Multi-stage partitioned combustion structure for gas turbine

A technology of gas turbine and combustion structure, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems that combustion stability and low emission can not be well balanced, achieve flameout performance and low emission, ensure high-efficiency combustion, reduce The effect of small NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

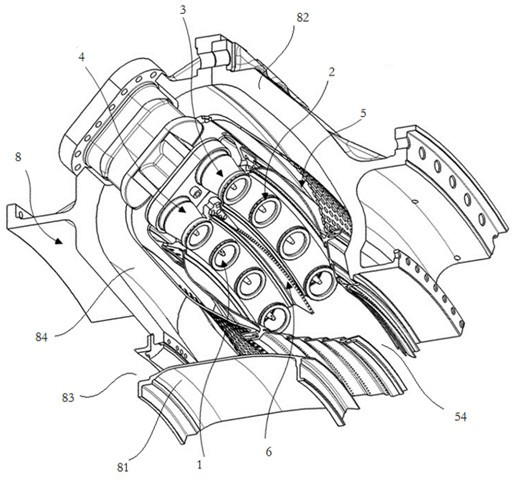

[0039] like Figure 1 - Figure 7 As shown, the present embodiment is designed for a multi-stage partition combustion structure for a gas turbine, including a combustion chamber casing 8, a flame barrel 5, a plurality of swirl devices, and a splitter 6.

[0040] The combustion chamber casing 8 has an annular groove cavity 84; the outlet of the lucacea 84 towards the rear side of the gas turbine. And the combustion chamber casing 8 is used in the mounting of the flame bar 5.

[0041] The flame bar 5 is disposed in the lumen 84 of the combustion chamber casing 8, which has a loop-shaped combustion chamber. The combustion outlet 54 of the combustion chamber is the same as the outlet of the lumen 84 of the combustion chamber casing 8; the gas is discharged from the combustion outlet 54 after the flame bar 5 is burned.

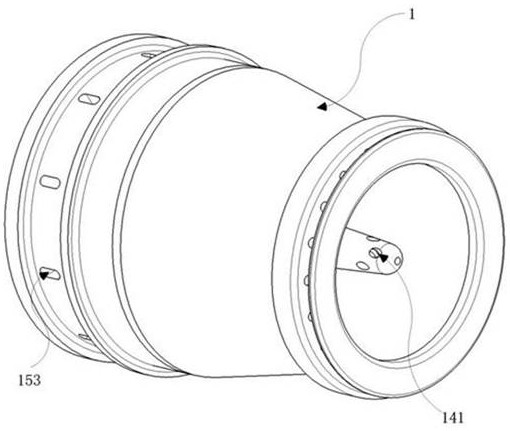

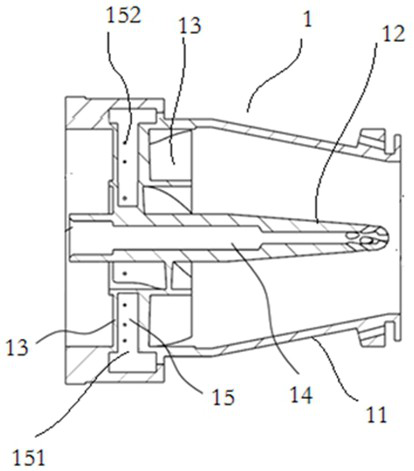

[0042] The combustion chamber of the swirl is used to introduce air and gas into the combustion chamber; each cyclone includes a swirling shell 11, a central cone 12, an...

Embodiment 2

[0052] In this example, a plurality of working modes are designed in the multi-level partition-type combustion structure for gas turbines in the first embodiment, which are ignition state mode, small state mode, transition status working mode, and large load state mode of operation, four The working mode is divided by the operating mode of each cyclone group.

[0053] When the ignition state mode is modeled, the various swirl groups are only transmitted from the second gas passage 14 of the value class swirl 1, and the principle of the ignition state mode of operation is: when this mode of operation, the gas supply amount And the amount of intake is small, and the emissions of the emission standard do not specify and require, all the gas is concentrated at a duty cyclone 1, and sprayed by the second gas passage 14 of the duty cyclone 1, using diffusion The advantage of high stability of combustion enables the combustion chamber to obtain a hydride ratio combustion in the ignition ...

Embodiment 3

[0058] like Figure 1 - Figure 7 As shown, based on the structure of Example 1, the present embodiment refines the structure of the flame barrel 5 and the main body 82.

[0059] The flame barrel 5 includes a rear segment 52 and a cylinder front section 51, the cylindrical front section 51 is a double layer structure, the inner layer is the front interior wall 513, the outer layer is the front section of the outer wall 513, and there is a sandwich channel between the front interior wall 513 514. A impact cooling hole 511 is provided at the outer wall of the cylinder front section 51, and the mounting portion 53 for mounting the swirl device is provided in the inner bottom portion of the cylinder front section 51.

[0060] A slit groove is provided in the inside of the cartridge, and the slot is provided toward the combustion outlet 54 and the bottom of the slot of the slot, and the slot cooling hole 521 outside the rear section 52 is provided, and the slot cooling hole 521 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com