Patents

Literature

35results about How to "Efficient blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

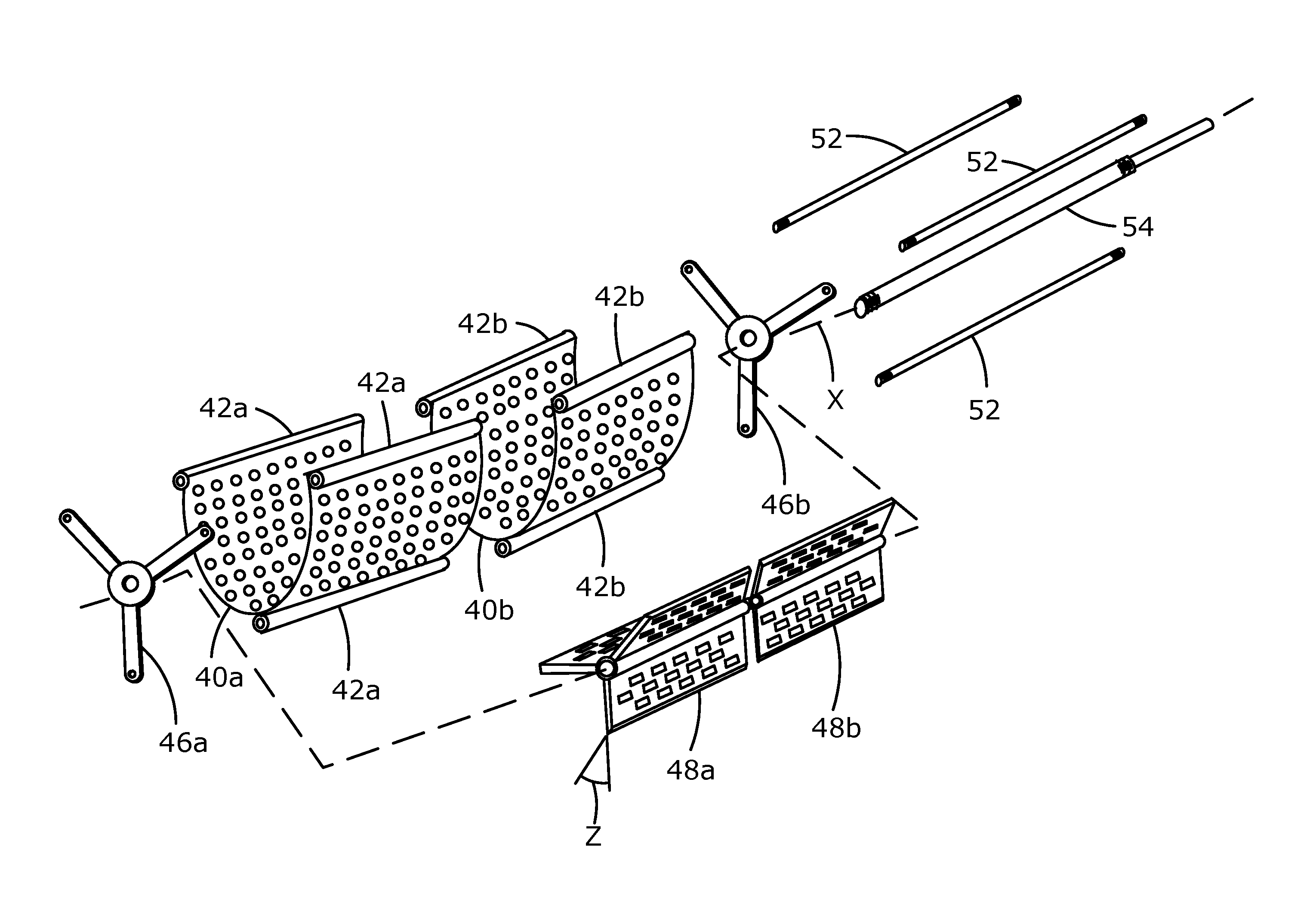

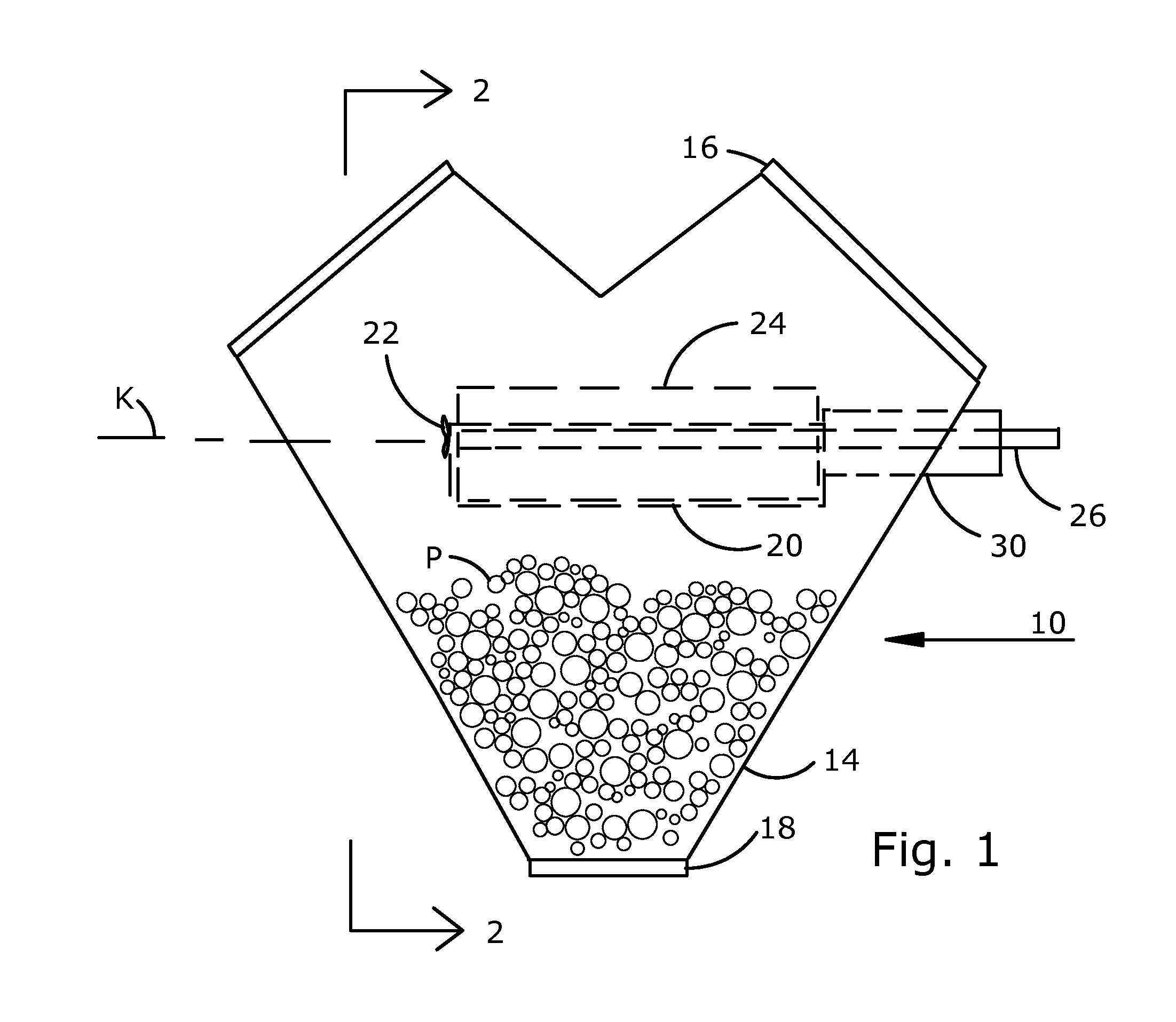

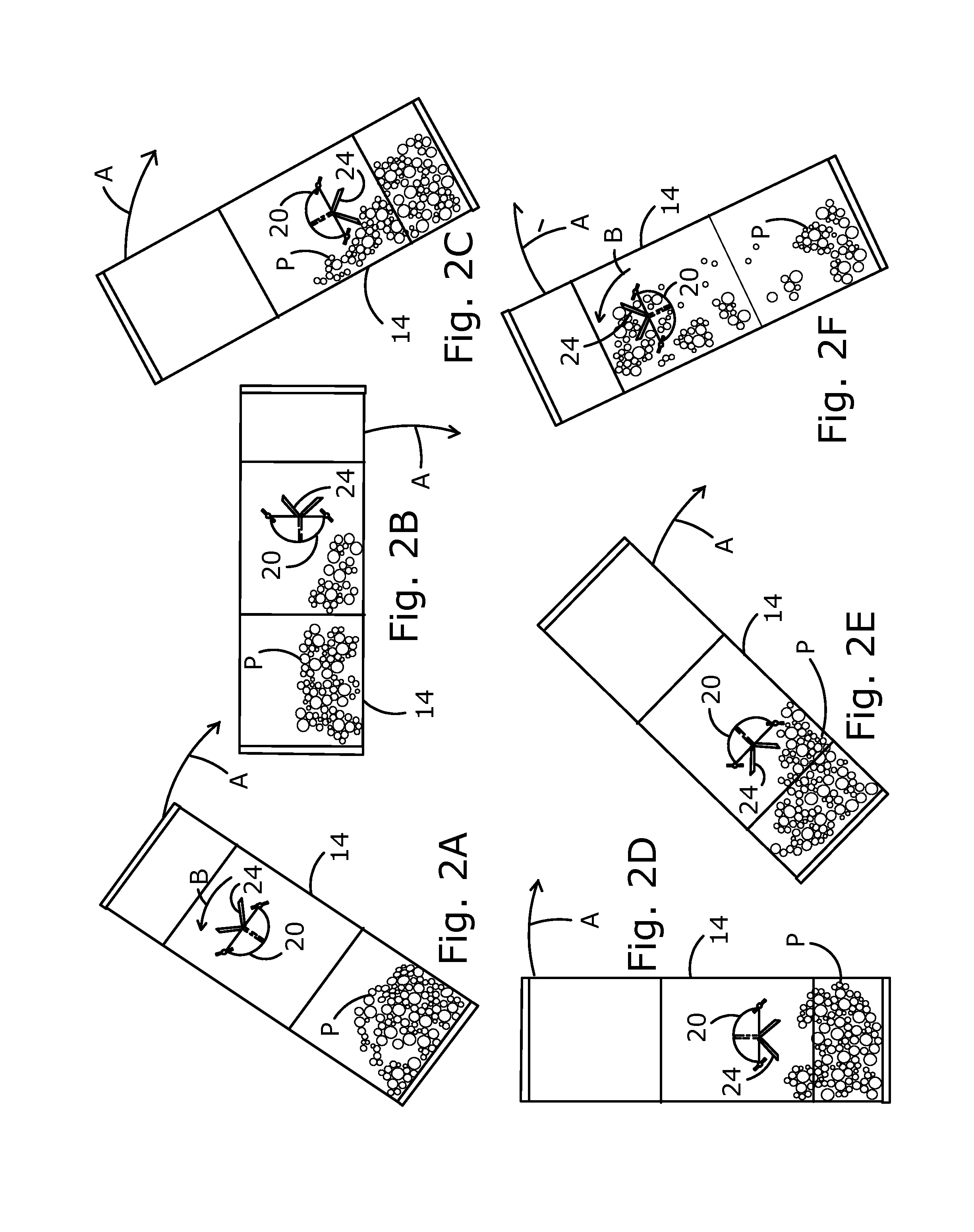

Apparatus for alternately sifting and blending powders in the same operation

ActiveUS8827545B2Efficiently siftingEfficient blendingSievingRotating receptacle mixersMechanical engineeringStructural engineering

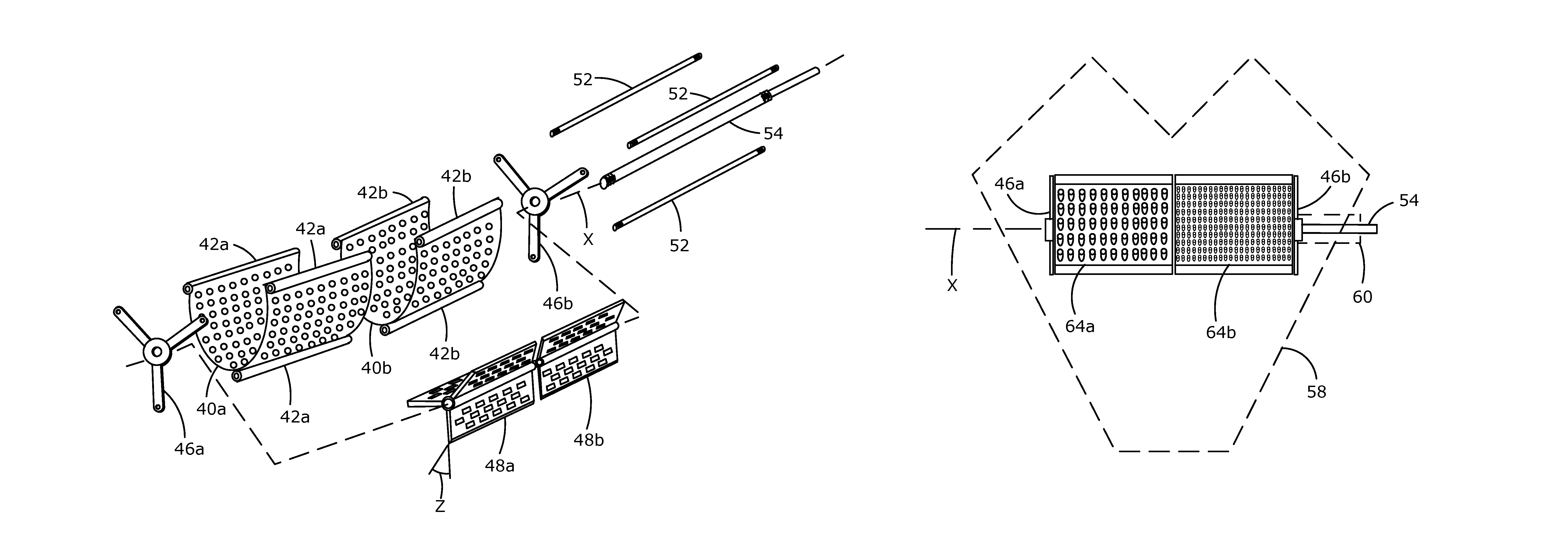

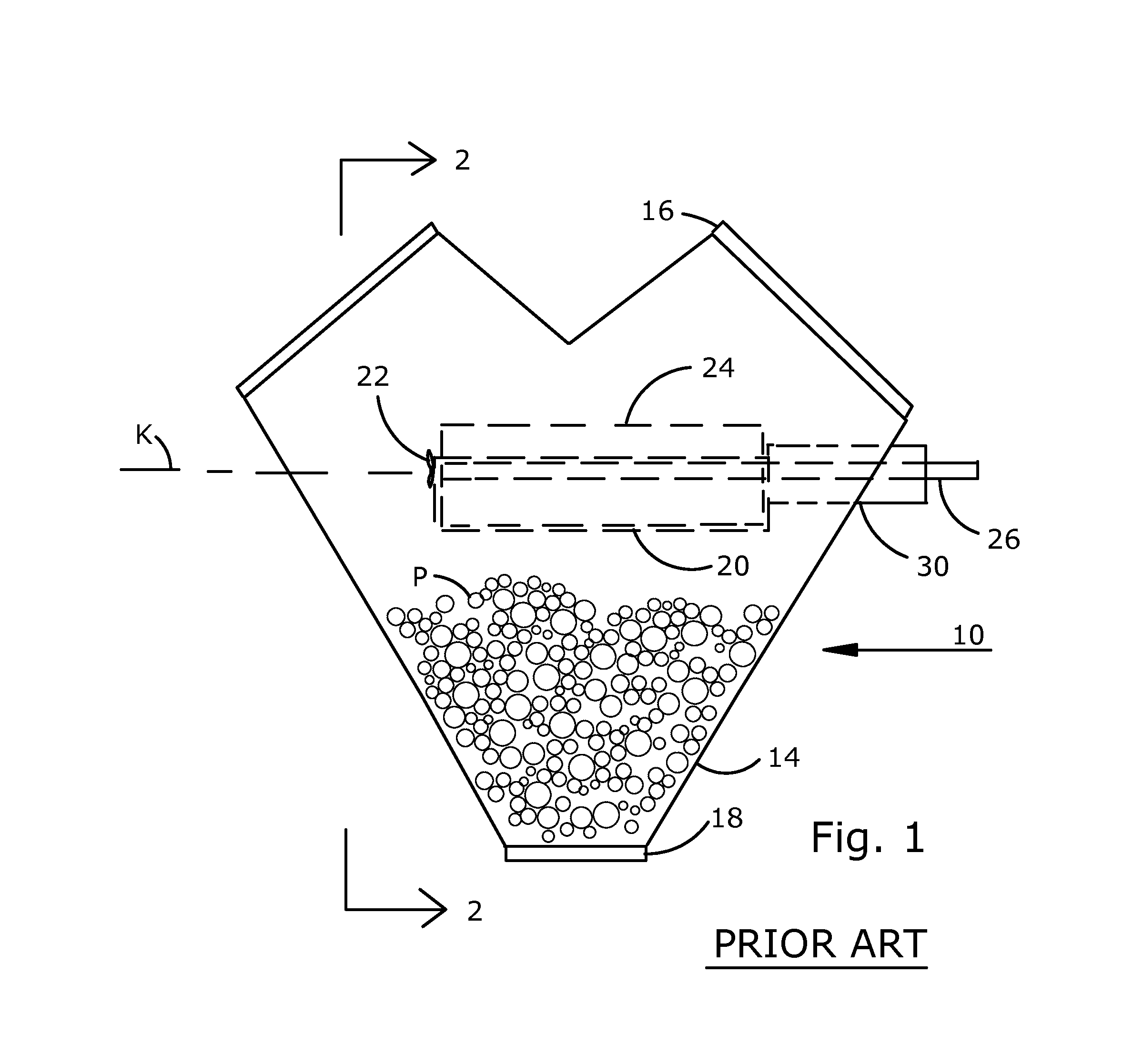

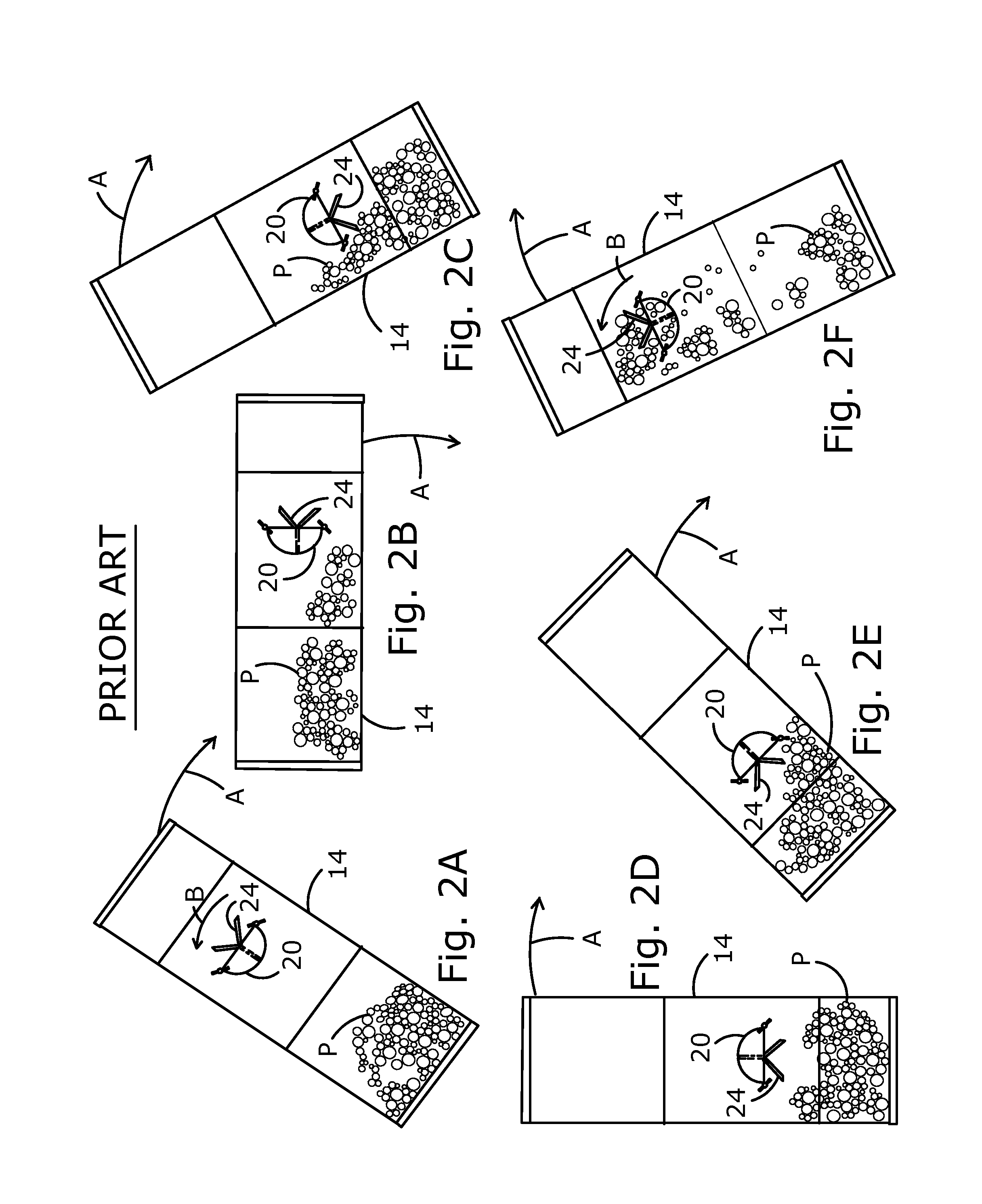

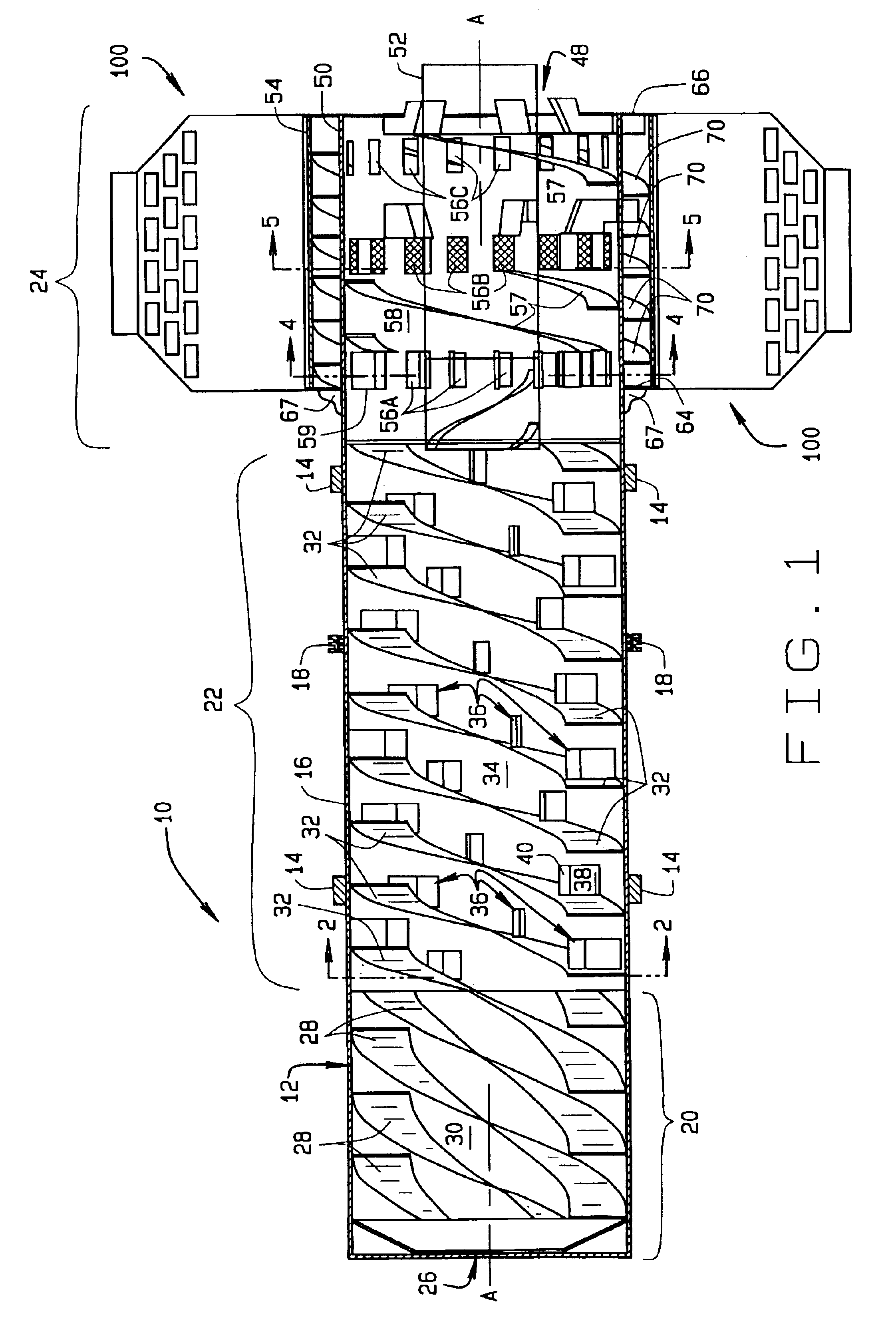

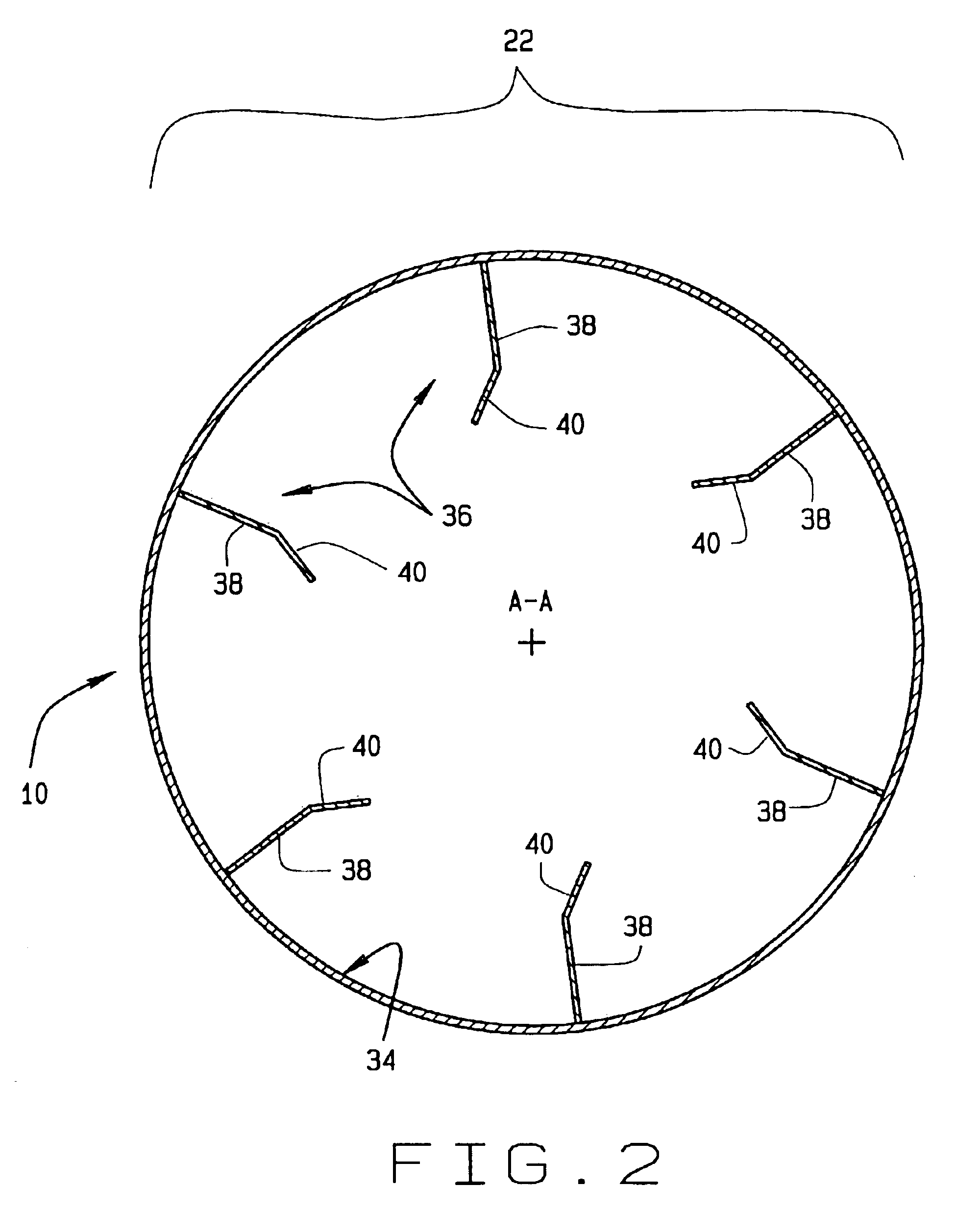

A tumbling container is mounted for rotation with a curved screen fixedly mounted within the tumbling container. A multiple vane paddle is mounted to a shaft that is rotatably mounted to the tumbling container. The paddle vanes are formed with angular edges. As the tumbler rotates and the paddle rotates, powder is repeatedly dropped onto the screen to be sifted with the aid of the paddle. Rotating the tumbler further drops unsifted portions of the powder from the screen to mix with additional powder in the tumbler body. Thus, sifting and blending of powders is accomplished in one single operation. The invention utilizes an apparatus having a multiple section screen and a multiple section paddle to enable assembly through the openings in the tumbling container. The screen of a second embodiment has a cowl adjacent to each screen opening to optimize powder lump disintegration.

