Rotary combustion type biomass particle fuel hot water boiler

A biomass particle and hot water boiler technology, applied in fuel supply, solid fuel combustion, combustion methods, etc., can solve the problems of fuel combustion slagging, unsafety, etc., to reduce slagging, eliminate backfire and pilot fuel bunker The effect of the hidden danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the given examples are not intended to limit the present invention.

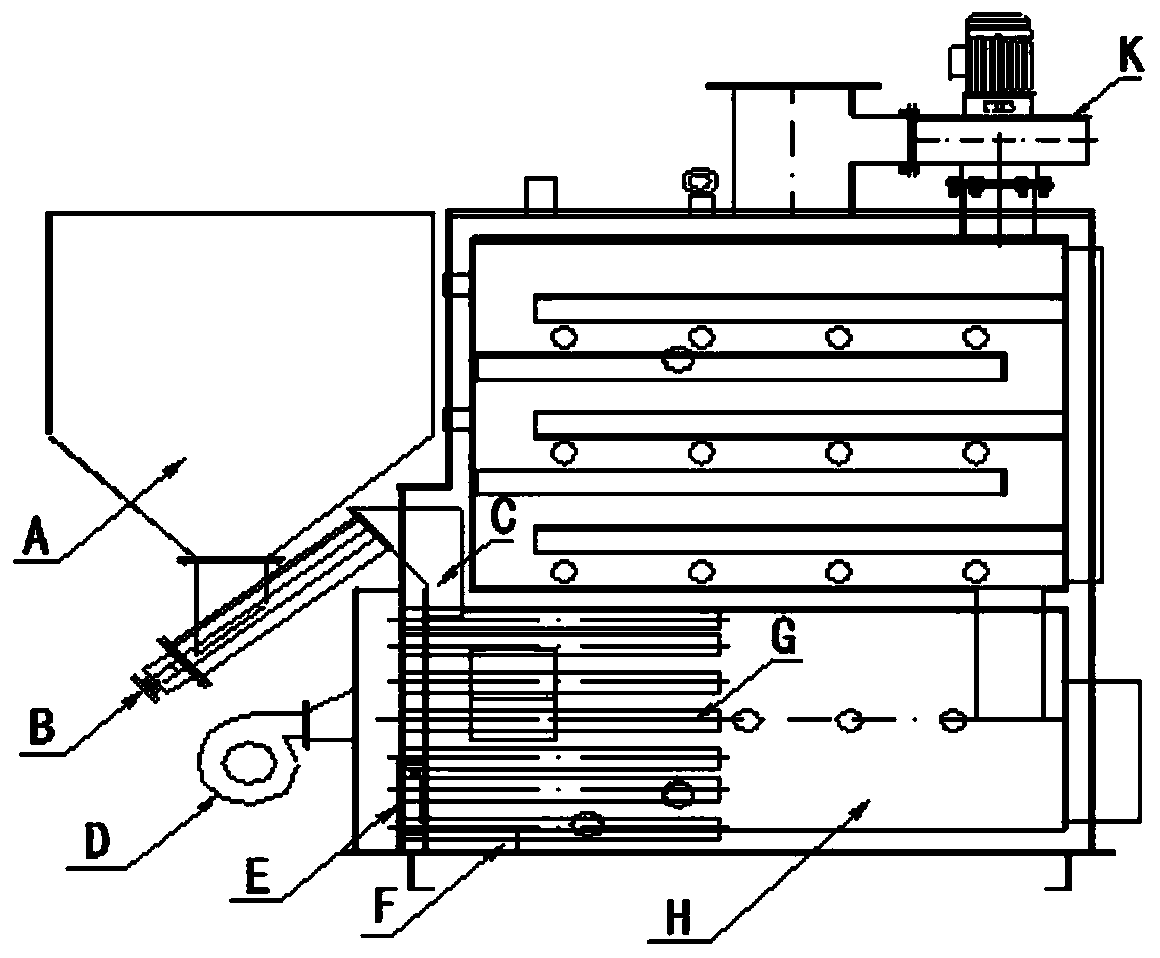

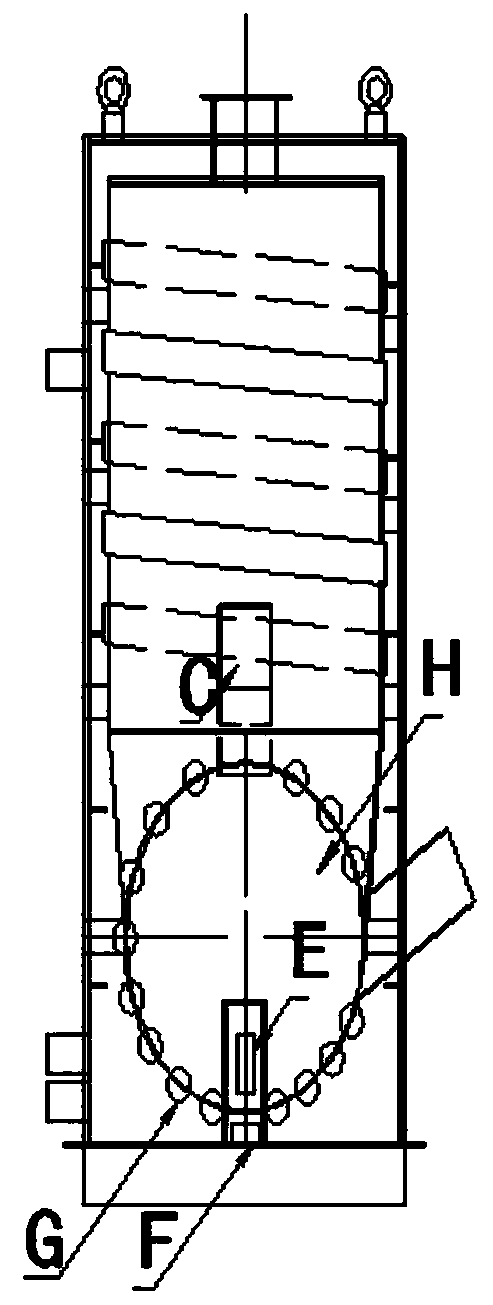

[0015] Such as figure 1 As shown, the embodiment of the present invention includes a furnace body and an ignition device E arranged at the left end, and also includes a feeding structure and a ventilation structure. The feeding structure includes a feed bin A, a spiral feeding channel B and a feeding channel C. A is set at the left end of the furnace body, the lower end of the bin A is provided with a spiral feeding channel B, and the unloading channel C is set at the right end of the spiral feeding channel B, the ventilation structure includes a blower D and an induced draft fan K, and the blower D is set in the furnace The right end of the body and the blower D is located below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com