Patents

Literature

467results about How to "Improve ignition performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

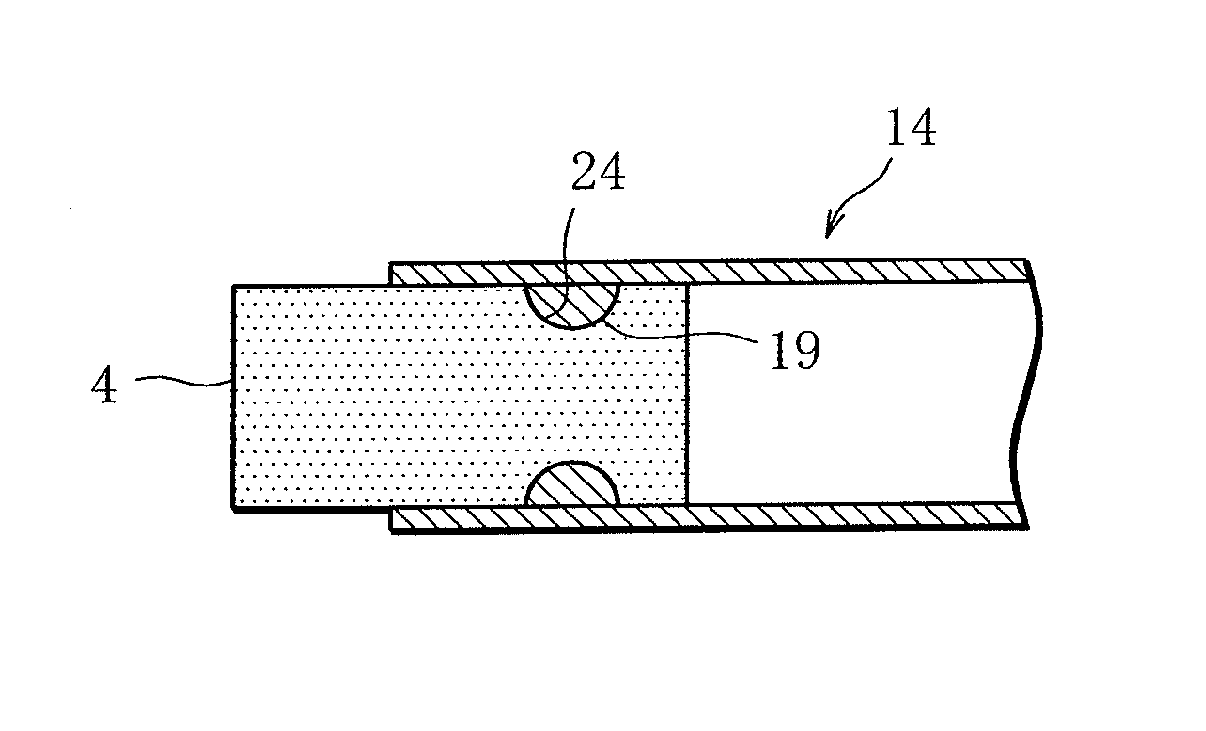

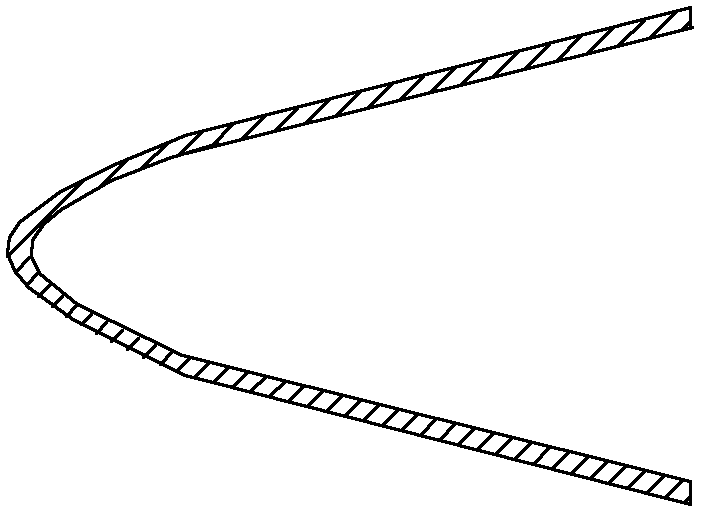

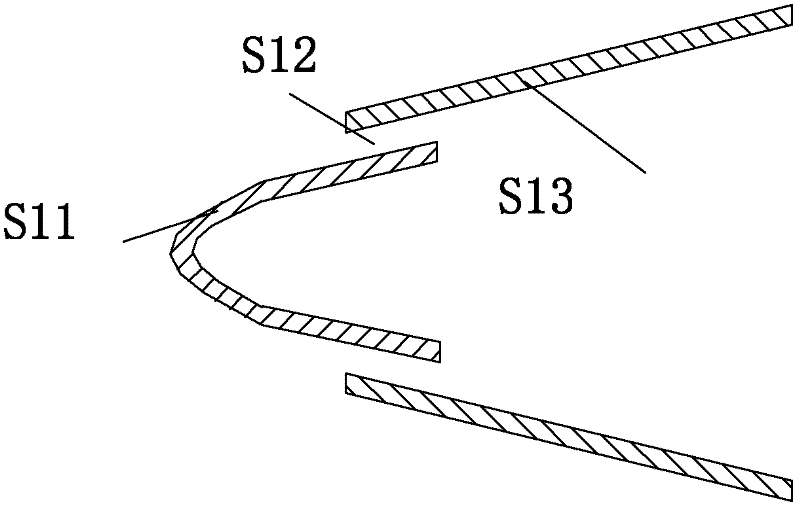

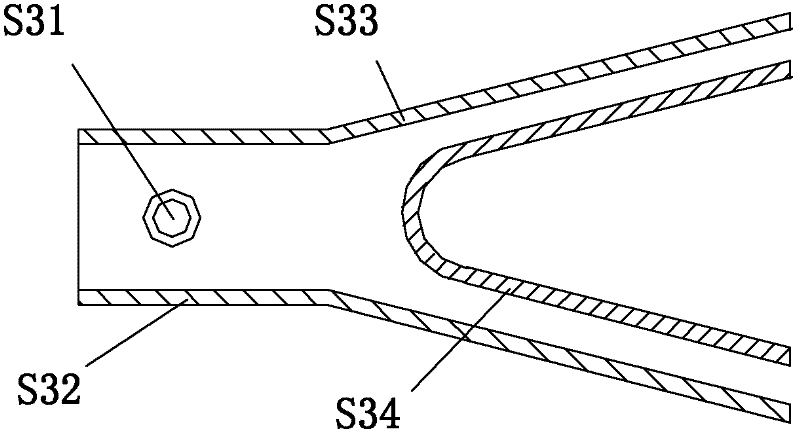

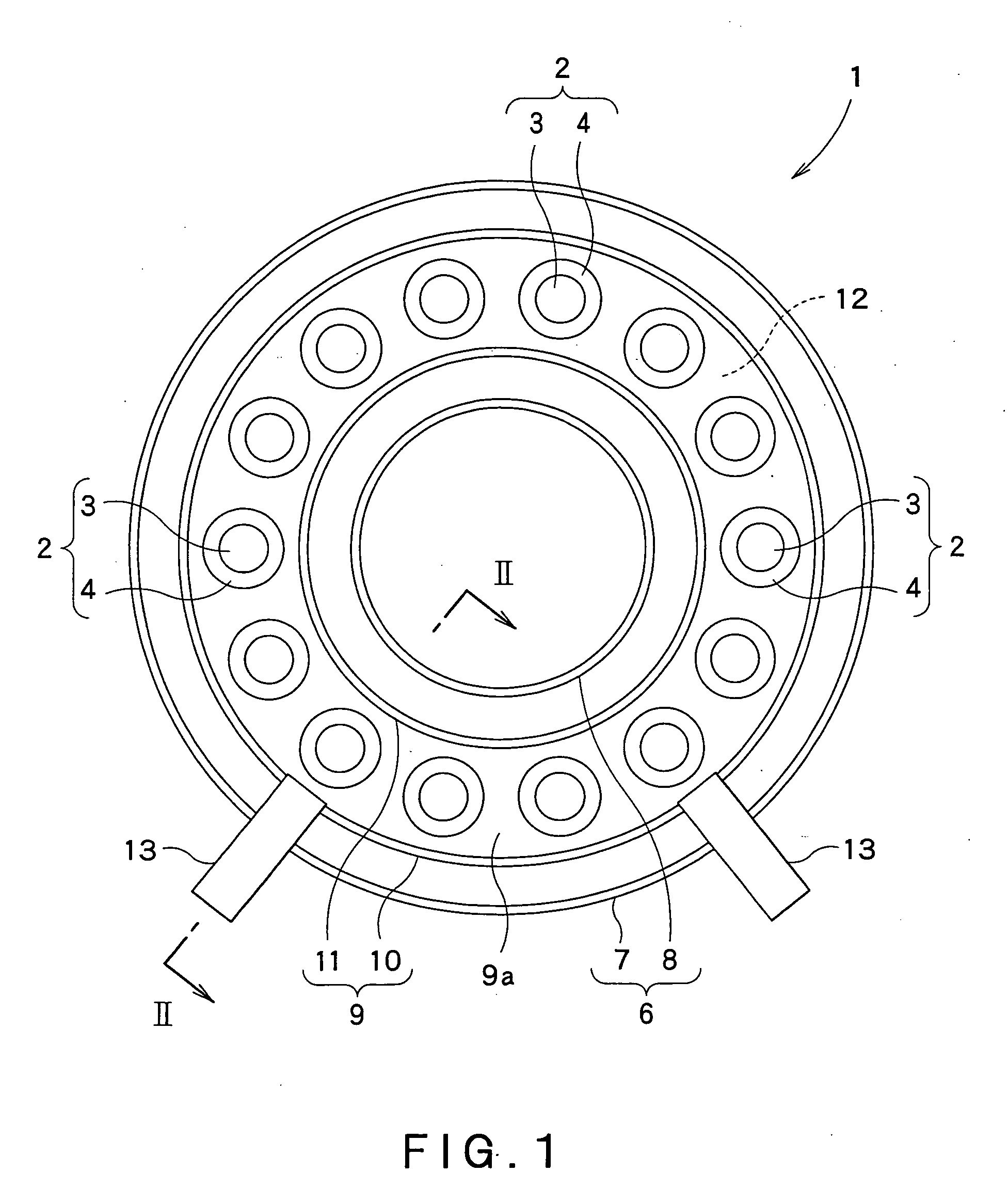

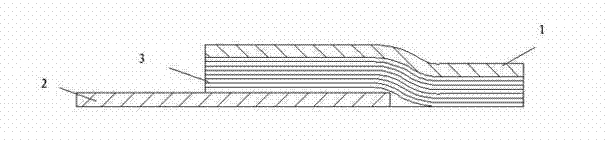

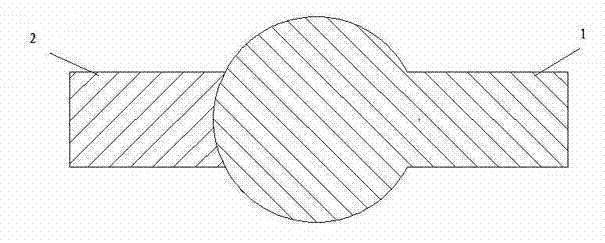

Smoking article

ActiveUS20130019888A1Reduce component countIncrease the diameterTobacco preparationTobacco treatmentFlavorEngineering

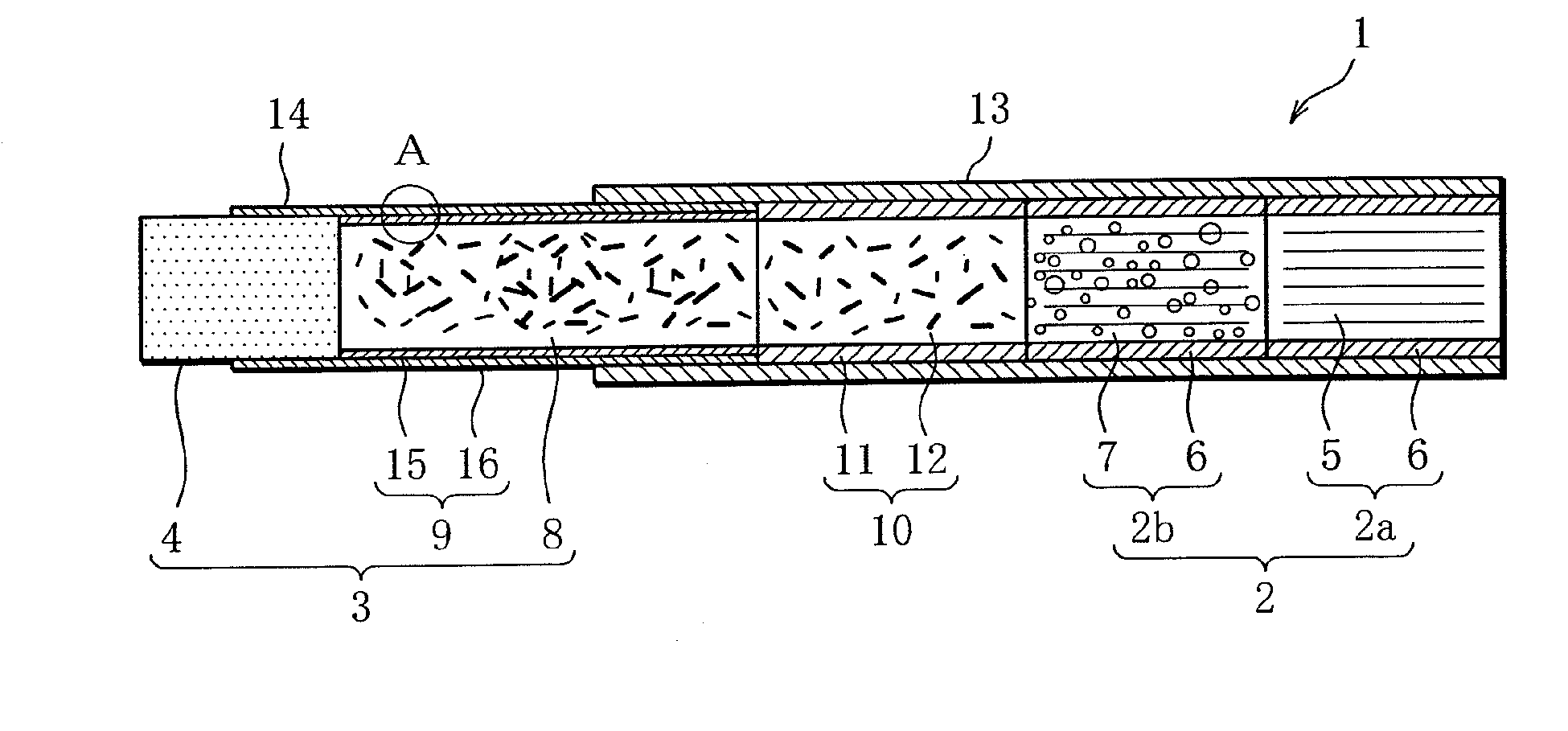

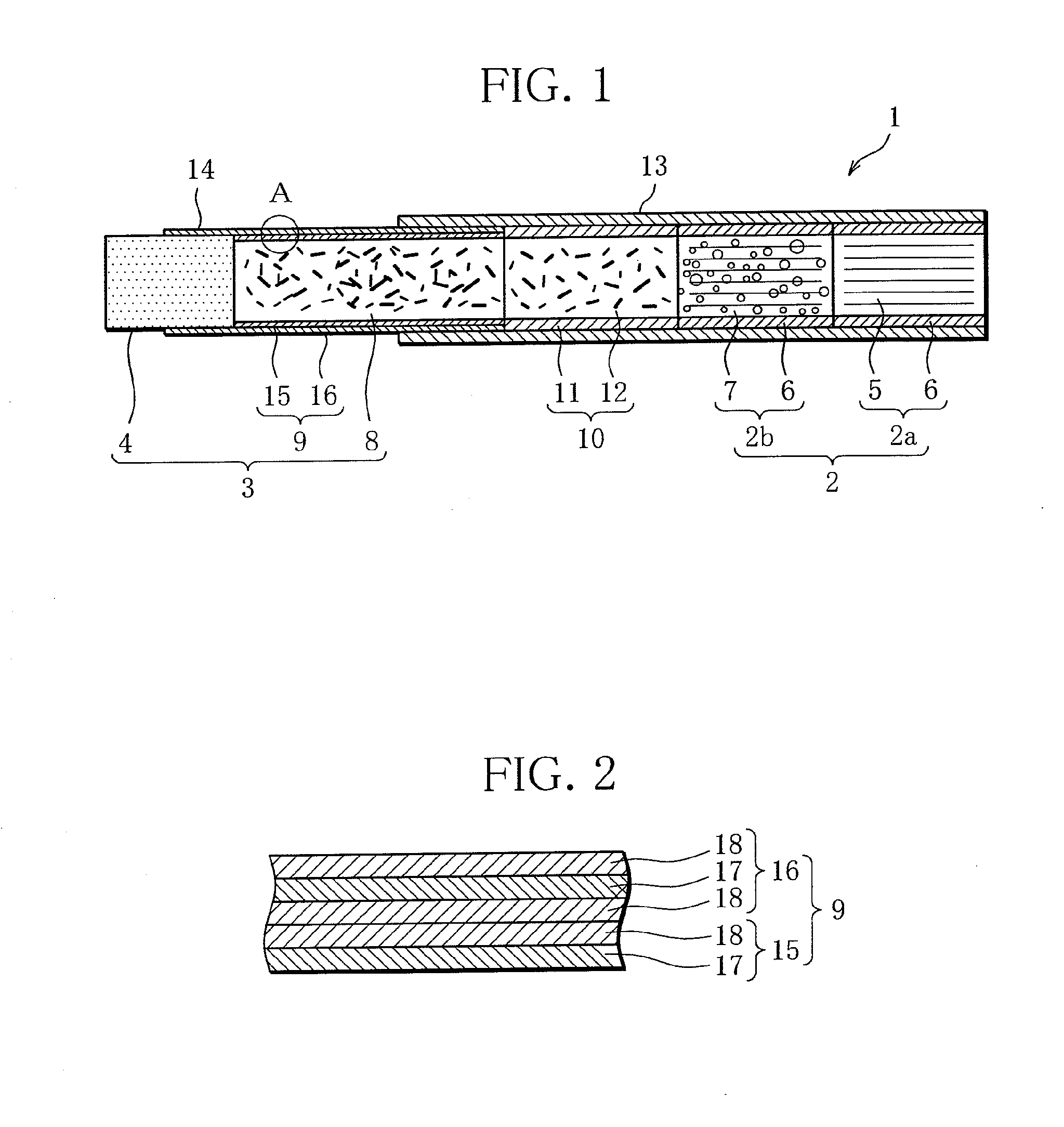

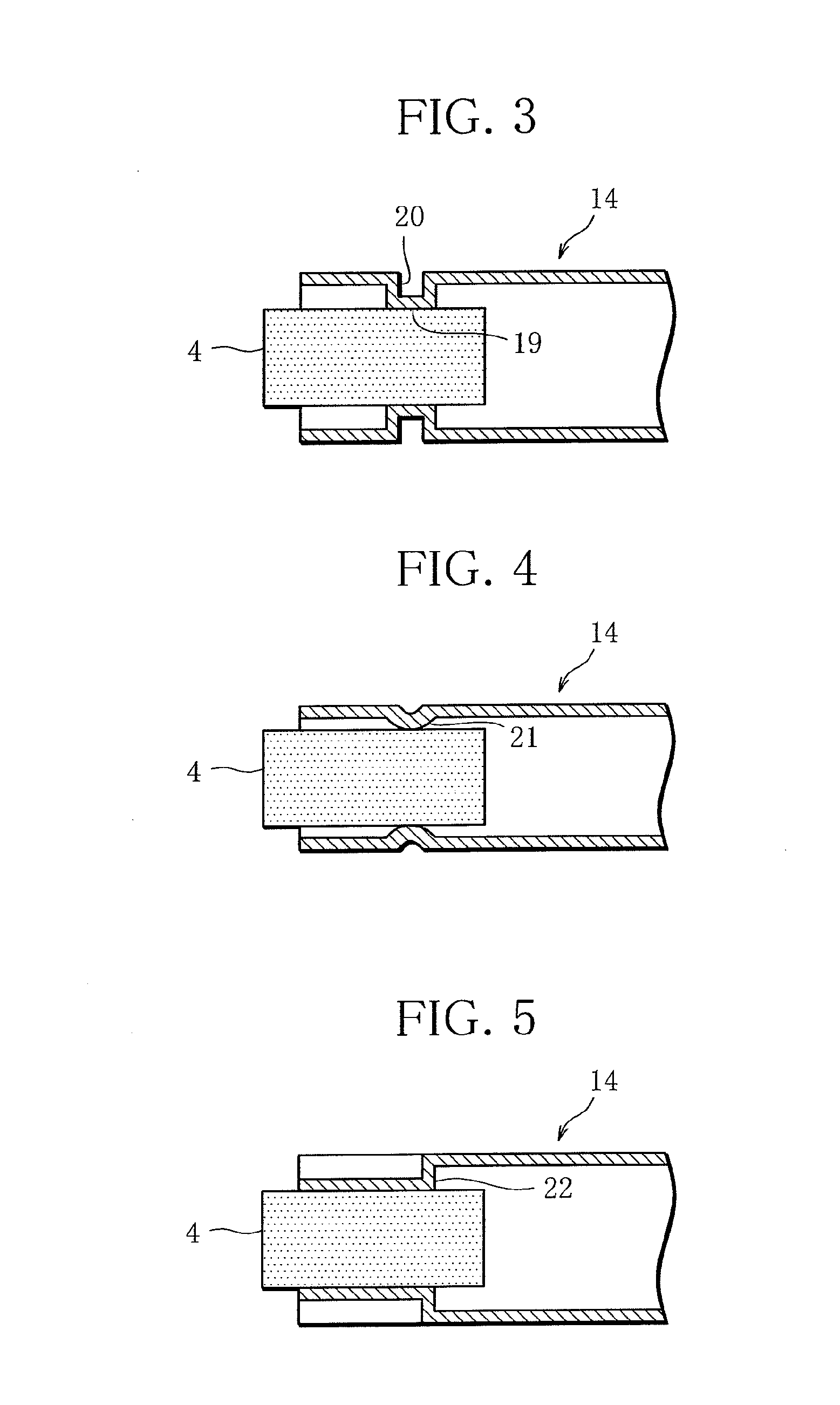

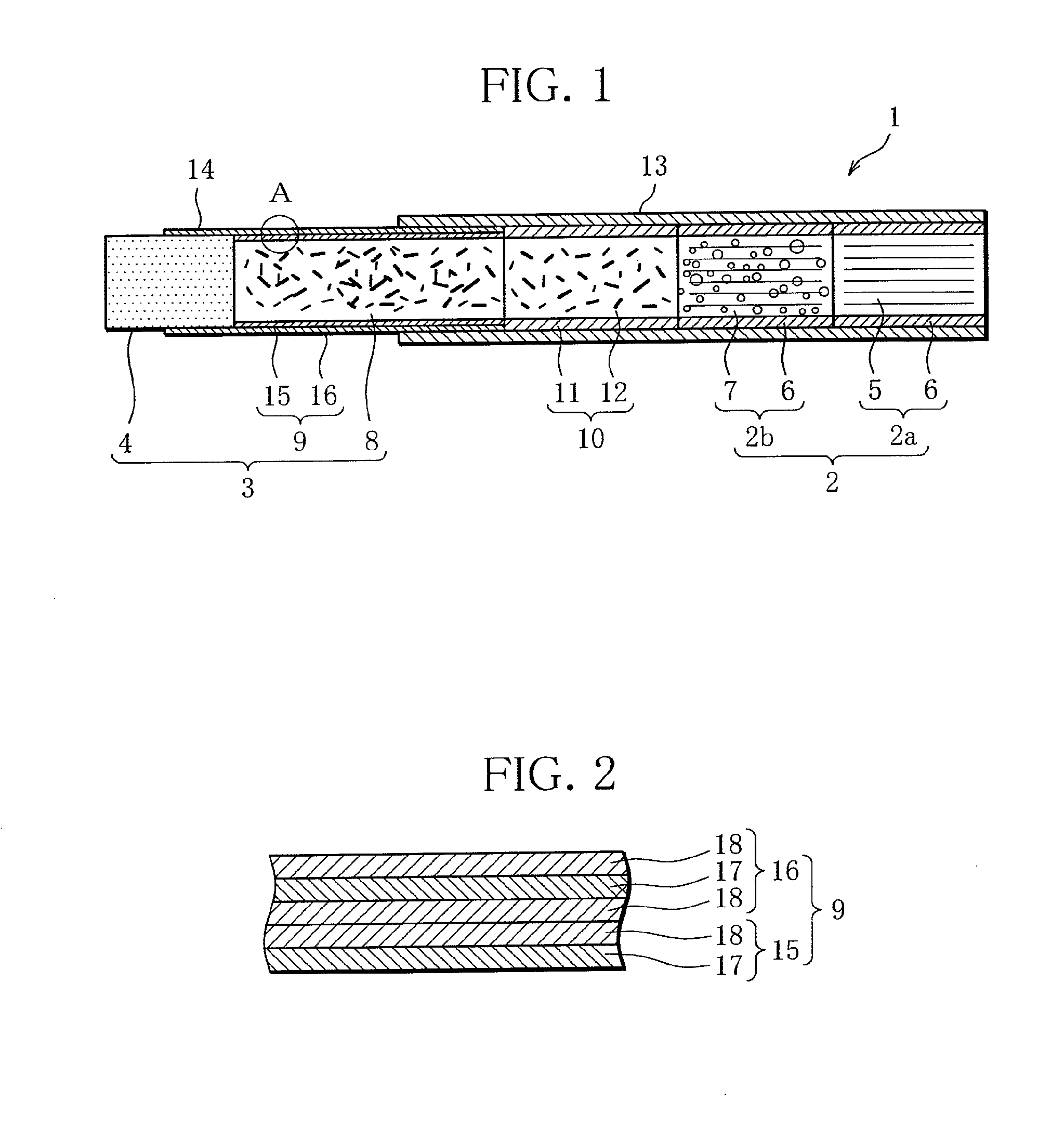

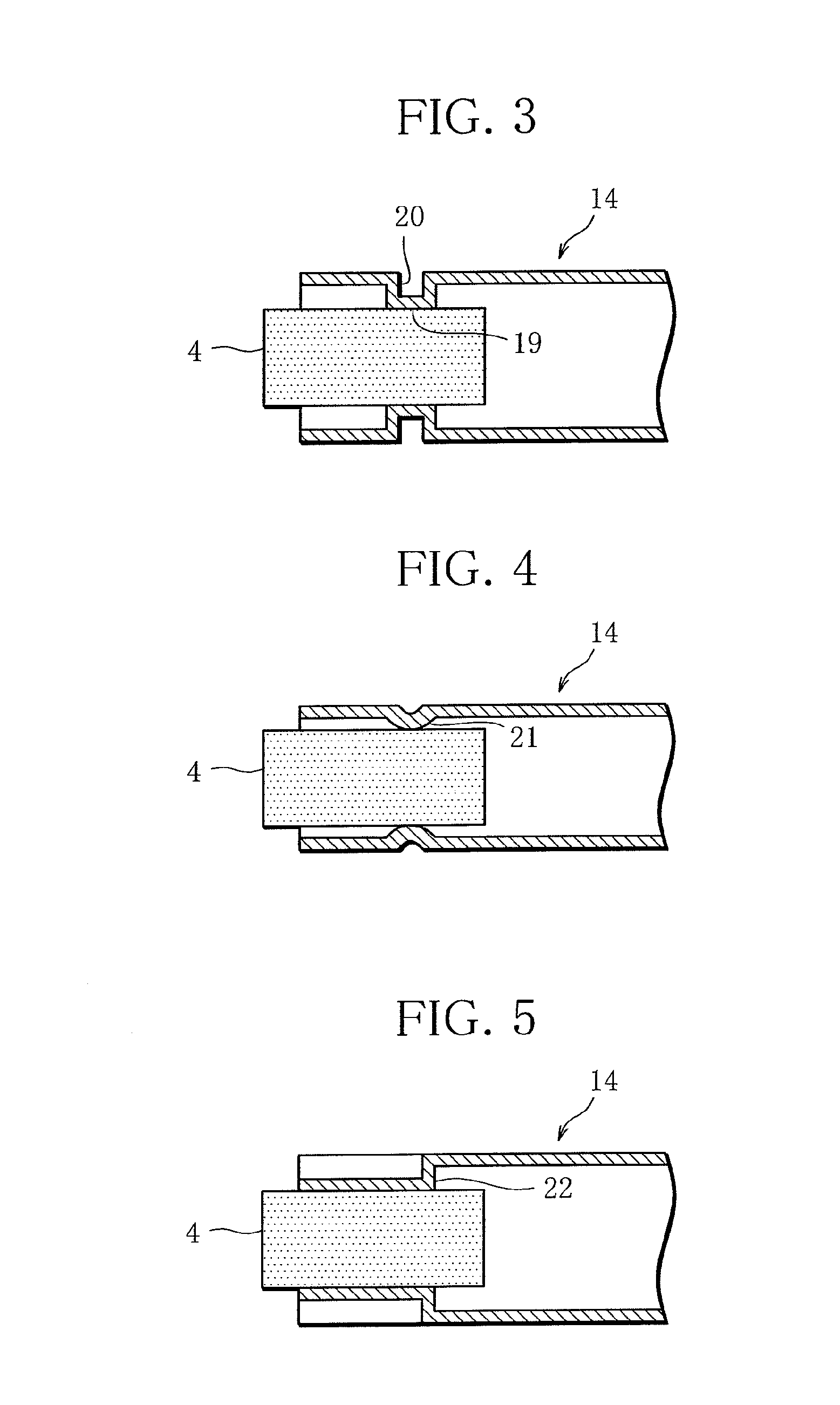

A smoking article comprises a multilayered tube member (9) including at least one metal layer and one paper layer, a carbon heat source (4) arranged in an end portion of the tube member (9) to be at least partly in direct close contact with an inner surface of the tube member (9), the carbon heat source emitting heat when ignited, a smoking flavor releasing source (8) arranged in the tube member (9) to adjoin the carbon heat source (4), and a holder part (14) keeping the carbon heat source (4) in direct contact with said end portion and holding the carbon heat source (4) against said end portion.

