Patents

Literature

79results about How to "Efficient and stable combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

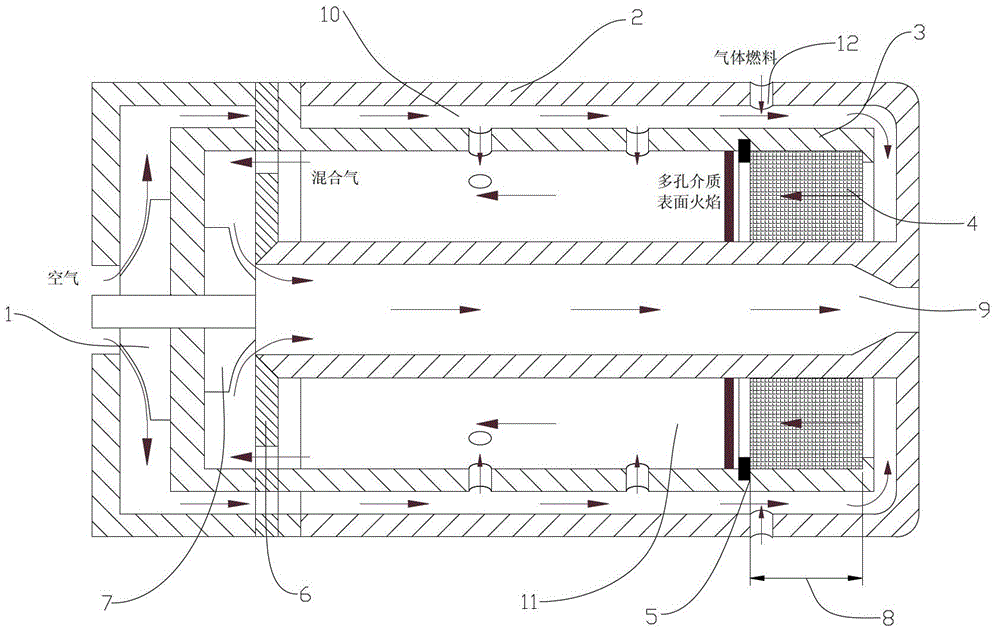

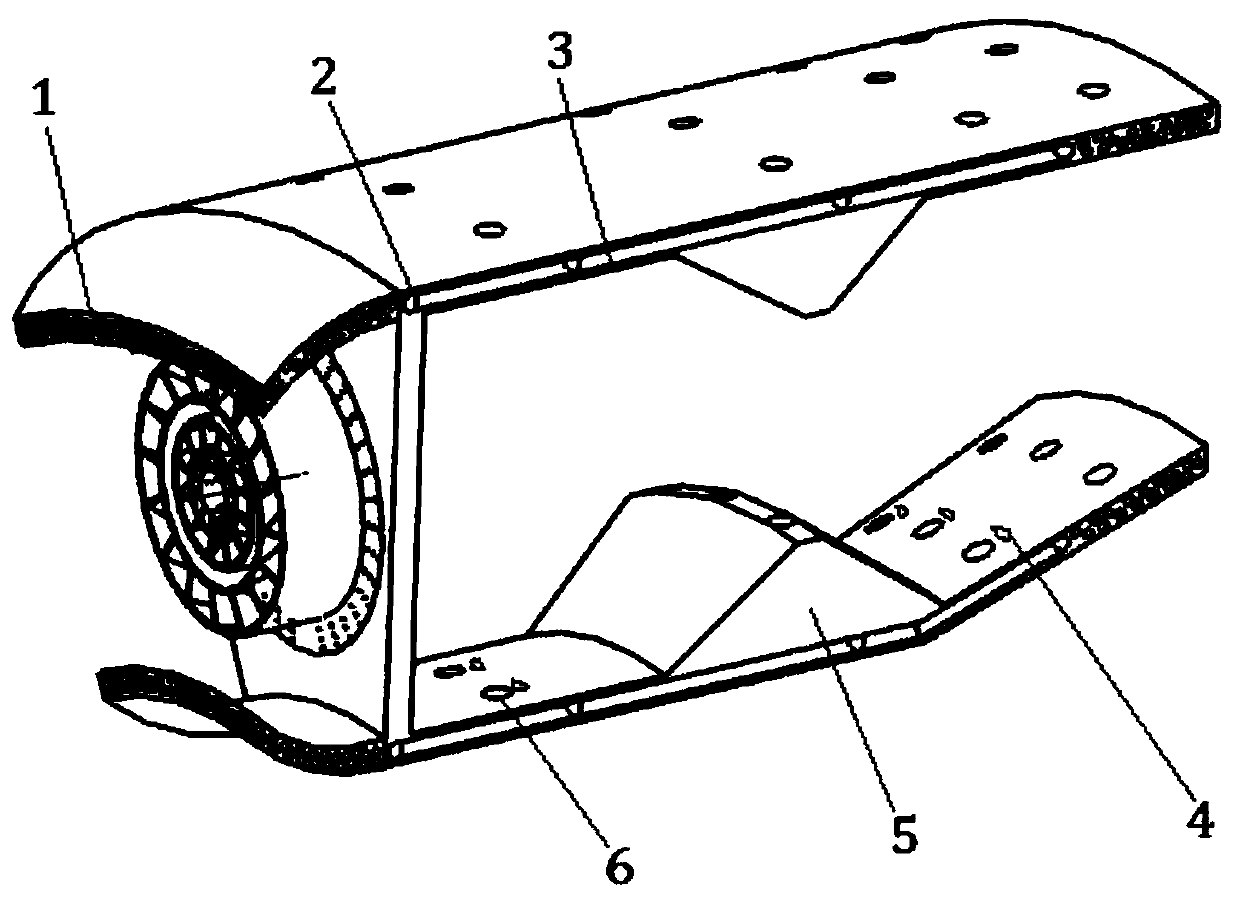

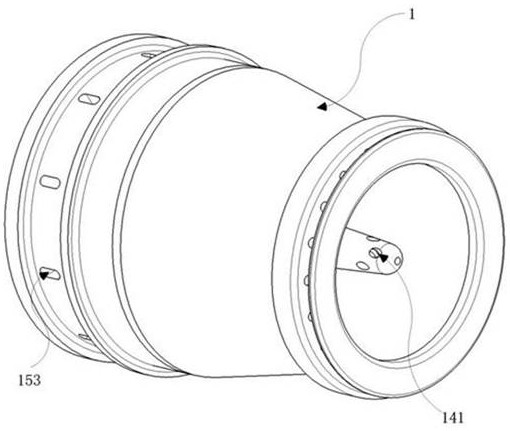

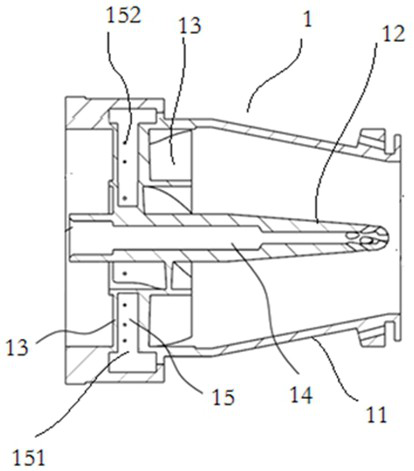

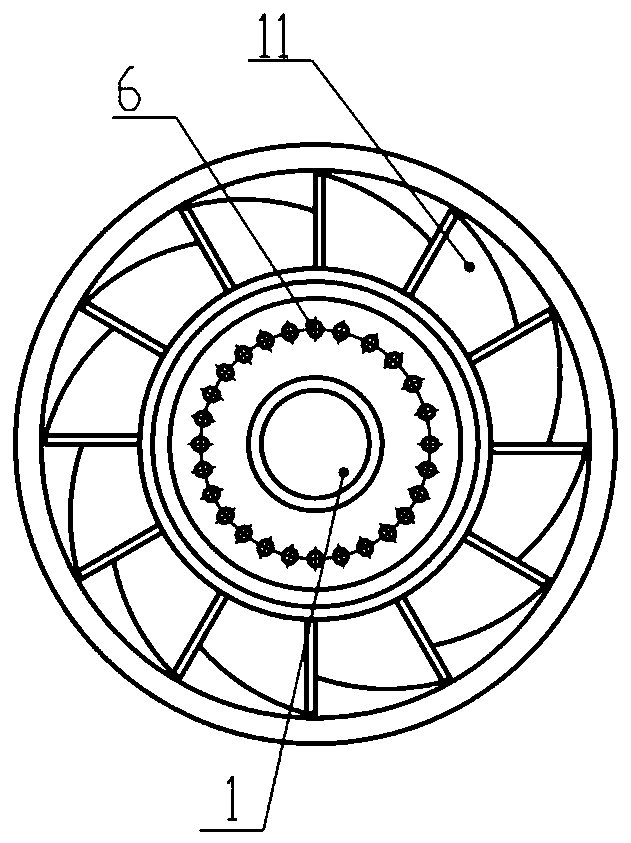

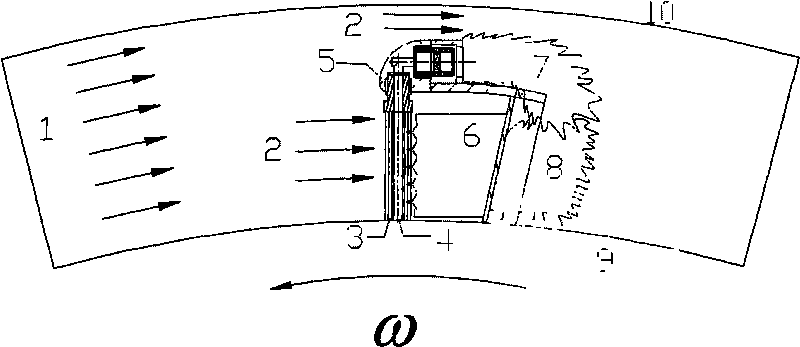

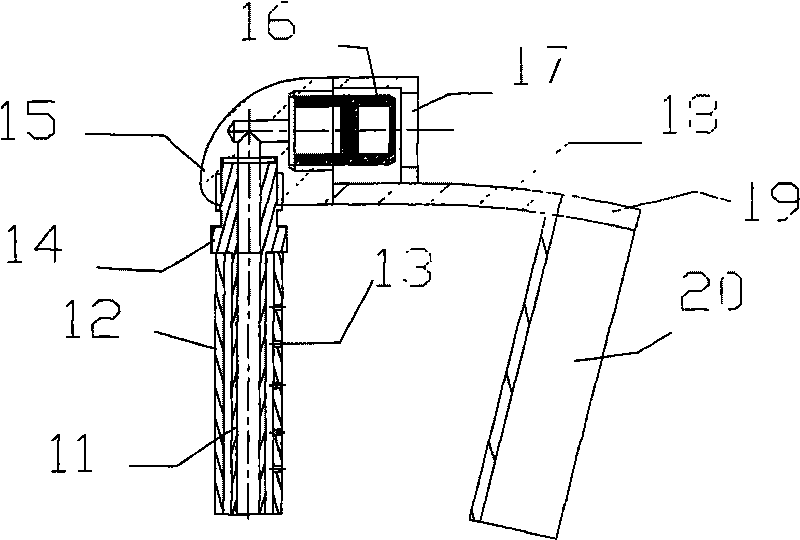

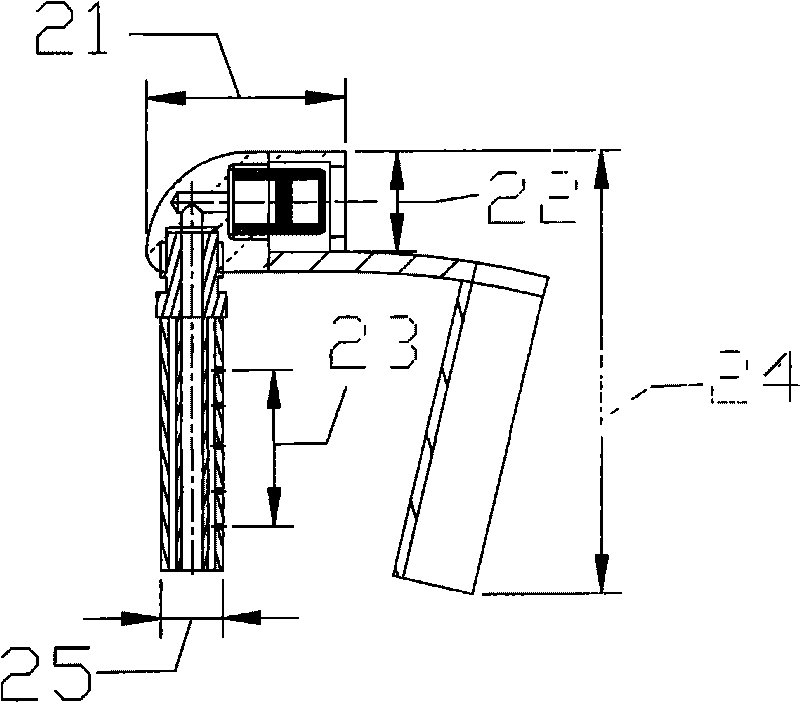

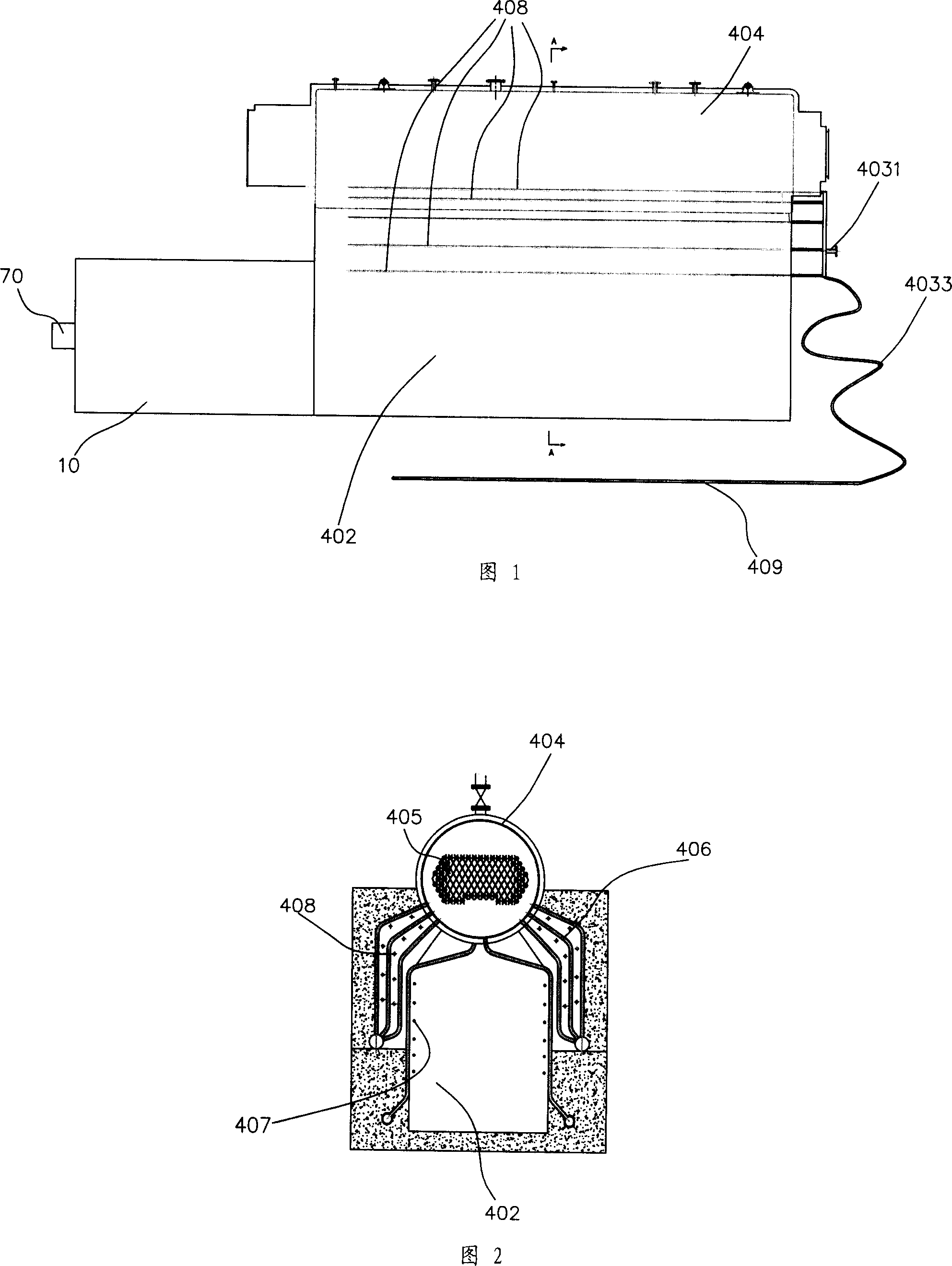

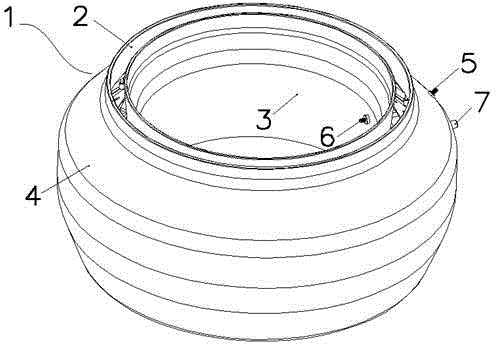

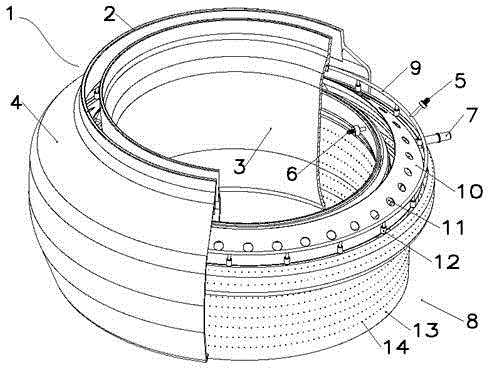

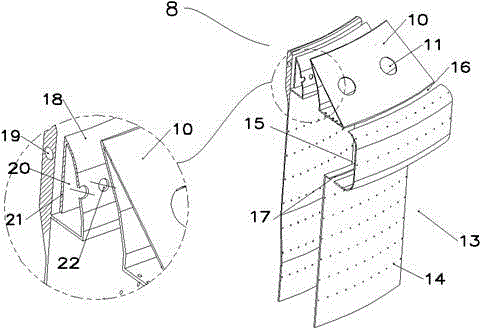

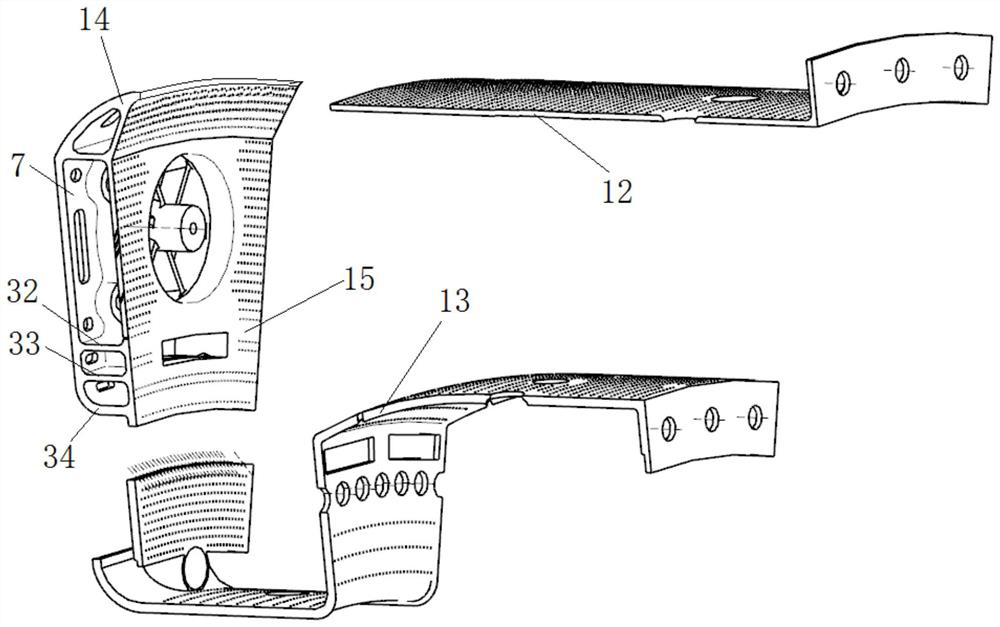

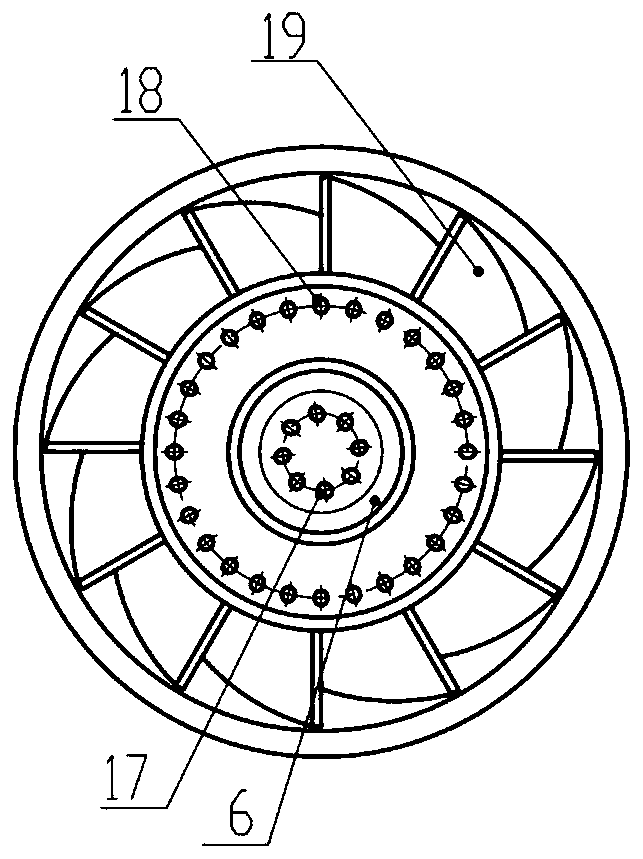

Rear-placed combustor with annular porous medium head for ultramicro turbojet engine

ActiveCN102878579AOvercoming short stay timeReduce foggingContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

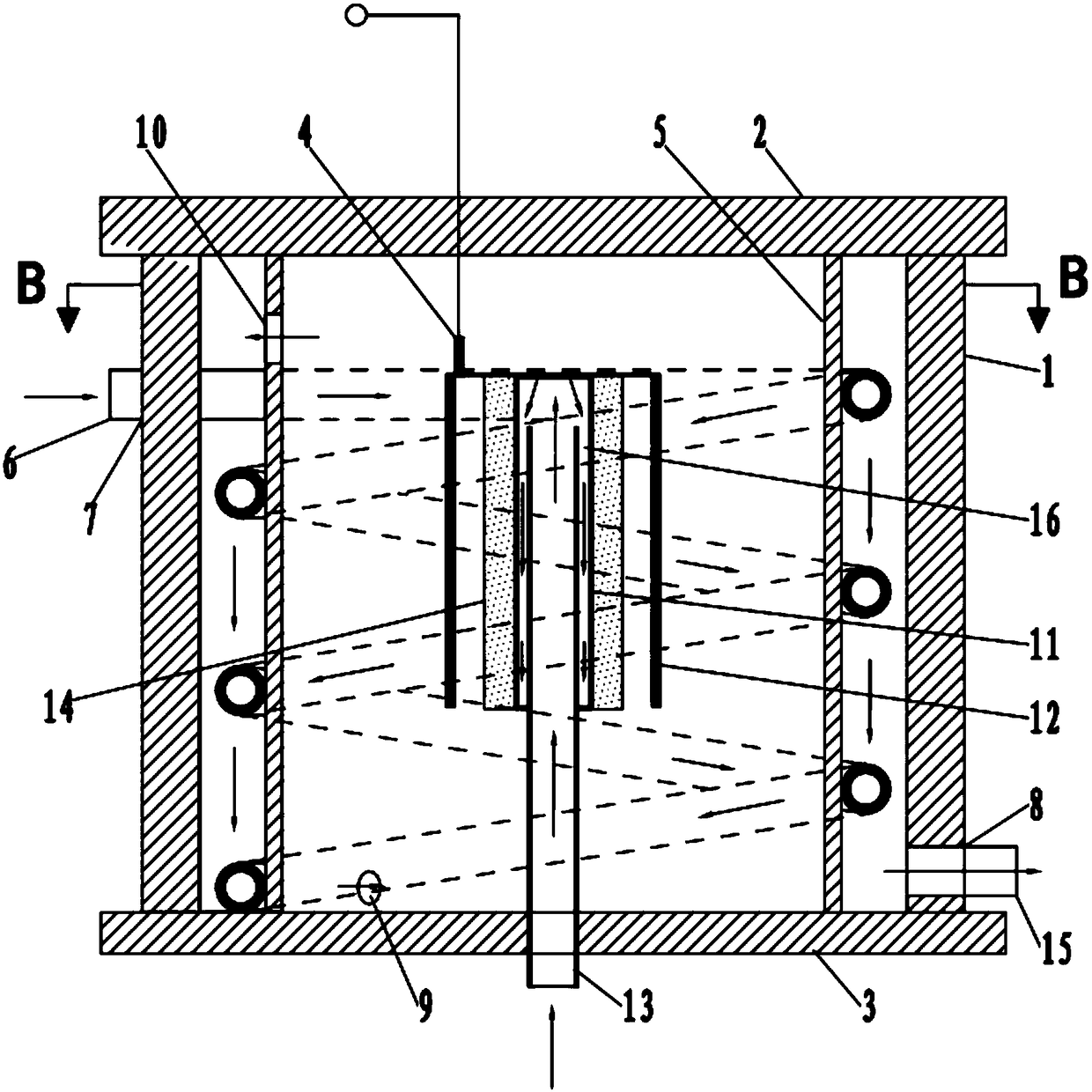

Disclosed is a rear-placed combustor with an annular porous medium head for an ultramicro turbojet engine. An annular reflux structure is adopted for the combustor which is formed by a combustor box, a flame tube wall, a combustor outlet and the annular porous medium head. Air flow passes through a centrifugal compressor of the engine for compression, enters an annular cavity channel of the combustor, and then is mixed with gas fuel which is jetted in horizontally; premixed gas is pre-heated through the flame tube wall and then flows back to enter a flame tube through the annular porous medium head, and stable ignition is achieved; the whole mixed gas combustion process is finished in the flame tube, and high-temperature gas is discharged from the outlet of the rear-placed combustor; and then the high-temperature gas is discharged into air through a tail pipe after turbine blades of an impact engine does work. The combustor box, the flame tube wall and the combustor outlet are connected through bolts with high temperature glue sprayed on annular edges to guarantee the sealing. According to the combustor, features and advantages of stable flame of the annular porous medium head can be adapted to and played to the greatest extent, proneness to flameout of ultramicro combustors can be improved, so that the combustor can work for the ultramicro turbojet engine reliably and stably.

Owner:BEIHANG UNIV

Hydrocarbon fuel reforming combustion method for micro combustor and micro combustor

InactiveCN101737779AImprove combustion efficiencyImprove mix qualityHydrogenIndirect carbon-dioxide mitigationGaseous hydrocarbonProcess engineering

The invention discloses a hydrocarbon fuel reforming combustion method for a micro combustor, which comprises the following steps: firstly, introducing gaseous hydrocarbon fuel and wet air into a reforming area filled with a gamma-Al2O3 catalyst to produce coupling self-heating reforming reaction so as to generate partial hydrogen; and then introducing the gas after the reaction into a combustion cavity for combusting, wherein the volume ratio of the gaseous hydrocarbon fuel to the wet air is 1: 1.2-1: 1.6. Meanwhile, the invention also discloses a device for implementing the method. The front end of the combustion cavity is provided with the reforming area, the gaseous hydrocarbon fuel and the wet air are introduced into the reforming area, and the gaseous hydrocarbon fuel and the wet air undergo the coupling self-heating reforming reaction (comprising the oxidation reaction of the hydrocarbon fuel and the oxygen and the reforming reaction of the hydrocarbon fuel and the water vapor) under the action of the gamma-Al2O3 catalyst to generate partial hydrogen so as to aid the efficient and stable combustion of the gaseous hydrocarbon fuel and the air in a combustion area.

