Patents

Literature

35results about How to "Reduce incomplete combustion heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

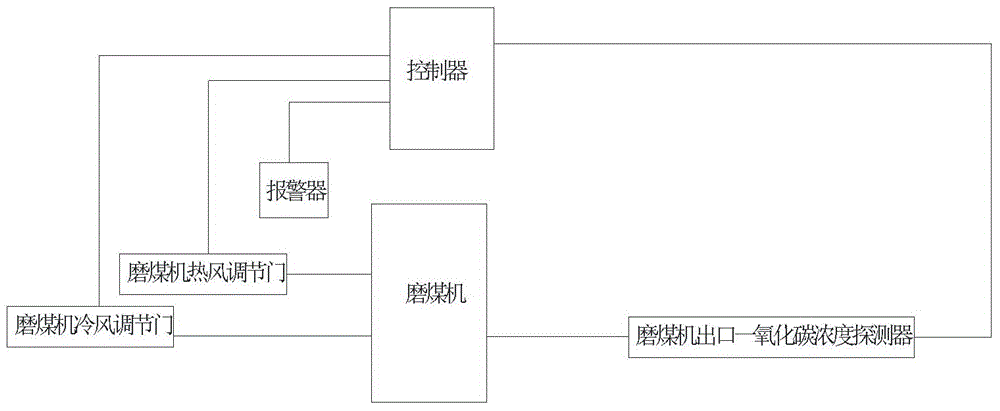

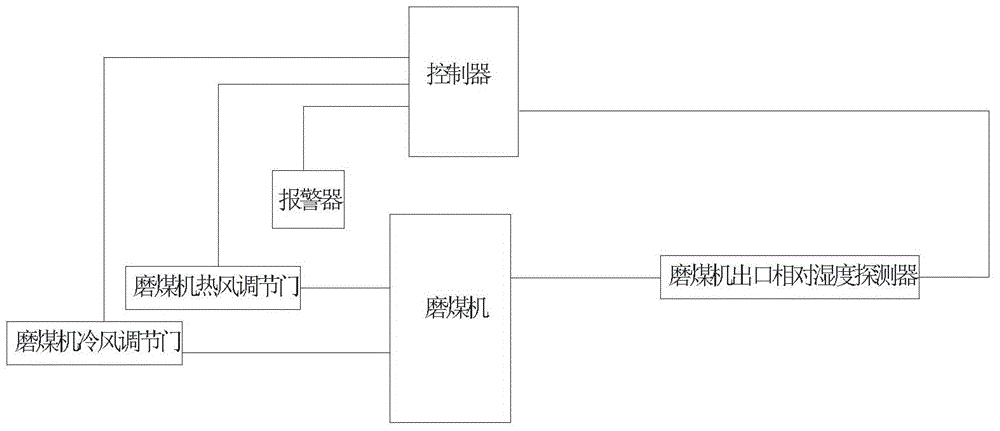

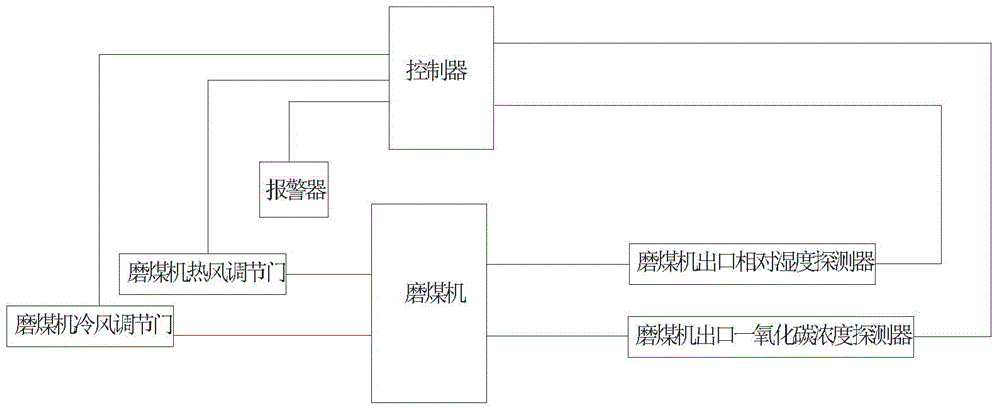

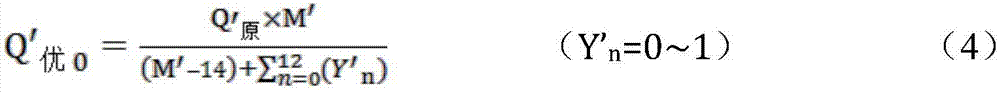

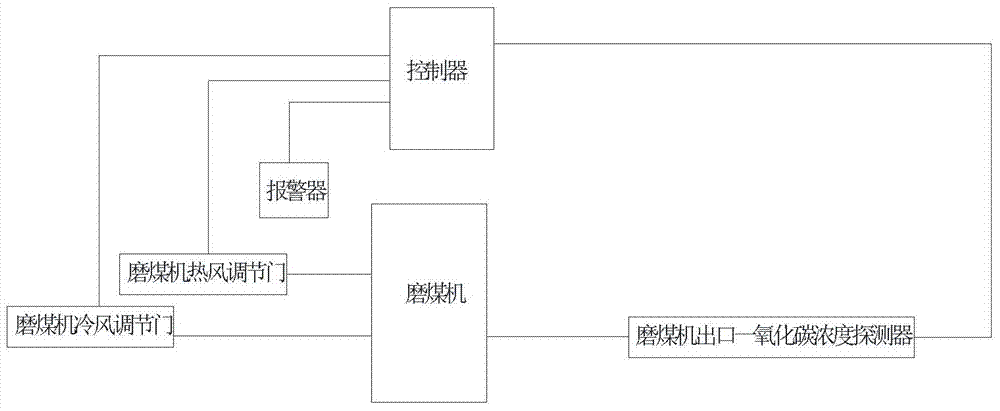

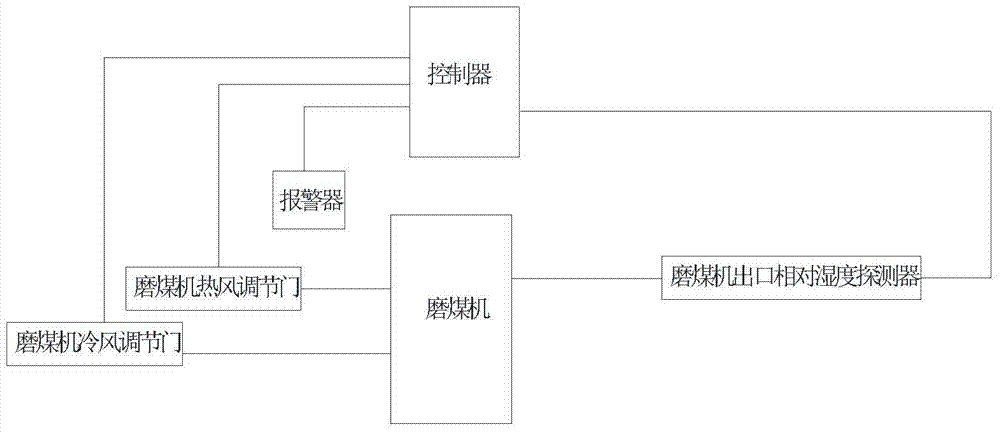

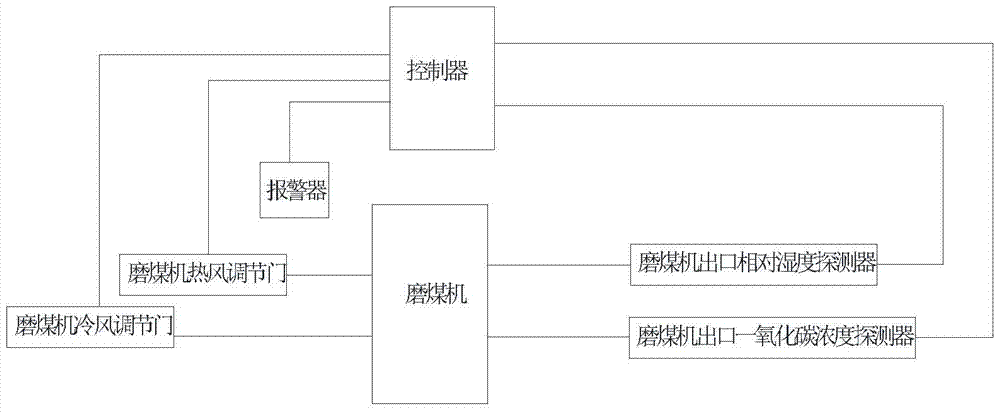

Control system and control method for outlet temperature of novel coal mill

ActiveCN104801416ARaise the outlet temperatureIncrease the level of automationGrain treatmentsLump/pulverulent fuel preparationTemperature controlCombustion

The invention discloses a control system and control method for outlet temperature of a novel coal mill. The control system comprises a controller, a coal mill outlet temperature detector and a coal mill hot air damper, wherein the coal mill outlet temperature detector is mutually connected with the controller; the controller is connected to the coal mill hot air damper. Compared with an existing control method, the control method disclosed by the invention can overcome the defects existing in an existing coal mill outlet temperature control method that a coal mill outlet temperature upper limit value is only set aiming at specific coal, the frequent change of the quality of coal supplied by the coal mill cannot be adapted, and a coal mill outlet temperature running value is low. According to the control system and the control method disclosed by the invention, the automatic level of coal mill operation can be improved, the outlet temperature of the coal mill is effectively improved, the power consumption generated during coal milling of the coal mill is reduced, and the carbon content of a product after pulverized coal combustion can be reduced.

Owner:SOUTHEAST UNIV

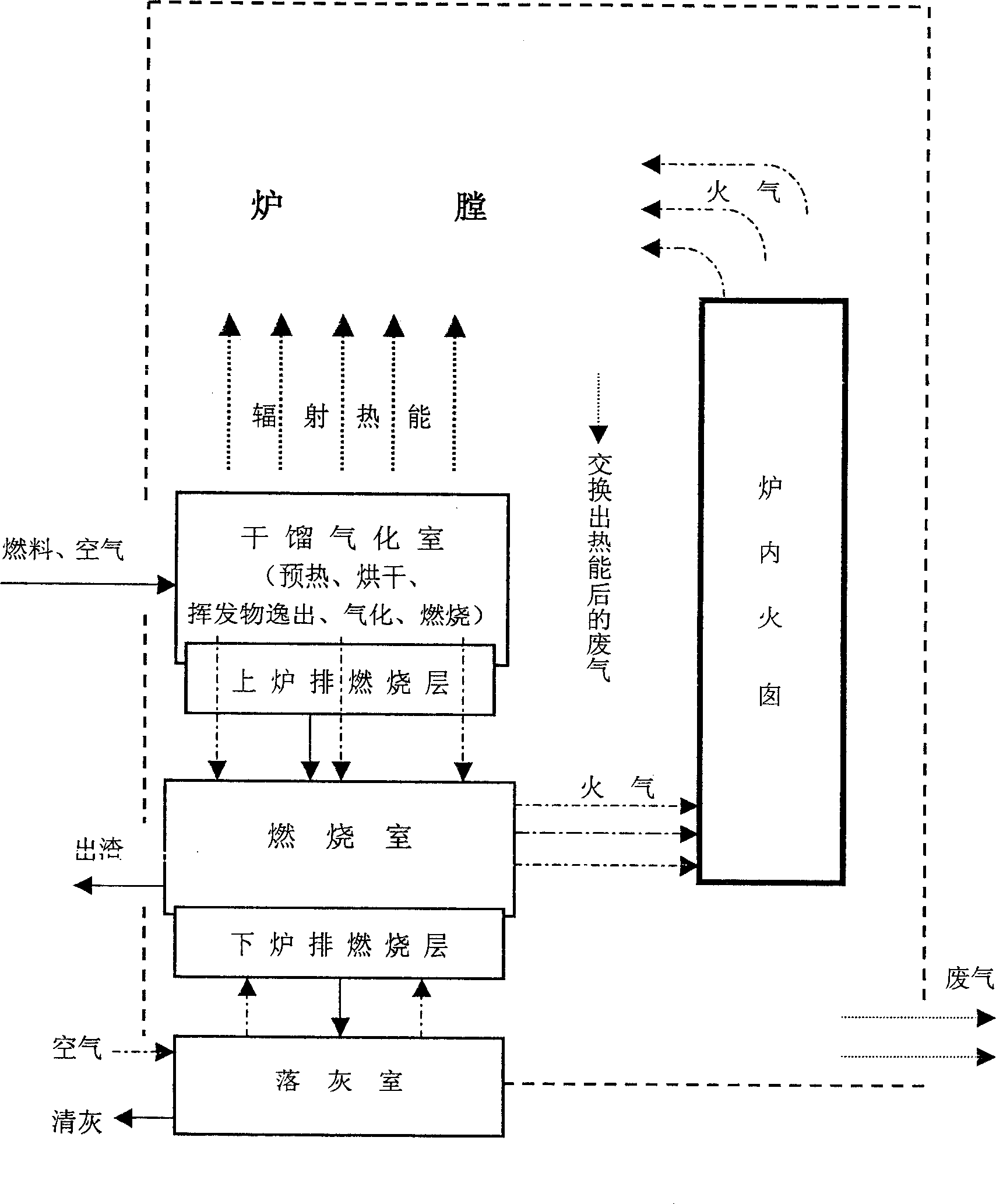

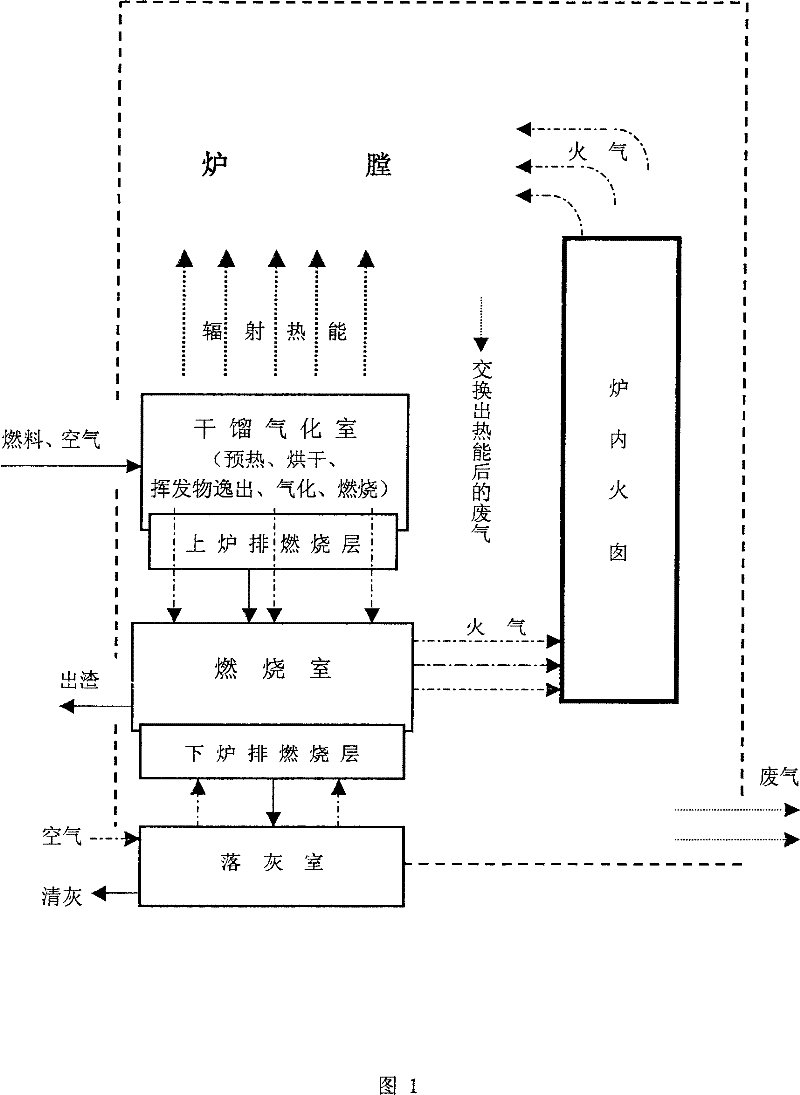

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490AAchieve clean combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

Industrial boiler for burning bio-briquettes

ActiveCN101818891AEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

Owner:ZHEJIANG JINGUO BOILER

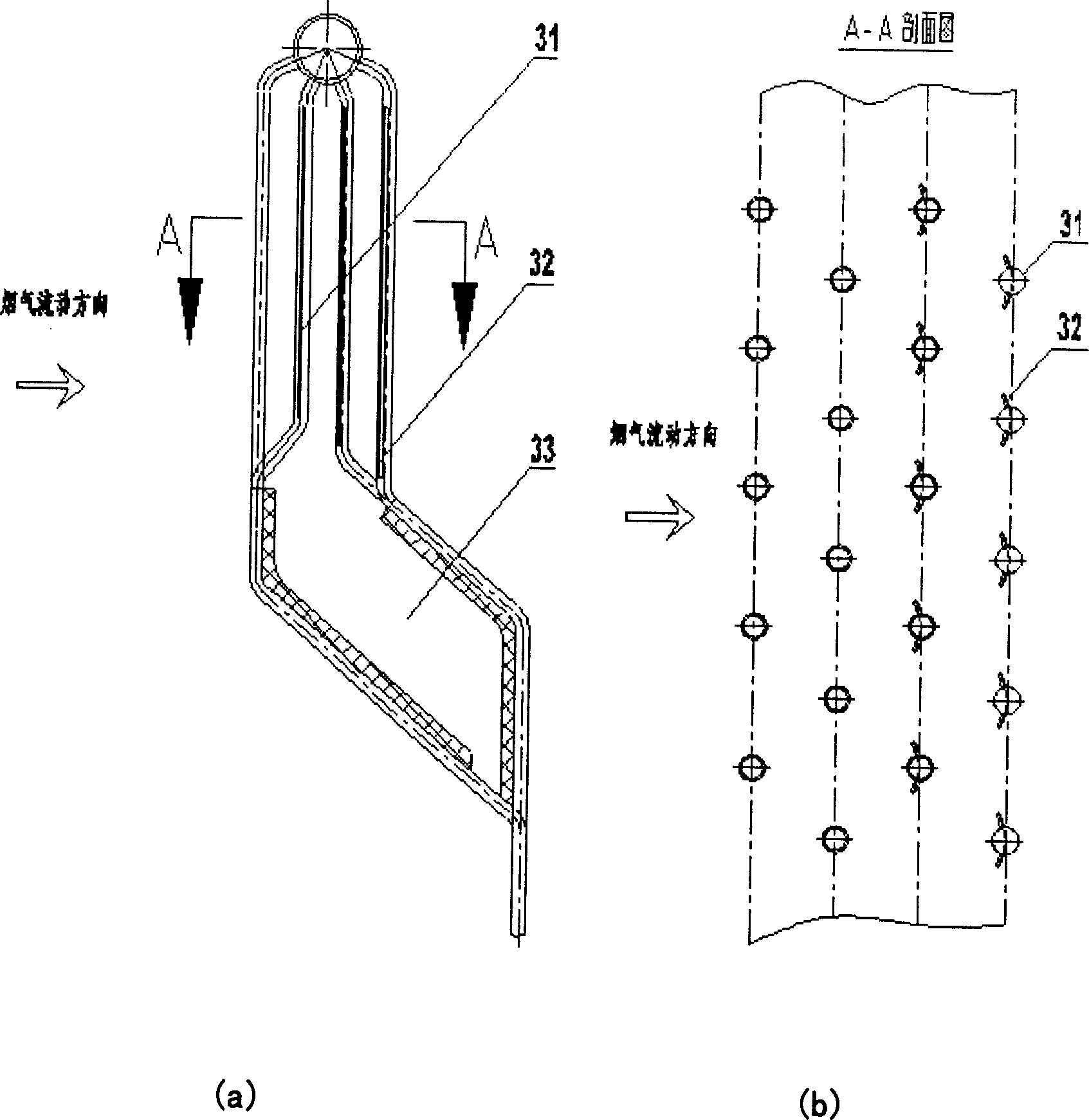

Internally circulating fluidized reburning device for fly ash based on high temperature separation

InactiveCN1884909AReduce carbon contentWith slagFluidized bed combustionApparatus for fluidised bed combustionSlagWater cooling

The invention relates to an ash internal cycle fluid afterburning device, based on high-temperature separation, wherein the invention uses furnace and secondary wind to realize initial high-temperature separation and sets high-temperature combined water cooling separator at the heated surface of water condense slag tube beam at the outlet of high-temperature smoke to realize ash high-temperature separation; and the separated ash is feedback to the high-temperature area to be cycle fluidized burnt, to meet the burning conditions as temperature, time, and disturbing mixing, to improve the burning rate and reduce the pollution. The invention can improve the burnt rate and the burning efficiency of coal.

Owner:XI AN JIAOTONG UNIV

Coke-removing and soot-cleaning combustion improver for boiler

InactiveCN101955818APromote combustionBurn safely and thoroughlyGaseous fuelsLiquid carbonaceous fuelsEngineeringSteam locomotive

The invention relates to a fuel additive, in particular to a coke-removing and soot-cleaning combustion improver for a boiler, suitable for various boilers, kilns, and other fuel furnaces using coal, oil, gas and natural gas as fuel, such as industrial boilers, civil boilers, ship boilers, drinking water boilers, steam locomotives, and the like. The coke-removing and soot-cleaning combustion improver is prepared from the following raw materials in percentage by weight: 12.5-30 percent of sodium nitrate, 17.50-25 percent of potassium nitrate, 5.50-11 percent of calcium nitrate, 15-19 percent of salt and 15-49.50 percent of borax. The coke-removing and soot-cleaning combustion improver can prevent the forming of new coke, is beneficial to the full combustion of the fuel, ensures that deposited chimney soot is fully combusted, reduces sticky carbon and carbide, plays a certain corrosion inhibition role to the boiler and prolongs the service life of the boiler.

