Temperature difference generator based on micro swirl combustion

A technology of thermoelectric power generation sheet and generator, which is applied in the direction of generator/motor, burner, combustion method, etc. It can solve the problems of unstable combustion of biomass fuel, poor use experience and poor power generation effect, and achieve stable and efficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with each accompanying drawing, the present invention is described in detail.

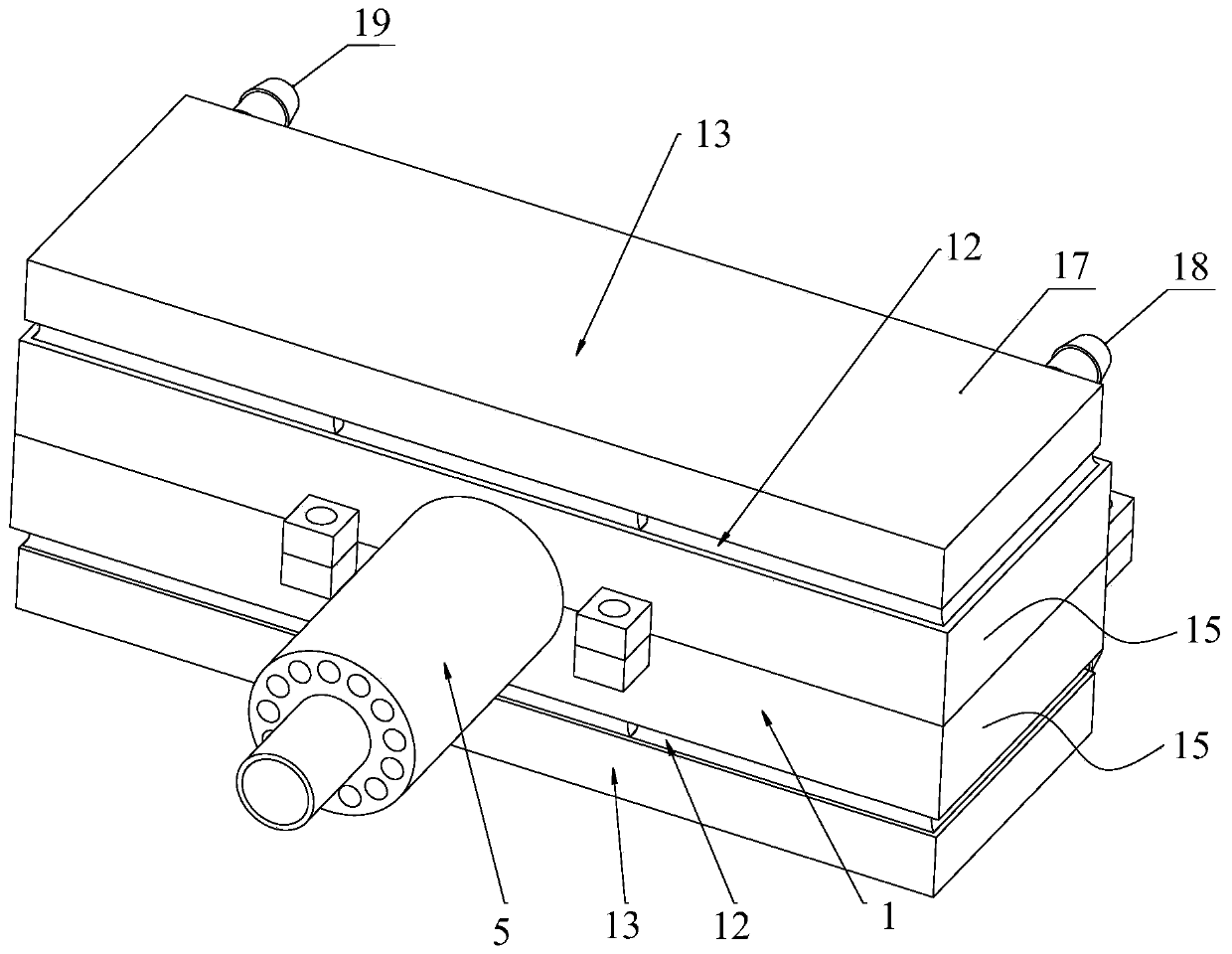

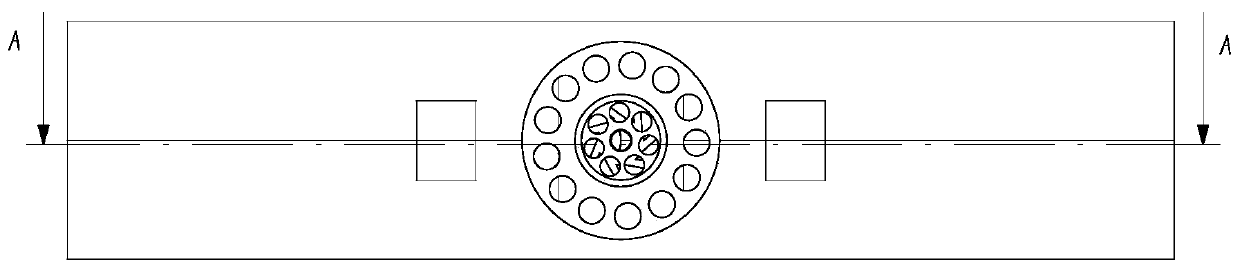

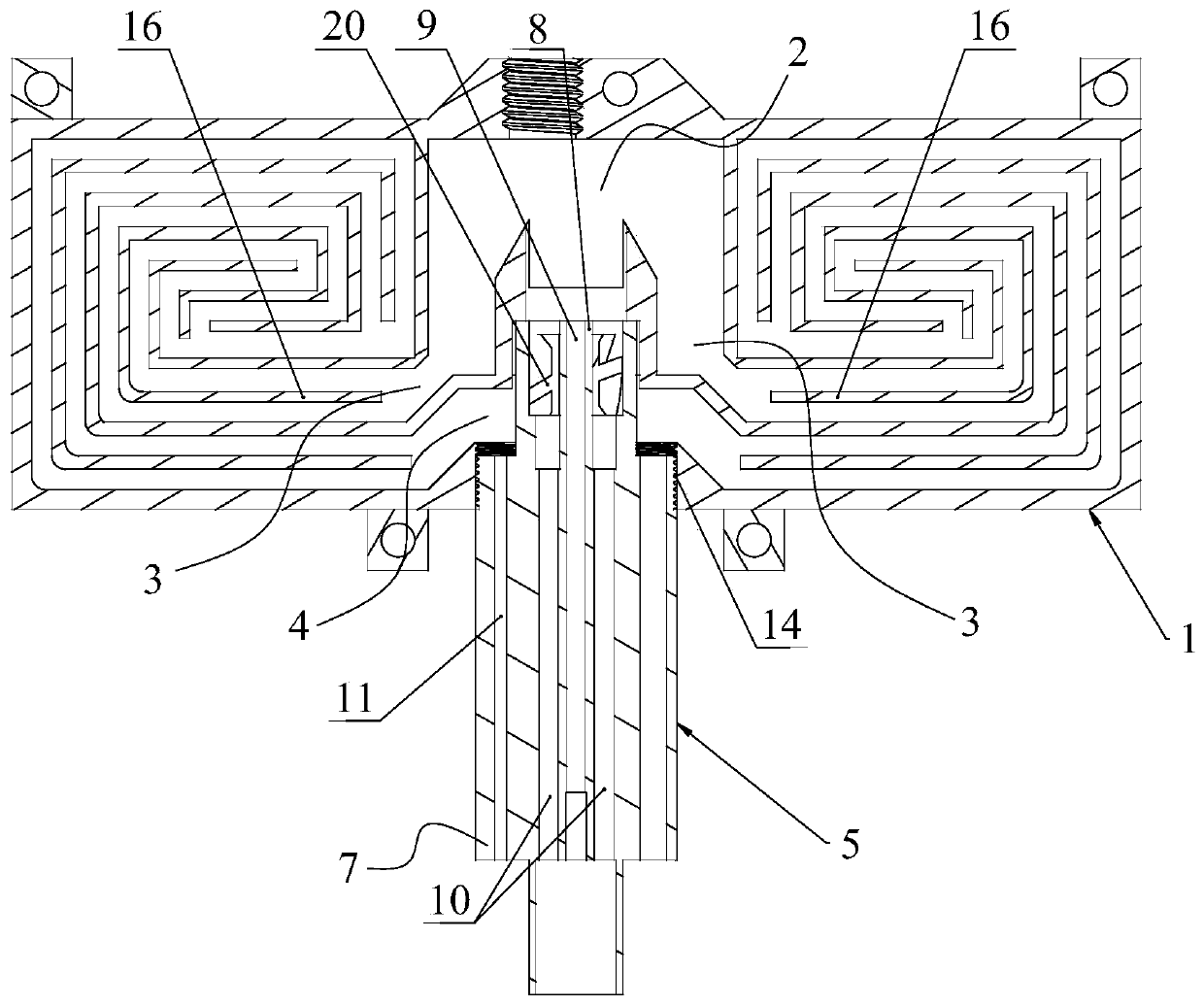

[0045] Such as figure 1 , 2 , 3, 4, 5 and 6, a thermoelectric generator based on micro-swirl combustion, including:

[0046] The heat conduction body 1, the heat conduction body 1 has a combustion chamber 2, an exhaust chamber 3 and a waste discharge chamber 4, one end of the exhaust chamber 3 communicates with the combustion chamber 2, and the other end communicates with the waste discharge chamber 4;

[0047] The air pipe 5 is installed on the heat conduction body 1, and the end part extends into the heat conduction body 1. The air pipe 5 includes a first pipe 6 and a second pipe 7 wrapped around the first pipe 6. The end of the first pipe 6 is connected to the combustion chamber 2 Connected, the middle part of the first pipe 6 has an inner pipe 8, the inner space of the inner pipe 8 is a fuel passage 9, and the end of the inner pipe 8 near the combustion chamber 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com