Patents

Literature

30results about How to "Operator safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

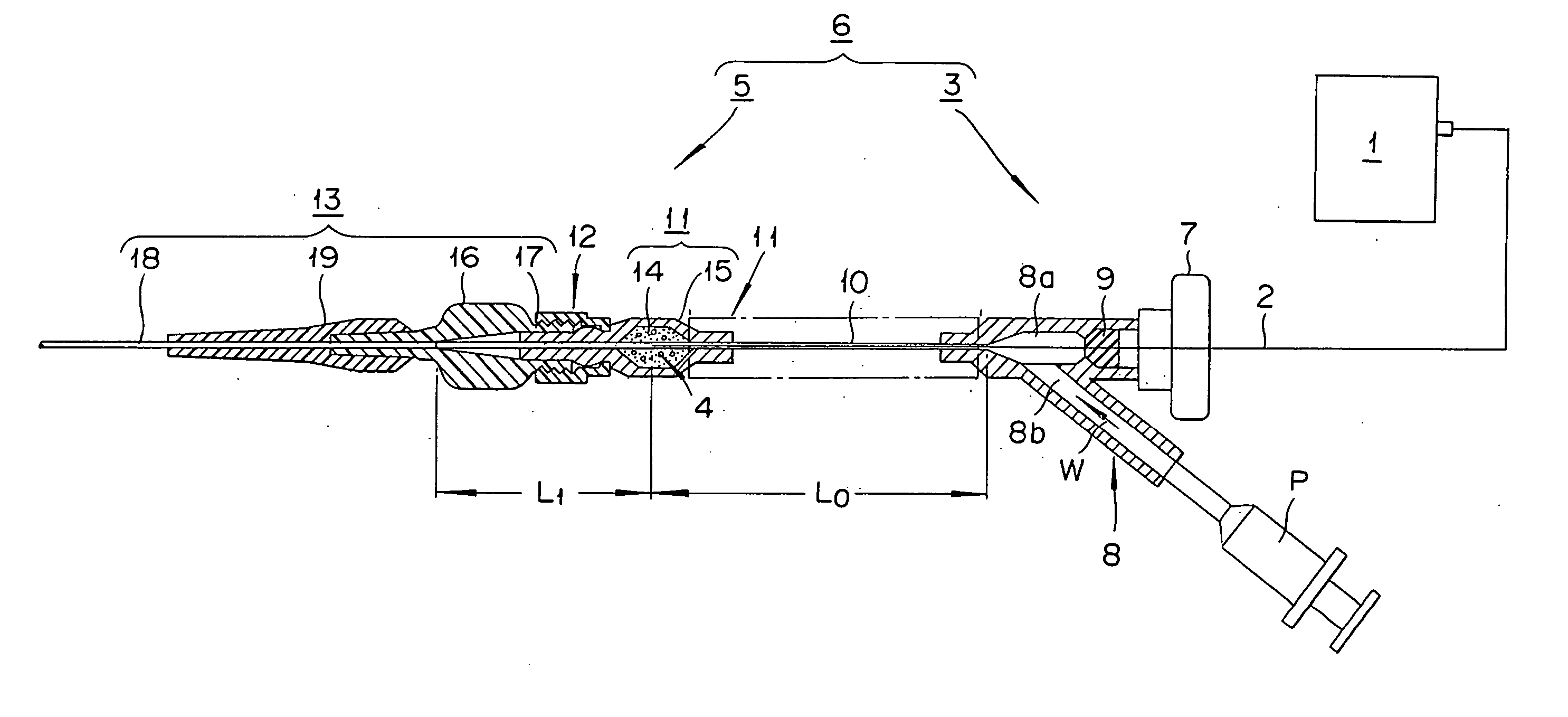

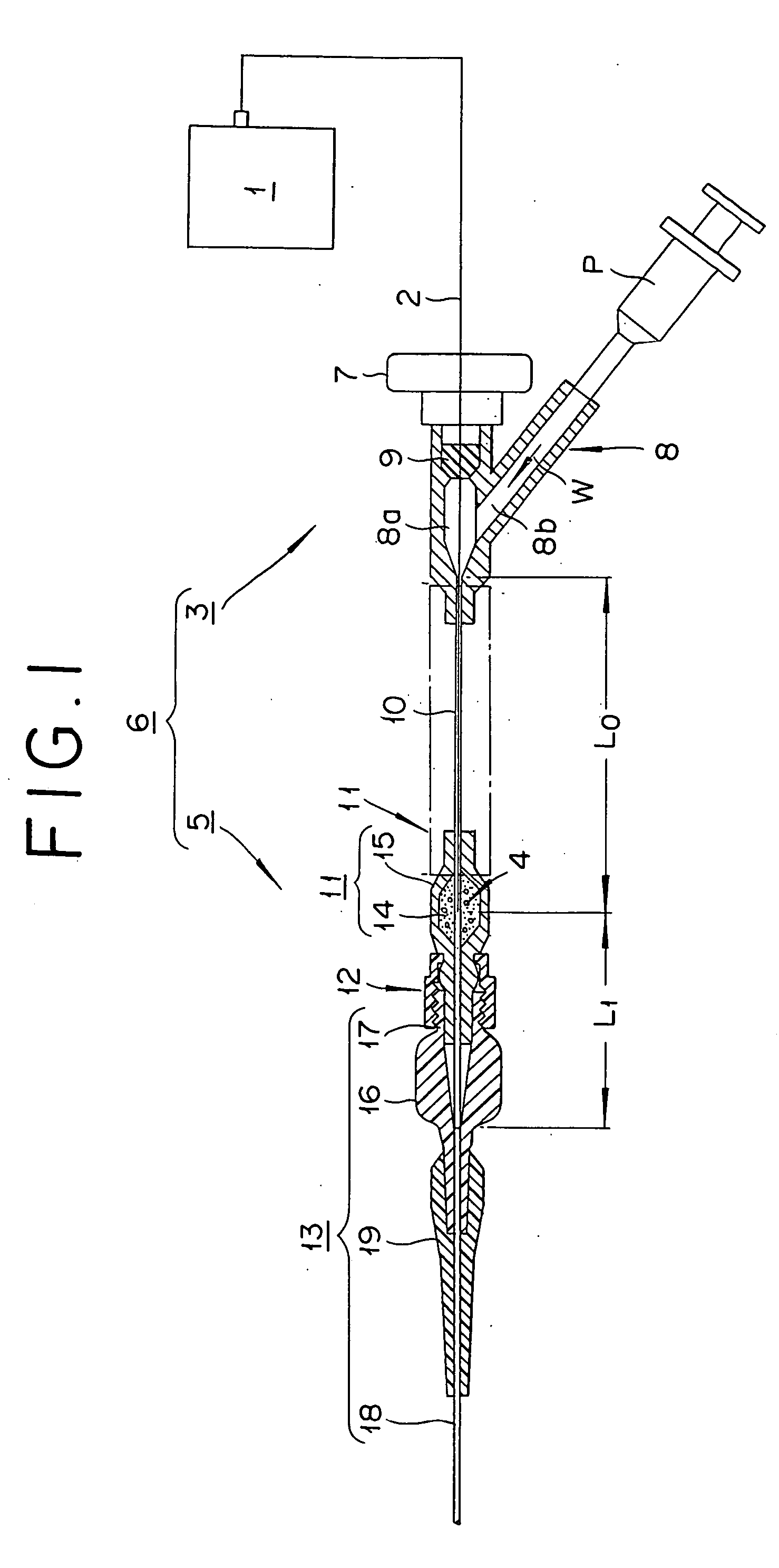

Laser induced liquid jet generating device

InactiveUS20060247743A1Operator safetyPatient SafetyElectrotherapySurgical instrument detailsLiquid jetJet flow

A laser induced liquid jet generating device comprising: a main body 6 adapted to be filled with a specified laser beam absorbing liquid and configured such that it can contain a laser irradiating part 4 of an optical fiber from which laser beams are emitted to generate jet streams J of said liquid W by irradiating said liquid W with laser beams, with said jet streams J ejected from said main body 6 to the outside; said main body 6 comprising: a catheter mounting unit mounted integrally or in a removable manner on a catheter member 13 into which said jet stream J is introduced; a jet generating tube unit 10 in which said laser irradiation part 4 is adapted to be positioned; and a heat transfer inhibition means 11 for inhibiting thermal effect due to laser beams irradiated by said laser irradiating part 4 from being transferred outside through said jet generating tube unit 10. Thus, it provides a laser induced liquid jet generating device that is safe for both the operator and the patient as it can apply irradiation of powerful laser beams for a long period of time without the catheter being thermally affected by the laser beams.

