Garbage incinerator with built-in chimney

A technology of waste incinerator and inner chimney

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

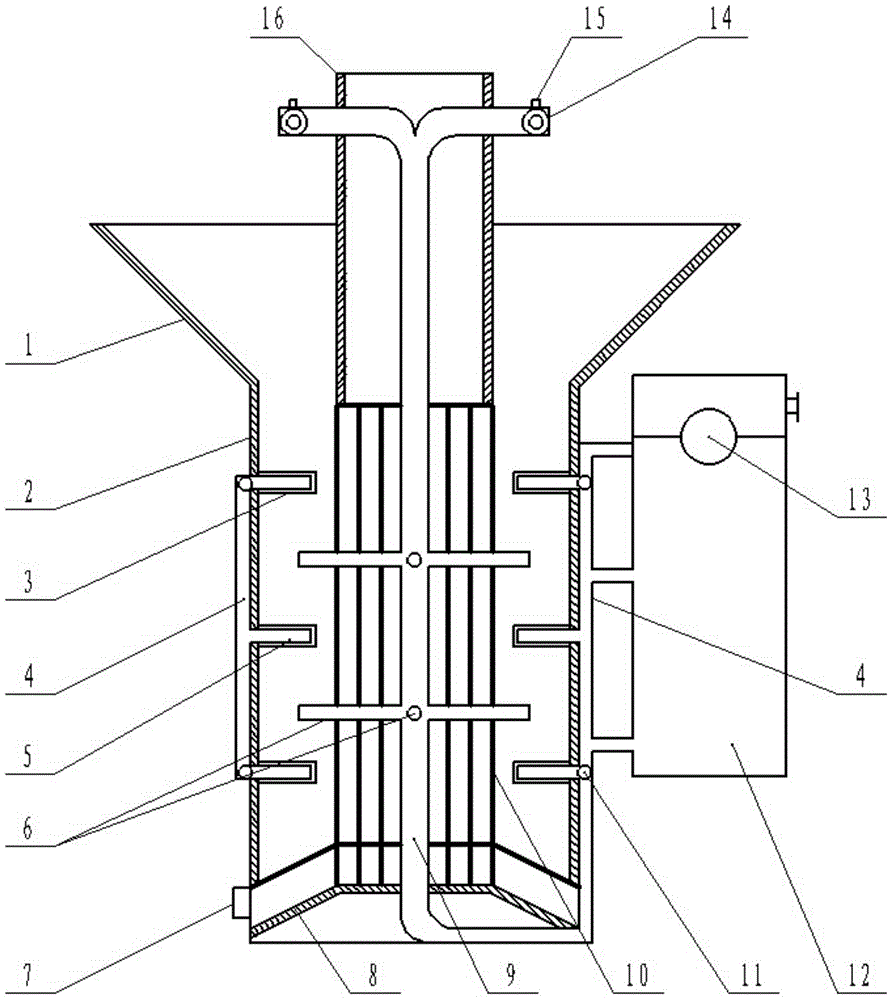

Embodiment 1

[0030] An inner chimney type garbage incinerator comprises a furnace body 2, a combustion chamber, a feed hopper 1, a support 10 and a chimney 16. The furnace body 2 is cylindrical. A feed hopper 1 is arranged above the furnace body 2, and a bracket 10 is arranged in the middle of the furnace body 2. The bracket 10 is in the shape of a long cage and is welded by a plurality of vertical seamless steel pipes and horizontal seamless steel pipes at a certain distance. Furnace body 2 and support 10 constitute combustion chamber, furnace body 2 and the bottom end of support 10 are provided with furnace bar and inclined plate 8, and described furnace bar is set as oblique type, and inclined plate 8 is conical, and is fixed on inclined plate 8 bracket10. The top of the support 10 is provided with a chimney 16 , the lower end of the chimney 16 is arranged in the feed hopper 1 , and the upper end is higher than the feed hopper 1 . The bottom of the furnace body 2 is provided with a co...

