Patents

Literature

76results about How to "Lower the fever" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-ejection grading combustion method and W flame boiler device for realizing same

ActiveCN101832549ALower the feverImprove flame stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir velocityCombustion

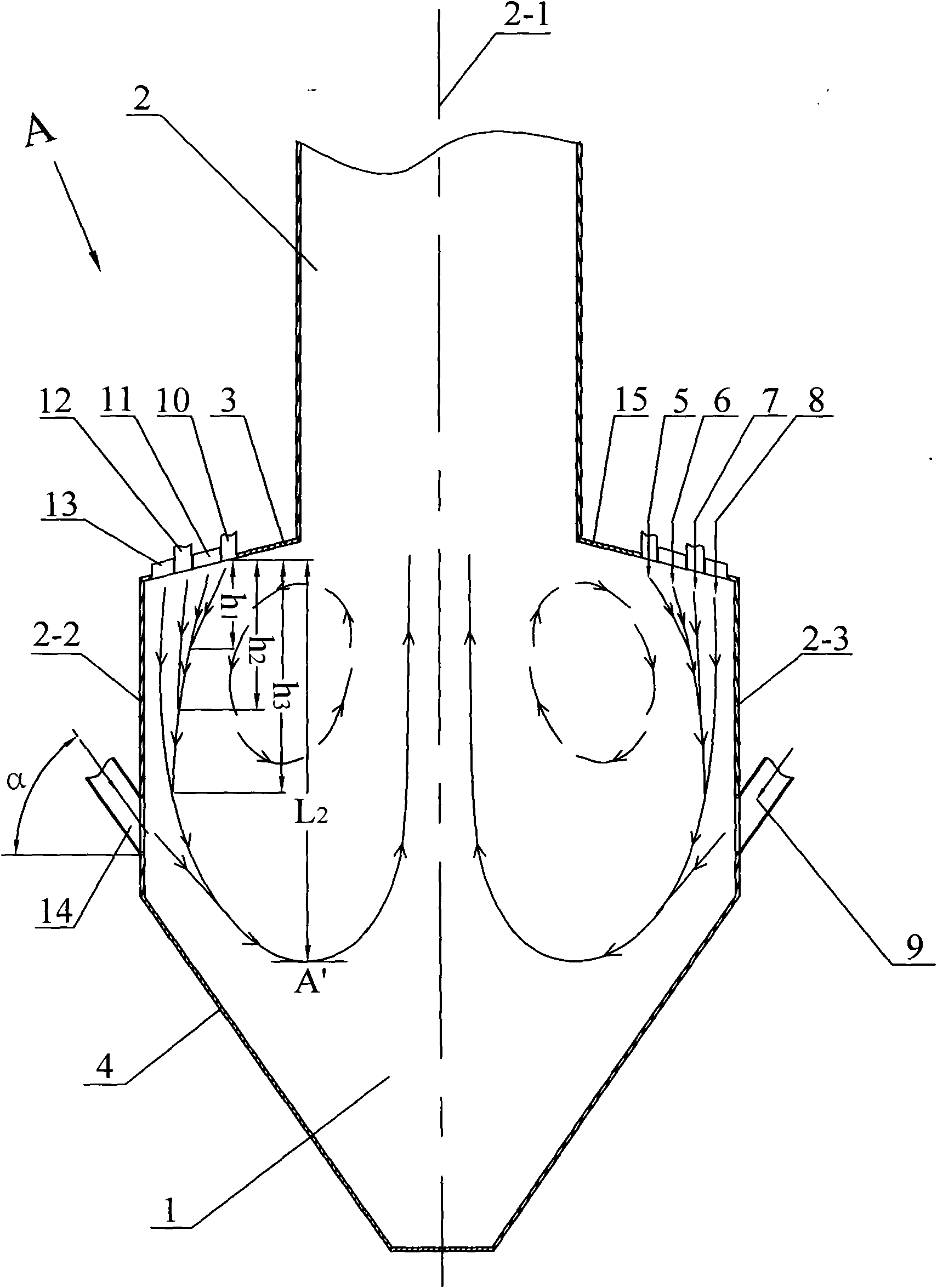

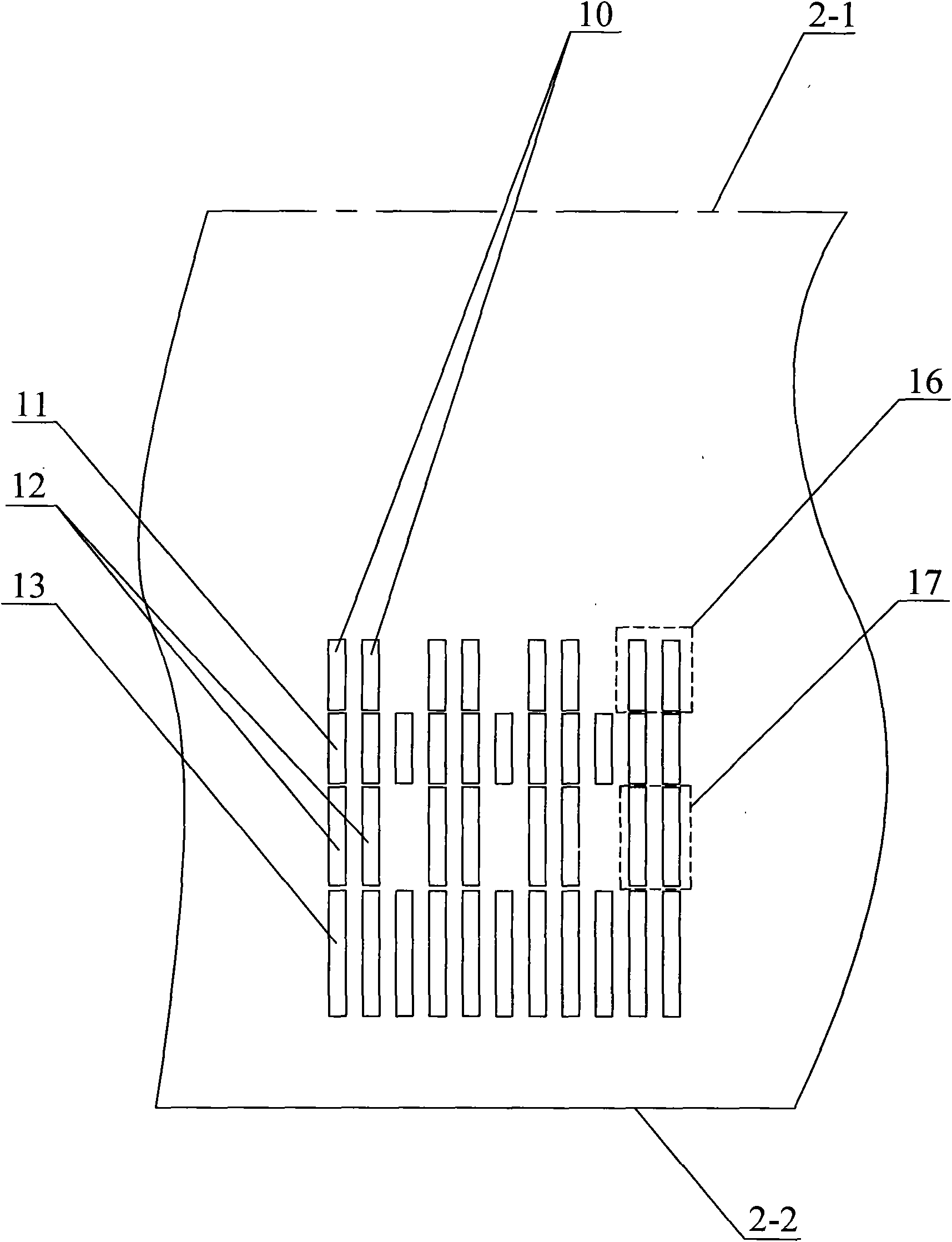

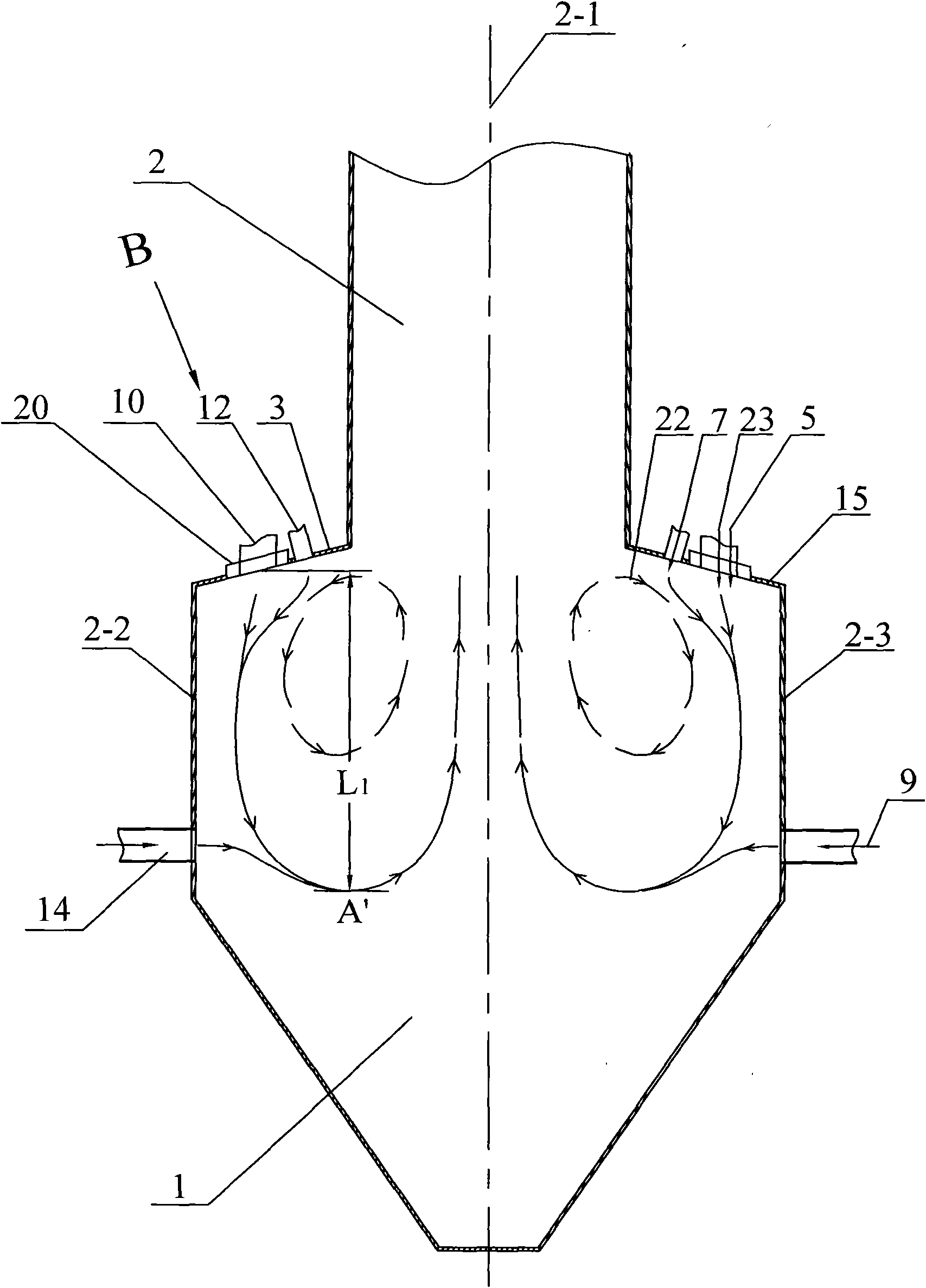

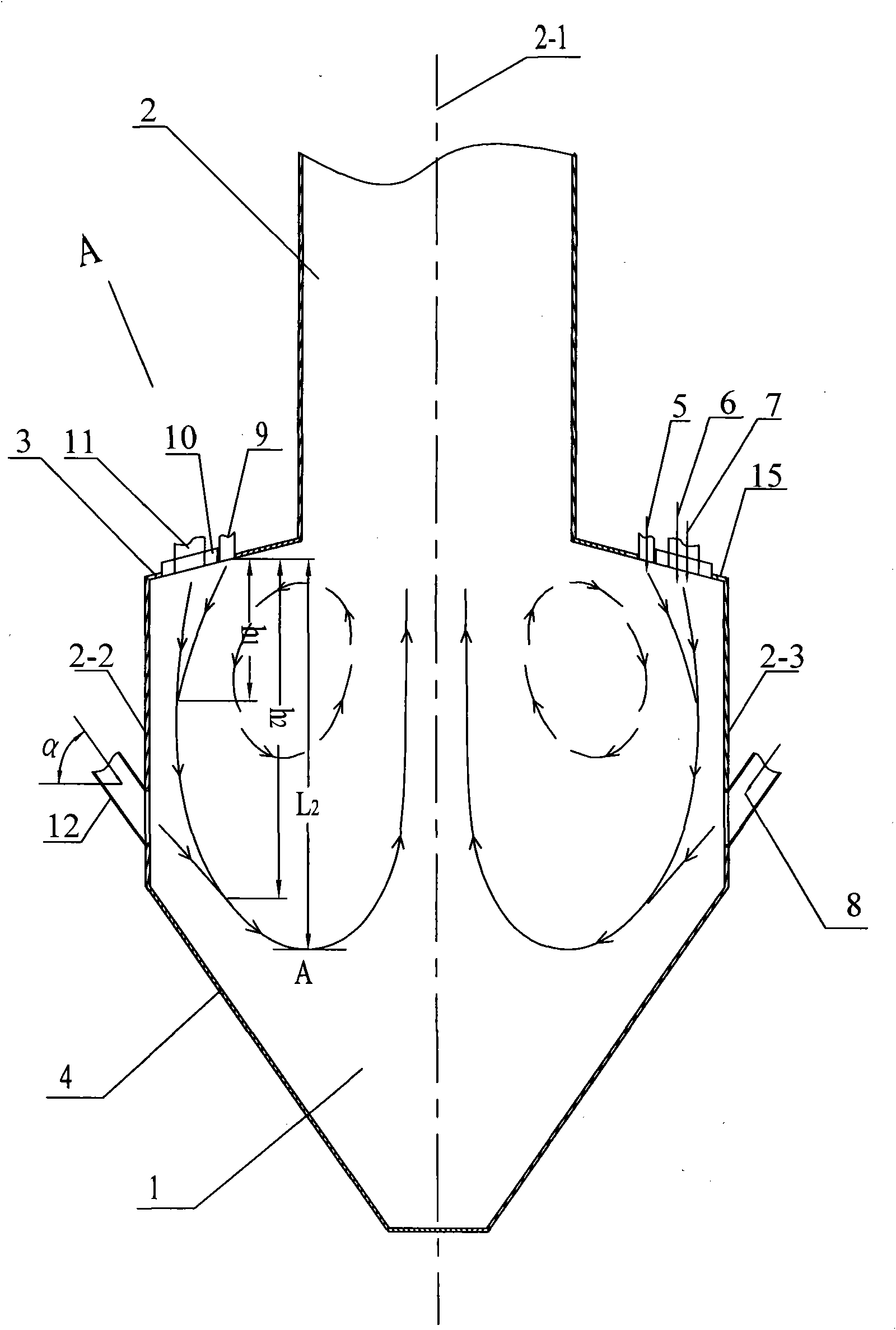

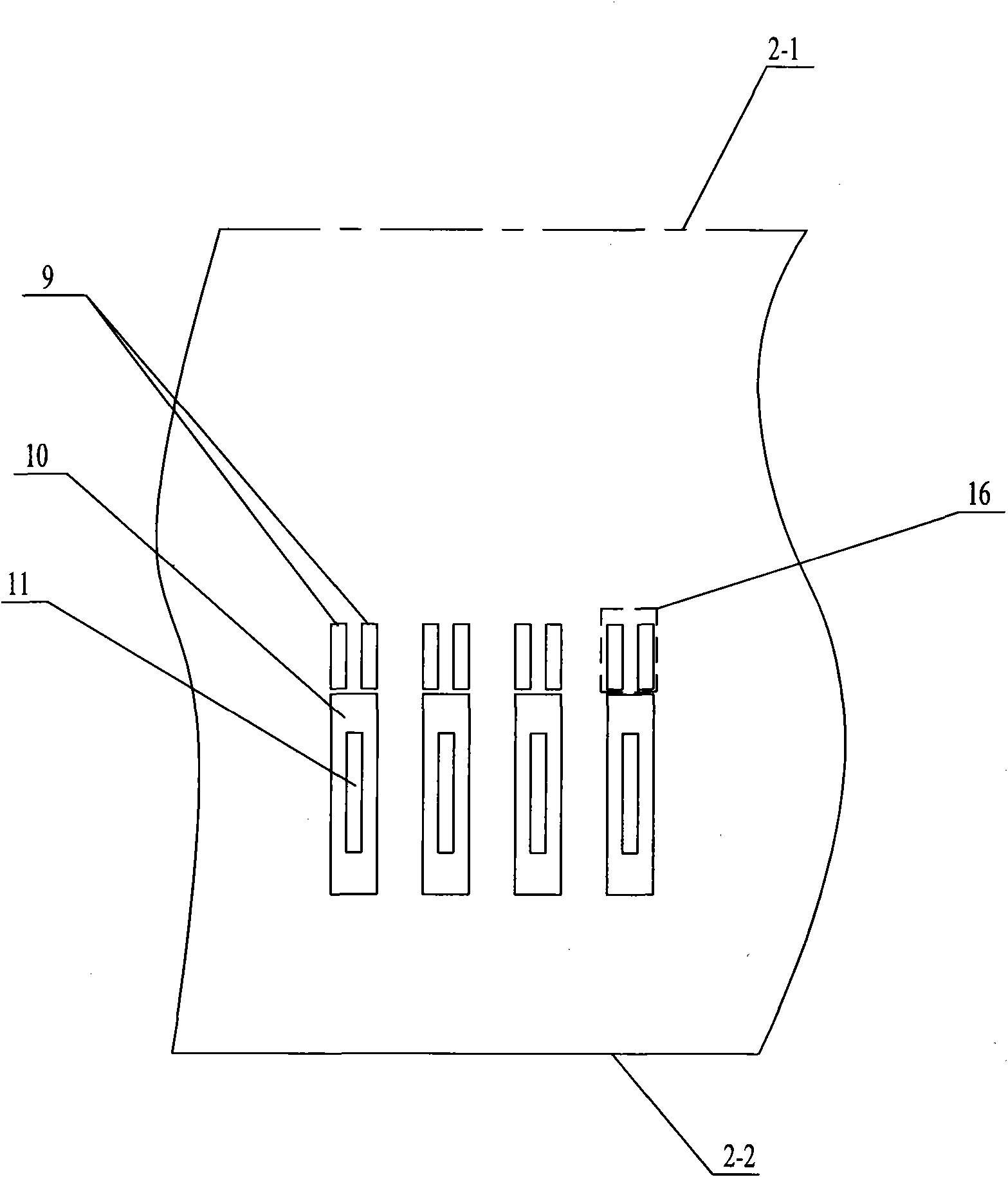

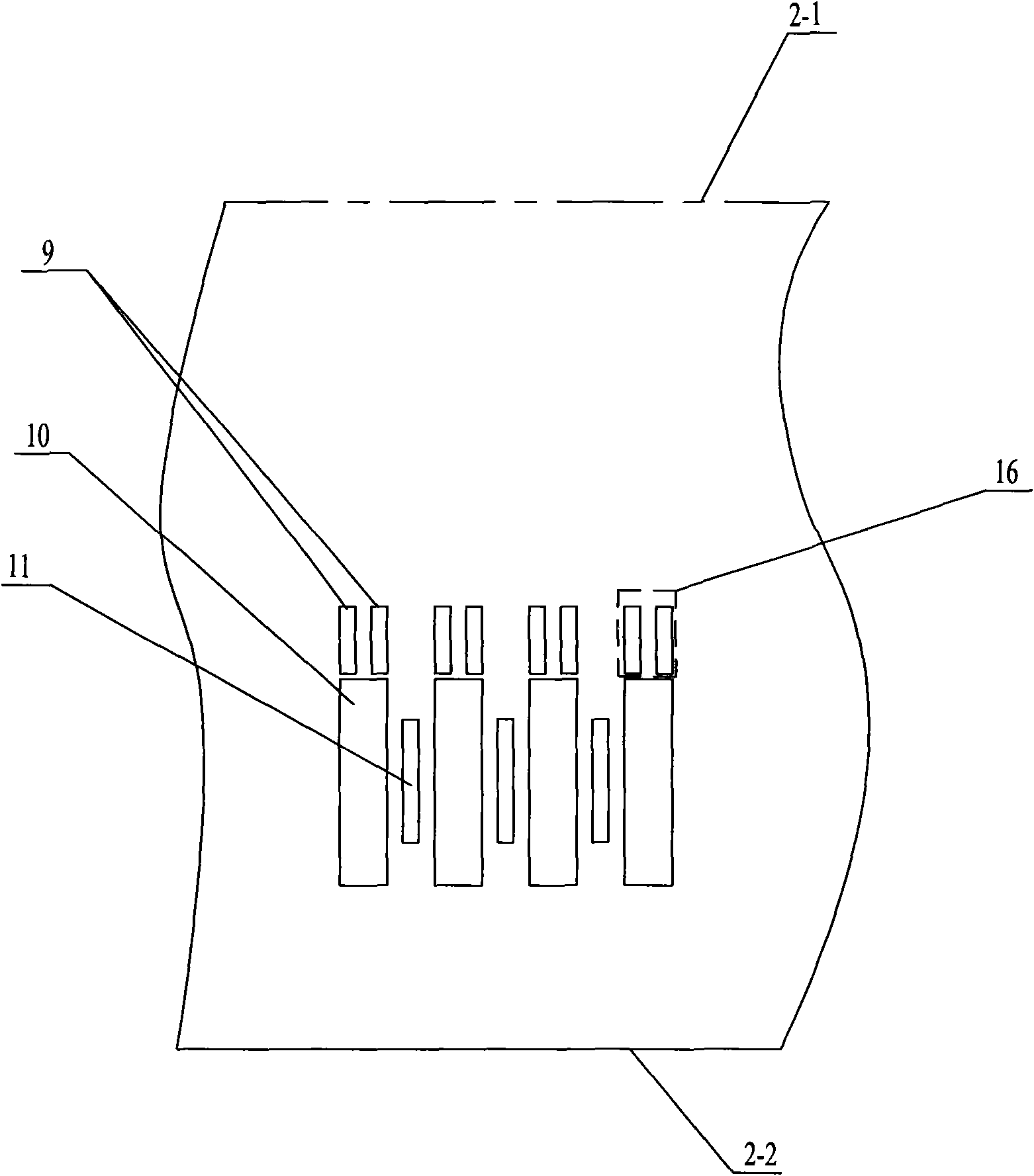

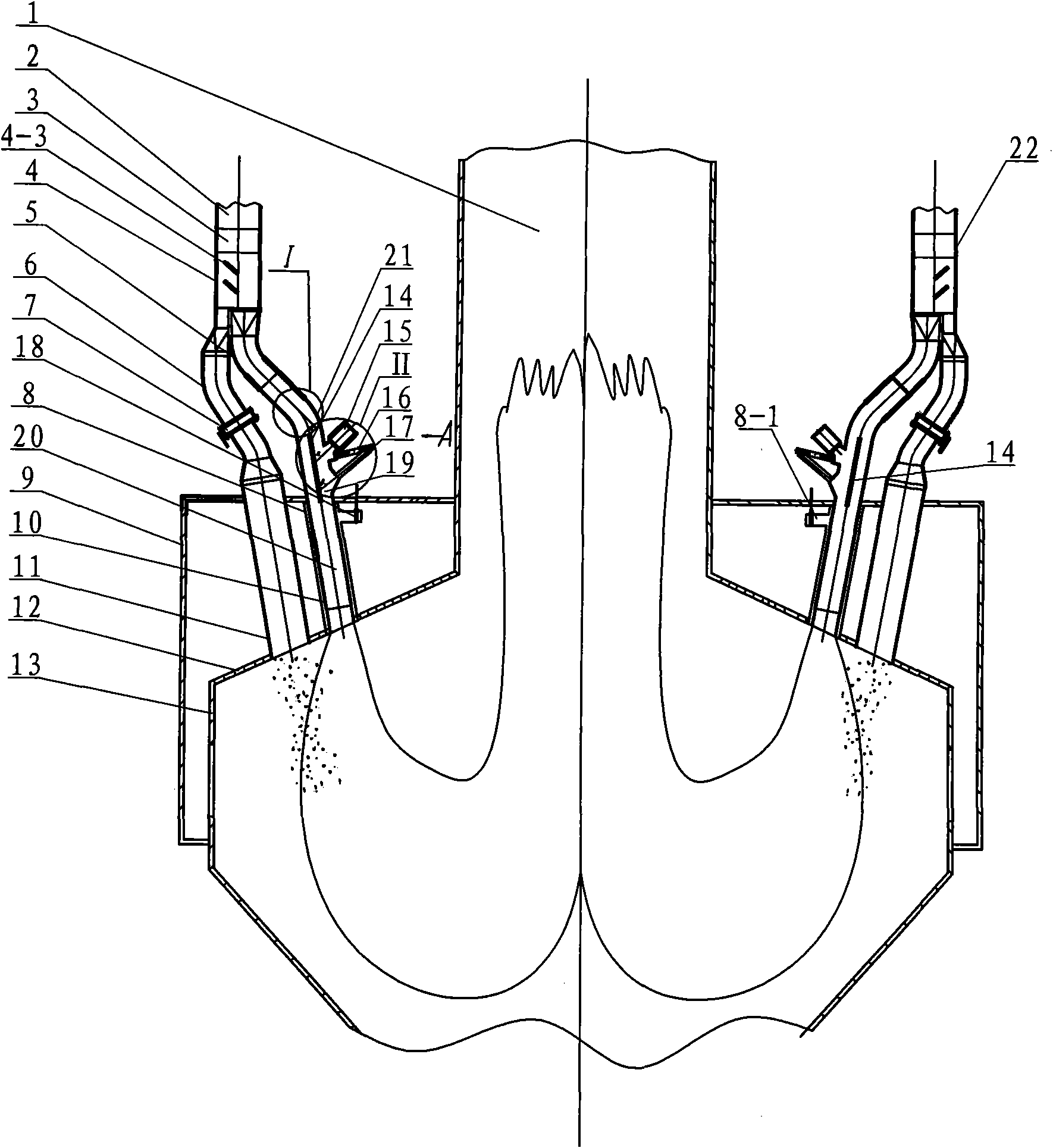

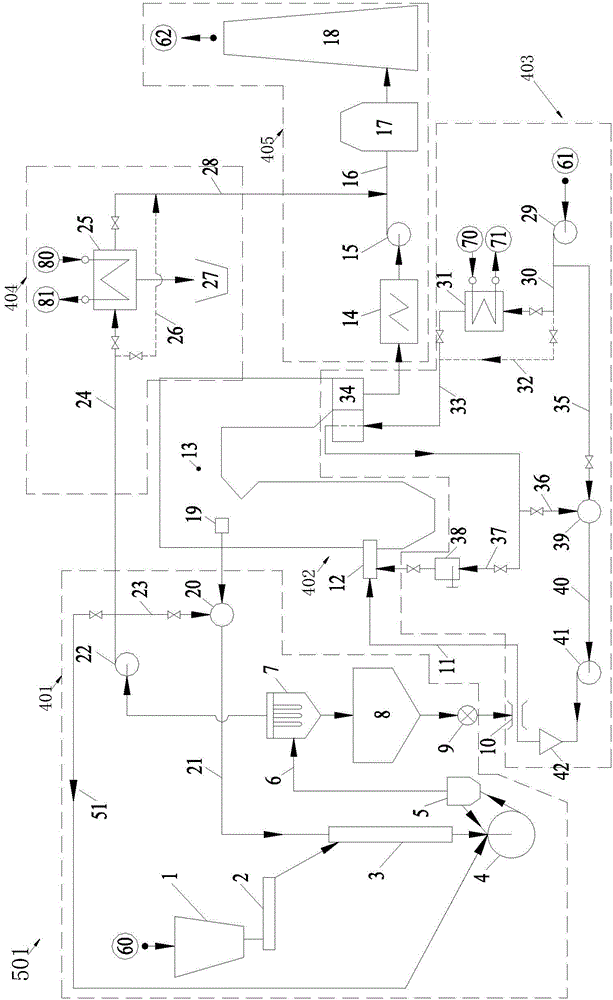

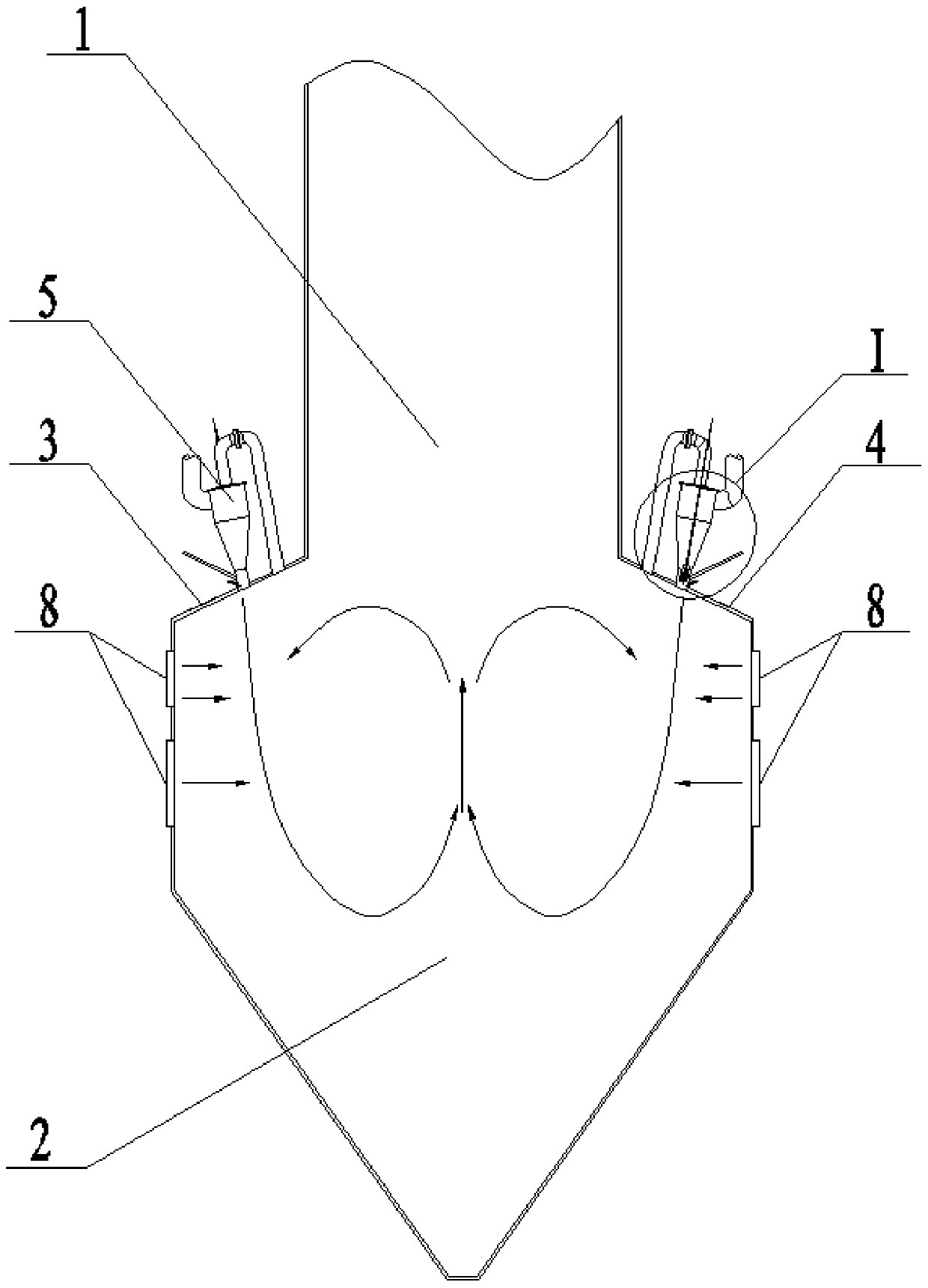

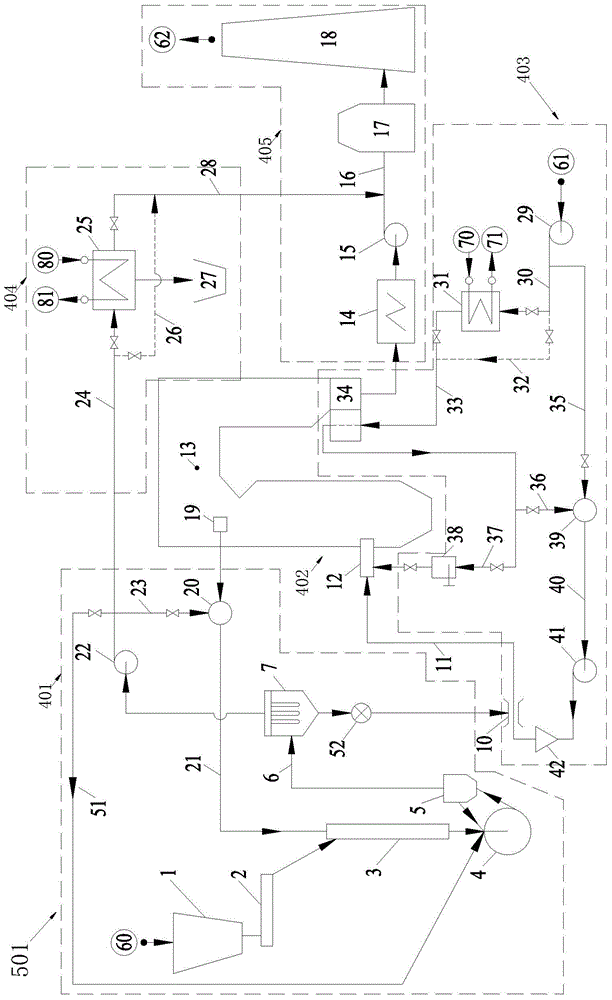

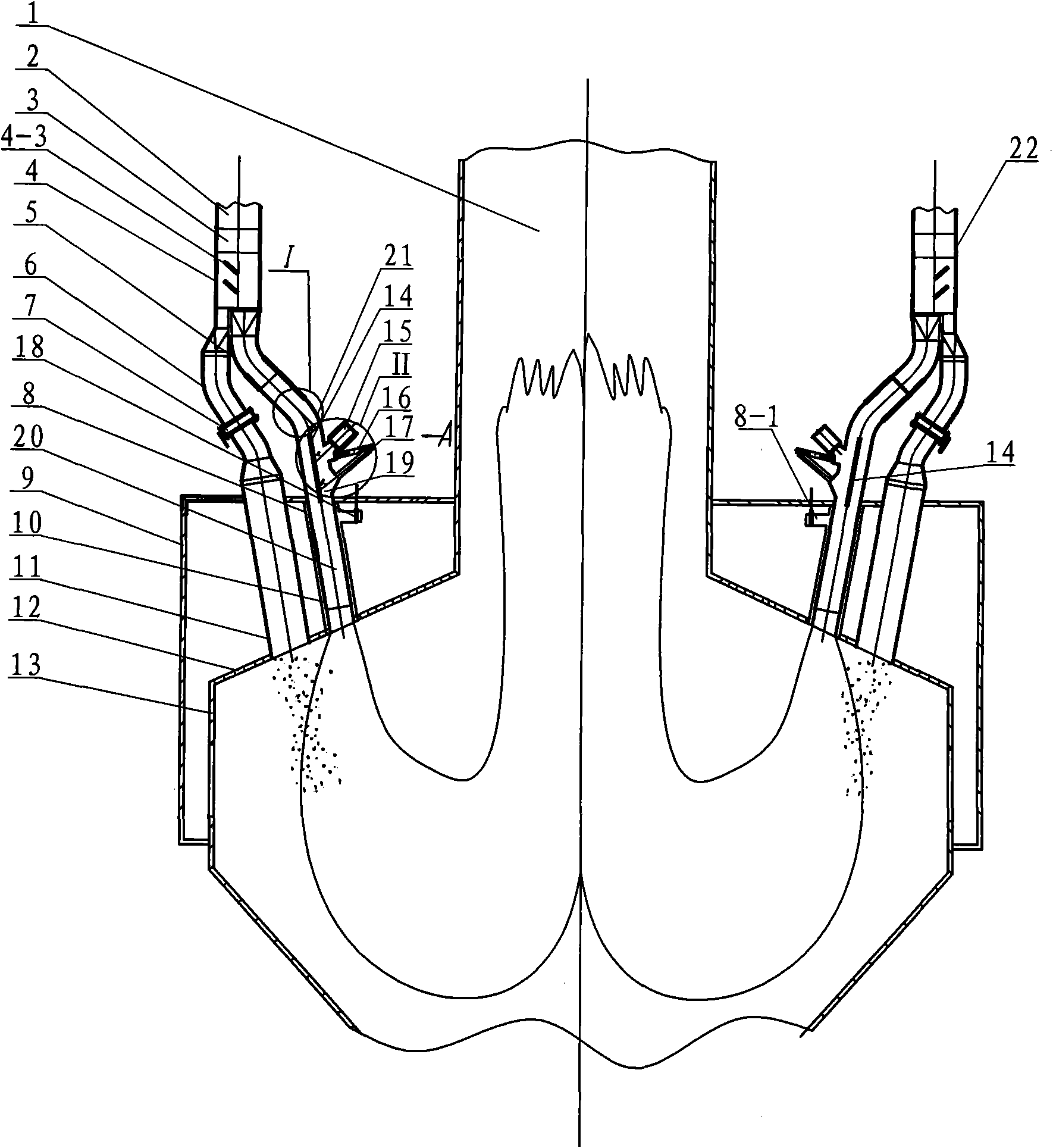

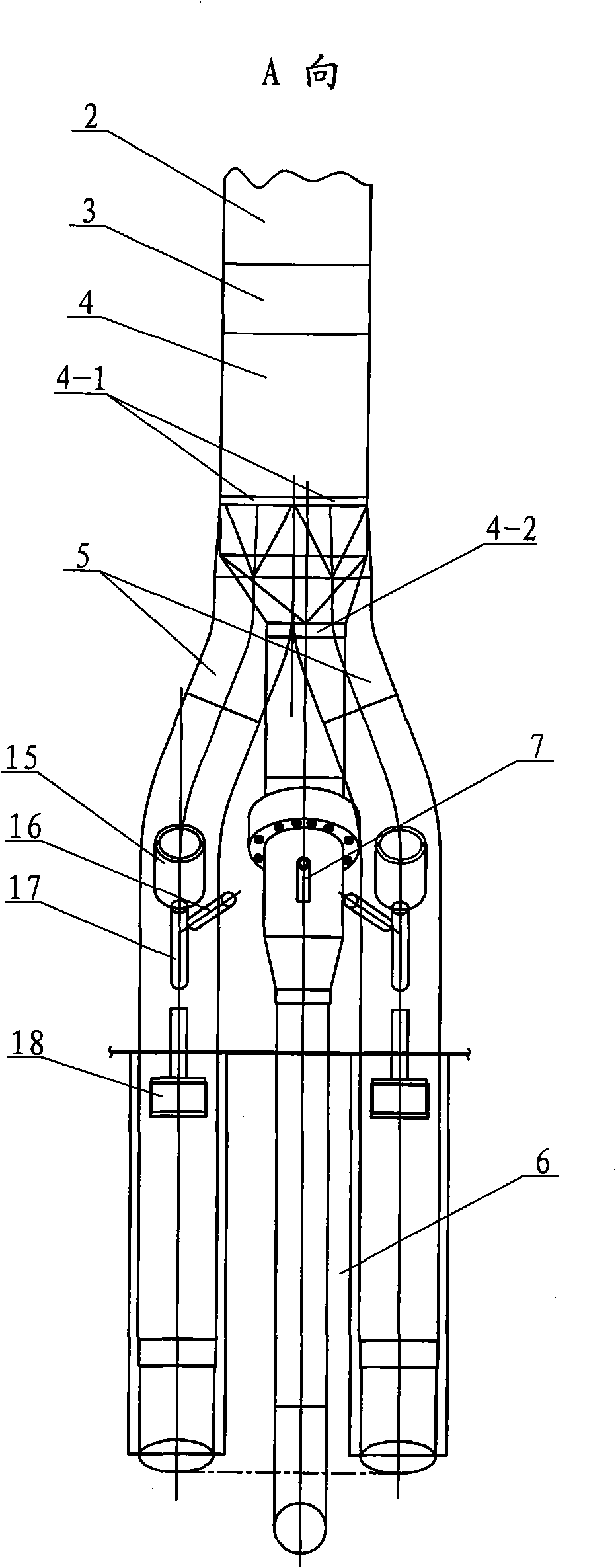

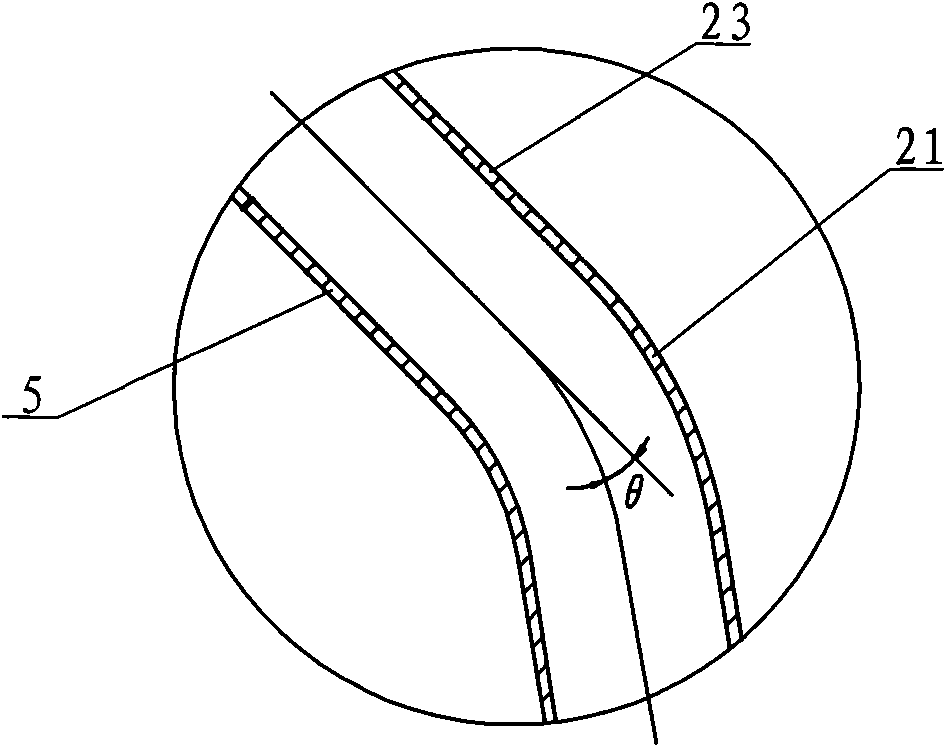

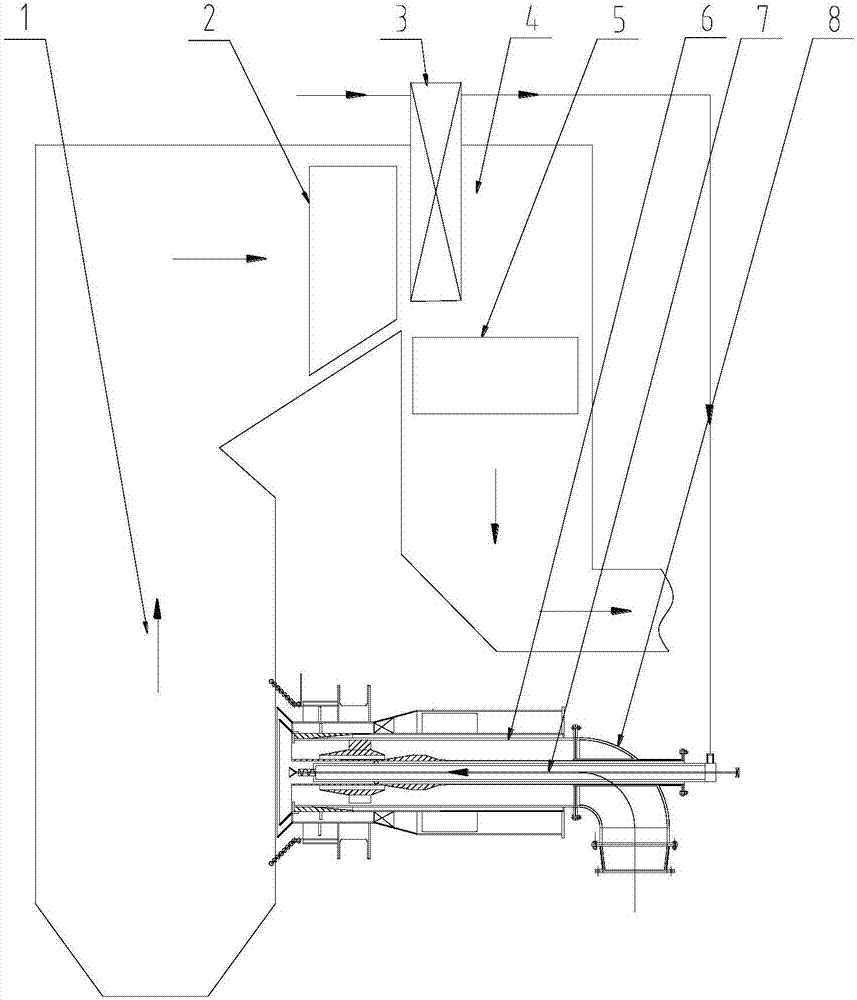

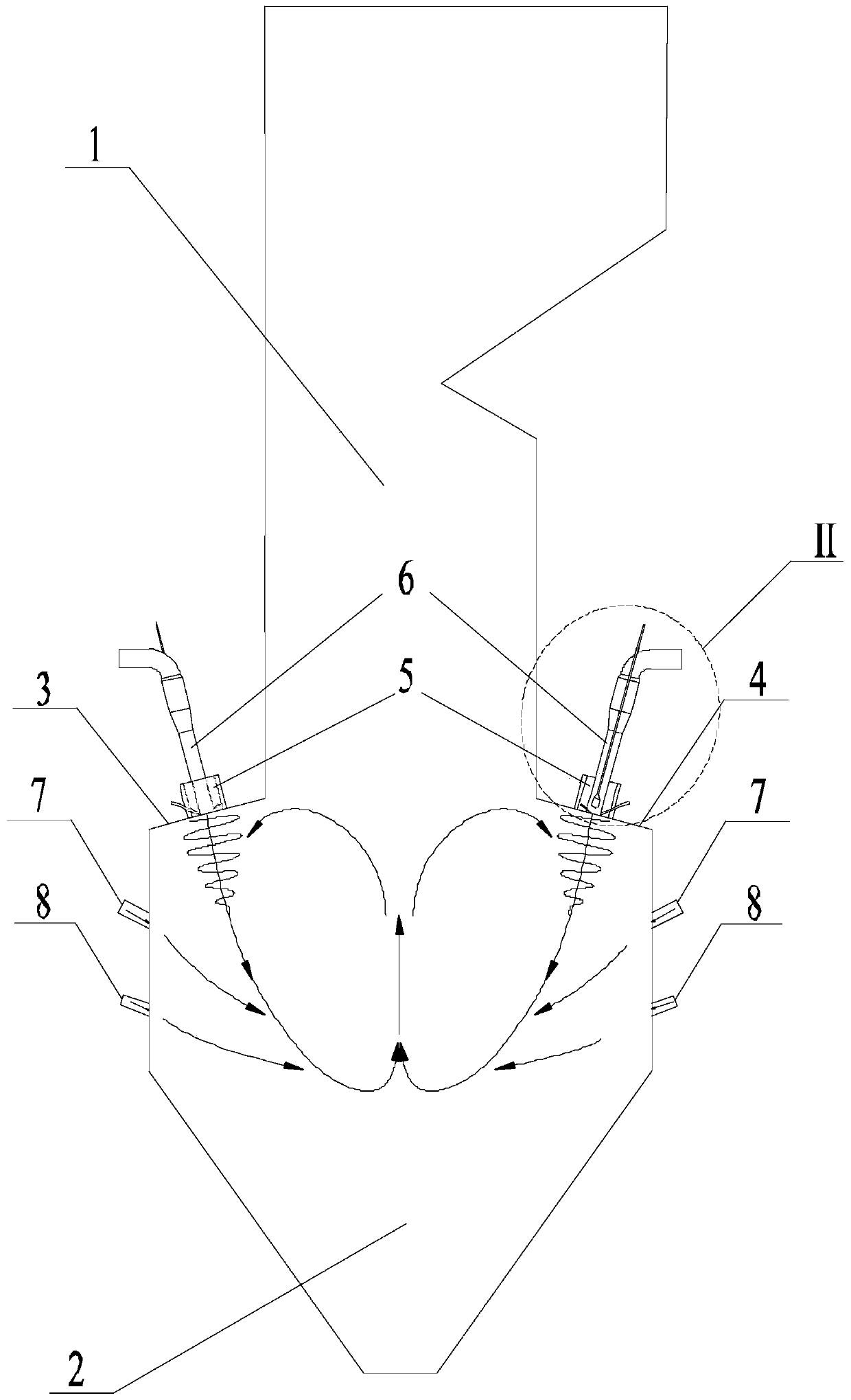

The invention discloses a W flame boiler device for realizing a multi-ejection grading combustion and a method thereof, and relates to a W flame boiler device of a grading combustion and a method, which aims at the problems of high NOx exhaust, high fly ash combustible material content, late fire of the pulverized coal airflow and bad flame stability in the W type flame boiler referred in the background technology.The method comprises the following steps of: ejecting internal and external secondary air at the air speed of 35-65m / s step by step and downwards ejecting by carrying a concentrated coal dust airflow at the air speed of 10-20m / s to realize first and second stage grading combustion; and injecting arch lower secondary air at the air speed of 35-65m / s into the lower heath by an arch lower secondary air nozzle to realize third stage grading combustion. A concentrated coal dust airflow nozzle, an internal secondary air nozzle, a light coal dust airflow nozzle and an external secondary air nozzle are sequentially distributed from the center side of the hearth to the water-cooling