Industrial boiler for burning bio-briquettes

An industrial boiler and biomass technology, applied in the direction of solid fuel combustion, non-flammable liquid/gas transportation, combustion chamber, etc., can solve the problems of black smoke from the boiler, unfavorable biomass briquette ignition and stable combustion, etc., to achieve Effects of increasing turbulence, promoting efficient and stable combustion, and accelerating start-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

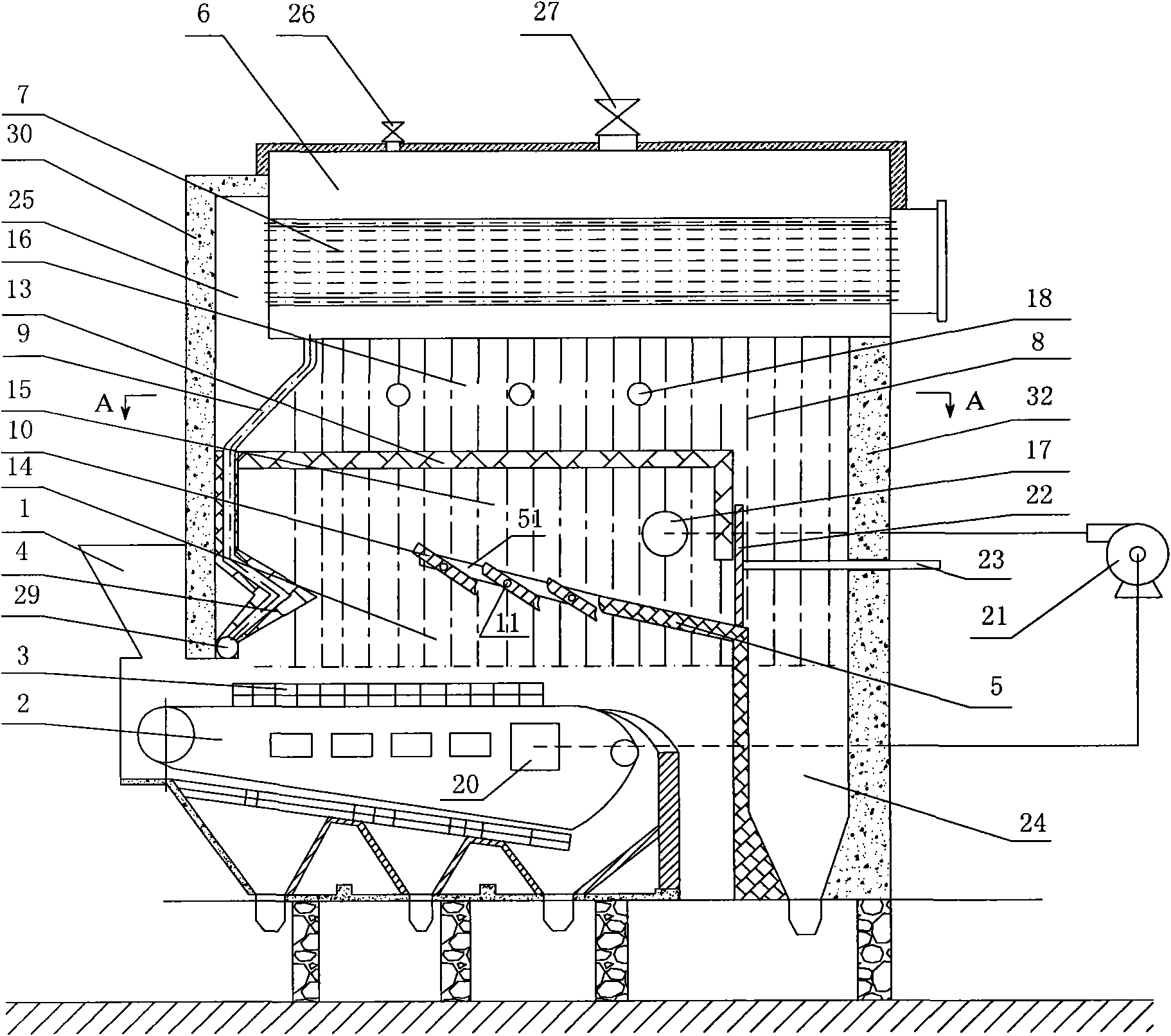