Owner:MICHELIN RECH & TECH SA +1

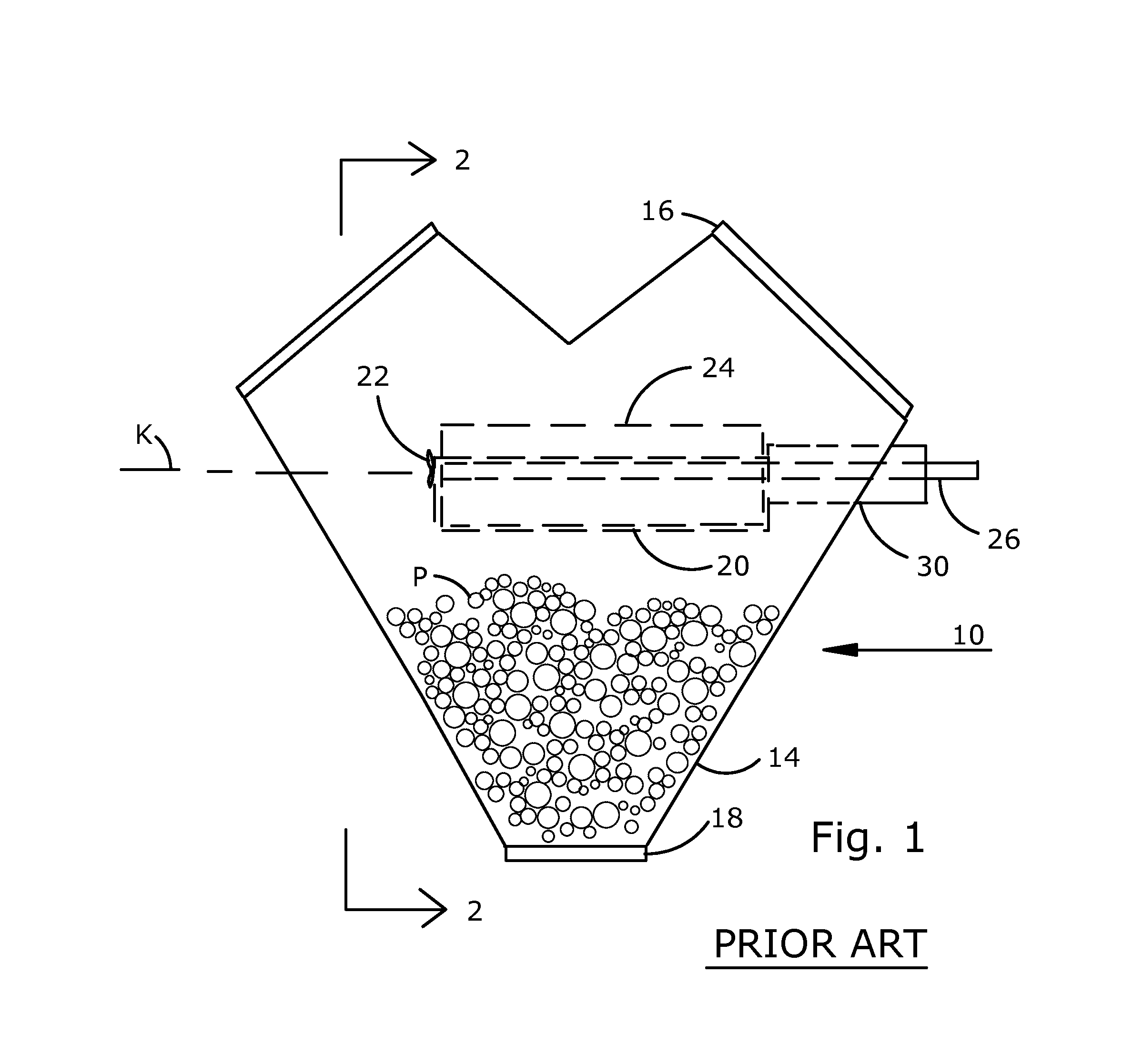

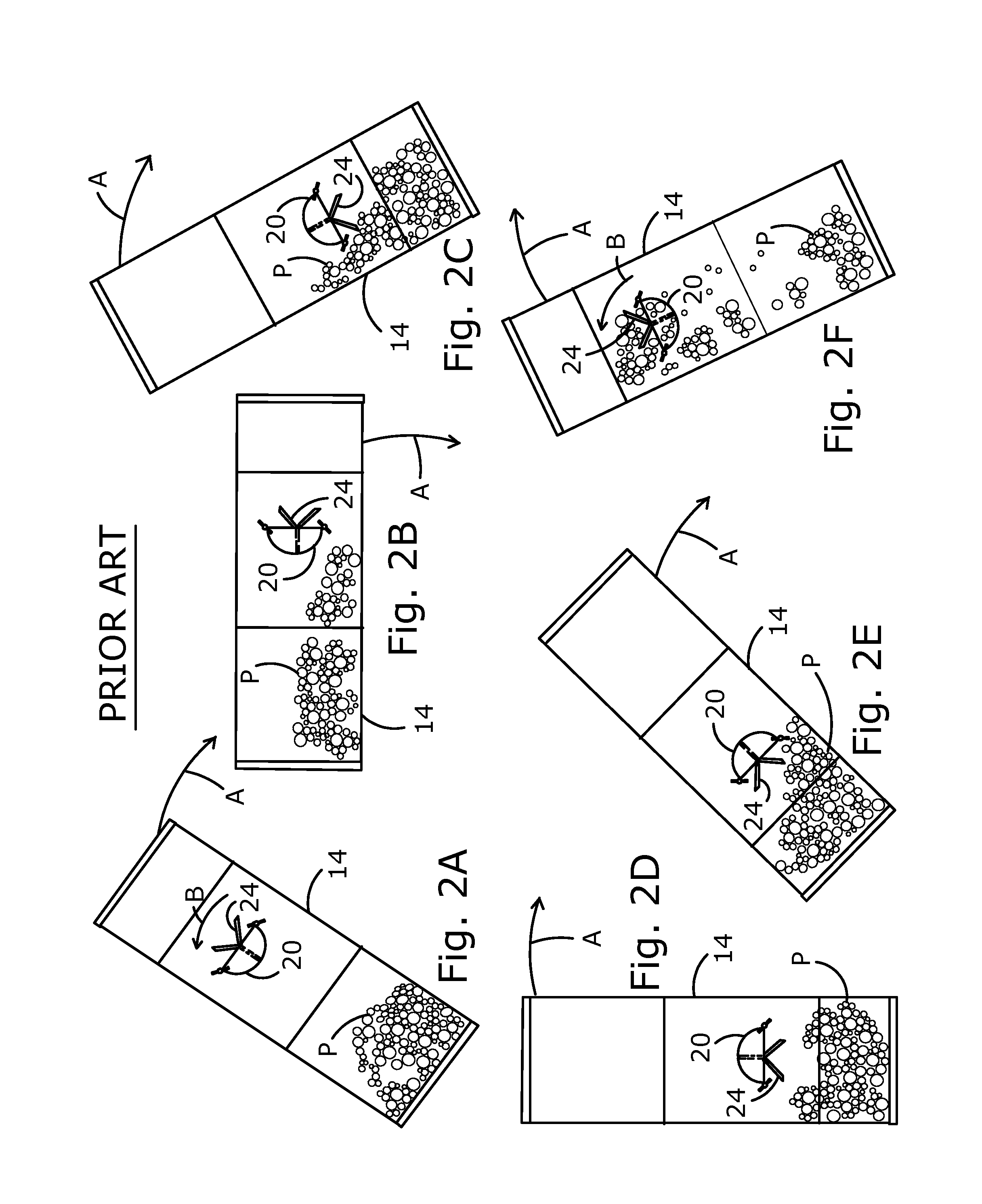

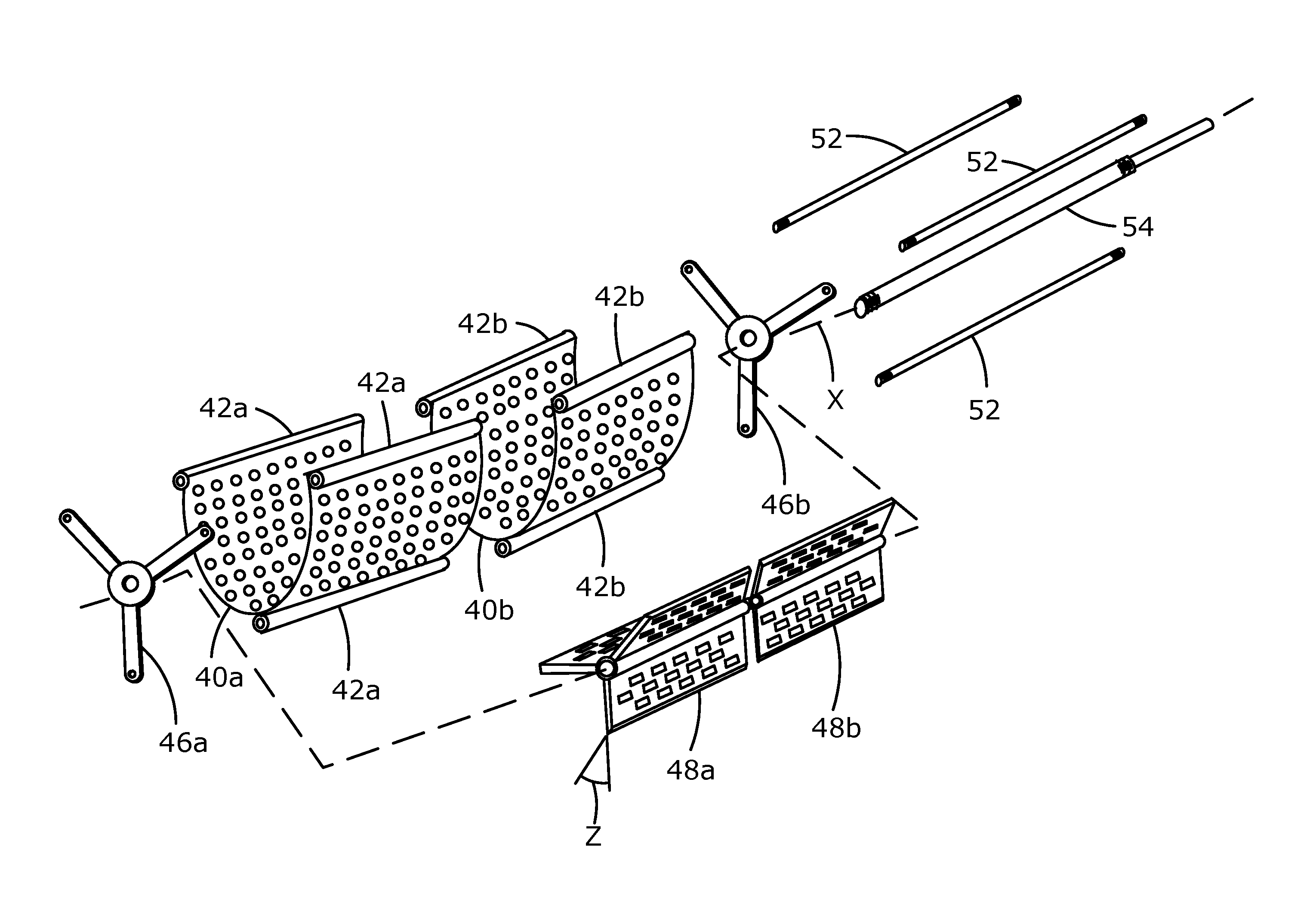

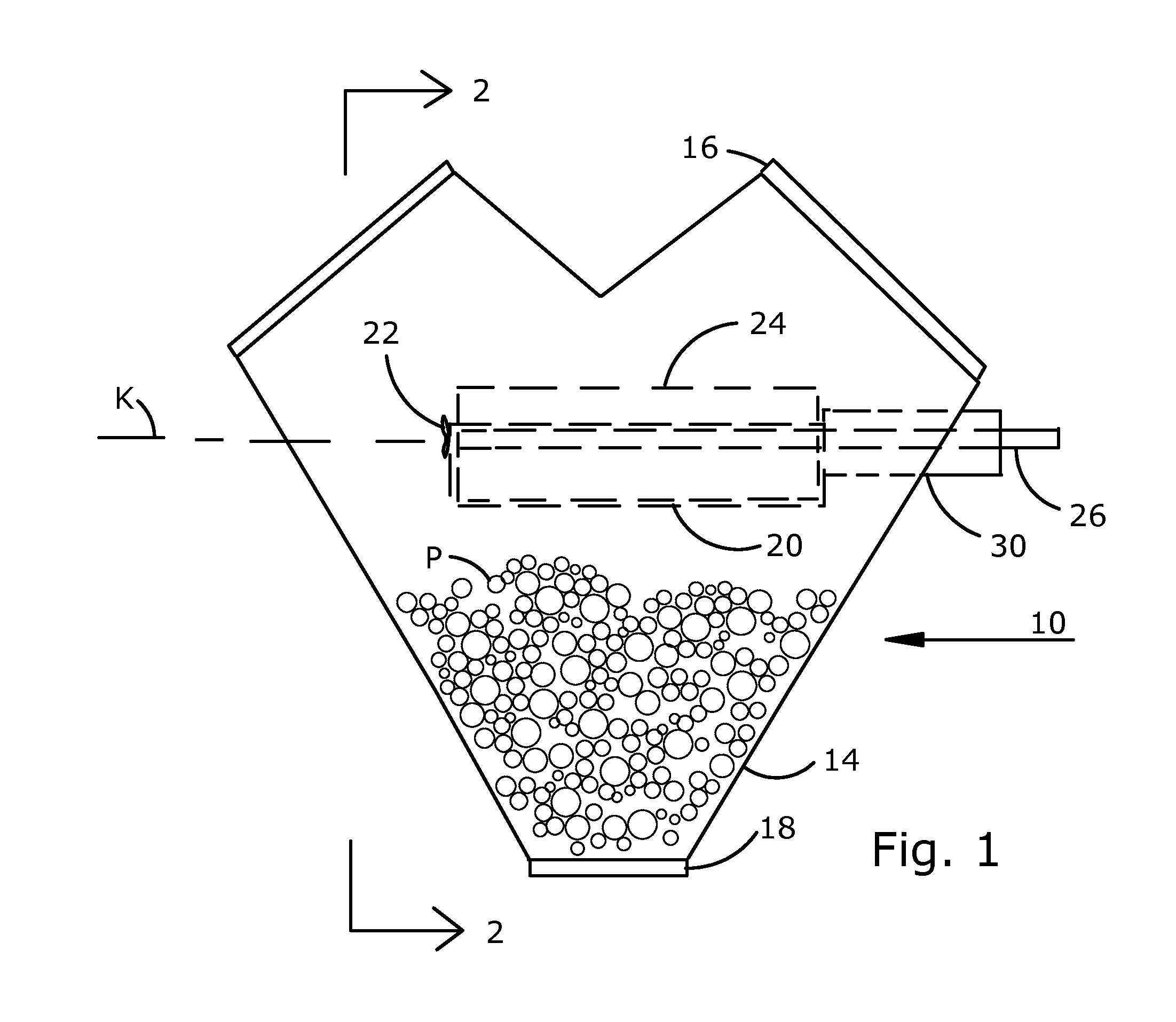

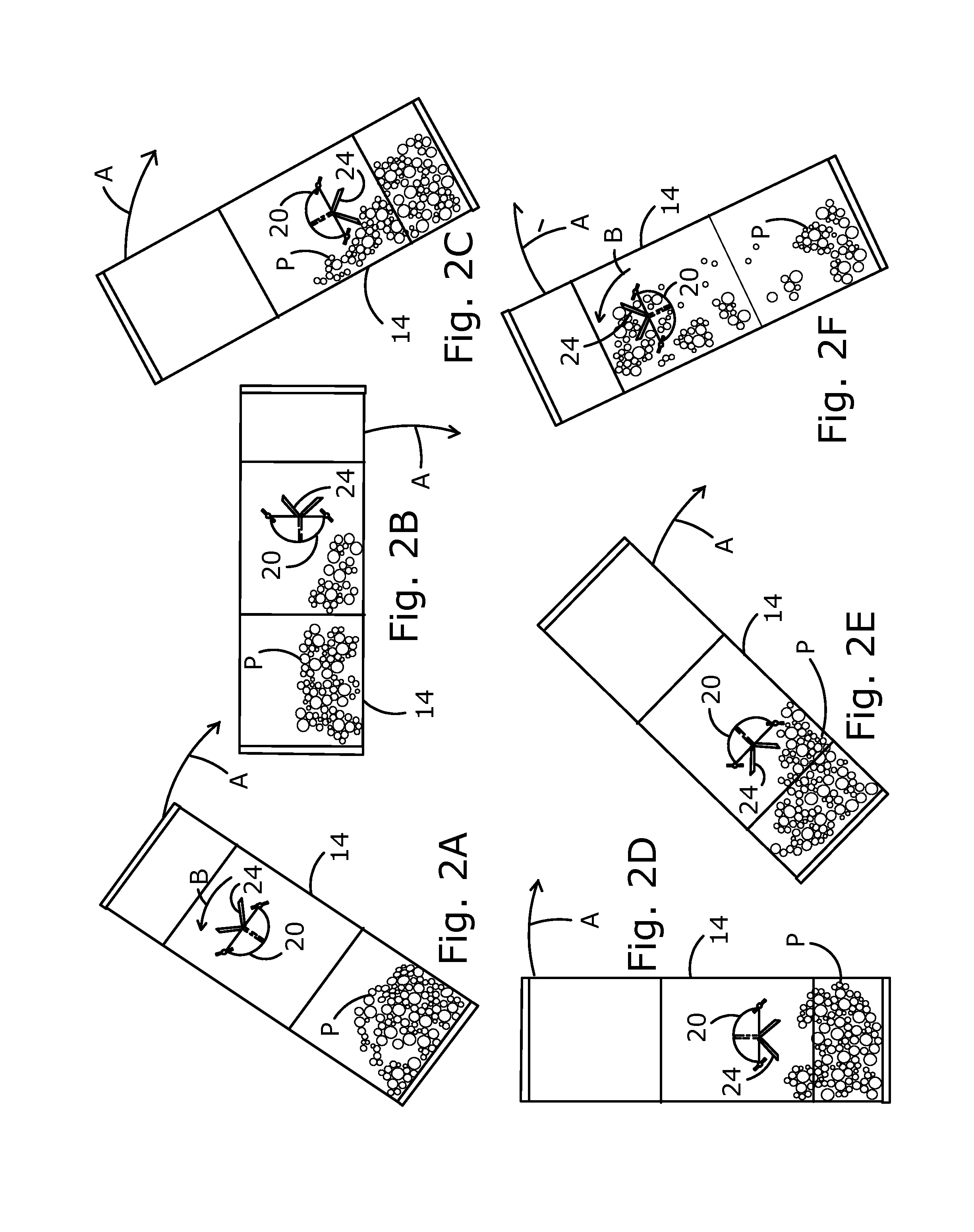

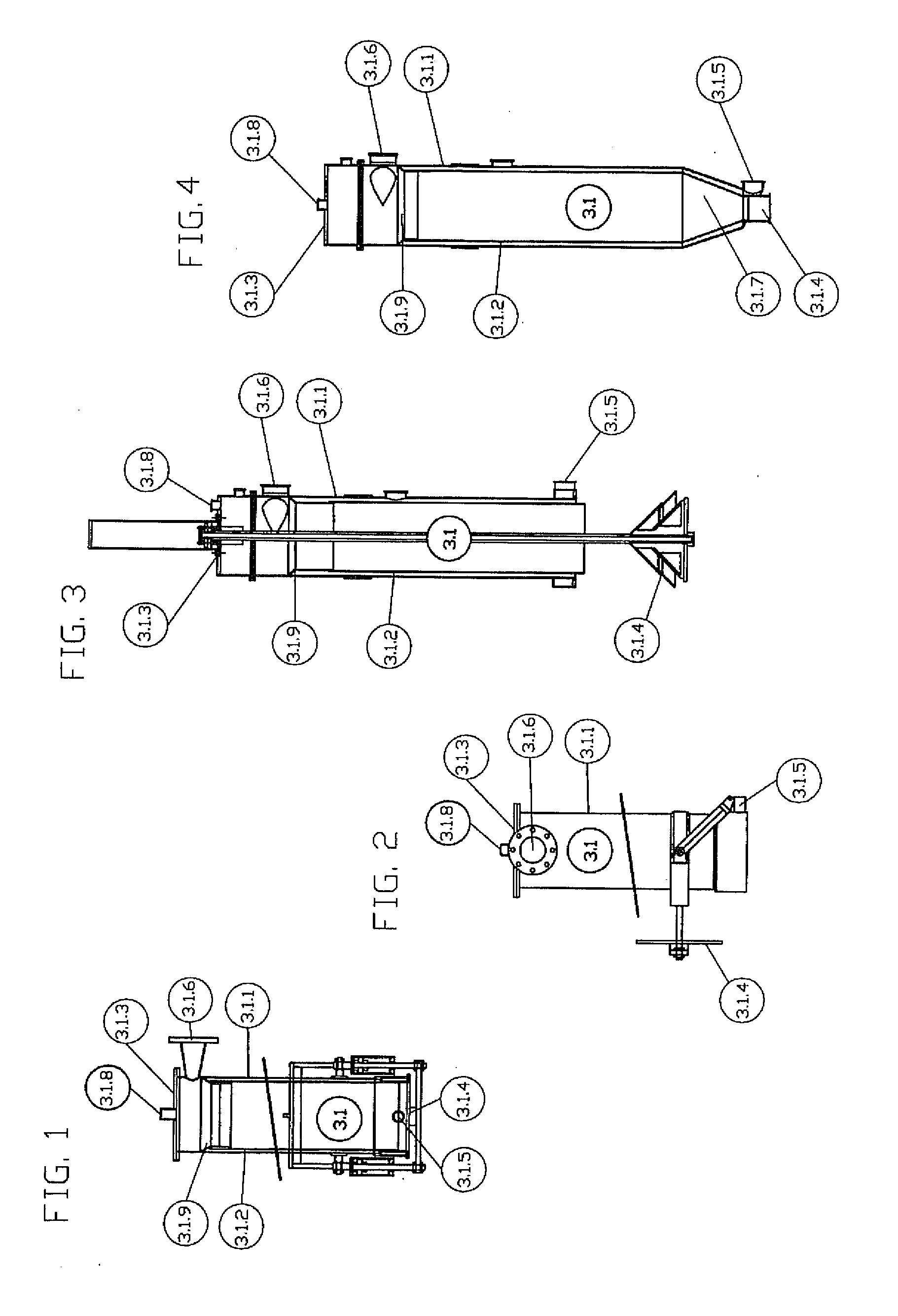

Apparatus for alternately sifting and blending powders in the same operation

ActiveUS8827545B2Efficiently siftingEfficient blendingSievingRotating receptacle mixersMechanical engineeringStructural engineering

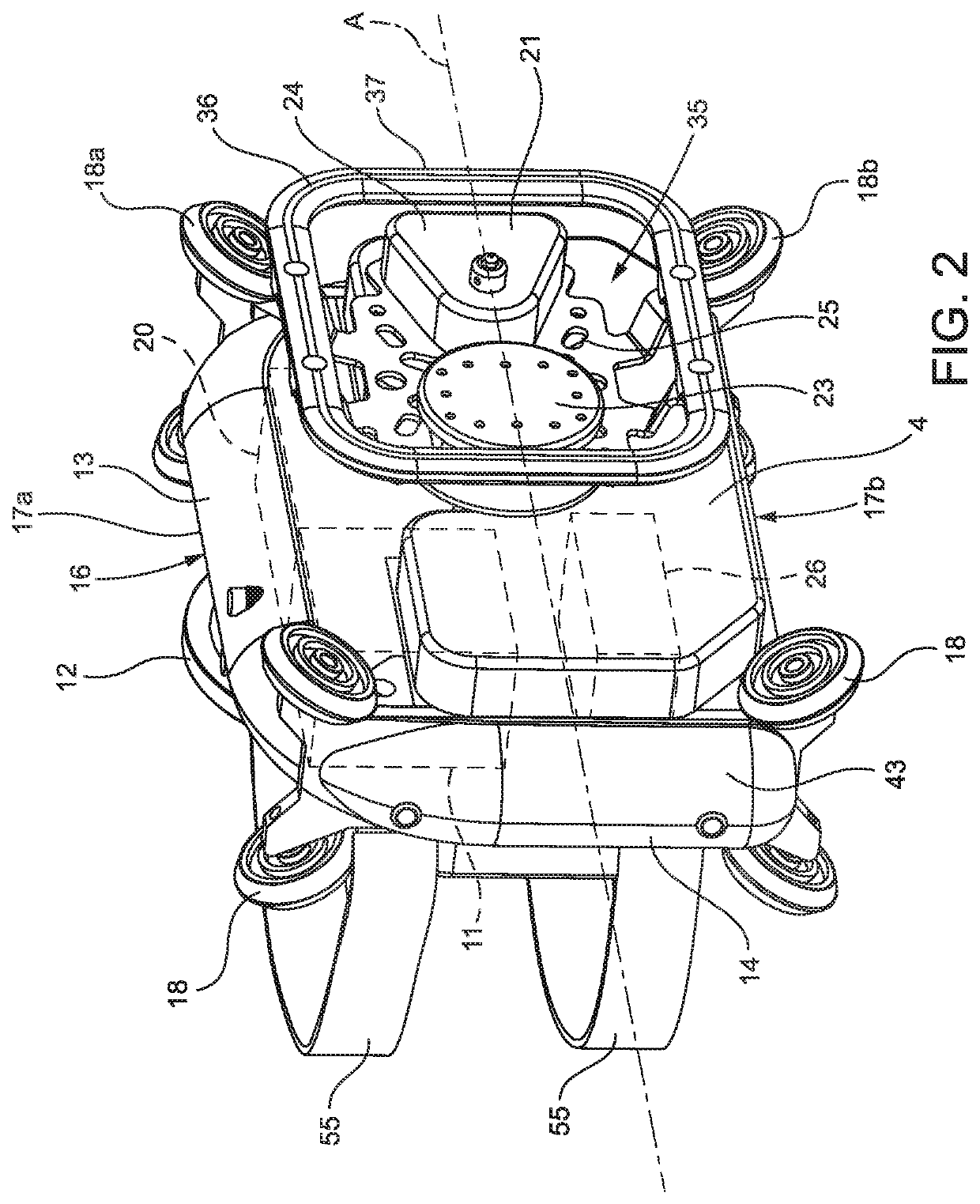

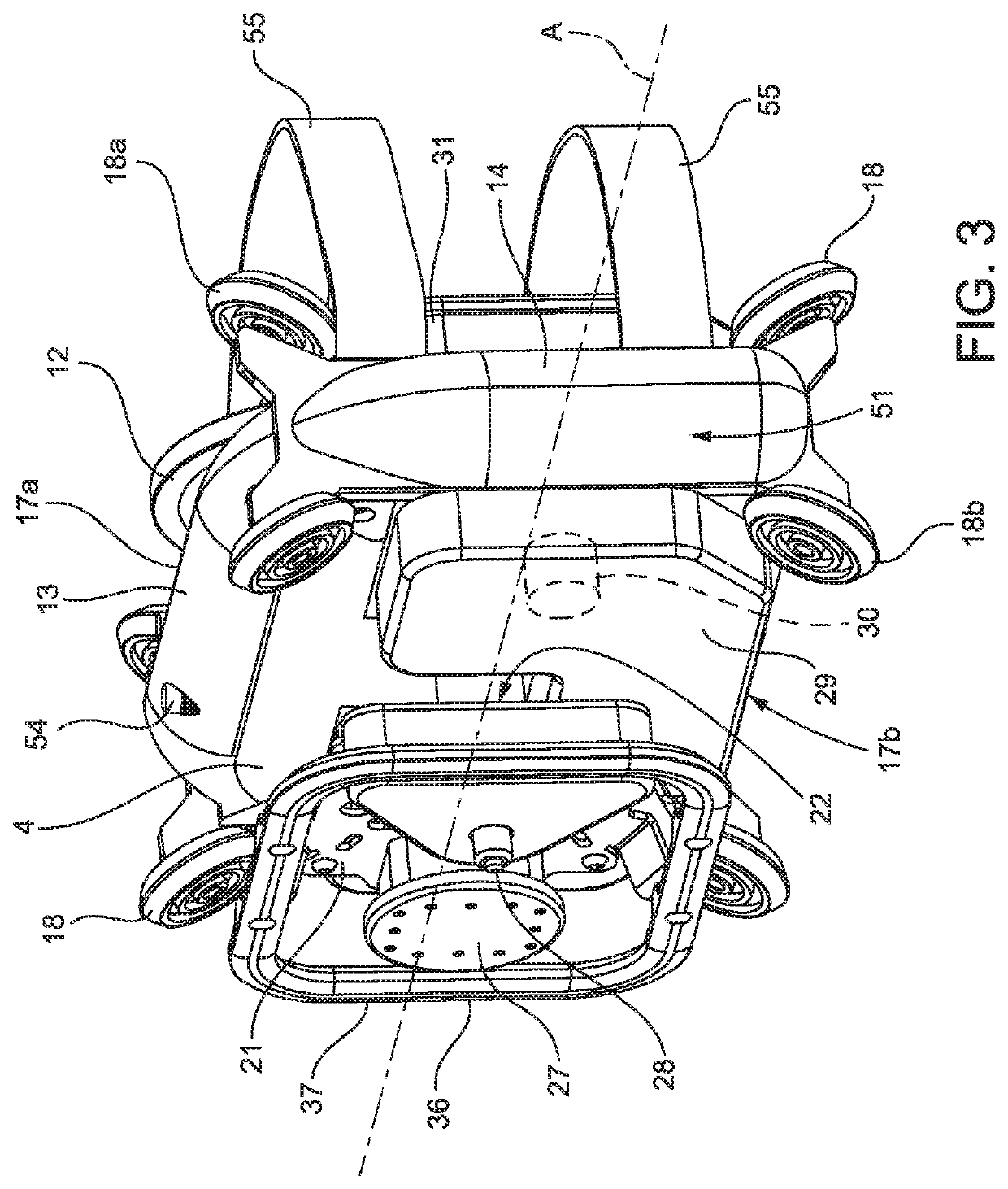

A tumbling container is mounted for rotation with a curved screen fixedly mounted within the tumbling container. A multiple vane paddle is mounted to a shaft that is rotatably mounted to the tumbling container. The paddle vanes are formed with angular edges. As the tumbler rotates and the paddle rotates, powder is repeatedly dropped onto the screen to be sifted with the aid of the paddle. Rotating the tumbler further drops unsifted portions of the powder from the screen to mix with additional powder in the tumbler body. Thus, sifting and blending of powders is accomplished in one single operation. The invention utilizes an apparatus having a multiple section screen and a multiple section paddle to enable assembly through the openings in the tumbling container. The screen of a second embodiment has a cowl adjacent to each screen opening to optimize powder lump disintegration.