wall of the front and rear wall of the lower hearth on a boiler arch; and the front and rear wall of the lower hearth is provided with the arch lower secondary air nozzle along the width direction of the hearth. The invention can greatly reduce NOx exhaust and fly ash combustible material content when used for the W flame boiler.

Owner:HARBIN INST OF TECH

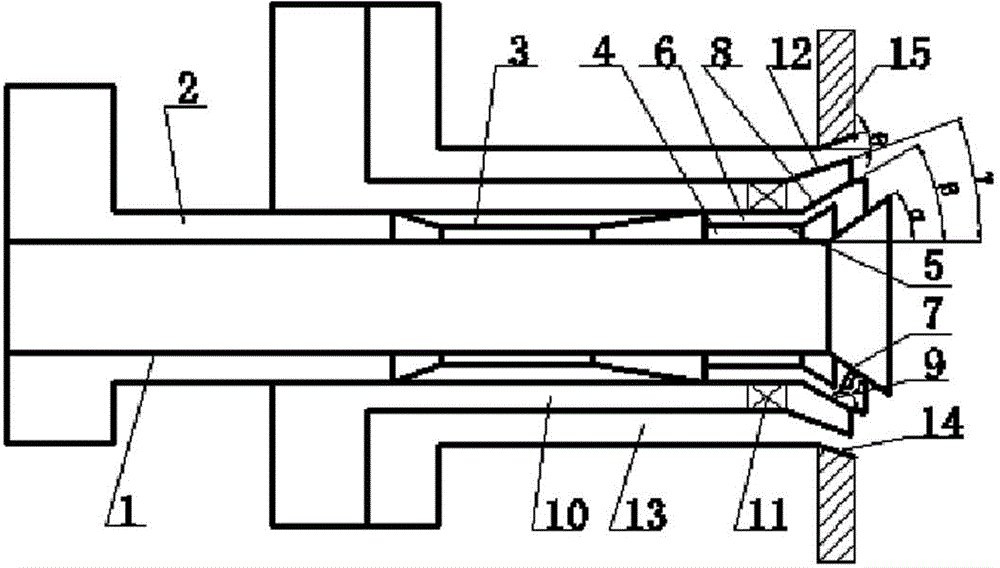

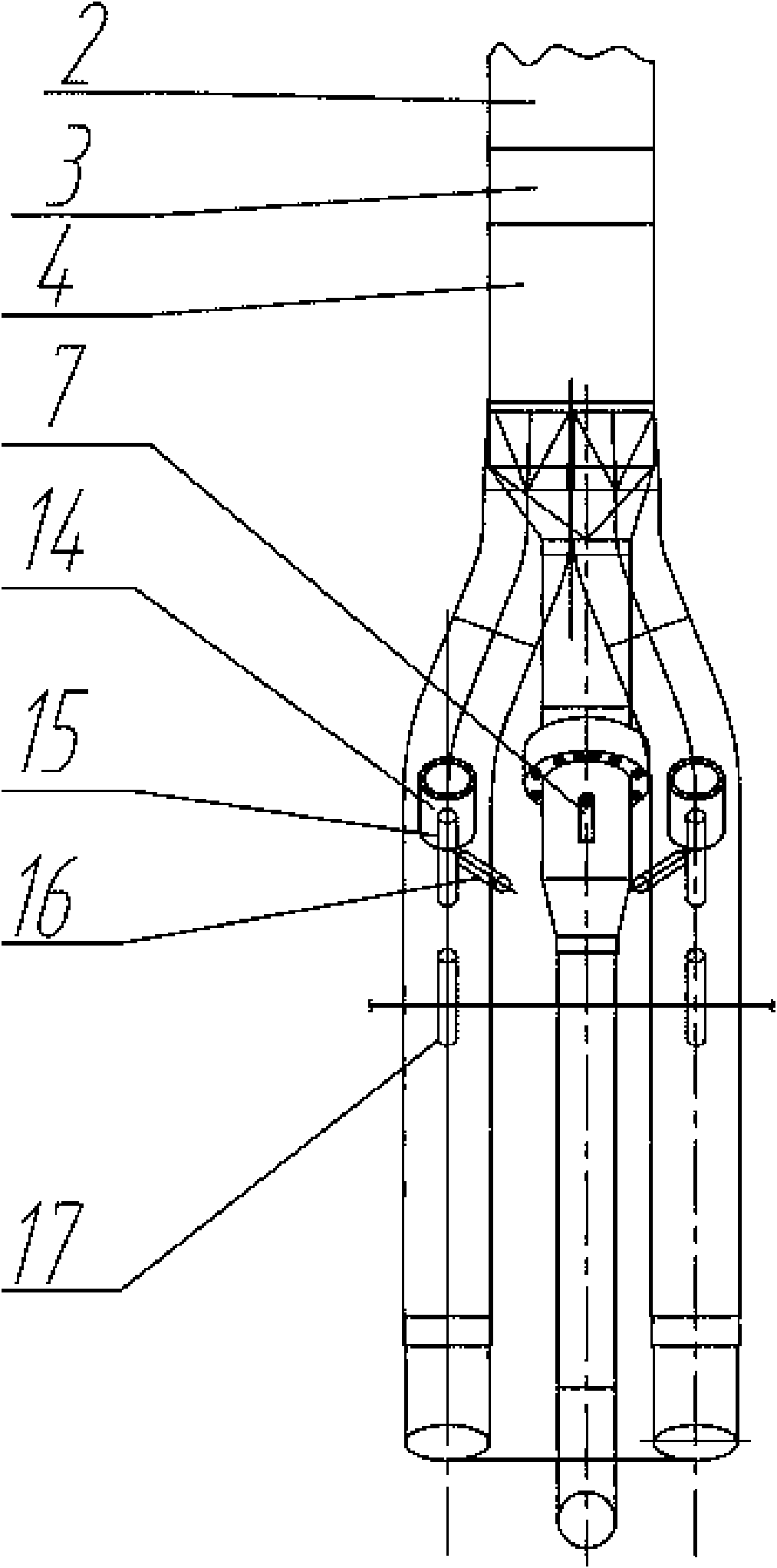

Method for arch single-stage injection fractional combustion and W flame boiler for realizing method

ActiveCN101832548AReduce combustible contentReduce slaggingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionSingle stage

A method for arch single-stage injection fractional combustion and a W flame boiler for realizing the method relate to a fractional combustion method and a W flame boiler. The invention aims at the problems that the W flame boiler has high NOx discharge, high flying ash combustible content, serious lagging on water cool wall front and behind a lower hearth and inferior flame stability. The method of the invention comprises the steps of gradually injecting through arch secondary air with an air speed of 35 to 65 m / s, taking thick coal powder airflow with the air speed of 10 to 20 m / s to inject downwards, and injecting the arch secondary air with the air speed of 35 to 65 m / s into the furnace through an arch secondary air nozzle. The boiler of the invention comprises a thick coal powder airflow nozzle, an arch secondary air nozzle and a thin coal powder airflow nozzle which are arranged on the furnace arch from the center of the furnace to the front and back water cool walls, wherein the thick coal powder airflow nozzle is abutted to the arch secondary air nozzle and an arch lower secondary air nozzle is arranged on the front and back water cool walls on the lower furnace along the width direction of the furnace. The W flame boiler for realizing the method of the invention can decrease the W flame boiler and the flying ash combustible content.

