The burner structure of the rear-mounted steam heating furnace

A technology of burners and heating furnaces, which is applied in the direction of steam boilers, combustion methods, combustion types, etc., and can solve problems such as ineffective control of flue gas temperature, overheating of superheater furnace tubes, and tube burst accidents, so as to avoid The effect of burning and bursting, uniform heating, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

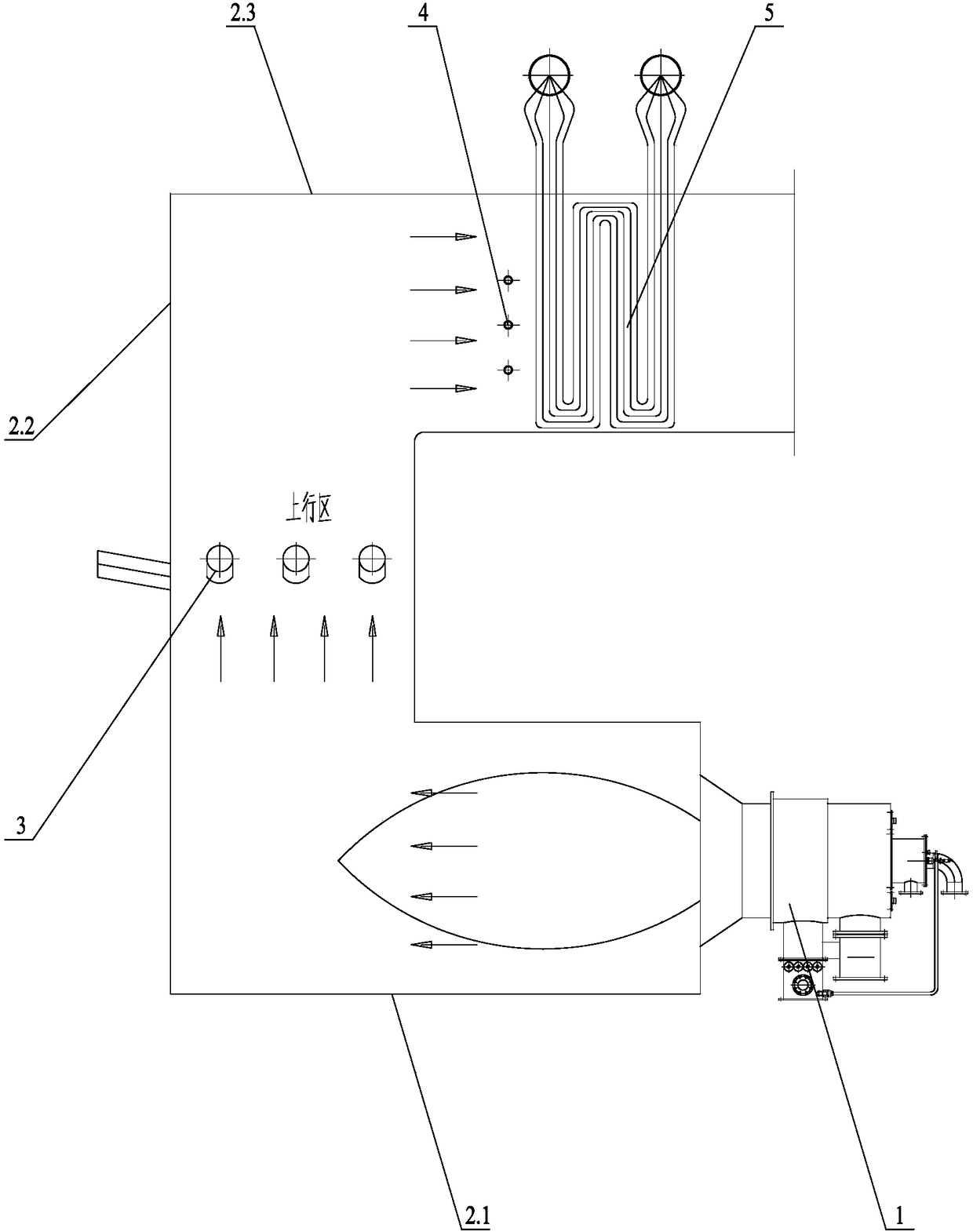

[0014] The burner structure of the post-mounted steam heating furnace includes a gas burner 1, a horizontal combustion section furnace 2.1, a vertical upward section furnace 2.2, a horizontal mixing section furnace 2.3, a flue gas cooler 3, a temperature detector 4 and a superheater tube bundle 5; A horizontal combustion section furnace 2.1 is connected to the lower end of the vertical upward section furnace 2.2, and a horizontal mixing section furnace 2.3 is connected to the upper end of the vertical upward section furnace 2.2, so that the horizontal combustion section furnace 2.1, the vertical upward section The furnace formed by the furnace 2.2 and the horizontal mixing section furnace 2.3 is in the shape of a "C". A gas burner 1 is installed outside the other end of the horizontal combustion section furnace 2.1, and a flue gas cooler 3 is installed in the vertical upward se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com