Owner:JAPAN TOBACCO INC

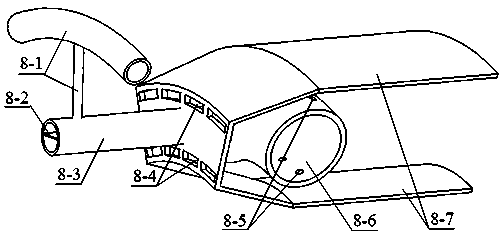

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

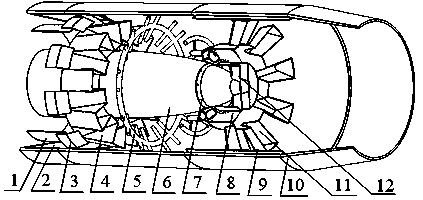

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

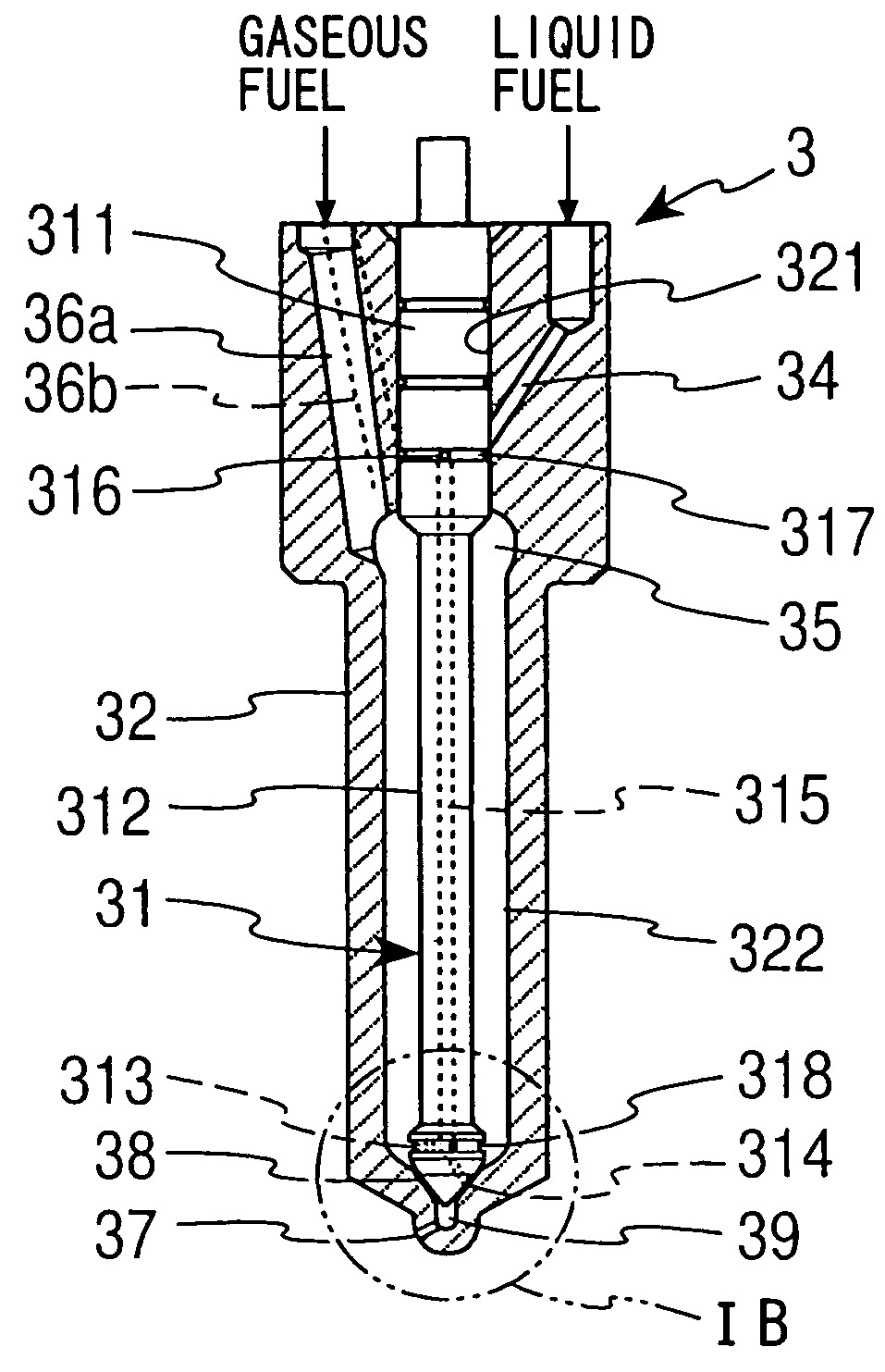

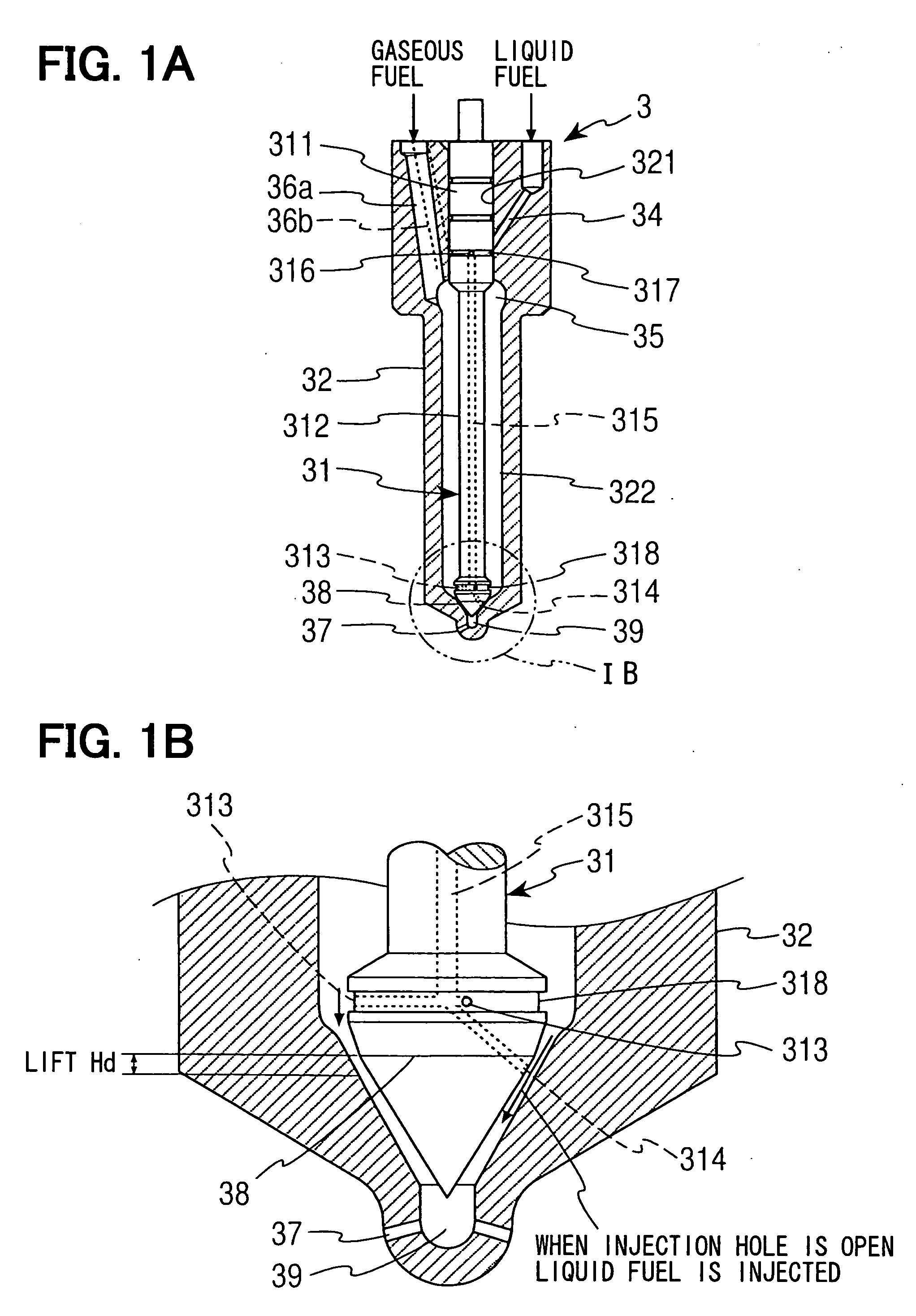

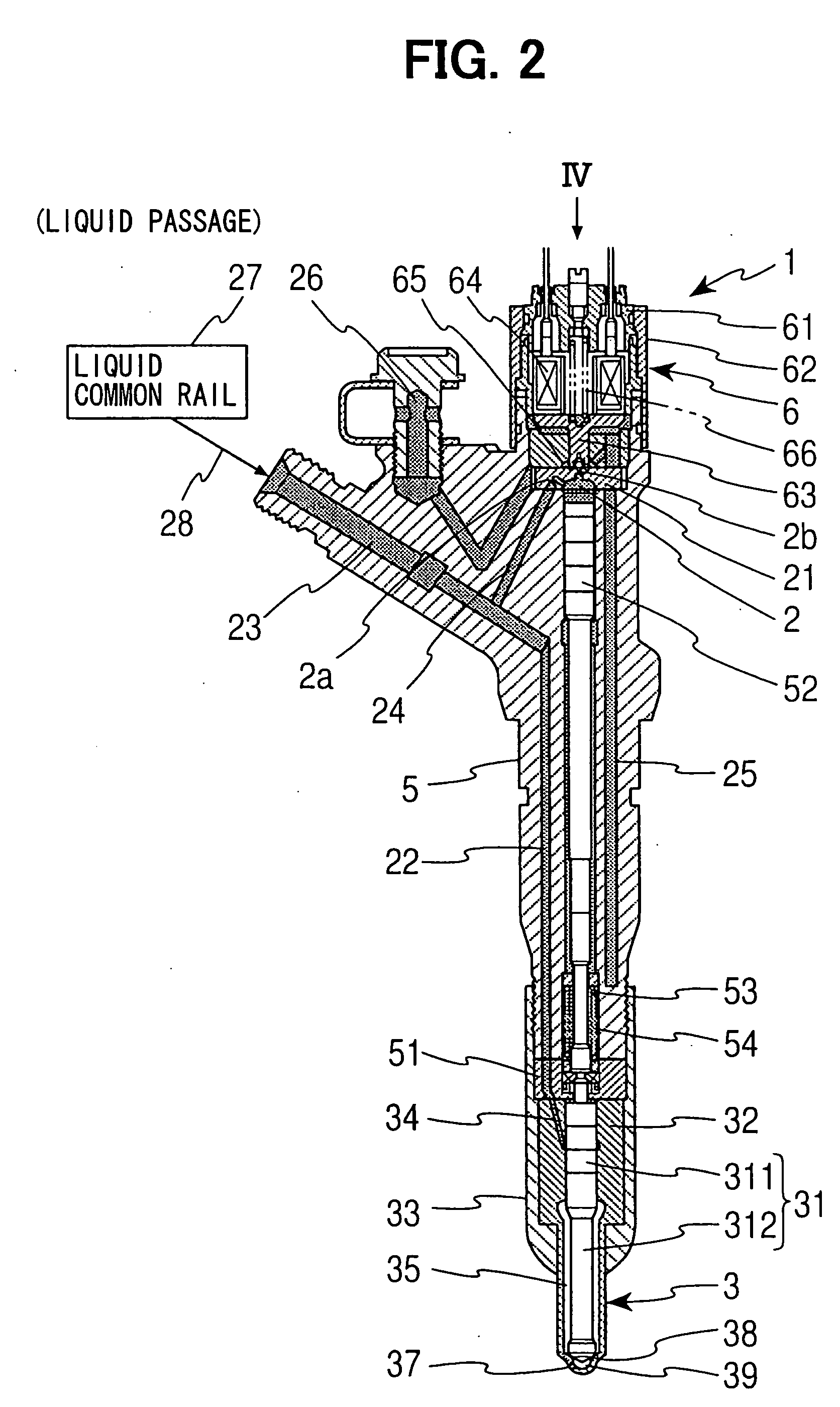

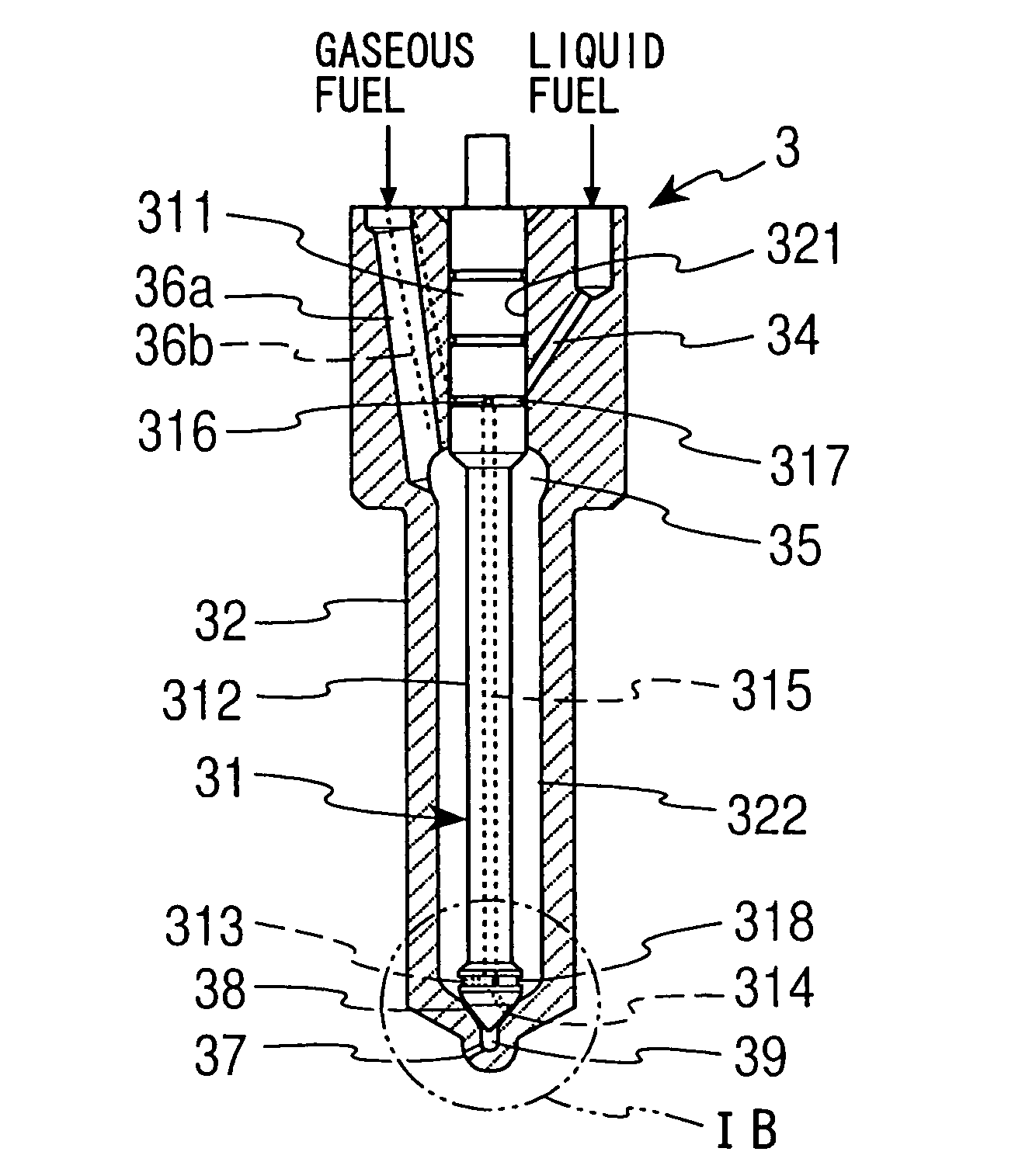

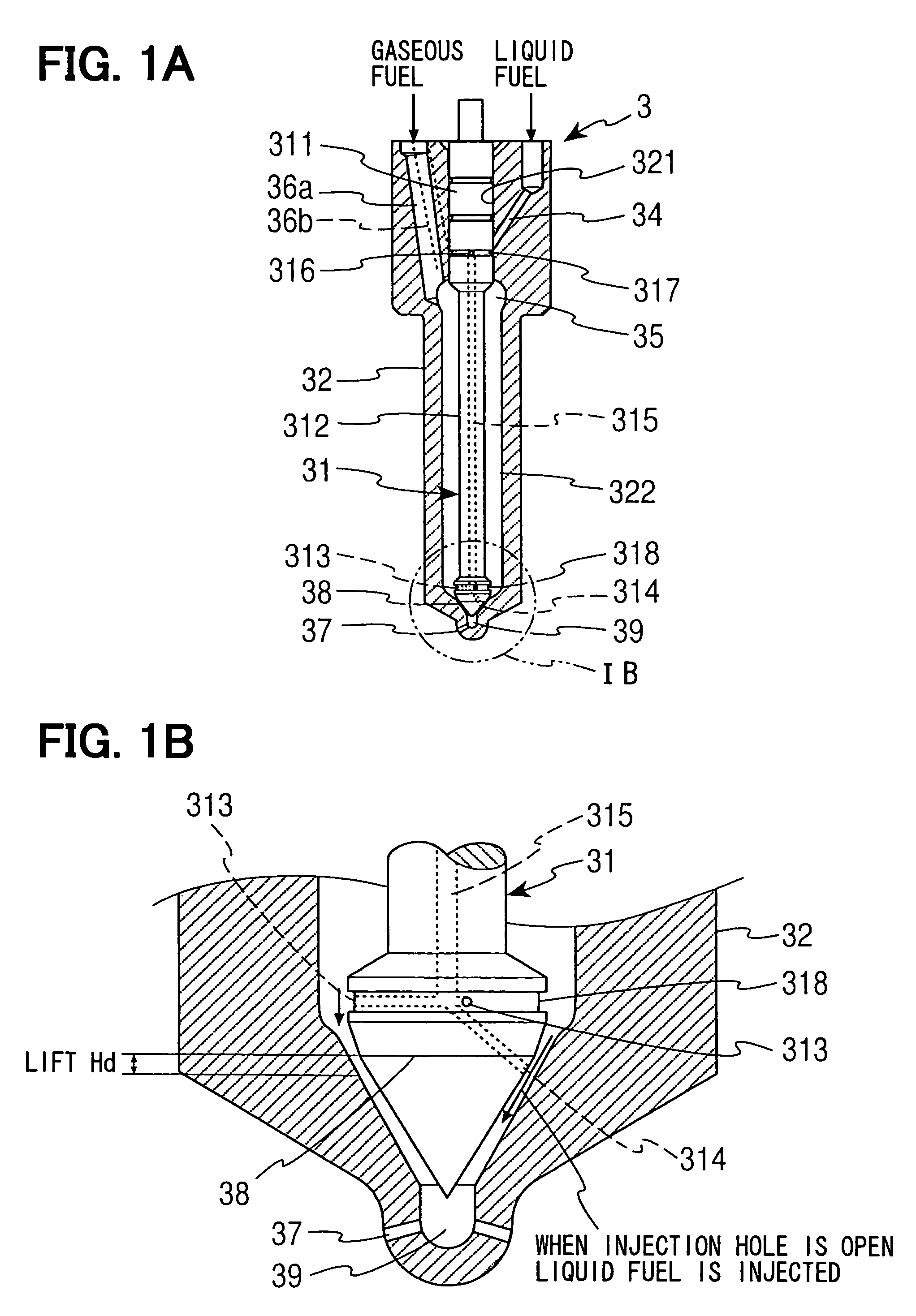

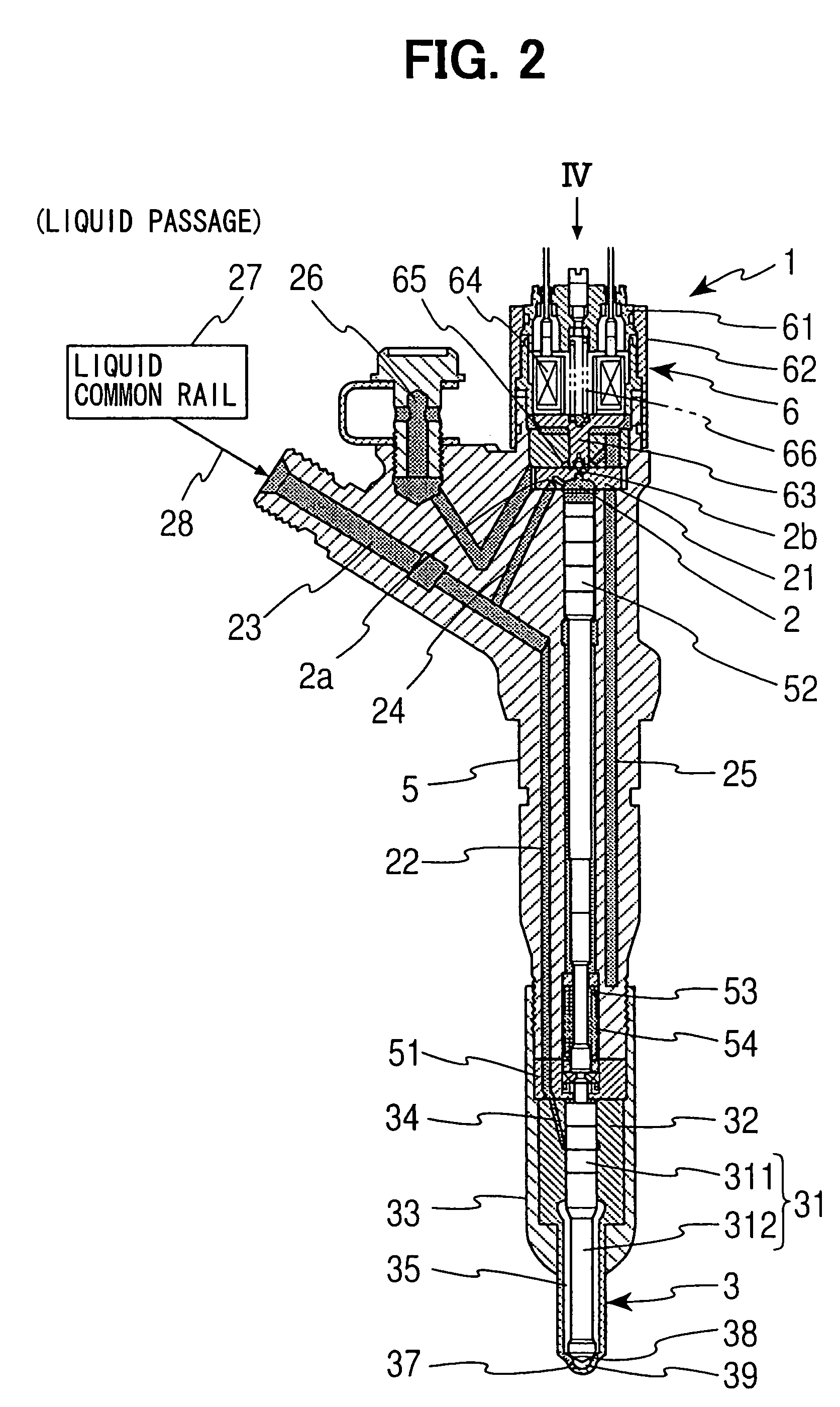

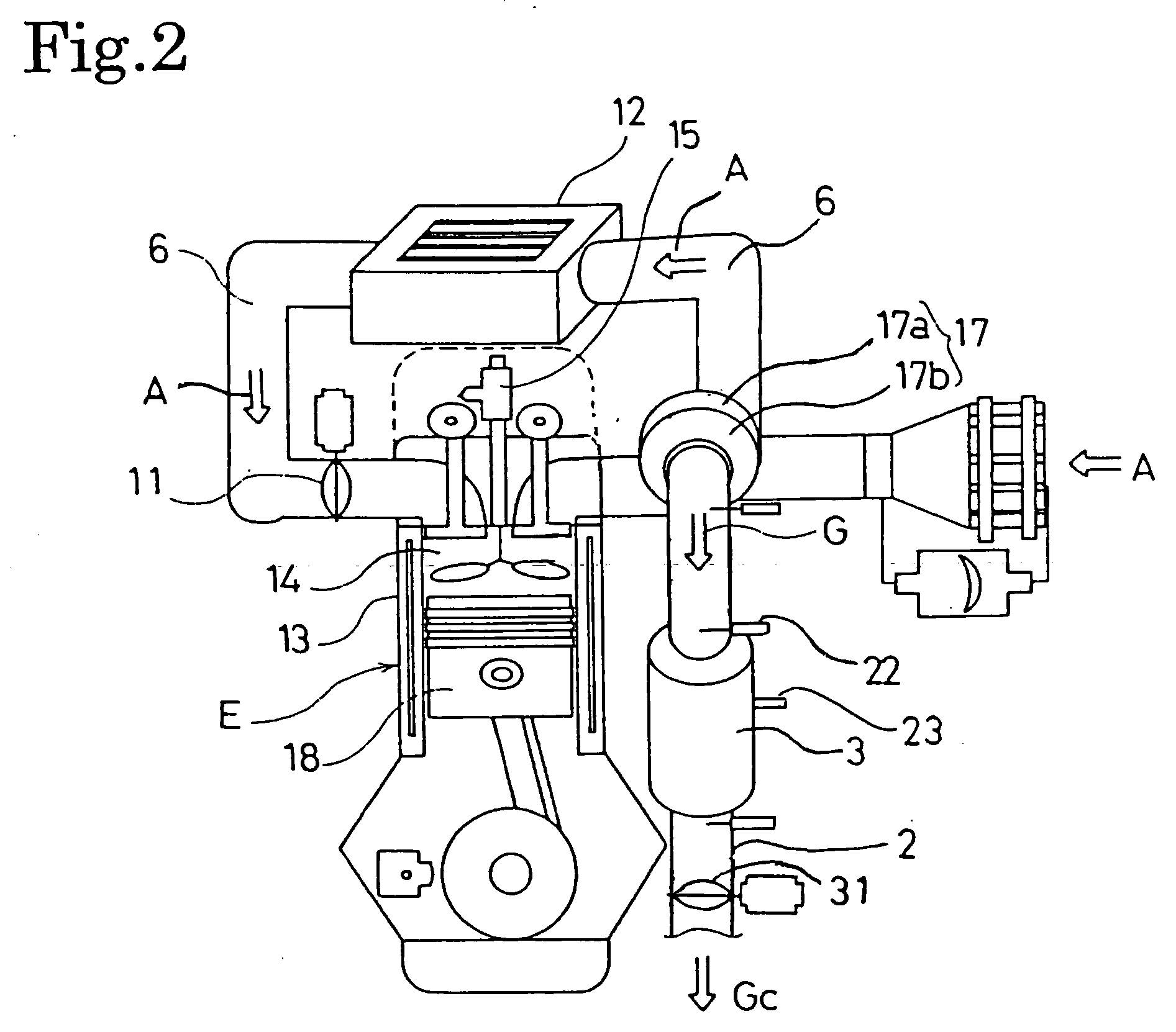

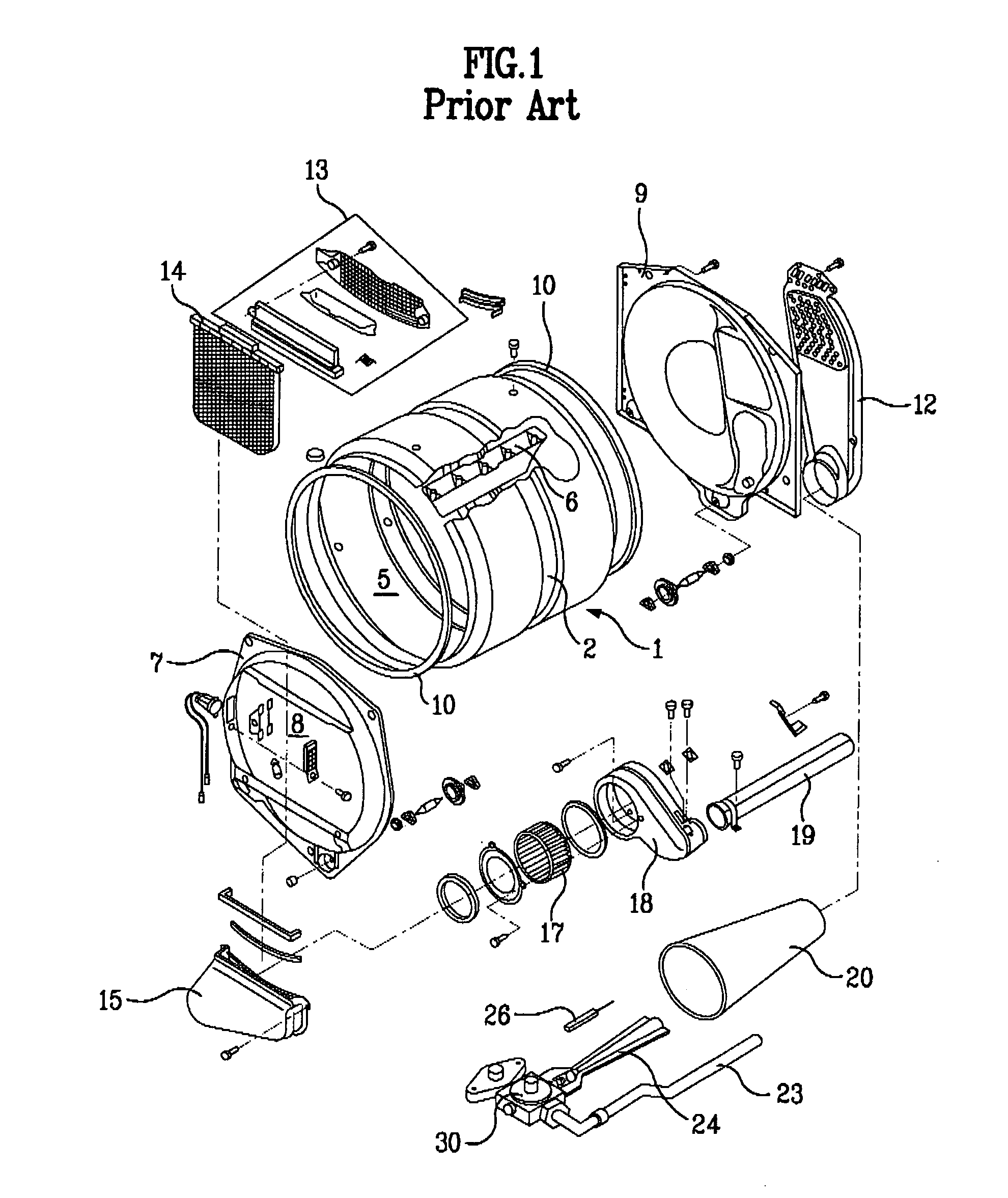

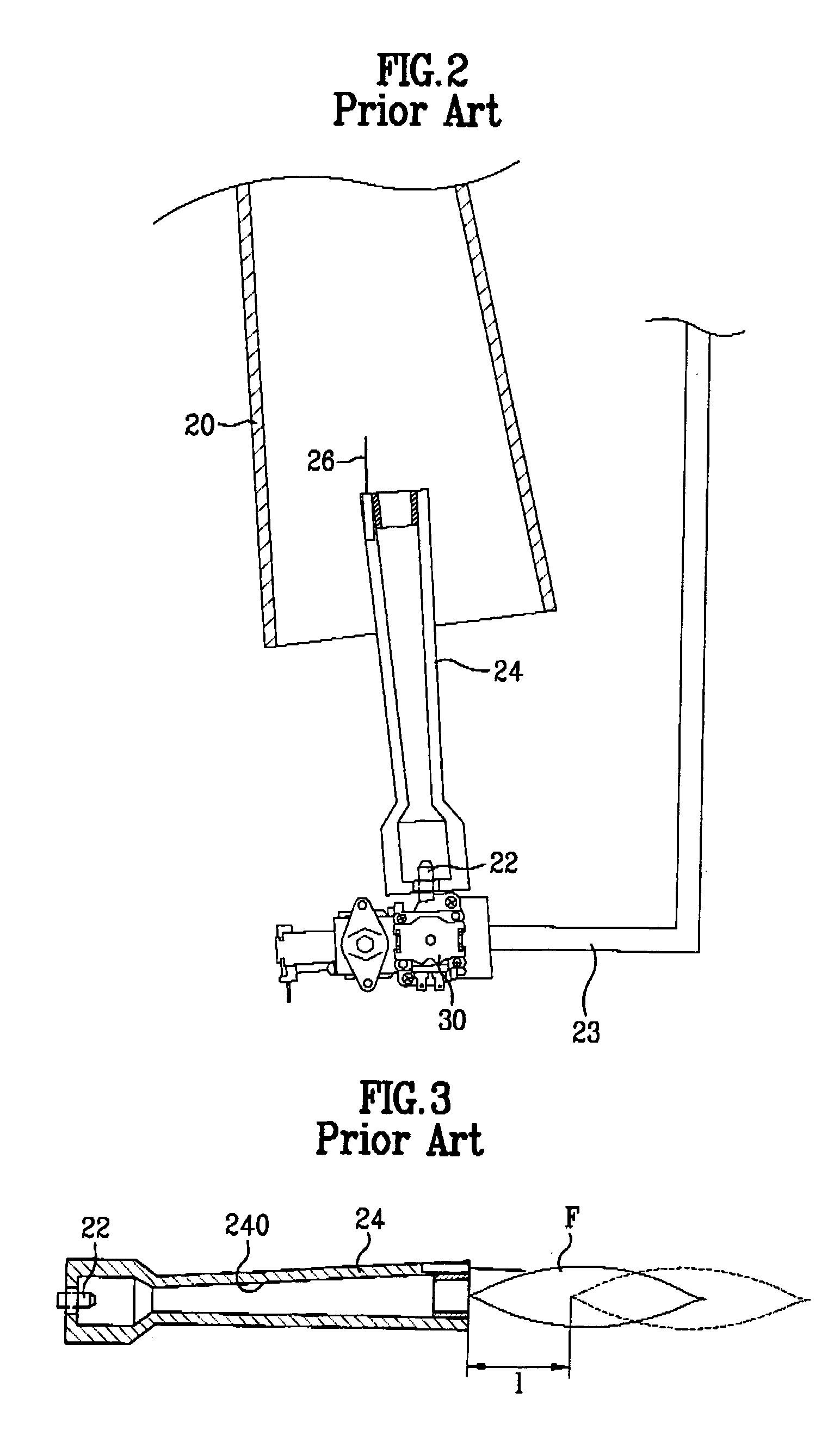

Gaseous fuel injector

InactiveUS20060086825A1Improve ignition performanceLimit wearInternal combustion piston enginesFuel supply apparatusWorking fluidEngineering

The injector includes a nozzle, a needle, a control chamber, a working fluid supply passage, an electric switching valve, a high-pressure gaseous fuel supply passage and a lubrication liquid fuel supply passage. The nozzle has an injection hole, through which high-pressure gaseous fuel is injected. The needle is axially reciprocably received in the nozzle to open and close the injection hole. The needle includes a sliding portion and a valve portion. The control chamber applies a pressure to the needle. The working fluid supply passage supplies liquid fuel to the control chamber. The electric switching valve controls an inflow / outflow of the liquid fuel to / from the control chamber. The high-pressure gaseous fuel supply passage supplies the high-pressure gaseous fuel to the injection hole. The lubrication liquid fuel supply passage supplies the liquid fuel from the working fluid supply passage to the sliding portion and the valve portion.

Owner:DENSO CORP

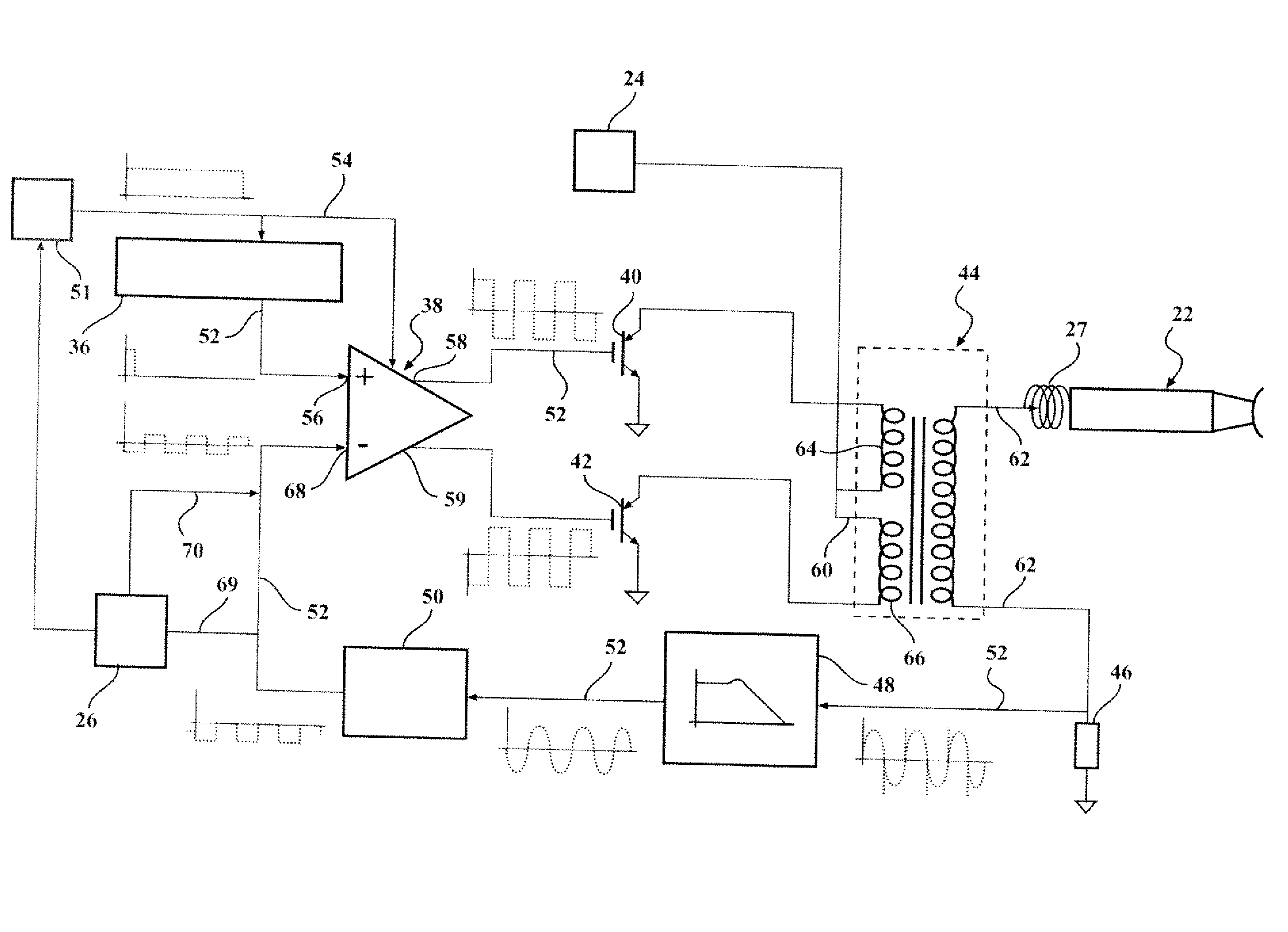

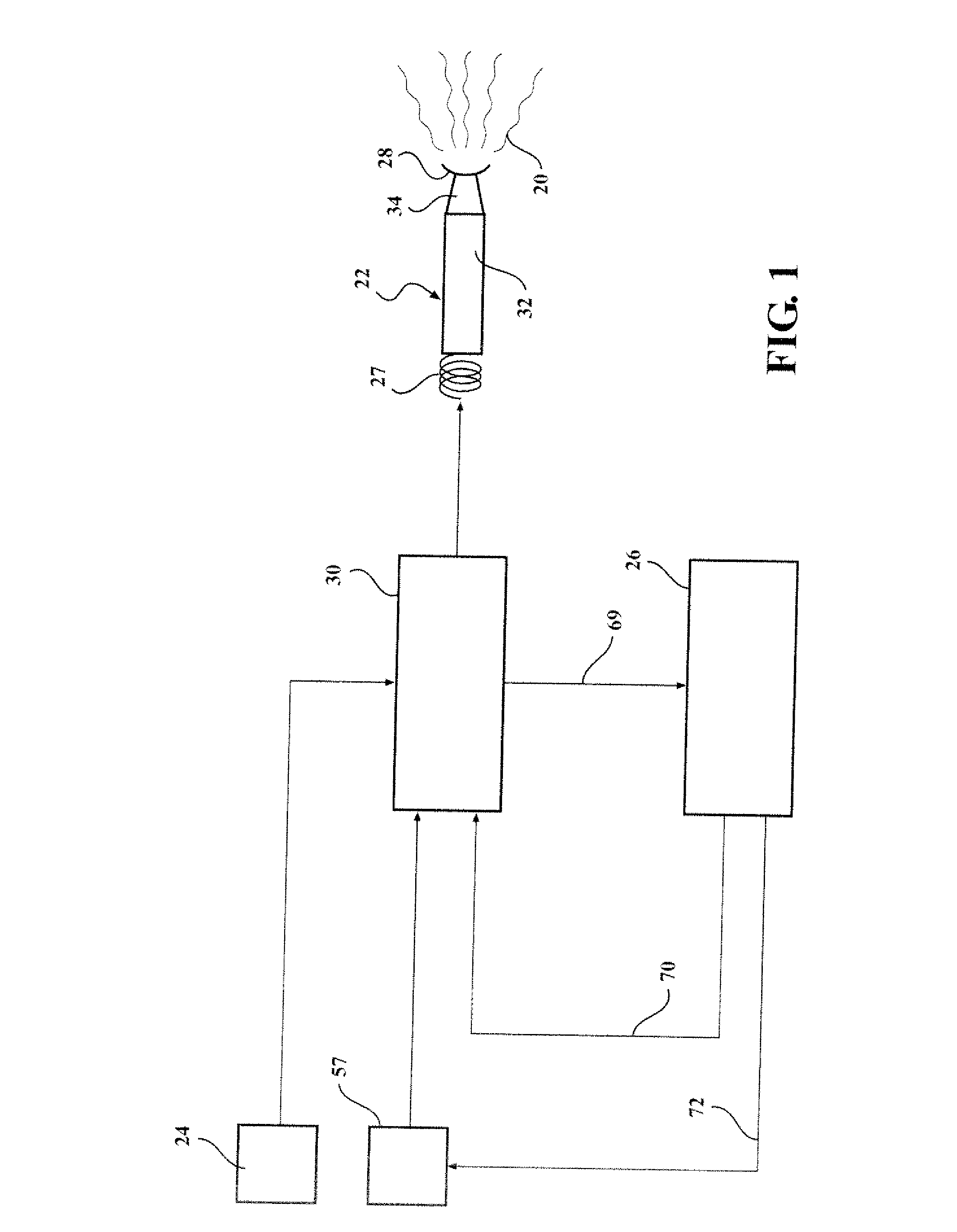

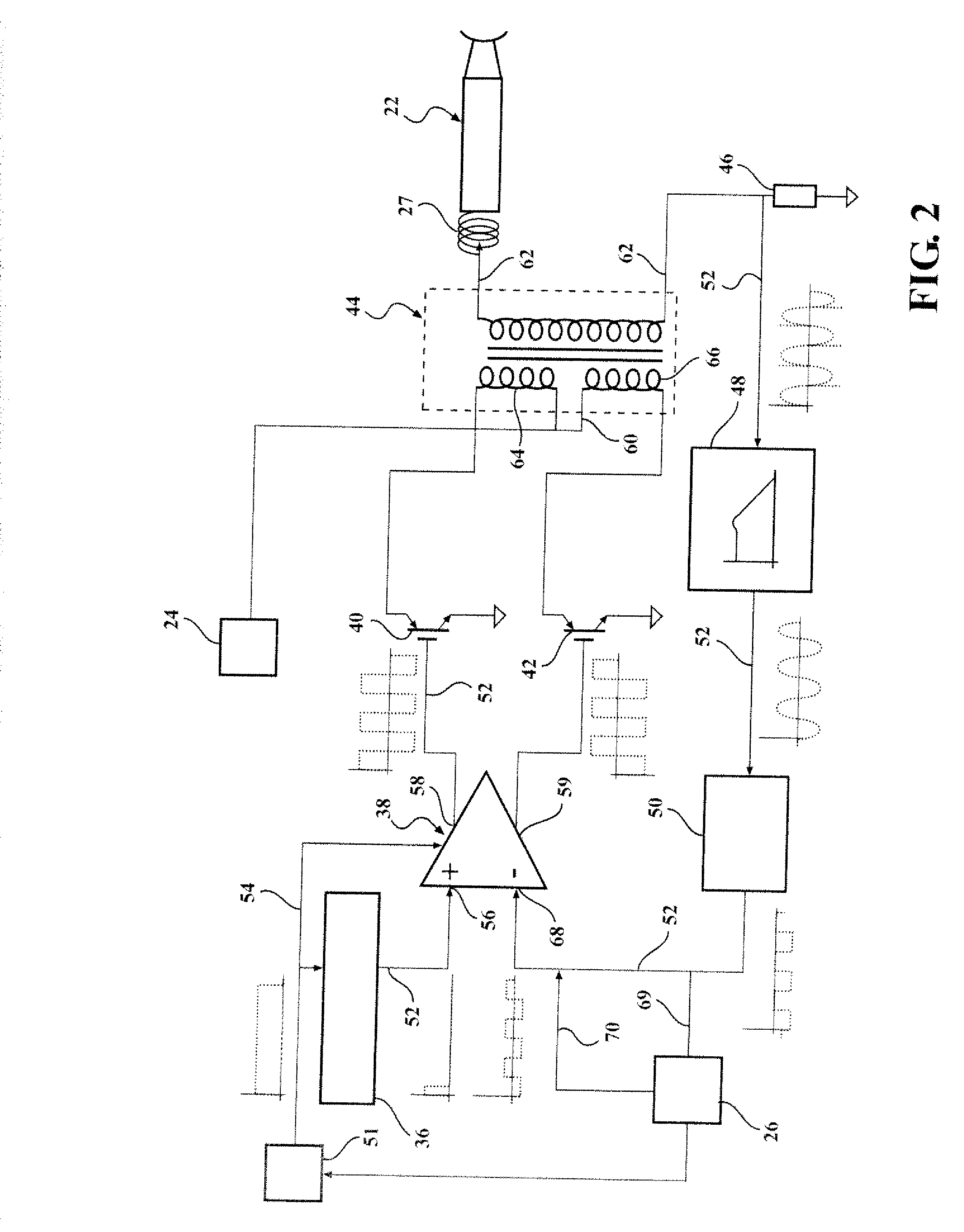

System and method for controlling arc formation in a corona discharge igntition system

ActiveUS20120249006A1Reduce voltageImprove energy efficiencyElectrical controlElectric light circuit arrangementElectricityCorona discharge