Owner:HARBIN INST OF TECH

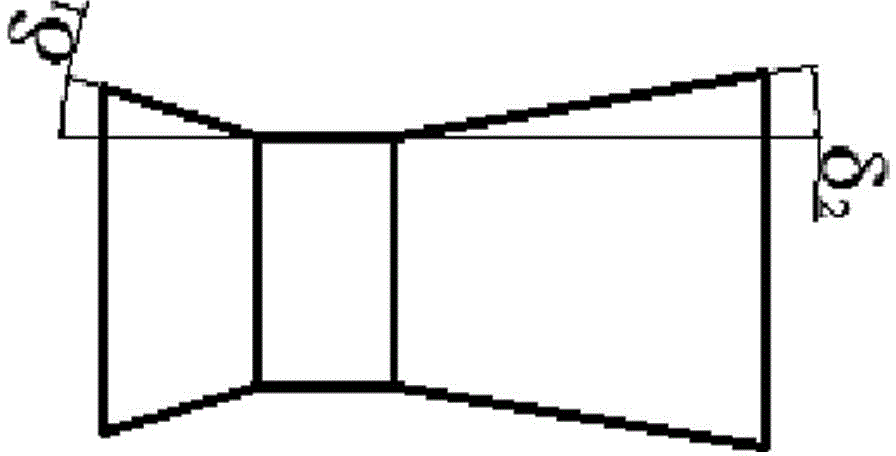

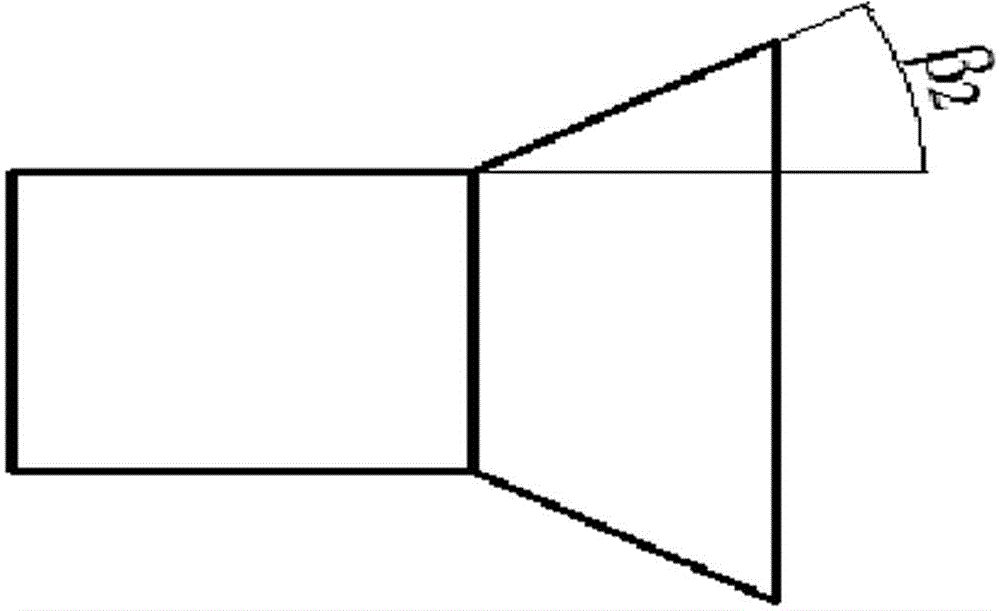

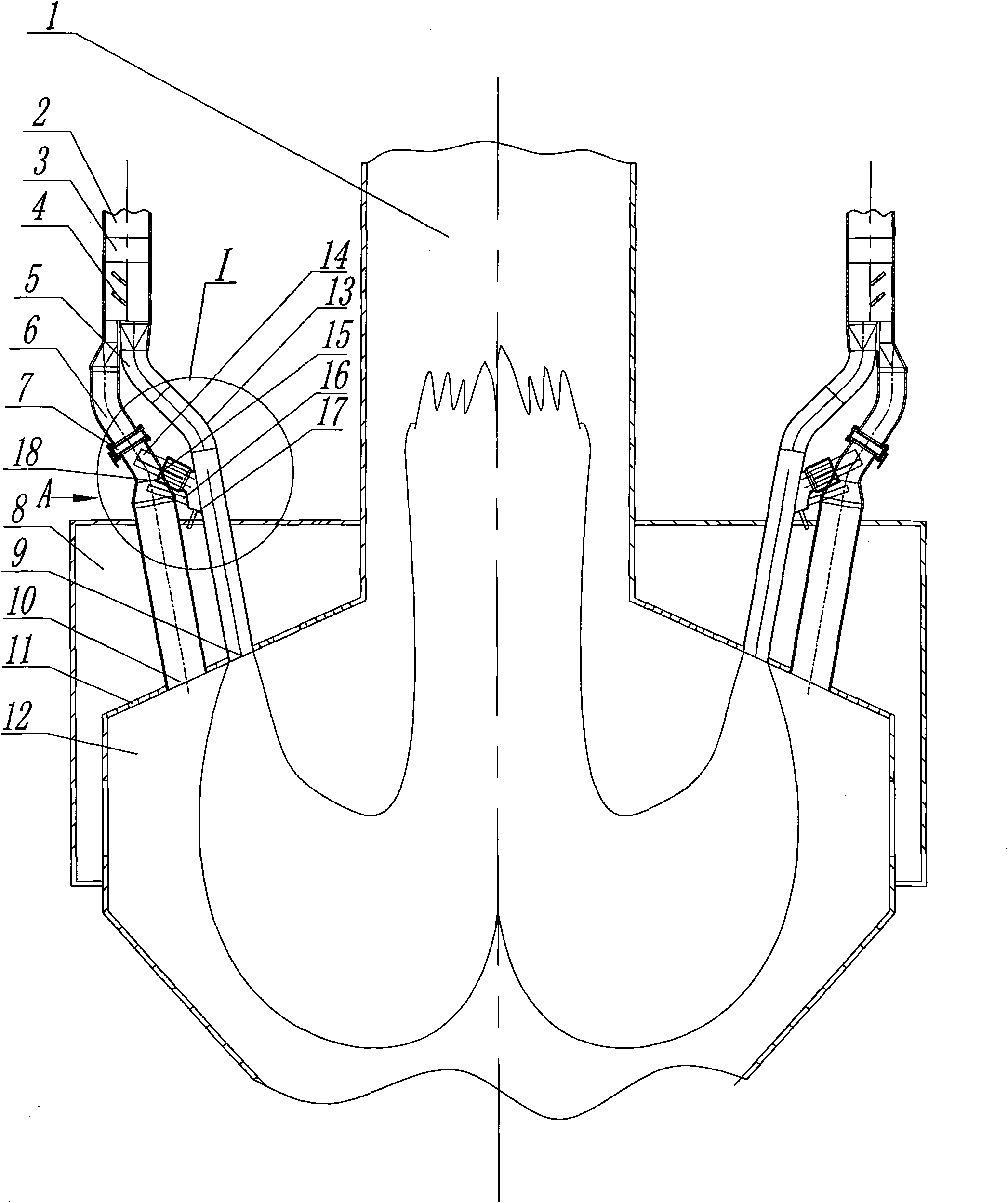

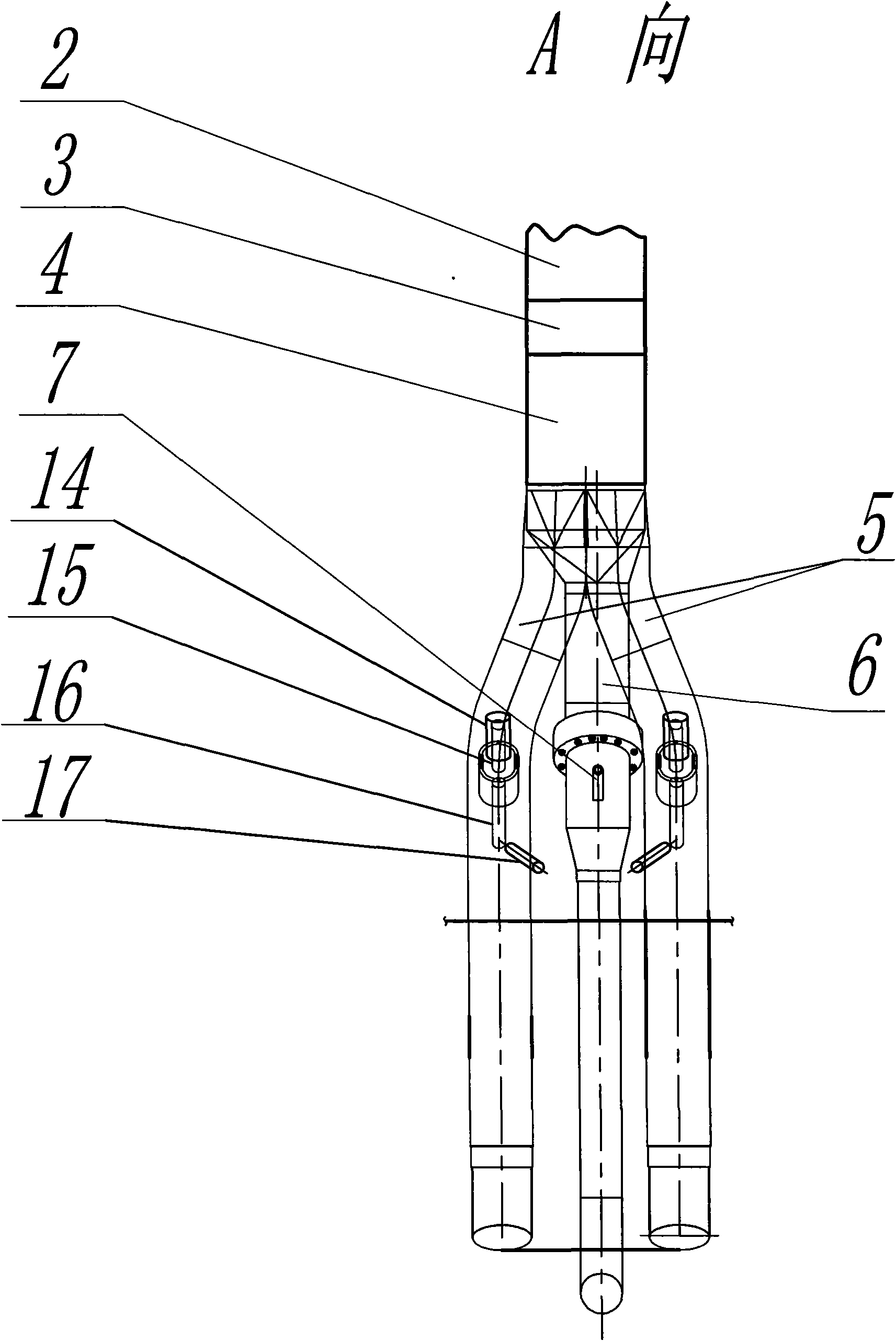

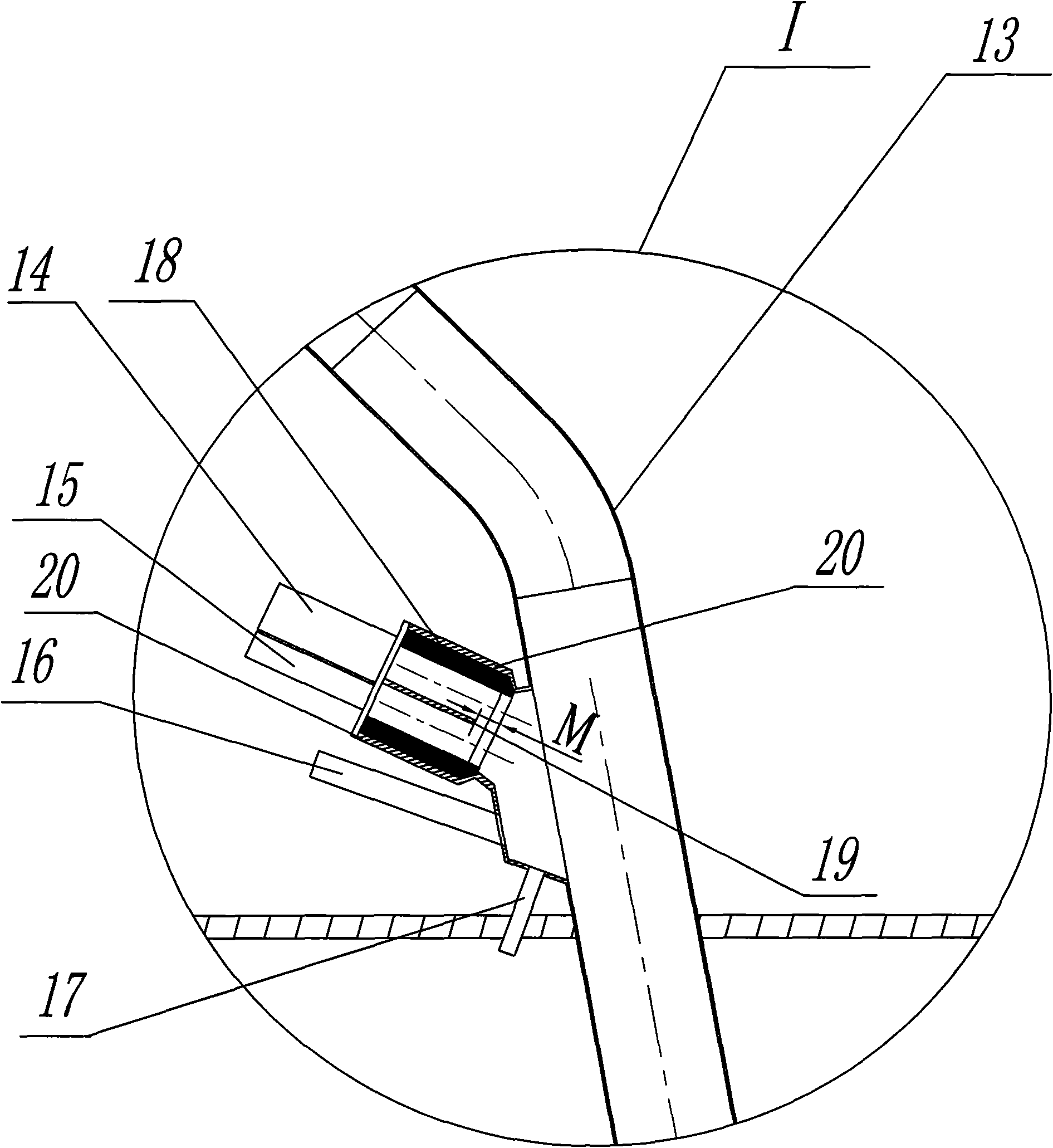

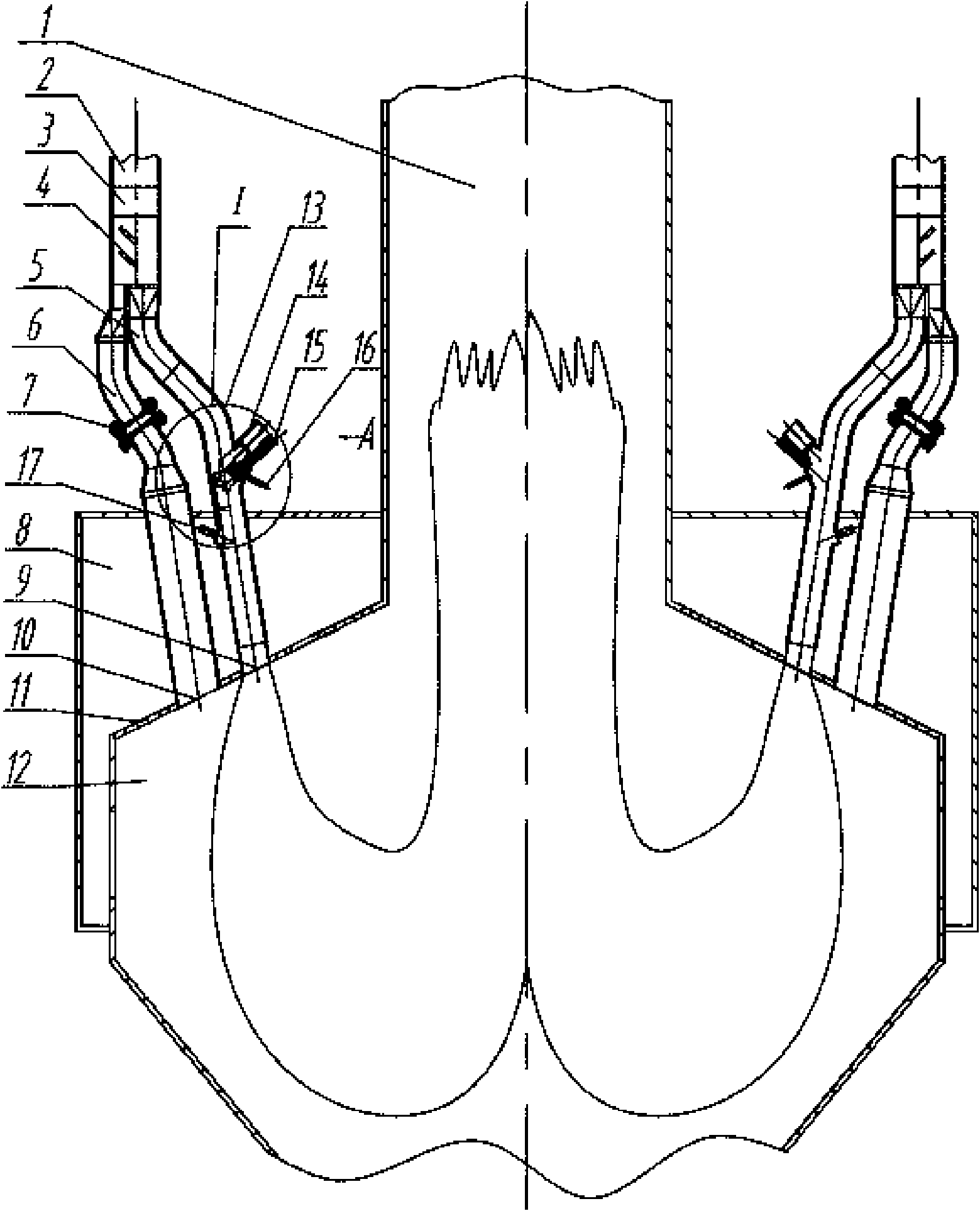

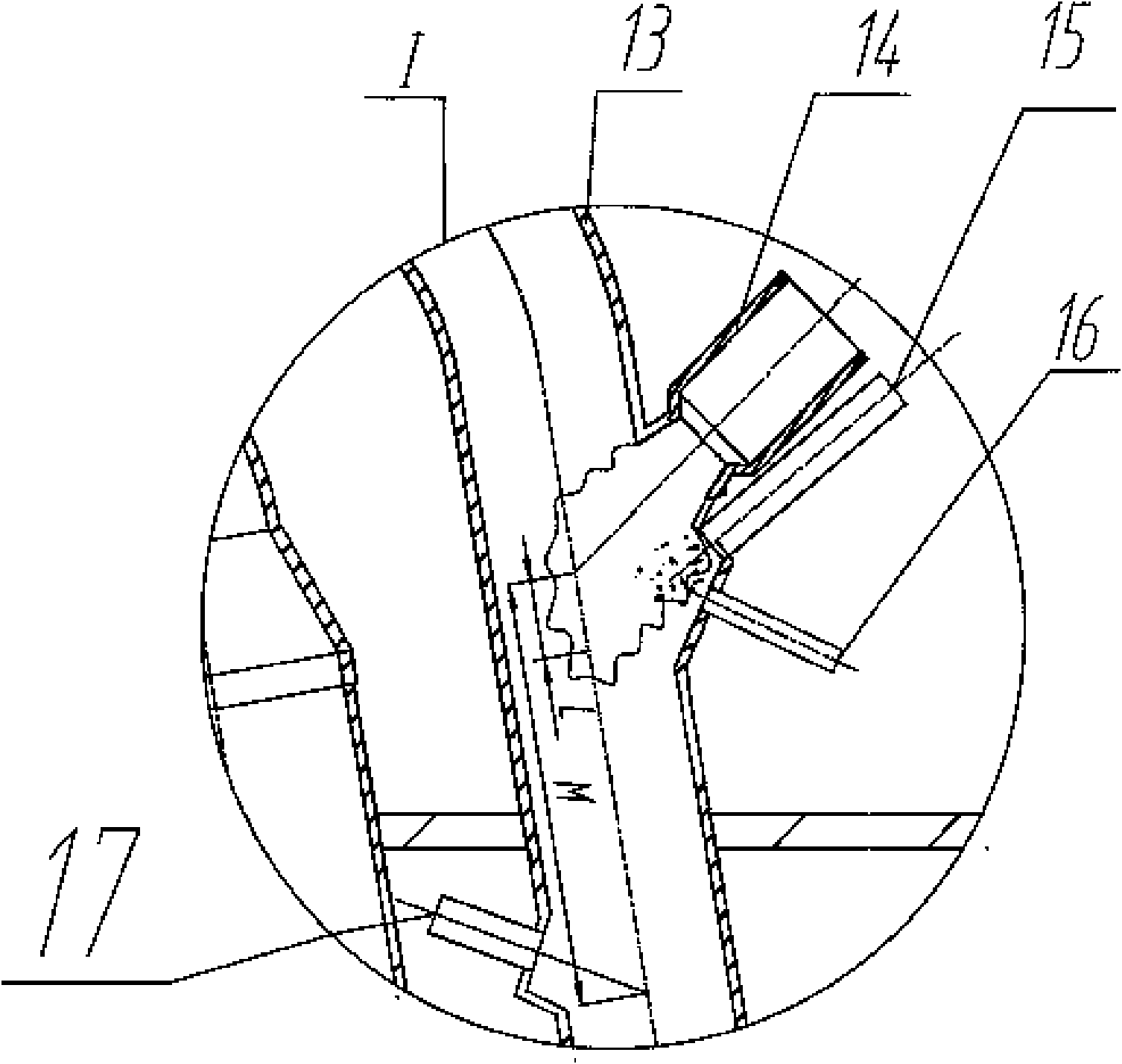

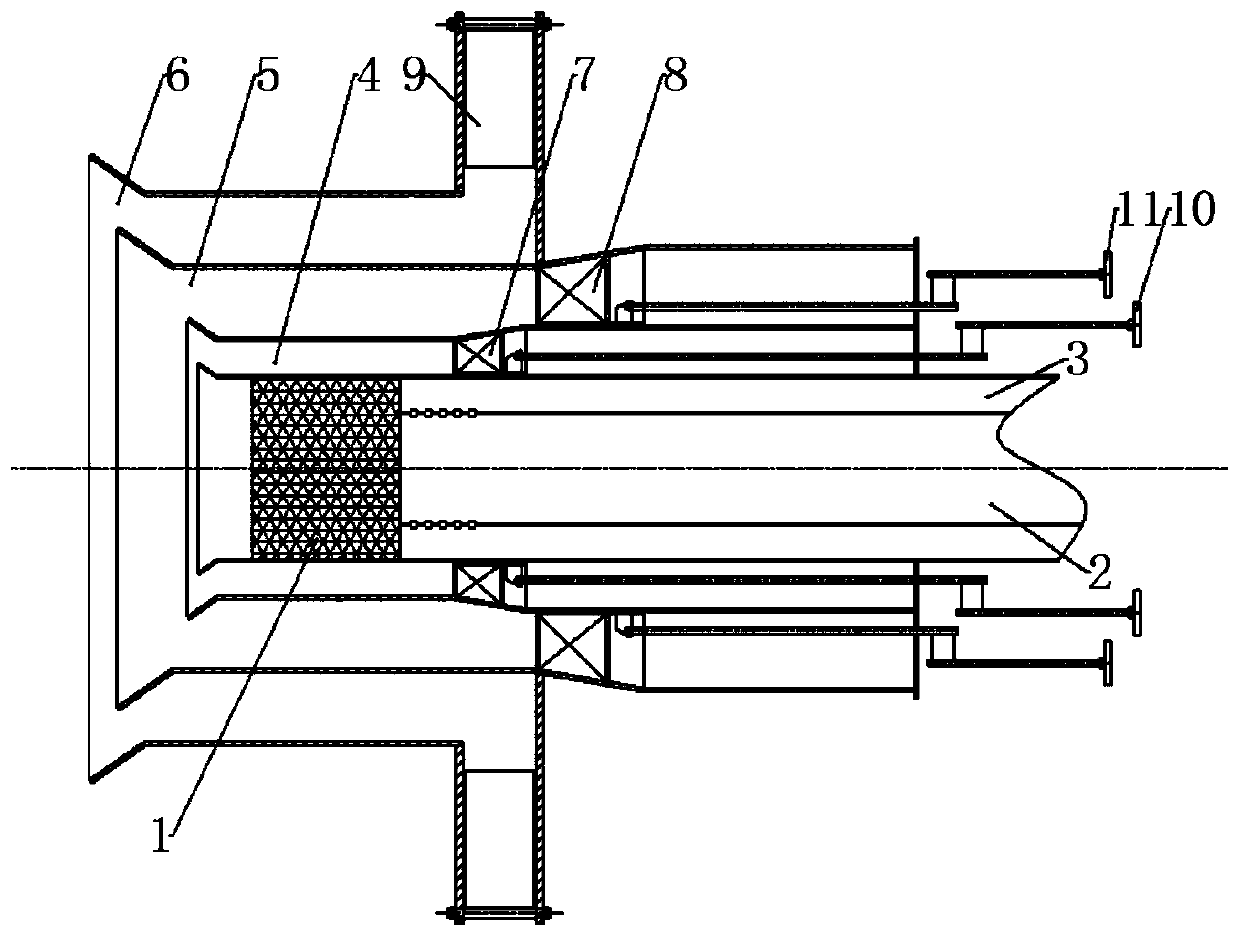

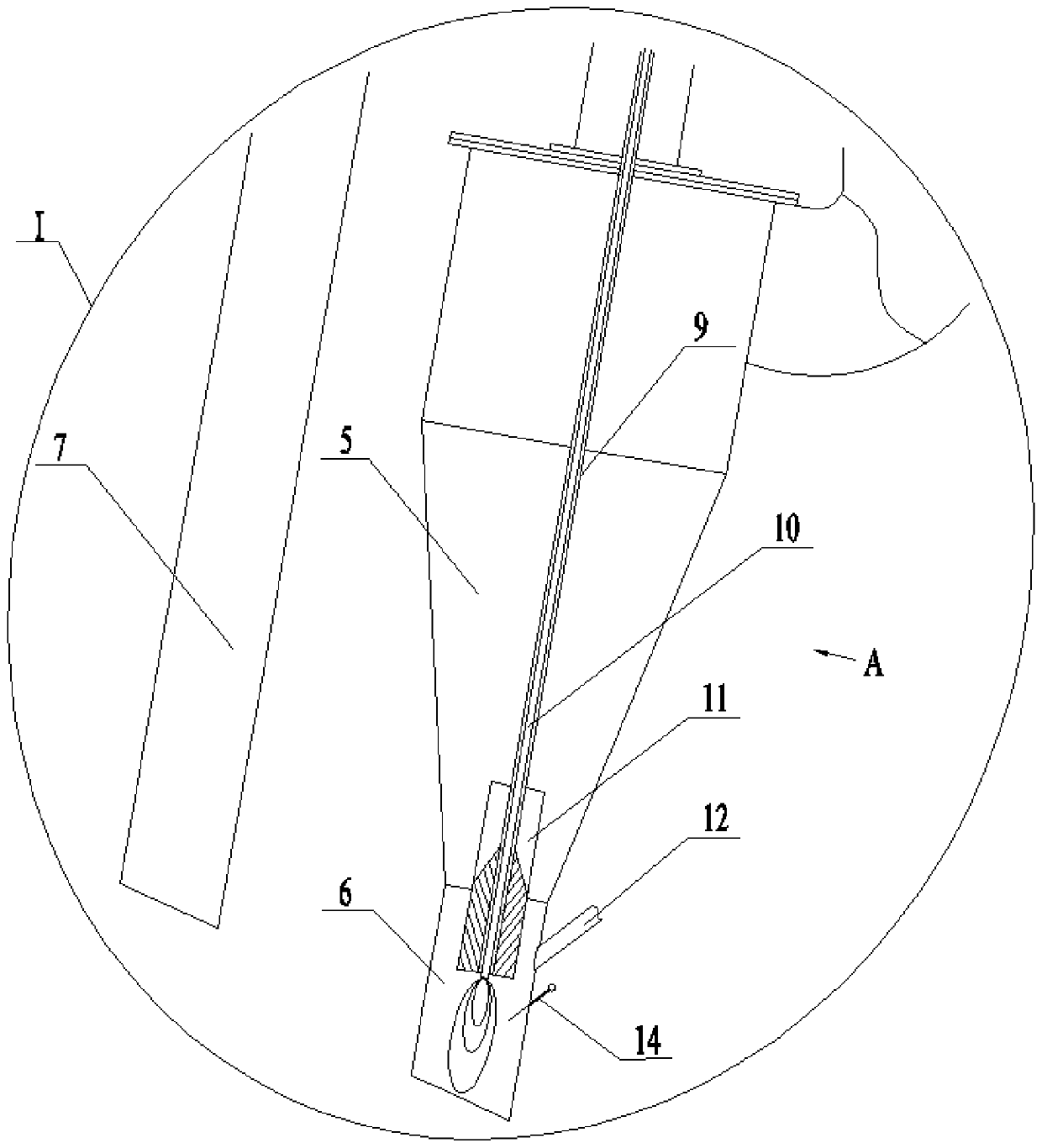

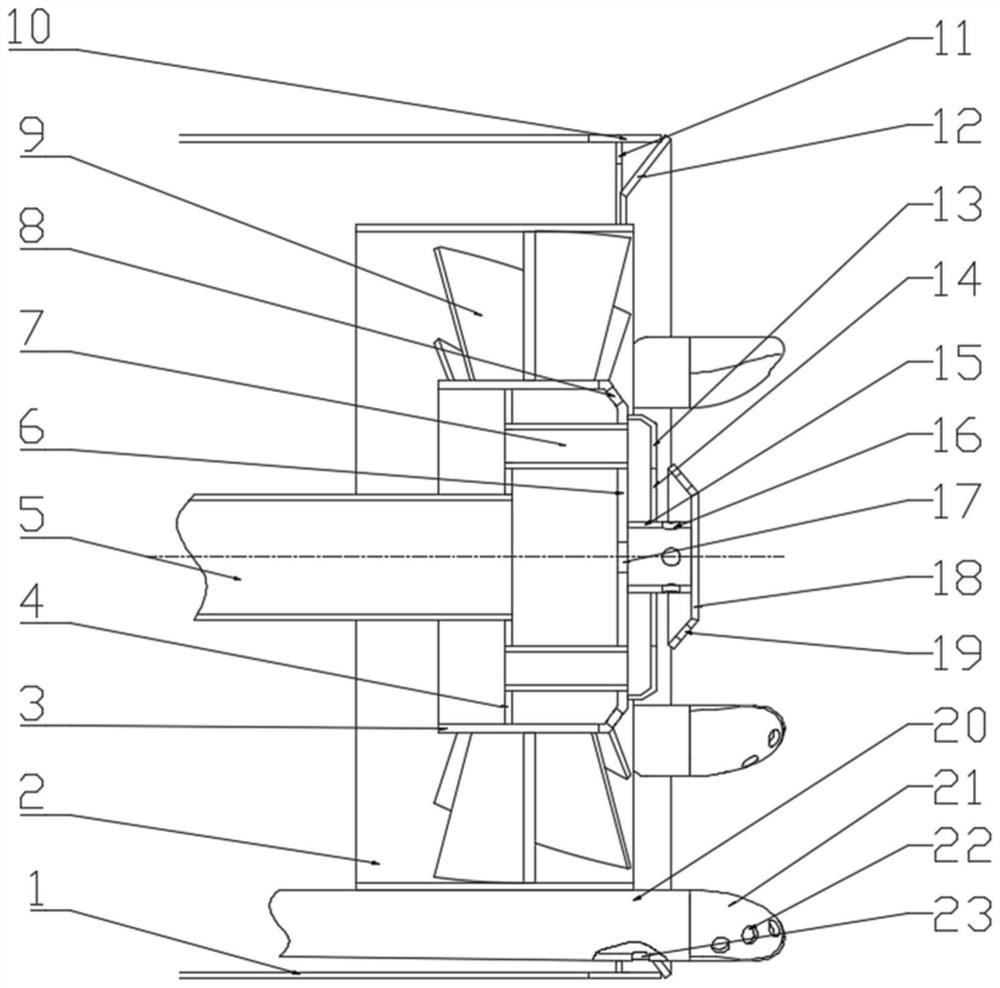

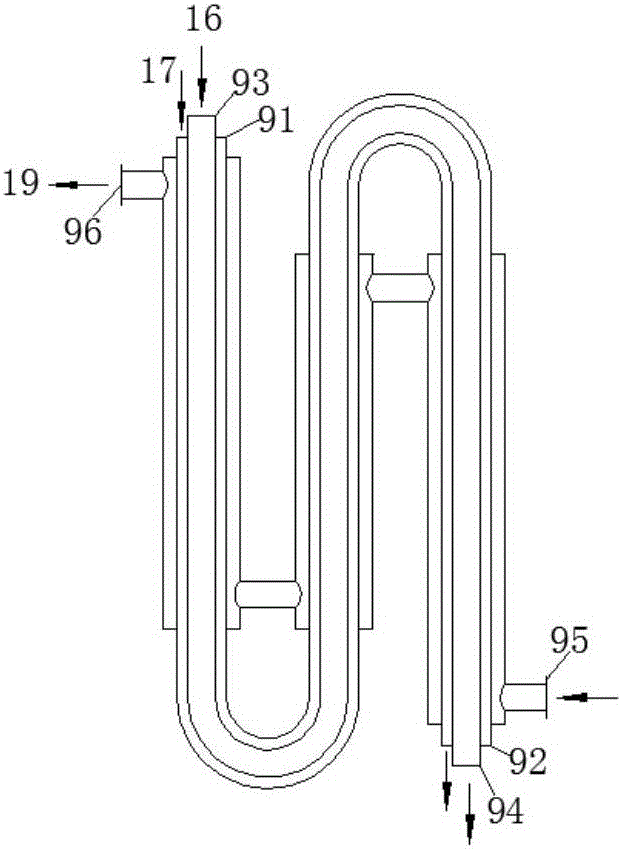

Secondary concentration double-nozzle micro-oil pulverized coal igniting device

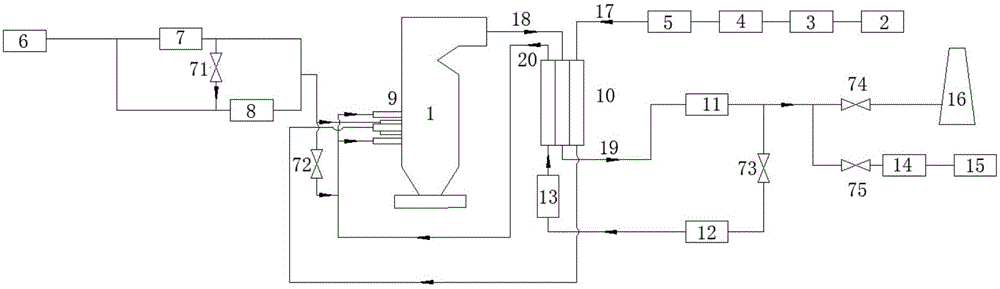

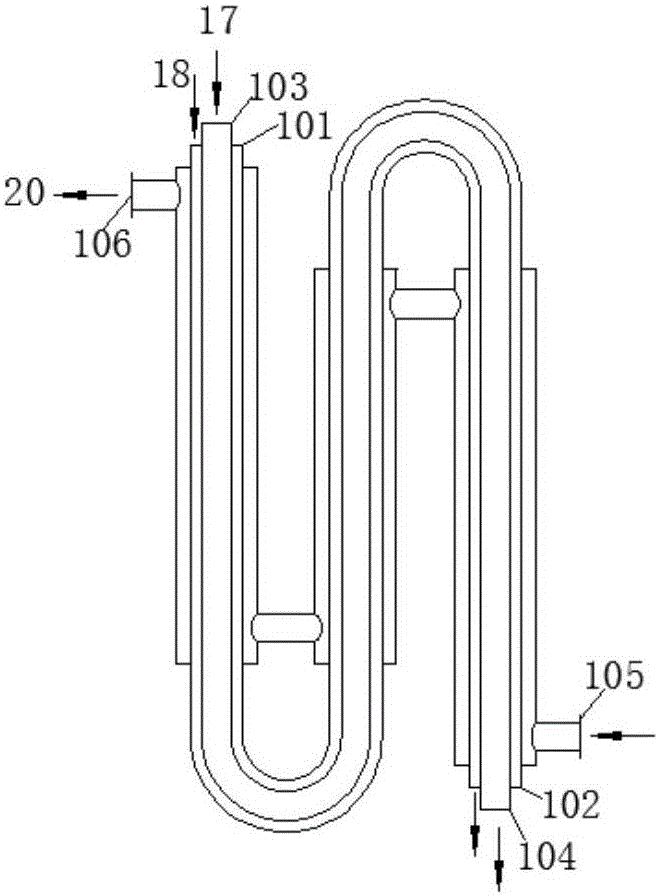

ActiveCN101561138ALower the feverLow ignition temperaturePilot flame ignitersPulverulent fuel combustion burnersFire detectorCombustion chamber