Owner:吉林鑫聚源节能材料有限责任公司

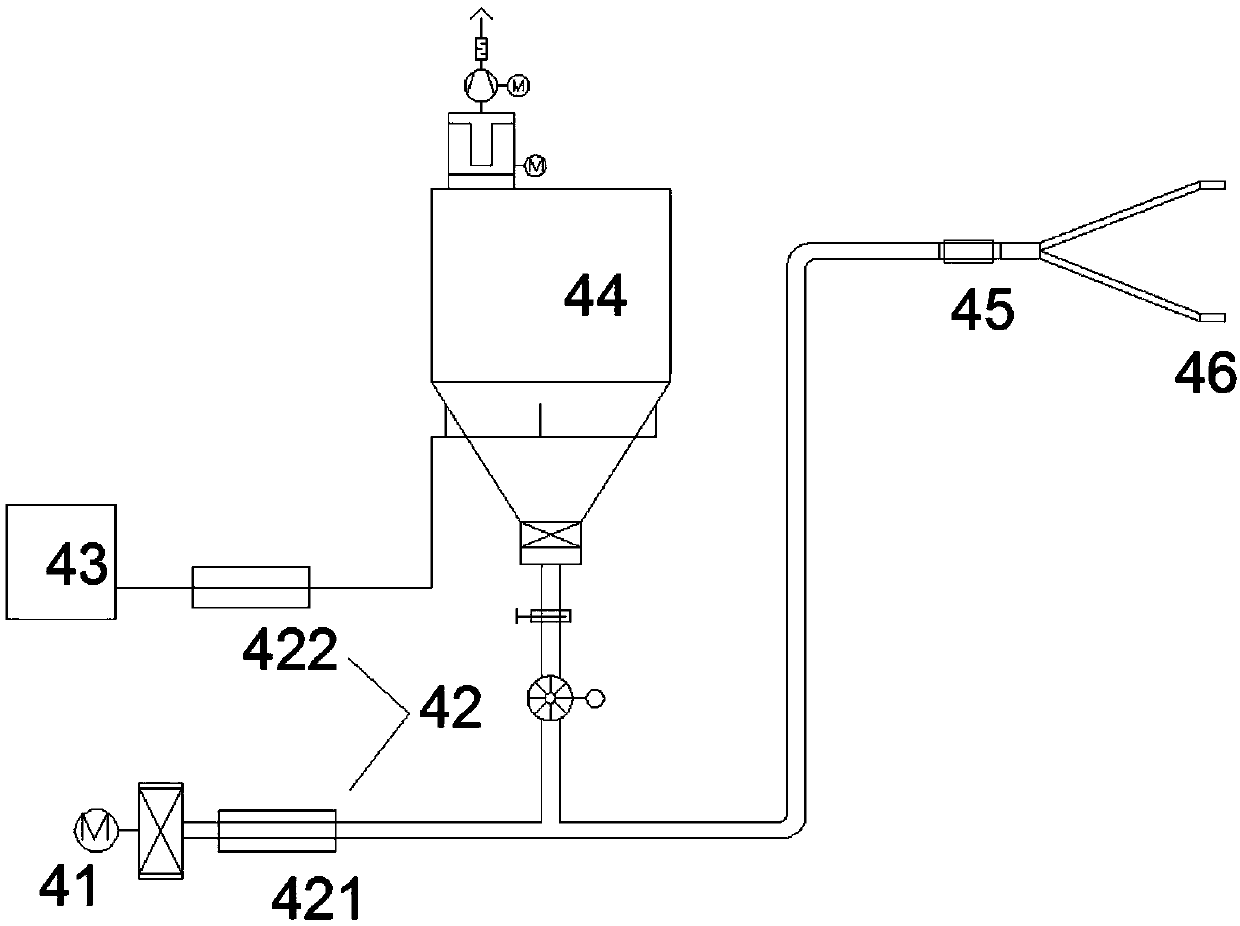

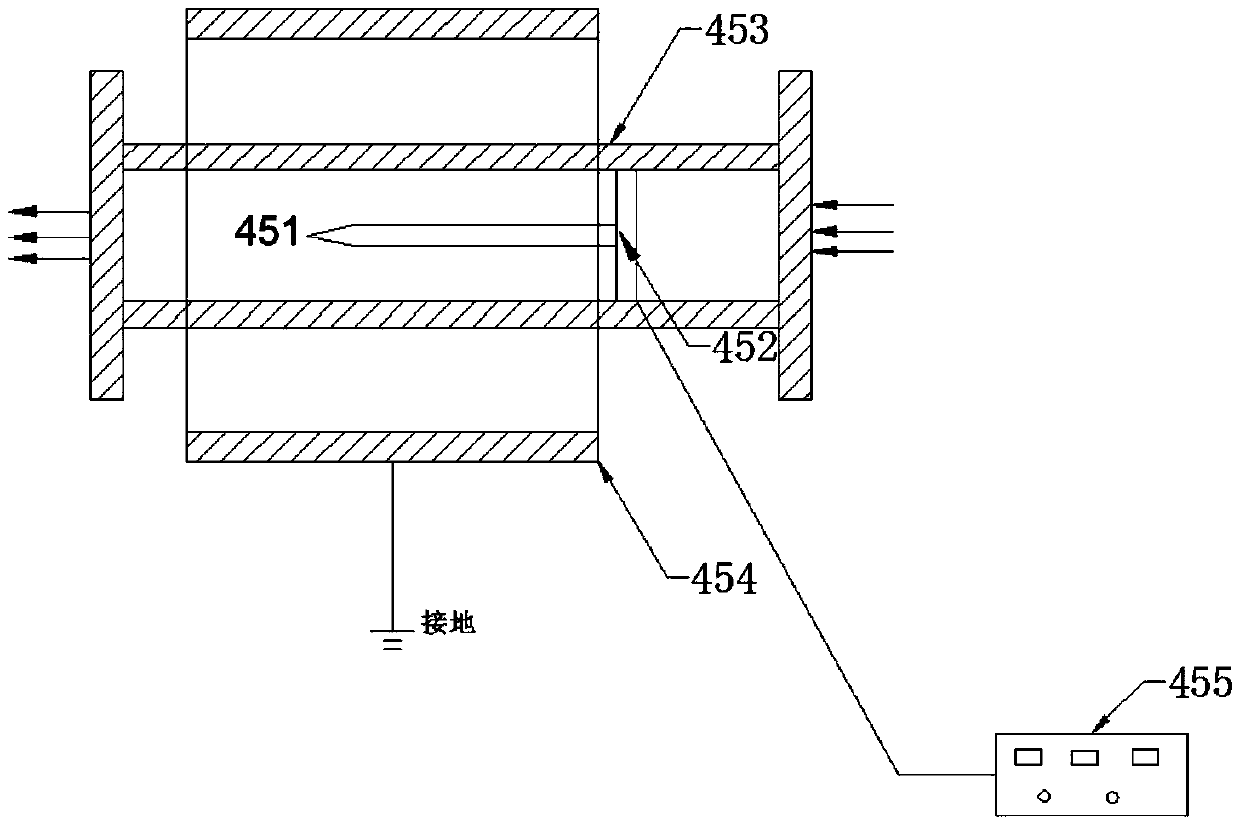

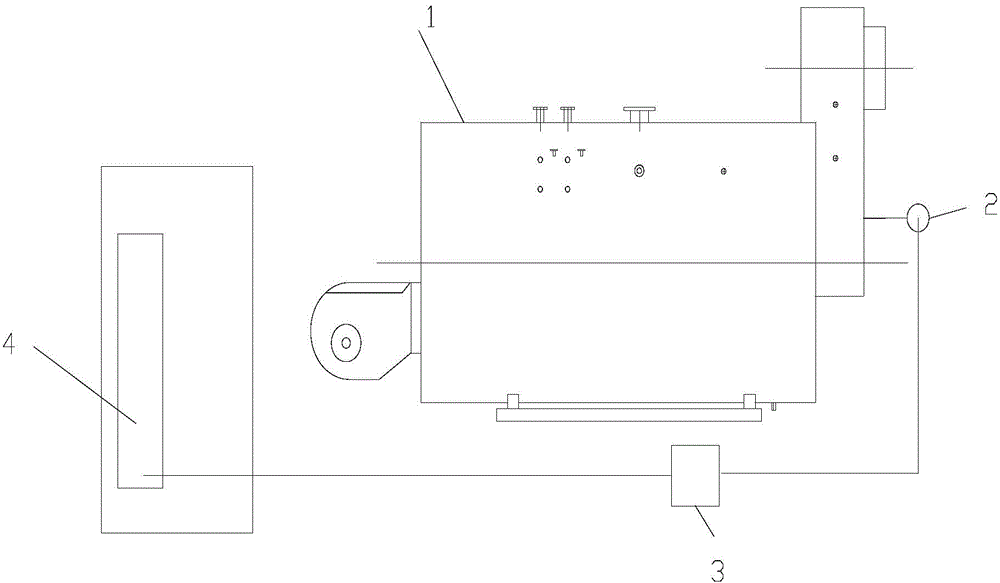

SCR inlet flue gas pre-treatment system and method

PendingCN110038433AUniform sectionSection NH

<sub>3</sub>

evenly distributedDispersed particle separationSolid fuel combustionAir preheaterHandling system

The invention relates to an SCR inlet flue gas pre-treatment system and method, relates to boiler pollutant control technology, and are used for new construction or renovation projects of ultra-cleanNOx emission of grate-firing coal-fired boilers. The SCR inlet flue gas pre-treatment system comprises a temperature regulating system, a urea solution or ammonia water solution ejector, and a cycloneequalization system. The system adopts a heating way of extracting high-temperature flue gas from a hearth outlet and then introducing the high-temperature flue gas into a cyclone tube, and a coolingway of adding a temperature-regulating economizer or extracting low-temperature flue gas from flue gas at a boiler dust collector outlet or an air preheater outlet and then introducing the low-temperature flue gas into the cyclone tube through a cold flue, and the average temperature of SCR inlet flue gas is controlled within the working range of catalysts. A urea solution is ejected in a burnoutchamber through the urea solution ejector; an ammonia water solution is ejected at an inlet pipe of a cyclone separator through the ammonia water solution ejector; NH3 is produced under the action ofthe high-temperature flue gas and mixed into the flue gas. Under the combined action of a flow equalization board and the cyclone tube, the flue gas and NH3 are mixed uniformly to achieve the effectsof equal temperature, equal concentration field and equal velocity, thereby meeting the requirements on the temperature, concentration field and velocity field at an SCR inlet.

Owner:HARBIN INST OF TECH

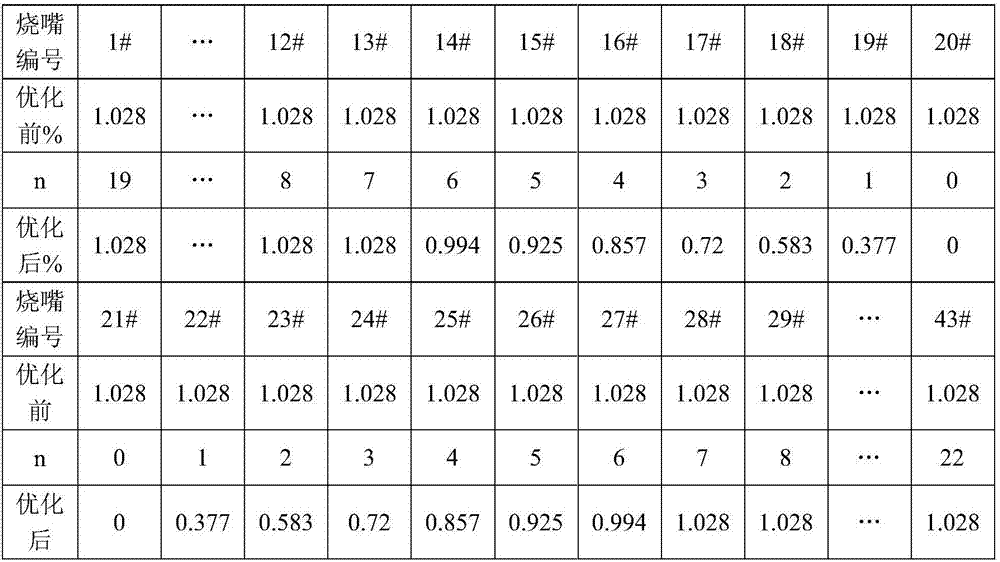

Combustion heat load distribution control method of CSP sheet billet roller bottom type tunnel heating furnace

ActiveCN106868287AImprove heating qualityMixed combustion time extensionFurnace typesHeat treatment process controlDistribution controlEngineering

The invention discloses a combustion heat load distribution control method of a CSP sheet billet roller bottom type tunnel heating furnace. The heating furnace comprises a heating section, a soak section, a swing section and a public holding section. According to the method, heat loads of combustion nozzles of the heating section, the soak section, the swing section and the public holding section are controlled. According to the combustion heat load distribution control method, the mixed combustion time of air and gas injected by the combustion nozzles is prolonged; the combustion efficiency and high-temperature combustion gas heat efficiency are improved; incomplete combustion heat losses and heat losses of discharge smoke are reduced; damage of secondary combustion to a heat exchanger is reduced; and finally the aims of reducing secondary combustion in a flue, reducing energy consumption of the heating furnace, improving the sheet billet heating quality, prolonging the service life of the heat exchanger and the like are achieved.

Owner:武汉钢铁有限公司

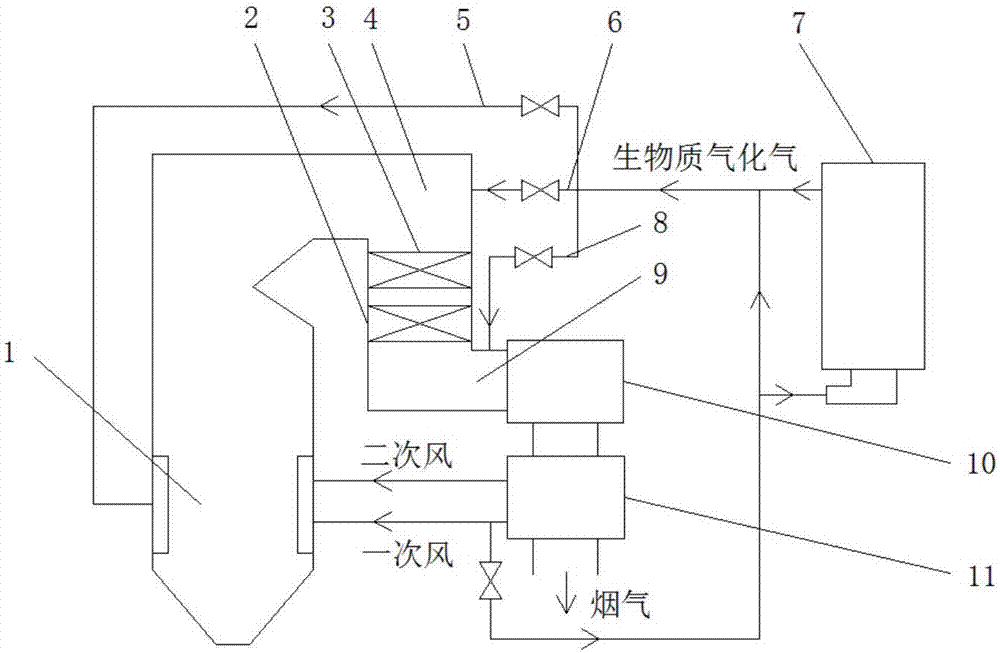

Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

InactiveCN107255269AIncrease smoke temperatureSafe and stable operationGas treatmentDispersed particle separationPower stationCombustion

The invention discloses a power station boiler system and a method for increasing the tail fume temperature of a power station boiler by integrating supplemental combustion for biomass gasification. According to the method, one or more fixed bed biomass gasifiers are additionally arranged, the gasifiers maintain the rated loads to continuously and stably operate, and hot primary air of the boiler is used as a gasification agent to promote the gasification efficiency of the gasifiers and increase the heat value of gasified gas; when the boiler operates with the low load, the biomass gasified gas is delivered into a flue behind a coal economizer or a steering fume chamber in front of the coal economizer, and the fume temperature at an outlet of the coal economizer is increased through supplemental combustion of the biomass gasified gas, so that a selective catalytic reduction fume denitration system operates safely and stably; supplemental-combustion gas is reduced correspondingly along with increasing of the loads, and the reduced gasification gas for supplemental combustion is delivered into the upper portion of a hearth so as to be combusted, and when the boiler operates with the full load, all the biomass gasified gas is delivered into the upper portion of the hearth so as to be combusted; and supplemental-combustion temperature increasing of the tail fume of the power station boiler is finally achieved through biomass resources, and meanwhile, the biomass resources can be further efficiently used for power generation.