Owner:KALIDINDI SANYASI R

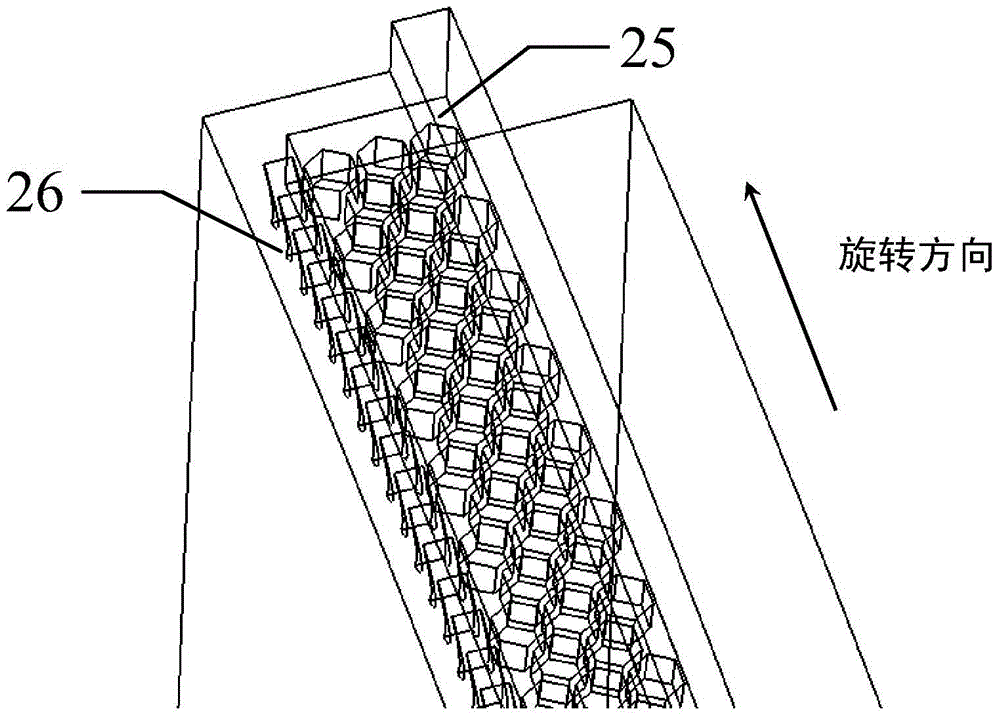

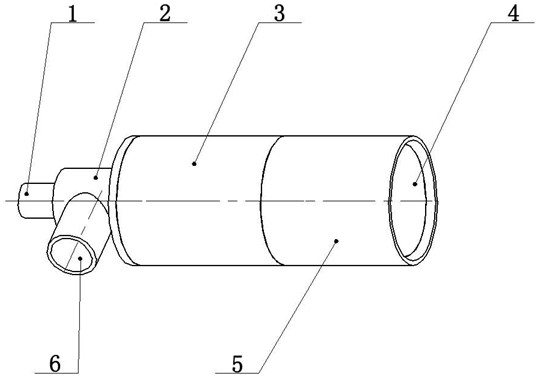

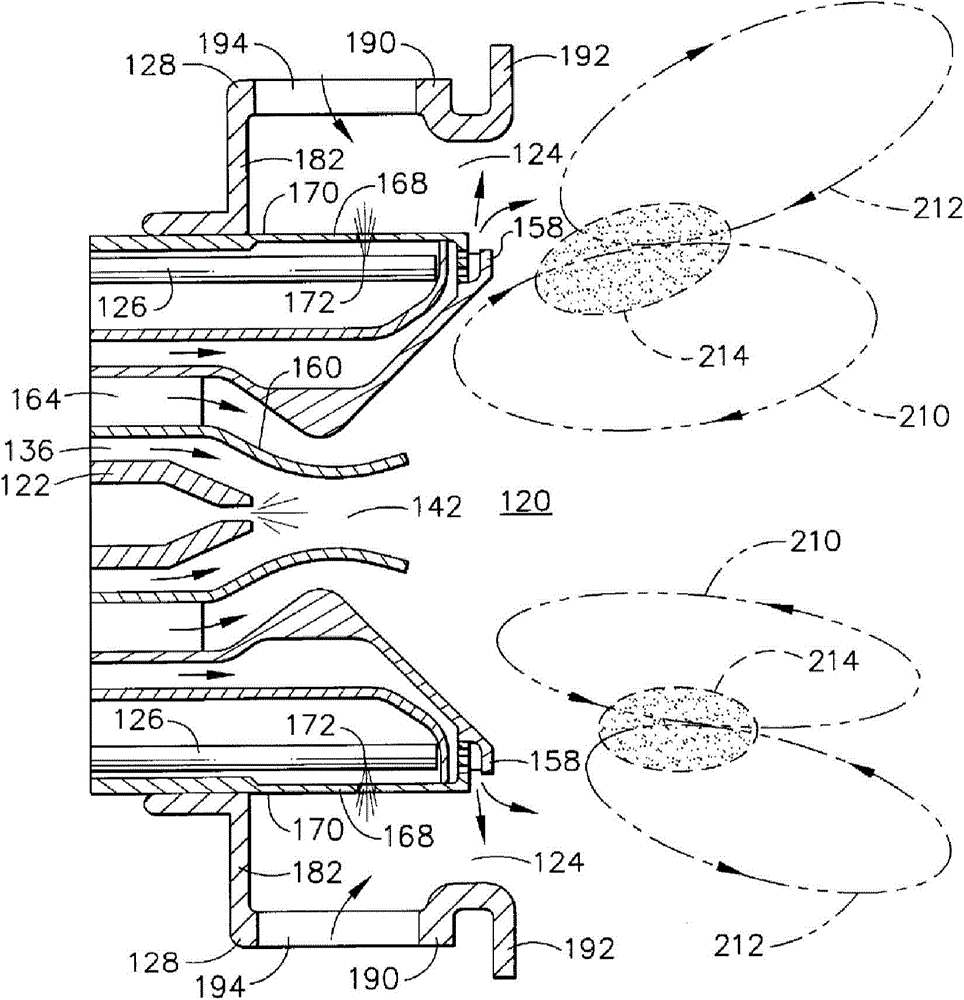

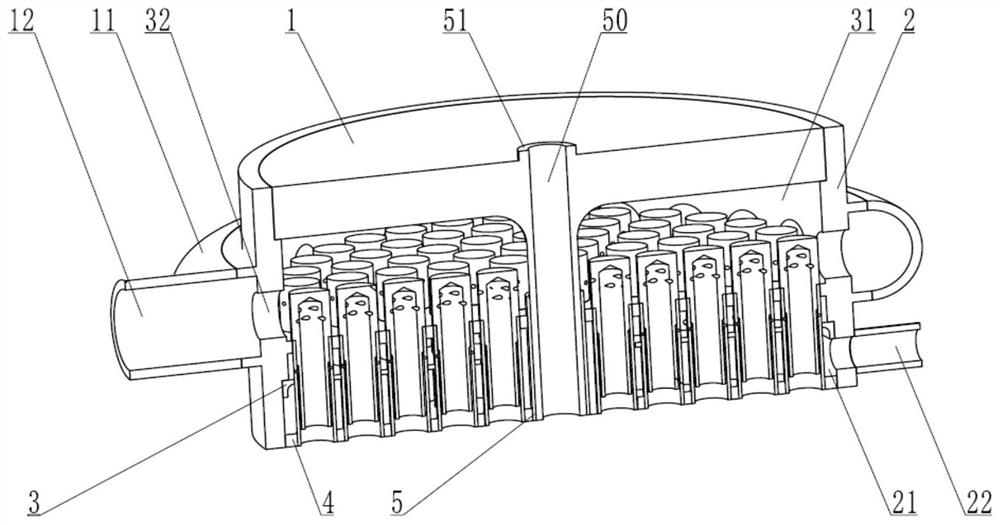

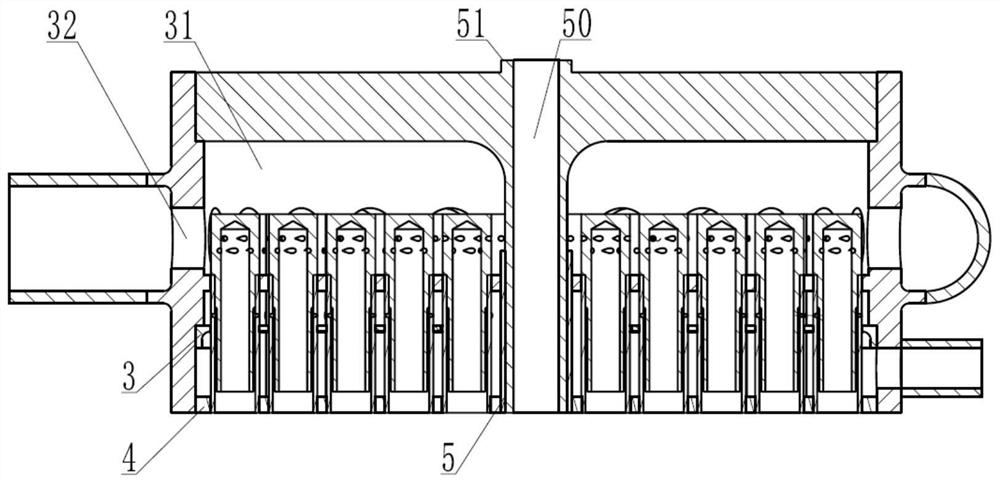

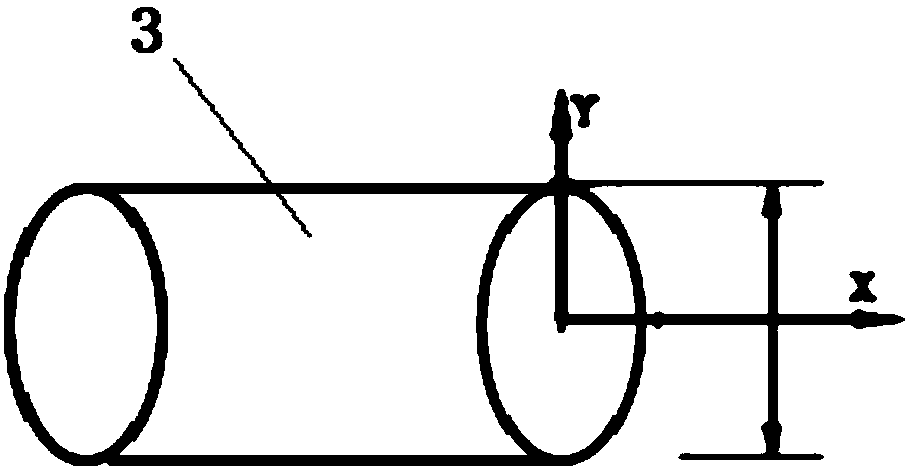

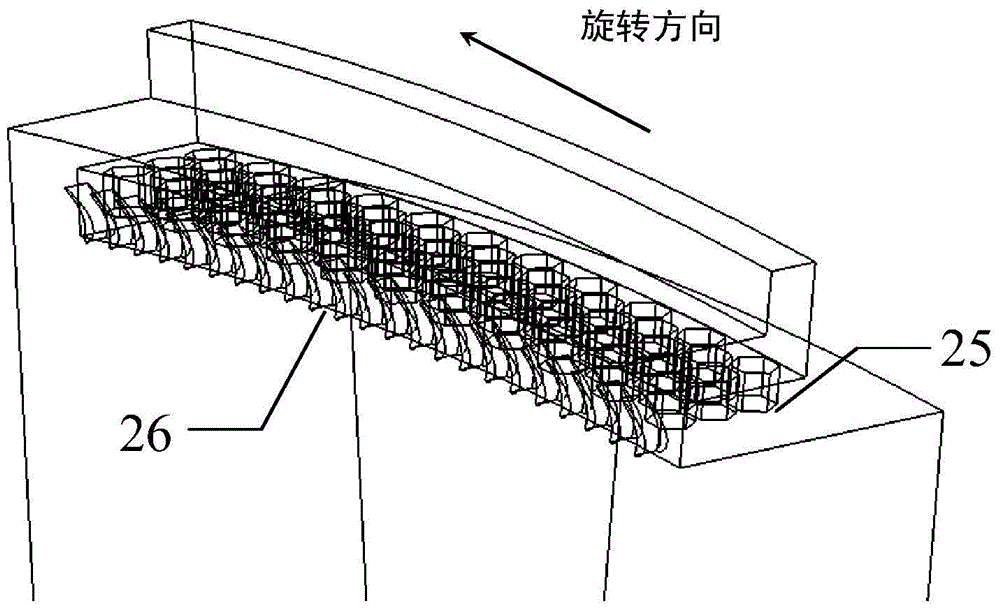

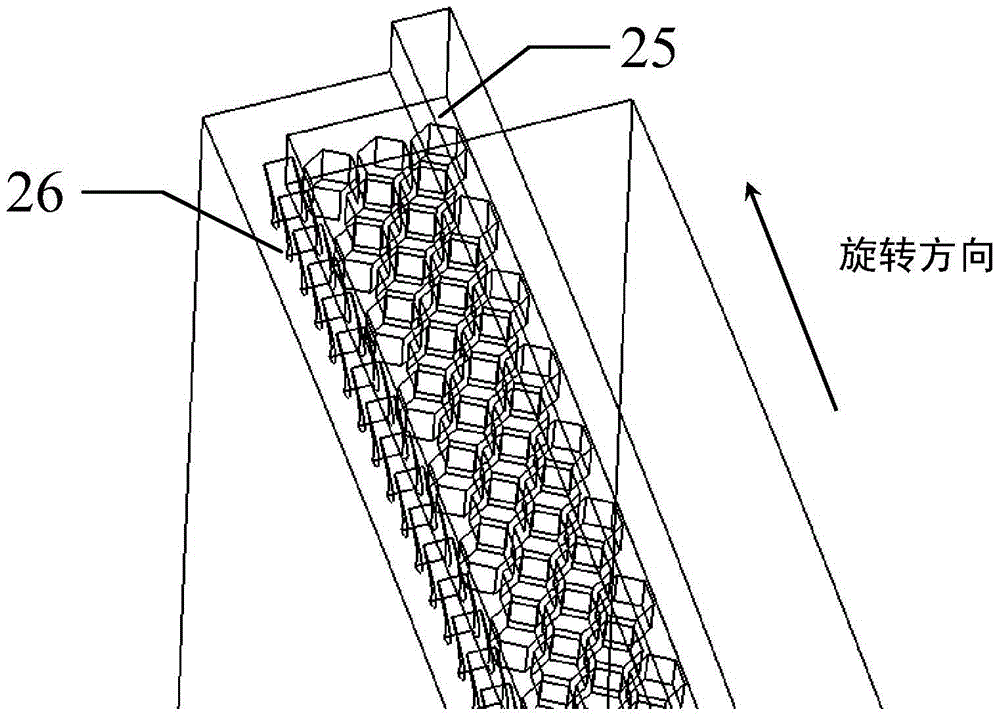

Granular product blending and cooling rotary drum

InactiveUS6896400B2Efficient blendingEffective coolingRotating receptacle mixersTransportation and packagingCounter flowMechanical engineering

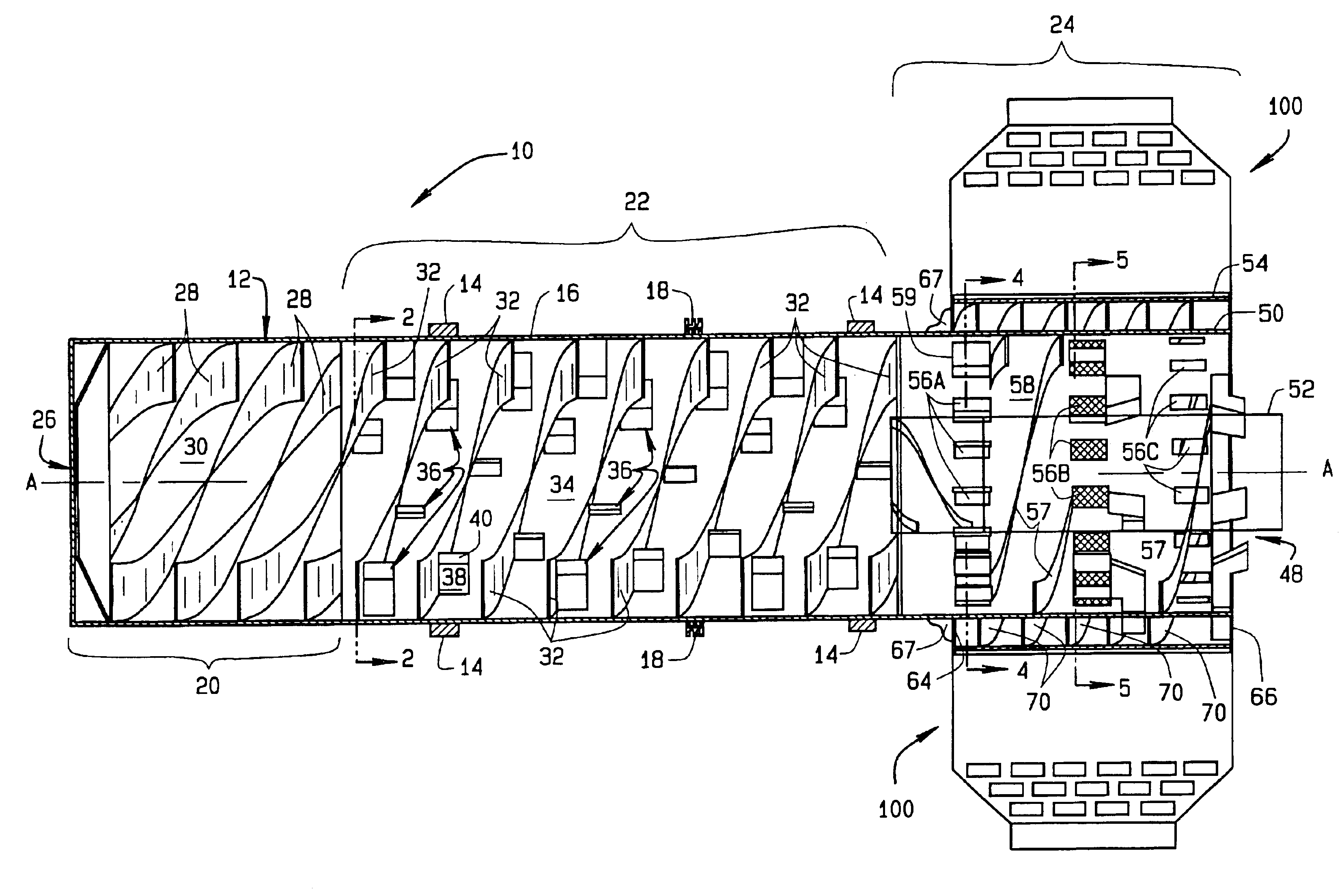

A rotary drum configuration for the efficient blending, cooling, and screening of granular products having an outer cylindrical shell, an intake end, and a discharge end. The rotary drum is normally rotated at a predetermined speed by means of a conventional drive package. Disposed on an inner surface of the cylindrical shell are a plurality of compound helical flights and scoops, configured to blend granular product as it cascades from the intake end to the discharge end of the rotary drum. A coaxially disposed cylindrical air passage adjacent the discharge end of the rotary drum directs a counter flow of cooling air through the rotary drum towards the intake end, cooling the cascading granular product as it approaches the discharge end, and plurality of discharge ports and grading screens in the surface of the outer cylindrical shell adjacent the discharge end provide a entrance for a second counter flow of cooling air while simultaneously providing passage for the granular product to drop downwards towards a outer coaxial discharge passage.

