Gas making compound combustion chain furnace

A chain furnace and chain grate technology are applied in the field of chain grate gas composite combustion chain furnace, which can solve the problems of low combustion intensity and combustion efficiency of chain grate, difficulty in adapting to volatile matter, and inability to catch fire immediately, and achieve gas blackness. The effect of stable compliance, intensified combustion in the furnace, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

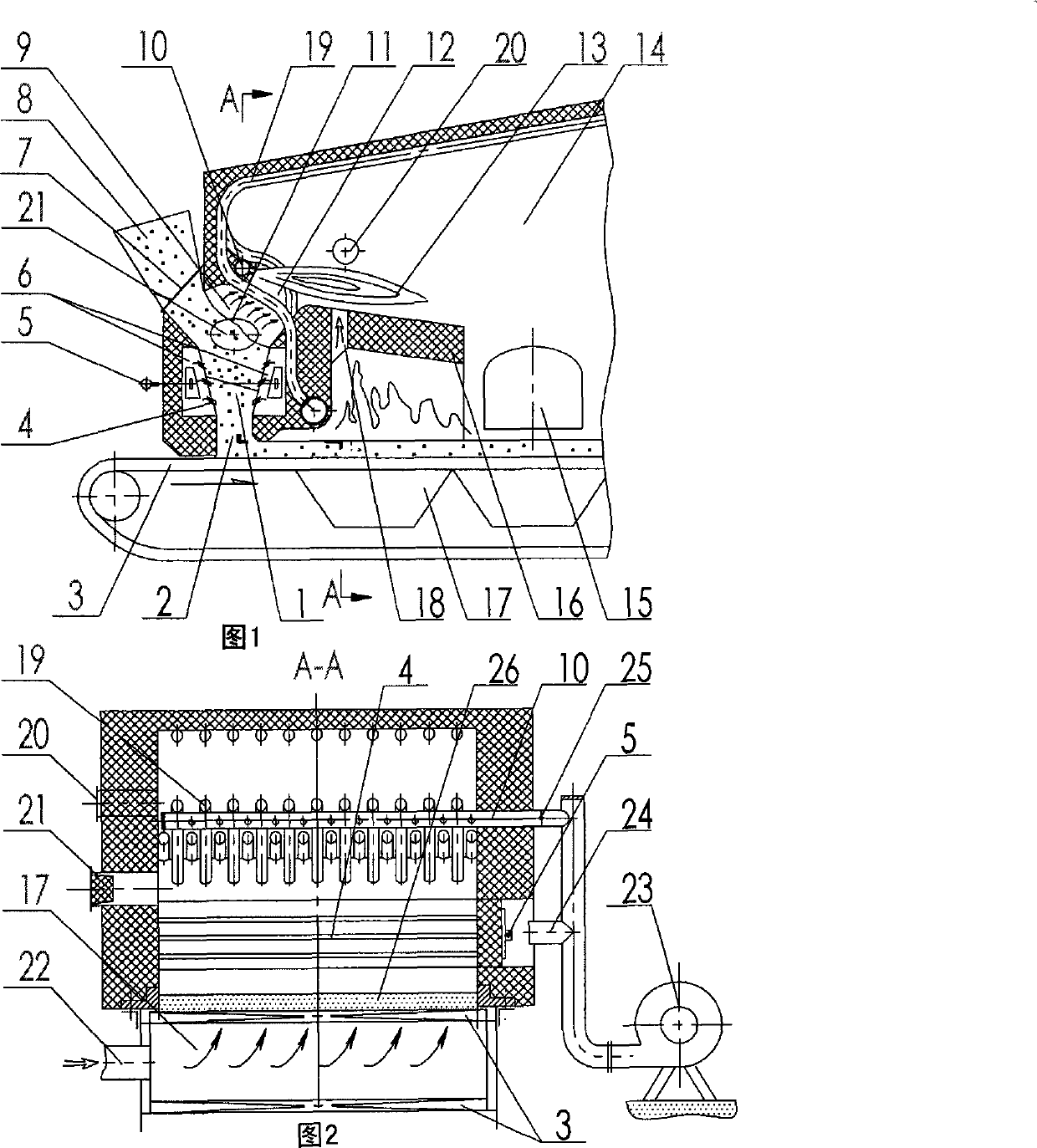

[0013] as attached figure 1 As shown, the present invention is provided with a front pre-combustion vertical furnace 1 at the front end of the chain grate 3, and an air chamber 6 with an air outlet 4 is arranged on both sides of its inner wall, and the upper end of the front pre-combustion vertical furnace 1 There is a coal-fired inlet 7 connected to the coal hopper 8, and the other end is provided with a gas outlet 12 connected to the chain furnace hearth 14, and the lower part of the pre-combustion vertical furnace 1 has a coal outlet 2 connected to the chain grate 3, In the gas chamber 9, there is an ejector air pipe 10, and at the front end of the chain furnace hearth 14, there is a downward-inclined front arch 16 and a gas ignition port 18 for enhanced combustion, and the front vertical furnace blower 23 is connected to the ejector air pipe 10. pass, as attached figure 2 As shown, the front vertical furnace blower 23 communicates with the air chamber 6 through the air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com