Owner:GUODIAN SCI & TECH RES INST

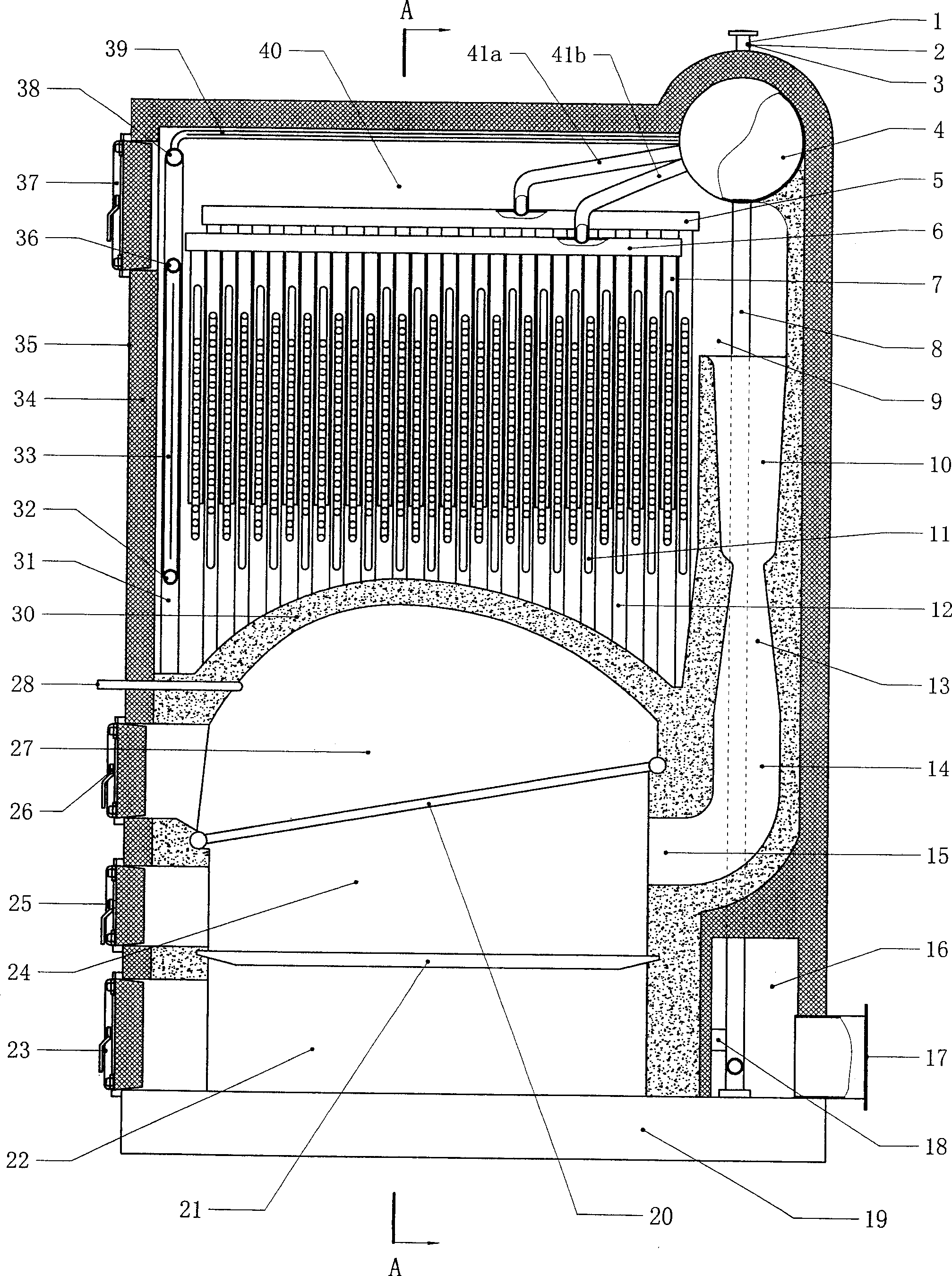

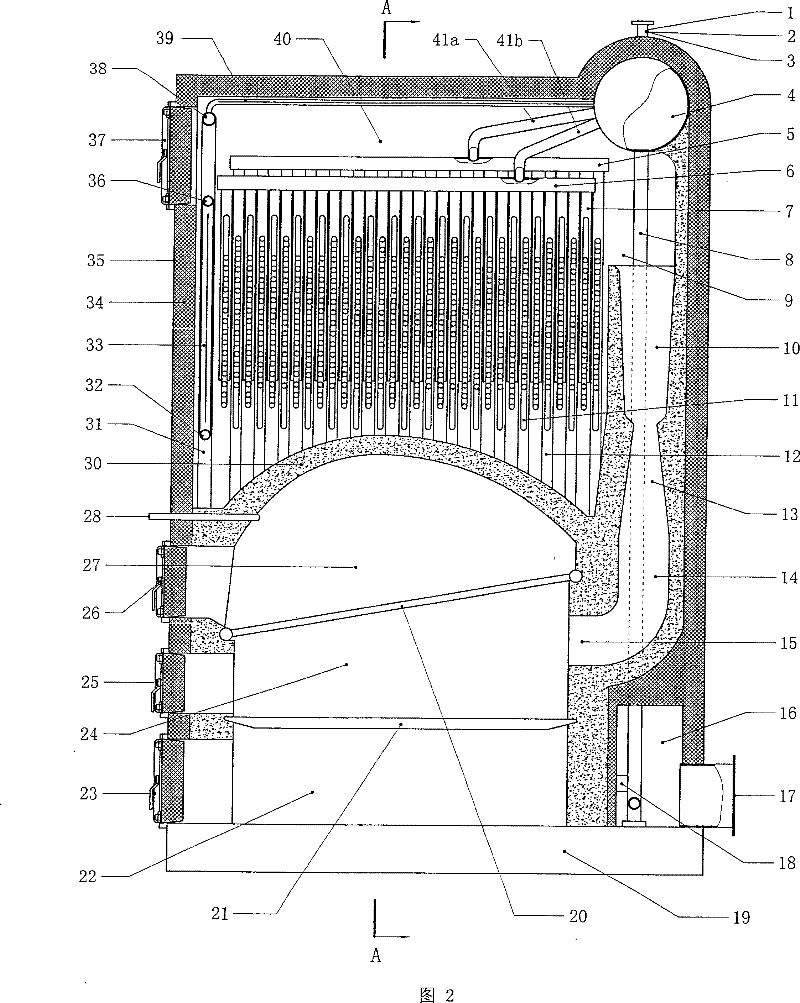

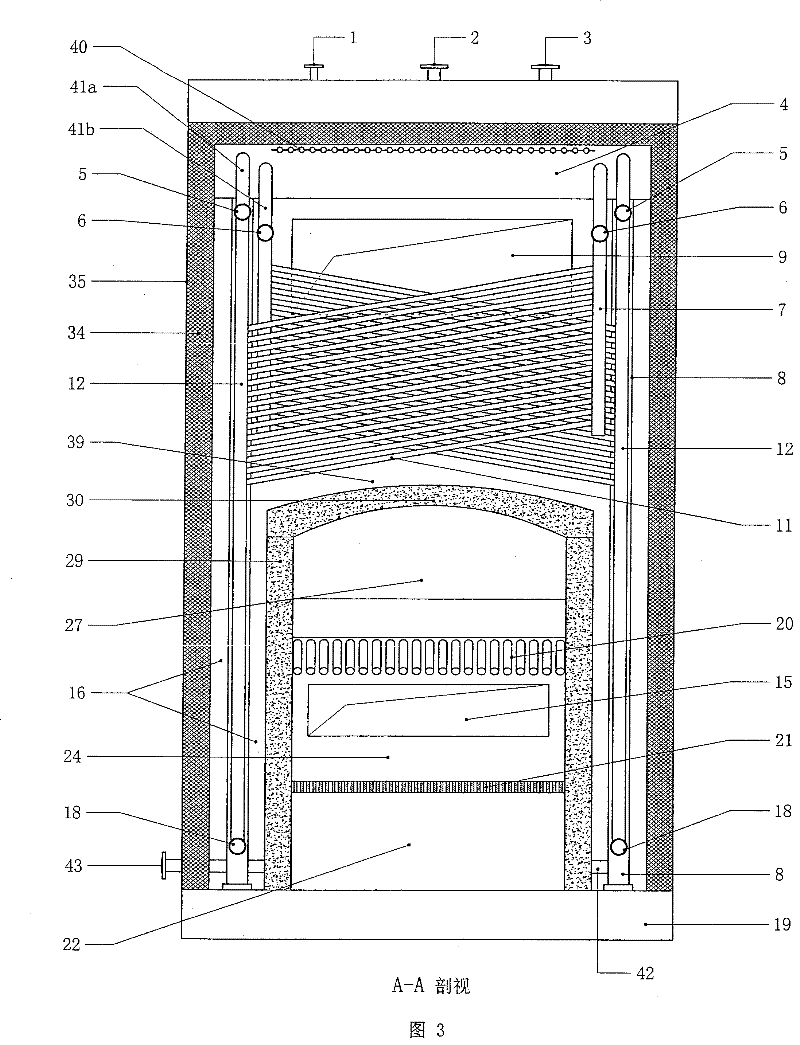

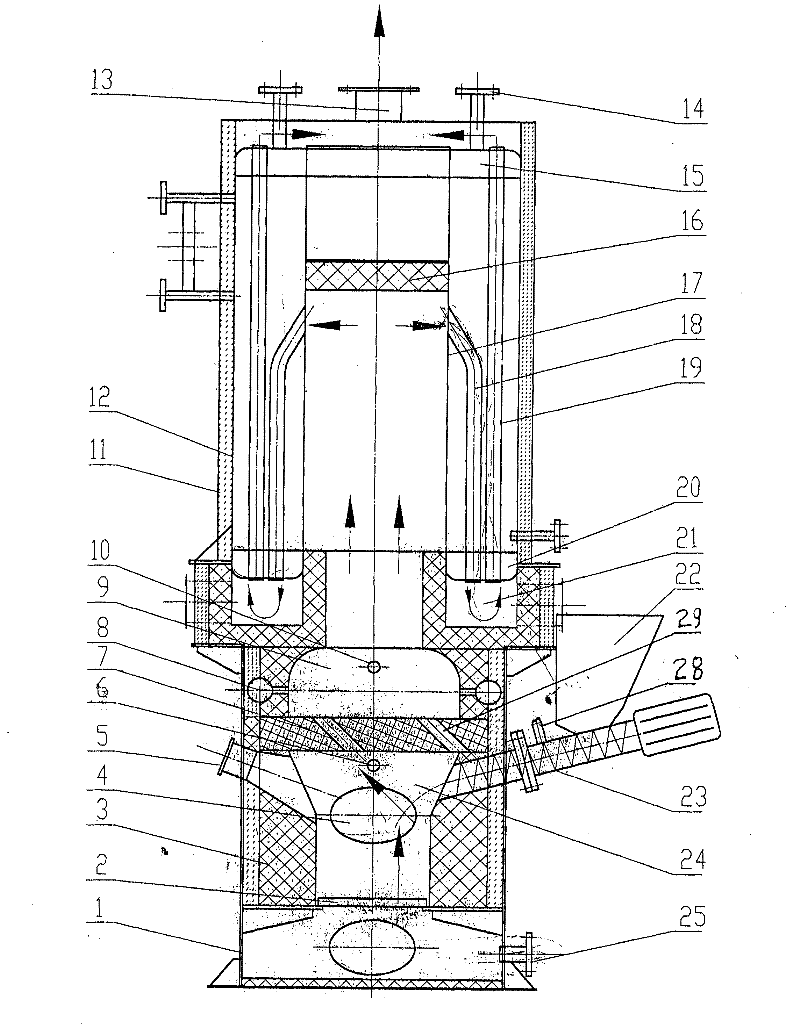

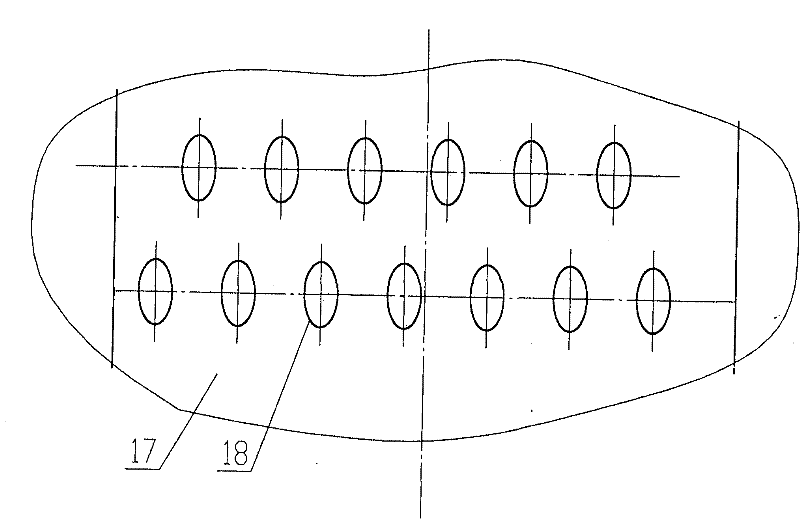

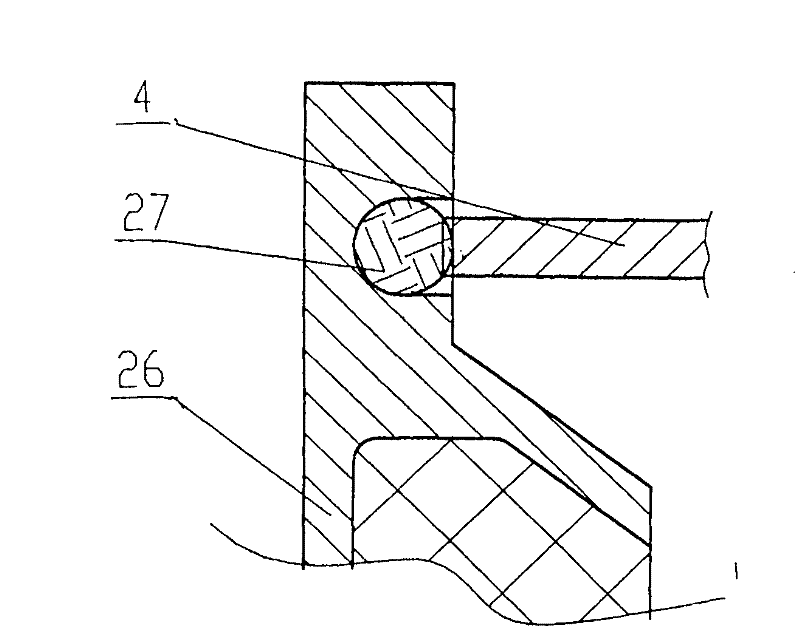

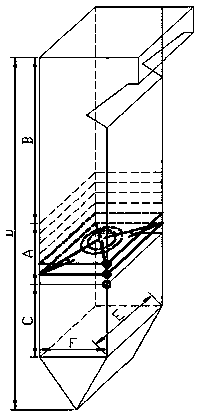

Environmental protection destructive distillation coal gasification laminar burning boiler

InactiveCN1793720AGuaranteed uptimeHigh outputSolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention relates to an environmental-protection coal carbonization-gasification layered fired boiler, comprising water-filling compression component water-cooling system, firepot, burning device, ash hopper, measuring meter and control valve all mounted in a boiler body, the front roaster of the firepot is high and the rear roaster is low, and between them, there are front, middle and rear partition walls partitioning the firepot into carbonization- gasification chamber, main combustion chamber, auxiliary combustion chamber and burnout chamber, the upper part of the front partition wall is provided with nozzle and the bottom plane of the front partition wall nears but does not contact with the coal layer surface on grate of combustion equipment, secondary air duct is arranged above the top wall of the front roaster, a channel communicating the primary and auxiliary combustion chambers is arranged below the middle partition wall, and the auxiliary combustion chamber is connected with the burnout chamber through the auxiliary nozzle. The advantages are simple operation and, low-synthetic cost, high power output and thermal efficiency and can reduce environmental pollution.

Owner:沈阳前进锅炉厂

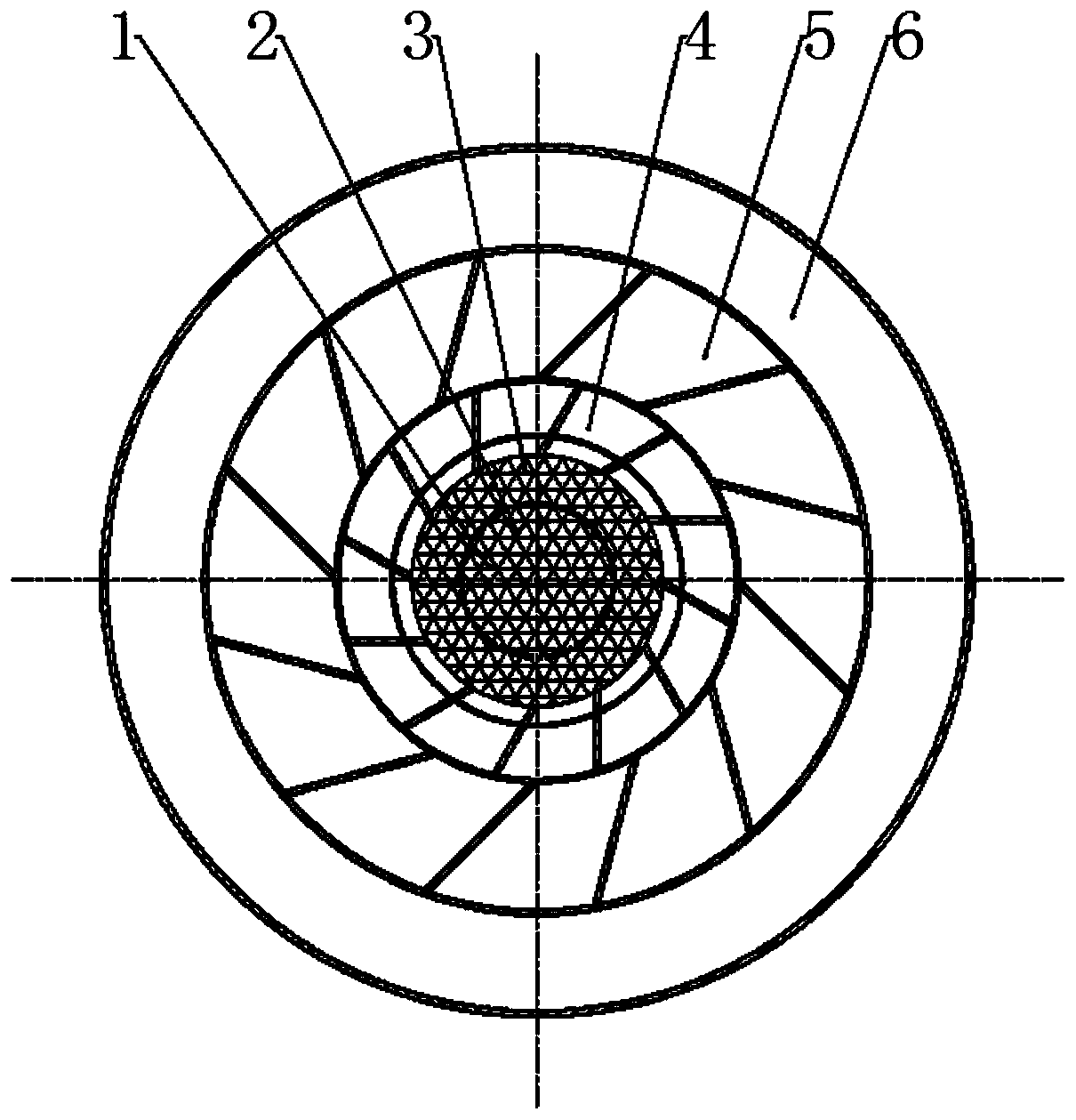

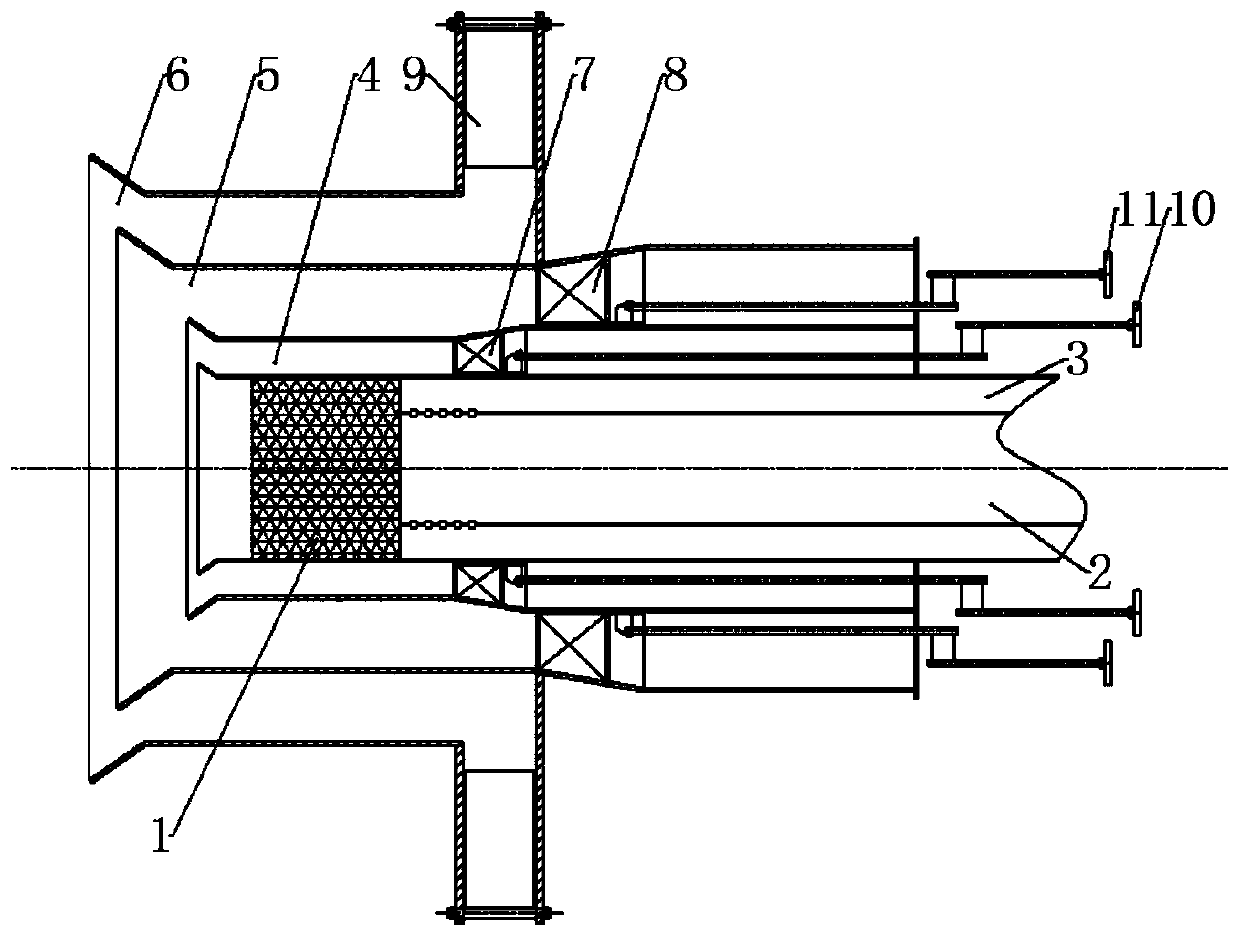

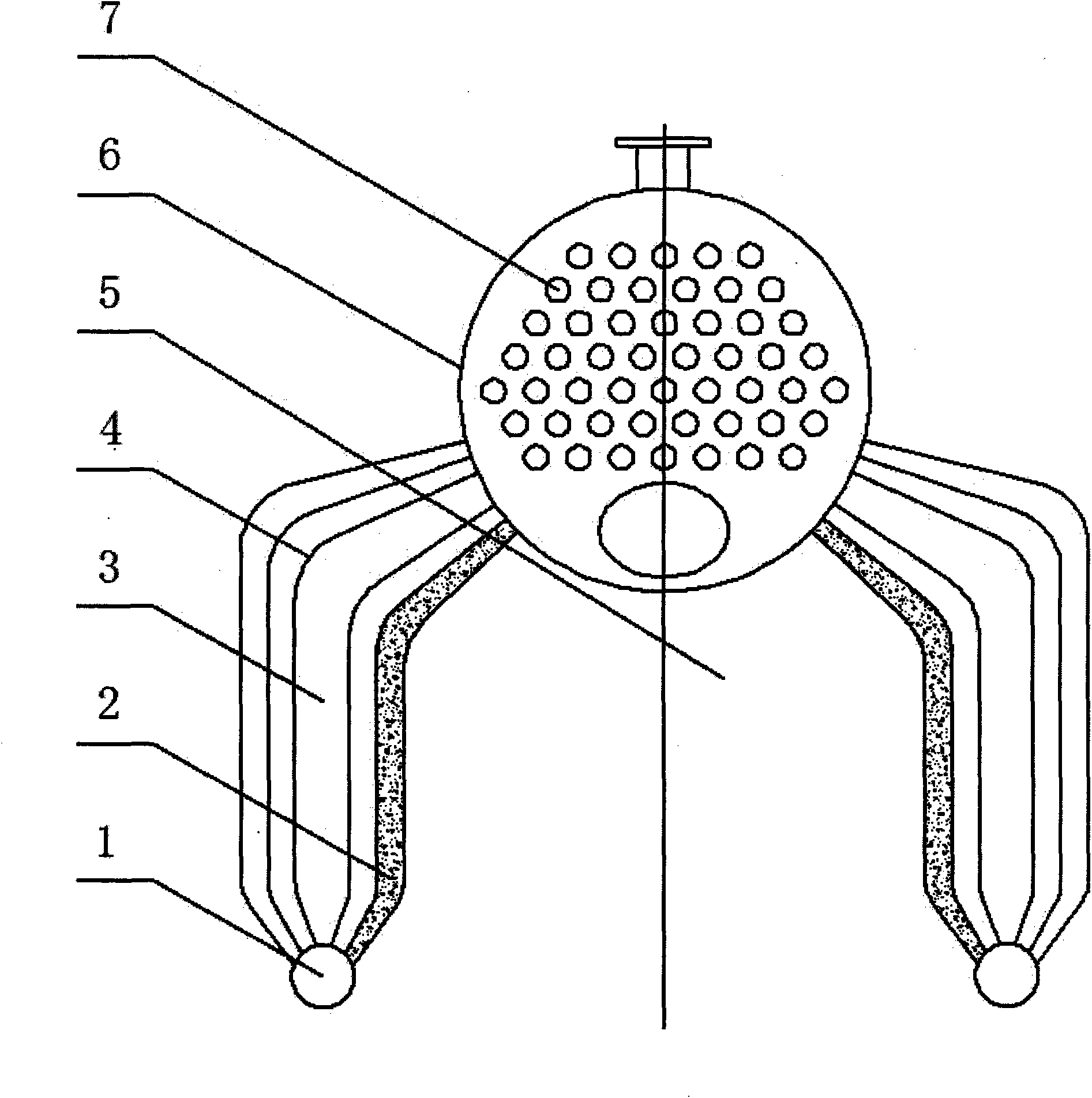

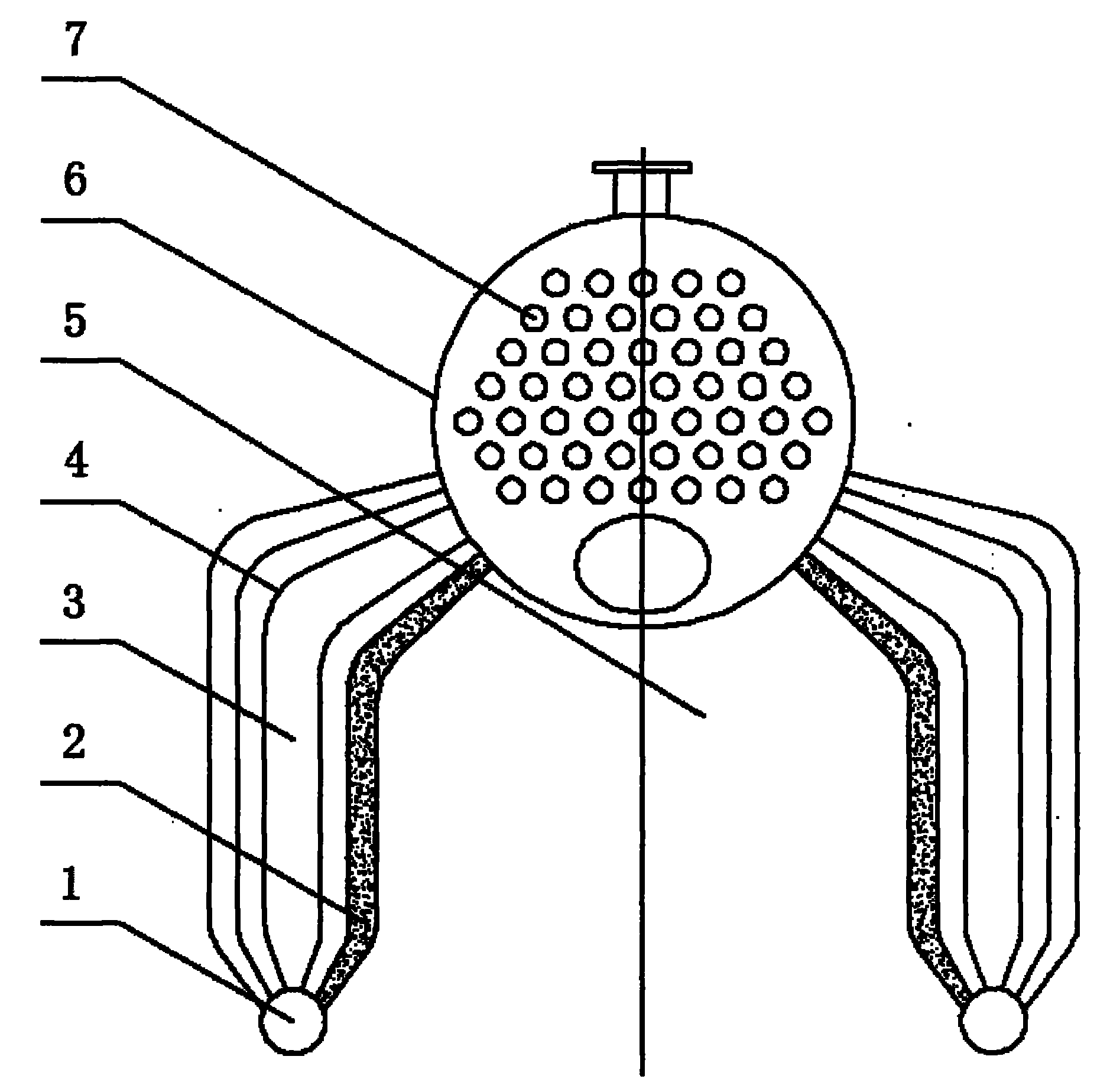

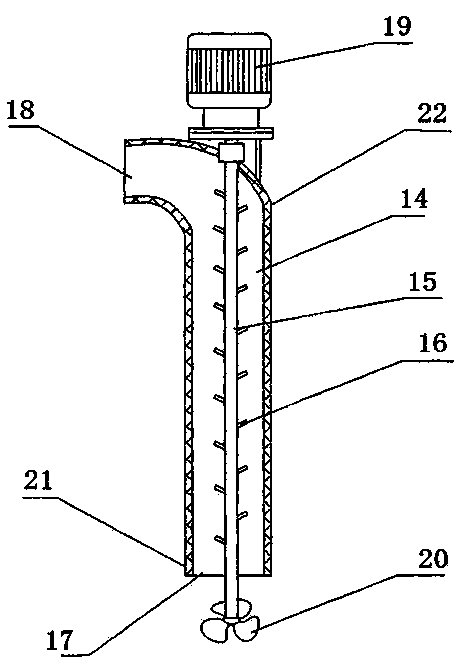

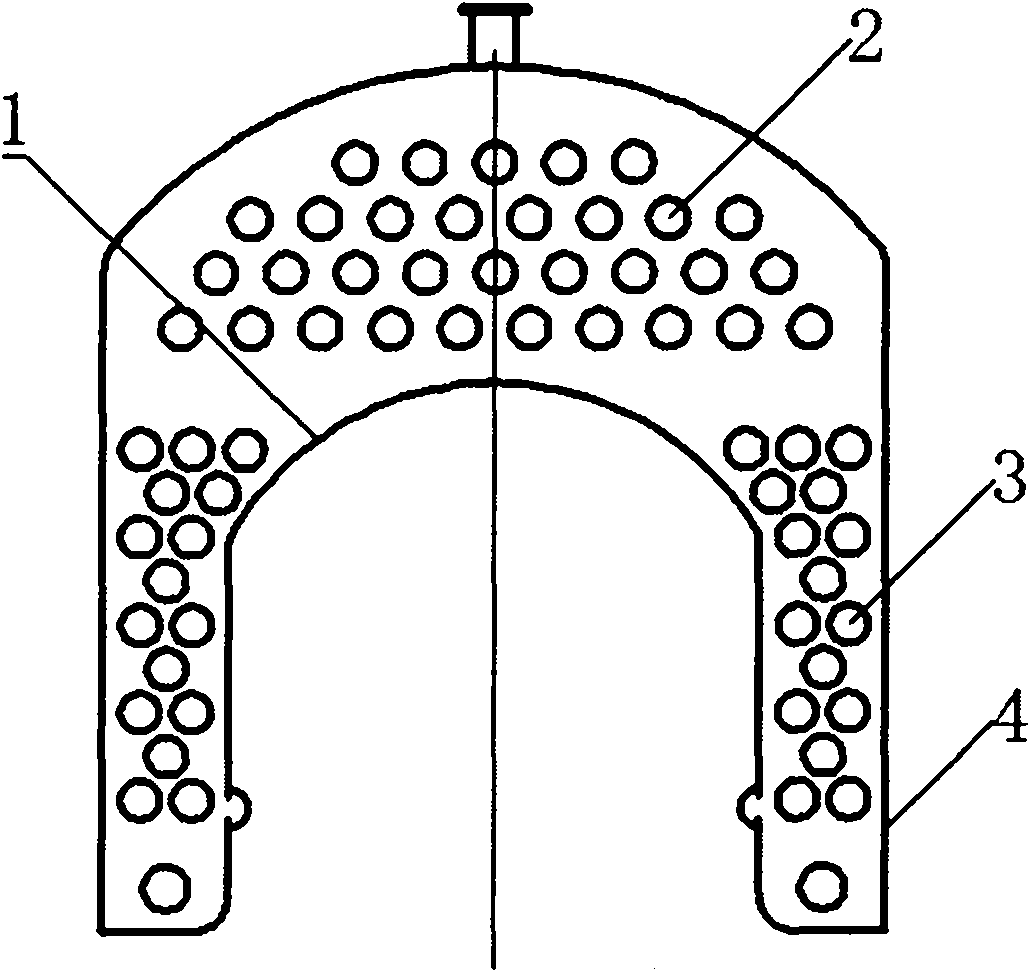

Heat storage premixed biomass gas combustor and using method thereof

PendingCN111396873AReduce incomplete combustion heat lossIncreased turbulenceIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a heat storage premixed biomass gas combustor and a using method thereof. The combustor comprises a porous medium heat storage premixing pipeline, an inner combustion-supporting air pipeline, an outer gas pipeline, an outer combustion-supporting air pipeline, a first sleeve, an inner combustion-supporting air rotational flow adjusting pull rod, a second sleeve, an outer gasrotational flow adjusting pull rod, a plurality of inner combustion-supporting air axial rotational flow blades and a plurality of outer gas axial rotational flow blades. The porous medium heat storage premixing pipeline, the inner combustion-supporting air pipeline, the outer gas pipeline and the outer combustion-supporting air pipeline are sequentially distributed from inside to outside, an outlet of the porous medium heat storage premixing pipeline is filled with a ceramic foam type porous medium, and an inlet of the porous medium heat storage premixing pipeline coaxially communicates witha central gas pipeline and a central combustion-supporting air pipeline. According to the combustor and the using method thereof, the purpose of efficient and low-pollution combustion of biomass gascan be achieved.