Owner:CHONGQING UNIV

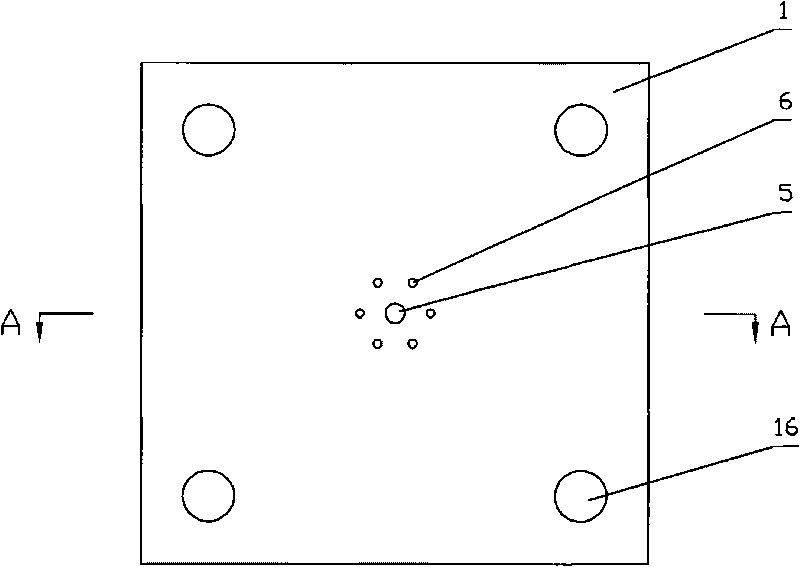

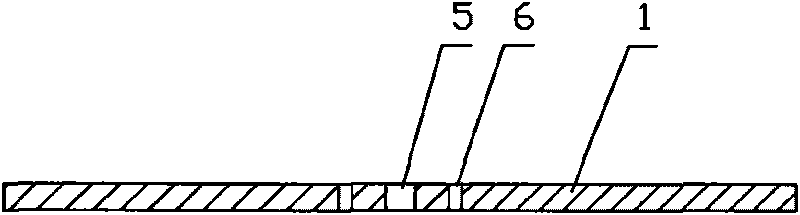

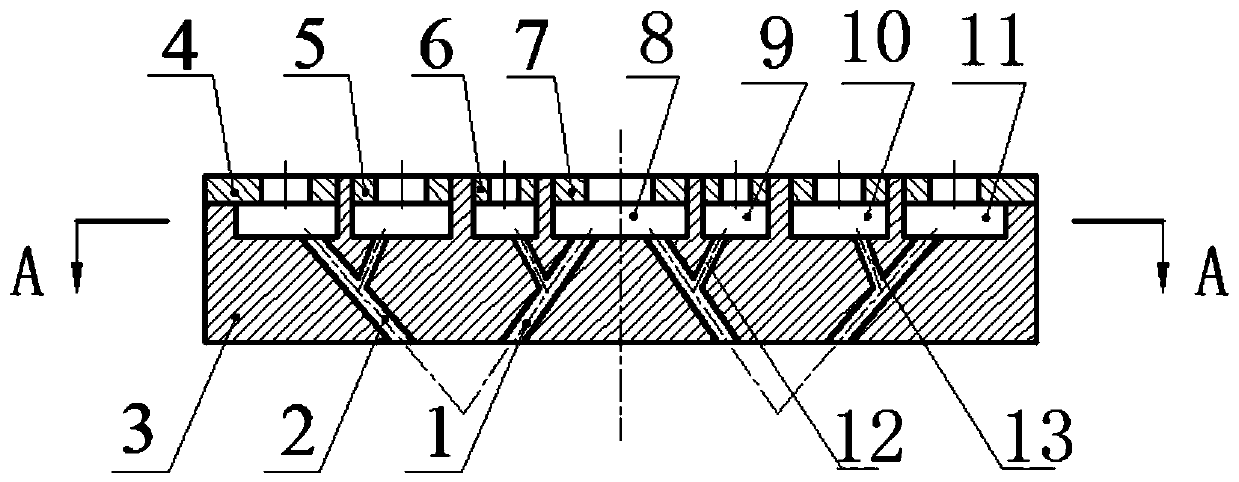

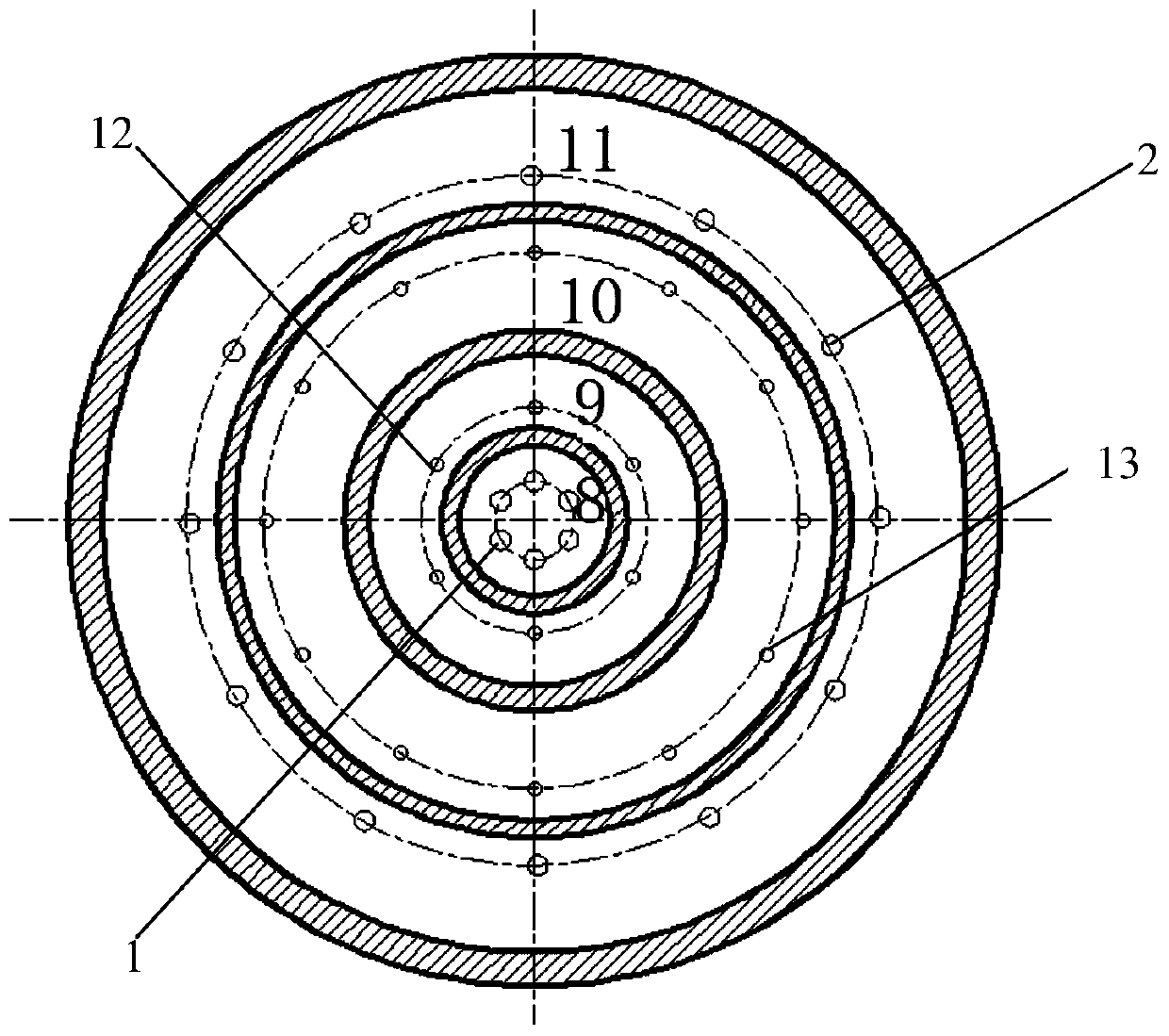

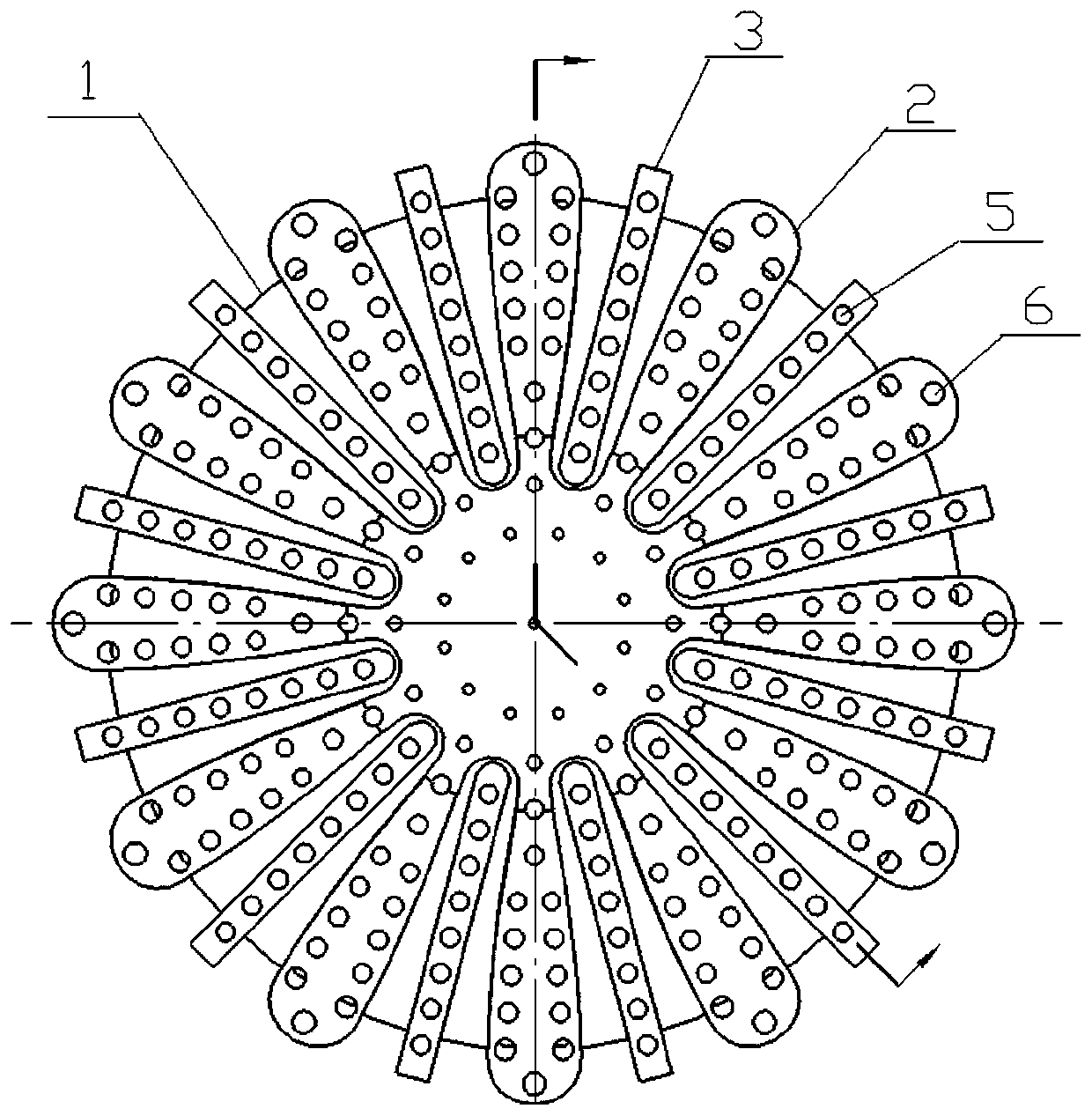

Pneumatic atomization liquid-liquid injection method and machine capable of realizing large-scale variable working conditions

ActiveCN109780541AReduce development costsRealize a wide range of variable thrust workBurnersJet flowSupport condition

The invention discloses a pneumatic atomization liquid-liquid injection method and machine capable of realizing large-scale variable working conditions. The injection machine comprises an atomizing gas collecting cavity, a fuel liquid collecting cavity and an oxidizing agent liquid collecting cavity. Atomizing gas nozzles are formed in the bottom of the atomizing gas collecting cavity, and fuel nozzles and oxidizing agent nozzles are correspondingly formed in the bottom of the fuel liquid collecting cavity and the bottom of the oxidizing agent liquid collecting cavity. The outlet ends of the fuel nozzles and the outlet ends of the oxidizing agent nozzles correspondingly communicate with the middle sections of the different atomizing gas nozzles of the atomizing gas collecting cavity at a certain angle. Fuel mist jet flow and oxidizing agent mist jet flow are separately formed, and the fuel mist jet flow collides with the oxidizing agent mist jet flow at one point to further enhance atomization and mixing, and supporting conditions are provided for high quality combustion of fuel and an oxidizing agent.

Owner:XIAN AEROSPACE PROPULSION INST

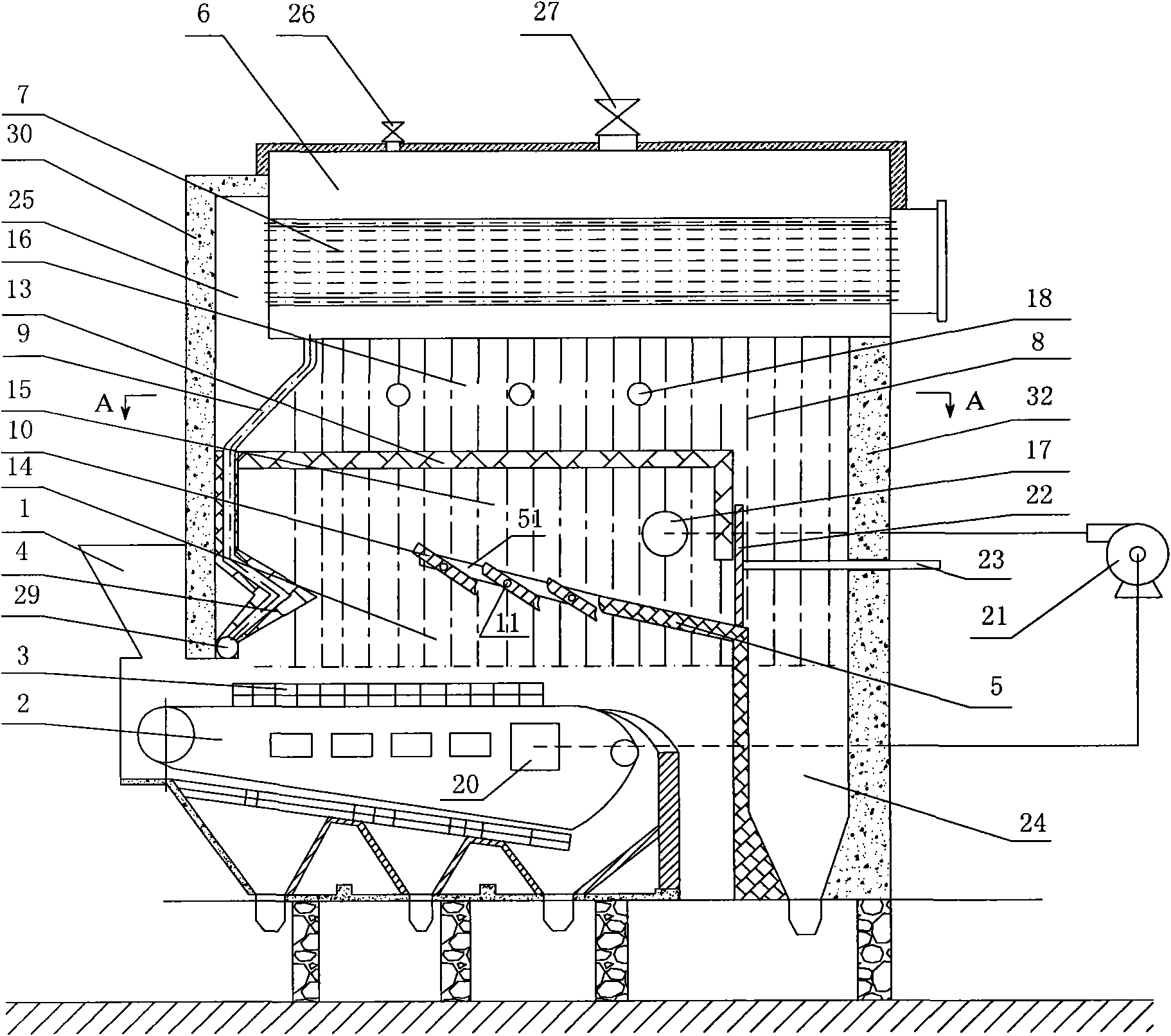

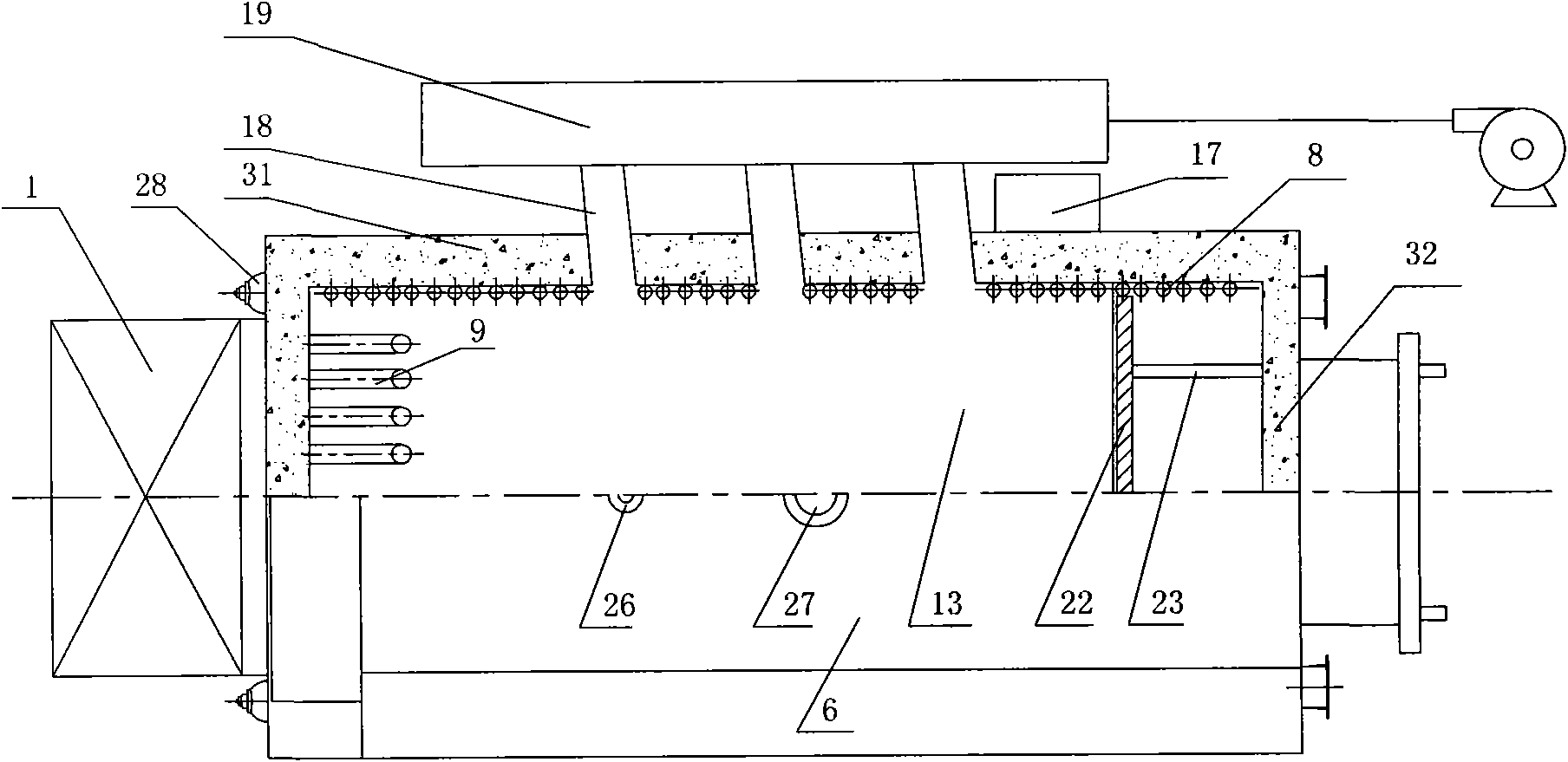

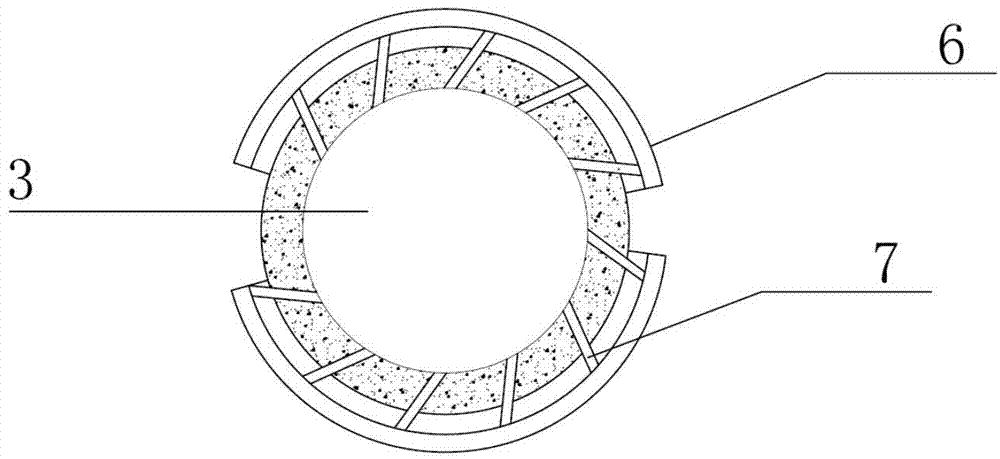

Industrial boiler for burning bio-briquettes

ActiveCN101818891AEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

Owner:ZHEJIANG JINGUO BOILER

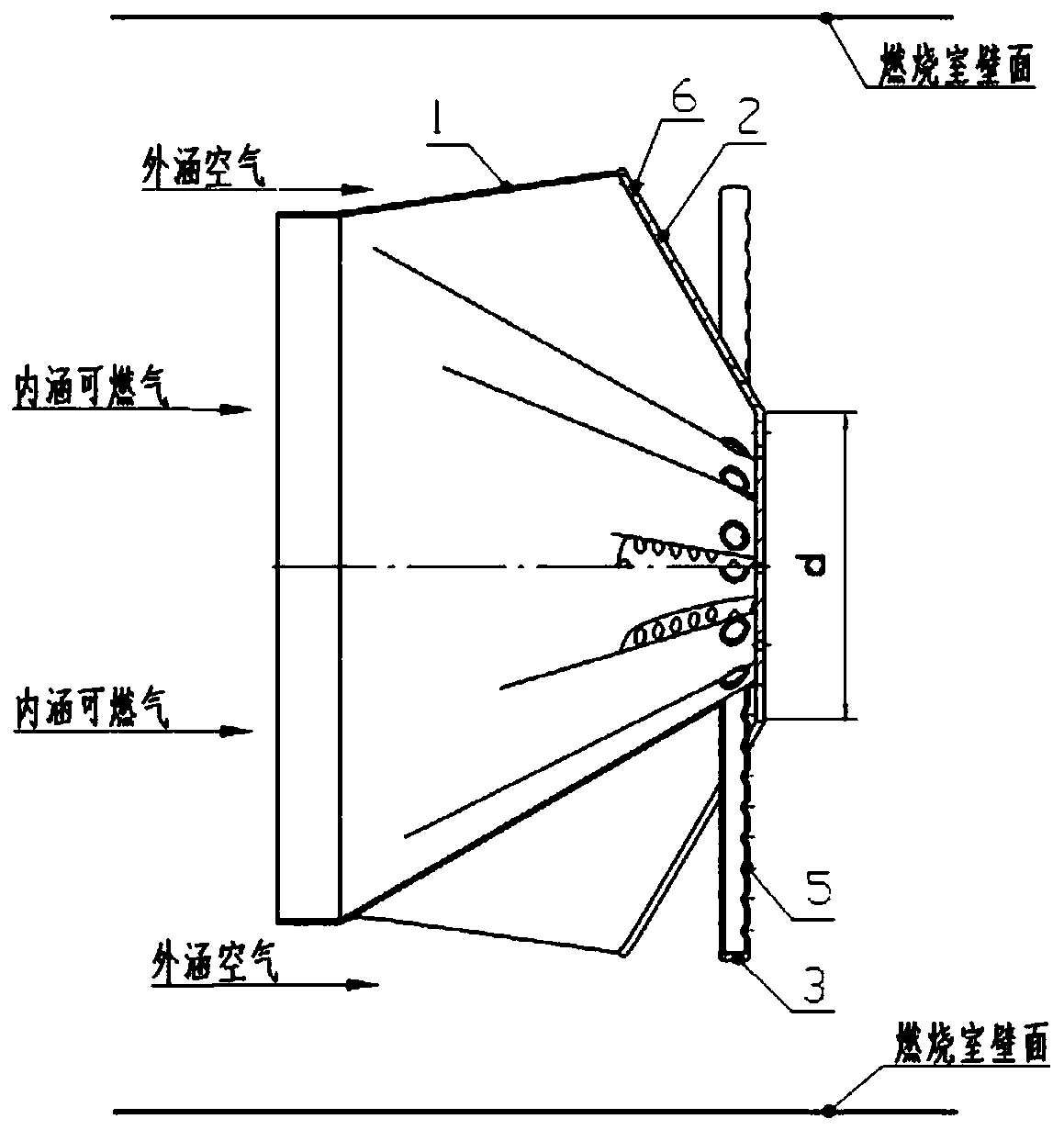

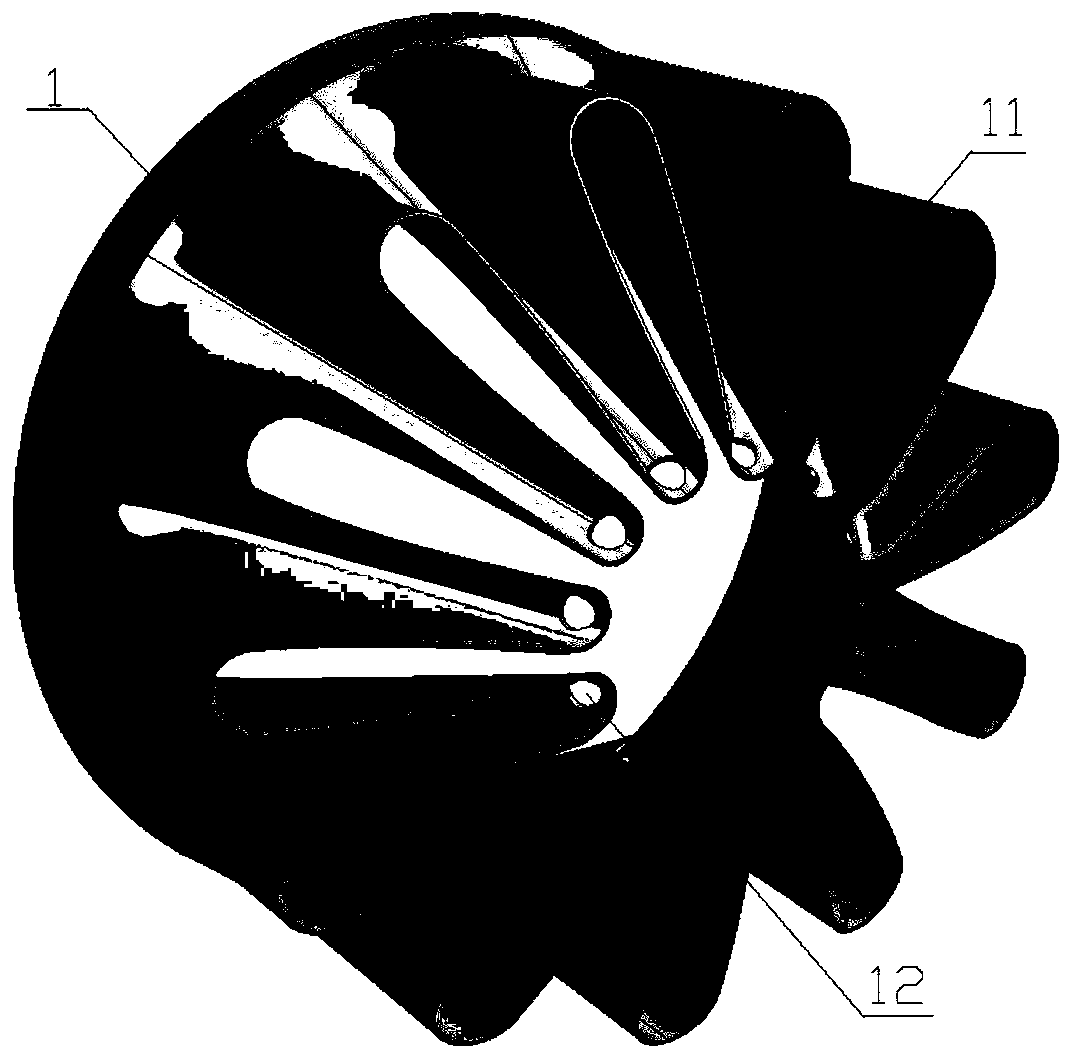

Mixing flame stabilizing device

PendingCN110939530AShorten the mixing distanceEfficient mixingContinuous combustion chamberRocket engine plantsCombustion chamberCombustible gas

The invention relates to the technical field of engines, and discloses a mixing flame stabilizing device. The mixing flame stabilizing device comprises a lobe mixer, a cover plate and turbulent flow columns, wherein a gas collecting cavity is formed between the cover plate and the lobe mixer; the turbulent flow columns are arranged at the position of an outer culvert air flow outlet of the lobe mixer; inner cavities of the turbulent flow columns communicate with the gas collecting cavity; the side walls of the turbulent flow columns and the cover plate are provided with spraying holes a and spraying holes b correspondingly; combustible gas is subjected to secondary flow dividing through the spraying holes a and the spraying holes b and then enters a combustion chamber to be mixed with air,the spraying pressure of the combustible gas is increased, accordingly, the penetrating capacity of the combustible gas in the gaseous environment is improved, and accordingly efficient mixing of twoair flows is achieved; and the turbulent flow columns are arranged at the position of the outer culvert air flow outlet of the lobe mixer, a large-scale radial vortex can be formed on the downstreamportion of the turbulent flow columns, outer culvert air is forced to flow in the circumferential direction of the turbulent flow columns at an outlet of the mixer, the mixing distance of the outer culvert air and inner culvert combustible gas is shortened, the mass exchange rate of the air and the combustible gas at an inner culvert outlet of the mixer is increased, and the mixing effect is improved.

