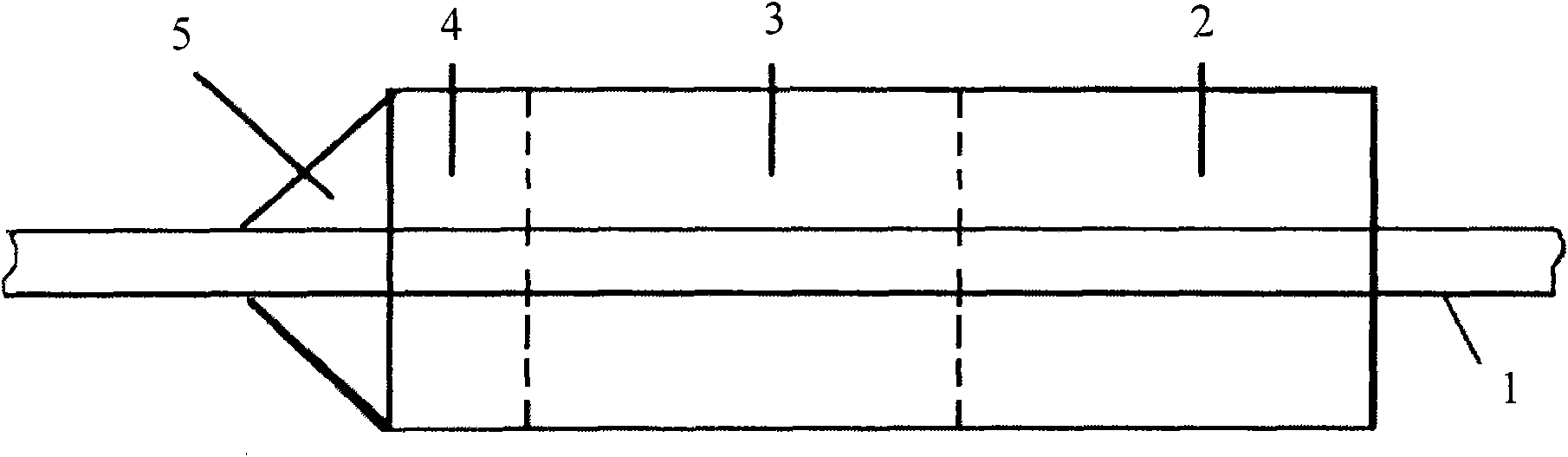

[0028] According to the method shown in the invention, the precipitation strengthening type Cu-Fe-P alloy in actual production was tested, and the alloy composition is shown in Table 1 below. Embodiment Considering the heat loss between the heat insulation layers, the method that the temperature of the strong heating zone is slightly higher than the temperature of the heat preservation zone (in practice, the temperature can be adjusted as required), the temperature of the strong heating zone is 860 ° C, and the length of this zone is 0.8 m; the temperature of the heat preservation area is 850°C, and the length of this area is 4.2m; the temperature of the temperature compensation area is 900°C, and the length of this area is 0.2m.

[0029] Table 1 Composition of Cu-Fe-P alloy used in test

[0030] alloy(%)

Fe

P

Zn

Impurities

Cu

Component range

2.1~2.4

0.01~0.035

0.1~0.15

≤0.01

margin

[0031] In the test, the ...

Embodiment 2

[0036] According to the method shown in the invention, the precipitation strengthening type Cu-Ni-Si alloy in actual production was tested, and the alloy composition is shown in Table 1 below. Embodiment Considering the heat loss between the heat insulation layers, the method that the temperature of the strong heating zone is slightly higher than the temperature of the heat preservation zone (in practice, the temperature can be adjusted as required), the temperature of the strong heating zone is 920 ° C, and the length of this zone is 0.72 m; the temperature of the heat preservation area is 900°C, and the length of this area is 7.2m; the temperature of the temperature compensation area is 1020°C, and the length of this area is 0.36m.

[0037] Table 1 Composition of Cu-Fe-P alloy used in test

[0038] alloy(%)

Ni

Si

Mg

Impurities

Cu

Component range

2.8~3.4

0.3~0.65

0.01~0.05

≤0.01

margin

[0039] In the test, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com