A system and method for controlling an arc formation in corona discharge ignition system is provided. The system includes a corona igniter for receiving energy at a voltage and providing a corona discharge. An energy supply providing the energy to the corona igniter at a voltage. The system also includes a corona controller for initiating a decrease in the voltage of the energy provided to the corona igniter in response to the onset of arc formation. The voltage is decreased until the arcing is depleted, and then the voltage is increased again to resume the corona discharge. Controlling the arc formation provides improved energy efficiency during operation of the corona discharge ignition system

Owner:FEDERAL MOGUL IGNITION

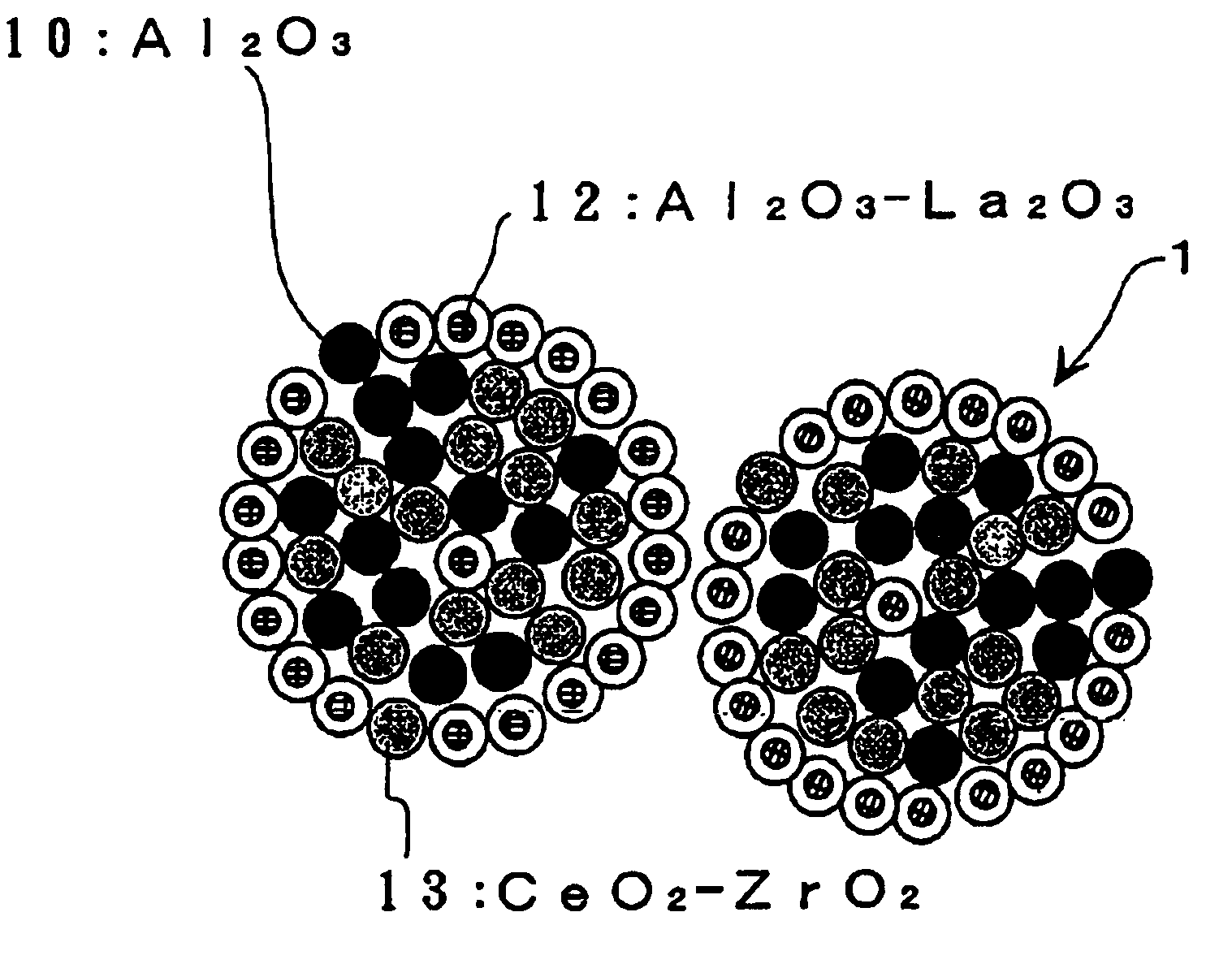

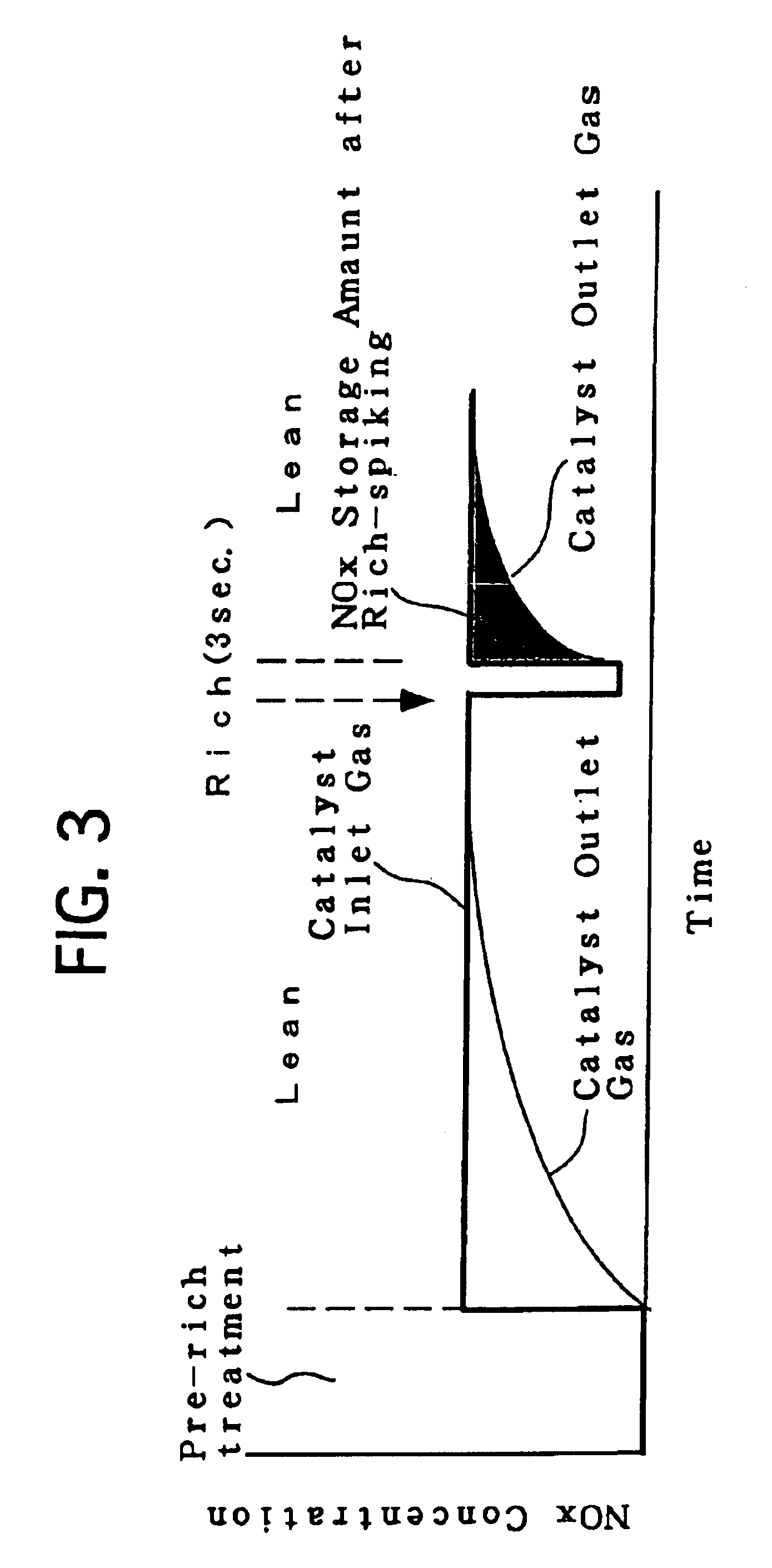

Composite oxide, process for producing the same, catalyst for purifying exhaust gas, and process for producing the same

InactiveUS6852665B2Improve performanceImprove ignition performanceCatalyst carriersMolecular sieve catalystsSulfurComposite oxide

A composite oxide includes agglomerated particles which have an average particle diameter of 20 μm or less, which are composed of a plurality of metallic element oxides being in form of fine particles having an average diameter of 50 nm or less, and which have a surface and an inner portion whose metallic element distributions differ with each other. The characteristics of the respective metallic elements are exhibited maximally. Hence, it is extremely useful as a support for an exhaust gas purifying catalyst. The catalyst exhibits the activities which degrade less even after it is subjected to a sever durability, is good in terms of the heat and sulfur-poisoning resistance, and can efficiently purify the harmful components in exhaust gases. Moreover, it is possible to produce such a composite oxide and catalyst easily and stably by production processes disclosed herein.

Owner:TOYOTA CENT RES & DEV LAB INC

Smoking article

ActiveUS8616217B2Reduce component countIncrease the diameterTobacco preparationTobacco treatmentFlavorEngineering

A smoking article comprises a multilayered tube member (9) including at least one metal layer and one paper layer, a carbon heat source (4) arranged in an end portion of the tube member (9) to be at least partly in direct close contact with an inner surface of the tube member (9), the carbon heat source emitting heat when ignited, a smoking flavor releasing source (8) arranged in the tube member (9) to adjoin the carbon heat source (4), and a holder part (14) keeping the carbon heat source (4) in direct contact with said end portion and holding the carbon heat source (4) against said end portion.