Owner:KALIDINDI SANYASI R

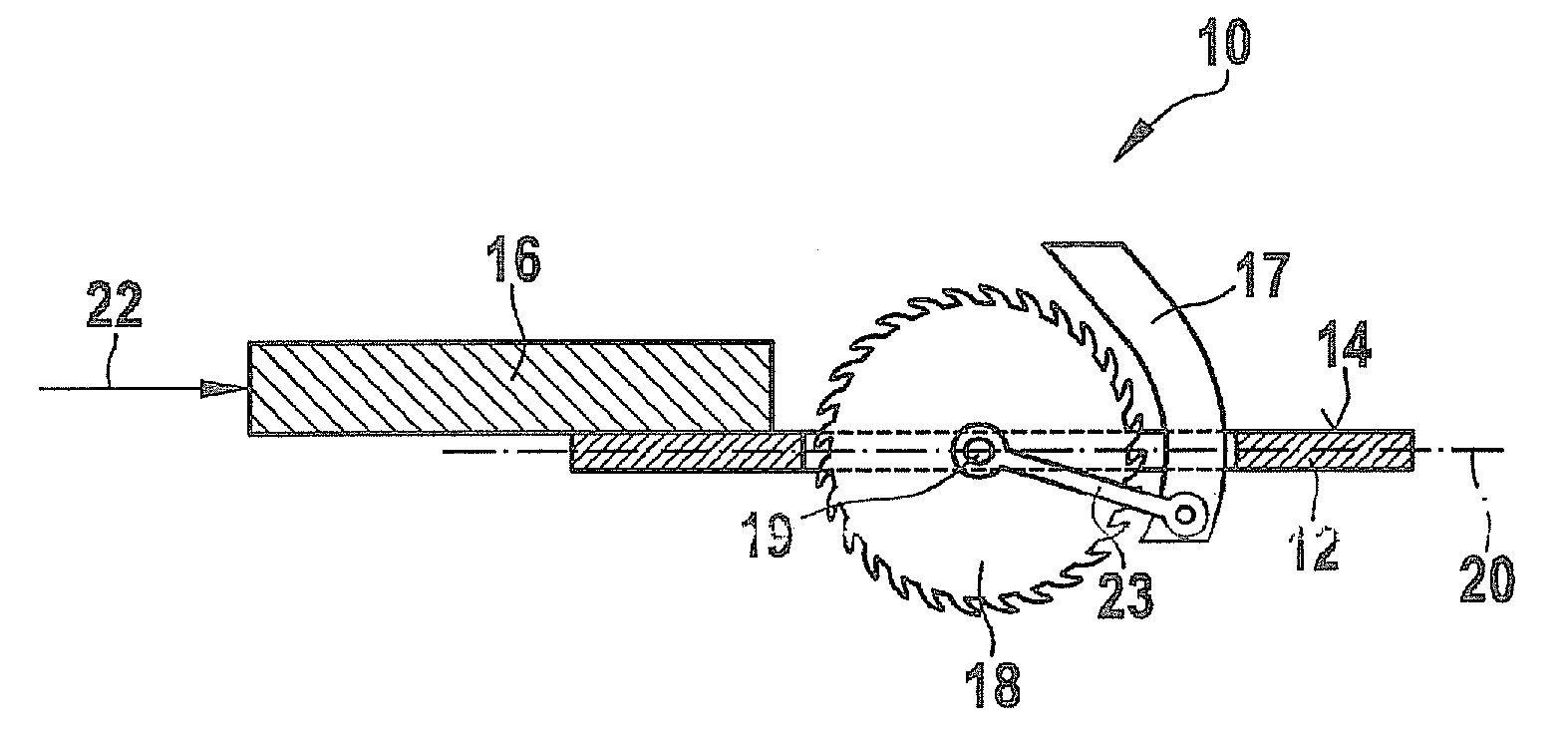

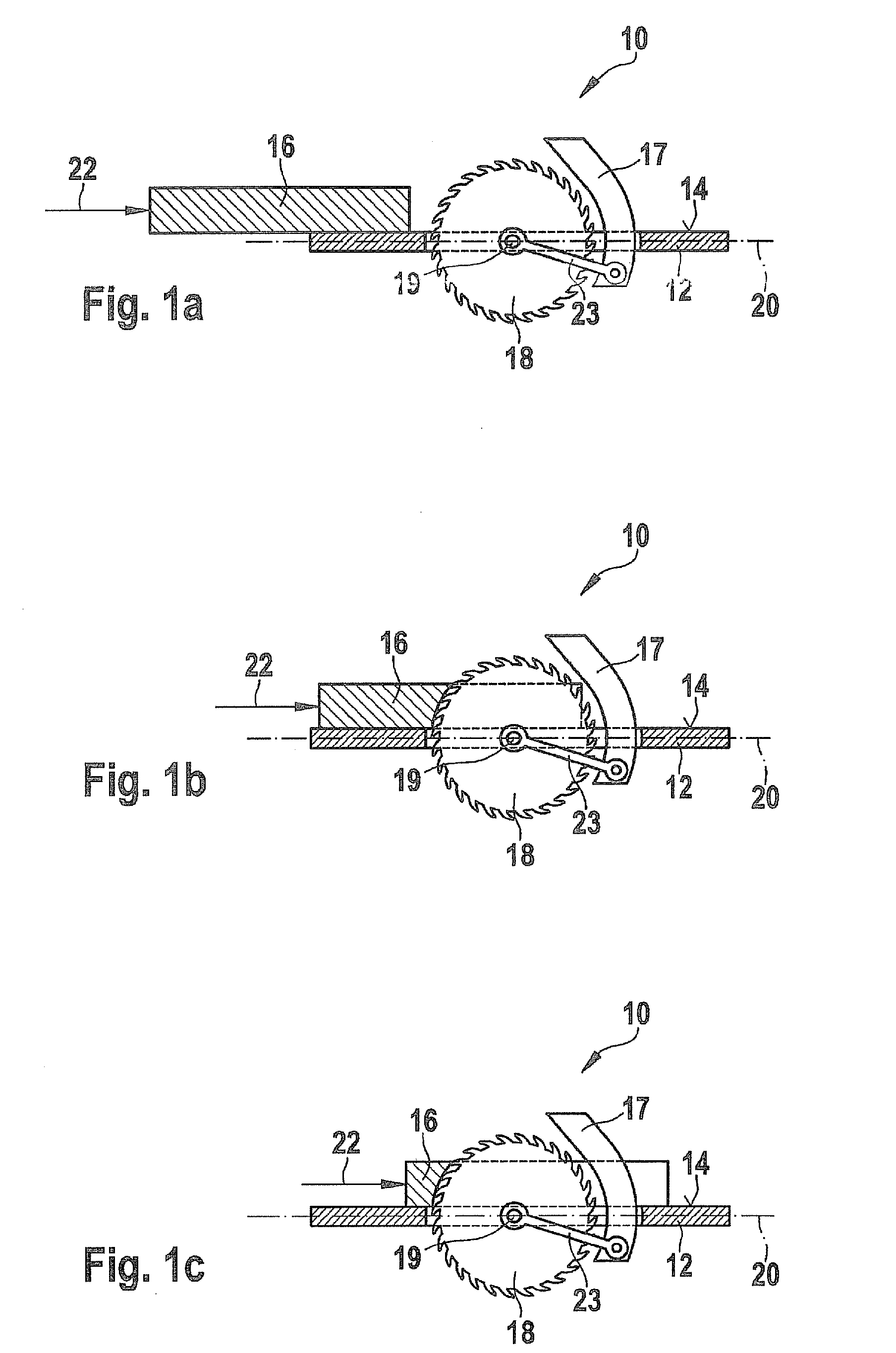

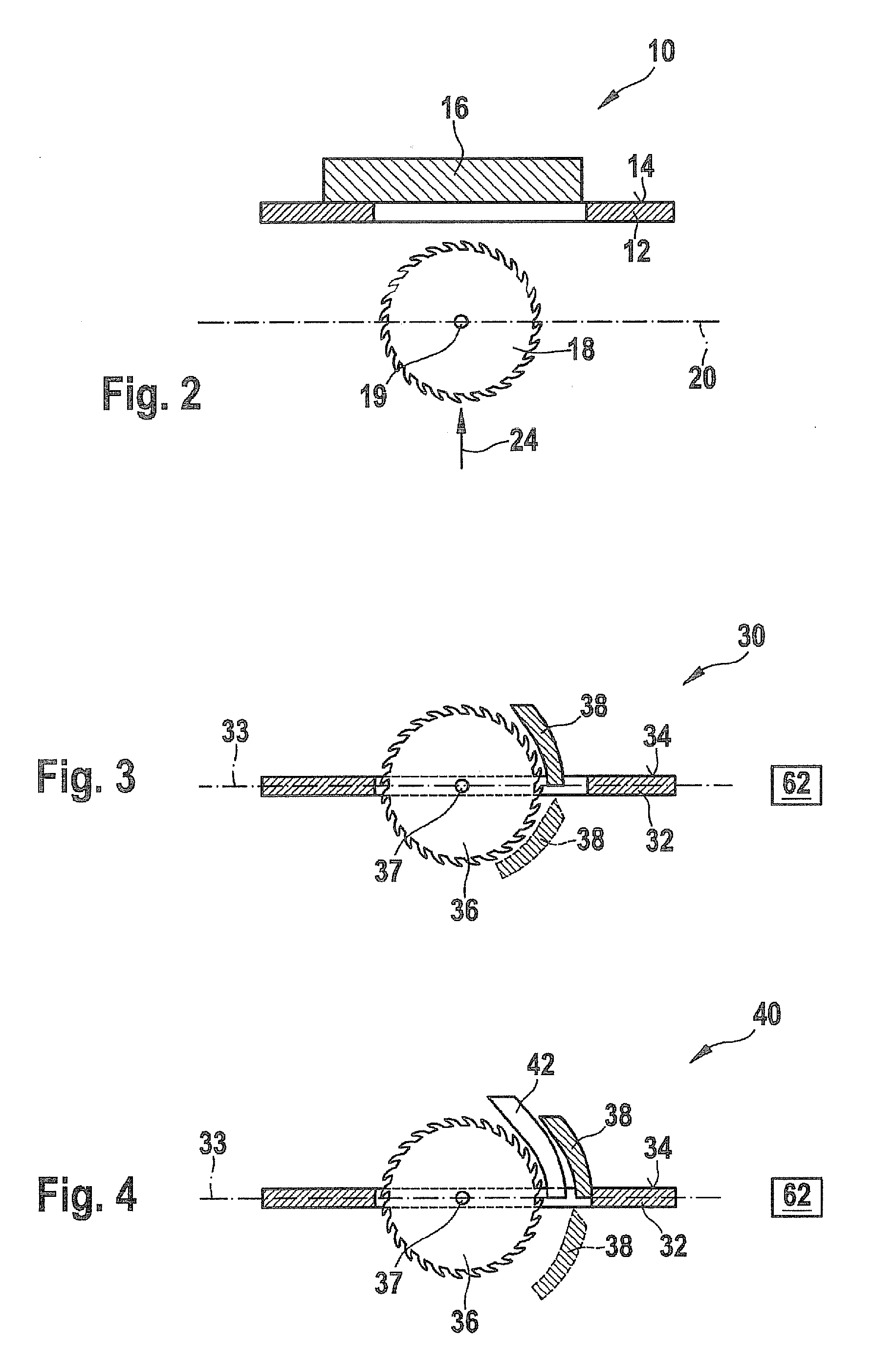

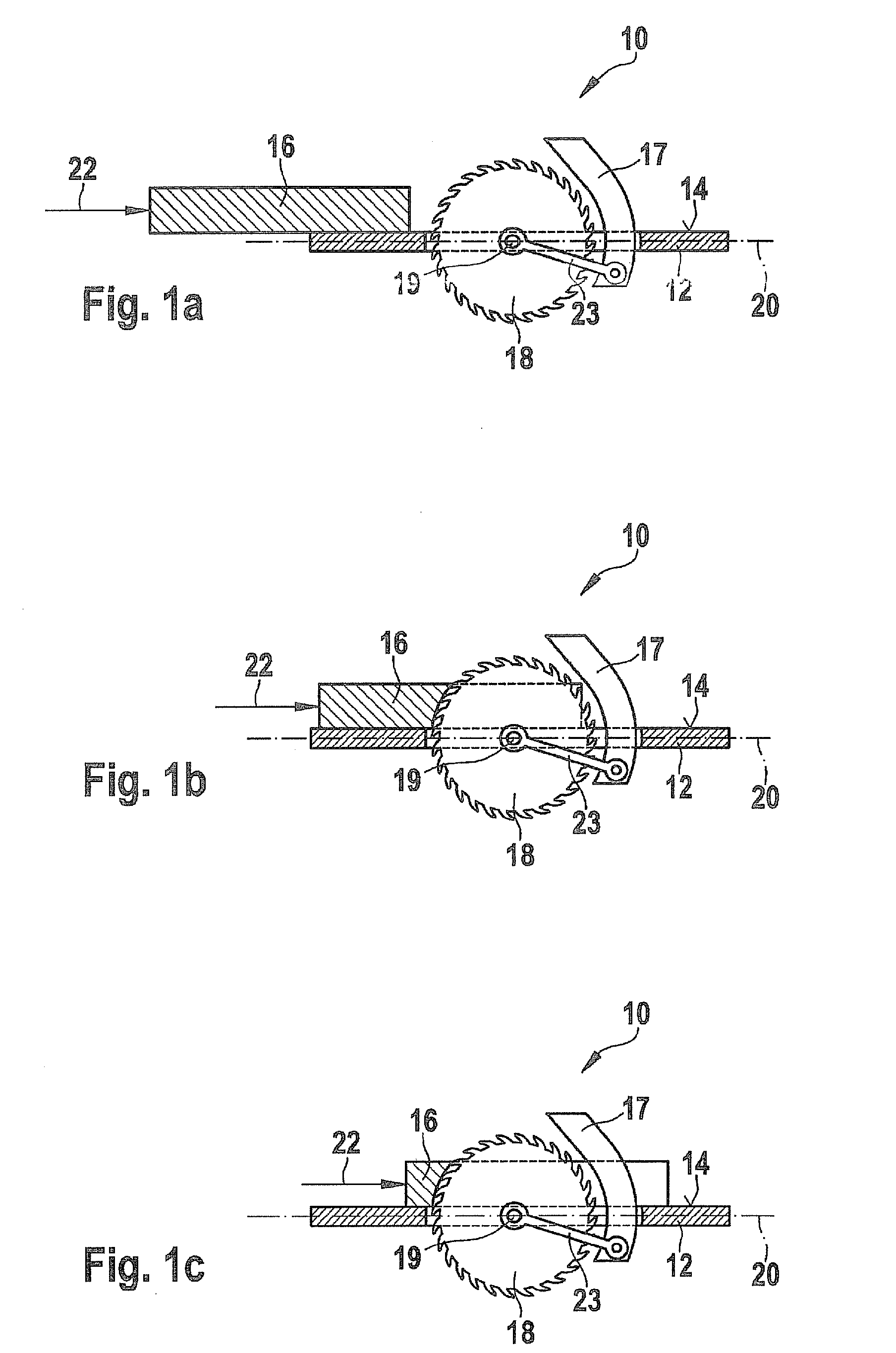

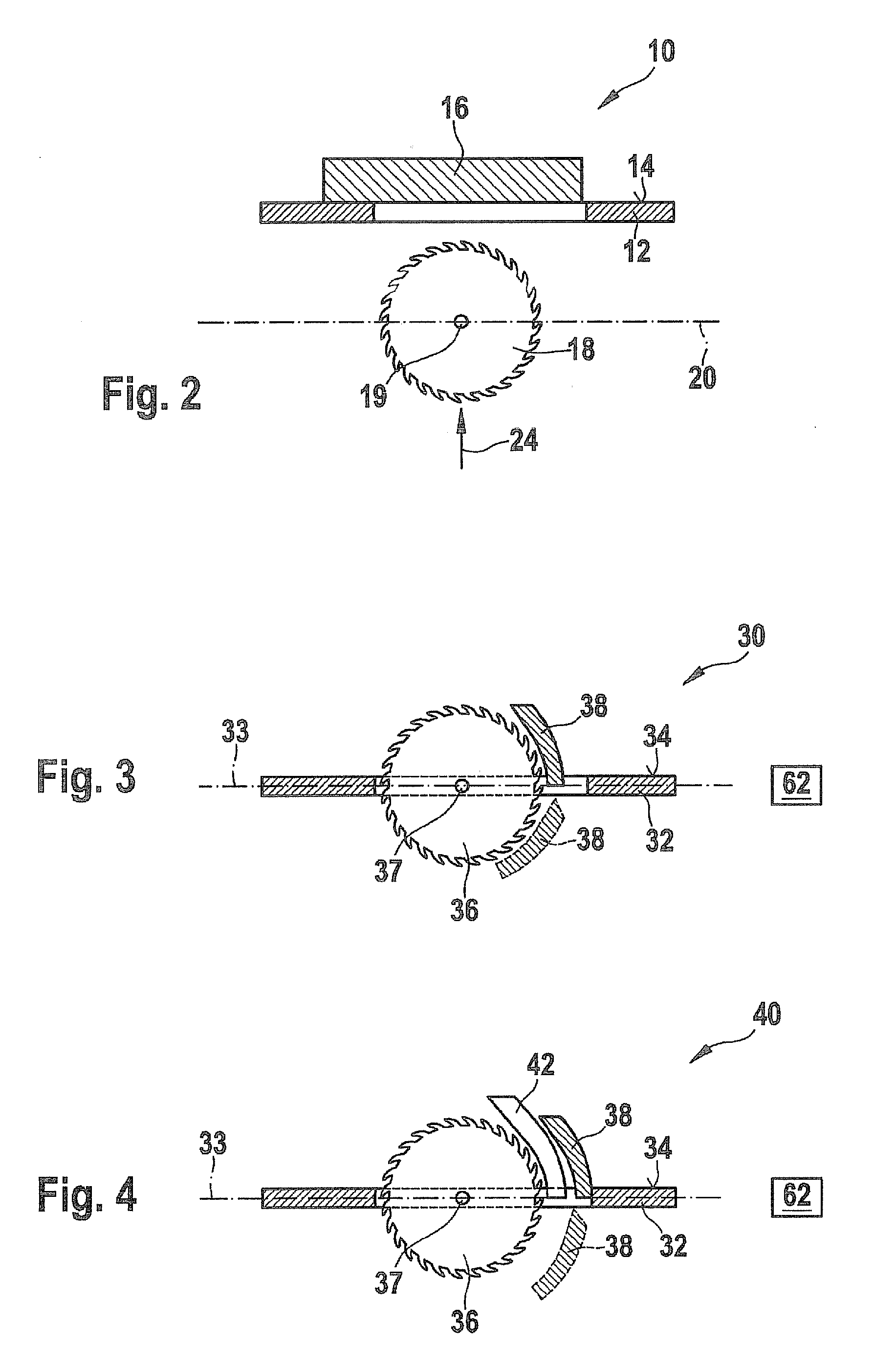

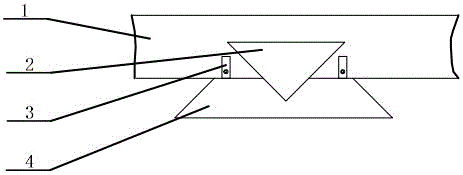

Circular saw

InactiveUS20100326251A1Reduce in quantityOperator safetyMetal sawing devicesShearing machinesRotational axisCircular saw

A circular saw including a saw blade (36) which may be rotatingly driven about a rotational axis, and at least one first splitting wedge is described. The circular saw is configured so that the first splitting wedge is movable relative to the rotational axis of the saw blade.

Owner:ROBERT BOSCH GMBH

Apparatus for alternately sifting and blending powders in the same operation

ActiveUS20140064020A1Easy to installSaferSievingRotating receptacle mixersEngineeringMechanical engineering

A tumbling container is mounted for rotation with a curved screen fixedly mounted within the tumbling container. A multiple vane paddle is mounted to a shaft that is rotatably mounted to the tumbling container. The paddle vanes are formed with angular edges. As the tumbler rotates and the paddle rotates, powder is repeatedly dropped onto the screen to be sifted with the aid of the paddle. Rotating the tumbler further drops unsifted portions of the powder from the screen to mix with additional powder in the tumbler body. Thus, sifting and blending of powders is accomplished in one single operation. The invention utilizes an apparatus having a multiple section screen and a multiple section paddle to enable assembly through the openings in the tumbling container. The screen of a second embodiment has a cowl adjacent to each screen opening to optimize powder lump disintegration.

