Grate-firing boiler with in-boiler two-level dedusting device

A technology for a dust removal device and a boiler, which is applied in the field of boilers, can solve the problems of decreased separation efficiency and insignificant effect of the initial smoke and dust emission concentration of the boiler, and achieves the effects of reducing heat loss, increasing continuous operation time and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

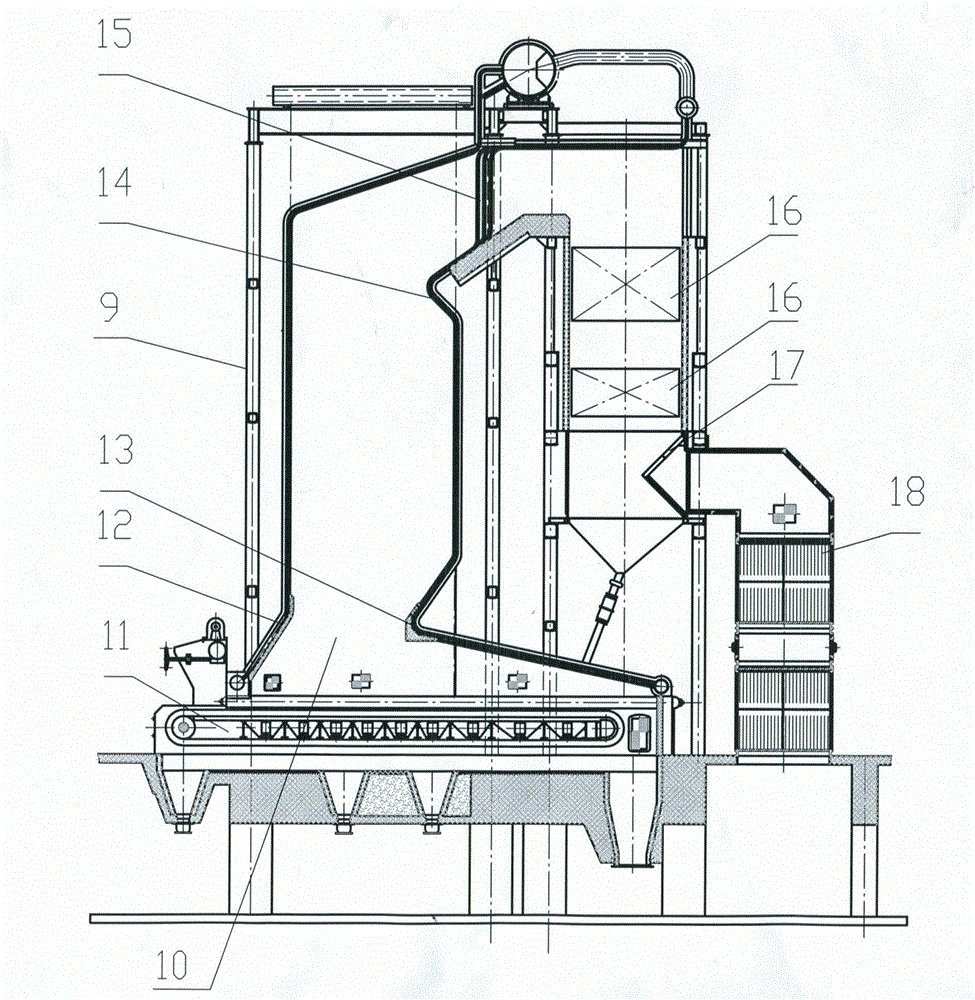

[0020] Such as figure 1 As shown, the present invention is a layer-fired boiler with a two-stage dust removal device in the furnace; it includes a furnace body 9, a furnace 10 in the furnace body, a fire grate 11, a front arch 12, a rear arch 13, a flame angle 14, and slag Tube separation device 15, economizer 16, inertial separation device 17, air preheater 18; the slag tube separation device is at the outlet of the furnace, and the inertial separation device is at the outlet of the economizer;

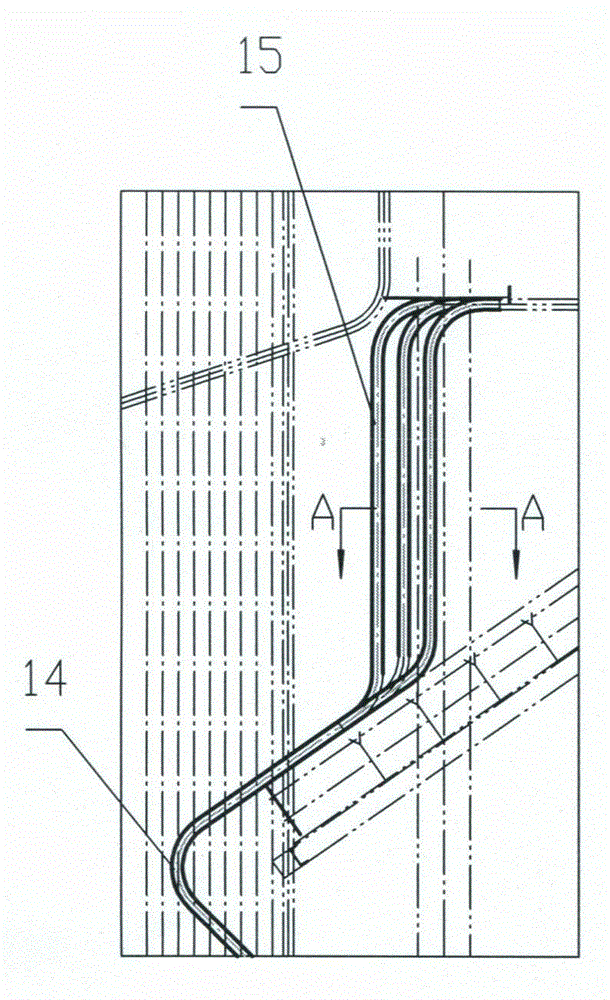

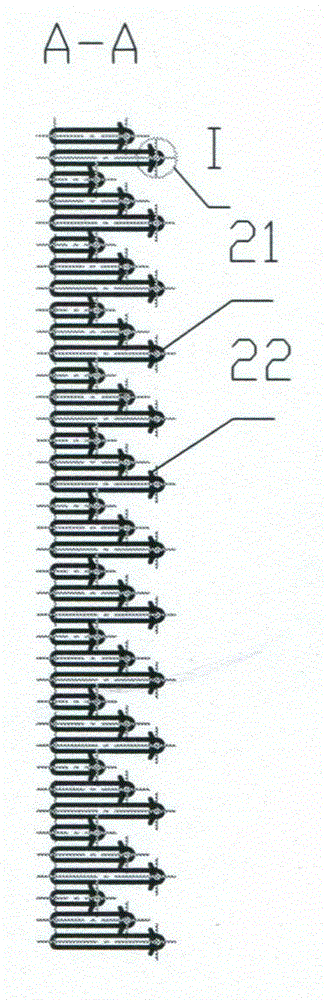

[0021] Such as figure 2 , 3 and Figure 4 As shown, the slag tube separation device at the furnace outlet is arranged in three rows of staggered arrangement by a row of rear water walls, and heat-resistant and wear-resistant fins 22 are welded on both sides of the slag tube 21; The heat cannot be transferred by the slag tubes in time to expand and deform,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com