Novel cyclone bias pulverized coal burner

A technology of thick and light pulverized coal and burners, which is applied in the direction of burners, burners burning powder fuel, and combustion types, etc., can solve the problems of high ignition temperature, poor flammability, low volatile content, etc., achieve high-efficiency combustion, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

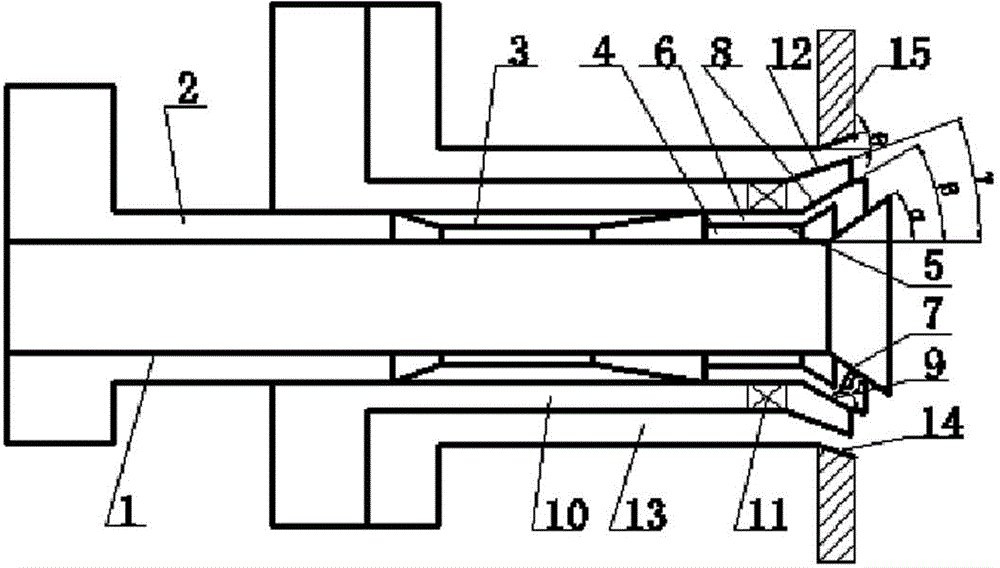

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

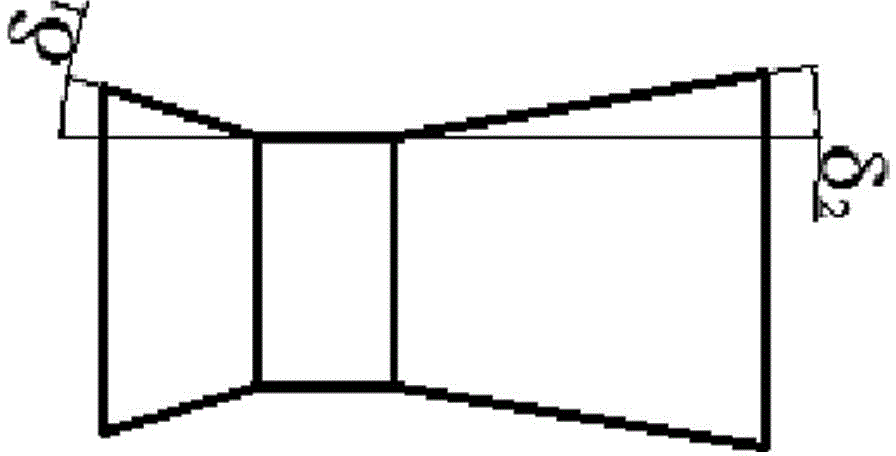

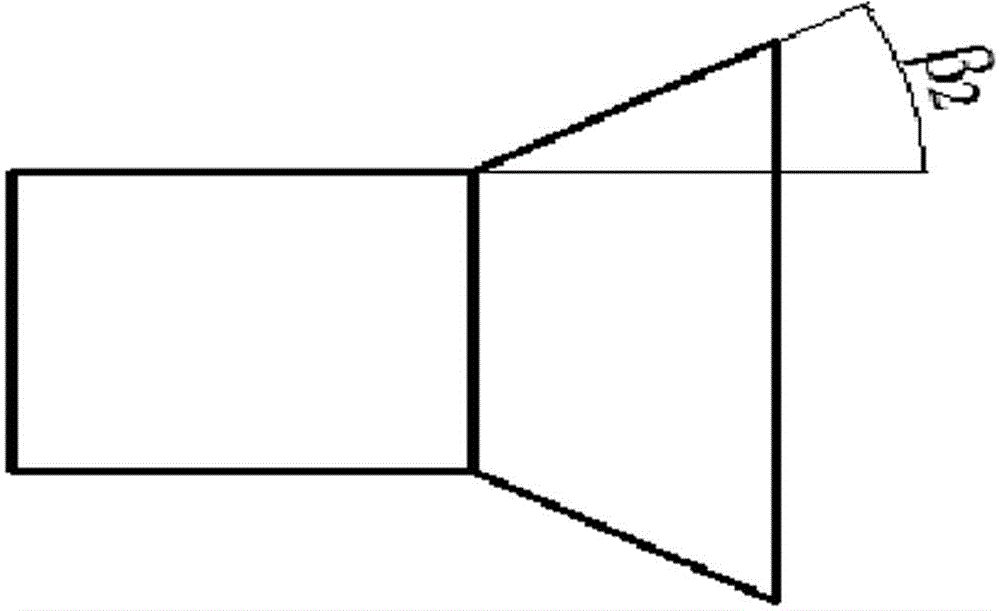

[0020] A new type of swirling thick-lean pulverized coal burner, including a center pipe, a primary air channel, a coal powder concentrating device, an inner primary air channel, an outer primary air channel, a coal powder thick-lean separation sleeve device, and a flared central tube from the inside to the outside. , Sleeve flaring, primary air duct flaring, secondary air channel, cyclone, secondary air duct flaring, tertiary air channel, tertiary air duct flaring, furnace wall.

[0021] The working principle is: the pulverized coal airflow sent from the primary air pulverized pipeline passes through the pulverized coal concentration device of the primary air duct and the pulverized coal concentration separation cylinder. During this transmission process, the pulverized coal enters the channel for pulverized coal concentration, forming a The thick pulverized coal airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com