Owner:XIAN AEROSPACE PROPULSION INST

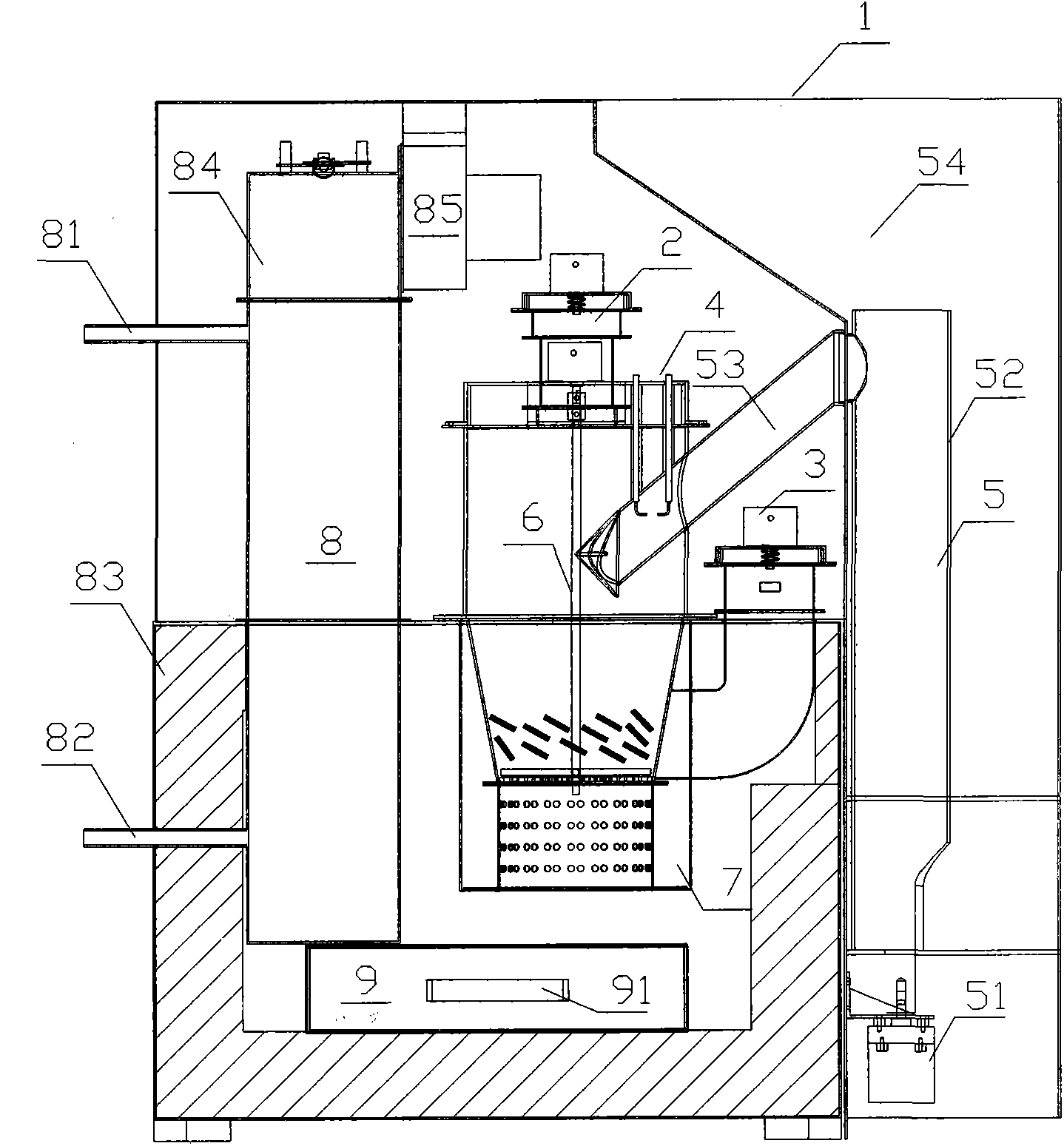

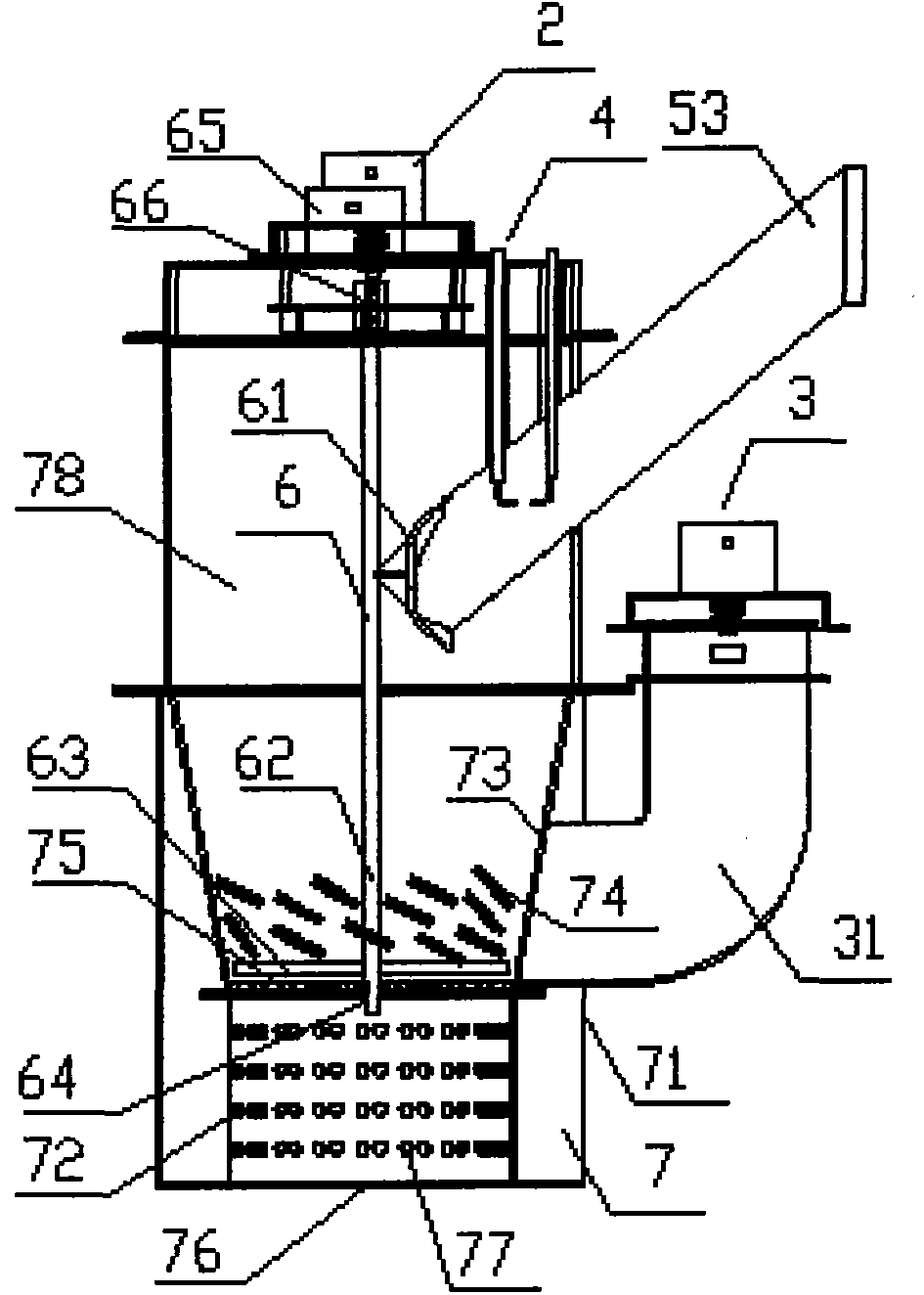

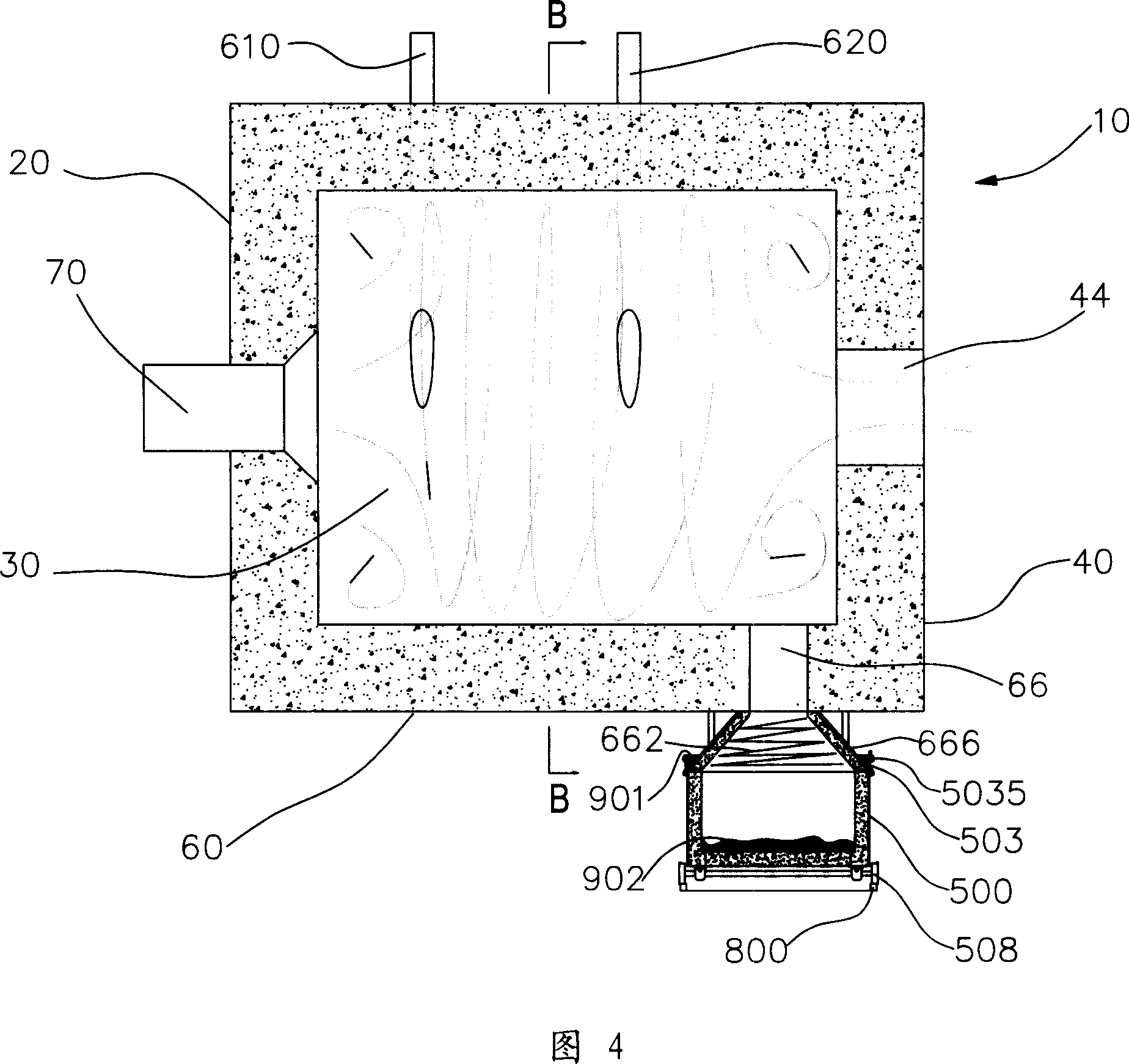

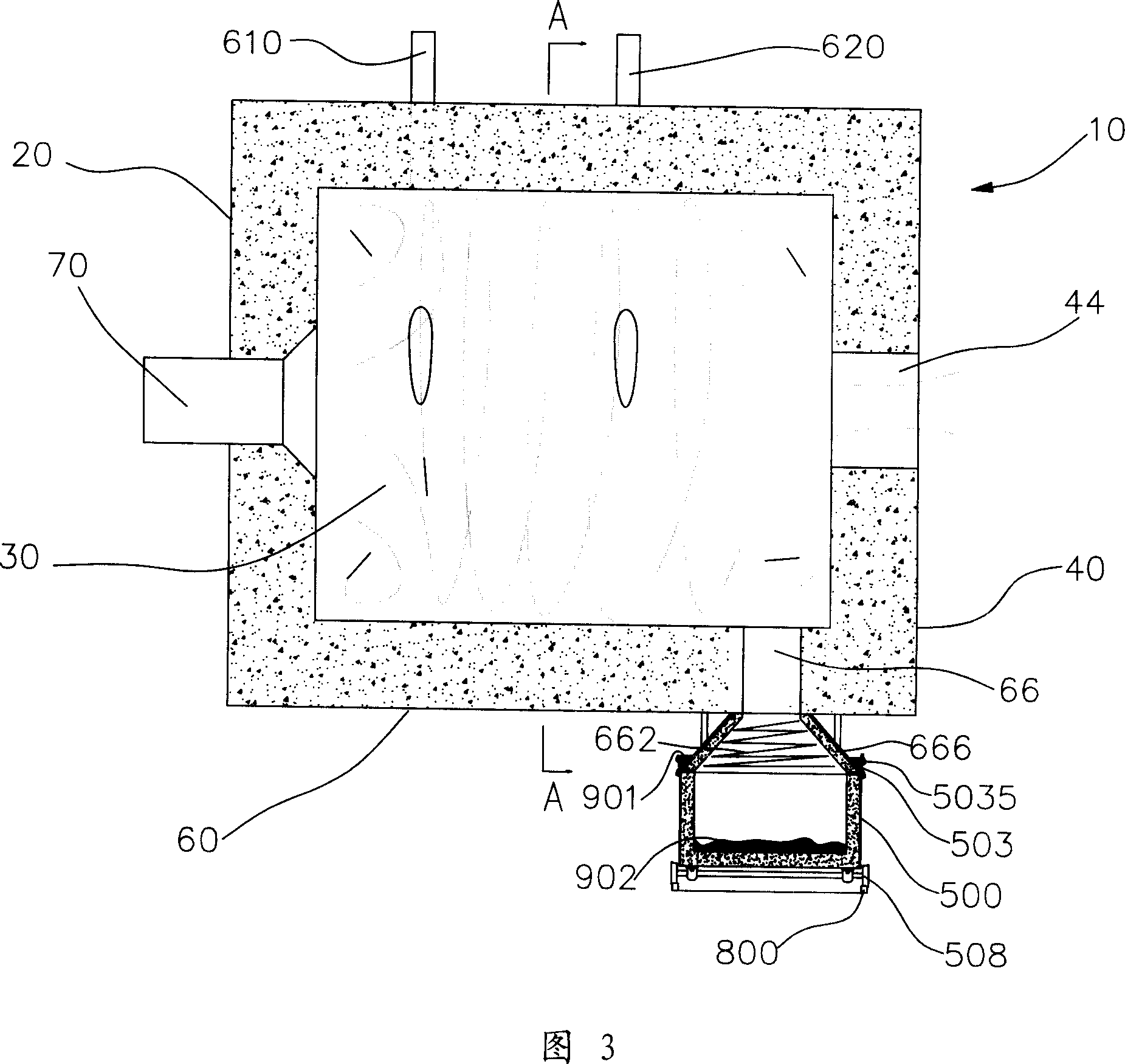

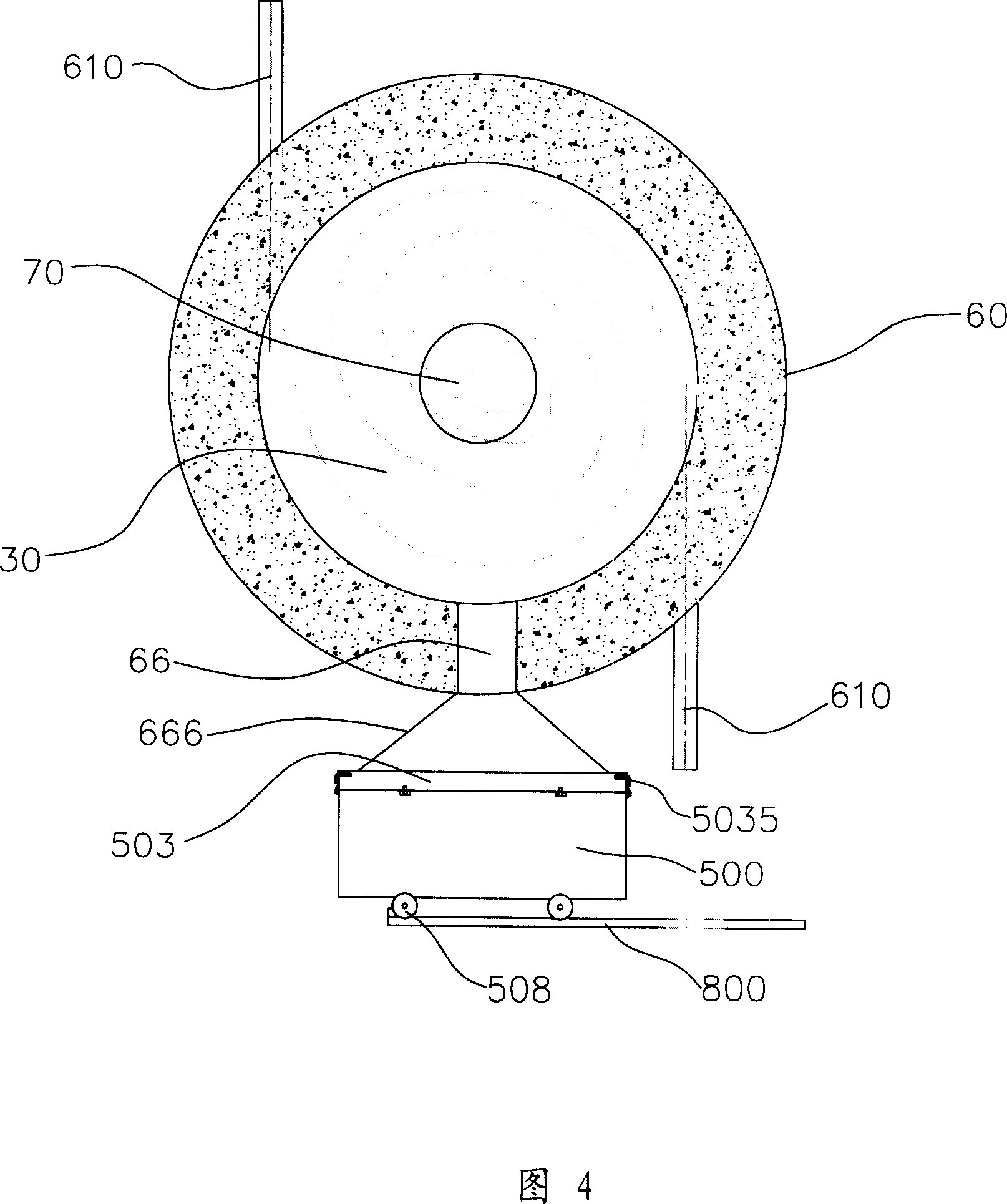

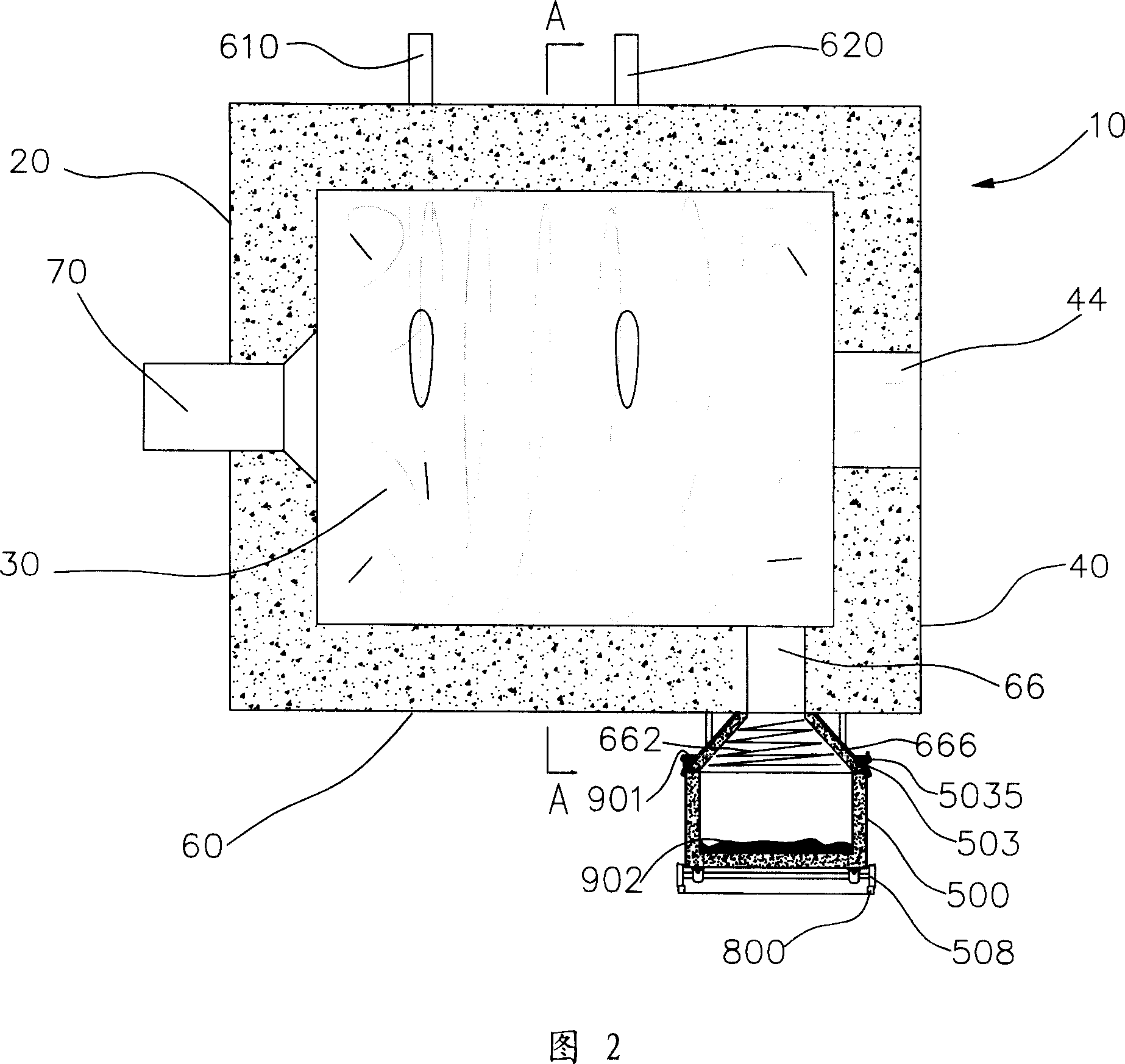

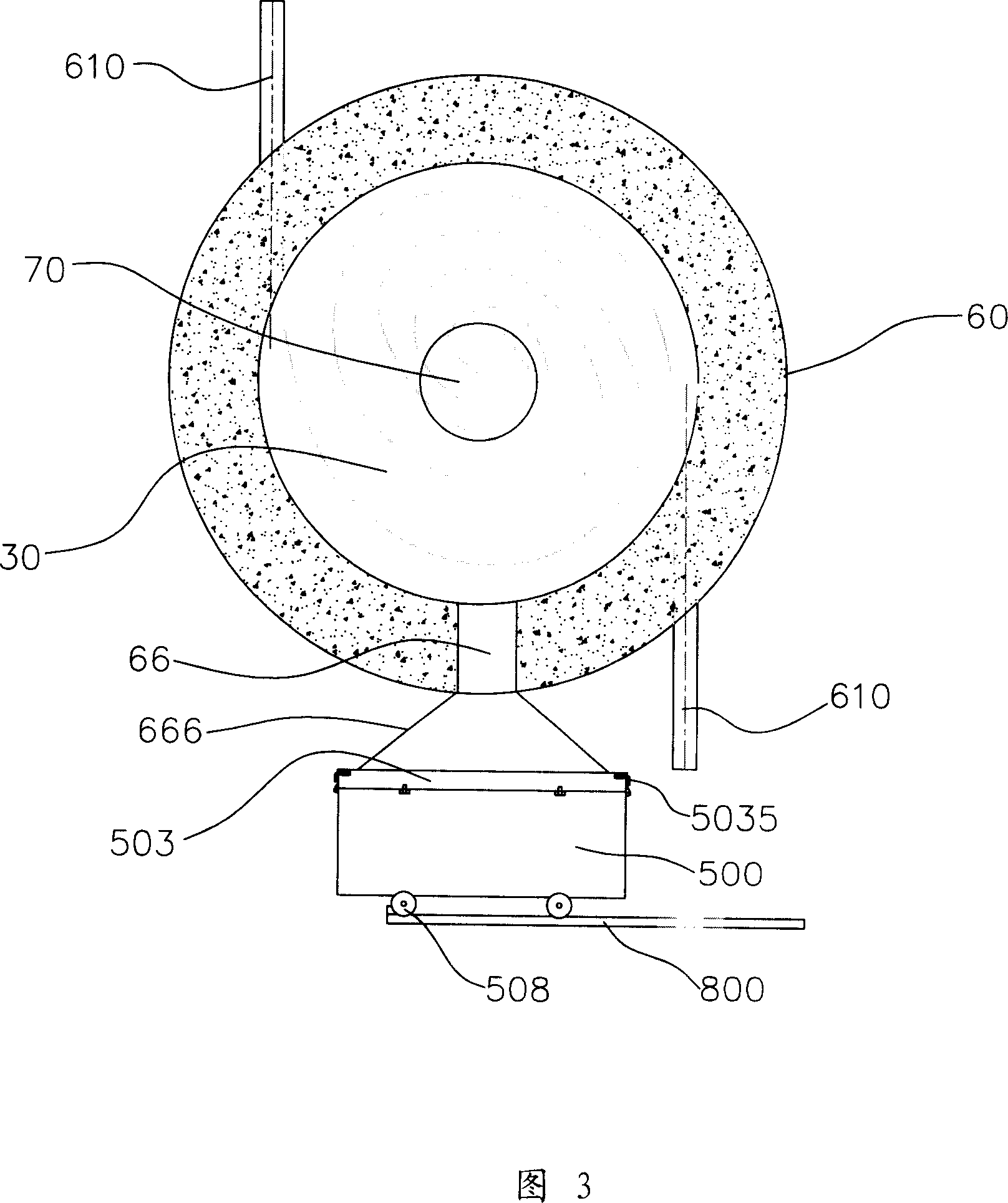

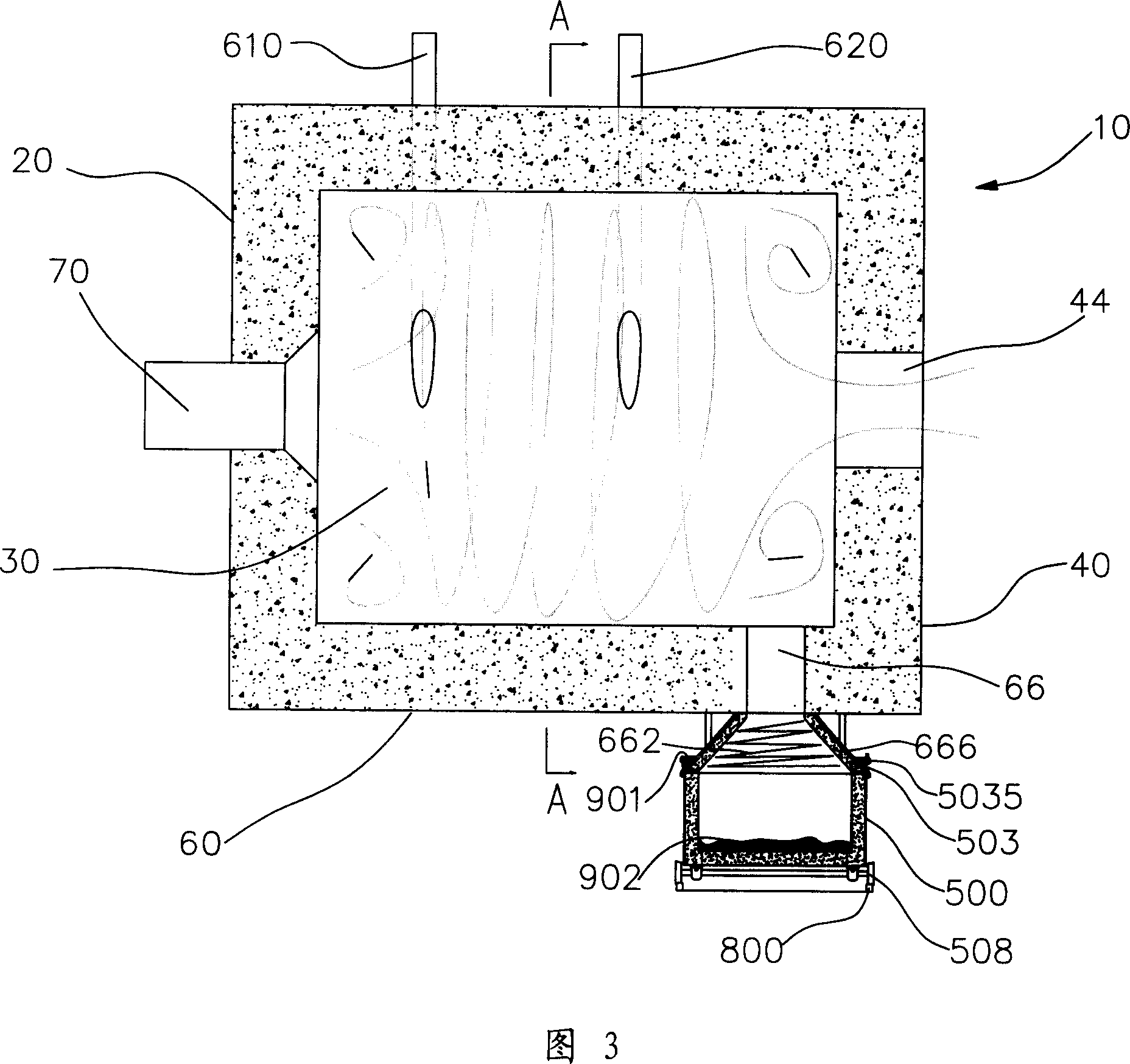

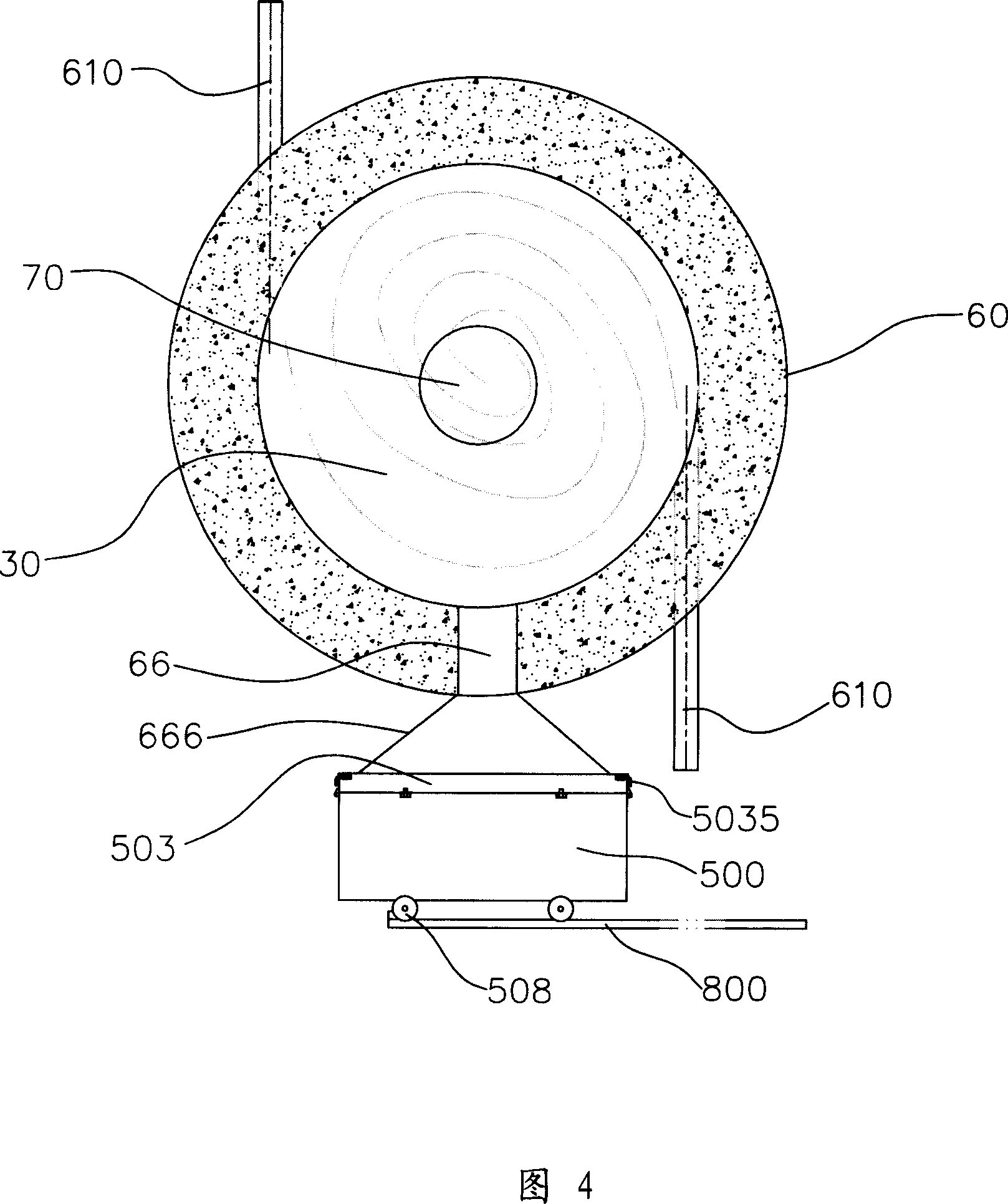

Stable and effective biomass pellet fuel combustion device and method

ActiveCN103912866APromotes efficient combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusAutomotive engineeringHigh energy

The invention discloses a stable and effective biomass pellet fuel combustion device and method. The stable and effective biomass pellet fuel combustion device comprises a combustion furnace shell, a primary air device, a secondary air device, an ignition device, a feed device, a burner, a heat exchange device, a stirring device and an ash tray. The stable and effective biomass pellet fuel combustion device and method are capable of guaranteeing the stable and effective combustion of the fuel and preventing slagging and caking in combustion so as to realize continuous stable combustion. The volatile component and fixed carbon in the biomass are burnt in two stages, the air quality is controlled, and the pollutant emission is lowered in combustion. The ignition device achieves low ignition energy consumption and low ignition pollutant emission; the combustion is safely isolated from stored materials; the stable and effective biomass pellet fuel combustion device and method have high energy conservation and emission reduction benefit and application value.