Owner:DIDION TECHNOLOGIES LLC

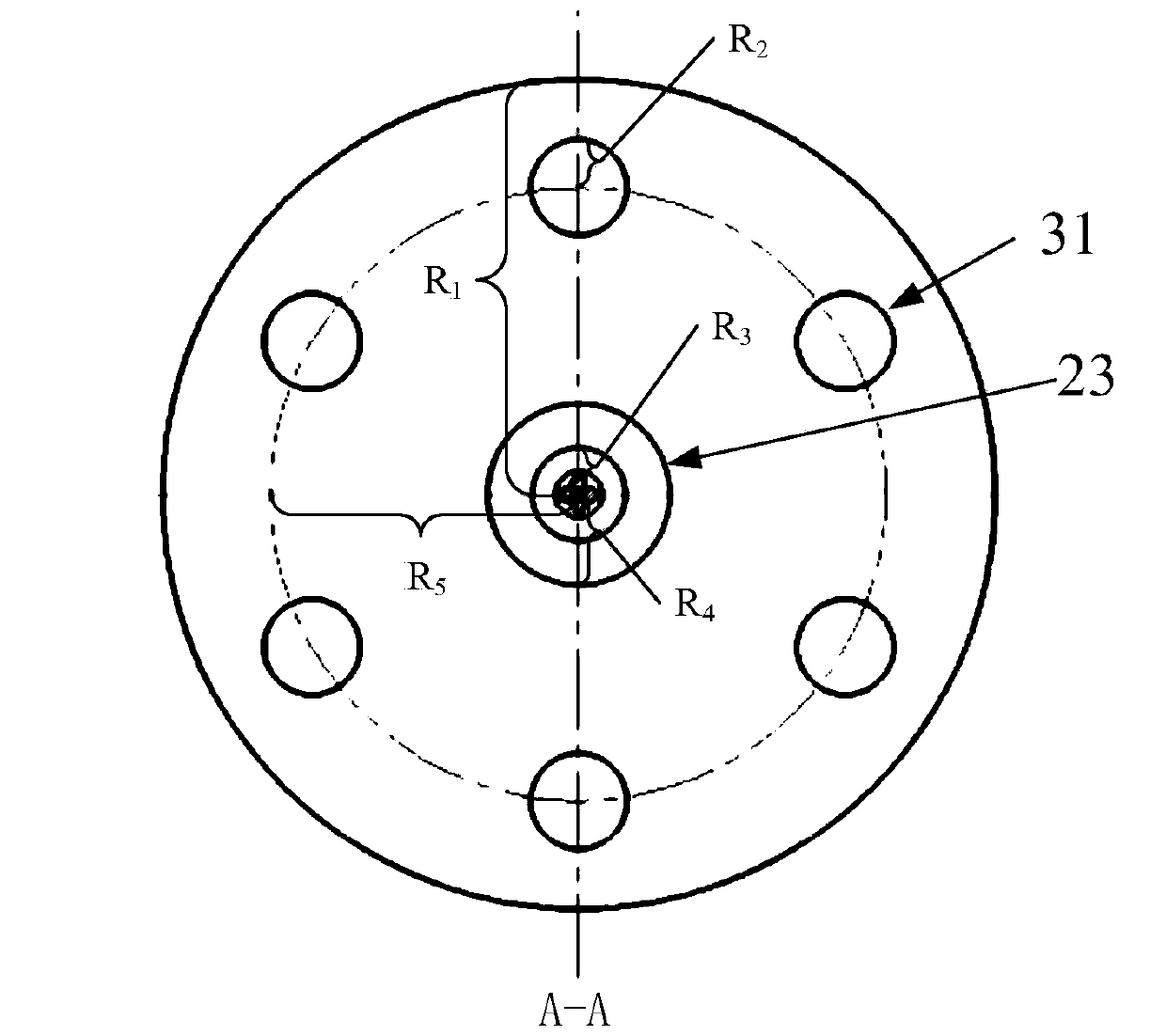

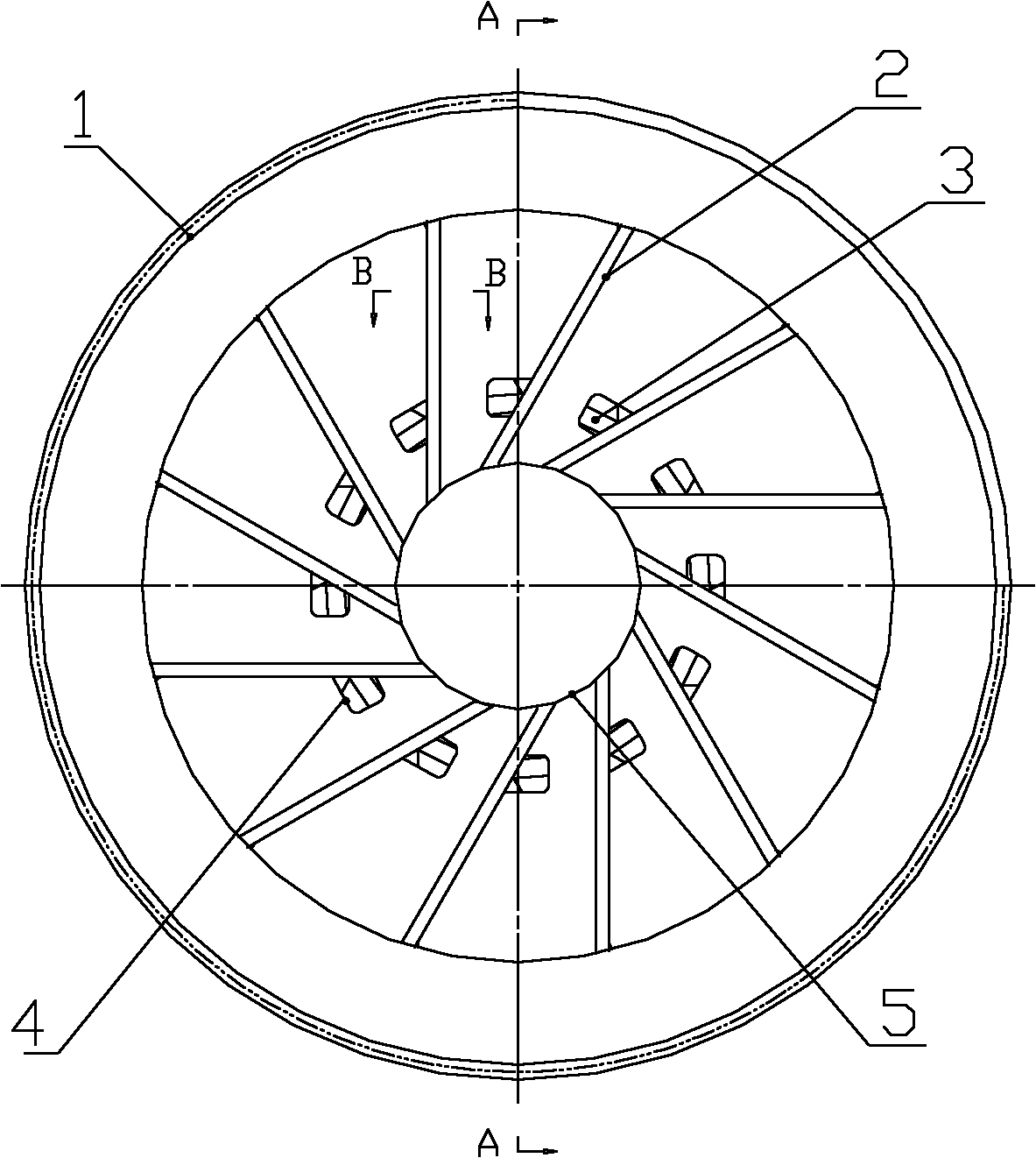

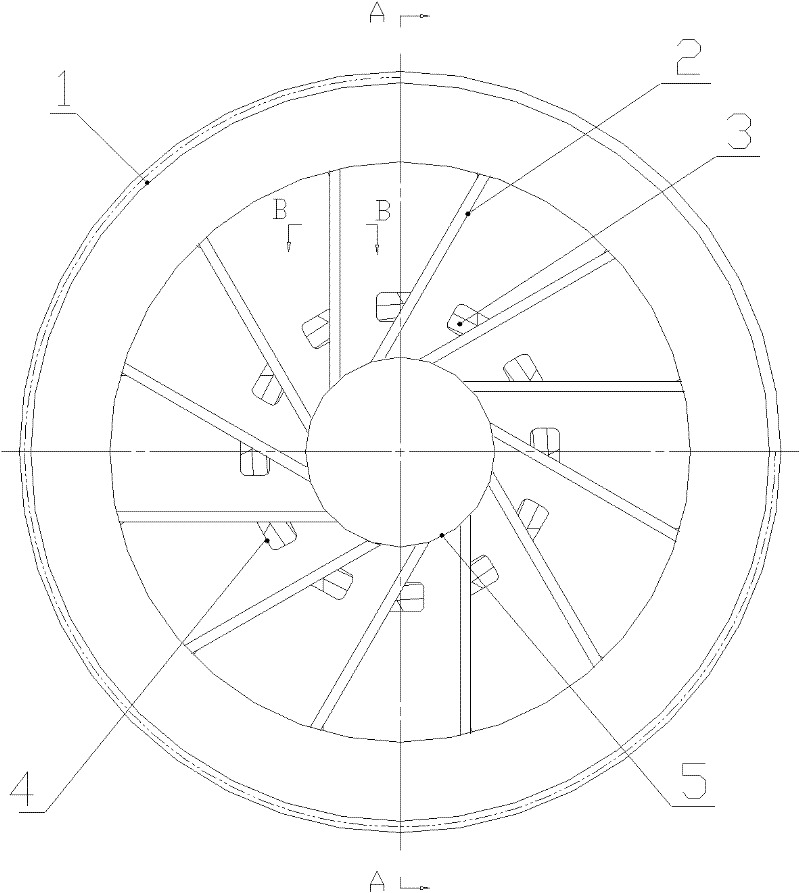

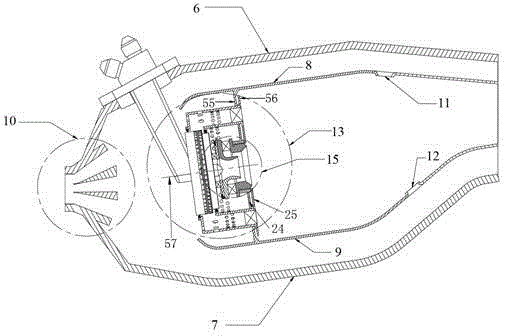

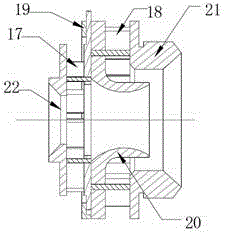

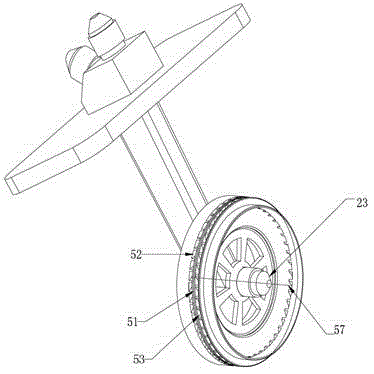

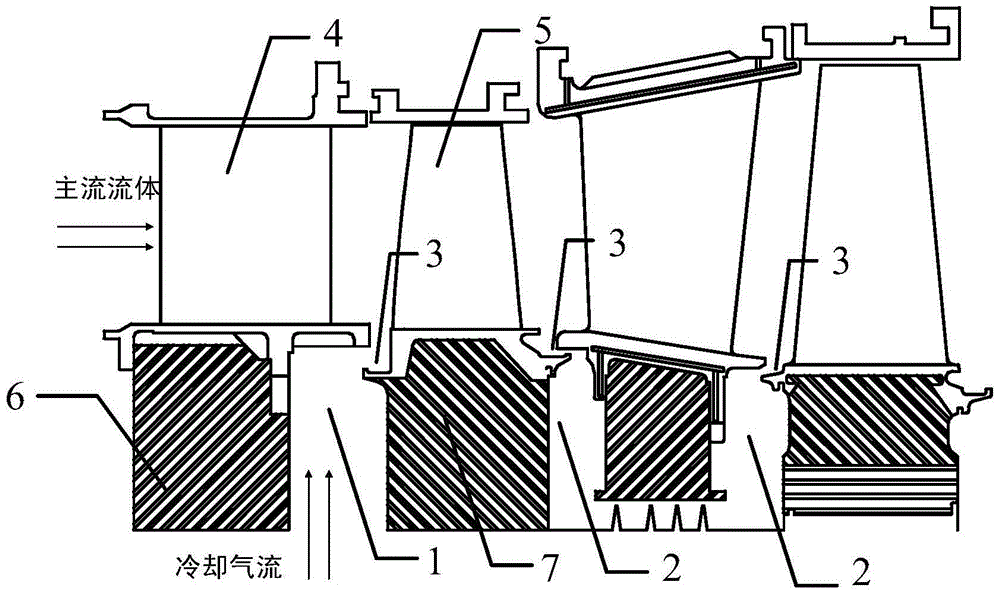

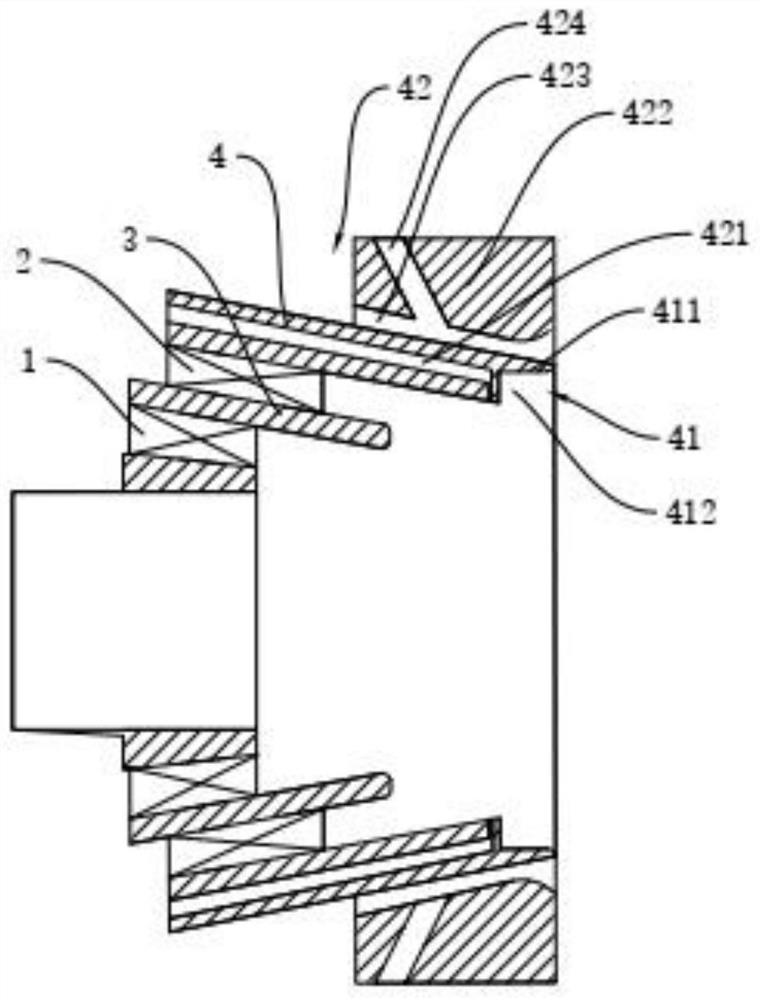

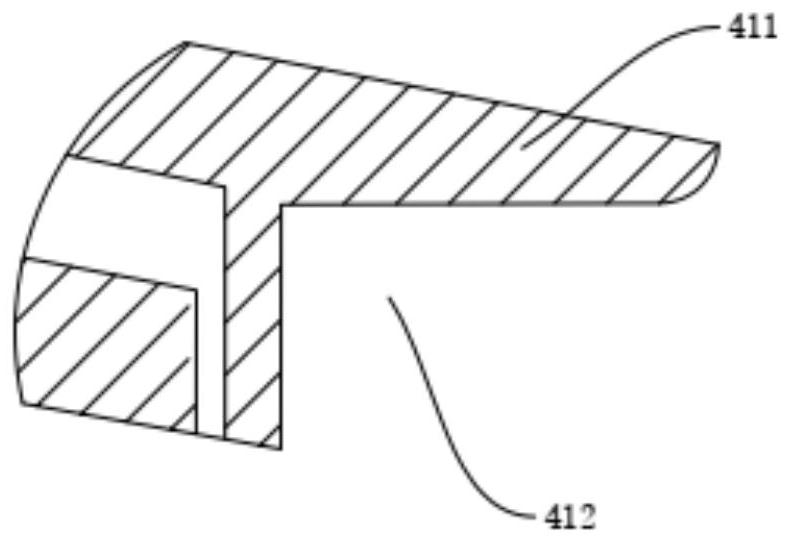

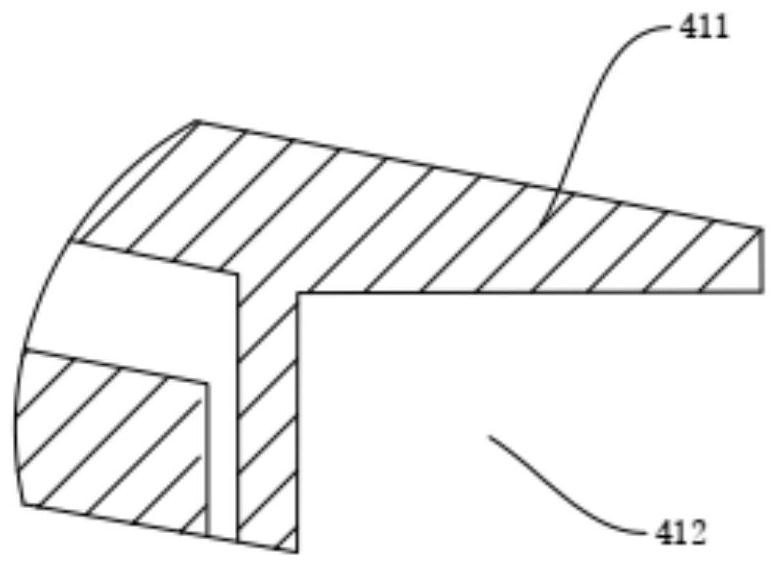

Radial rim sealing structure with damping holes and flow guide blades

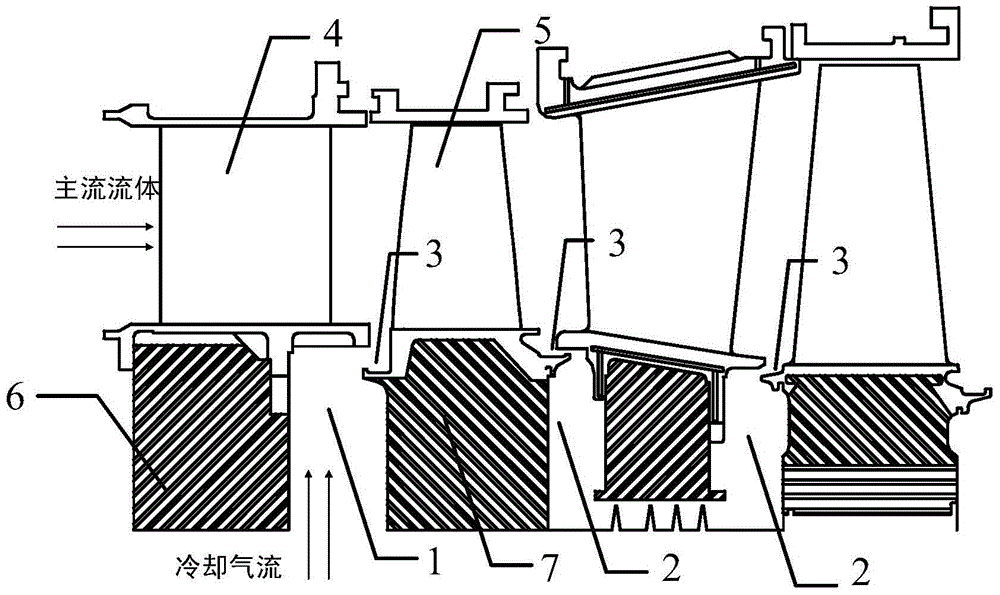

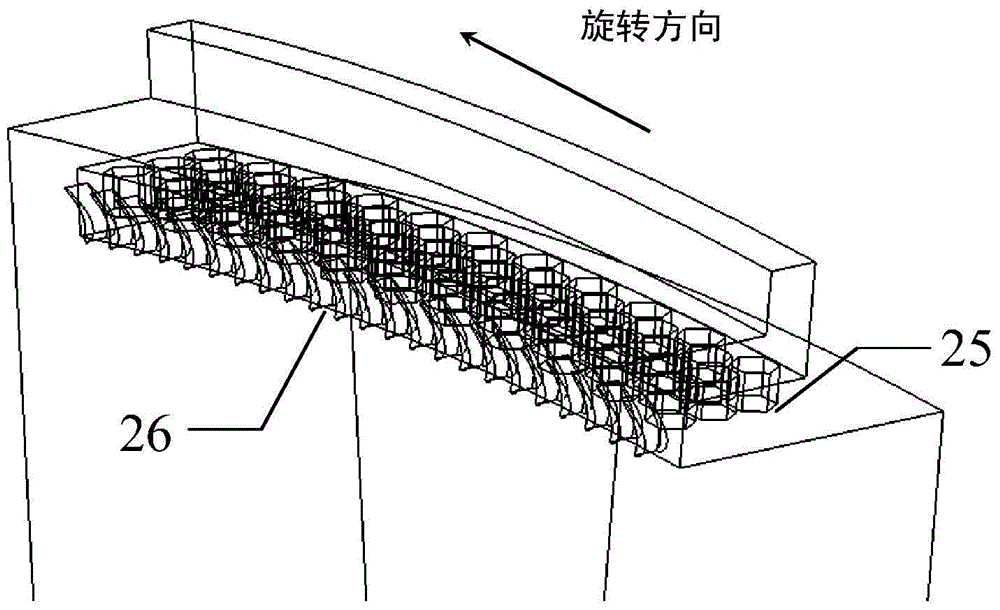

ActiveCN105134306AGood sealingIncrease flow resistanceLeakage preventionMachines/enginesEngineeringAir compressor

The invention discloses a radial rim sealing structure with damping holes and flow guide blades. The radial rim sealing structure is characterized in that the radial rim sealing structure is arranged in a gas turbine rotor-stator cavity or a gas turbine rotor-rotor cavity and comprises an outer tooth and a radial inner tooth which are matched; a plurality of damping holes are evenly formed in the upper end face of an inner tooth body of the radial inner tooth in the circumferential direction, and a plurality of flow guide blades are evenly arranged on the radial end face of the inner tooth body of the radial inner tooth in the circumferential direction; furthermore, the damping holes are in a cellular shape and are evenly distributed in a sealing tooth face in the circumferential direction; the flow guide blade are arranged on the end face of the sealing radial inner tooth with equal arcs, and the blades are provided with gradually-shrunk channels. The rim sealing structure can effectively lower the high-temperature gas invading degree and improve the sealing performance of rim sealing, and therefore the overheat failure of a turbine disc is avoided, the use amount of low-temperature cooling air flow introduced from the position of an air compressor can also be reduced, and the efficiency of a unit can be improved.

Owner:XI AN JIAOTONG UNIV

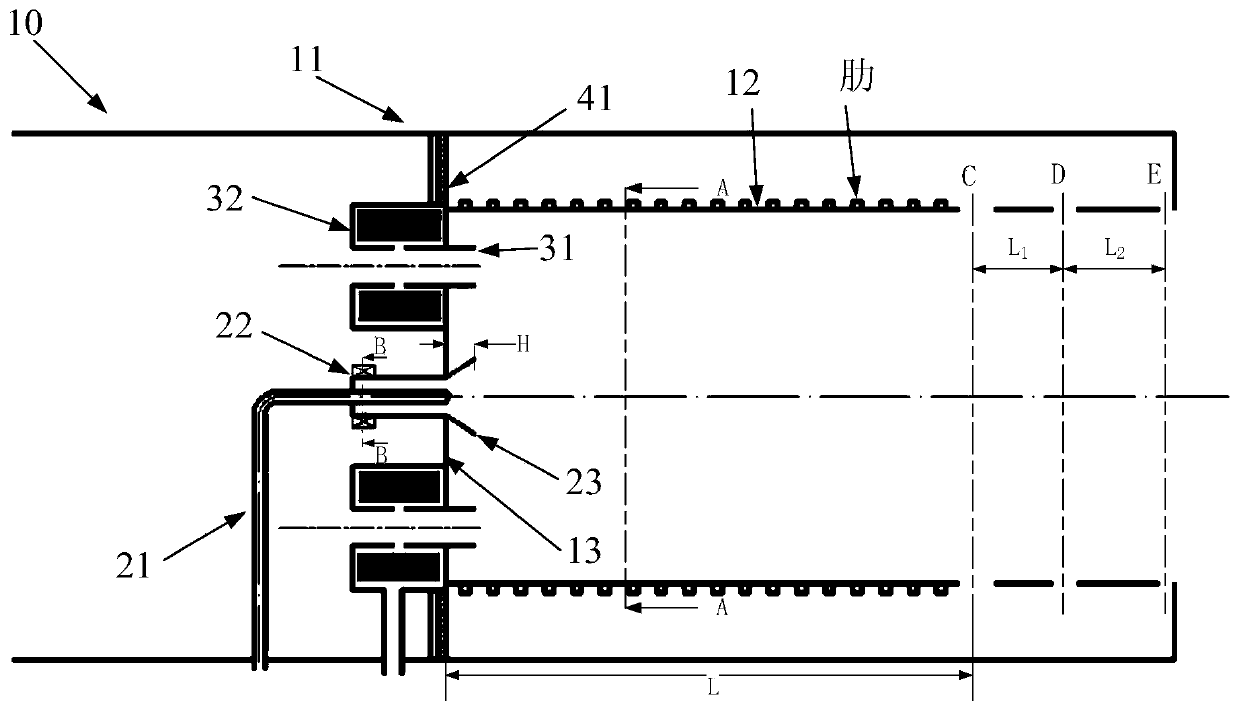

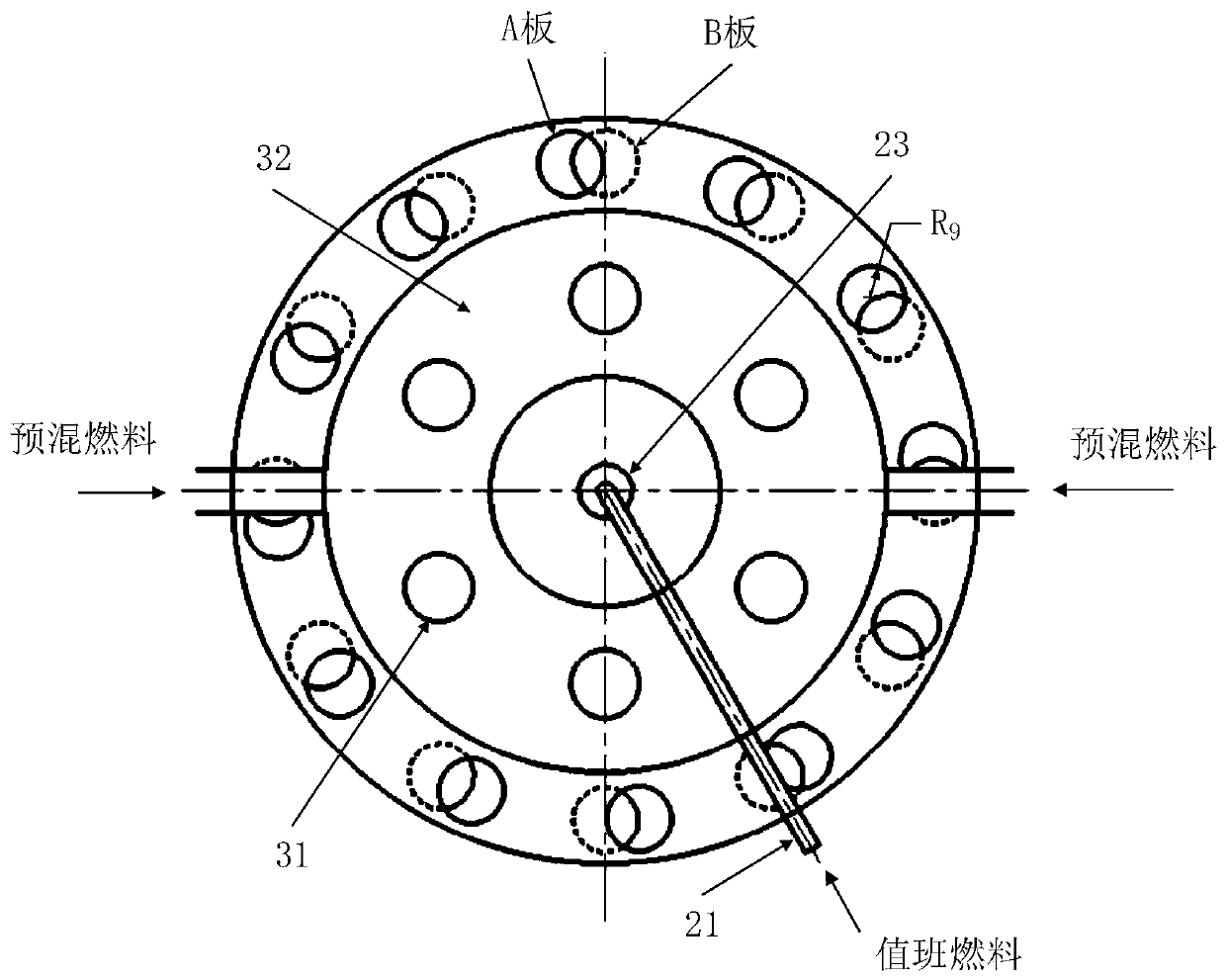

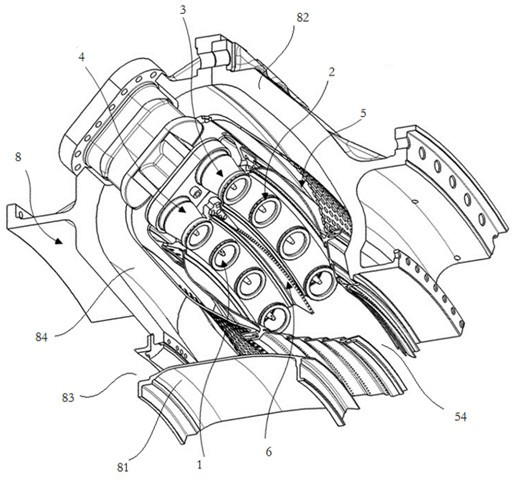

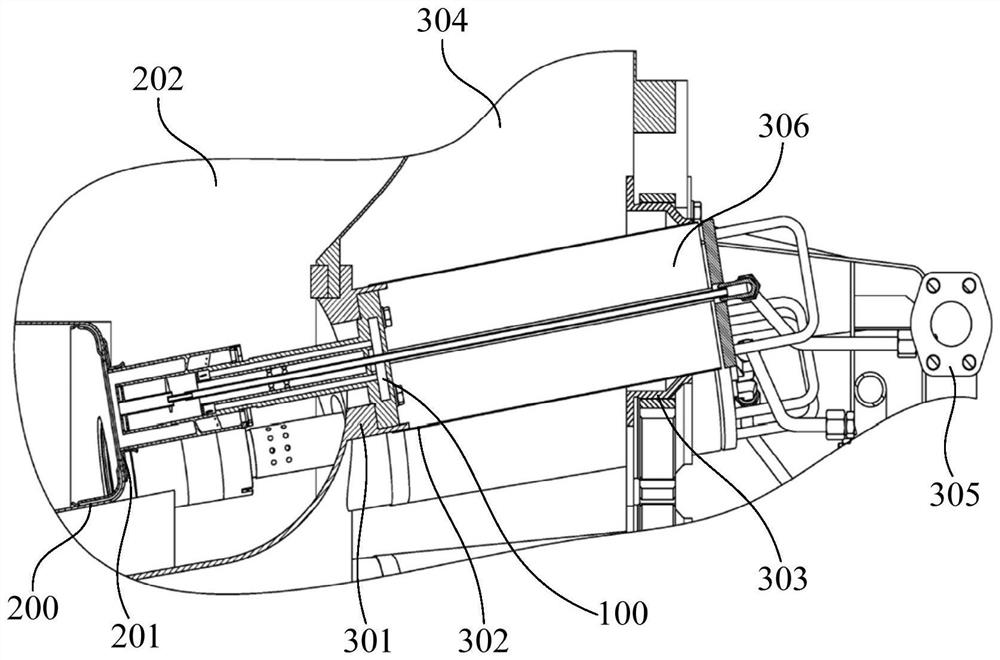

High-temperature smoke generator and control method thereof

ActiveCN110836383AReduce oxygen concentrationReduce the temperatureContinuous combustion chamberCombustion chamberNitrogen oxides

The invention provides a high-temperature smoke generator and a control method thereof. A duty nozzle assembly is arranged at the center of a combustion chamber head baffle, and a premixing nozzle assembly is uniformly distributed on the combustion chamber head baffle in the circumferential direction. An annular air channel is formed between the outer wall of a combustion chamber and a combustionchamber flame tube, and an airflow rate distributing adjusting valve is arranged at an annular channel inlet. High-speed jet flow of premising nozzles forms entrainment backflow in the middle of the combustion chamber, and through a smoke internal circulation mechanism, the forming amount of nitrogen oxide in the combustion chamber is decreased. The outer wall surface of the combustion chamber flame tube is provided with a fin structure to enhance cooling of air in the annular channel to the flame tube. The tail of the combustion chamber flame tube is provided with a plurality of rows of mixing holes, by reasonably distributing the hole diameter and the position of the mixing holes, smoke and mixed air are sufficiently mixed, and accordingly, the uniformity of the outlet smoke temperatureand component distribution is ensured. The high-temperature smoke generator cooperates with the airflow rate adjusting valve, so that effective adjusting of the outlet smoke temperature is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Apparatus for alternately sifting and blending powders in the same operation

ActiveUS20140064020A1Easy to installSaferSievingRotating receptacle mixersEngineeringMechanical engineering

A tumbling container is mounted for rotation with a curved screen fixedly mounted within the tumbling container. A multiple vane paddle is mounted to a shaft that is rotatably mounted to the tumbling container. The paddle vanes are formed with angular edges. As the tumbler rotates and the paddle rotates, powder is repeatedly dropped onto the screen to be sifted with the aid of the paddle. Rotating the tumbler further drops unsifted portions of the powder from the screen to mix with additional powder in the tumbler body. Thus, sifting and blending of powders is accomplished in one single operation. The invention utilizes an apparatus having a multiple section screen and a multiple section paddle to enable assembly through the openings in the tumbling container. The screen of a second embodiment has a cowl adjacent to each screen opening to optimize powder lump disintegration.

