Single concave cavity trapped vortex combustor

A combustor and cavity technology, applied in the field of new concept aviation gas turbine combustion, can solve the problems of stability and combustion efficiency limitation of trapped vortex combustor, complex fuel system, etc., to improve combustion efficiency and ignition performance, simple fuel system, The effect of reducing the weight of the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

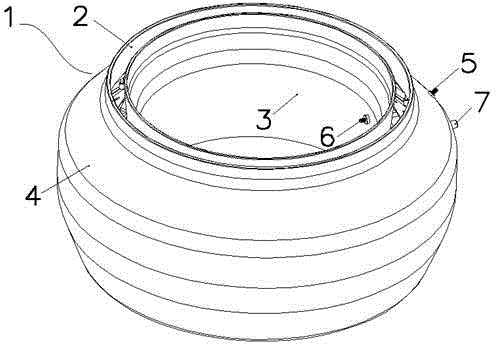

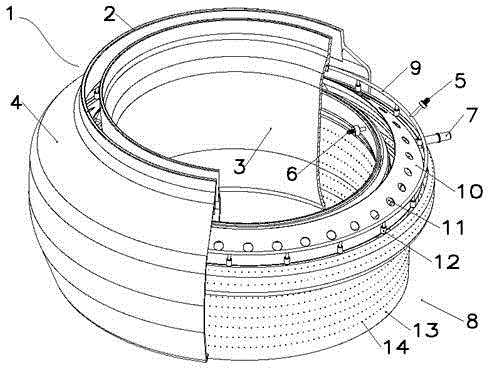

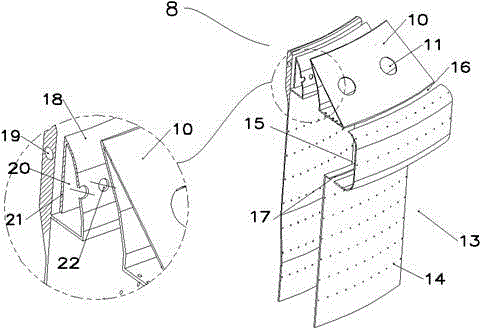

[0041] Please refer to Figure 1 to Figure 5 As shown, the single-cavity vortex combustion chamber of the present invention is mainly composed of a diffuser 2, a combustion chamber casing 3 and an outer casing 4, a flame cylinder 8 with a single-cavity structure, a flow guiding device 10, a pre-evaporation device 18, etc. composition. The single-cavity vortex combustion chamber has a full ring structure, using the vortex formed by the concave cavity 15 in the flame tube to stabilize the flame, relying on the cross-flame support plate 23 to transmit the flame from the concave cavity 15 to the main flow 25, combined with RQL combustion technology and LPP staged combustion technology achieves high efficiency and low emissions.

[0042] A diffuser 2 is arranged at the inlet of the combustion chamber, and its main function is to reduce the air v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com