Owner:济南长城空调公司

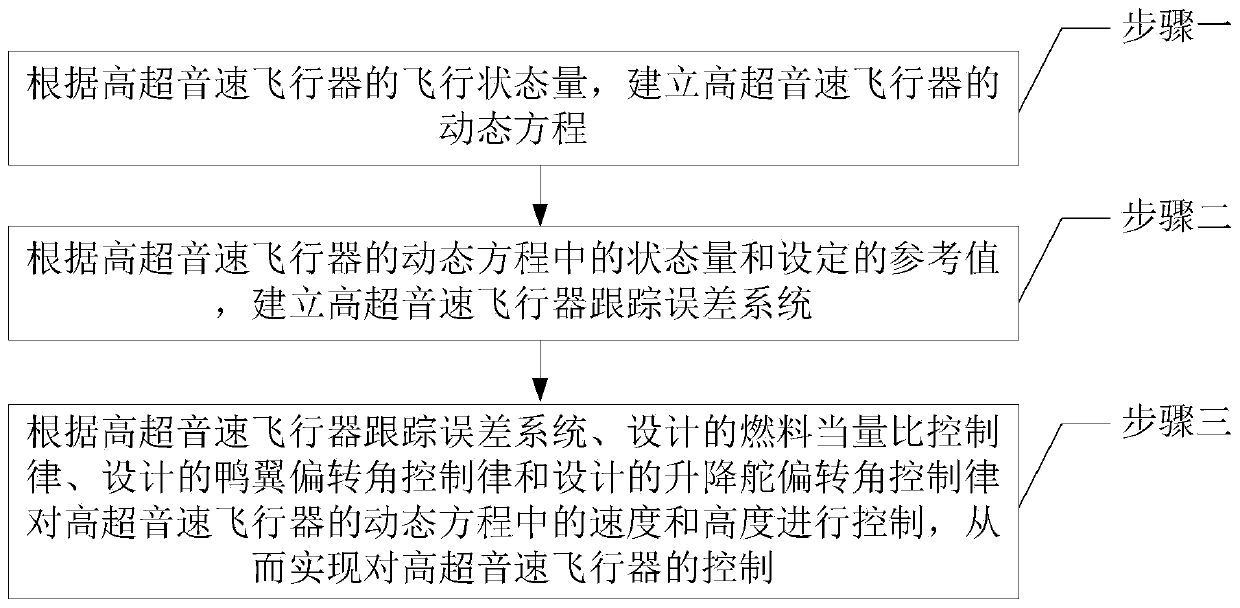

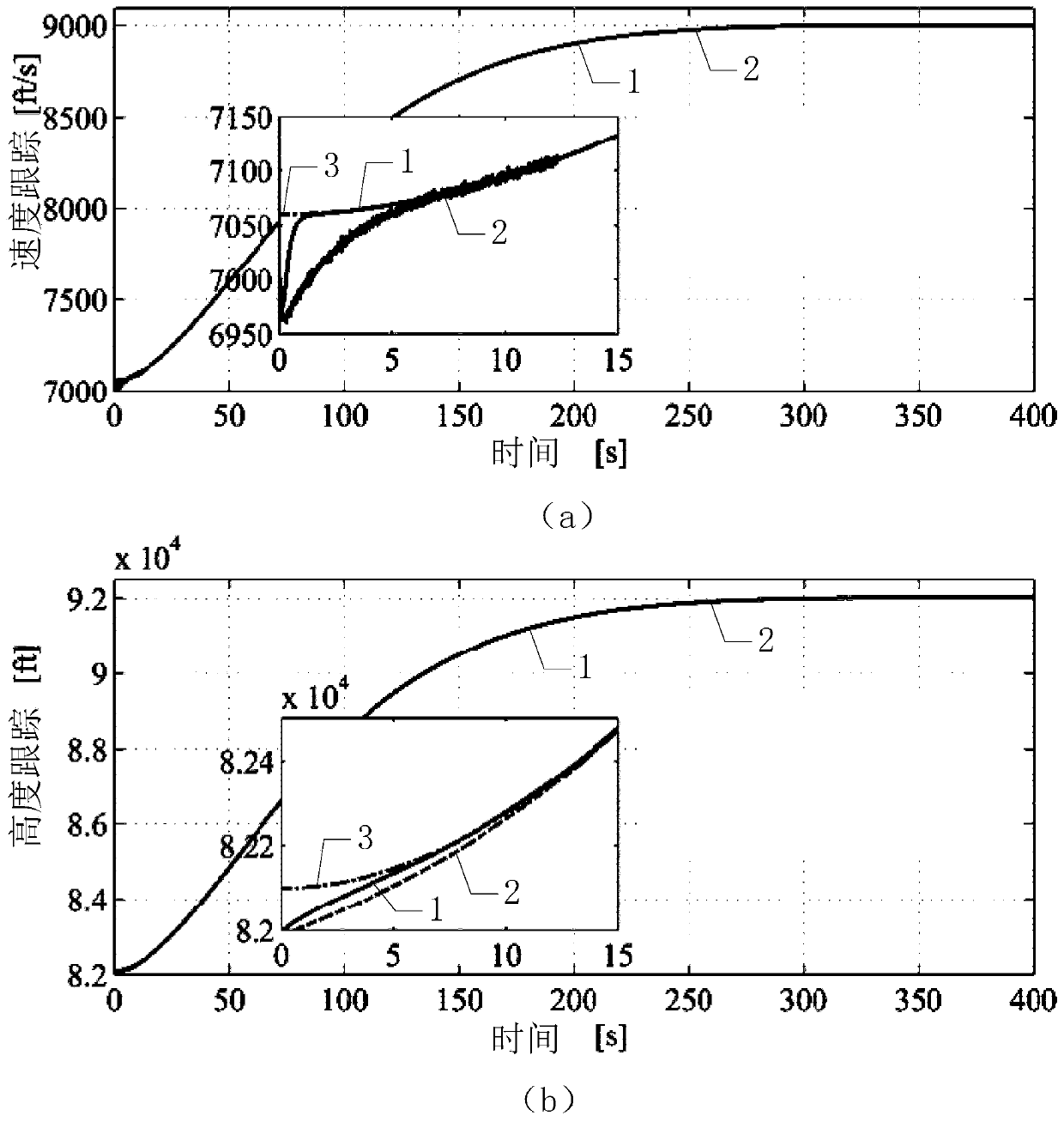

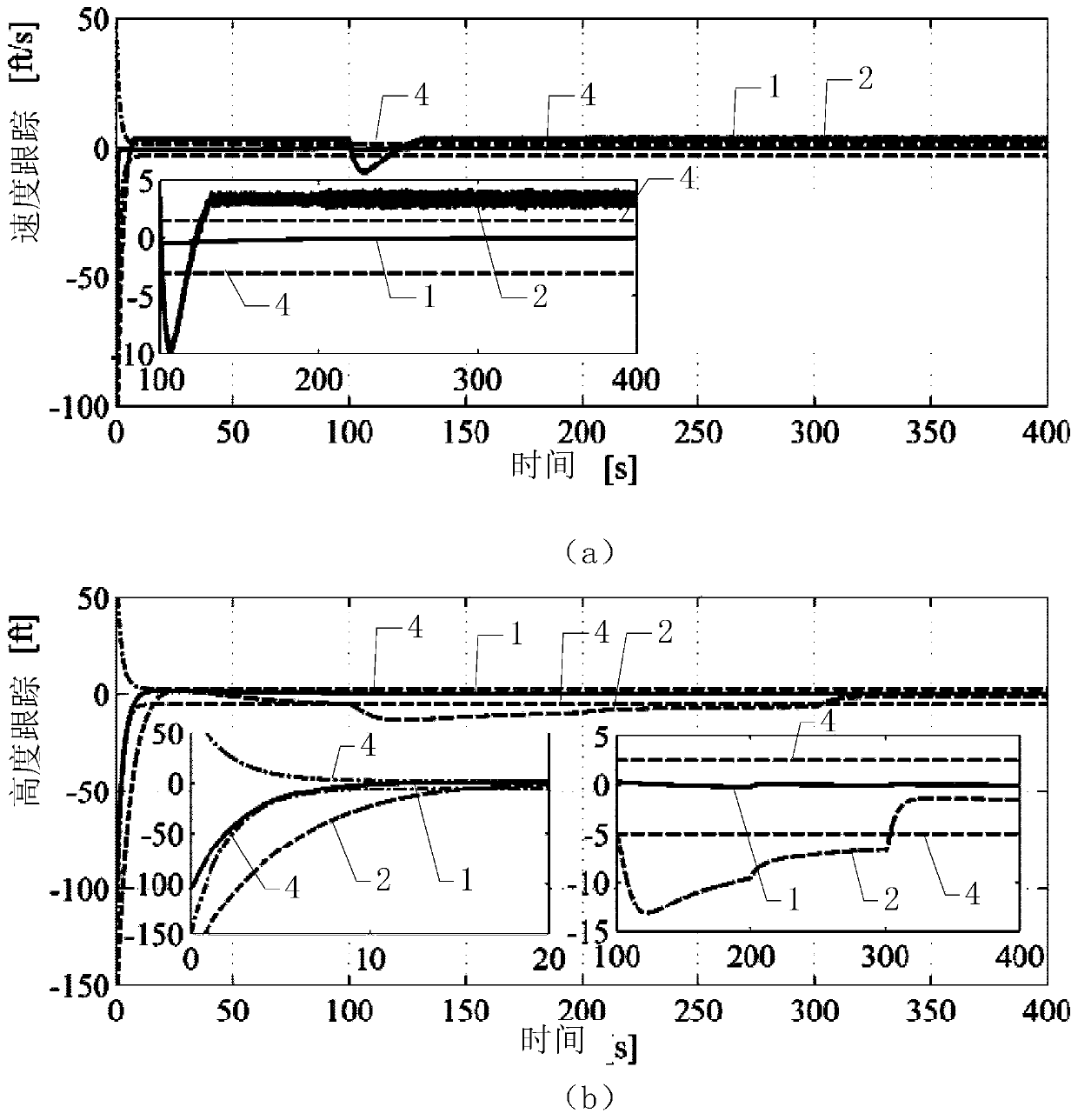

Hypersonic aircraft self-adaptive control method considering attack angle constraints

InactiveCN111158398AImprove stabilityImprove robustnessPosition/course control in three dimensionsDynamic equationEquivalence ratio

The invention discloses a hypersonic aircraft self-adaptive control method considering attack angle constraints, and relates to the field of aerospace control. The invention aims to solve the problemsof poor transient performance and insufficient combustion of a scramjet engine of an existing hypersonic aircraft under the conditions that an actuator of the hypersonic aircraft is often in a faultcondition and the attack angle of the hypersonic aircraft is limited. The method comprises: 1, establishing a kinetic equation of the hypersonic aircraft according to the flight state quantity of thehypersonic aircraft; 2, establishing a hypersonic aircraft tracking error system according to the state quantity in the dynamic equation of the hypersonic aircraft and a set reference value; and 3, controlling the speed and the height in the dynamic equation of the hypersonic aircraft according to the hypersonic aircraft tracking error system, the designed fuel equivalence ratio control law, the designed canard deflection angle control law and the designed elevator deflection angle control law so as to control the hypersonic aircraft. The methodis used to control an aircraft.

Owner:HARBIN INST OF TECH

Mild gas turbine combustion chamber

ActiveCN111520747AReasonable coolingFully warmed upContinuous combustion chamberCombustion chamberCombustor

The invention provides a mild gas turbine combustion chamber, and relates to the technical field of gas turbines. Based on the defects that a traditional gas turbine combustion chamber is severe in working environment, large in heat load, high in temperature and speed, complex in flow field and the like, a fuel oil single-point injection combustor is changed into multi-point injection of the wallsurface of a flame tube, multi-point mixing of fuel oil and air can be achieved, a mild combustion area is established, and stable and efficient combustion is achieved; the wall surface of the flame tube is designed to be of a double-layer wall structure, the middle of the flame tube is designed to be of a honeycomb sandwich structure, high-temperature airflow inside the flame tube can be reasonably cooled, it is guaranteed that the fuel oil in a fuel oil branch pipe is sufficiently preheated, and meanwhile, the effect of reducing noise generated in the working process of the combustion chamber can be achieved; and a boss structure is designed in the flame tube, the flame tube can be partitioned, flames can be quenched to the mild combustion area from an fuel-rich combustion area rapidly,emission of nitric oxide is reduced, and the stable combustion of the fuel in the flame tube is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