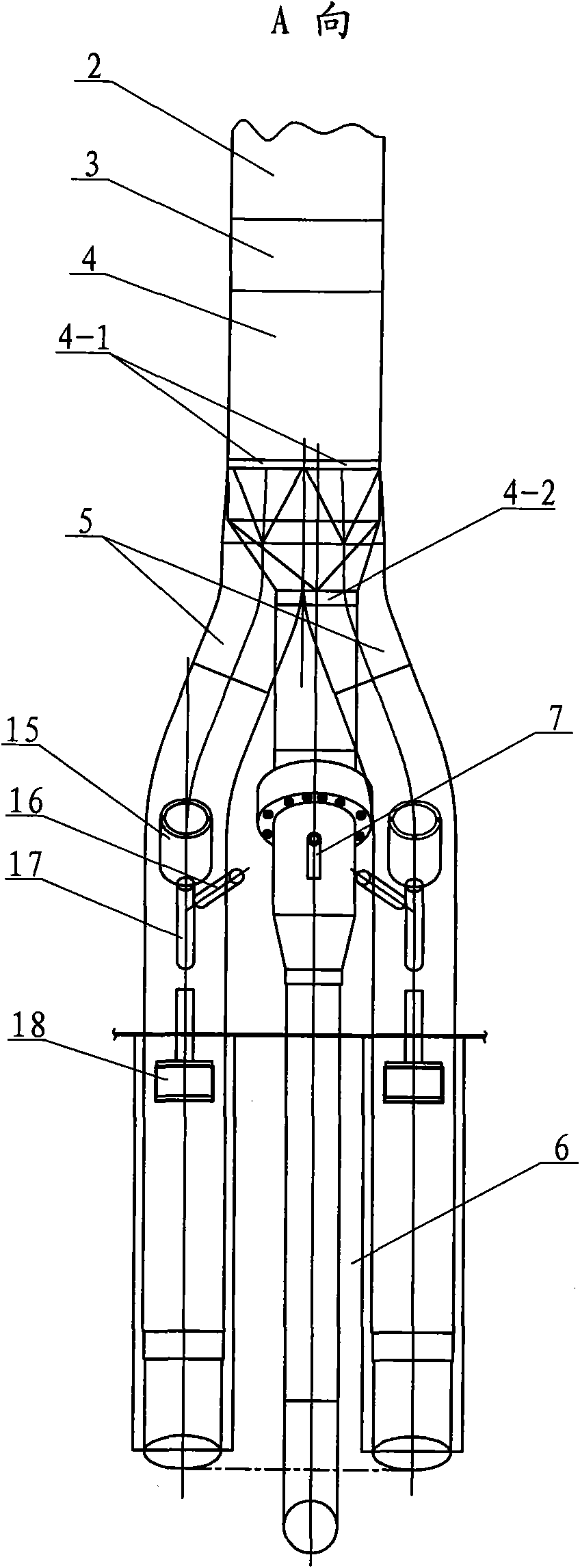

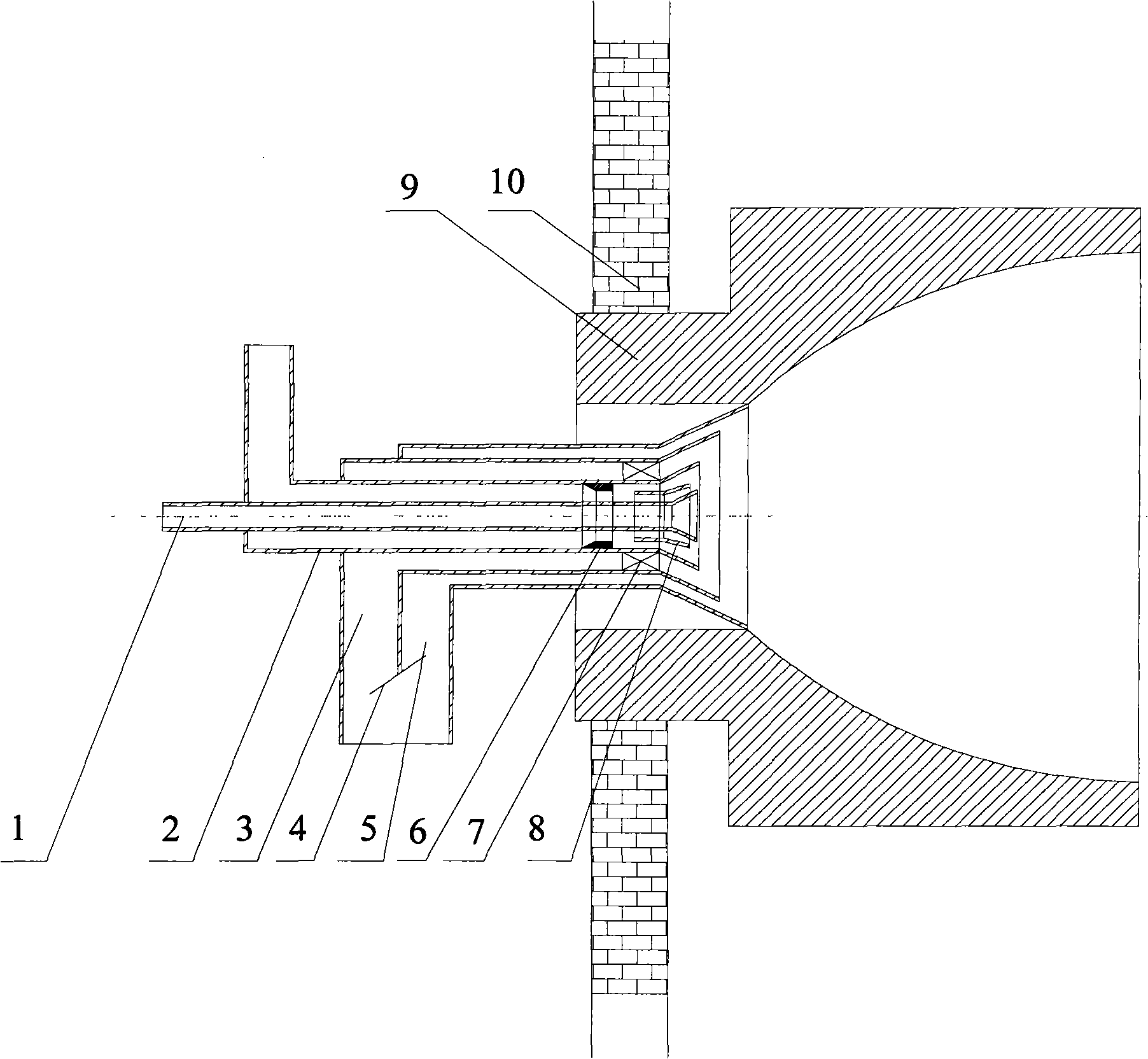

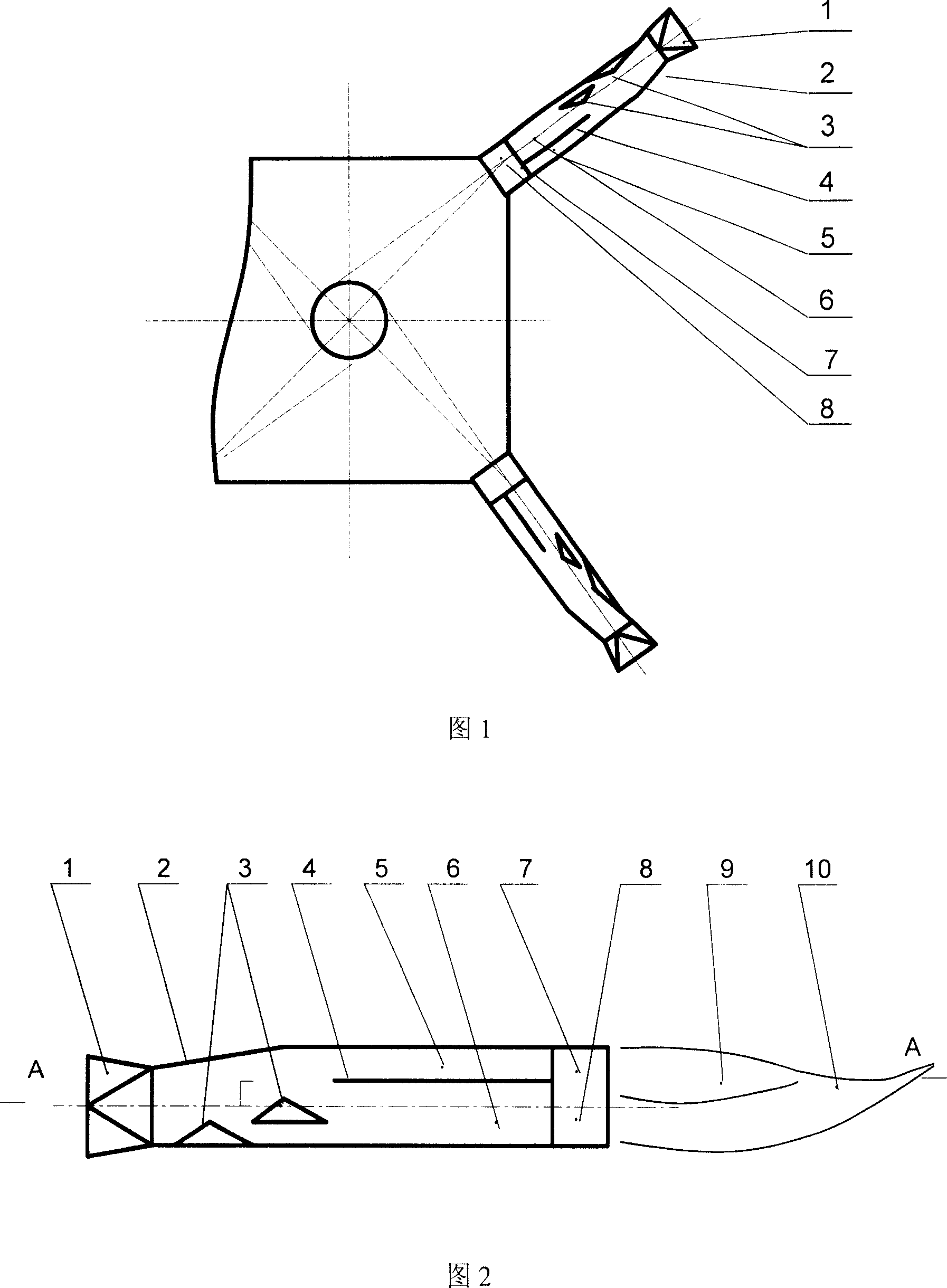

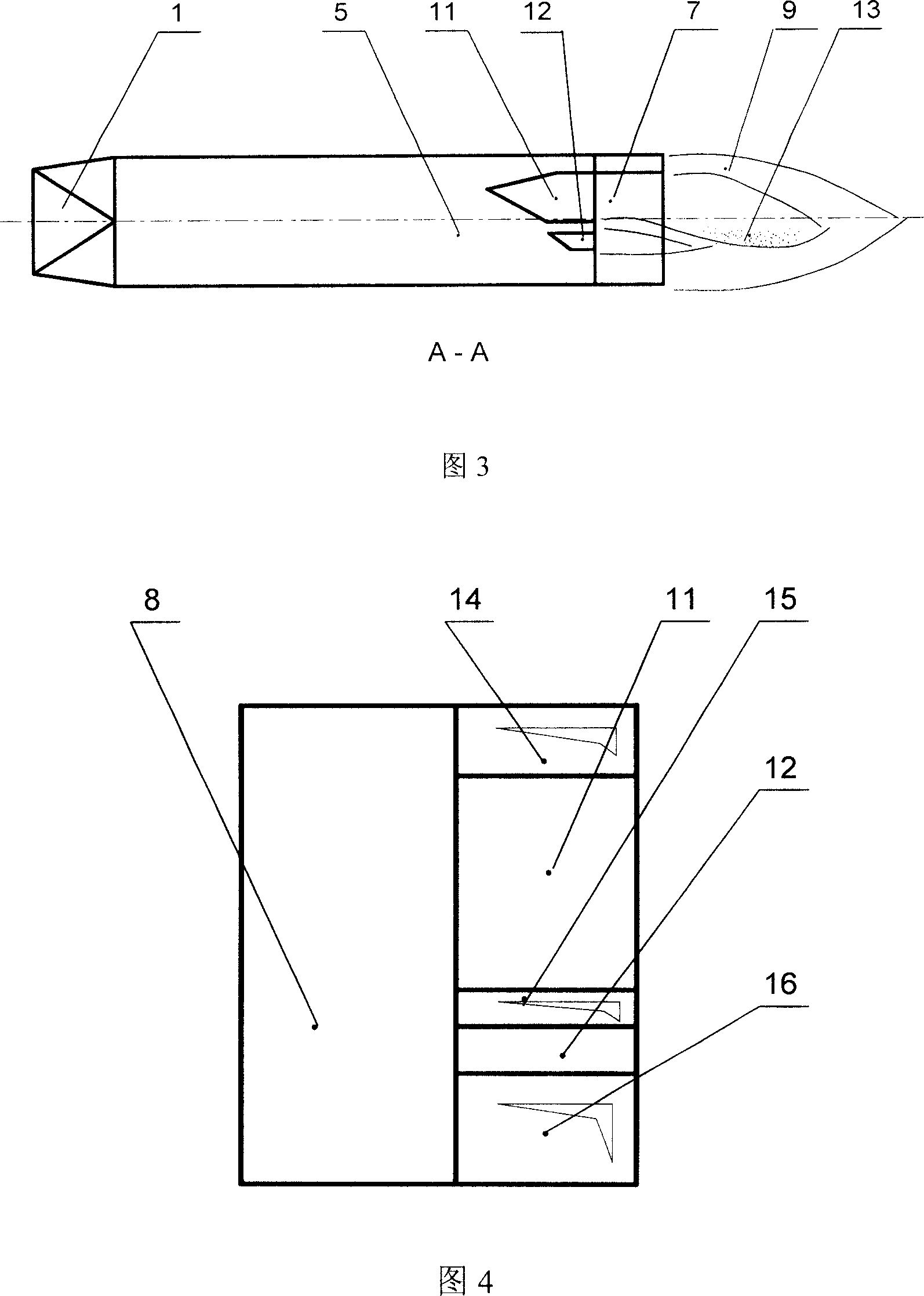

The invention provides a secondary condensation double-nozzle micro-oil pulverized coal igniting device, and relates to a micro-oil pulverized coal igniting device of a W-shaped flame boiler. The device solves the problems of high heat absorption capacity, high ignition heat value and difficult ignition existing in the micro-oil pulverized coal igniting device of the prior W-shaped flame boiler. Both ends of a grid evenly dividing device are connected with a primary air pipe and a pulverized coal rich-lean separator respectively; the lower end of the pulverized coal rich-lean separator is connected with two rich pulverized coal pipes and two lean pulverized coal pipes respectively; the lower ends of the rich pulverized coal pipes and the lean pulverized coal pipes are communicated with a lower hearth respectively; the rich pulverized coal pipes are provided with bent pipe segments; a main oil gun, a fire detector and an auxiliary oil gun are orderly arranged on the outer side walls of the rich pulverized coal pipes from top to bottom and under the bent pipe segments; and a cavity formed between a clapboard and the main oil gun is a first-level combustion chamber, and a cavity formed under the clapboard is a second-level combustion chamber. In the device, the secondary concentration is carried out by the bent pipe segments in the two rich pulverized coal pipes of the pulverized coal rich-lean separator, so that the concentration of the pulverized coal is improved, and the pulverized coal is easily ignited.

Owner:HARBIN INST OF TECH

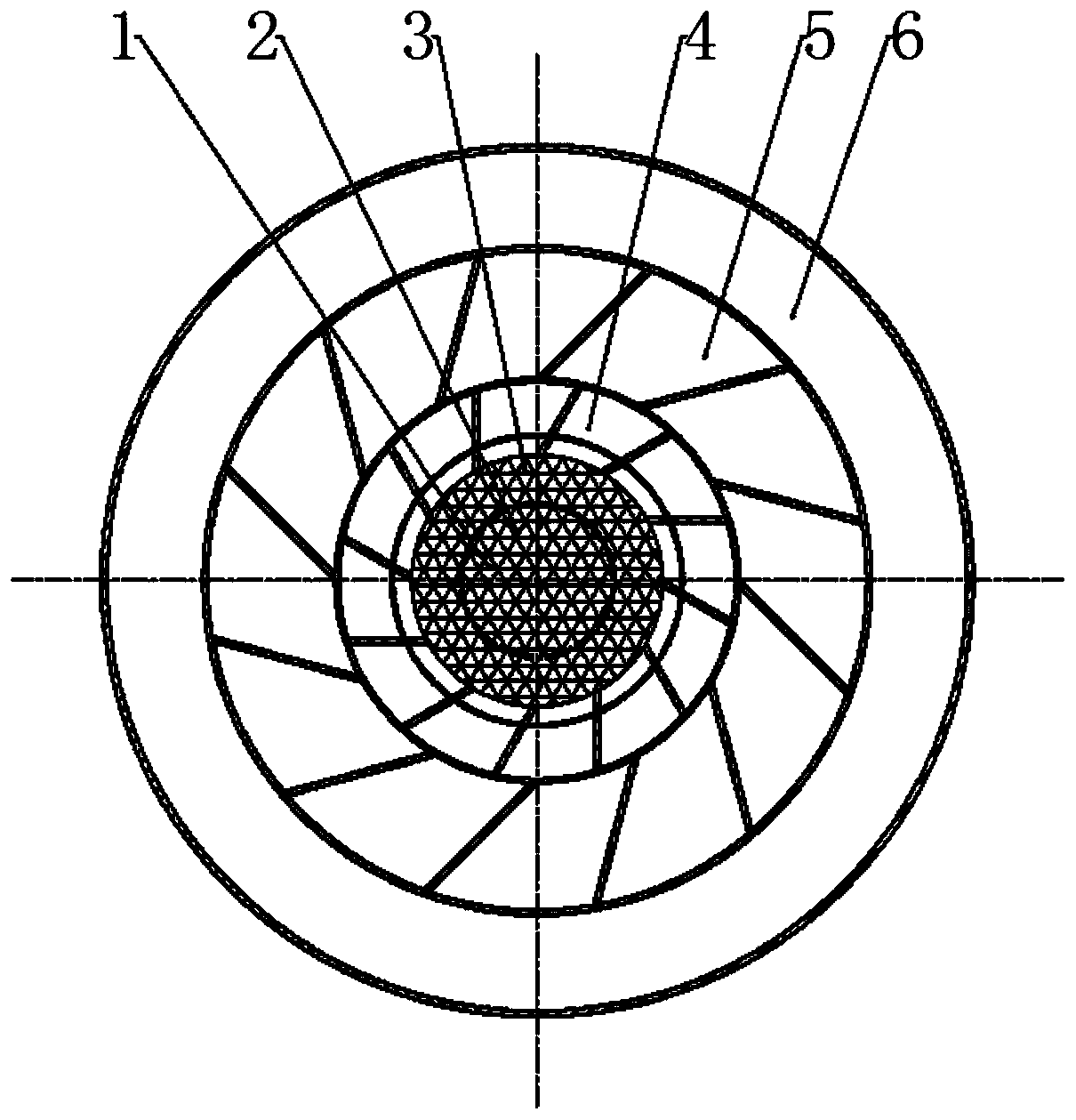

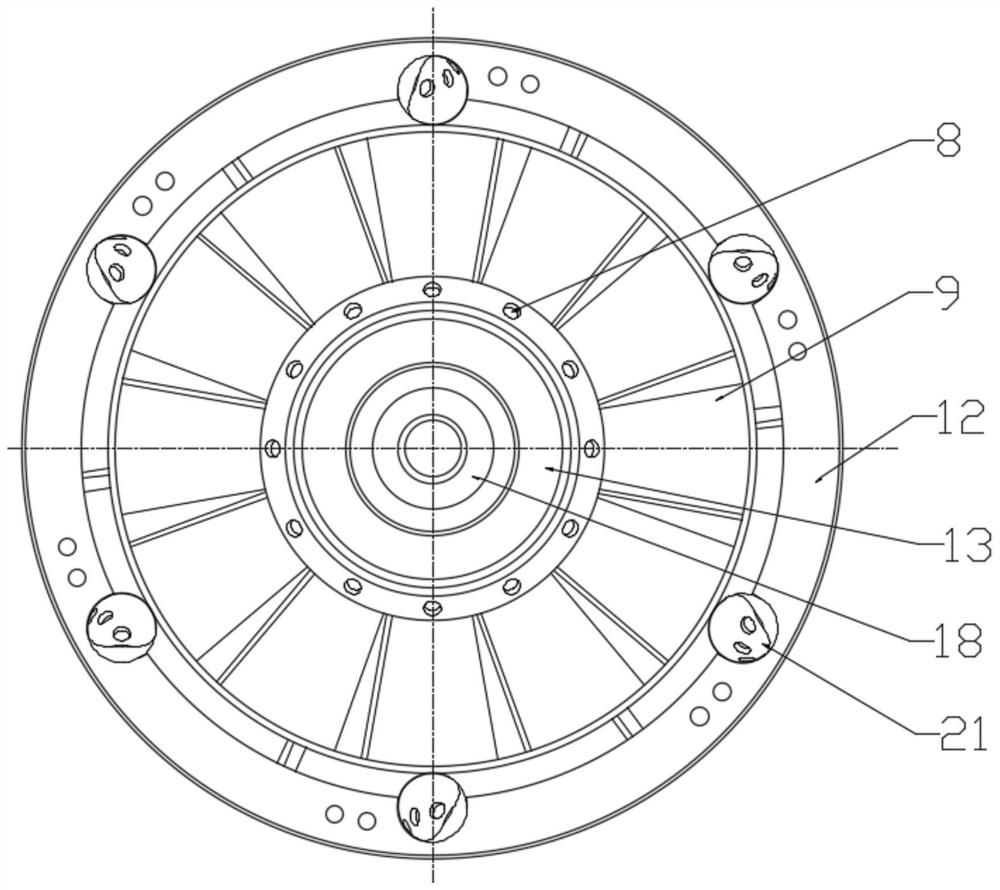

Novel cyclone bias pulverized coal burner

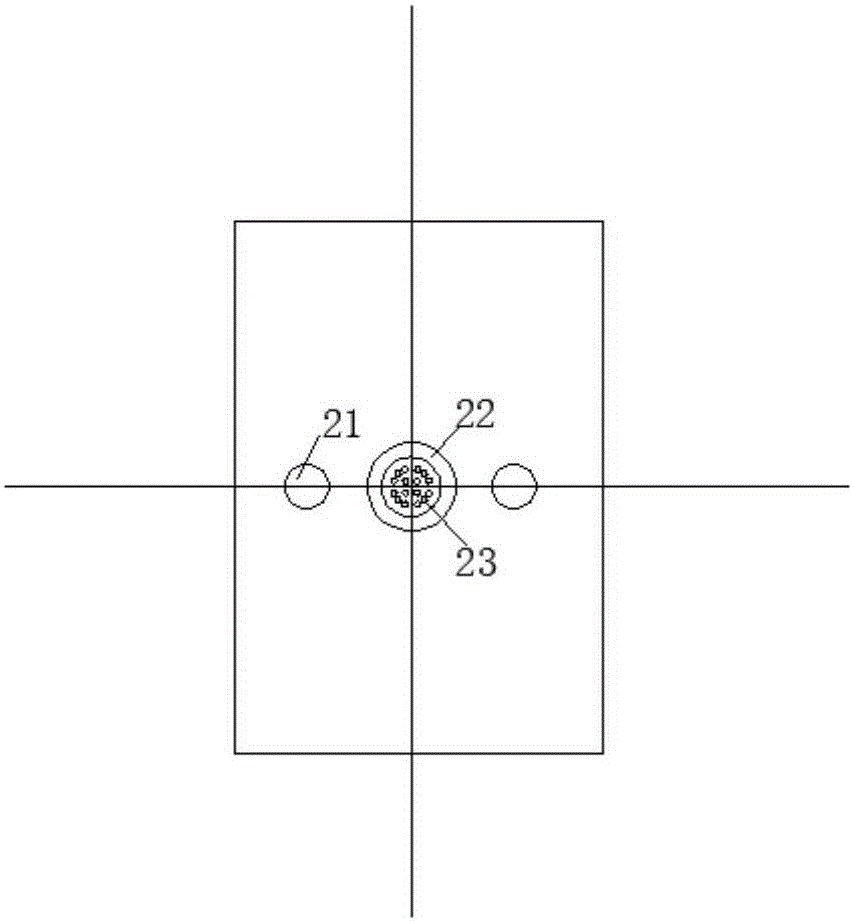

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

Energy-saving optimal control system and method for outlet temperature of medium-speed coal mill in supercritical unit

ActiveCN107855210AHigh outputImprove combustion stabilityIndirect carbon-dioxide mitigationGrain treatmentsCold airCombustor