Owner:JAPAN TOBACCO INC

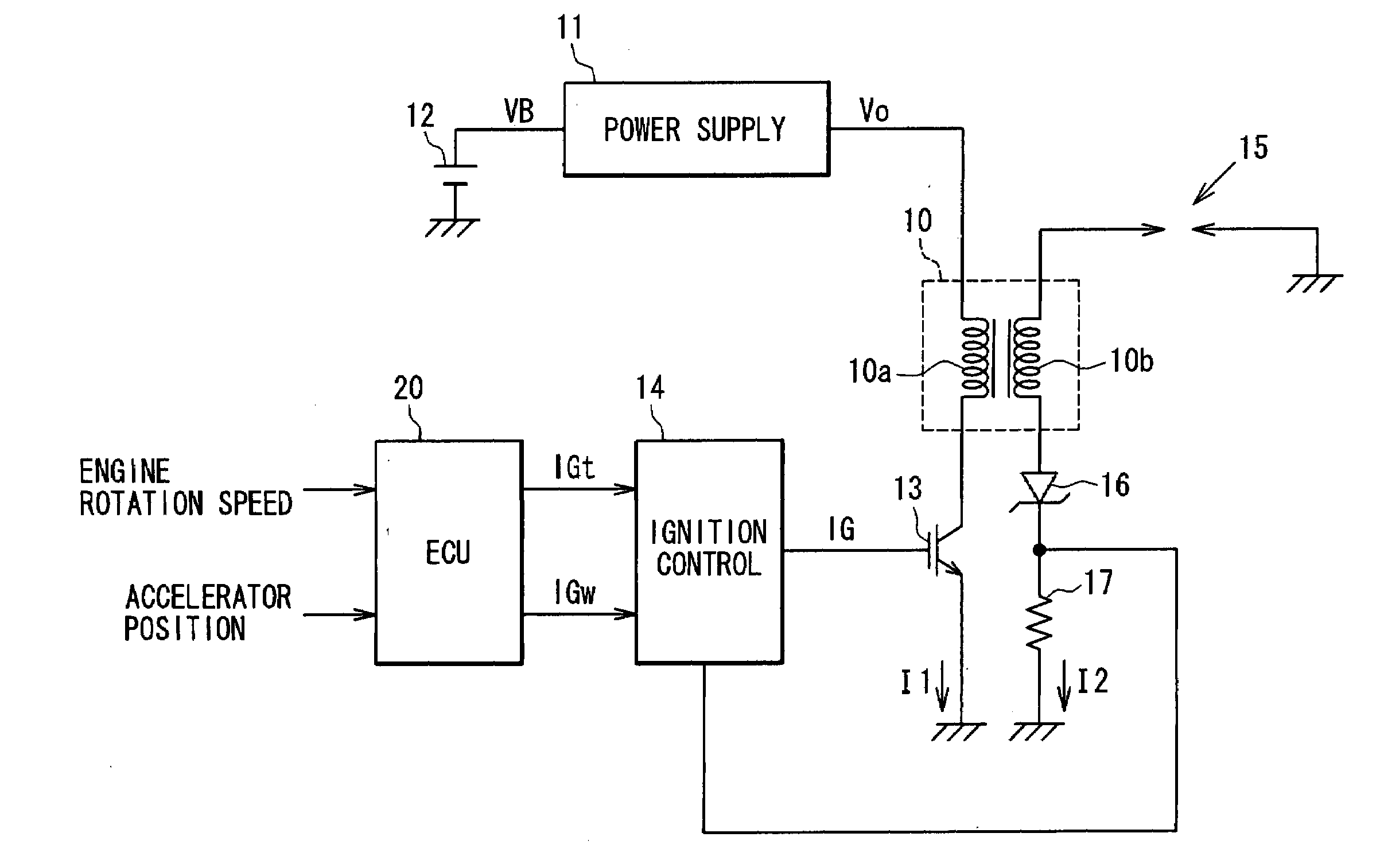

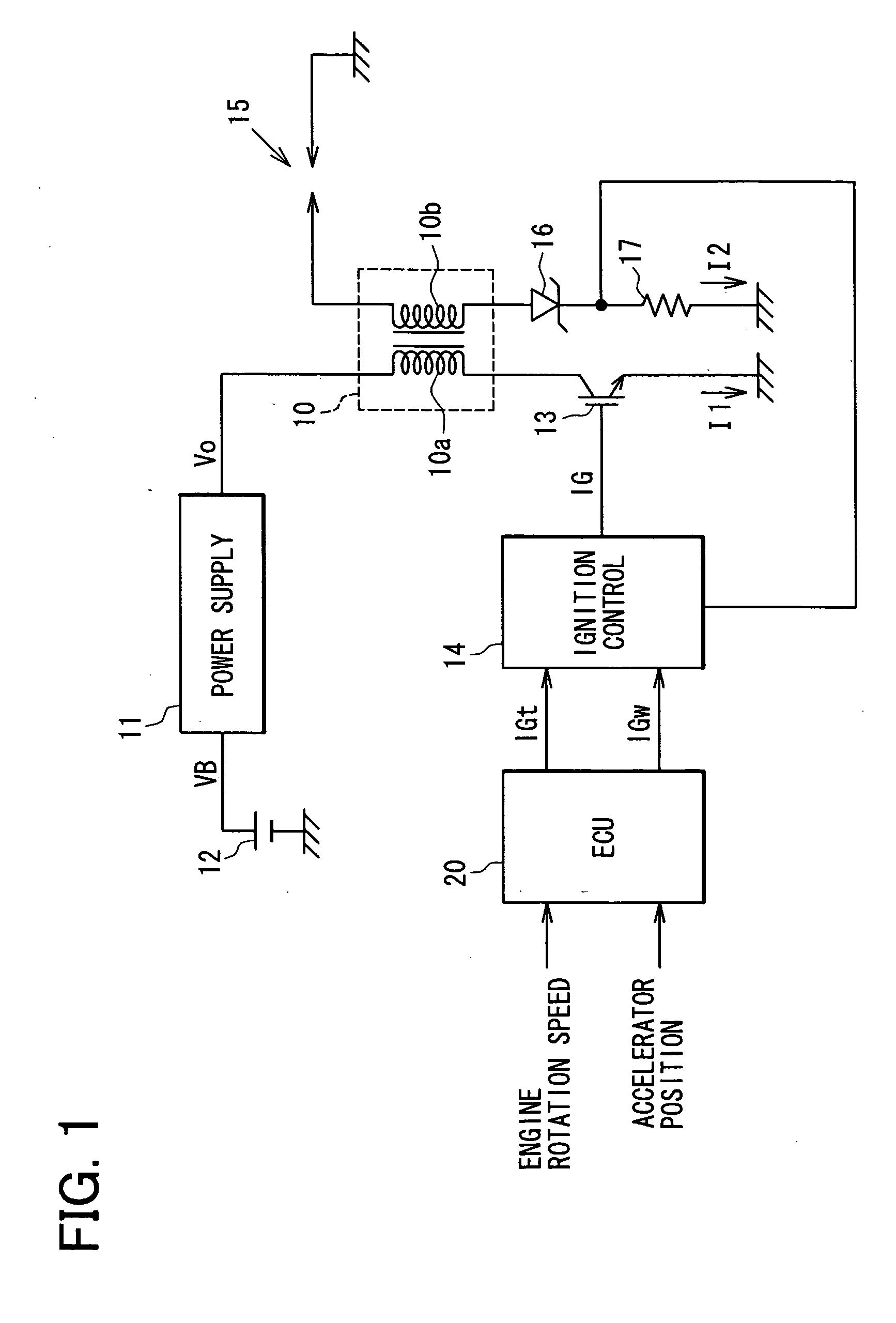

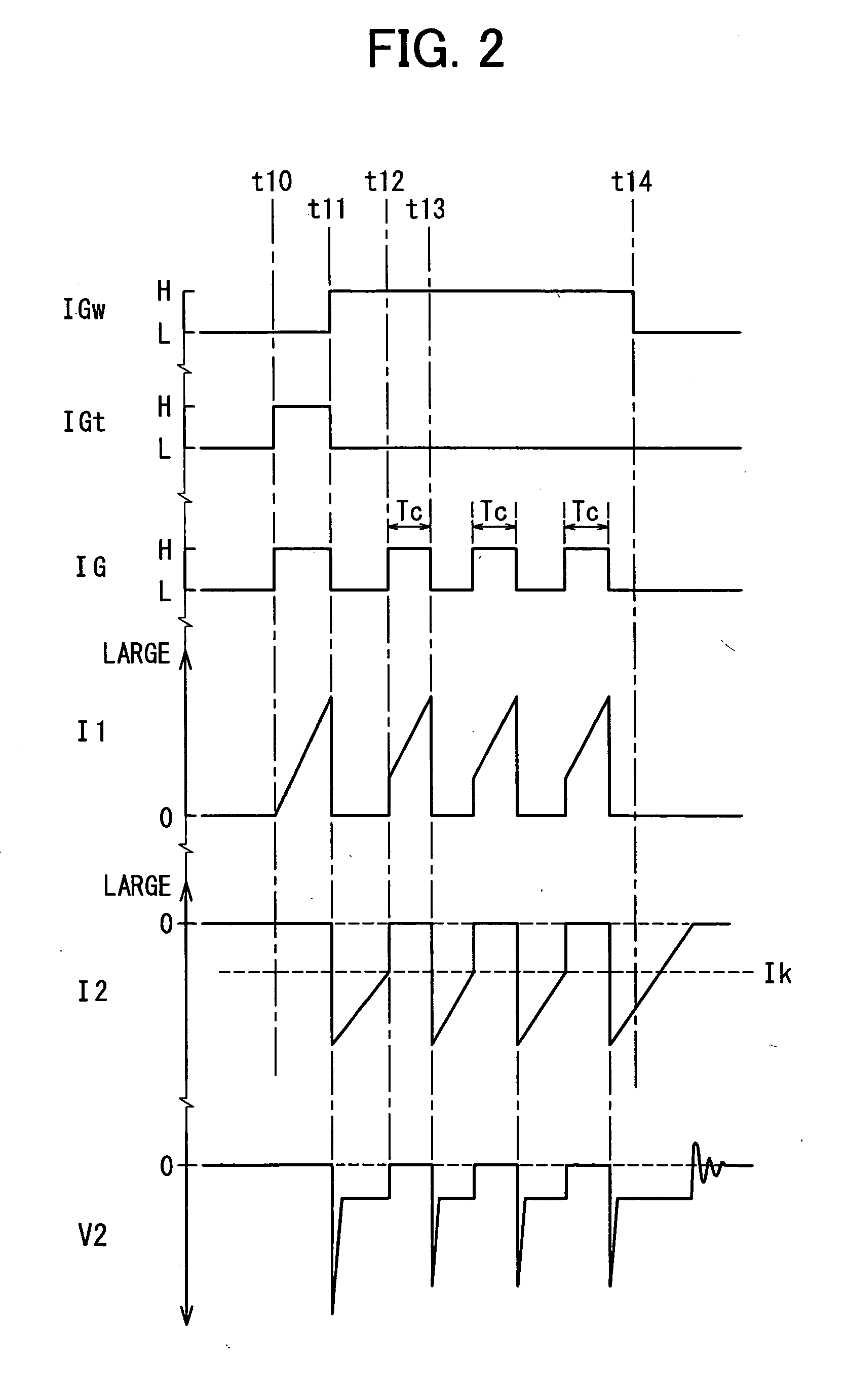

Multiple-spark ignition system for internal combustion engine

ActiveUS20070175461A1Good fuel ignition performanceImprove ignition performanceInternal combustion piston enginesAdvancing/retarding ignitionIgnition coilMixed gas

An ignition system for an internal combustion engine includes an ignition coil, electric power supply circuit, a switching transistor, engine condition detecting element or unit that detects a signal relating to flow speed of air-fuel-mixture gas in the engine, and ignition control unit that controls the switching transistor to provide multiple ignition sparks in a predetermined ignition period. The ignition control unit controls the switching transistor to maintain each of the ignition sparks according to the signal relating to the flow speed of air-fuel-mixture gas in the engine to maintain sufficient spark energy for igniting the air-fuel mixture gas.

Owner:DENSO CORP

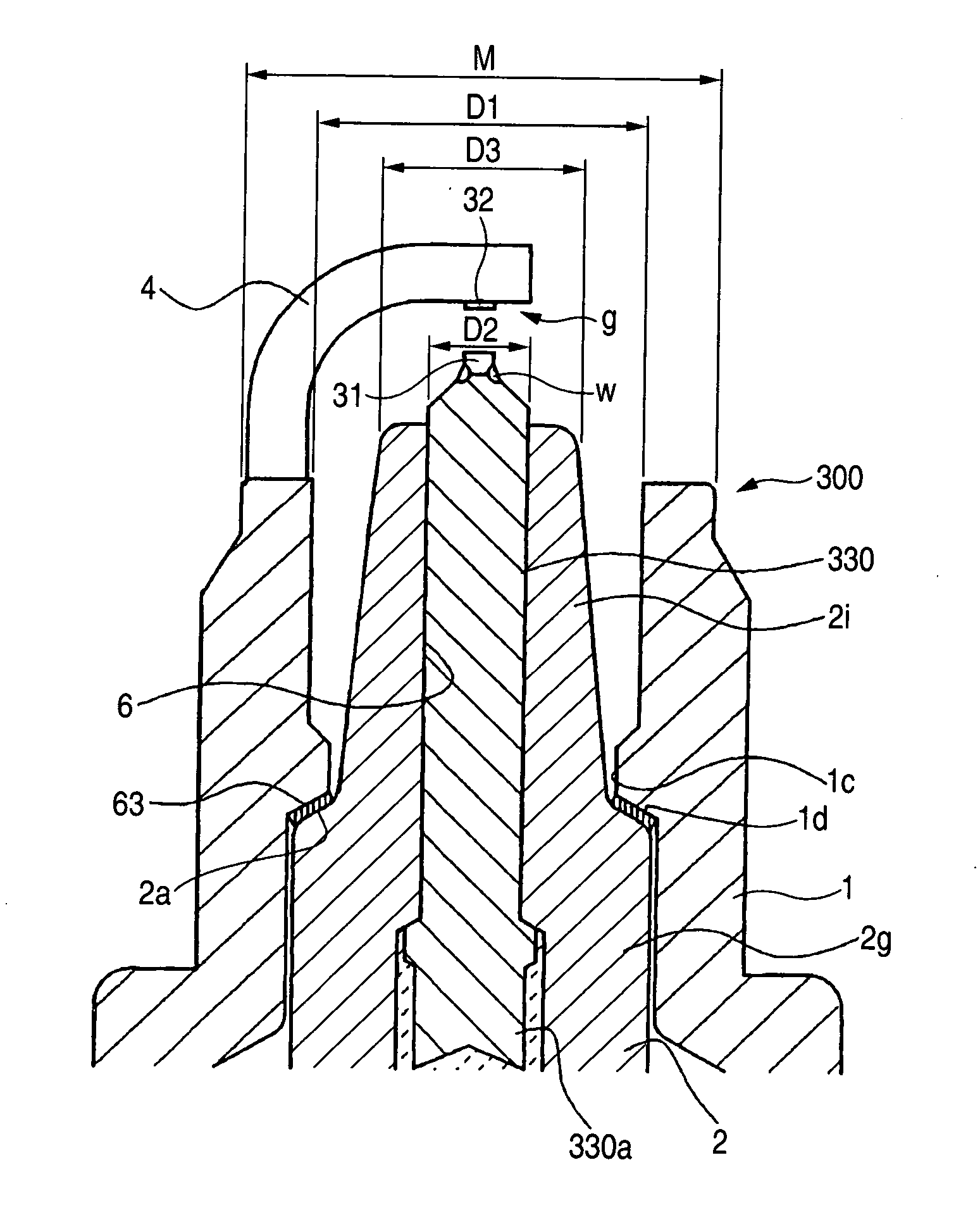

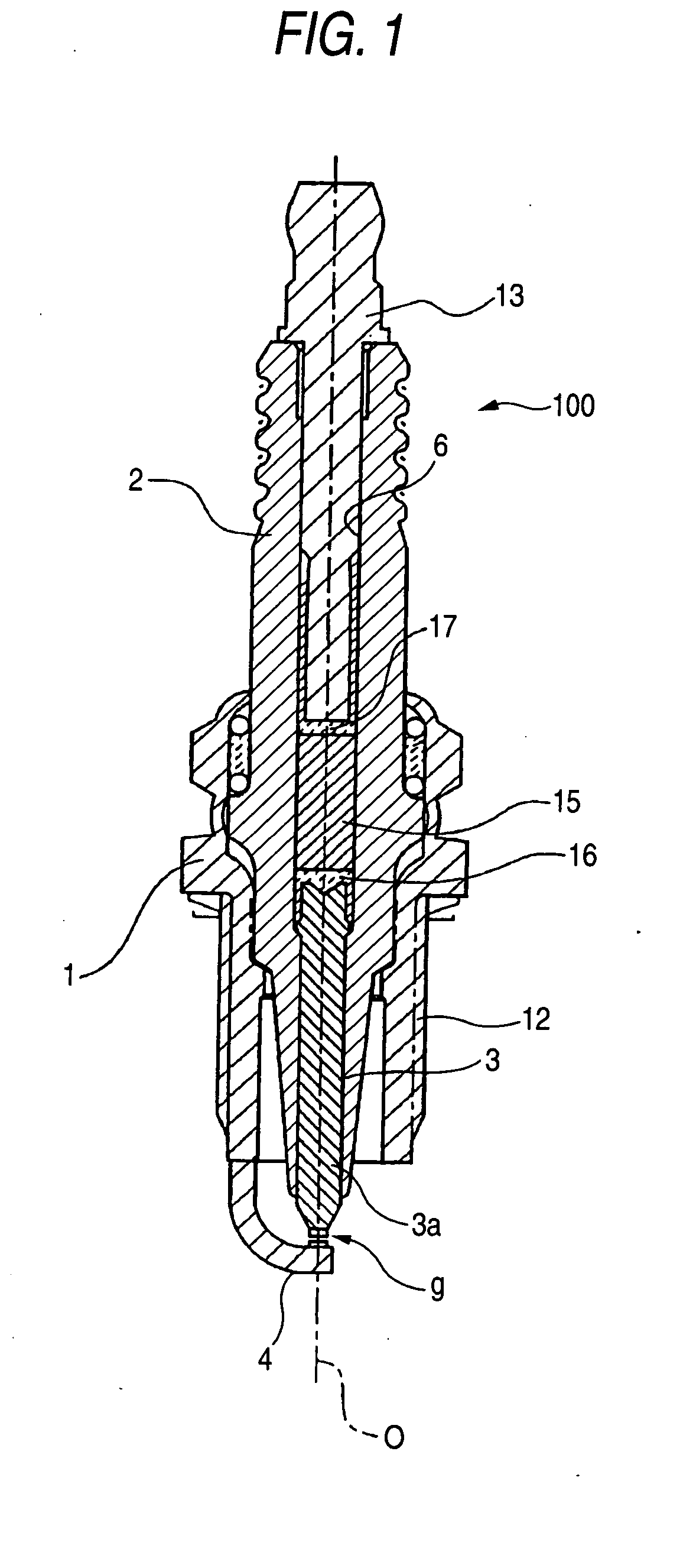

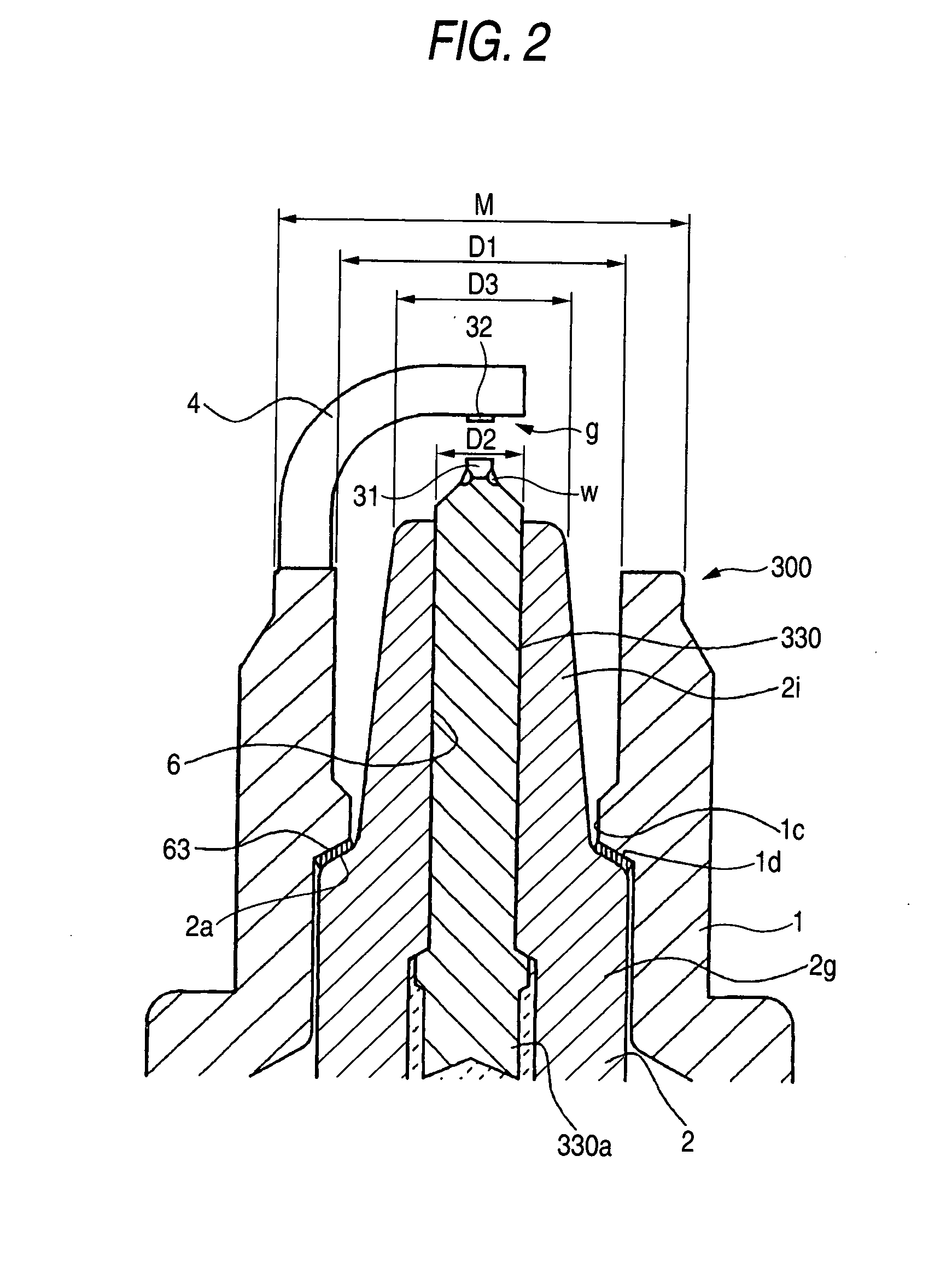

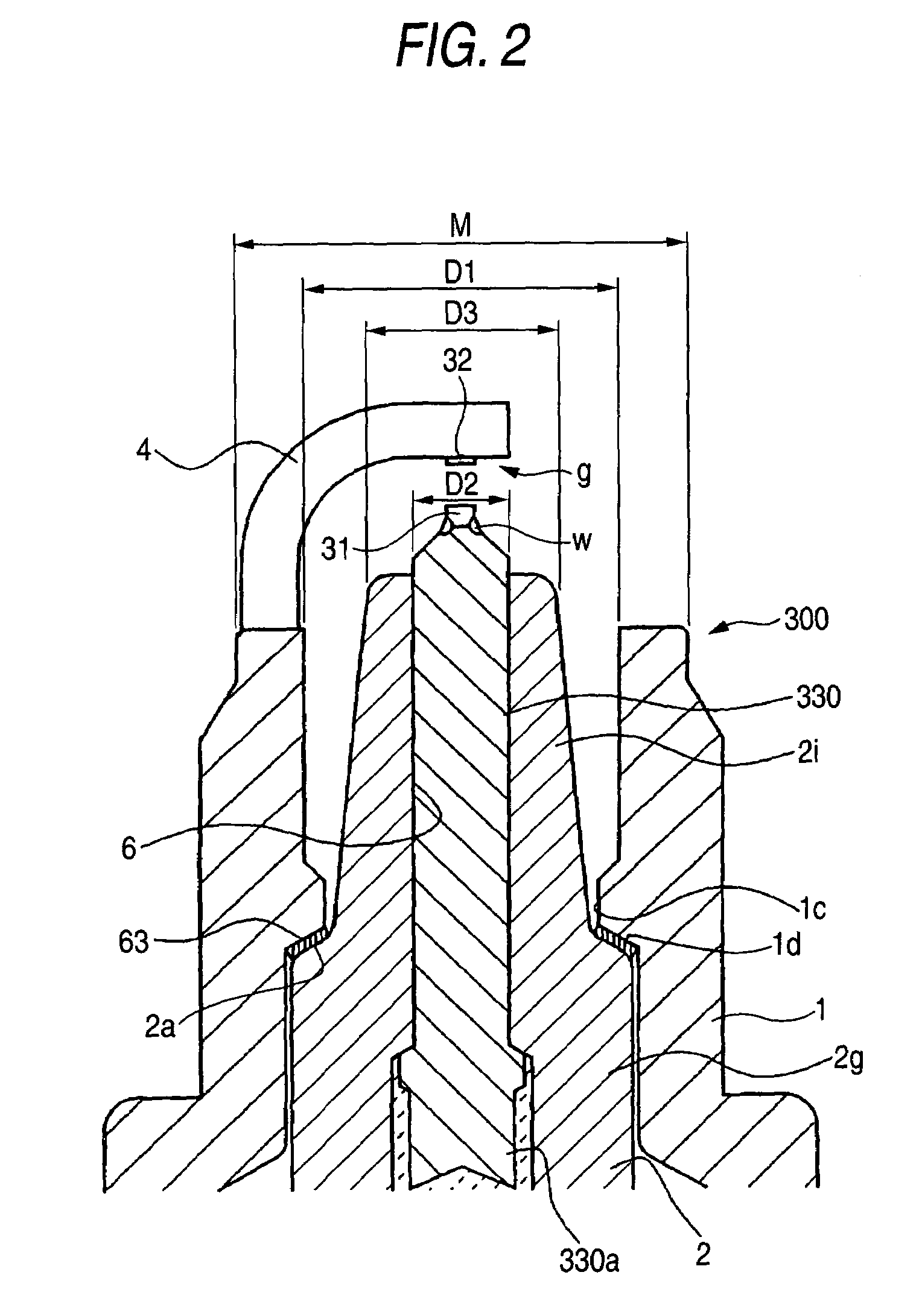

Spark plug

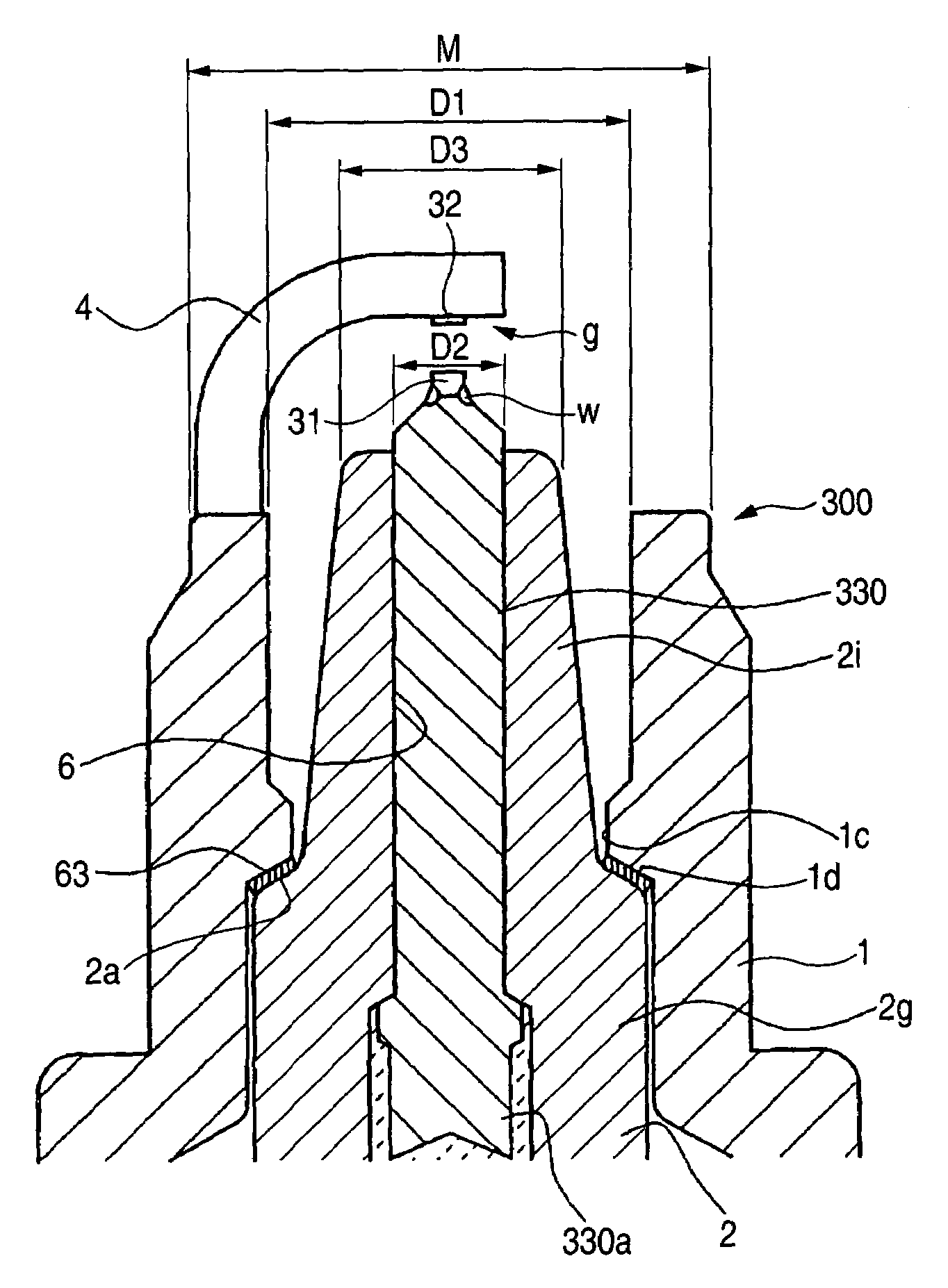

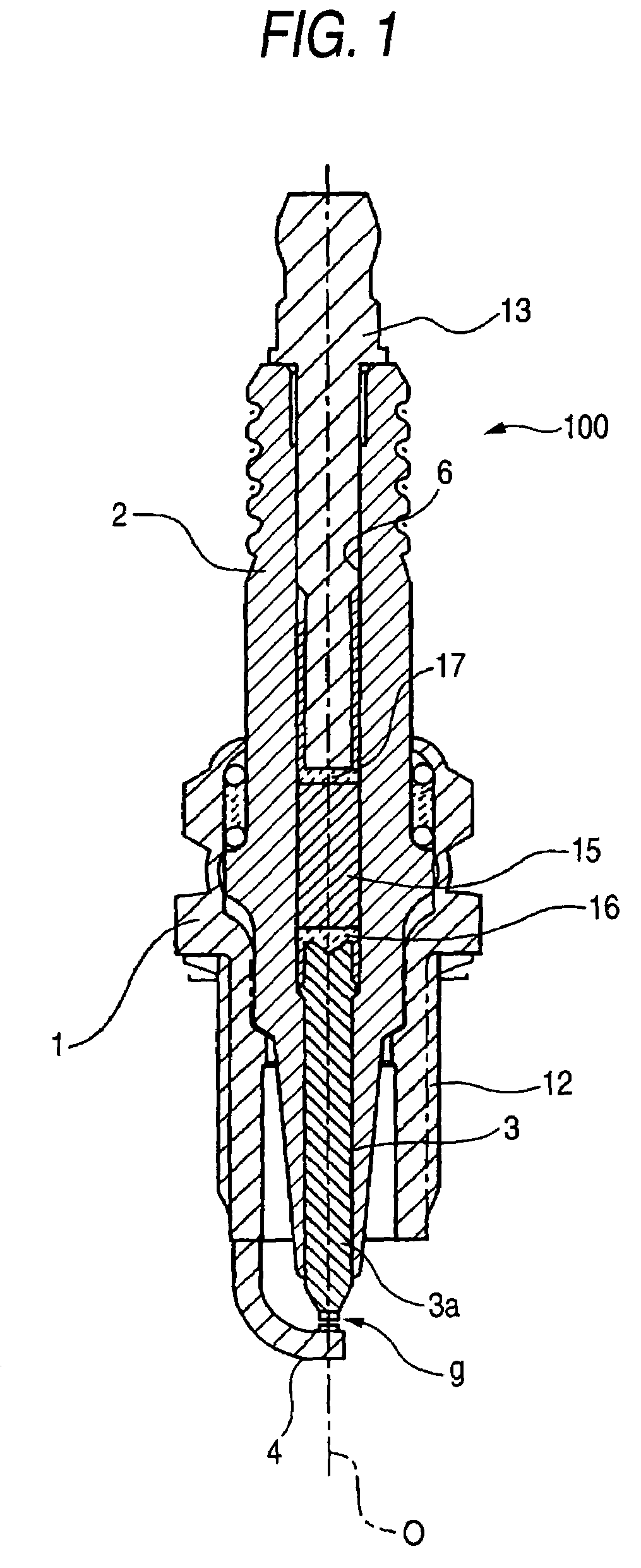

A spark plug including an insulator having an axial hole in an axial direction; and a center electrode disposed in a tip end side of the axial hole of the insulator so as to project a tip end of the center electrode from the tip end side of the insulator. The center electrode includes an electrode base member made of pure Ni or an Ni alloy containing 85 wt % or more of Ni; and a noble metal chip fixed to a tip end of the electrode base. The spark plug further includes a metal shell surrounding the insulator; and a ground electrode in which one end is joined to the metal shell, and another end portion opposes the noble metal chip to form a spark discharge gap between the ground electrode and noble metal chip, wherein M, D1, and D2 as defined herein satisfy M≦10.1 mm, 0.5 mm≦D2<1.4 mm, and D1 / D2≧3.5.