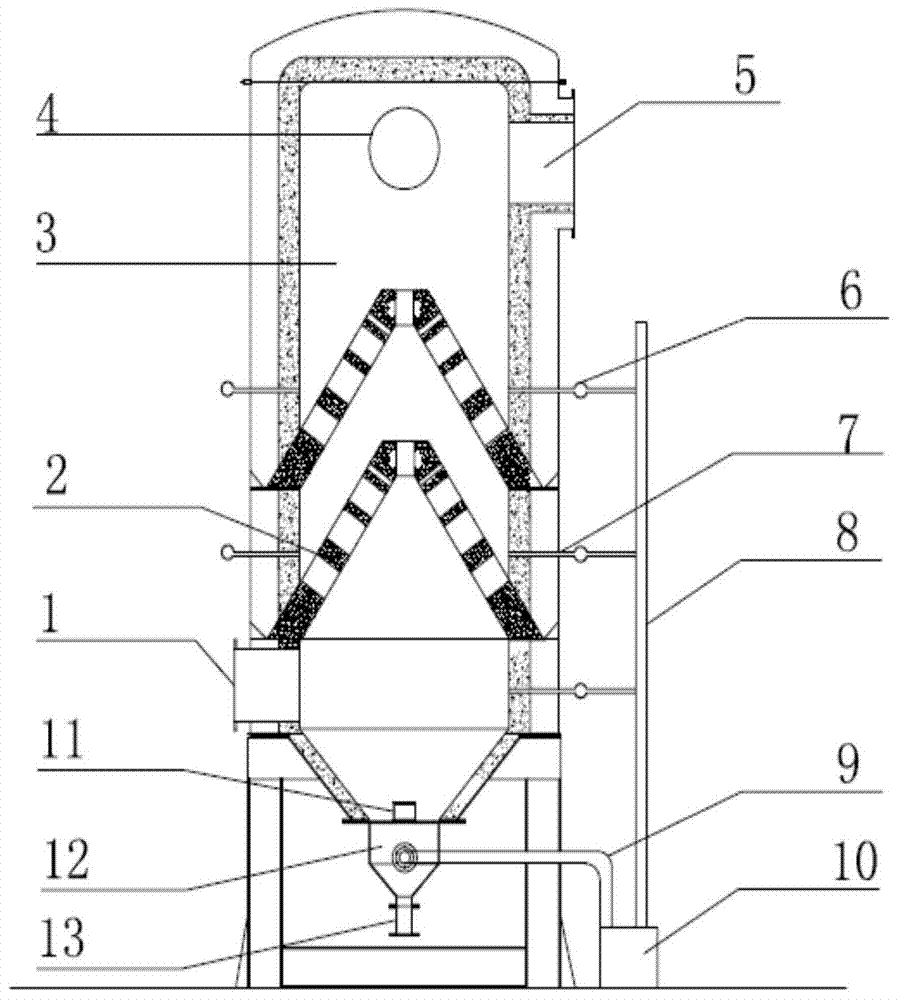

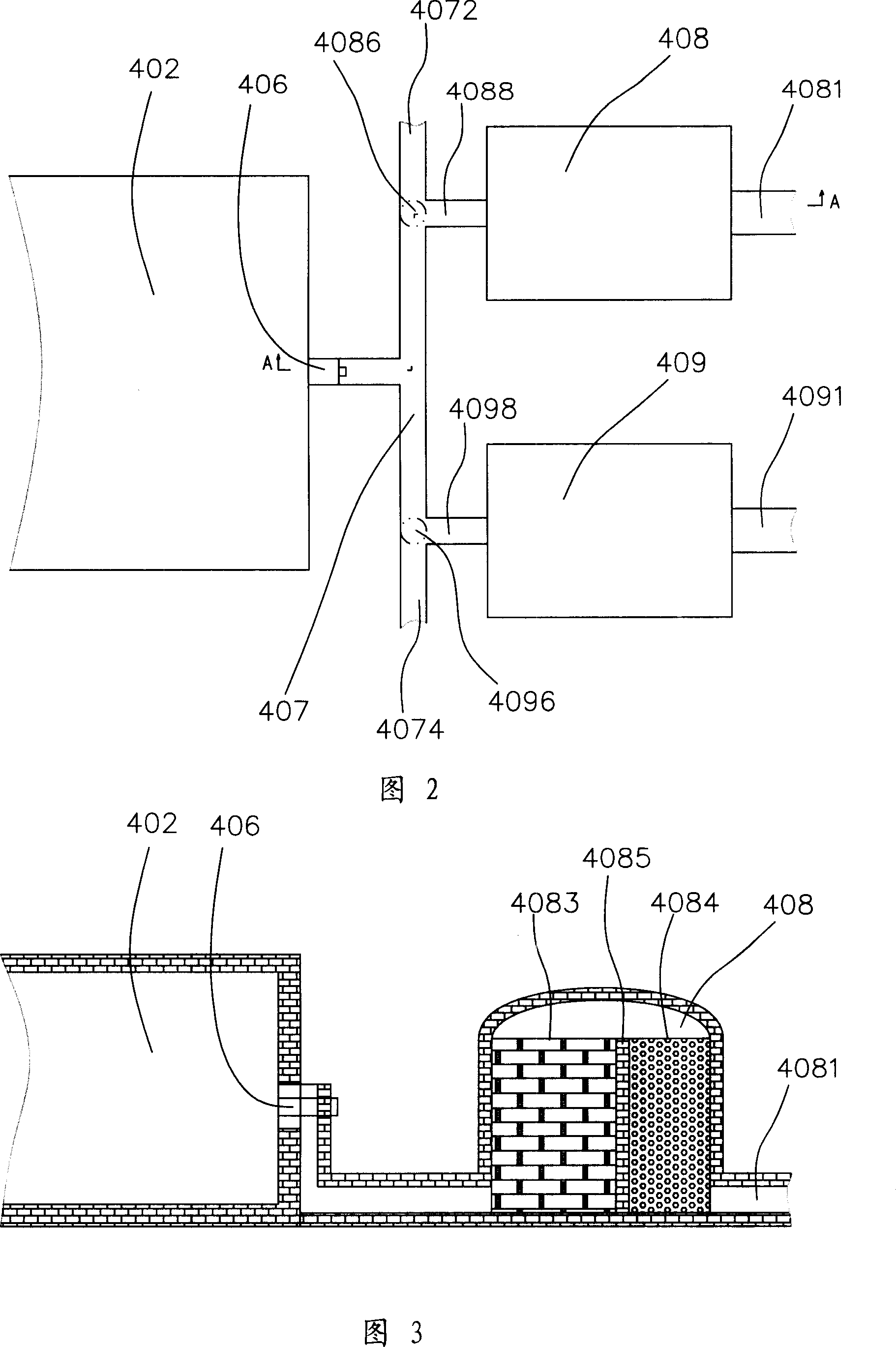

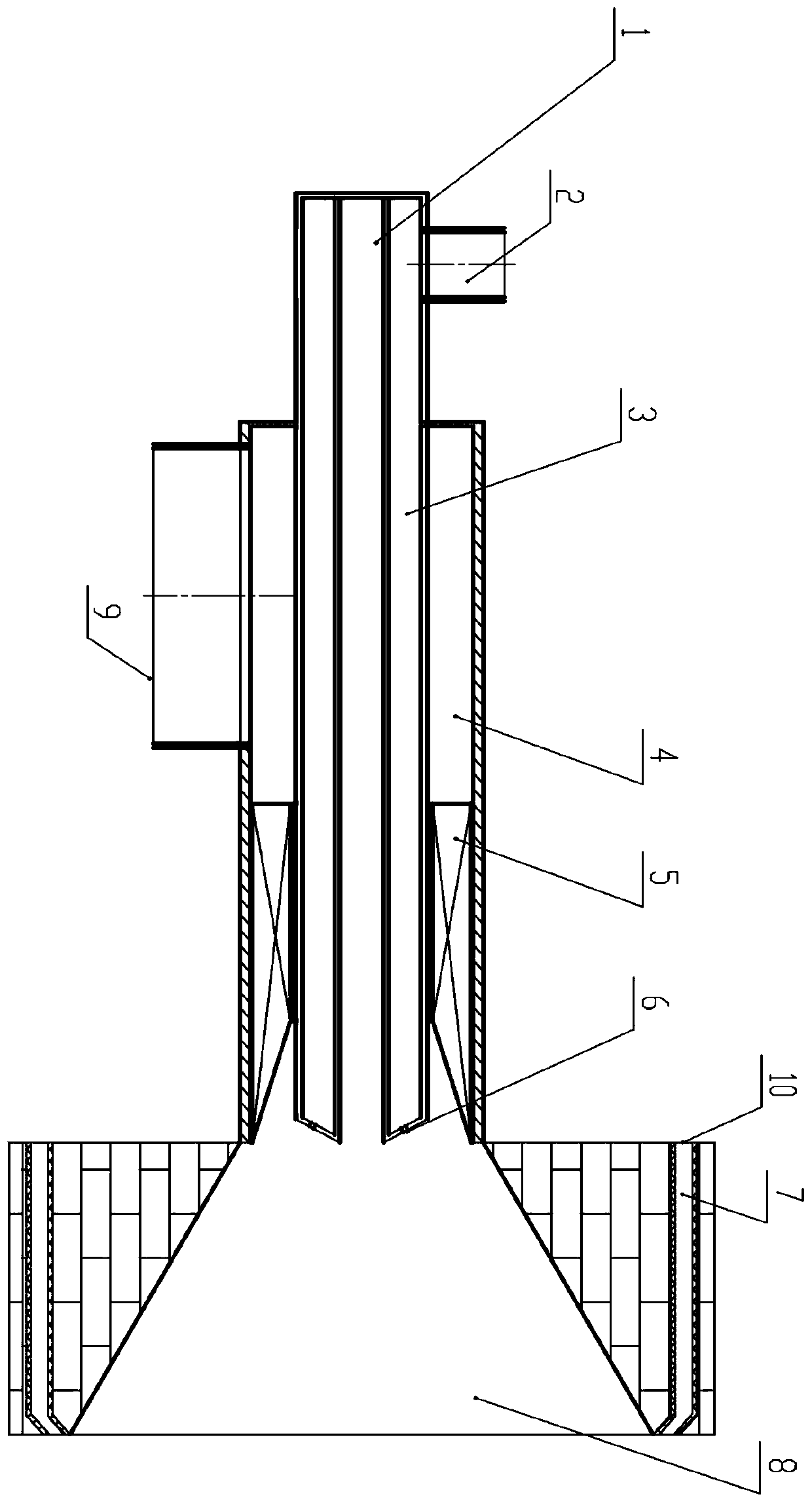

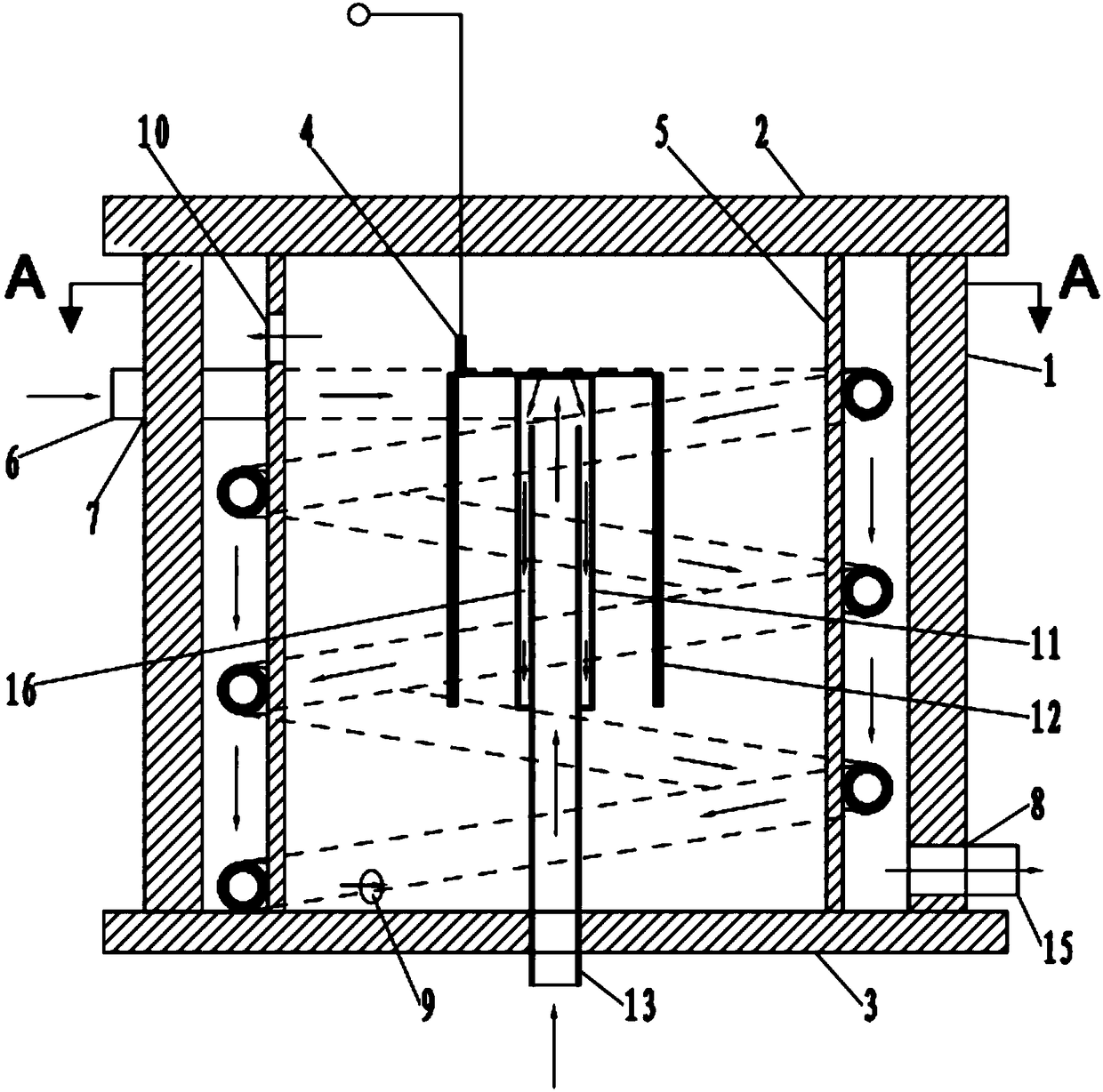

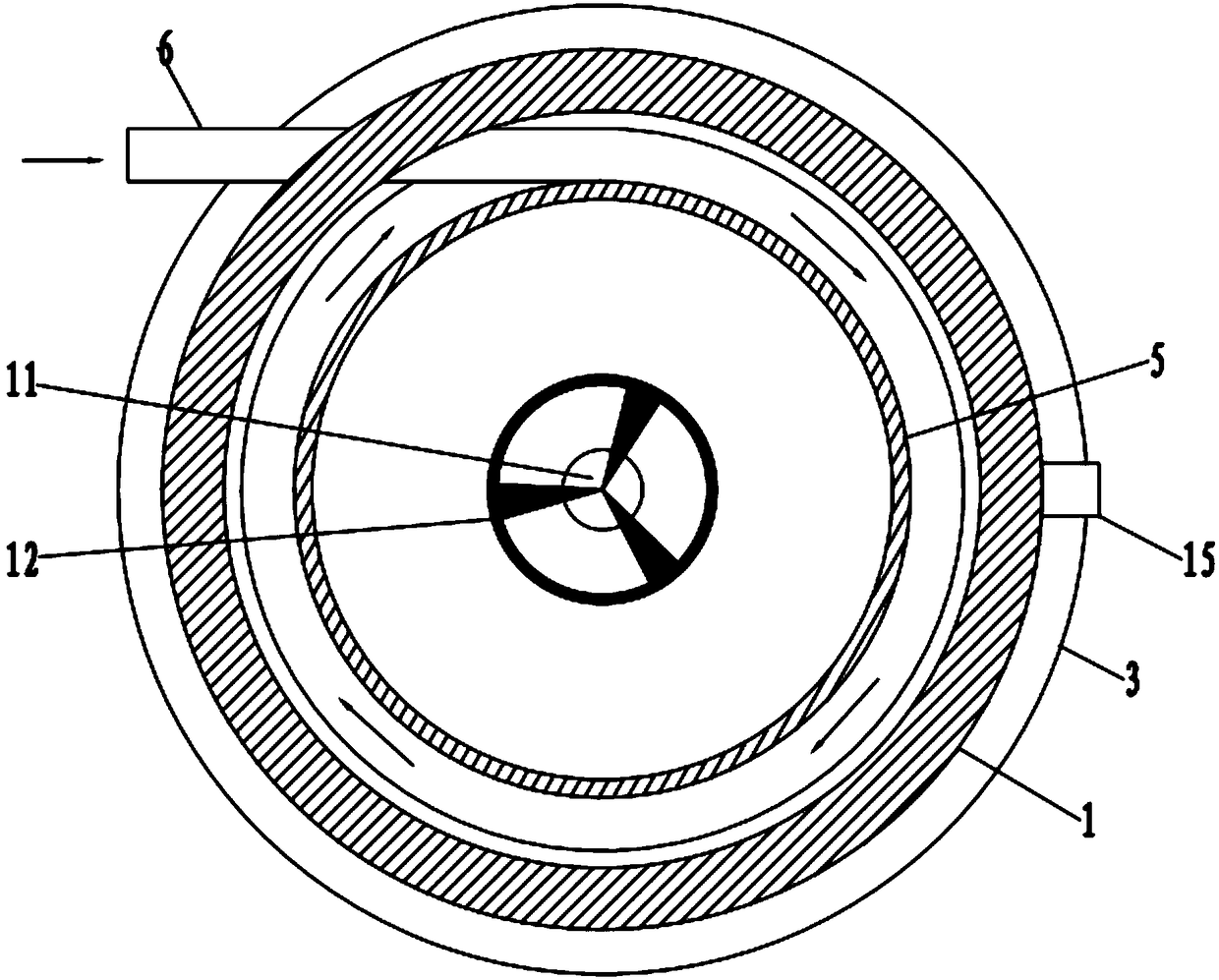

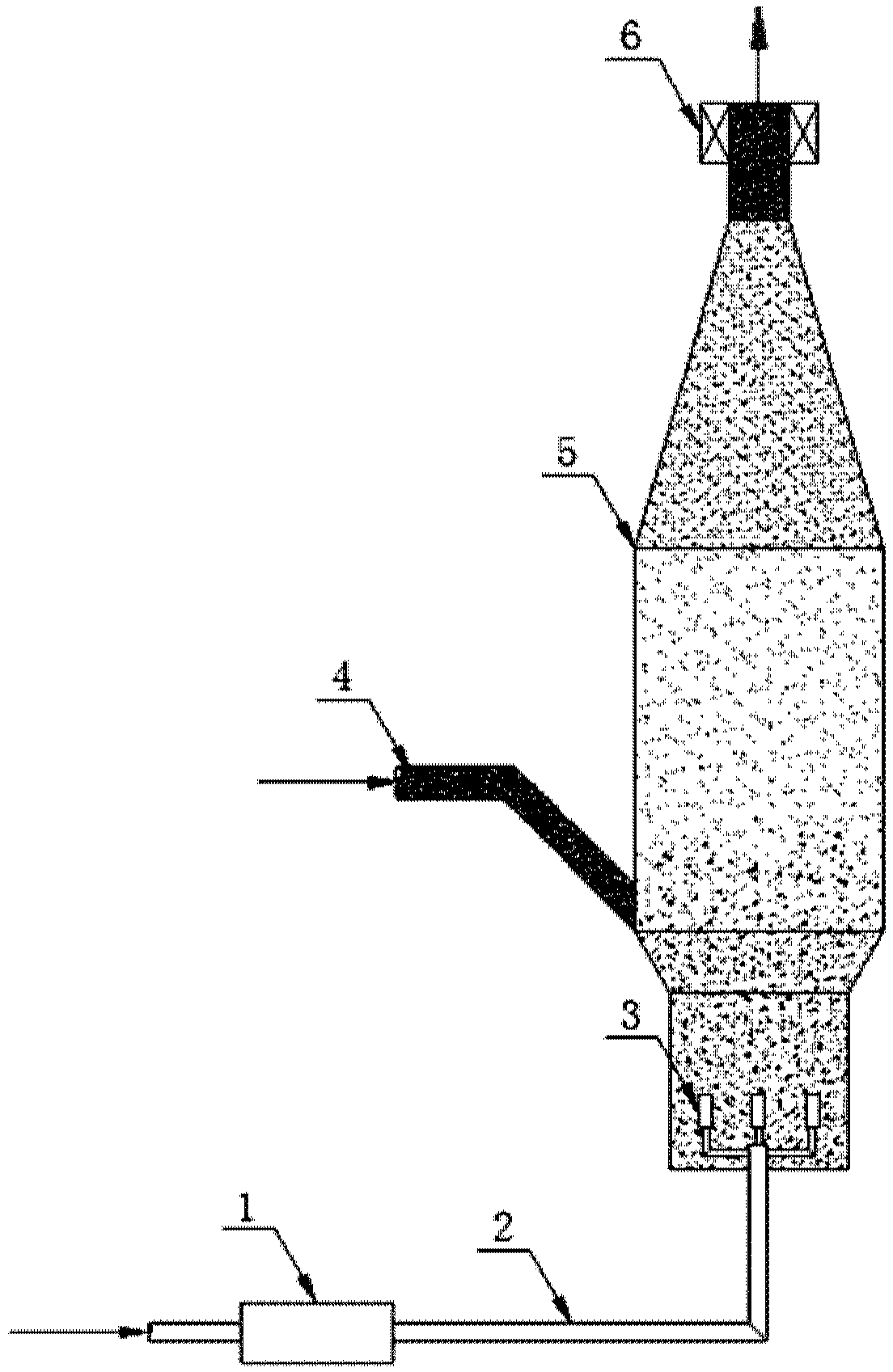

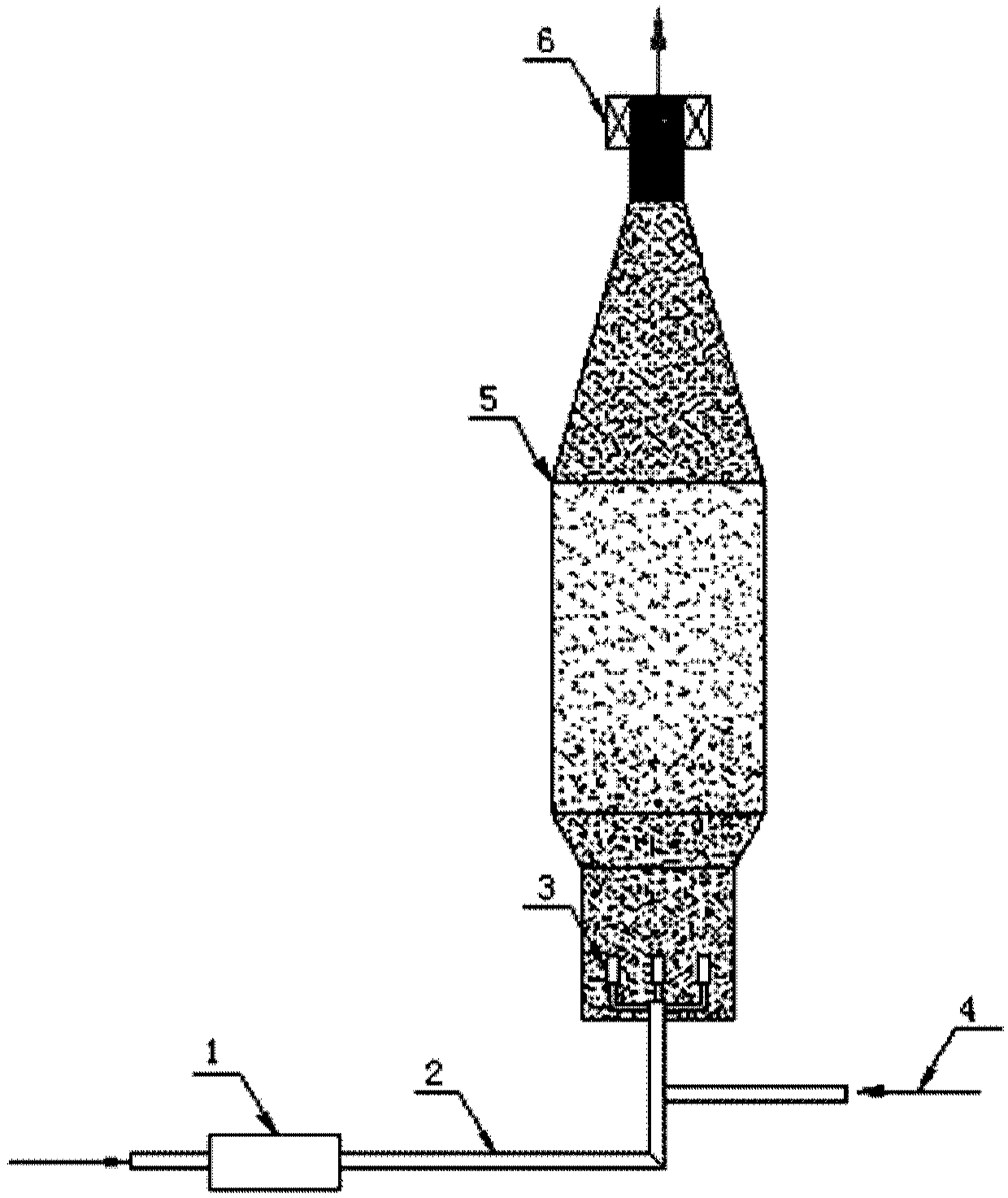

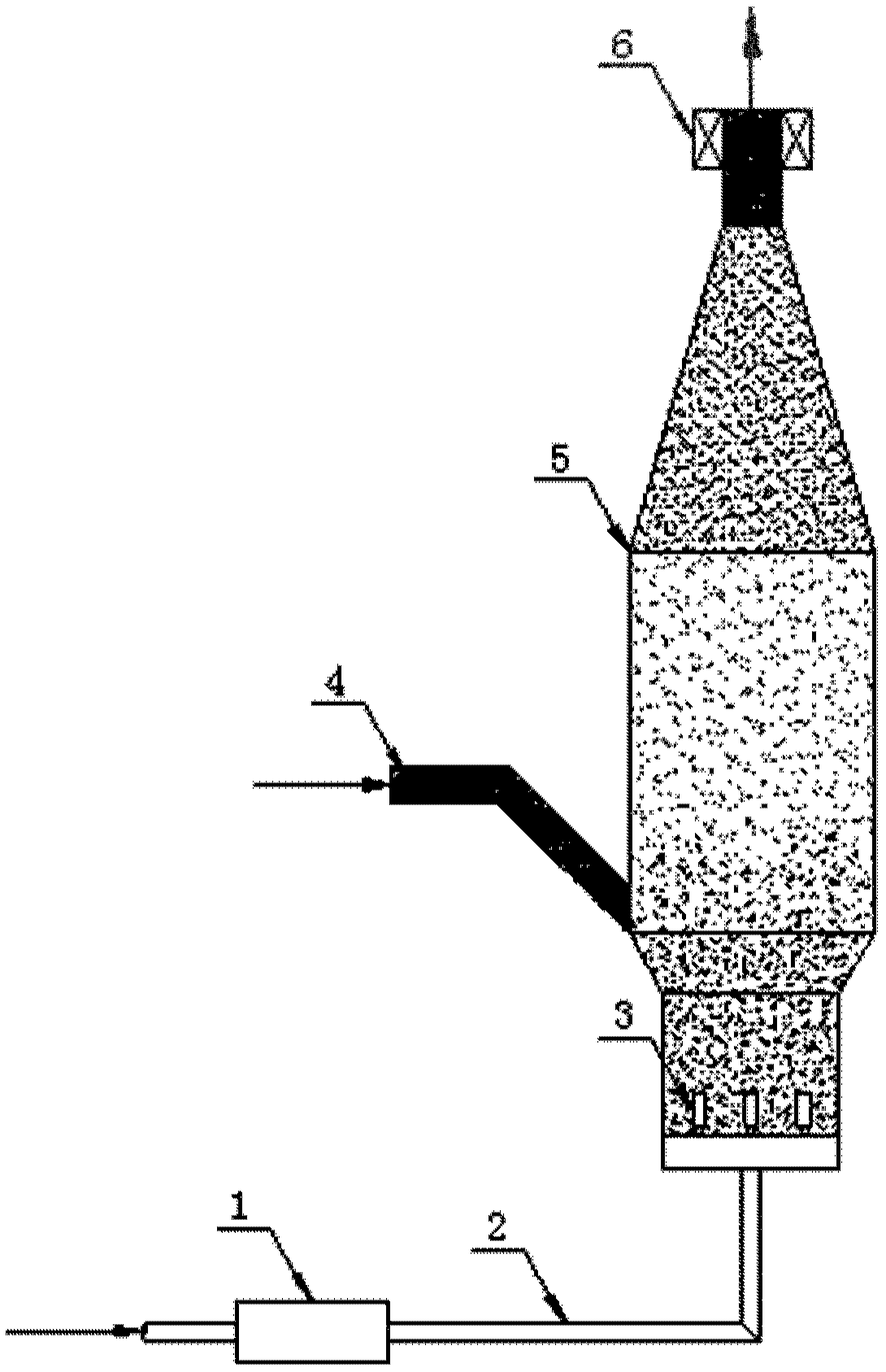

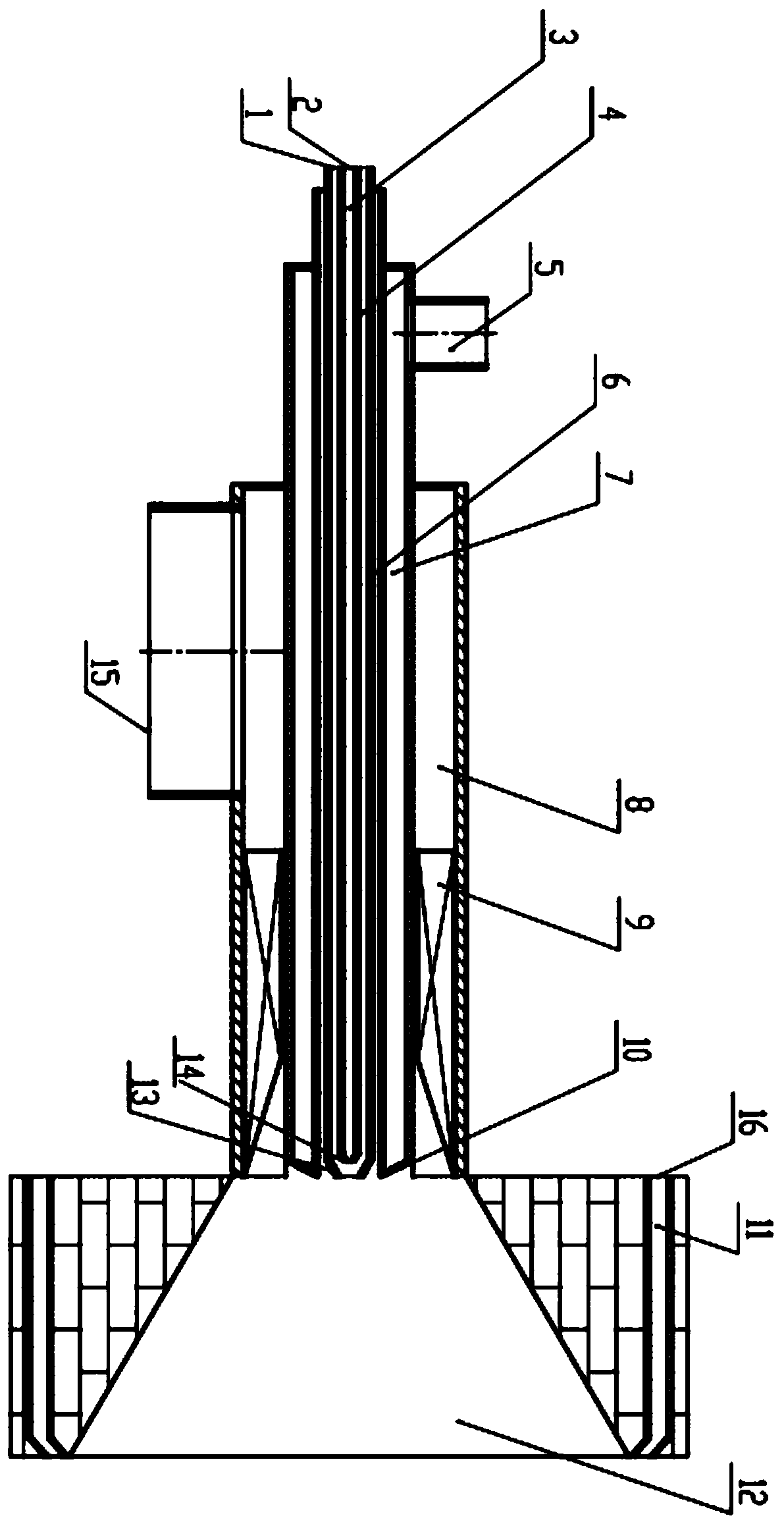

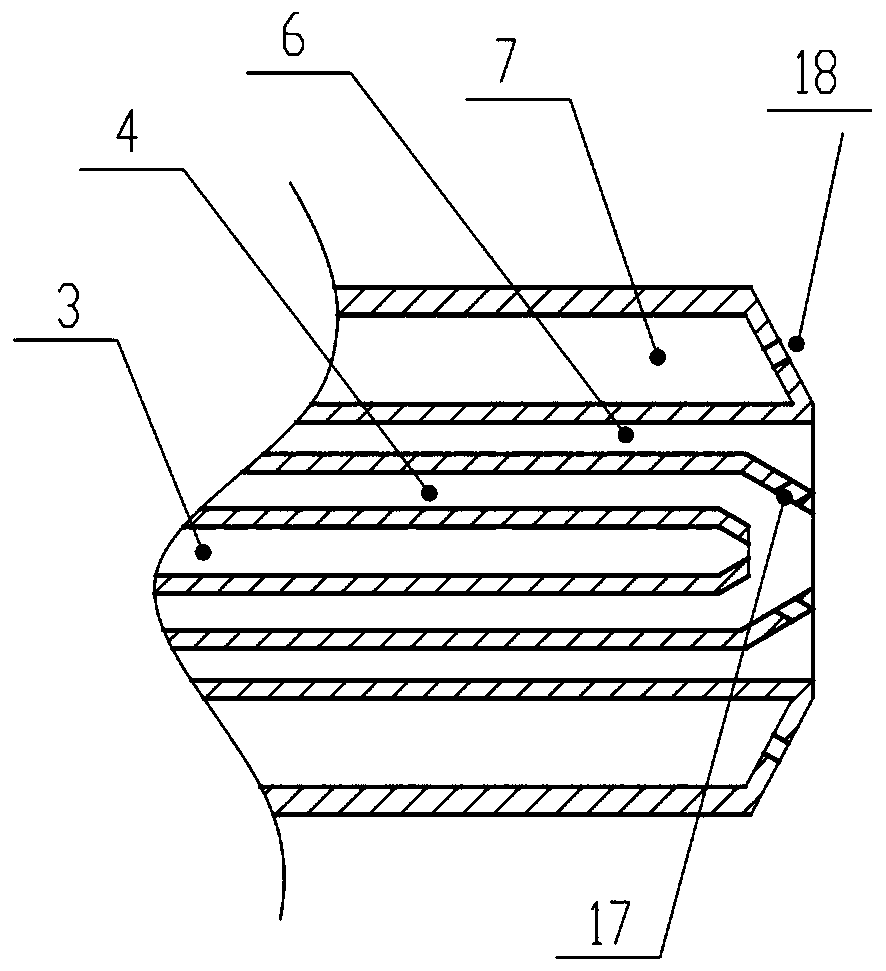

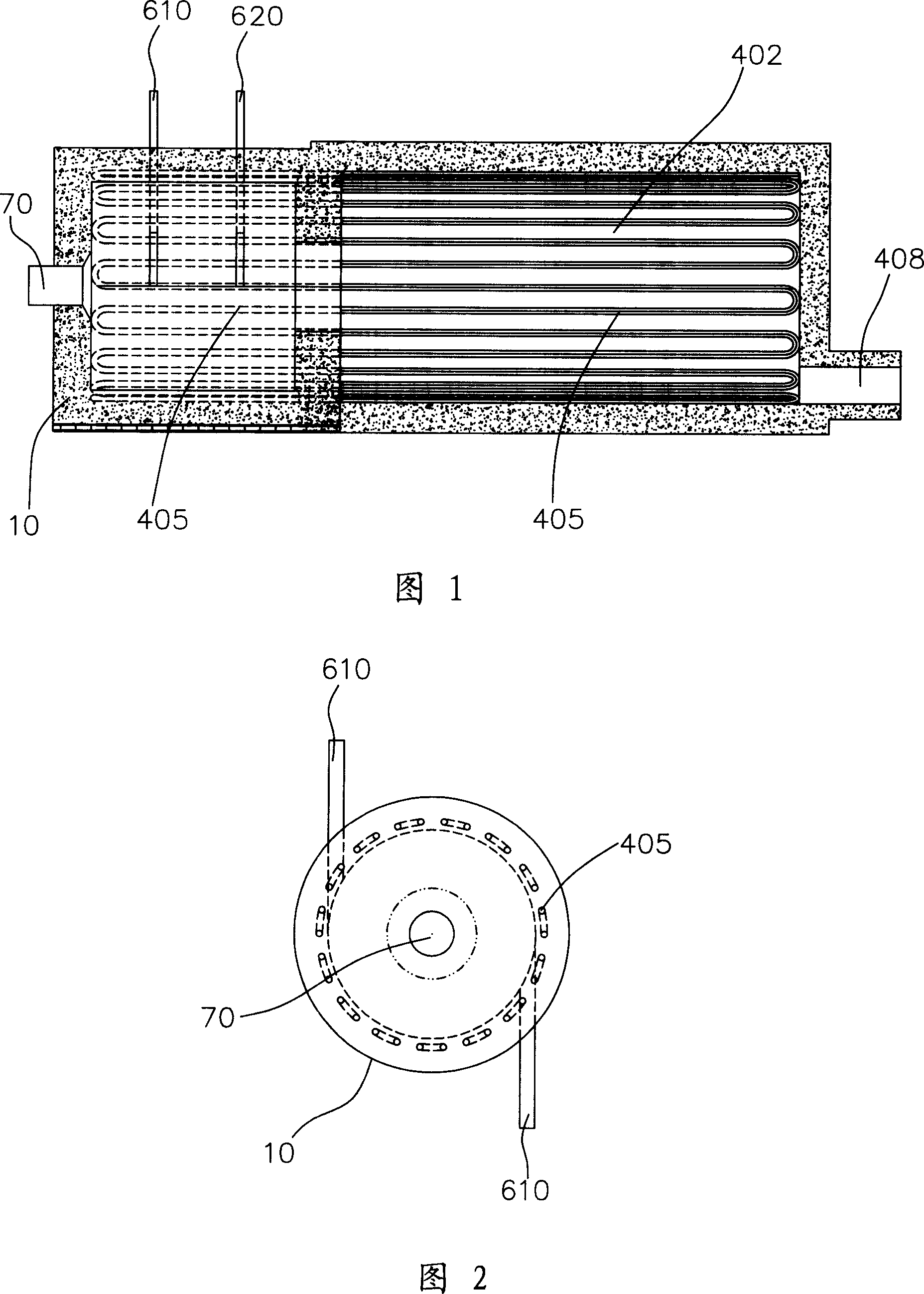

Regenerative combustion device applicable to stable combustion of compounded tangent-flow and direct-flow gas with low calorific value

InactiveCN103868055AAchieve efficient and stable combustionIncreased fluid mixingNon-combustible gases/liquids supplyProcess engineeringHeat supply

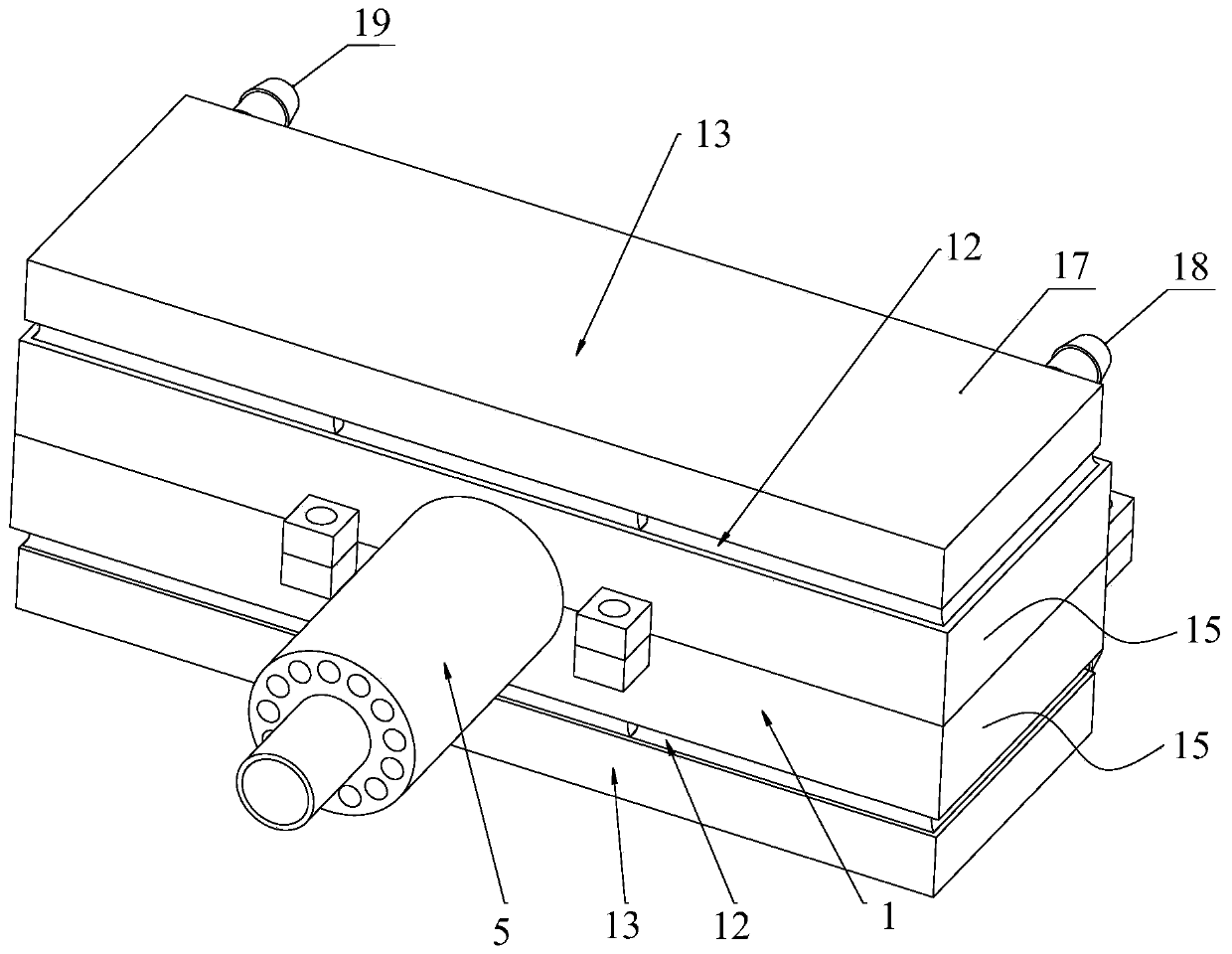

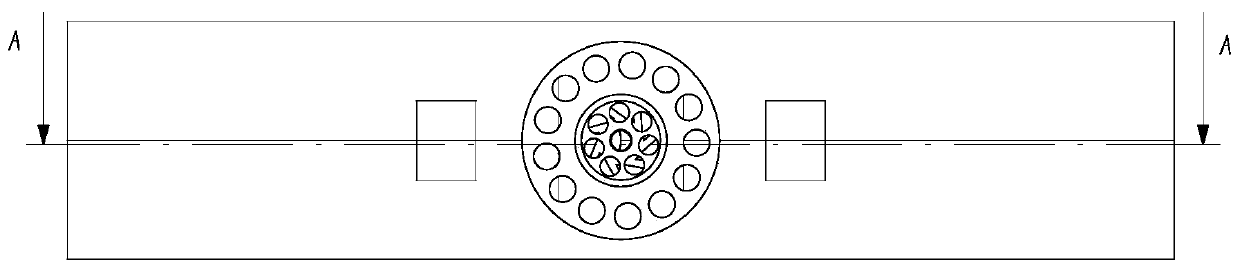

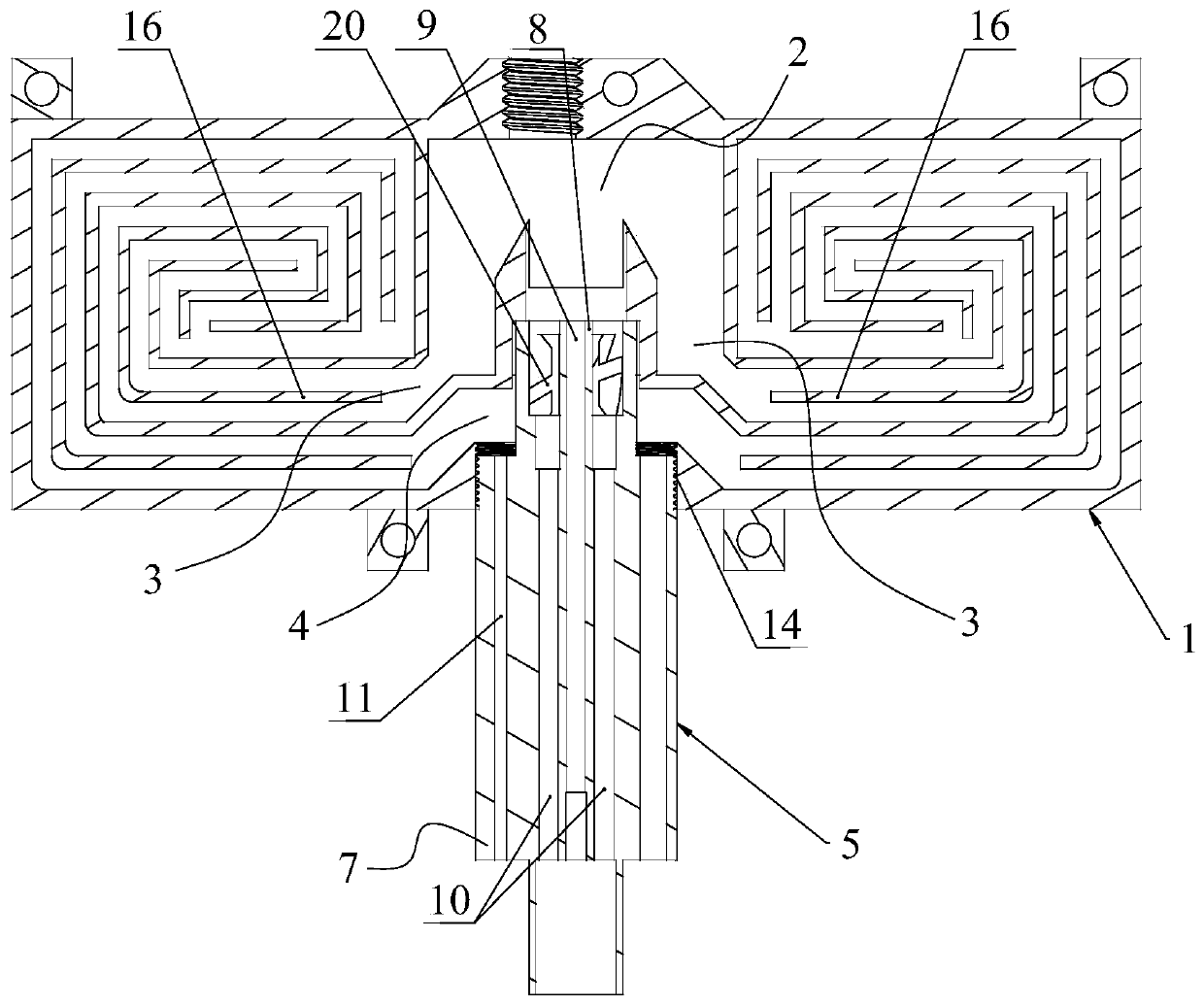

The invention relates to the clean utilization field of gas and relates to a device applicable to combustion of gas with the low calorific value. The device comprises a combustion tower (3), a gas inlet (1), a smoke outlet (5), a primary air pipe (9) which is communicated with an air chamber (12), an ignition hole (11), a secondary air pipe (8) and a combustion stabilizing cone (2), wherein the secondary air pipe (8) is connected with a plurality of branch gas pipes (7) through multistage of annular distributors (6); the branch gas pipes (7) are tangentially communicated with the inside of the combustion tower (3); the combustion stabilizing cone (2) is cone-shaped or frustum-shaped and arranged above the gas inlet (1) in the combustion tower (3); a plurality of channels are evenly formed in the wall surface of the combustion stabilizing cone. The device is capable of reducing heat needed by igniting the gas with the low calorific value in a hierarchical air supply manner, increasing the ignition heat supply through a multi-channel regenerative combustion stabilizing cone, facilitating the mixing of the compounded tangent-flow and direct-flow gas and the air in a manner of compounding tangent flows and direct flows, so that the efficient and stable combustion of the gas with the low calorific value is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

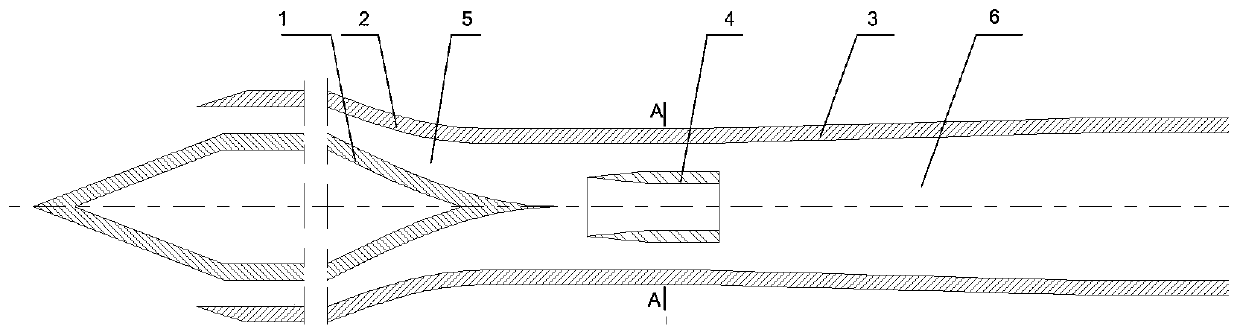

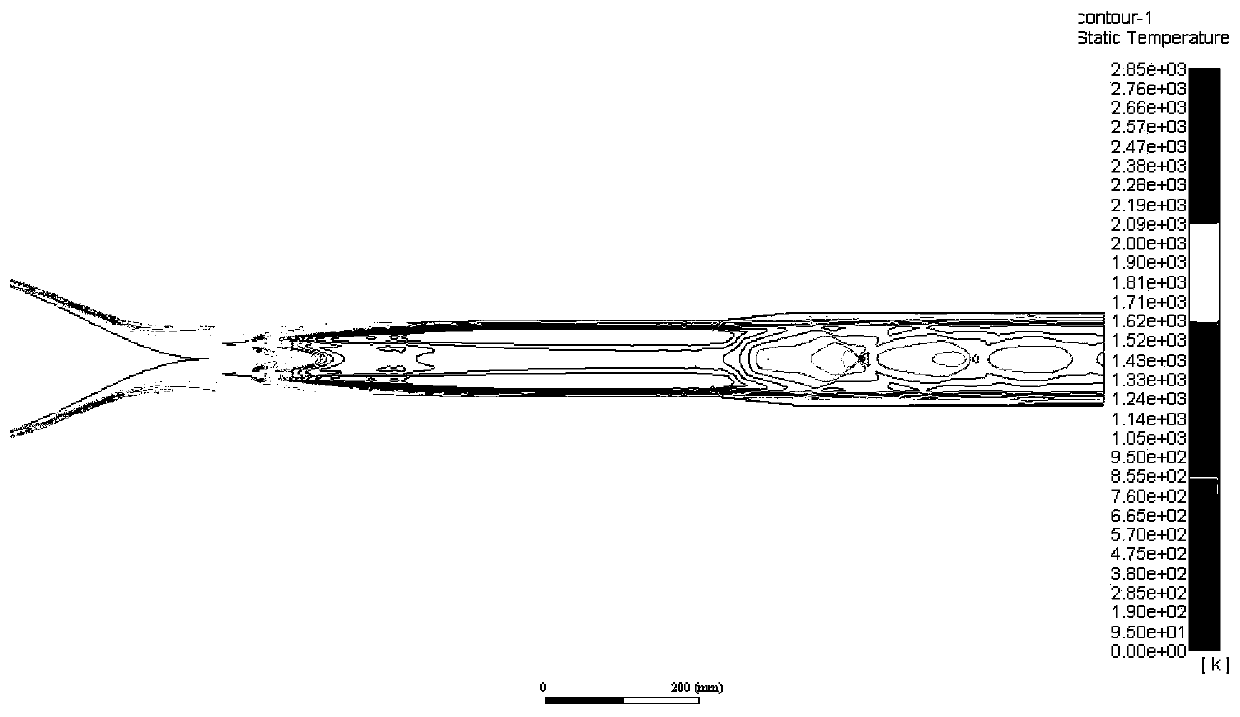

Scramjet engine flow channel structure adopting center combustion and scramjet engine

InactiveCN110793062ASolve difficultySolve the integrationContinuous combustion chamberCombustion chamberInlet flow

The invention provides a scramjet engine flow channel structure adopting center combustion and a scramjet engine. The flow channel structure design comprises a support plate injector, a gas inlet flowchannel and a combustion chamber flow channel, wherein the gas inlet flow channel and the combustion chamber flow channel are connected in a smooth transition manner in the flow incoming direction. The support plate ejector is arranged in the combustion chamber flow channel. The axis of the support plate injector coincides with the axis of the combustion chamber flow channel. In the direction ofthe axis of the support plate injector, the cross section of the support plate injector is in an annular shape. By means of the scheme, the technical problem that the low heat protection difficulty and the high air utilization rate cannot be considered at the same time in an existing scramjet engine flow channel scheme can be solved.