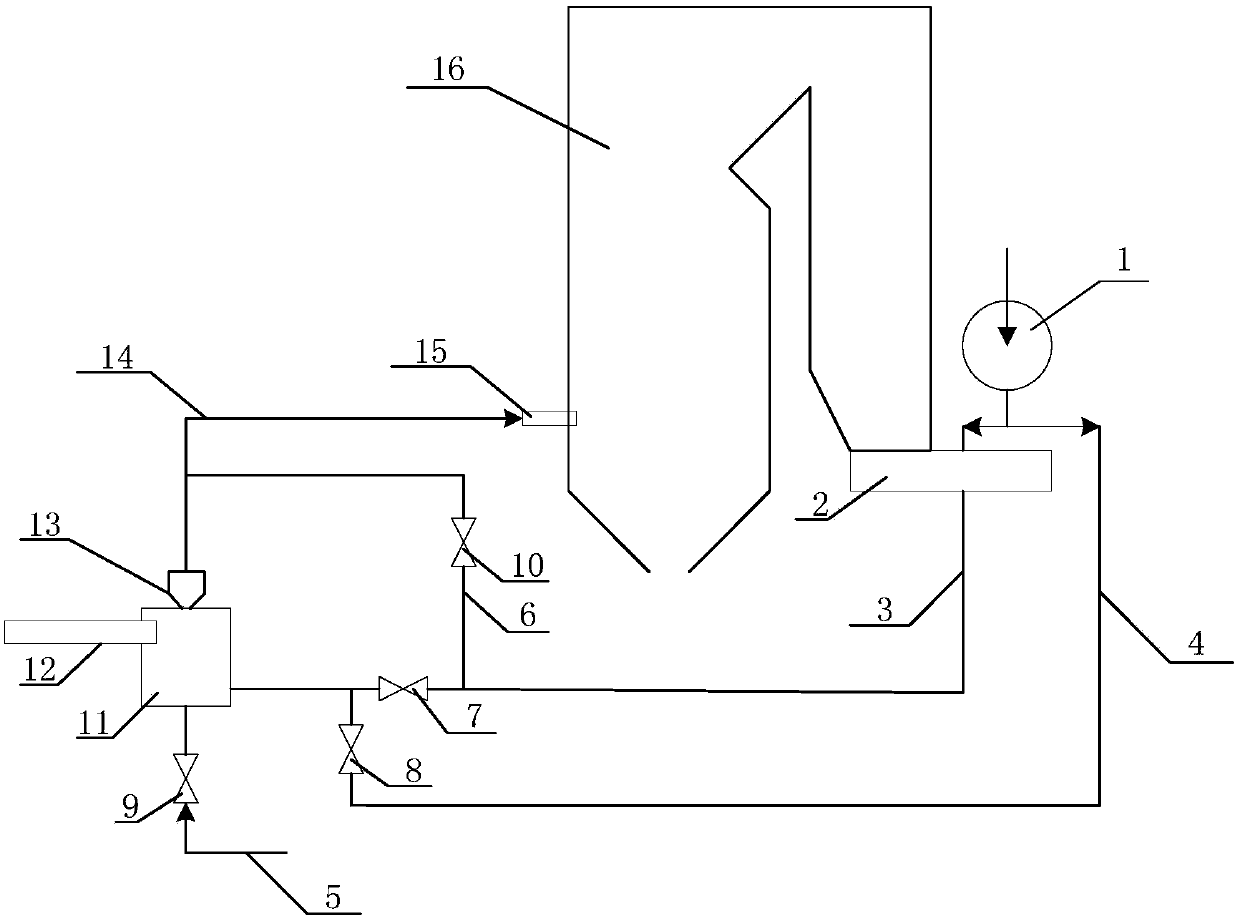

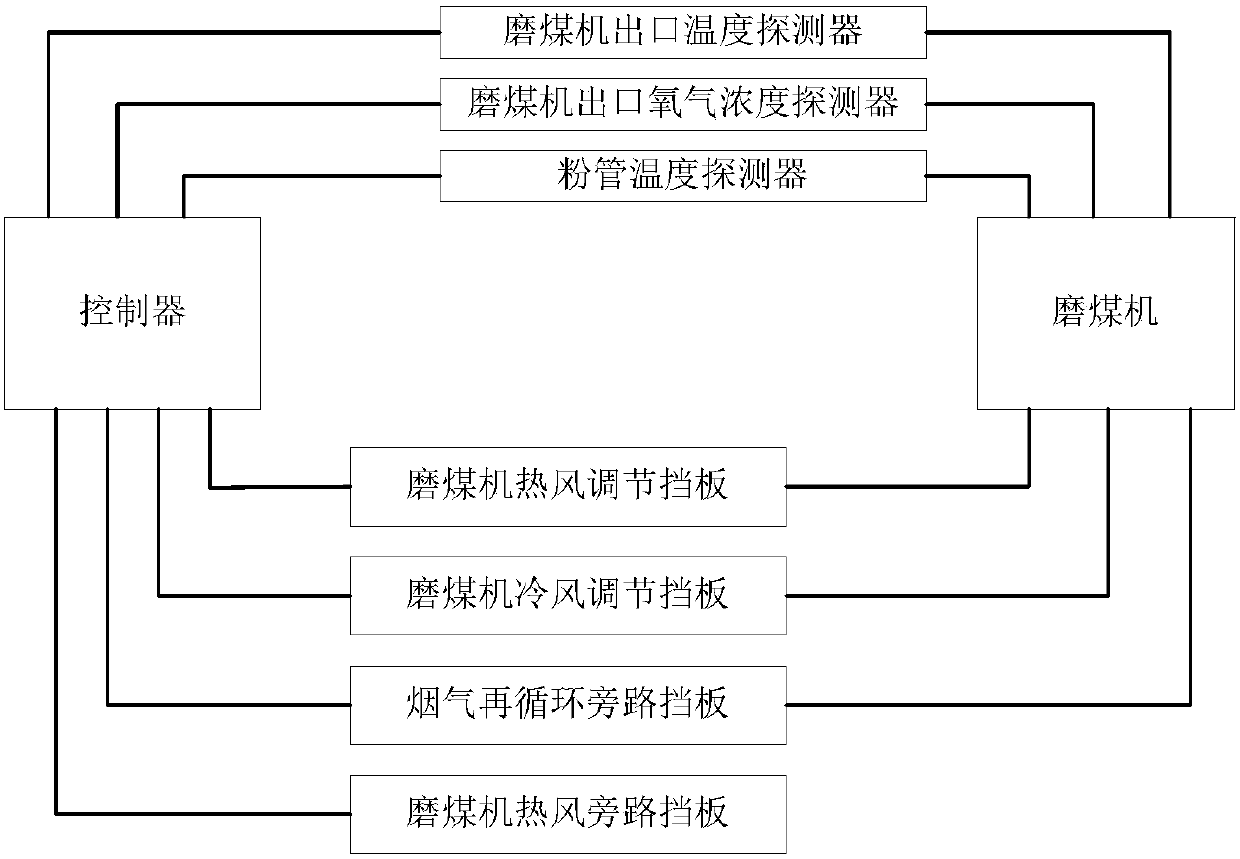

The invention discloses an energy-saving optimal control system and method for the outlet temperature of a medium-speed coal mill in a supercritical unit. The system comprises a primary draught fan, an air pre-heater, a hot primary air pipe, a cold primary air pipe, a smoke recycling bypass pipeline, a coal mill hot air bypass pipeline, a coal mill hot air adjusting baffle, a coal mill cold air adjusting baffle, a smoke recycling bypass baffle, a coal mill hot air bypass adjusting baffle, a coal mill, a coal feeder, a rough powder separator, a primary air powder pipeline, a combustor, a boiler, a controller, a coal mill outlet temperature detector, a coal mill outlet oxygen concentration detector and a powder pipe temperature detector. By means of the energy-saving optimal control system and method, the smoke recycling bypass pipeline is additionally arranged in a medium-speed coal mill direct blowing type powder manufacturing system, the outlet temperature of the coal mill is increased, and single powder consumption is reduced; and the coal mill hot air bypass pipeline is additionally arranged at the outer portion of the coal mill so that decoupling control over the outlet temperature of the coal mill and the air powder temperature in the primary powder pipe is achieved, the coal powder fire catching and combustion stabilizing performance is improved, and the adaptability of acoal-fired powder unit participating in depth peak regulating is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Adjustable type petroleum coke powder strengthening and burning device

InactiveCN101539292ACatch fire quicklyEasy to catch firePulverulent fuel combustion burnersCombustorMature technology

The invention relates to an adjustable type petroleum coke powder strengthening and burning device which comprises a high-temperature heat storage cavity and an adjustable type multi-stage burner. Aiming at the characteristics of low volatile component content and high burning NOx content of the petroleum coke powder, the device adopts a method for combining techniques of strengthening the heating-up speed of the petroleum coke powder, reducing the ignition heat, and the like so as to achieve the stable ignition and low-pollution burning of the petroleum coke powder. The depth of both the high-temperature heat storage cavity and a flaring structure of a central pipe for inserting in a hearth can be adjusted so as to adapt to the influence of the load change of a burning device. The device has strong pertinence and has the characteristics of convenience, adjustment, mature technology, high burning efficiency and convenient processing and manufacturing.

Owner:XI AN JIAOTONG UNIV

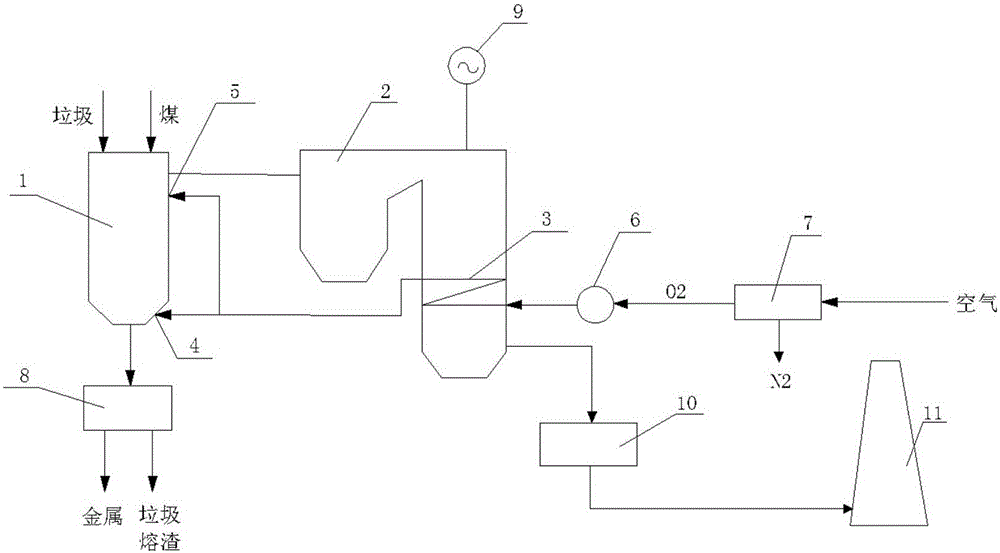

Device and method for heating and melting rubbish under oxygen-rich condition

InactiveCN105864782ALow ignition temperatureReduce usageIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterCombustion

The invention discloses a device and method for heating and melting rubbish under the oxygen-rich condition. The device comprises a rubbish melting furnace. The rubbish melting furnace is connected with an oxygen supply system. The bottom of the rubbish melting furnace is connected with a cooling device. The oxygen supply system comprises an air separation device, an air feeder and an air preheater which are connected sequentially. A first air blowing opening is formed in the upper portion of the rubbish melting furnace. A second air blowing opening is formed in the bottom of the rubbish melting furnace. Both the first air blowing opening and the second air blowing opening communicate with the air preheater. The oxygen supply system supplies separated oxygen-rich gas to the rubbish melting furnace, and the oxygen-rich gas is used as an oxidizing agent for melting the rubbish. The beneficial effects of the oxygen-rich combustion and melting treatment are used, combustion heat of fuel is used, fly ash of the rubbish is molten at the high temperature, stable glassy state slag is formed after cooling, organic components of Dioxin and the like are destroyed, and most of heavy metals are solidified in the glassy state slag.

Owner:SHANDONG UNIV

A swirl burner

The invention discloses a swirl burner, comprising a primary air passage, an inner secondary air passage, an outer secondary air passage and a central air passage, wherein the inner secondary air passage is connected with the outer secondary air passage, and the The inner secondary air channel is equipped with a primary air channel, the primary air channel is equipped with a central air channel, the primary air channel is equipped with a tooth ring burner, and the primary air channel is equipped with a swirl flow Blades, the inner secondary air channel is equipped with swirl blades, and the outer secondary air channel is equipped with swirl blades. The invention can form a stable backflow area, which is beneficial to the ignition of pulverized coal, the internal and external secondary air diffuses outward, and will not participate in the ignition process of pulverized coal, and the ignition heat required by the pulverized coal airflow can be reduced to a minimum, even if anthracite is used. Stable combustion.