Owner:KALIDINDI SANYASI R

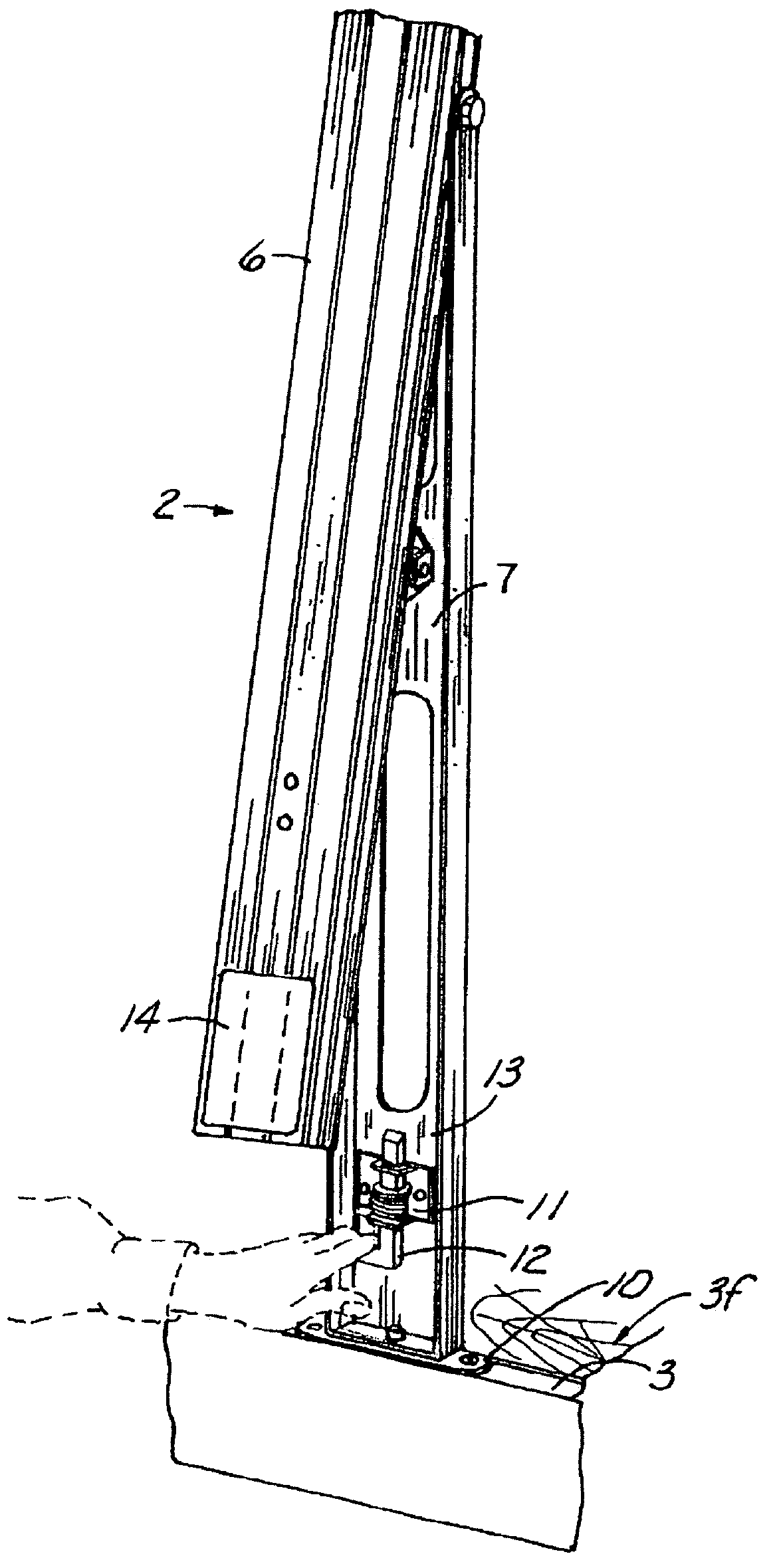

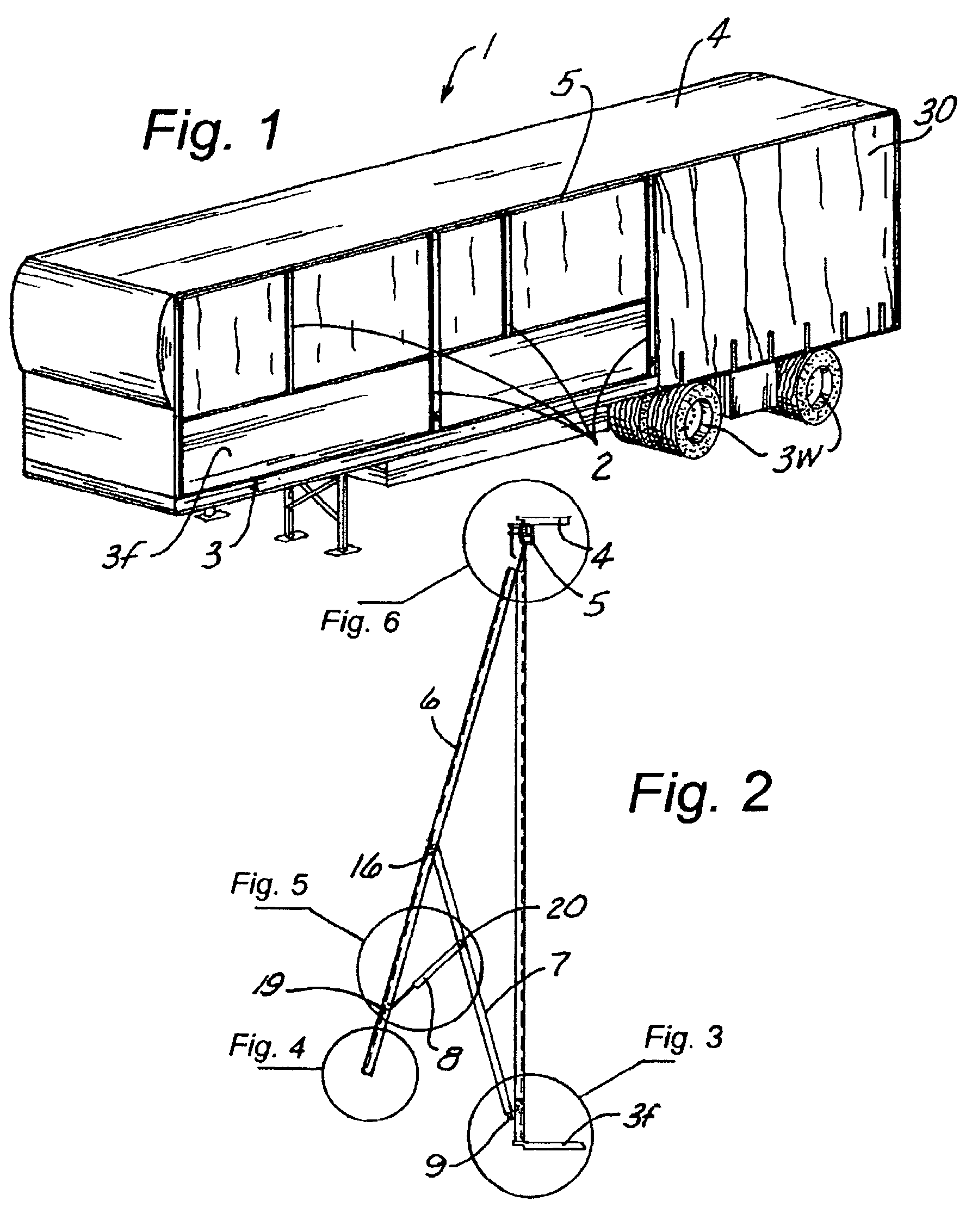

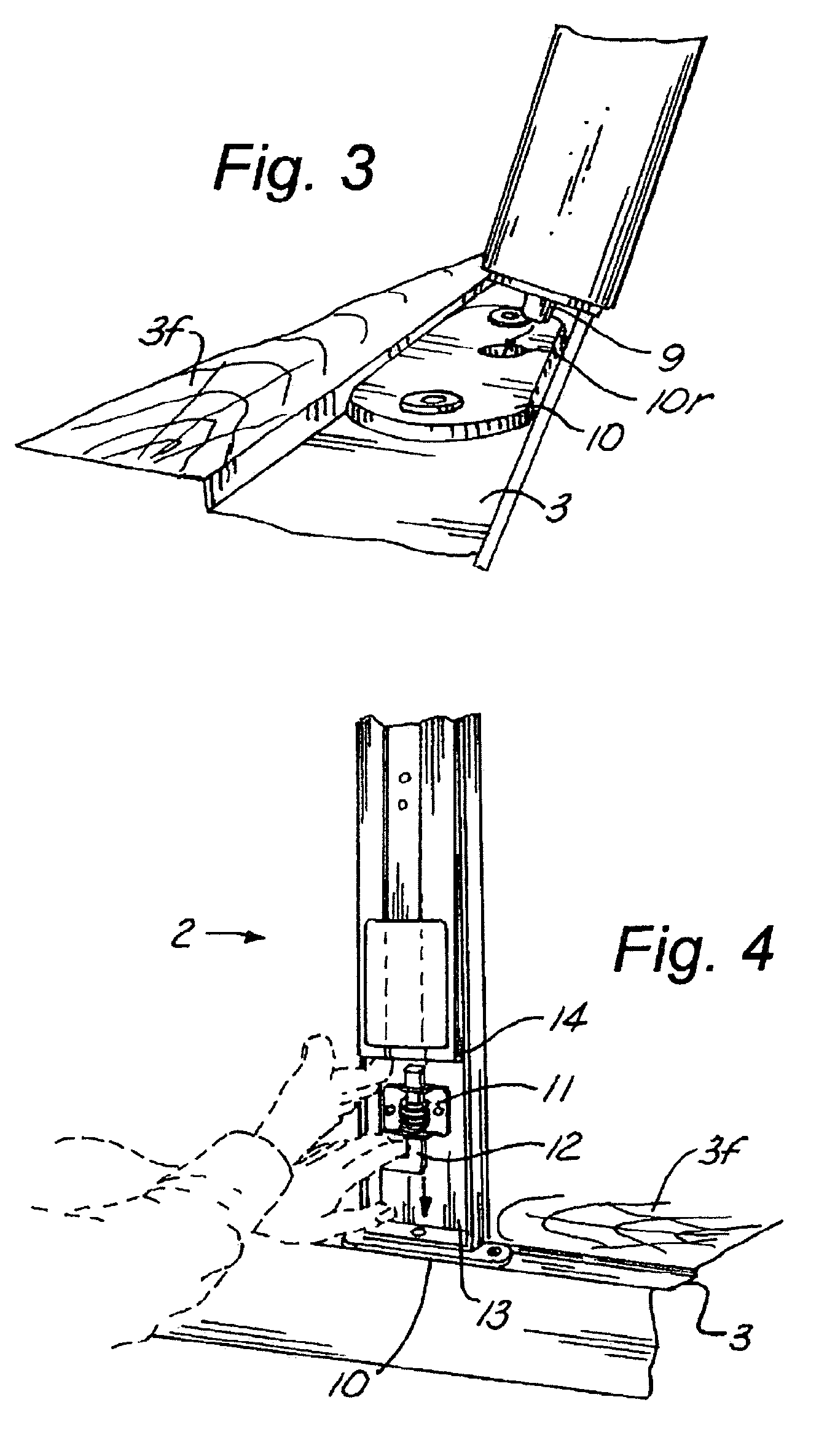

Apparatus for decreasing opening velocities of support pillars

ActiveUS7578539B1Facilitate widening loadingFacilitate unloading widthSuperstructure subunitsDoorsEngineeringLateral movement

The invention relates generally to an apparatus for use with curtain side trailers, including a pillar with a hydraulic dampening device and two members, and providing a way for the pillar to be locked and released from lateral movement along a railing or framework. The invention is generally used as an intermediary support for the curtain and the roof, and extends from the trailer bed to the roof. Since the pillars can move laterally along the railing or framework once released and opened, the width for loading and unloading is increased. The dampening device of present invention helps with safety issues of prior inventions by decreasing the velocity of the opening pillar.