Owner:HUANENG POWER INTERNATIONAL +2

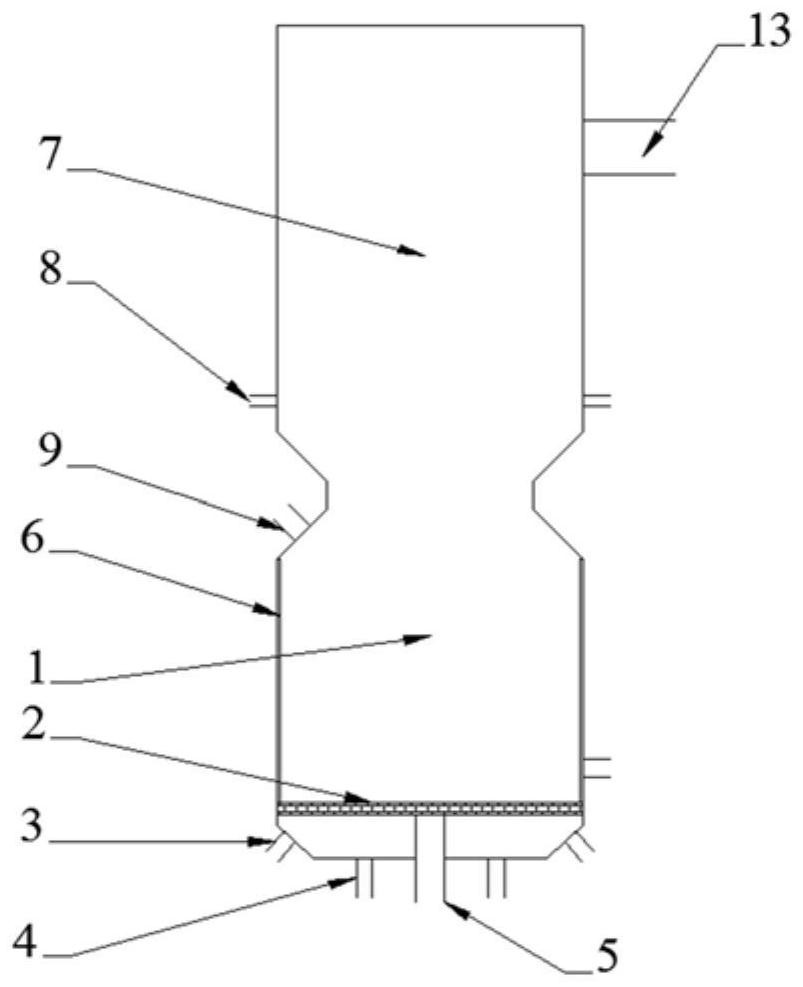

Coal gasification boiler by reverse coal combustion

InactiveCN101382294AEfficient and clean combustionBurn fullyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAutomatic controlBoiler furnace

The invention discloses a novel gasification counter-heating water boiler, which comprises a boiler shell, a boiler furnace, a fire grate, a coal door, a poke door, an ash door, a smoke channel, a chimney and an automatic control device, and is characterized in that: the coal door, the poke door and the ash door are all visible sealed furnace doors with micro positive pressure, and the novel gasification counter-heating water boiler further comprises a circumferential multipoint air distributing device, a wet desulfurizing dust remover of a built-in pipe burying afterheat recycling device, and a smoke gas afterheat recycling air heater. The novel gasification counter-heating water boiler has the advantages of less equipment investment, low running cost, automated operation, 85 percent of the boiler thermal efficiency, low pollutant discharge and boiler modularization, and can be widely used in places needing small-scale heat supply such as residential houses, bath centers, factories, hotels, government agencies and the like.

Owner:QINHUANGDAO JIEMEI BOILERS MFG

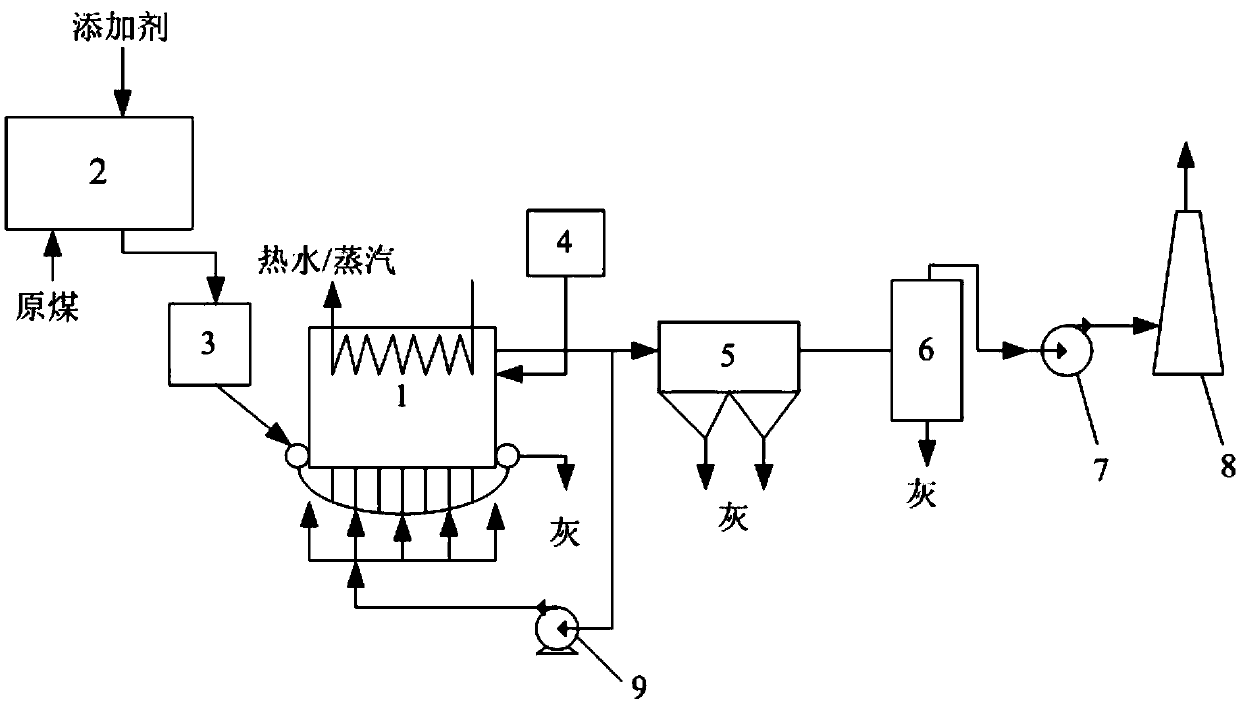

Low-emission system of coal-fired boiler and treatment method of low-emission system

InactiveCN109539239AOptimize dwell timeOptimize reaction conditionsSolid fuel combustionCombustion apparatusBriquetteHeating efficiency

The invention provides a low-emission system of a coal-fired boiler and a treatment method of the low-emission system. The system comprises a charging unit, a layer-burning boiler, an additive addingunit, a flue gas dust removal unit and a tail gas desulfurization and denitrification unit. A material outlet of the charging unit is connected with a fire coal inlet of the layer-burning boiler, anda material outlet of the additive adding unit is connected with a hearth of the layer-burning boiler. A flue gas outlet of the layer-burning boiler is sequentially connected with the flue gas dust removal unit and the tail gas desulfurization and denitrification unit. Briquette coal suitable for the layer-burning boiler is adopted, the burning conditions of fire coal in the layer-burning boiler are improved, an additive is sprayed, the adding manner of the additive is optimized, in combination with the tail gas treatment process, the heat loss caused by flue gas exhaust is finally reduced, theheat loss caused by the fact that solids are not completely burnt is reduced, the leakage amount of fine coal is reduced, the heat efficiency of the boiler is improved, emission of pollutants is reduced, and ultra-low emission of the industrial boiler is achieved.

Owner:YANKUANG GRP CO LTD +1

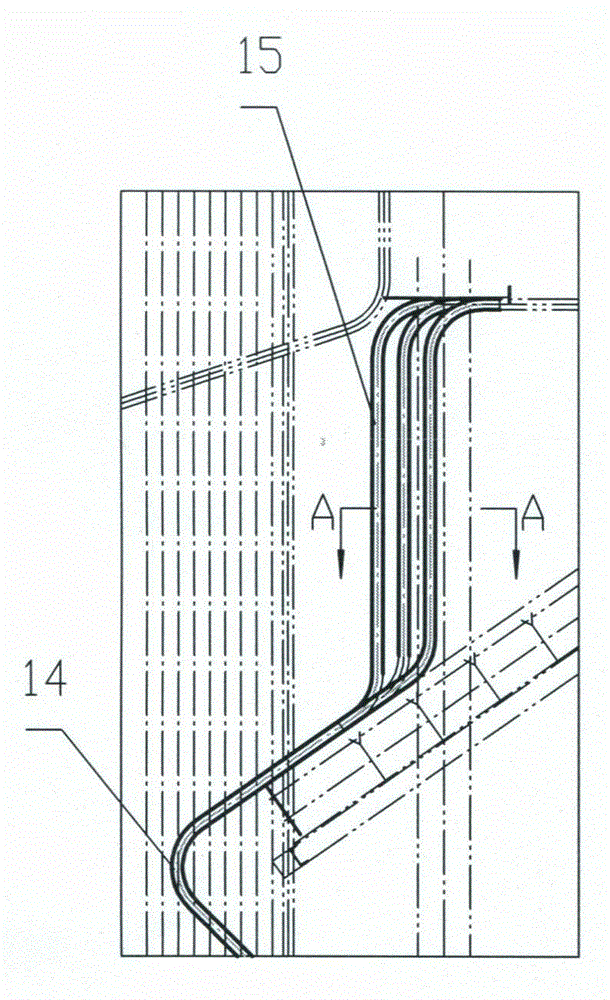

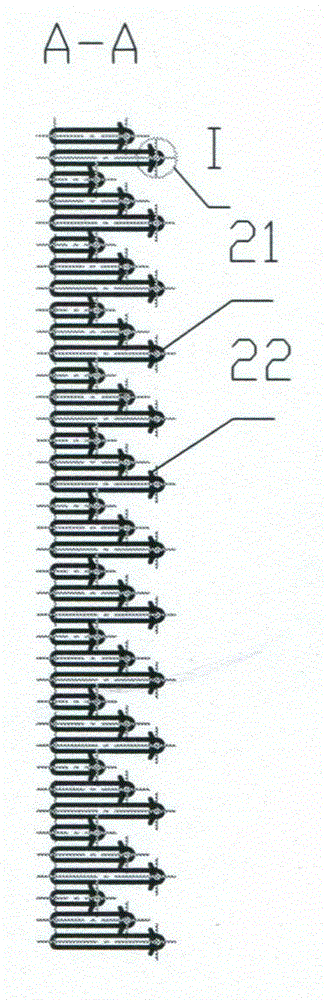

Side over fire air distribution method and coal-fired boiler

InactiveCN106642083AReduce incomplete combustion heat lossImprove combustion efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionCombustorUnit operation

The invention relates to the technical field of pulverized coal combustion of a large-scale coal-fired power plant boiler, and concretely relates to a side over fire air distribution method and a coal-fired boiler. Aiming at the defects such as large combustion heat loss, poor unit operation economy and high temperature corrosion of a water cooled wall caused by poor side over fire air supplying of an existing domestic coal-fired power plant boiler, the invention provides the side over fire air distribution method and the coal-fired boiler. The air distribution method is characterized in that hot primary air in a hot primary air bus pipe is used as an air source, air is fed to a side over fire air area of the coal-fired boiler, the fed hot primary air can deeply penetrate through flue gas, and incompletely combusted pulverized coal and generated combustible gases such as carbon monoxide are continuously combusted sufficiently, so that incomplete combustion heat loss of the boiler is reduced, the combustion efficiency of the boiler is improved, meanwhile, an after-combustion effect of the over fire air is improved, a trend of the high temperature corrosion occurred on the water cooled wall between a main combustor and the over fire air is alleviated, and the operating economy and the safety of the coal-fired boiler adopting the air distribution method are greatly improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Counter current heat exchanging water-fire tube boiler capable of saving energy and protecting environment

InactiveCN102116526AReduce incomplete combustionReduce lossesWater heatersCombustion chamberFlue gas

The invention relates to a counter current heating exchanging water-fire tube boiler capable of saving energy and protecting the environment, which comprises a boiler shell, a containing box, a convection tube, a smoke-fire tube, a smoke separating wall, a combustion chamber and a convection tube flue, wherein high-temperature flue gas with two return trips firstly passes through a position with higher water temperature at the water side of the smoke-fire tube in the boiler shell for exchanging heat, then lower-temperature flue gas with three return trips passes through the convection tube with lower temperature at the water side of the convection tube flue for exchanging heat, and the flue gas is discharged out of the boiler body after the heat exchange; the original downstream heat exchanging means is completely changed; counter current heat exchange is realized; energy sources are saved; carbon dioxide emission is reduced; the purposes of saving energy and protecting the environment are achieved; the counter current heating exchanging water-fire tube boiler can be produced by adopting a normal boiler production technology; and the reconstruction of an existing boiler can be realized by only changing the flow of the flue gas.

Owner:陈雅华

Slag cooling system for reducing amount of boiler circulating ash and working method

InactiveCN108240622AImprove heat transfer efficiencyFully automatedFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

The invention relates to a slag cooling system for reducing the amount of boiler circulating ash and a working method. The main cooling manner of existing slag coolers is a water cooling manner, and the structural forms of the existing slag coolers roughly include a packing auger type water-cooling slag removing machine, an external water-cooling sleeve rotation type water-cooling slag removing machine, an automatic slag-falling staggering type water-cooling slag removing machine and the like. The slag removing machines have the main advantages that the slag removing machines can easily meet the spatial arrangement requirements and can be independently used for producing products, and certain slag removing machines have long service lives. The slag removing machines have the disadvantagesthat a large number of cooling water and independent water circulating systems are required, the sealing effects are poor, circulating water is easily leaked, certain extra power consumption is required, meanwhile, mechanical systems are relatively complex during operation, and fault rates are relatively high. Boilers are easily shut down due to the faults of the slag coolers, so that the slag coolers are not widely used. The slag cooling system comprises a combustion chamber (1), a cooling chamber (3) and an air chamber (5), wherein the combustion chamber is connected with the cooling chamber, and the cooling chamber is connected with the air chamber. The slag cooling system is applied to the cooling of ash slag and reutilization of waste heat of boilers.

Owner:HARBIN SHUNZHI TECH CO LTD

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490BSolve the problem of air pollutionPollution realizedSolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

Biomass boiler

InactiveCN103836613AAvoid corrosionPrevent corrosionSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberSlag

The invention provides a biomass boiler. The biomass boiler comprises a boiler body, a hearth combustion chamber arranged inside the boiler body, a water steam system above the combustion chamber, a smoke exhaust port communicated with the combustion chamber, a draught fan connected with the smoke exhaust port through a pipeline, and a movable fire gate which is arranged at the bottom of the combustion chamber and extends towards the discharging direction, wherein a primary air inlet chamber is arranged below the fire gate, a secondary air inlet chamber is arranged above the fire gate, an electric spiral feeding device is arranged in the feeding position of the fire gate, and an electric spiral slag outlet device is arranged in the discharging position of the tail end of the fire gate. The biomass boiler is simple in structure, high in heat efficiency, sufficient and stable in combustion and low in operation cost, saves the operation cost by about 10% compared with a coal-fired method, and saves more energy.