Owner:大连经济技术开发区水国燃烧器有限公司

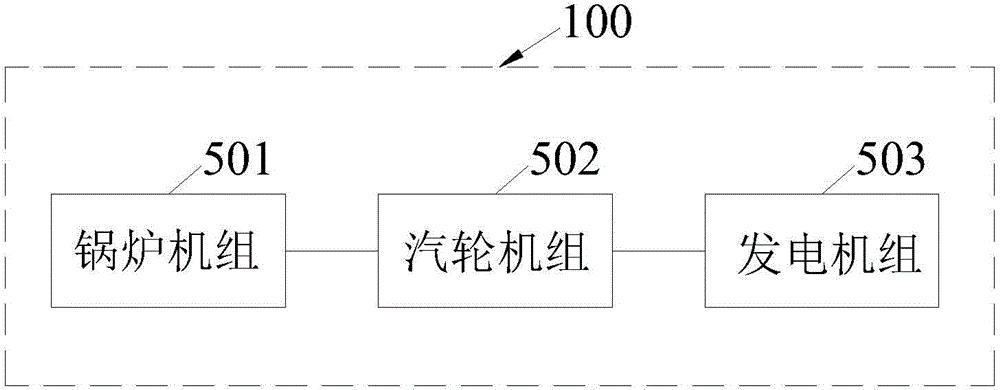

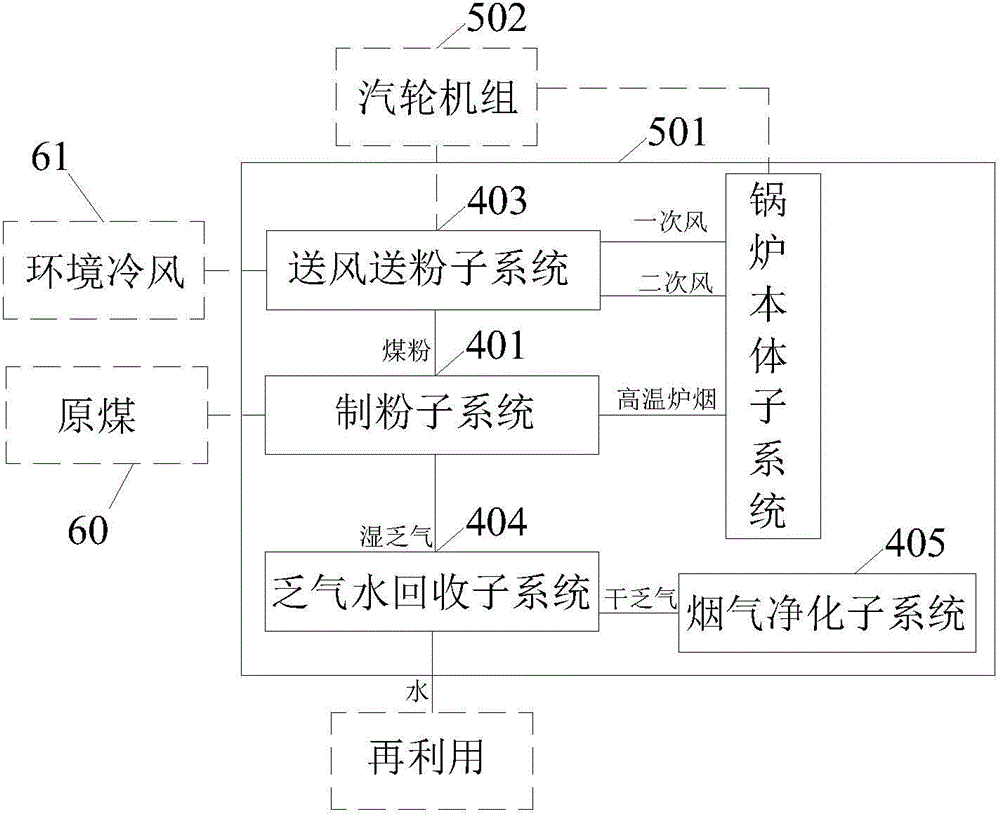

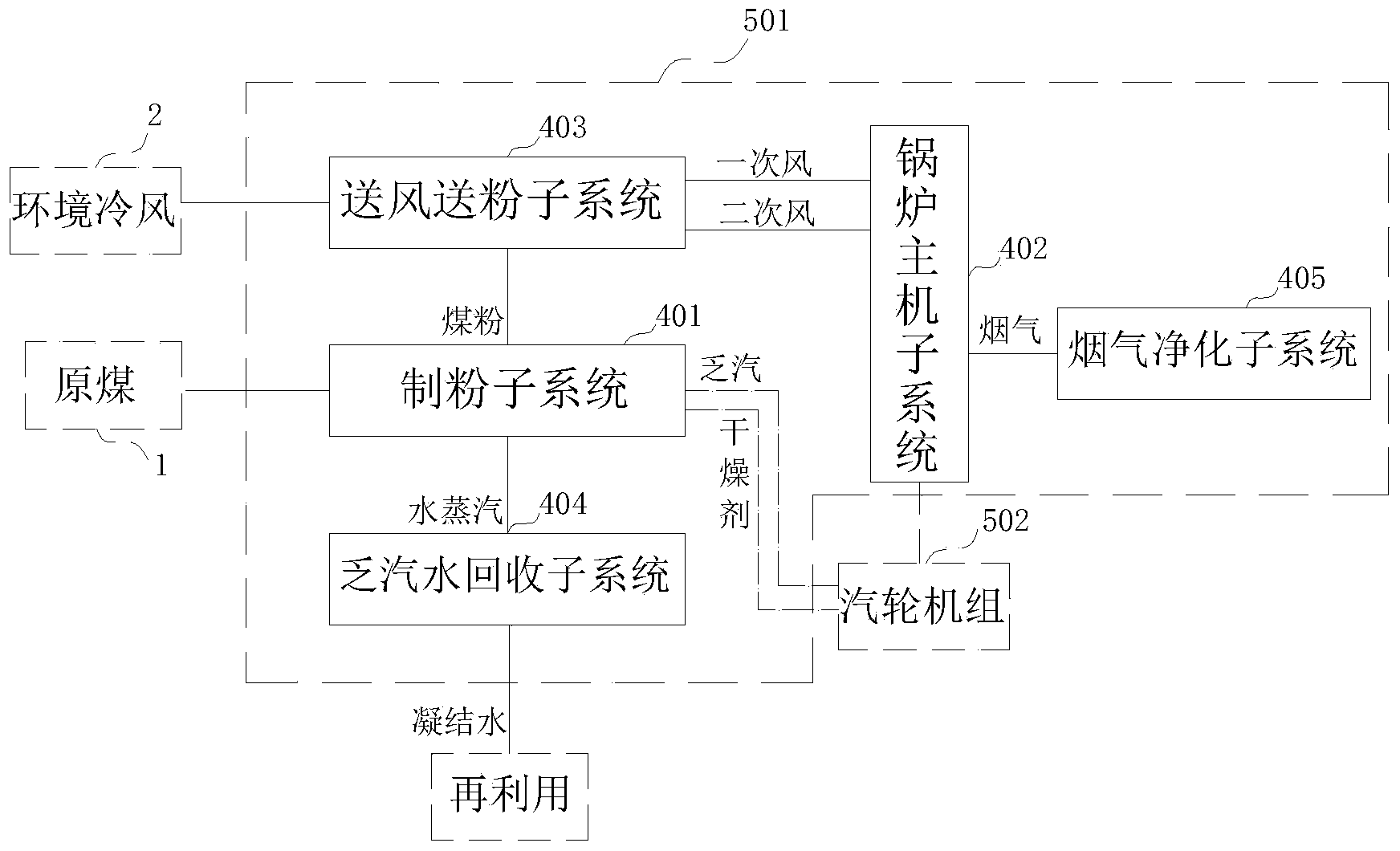

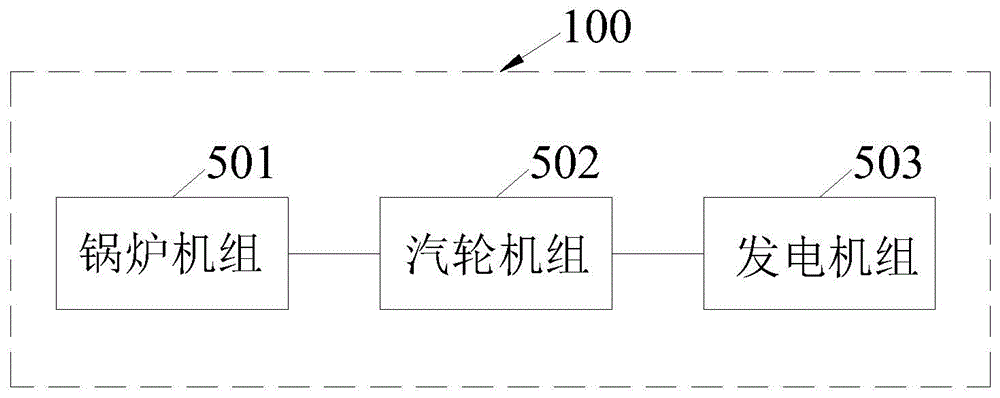

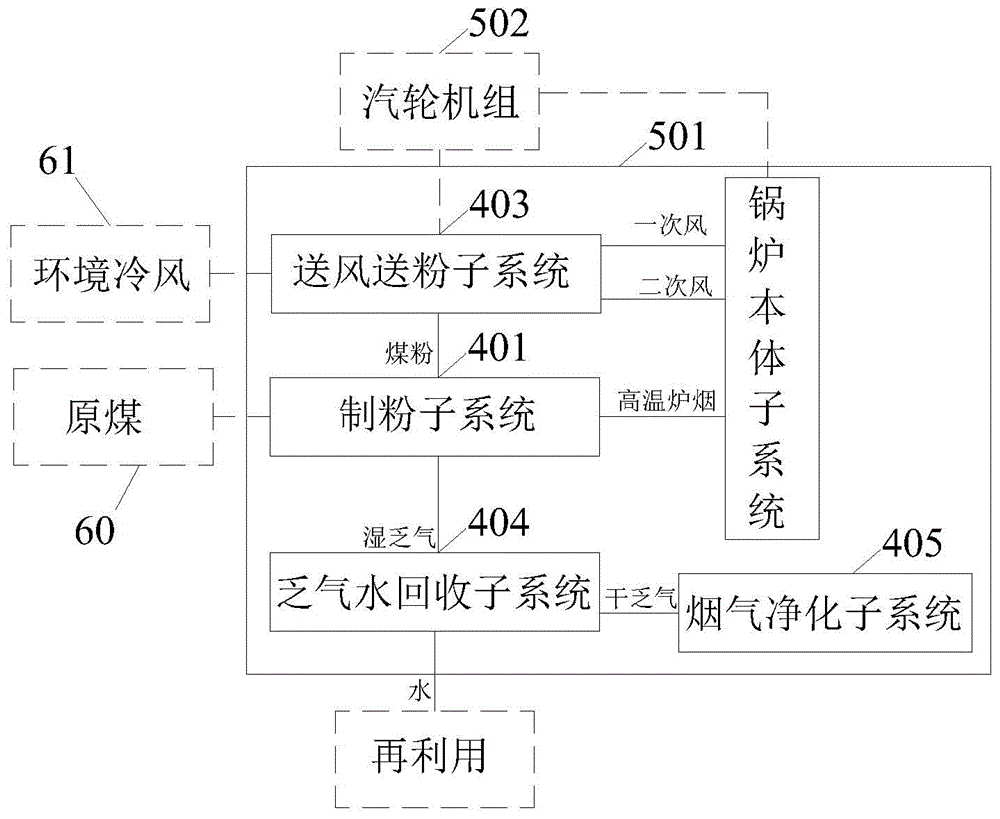

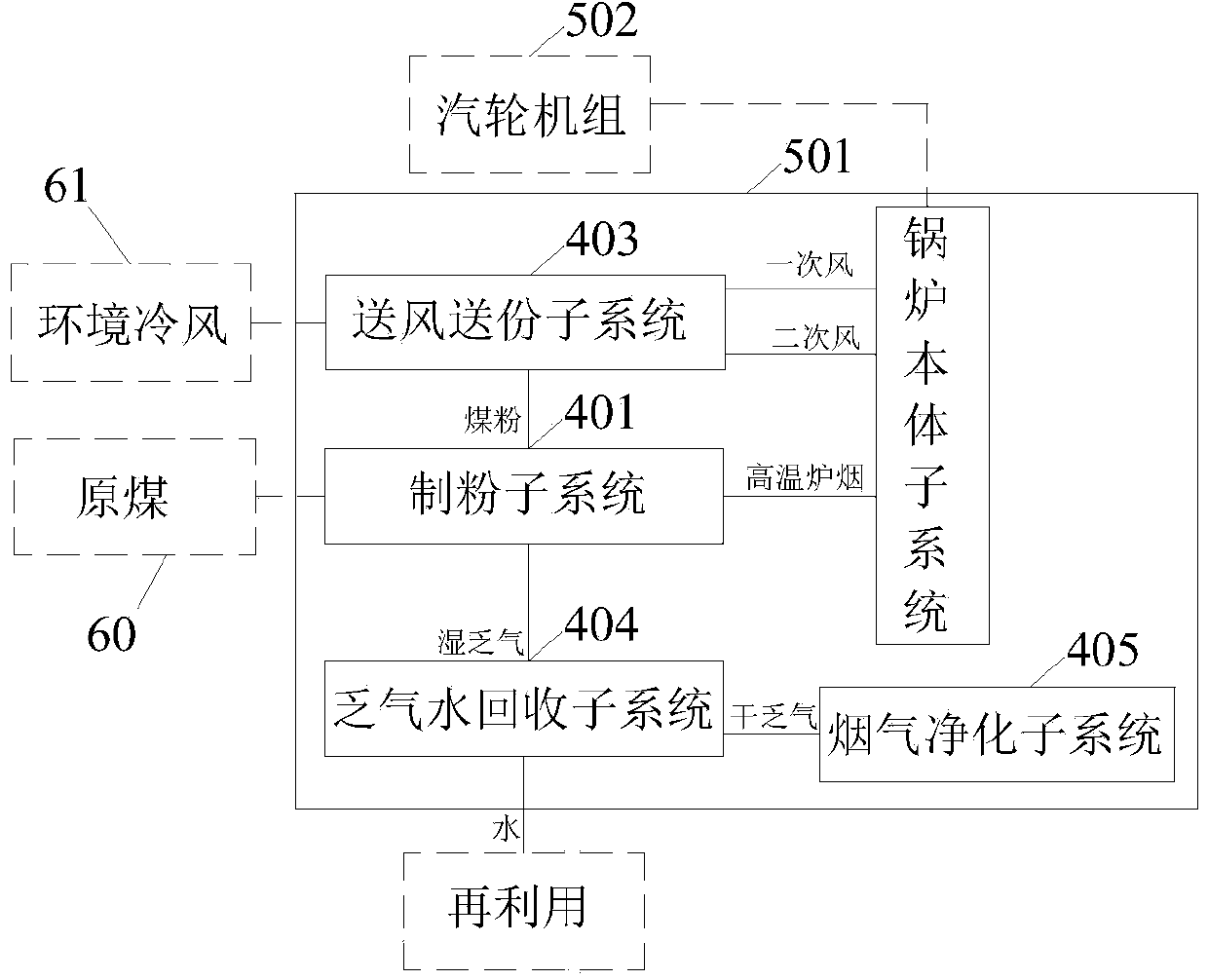

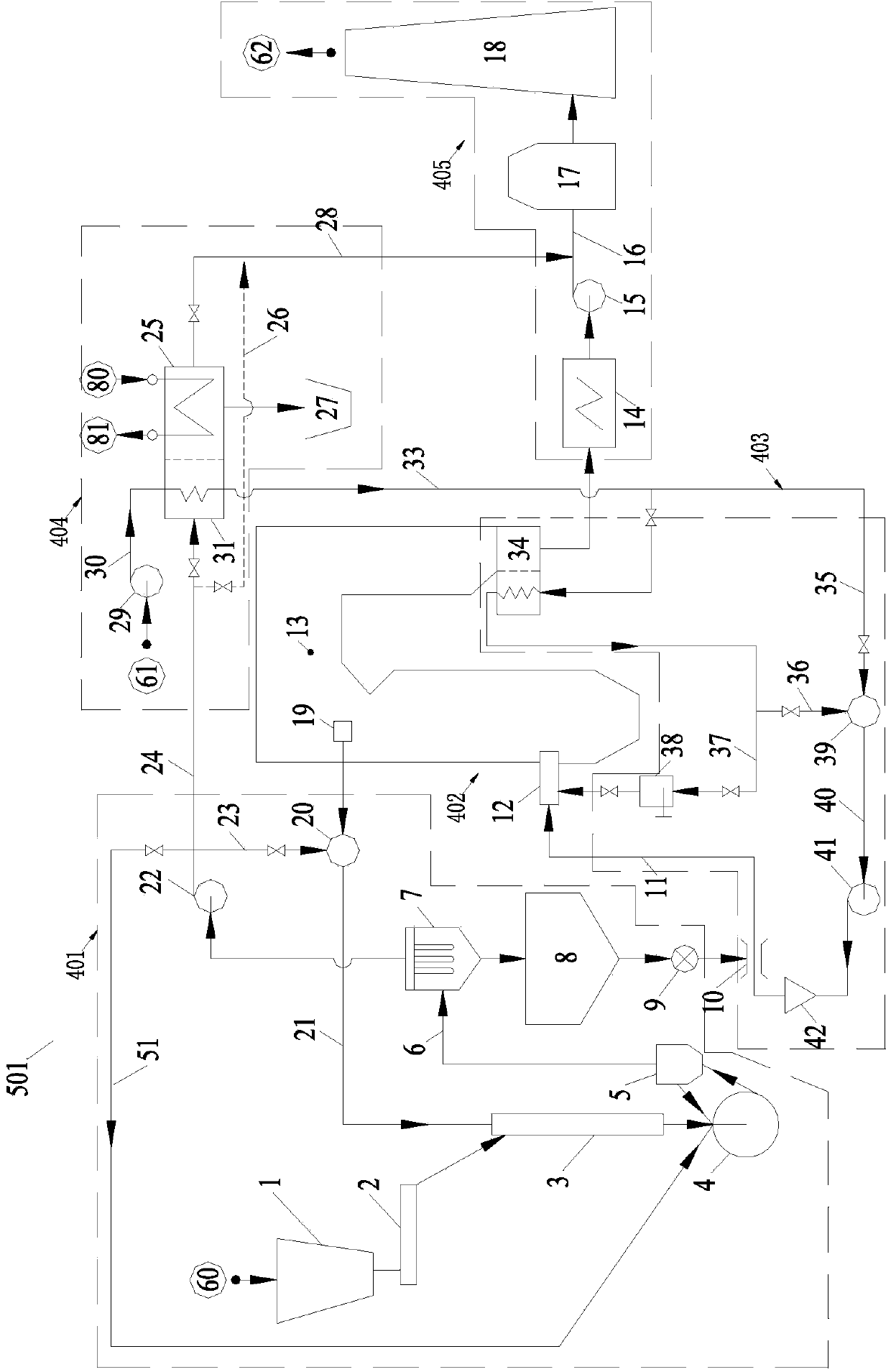

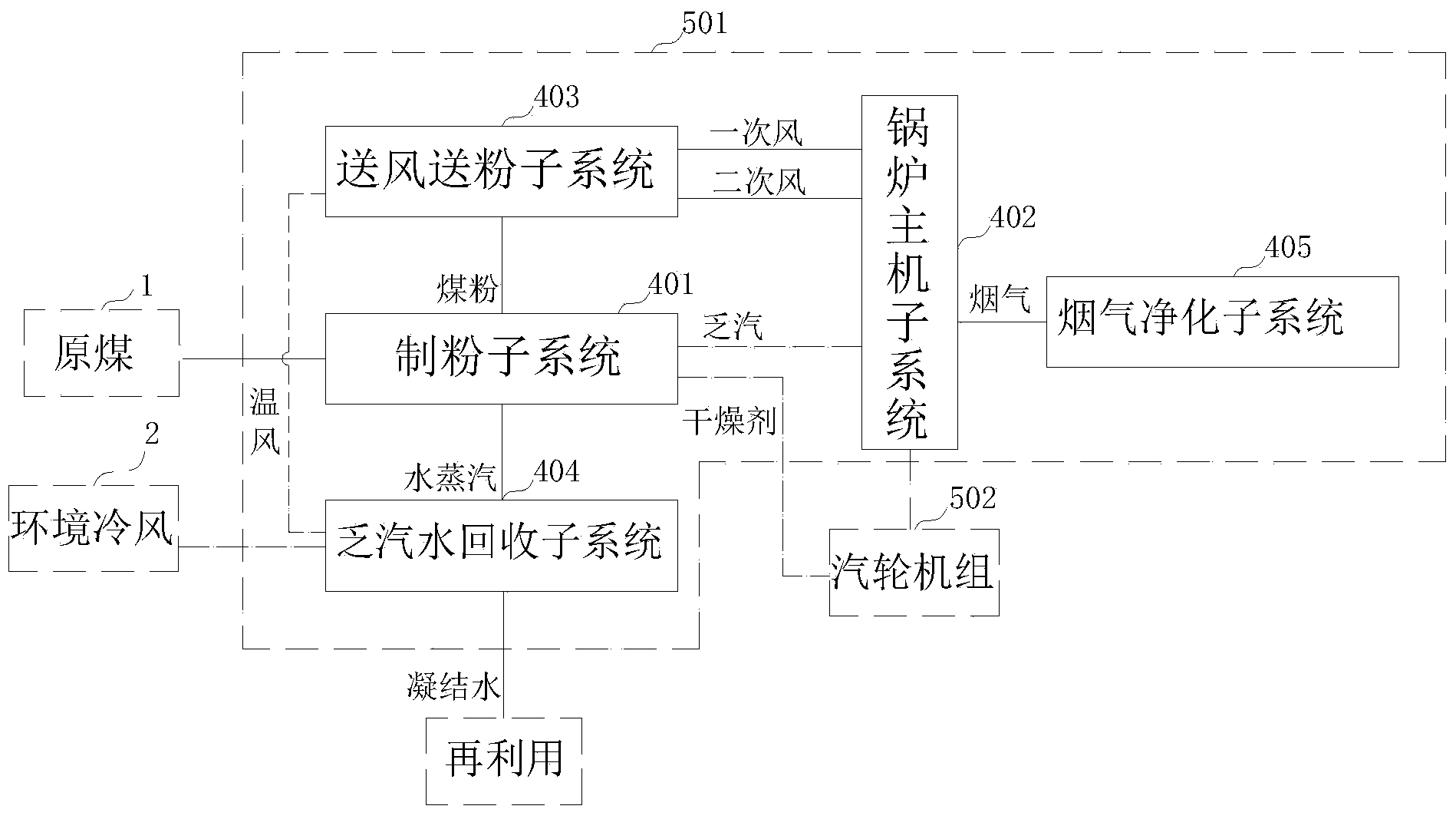

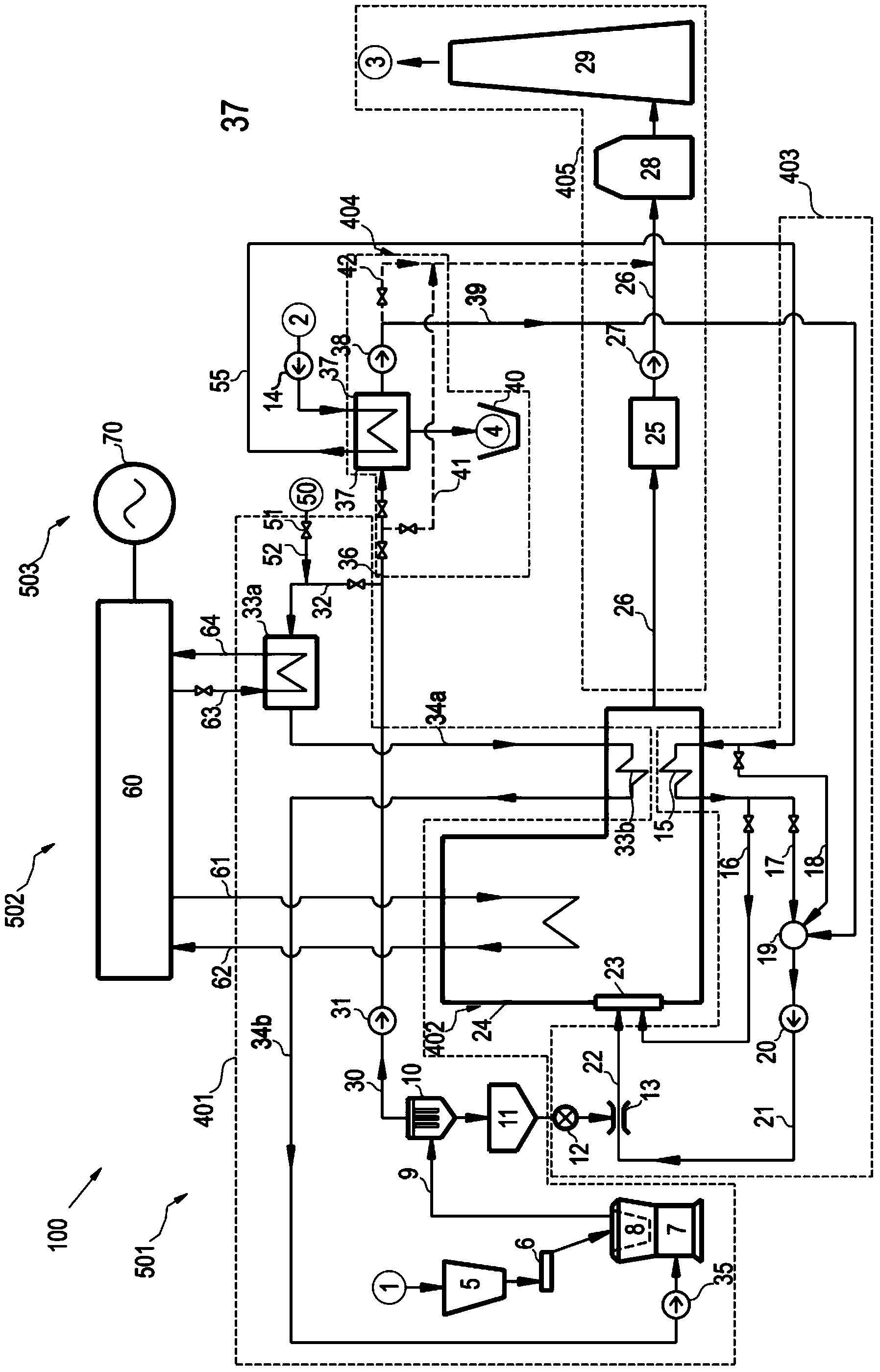

Open powder making steam warm air type boiler unit and power generation system thereof

InactiveCN104132364AHigh implementabilityCost-Effective RecyclingIndirect carbon-dioxide mitigationSteam engine plantsCold airAir preheater

The invention provides an open powder making steam warm air type boiler unit used for burning raw coal and being connected with a turbine unit with a turbine. The open powder making steam warm air type boiler unit is characterized in that a drying agent mixing chamber is connected with a smoke extraction opening and a gas outlet of a coal powder collector, a first part exhaust extracted from exhaust and part of smoke extracted out of the smoke extraction opening are mixed and used as drying agents to be fed to a raw coal pre-drying device, a cold air pre-heating device preheats environment cold air to obtain warm air through low-pressure steam extracted out of a steam extraction opening of the turbine, an air preheater further heats the warm air to obtain hot air, one part of the hot air and the environment cold air are mixed to be used as primary air, an air and powder mixer mixes the primary air and coal powder to obtain air and powder mixtures, and the other part of the hot air is used as secondary air to be directly fed in a coal powder burner. The invention further provides a power generation system including the open powder making steam warm air type boiler unit and the turbine unit with the turbine.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Micro oil content ignition coal powder burner capable of improving initial ignition heat

ActiveCN101806452AReduce outputNot easy to ignitePulverulent fuel combustion burnersCoalPetroleum engineering

The invention provides a micro oil content ignition coal powder burner capable of improving initial ignition heat, which relates to a burner. The invention solves the problems of difficult ignition of coal powder and unstable burning of the existing burner. The invention has the technical scheme that the micro oil content ignition coal powder burner capable of improving the initial ignition heat of the invention comprises a No.1 main oil gun, a No.2 main oil gun, an oil gun installing branch pipe and a heat insulation burning sleeve barrel, wherein the heat insulation burning sleeve barrel is arranged in the inlet end of the oil gun installing branch pipe, the No.1 main oil gun and the No.2 main oil gun are arranged in the inlet end of the oil gun installing branch pipe from top to bottom, and both of the No.1 main oil gun and the No.2 main oil gun are communicated with an inner cavity of the heat insulation burning sleeve barrel. The invention is mainly applied to W flame boilers, the burnt and used coal types belong to lean coal and blind coal with the characteristics of low volatilization constituent content, high ignition temperature and difficult ignition.

Owner:HARBIN INST OF TECH

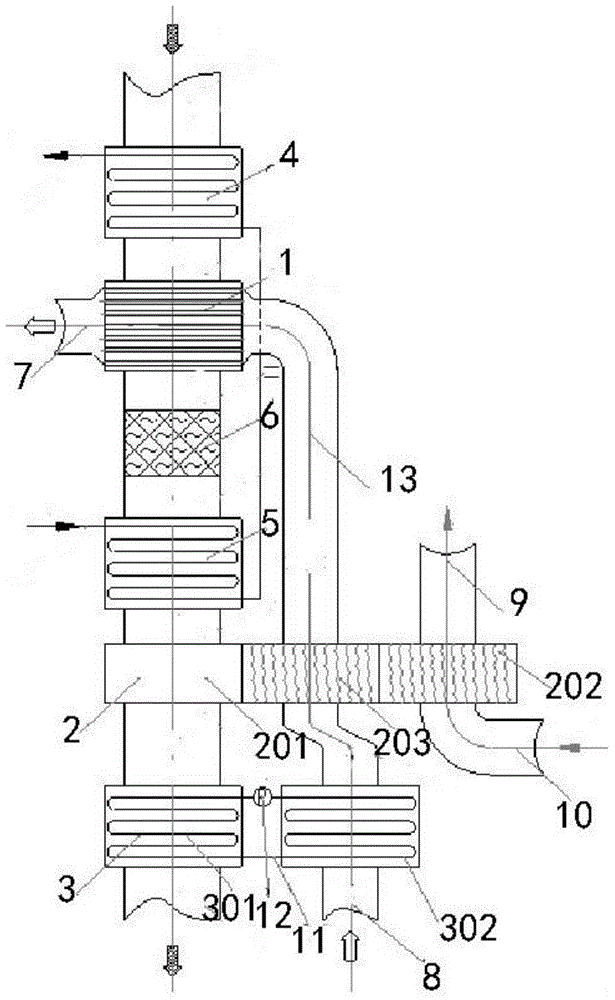

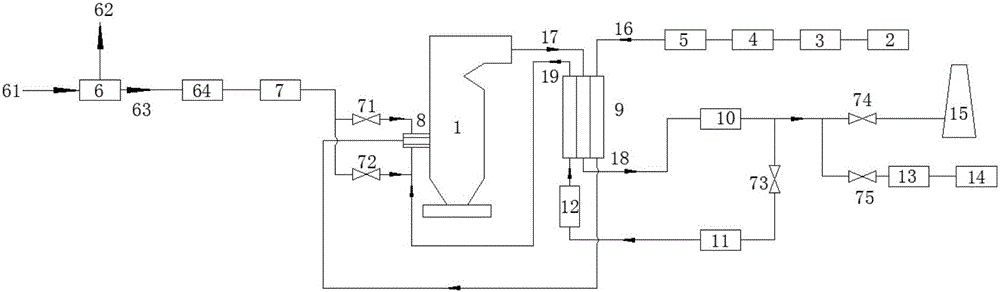

Boiler tail exhaust gas heat utilization system

ActiveCN104976635ALower the feverImproved stable fireCombustion processIndirect carbon-dioxide mitigationExhaust gasFlue

The invention discloses a boiler tail exhaust gas heat utilization system which comprises multiple stages of preheaters with the progressively-increasing and mixed temperatures and a coal economizer. The preheaters are communicated with the coal economizer through a flue. The boiler tail exhaust gas heat utilization system further comprises a secondary flue (13) penetrating through all the preheaters. Some heat of boiler tail exhaust gas is absorbed by the coal economizer, and the rest of the heat is totally used for heating primary air and secondary air entering a boiler, so that the boiler efficiency is improved by 0.5%-2%, and the coal consumption is lowered.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

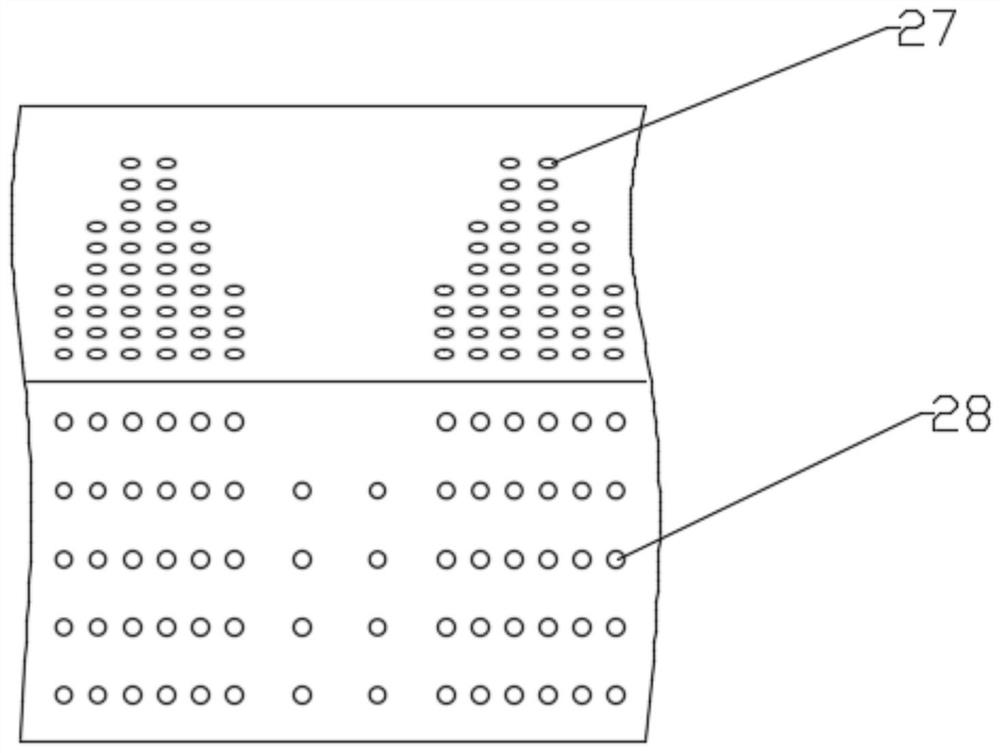

Trace oil igniting coal dust firing device for multiple oil guns

InactiveCN101603684AEasy to igniteNot easy to ignitePilot flame ignitersPulverulent fuel combustion burnersCoal dustHigh heat

The invention provides a trace oil igniting coal dust firing device for multiple oil guns, relates to a firing device, and solves the problem of easily failed ignition due to the fact that distance between a main oil gun and an auxiliary oil gun on the same side is large, and the main oil gun and an auxiliary oil gun on the opposite side are not alternately arranged in the prior firing device. The main oil gun and the auxiliary oil gun on the opposite side are alternately and oppositely arranged on side walls of a concentrated coal dust pipeline; distances of crossing points among the central line of the main oil gun, the central line of the auxiliary oil gun on the same side and the central line of the concentrated coal dust pipeline are between 80 and 100mm; and distances of the crossing points of the central line of the main oil gun, the central line of the auxiliary oil gun on the opposite side and the central line of the concentrated coal dust pipeline are between 500 and 700mm. The distance between the main oil gun and the auxiliary oil gun on the same side is close so as to ensure that fuel which is sprayed from the auxiliary oil gun and has excellent atomization can be directly sprayed into high temperature flame generated by ignition of the main oil gun for fierce firing, and the flame generated after fuel sprayed from the main oil gun and the auxiliary oil gun is fired can support each other to form whole flame which has large length and roughness and good rigidity and can ignite high concentrated coal dust.

Owner:HARBIN INST OF TECH

Heat storage premixed biomass gas combustor and using method thereof

PendingCN111396873AReduce incomplete combustion heat lossIncreased turbulenceIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a heat storage premixed biomass gas combustor and a using method thereof. The combustor comprises a porous medium heat storage premixing pipeline, an inner combustion-supporting air pipeline, an outer gas pipeline, an outer combustion-supporting air pipeline, a first sleeve, an inner combustion-supporting air rotational flow adjusting pull rod, a second sleeve, an outer gasrotational flow adjusting pull rod, a plurality of inner combustion-supporting air axial rotational flow blades and a plurality of outer gas axial rotational flow blades. The porous medium heat storage premixing pipeline, the inner combustion-supporting air pipeline, the outer gas pipeline and the outer combustion-supporting air pipeline are sequentially distributed from inside to outside, an outlet of the porous medium heat storage premixing pipeline is filled with a ceramic foam type porous medium, and an inlet of the porous medium heat storage premixing pipeline coaxially communicates witha central gas pipeline and a central combustion-supporting air pipeline. According to the combustor and the using method thereof, the purpose of efficient and low-pollution combustion of biomass gascan be achieved.

Owner:HUANENG POWER INTERNATIONAL +2

Coal pulverizing system of boiler

InactiveCN106940026ACoal fineStrong load regulation abilityLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationAir preheaterCombustor

The invention discloses a boiler pulverizing system, one way of the air outlet side of the primary fan is communicated with the air inlets of at least two coal mills after passing through the air preheater, and the other way is directly connected with the air inlets of at least two coal mills connected; the air outlet side of the air blower communicates with the burner of the boiler after passing through the air preheater and the secondary air box; its pulverized coal delivery system includes at least one first pulverized coal delivery system and at least one second pulverized coal delivery system, The first pulverized coal conveying system includes an intermediate powder silo, a powder feeder and a powder discharge fan. One end of the intermediate powder silo communicates with the discharge port of the corresponding coal mill, and the other end passes through the intermediate powder silo and the powder feeder in sequence and then connects with the The burner is connected, one end of the powder exhaust fan is connected with the air outlet of the air preheater, and the other end is connected with the air inlet of the powder feeder. The discharge port of the coal machine is connected, and the other end is connected with the burner.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

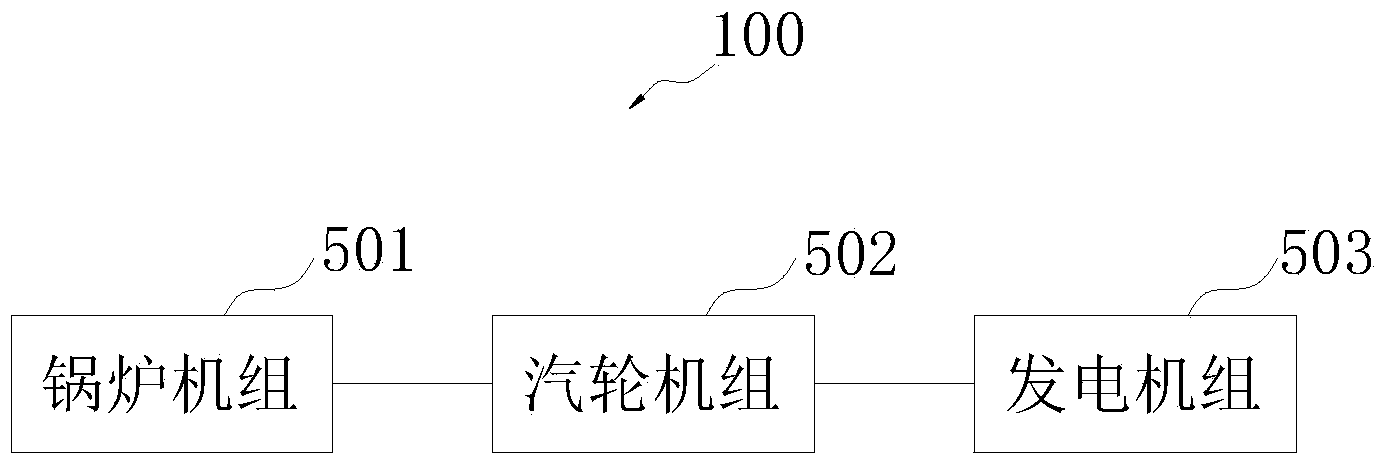

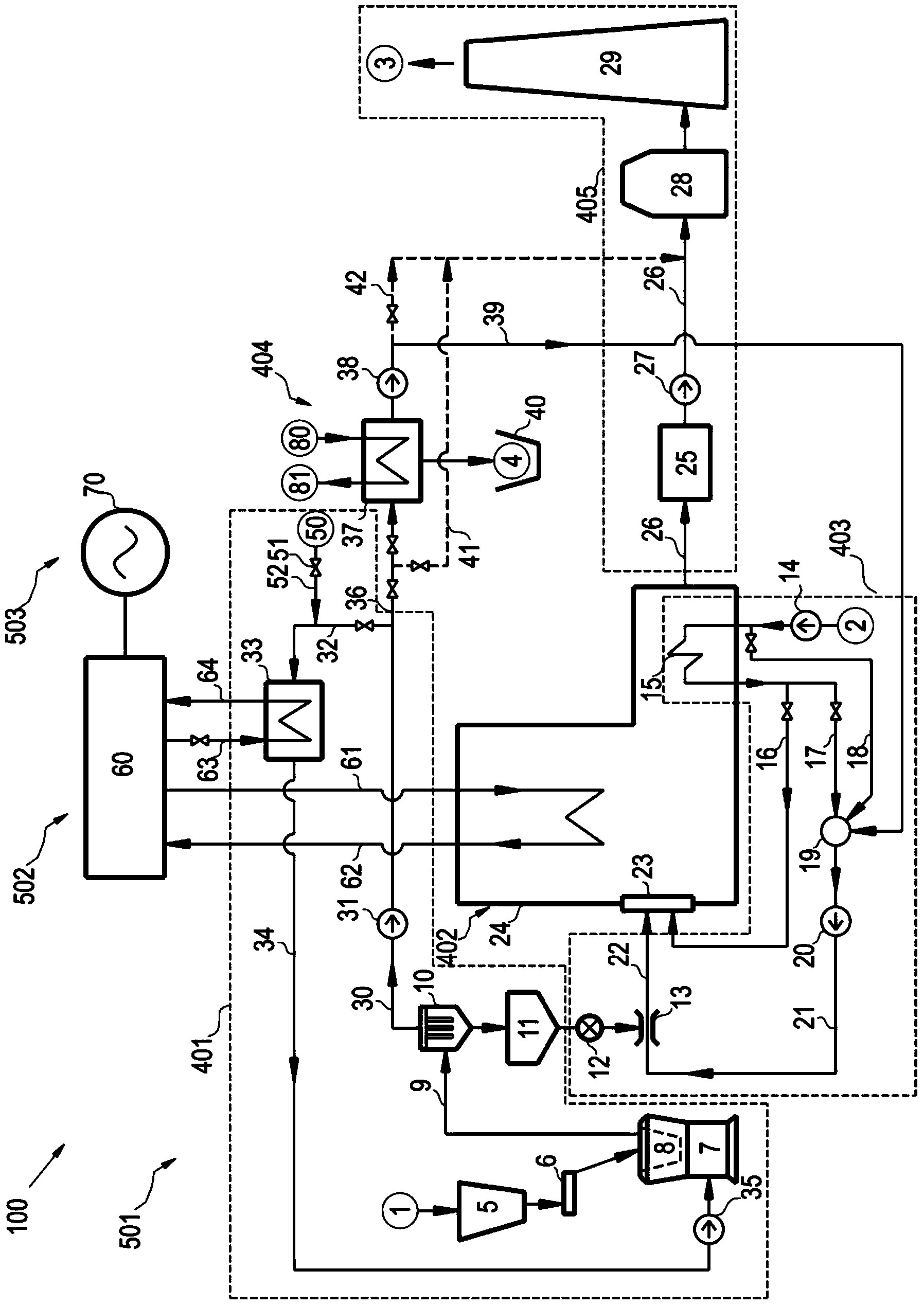

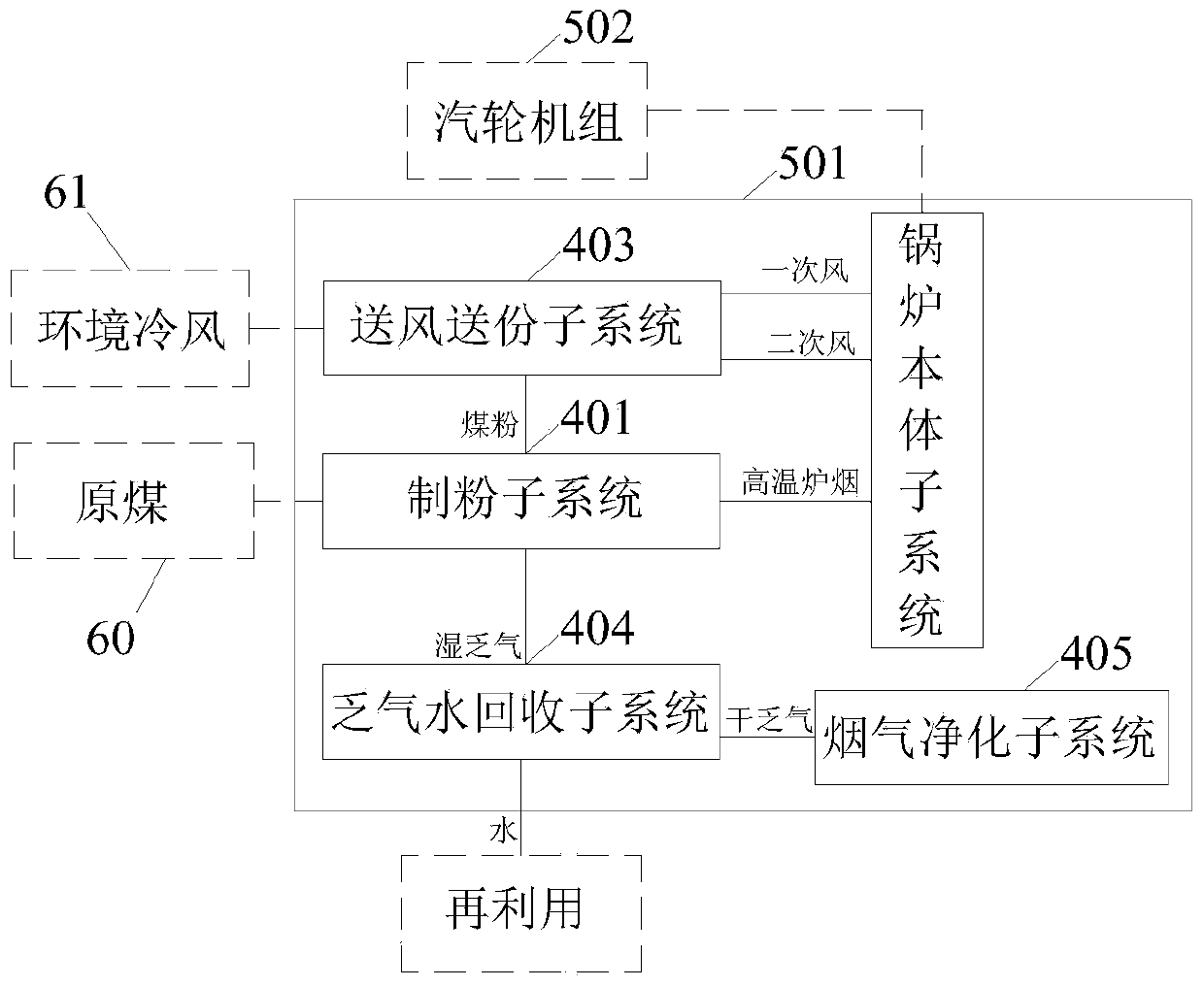

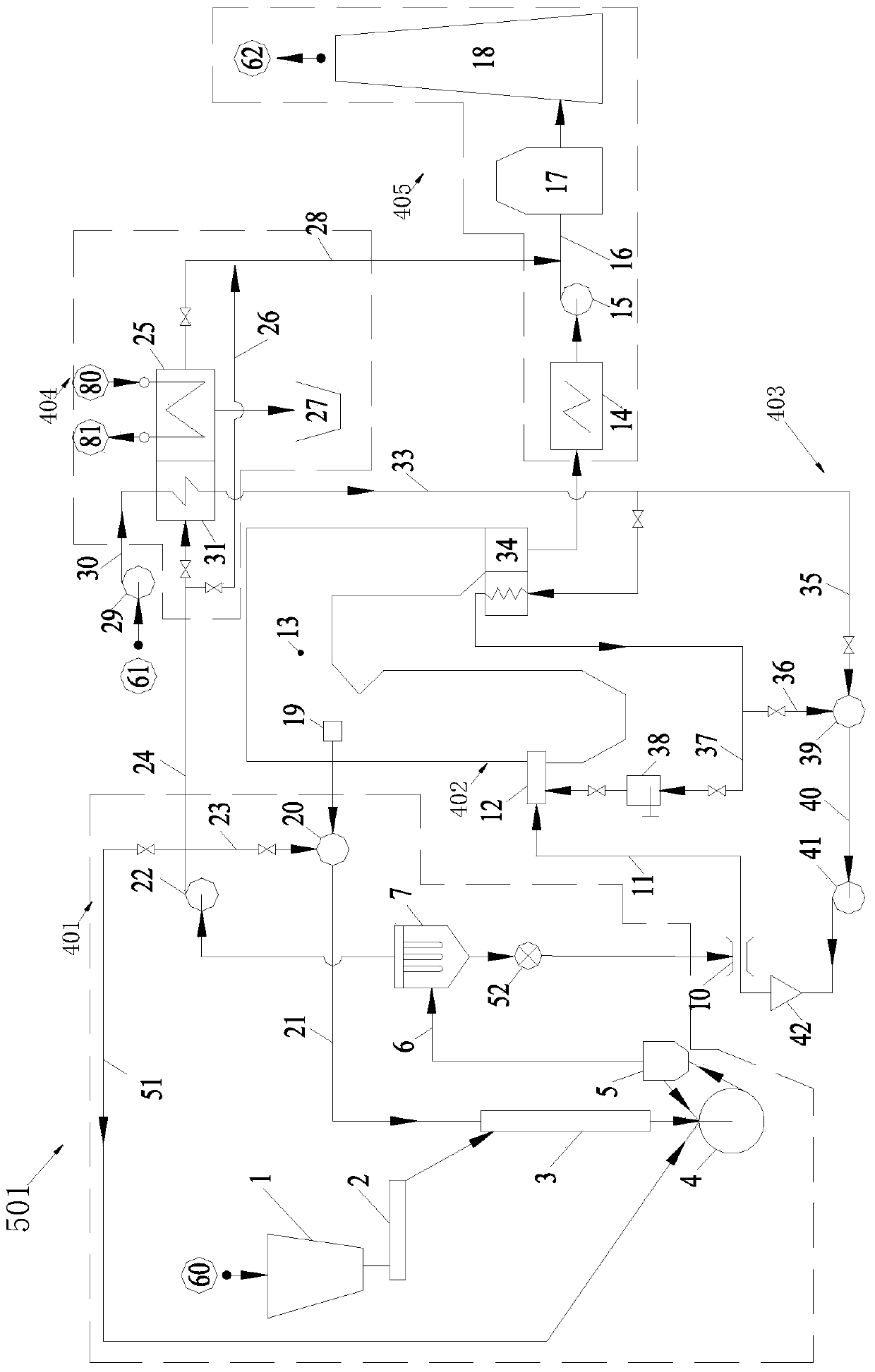

Superheated steam drying power-making coal-fired power generation system

ActiveCN104329667AGuaranteed uptimeAchieve recyclingSteam useDrying gas arrangementsAir preheaterPowder mixture

