Combustor

a combustor and combustor technology, applied in the field of combustor, can solve the problems of adversely limited conditions, liable to undergo pressure fluctuation, and the conventional combustor mentioned above cannot serve satisfactorily as the combustor used in the boiler,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

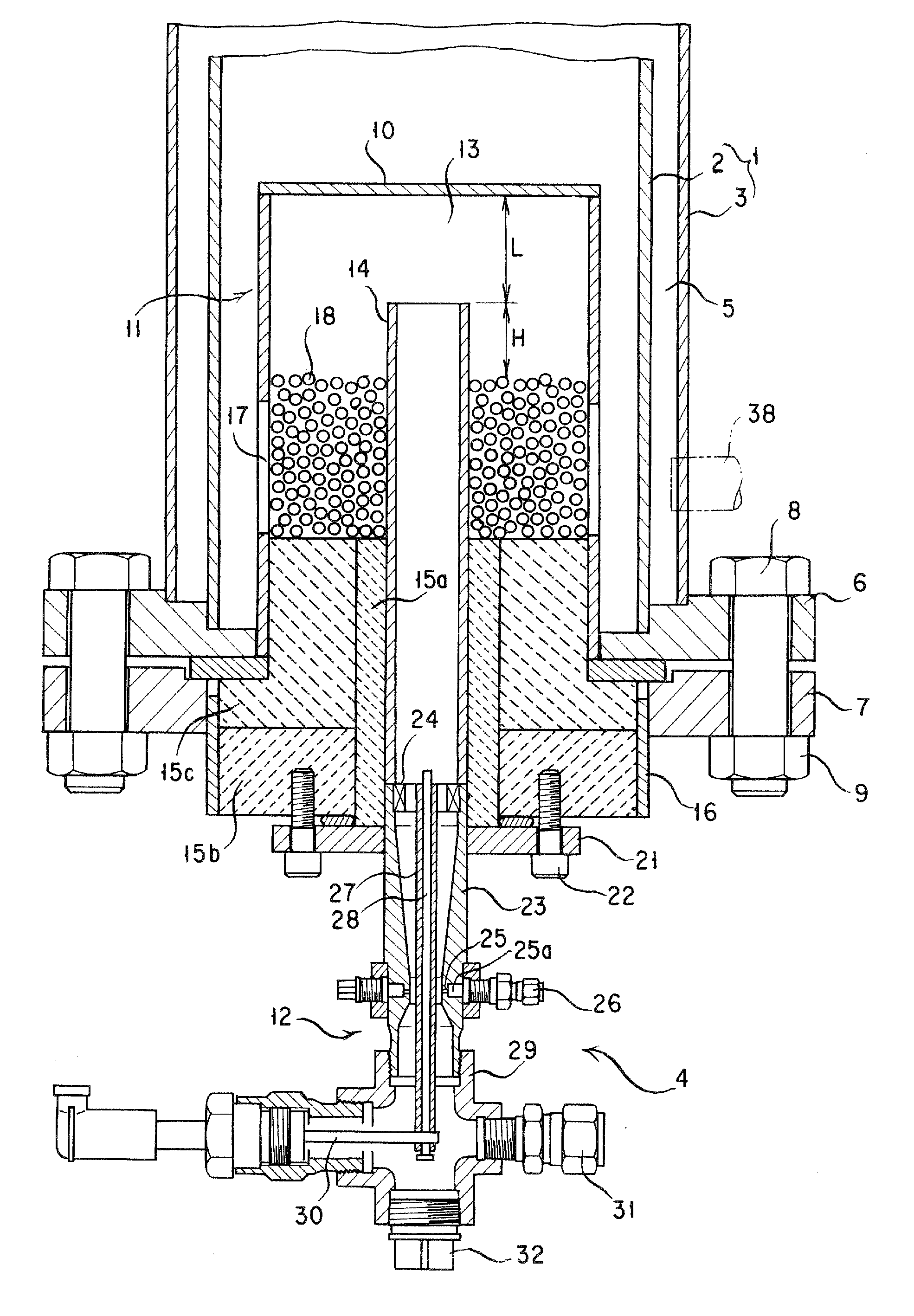

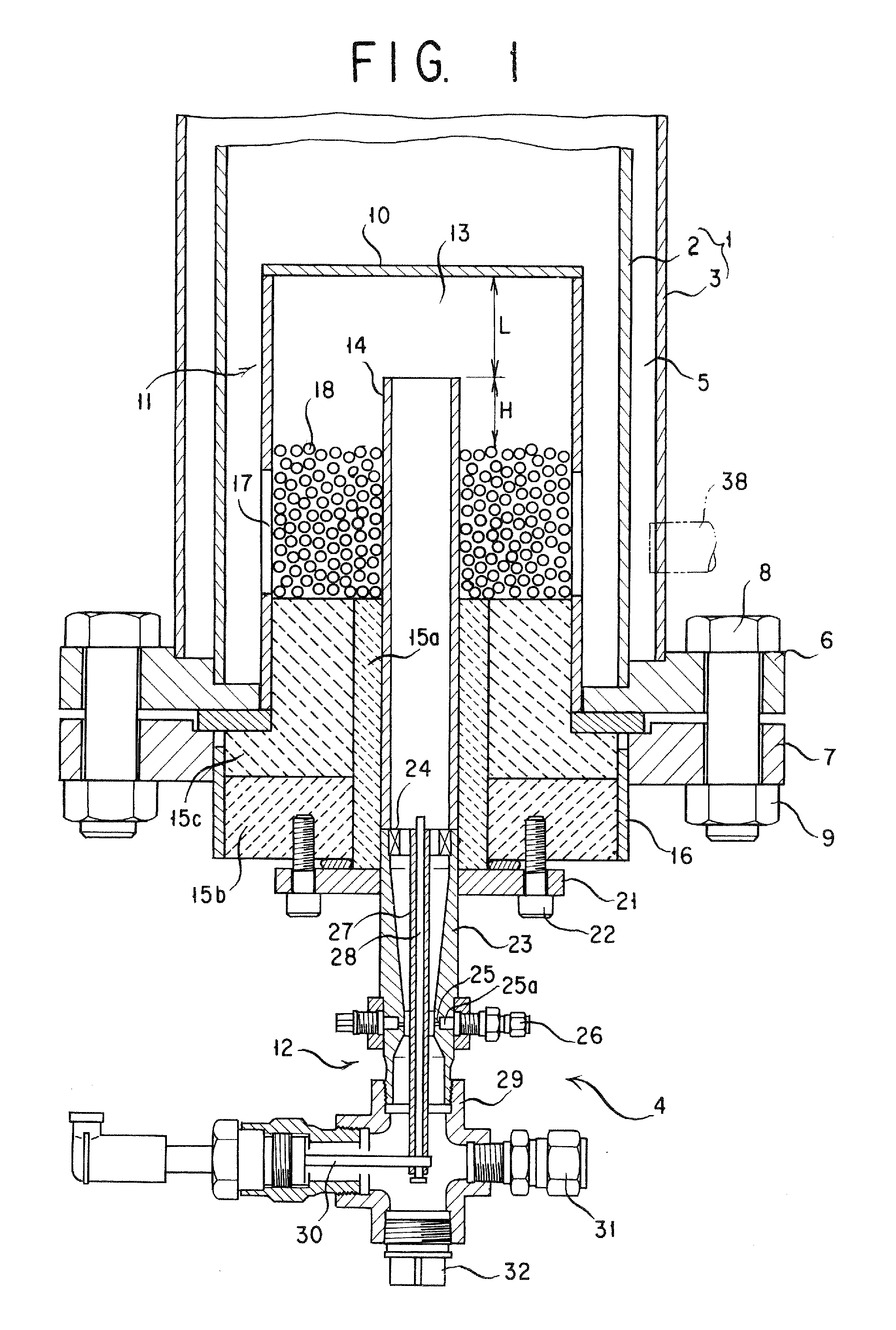

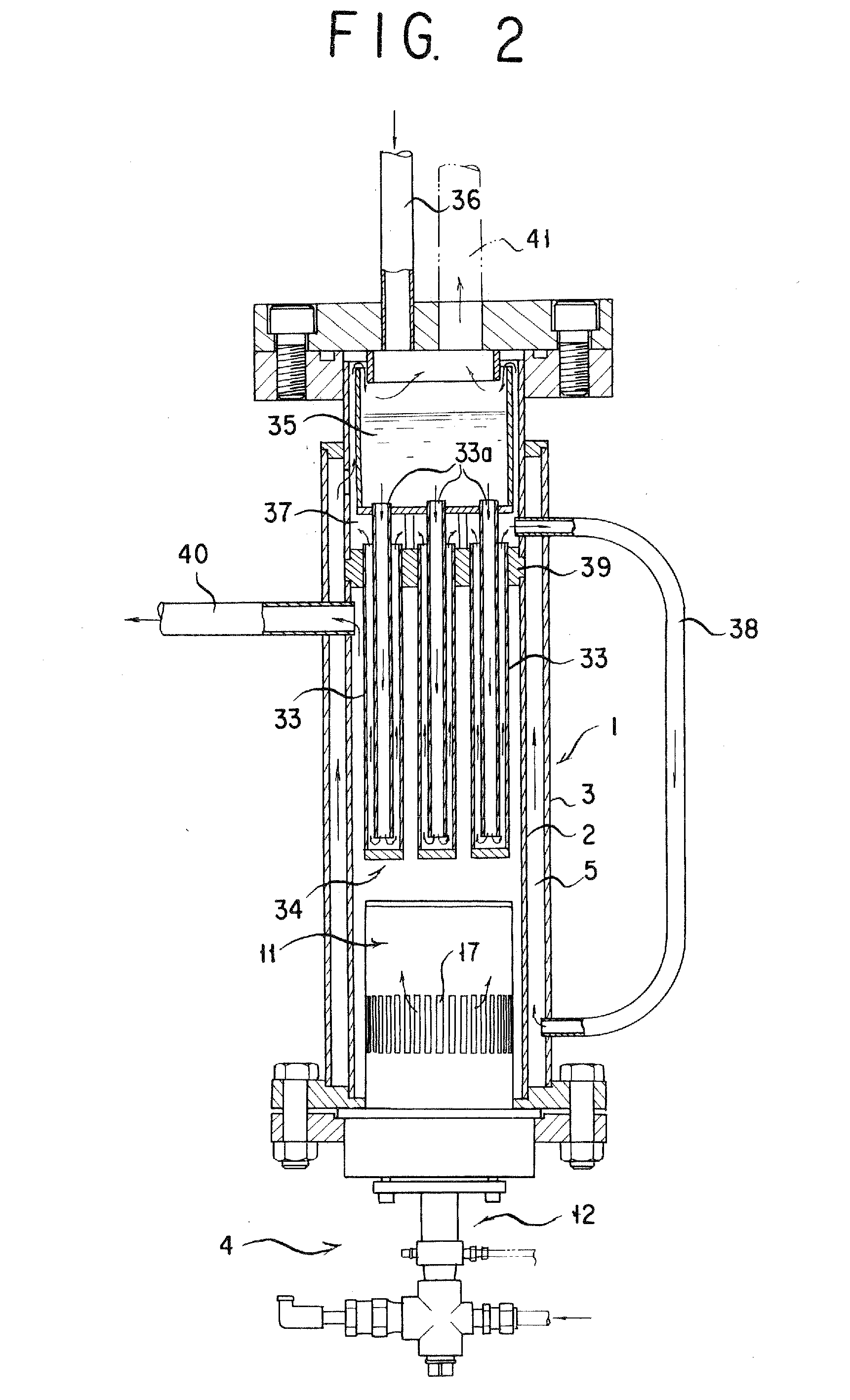

[0024]An explanation is given of a first form of implementation of the present invention with reference to FIGS. 1 and 2. FIG. 1 shows in a cross section the essential parts of a combustor of the present invention, and FIG. 2 shows in a cross section a form of boiler in which the combustor of the invention is used.

[0025]In FIG. 1, a boiler main body 1 comprises an inner cylinder 2 and an outer cylinder 3 coaxially arranged. Mounted at the lower end of the boiler main body 1 is a combustor 4 according to the present invention. A high temperature combustion gas generated by the combustor 4 is supplied into the inner cylinder 2 of the boiler main body 1 along its inner surface to heat the inner surface of the inner cylinder 2 whereby water (evaporating medium) supplied in a heating medium jacket 5 formed between the inner and outer cylinders 2 and 3 coaxially arranged to generate a high temperature steam. A boiler lower flange 6 is coupled integrally with the lower end of the boiler ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com