Owner:ROLAND CURTAINS

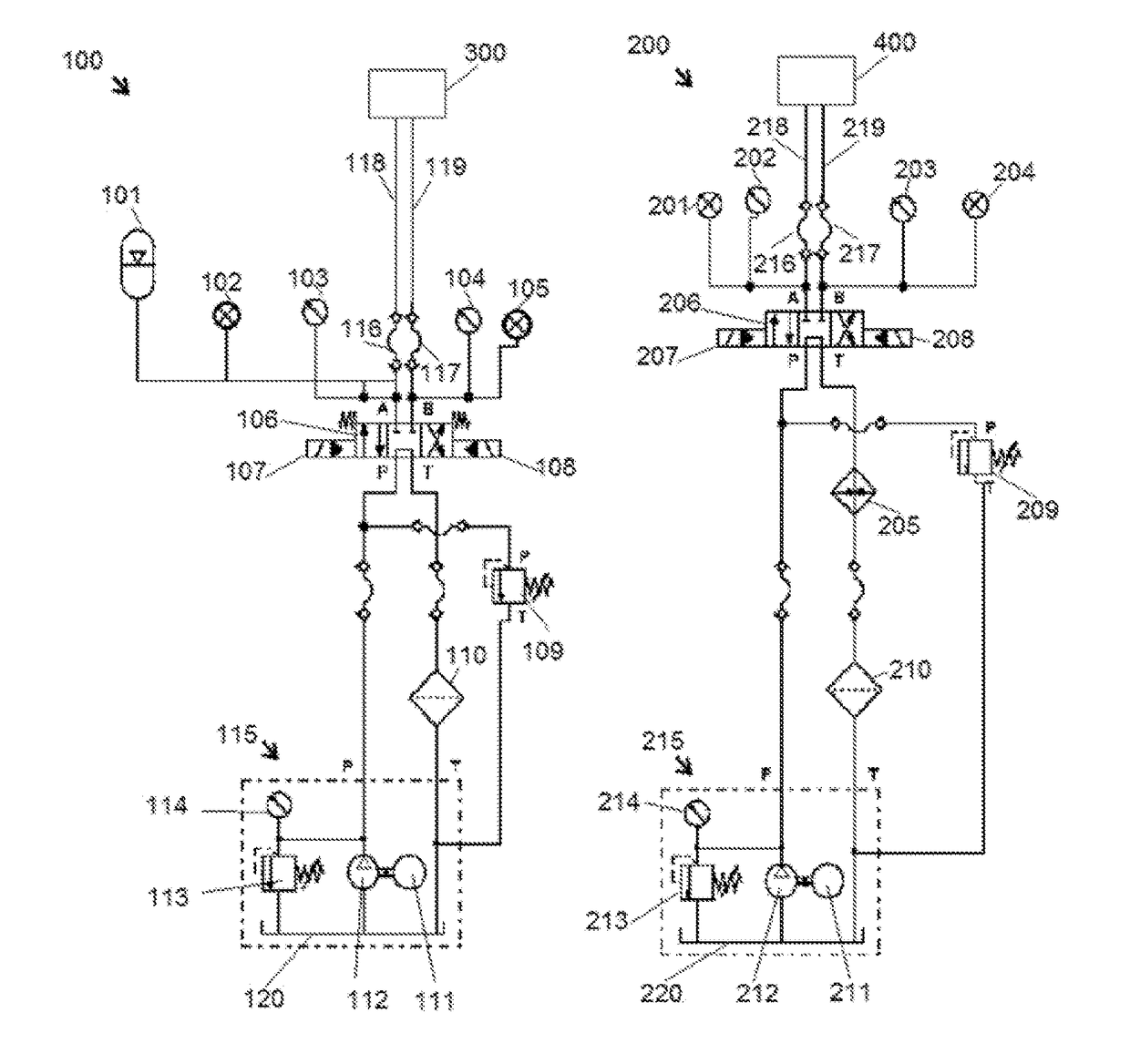

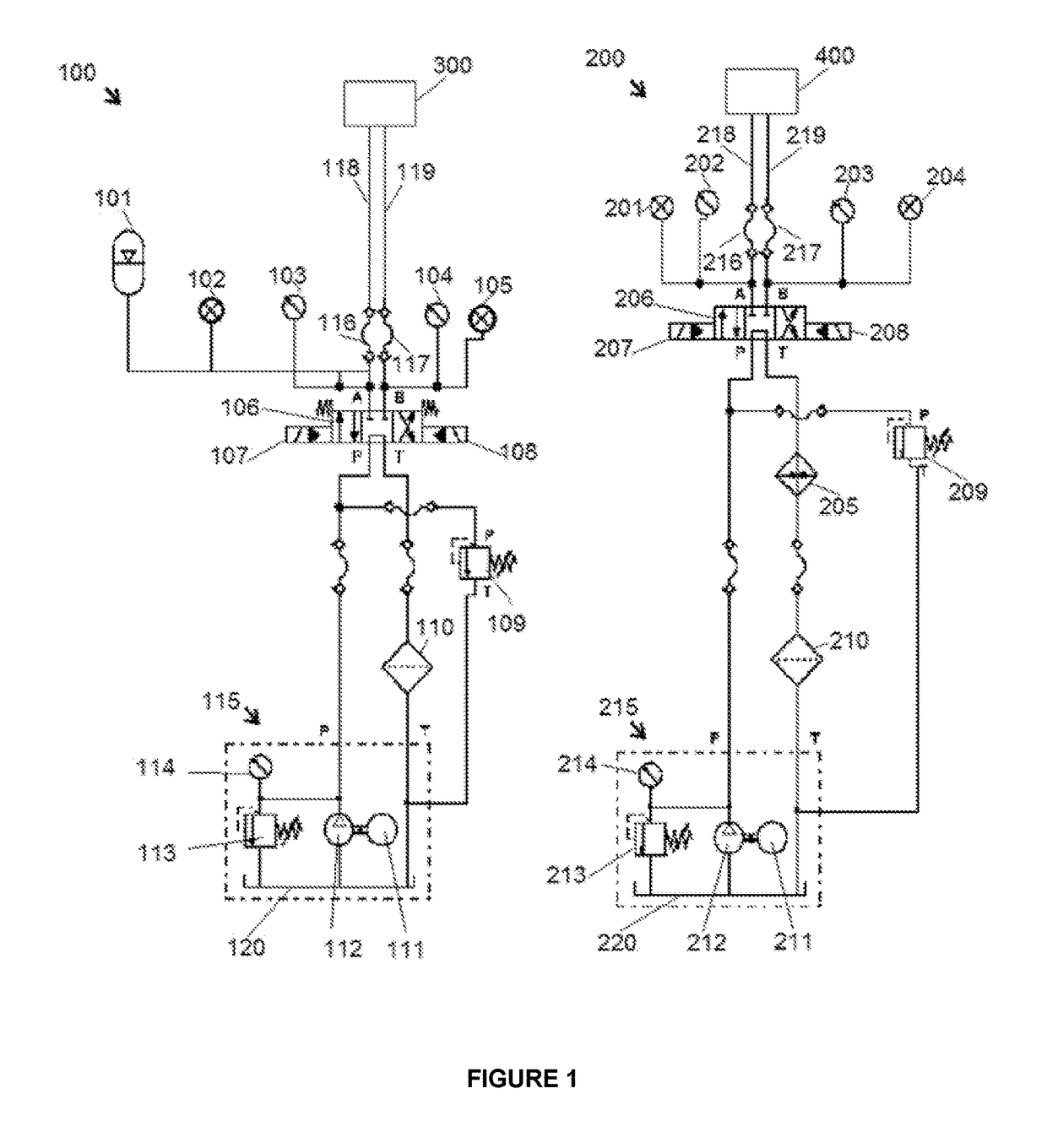

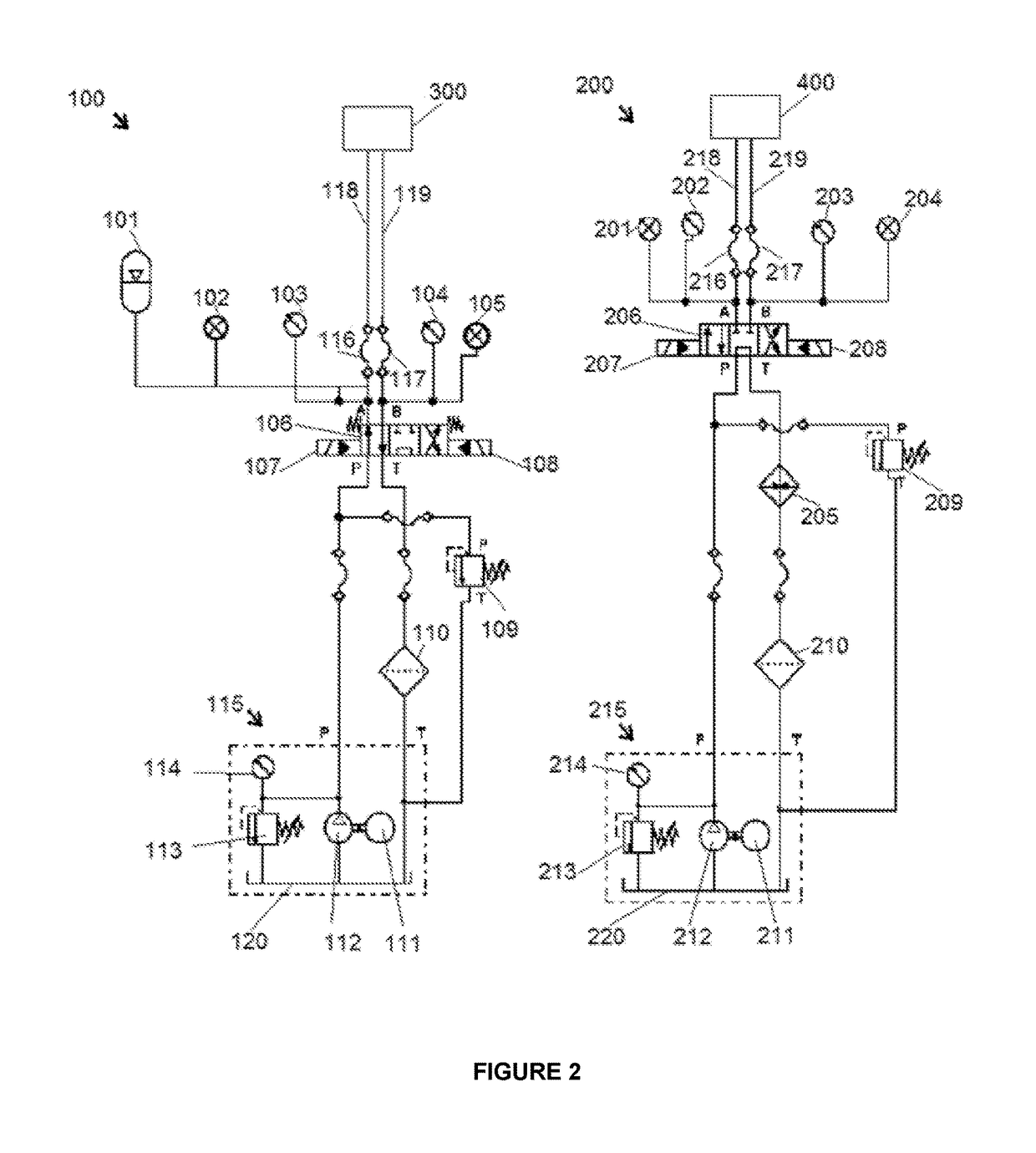

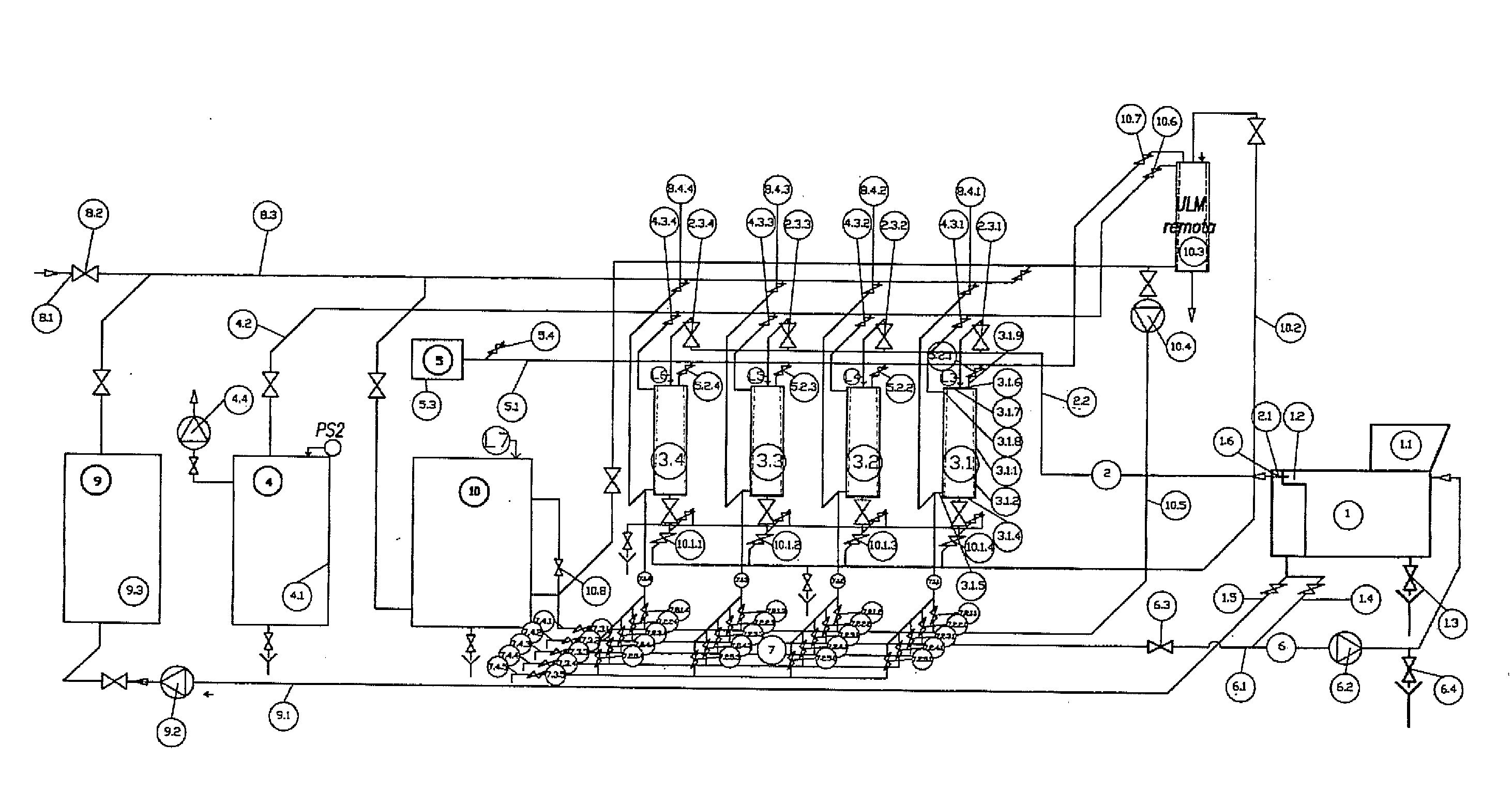

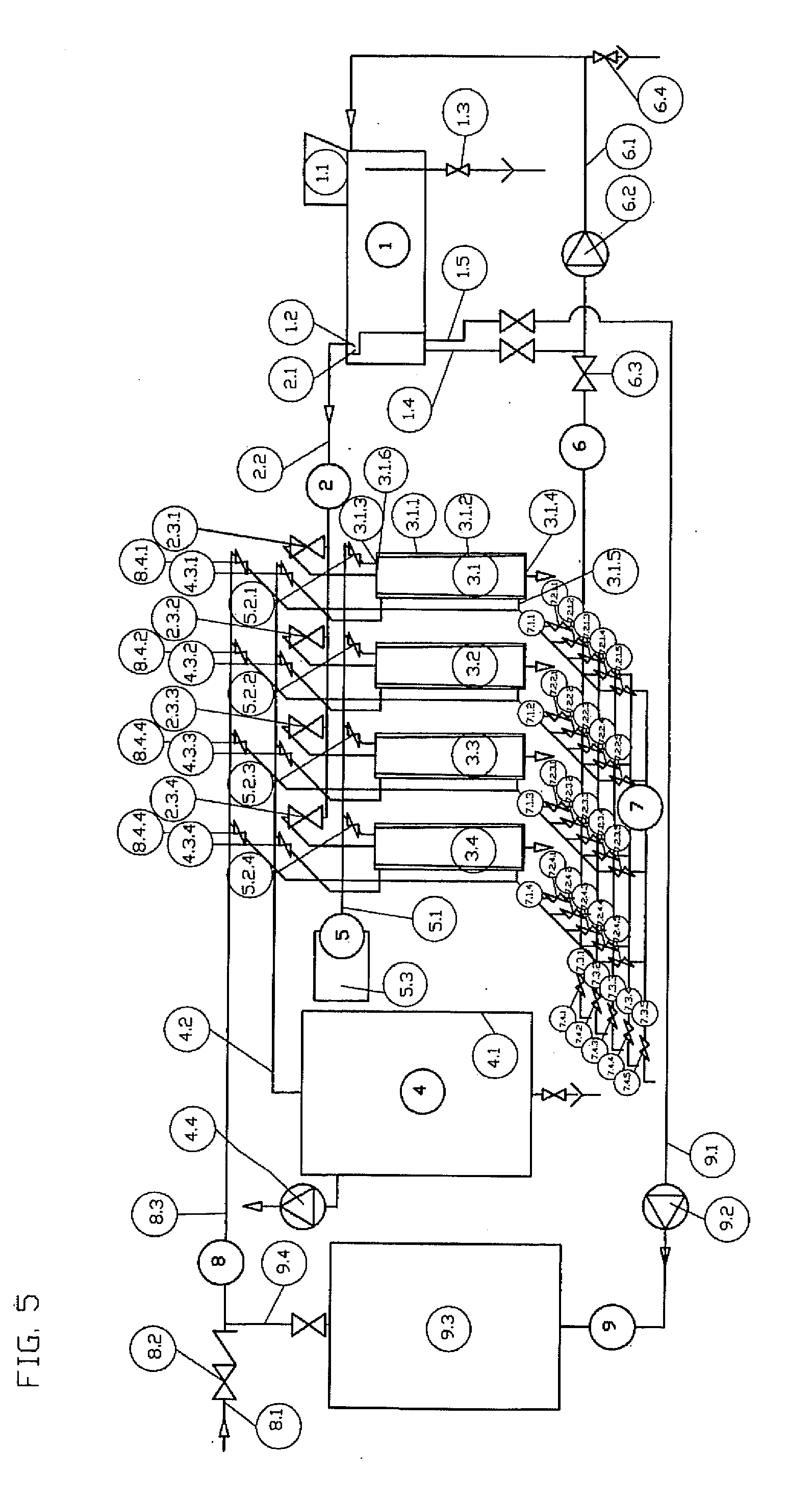

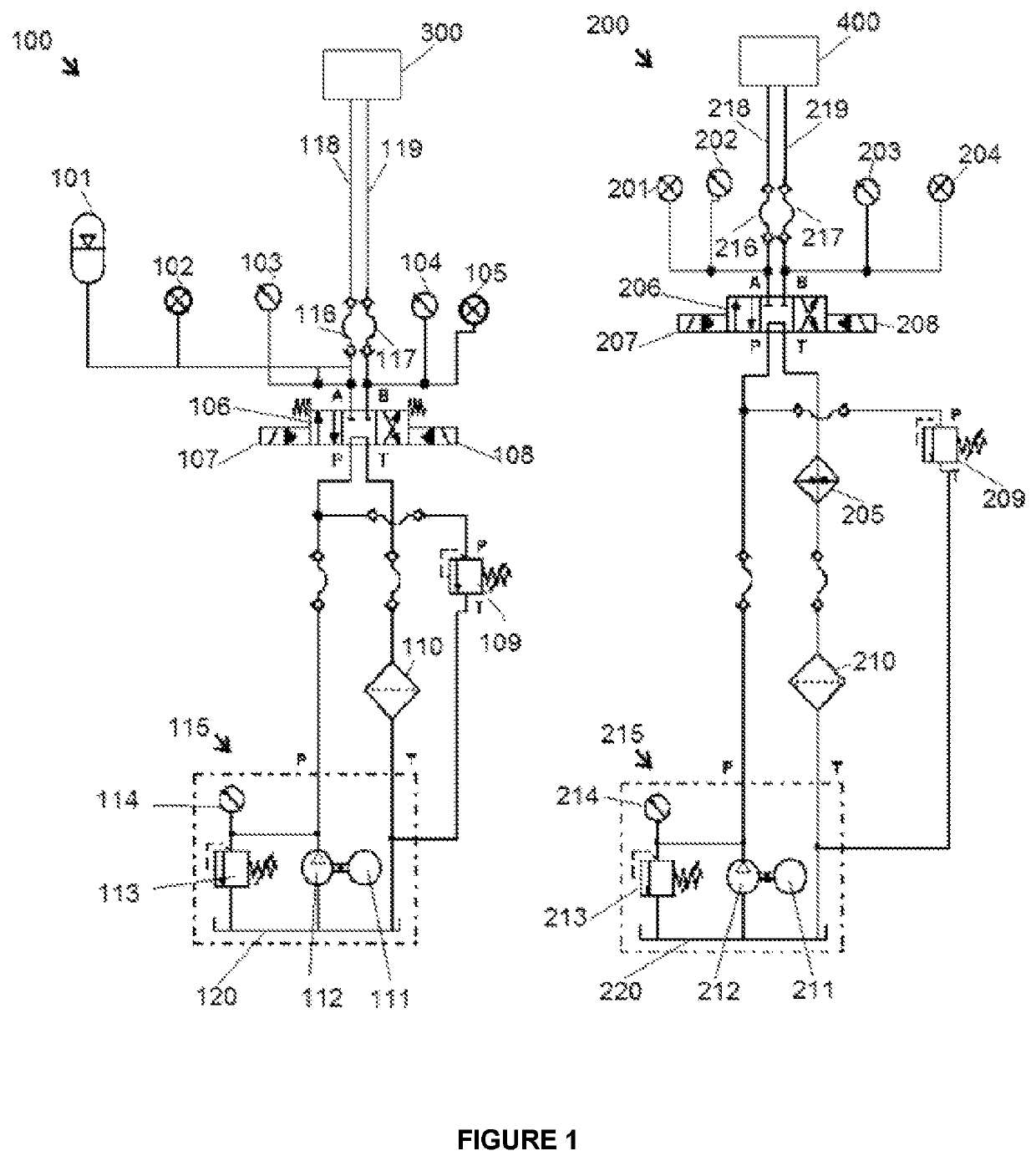

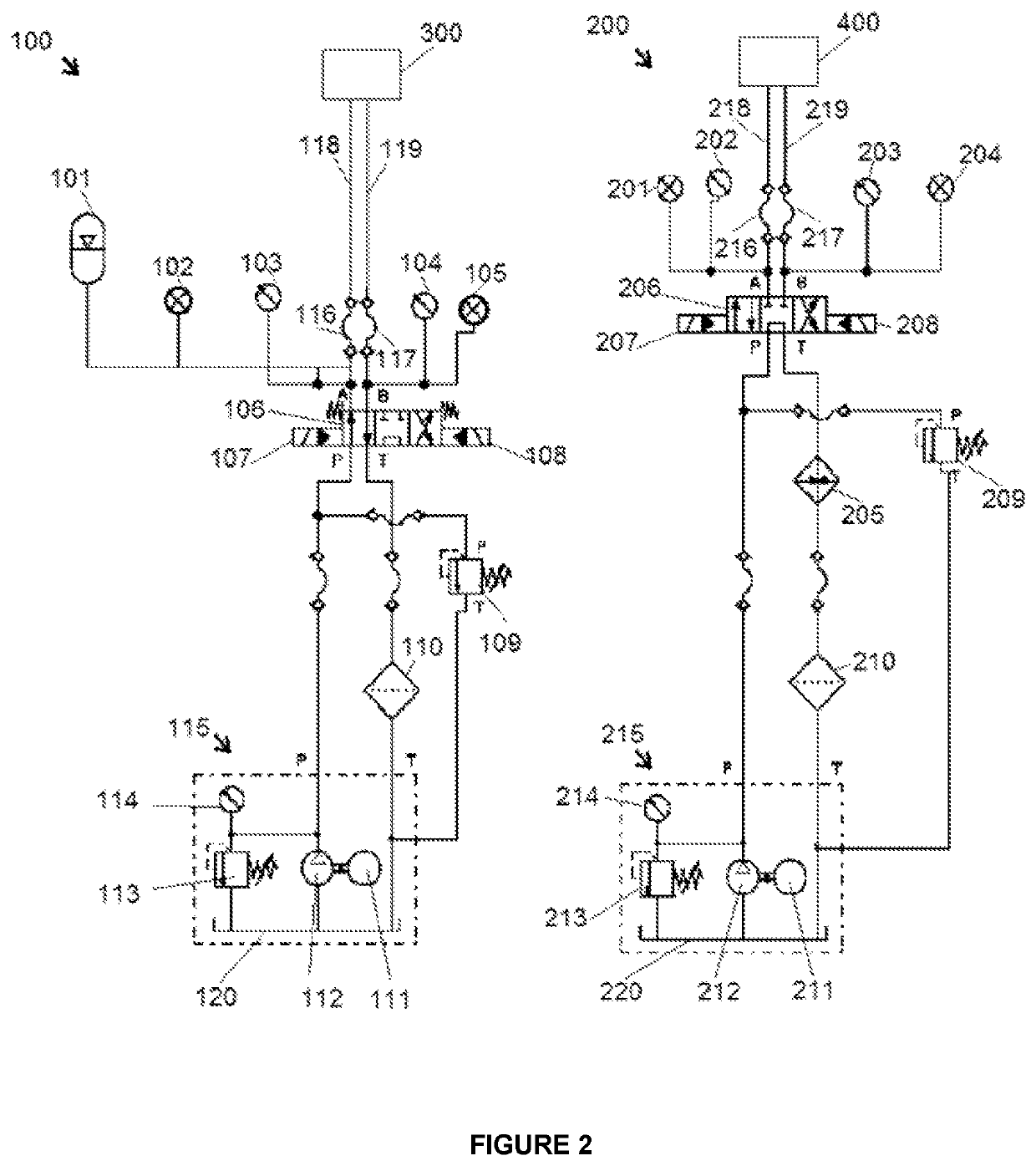

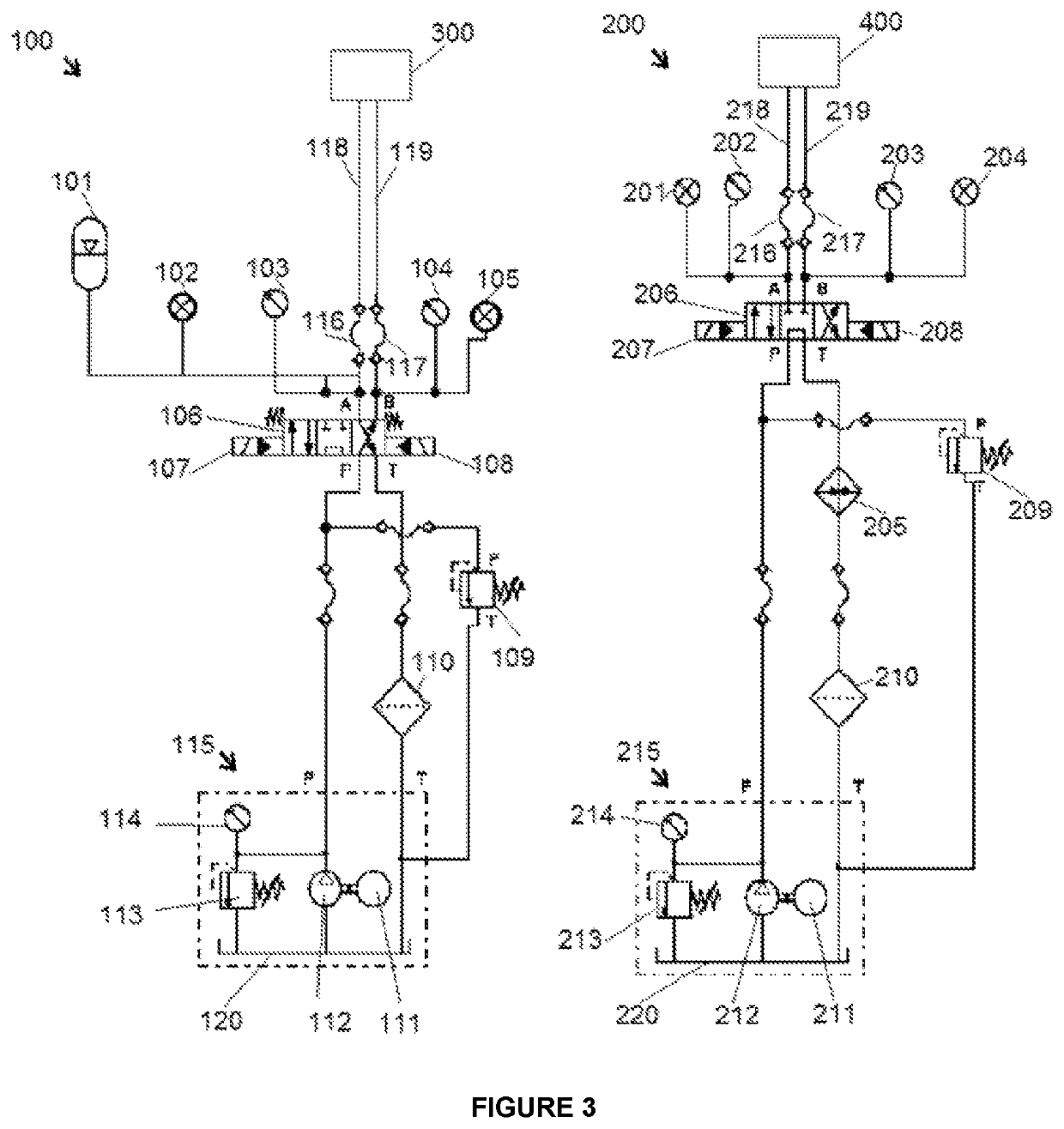

System and method for the diagnosis, evaluation and prediction of leakages in different hydraulic circuits, quickly and safely for the operator

Transportable system for the diagnosis, evaluation and prediction of leakages in hydraulic circuits of low pressure between 0 to 7 bar and of high pressure from 0 to 170 bar, quickly and safely for the operator is provided having a first independent circuit of high pressure and low flow and a second independent circuit of low pressure and high flow wherein the first independent circuit comprises: a first pressure subsystem, which delivers pressure to a first 4 / 3 valve with ports A, B, P and T, which is actuated by first solenoids, to deliver pressure to a first coupling A or to a first coupling B, in fluid communication with the ports A and B of the first 4 / 3 valve respectively a computer arranged to control the pressure of each pressure subsystem and associated method.

