Low-emission system of coal-fired boiler and treatment method of low-emission system

A technology for coal-fired boilers and boilers, which is used in the combustion of solid fuels, combustion equipment, lighting and heating equipment, etc., can solve the problems of high operating costs, low boiler thermal efficiency, and high pollutant emissions, and achieves lower furnace temperatures. Reaction conditions, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

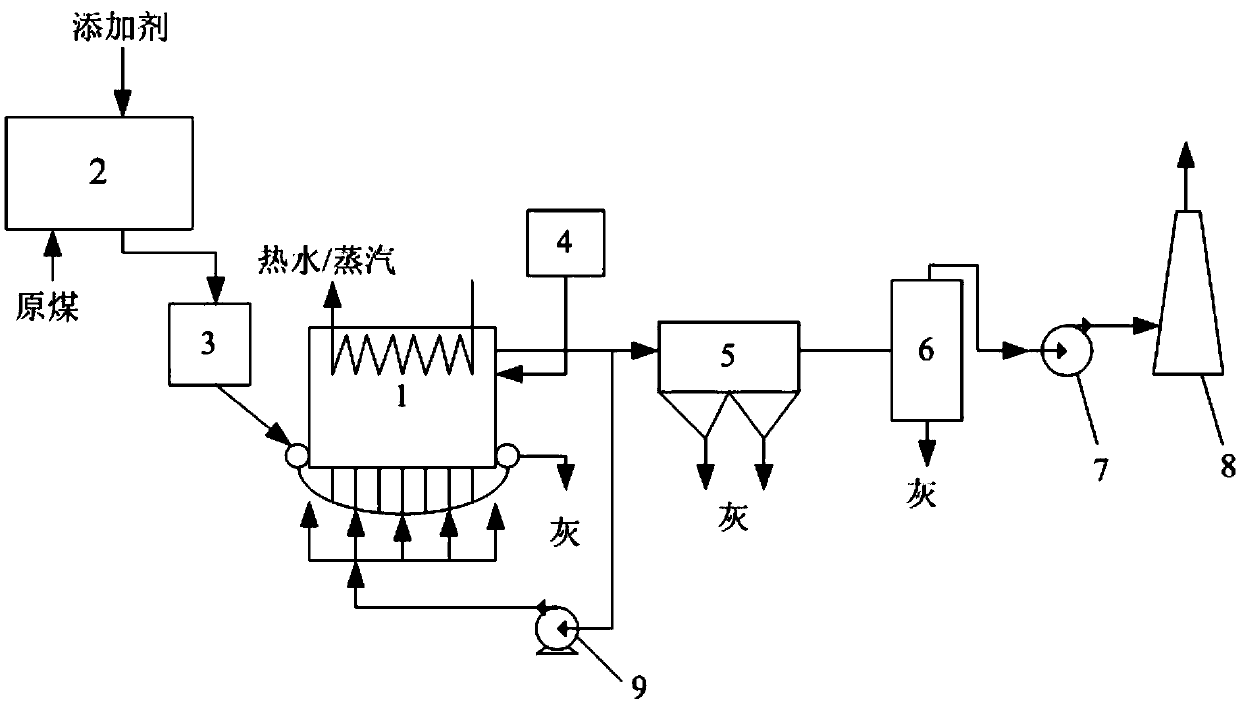

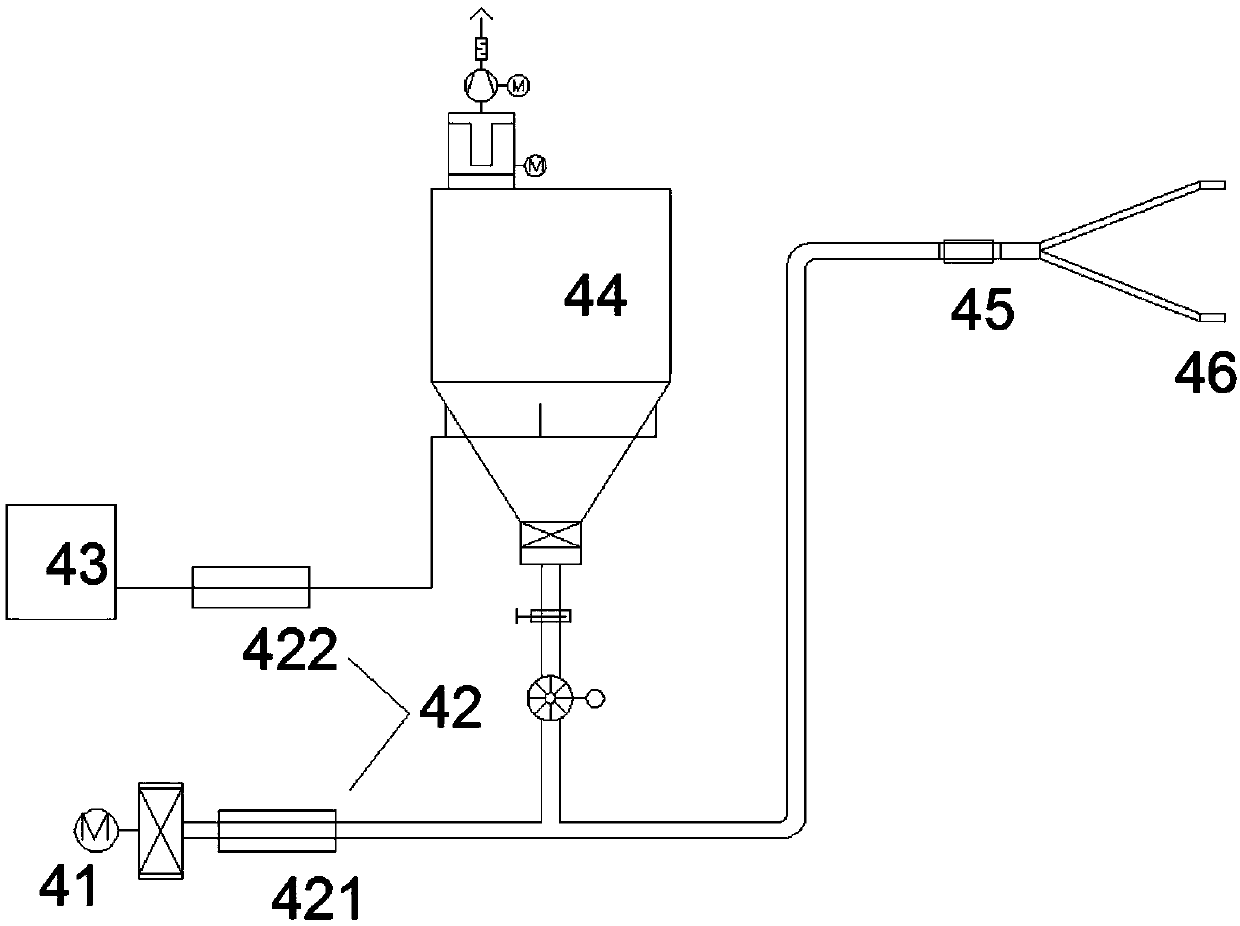

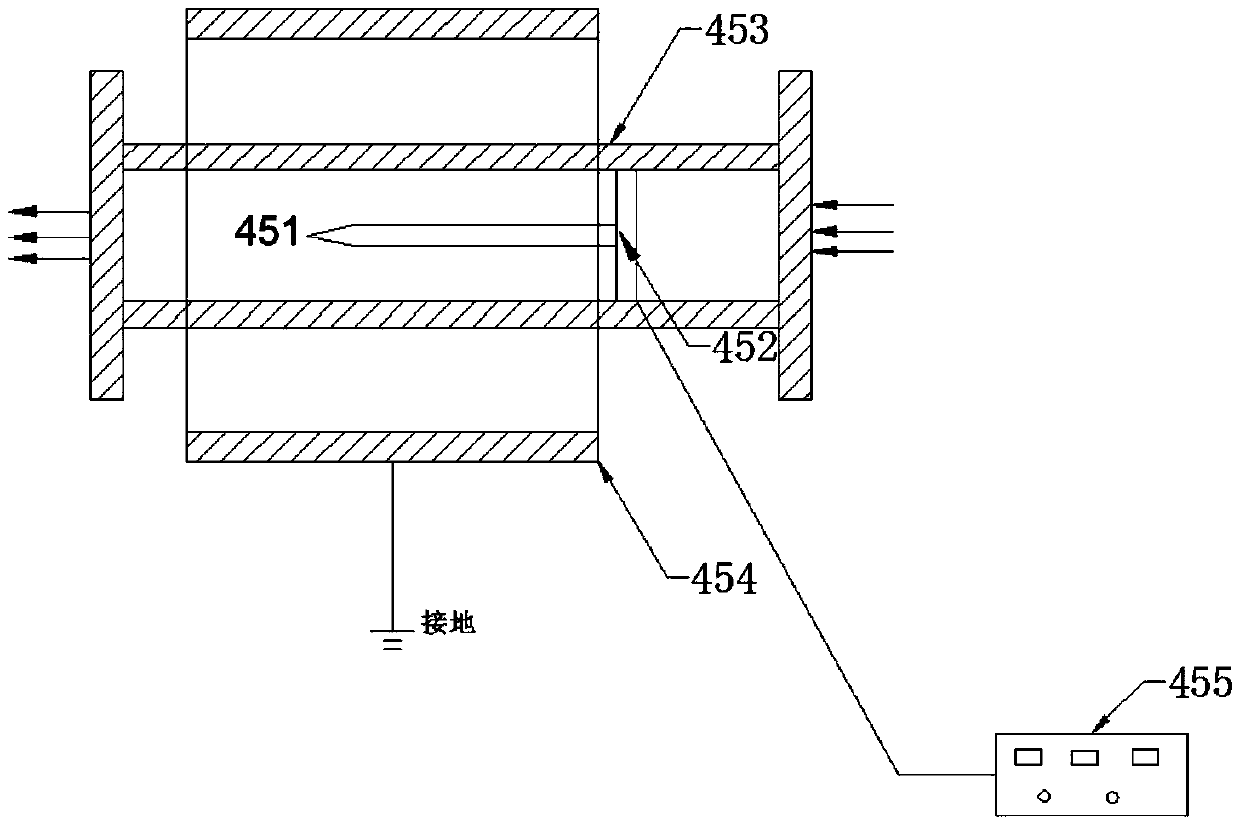

[0117] This embodiment provides a low-emission system of a coal-fired boiler and its treatment method, such as figure 1 As shown, the system includes a feeding unit, a layer-fired boiler 1, an additive adding unit 4, a flue gas dedusting unit 5, a tail gas desulfurization and denitrification unit 6, a second gas delivery device 7 induced draft fan and a chimney 8; the material outlet of the feeding unit is connected to the The coal-fired inlet of the layer-fired boiler 1 is connected, the material outlet of the additive addition unit 4 is connected with the furnace of the layer-fired boiler 1; the flue gas outlet of