Vertical environment-friendly boiler for triple dedusting burning wood and biomass particle fuel in boiler

A technology of pellet fuel and wood pellets, applied in the field of boilers, can solve the problems of insufficient burning of carbon particles, high dust concentration of boilers, large excess air coefficient, etc., so as to reduce the heat loss of incomplete combustion of gas and suppress the blackening of boilers. Smoke, fast burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

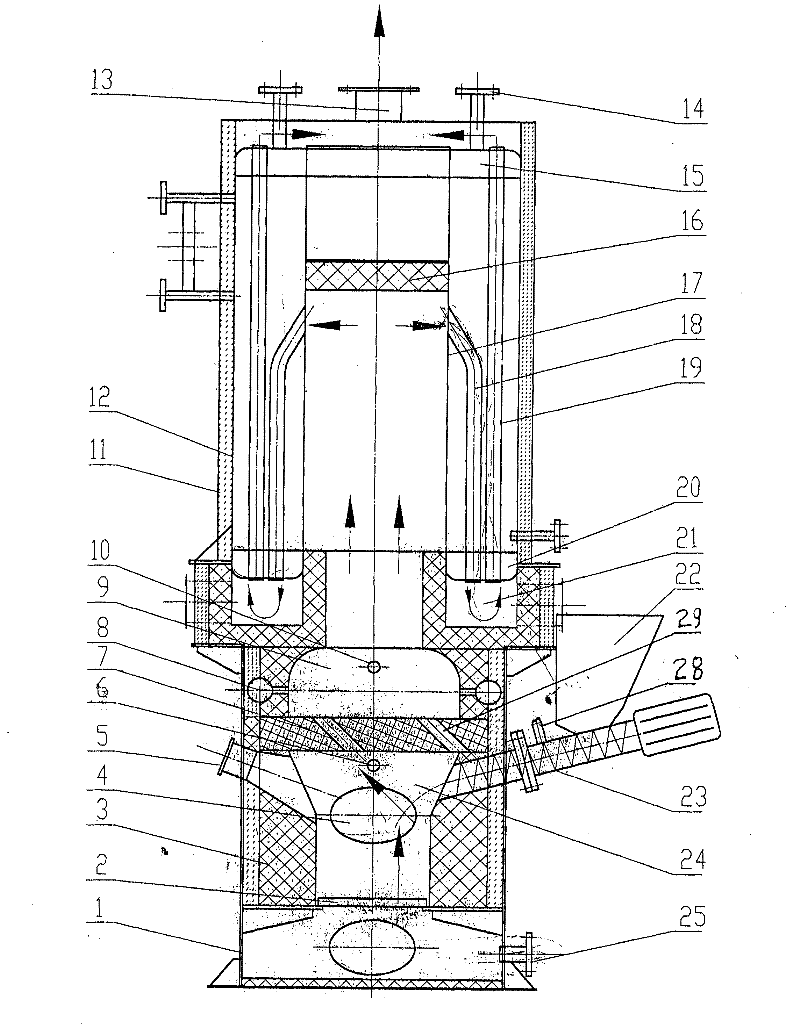

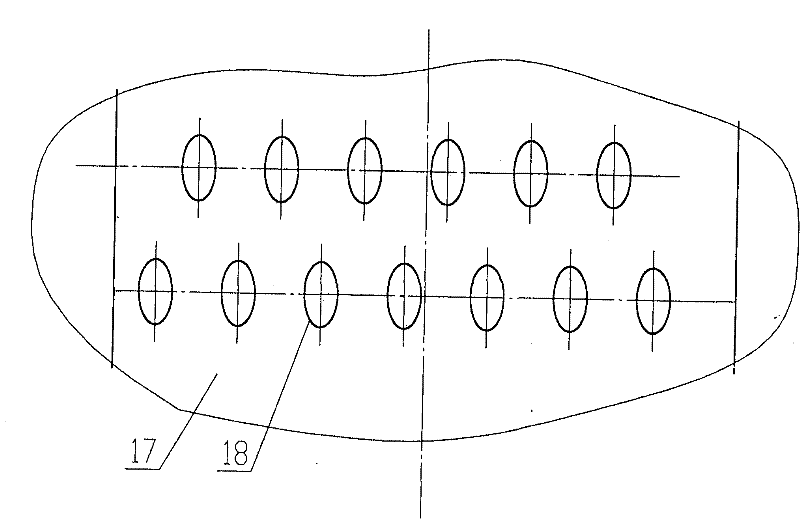

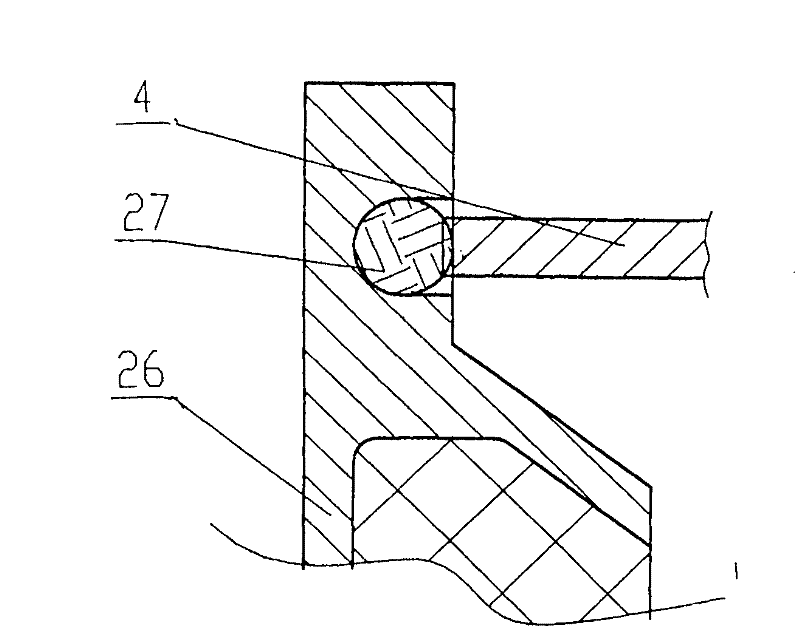

[0023]The woody biomass pellet fuel falls into the pellet fuel combustion chamber 24 from the stepless speed-regulating screw feeding device 23 with seeding and cooling wind. Most of the gasification process is completed, and the combustible gas and flue gas produced flow out from the swirling air outlet in the high-temperature regenerative combustion furnace arch 7 with a built-in inclined rotating air outlet to remove dust and start to ignite here, after which the combustible gas and smoke The gas is completely burned in the adiabatic gas combustion chamber 9 to produce high-temperature flue gas. The high-temperature flue gas goes up through the middle channel of the middle heat exchanger seat and enters the inner tank 17 for radiation heat release, and then the hot flue gas enters the downward threaded smoke pipe 18 for convective heat release, and then the hot flue gas enters the middle smoke through the outlet of the second downward threaded smoke pipe The gas turns to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com