Owner:SOC RAMIREZ E HIJO LTDA

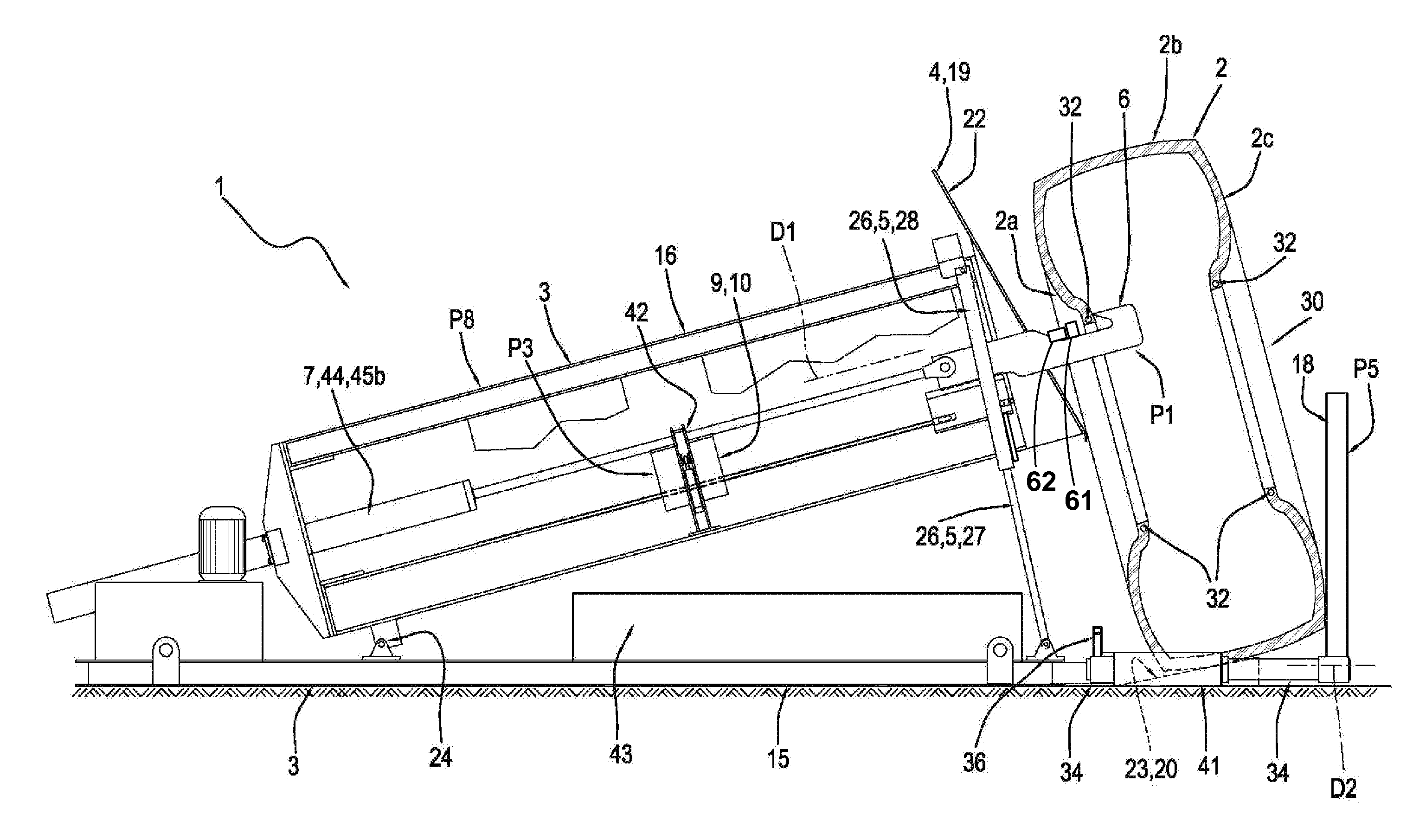

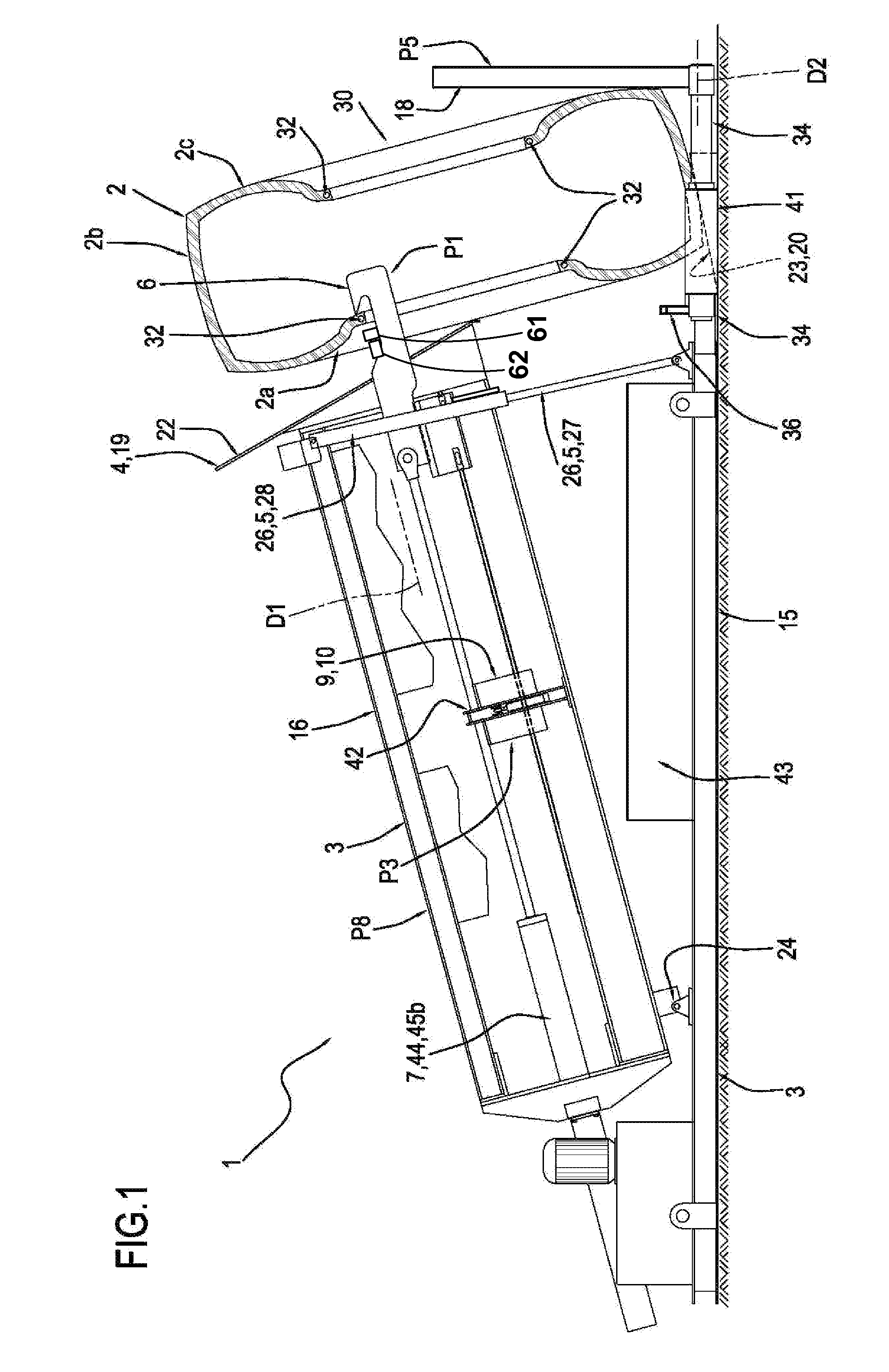

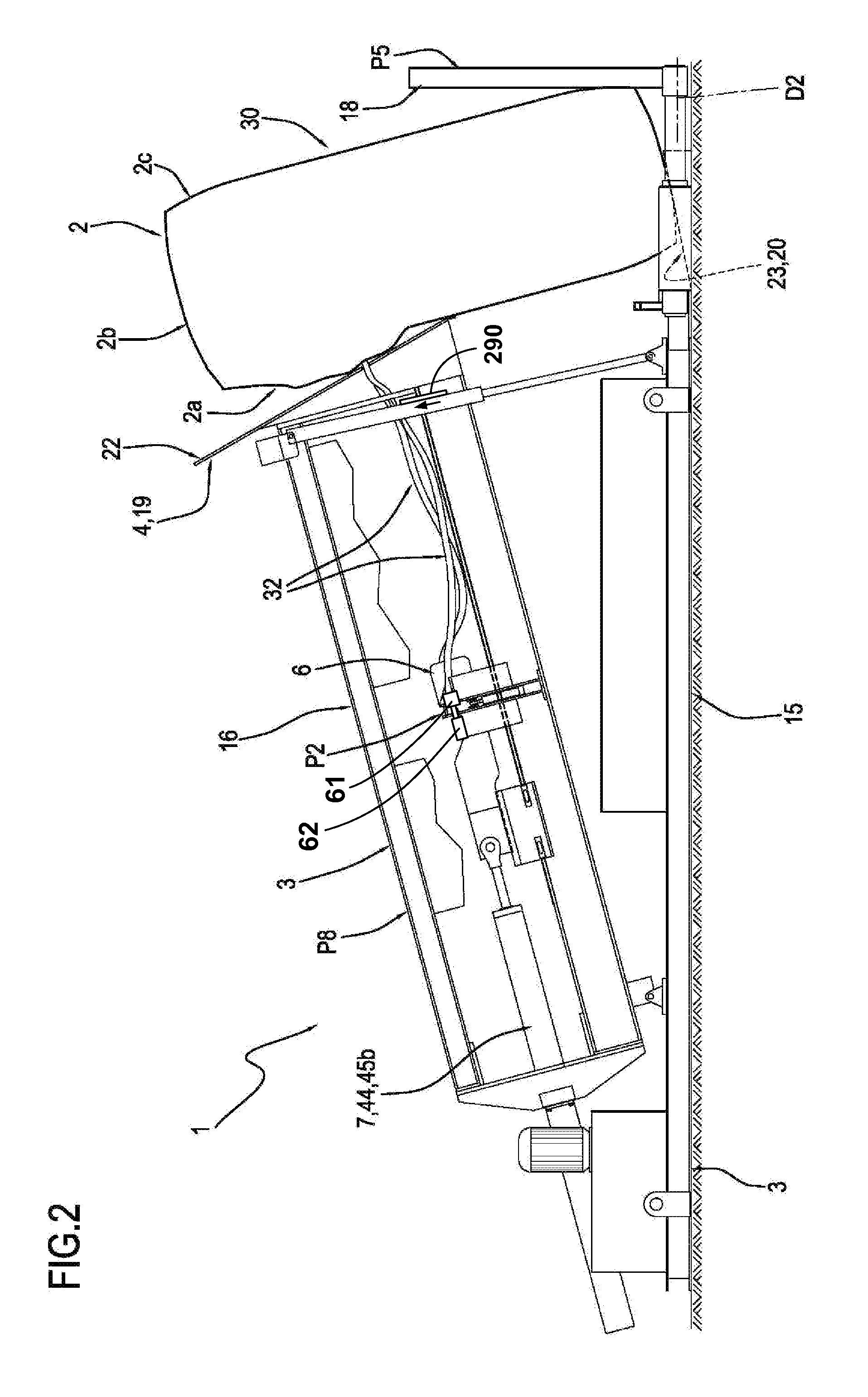

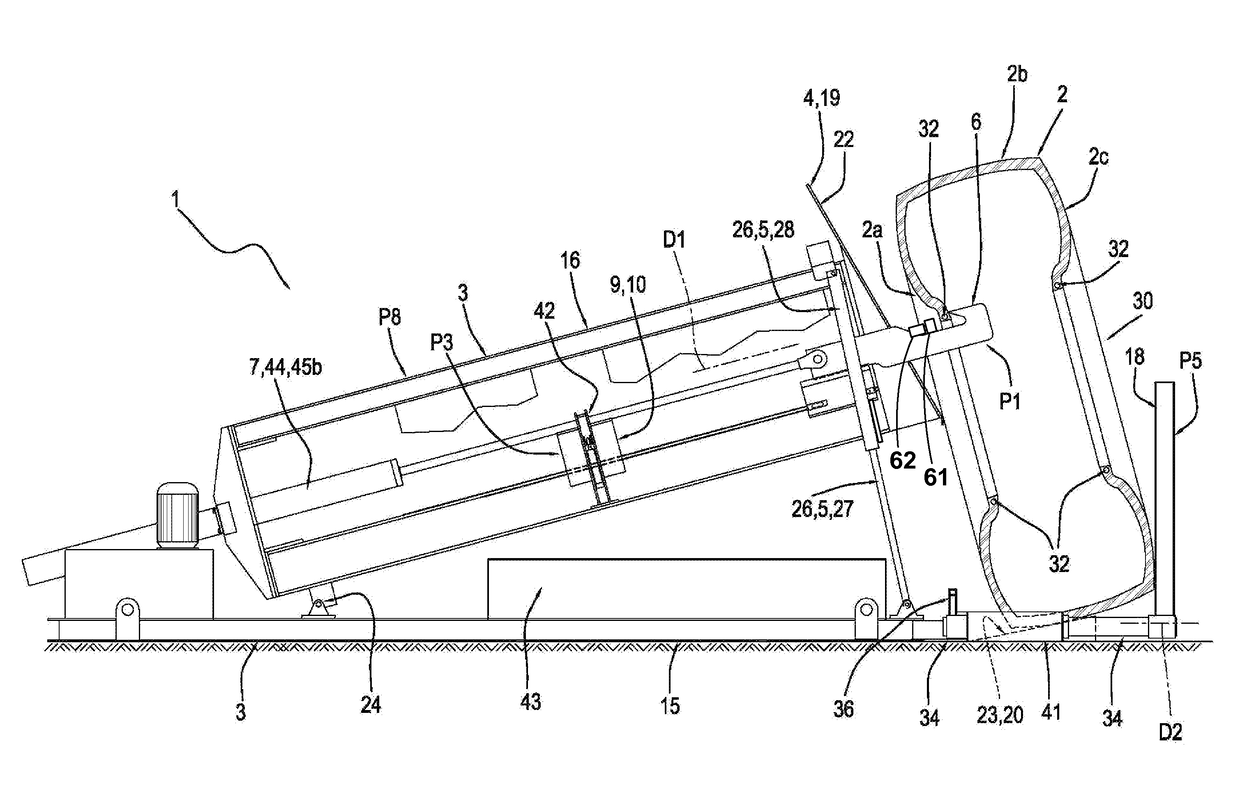

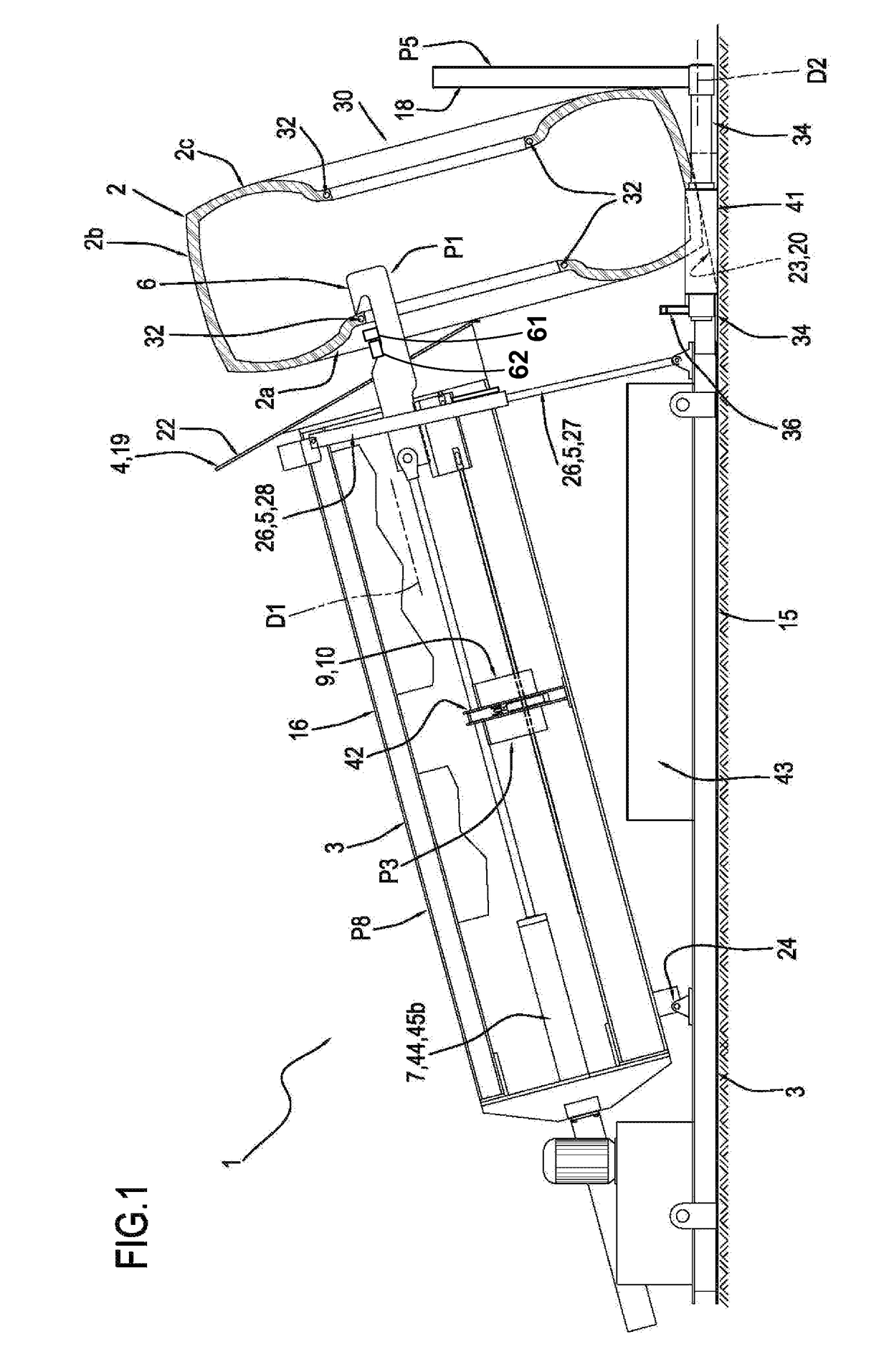

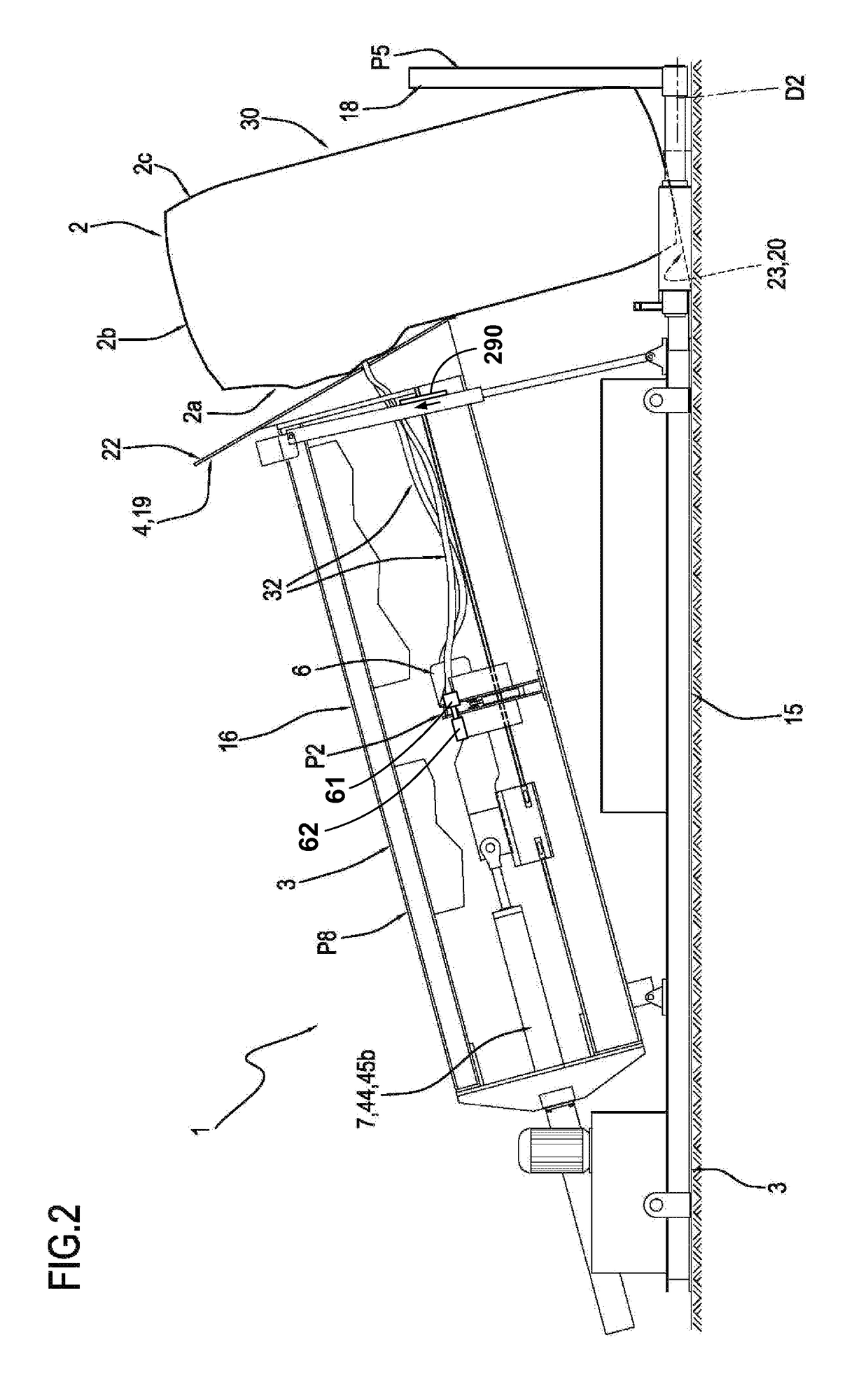

Machine and method for removing beads from tires at the end of life

ActiveUS20150290841A1Efficient extractionOperator safetyPlastic recyclingTyresCommand and controlMetallic materials

Machine for extracting a cord made of metal material from a sidewall of a tire, being part of the sidewall and defining a support structure of said tire, including: a frame; support means for the tire configured to support said tire resting on one sidewall in a loading zone; a hook for extracting said cord from the sidewall of the tire; means for manipulating said hook, configured to manipulate the hook with respect to the frame in an extraction direction between a position for engagement with said tire in the loading zone and a position for disengagement from said tire and extraction of said cord; a command and control unit to command said means for manipulating the hook,:an element able to move with respect to the frame to detach the cord from the hook when the hook is in position for disengagement;and means for manipulating the movable element, to manipulate the movable element from a first position to a second position to carry out releasing of the cord from the hook.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

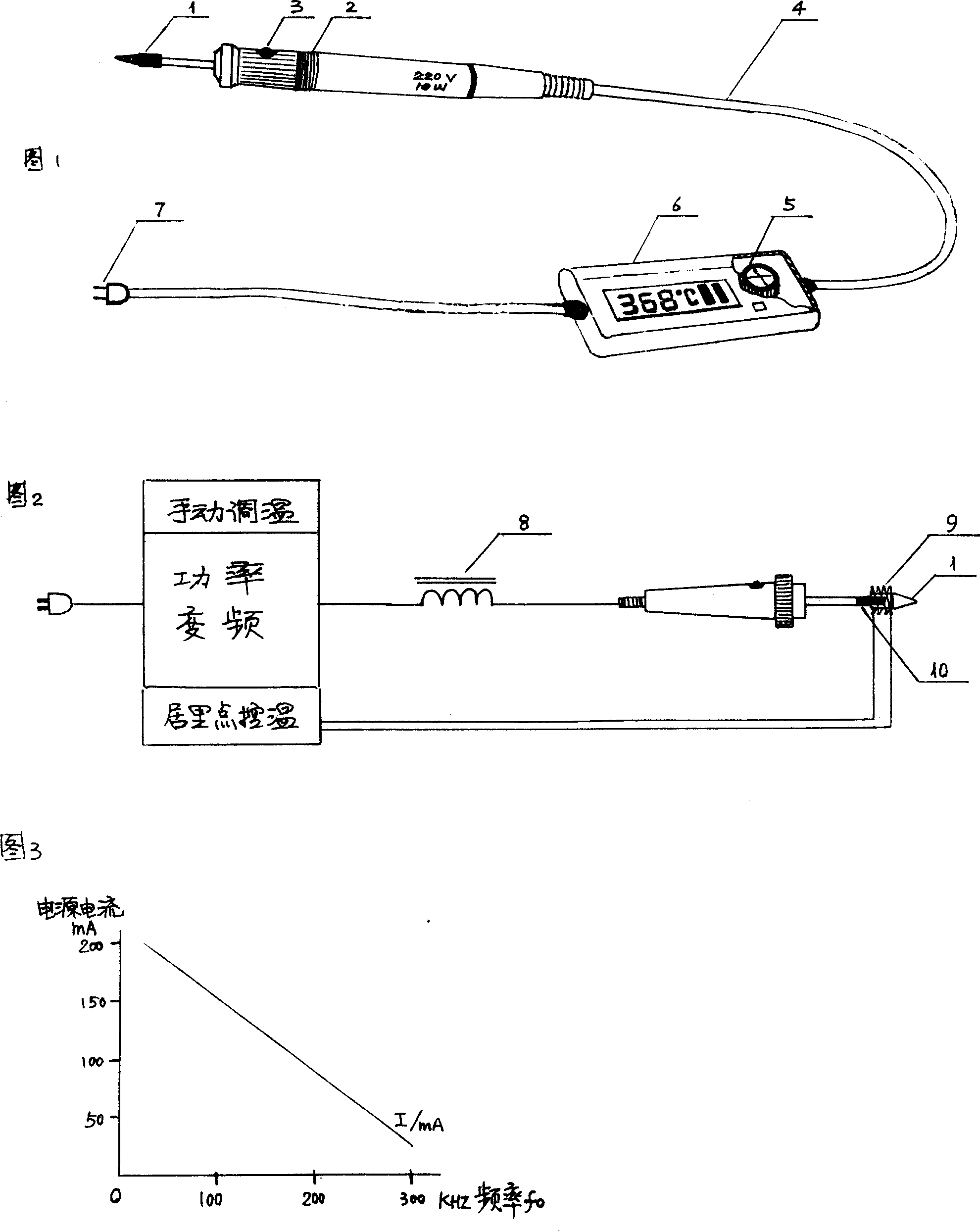

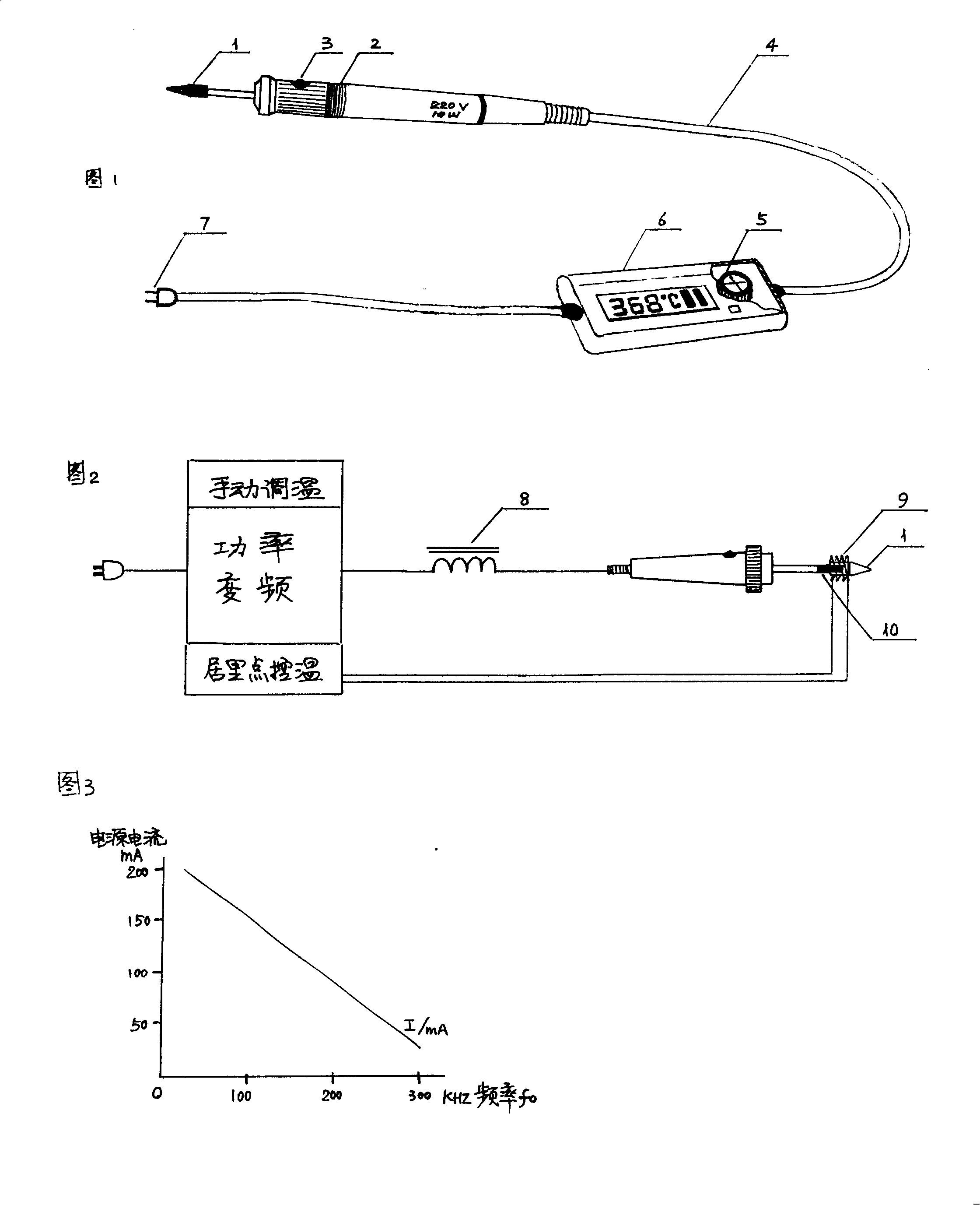

Variable frequency rapid electric iron

InactiveCN1935436AImprove thermal efficiencyHigh and low thermal efficiencySoldering ironTemperature controlTransformer

The present invention relates to a variable frequency quick electric soldering iron which need not be preheated or be heat-insalated, and can quickly heat to the 360 deg.C for milting soldering tin from room temperature within 2-6 Sec. and can be quickly cooled to room temperature when it is not used. It is characterized by that said invention adopts integrated circuit chip or semiconductor to make frequency change and temperature regulation, and adopts Curie point magnetic torque lattice physical temperature control sensing technique and amorphous nano alloy high-frequency transformer so as to change the traditional 50H2 electric soldering table into the invented electric soldering iron which can be worked under the 1000 H2 to 1200KH2 frequency.

Owner:徐小羚

Method and equipment for the washing against current, for the transportation and the physical/chemical treatment of vegetables and fruits, in a restricted environment, with high water and energy efficiency

ActiveUS20110048466A1Easy to operateMinimal labor costClimate change adaptationCleaning using liquidsWater useChemical treatment

The technology of washing and treatment MWU (modular washing unit) is conceived to wash and treat fruits and vegetables in a confined environment, with progressively more and more clean water (counter-current) and with an optimal ratio between the quantities of water used and processed products. The system allows important savings of water, chemicals and energy. The technology of washing and treatment MWU (modular washing unit) is conceived to allow the transport and the treatment of the product in confined environment, with clean water (counter-current) In the MWU the product is submitted to sequence of filling and emptying with appropriated solutions, progressively cleaner, prior to subsequent discretionary treatments. A treatment plant can be equipped with a variable number of MWUs, with additional remote MWUs to meet the desired production capacity. Each MWU consists of a vertical watertight cylinder containing a concetric basket; on the top it is connected to the main product manifold and to the vacuum collector, and at the bottom it is connected to the product drain collector, to the load / unload manifold and to the fluids recycling manifolds. Each MWU is connected to the other MWU of the plant, and to the external tank, through independent manifolds, by appropriate valves, to prevent the mixing of fluids and the cross-contamination.