Owner:KALIDINDI SANYASI R

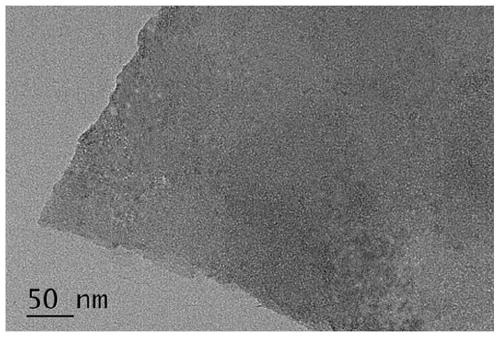

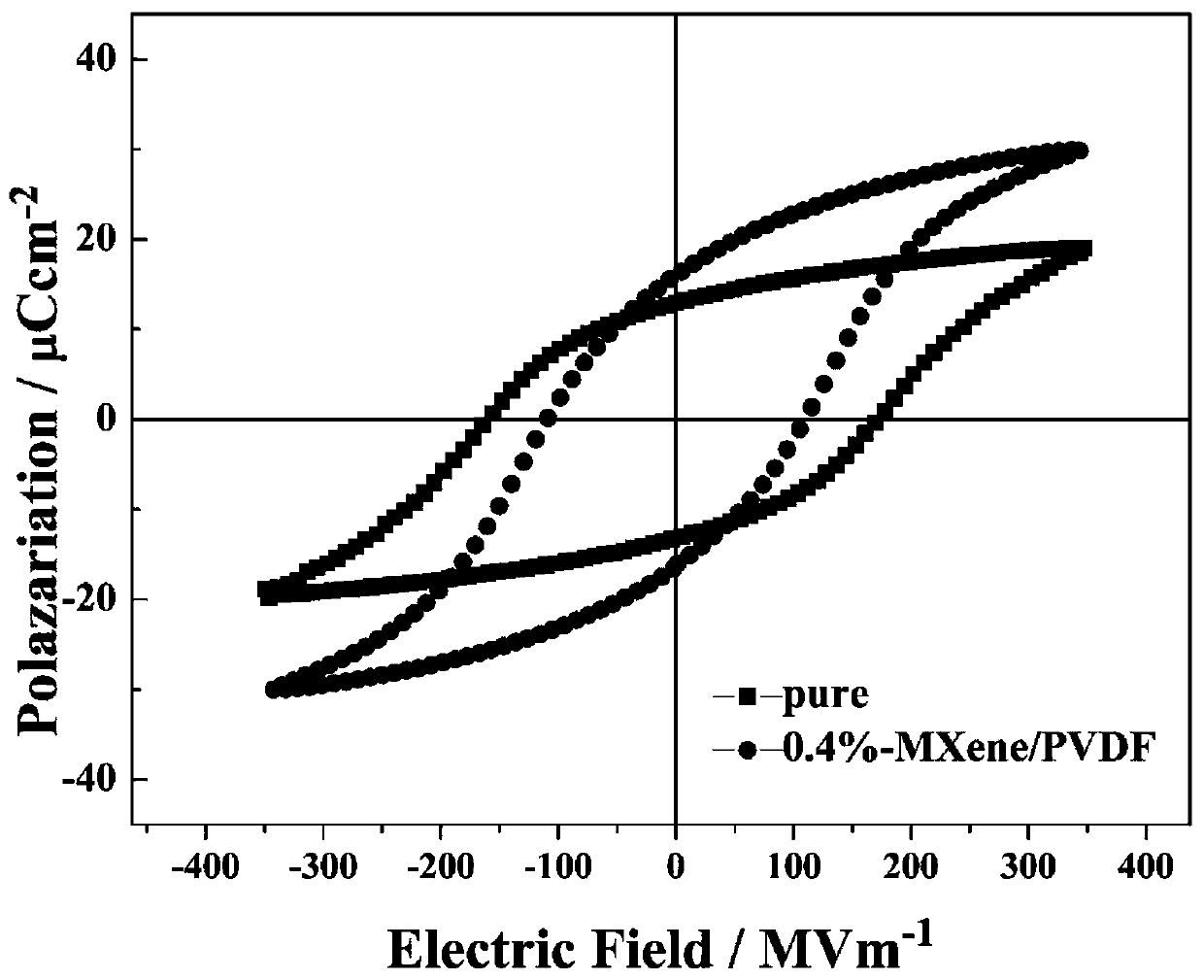

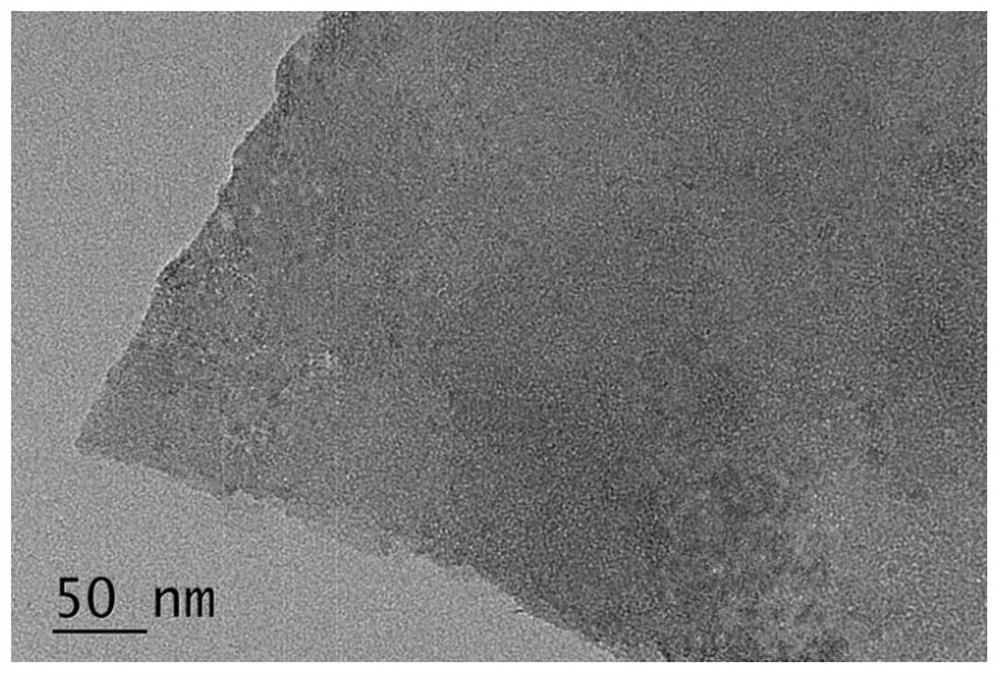

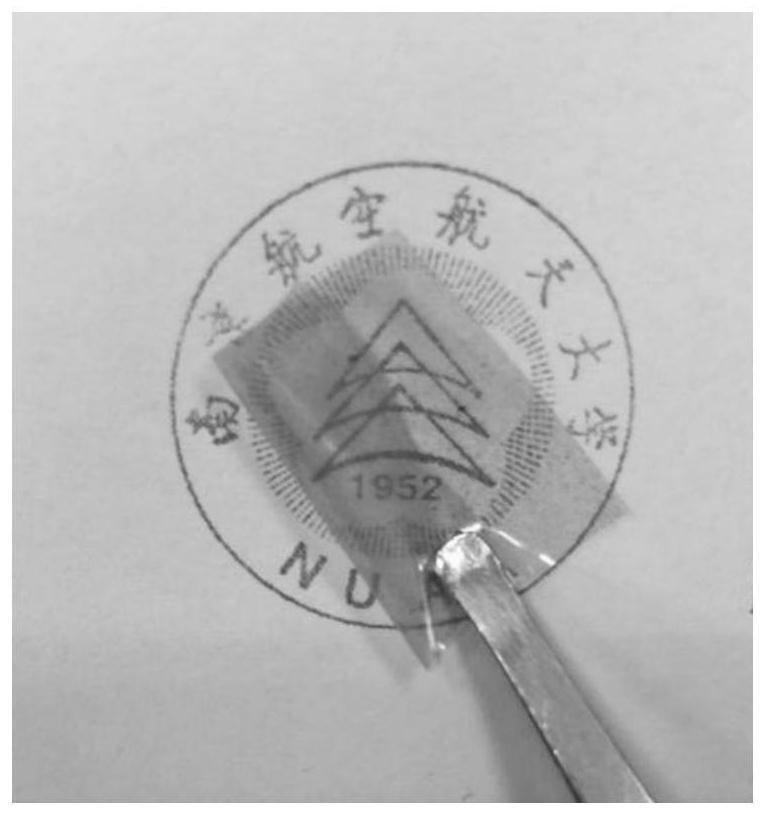

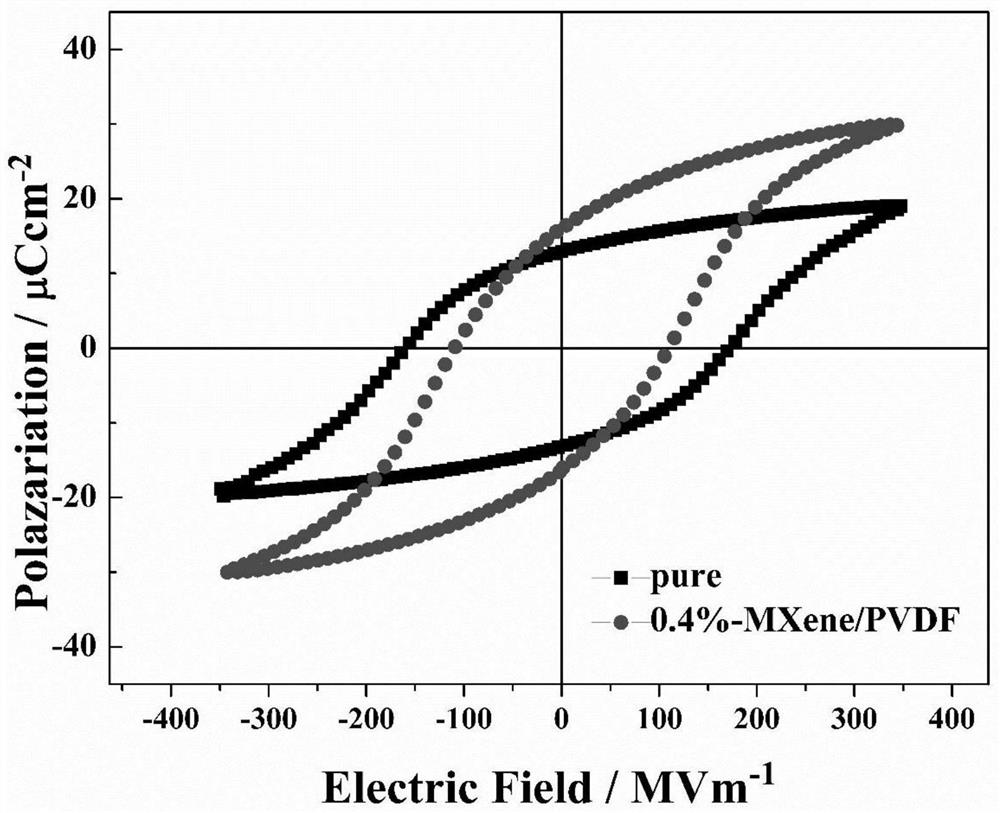

Polymer-based piezoelectric film, and preparation method and application thereof

ActiveCN111363277AExcellent piezoelectric propertiesImprove breakdown performancePiezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsPolymer sciencePolyvinylidenefluoride-trifluoroethylene

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a polymer-based piezoelectric film and a preparation method and application thereof. The polymer-based piezoelectric film provided by the invention comprises a polymer and a doped two-dimensional layered structure compound, wherein a mass ratio of the polymer to the two-dimensional layered structure compound is 100: (0.1-2); the polymer is one or more selected from a group consisting of polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene and polyvinylidene fluoride-trifluoroethylene; the chemical composition of the two-dimensional layered structure compound is M<n+1>X<n>T<y>, n is equal to 1, 2 or 3, M is a transition metal element, T is a -O, -OH or -F functional group, and X is a carbon element or a nitrogen element. According to the polymer-based piezoelectric film provided by the invention, the problem that the piezoelectric property of a traditional PVDF material is insufficient is solved; and experimental effect shows that the polymer-based piezoelectric film provided by the invention has good flexibility and excellent ferroelectric property and piezoelectricproperty.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

