System and method for coal particle and steam co-production of biomass

A technology of biomass charcoal and steam, applied in combustion methods, biofuels, steam superheating, etc., can solve problems such as increased production and operation costs, difficult organization of combustion atmosphere, blockage of pipelines and equipment, and avoid deposition and high-temperature corrosion problems , Efficient and stable temperature uniform distribution, the effect of reducing the production of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

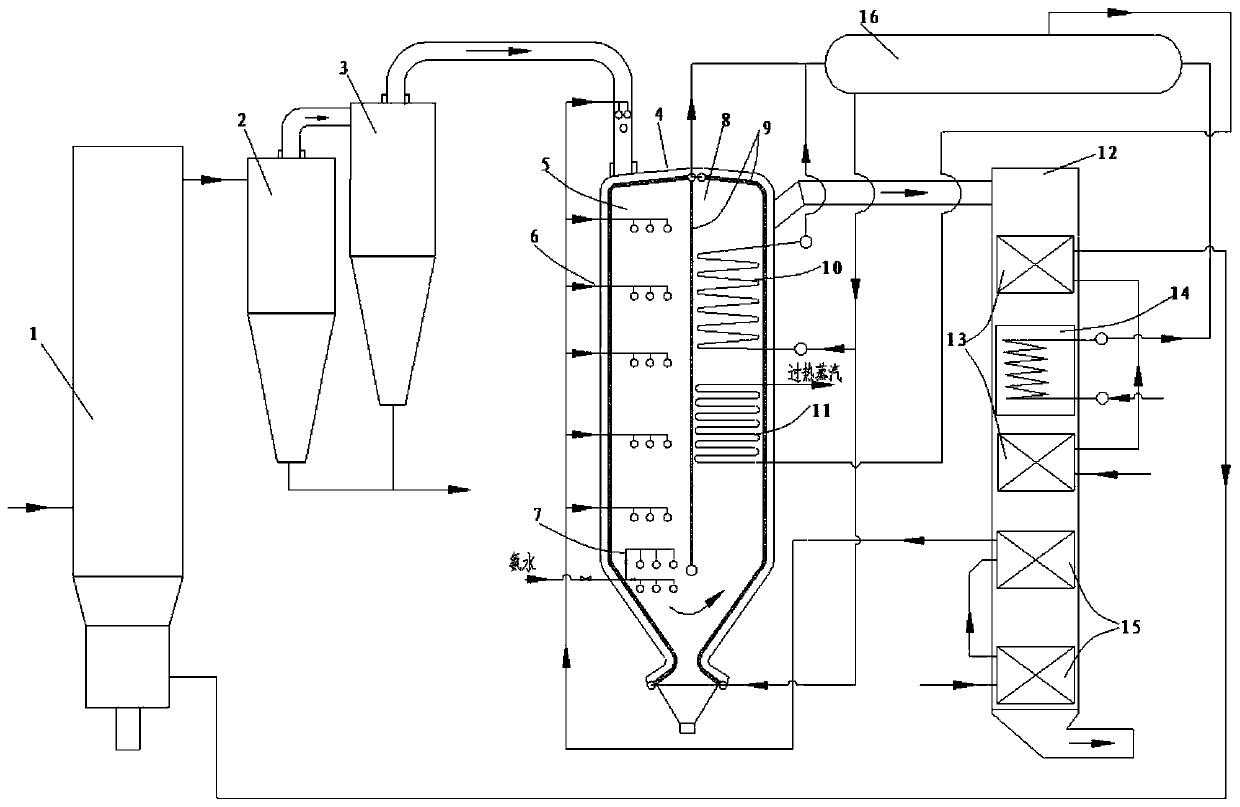

[0057] The biomass is selected from furfural slag, and the feed rate is 24t / h. Partial gasification reaction occurs in the fluidized bed gasifier 1 with the 300°C high-temperature gasification wind from the gasification air preheater 13, and the reaction temperature is about 650°C , the reaction produces high-temperature gasification gas, carbon particles and a small amount of fine ash particles. The carbon particles are separated with the high-temperature gasification gas through the primary cyclone separator 2 and the secondary cyclone separator 3, and the carbon particle production is 2.52t / h. The produced carbon particles can be used as carbon products for the production of activated carbon, carbon-based fertilizers, etc.

[0058] The high-temperature gasification gas from the secondary cyclone separator 3 enters the combustion chamber 5 of the gas boiler 4 and combusts with the fuel air sent in by the multi-stage fuel air pipe 6, and the combustion temperature is about 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com