Cylindrical porous jetting-type miniature liquid combustor and combustion method thereof

A micro-liquid and burner technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of sufficient air mixing and difficult rapid evaporation of liquid fuel, etc., and achieve the effects of increasing contact time, convenient ignition process, and accelerating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

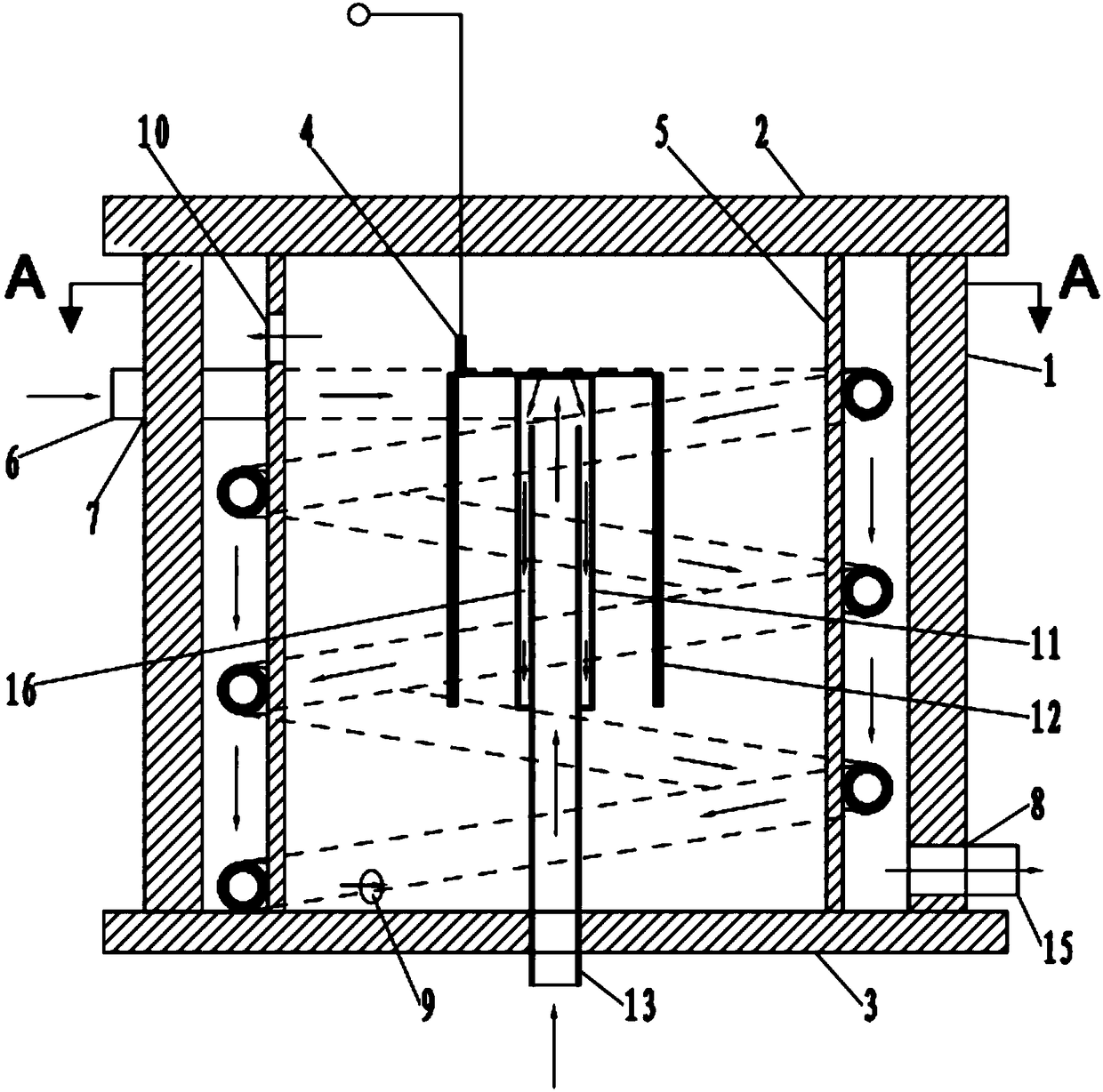

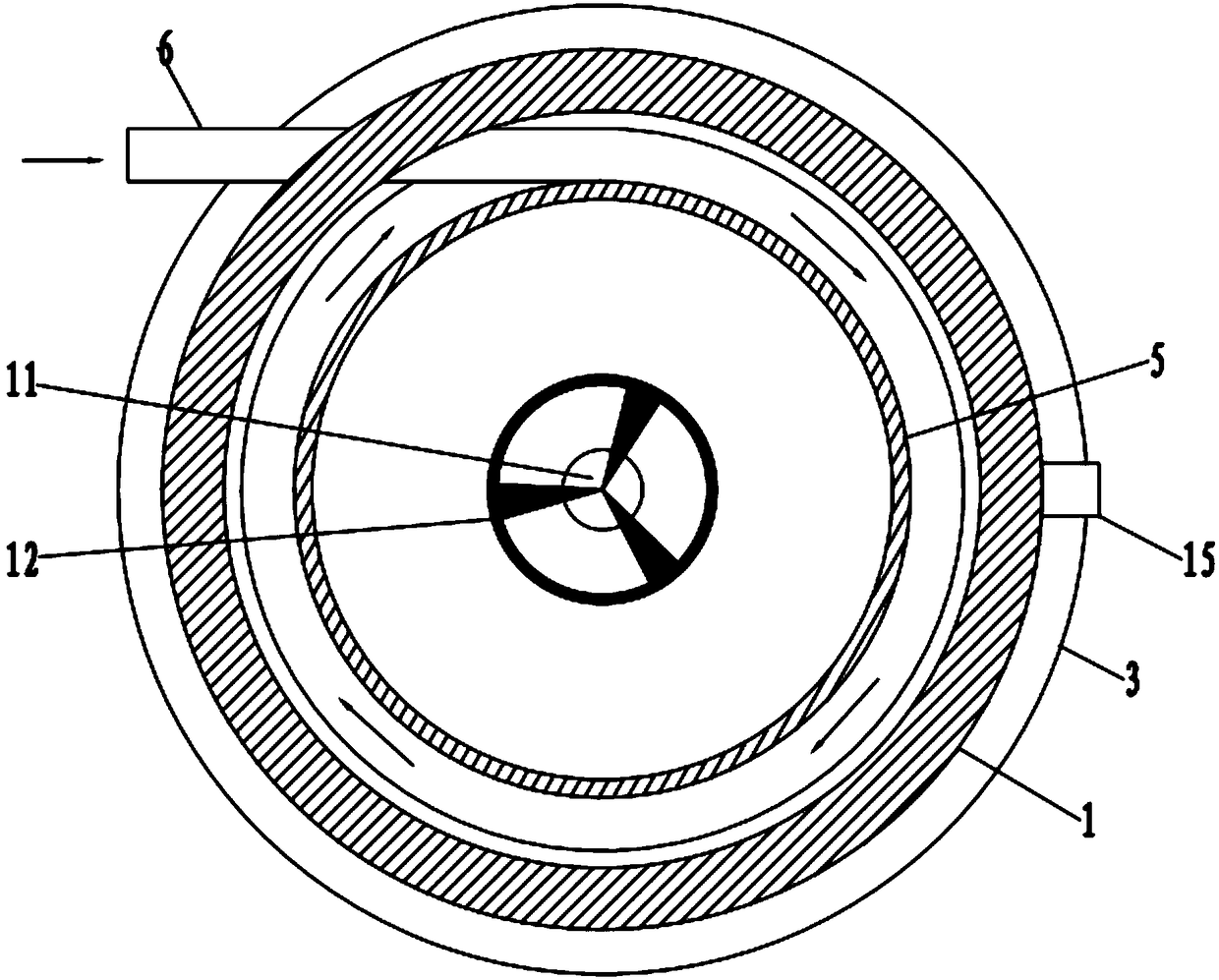

[0032] Such as figure 1 , figure 2 , Figure 5 , Figure 6 A cylindrical multi-hole injection type miniature liquid burner shown includes a combustion chamber 5, an upper sealing plate 2, a lower sealing plate 3, an air intake duct 6 and an igniter 4, and the upper sealing plate 2 is sealed in the combustion chamber 5, the lower sealing plate 3 is sealed to the lower end of the combustion chamber 5, the combustion chamber 5 has a first air inlet 9 and a first exhaust port 10, and one end of the air inlet pipe 6 runs through the first The air inlet 9 is to the inside of the combustion chamber 5, and the inside of the combustion chamber 5 is provided with a feed pipe 13 and a burner, and the burner includes a fuel column 11 and a metal grid sleeve 12, and the metal grid sleeve The bottom end of the cylinder 12 is open, the metal grid sleeve 12 is sleeved on the fuel column 11, the top of the fuel column 11 is sealed, and the side wall of the fuel column 11 has a plurality of...