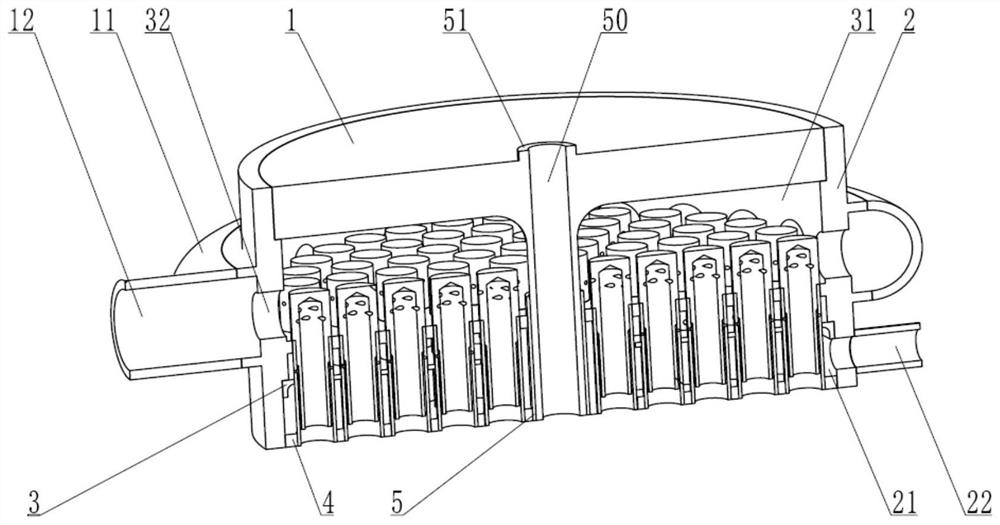

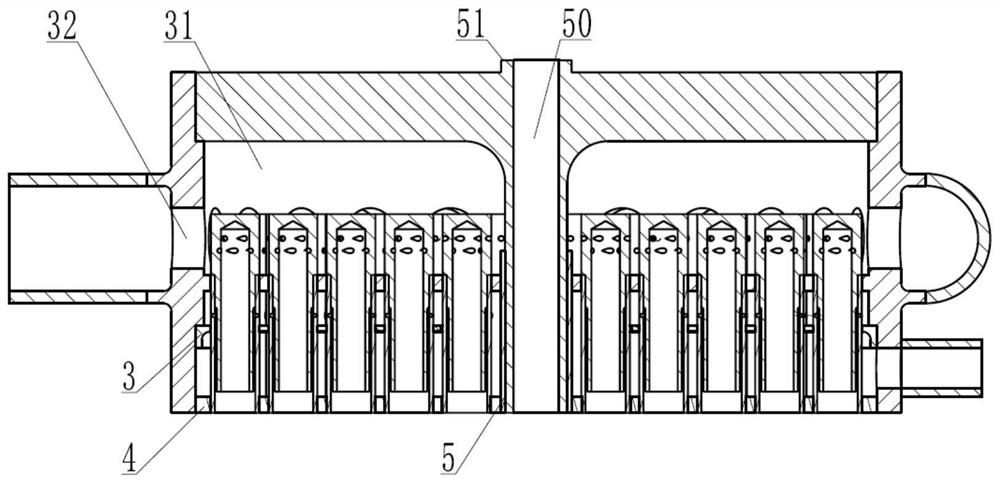

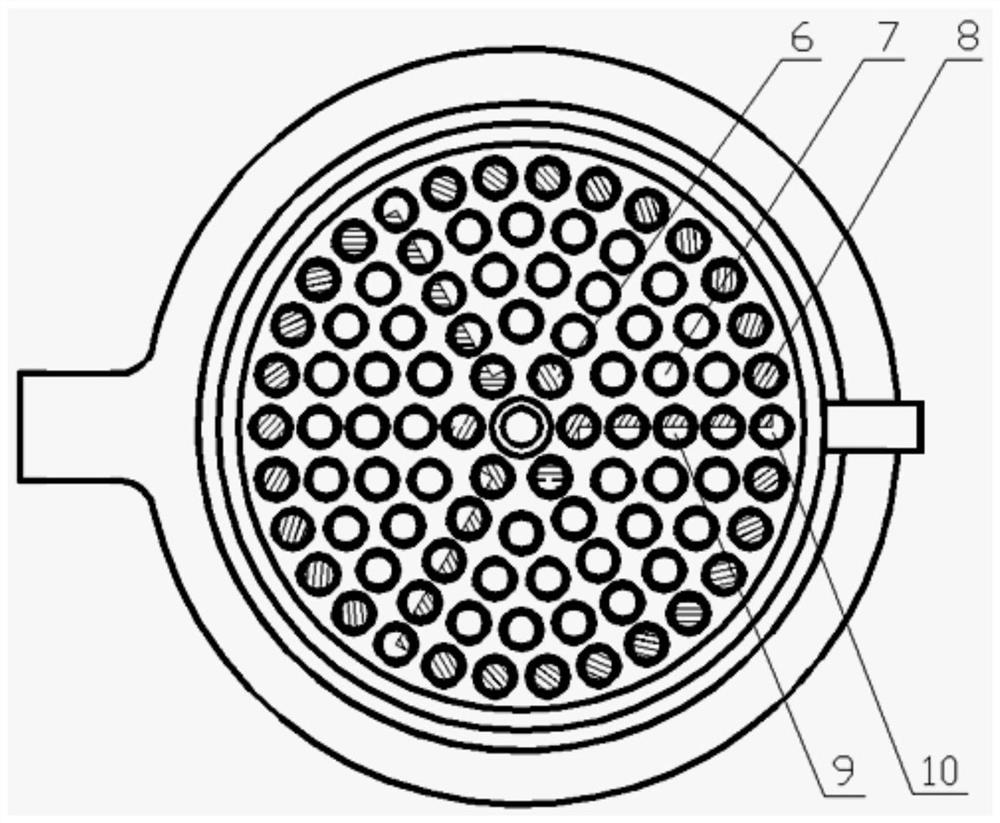

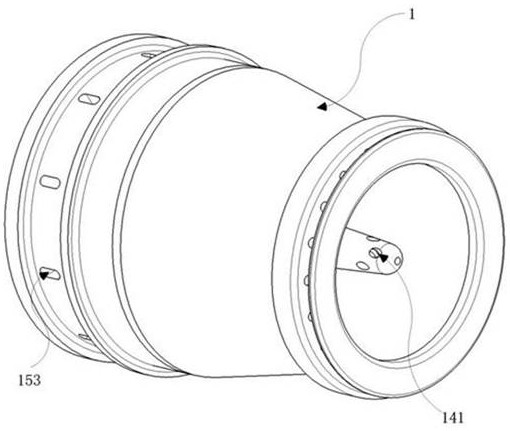

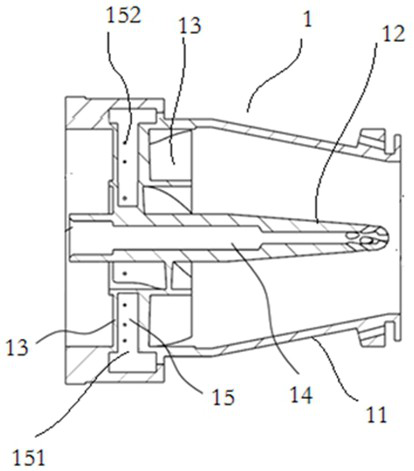

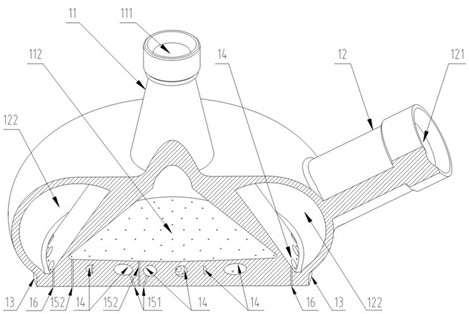

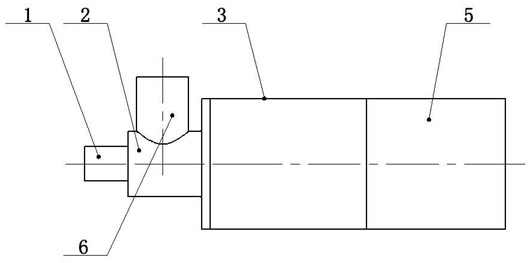

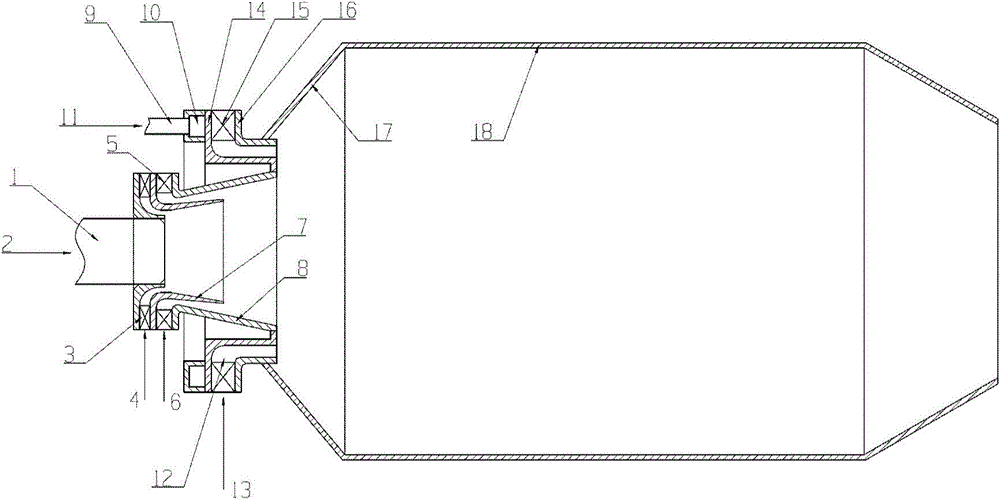

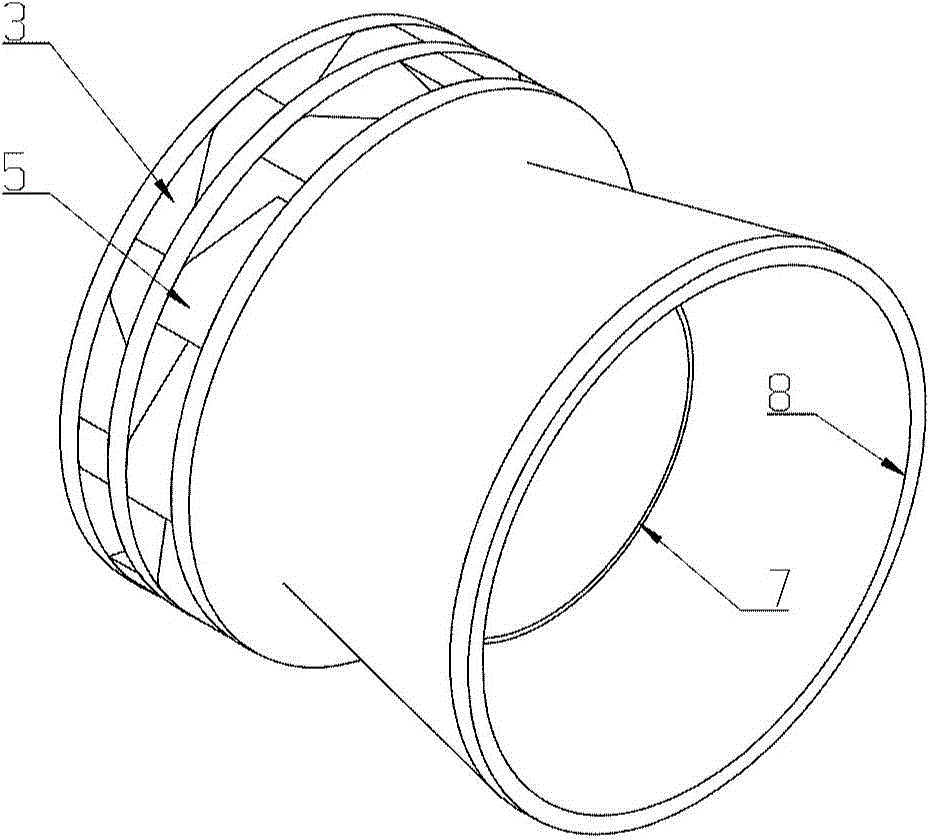

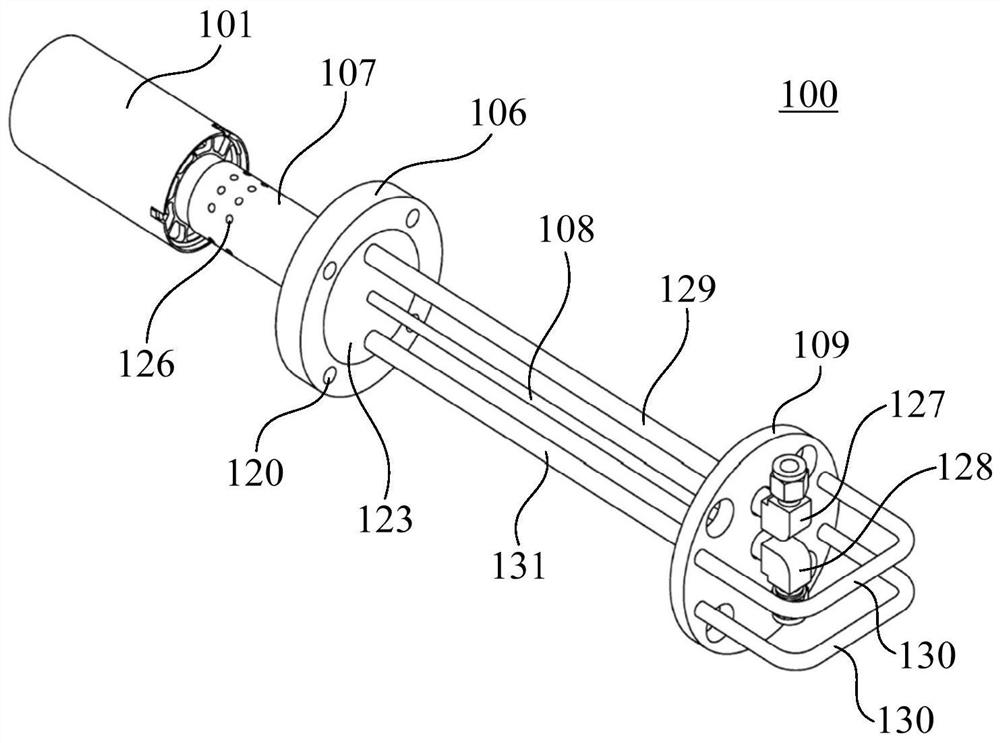

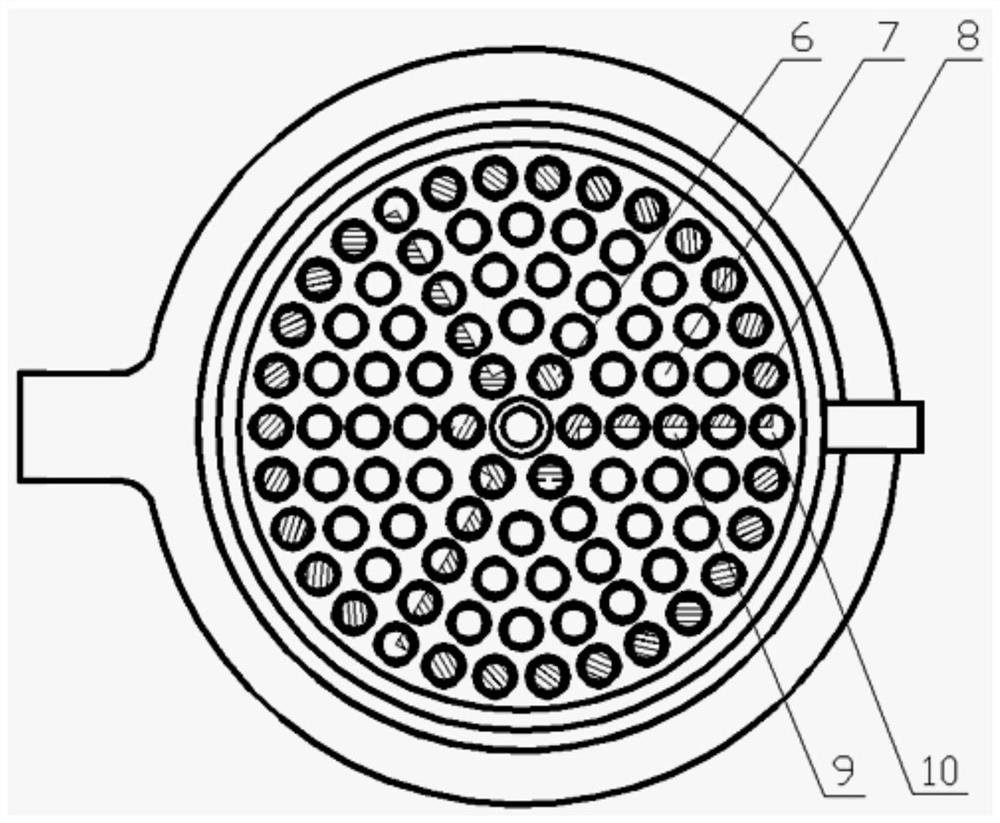

Liquid oxygen methane thrust chamber injector

ActiveCN113339160AImprove combustion stabilityImprove blending effectIndirect carbon-dioxide mitigationRocket engine plantsMultiple injectionThrust chamber

The invention relates to a thrust chamber injector, in particular to a liquid oxygen methane thrust chamber injector, and aims to solve the problems that in the working process of an existing liquid oxygen methane injector, both liquid oxygen and methane belong to liquid low-temperature propellants, a direct-current shear type nozzle or an impact type injector structure is adopted and consequently the propellant mixing effect of the thrust chamber injector is poor, and the combustion efficiency is insufficient. The liquid oxygen methane thrust chamber injector comprises a plurality of injection units, a middle bottom, a top cover, a fluid director and an inner bottom, wherein the top cover, the fluid director and the inner bottom are coaxially and sequentially arranged on the middle bottom. The multiple injection units are fixed to the middle bottom, the fluid director and the inner bottom; a liquid oxygen cavity is formed among the top cover, the middle bottom and the multiple injection units, and a methane cavity is formed among the middle bottom, the inner bottom and the multiple injection units; and the multiple injection units are provided with nozzles with retraction chambers, and the nozzles comprise a central area nozzle, a main combustion area nozzle and an edge area nozzle.

Owner:XIAN AEROSPACE PROPULSION INST

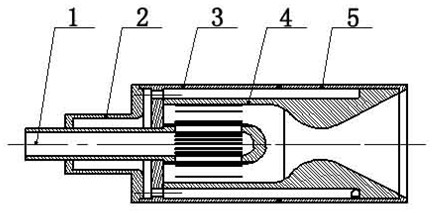

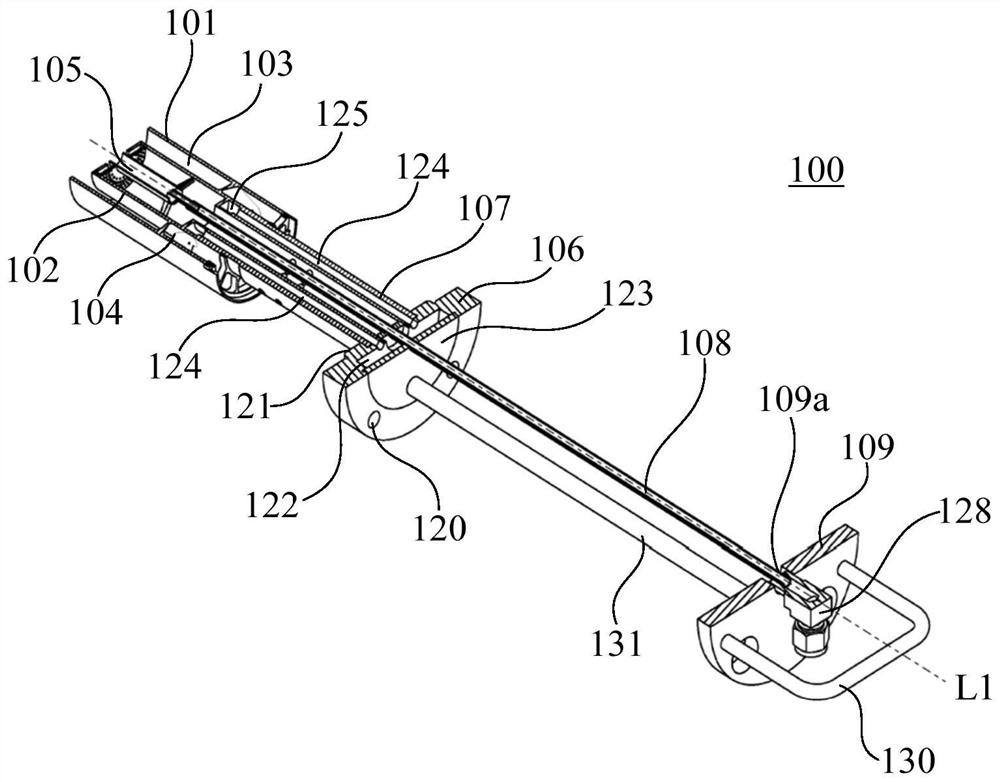

High-pressure and low-frequency autooscillation pulse gas-liquid jet nozzle

InactiveCN105642456AImprove instant strike powerImprove work efficiencySpray nozzlesLiquid jetEffective action

The invention discloses a high-pressure and low-frequency autooscillation pulse gas-liquid jet nozzle capable of being applied to the fields of jet cutting, crushing, washing, mixing, pipeline delivery and the like. As an upper nozzle and a lower nozzle in the invention are both in high-precision clearance fit with a cavity body, defects, such as low coaxiality, caused by cavity length adjustment during the spiral transmission of a traditional method are avoided. In work, a connecting base capable of rotating drives the cavity body and the lower nozzle to rotate, thereby realizing continuous cavity length adjustment. When cavity length reaches a preset value, the connecting base can be fixed through tightening a cylindrical screw. At the same time, low-frequency modulation is realized on high-pressure jet through automatic gas inhalation, and accurate control over jet oscillation frequency is further finished in a low-frequency range through the combined action of gas flow and cavity length. The modulation scheme is much better than a traditional mechanical jet modulation method and can greatly improve jet impact and effective acting range.

Owner:HUNAN UNIV OF TECH

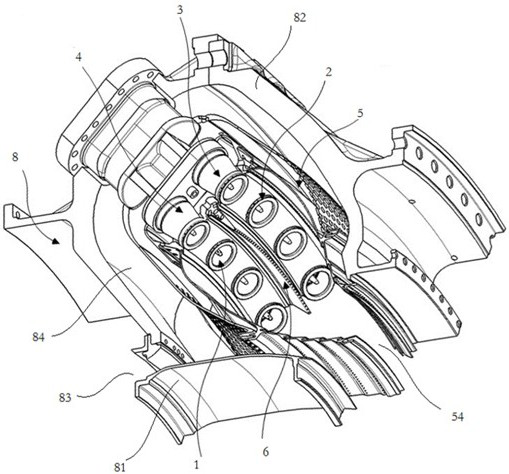

Multi-stage partitioned combustion structure for gas turbine

ActiveCN113251440AEfficient and stable combustionReduce NOx emissionsContinuous combustion chamberFuel supplyNitrogen oxides

The invention belongs to the technical field of gas turbines, and particularly relates to a multi-stage partitioned combustion structure for a gas turbine. The multi-stage partitioned combustion structure for the gas turbine comprises a combustion chamber casing, a flame tube, a plurality of cyclones and a diverter. The cyclones are divided into an on-duty cyclone, a flame transfer cyclone, a first main combustion cyclone and a second main combustion cyclone, each cyclone is provided with a first fuel gas channel, and the first fuel gas channels convey fuel gas used for premixed combustion. A second fuel gas channel is further arranged at the on-duty cyclone, and the second fuel gas channel is used for conveying fuel gas for diffusive combustion. The installation angles of blades of the cyclones are different, and the flow fields of rotating airflow generated by the cyclones are relatively independent, so that the cyclones participate in independent partitioned combustion. According to the multi-stage partitioned combustion technology in the scheme, the four stages of different cyclones are combined with the diverter, multi-stage partitioned organization combustion is formed in a staged fuel supply mode, the requirements of all working conditions are met, the ignition and flameout performance and combustion stability of a combustion chamber are guaranteed, and the requirement for low emission of nitric oxide is met.

Owner:成都中科翼能科技有限公司

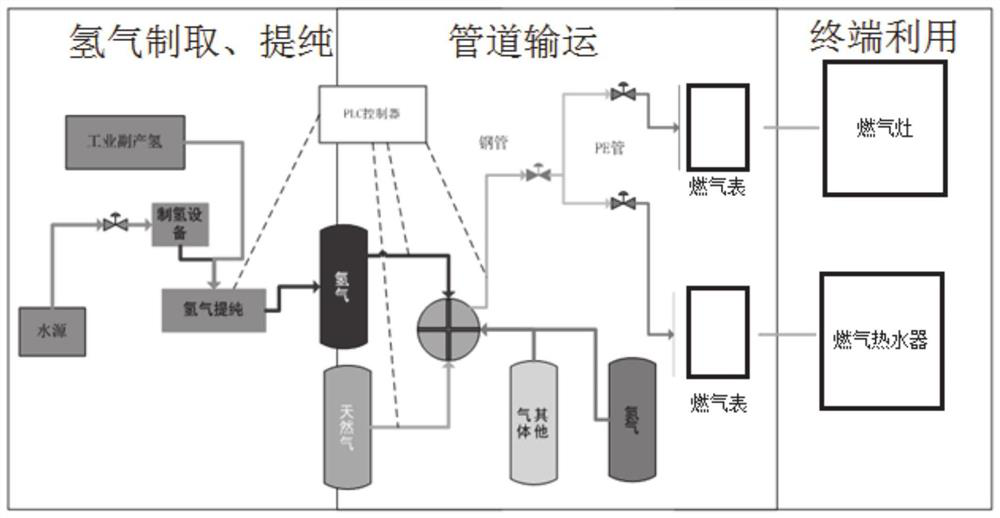

Medium-low pressure hydrogen-containing pipeline experiment system and method

PendingCN113341060AEfficient blendingEfficient liquidityChemical analysis using combustionHydrogen concentrationThermodynamics

The invention provides a medium-low pressure hydrogen-containing pipeline experiment system and method. The medium-low pressure hydrogen-containing pipeline experiment system comprises a mixing device, a medium-low pressure test pipeline, a control terminal and a terminal test element connected with the control terminal, the mixing device comprises a plurality of input ports, at least one first input port is communicated with a hydrogen source, at least one second input port is communicated with a non-hydrogen source, and an output port of the mixing device is communicated with a terminal test element through a medium and low pressure test pipeline; the output port of the mixing device is provided with a hydrogen concentration detection element connected with the control terminal, and the middle and low pressure test pipeline is connected with at least one sensing element connected with the control terminal; the control terminal controls the pressure and / or flow of the mixing device and the outlet pressure and / or flow of each gas source according to the hydrogen concentration detection result; blending, flowing and utilization experiments of a pure hydrogen pipeline and a hydrogen-doped pipeline can be carried out more efficiently.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

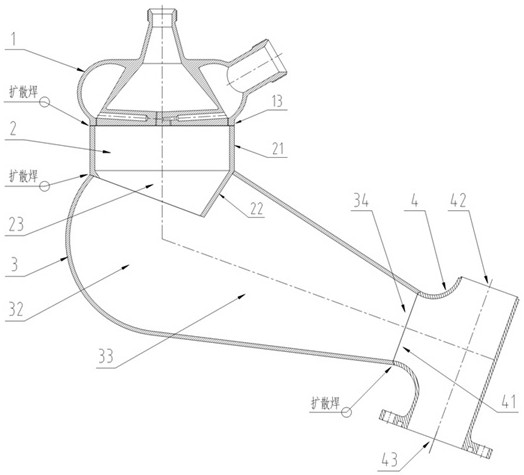

Fuel gas generator

The invention provides a fuel gas generator. The fuel gas generator is composed of an injector, an eccentric turbulent flow ring, a spherical-cone-shaped combustion chamber and a three-way bent pipe. The injector is in a round cake shape, the whole injector is printed through a 3D printer, the upper half part of the eccentric turbulent flow ring is a cylindrical ring, the top face of the cylindrical ring is fixedly welded with the edge of the bottom face of a lower boss of the injector, the bottom edge of the side face of the cylindrical ring is fixedly welded with the hole wall of a side hole of the spherical-cone-shaped combustion chamber, and the lower half part of the eccentric turbulent flow ring is a conical ring with an eccentric opening. The spherical-cone-shaped combustion chamber comprises a spherical cavity and a cone cavity, a side hole is formed in the side face of the spherical cavity, an outlet is formed in the top of the cone cavity and fixedly welded with a middle inlet of the three-way bent pipe, the three-way bent pipe is integrally in a side T shape, a left port is formed in the left side of the three-way bent pipe, a flange structure connection mode is adopted, a right port is formed in the right side of the three-way bent pipe, a middle inlet is formed in the middle part of the three-way bent pipe, and a boss positioning form is adopted. The structure of the fuel gas generator is optimized, propellants can be efficiently atomized, mixed and combusted, and the combustion efficiency is improved.

Owner:星河动力(北京)空间科技有限公司 +1

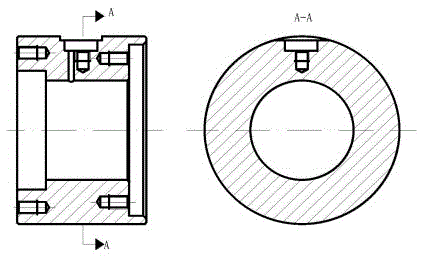

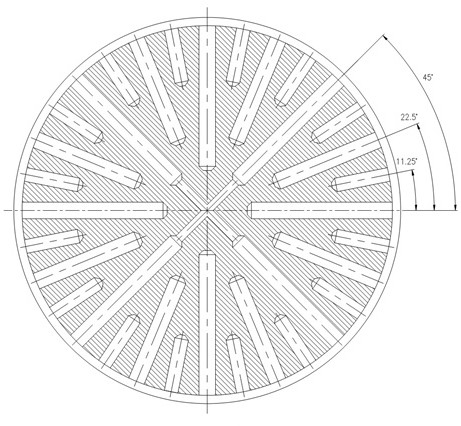

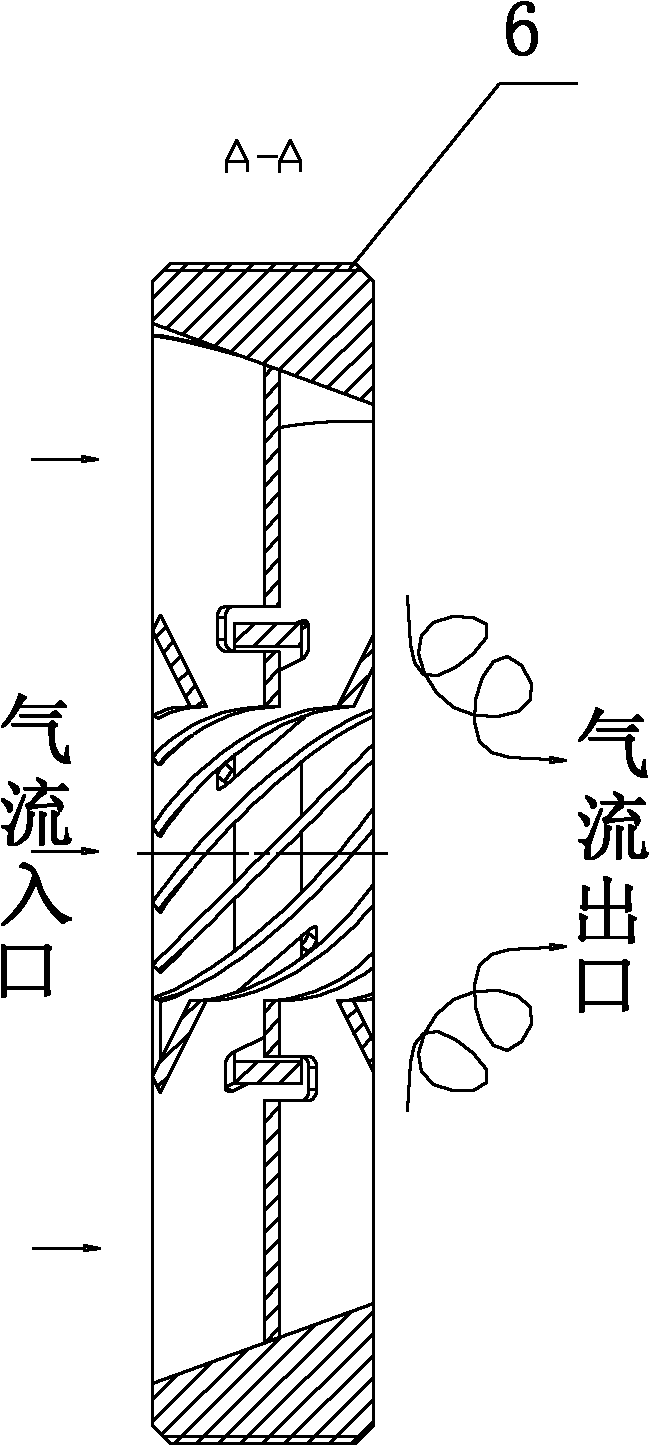

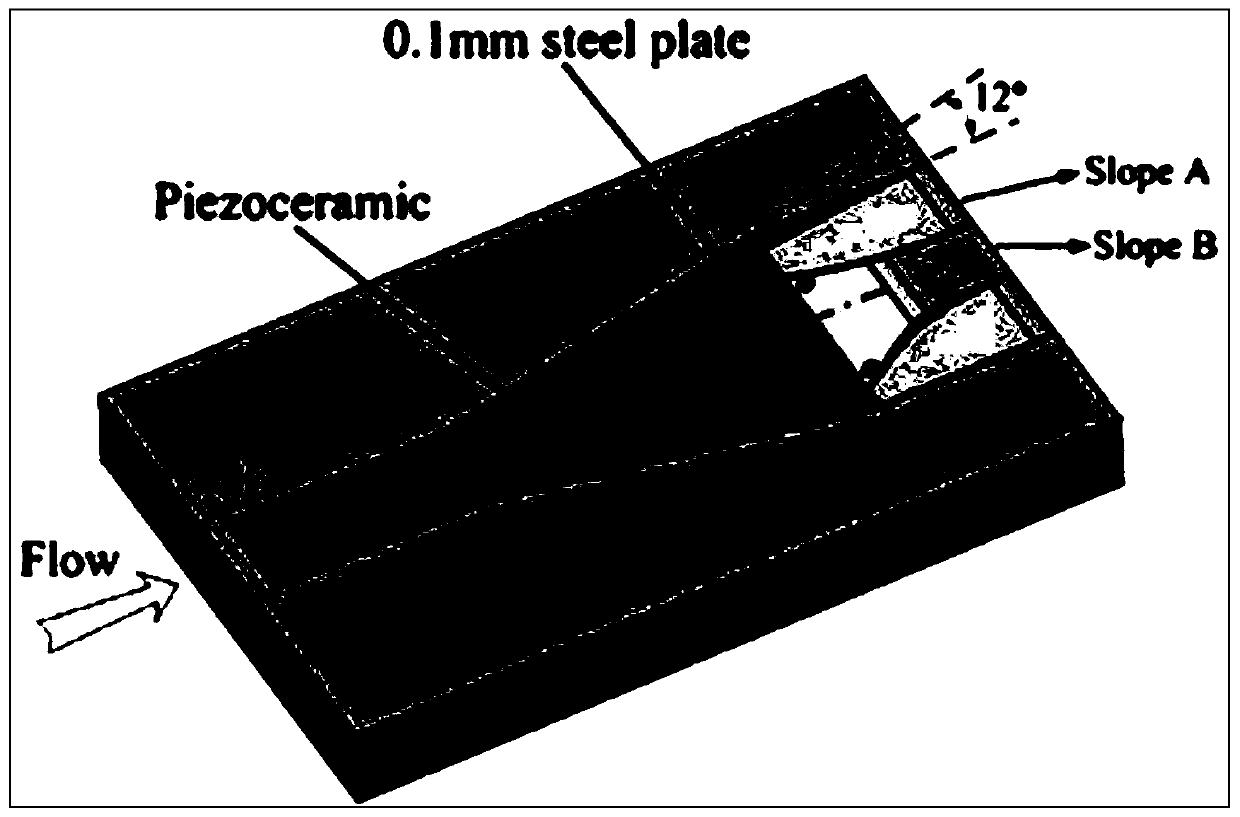

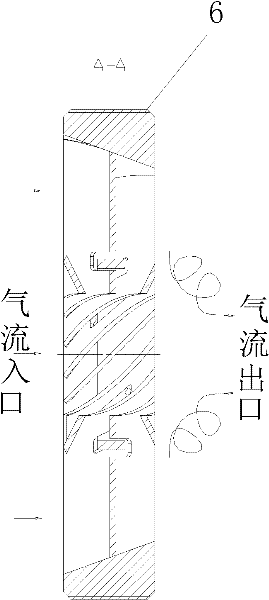

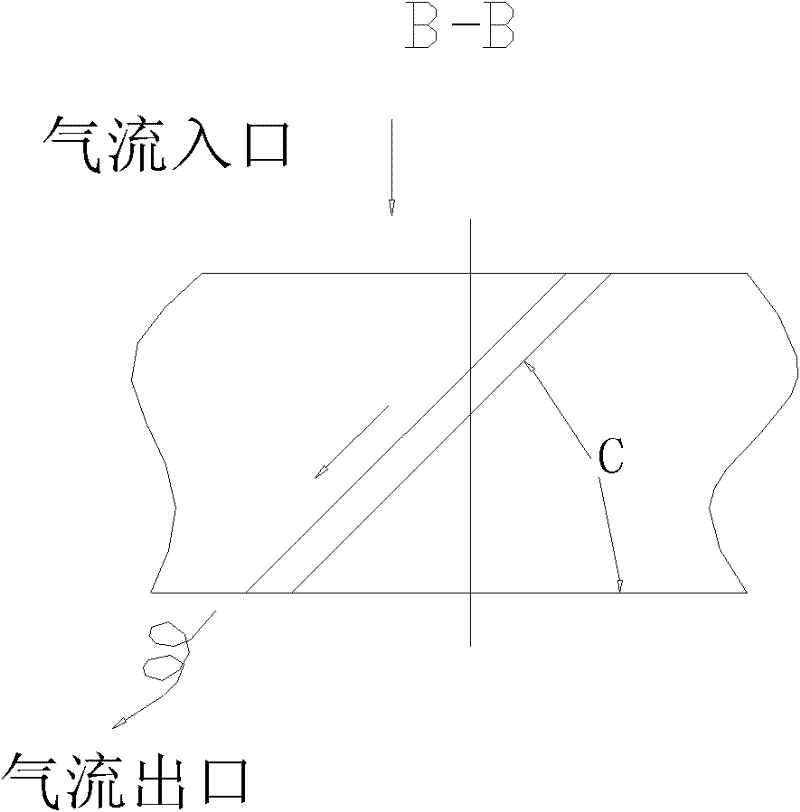

High-reliability multiblade cold/hot air flow mixed spoiler

ActiveCN102042908AImprove temperature field uniformityEfficient blendingGas-turbine engine testingJet-propulsion engine testingAirflowEngineering

