A high-strength titanium-based boron-tungsten composite shielding material and its preparation method

A composite shielding, titanium-based technology, applied in the field of high-strength titanium-based boron-tungsten composite shielding materials and its preparation, can solve the problems of single function, material strength, low service temperature, etc., achieve simple operation process, improve tensile strength performance, Avoid the effect of heating and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

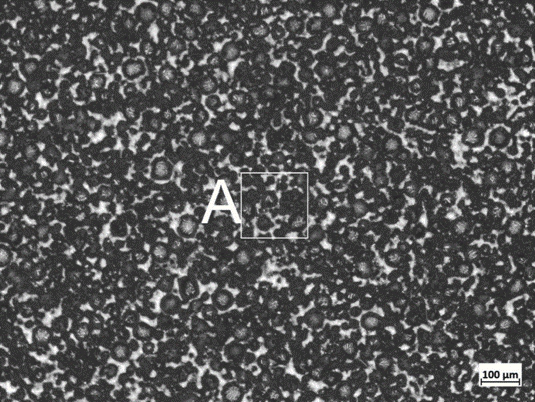

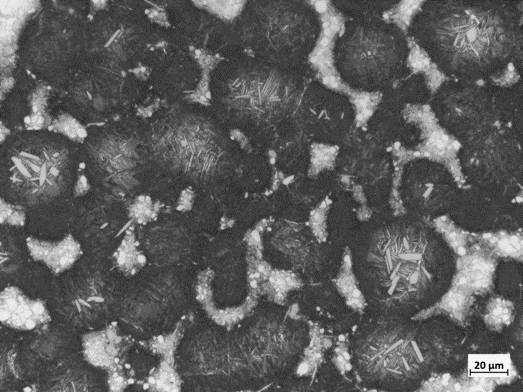

Image

Examples

Embodiment 1

[0032] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: boron 0.79%, tungsten 32.45%, and titanium 66.76%.

[0033] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0034] Step 1. Prepare boron powder with a mass purity of 99.93% and a particle size of 4 μm, tungsten powder with a mass purity of 99.95% and a particle size of 3 μm, and titanium powder with a mass purity of 99.94% and a particle size of 63 μm. Weigh the boron Powder 1.58g, tungsten powder 64.90g and titanium powder 133.52g, a total of 200g, mixed to obtain a mixed powder; wherein, the volume fraction of each raw material powder in the mixed powder is: boron powder 2%, tungsten powder 10%, titanium powder 88%.

[0035] Step 2, according to the mass ratio of bearing steel ball and mixed powder 5:1, w...

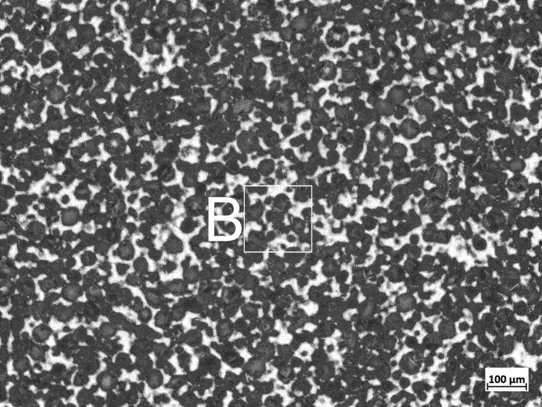

Embodiment 2

[0039] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: 0.84% boron carbide, 32.43% tungsten, and 66.73% titanium.

[0040] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0041] Step 1. Prepare boron carbide powder with a mass purity of 99.95% and a particle size of 5 μm, tungsten powder with a mass purity of 99.95% and a particle size of 4 μm, and titanium powder with a mass purity of 99.94% and a particle size of 35 μm. Weigh the above 1.68g of boron carbide powder, 64.86g of tungsten powder and 133.46g of titanium powder, 200g in total, mixed well to obtain a mixed powder; wherein, the volume fraction of each raw material powder in the mixed powder is: boron carbide powder 2%, tungsten powder 10% , 88% titanium powder.

[0042] Step 2, according to the m...

Embodiment 3

[0049] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: 0.40% boron, 0.42% boron carbide, 32.44% tungsten, and 66.74% titanium.

[0050] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0051] Step 1, prepare mass purity as 99.93%, boron powder with a particle size of 3 μm, mass purity of 99.95%, boron carbide powder with a particle size of 5 μm, mass purity of 99.95%, tungsten powder with a particle size of 5 μm, with a mass purity of 99.94%, titanium powder with a particle size of 70 μm, weigh 0.8g of the above-mentioned boron powder, 0.84g of boron carbide powder, 64.88g of tungsten powder and 133.48g of titanium powder, a total of 200g, and mix well to obtain a mixed powder; wherein, each of the mixed powder The volume fraction of raw material powder is: bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com