Owner:浙江中吉新能源有限公司

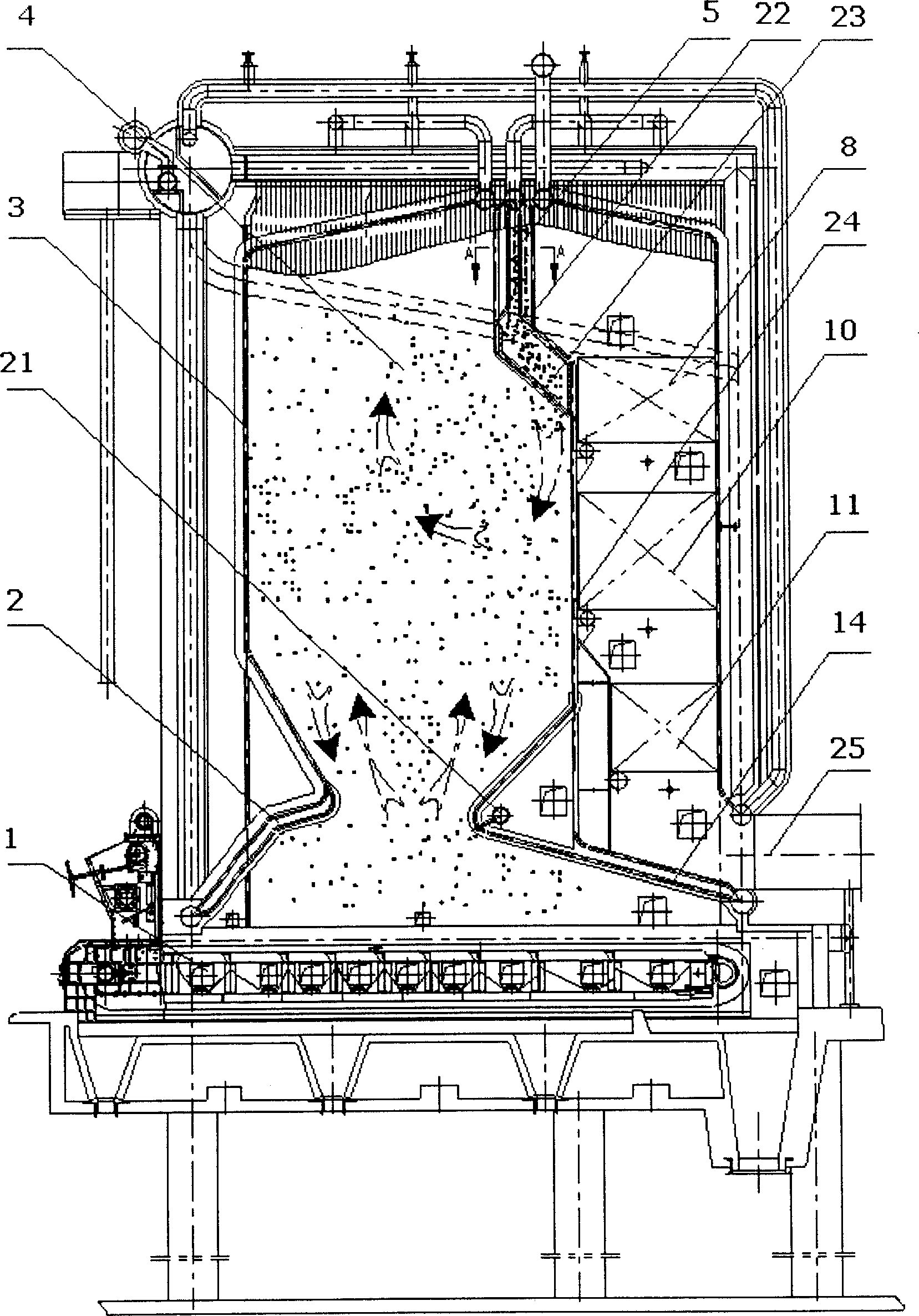

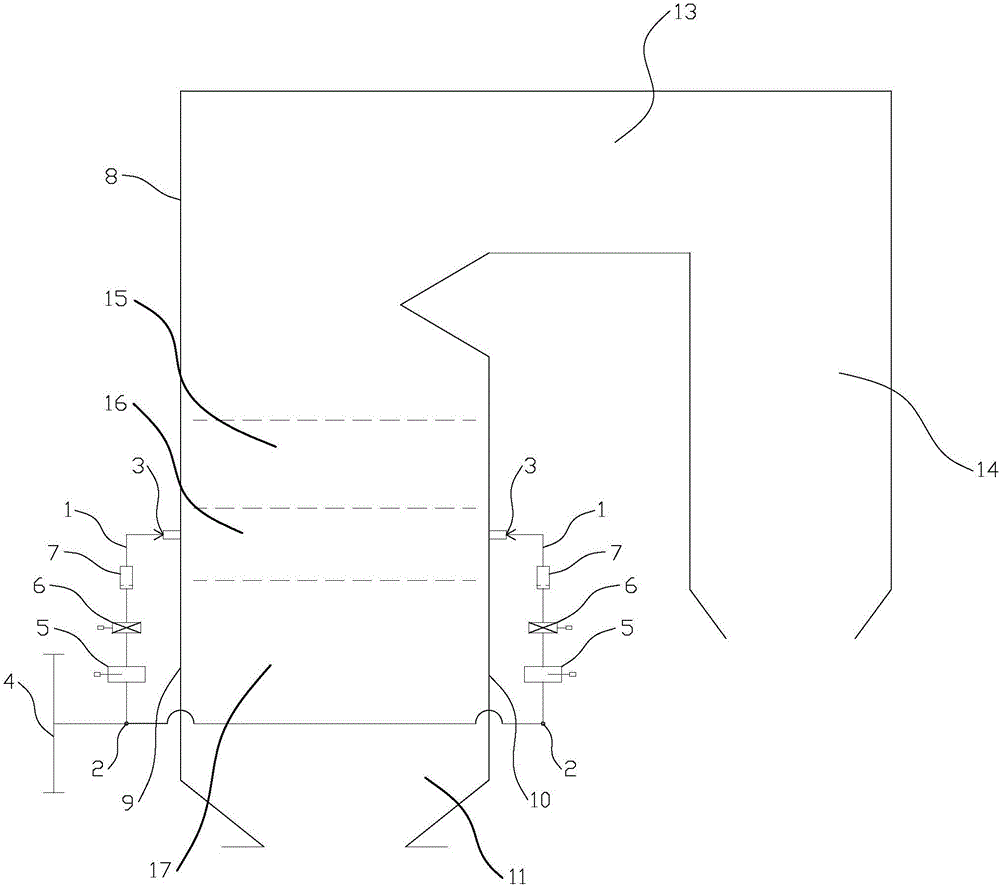

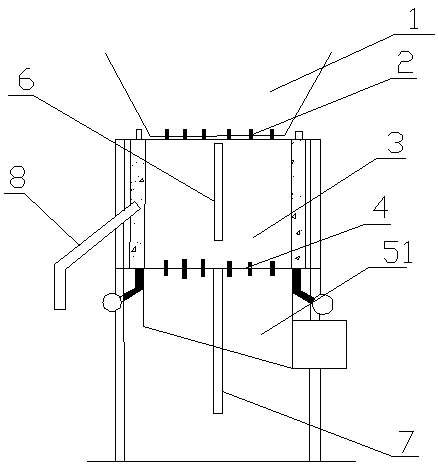

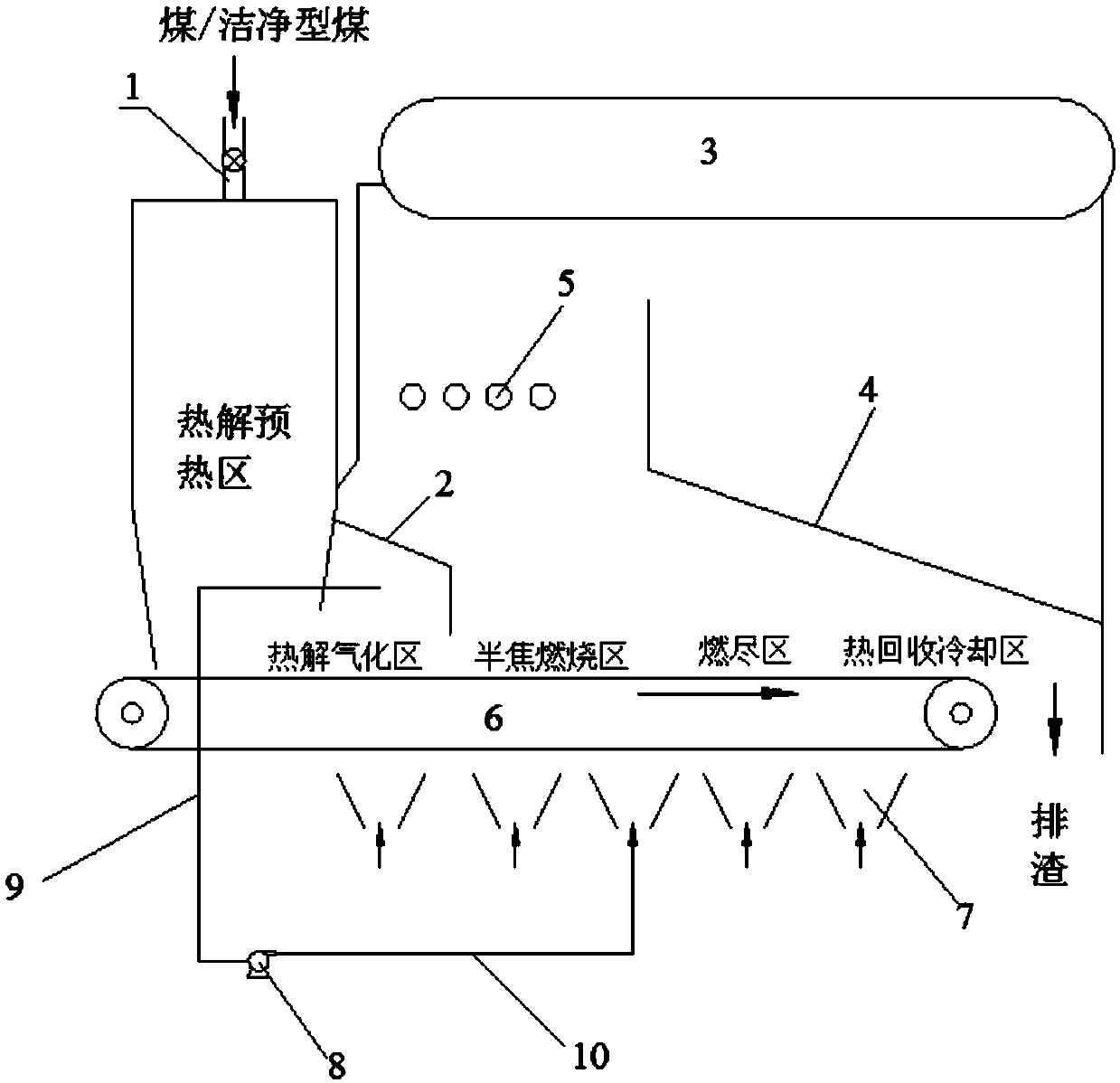

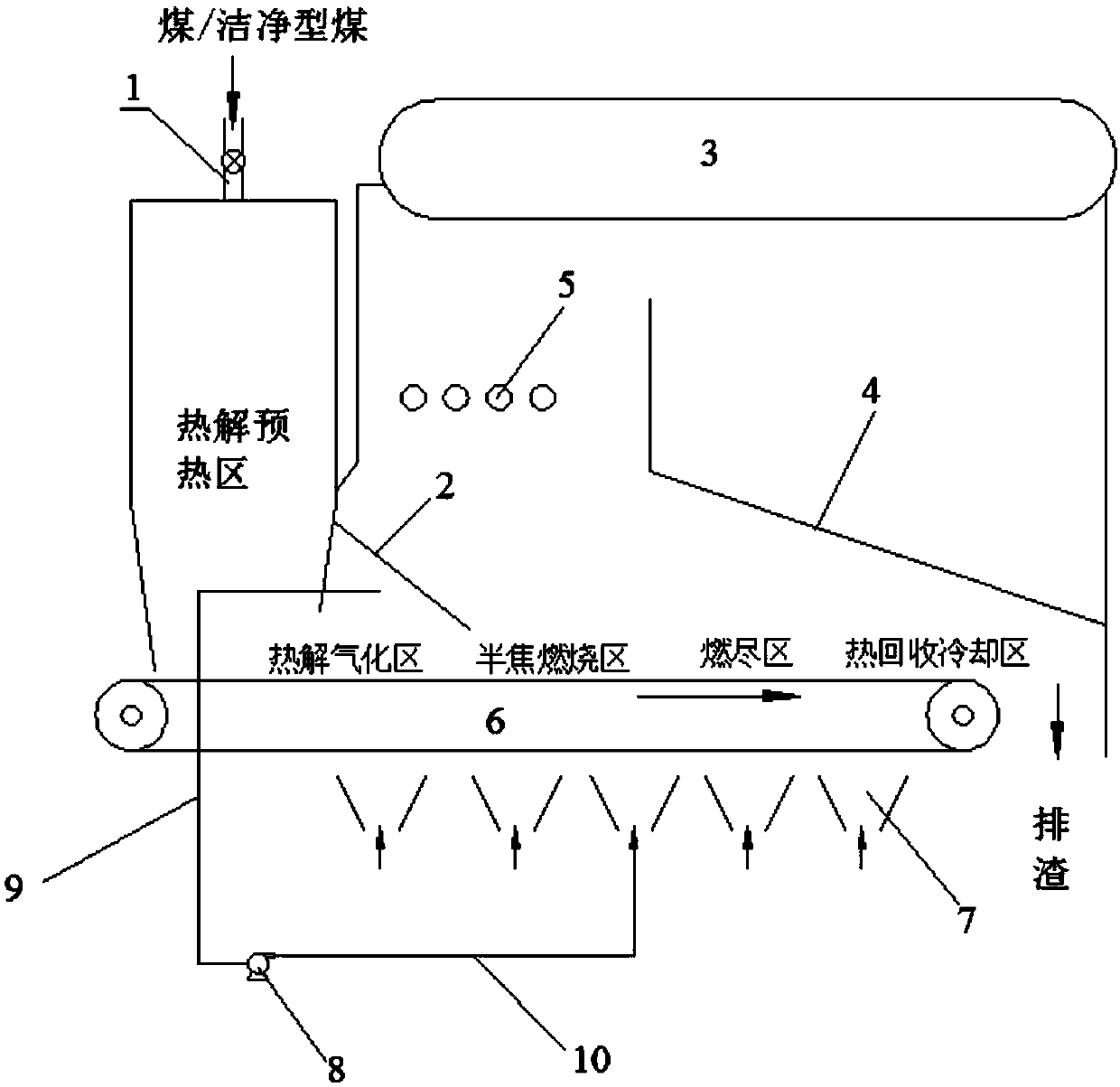

Environment-friendly flue gas circulation layer-burning boiler and treatment method thereof

InactiveCN109539241AIncrease disturbanceReduce incomplete combustion heat lossSolid fuel combustionLump/pulverulent fuel preparationFlue gasEngineering

The invention provides an environment-friendly flue gas circulation layer-burning boiler and a treatment method thereof. A boiler body of the layer-burning boiler internally comprises a first cavity and a second cavity, wherein the bottom of the first cavity communicates with the bottom of the second cavity. Coal adding openings / a coal adding opening are / is formed in the top and / or the side of thefirst cavity, a partition is arranged in the second cavity, and the partition is connected with the connecting portion of the first cavity and the second cavity. A steam pocket is arranged on the topof the second cavity, a rear arch is arranged on the portion, below the steam pocket, of the boiler wall of the second cavity, and burn-off tuyeres are formed in the end, close to the first cavity, of the rear arch. A first chain grate stoker is arranged on the lower portions of the first cavity and the second cavity. At least two air chambers are formed below the first chain grate stoker. A gasconveying device is arranged outside the layer-burning boiler. Pipelines in the gas conveying device are connected with a pyrolysis and gasification region and a semi-coke burning region. By means ofthe layer-burning boiler, emission of NOx, Co and other multiple pollutants can be effectively reduced, and the burn-off rate of dyestuff is increased.