The invention provides a high-reliability multiblade cold / hot air flow mixed spoiler which comprises an outer ring and a spoiling component, wherein the outer ring can be connected with the inner wall of the pipeline through screws, and the spoiling component is arranged on the inner wall of the outer ring; the spoiling component comprises a plurality of flat blades and a spacing ring, and the blades are uniformly distributed in the circumferential direction; one end of each blade is welded on the inner wall of the outer ring and forms a certain included angle with the approach flow direction, and the other end of each blade is a free end and extends towards the central axis of the outer ring to form a center hole; the free end of each blade is provided with a spacing hole of which the cross-sectional shape is greater than that of the spacing ring; and the spacing ring orderly penetrates through the spacing hole of each blade. The invention overcomes the defect that the air flow temperature field uniformity of the existing high-flow high-temperature simulated ground equipment can not satisfy the requirements, provides a static mixed mode of multiblade spoiling and variable cross-section pipelines, and has the advantages of high flow, high temperature difference and high reliability.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

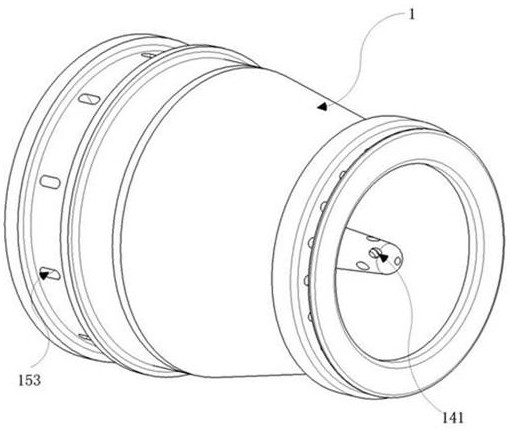

Double-stage axial swirler capable of strengthening oil-gas mixing in cavity and aero-engine

ActiveCN113137638AImprove ignition performanceEfficient blendingContinuous combustion chamberEfficient propulsion technologiesCombustion instabilityCombustion chamber

The invention discloses a double-stage axial swirler capable of strengthening oil-gas mixing in a cavity. The double-stage axial swirler comprises a first-stage swirler and a second-stage swirler, a venturi tube is arranged between the first-stage swirler and the second-stage swirler, a sleeve is arranged on the second-stage swirler, the first-stage swirler is arranged on a center nozzle in a sleeving manner, and a flow mixing part and a cooling part are further included. The flow mixing part is arranged at the end part of the sleeve and is used for fully mixing oil and gas in a combustion chamber again; and the cooling part is arranged on the sleeve and is used for conveying cooling gas and carrying out cooling protection on a combustion chamber swirler shell, and meanwhile, the problems that combustion instability is caused, the stability of the flame of the combustion chamber is reduced and flame stability is not facilitated due to the fact that unstable vortex core precession (PVC) flow generally exists in a flow field of a double-stage axial swirler are solved.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

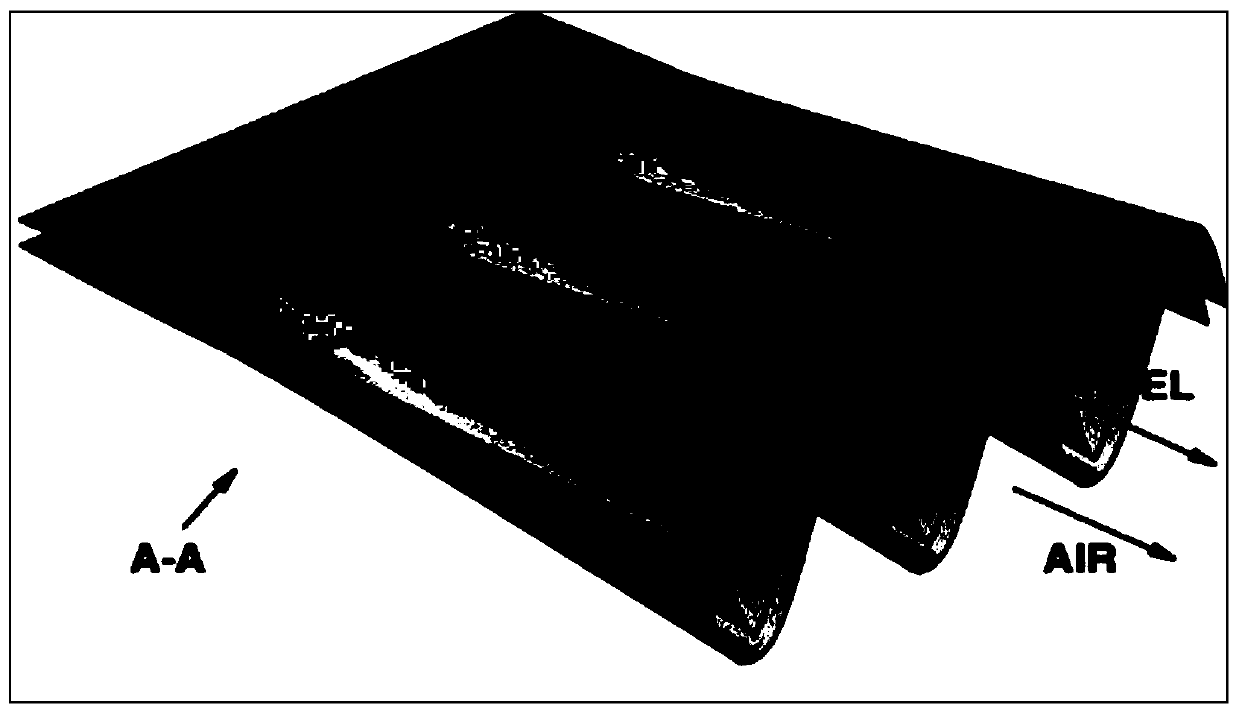

Solid rocket scramjet engine adopting multi-stage combustion enhancing device

ActiveCN110319456AEfficient combustionEfficient blendingContinuous combustion chamberRocket engine plantsCombustion chamberScramjet engine

The invention discloses a solid rocket scramjet engine adopting a multi-stage combustion enhancing device. The engine comprises an isolation section, a combustion chamber, a plurality of flow disturbing devices, concave cavities and a group of wedge units; the isolation section is a cavity body with a gas inlet end and a gas outlet end; the combustion chamber is a cavity body with a gas inlet endand a gas outlet end, and the gas inlet end of the combustion chamber is integrally connected with the gas outlet end of the isolation section; the flow disturbing devices are combinations of the concave cavities and one group of wedge units; the concave cavities are formed in the upper wall and the lower wall of the combustion chamber in an axially spaced mode, and the concave cavities in the upper wall and the concave cavities in the lower wall surface are arranged in a staggered manner; and one group of wedge units are arranged between two adjacent concave cavities in the same wall surfaceand correspond to the concave cavities in the opposite side wall in position. According to the solid rocket scramjet engine, the mixing degree between fuel-rich gas generated by a solid rocket and thesupersonic-velocity air flow is enhanced, the range of a combustible area is expanded, the combustion efficiency of the rocket fuel-rich gas is improved, so that the overall performance of the engineis improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