Owner:NGK SPARK PLUG CO LTD

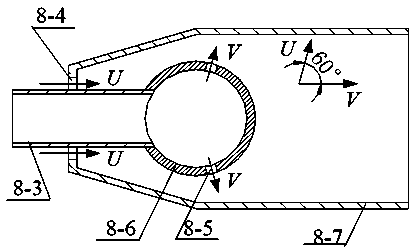

On-duty flame stabilizer

The invention discloses an on-duty flame stabilizer, which comprises an atomization slot, an oil injection rod, an evaporation tube, a stabilizer side wall and air injection holes, wherein the atomization slot is a slot-shaped structural part with certain wall thickness and is arranged in the evaporation tube, a slot mouth points downstream, and the oil injection rod is at downstream position; the oil injection rod is provided with a plurality of oil injection holes and is arranged in the evaporation tube; the evaporation tube is a slot-shaped structural part with the air injection holes at both sides and certain wall thickness, and the outer side of the evaporation tube is provided with a stabilizer side wall; the stabilizer side wall is a two-side plat plate type structural part with certain wall thickness, and two flat plates have a certain flare angle downstream; a gap is left between the atomization slot and the evaporation tube, and the gap is flush at the head part of the stabilizer; a gap is left between the evaporation tube and the stabilizer side wall, and the gap is flush at the head part of the stabilizer; the air injection holes are positioned at both sides of the evaporation tube close to the bottom; and the on-duty flame stabilizer can be used in an aircraft engine and a stamping engine to improve the ignition performance, the flame stability and the combustion efficiency.

Owner:PEKING UNIV

Candle body composition for colored flame candles and use thereof

The present invention discloses a novel candle body composition for colored flame candles, which can be directly press-molded or provided in any containers in a form of bulk materials and combined with a candle combustion wick to form a colored flame candle. The candle body composition according to the present invention is also suitable for DIY articles. Compared with conventional solid colored flame candles, the colored flame candle according to the present invention can be manufactured in a simple manner, with the heat shaping step being dispensed with and the problem of environmental pollution being largely avoided. Furthermore, the colored flame candle according to the present invention has a good ignition property, a pure and sharp flame and a high retention of flame, and is an environmentally friendly product.

Owner:JIANDE JIAXUAN ARTICLES

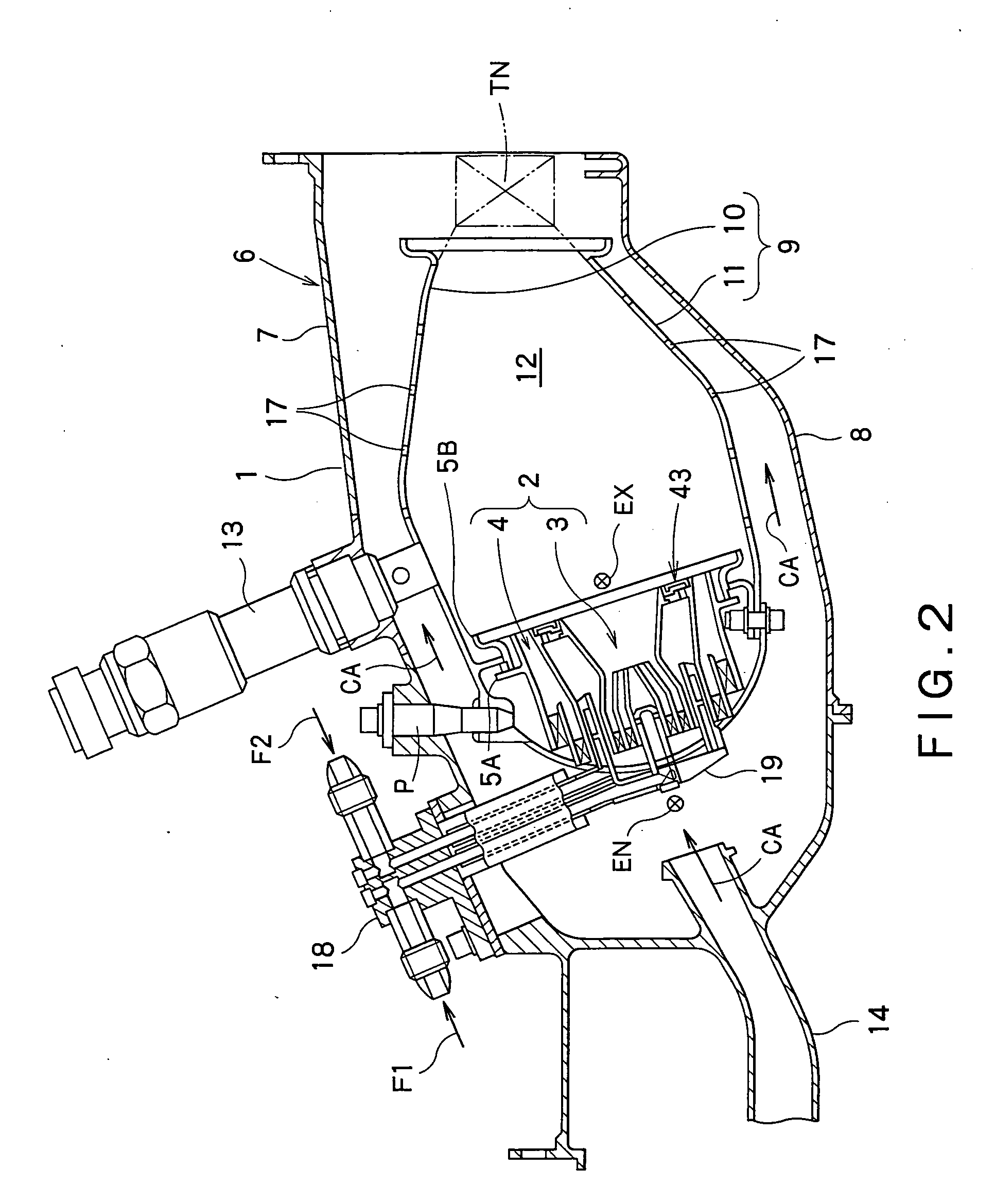

Combustor of a gas turbine engine

InactiveUS20080289340A1Enhance stabilityWell combustibleBurnersContinuous combustion chamberAutomotive engineeringGas turbines

The present invention provides a combustor of a gas turbine engine, including: a fuel spray portion configured to spray a fuel so as to create a diffusion combustion region in a combustion chamber; a pre-mixture supply portion configured to supply a pre-mixture gas including the fuel and an air so as to create a pre-mixture combustion region in the combustion chamber, the pre-mixture supply portion being positioned concentrically with the fuel spray portion so as to surround the fuel spray portion; and an annular separation portion disposed between a downstream end of the fuel spray portion and a downstream end of the pre-mixture supply portion so as to separate the diffusion combustion region and the pre-mixture combustion region from each other.

Owner:KAWASAKI HEAVY IND LTD

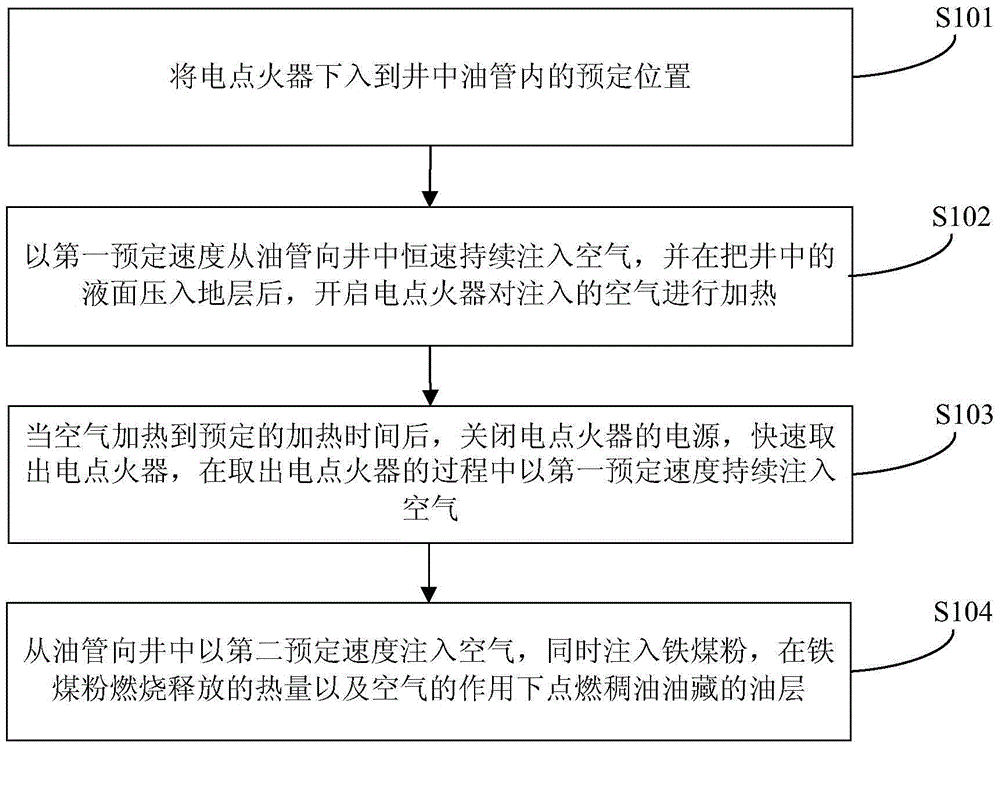

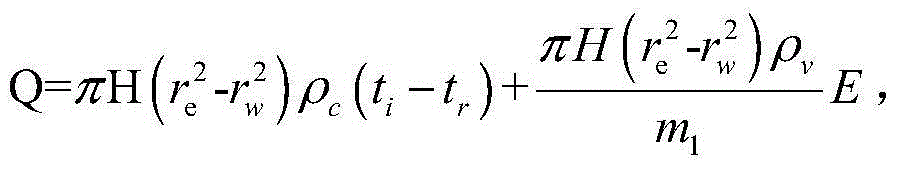

In-situ combustion combustion-supporting ignition method

ActiveCN104453817AReduce moisturePlay the role of profile control and channel sealingFluid removalElectricityHeating time

The invention discloses an in-situ combustion combustion-supporting ignition method. The method comprises the steps that an electric igniter is tripped in the preset position in an oil tube in a well; air is continuously injected into the well from the oil tube at a first preset speed, and after a liquid level in the well is pressed into a stratum, the electric igniter is started to heat the injected air; after the air is heated by the preset heating time, a power source of the electric igniter is turned off, the electric igniter is taken out, and the air is continuously injected at the first preset speed in the process of taking out the electric igniter; air is injected into the well from the oil tube at a second preset speed, meanwhile, iron pulverized coal is injected, and an oil layer of a heavy oil reservoir is ignited under the action of heat released by combustion of the iron pulverized coal and the air. Through the electric igniter, the oil layer is preheated, and water of near bore zones is reduced. The iron pulverized coal has the functions of profile correction and channeling blocking, combustion products are stored in holes, a gas entry profile continues to be adjusted, ignition is facilitated better, gas channeling is reduced, and meanwhile fast ignition is achieved.

Owner:PETROCHINA CO LTD

Elongating arc plasma jet ignition device

ActiveCN104454290AIncrease the speed of flame spreadStrong penetrating powerMachines/enginesEngine ignitionPlasma jetFlame spread

Disclosed is an elongating arc plasma jet ignition device. A swirler is fixed to the bottom of an inner cavity of a shell; a positive pole is located in the shell and fixedly connected with the swirler; the lower end of an insulation sleeve is installed in a central hole of the swirler, and an air chamber is formed in the gap between the outer peripheral surface of the middle of the insulation sleeve and the inner surface of the shell. A negative pole is embedded on a negative pole installation base, and the arc end of the negative pole extends out of the lower end of the insulation sleeve to be located in the positive pole. An arcing distance 2-8 mm long is kept between the arc end of the negative pole and a nozzle of the positive pole; an air inlet pipe is located at the upper end of the shell and communicated with the space of the air chamber formed between the insulation sleeve and the shell. The taper angle beta of the arc end of the negative pole is 40 degrees. The taper angle alpha of a contraction section of the positive pole is 60-90 degrees. Eight swirling holes with the spiral angle of 45 degrees are evenly distributed in an end surface of the swirler, and work media passing through the swirler generate swirling flow. The elongating arc plasma jet ignition device has the advantages of being high in flame spreading speed, high in penetrating power and rich in active air plasma.

Owner:AIR FORCE UNIV PLA

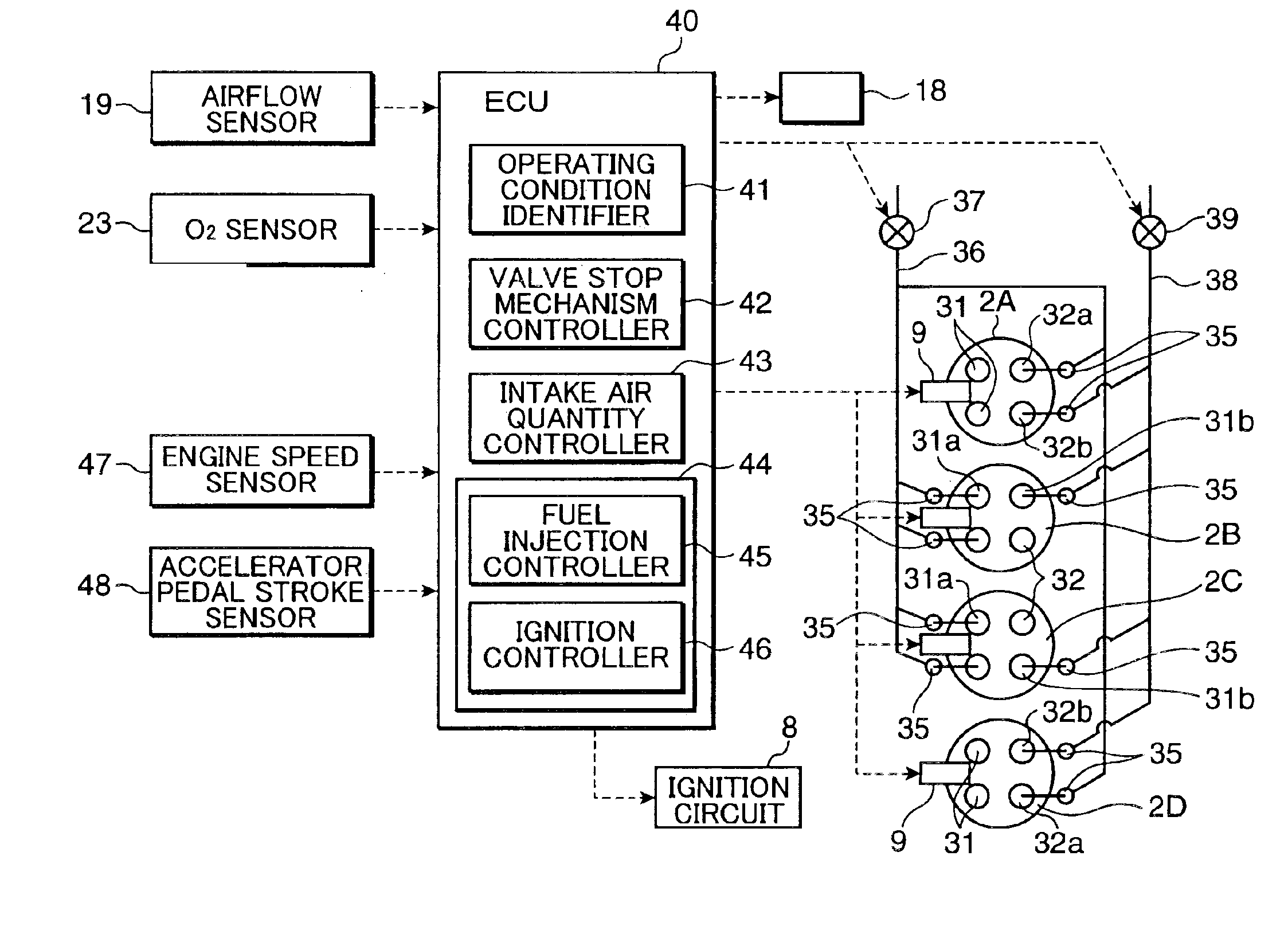

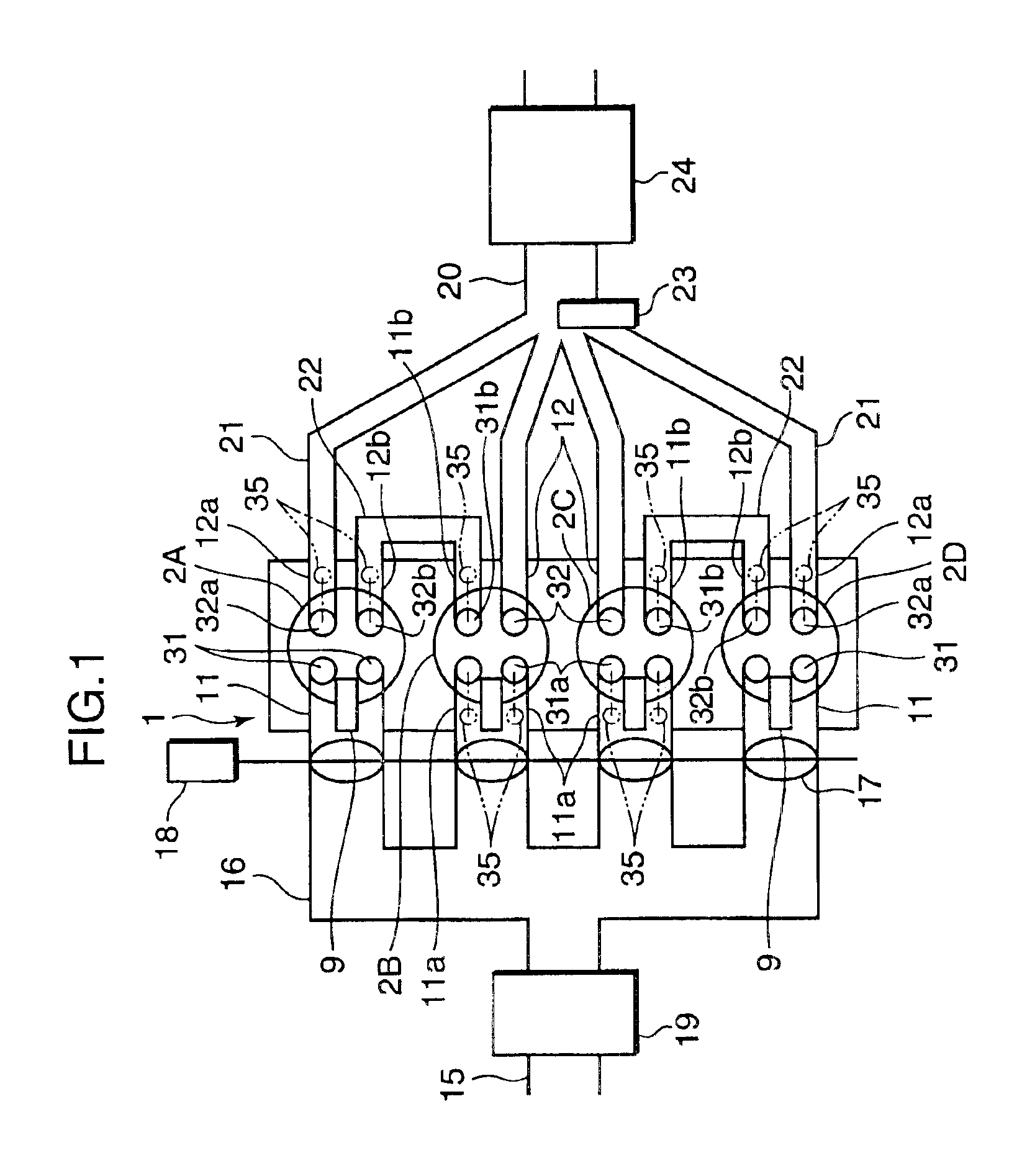

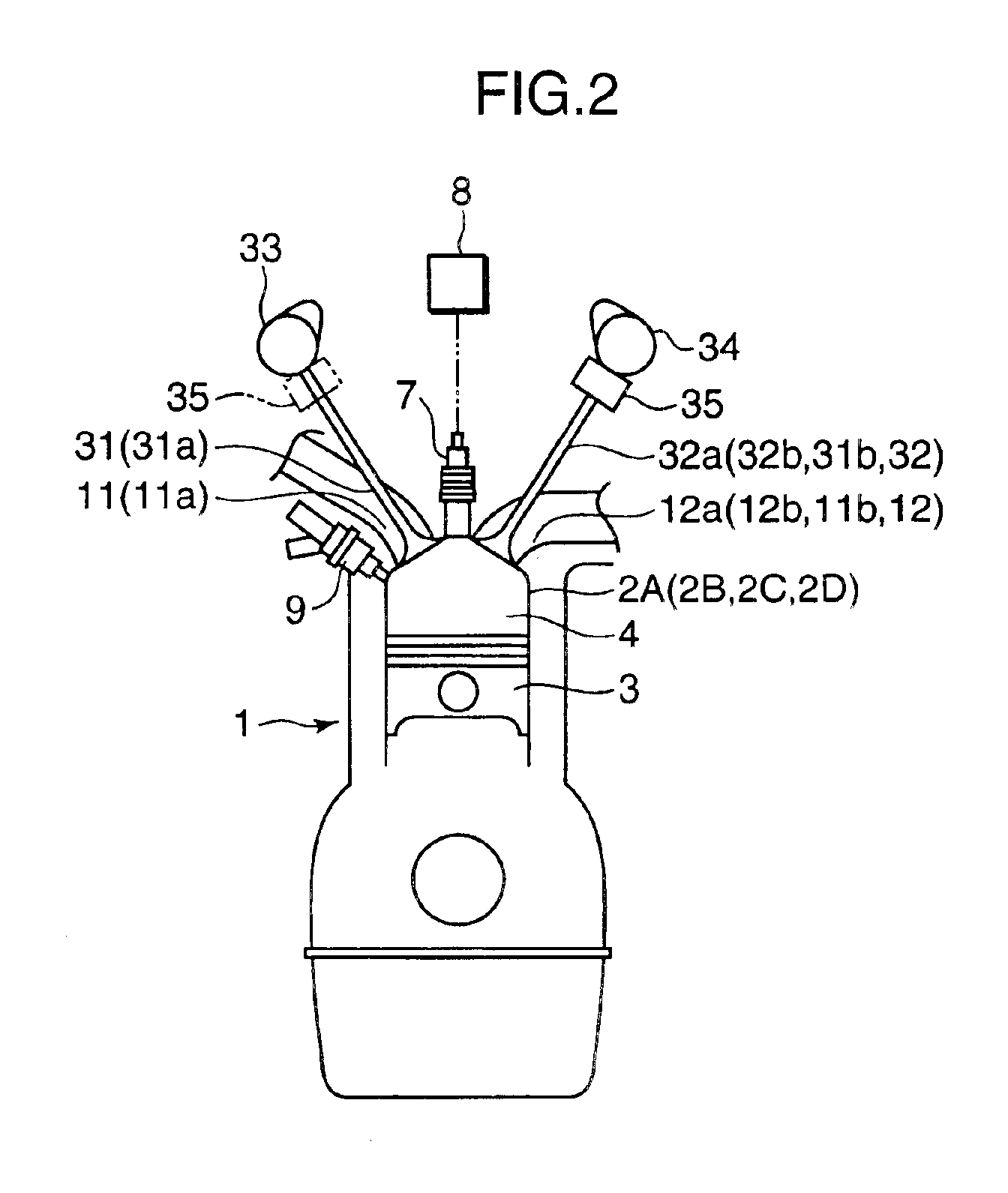

Spark-ignition engine controller

InactiveUS6877464B2Large operating rangeImprove fuel economyValve arrangementsElectrical controlOperation modeFuel injection

Intake air / exhaust gas flow control is performed in an partial load range of an engine such that burned gas which is discharged from an exhaust stroke side preceding cylinder of a pair of cylinders having an overlapping exhaust stroke and intake stroke is introduced into an intake stroke side following cylinder through an intercylinder gas channel. In an operating range set as a special operation mode, a combustion condition controller executes control such that combustion is performed in the following cylinder by means of compression ignition. In an operating condition in which knocking is likely to occur within the compression ignition range of the following cylinder, control is executed by a fuel injection controller such that the timing of fuel injection into the following cylinder is retarded relative to that of an operating condition in which knocking is unlikely to occur.