Owner:TURATTI S R I

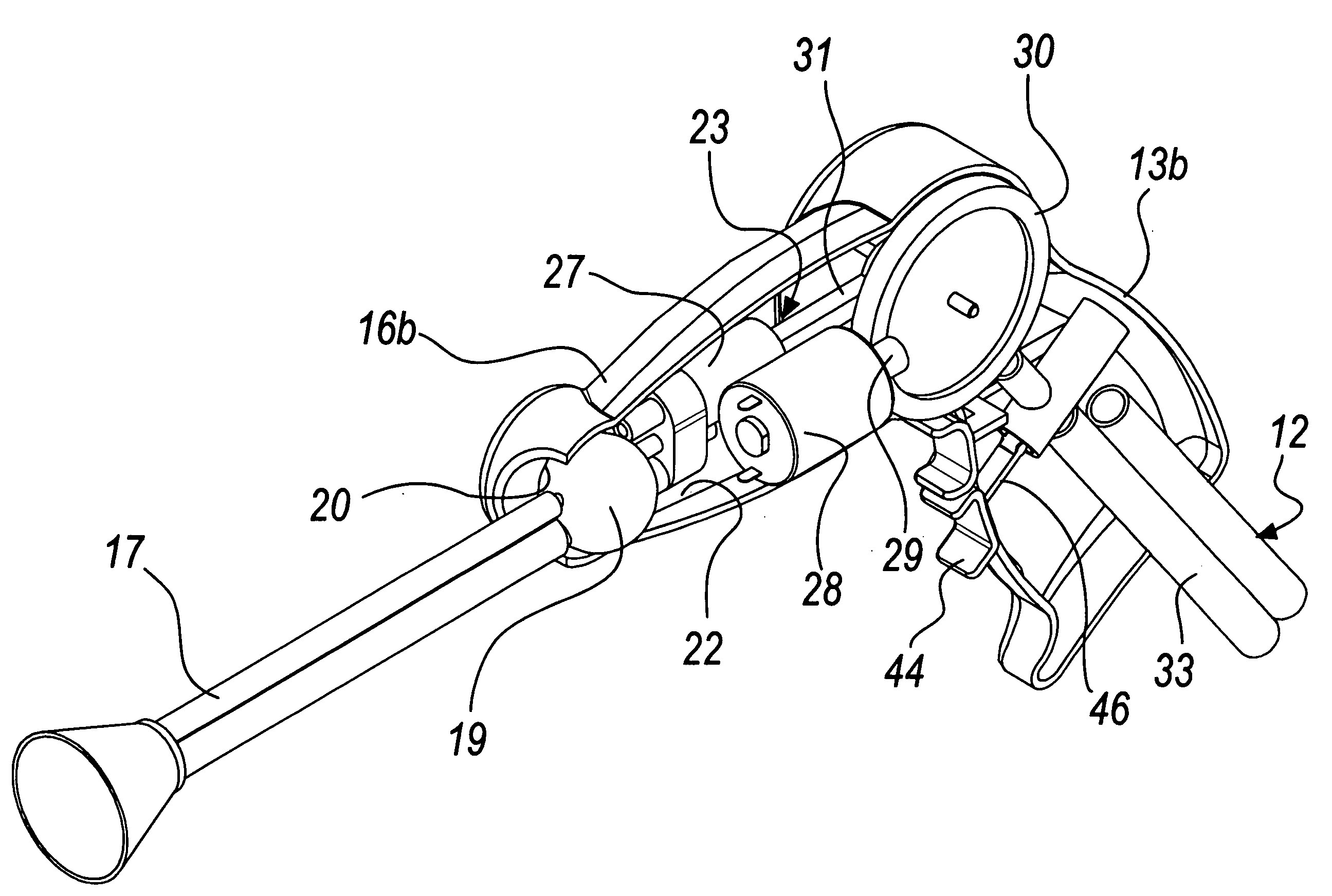

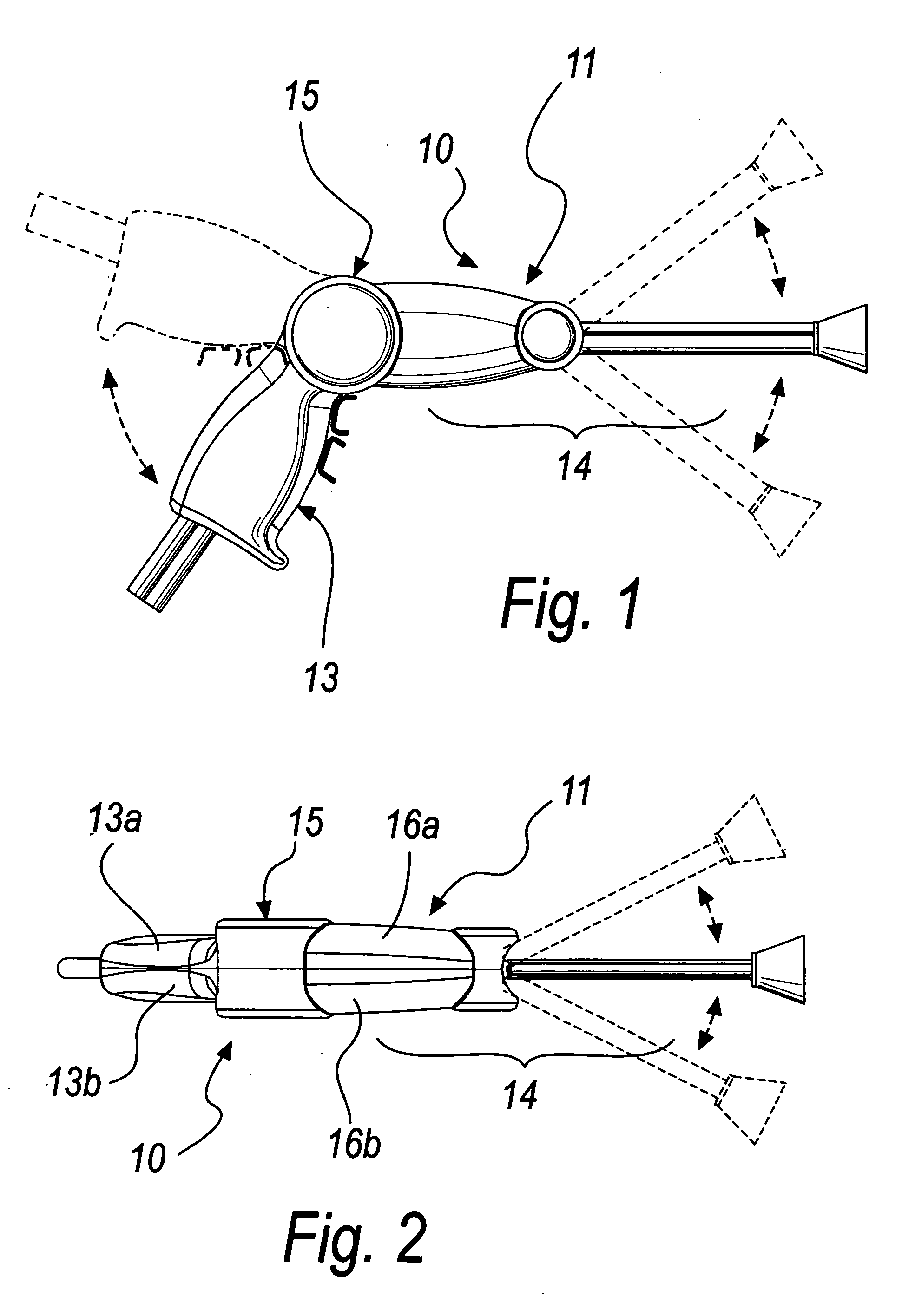

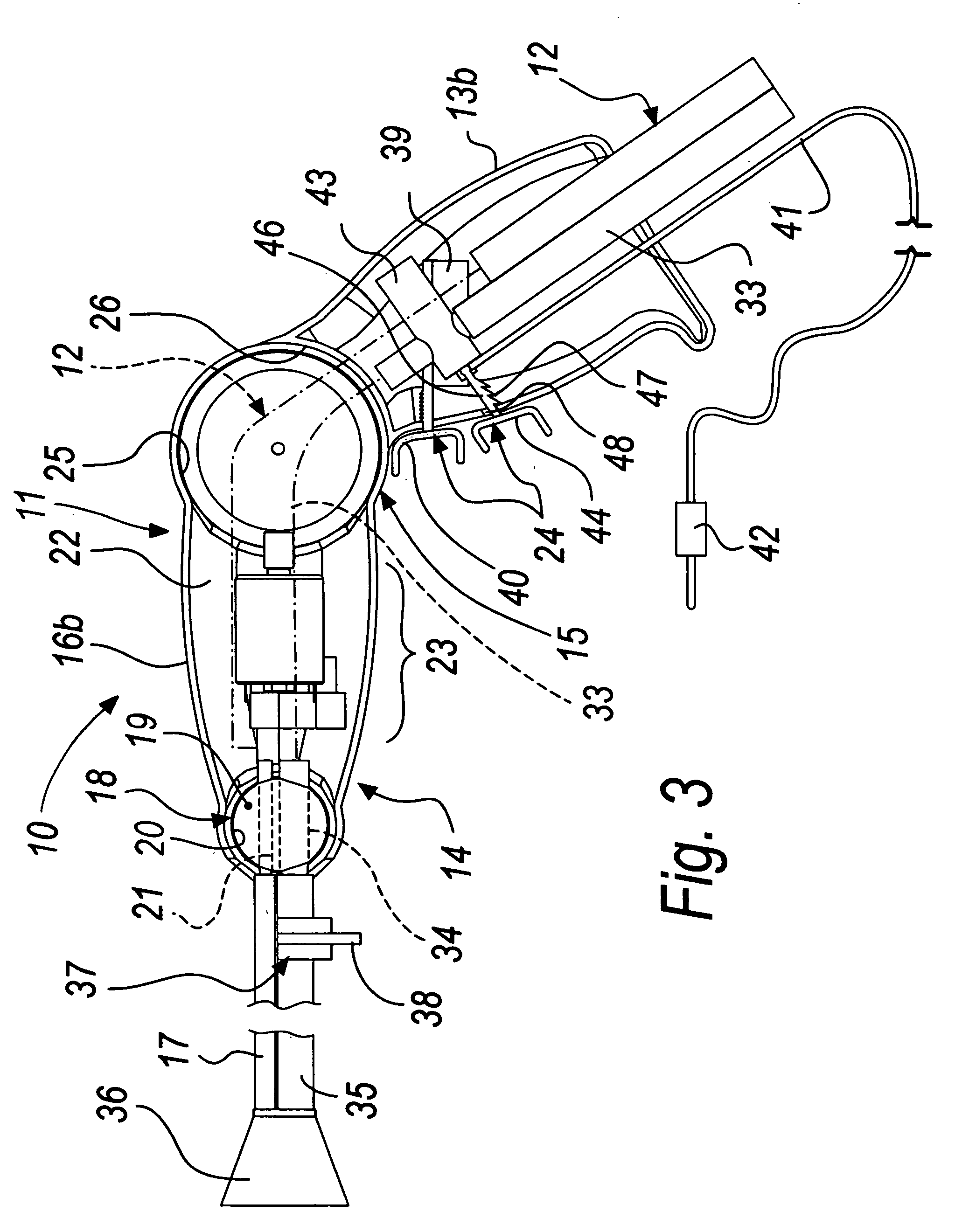

Surgical irrigator

InactiveUS20080319379A1Certain flexibilityEasy to handleIntravenous devicesSuction irrigation systemsTransformerEngineering

A surgical irrigator for washing body regions subjected to a procedure, provided with a containment shell inside which there are elements for supplying a washing liquid that arrives from an associable reservoir, such containment shell being constituted substantially by two distinct portions, respectively a grip portion for the hand of the user and a portion for ejecting the washing liquid toward the region to be washed, wherein the irrigator is powered by a transformer connected to the mains.