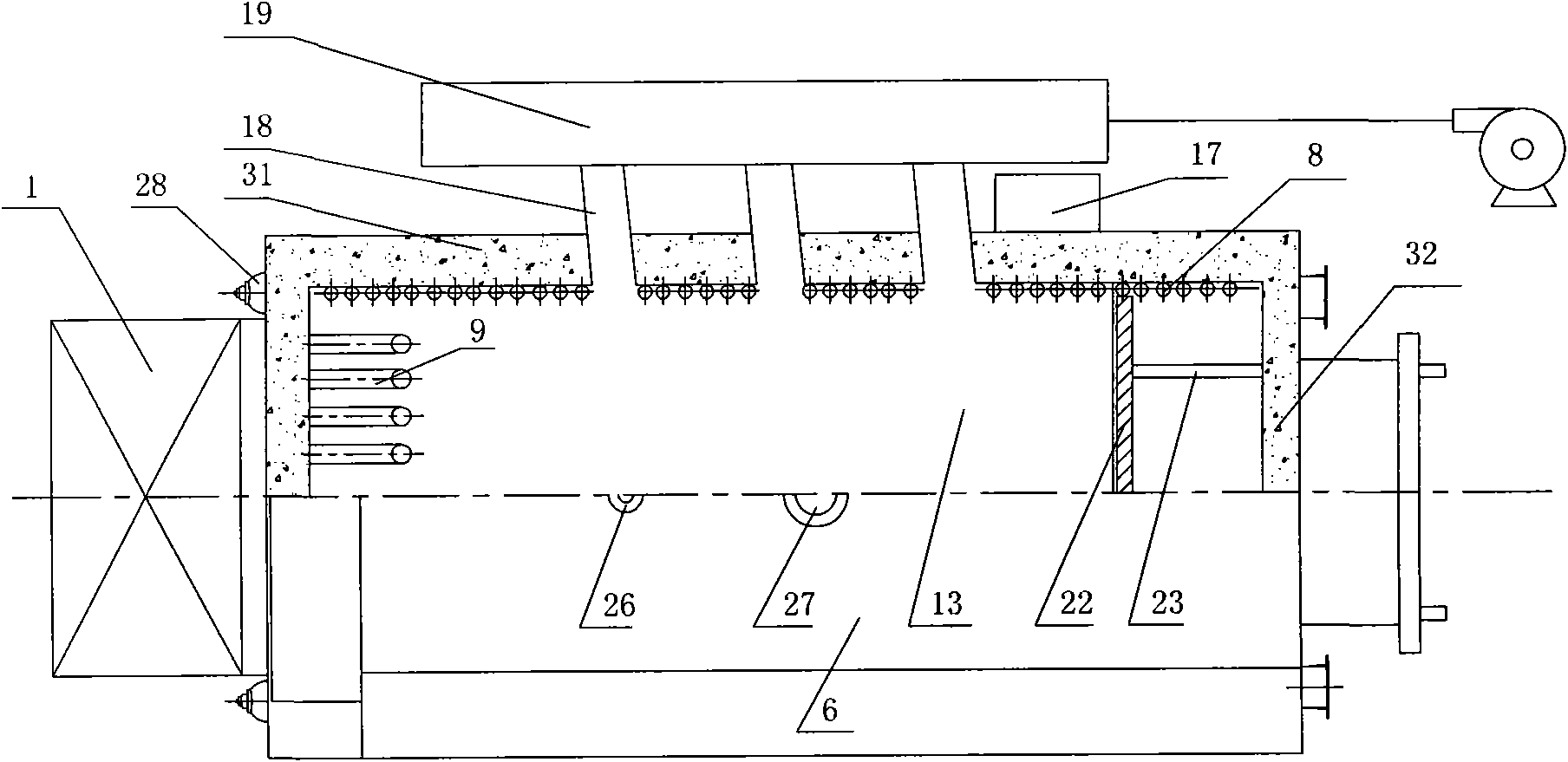

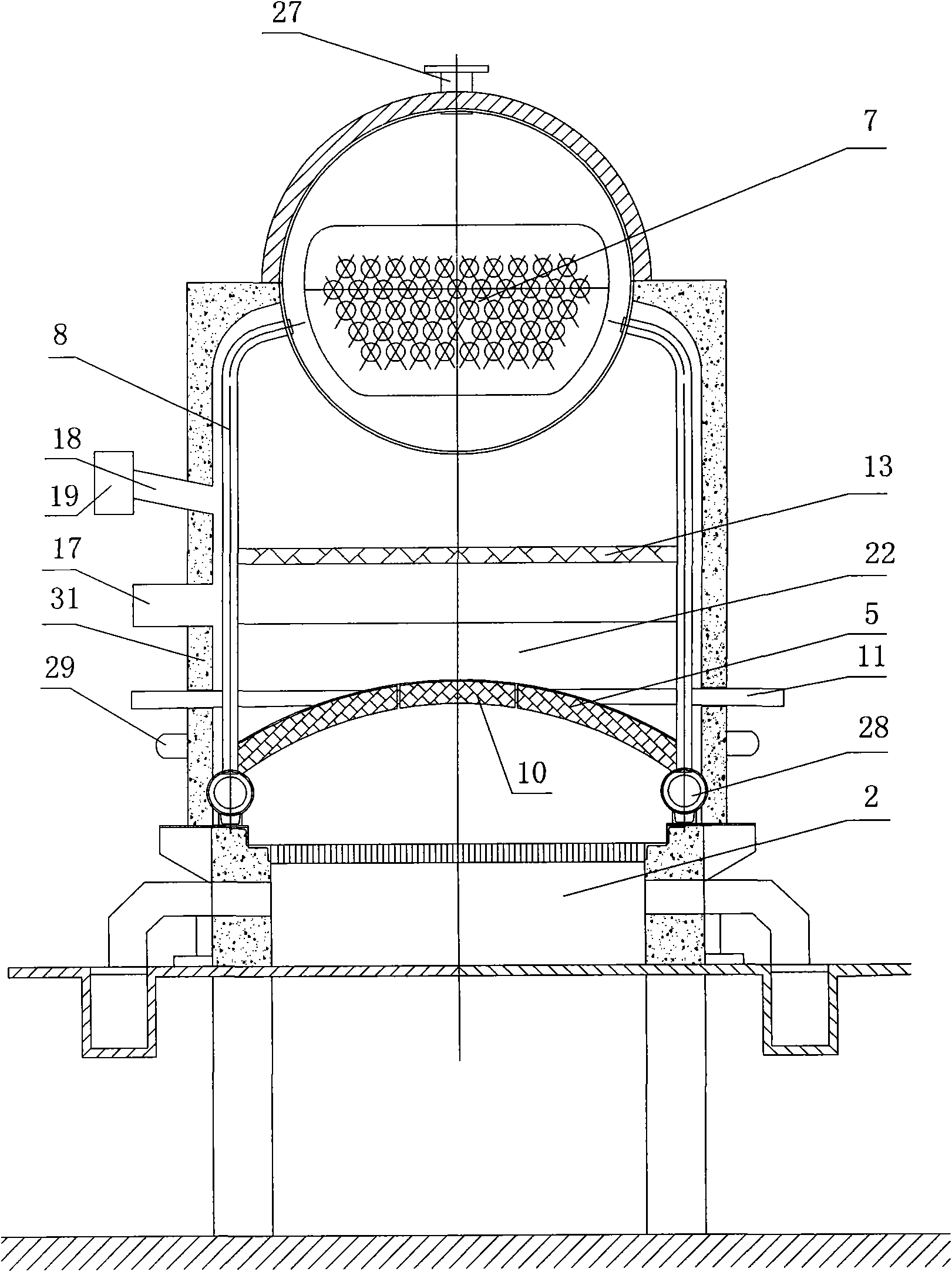

[0026] As the first embodiment of the present invention, such as figure 1 As shown, the furnace body 30 is provided with a front arch 4 and a rear arch 5 with a "fork" shape at the front. Such as Figure 6 As shown, grooves 12 are formed on the upper edges of two adjacent interdigital portions 51 of the rear arch 5 . Such as Figure 5 As shown, the two sides of the block 10 are fixedly connected with the rotating shaft 11, the rotating shaft 11 is matched with the groove 12, and the groove 12 can be used to place the rotating shaft 11. After the block 10 is fixedly connected with the rotating shaft 11, as Figure 4 As shown, the rotating shaft 11 is placed on the corresponding grooves 12 of two adjacent finger parts 51 , so that the stopper 10 is placed between the two adjacent finger parts 51 . One end of the rotating shaft 11 passes through the side wall of the furnace body 30 and is connected with the rotation driving device outside the furnace body 30 . The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com