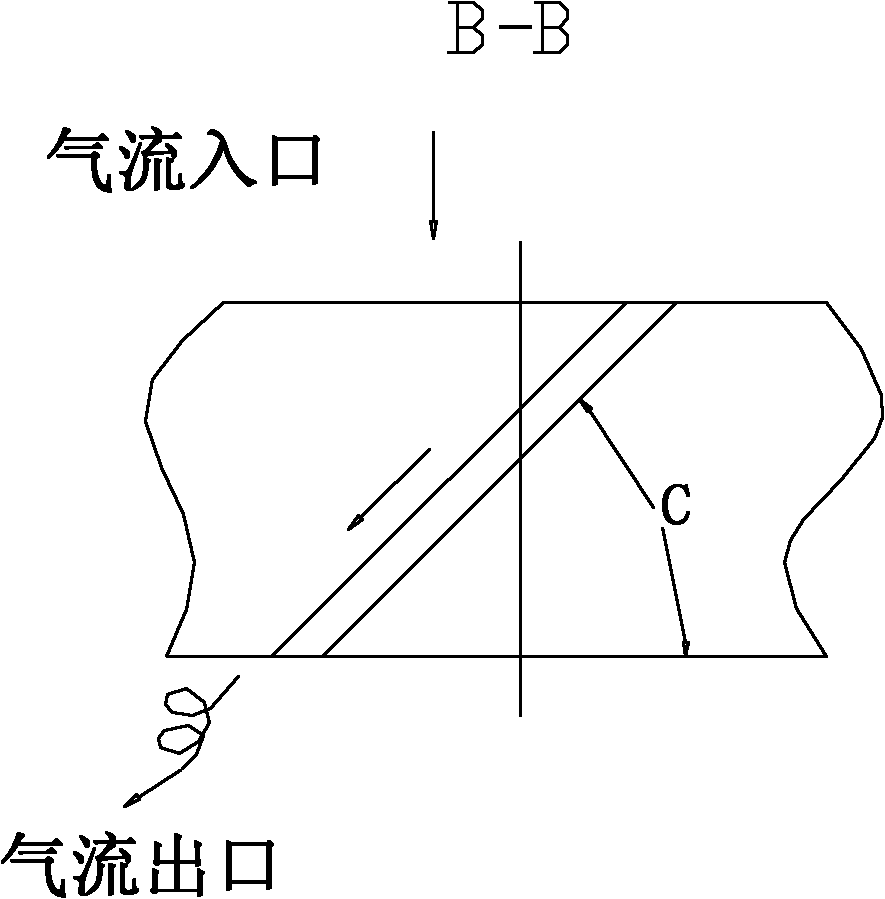

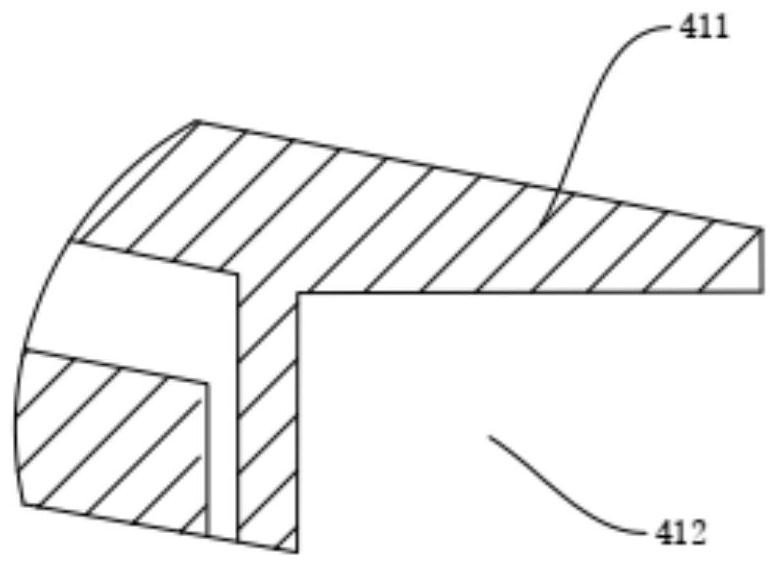

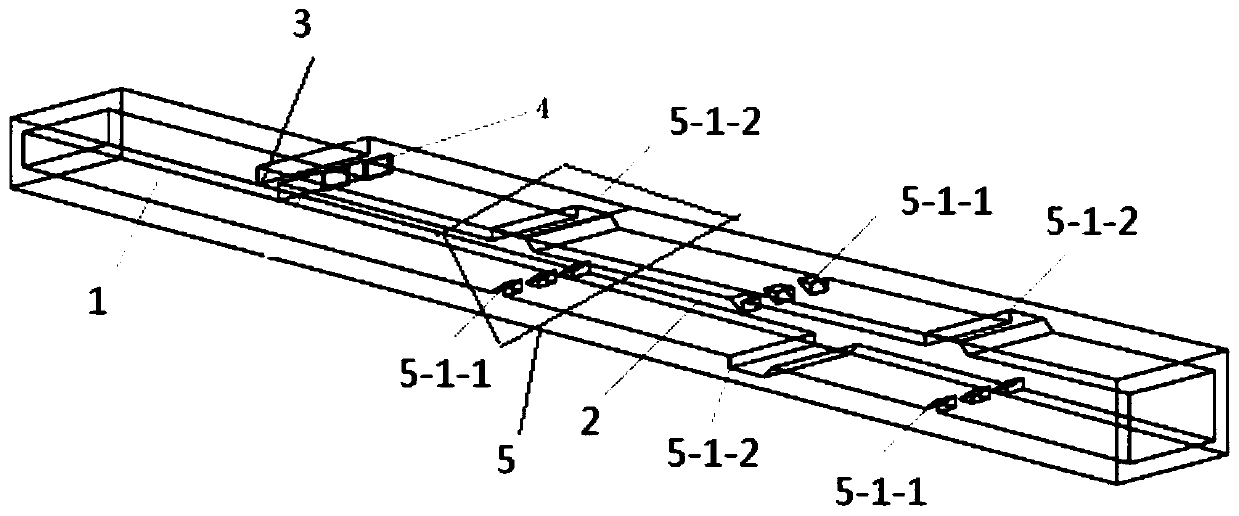

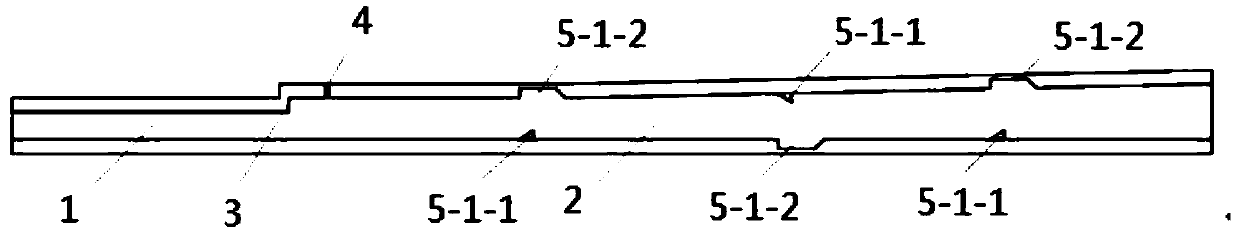

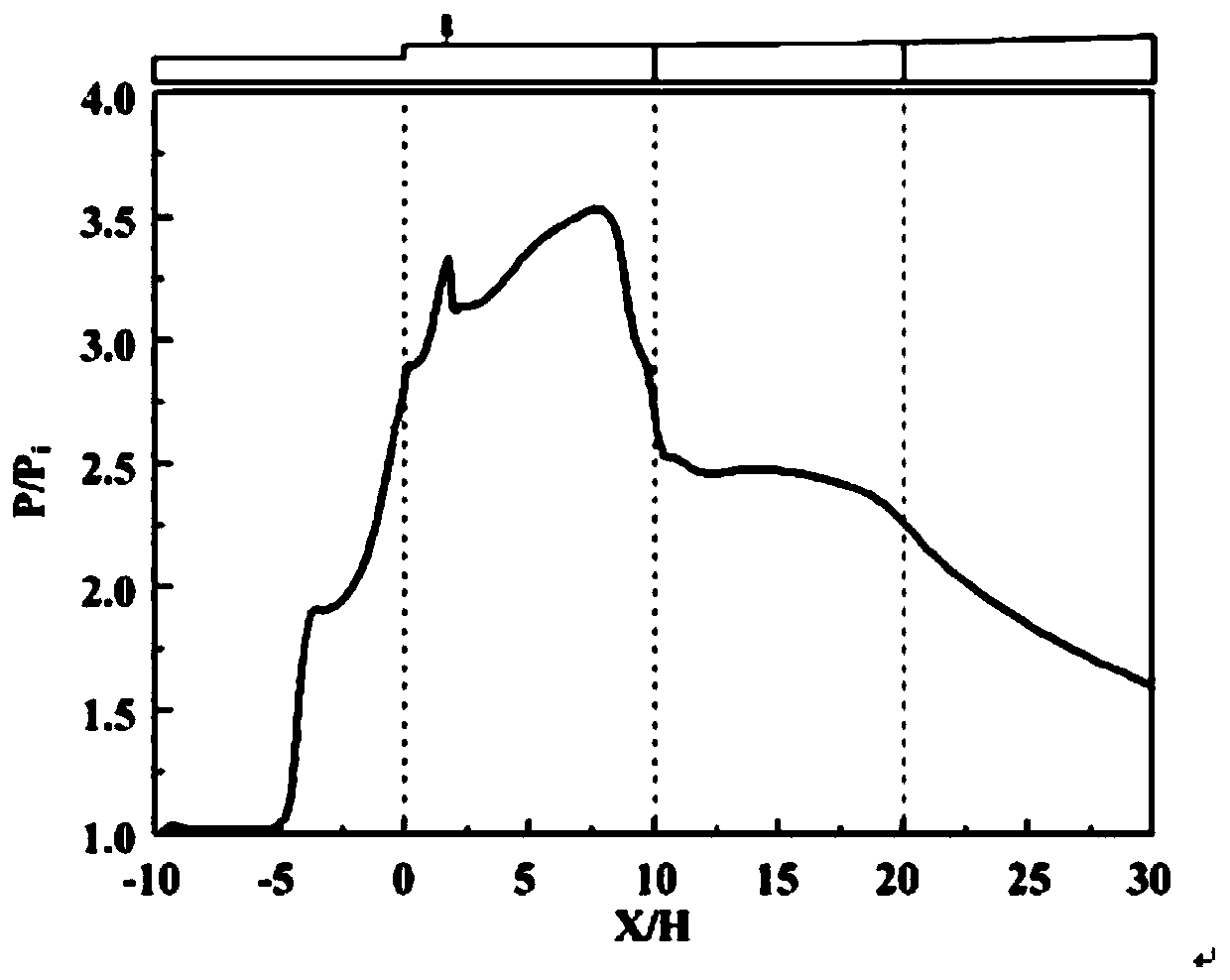

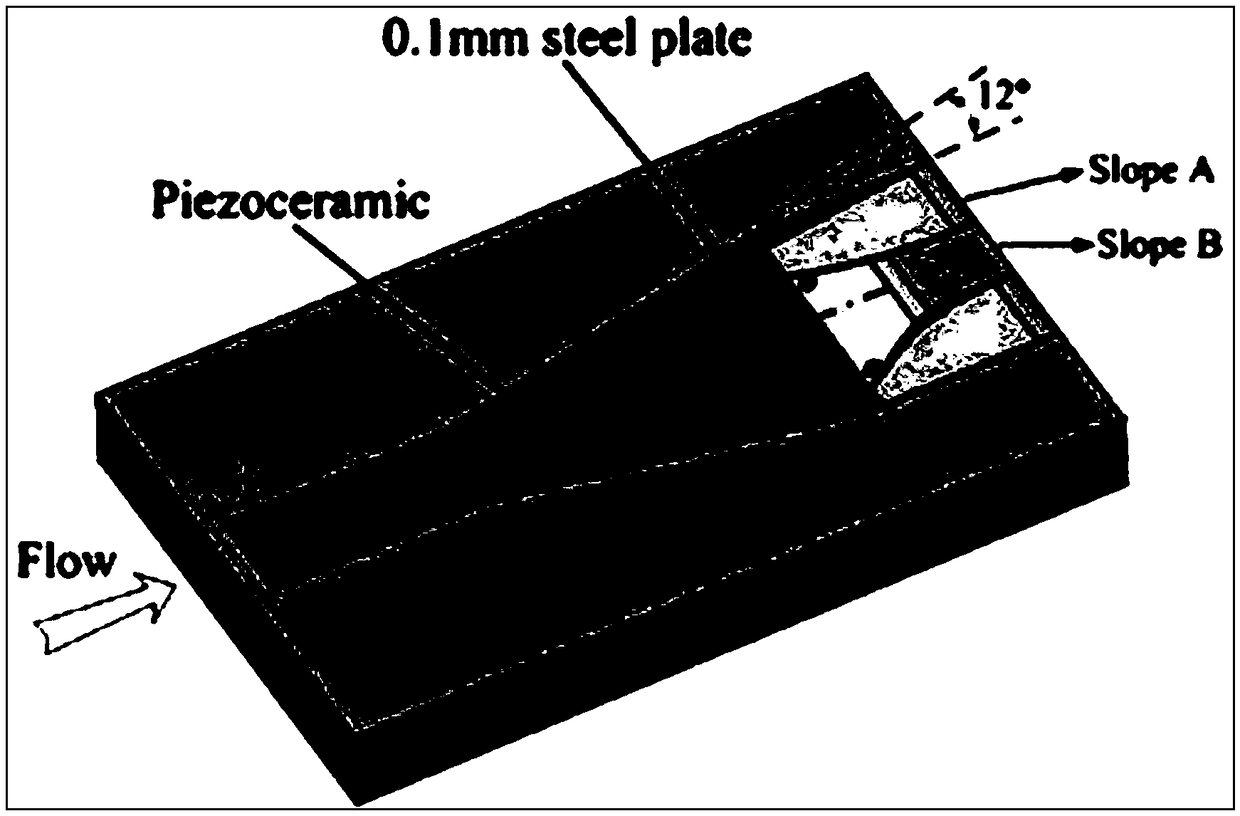

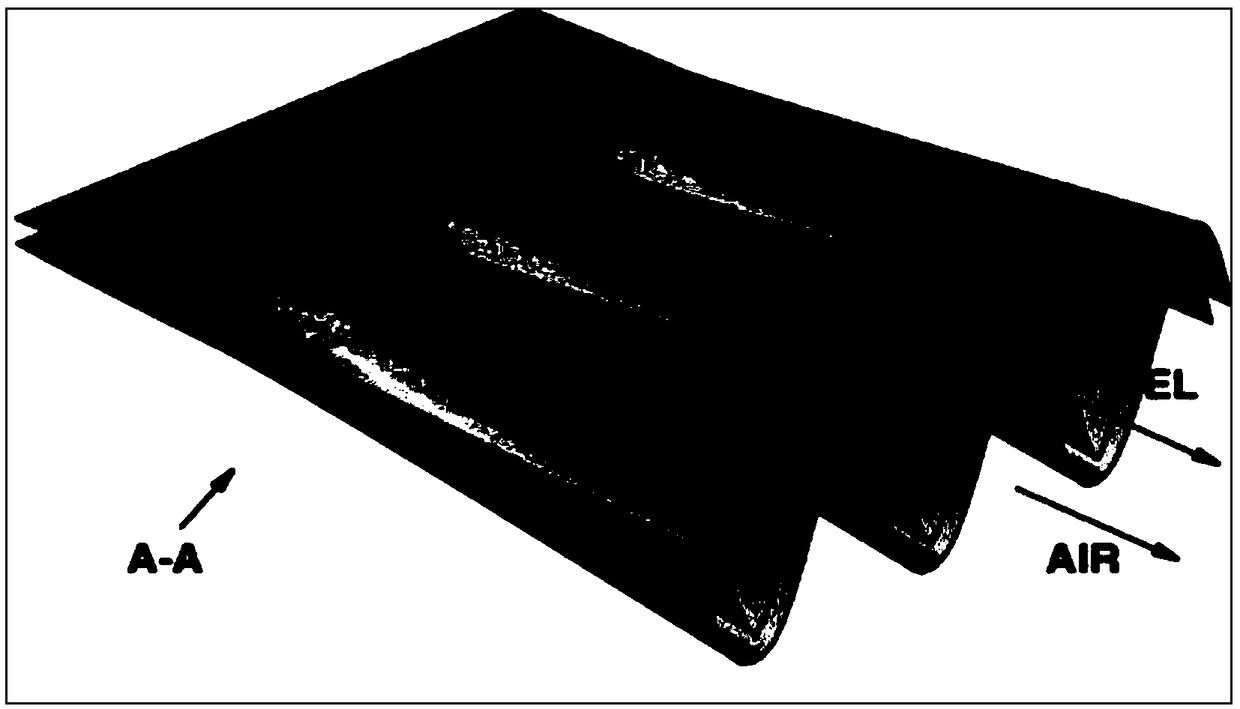

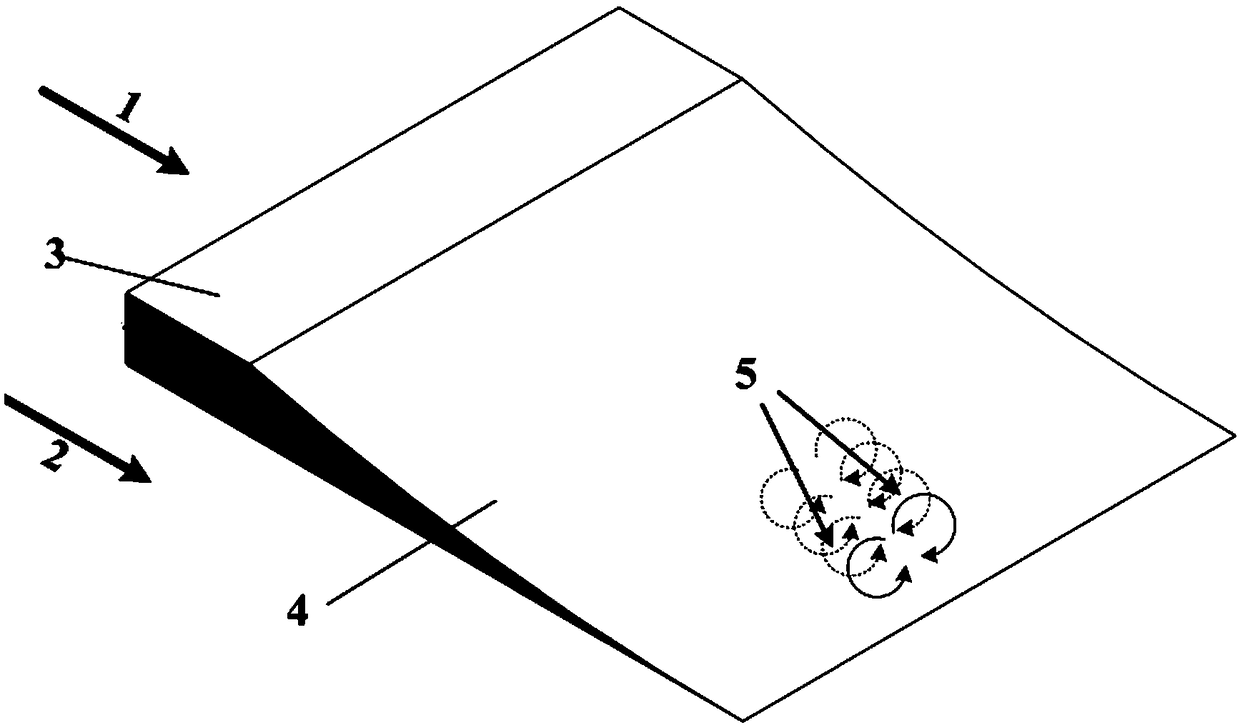

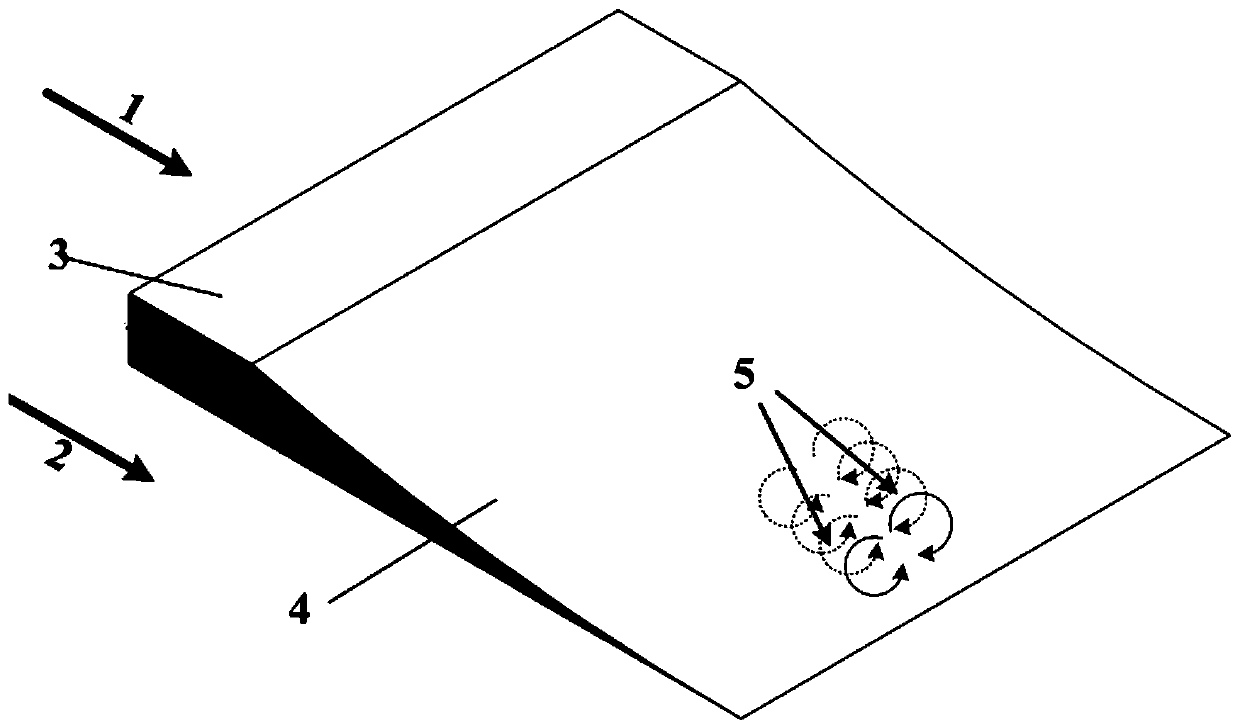

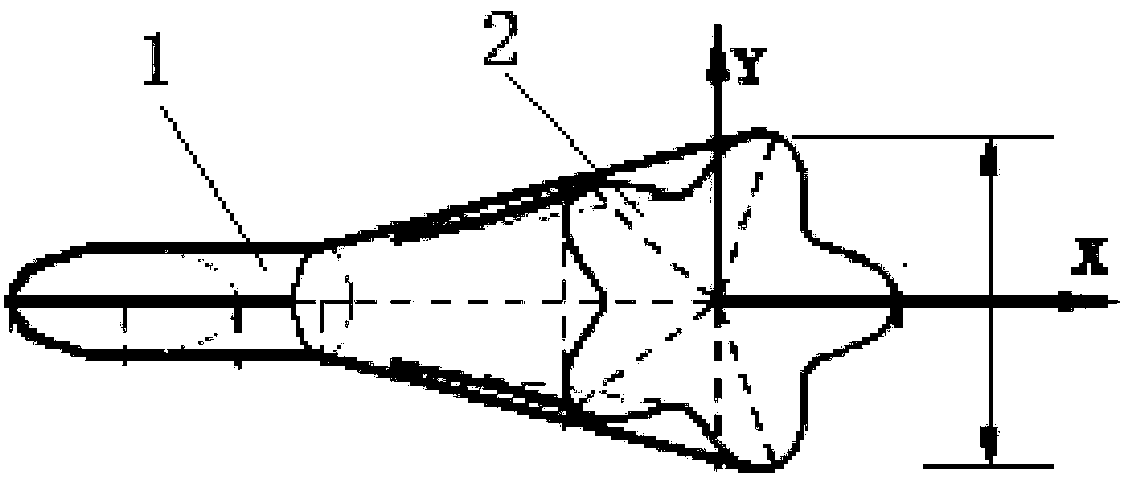

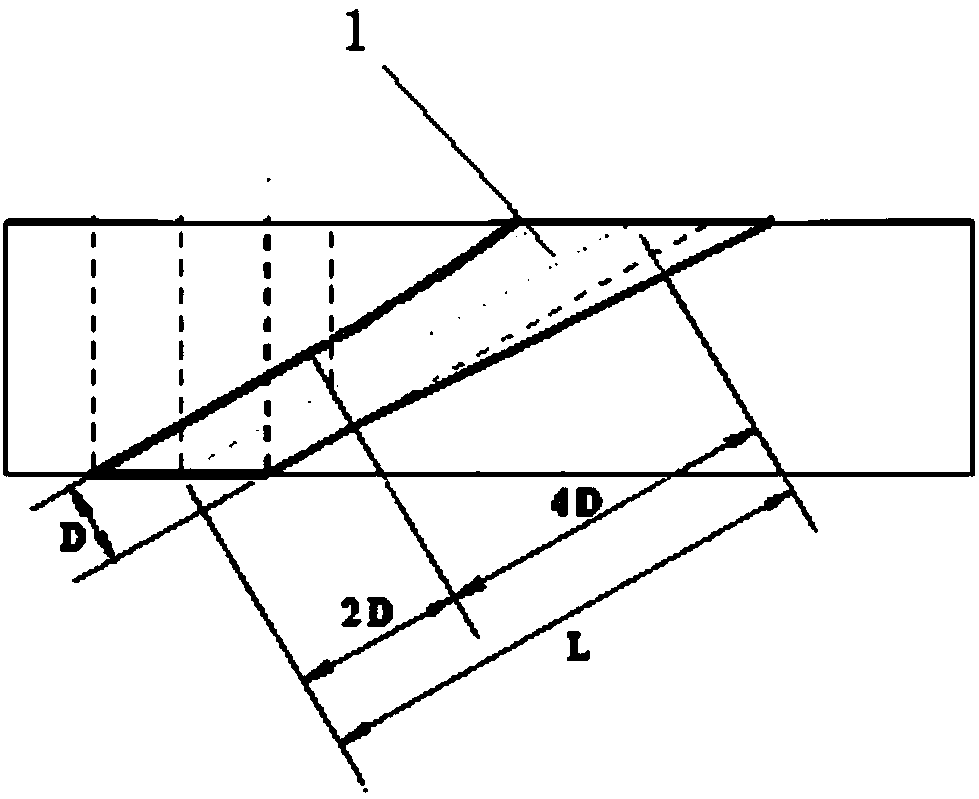

Supersonic flow mixing enhancement device

ActiveCN109139267AEnhanced blendingEfficient blendingTurbine/propulsion fuel supply systemsRam jet enginesInstabilityEngineering

The invention provides a supersonic flow mixing enhancement device aiming at defects of structural complexity, difficulty in optimization and high flow resistance and total pressure loss of an existing active / passive mixing enhancement device in the prior art. The supersonic flow mixing enhancement device comprises a flow mixing enhancement plate between supersonic flow passages of two supersonicairflows, the front section of the flow mixing enhancement plate is provided with a flat plate in certain thickness, the rear section of the flow mixing enhancement plate is provided with a curved plate, and the front end of the flat plate and the front end of the curved plate are connected to form the flow mixing enhancement plate. By interaction of a vortex structure and a mixing layer, efficient flow mixing is promoted. The supersonic flow mixing enhancement device has advantages that extra excitation energy is avoided, simple structure is realized, the defect of high flow resistance and total pressure loss is overcome, flow mixing is promoted through intrinsic instability of a curved device, and high applicability is realized.

Owner:NAT UNIV OF DEFENSE TECH

supersonic flow mixing device

ActiveCN109139267BEnhanced blendingEfficient blendingTurbine/propulsion fuel supply systemsRam jet enginesIntrinsic instabilityInstability

The invention provides a supersonic flow mixing enhancement device aiming at defects of structural complexity, difficulty in optimization and high flow resistance and total pressure loss of an existing active / passive mixing enhancement device in the prior art. The supersonic flow mixing enhancement device comprises a flow mixing enhancement plate between supersonic flow passages of two supersonicairflows, the front section of the flow mixing enhancement plate is provided with a flat plate in certain thickness, the rear section of the flow mixing enhancement plate is provided with a curved plate, and the front end of the flat plate and the front end of the curved plate are connected to form the flow mixing enhancement plate. By interaction of a vortex structure and a mixing layer, efficient flow mixing is promoted. The supersonic flow mixing enhancement device has advantages that extra excitation energy is avoided, simple structure is realized, the defect of high flow resistance and total pressure loss is overcome, flow mixing is promoted through intrinsic instability of a curved device, and high applicability is realized.

Owner:NAT UNIV OF DEFENSE TECH

Continuous rotation detonation ramjet engine capable of supplying oil and gas in radial direction

InactiveCN114777162AStable jobSolve the problem of long-term reliable workExplosive combustion chamberRam jet enginesRamjetCombustion chamber

The invention provides a continuous rotation detonation ramjet engine capable of supplying oil and gas in the radial direction, and belongs to the technical field of aero-engines, the continuous rotation detonation ramjet engine comprises an oxidant injection mandrel used for oxidant inflow, a fuel pressure stabilization cavity used for fuel pressure stabilization and a combustion chamber, and a pressure stabilization space is formed in the oxidant injection mandrel; a plurality of first gaps are evenly distributed in the oxidizing agent injection mandrel, oxidizing agents enter the combustion chamber through the first gaps, and a plurality of second gaps used for introducing fuel into the combustion chamber are evenly distributed in the radial direction of the fuel pressure stabilizing cavity. According to the ramjet engine, the feeding direction of fuel is changed into the radial direction, so that the fuel and an oxidizing agent are subjected to radial hedging in the combustion chamber, and good mixing is achieved; the oxidant and the fuel cavity are respectively provided with a pressure stabilizing structure, and gap flow channels which are uniformly distributed at 360 degrees also play a role in flow equalization; and the combustion chamber is self-cooled by adopting fuel required by the combustion chamber, so that stable work of the detonation combustion chamber in a long-time detonation state is realized, and the problem of long-time reliable work of the detonation ramjet engine is solved.

Owner:清航空天(北京)科技有限公司

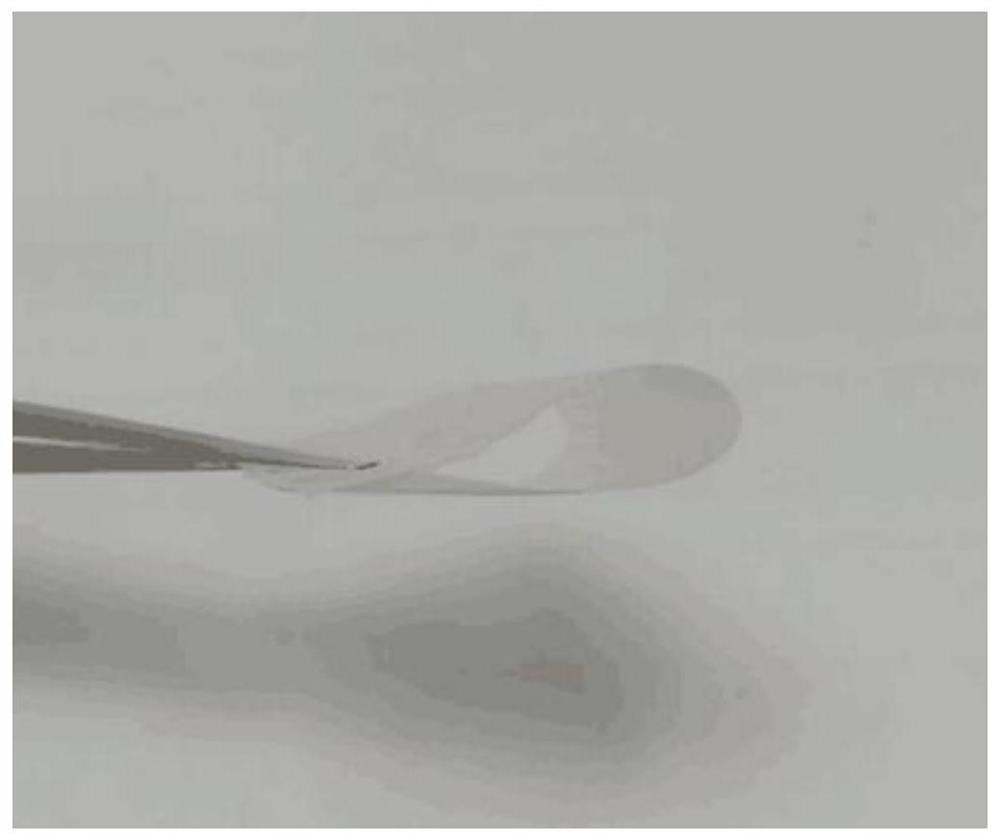

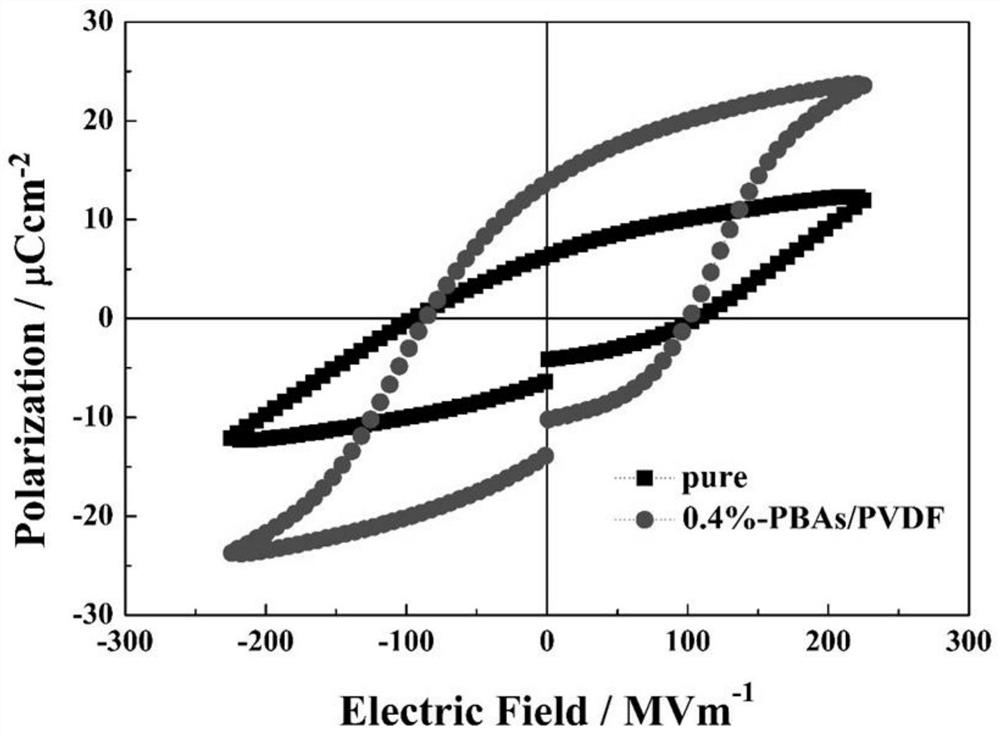

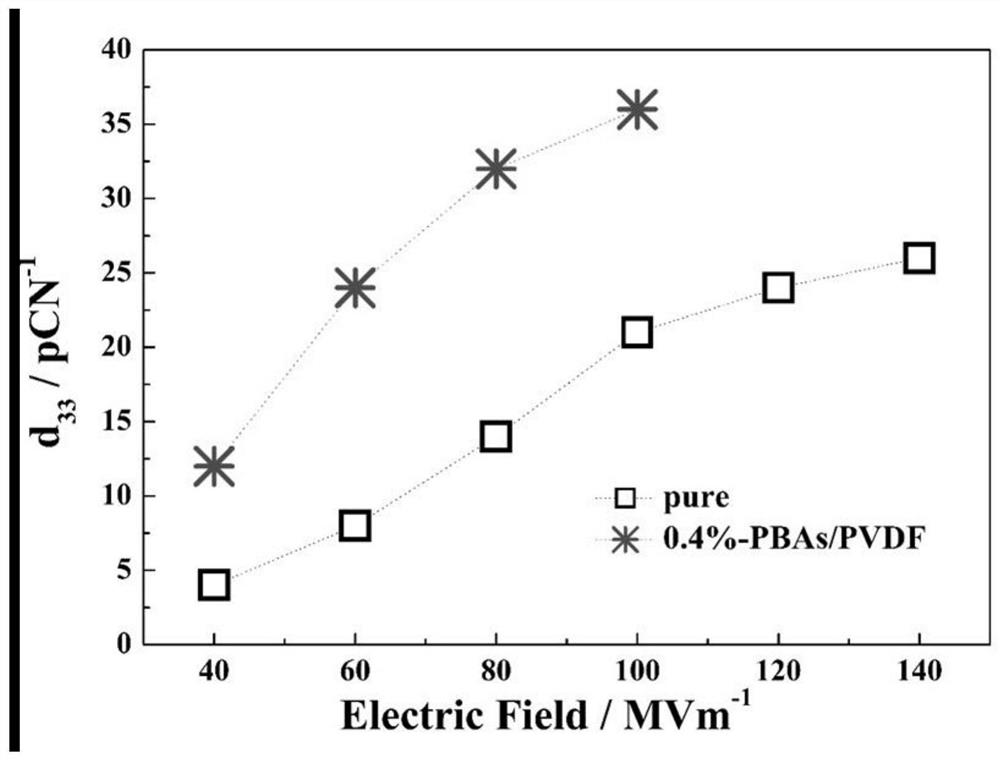

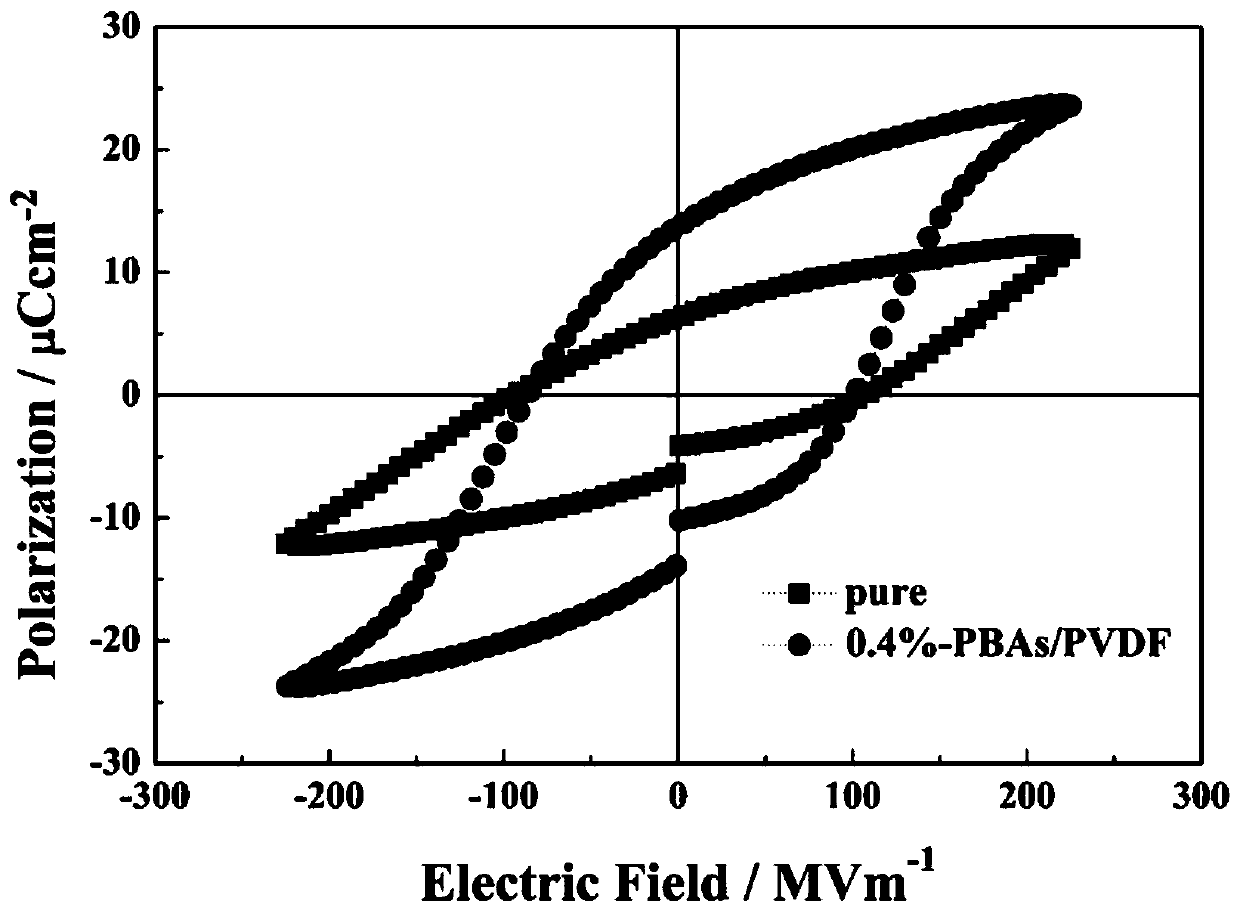

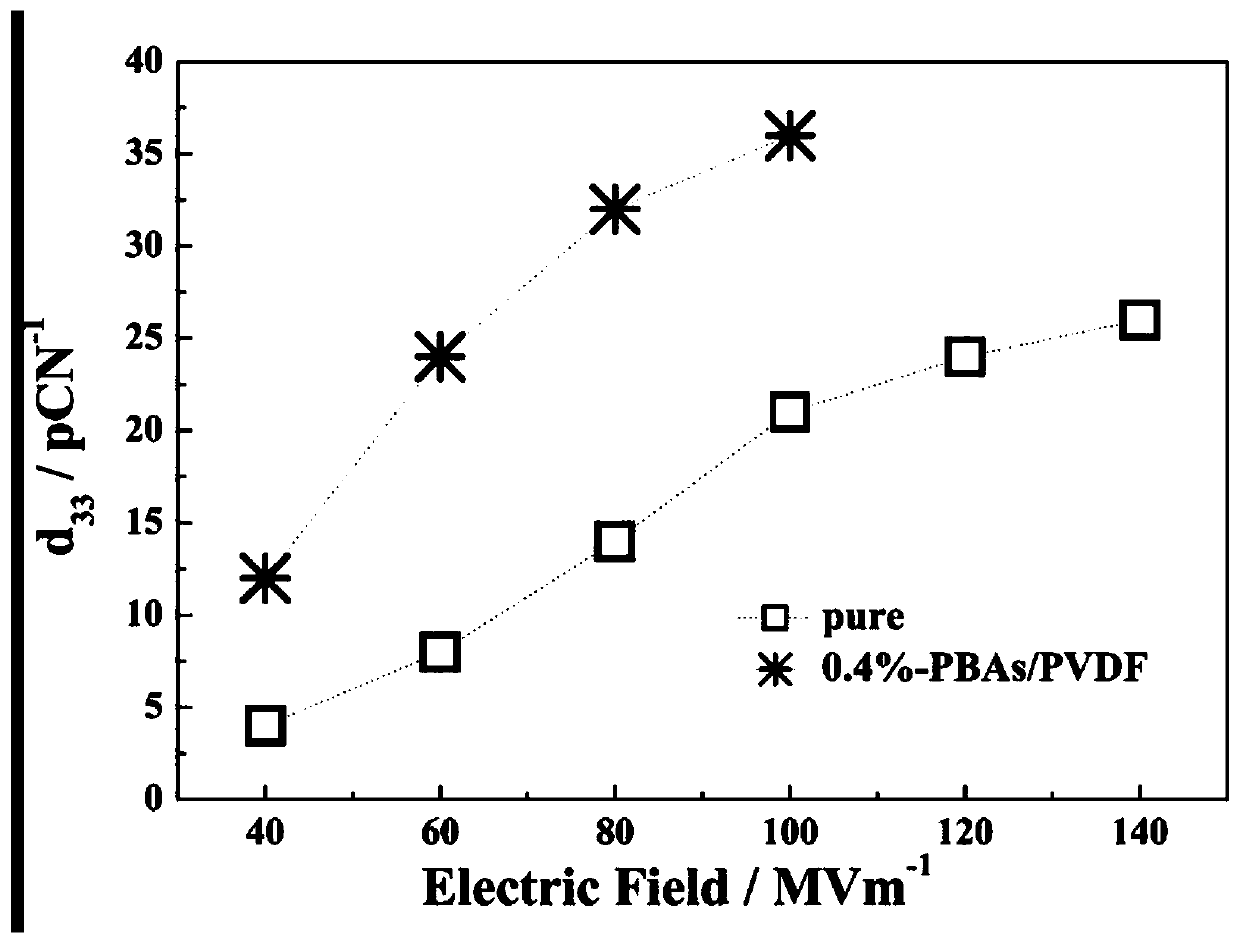

A kind of polyvinylidene fluoride composite piezoelectric film and its preparation method and application

ActiveCN110760144BExcellent piezoelectric propertiesEfficient blendingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPolymer scienceThin membrane

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a polyvinylidene fluoride composite piezoelectric film and a preparation method and application thereof. The polyvinylidene fluoride composite piezoelectric film provided by the present invention includes polyvinylidene fluoride and Prussian blue analogs; the Prussian blue analogs are Co 3 [Co(CN) 6 ] 2 . The invention provides a polyvinylidene fluoride composite piezoelectric film, which solves the problem of insufficient piezoelectric performance of traditional PVDF materials, and has excellent piezoelectric performance and low cost. The experimental results show that the polyvinylidene fluoride composite piezoelectric film provided by the present invention has good flexibility, and compared with pure PVDF material, the remanent polarization is significantly increased, the polarization is more sufficient, and the ferroelectric performance is more excellent; Compared with pure PVDF material, the piezoelectric constant d 33 significantly increased, showing excellent piezoelectric properties.