Embodiment 2

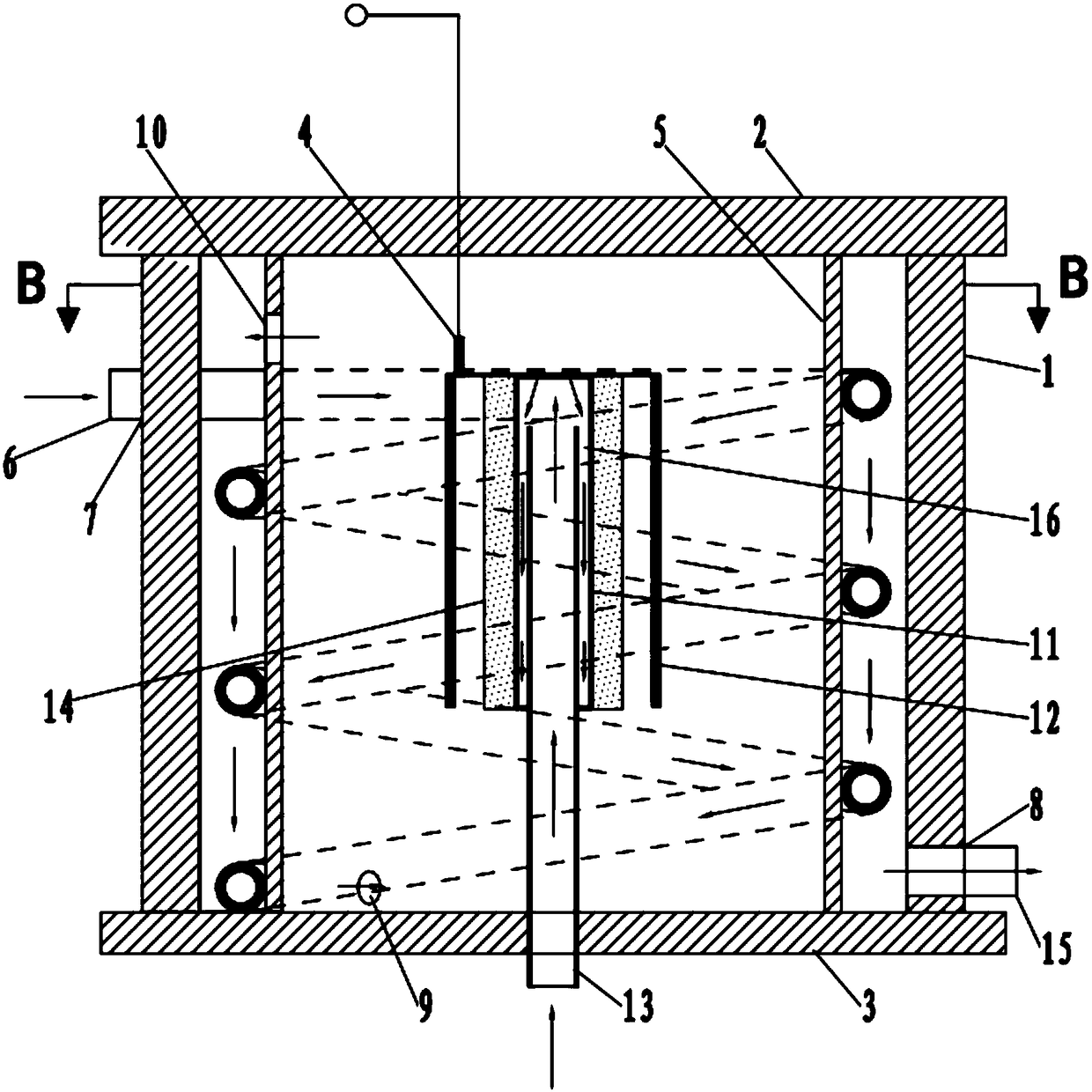

[0043] This embodiment also includes the following technical features on the basis of Embodiment 1:

[0044] Such as Figure 3-Figure 6 As shown, the burner also includes a porous medium layer 14 , the porous medium layer 14 is closely attached to the side wall of the fuel column 11 , and there is a gap between the porous medium layer 14 and the metal grid sleeve 12 . The gap between the metal mesh sleeve 12 and the porous medium layer 14 is 2mm, the porous medium layer 14 is attached to the outer sidewall of the fuel column 11, and the porous medium layer 14 is a porous structure, and the discharge of liquid fuel from the fuel column 11 The flow sprayed out from the hole passes through the porous medium layer 14 to disperse and gasify. The porous medium layer 14 increases the evaporation surface area of the liquid fuel, which is beneficial to the dispersion and heat-absorbing evaporation of the liquid fuel. The porous medium layer 14 is made of aluminum foam or ceramic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com