Owner:MAZDA MOTOR CORP

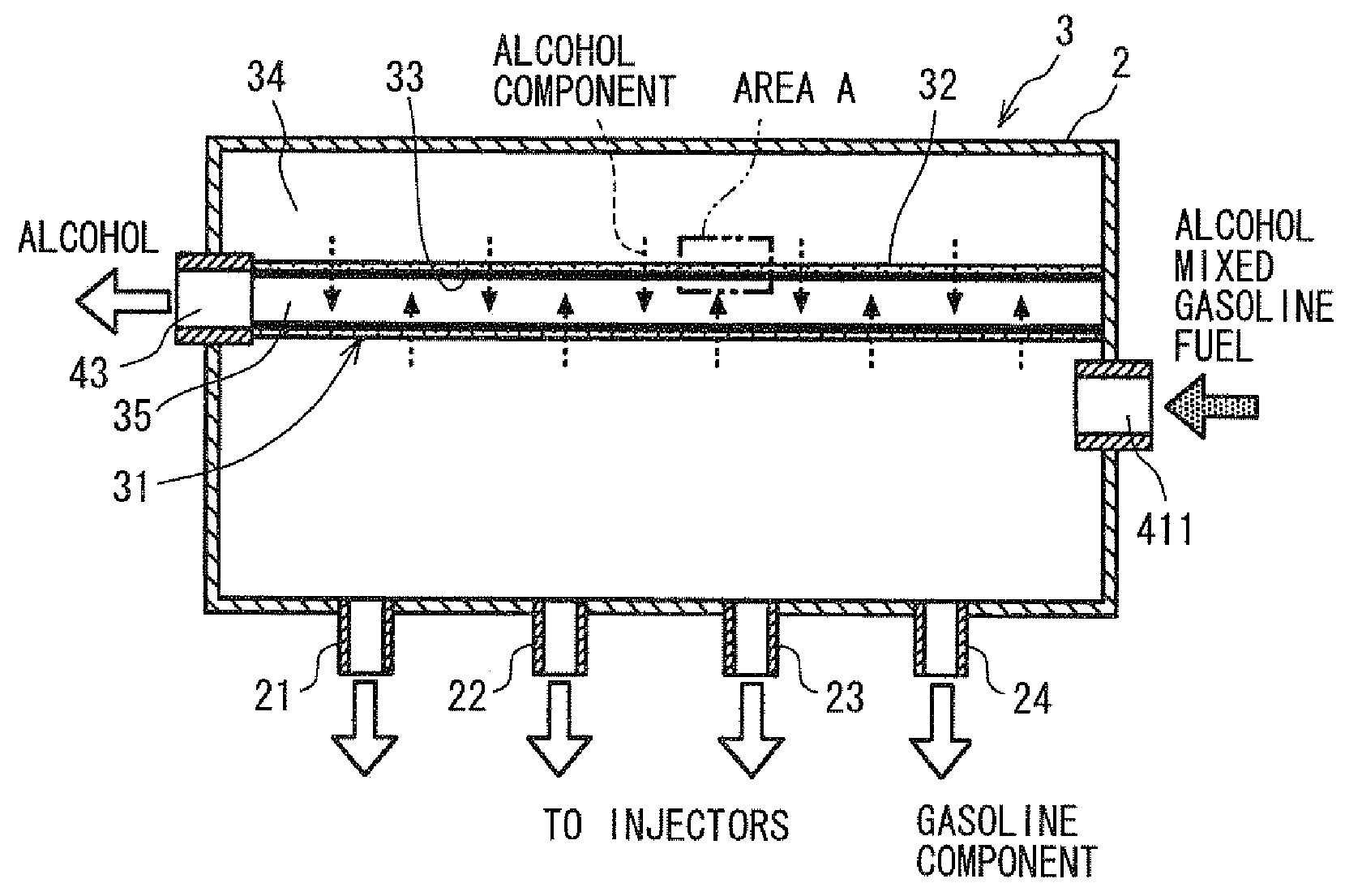

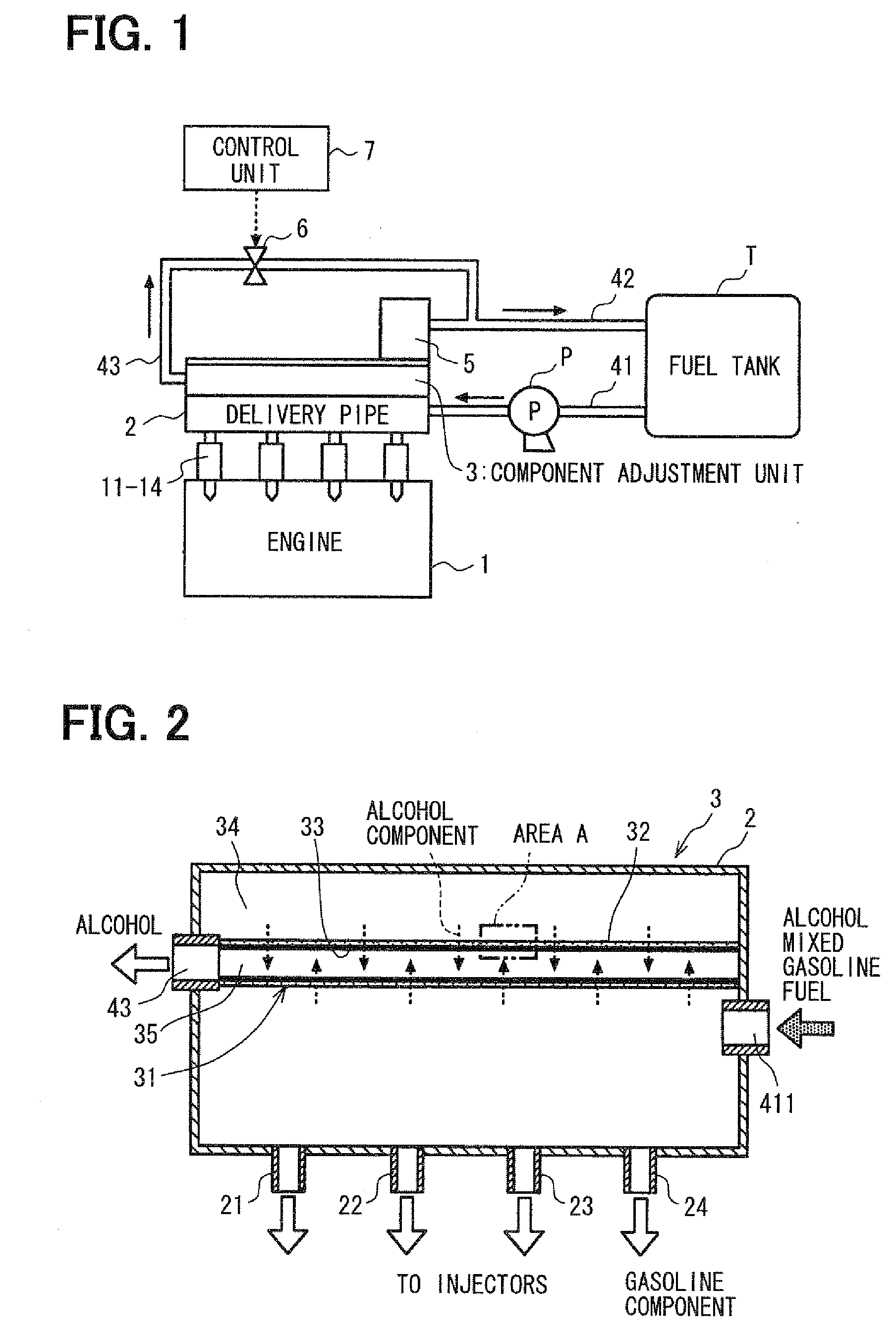

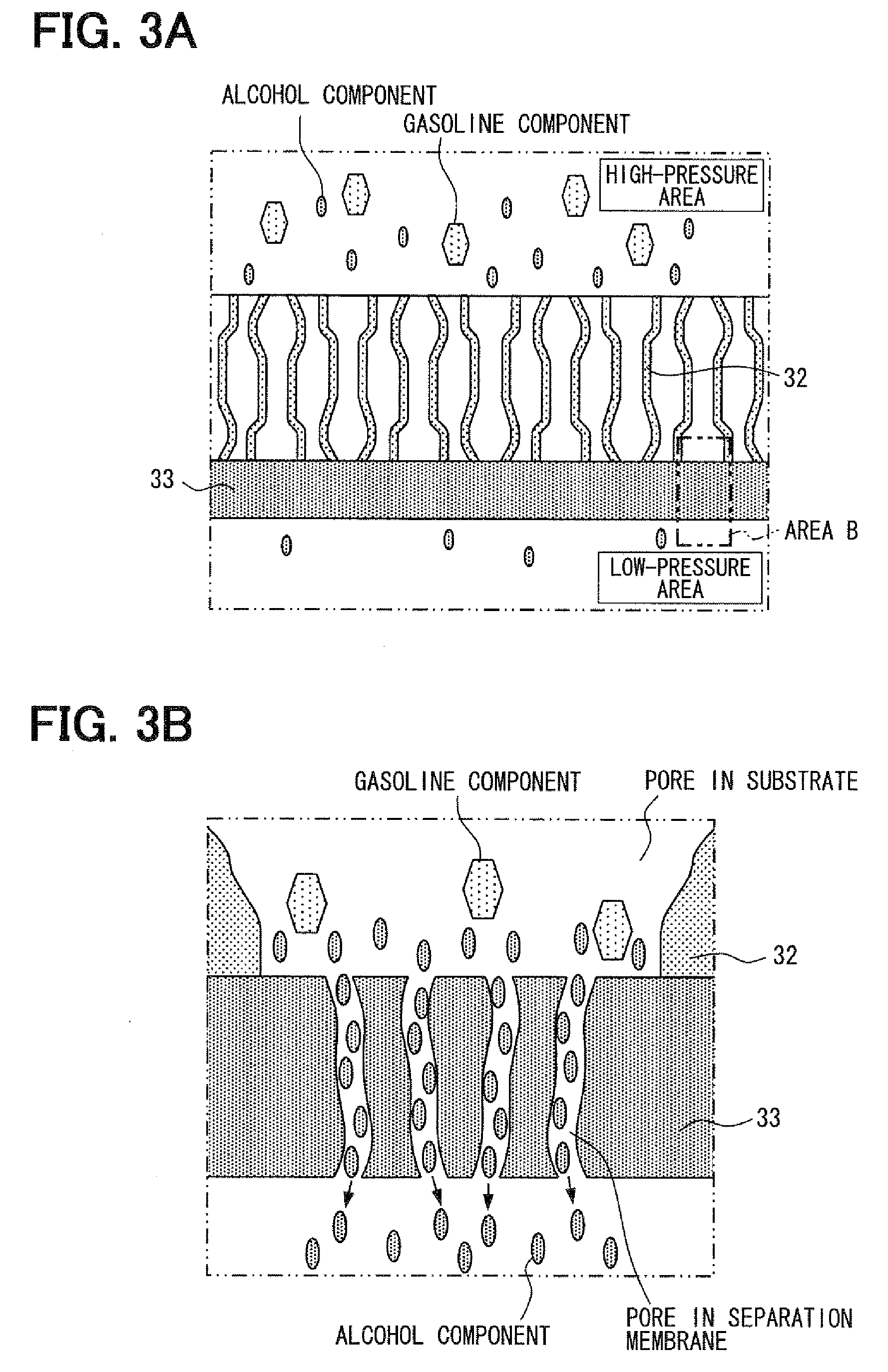

Fuel supply apparatus and fuel supply control apparatus for internal-combustion engine

InactiveUS20080092851A1Startability is improvedSimple configurationSemi-permeable membranesCombustion enginesFuel supplyComponent separation

A fuel supply apparatus includes a component adjustment unit, a low-pressure side passage, and a valve. The unit adjusts component composition of fuel by separating a particular component from fuel. The unit includes a component separation wall, which divides an interior of a portion of a fuel supply passage between an anterior chamber and a posterior chamber. The wall includes a separation membrane, which the particular component of fuel in the anterior chamber selectively permeates to be separated. The particular component after passing through the wall is temporarily stored in the posterior chamber. When the low-pressure side passage connected to the posterior chamber is opened by the valve, the particular component is separated. Fuel, from which the particular component is separated, is supplied to an injection valve from the anterior chamber. When the low-pressure side passage is closed by the valve, the separation of the particular component is restricted.

Owner:DENSO CORP

Energy-saving and high efficiency fuel coal combustion improver and preparation method thereof

The invention discloses an energy-saving and high efficiency fuel coal combustion improver and a preparation method thereof. The combustion improver comprises the following components by weight percentage: 40-60% of zinc oxide, 40-60% of manganese dioxide, preferably 50% of zinc oxide and 50% of manganese dioxide, wherein the manganese dioxide can be prepared by: weighing KMnO4 and MnC12.4H2O according to a weight ratio of 1:1, and fully grinding the materials in a container under room temperature for 20-50min to carry out solid phase reaction. The preparation method of the energy-saving and high efficiency fuel coal combustion improver includes the steps of: a. weighing the raw materials according to the following weight percentage: 40-60% of zinc oxide and 40-60% of manganese dioxide; b. grinding; c. dipping and drying; and d. roasting. The combustion improver provided by the invention reduces corrosion to boilers, improves the service life of boilers, significantly raises the flame temperature, improves the combustion activity and ignition performance of coal, improves the speed of ignition speed and combustion speed of coal, and has significant energy saving and environmental protection effects.

Owner:HARBIN HONGTIAN RUIDA TECH

Gas generating composition

InactiveUS20050127324A1Combustion temperature can be reducedReduce generationNitrogen compoundsX-ray tube gas fillingAluminium hydroxideOxygen

A gas generating composition, in which a combustion temperature is low and the generation amounts of carbon monoxide, ammonia, and nitrogen oxide after combustion is suppressed, comprises the following components (a) to (c) and, based on necessity, further comprises the components selected from the following components (d) to (f): (a) an organic compound as fuel, (b) an oxygen-containing oxidizing agent, (c) magnesium hydroxide or a mixture of magnesium hydroxide and aluminum hydroxide, (d) a binder, (e) an additive selected from metal oxides and metal carbonates, and (f) silicon dioxide having a specific surface area of 100 to 500 m2 / g.

Owner:DAICEL CHEM IND LTD

Gaseous fuel injector

InactiveUS7438238B2Improve reliabilityImprove ignition performanceInternal combustion piston enginesFuel supply apparatusWorking fluidEngineering

The injector includes a nozzle, a needle, a control chamber, a working fluid supply passage, an electric switching valve, a high-pressure gaseous fuel supply passage and a lubrication liquid fuel supply passage. The nozzle has an injection hole, through which high-pressure gaseous fuel is injected. The needle is axially reciprocably received in the nozzle to open and close the injection hole. The needle includes a sliding portion and a valve portion. The control chamber applies a pressure to the needle. The working fluid supply passage supplies liquid fuel to the control chamber. The electric switching valve controls an inflow / outflow of the liquid fuel to / from the control chamber. The high-pressure gaseous fuel supply passage supplies the high-pressure gaseous fuel to the injection hole. The lubrication liquid fuel supply passage supplies the liquid fuel from the working fluid supply passage to the sliding portion and the valve portion.

Owner:DENSO CORP

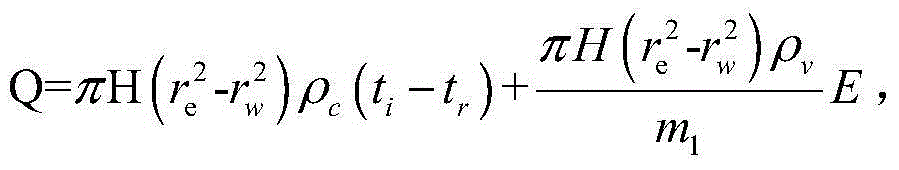

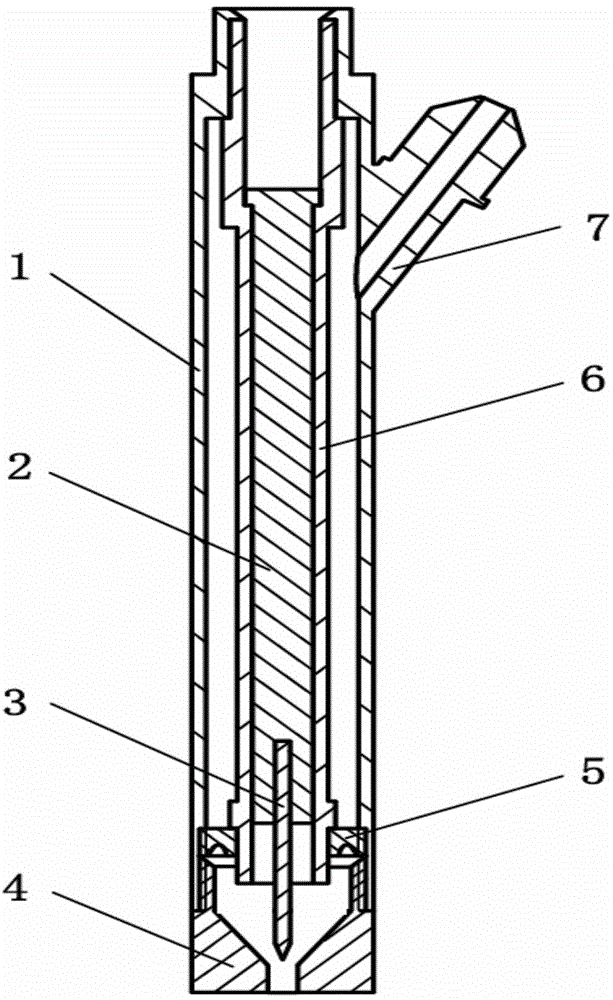

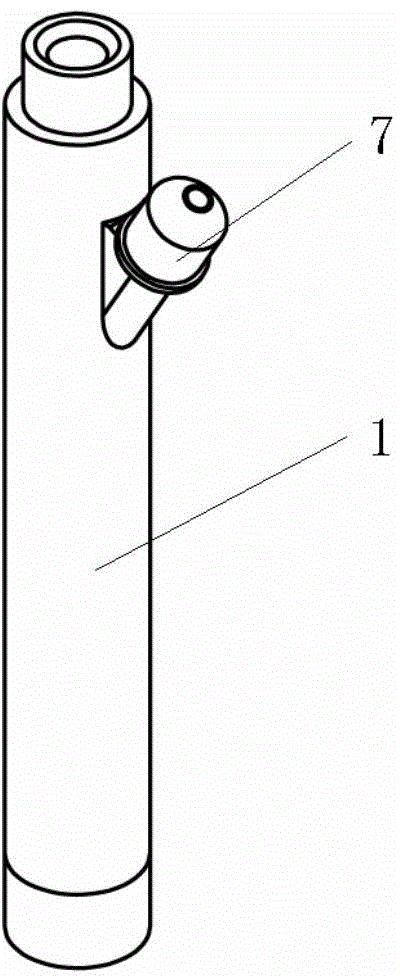

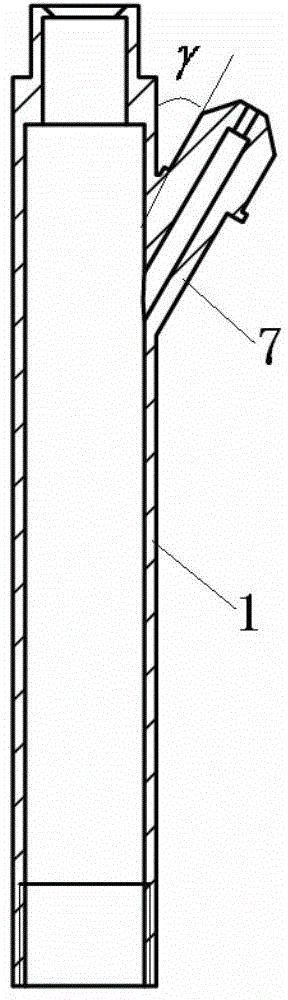

Device for injecting pulverized coal into oil layer and ignition method for in-situ oil combustion

ActiveCN106050207AReduce moisture contentImprove ignition performanceFluid removalCombustionInjection well

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

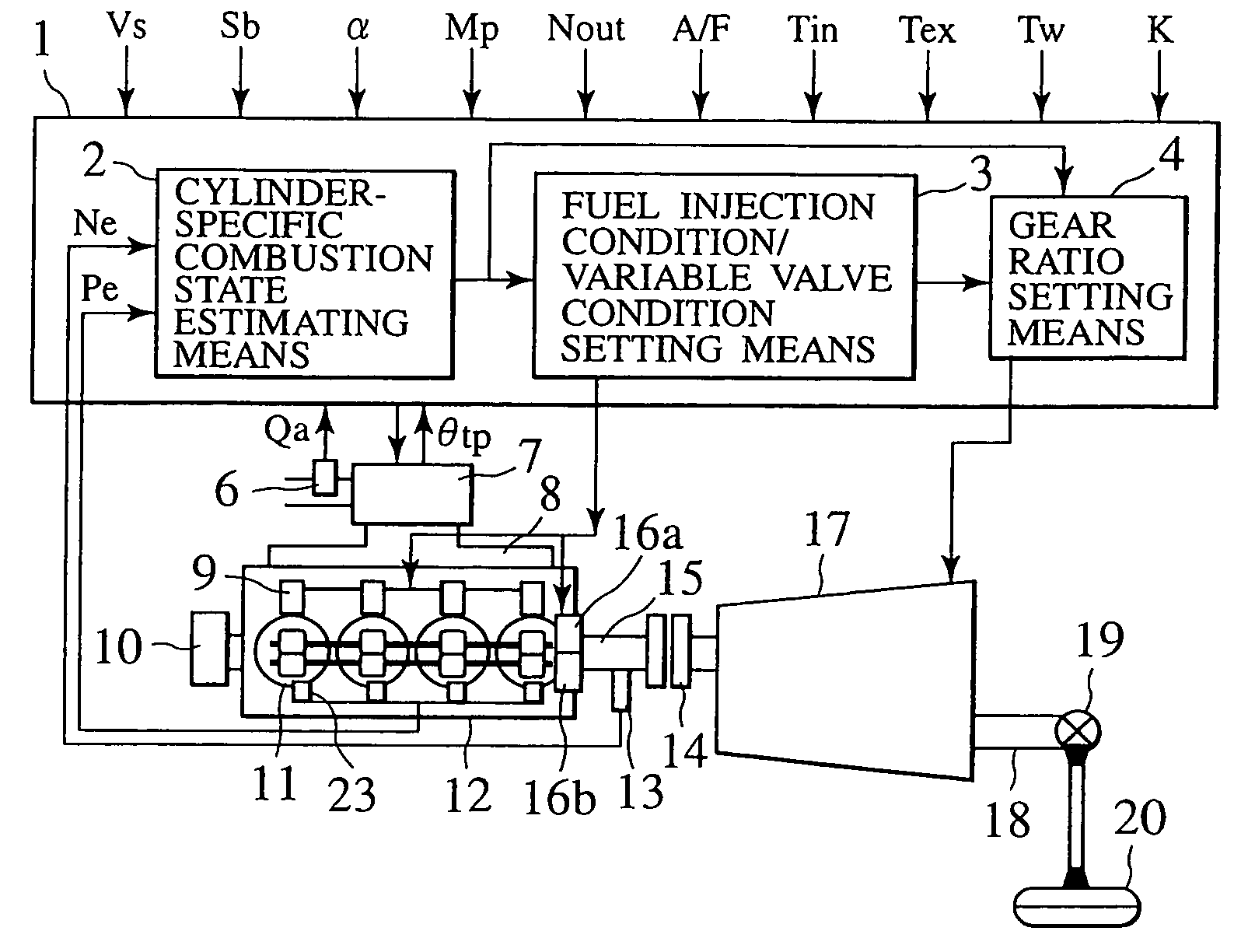

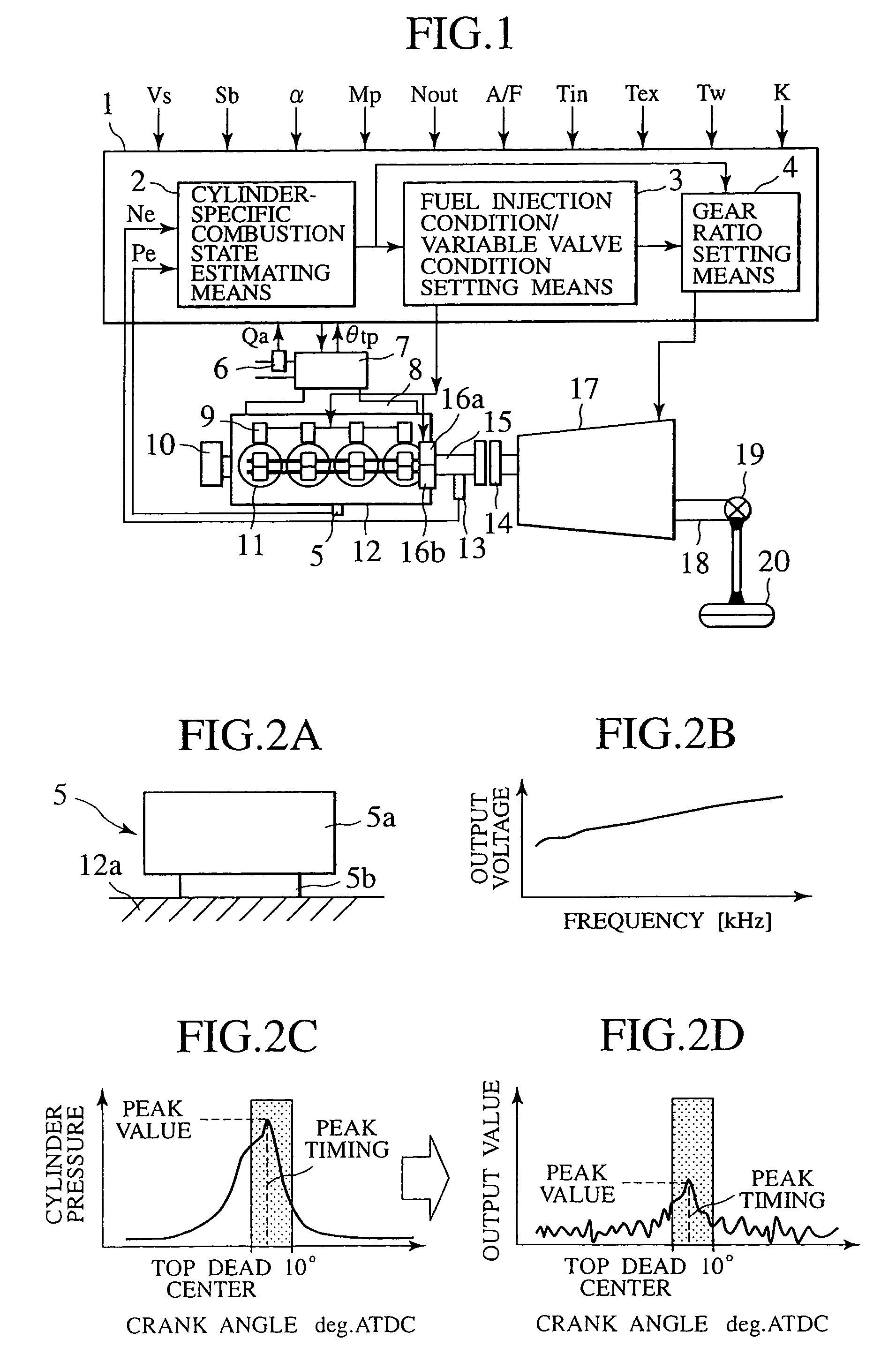

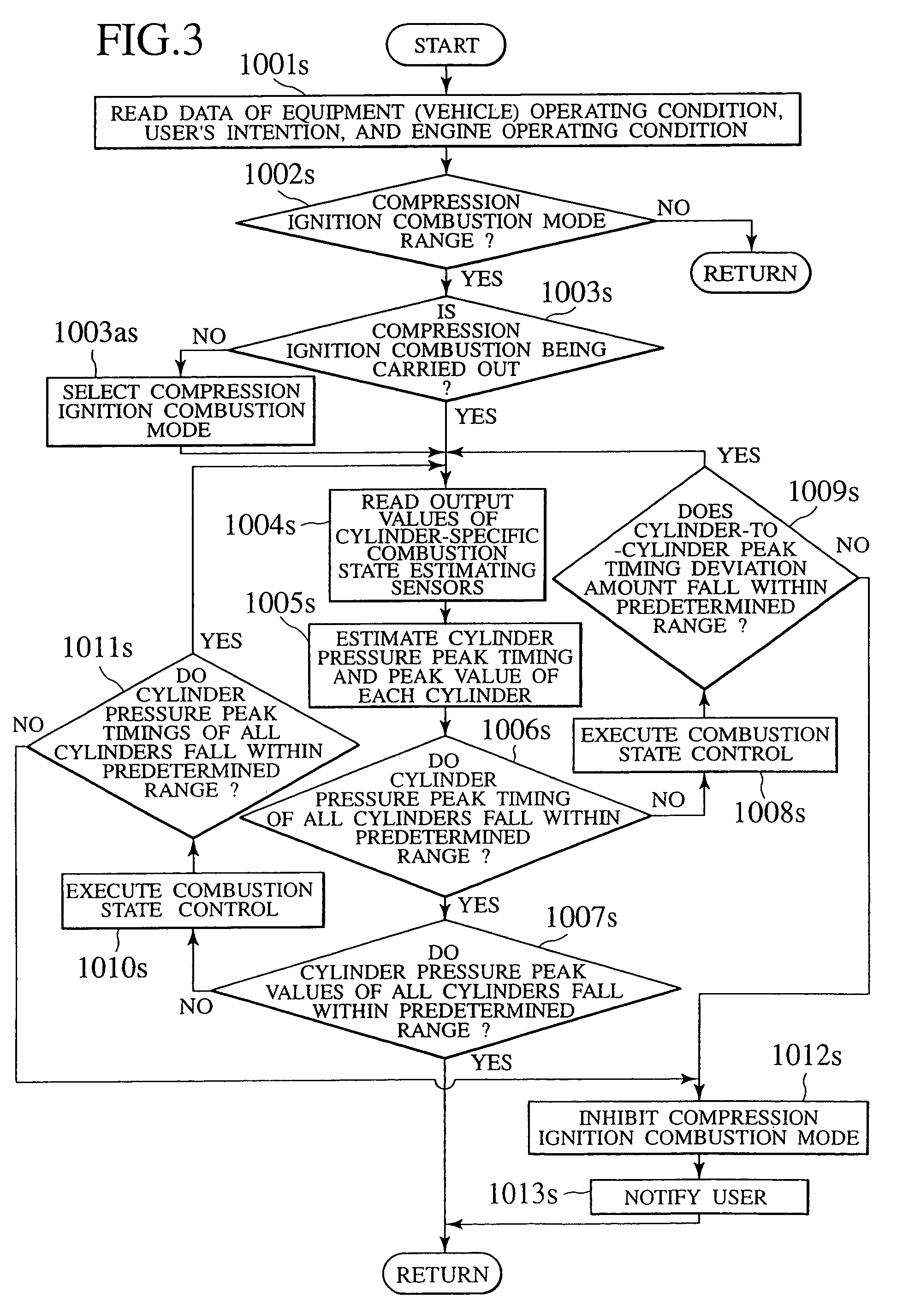

Control apparatus and control method for multi-cylinder engine

InactiveUS6976936B2Increase fuel consumptionGood exhaust emission characteristicElectrical controlInternal combustion piston enginesCylinder headPeak value

In a multi-cylinder engine having a compression ignition combustion mode, a vibration detecting sensor that is preferably mounted in a cylinder block or a cylinder head is used to detect a frequency and the detected frequency is appropriately analyzed to detect or estimate a cylinder pressure peak value and peak timing for each cylinder. An amount of internal EGR, a fuel injection condition, an engine speed and the like are then controlled so as to bring each of these parameters into an appropriate range thereof. The control apparatus suppresses variations in combustion states among different cylinders and different cycles arising from unit-to-unit variations or deterioration in the engine or part-to-part variations or deterioration in a component thereof.