Embodiment 2

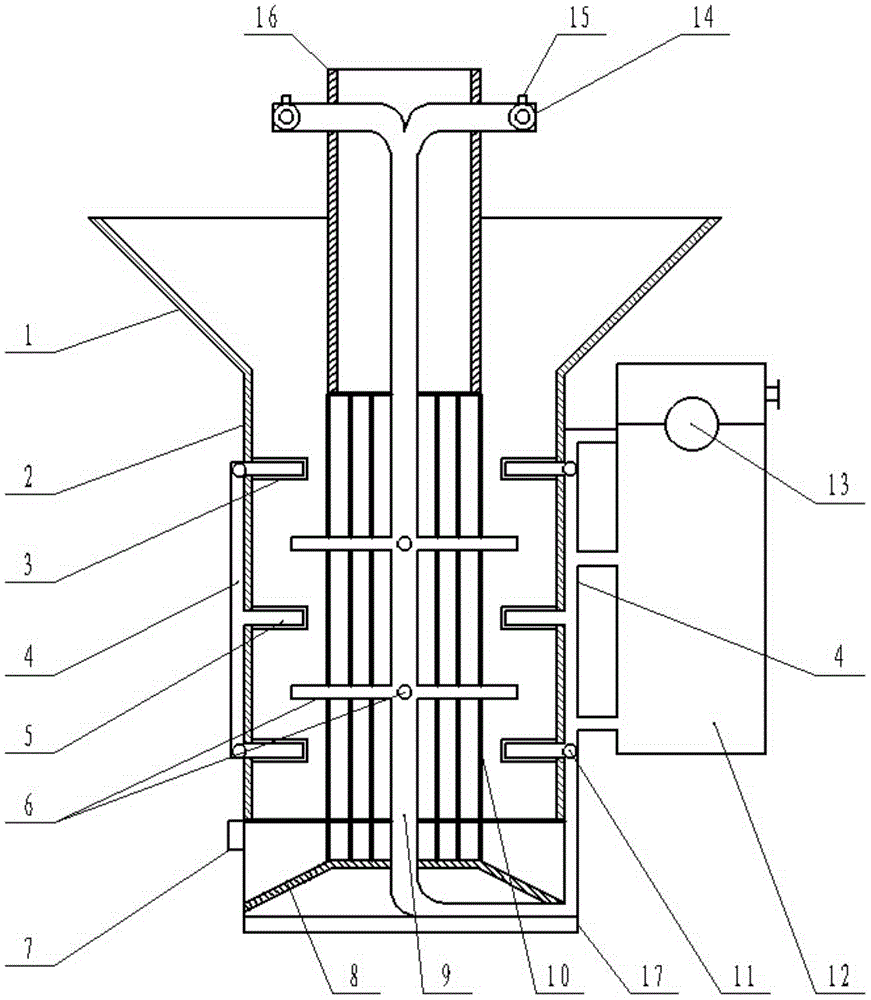

[0033]An inner chimney type garbage incinerator comprises a furnace body 2, a combustion chamber, a feed hopper 1, a support 10 and a chimney 16. The body of furnace 2 is in the shape of a square tube, and a fixed base 17 is arranged at the lower end. A feed hopper 1 is arranged above the furnace body 2, and a bracket 10 is arranged in the middle of the furnace body 2. The bracket 10 is in the shape of a long cage and is welded by a plurality of vertical seamless steel pipes and horizontal seamless steel pipes at a certain distance. Furnace body 2 and support 10 constitute combustion chamber, furnace body 2 and the bottom end of support 10 are provided with furnace bar and inclined plate 8, and described furnace bar is arranged as horizontal, inclined plate 8 is square cone shape, on inclined plate 8 Fixed bracket 10. The top of the support 10 is provided with a chimney 16 , the lower end of the chimney 16 is arranged in the feed hopper 1 , and the upper end is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com