Mild gas turbine combustion chamber

A technology of gas turbines and combustion chambers, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as large heat loads and complex flow fields, and achieve the effects of reducing thermal stress, uniform temperature distribution, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now in conjunction with accompanying drawing:

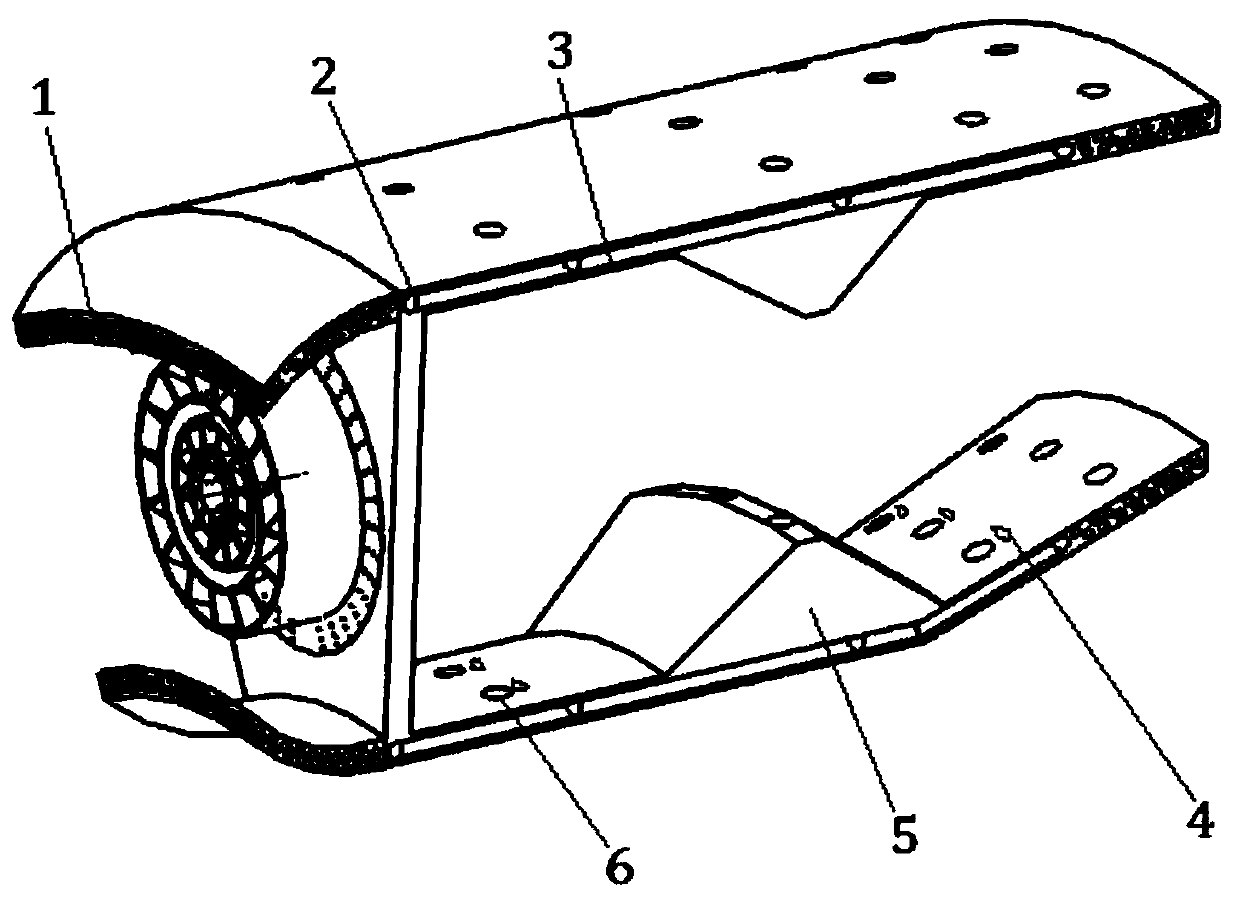

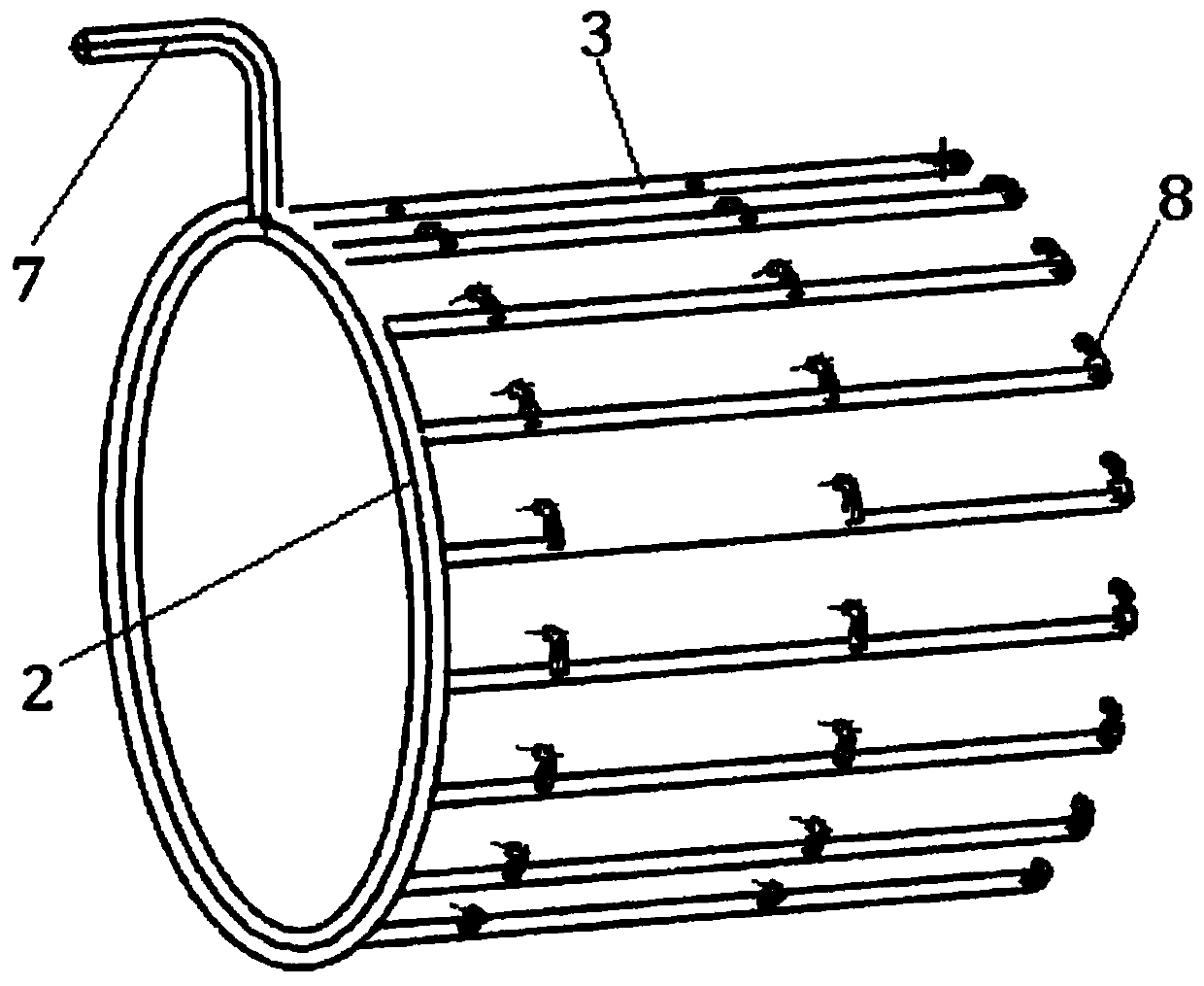

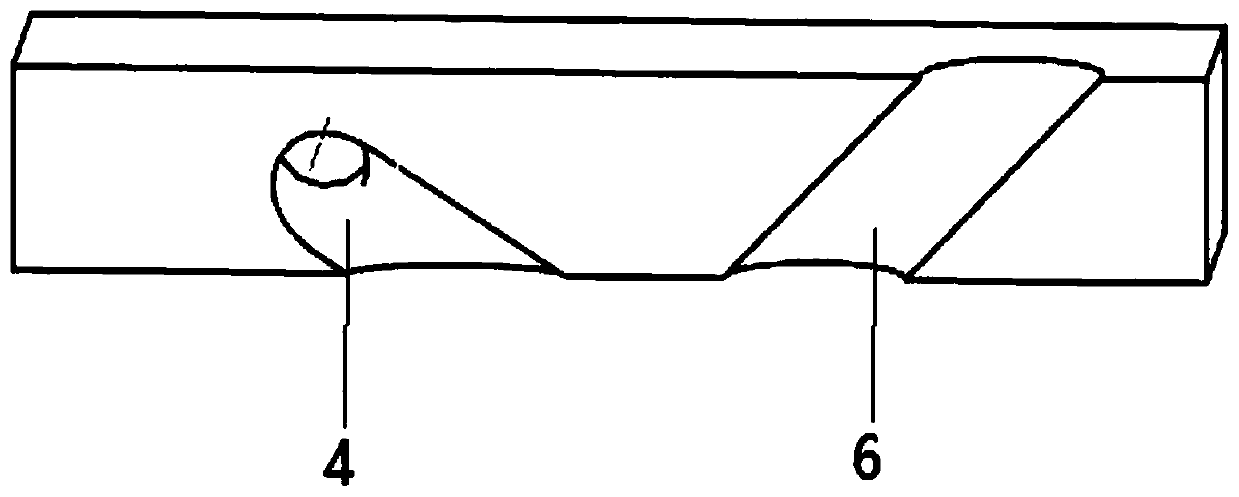

[0023] combine Figure 1-5 , The invention provides a technical proposal for a soft gas turbine combustor. figure 1 It is a schematic diagram of the overall structure of the soft combustion chamber, figure 2 A schematic diagram of the fuel pipeline structure, image 3 It is a schematic diagram of the matching relationship between the fuel injection hole and the air flow hole, Figure 4 A schematic diagram of the details of the injection hole, Figure 5 A schematic diagram of the honeycomb sandwich structure.

[0024] When the gas turbine is working, the fuel flows into the annular fuel main pipe 2 from the oil delivery pipe 7. After the fuel fills the entire annular cavity, it enters the fuel branch pipe 3 evenly under the action of pressure, which can ensure that the fuel in the fuel branch pipe is fully preheated in the wall of the flame tube. Three secondary branch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com