Boilers Using Pyrolysis Vaporization Combustion Method

A combustion method and pyrolysis technology, applied in the field of boilers, can solve the problems of large differences in particle size, specific gravity, ash content, loose organizational structure, and impermanence, and achieve the effect of wide application range, small resistance and reducing dust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

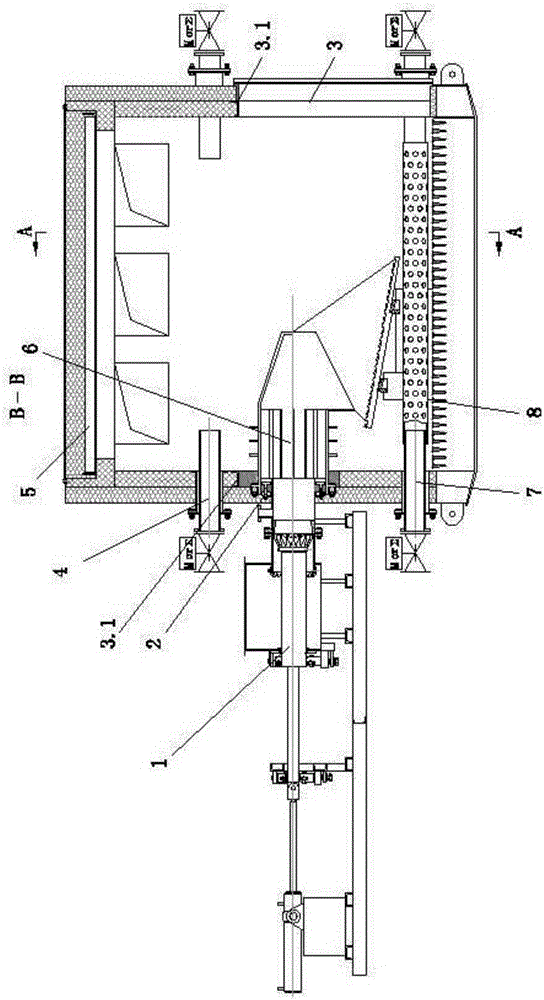

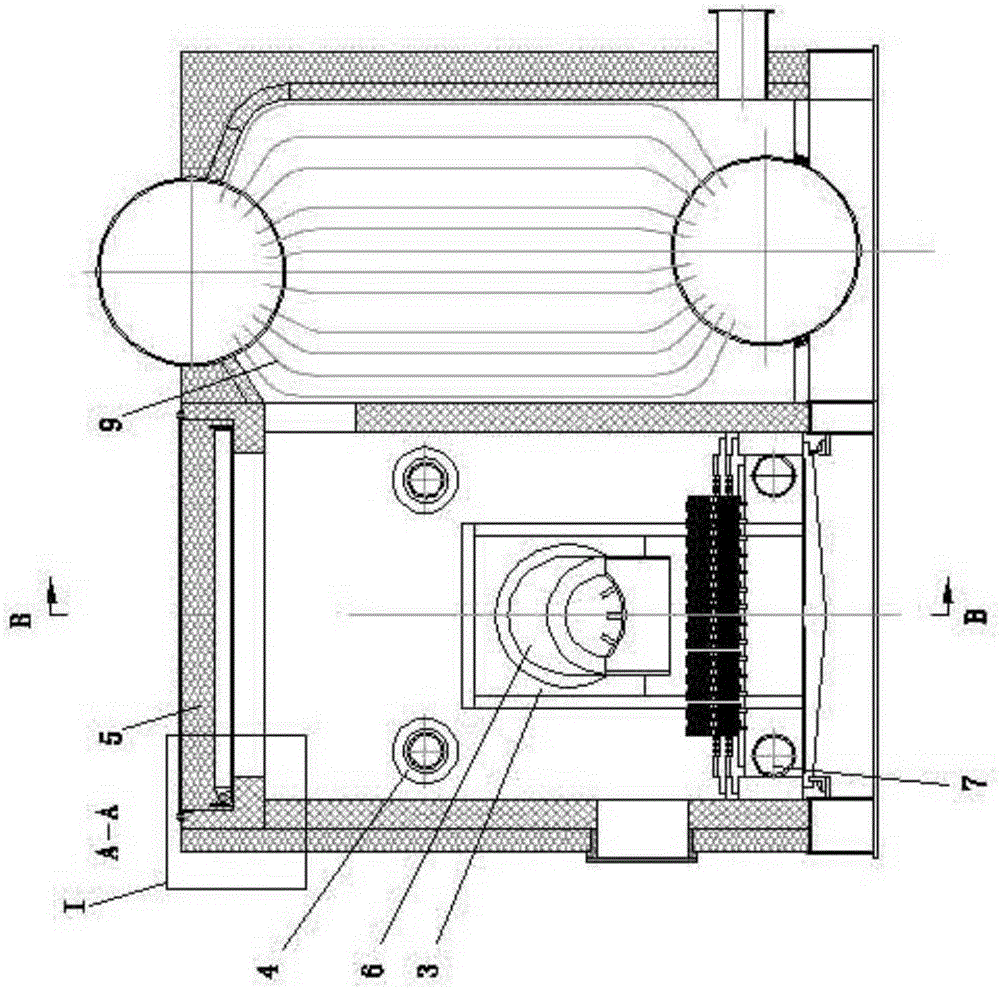

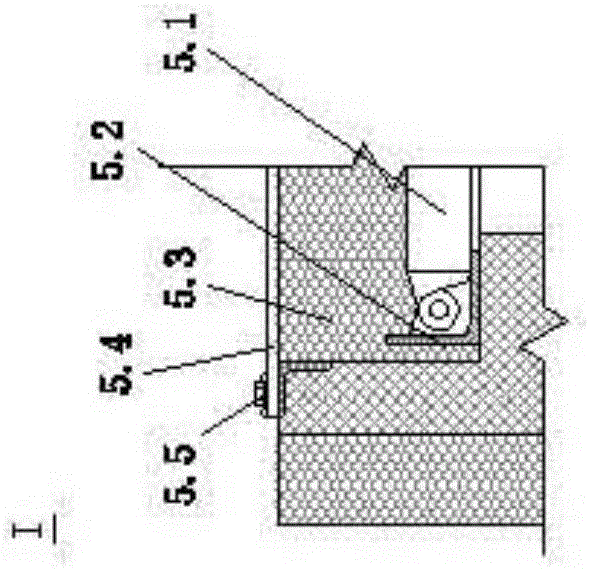

[0081] (refer to figure 1 , figure 2 , image 3 ) There is a furnace wall opening 3 on the furnace wall on both sides of the furnace, a furnace wall opening frame 3.1 is arranged on the edge of the opening, an explosion-proof door 5 is arranged on the furnace, the explosion-proof door panel 5.1 is placed on the explosion-proof door frame 5.2, and thermal insulation material 5.3 is laid on it , and then lay the sealing film 5.4, and fix the sealing film with bead 5.5. There is an ember grate 8 in the lower part of the hearth. A channel type pyrolysis device 6 is installed inside the furnace, and a piston type feeding device 1 is installed outside the furnace. The heat exchanger 9 has no restriction on selection and arrangement. Channel type pyrolysis device 6 is made up of pyrolysis cylinder 6.1, pyrolysis grate 6.2 (referring to Figure 4-Figure 8 ). The pyrolysis cylinder is divided into two sections, one section is cylindrical, with heat conducting fins 6.1.2 on the ...