The invention provides a superheated steam drying powder-making coal-fired power generation system, which is used for driving a generator to generate power after burning of raw coal. The superheated steam drying power-making coal-fired power generation system comprises a boiler unit and a turboset, wherein the boiler unit comprises a powder-making subsystem, a boiler host machine subsystem, an air supply and powder supply subsystem and a dead steam water recovery subsystem; the powder-making subsystem comprises a steam and powder generating and drying device, a steam and powder separating device and a drying agent generating device; a dead steam heater of the drying agent generating device is used for heating dead steam in the dead steam heater by using steam extracted from a steam turbine to form superheated steam; an air preheater is used for heating a portion of environmental cold air to obtain hot air; a portion of the hot air is mixed together with the other portion of the environmental cold air in a primary air mixing chamber, and the mixed air enters an air and powder mixer as primary air; the other portion of the hot air is directly supplied to a pulverized coal burner as secondary air; the pulverized coal burner is used for burning pulverized coal in an air-powder mixture; the pulverized coal burns in a hearth together with the primary air and the secondary air to generate flue gas.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

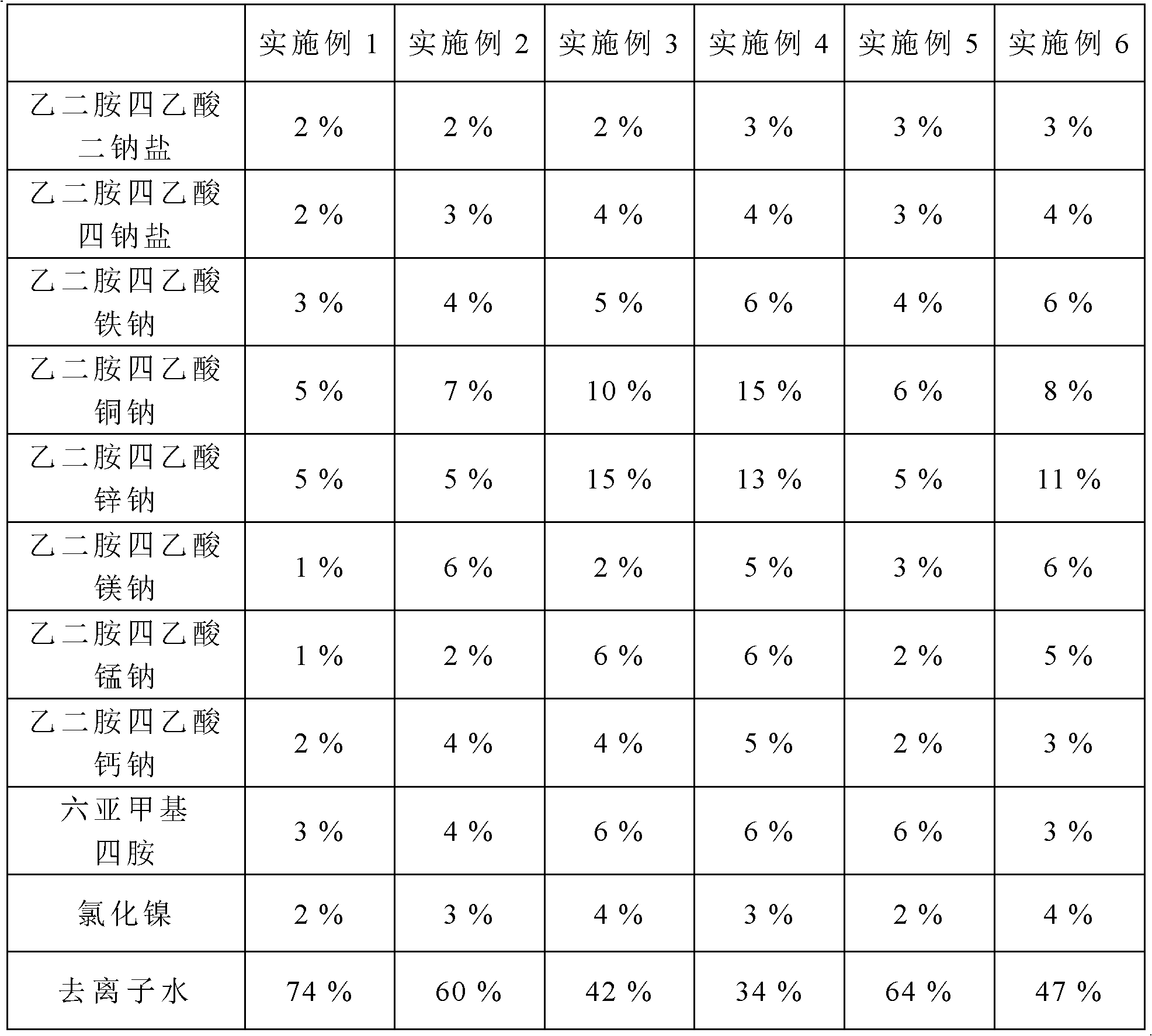

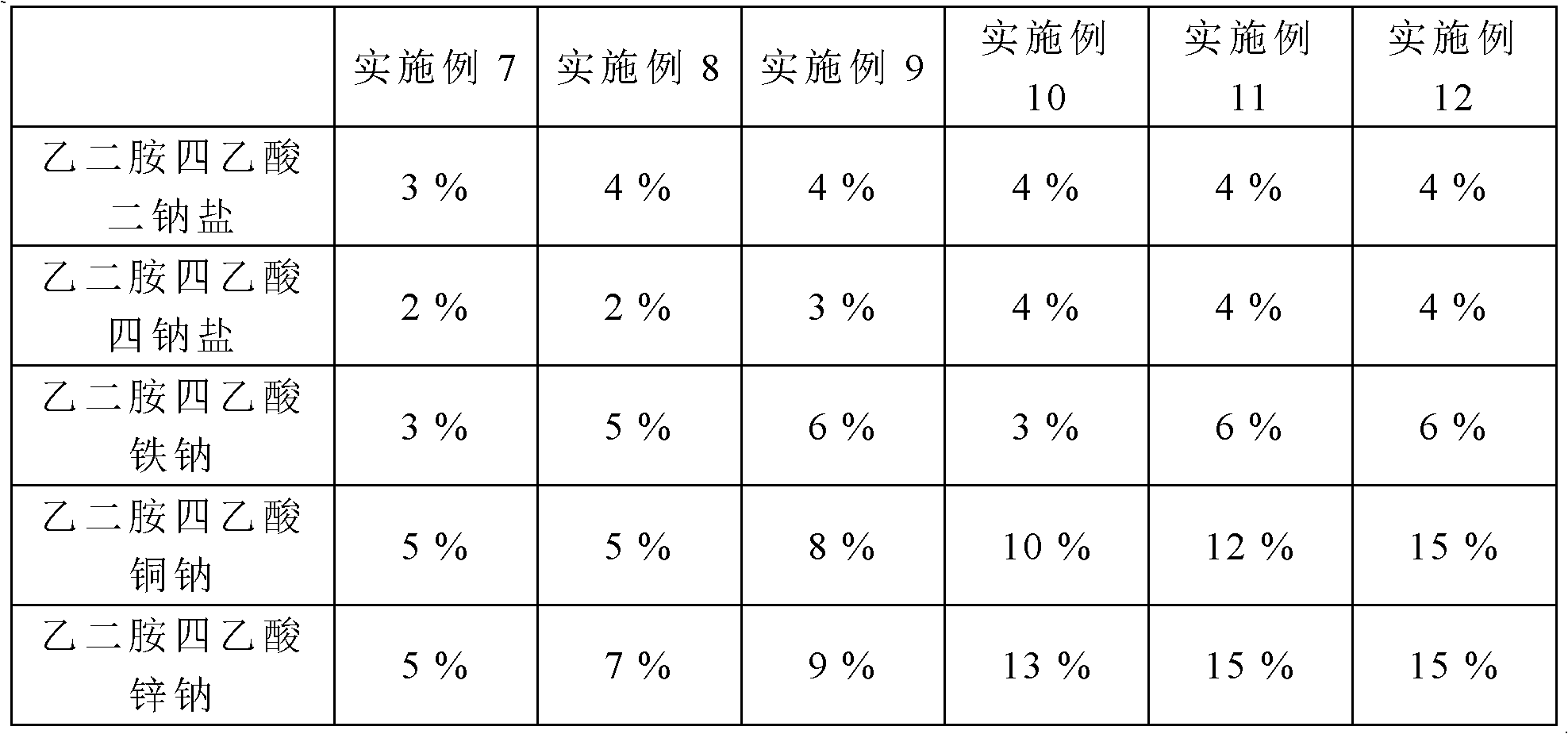

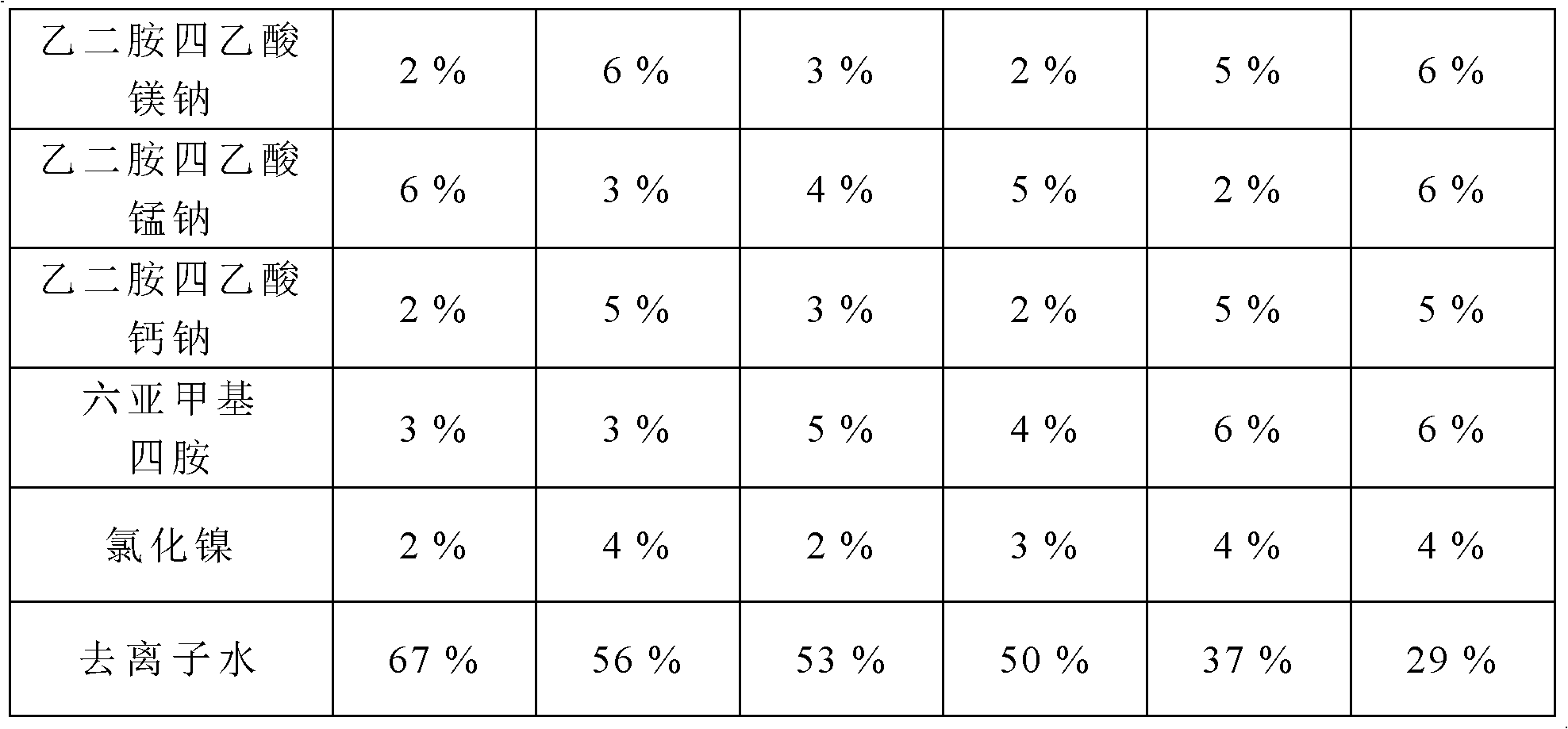

High-efficiency environment-friendly coal synergistic agent

The invention discloses a high-efficiency environment-friendly coal synergistic agent. The synergistic agent comprises one or more metal ion chelates. Furthermore, each metal ion chelate is edentate. The edentate is any one of EDTA (ethylene diamine tetraacetic acid) disodium salt, EDTA tetrasodium salt, EDTA ferrisodium, EDTA copper sodium, EDTA zinc sodium, EDTA magnesium sodium, EDTA manganese sodium and EDTA calcium sodium. The solutes dissolve in deionized water and are mixed uniformly, so that the high-efficiency environment-friendly coal synergistic agent is prepared. The high-efficiency environment-friendly coal synergistic agent takes the metal ion chelates as a catalyst main body, so as to greatly improve the safety and the stability in use, and ensure that the high-efficiency environment-friendly coal synergistic agent doesn't sublimate in a high-temperature coal milling stage and can be widely used in powder coal furnaces and circulating fluidized bed furnaces in large-scale fuel electric plants as well as rotary kilns in cement plants.

Owner:BEIJING HUAYE ZHONGKE TECH DEV

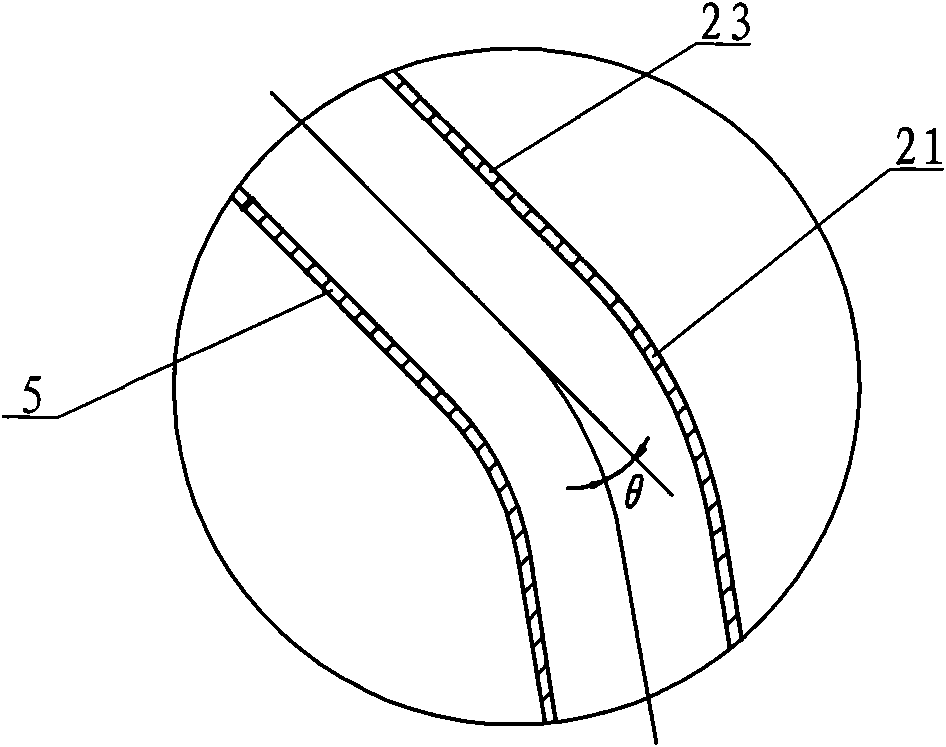

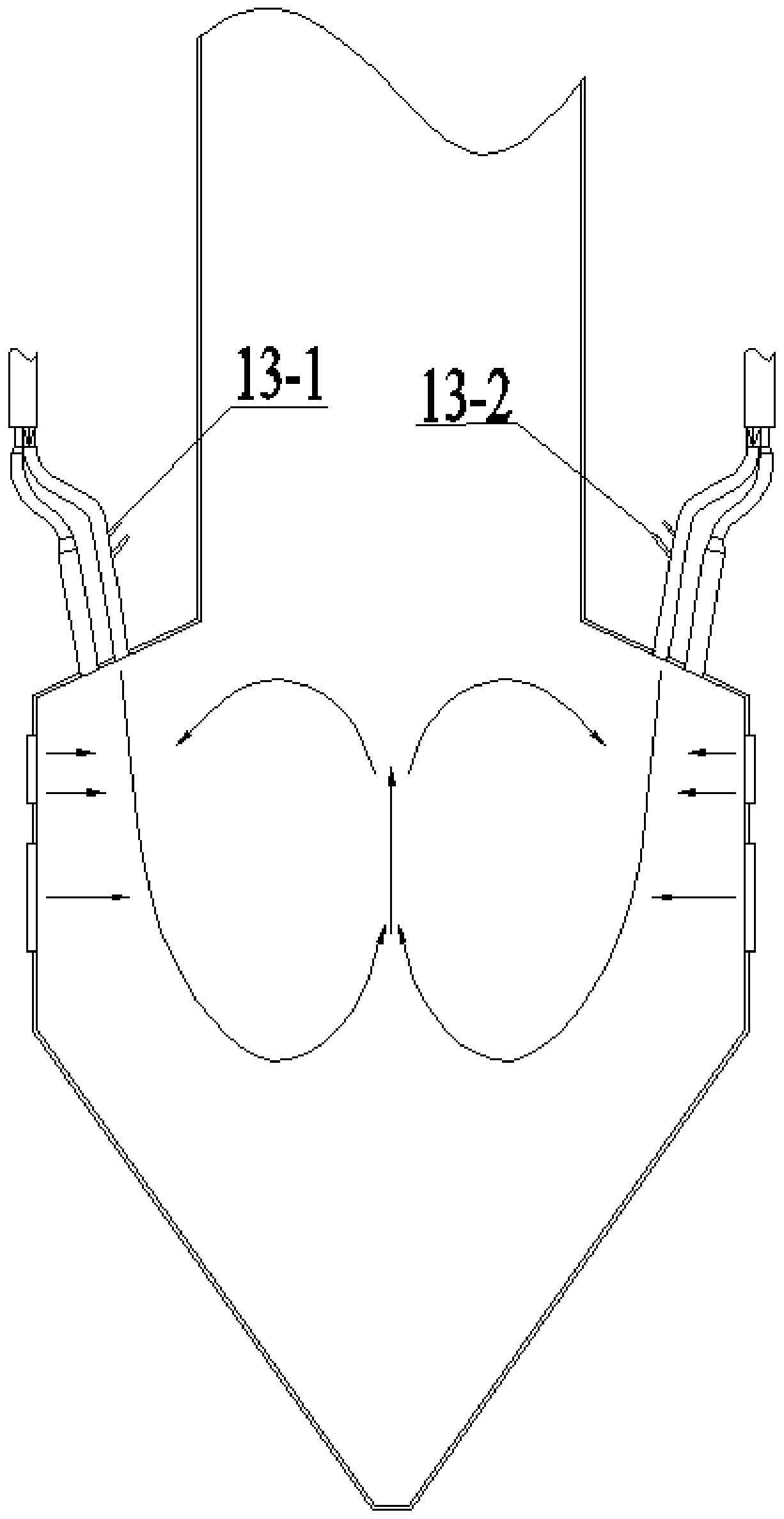

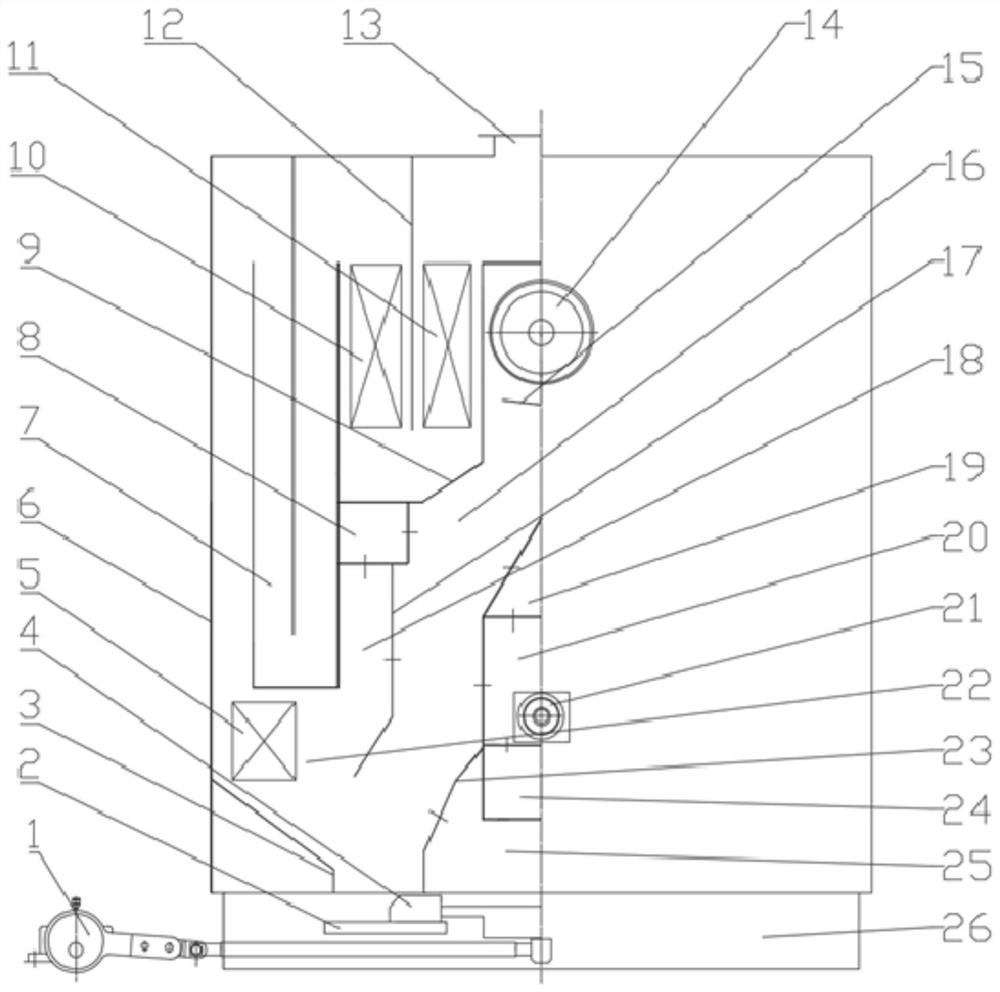

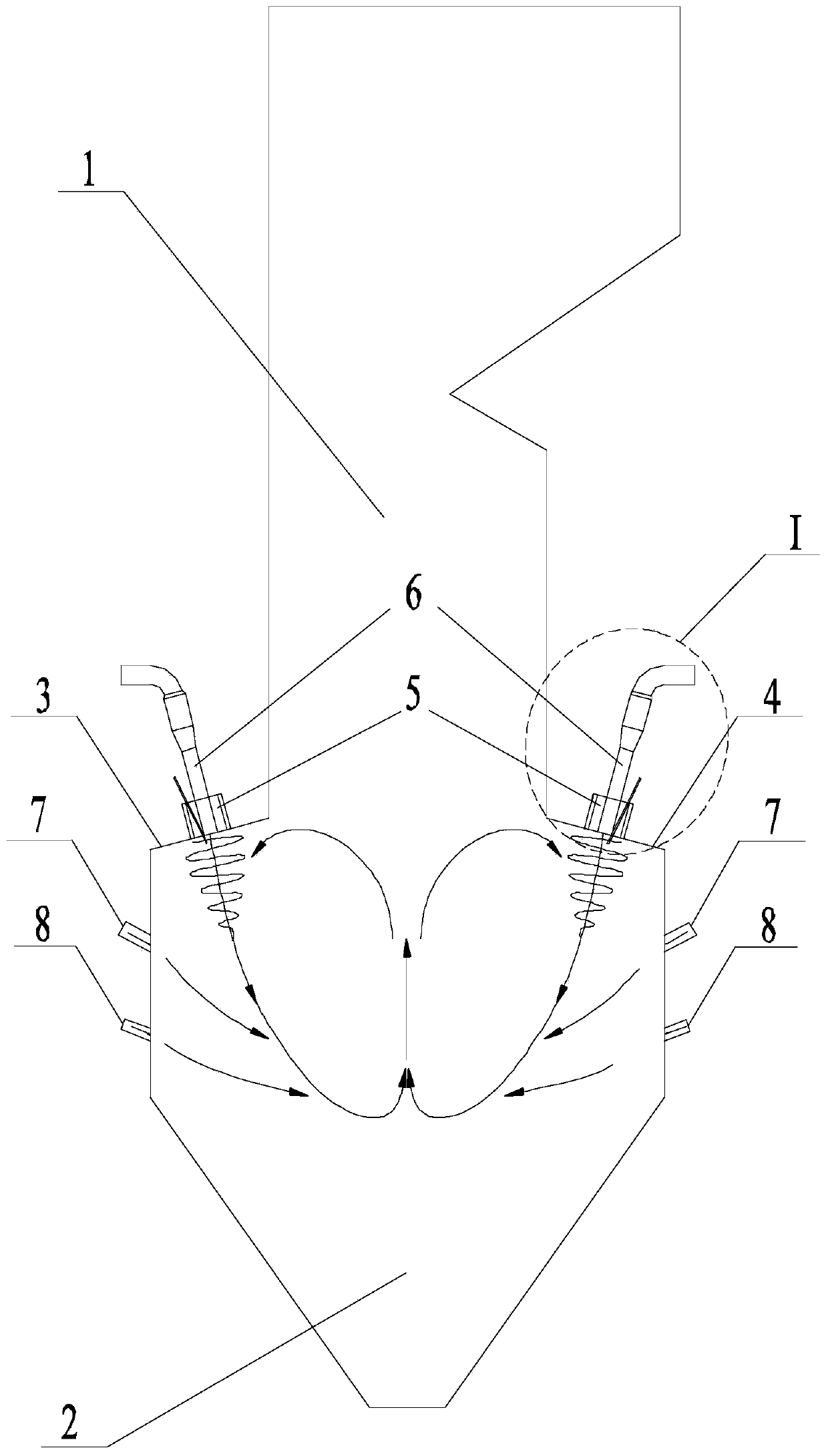

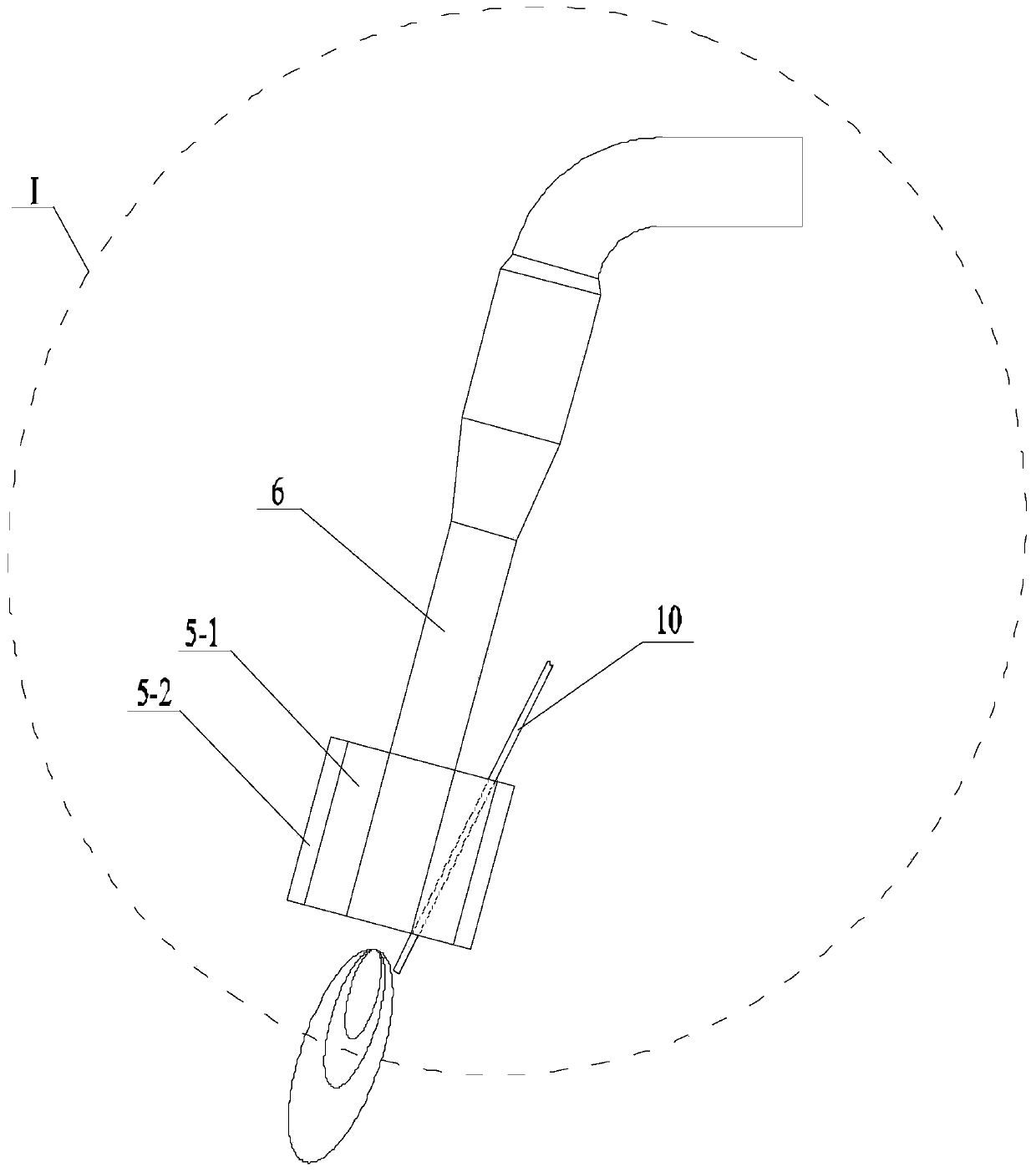

W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors

InactiveCN111023084APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorPower station

The invention provides a W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors, and relates to a power station boiler which adopts the flexible peak regulation technology. The W flame boiler with the double-cyclone-barrel thick and thin pulverized coal separation type combustors is used for solving the problems that a W flame boiler is poor in ultralowload stable combustion and operation capacity, and the flexible peak regulation load cannot be 20%. The W flame boiler comprises an upper combustion chamber, a lower combustion chamber, a front boiler arch, a rear boiler arch, a front wall, a rear wall, the multiple double-cyclone-barrel thick and thin pulverized coal separation type combustors and multi-layer arch bottom secondary air nozzles. Each double-cyclone-barrel thick and thin pulverized coal separation type combustor comprises two thick pulverized coal airflow nozzles and two exhaust air nozzles. The upper combustion chamber, the front boiler arch, the front wall, the lower combustion chamber, the rear wall and the rear boiler arch are combined to form a boiler body. The multi-layer arch bottom secondary air nozzles are arrangedon the front wall and the rear wall in sequence from top to bottom. The double-cyclone-barrel thick and thin pulverized coal separation type combustors are installed on the front boiler arch and therear boiler arch in a linear mode, and the corresponding thick pulverized coal airflow nozzles and the corresponding exhaust air nozzles of each double-cyclone-barrel thick and thin pulverized coal separation type combustor communicate with the boiler body. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