Owner:裘天政 +2

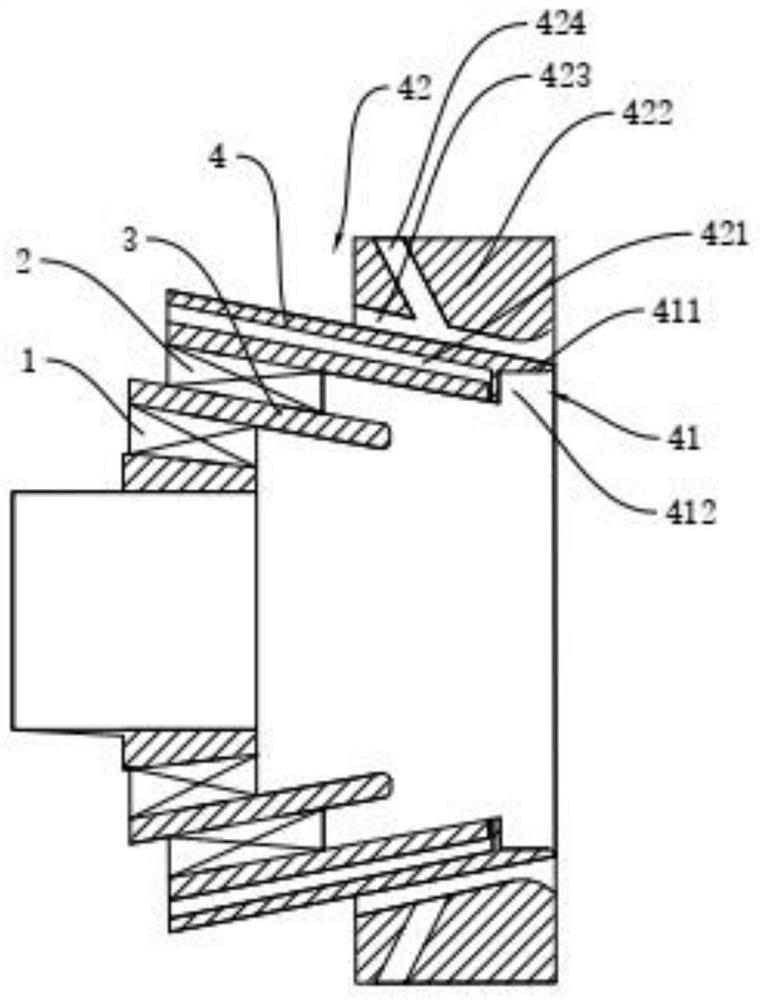

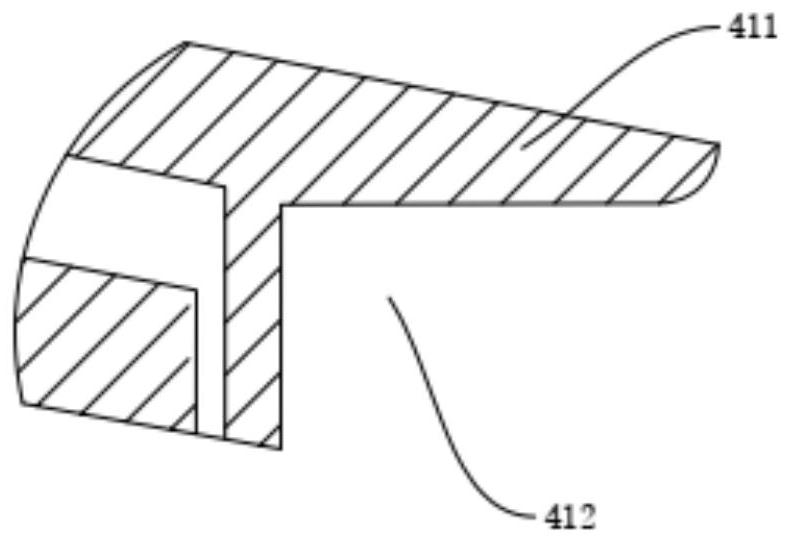

A combustion chamber adopting the pre-film atomization method of the trailing edge of the swirl blade

ActiveCN104329689BShort blending distanceShorten flame lengthContinuous combustion chamberCombustion chamberTrailing edge

The invention provides a combustion chamber adopting a swirl vane tail edge pre-film atomization mode. The combustion chamber comprises a combustion chamber flame tube, a center level oil and gas mixing assembly and a main combustion level oil and gas mixing assembly which is arranged at the front end of the combustion chamber flame tube and the periphery of the center level oil and gas mixing assembly. The main combustion level oil and gas mixing assembly comprises a main combustion level swirl channel, N wedge-shaped swirl vanes and M vane interior oil paths; the N wedge-shaped swirl vanes are slantly fixed to the interior of the main combustion level swirl channel, and the M vane interior oil paths are arranged in at least one part of wedge-shaped swirl vanes respectively; the front end of each vane interior oil path is connected with a main combustion level oil cavity, and the tail end of the each vane interior oil path extends to the tail edge of the corresponding wedge-shaped swirl vane; the M is smaller than or equal to the N. The swirl vanes are wedge-shaped; velocity gradients are formed at the tail edges of the swirl vanes; a fuel liquid film flowing out of the tail edges of the swirl vanes is rapidly shorn and atomized under the action of the velocity gradients; the oil and gas blending distance is short, and the flame length and the length of the flame tube are shortened.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Polyvinylidene fluoride composite piezoelectric thin film, and preparation method and application thereof

ActiveCN110760144AExcellent piezoelectric propertiesEfficient blendingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPolymer scienceThin membrane

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a polyvinylidene fluoride composite piezoelectric thin film, and a preparation method and application thereof. The provided polyvinylidene fluoride composite piezoelectric thin film includes polyvinylidene fluoride and a prussian blue analog, the prussian blue analog is Co3[Co(CN)6]2. According tothe provided polyvinylidene fluoride composite piezoelectric thin film, the problem of insufficient piezoelectric property of a traditional PVDF material is solved, and excellent piezoelectric properties and low cost are achieved; experimental results show that the provided polyvinylidene fluoride composite piezoelectric thin film has good flexibility, compared with a pure PVDF material, the residual polarization intensity is increased significantly, polarization is more sufficient, and more excellent ferroelectric properties are shown; and compared with the pure PVDF material, the piezoelectric constant d33 is significantly increased, and excellent piezoelectric properties are shown.

Owner:裘天政 +2

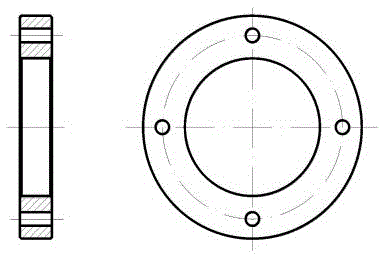

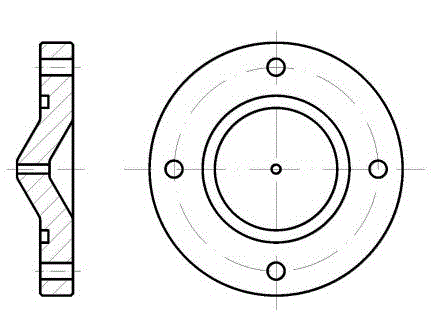

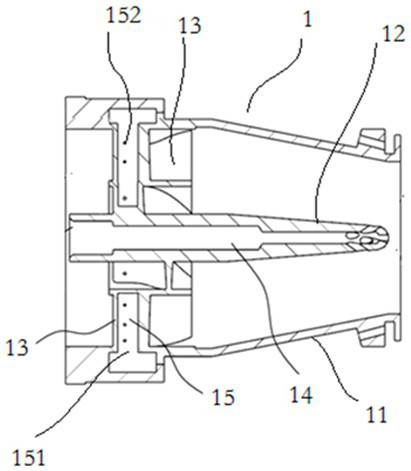

Fuel nozzle of gas turbine

PendingCN112082175ASimple structureEasy to disassemble and maintainContinuous combustion chamberCombustion chamberFuel tank

The invention provides a fuel nozzle of a gas turbine. The fuel nozzle comprises a cylindrical center body, an outer wall surface, an annular gas channel, a swirl vane, a support sleeve, a mounting flange, a rear cover plate, a main fuel pipe and an on-duty fuel pipe, wherein the annular gas channel is arranged between the outer wall surface and the center body; the swirl vane is arranged in the annular gas channel; a fuel channel and a first fuel tank communicated with the surface of the swirl vane are arranged in the wall of the support sleeve; a second fuel tank is arranged in the mountingflange; the rear cover plate is provided with a first fuel pipe interface and a second fuel pipe interface; the main fuel pipe is connected with the first fuel pipe interface and the second fuel tank;and the on-duty fuel pipe is connected with the second fuel pipe interface and a flow guide pipe. According to the invention, the main fuel pipe and the on-duty fuel pipe are introduced, and when thedistance between the interface of the nozzle on a combustion chamber and a gas turbine shell is larger, fuel and air are well mixed, so that low-pollution energy-saving and environment-friendly combustion is realized, and the fuel nozzle can be applied to a ground gas turbine with strict pollutant emission limitation; and the nozzle also has the advantages of simple structure, convenience in disassembly and maintenance and low manufacturing cost.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

A Multistage Partitioned Combustion Structure for Gas Turbine

ActiveCN113251440BEfficient and stable emissionEmission reductionContinuous combustion chamberCombustion chamberNitrogen oxides

The invention belongs to the technical field of gas turbines, and specifically relates to a multi-stage partitioned combustion structure for gas turbines, which includes a combustion chamber casing, a flame tube, a plurality of swirlers and flow dividers, and the swirlers are divided into on-duty swirlers, The flame transfer swirler, the first and the second main combustion swirlers, each swirler is provided with a first gas channel, and the first gas channel transports the gas used for premixed combustion; at the duty swirler A second gas channel is also provided, and the second gas channel transports the gas used for diffusion combustion; the installation angles of the swirler blades are different, and the swirling air flow fields generated by each swirler are relatively independent, so that each swirler The streamer participates in the combustion of independent zones. In this scheme, the multi-stage partition combustion technology uses four different cyclones combined with diverters to form a multi-stage partition organization combustion in the form of graded fuel supply, which meets the needs of all working conditions and ensures the combustion chamber ignition performance and combustion stability. , to achieve the demand for low emission of nitrogen oxides.

Owner:成都中科翼能科技有限公司

Liquid oxygen methane thrust chamber injector

ActiveCN113339160BImprove combustion stabilityImprove blending effectIndirect carbon-dioxide mitigationRocket engine plantsMultiple injectionThrust chamber

The invention relates to a thrust chamber injector, in particular to a liquid oxygen methane thrust chamber injector, so as to solve the problem that in the current working process of the liquid oxygen methane injector, since both liquid oxygen and methane belong to liquid low-temperature propellants, the The structure of the DC shear nozzle or the impact injector will lead to the poor mixing effect of the propellant in the thrust chamber injector and the problem of insufficient combustion efficiency. A liquid oxygen methane thrust chamber injector includes a plurality of injection units, a midsole, and a top cover, a flow guide and an inner bottom that are coaxially arranged on the midsole in sequence; the plurality of injection units are fixed in the midsole. On the bottom, the deflector and the inner bottom; a liquid oxygen cavity is formed between the top cover, the middle bottom and multiple injection units, and a methane cavity is formed between the mid bottom, inner bottom and multiple injection units; multiple injection units All nozzles with indented chambers are used, and the nozzles include central area nozzles, main combustion area nozzles, and edge area nozzles.

Owner:XIAN AEROSPACE PROPULSION INST

High-reliability multiblade cold/hot air flow mixed spoiler

ActiveCN102042908BImprove temperature field uniformityEfficient blendingGas-turbine engine testingJet-propulsion engine testingField uniformityTemperature difference

The invention provides a high-reliability multiblade cold / hot air flow mixed spoiler which comprises an outer ring and a spoiling component, wherein the outer ring can be connected with the inner wall of the pipeline through screws, and the spoiling component is arranged on the inner wall of the outer ring; the spoiling component comprises a plurality of flat blades and a spacing ring, and the blades are uniformly distributed in the circumferential direction; one end of each blade is welded on the inner wall of the outer ring and forms a certain included angle with the approach flow direction, and the other end of each blade is a free end and extends towards the central axis of the outer ring to form a center hole; the free end of each blade is provided with a spacing hole of which the cross-sectional shape is greater than that of the spacing ring; and the spacing ring orderly penetrates through the spacing hole of each blade. The invention overcomes the defect that the air flow temperature field uniformity of the existing high-flow high-temperature simulated ground equipment can not satisfy the requirements, provides a static mixed mode of multiblade spoiling and variable cross-section pipelines, and has the advantages of high flow, high temperature difference and high reliability.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Low pressure rear cylinder water spray hole of turbine and design method of low pressure rear cylinder water spray hole

The invention discloses a low pressure rear cylinder water spray hole of turbine and a design method of the low pressure rear cylinder water spray hole. According to the invention, a traditional roundwater spray hole water outlet is changed to a variable section star shape. After incoming water drops pass through the star-shaped hole, the expansion range is enlarged, so that mutual mixture of theincoming water drops and high temperature discharged steam is enhanced. At the same time, local gradually expanding treatment is performed on an inclined channel of the incoming hole and optimizationis performed on the inclination angle of the channel, so that the incoming speed of the incoming water drops decrease after passing through the channel and the incoming position becomes more adjacentto a high temperature area, and the turbulent mixing of the water drops and the high temperature discharge steam is improved further. Through a method of expanding the expansion range of the incomingwater drops in the air cylinder, reducing the incoming speed of the water drops and ensuring the proper direct spray direction of the water drops, requirements for high-efficiency mixture of the water drops and the high temperature discharged steam are met and aims of improving performance of a water spray system and improving the low pressure tail stage safety and stability are achieved.

Owner:XIAN XIRE ENERGY SAVING TECH +1

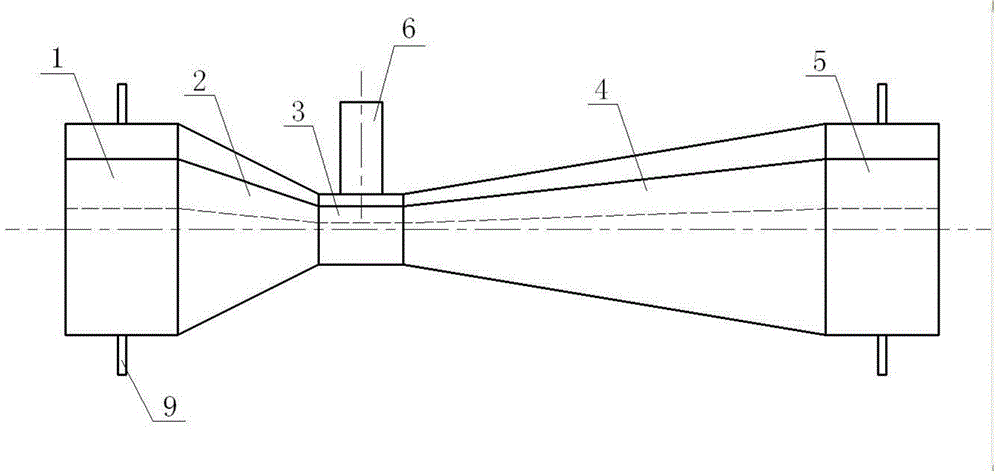

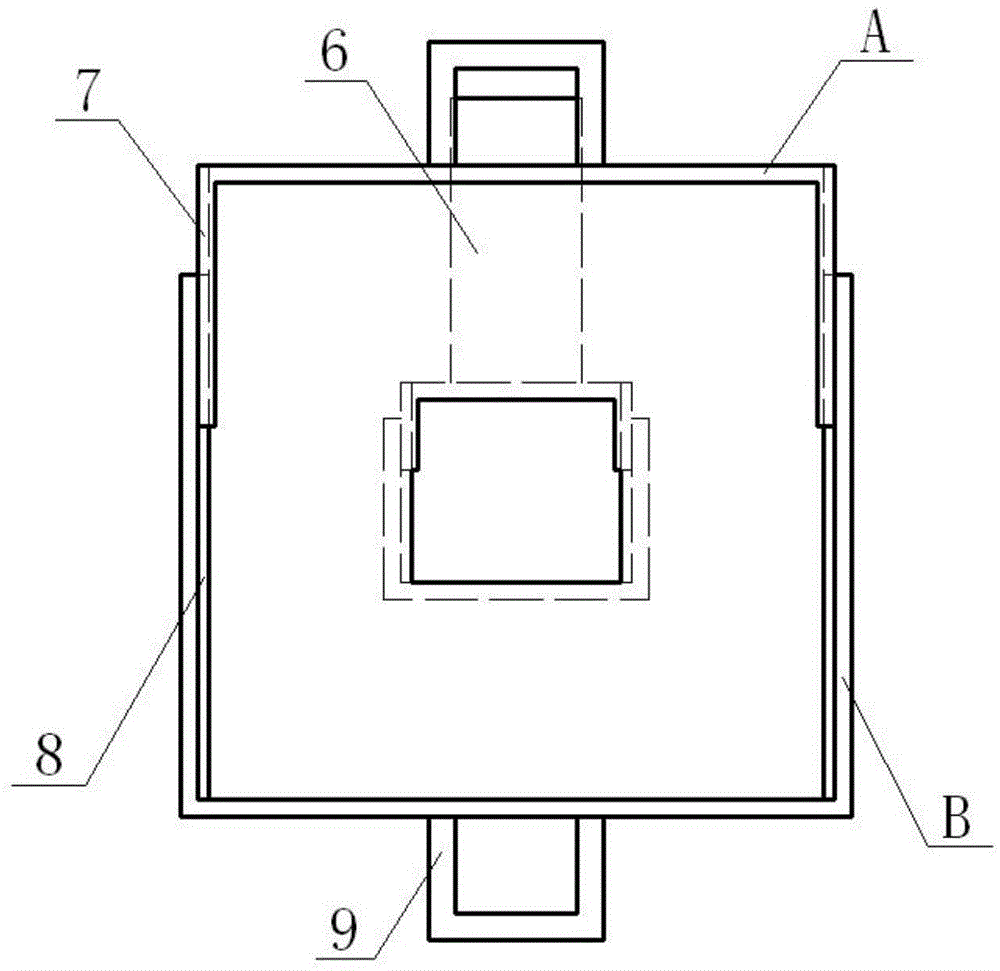

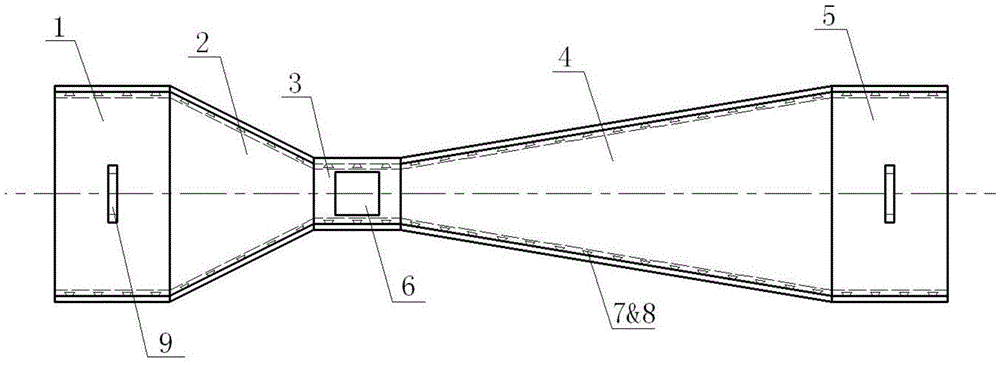

A square Venturi mixer with a push-pull structure

A square Venturi mixer with a push-pull structure, including a mainstream fluid inflow pipeline, a mainstream fluid constriction section, a mainstream fluid throat pipeline, a mainstream fluid diffusion section, and a mainstream fluid outflow pipeline, which are connected in sequence and arranged on the upper end of the mainstream fluid throat pipeline And the side inlet fluid inlet pipeline connected with it, the mainstream fluid inlet pipeline, the mainstream fluid throat pipeline, the mainstream fluid outflow pipeline and the inlet fluid inlet pipeline are all square pipelines, and the mainstream fluid constriction section and the mainstream fluid diffusion section are quadrangular pyramid-like structures; The mainstream fluid inflow pipe, the mainstream fluid constriction section, the mainstream fluid throat pipe, the mainstream fluid diffusion section and the mainstream fluid outflow pipe all include an upper part and a lower part, with grooves on the vertical wall surface of the upper part, and grooves on the vertical wall surface of the lower part. With ribs adapted to the shape of the groove; the invention is applicable to a wider range of flow ratios of mainstream fluid and introduced fluid, and effectively improves the mixing efficiency of continuous phase fluid and dispersed phase fluid.

Owner:度测(上海)科技服务中心

A Premixed Preevaporation Combustion Chamber Using a Radial Film-forming Main Combustion Stage

ActiveCN102889617BSimple structureHas a modular featureContinuous combustion chamberCycloneDiffusion flame

A premixing and pre-evaporation combustor for a main combustion stage using radial film formation consists of a diffuser, an outer combustor case, an inner combustor case, a pre-combustion stage, the main-combustion stage, a flame barrel outer wall and a flame barrel inner wall, wherein the flame of the pre-combustion stage is stabilized by a low-speed return flow zone formed by cyclone generated when a pre-combustion stage cyclone assembly enters the combustor; after being sprayed out by a plurality of tangential spraying openings of a main combustion stage nozzle, fuel oil of the main combustion stage spreads in a fuel oil film formation region and realizes connection, so that a peripheral continuous oil film is formed; the cyclone of an upstream cyclone ring of the main combustion stage nozzle and the cyclone of a downstream cyclone ring of the main combustion stage nozzle secondarily atomize the fuel oil, the fuel oil is brought to a premixing and pre-evaporation section to evaporate and is mixed with air, and uniform oil-gas mixtures are formed at an outlet of the premixing and pre-evaporation section, are jetted into a flame barrel, are ignited by the flame of the pre-combustion stage and then are combusted. The premixing and pre-evaporation combustor is simple in structure; and pollutant discharge can be effectively reduced while a normal working state of an aerial engine is guaranteed.

Owner:BEIHANG UNIV

A radial rim seal structure with damping holes and guide vanes

ActiveCN105134306BEfficient blendingImproved heat transfer stabilityLeakage preventionMachines/enginesEngineeringAir compressor

The invention discloses a radial rim sealing structure with damping holes and flow guide blades. The radial rim sealing structure is characterized in that the radial rim sealing structure is arranged in a gas turbine rotor-stator cavity or a gas turbine rotor-rotor cavity and comprises an outer tooth and a radial inner tooth which are matched; a plurality of damping holes are evenly formed in the upper end face of an inner tooth body of the radial inner tooth in the circumferential direction, and a plurality of flow guide blades are evenly arranged on the radial end face of the inner tooth body of the radial inner tooth in the circumferential direction; furthermore, the damping holes are in a cellular shape and are evenly distributed in a sealing tooth face in the circumferential direction; the flow guide blade are arranged on the end face of the sealing radial inner tooth with equal arcs, and the blades are provided with gradually-shrunk channels. The rim sealing structure can effectively lower the high-temperature gas invading degree and improve the sealing performance of rim sealing, and therefore the overheat failure of a turbine disc is avoided, the use amount of low-temperature cooling air flow introduced from the position of an air compressor can also be reduced, and the efficiency of a unit can be improved.

Owner:XI AN JIAOTONG UNIV

Two-stage axial swirler and aero-engine with cavity enhanced oil and gas mixing

ActiveCN113137638BImprove ignition performanceEfficient blendingContinuous combustion chamberEfficient propulsion technologiesCombustion instabilityCombustion chamber

The invention discloses a dual-stage axial cyclone with a concave cavity for enhancing the mixing of oil and gas, comprising a primary cyclone and a secondary cyclone, wherein the first cyclone and the secondary cyclone A venturi is arranged between the two cyclones, a sleeve is arranged on the secondary cyclone, the primary cyclone is sleeved on the central nozzle, and also includes: a mixed flow part, and the mixed flow part is arranged on the sleeve At the end of the combustion chamber, the mixing part is used to fully mix the oil and gas in the combustion chamber again; the cooling part is arranged on the sleeve, and the cooling part is used to transport the cooling gas and swirl the combustion chamber. The vortex core precession (PVC) flow instability commonly exists in the flow field of the dual-stage axial swirler, which will cause combustion instability and reduce the flame stability of the combustion chamber, which is not conducive to the flame. stable effect.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

A polymer-based piezoelectric film and its preparation method and application

ActiveCN111363277BExcellent piezoelectric propertiesImprove breakdown performancePiezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsPolymer sciencePolyvinylidenefluoride-trifluoroethylene

The invention belongs to the technical field of piezoelectric materials, and in particular relates to a polymer-based piezoelectric film and its preparation method and application. The polymer-based piezoelectric film provided by the invention includes a polymer and a doped two-dimensional layered structure compound; the mass ratio of the polymer to the two-dimensional layered structure compound is 100: (0.1-2); the The polymer is one or more of polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene and polyvinylidene fluoride-trifluoroethylene; the chemical composition of the two-dimensional layered structure compound is M n+1 x n T y , wherein n=1, 2 or 3, M is a transition metal element, T is -O, -OH or -F functional group, and X is carbon or nitrogen. The polymer-based piezoelectric film provided by the present invention solves the problem of insufficient piezoelectric properties of traditional PVDF materials. Experimental results show that the polymer-based piezoelectric film provided by the present invention has good flexibility and excellent ferroelectric and piezoelectric properties. .

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com