Owner:BEIJING AEROSPACE TECH INST

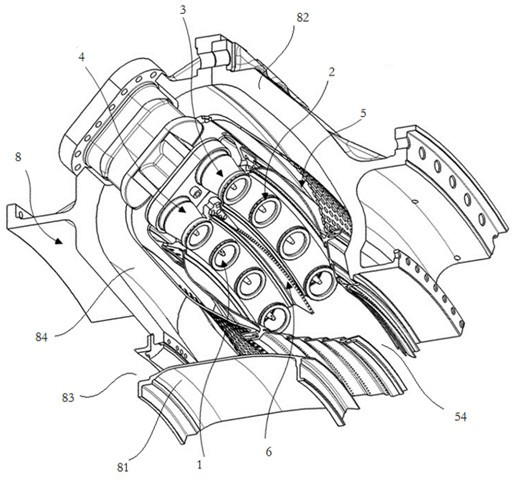

Multi-stage partitioned combustion structure for gas turbine

ActiveCN113251440AEfficient and stable combustionReduce NOx emissionsContinuous combustion chamberFuel supplyNitrogen oxides

The invention belongs to the technical field of gas turbines, and particularly relates to a multi-stage partitioned combustion structure for a gas turbine. The multi-stage partitioned combustion structure for the gas turbine comprises a combustion chamber casing, a flame tube, a plurality of cyclones and a diverter. The cyclones are divided into an on-duty cyclone, a flame transfer cyclone, a first main combustion cyclone and a second main combustion cyclone, each cyclone is provided with a first fuel gas channel, and the first fuel gas channels convey fuel gas used for premixed combustion. A second fuel gas channel is further arranged at the on-duty cyclone, and the second fuel gas channel is used for conveying fuel gas for diffusive combustion. The installation angles of blades of the cyclones are different, and the flow fields of rotating airflow generated by the cyclones are relatively independent, so that the cyclones participate in independent partitioned combustion. According to the multi-stage partitioned combustion technology in the scheme, the four stages of different cyclones are combined with the diverter, multi-stage partitioned organization combustion is formed in a staged fuel supply mode, the requirements of all working conditions are met, the ignition and flameout performance and combustion stability of a combustion chamber are guaranteed, and the requirement for low emission of nitric oxide is met.

Owner:成都中科翼能科技有限公司

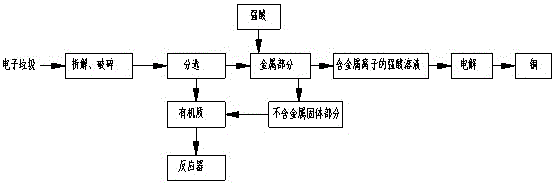

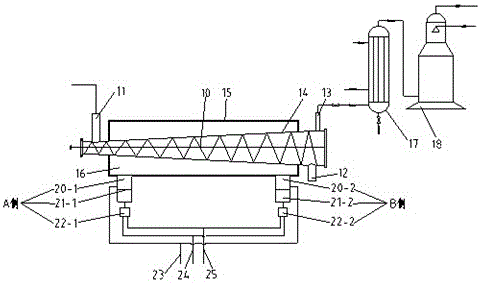

Conical screw heat accumulation type fuel-gas pyrolyzing system for electronic waste

PendingCN106497583AFully pyrolyzedRealize the function of propulsion while pyrolysisPhotography auxillary processesIndirect heating destructive distillationCooling towerProcess engineering

The invention relates to the technical field of the pyrolyzation of waste, and particularly relates to a conical screw heat accumulation type fuel-gas pyrolyzing system for electronic waste. The system comprises a raw material treating system, a metal recovering system and an electronic waste pyrolyzation reaction system, wherein the raw material treating system comprises a crushing device and a sorting device; the metal recovering system comprises an acid leaching tank and an electrolytic tank; the electronic waste pyrolyzation reaction system comprises an electronic waste pyrolyzation reactor, a heat accumulation type fuel-gas heating system and a cooling and separating system, wherein the electronic waste pyrolyzation reactor comprises a material pyrolyzing component and a reactor shell; the material pyrolyzing component comprises a conical screw shell and a conical boosting screw; the heat accumulation type fuel-gas heating system comprises a heat accumulation type combusting device and a fume passage; the cooling and separating system comprises an indirect heat exchanger and a cooling tower. The system has the advantages of being high in pyrolyzation efficiency, continuous in material feeding and discharging, saving energy, protecting environment and the like.

Owner:SHENWU TECH GRP CO LTD

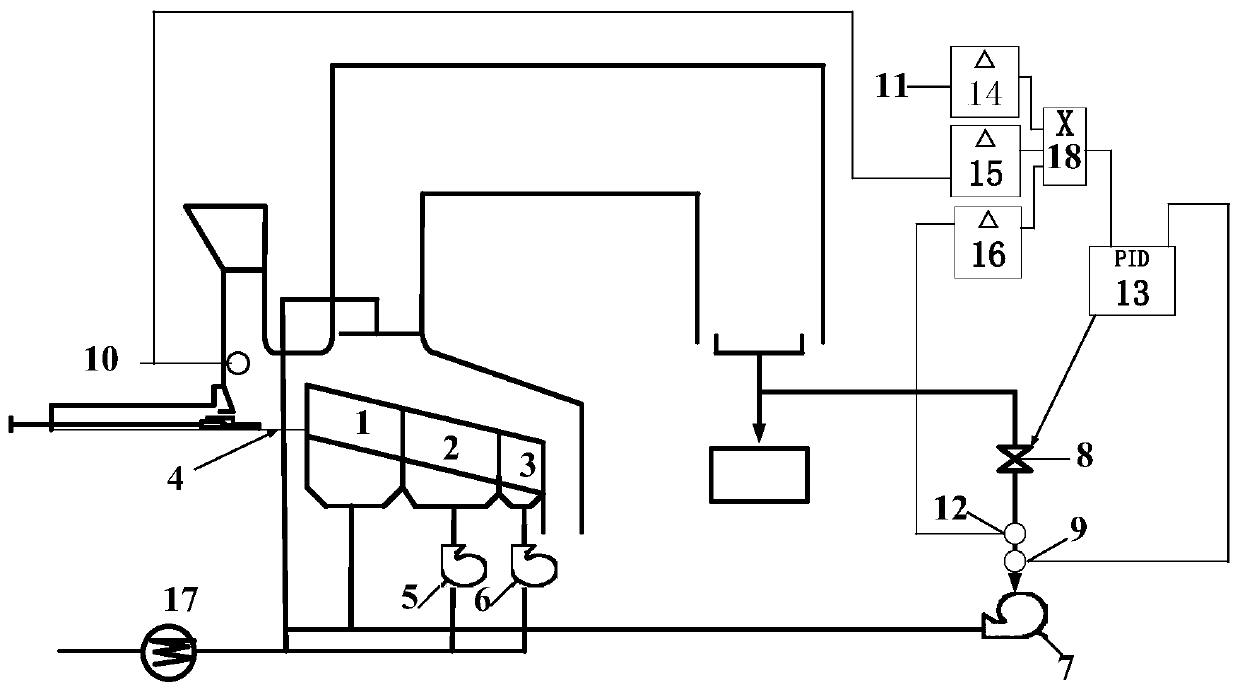

Primary drying air control system and method for mechanical-grate garbage incinerator

PendingCN111322623ALow oxygenEmission reductionDrying gas arrangementsIncinerator apparatusFlue gasControl system

The invention discloses a primary drying air control system and method for a mechanical-grate garbage incinerator. The system comprises a flue gas recirculation baffle, a flue gas recirculation fan, arecirculation flue gas flow sensor, a recirculation flue gas temperature sensor, a garbage moisture content sensor, a recirculation flue gas temperature sensor gain module, a garbage moisture sensorgain module, a binary multiplication operation module and a PID controller. The flue gas recirculation baffle and the flue gas recirculation fan are installed at the tail of a boiler, the recirculation flue gas flow sensor and the recirculation flue gas temperature sensor are installed between the flue gas recirculation baffle and the flue gas recirculation fan, the garbage moisture content sensoris installed at an outlet of a garbage hopper, the recirculation flue gas temperature sensor gain module is connected with the recirculation flue gas temperature sensor, the garbage moisture sensor gain module is connected with the garbage moisture content sensor, the binary multiplication operation module is connected with a boiler outlet steam set value gain module, the garbage moisture sensorgain module and the recirculation flue gas temperature sensor gain module, and the PID controller is connected with the binary multiplication operation module, the flue gas recirculation baffle and the recirculation flue gas flow sensor. According to the primary drying air control system and method for the mechanical-grate garbage incinerator, the economical efficiency and the adjusting performance of a primary air system are thoroughly improved, the incineration efficiency of the grate incinerator is improved, and pollutant emission is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

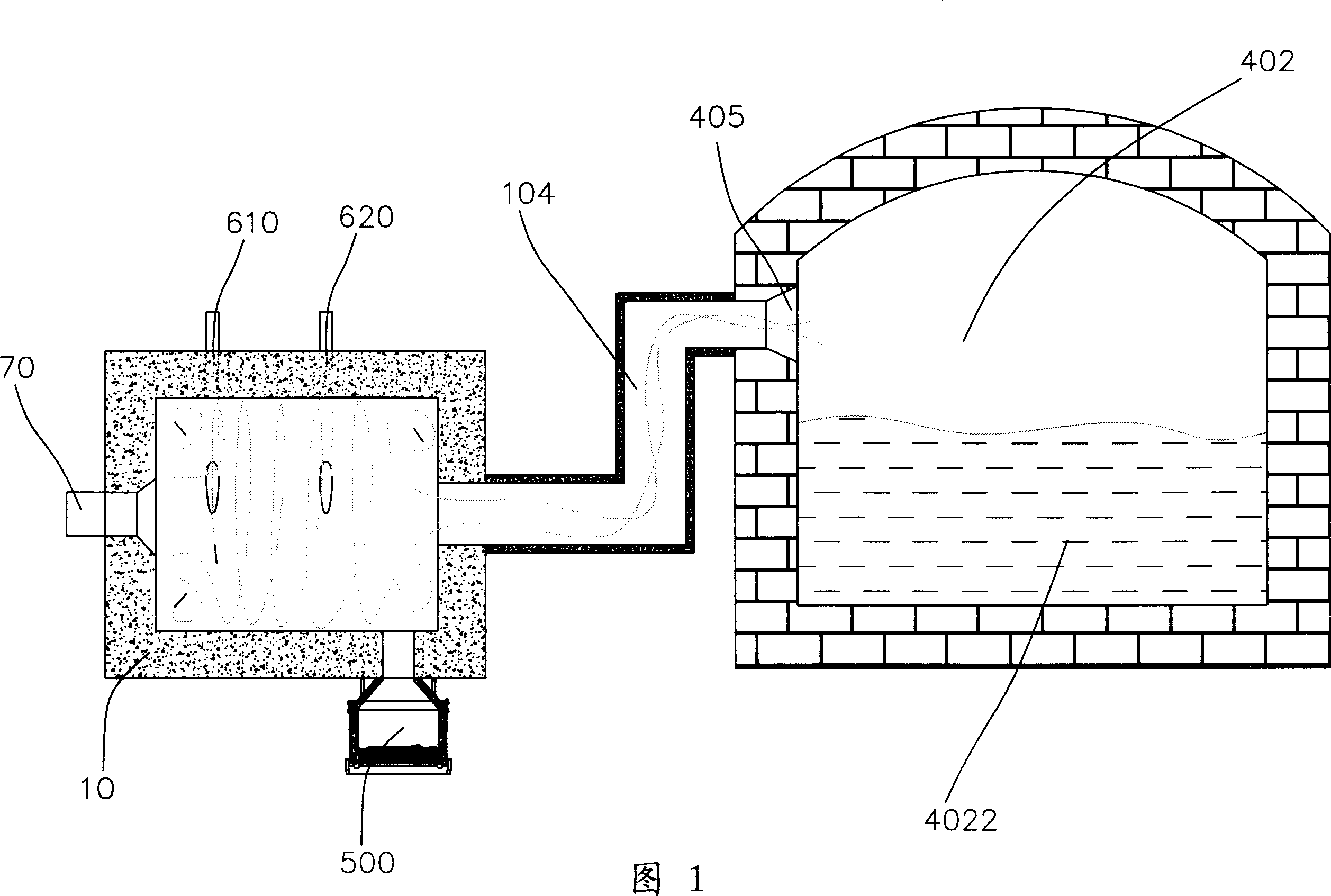

Glass kiln with emulsified coke slurry burner

InactiveCN101020596AEfficient and stable combustionMake up for the shortcomings of low calorific valueGlass furnace apparatusGlass productionBurn unitsBrick

The glass kiln with emulsified coke slurry burner includes one kiln body and one emulsified coke slurry burner. The kiln body includes one hearth, one flame inlet and one fume outlet. The emulsified coke slurry burner includes one casing forming one inside cylindrical burning space, at least one emulsified coke slurry burning unit, at least one oil / gas burner, one outlet communicated via hot blast pipe to the flame inlet of the hearth. The glass kiln includes also two or more switchable heat accumulating chambers connected via pipeline with the fume outlet of the kiln body. The present invention has double heat accumulation with lattice brick and ceramic ball reaching a heat accumulating temperature as high as 1200 deg.c to make up the low heat value emulsified coke slurry.

Owner:GUANGZHOU DEVOTION THERMAL TECH

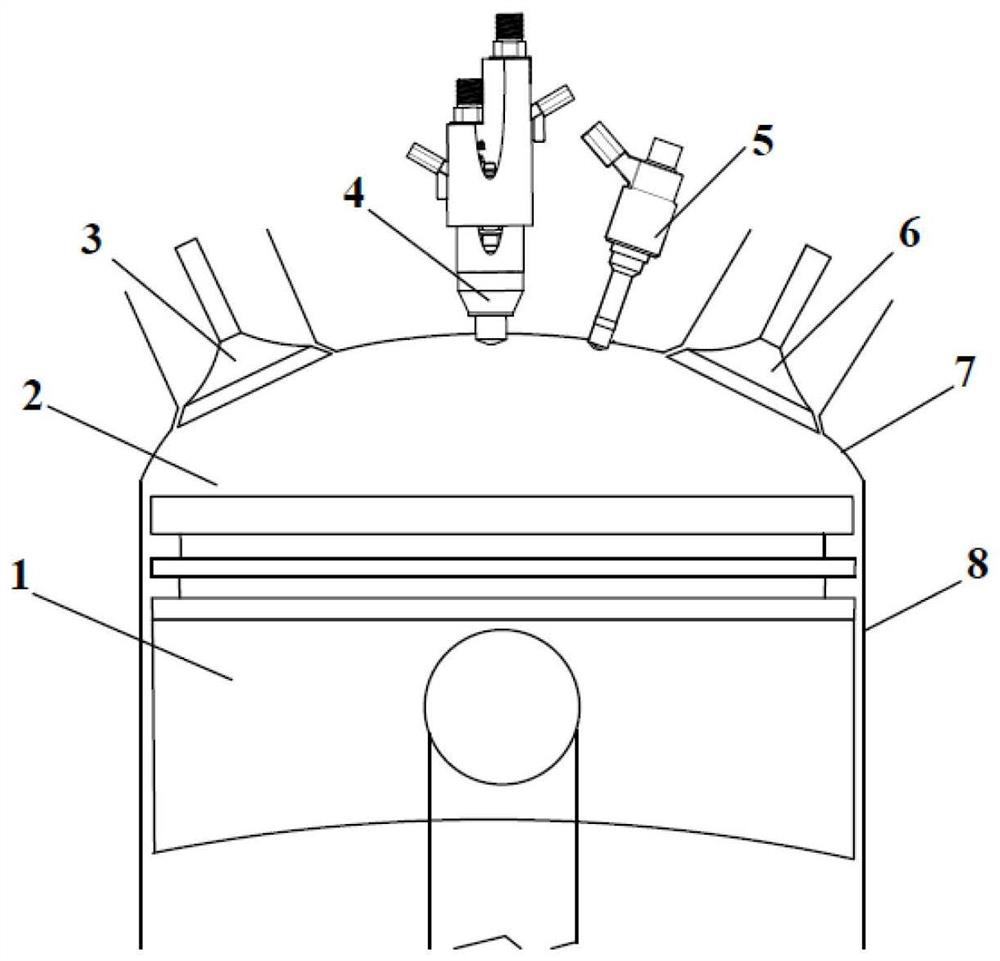

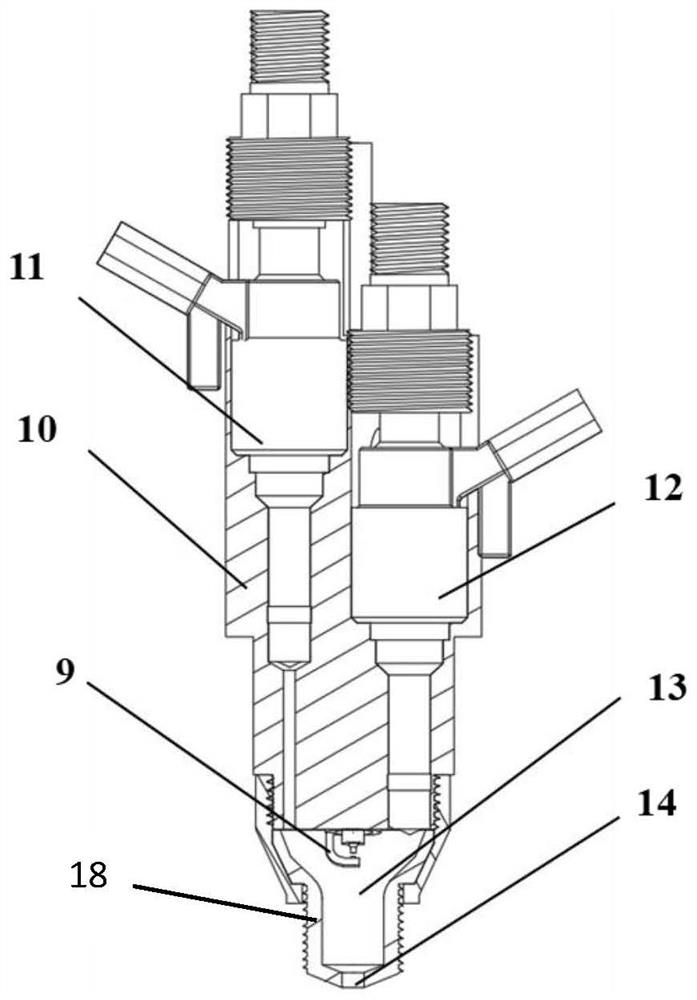

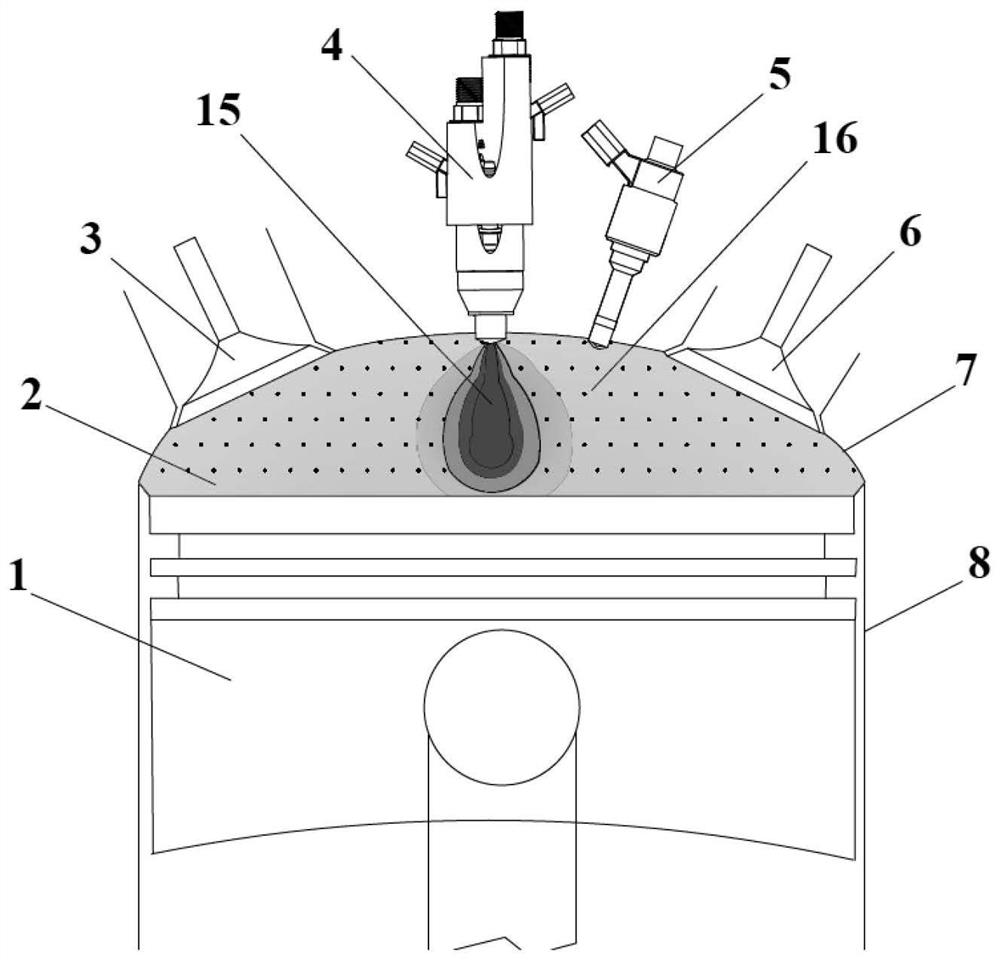

Multi-combustion-mode ammonia fuel engine and control method thereof

ActiveCN114320572AFlexible organizationGuaranteed stabilityElectrical controlInternal combustion piston enginesCombustion chamberInlet valve

The invention discloses a multi-combustion-mode ammonia fuel engine which comprises an engine cylinder cover, a cylinder sleeve, a piston, a main combustion chamber, an air inlet valve and an air outlet valve and further comprises a jet ignition device arranged on the cylinder cover and used for providing an ignition source for the main combustion chamber and an ammonia injector used for providing mixed gas for the main combustion chamber. The jet ignition device comprises an air ejector, a fuel ejector, a spark plug and a pre-combustion chamber for generating jet flames, and a nozzle of the spark plug, a nozzle of the air ejector and a nozzle of the fuel ejector are arranged on the same side of the pre-combustion chamber; and an axial included angle between the jet ignition device and a nozzle of the ammonia gas ejector is 40-60 degrees. The invention further discloses a control method of the multi-combustion-mode ammonia fuel engine. The timing sequence of ammonia injection of the main combustion chamber and jet generation of the pre-combustion chamber is controlled, the fuel / air mixing state before ignition of the main combustion chamber is adjusted, and finally a premixed combustion mode or a diffusion combustion mode is formed in the main combustion chamber.

Owner:TIANJIN UNIV

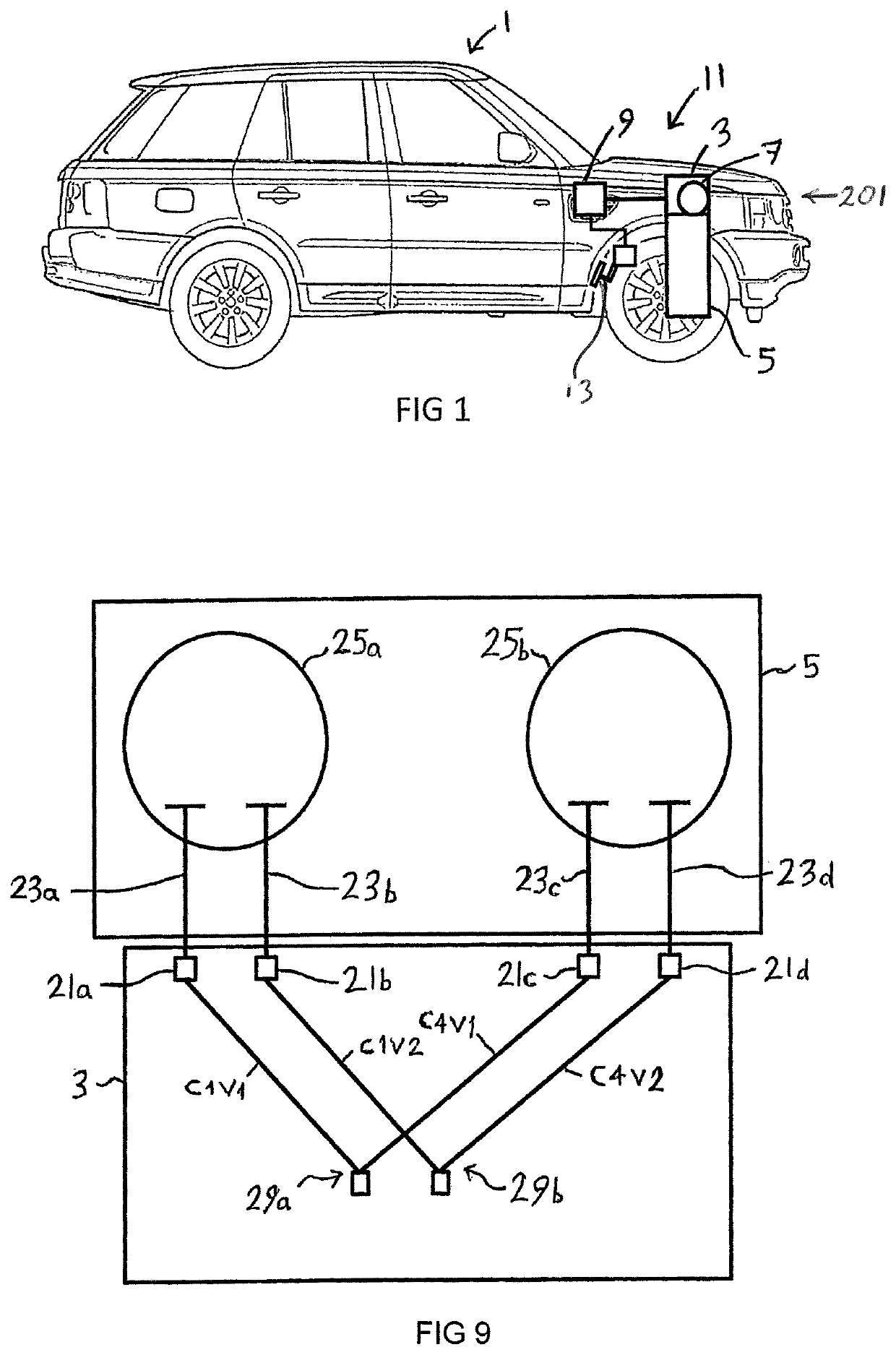

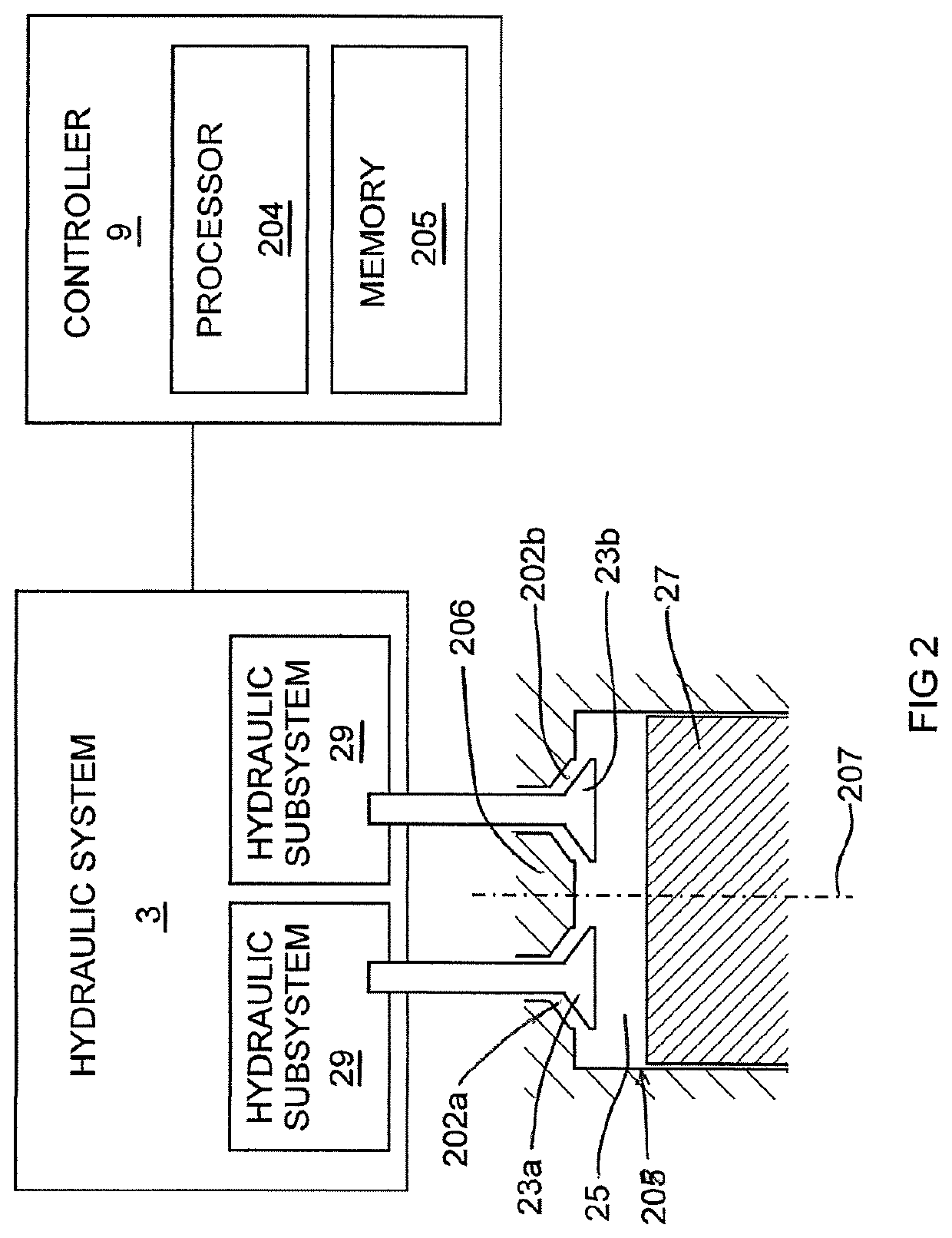

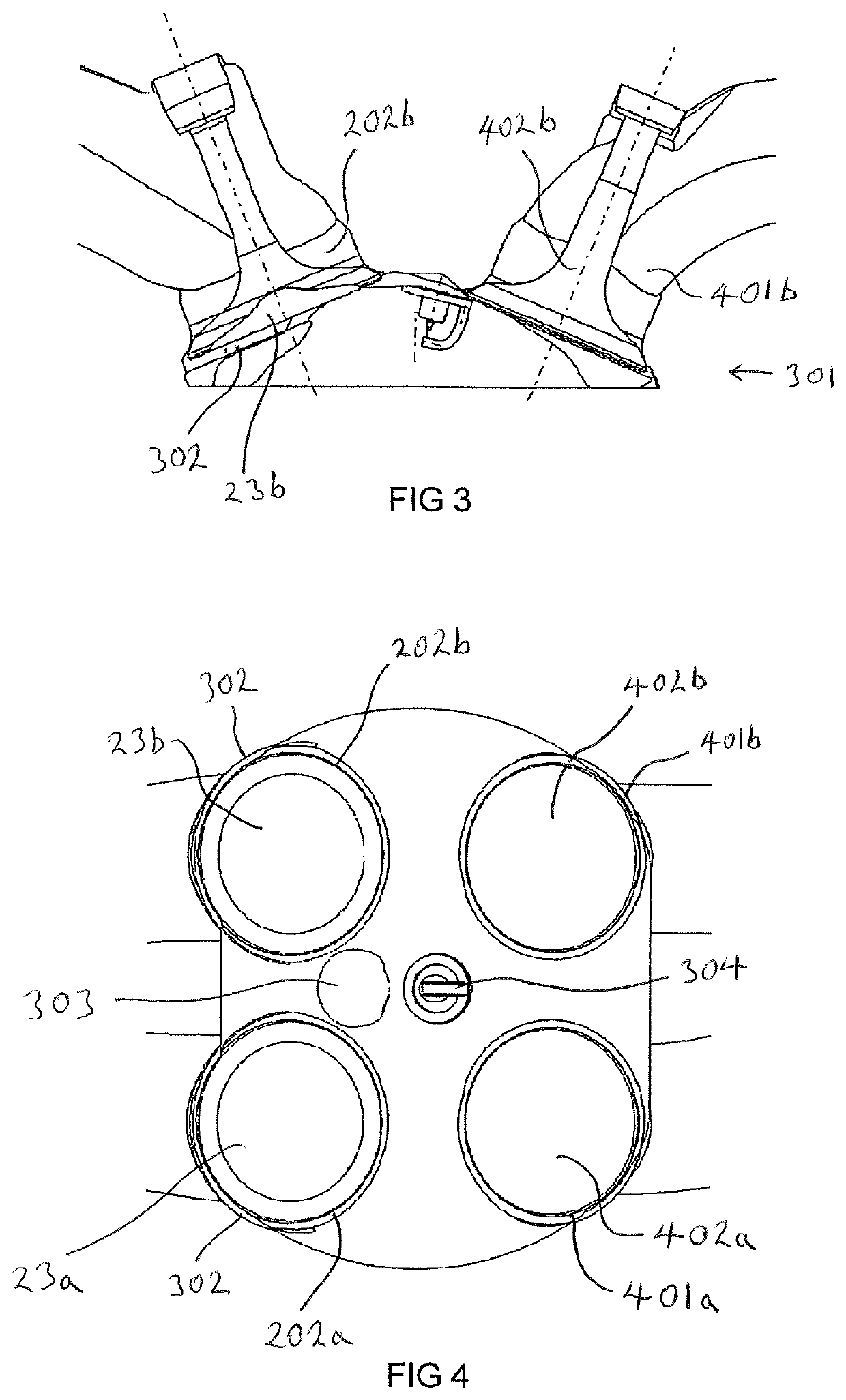

Controlling intake valves in an internal combustion engine

ActiveUS10907551B2Efficient and stable combustionNone provides advantagesInternal combustion piston enginesValve drivesCombustion chamberInlet valve