Open powder making steam warm air type boiler unit and power generation system thereof

InactiveCN104132360AImprove operational safetyHigh implementabilityIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterCold air

The invention provides an open powder making steam warm air type boiler unit connected with a turbine unit with a turbine. The open powder making steam warm air type boiler unit is characterized in that a weighing coal feeder meters, adjusts and controls the raw coal weight corresponding to the boiler coal supply quantity fed in a hearth, a coal powder collector separates air and powder mixtures to obtain coal powder and exhaust, an air lock is used for preventing the coal powder against air channeling so as to keep the coal powder smooth in circulation, a cold air pre-heating device preheats environment cold air to obtain warm air through low-pressure steam drawn out of a steam extraction opening of the turbine, an air preheater further heats the warm air to obtain hot air, one part of the hot air and part of the environment cold air are mixed to be used as primary air, an air and powder mixer mixes the primary air and the coal powder to obtain the air and powder mixtures, the other part of the hot air is used as secondary air to be directly fed into a coal powder burner, and the first part of the exhaust and part of smoke extracted out of a smoke extraction opening are mixed to be fed into a raw coal pre-drying device through a drying agent mixing chamber.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

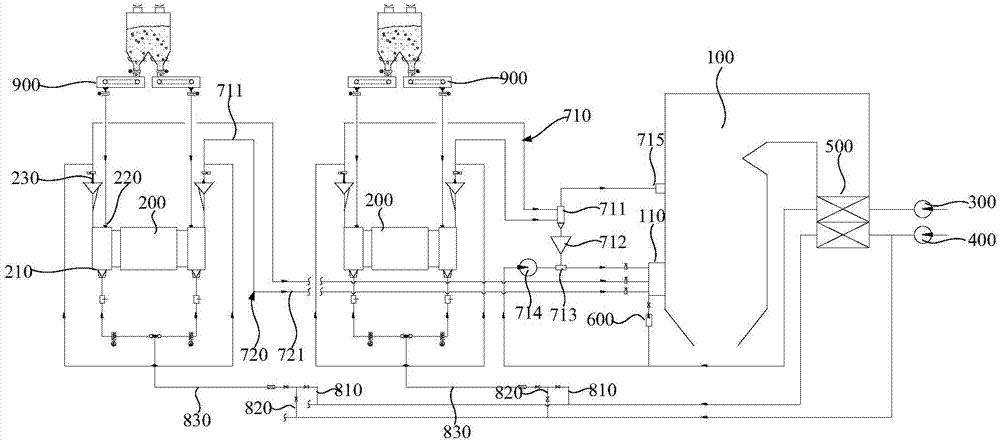

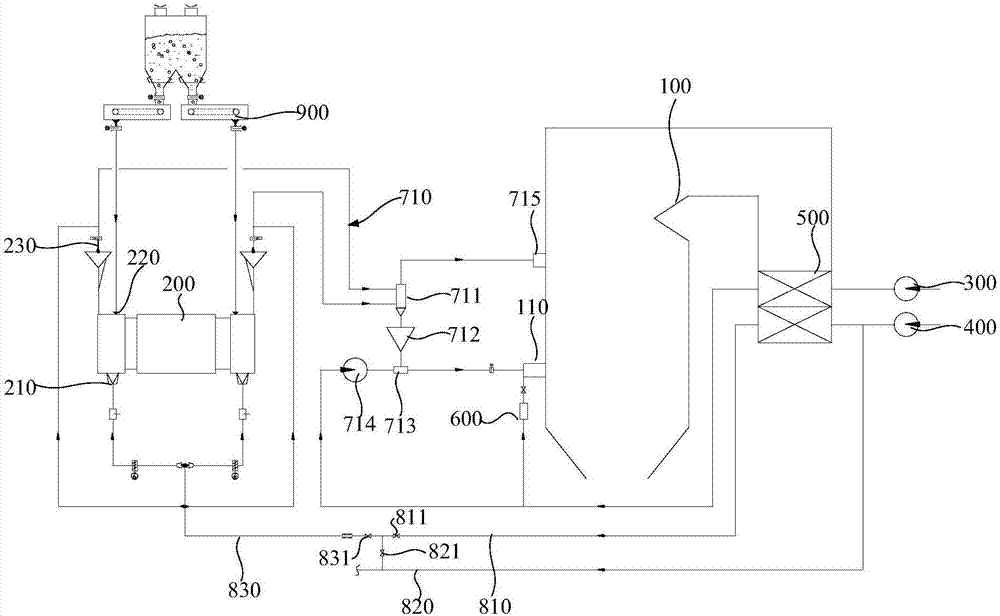

Coal water slurry flame-free oxygen-enriched combustion system

ActiveCN105757651ASolve the problem of high capture costEmission reductionBurnersIndirect carbon-dioxide mitigationGas heaterOxygen tank

The invention discloses a coal water slurry flame-free oxygen-enriched combustion system. The system comprises a hearth, a high-speed atomization combustor, a slurry supply system, an oxygen supply system, a flue gas circulating system and a flue gas discharging and recycling system. The high-speed atomization combustor comprises a primary air nozzle, a secondary air nozzle and a coal water slurry atomization nozzle; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an oxygen tank, a gas heater and a gas pressurizing pump; the flue gas circulating system comprises a flue gas heat exchanger, a dust remover, a circulating draught fan and a condenser; and the flue gas discharging and recycling system comprises a CO2 compression and storage device and a chimney. According to a coal water slurry flame-free oxygen-enriched combustion technology provided by the invention, oxygen is pressurized and heated and is mixed with circulating flue gas, and mixed gas is sprayed into a furnace to form volume combustion; coal water slurry is subjected to heat exchange through the flue gas heat exchanger, so that the initial temperature is improved and ignition heat is reduced; and the problems of a current coal water slurry boiler that the combustion efficiency is relatively low, the emission of NOx is high and the capturing cost of CO2 is high and the like can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

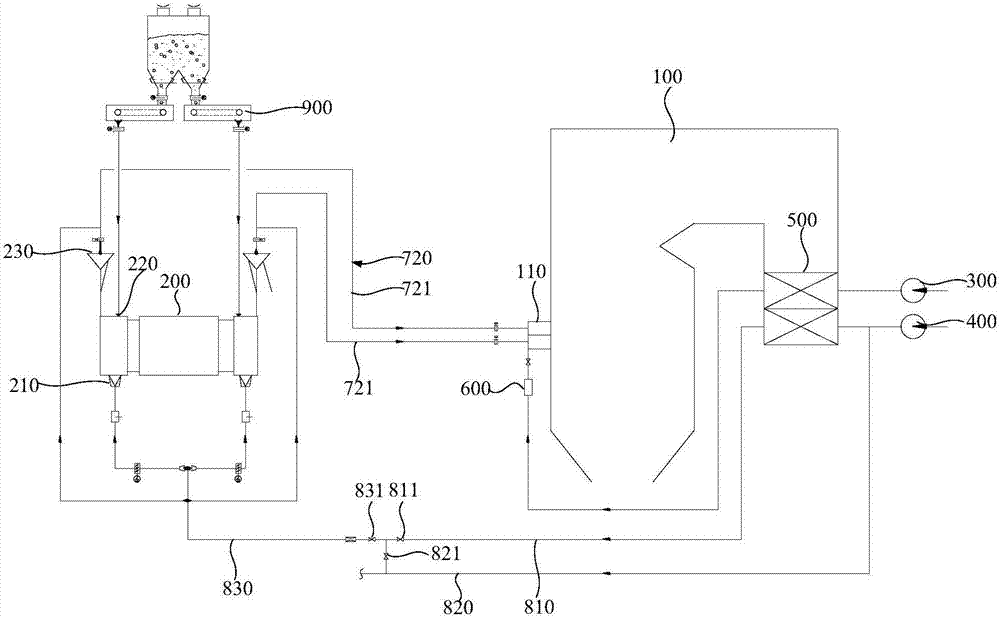

Solid waste decoupling combustion device, solid waste decoupling combustion system device and combustion method of solid waste decoupling combustion device

PendingCN112879912AIncrease temperatureEasy to dry and heat up quicklyIncinerator apparatusCombustion systemFlue gas

The invention provides a solid waste decoupling combustion device, a solid waste decoupling combustion system device and a combustion method of the solid waste decoupling combustion device. The combustion device comprises a shell, wherein the interior of the shell is divided into a feeding combustion channel, a flue gas mixed combustion channel and a flue gas afterflame channel which are sequentially communicated through partition plates in the material flowing direction, and the feeding combustion channel is divided into a preheating drying area, a pyrolysis gasification area, a semi-coke area and a burnout area in the material flowing direction; an air distribution device is arranged below the feeding end in the feeding combustion channel, and vent holes are formed in the outer wall of the side, close to the preheating drying area and the pyrolysis gasification area, of the air distribution device; at least one deflection baffle is arranged in the flue gas afterflame channel, and a rotary deflection flue gas flow channel is formed in the flue gas afterflame channel through the deflection baffles; and an air-smoke heat exchanger is arranged in the flue gas afterflame channel close to the outlet. Through the reasonable flue and air distribution design and the optimized combustion process, materials are fully combusted, and the combustion device has the advantages of being compact in structure, small in pollutant emission and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Fuel gas decoupling combustor and using method thereof

The invention relates to a fuel gas decoupling combustor and a using method thereof. The fuel gas decoupling combustor adopts a partition staged combustion mode of central and peripheral oxygen deficit and central area lean combustion, diffusion type oxygen-deficient combustion with high combustion stabilizing capacity and low heat intensity is adopted in the central combustion area, reliable ignition and low-load stable combustion of the oxygen-deficient combustion area are ensured, the peripheral oxygen-deficient combustion area controls temperature distribution of a combustion chamber by accurately controlling partition mixing of fuel gas and air, the radiation heat transfer capacity is improved, and mixed burnout of the peripheral fuel gas and the main combustion area is promoted. In aword, the problem that the combustion temperature of a diffusion combustion mode is too high in the central stage is effectively solved by the fuel gas decoupling combustor and the using method thereof, the combustion chamber is more uniform in heat intensity, high in flame fullness, high in heat transfer capacity and long in smoke retention time, the combustion efficiency is guaranteed under thecondition of low fan power consumption, meanwhile, generation of thermal NOX is reduced, and decoupling combustion of the fuel gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Secondary concentration double-nozzle micro-oil pulverized coal igniting device

ActiveCN101561138BLower the feverLow ignition temperaturePilot flame ignitersPulverulent fuel combustion burnersFire detectorCombustion chamber

The invention provides a secondary condensation double-nozzle micro-oil pulverized coal igniting device, and relates to a micro-oil pulverized coal igniting device of a W-shaped flame boiler. The device solves the problems of high heat absorption capacity, high ignition heat value and difficult ignition existing in the micro-oil pulverized coal igniting device of the prior W-shaped flame boiler. Both ends of a grid evenly dividing device are connected with a primary air pipe and a pulverized coal rich-lean separator respectively; the lower end of the pulverized coal rich-lean separator is connected with two rich pulverized coal pipes and two lean pulverized coal pipes respectively; the lower ends of the rich pulverized coal pipes and the lean pulverized coal pipes are communicated with a lower hearth respectively; the rich pulverized coal pipes are provided with bent pipe segments; a main oil gun, a fire detector and an auxiliary oil gun are orderly arranged on the outer side walls ofthe rich pulverized coal pipes from top to bottom and under the bent pipe segments; and a cavity formed between a clapboard and the main oil gun is a first-level combustion chamber, and a cavity formed under the clapboard is a second-level combustion chamber. In the device, the secondary concentration is carried out by the bent pipe segments in the two rich pulverized coal pipes of the pulverizedcoal rich-lean separator, so that the concentration of the pulverized coal is improved, and the pulverized coal is easily ignited.

Owner:HARBIN INST OF TECH

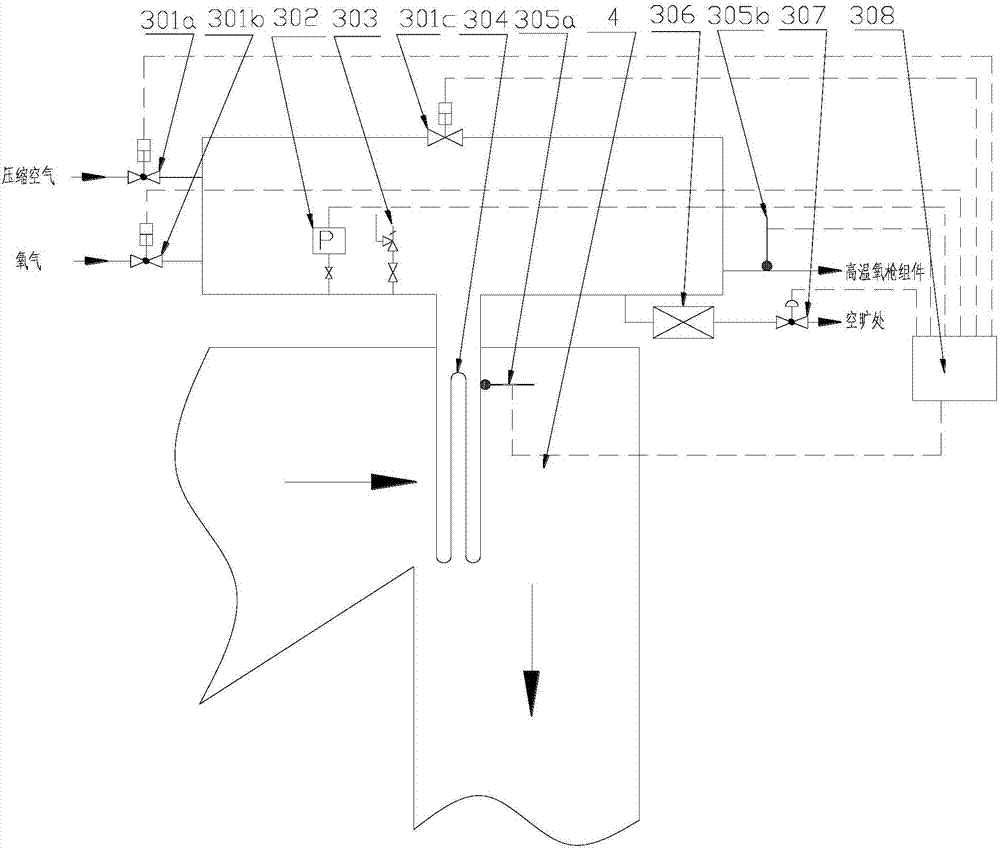

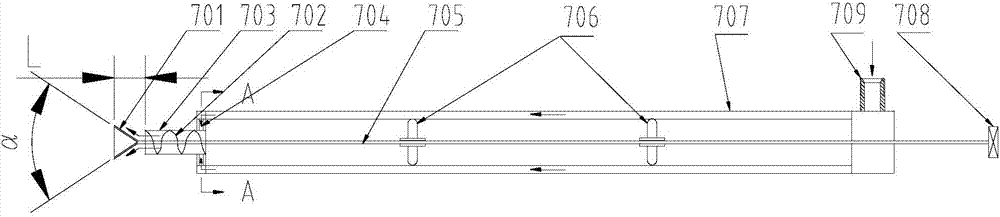

Automatic combustion stabilizing system used for opposed-firing boiler

ActiveCN107228356ANovel installation positionImprove combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelRefluxCombustion

The invention belongs to the field of lower-load combustion stabilizing of large power station boilers, and particularly relates to an automatic combustion stabilizing system used for an opposed-firing boiler, and the automatic combustion stabilizing system mainly solves the problem that oil consumption is great during low-load combustion stabilizing of the opposed-firing boiler. The automatic combustion stabilizing system comprises a high-temperature superheater, an oxygen gas heating device, a low-temperature reheater, a swirling burner, a high-temperature oxygen lance assembly, a pulverized coal tube elbow and the like. According to the automatic combustion stabilizing system, oxygen gas is heated to 800 DEG C by high-temperature flue gas on the tail part of the boiler, and is conveyed to a spray hole of the swirling burner to mix with pulverized coal turbulent gas flow through a high-temperature oxygen gas assembly; pulverized coal combustion is stabilized through high-temperature characteristics and strong oxidability of the high-temperature oxygen gas assembly, and needs of different operation working conditions can be met by changing a dispersion angle of high-temperature oxygen gas and reflux strength of high-temperature flue gas, so that lowest oil-free combustion stabilizing load of the boiler can be reduced to be 20% of rated load, and therefore, the oil-free combustion stabilizing purpose is realized.

Owner:SHANXI UNIV

W flame boiler adopting turbulent burners

ActiveCN111023083APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPower stationCombustor

The invention discloses a W flame boiler adopting turbulent burners, relates to a power station boiler adopting a flexible peak shaving technology, and belongs to the field of boilers. The invention aims to solve the problem that the W flame boiler adopts the turbulent pulverized coal burners in the prior art, the maximum peak shaving capacity of a boiler with a common micro-oil ignition mode is about 50%, the requirement of the government on the flexible peak shaving capacity of the power station boiler cannot be met; the W flame boiler adopting the turbulent burners comprises an upper hearth, a lower hearth, a front furnace arch, a rear furnace arch, a front wall, a rear wall and a plurality of turbulent pulverized coal burners, each turbulent pulverized coal burner comprises an adjustable cone pulling rod, a micro oil ignition gun and a flow guide cone, wherein the micro oil ignition guns are installed in the adjustable cone pulling rods, the bottom ends of the adjustable cone pulling rods are fixedly installed in the flow guide cones, the adjustable cone pulling rods, the micro oil ignition guns and the flow guide cones are installed in shells of the turbulent pulverized coal burners, and the turbulent pulverized coal burners are installed on a front furnace arch water wall and a rear furnace arch water wall correspondingly.

Owner:HARBIN INST OF TECH

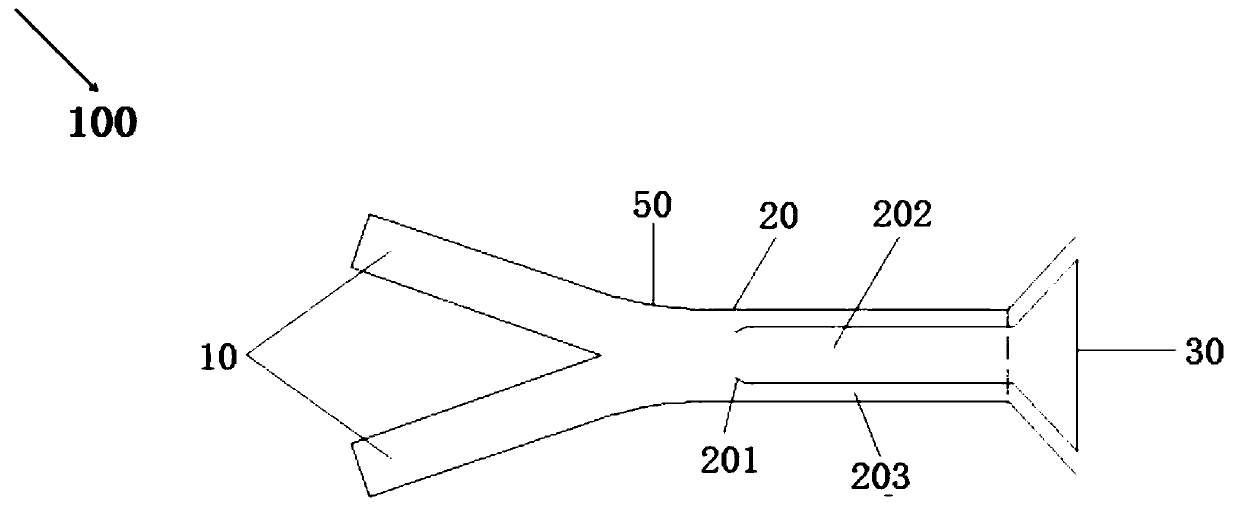

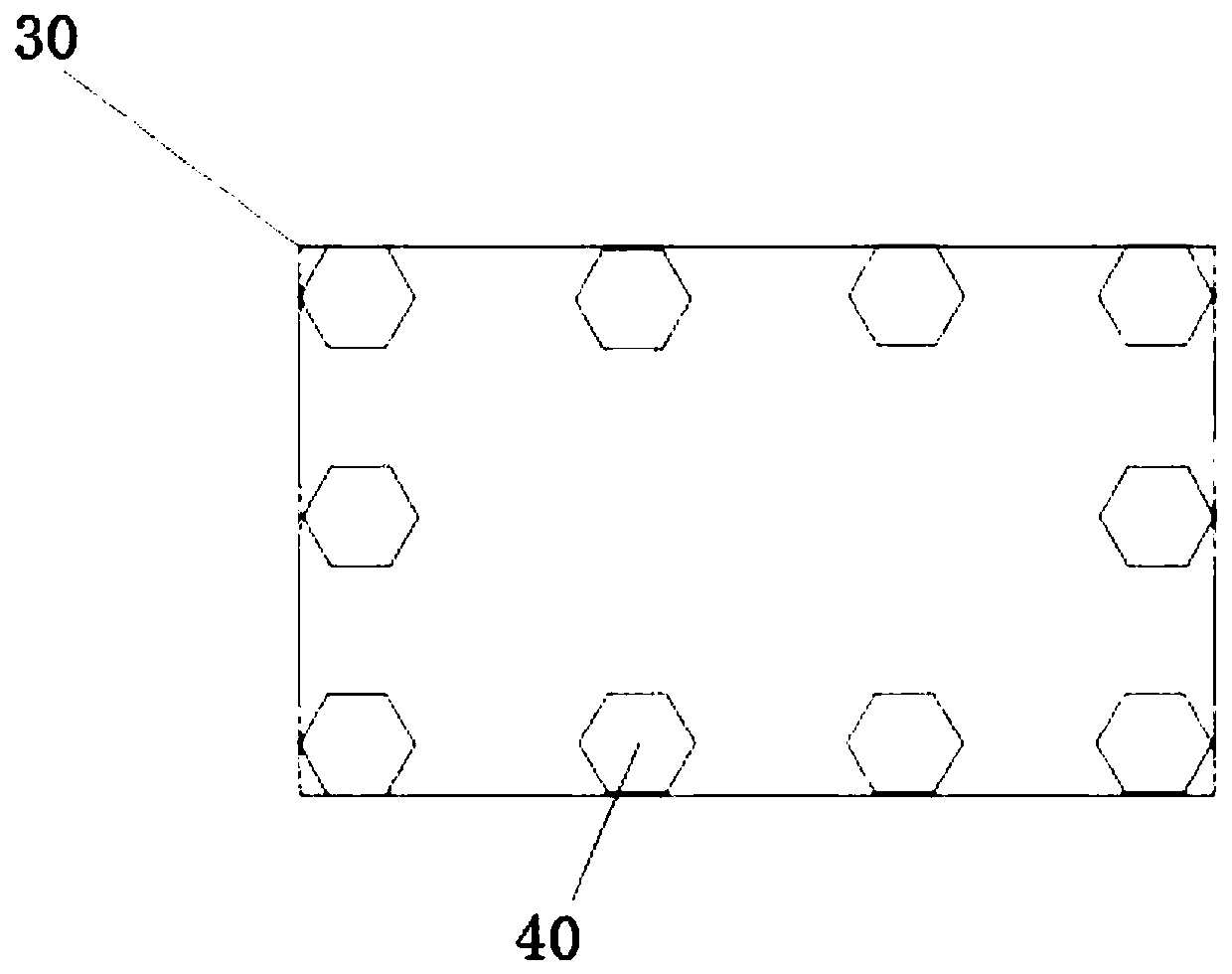

Horizontal dense-dilute concentration type direct flow pulverized coal burner

InactiveCN101109506ACompact structureEasy to transformPulverulent fuel combustion burnersCombustorLow load

A horizontal gradation rich direct-flow coal-powder burner is provided, which relates to a coal-powder gradation burner with four corners arranged tangentially. The invention is characterized in that, the air flow of the primary air coal powder is separated by gradation, at the outlet of the channel for the thicker air flow, a stage-I separating block and a stage-II separating block for thicker whiff are provided so as to separate the air flow with thick powder into upper, middle and lower whiffs; the nozzle structure uses a nozzle structure for rich thick whiff. The ignition process is completed in three stages. The invention not only reduces the firing heat necessary for firing, is good for firing and burning, but also solves the low-load de-oiling steady burning when a 300-600MWe boiler burns difficult-to-burn coal; is especially suitable for 100, 200, 300 and 600MWe boilers to burn low-quality bituminous coal, poor coal, semi anthraciferous coal and anthraciferous coal as well as suitable for rebuilding the said boilers, also is good for reducing the emission of NOx and eliminating slagging scorification and corrosion under high temperature of the water-cooled wall in the burner area.

Owner:TSINGHUA UNIV

Exhaust warm air type boiler unit for open coal pulverization

InactiveCN104165372AHigh thermal efficiencyCost-Effective RecyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterMixing chamber

The invention provides an exhaust warm air type boiler unit for open coal pulverization. The boiler unit is used for burning raw coal and is characterized in that a weighing coal feeder is used for measuring, adjusting and controlling raw coal weight corresponding to the amount of boiler supplied coal conveyed into a hearth, an air locking device is used for preventing air cross flow of pulverized coal and maintaining smooth flowing of pulverized coal, a drying agent mixing chamber is connected with a smoke extracting opening and a gas outlet of the pulverized coal collector respectively, the first part of exhaust air extracted from the exhaust air and a part of the smoke extracted from the smoke extracting opening are mixed to be used as a drying agent which is sent into a raw coal pre-drying device, a cold air exhaust-air preheating device is used for preheating environment cold air through an exhaust warm air device to obtain warm air, a part of the warm air is further heated by an air preheater to obtain hot air, a part of the hot air and the other part of the warm air are mixed to be used as primary air, an air-pulverized-coal mixer mixes the primary air and pulverized coal to obtain air-pulverized-coal mixture, and the other part of the hot air is used as secondary air to be directly sent into a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Thick-thin burner

ActiveCN111237750AReduce wearUniform flow fieldPulverulent fuel combustion burnersThermodynamicsCombustor

The invention provides a thick-thin burner. The thick-thin burner comprises two pulverized coal inlet pipelines, a horizontal main pipeline, a spray hole and a plurality of blunt body components, wherein ends of the two pulverized coal inlet pipelines are provided with pulverized coal inlets, and the other ends of the two pulverized coal inlet pipelines are crossed with each other to form a V shape; the horizontal main pipeline is connected to a crossed part of the two pulverized coal inlet pipelines, and a guide plate is arranged inside the horizontal main pipeline, a pulverized coal primarypipeline is arranged inside the guide plate, and a pulverized coal auxiliary pipeline is arranged outside the guide plate; the spray hole is horn-shaped, and is connected to the guide plate; the bluntbody components are distributed at the periphery, close to the outlet end, of the spray hole, the horizontal main pipeline and the pulverized coal inlet pipelines are connected in a 150-degree roundchamfer; through the round chamfer, concentration of pulverized coal at the two sides of the horizontal main pipeline is lower than center concentration, so that primary thick-thin separation of pulverized coal is accomplished; one side, close to the pulverized coal inlet pipelines, of the guide plate and a pulverized coal incoming direction define an angle of 120-150 degrees, so that low-concentration pulverized coal at the two sides of the pulverized coal main pipeline is separated out and enters the pulverized coal auxiliary pipeline; and through the spray hole, pulverized coal cannot be quickly diffused to the boundary, so that center concentration of the pulverized coal at the spray hole is high, and peripheral concentration is low, and therefore, thick-thin separation is accomplished.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Exhaust warm air type boiler unit for open coal pulverization

InactiveCN104165373AHigh implementabilityIncrease the moisture content of exhaust gasIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionExhaust gasCoal

The invention provides an exhaust warm air type boiler unit for open coal pulverization. The boiler unit is used for burning raw coal and is characterized in that a drying agent mixing chamber is connected with a smoke extracting opening and a gas outlet of the pulverized coal collector respectively, the first part of exhaust air extracted from the exhaust air and a part of the smoke extracted from the smoke extracting opening are mixed to be used as a drying agent which is sent into a raw coal pre-drying device, a cold air exhaust-air preheating device is used for preheating environment cold air through an exhaust warm air device to obtain warm air, a part of the warm air is further heated by an air preheater to obtain hot air, a part of the hot air and the other part of the warm air are mixed to be used as primary air, an air-pulverized-coal mixer mixes the primary air and pulverized coal to obtain air-pulverized-coal mixture, and the other part of the hot air is used as secondary air to be directly sent into a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Superheated steam drying powder making type coal-fired power generation system

InactiveCN104373949AGuaranteed uptimeAchieve internal generationMachines/enginesIndirect carbon-dioxide mitigationCold airPulp and paper industry

The invention provides a superheated steam drying powder making type coal-fired power generation system which is used for driving a power generator to generate power after raw coal is burned. The coal-fired power generation system comprises a boiler unit and a turbine unit, wherein the boiler unit comprises a powder making sub system, a boiler main machine sub system, a wind and powder feeding sub system and a waste steam and water recycling sub system; the turbine unit comprises a water feeding pipe, a steam conveying pipe and a steam turbine. The powder making sub system comprises a steam powder generating and drying device, a steam powder separating device and a drying agent generating device. The drying agent generating device comprises a waste steam pumped steam heater and a waste steam smoke heater, wherein the waste steam pumped steam heater is used for preheating the waste steam through the condensation released heat generated by the steam pumped from the steam turbine to form the hot waste steam, and the waste steam smoke heater is used for further heating the hot waste steam through the smoke from a hearth to form the superheated steam serving as the drying agent. The waste steam and water recycling sub system comprises a waste steam and water recycling device for conducting condensation recycling on one part of the waste steam through the environmental cold air.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Coal water slurry oxygen-rich combustion system

InactiveCN105910098ASolve the problem of high capture costEmission reductionIndirect carbon-dioxide mitigationStationary tubular conduit assembliesOxygen tankHearth

The invention discloses a coal water slurry oxygen-rich combustion system. The coal water slurry oxygen-rich combustion system comprises a hearth, a combustor, a slurry supply system, an oxygen supply system, a flue gas circulation system and a flue gas discharging and recovering system; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an air separation device compressor and an oxygen tank; the flue gas circulation system comprises a flue gas heat exchanger, a deduster, a circulation fan and a condenser; and the flue gas discharging and recovering system comprises a CO2 compression and storage device and a chimney. Coal water slurry exchanges heat with high temperature flue gas, so the initial temperature is improved, and the ignition heat is reduced; and pure oxygen jet combustion is used in the igniting stage to reduce the igniting temperature of the coal water slurry and rapidly improve the combustion rate of the coal water slurry, and an oxygen-rich combustion technology is combined to solve the problems of difficult ignition, low combustion efficiency, high discharge of NOx and high CO2 capture cost of present coal water slurry boilers.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com