Pneumatic atomization liquid-liquid injection method and machine capable of realizing large-scale variable working conditions

A technology of aerodynamic atomization and variable working conditions, which is applied in the direction of combustion method, burner, combustion type, etc., can solve problems such as poor atomization quality, and achieve the effect of reducing development cost and realizing large-scale variable thrust work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

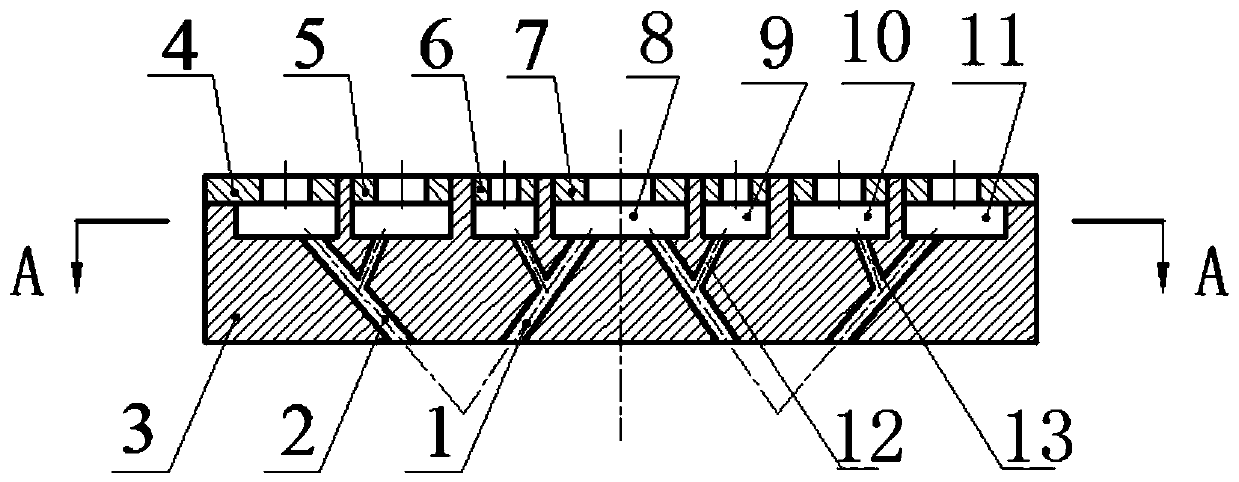

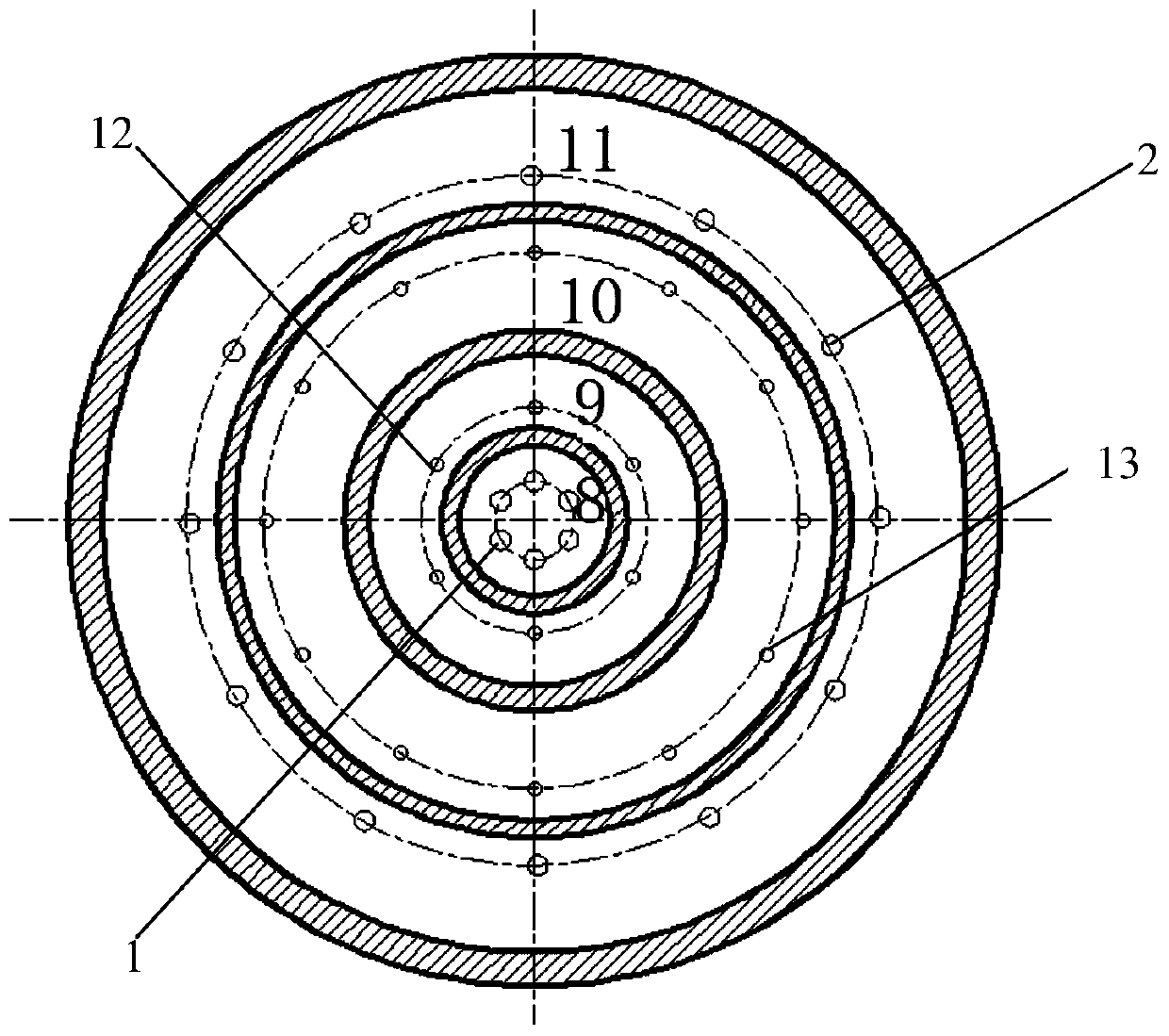

[0024] This embodiment takes n=2, m=1 as an example for illustration, as figure 1 As shown, the pneumatic atomizing liquid injector with a wide range of variable working conditions in this embodiment includes a spraying plate 3, grooves are provided on the upper end surface of the spraying plate 3, and each groove forms a first atomizing gas collection chamber 8 respectively. , the fuel collecting chamber 9, the oxidizing agent collecting chamber 10 and the second atomizing gas collecting chamber 11, the first atomizing gas collecting chamber 8 is located at the center of the upper end surface of the injection plate 3, the fuel collecting chamber 9, the oxidant collecting chamber The chamber 10 and the second atomizing gas collecting chamber 11 are annular chambers with the center of the first atomizing gas collecting chamber 8 as the center. In this embodiment, from the outermost circle to the center, there are the second atomized gas collecting chamber 11 , the oxidizing age...

Embodiment 2

[0029] When n>2, it is sufficient to continue to arrange corresponding chambers on the outer ring of the second atomizing gas collecting chamber 11 , and the fuel mist jet and the oxidant mist jet collide at one point through the corresponding atomizing gas nozzles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com