Owner:JAGUAR LAND ROVER LTD

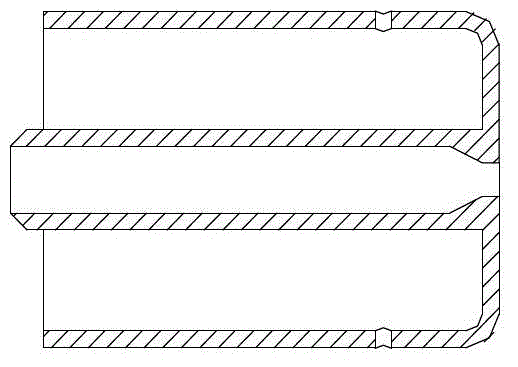

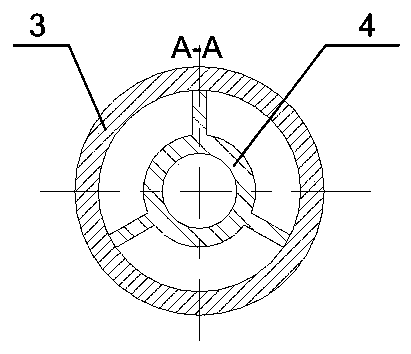

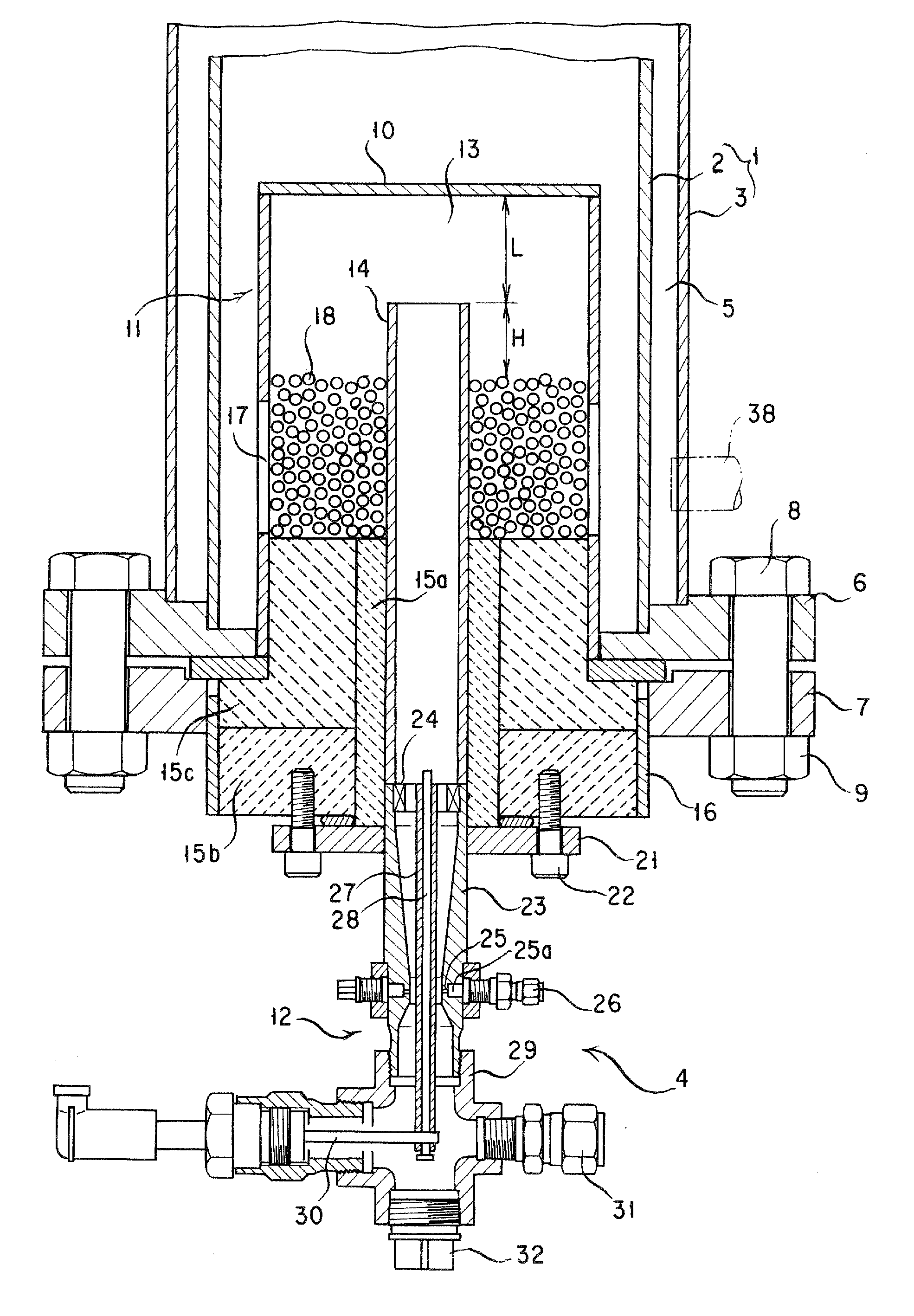

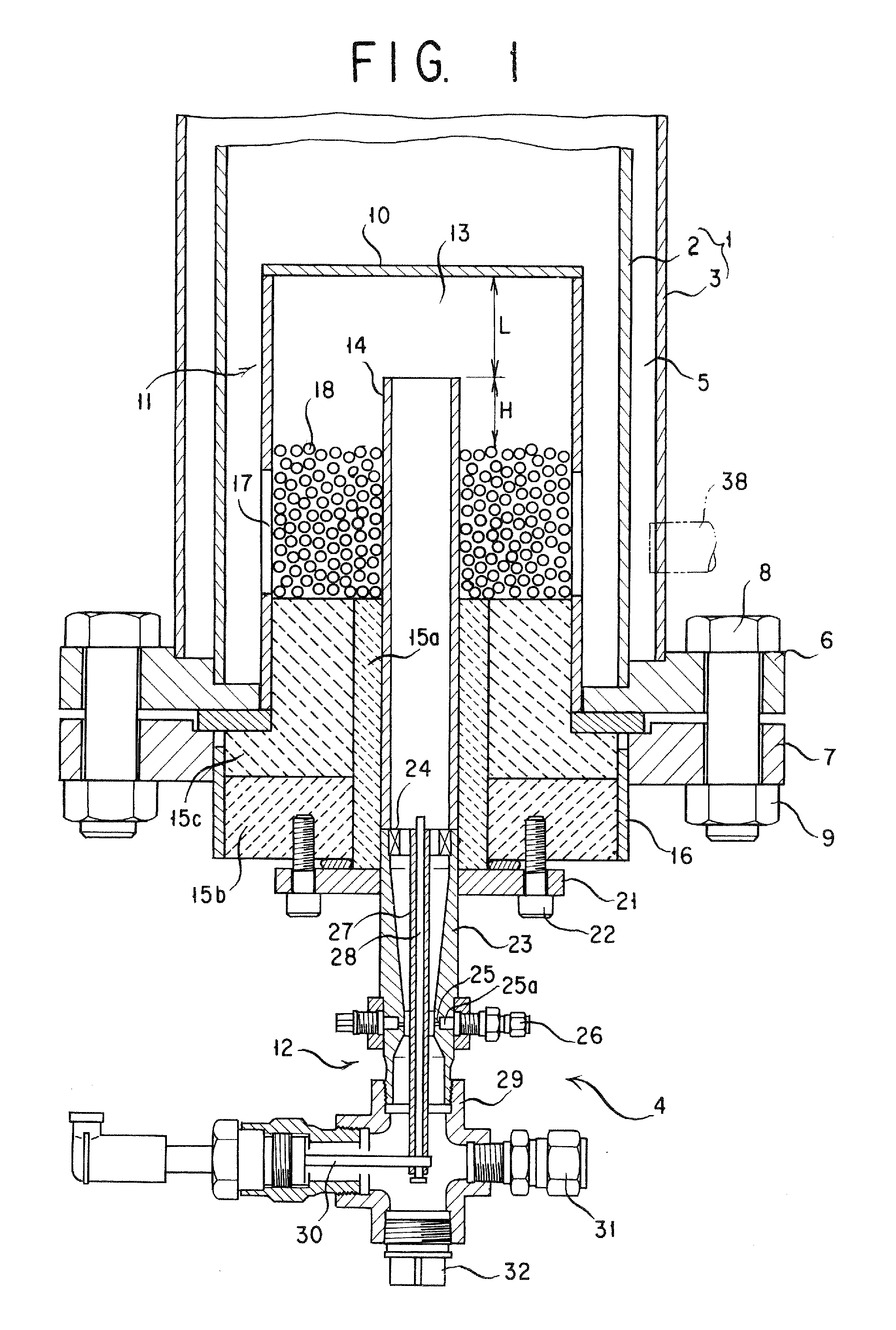

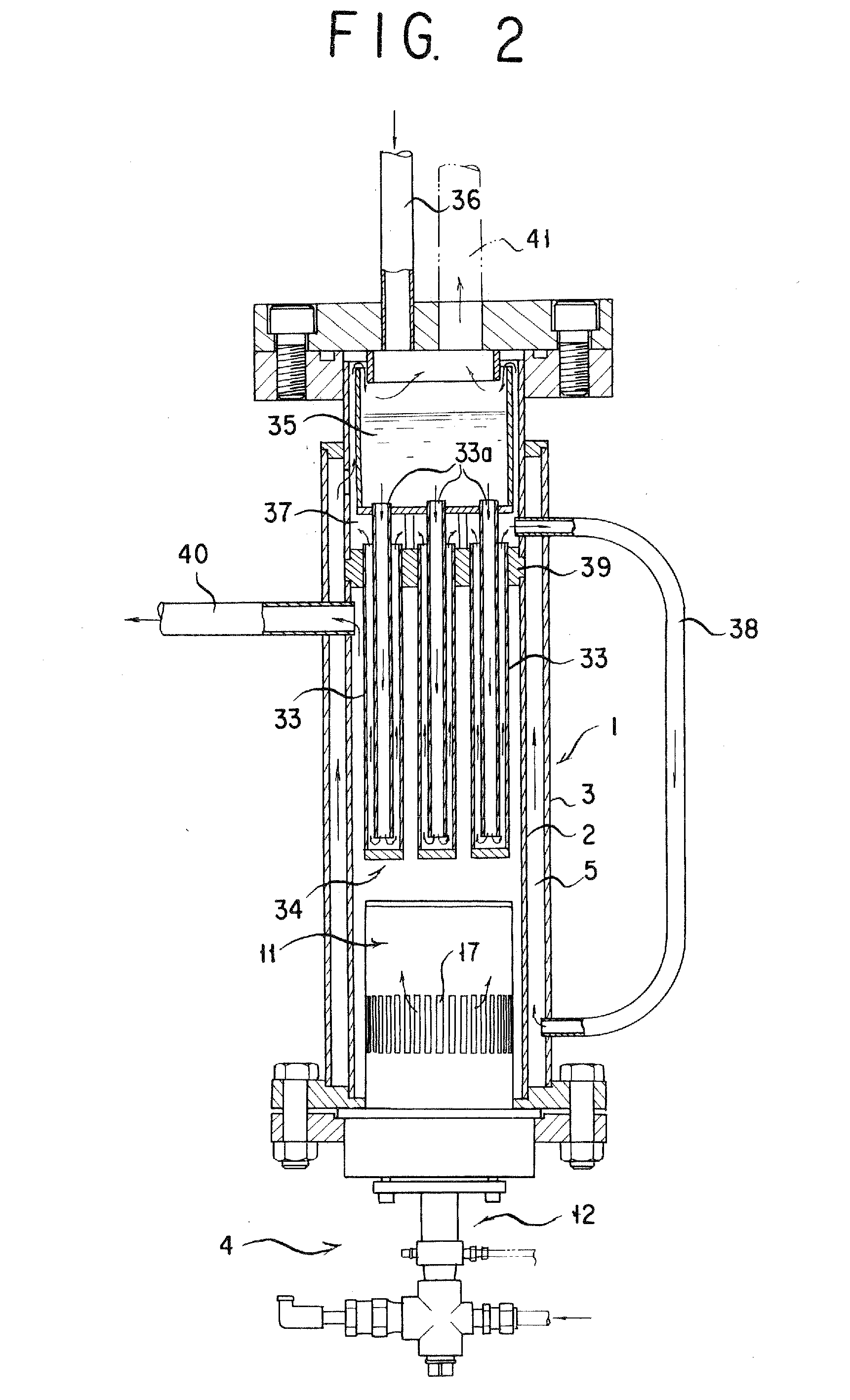

Combustor

InactiveUS20090239181A1Burn completelyObtain a combustion gas stablyCombustion using catalytic materialFirebridgesCombustion chamberCombustor

A combustor is proposed which is compact and eliminates generation of NOx and unburned combustible and is capable of stable combustion.A combustor is accordingly provided which comprises a combustion section 11, a fuel supply section 12 coupled to the combustion section for supplying a fuel air mixture wherein the fuel supply section comprises a mixer of venturi tube type having a fuel supply port 25 on an inner peripheral surface of a throat part, a combustion air supply port 31 connected to a base end of the mixer of venturi tube type and an igniter made capable of generating a spark at an extremity of the mixer of venturi tube type and the combustion section comprises a frame 16 coupled to the boiler main body and a ceramic combustion tube 14 supported by the frame 16 via heat insulators 15a, 15b and 15c and having one end lying in communication with the extremity of the mixer of venturi tube type in the fuel supply section and the other end projecting into the boiler main body and wherein the ceramic combustion tube is made of a ceramic functioning as an oxidation catalyst.

Owner:NIPPON CHEM PLANT CONSULTANT

Gas fuel low-nitrogen combustor

PendingCN110056864AEfficient and stable combustionInhibit and reduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

The invention discloses a gas fuel low-nitrogen combustor, in particular to a combustor suitable for gas fuels with low heat values. The gas flow low-nitrogen combustor comprises a pre-heating tube, agas gun, an air flue, and a spray nozzle assembly, wherein the pre-heating tube is a cylinder, is arranged on the middle part of a combustor main body, and is coaxial with the center line of the combustor; the gas gun surrounds the outer side of the pre-heating tube, and comprises a fuel gas tube, and a fuel gas spray nozzle assembly; the air flue comprises a primary air flue and a secondary airflue; the primary air flue is arranged on the outer side surface of the gas gun in a sleeving mode; a swirler is arranged in the primary air flue; the tail end of the swirler is connected to a flaringtype flame holder; the flaring type flame holder is connected to a combustion chamber, and is embedded into a combustion chamber furnace wall; and a plurality of secondary air inlets are formed around the flaring type flame holder. The gas fuel low-nitrogen combustor can promote mixing of fuels and air, strengthens combustion of the fuels, combines technologies such as air grading and flue gas circulating, and reduces generation and emission of nitric oxides.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

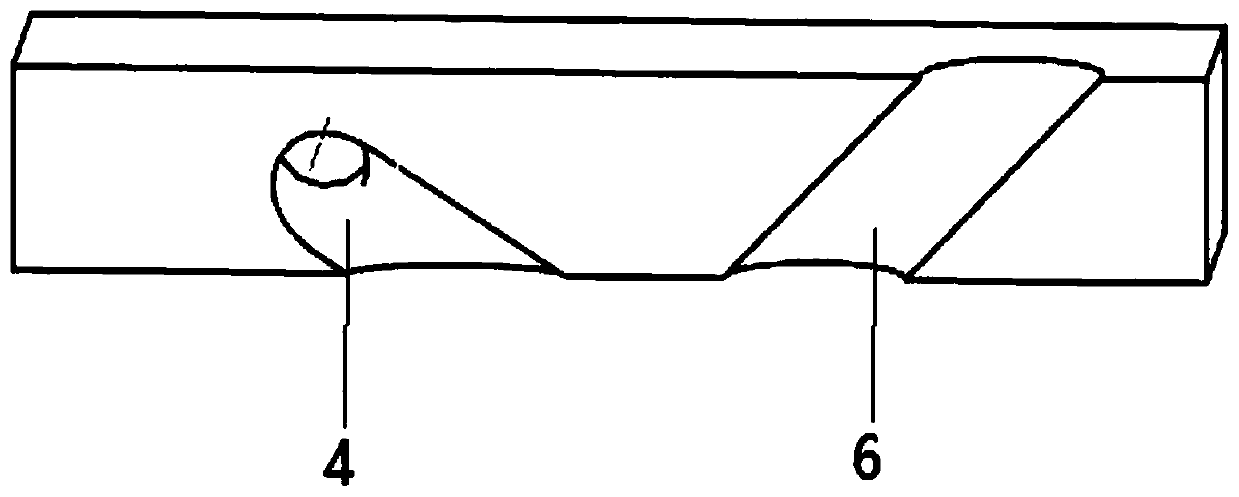

Integrated burner with back step precombustion stage and V-groove main combustion stage

InactiveCN101749142AEfficient and stable combustionIncrease the areaRam jet enginesCombustion systemLow speed

An integrated burner with a back step precombustion stage and a V-groove main combustion stage consists of a precombustion stage and a main combustion stage, wherein the precombustion stage adopts a low-speed recirculation region produced by a back step flame holder to stabilize the flame, stable flame jet is produced at a high position of a combustion channel, and the high-temperature flame jet is propagated to a low position by using the rotating centrifugal force of a rotary engine, thereby igniting fuels of the main combustion stage arranged at the low position and providing stable ignition source for the main combustion stage; and the main combustion stage adopts a multipoint direct-injection type oil injection method, and a V-groove is added in front of the igniting to stabilize the main combustion stage so as to lead the main combustion stage to have excellent flame stability and crossed flame reliability. The integrated burner can provide stable high-position combustion source and excellent low-position combustion efficiency for a combustion system of the rotary engine, and ensures the whole combustion system to have wide and stable working range and high-efficient combustion. The integrated design ensures simple and compact structure as well as saving the weight, and provides convenience for the future application.

Owner:BEIHANG UNIV

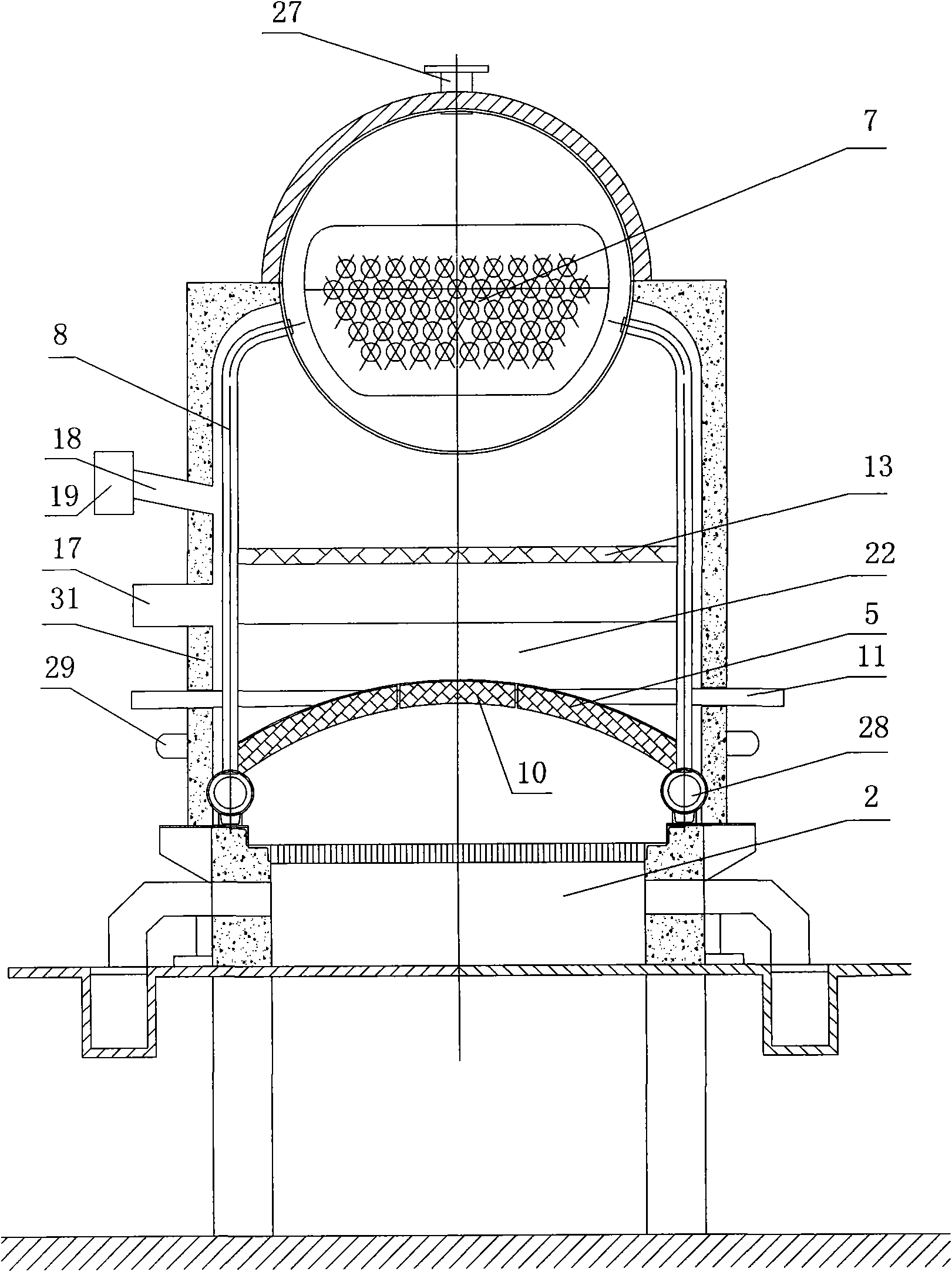

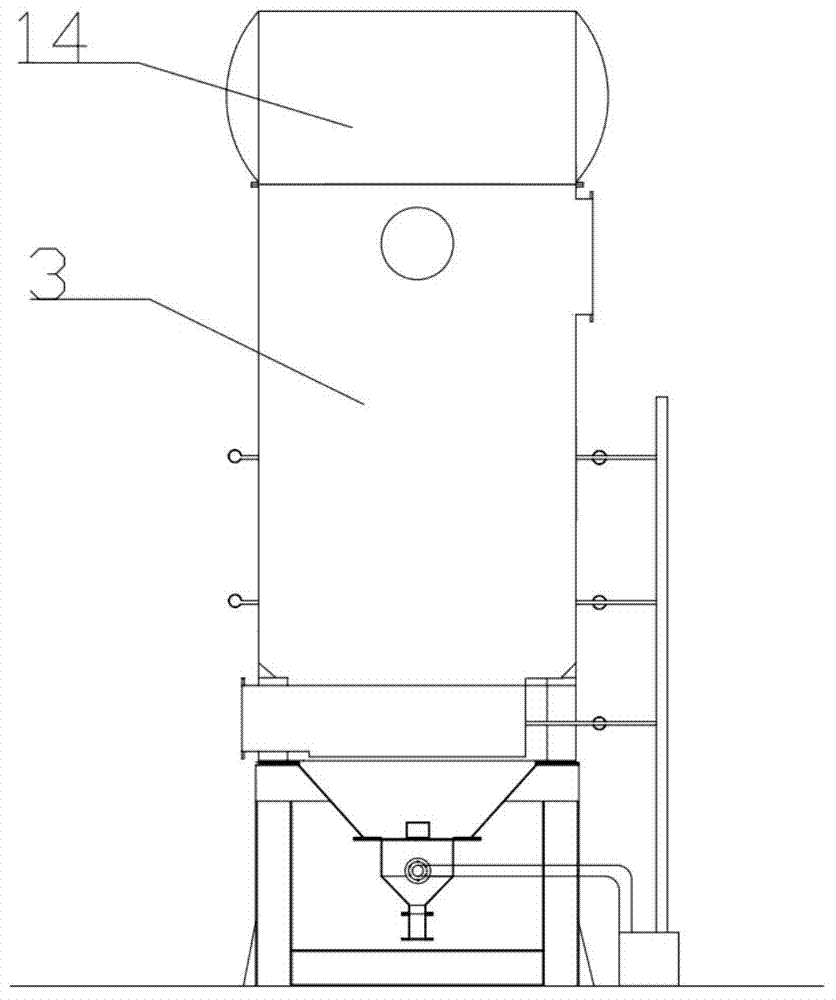

Industrial boiler using emulsifying coke mortar burning device

InactiveCN101021326AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses an industrial boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. The boiler self-body includes furnace cavity, boiler barrel set over the furnace cavity, water pipe which is set in the upper portion of said furnace cavity and is adjacent to the side wall of furnace cavity and fire pipe which is set in the central zone of boiler barrel and is soaked in the water of boiler barrel interior. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, in said shell body interior a cylindrical combustion space is formed, on the front end wall are set at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor and on the rear end wall an outlet is cut, said outlet is communicated with the furnace cavity. Said invention also provides the working principle of said industrial boiler and its concrete operation method.