no. 2 example

[0091] Second embodiment (refer to Figure 28 )

[0092] On the basis of the above-mentioned embodiments, a gas burner chamber 10 is set up separately on the side of the furnace to improve the dust removal effect before the heat exchanger. The heat exchanger can use heat pipes 11 for heat transfer, and can be designed as a hot blast stove for heating air.

no. 3 example

[0094] Adopt tank-type pyrolysis device, form track support 19 with refractory brick stacking certain height on burner grate 8, track crossbeam 13 (referring to Figure 31 , Figure 32 ) on the track bracket 19, the track beam 13 has a card slot 13.1, the web 14.1 of the track bar 14 is stuck in the card slot 13.1, the track bar 14 is fixed horizontally, and there is a shoulder 14.2 on the web 14.1 of the track bar 14 Stand on the side of the crossbeam and fix the track bar 14 vertically.

[0095] Pyrolysis tank 12 (refer to Figure 33 , Figure 34 , Figure 35 ) is composed of chassis car 12.1, pyrolysis grate 12.2, basket 12.3, outer cover 12.4, etc., chassis car 12.1 is composed of lifting beam 12.1.1, car beam 12.1.2, car frame 12.1.3, basket limit gear 12.1. 4. Composition of wheels 12.1.5. Pyrolysis grate 12.2 (see Figure 36 , Figure 37 , Figure 38 ) has a vertical bar 12.2.1 and a horizontal bar 12.2.2. The vertical bar and the horizontal bar are fixed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com