Owner:YANKUANG GRP CO LTD +1

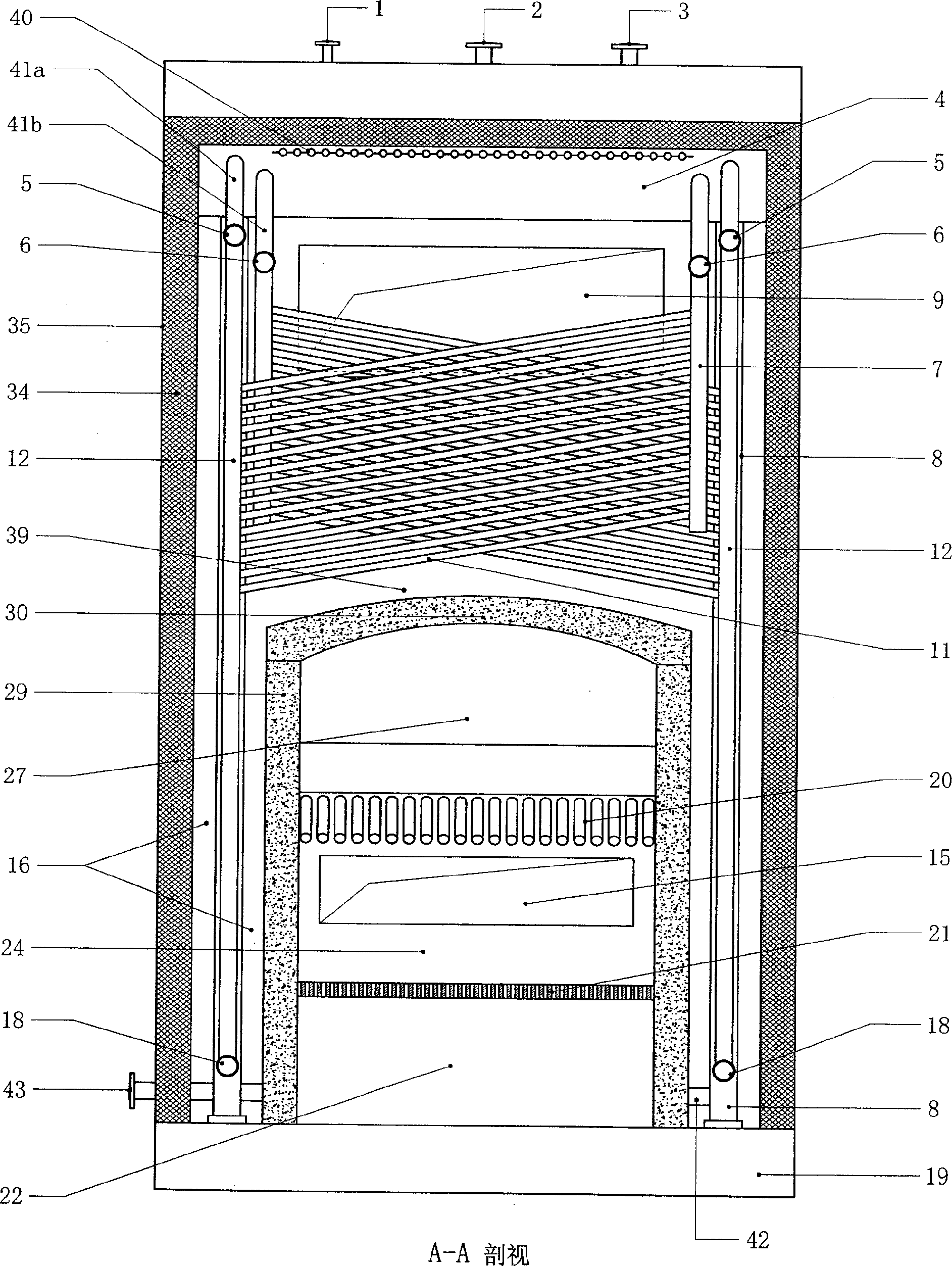

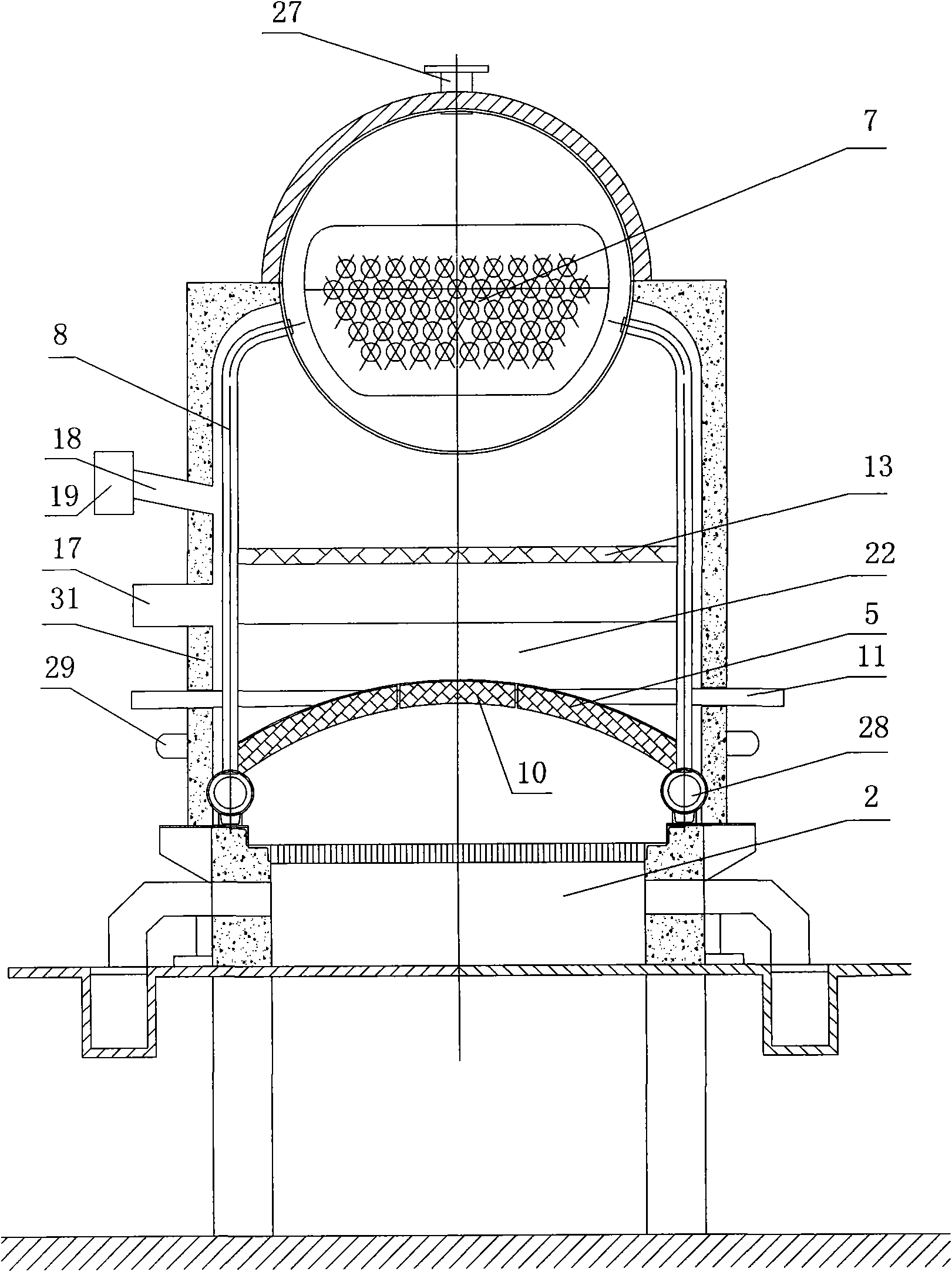

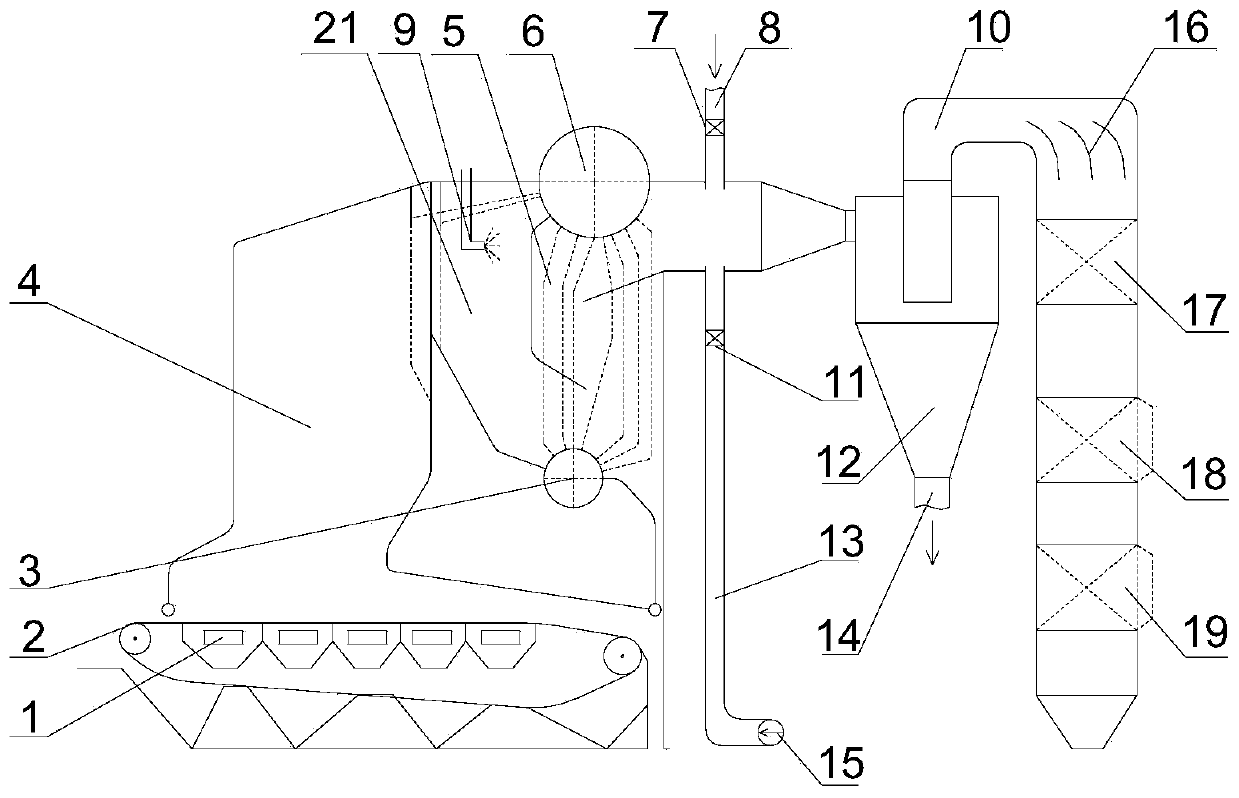

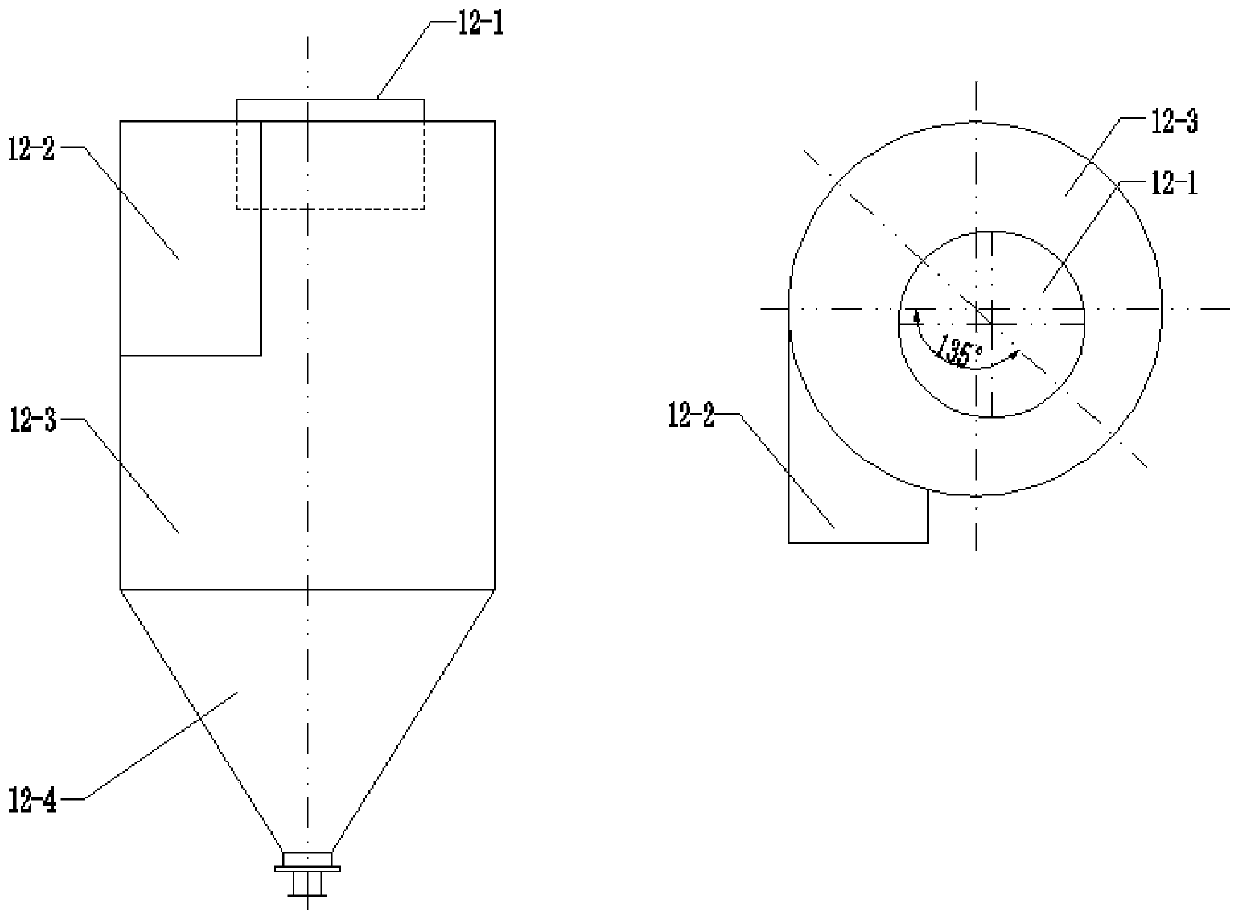

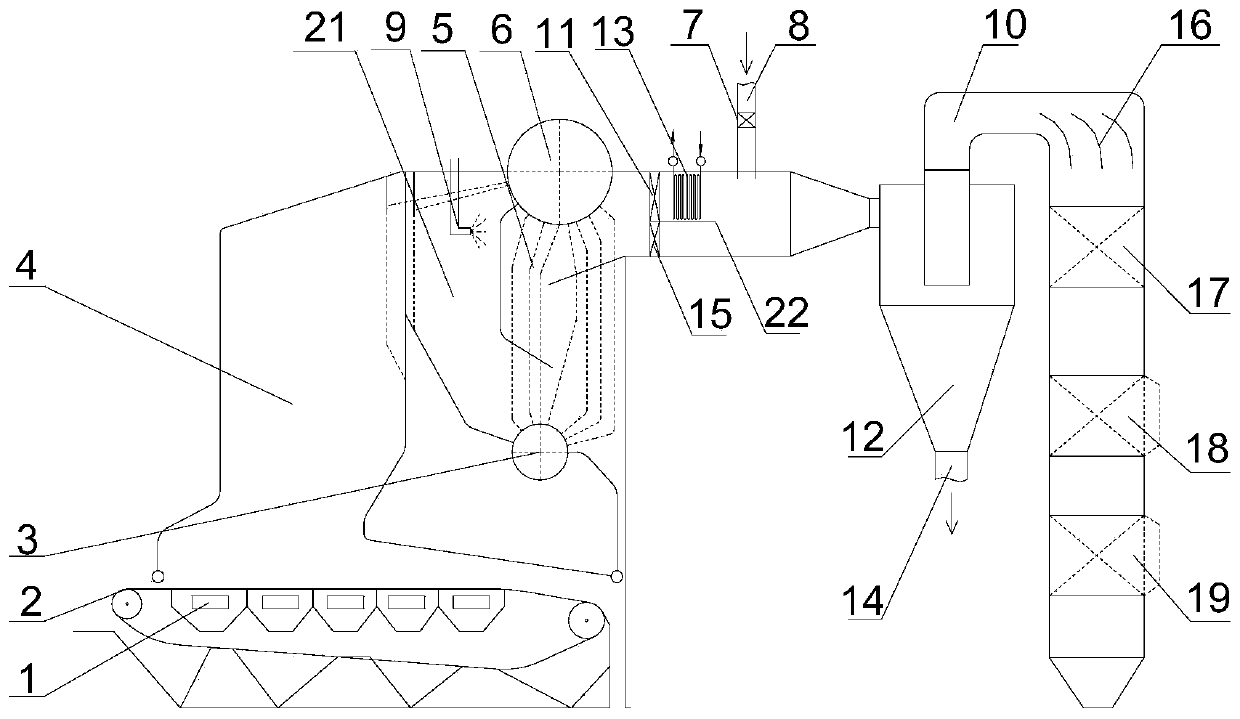

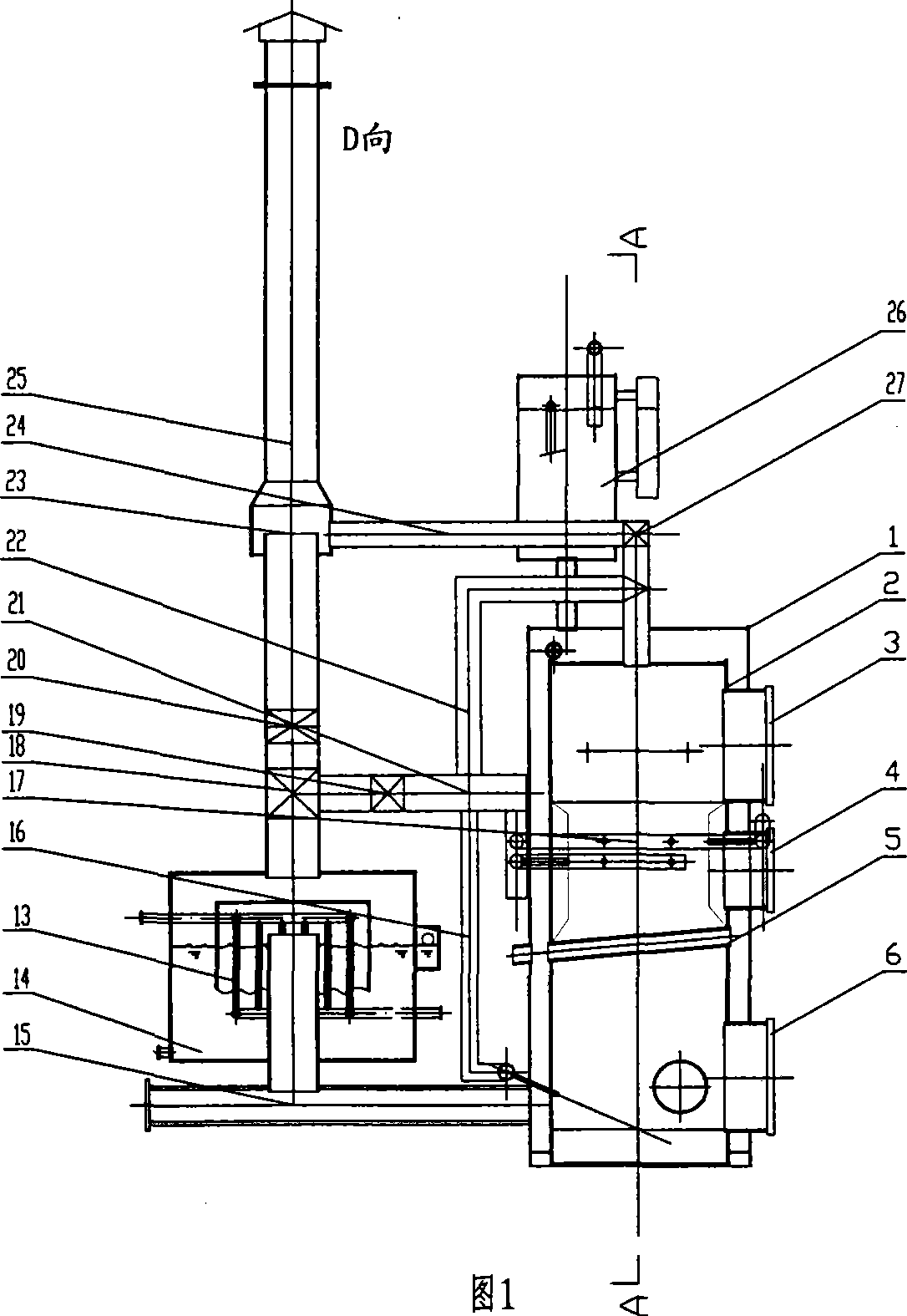

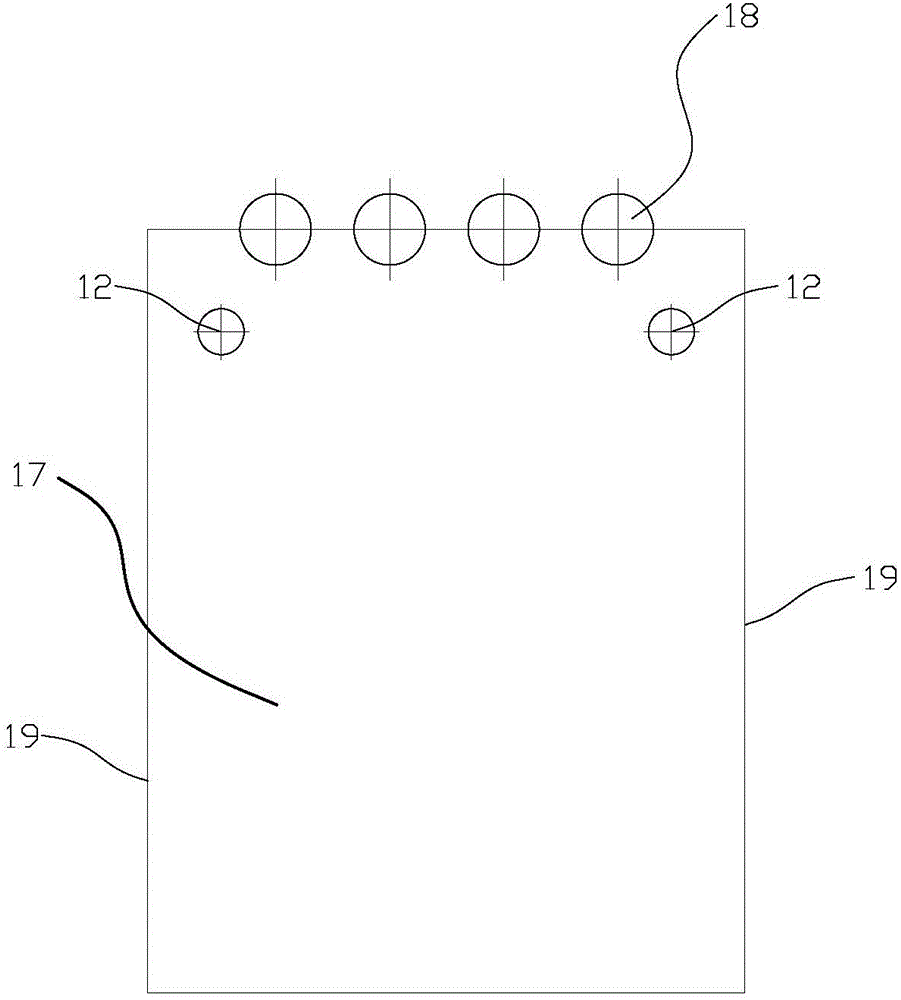

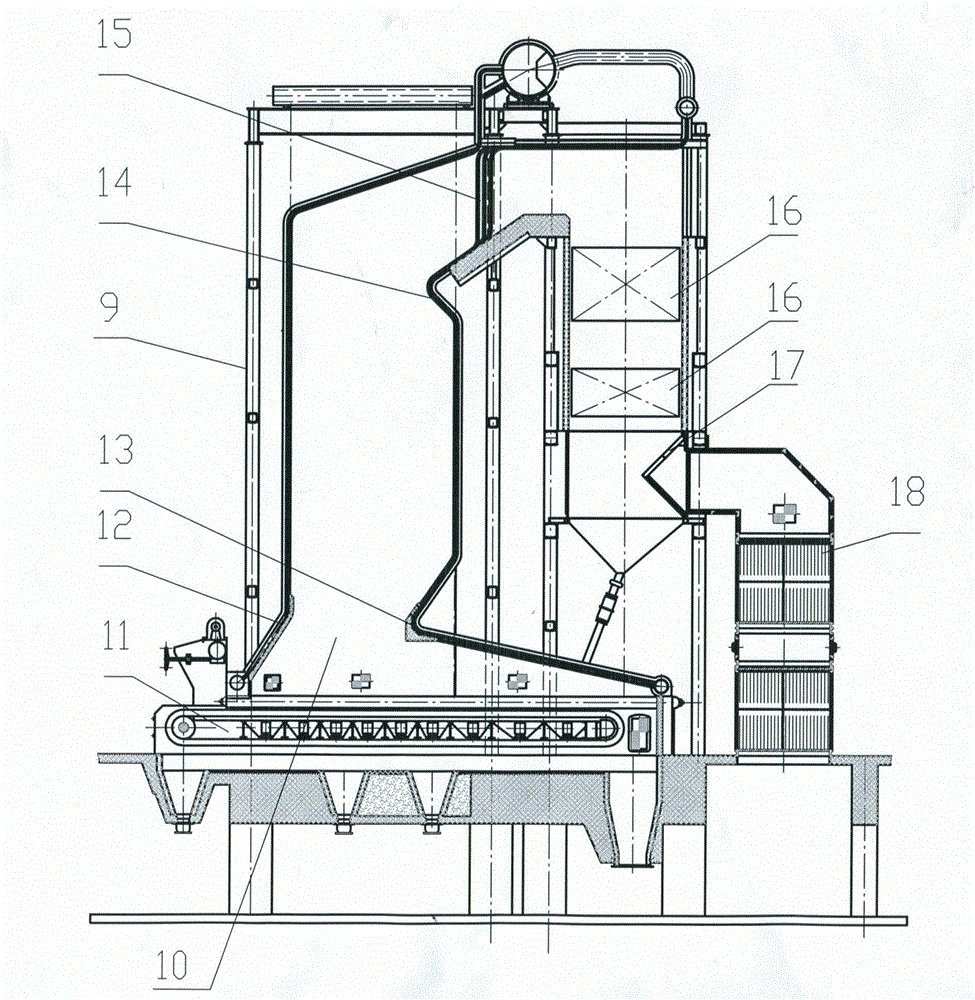

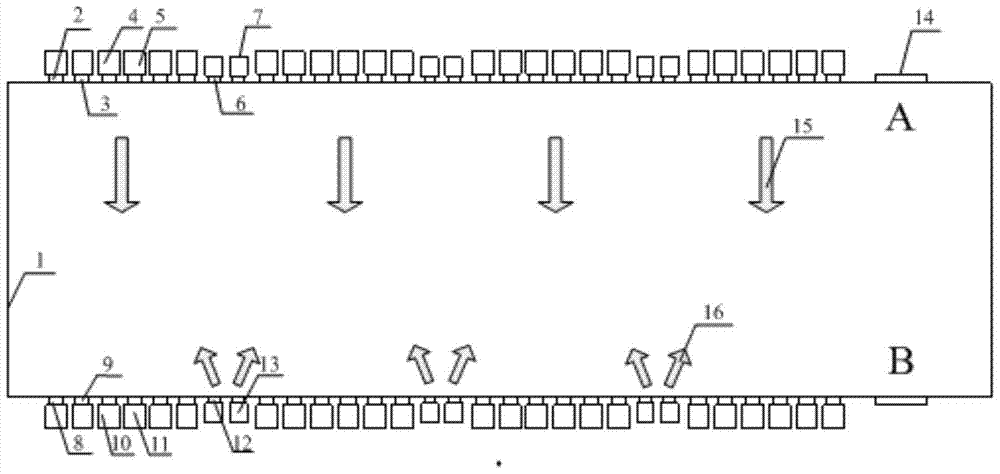

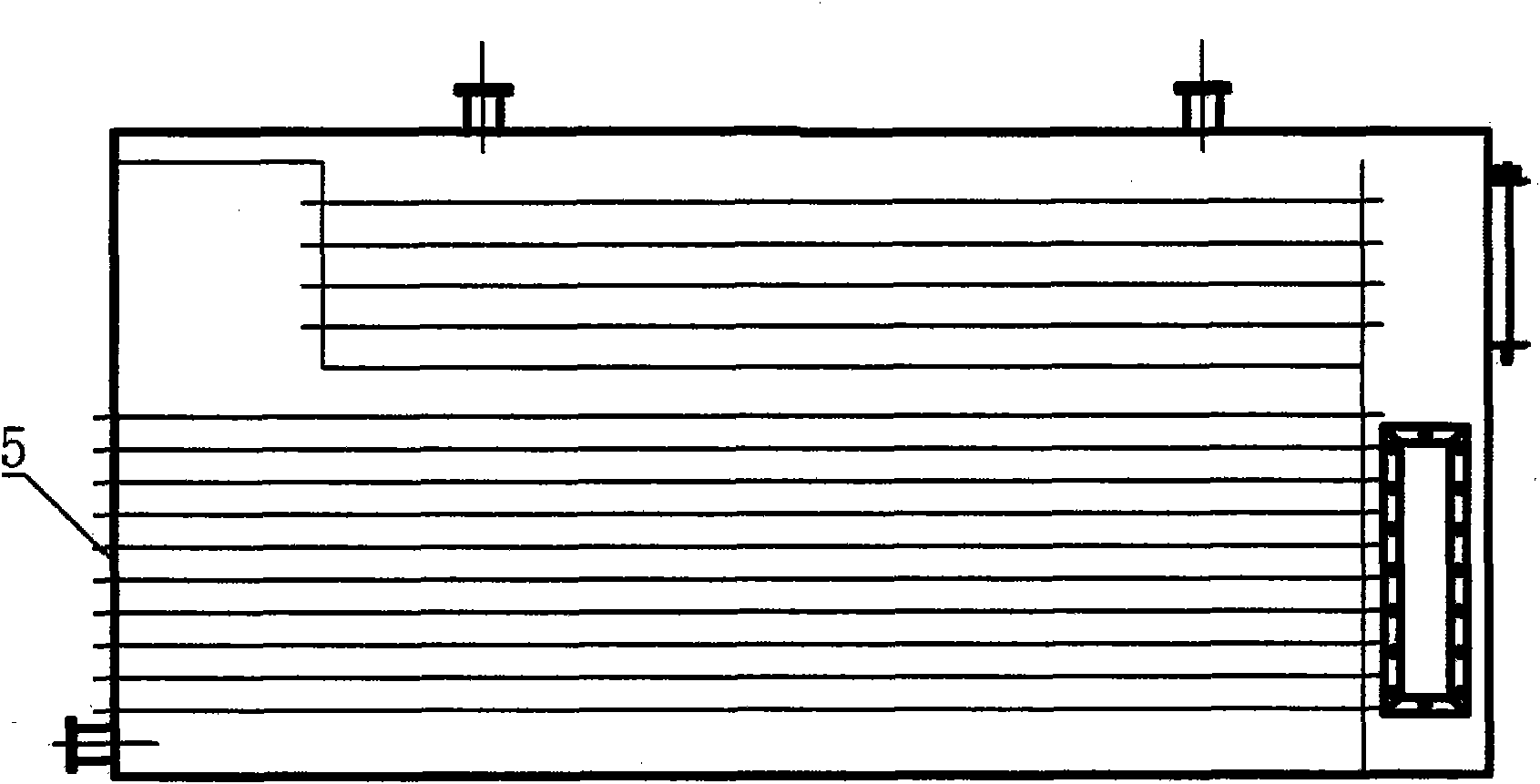

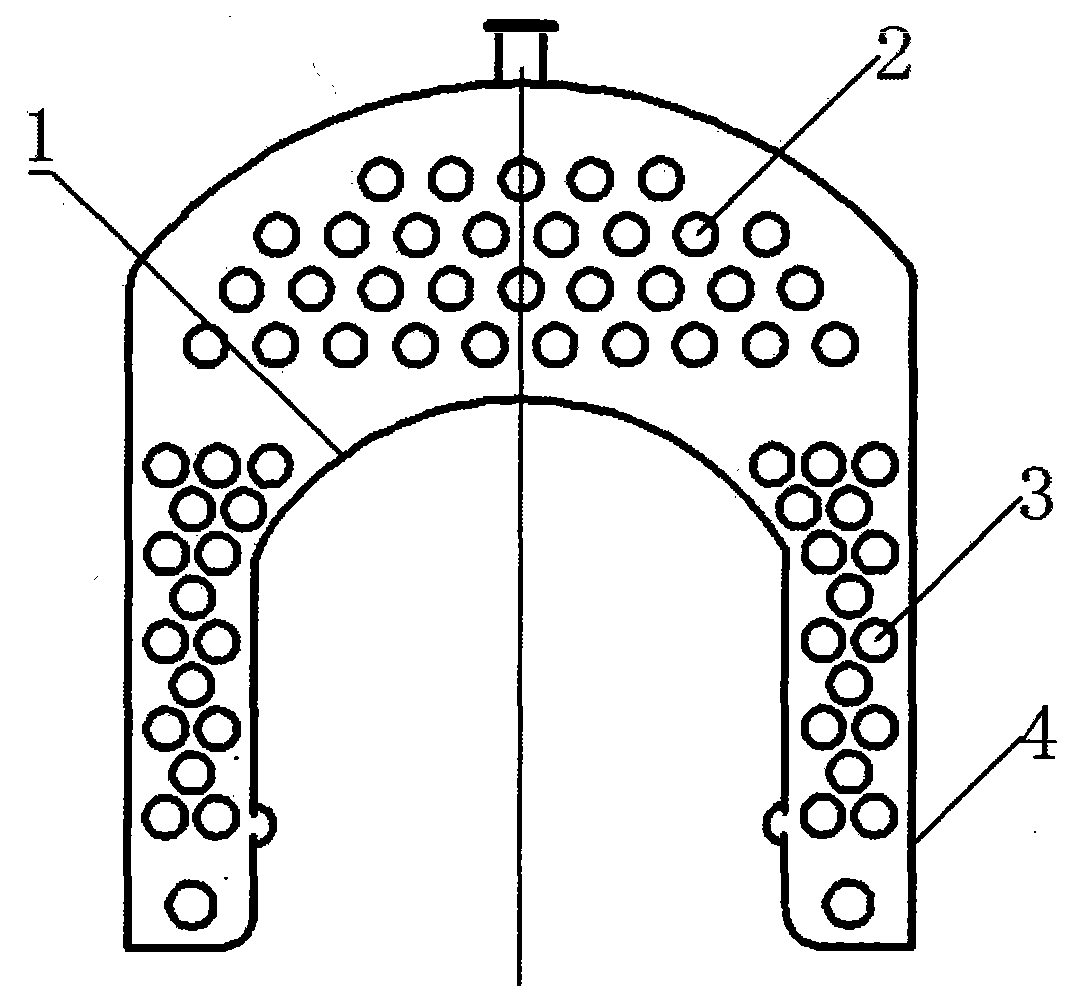

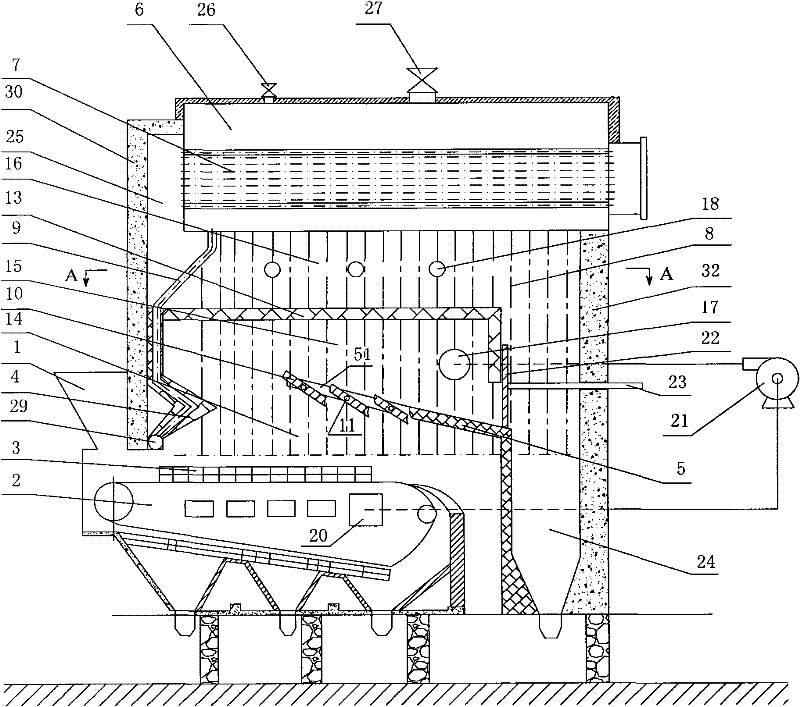

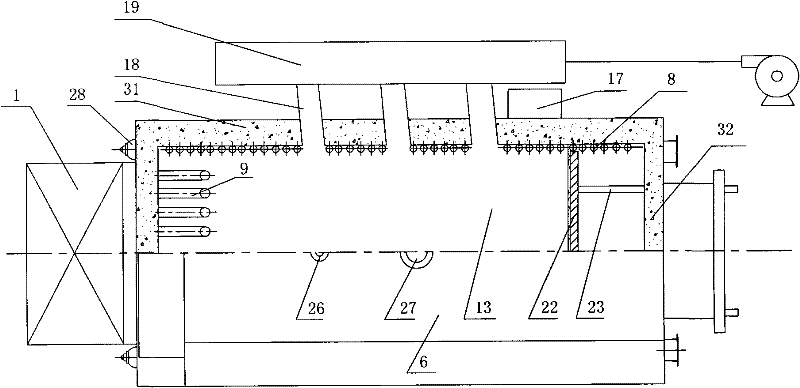

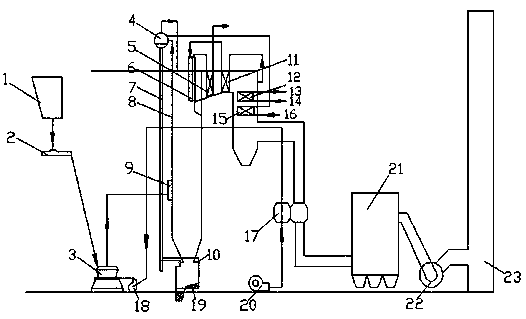

Grate-firing boiler with in-boiler two-level dedusting device

InactiveCN102748751AReduce the initial emission concentrationReduce incomplete combustion heat lossSolid fuel combustionSolid removalAir preheaterHearth

The invention provides a grate-firing boiler with an in-boiler two-level dedusting device. The grate-firing boiler comprises a boiler body, a boiler hearth, a boiler grate, a front arch, a rear arch, a furnace arch, a crust block pipe separating device, a coal saver, an inertia separating device and an air preheater, wherein the boiler hearth, the boiler grate, the front arch, the rear arch, the furnace arch, the crust block pipe separating device, the coal saver, the inertia separating device and the air preheater are arranged in the boiler body. The grate-firing boiler is characterized in that the grate-firing boiler adopts twice separation, smoke is performed with primary separation through the crust block pipe separating device so as to separate most of crude particles and small amount of fine particles, and the crude particles and fine particles are rekindled after being fed into the boiler hearth through the furnace arch. The smoke performed with the primary separation moves downwards on the tail flue and then is returned back by the inertia separating device to be performed with secondary separation, the particles separated from the secondary separation are conveyed to the rear portion of the fire grate through air force to be rekindled. By means of the twice separation, mechanical incomplete combustion loss is reduced by 4%-6.5%, initial smoke discharging concentration of the boiler is reduced by more than 61%, abrasion of a tail heating surface is reduced, and continuous operation time of the device is added.