the layer-fired boiler 1 is connected with the flue gas dust removal unit 5 and the tail gas desulfurization and denitrification unit 6 in sequence, and the tail gas The flue gas discharged from the desulfurization and denitrification unit is sent to the chimney 8 through the second gas delivery device 7;

[0118] Wherein, the floor-fired boiler 1 is a chain grate ...

Embodiment 2

[0131] This embodiment provides a low-emission system of a coal-fired boiler and its treatment method. The structure of the system refers to the structure in Embodiment 1, the difference is that: Figure 5 As shown, the static desulfurization and denitration device includes a pipeline and a desulfurization module 63 and a denitration module 64 arranged inside the pipeline in sequence. The flue gas dust removal unit 5 is placed in front of the desulfurization module 63 in the pipeline, and the desulfurization module 63 is a desulfurization module. denitration agent box, the box body of the desulfurization agent box is a net cage, and the desulfurization adsorbent is built in the net cage; The porosity of the denitrification adsorbent is 0.5% to 0.53%.

[0132] The treatment method of the low-emission system refers to Example 1, the difference is that the volatile content in the briquette in step (a) is 30wt% to 33wt%, the additive content is 14wt% to 15wt%, and the ash content ...

Embodiment 3

[0135] This embodiment provides a low-emission system of a coal-fired boiler and its treatment method. The structure of the system refers to the structure in Example 1, the difference is that the porosity of the desulfurization adsorbent is 0.58% to 0.6%, and the denitrification adsorbent The porosity is 0.58% to 0.6%.

[0136] The treatment method of the low-emission system refers to Example 1, the difference is that the volatile content in the briquette in step (a) is 33wt% to 35wt%, the additive content is 10wt% to 12wt%, and the ash content <25wt%. 1. During the operation, the coal-fired accumulation thickness on the grate is 12cm-13cm. The speed of the fire grate during the operation of the layer-fired boiler 1 is 7m / h-8m / h, and the volume content of the flue gas discharged from the furnace body is 18 % to 20% of the flue gas is returned to the air chamber of the layer-fired boiler 1; the average particle size of the composite addition in step (b) is 0.38mm.

[0137] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com