Owner:HITACHI LTD

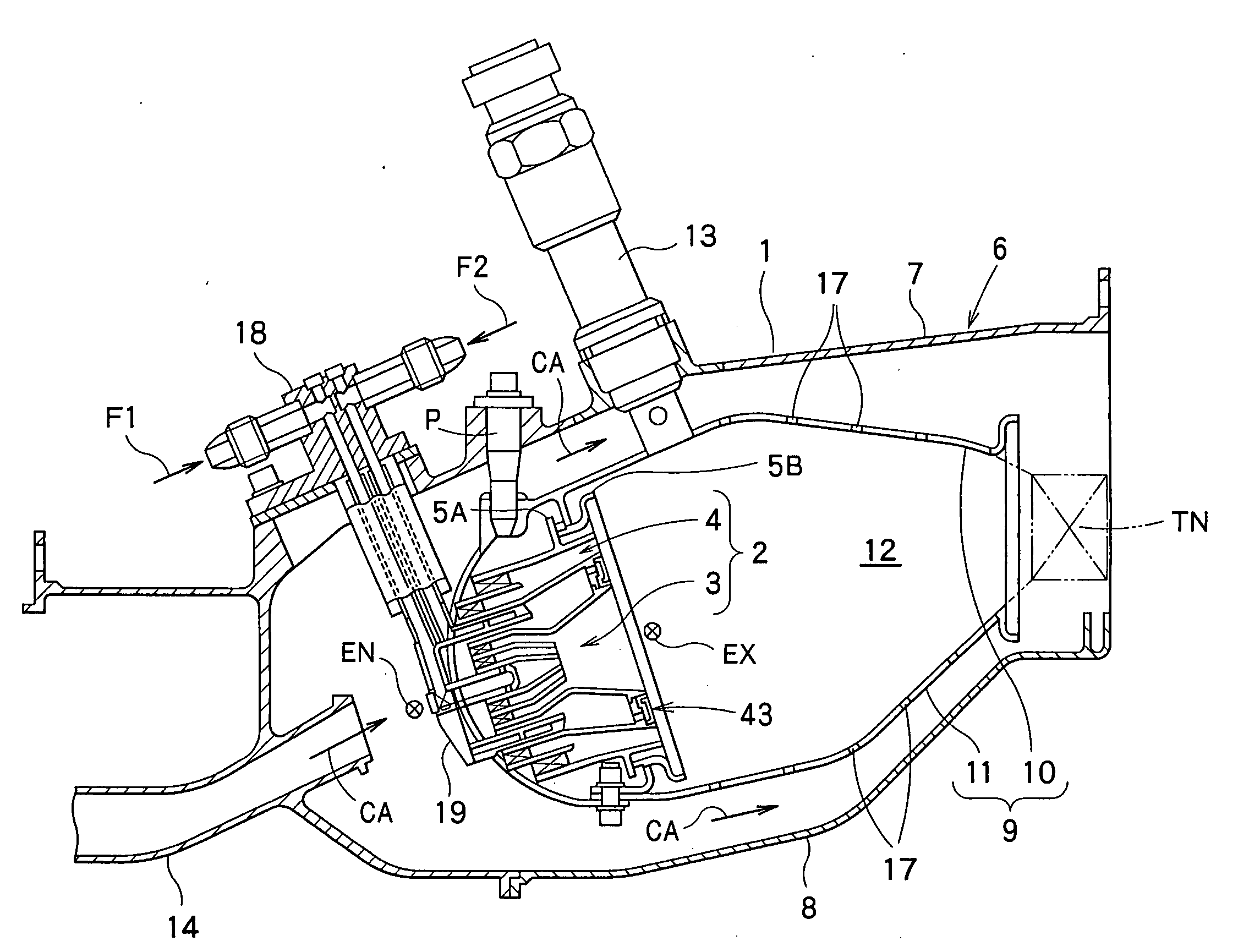

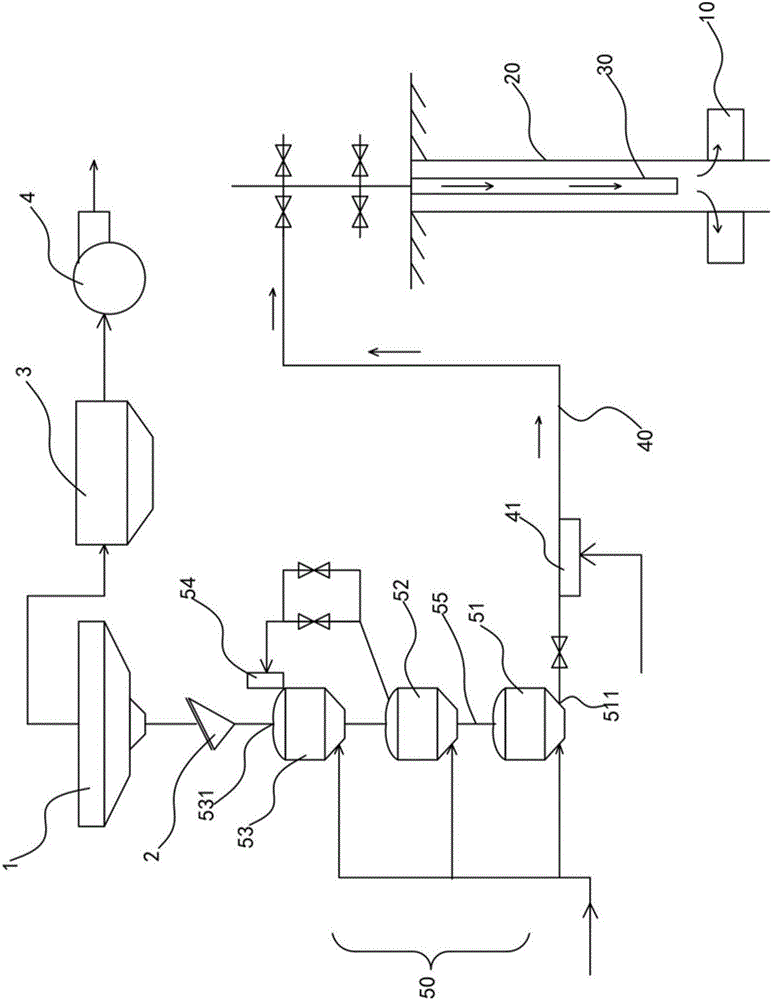

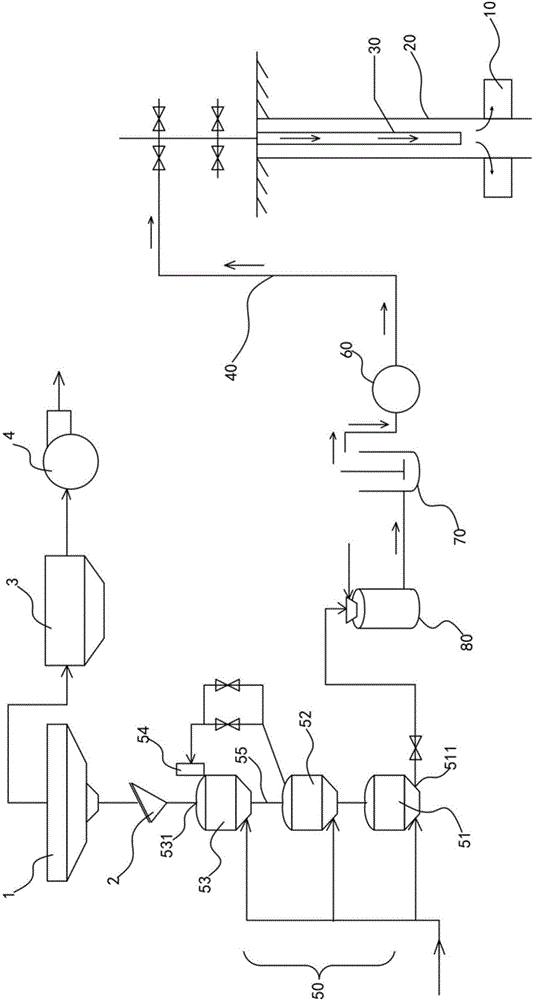

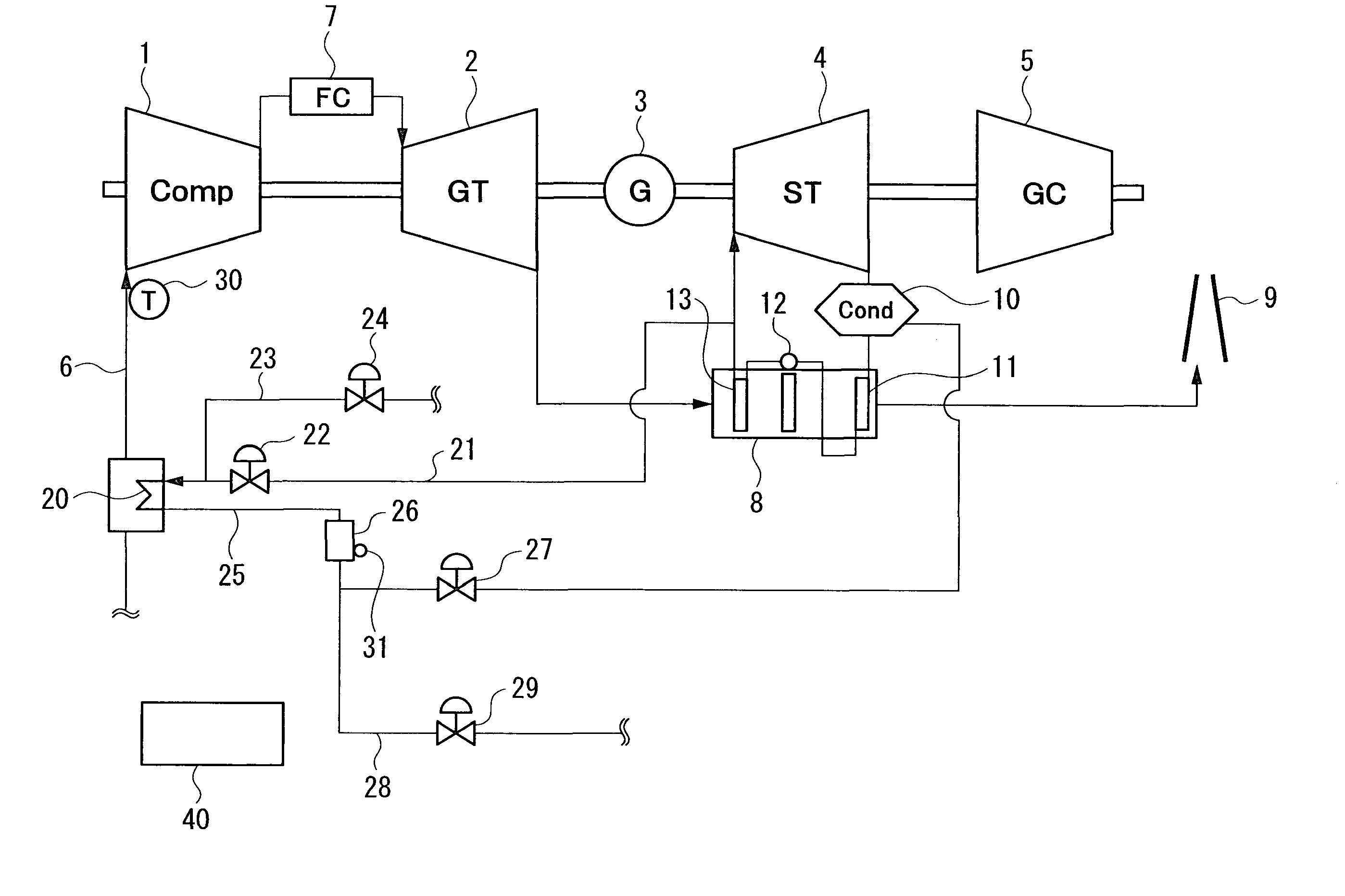

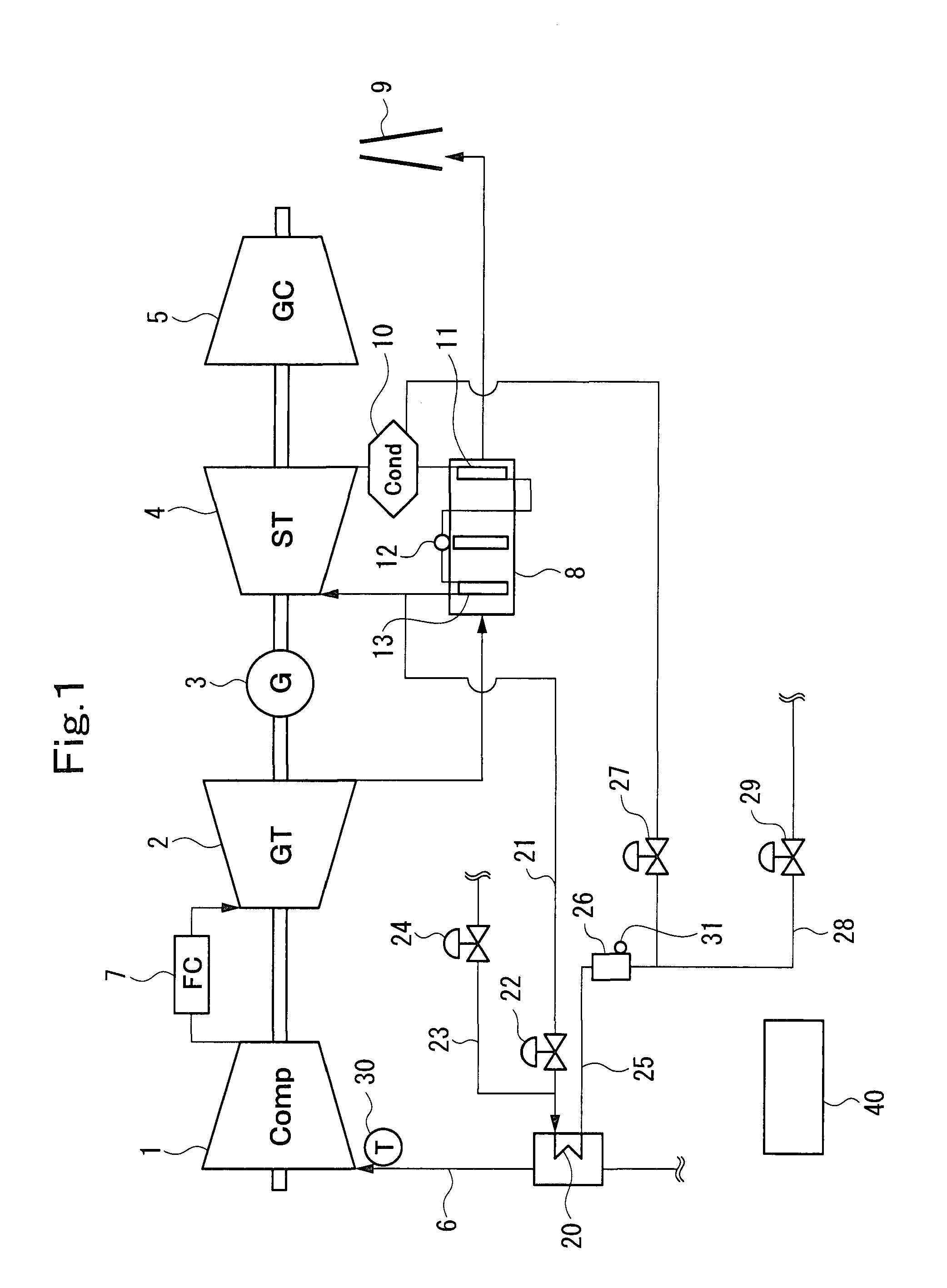

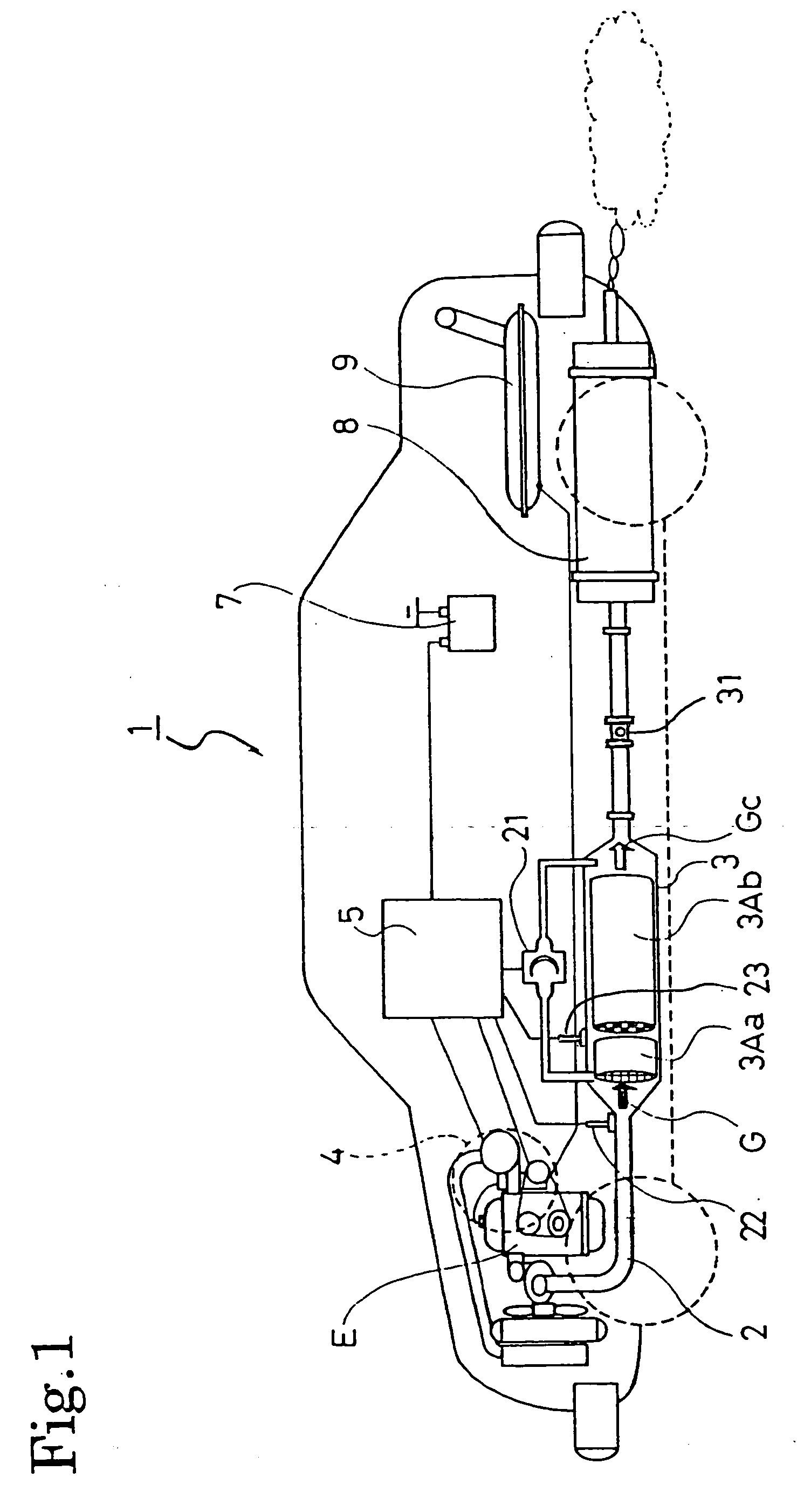

Intake air heating system of combined cycle plant

ActiveUS20100089023A1Efficient heatingImprove ignition performanceBiofuelsGas turbine plantsElectricityCombustor

A gas turbine 2 is driven by a combustion gas produced when BFG compressed by a gas compressor 5 and air compressed by a compressor 1 are burned in a combustor 7. Steam is generated from a waste heat boiler 8 by utilization of heat of an exhaust gas from the gas turbine 2, and a steam turbine 4 is driven by this steam. An electric generator 3 generates electricity upon driving of the turbines 2 and 4. A condensing heat exchanger 20 is disposed in an air intake duct 6, and part of steam from the waste heat boiler 8 is flowed through the heat exchanger 20 to heat intake air. The amount of steam flowed through the heat exchanger 20 is adjusted by the adjustment of the degree of opening of a steam control valve 22 by a control device 40. By so doing, the ignition performance of the gas turbine in a BFG-fired gas turbine combined cycle plant is enhanced even in an extremely cold district.

Owner:MITSUBISHI POWER LTD

Lighter fluid composition

InactiveUS6843812B2Clean burningLow VOC emissionSolid fuelsLiquid carbonaceous fuelsCross-linkMethanol

A lighter fluid composition usable for starting barbecues and the like that comprises naturally occurring combustible materials, which is clean burning and results in low volatile organic compound (VOC) emission during combustion, which is biodegradable and easily disposable, and which burns with a pleasant aroma and does not impart any unpleasant hydrocarbon odor or flavor to food cooked on a barbecue. The composition preferably comprises between approximately 0.5 weight percent and approximately 90 weight percent of a terpene or terpenoid oil, and between approximately 0.5 weight percent and approximately 98.5 weight percent of short chain alcohol, between approximately 0.5 weight percent and approximately 60 weight percent of water, between approximately 0.1 weight percent and approximately 10 weight percent of surfactant, and between approximately 0.5 weight percent and approximately 10 weight percent of thickening agent. The preferred terpene preferably comprises d-limonene or a citrus derived oil containing d-limonene such as cold-pressed orange oil. The preferred alcohols are methanol and ethanol. The preferred surfactant is a non-ionic detergent or detergents, and the preferred thickener is a pH controllable slightly cross-linked polyacrylic acid material.

Owner:STEPHANOS PRODROMOS PERICLES

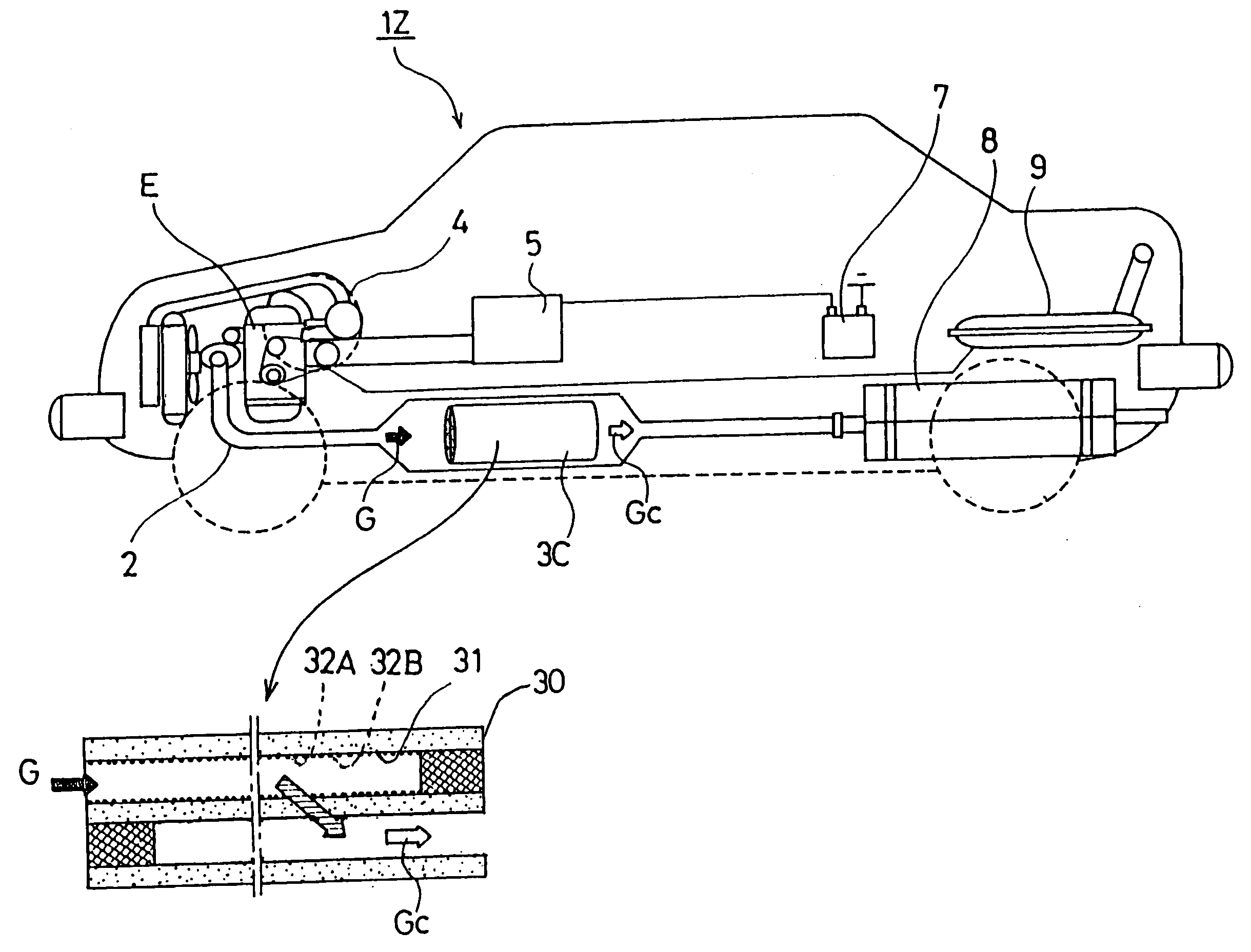

Exhaust gas cleaning system

ActiveUS20060201144A1Improve fuel efficiencyReduce exhaust temperatureElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