Owner:TAIYUAN BOILER GROUP

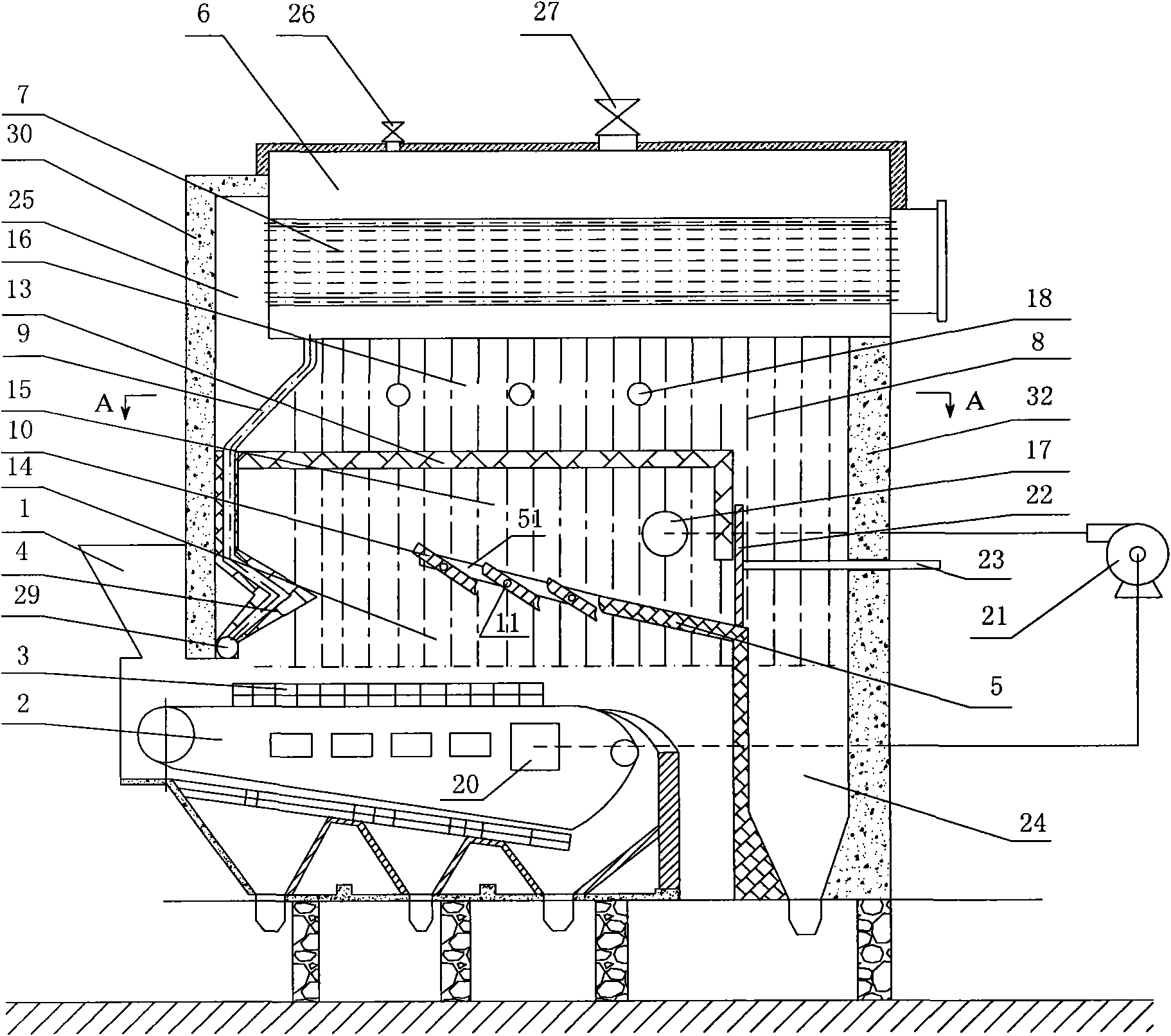

A regenerative heating furnace and its flue gas circulation combustion method

ActiveCN105087899BReduce oxidationReduce oxidation lossFurnace typesHeat treatment furnacesCombustionFlue gas

The invention relates to a regenerative heating furnace and a flue gas circulating combustion method thereof. On the basis of a conventional regenerative heating furnace, two regenerative heating furnaces are respectively installed between each heating section. Flue gas auxiliary burner. The entrance direction of the flue gas auxiliary burner is at a certain angle to the furnace width direction, and is biased towards the adjacent gas or combustion air burner; the outlet of the regenerator of the auxiliary burner is connected to the flue gas pipeline. During the operation of the heating furnace, part of the flue gas in the flue is drawn back, and sent to the furnace for secondary combustion through the auxiliary flue gas burner, and its flow direction is opposite to that of the combustion-supporting air and gas. The invention achieves the purpose of improving the energy utilization rate and reducing the oxidation burning loss rate through the recycling of flue gas.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Coke-removing and soot-cleaning combustion improver for boiler

InactiveCN101955818BPromote combustionBurn safely and thoroughlyGaseous fuelsLiquid carbonaceous fuelsEngineeringSteam locomotive

The invention relates to a fuel additive, in particular to a coke-removing and soot-cleaning combustion improver for a boiler, suitable for various boilers, kilns, and other fuel furnaces using coal, oil, gas and natural gas as fuel, such as industrial boilers, civil boilers, ship boilers, drinking water boilers, steam locomotives, and the like. The coke-removing and soot-cleaning combustion improver is prepared from the following raw materials in percentage by weight: 12.5-30 percent of sodium nitrate, 17.50-25 percent of potassium nitrate, 5.50-11 percent of calcium nitrate, 15-19 percent of salt and 15-49.50 percent of borax. The coke-removing and soot-cleaning combustion improver can prevent the forming of new coke, is beneficial to the full combustion of the fuel, ensures that deposited chimney soot is fully combusted, reduces sticky carbon and carbide, plays a certain corrosion inhibition role to the boiler and prolongs the service life of the boiler.

Owner:吉林鑫聚源节能材料有限责任公司

Counter current heat exchanging smoke-fire constant pressure boiler capable of saving energy and protecting environment

The invention relates to a counter current heat exchanging smoke-fire constant pressure boiler capable of saving energy and protecting the environment, which makes use of the counter current heat exchanging principle and comprises a boiler furnace, an upper smoke-fire tube, a lower smoke-fire tube, a boiler shell and a tube sheet, wherein high-temperature flue gas with two return trips firstly passes through a position with higher water temperature at the water side of the upper smoke-fire tube in the boiler shell for exchanging heat, then lower-temperature flue gas with three return trips passes through a position with lower water temperature at the water side of the lower smoke-fire tube in the boiler shell for exchanging heat. The flue gas is discharged out of the boiler body after the heat exchange; the original downstream heat exchanging means is completely changed; counter current heat exchange is realized; energy sources are saved; and carbon dioxide emission is reduced; as the constant pressure design is adopted, steel consumption is reduced, and the purposes of saving energy and protecting the environment are achieved; and the counter current heat exchanging smoke-fire constant pressure boiler can be produced by adopting a normal boiler production technology.

Owner:陈雅华

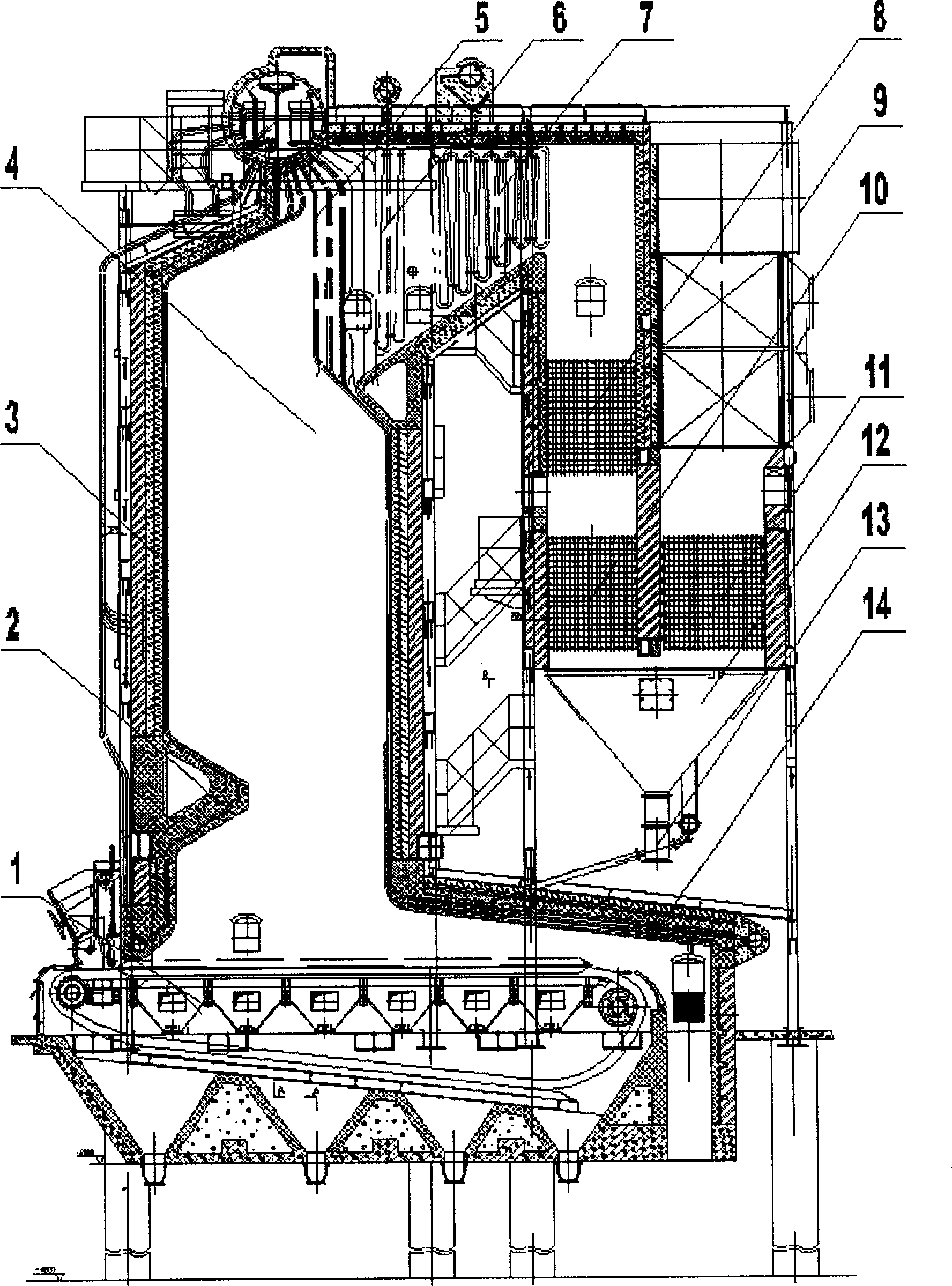

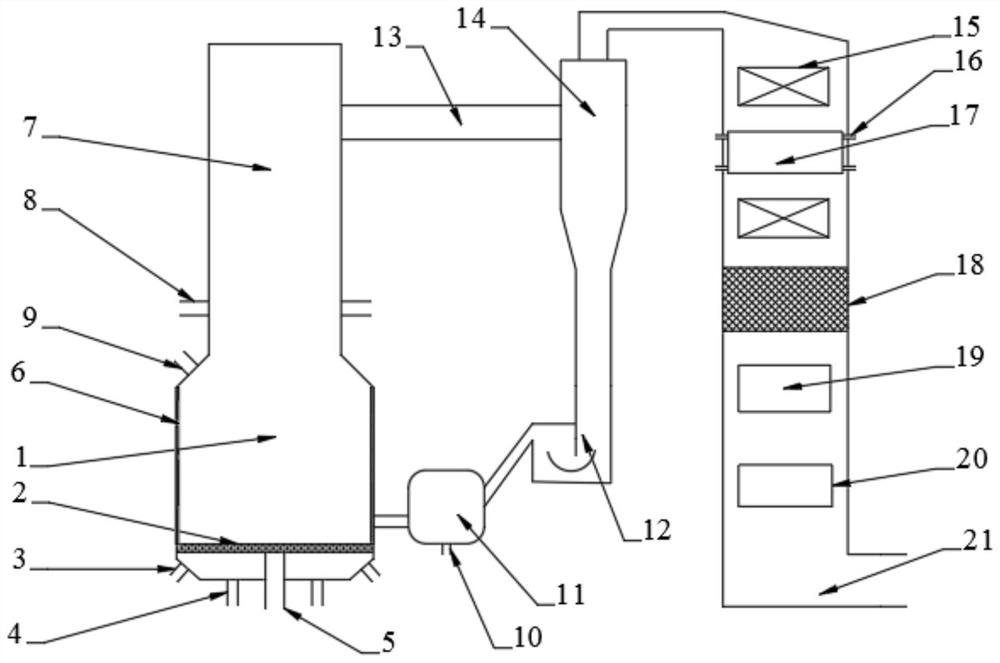

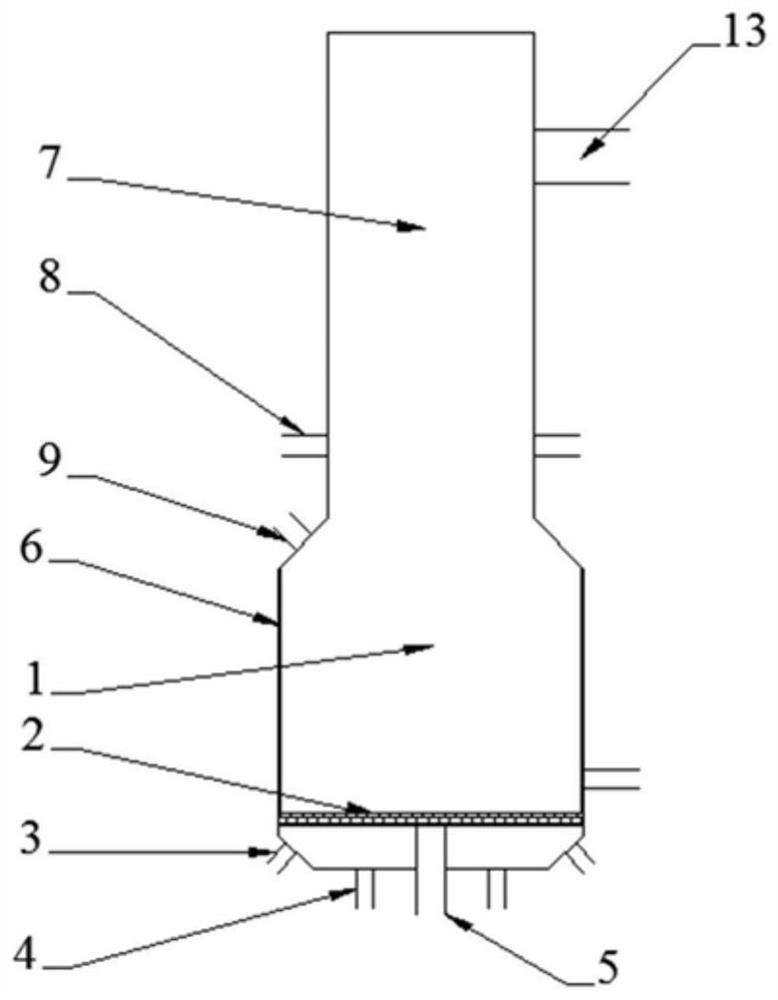

Low NOx emission variable cross-section circulating fluidized bed staged combustion boiler system and method

InactiveCN111706857ALower raw emissionsInhibitory activityFluidized bed combustionEmission preventionAir preheaterCombustion chamber

The invention discloses a low NOx emission variable cross-section circulating fluidized bed staged combustion boiler system and method. The system comprises a variable cross-sectional area furnace, afluidized bed activation chamber and a CO catalytic device; an upper flue gas outlet of the variable cross-sectional area furnace is connected with an adiabatic cyclone separator, the fluidized bed activation chamber is additionally arranged between a lower part returning mechanism of the adiabatic cyclone separator and a fuel-rich combustion chamber, the upper flue gas enters a vertical flue channel after discharging, and enters a supplementary air combustion chamber after heat exchange with a convection heat exchange surface; and a CO catalytic oxidation device is arranged on the downstreamof the supplementary air combustion chamber. According to the variable cross-section circulating fluidized bed boiler system, graded and efficient combustion of coal can be achieved, original emissionof NOx is reduced, and air pollution is reduced; to a certain extent, the problem of ash accumulation and slagging on the heating surface of the tail part is alleviated; returned materials are activated before entering a furnace, and the carbon conversion rate is improved; and an SCR denitrification device is eliminated, so that construction costs are saved, and problems such as catalyst deactivation and air preheater blockage caused by ammonia escape are avoided.

Owner:XI AN JIAOTONG UNIV

Combustion heat load distribution control method of csp thin slab roller hearth tunnel heating furnace

ActiveCN106868287BImprove heating qualityMixed combustion time extensionFurnace typesHeat treatment process controlDistribution controlThin slab

The invention discloses a combustion heat load distribution control method of a CSP sheet billet roller bottom type tunnel heating furnace. The heating furnace comprises a heating section, a soak section, a swing section and a public holding section. According to the method, heat loads of combustion nozzles of the heating section, the soak section, the swing section and the public holding section are controlled. According to the combustion heat load distribution control method, the mixed combustion time of air and gas injected by the combustion nozzles is prolonged; the combustion efficiency and high-temperature combustion gas heat efficiency are improved; incomplete combustion heat losses and heat losses of discharge smoke are reduced; damage of secondary combustion to a heat exchanger is reduced; and finally the aims of reducing secondary combustion in a flue, reducing energy consumption of the heating furnace, improving the sheet billet heating quality, prolonging the service life of the heat exchanger and the like are achieved.

