Pulverized coal preheating burner and pulverized coal preheating combustion method

A burner and pulverized coal technology, applied in the field of combustion, can solve problems such as difficult application, difficult to provide pulverized coal, and increase system complexity, and achieve low NOX emission combustion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

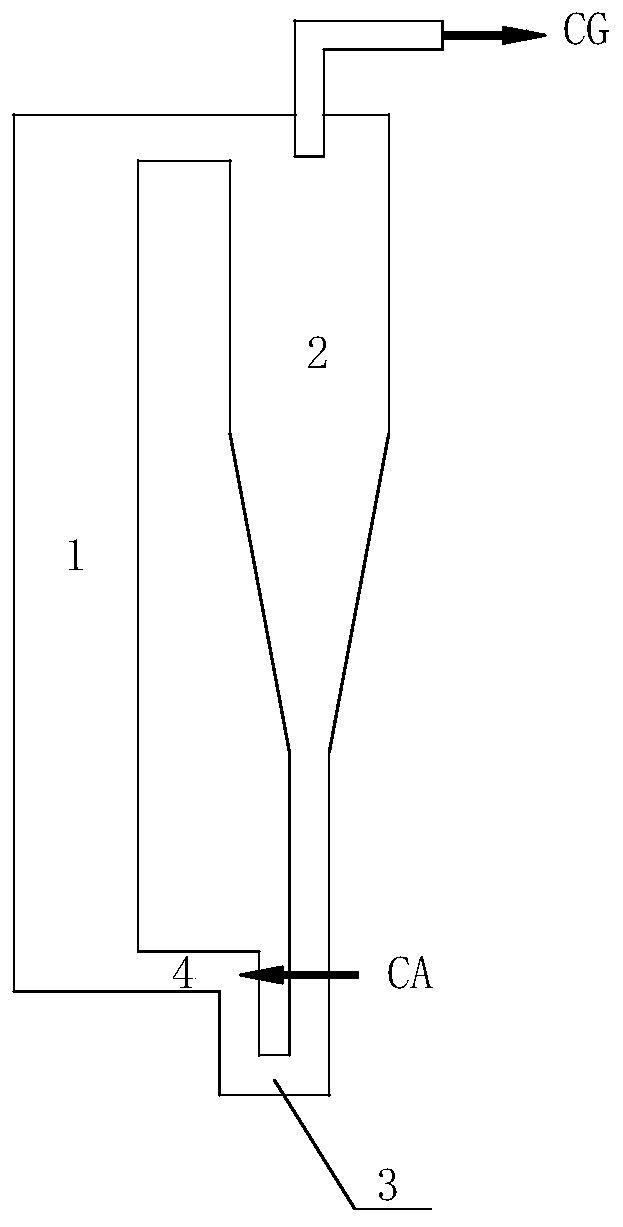

[0040] Such as figure 1 The pulverized coal preheating combustion device shown includes a preheating combustion chamber 1, a gas-solid separator 2, and a U-shaped feeder 3 connected in sequence. The preheating combustion chamber 1 is a vertical cylinder, and the bottom is connected through a horizontal The pipeline 4 is connected to the feeder 3, and the top is connected to the gas-solid separator 2; the top outlet of the ascending section of the feeder 3 is provided with an air-powder mixture inlet, and the air-powder mixture CA is introduced. The air-powder mixture is coal powder with a particle size not exceeding 500 μm carried by the pulverized coal exhaust gas from the pulverized coal boiler pulverization system. The ratio of coal grinding exhaust gas to coal powder is equivalent to the amount of oxygen / theoretical oxygen amount of fuel combustion = 0.1~0.2. The gas outlet of the gas-solid separator, that is, the outlet of the preheating combustion device, is connected w...

