Oil-gas dual-purpose low-nitrogen combustor for boiler combustion

A low-nitrogen burner, boiler combustion technology, applied in the direction of combustion air/fuel supply, gas fuel burner, burner, etc., can solve the problem of limited use of fuel quality, insufficient combustion, unsatisfactory nitrogen oxide emissions, etc. To achieve the effect of suppressing generation and emissions, reducing generation and emissions, and stabilizing and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

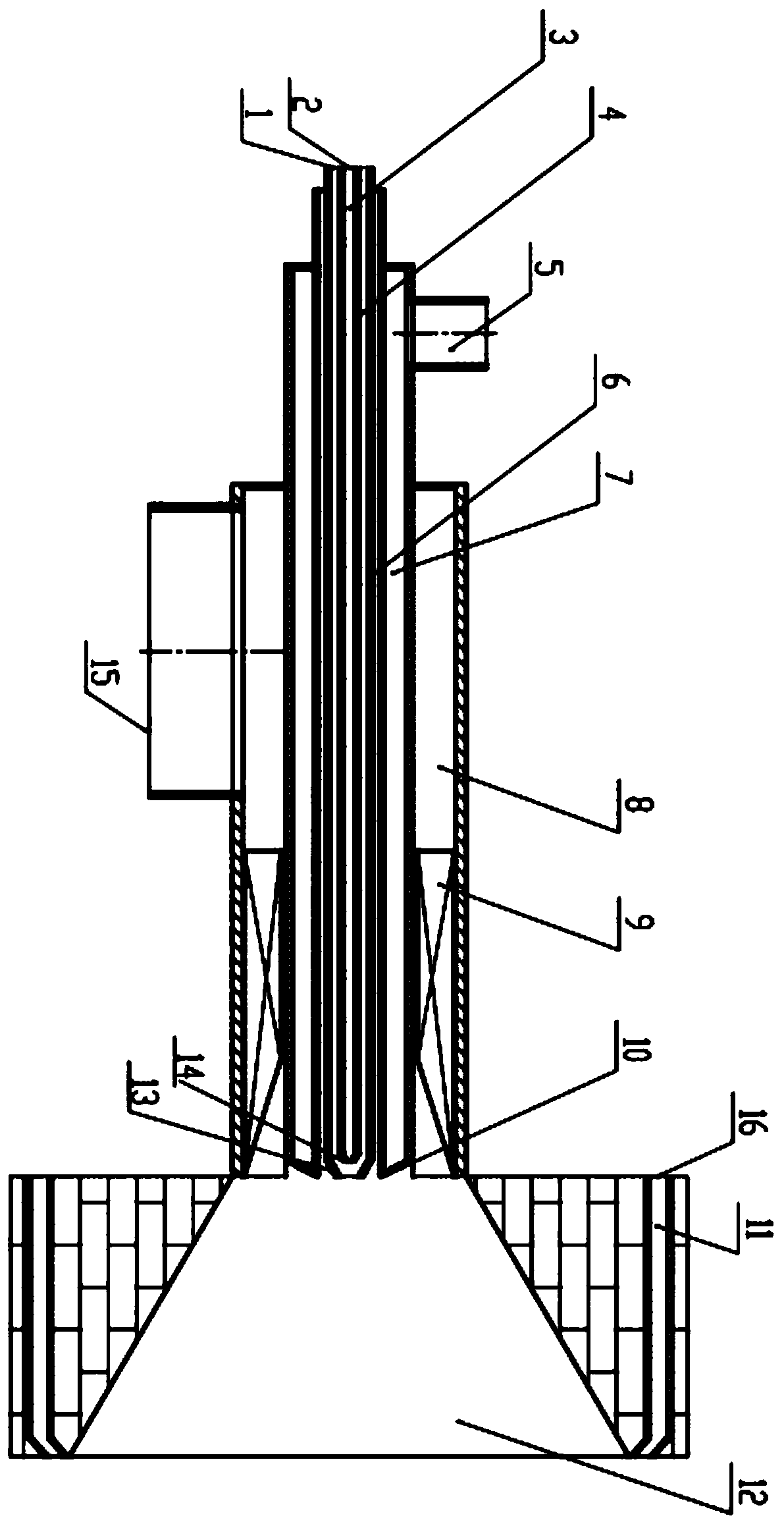

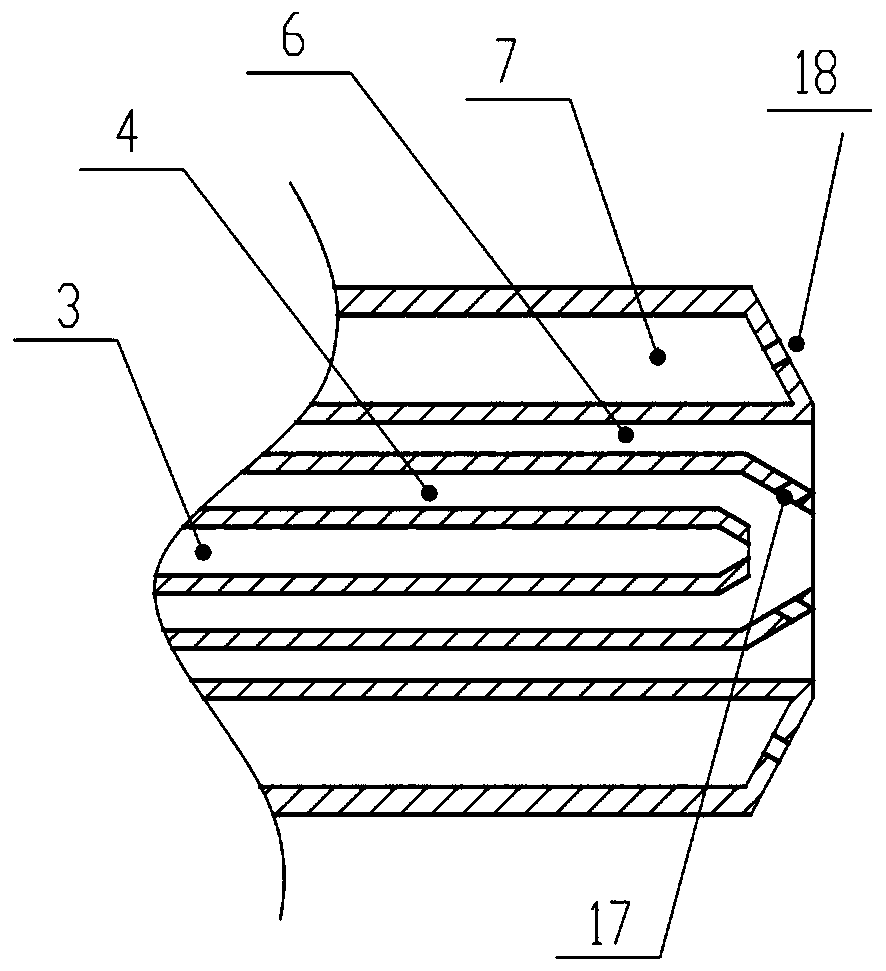

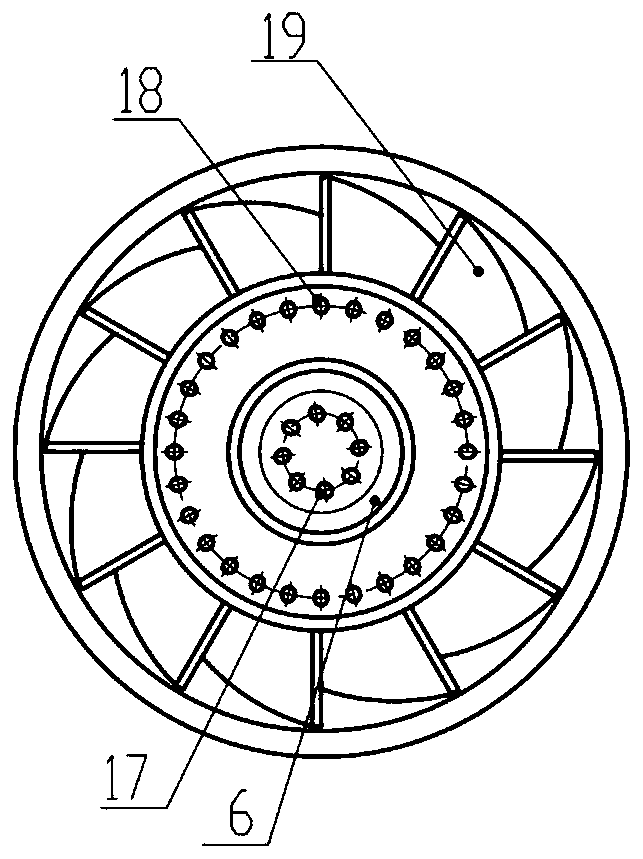

[0024] Please refer to Figure 1 to Figure 3 ,in, figure 1 It is a structural schematic diagram of an oil-gas dual-purpose low-nitrogen burner in an embodiment of the present invention; figure 2 and image 3 It is a schematic structural diagram of a nozzle assembly in an embodiment of the present invention.

[0025] The invention discloses an oil-gas dual-purpose low-nitrogen burner for boiler combustion, which includes the following components:

[0026] 1. Oil gun

[0027] The oil gun is a double-tube structure, including an atomizing medium pipe 3 , a fuel pipe 4 and a fuel nozzle 10 . The atomizing medium pipe 3 is in the shape of a cylindrical tube. The front end of the atomization medium pipe 3 is connected to the atomization medium inlet 1, and the rear end is connected to the atomization medium outlet 14, which is tapered. The fuel pipe 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com