Owner:武汉钢铁有限公司

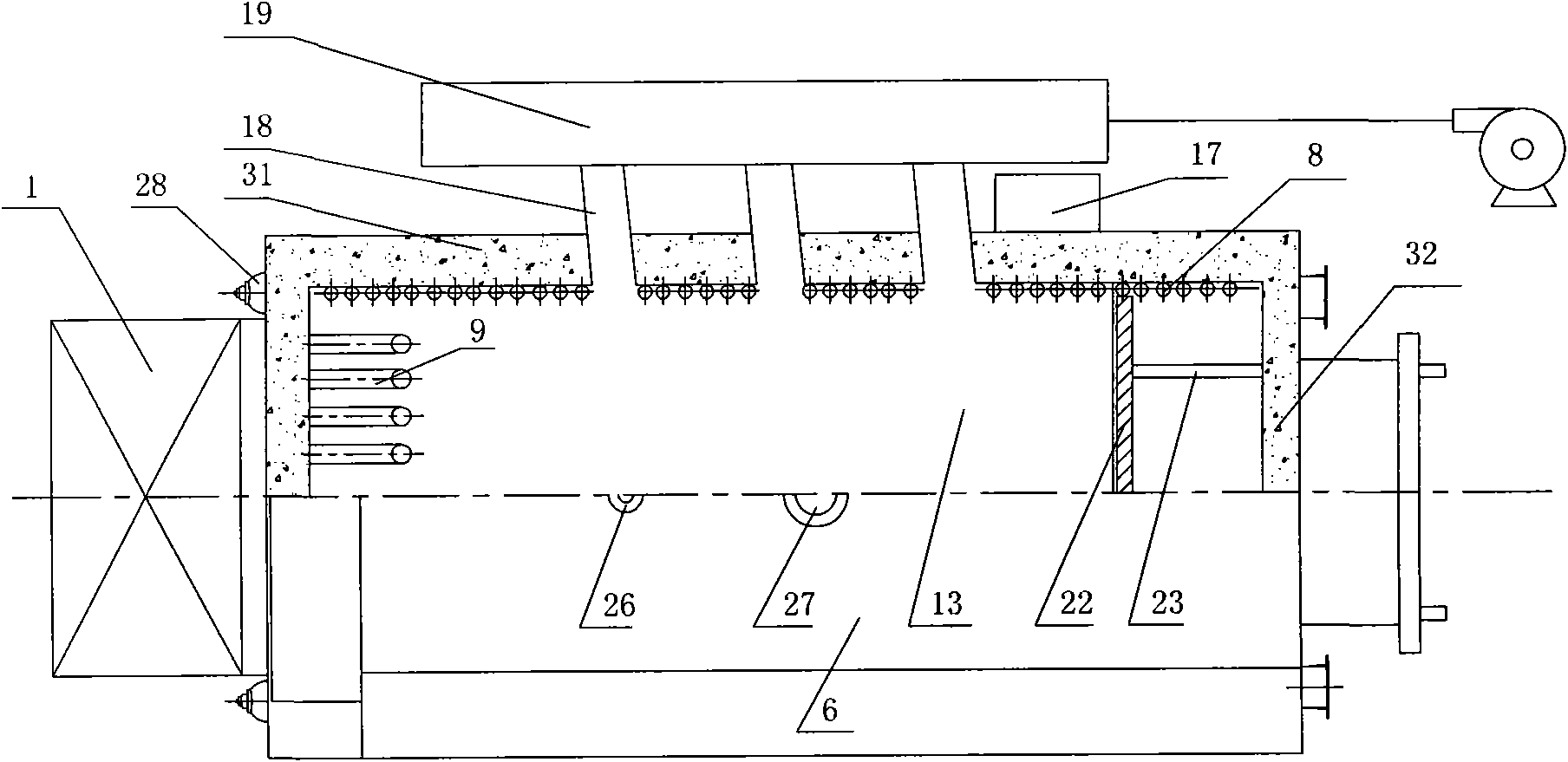

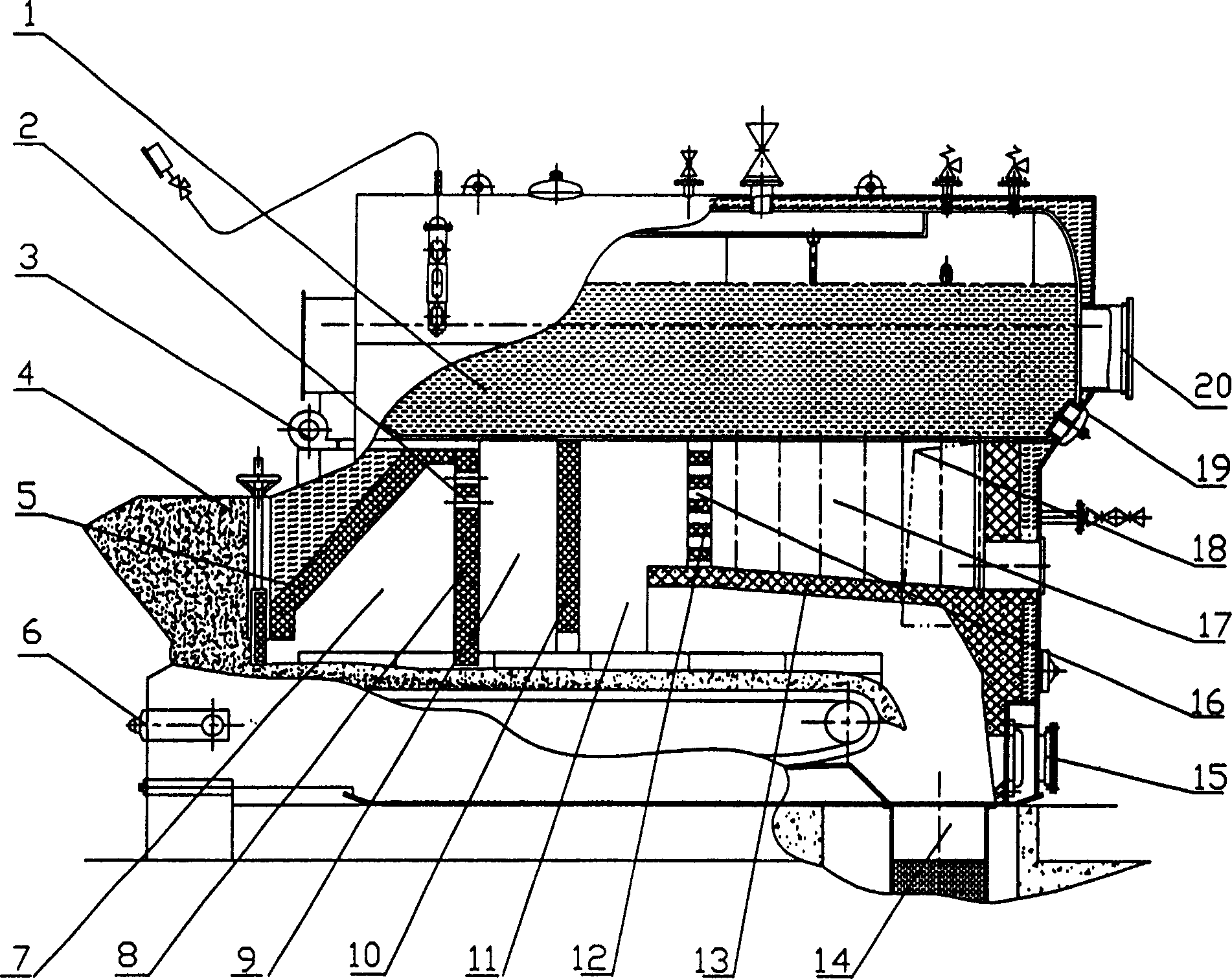

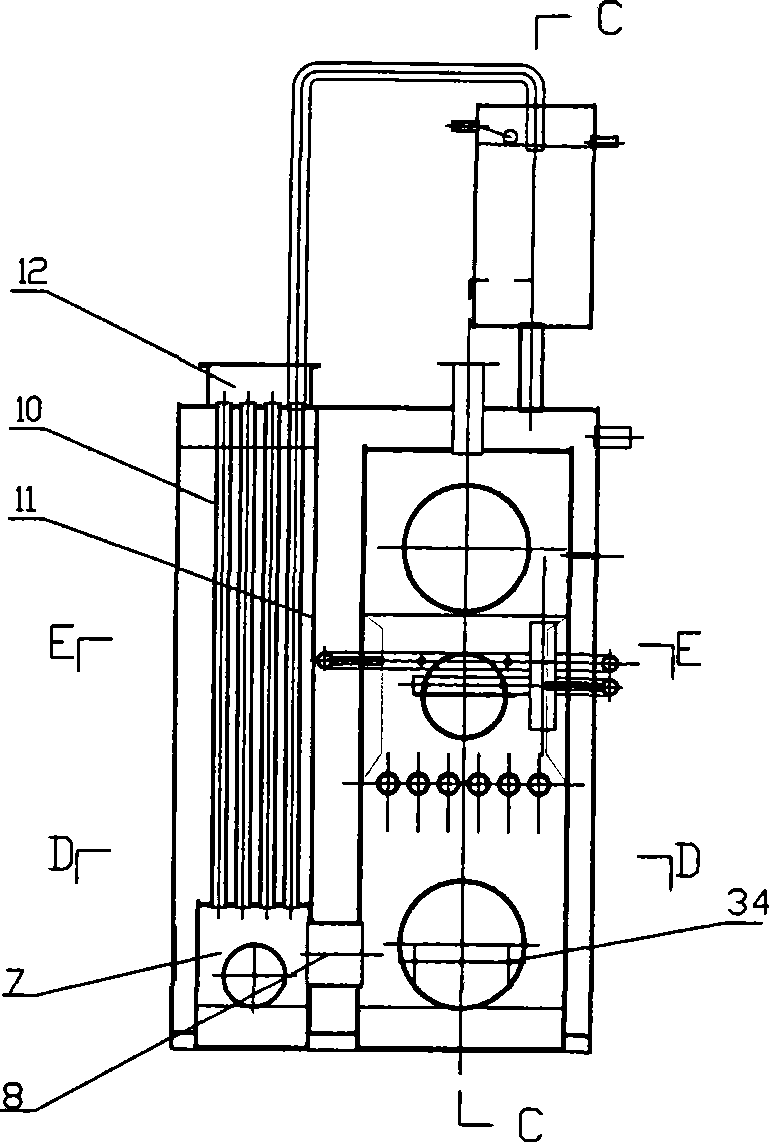

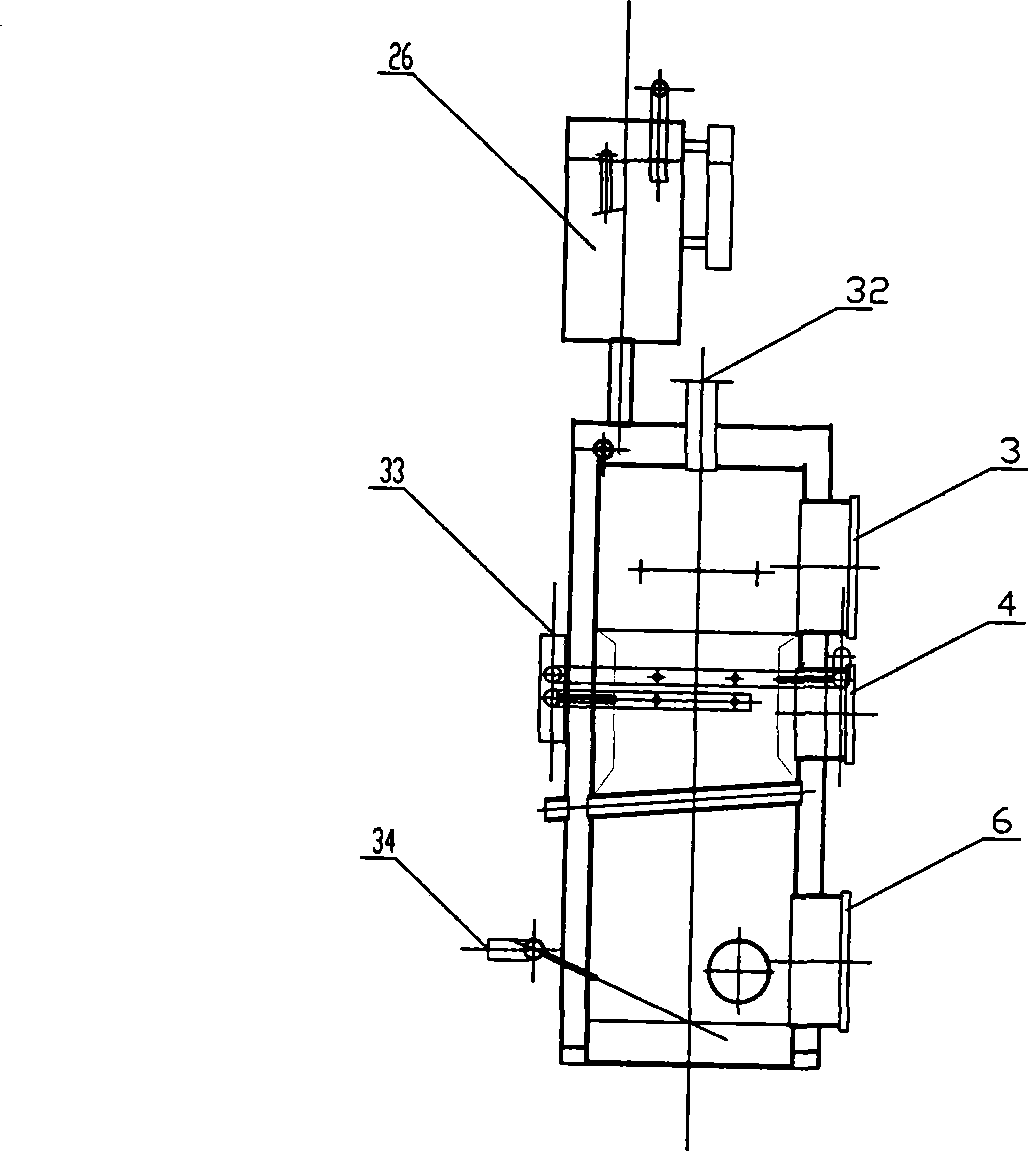

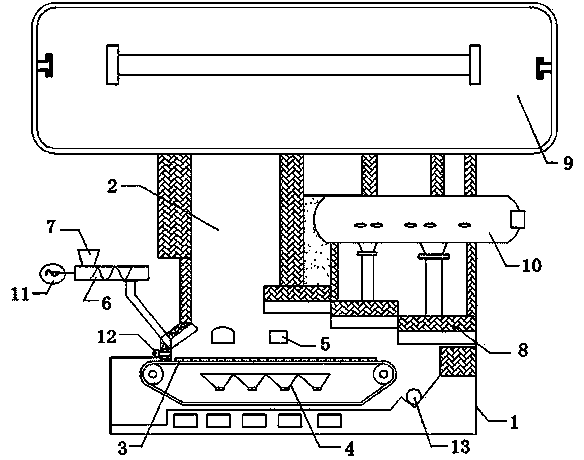

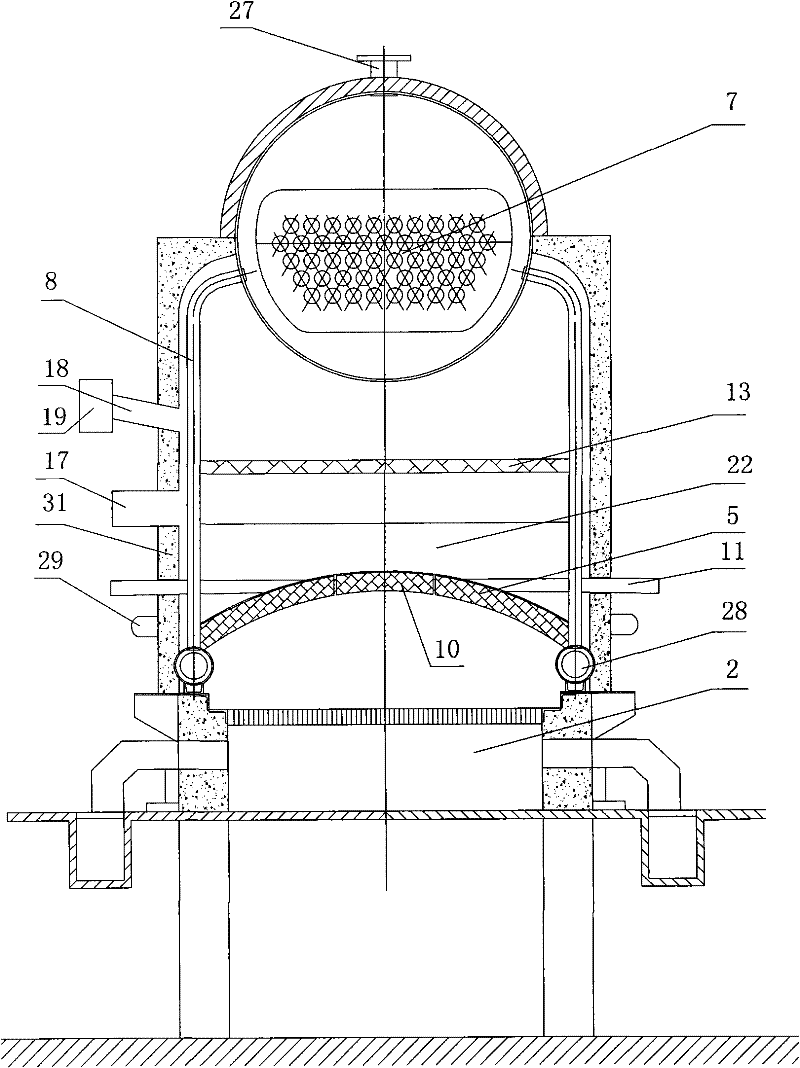

Industrial boiler for burning bio-briquettes

ActiveCN101818891BEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention discloses an industrial boiler for burning bio-briquettes. A front arch and a rear arch of which the front part is in an interdigitated shape are arranged in a body of the boiler; upper edges of two adjacent interdigitated parts of the rear arch are provided with corresponding grooves; a check block is arranged between two adjacent interdigitated parts; and two sides of the check block are fixedly connected with rotating shafts which are respectively arranged in the corresponding grooves. Furthermore, a figure-7 partition laminate is arranged above the rear arch; a movable division door is arranged between the rear end of the partition laminate and the rear arch; a circulating air pipe is connected with an air inlet of a draught fan outside the body through an air pipe; the air outlet of the draught fan is connected with a last-stage air bin of a chain grate; and a secondary air pipe at the air inlet on the side wall of a third combustion chamber is deflected toward the lower rear part, and is communicated with a main secondary air pipe outside the body. The industrial boiler has the advantages that: the bio-briquettes are efficiently and stably combusted; the boileris started at a high speed and has high heat efficiency; black smoke is not generated when the boiler is started; and the integral delivery of the boiler can also be realized.

Owner:ZHEJIANG JINGUO BOILER

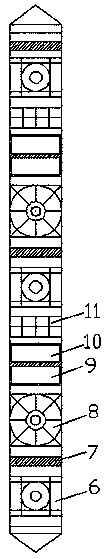

Vertical environment-friendly boiler for triple dedusting burning wood and biomass particle fuel in boiler

InactiveCN101907292BFully embersFully vaporizedSolid fuel combustionCasings/liningsDust controlHearth

The invention relates to a vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in a boiler, belonging to heating technology. The invention is used for burning wood and biological particles to obtain hot water or steam, and overcomes the defects of black smoke emission, low thermal efficiency, and the like of the similar traditional boilers. The boiler comprises a wind chamber, a fire grate, a carbon powder and gas burning hearth, a first wind inlet, a secondary wind inlet, and a heat exchanger above the hearth. The boiler is characterized in that the hearth is provided with a porous boiler crown of an inclined air vent; the upper end of an inner liner is provided with a smoke blocking wall; a downward screwed smoke tube is arranged between the wall of the inner liner and a lower end socket; an upward screwed smoke tube penetrates through an upper closing plate and a lower closing plate; and a heat exchanger seat of a smoke diversion dedusting chamber in the shape of a ring cavity is arranged on the circumference of the lower end of the heat exchanger. The invention has the advantages of sufficient burning of carbon powders, sufficient gasification and high thermal efficiency. Smoke is dedusted three times in the boiler, and the exhausted smoke has low dust capacity. The invention can be manufactured in a split mode, and is convenient to transport. The tonnage can be greatly increased.

Owner:袁福林

A device for increasing the combustion value of boilers in power plants

ActiveCN107289445BLow ignition temperatureEnhance mutual combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHigh concentrationCombustion

A device for increasing the combustion value of a boiler in a power plant, which relates to a boiler device in a power plant. The device adopts impingement flow, four nozzles, primary air opposing impact, double secondary air, four-corner tangential arrangement, reverse double tangential circle and air staged combustion, The four-nozzle primary air carries pulverized coal to form opposing impacts in the center of the furnace; the secondary air is divided into upper and lower winds, which are strong tuyere (10) and weak tuyere (9), both of which adopt the four-corner tangential combustion method at the center of the outlet jet. The line forms two different angles with the center line of the water wall, so that two imaginary tangential circles with the same direction but different diameters are formed in the center of the furnace. The device is equipped with four nozzles of the primary wind of the impingement flow, which collide against each other. In the impingement area, a high-concentration area where pulverized coal accumulates and a highly turbulent and oscillating area of flow state will be formed. And because of the highly turbulent and oscillating nature of the impact zone, the contact between air and pulverized coal is increased, the mutual combustion effect of airflow is enhanced, and the stability and economy of combustion are improved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

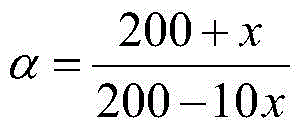

Device capable of improving burning efficiency of gas furnace by controlling oxygen content of exhaust gases from gas furnace and application of device

InactiveCN104807037AReduce concentrationReduce tail exhaust heat lossAir supply regulationProcess engineeringOxygen content

The invention relates to a device capable of improving the burning efficiency of a gas furnace by controlling oxygen content of exhaust gases from the gas furnace and application of the device. The device comprises an oxygen concentration sensor and a control module, wherein the oxygen concentration sensor is arranged at an exhaust outlet of the gas furnace and is used for detecting actual oxygen concentration in the exhaust gases from the gas furnace; the control module is respectively connected with the oxygen concentration sensor and the gas furnace and is used for setting an excess air coefficient in gas inlet of the gas furnace according to the target oxygen concentration of the exhaust gases from the gas furnace and correcting the excess air coefficient in the gas inlet of the gas furnace according to the target oxygen concentration and the actual oxygen concentration. Compared with the prior art, the device disclosed by the invention has the advantages that by setting and regulating the excess air coefficient, the concentration of oxygen in the exhaust gases from the gas furnace is reduced, unnecessary tail smoke exhaust hot loss or incomplete burning hot loss is reduced, the burning efficiency is improved, and eventually the aim of saving energy is achieved.

Owner:南京祥源动力供应有限公司

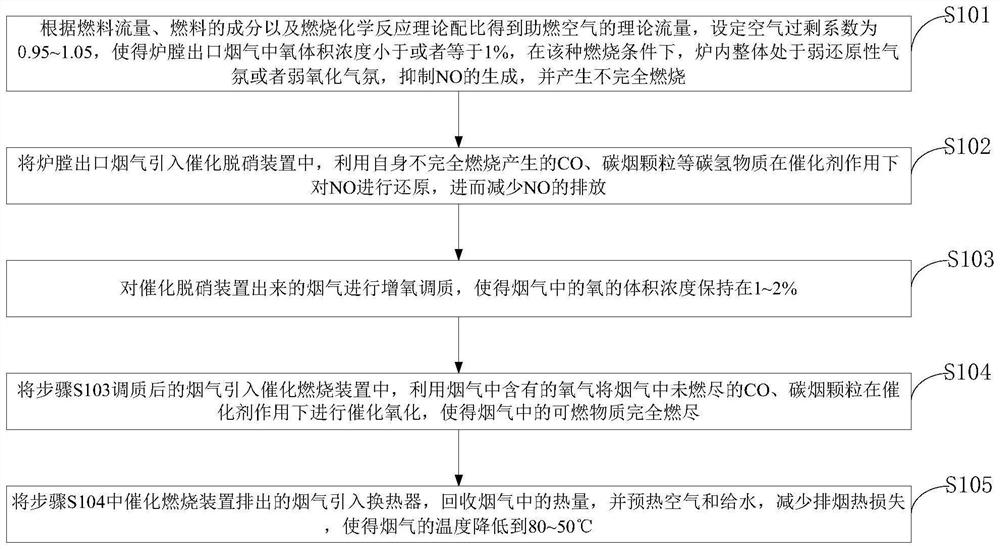

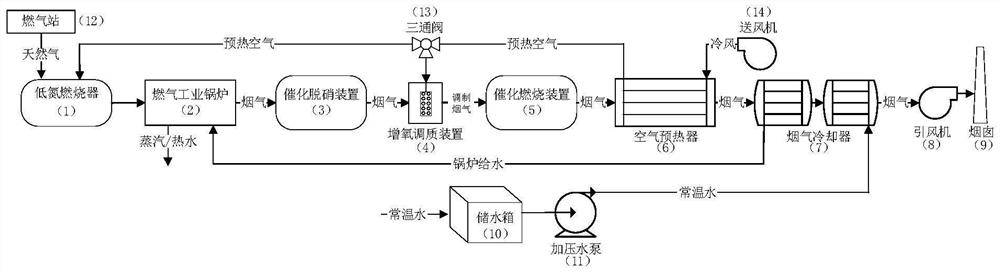

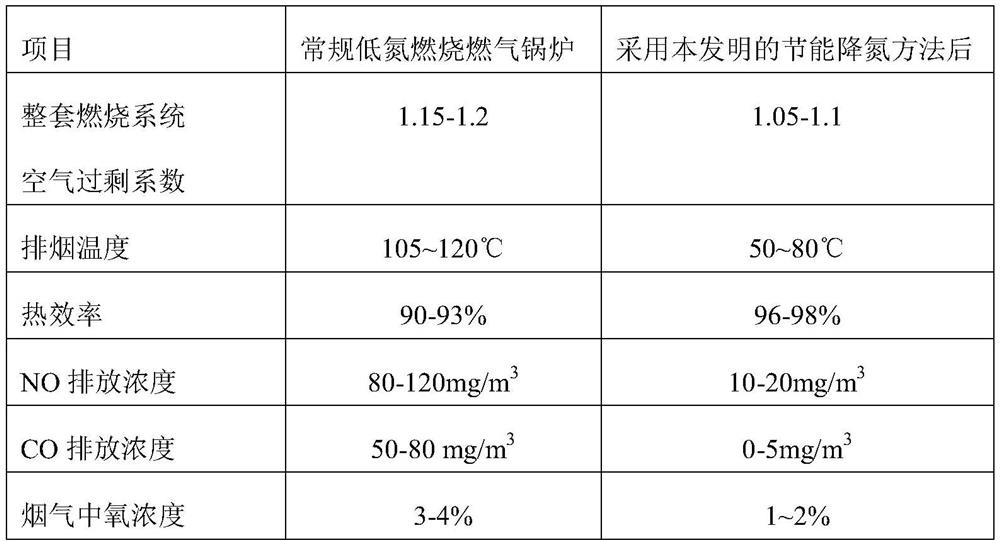

Combustion method and system for realizing energy conservation and low nitrogen emission of gas industrial boiler

PendingCN114151816AEfficient emissionsImprove efficiencyEmission preventionCombustion technology mitigationLow nitrogenLow oxygen

The invention belongs to the technical field of gas industrial boilers, and discloses a combustion method and system for achieving energy conservation and low nitrogen emission of a gas industrial boiler. The method comprises the following steps: firstly, controlling the generation of oxynitride and generating high-concentration carbon monoxide by adopting low-nitrogen combustion under the condition of a low coefficient of excess air in a furnace, and secondly, carrying out further catalytic reduction on nitrogen oxides in the flue gas in a flue region by utilizing incomplete combustion products such as carbon monoxide and soot particles in the flue gas as a reducing agent, and finally, incomplete combustion hydrocarbon substances remaining in the flue are eliminated in a catalytic combustion mode. A staged low-nitrogen combustion technology, a low-oxygen (low excess air coefficient) combustion technology, a hydrocarbon catalytic reduction denitration technology, a catalytic combustion technology and a deep flue gas waste heat recovery technology are organically combined, efficient combustion and low-nitrogen emission of the gas industrial boiler are achieved, meanwhile, the boiler efficiency is improved, and fuel consumption is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

A New Coal Pulverizer Outlet Temperature Control System and Its Control Method

ActiveCN104801416BRaise the outlet temperatureIncrease the level of automationGrain treatmentsLump/pulverulent fuel preparationTemperature controlPresent method

The invention discloses a novel coal mill outlet temperature control system and its control method, wherein the control system includes a controller, a coal mill outlet temperature detector, a coal mill hot air regulating door, and the coal mill outlet temperature detector is located at the The controllers are connected to each other, and the controllers are connected to the hot air regulating door of the coal mill. Compared with the current control method, the control method involved in the present invention can solve the problem that the upper limit of the coal pulverizer outlet temperature in the current coal pulverizer outlet temperature control method is only set for a specific coal type and cannot be adapted to coal pulverizers. The quality of coal fed to the mill frequently changes and the operating value of the outlet temperature of the coal mill is low. It can improve the automation level of the operation of the coal mill, effectively increase the outlet temperature of the coal mill, reduce the coal grinding power consumption of the coal mill, and reduce the carbon content in the pulverized coal combustion product.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com