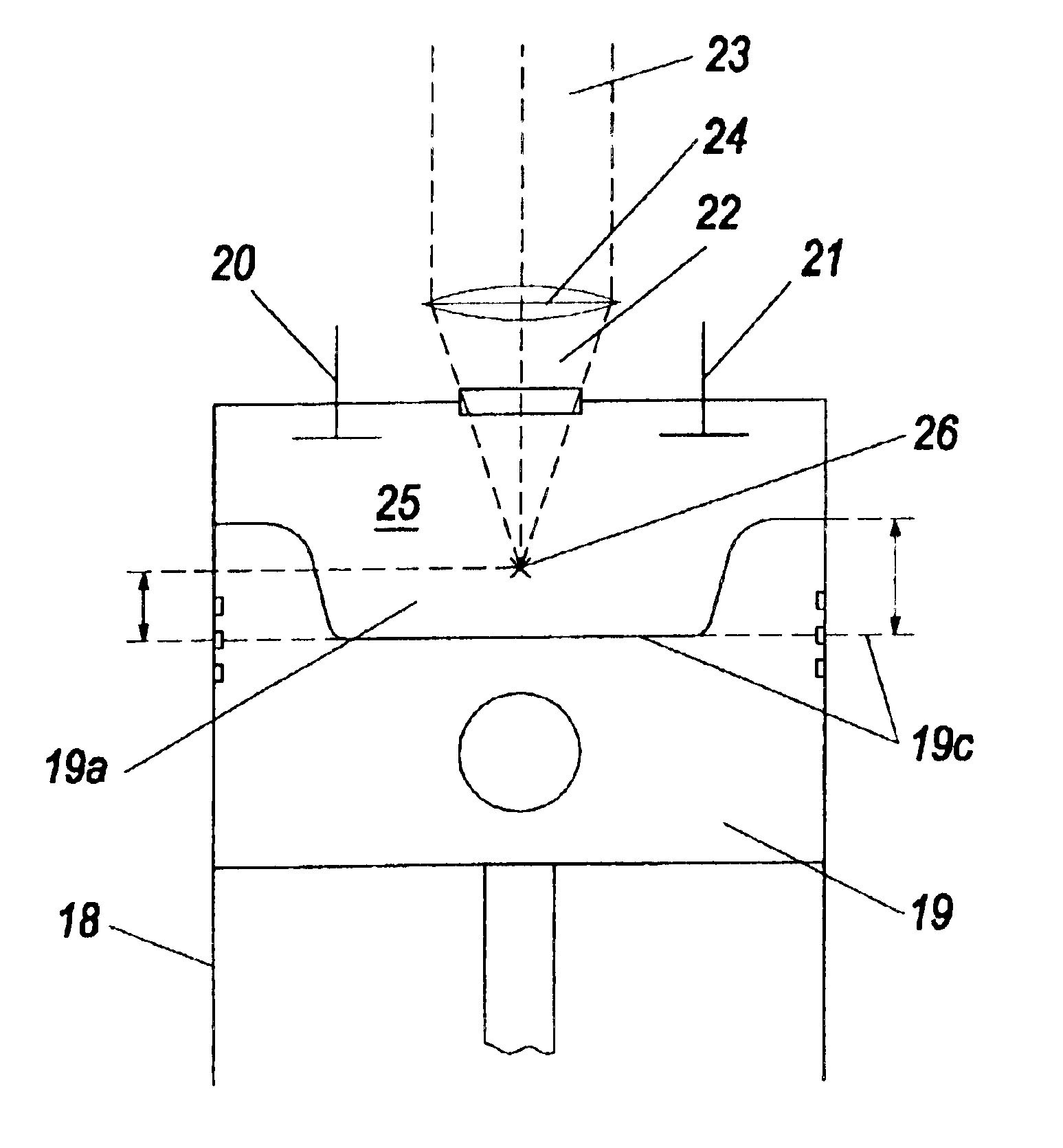

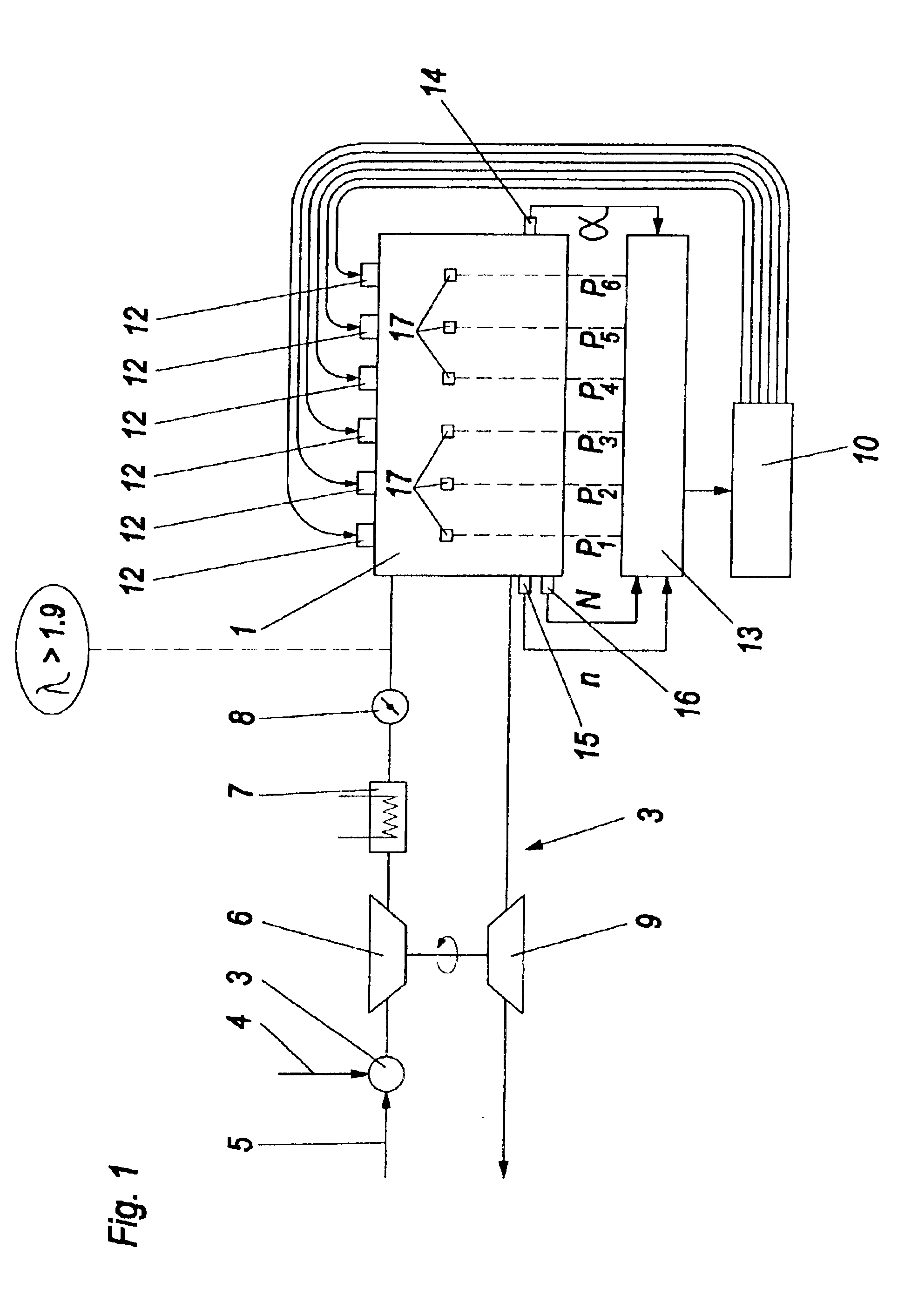

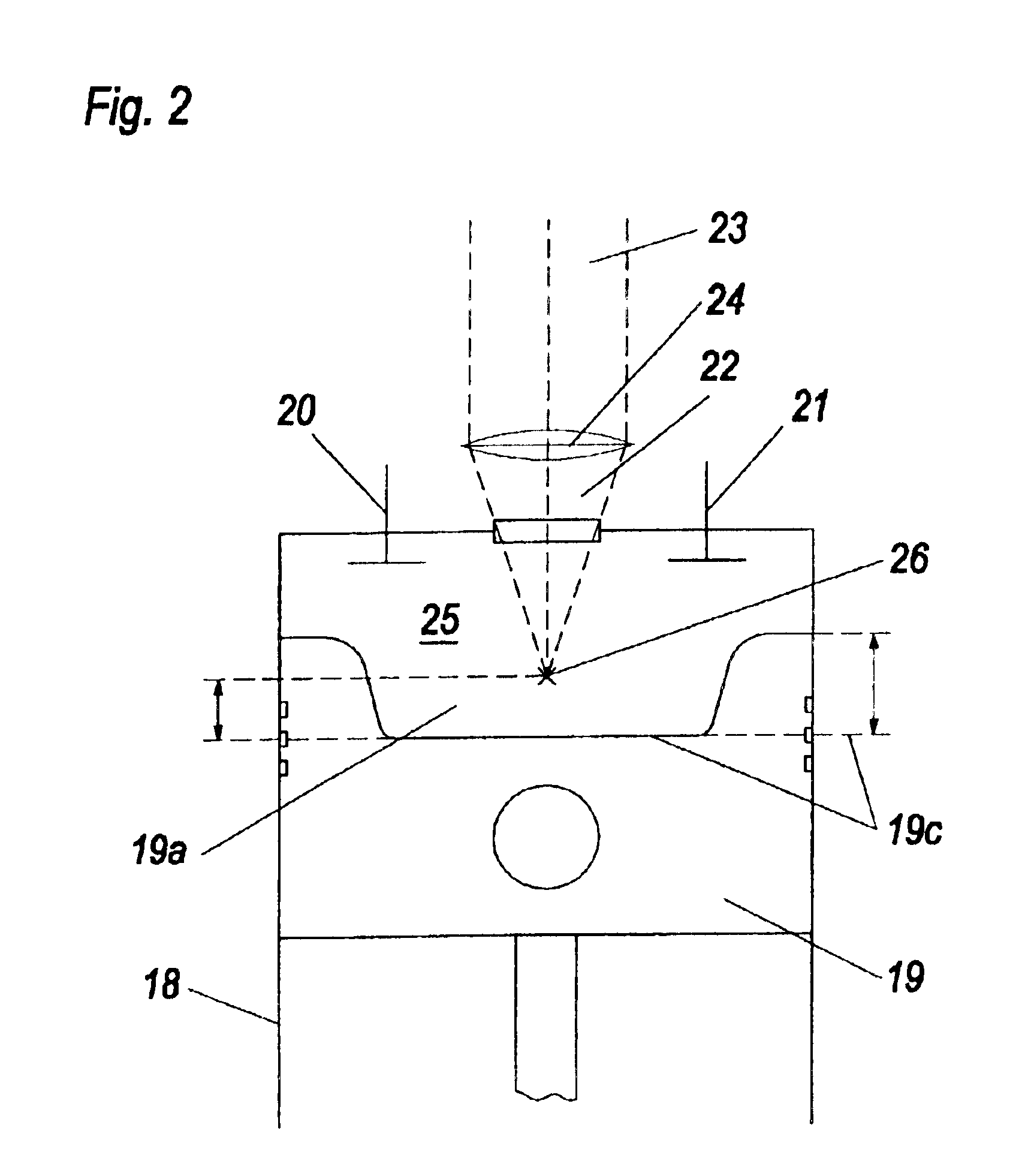

Internal combustion engine

InactiveUS7040270B2High spatial energy densityReliable ignitionLaser detailsElectrical controlCombustion chamberLaser light

Internal combustion engine with at least one cylinder, in which the combustion of a homogeneous air / fuel mixture compressed in the cylinder by a piston is initiated by a time-controlled external ignition, the air / fuel ratio of the air / fuel mixture in the combustion chamber (25) being greater than 1.9 and, for the time-controlled external ignition, at least one laser light source (10), at least one optical transmission apparatus (11) and at least one coupling optic (12) for the focussing of laser light into a combustion chamber (25) being provided.

Owner:GE JENBACHER

Small size spark plug having side spark prevention

A spark plug including an insulator having an axial hole in an axial direction; and a center electrode disposed in a tip end side of the axial hole of the insulator so as to project a tip end of the center electrode from the tip end side of the insulator. The center electrode includes an electrode base member made of pure Ni or an Ni alloy containing 85 wt % or more of Ni; and a noble metal chip fixed to a tip end of the electrode base. The spark plug further includes a metal shell surrounding the insulator; and a ground electrode in which one end is joined to the metal shell, and another end portion opposes the noble metal chip to form a spark discharge gap between the ground electrode and noble metal chip, wherein M, D 1 , and D 2 as defined herein satisfy M<=10.1 mm, 0.5 mm<=D 2 <1.4 mm, and D 1 / D 2 >=3.5.

Owner:NGK SPARK PLUG CO LTD

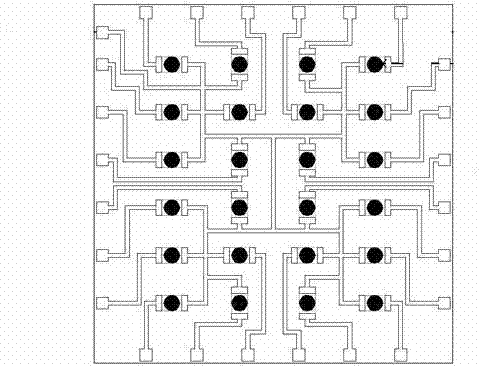

Dielectric Al/CuO composite film energetic electric ignition bridge and ignition bridge array

The invention discloses a dielectric Al / CuO composite film energetic electric ignition bridge and an ignition bridge array. The bridge body of the ignition bridge is formed by overlapping an upper electrode, a lower electrode and a dielectric layer; two layers of metal films with the same size and different directions serve as the upper electrode and the lower electrode; an Al / CuO composite film layer with the same size and direction as the upper electrode metal film is sandwiched between the two layers of metal films to serve as the dielectric layer; partial Al / CuO composite film layer is coated and overlapped on the lower electrode metal film; and the upper electrode metal film is completely coated and overlapped on the Al / CuO composite film layer. In the ignition array taking the dielectric Al / CuO composite film energetic electric ignition bridge as a basic unit, a plurality of dielectric Al / CuO composite film energetic electric ignition bridges are connected through leads preparedfrom Au metal films or Cu metal films to form the ignition array. The invention has the advantages of high safety, high ignition capacity and good compatibility.

Owner:NANJING UNIV OF SCI & TECH

Catalyst for exhaust gas purification, production method therefor, and method for purification of exhaust gas using the catalyst

ActiveUS7923407B2Improve ignition performanceEfficient productionInternal combustion piston enginesMolecular sieve catalystsPlatinumActive component

Owner:UMICORE SHOKUBAI JAPAN CO LTD +1

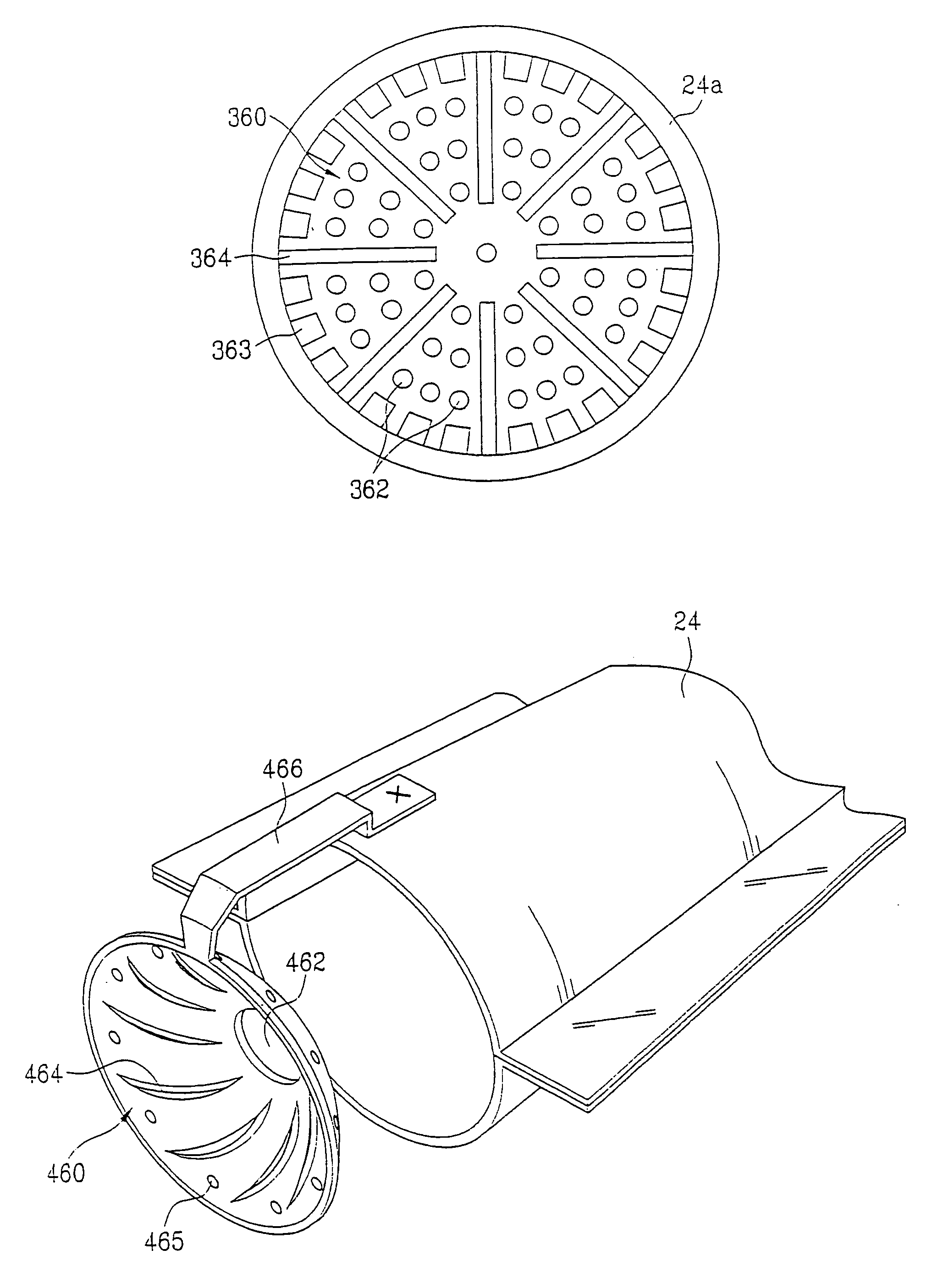

Gas burner for dryer

InactiveUS7204688B2Improves initial ignition performanceHigh temperatureDrying solid materials with heatElectric spark ignitersProcess engineeringGas burner

Gas burner for a dryer including a gas nozzle for receiving, and injecting gas, a mixing tube for mixing the gas injected from the gas nozzle and primary air, igniter fitted to an outlet of the mixing tube for igniting the gas mixed with the primary air coming out of the outlet of the mixing tube, and a flame holder fitted to the outlet of the mixing tube having flame holes for splitting, and ejecting the gas mixed with the primary air in burning the gas, thereby forming shorter flame lengths, and securing stability of the flame by enhancing an initial igniting capability, and splitting the flame into many parts to increase introduction of secondary air into the flame.

Owner:LG ELECTRONICS INC

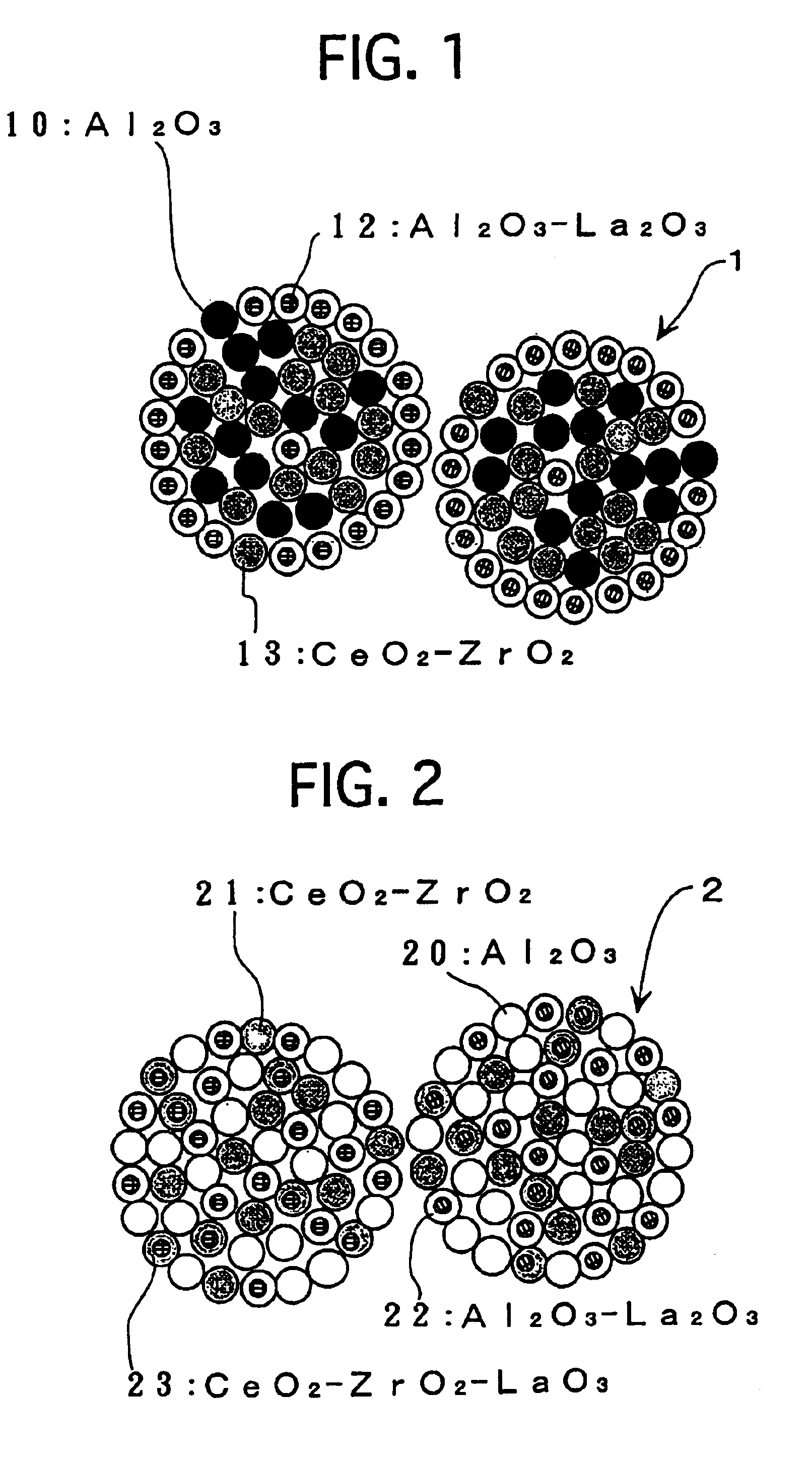

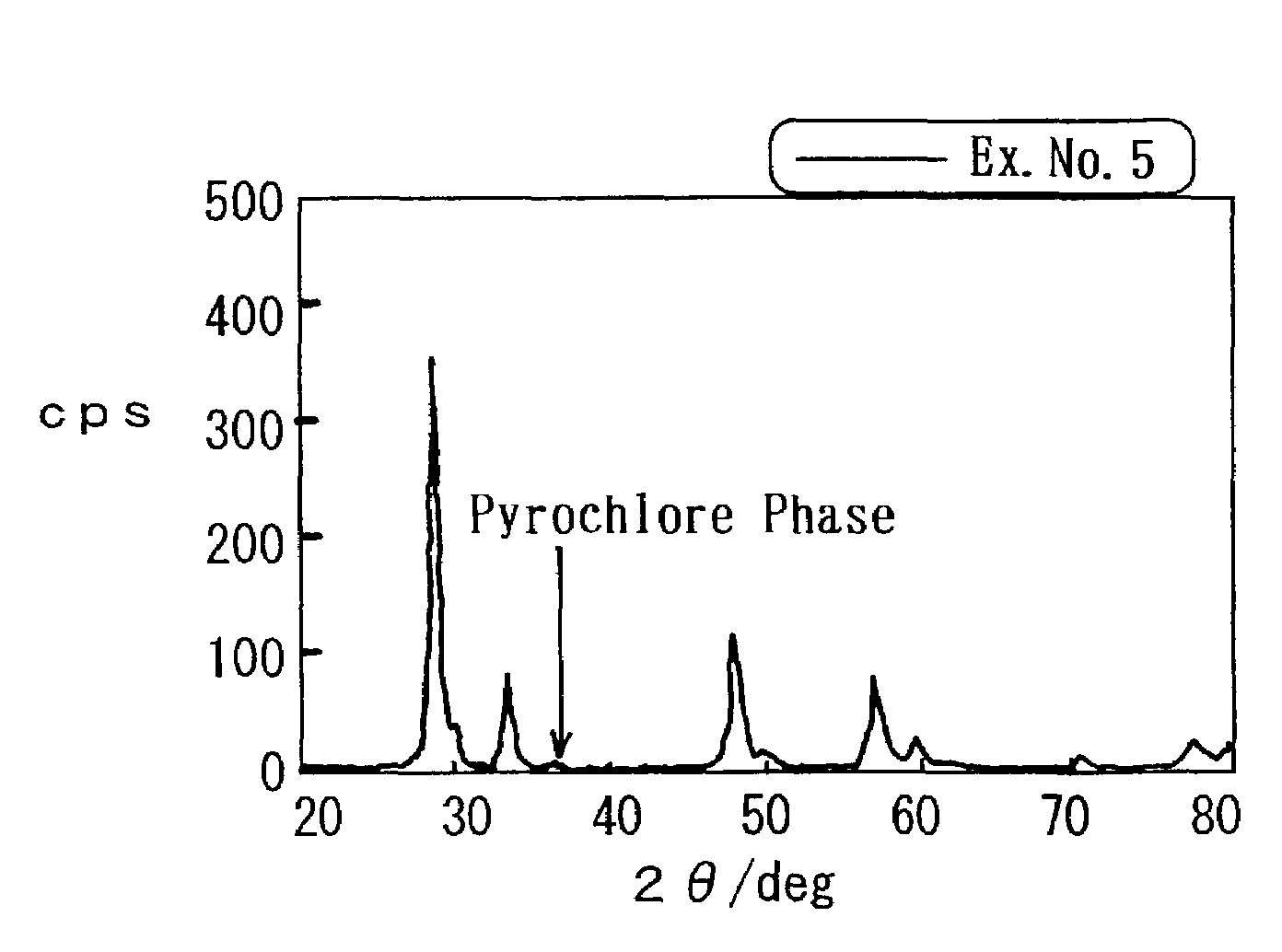

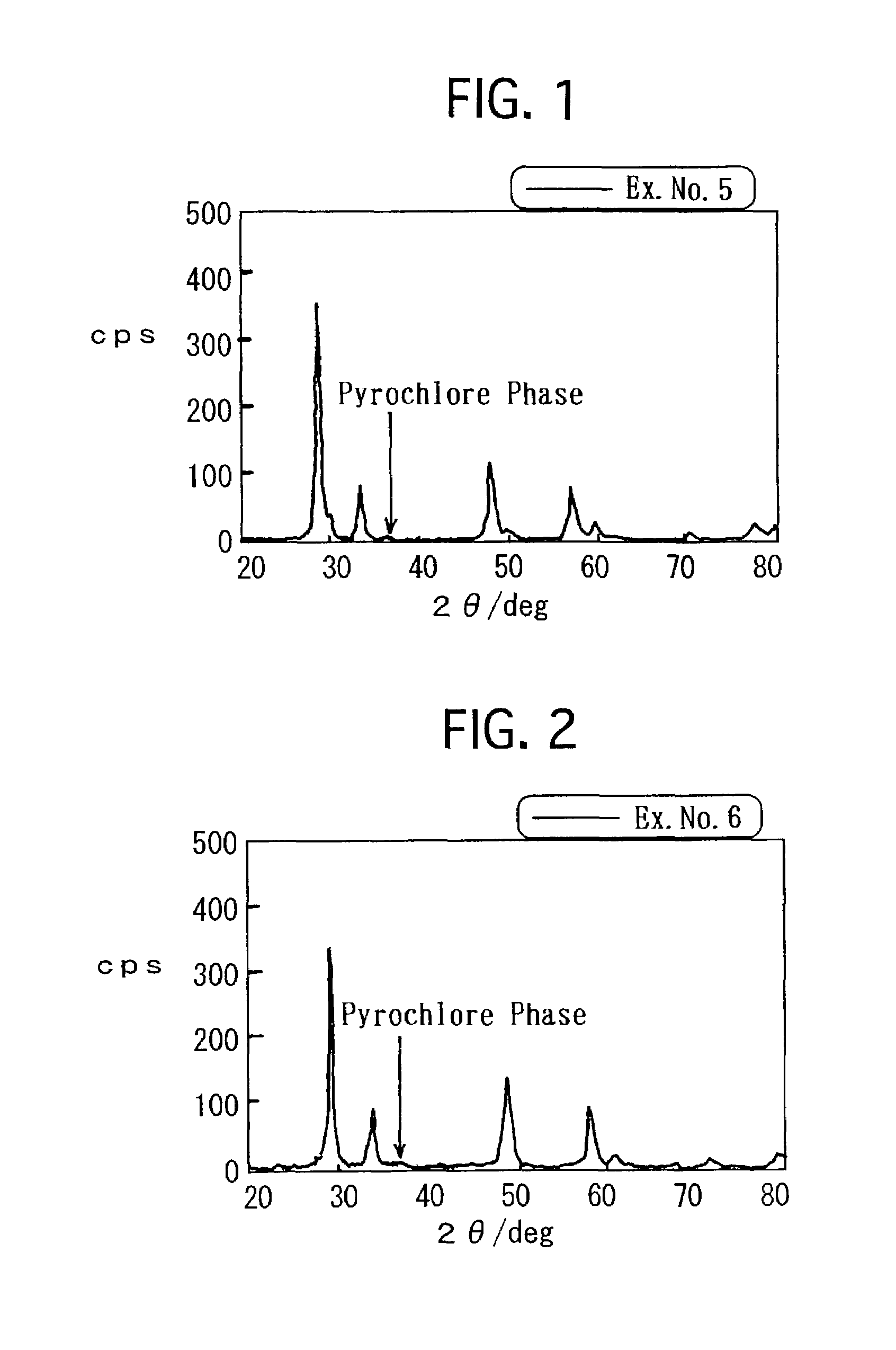

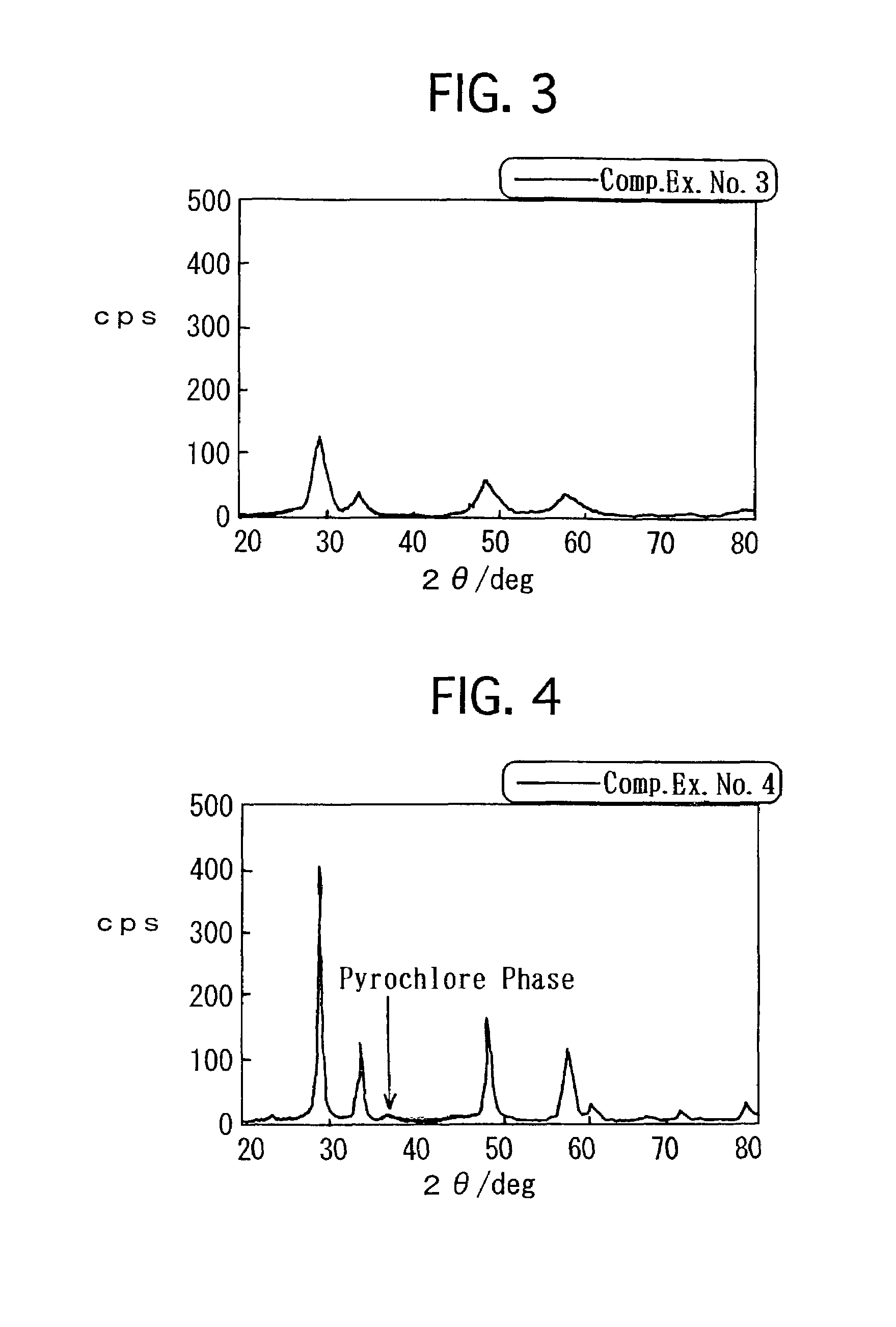

Composite oxide, process for producing the same, and exhaust gas reducing co-catalyst

ActiveUS7247597B2Decrease in activityLack of durabilityDispersed particle separationCatalyst activation/preparationExhaust gasComposite oxide

A composite oxide includes CeO2, ZrO2 and a metallic oxide being free from reacting with CeO2 and ZrO2 at 700° C. or more, preferably at 900° C. or more and further preferably at 1,000° C. or more. The composite oxide has a regulatory oriented phase, such as a pyrochlore phase, etc., in which at least a part of Ce cations and Zr cations are oriented regularly. The composite oxide makes a catalytic support. The CeO2—ZrO2 composite oxide and the reaction-free metallic oxide make barriers each other which suppress the granular growth when the composite oxide is subjected to high-temperature heat in a reducing heat treatment to form the regulatory oriented phase. The regulatory oriented phase improves the oxygen storage-and-release capability of the catalytic support. Thus, it is possible to simultaneously attain a large a specific surface area and a high oxygen storage-and-release capability.

Owner:TOYOTA CENT RES & DEV LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com