Owner:广州迪森热能设备有限公司

Single concave cavity trapped vortex combustor

InactiveCN103277811BEfficient Emissions CombustionHigh Efficiency and Low Emissions CombustionContinuous combustion chamberCombustion chamberCombustor

A single-cavity trapped vortex combustor comprises a pressure expander, an inner cartridge receiver, an outer cartridge receiver, a flame tube, a flow guide device, a pre-evaporation device, an oil supply system and a high-energy spark plug, wherein airflow at an inlet of the combustor enters the combustor through the pressure expander, the flame tube is of a single-cavity structure, the inner cartridge receiver, the outer cartridge receiver and the flame tube form an inner duct and an outer duct of the combustor, the flow guide device separates the main flow from the air of the outer duct, air is decelerated and pressurized through the pressure expander, is divided into four paths through the flow guide device and the pre-evaporation device, and respectively enters the main flow, the pre-evaporation device, the inner duct and the outer duct, and the high-energy spark plug is arranged at the bottom of the cavity. The combustion area of the single-cavity trapped vortex combustor is divided into a trapped vortex area and a main combustion area, and the single-cavity trapped vortex combustor further comprises a flame joint supporting plate which transmits flames from a cavity to the main flow.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

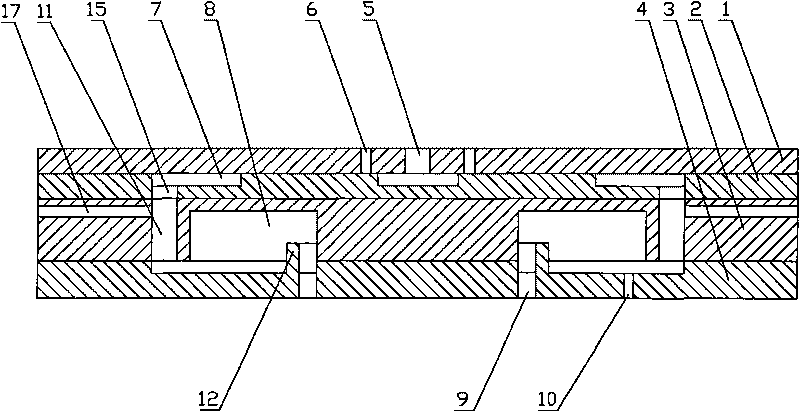

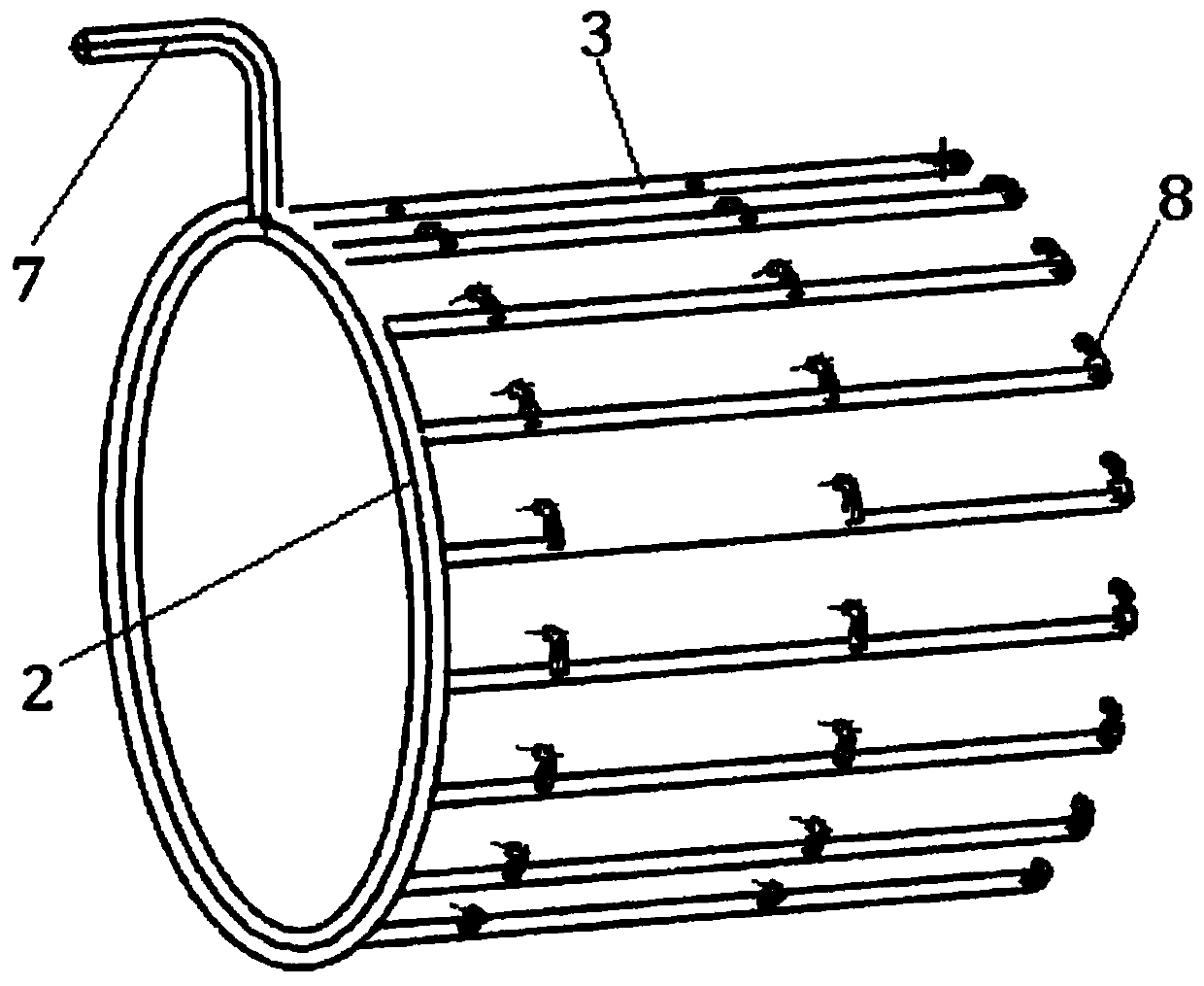

Cylindrical porous jetting-type miniature liquid combustor and combustion method thereof

The invention relates to a miniature liquid fuel combusting device, and discloses a cylindrical porous jetting-type miniature liquid combustor. The cylindrical porous jetting-type miniature liquid combustor comprises a combustion chamber, an upper sealing plate, a lower sealing plate and an air inlet pipeline, the upper sealing plate and the lower sealing plate are used for sealing the combustionchamber, the combustion chamber is provided with a first air inlet and a second air exhaust, and one end of the air inlet pipeline penetrates through the first air inlet and extends into the combustion chamber; the combustion chamber is internally provided with a feeding pipeline and a cumbustor body, one end of the feeding pipeline is located inside the combustor body, the bottom of the combustorbody is connected with the middle of the feeding pipeline, and the other end of the feeding pipeline penetrates through the lower sealing plate. The invention further provides a combustion method ofthe cylindrical porous jetting-type miniature liquid fuel combustor. The miniature liquid fuel combustor and the combustion method thereof have the advantages that the superficial area of liquid fuelis increased, so that the liquid fuel is sufficiently mixed with air, and meanwhile, evaporation of the liquid fuel is accelerated at the same time so that combustion can be stably and efficiently conducted.

Owner:SOUTH CHINA UNIV OF TECH

Temperature difference generator based on micro swirl combustion

PendingCN110677074AStable combustionEfficient and stable combustionGenerators/motorsGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a temperature difference generator based on micro swirl combustion, which comprises a heat conduction body, an air pipe, a temperature difference generation sheet, a cooling device and a controller, wherein the heat conduction body is provided with a combustion chamber, an exhaust chamber and a waste discharge chamber, one end of the exhaust chamber is communicated with thecombustion chamber and the other end is communicated with the waste discharge chamber; the air pipe is installed on the heat conduction body and comprises a first pipe and a second pipe, an inner pipe is arranged in the middle of the first pipe, a swirler is installed at the end of the inner pipe, the first pipe is further provided with a plurality of combustion-supporting air channels, the second pipe is provided with a waste discharge channel, one end of the waste discharge channel is communicated with the waste discharge cavity, and the other end is communicated with external air or an exhaust pipe; the temperature difference generation sheet abuts against the outer side wall of the heat conduction body. The swirler is arranged on the inner pipe of the temperature difference generator,so that the flow direction of combustion-supporting gas can be changed, rotational flow combustion-supporting gas is formed, and fuel can be combusted stably and efficiently.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

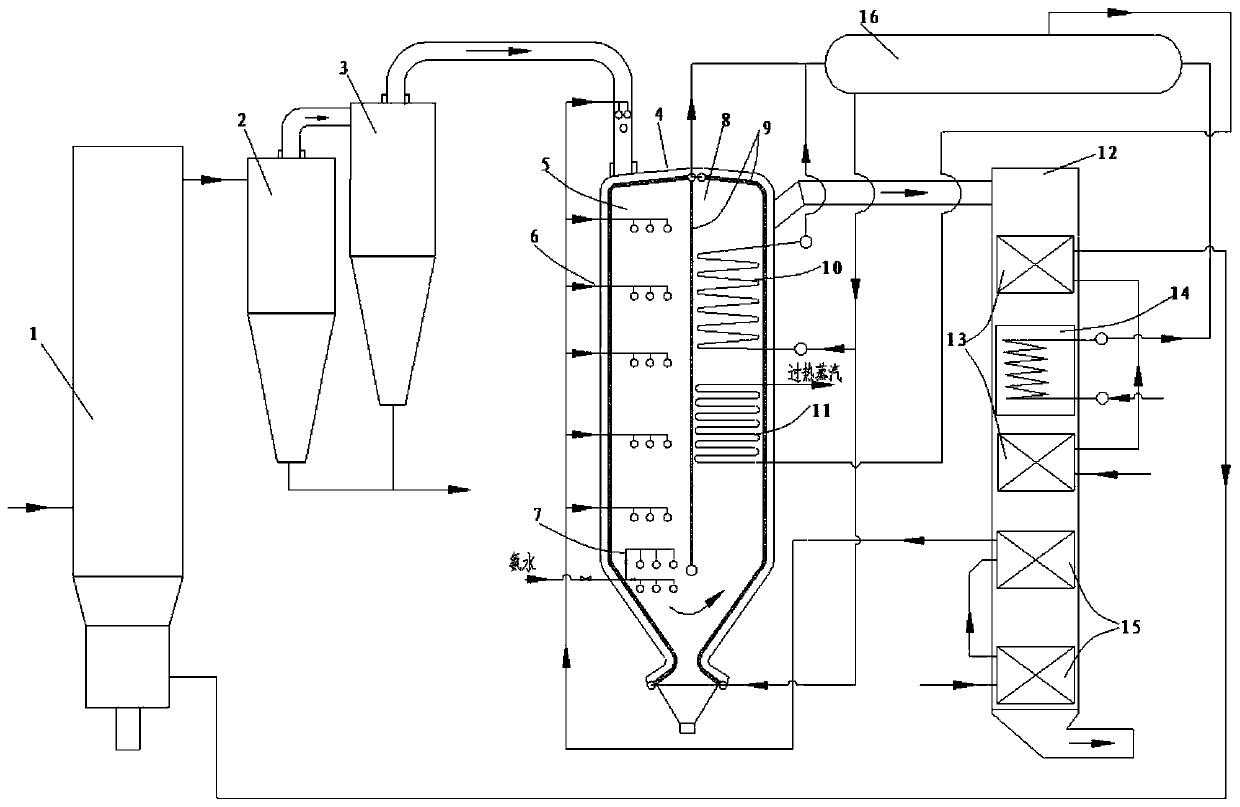

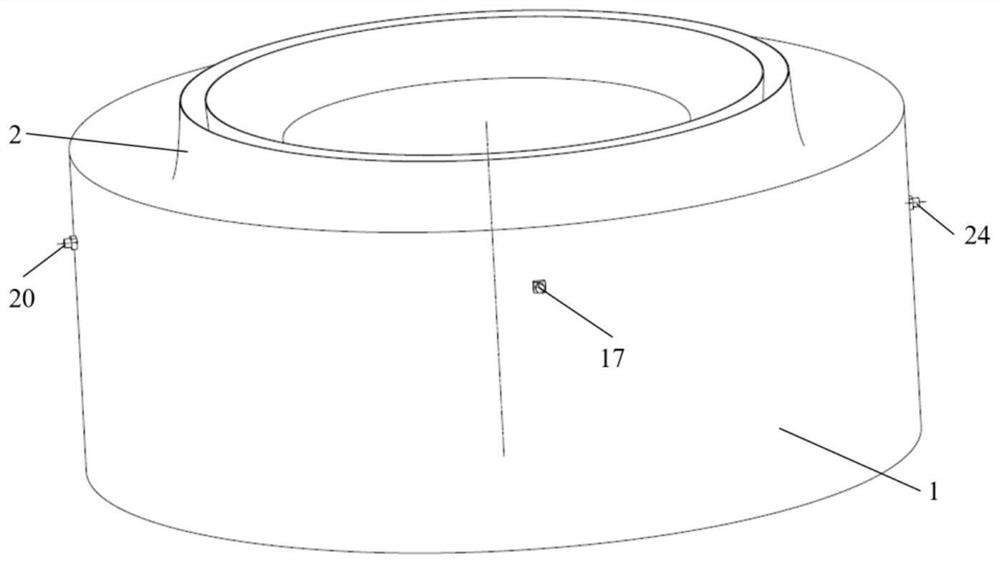

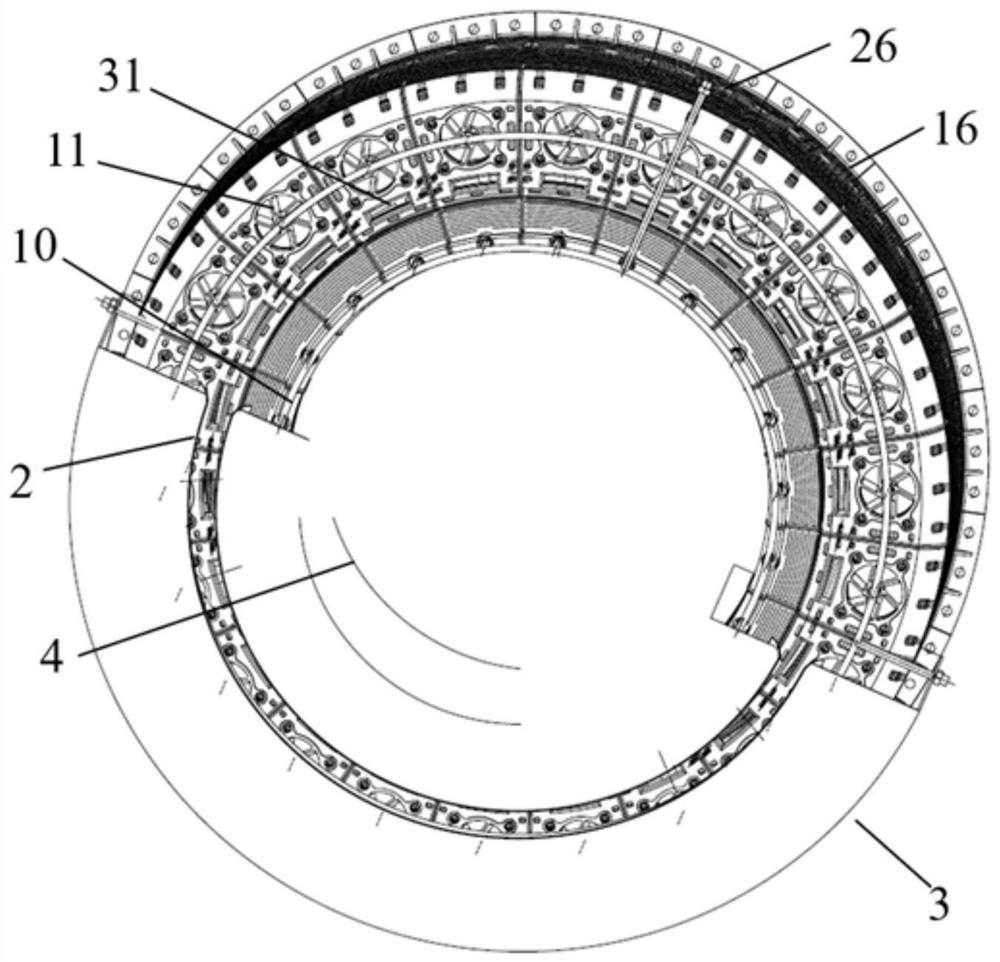

System and method for coal particle and steam co-production of biomass

PendingCN110160029AEfficient productionReduce burn shareCombustion processBiofuelsCombustion chamberSuperheater

The invention relates to a system and a method for coal particle and steam co-production of biomass. The system comprises a fluidized bed gasifier, a gas-solid separation mechanism and a fuel gas boiler which are connected in sequence; the inner wall of a fuel gas staged combustion burn-out boiler is a water-cooled wall, a partition water-cooled wall is arranged inside the fuel gas staged combustion burn-out boiler, and the partition water-cooled wall divides the fuel gas boiler into a combustion chamber and a waste heat recovery chamber with the bottoms in communication with each other; fuelstaged combustion air pipes are arranged in a combustion burn-out chamber and an inlet flue, a heating surface is arranged in the waste heat recovery chamber, and a tail flue used for discharging fluegas is connected to the side of the waste heat recovery chamber of the fuel gas boiler; the fuel gas boiler is connected to a steam pocket used for collecting superheated steam generated by the water-cooled wall, the partition water-cooled wall and a superheater; and the steam pocket is used for supplying saturated steam into the water-cooled wall, the partition water-cooled wall and the superheater for circulation. According to the system and method, the structure of the system is improved, so that coal particles and the superheated steam can be efficiently produced.

Owner:ZHEJIANG UNIV

A Swirling Vortex Combustion Chamber

ActiveCN113405119BEfficient combustionBroaden the dot-flame boundaryContinuous combustion chamberCombustion chamberStaged combustion

The invention discloses a swirling vortex zone combustion chamber, which comprises a diffuser, an inner casing, an outer casing, an oil supply module, a high-energy ignition nozzle and a flame tube. The diffuser passes all the required airflow through the combustion chamber, decelerating and boosting the incoming airflow. The inner and outer casings and the wall of the flame tube divide the combustion chamber into inner and outer ducts and the inner area of the flame tube. The flame tube is composed of the duty-level trapped vortex area and the main combustion level swirl area: the trapped vortex area is a single concave cavity structure formed by the geometry of the flame tube; the main combustion level is composed of a single-stage axial swirler and a channel-support plate structure constitute. The oil supply system is divided into three routes, duty-level fuel supply, main fuel-level channel fuel supply, and main fuel-level cyclone fuel supply. The high-energy ignition nozzle extends into the single-cavity structure. The invention realizes combustion with a high oil-gas ratio and widens the stable working range of the high-temperature-rising combustion chamber through the staged combustion zone setting.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pulverized coal fluidized self-preheating device and method

InactiveCN110307561ALarge heat storageGuaranteed uptimeLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationProcess engineeringOxygen

The invention provides a coal powder fluidized self-preheating device and method. The coal powder fluidized self-preheating device comprises a fluidized preheating chamber, a coal injection pipe and afluidized air pipe, wherein a large amount of bed materials capable of being fluidized are arranged in the fluidized preheating chamber; the coal injection pipe is arranged at the bottom of the fluidized preheating chamber and conveys pulverized coal to the fluidized preheating chamber; one end of the fluidized air pipe extends to the bottom of the fluidized preheating chamber to provide fluidized air for fluidizing the bed materials and the pulverized coal; and the separation of the bed materials and the preheated pulverized coal is completed in the fluidized preheating chamber by utilizingthe difference in particle terminal velocities caused by the difference in particle sizes between the bed materials and the pulverized coal in combination with different airflow velocity distributions. The invention further provides a method for preheating the pulverized coal by using the device. The large amount of hot bed materials are utilized to rapidly preheat the pulverized coal to a temperature above an ignition point, and partial heat of oxygen-poor combustion is utilized to maintain the temperature of the bed materials, so that the operation is stable, and a technology is simple.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Heat conductive oil furnace using emulsifying coke mortar vortex burning device

InactiveCN101021357AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHeat conductingLiquid slag

The invention discloses a heat-conducting oil stove used the emulsifying burnt plasma vortex burning device. It includes the oil stove body and the emulsifying burnt plasma vortex burner which includes the shell composed by the front wall, the back wall and the side wall. The burning room is formed in the shell. At least one emulsifying burnt plasma vortex burner and at least one oil burner or at least one gas burner is set in the front wall; an outlet is set in the back wall which is connected with the flame inlet of furnace chamber by the warm-air pipe. The two or above groups of tangential wind inlets are set on the shell side wall alternately; the outlet of the liquid slag is on the side wall of the burning room bottom which is near to the back wall. The invention uses the emulsifying burnt plasma as the fuel, so it can save the cost.

Owner:广州迪森热能设备有限公司

Oil-gas dual-purpose low-nitrogen combustor for boiler combustion

PendingCN109973999AEfficient and stable combustionInhibition of production and emissionsIndirect carbon-dioxide mitigationAir/fuel supply for combustionFuel lineNitrogen oxides

The invention provides an oil-gas dual-purpose low-nitrogen combustor for boiler combustion. The oil-gas dual-purpose low-nitrogen combustor comprises an oil gun, a preheating tube, a gas gun, an airduct and a nozzle assembly. The oil gun is arranged in the middle of a combustor main body and comprises an atomizing medium pipe, a fuel pipe and an oil mist nozzle assembly. The preheating tube is in a hollow annular cylindrical shape and is arranged on the outer side face of the fuel tube in a surrounding mode. The air gun is arranged on the outer side of the preheating tube in a surrounding mode and comprises a fuel gas pipe and a fuel gas nozzle assembly. The air duct comprises a primary air duct and a secondary air duct. The primary air duct sleeves the outer side face of the air gun. Aswirler is arranged in the primary air duct. The tail end of the swirler is connected with a flaring type flame stabilizer; the flaring flame stabilizer is connected with a combustion chamber and is arranged in a furnace wall of the combustion chamber in a nested mode; and a plurality of secondary air inlets are formed in the periphery of the flaring type flame stabilizer. According to the oil-gasdual-purpose low-nitrogen combustor, the mixing of the oil and gas dual fuel and air can be promoted, the combustion of fuel is enhanced, the technologies such as air wind level and flue gas circulation are combined, and the generation and emission of nitrogen oxides are reduced.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Gas injection boiler using the emulsifying coke mortar combustion device

InactiveCN101021313AEfficient and stable combustionReasonable useCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses a steam-injecting boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. Said boiler self-body includes furnace cavity, at least one steam pipe set in the furnace cavity interior and smoke outlet cut on one end wall far-separated from the emulsified coke slurry combustion equipment. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, a cylindrical combustion space is formed in the shell body, on the front end wall at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor are set, its rear end wall is equipped with an outlet, said outlet is communicated with furnace cavity.

Owner:广州迪森热能设备有限公司

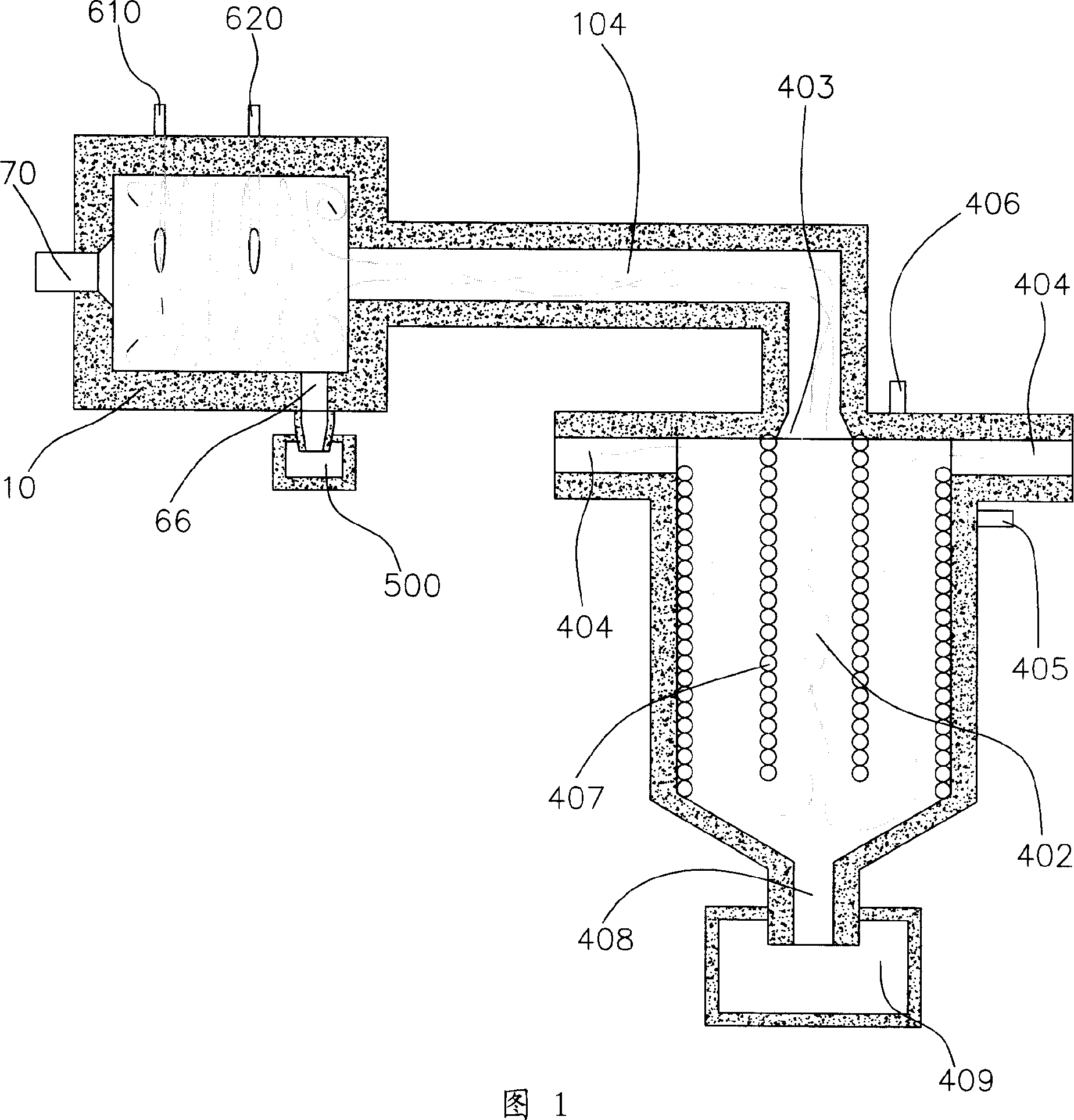

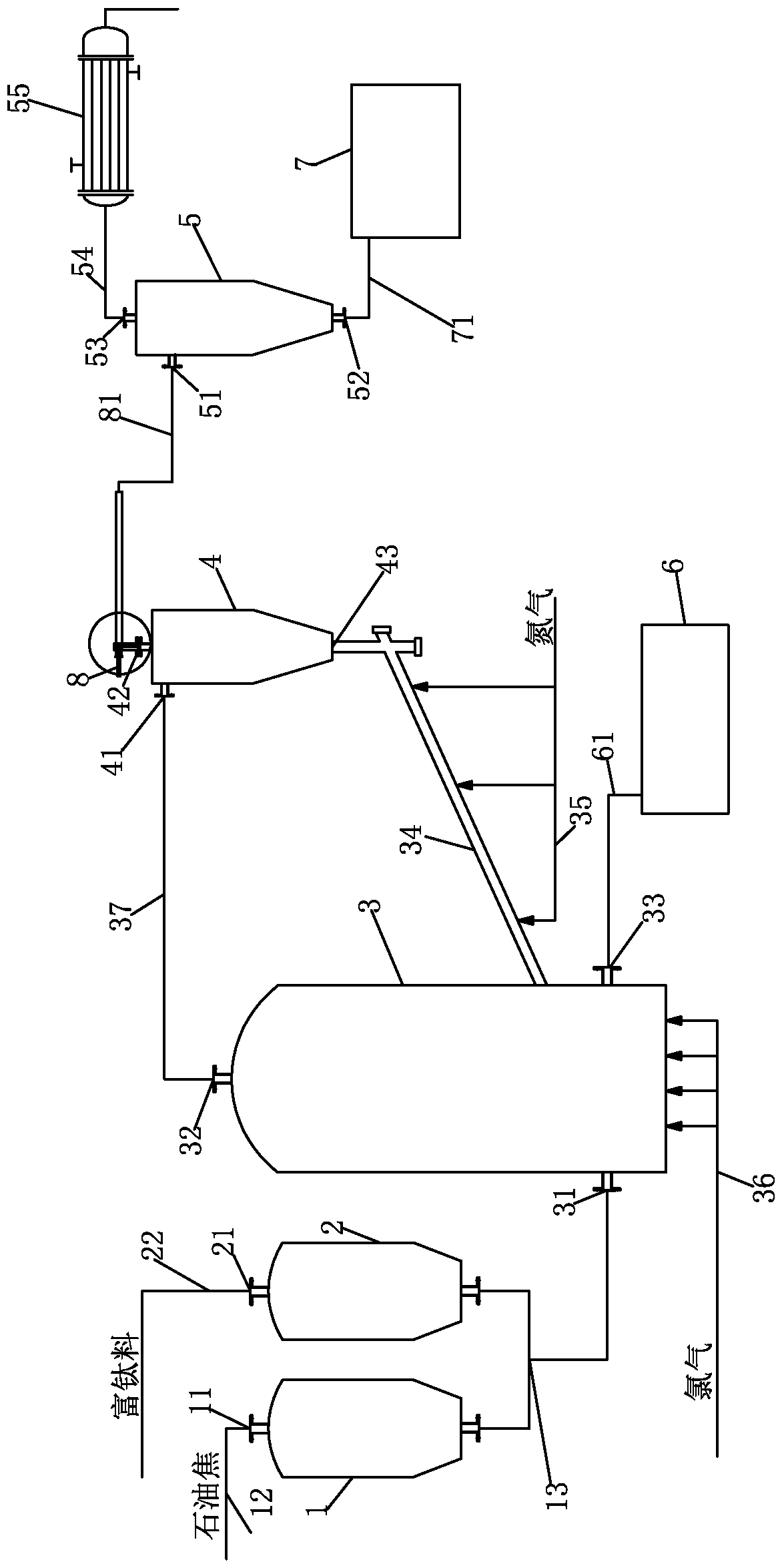

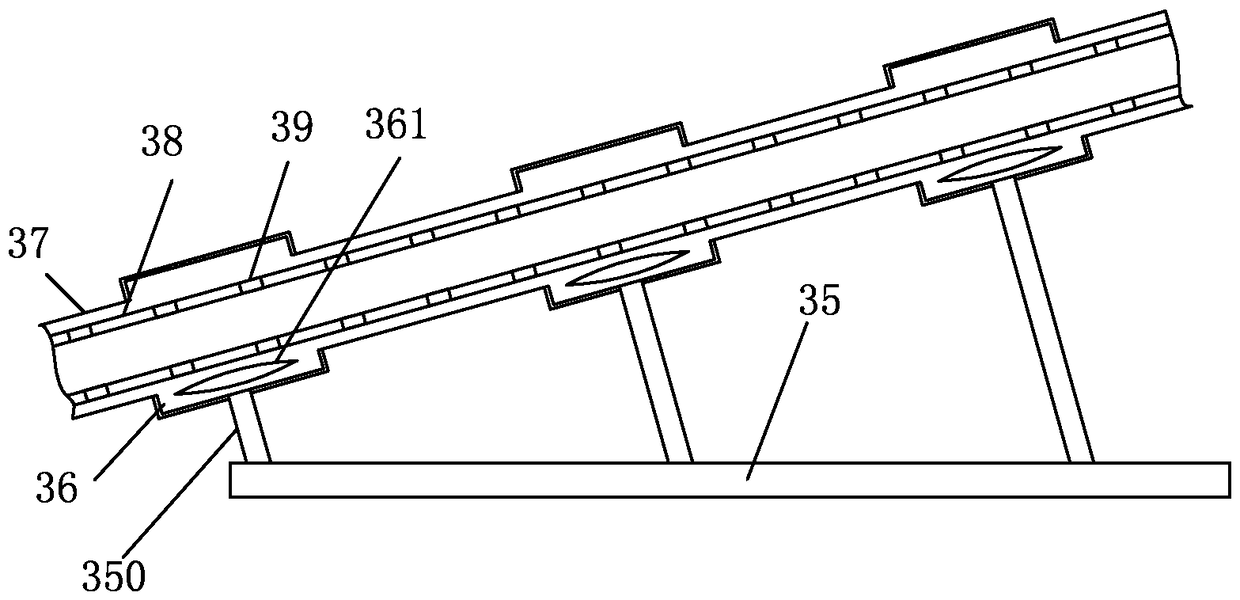

Novel chlorination furnace circulating fluidization system

PendingCN108101104AWon't clogGuaranteed to loop multiple timesTitanium tetrachlorideCycloneCombustion

The invention provides a novel chlorination furnace circulating fluidization system. A discharging opening of a petroleum coke raw material tank is connected with a discharging pipe in parallel and then is connected with a lower inlet of a chlorination furnace; a plurality of chlorine gas inlets and a dreg discharging opening are further formed in the bottom of the chlorination furnace; the plurality of chlorine gas inlets are connected with a chlorine gas pipe; the dreg discharging opening is connected with a dreg discharging pipe; an outlet is formed in the top of the chlorination furnace; the outlet is connected with a side part inlet of a high-temperature cyclone separator through a feeding pipe; a liquid discharging opening is further formed in the top of the high-temperature cycloneseparator; the liquid discharging pipe is connected with the top of a low-temperature cyclone separator through a liquid discharging pipe; a liquid outlet is further formed in the top of the low-temperature cyclone separator. The novel chlorination furnace circulating fluidization system provided by the invention has the characteristics of compact structure, convenience for installation, stabilityin operation, safety and environment protection and the like. The whole reaction system has a circulating fluidization function and the dreg discharging pipe is not blocked; the high-temperature cyclone separator and the low-temperature cyclone separator are matched to use, so that a plurality of times of circulation, repeated combustion and reaction of a titanium tetrachloride mixed solution areensured.

Owner:仙桃市中星电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com