Embodiment 2

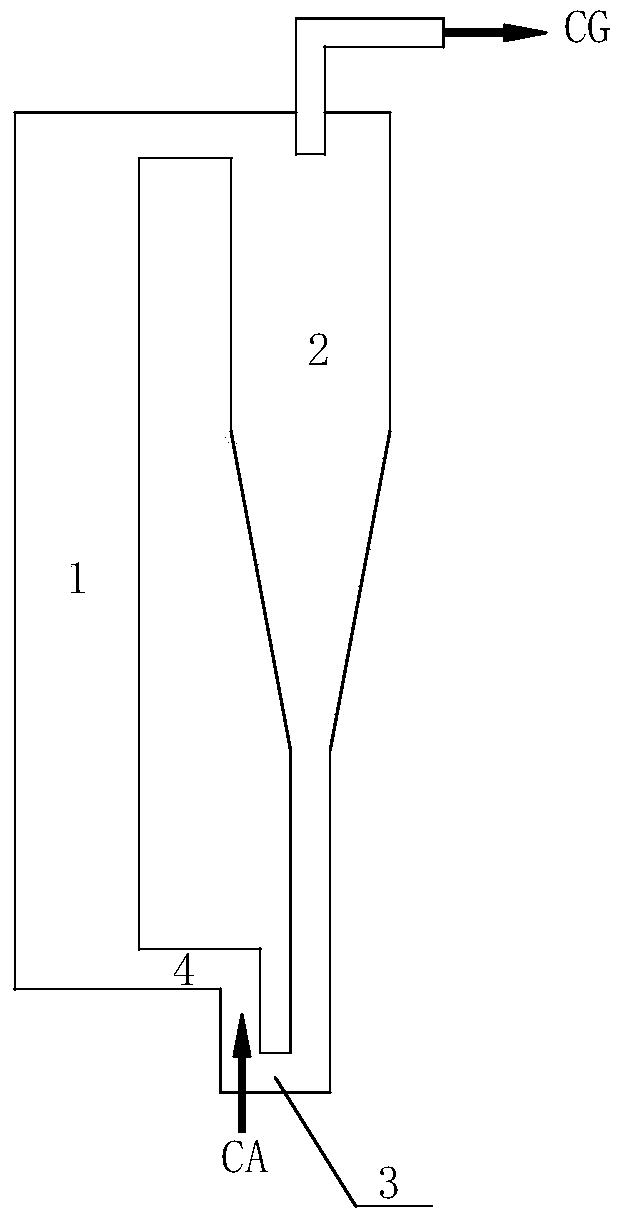

[0042] Such as figure 2 The difference between the pulverized coal preheating combustion device shown in Example 1 is that the air powder mixture inlet is arranged at the upper middle part of the rising section of the U-shaped feeder 3 .

Embodiment 3

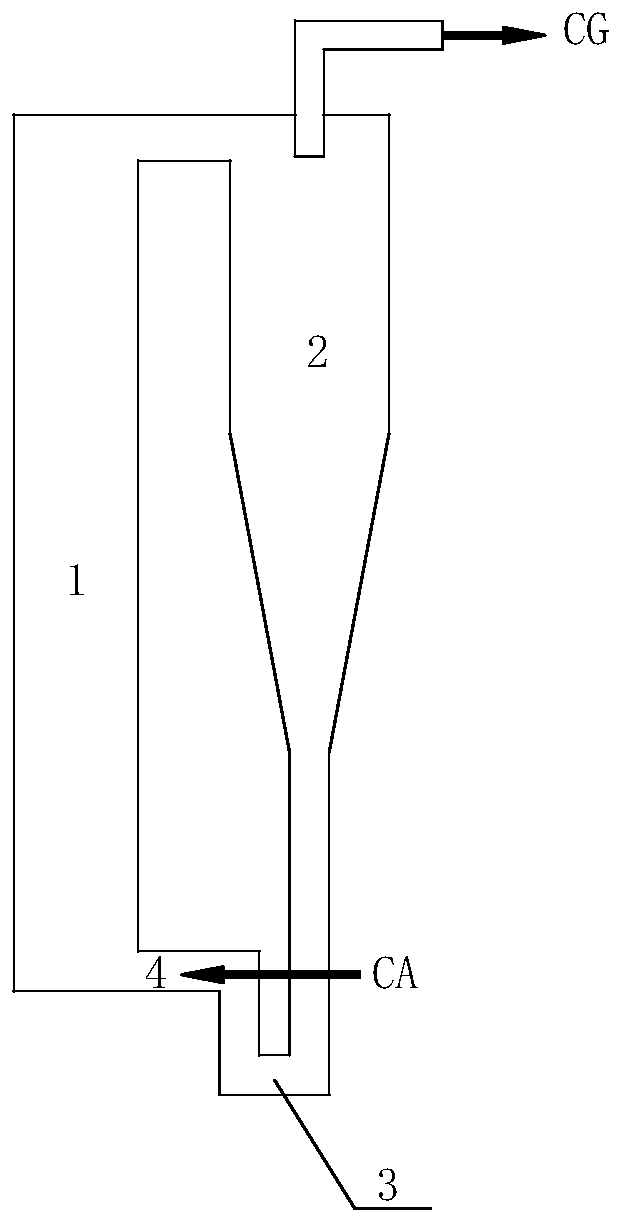

[0044] Such as image 3 The pulverized coal preheating combustion device shown differs from Embodiment 1 in that the air powder mixture inlet is arranged on the horizontal connecting pipe 4 connected to the bottom of the preheating combustion chamber 1 and the rising section of the U-shaped feeder 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com