Owner:BIDOIA S DI GIANFRANCO BIDOIA E C

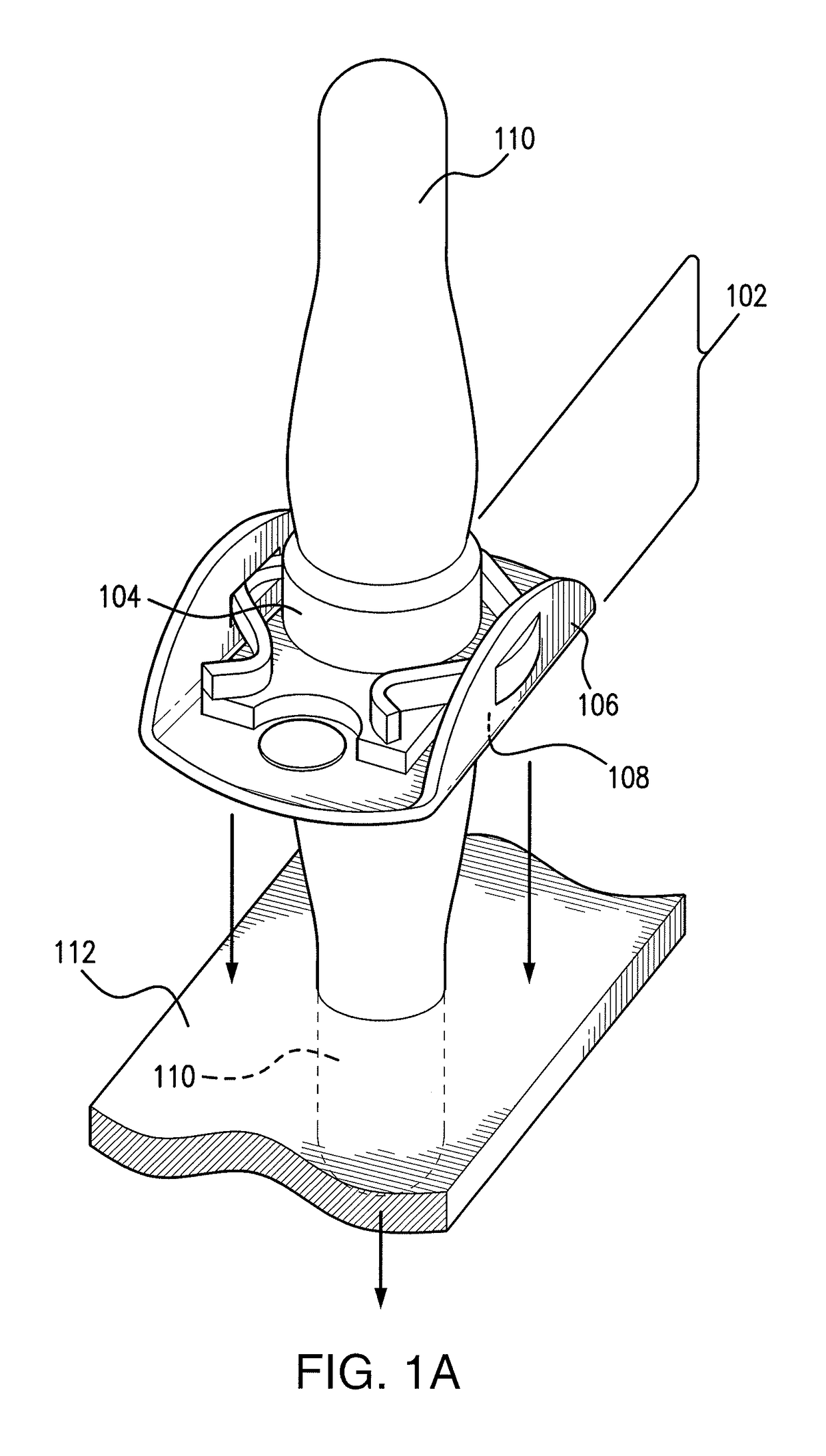

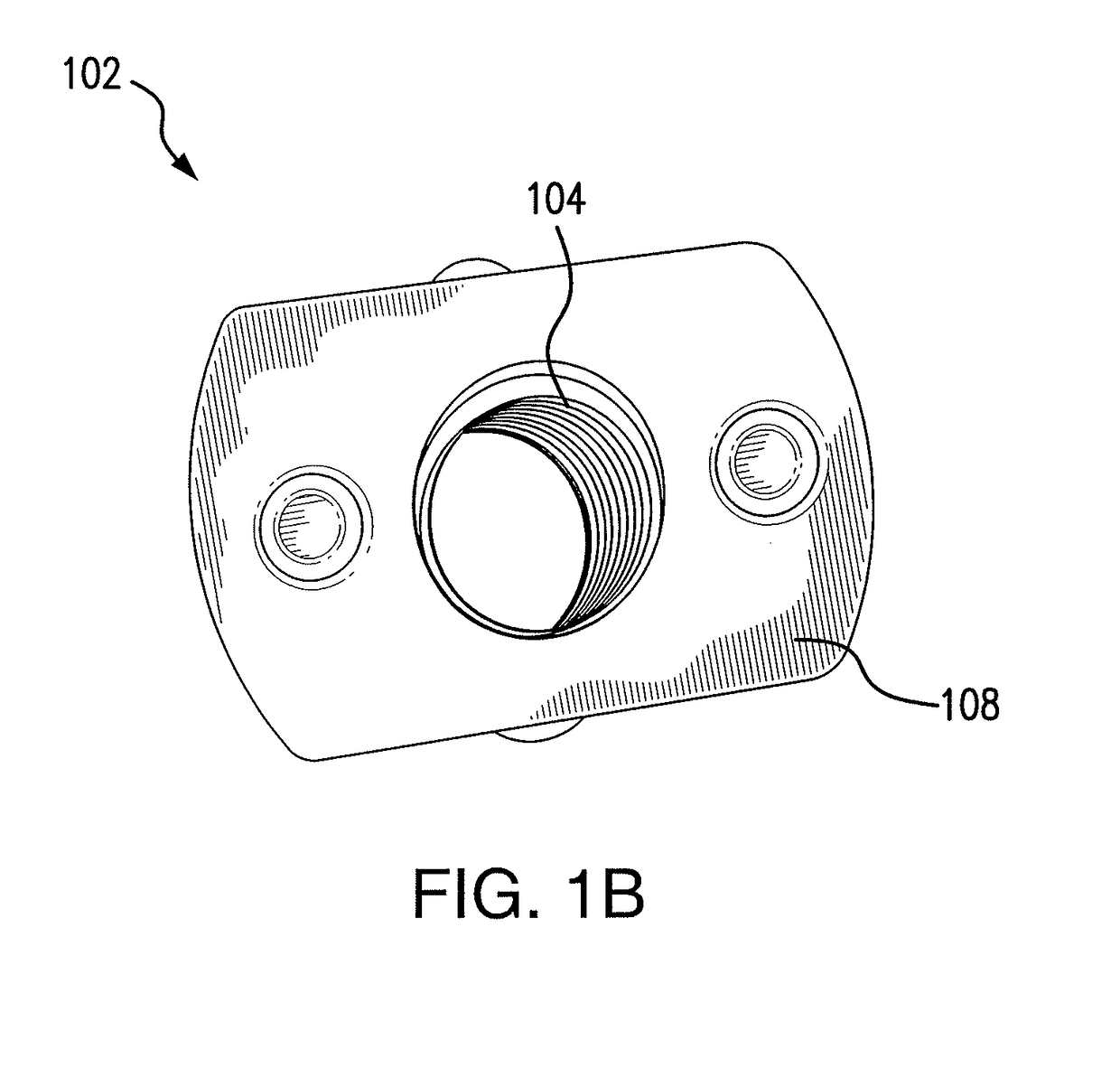

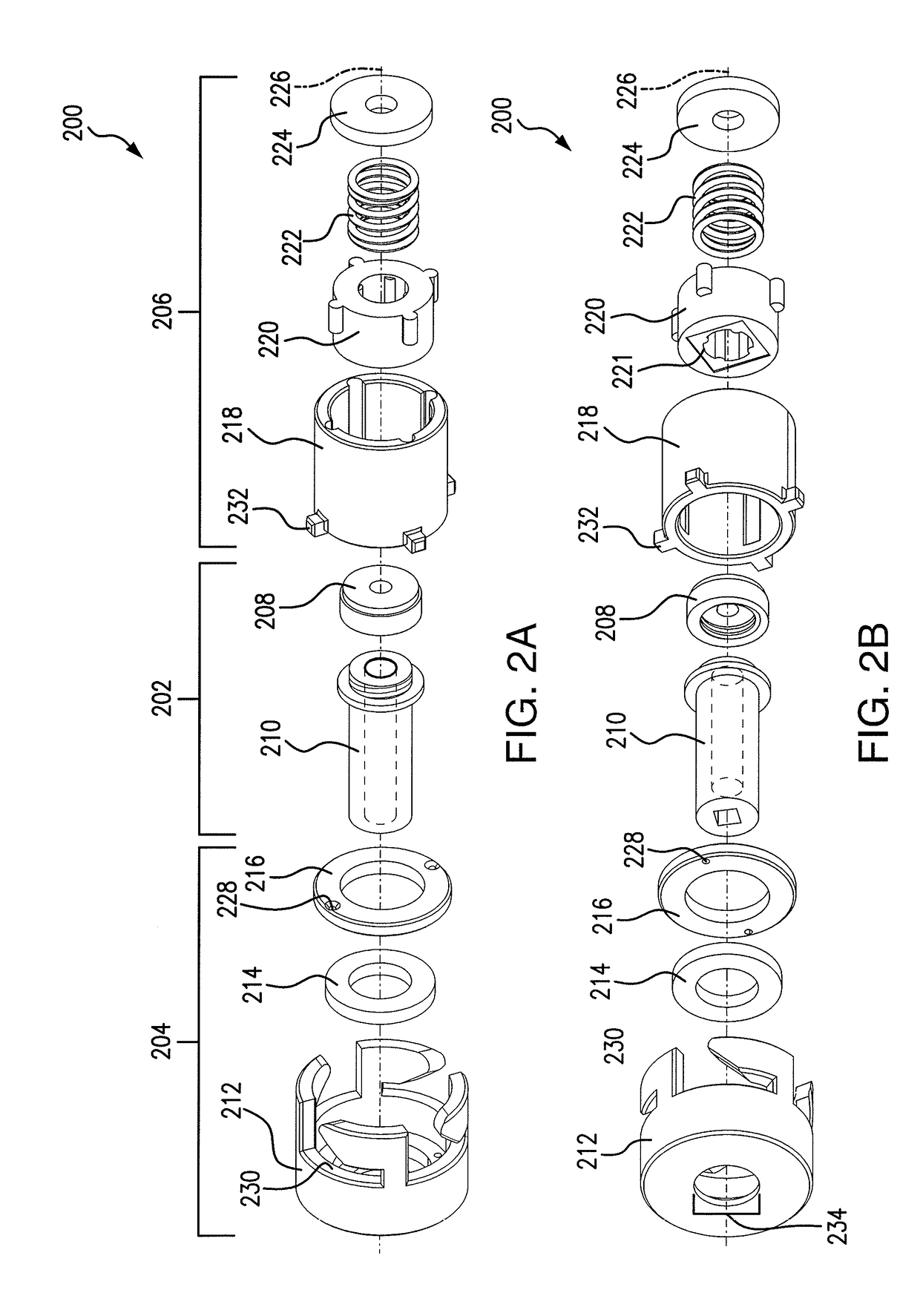

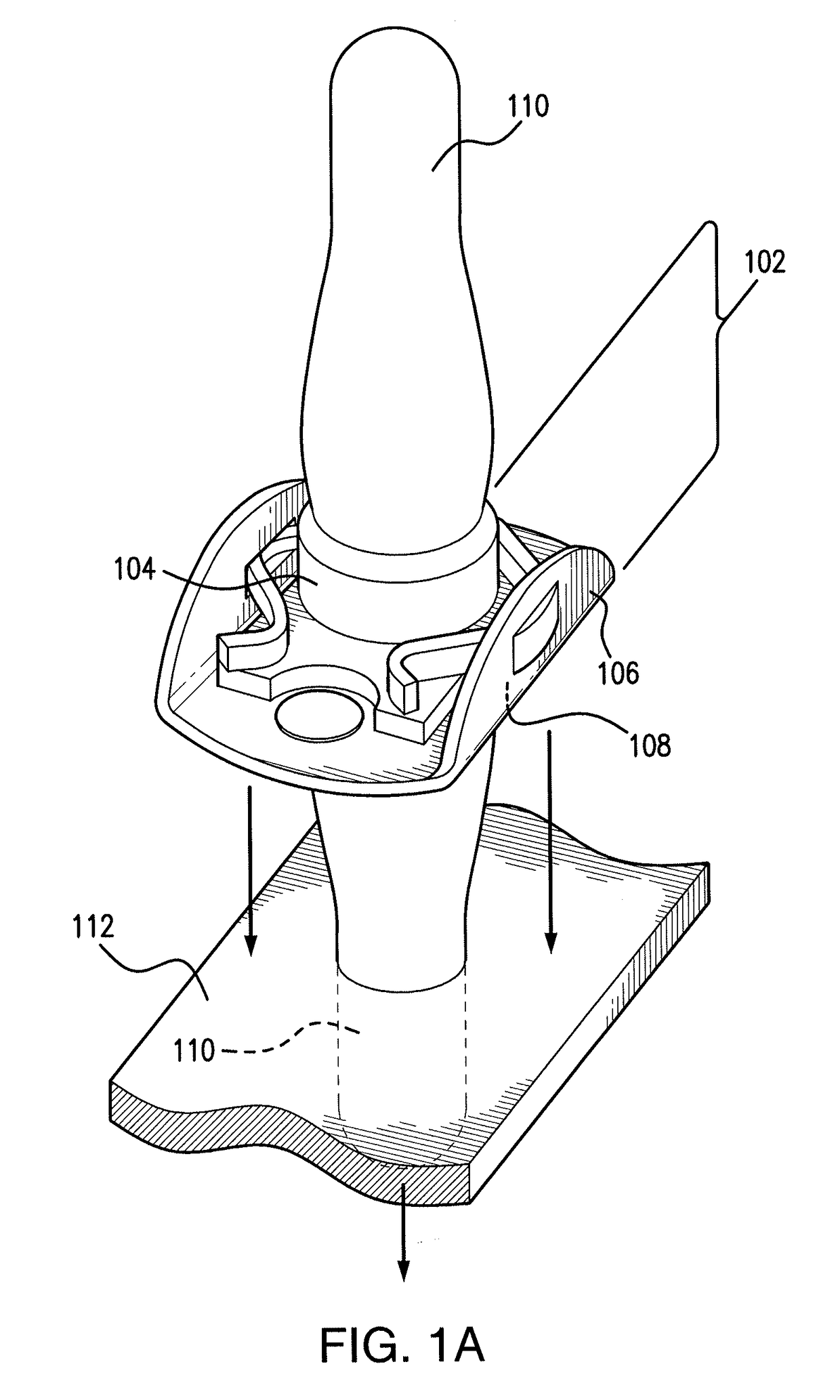

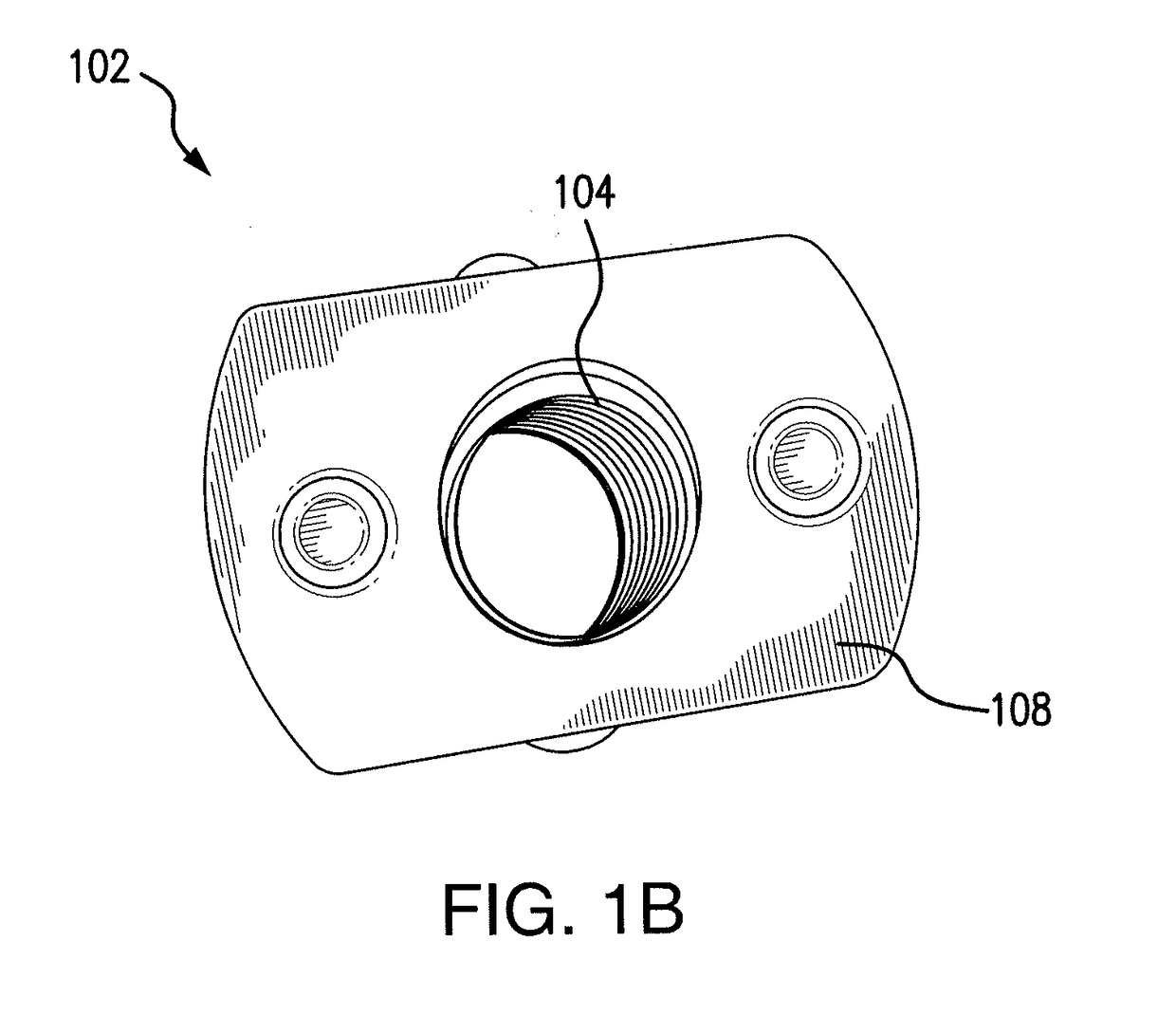

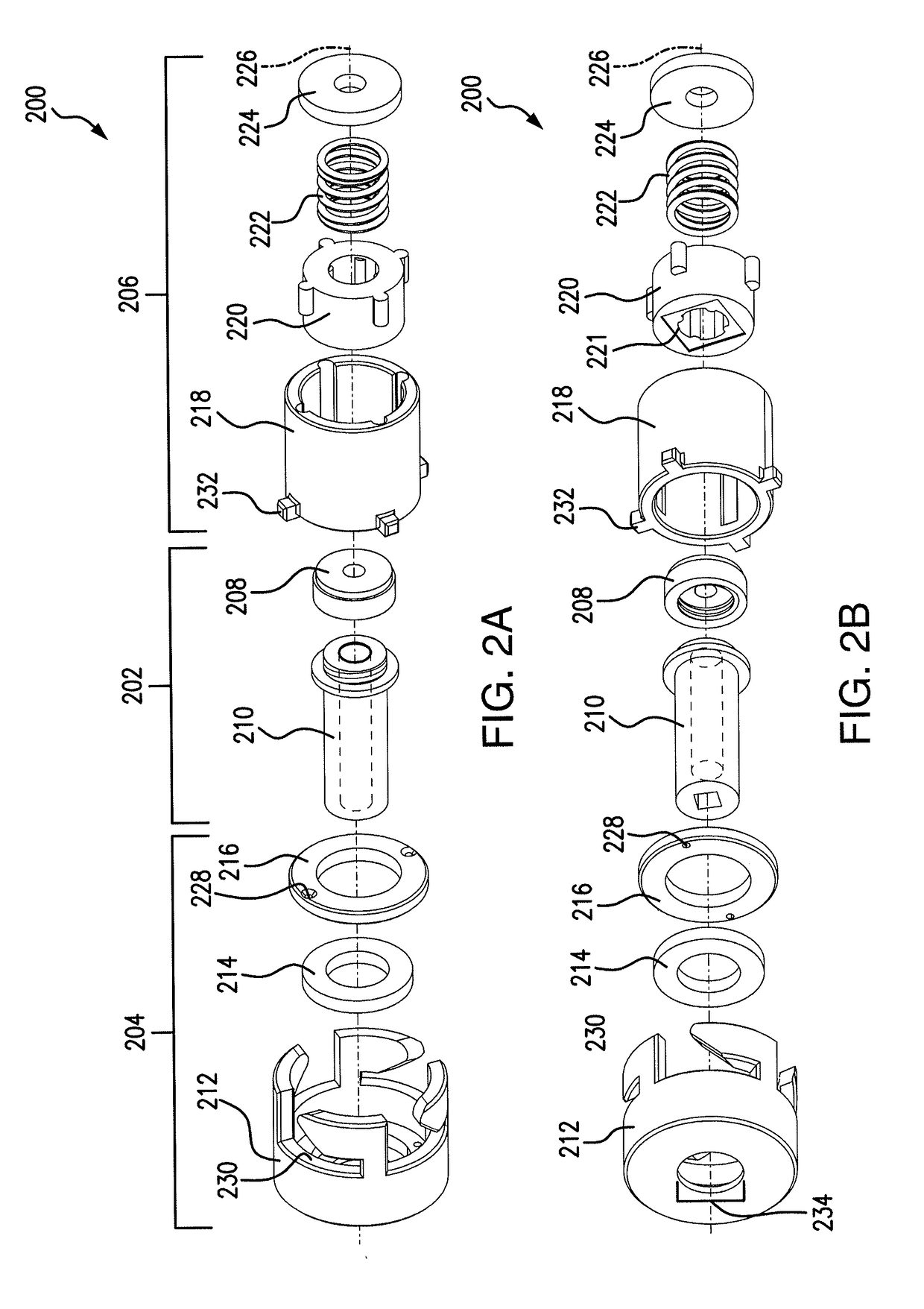

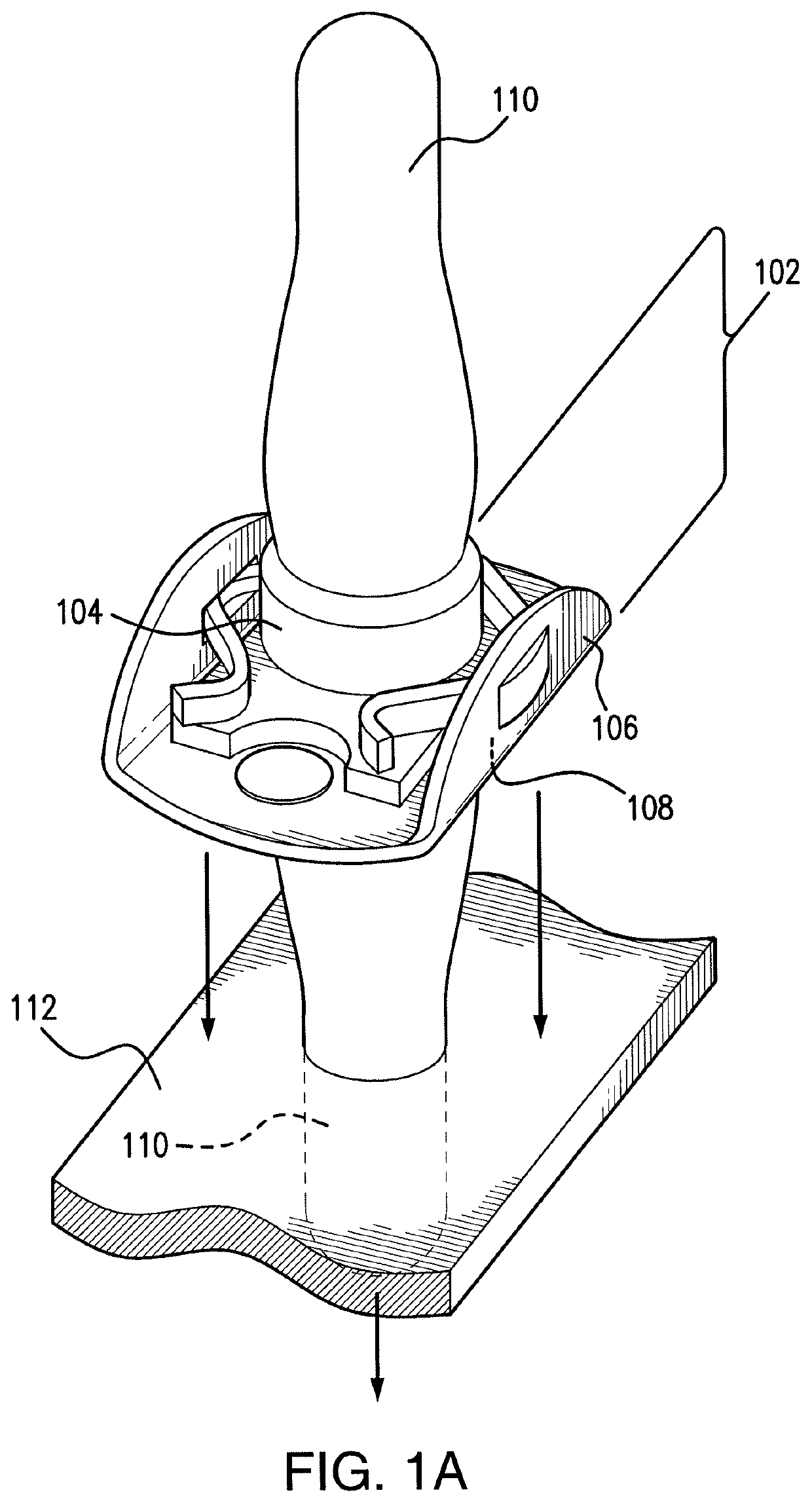

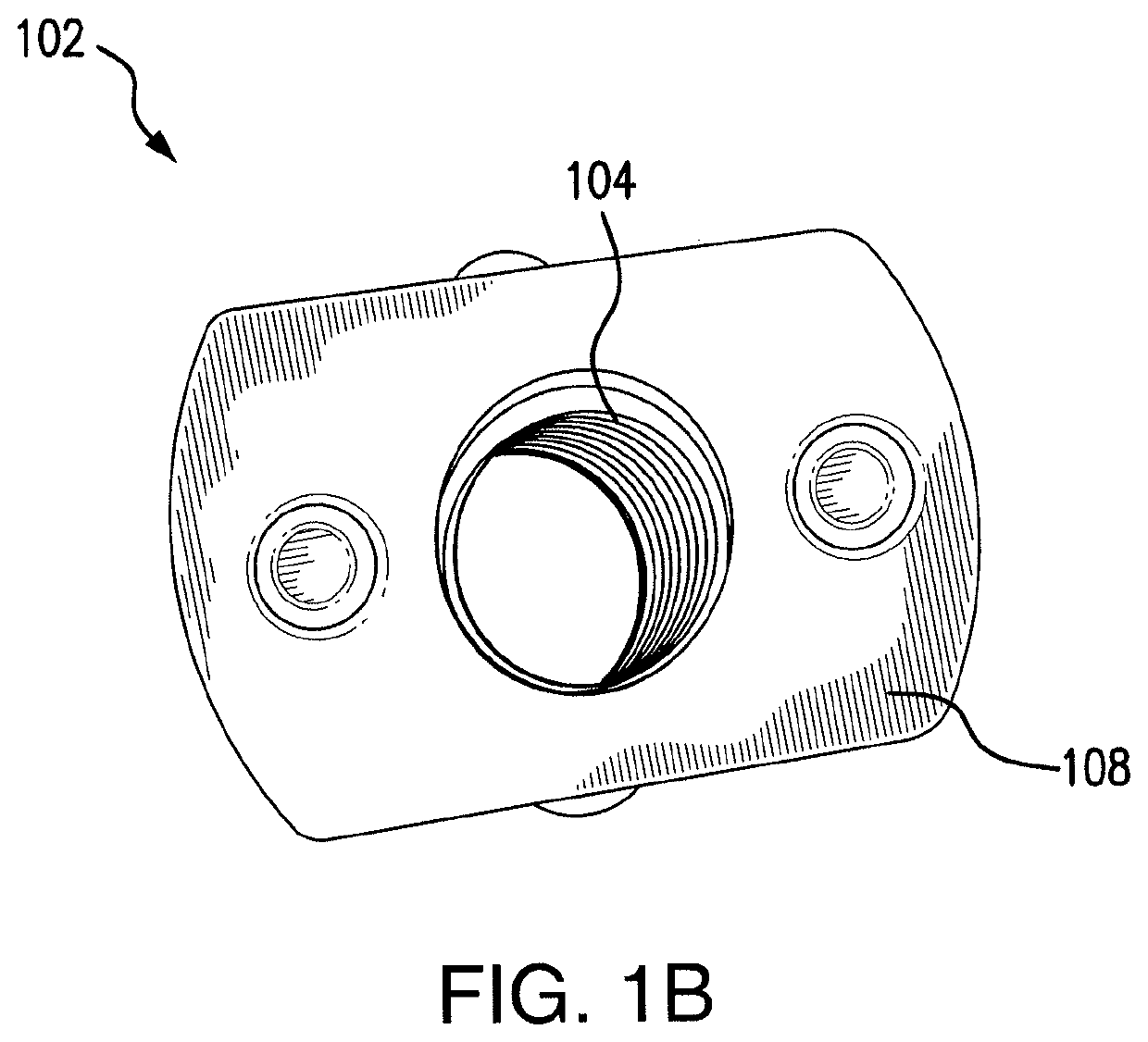

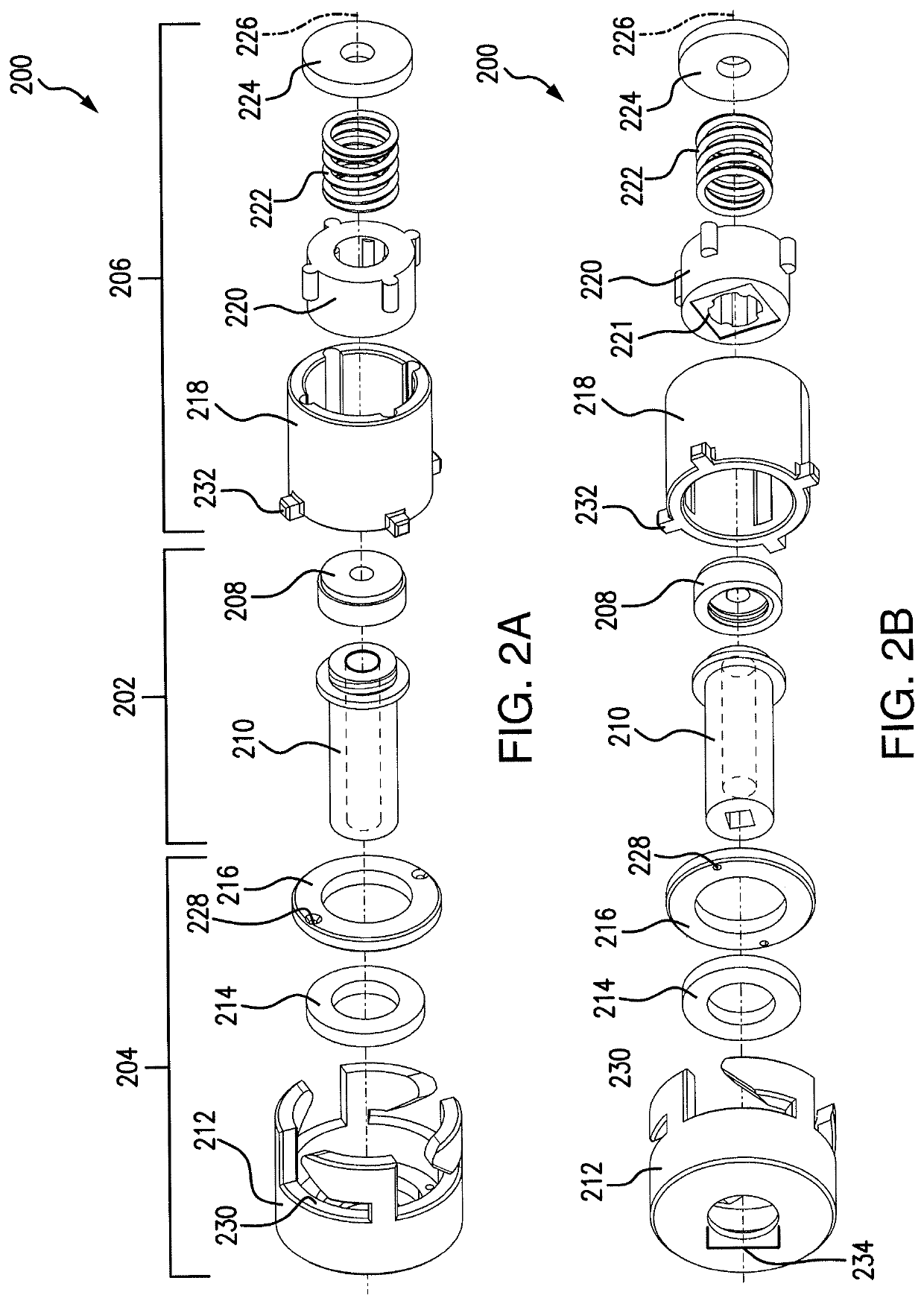

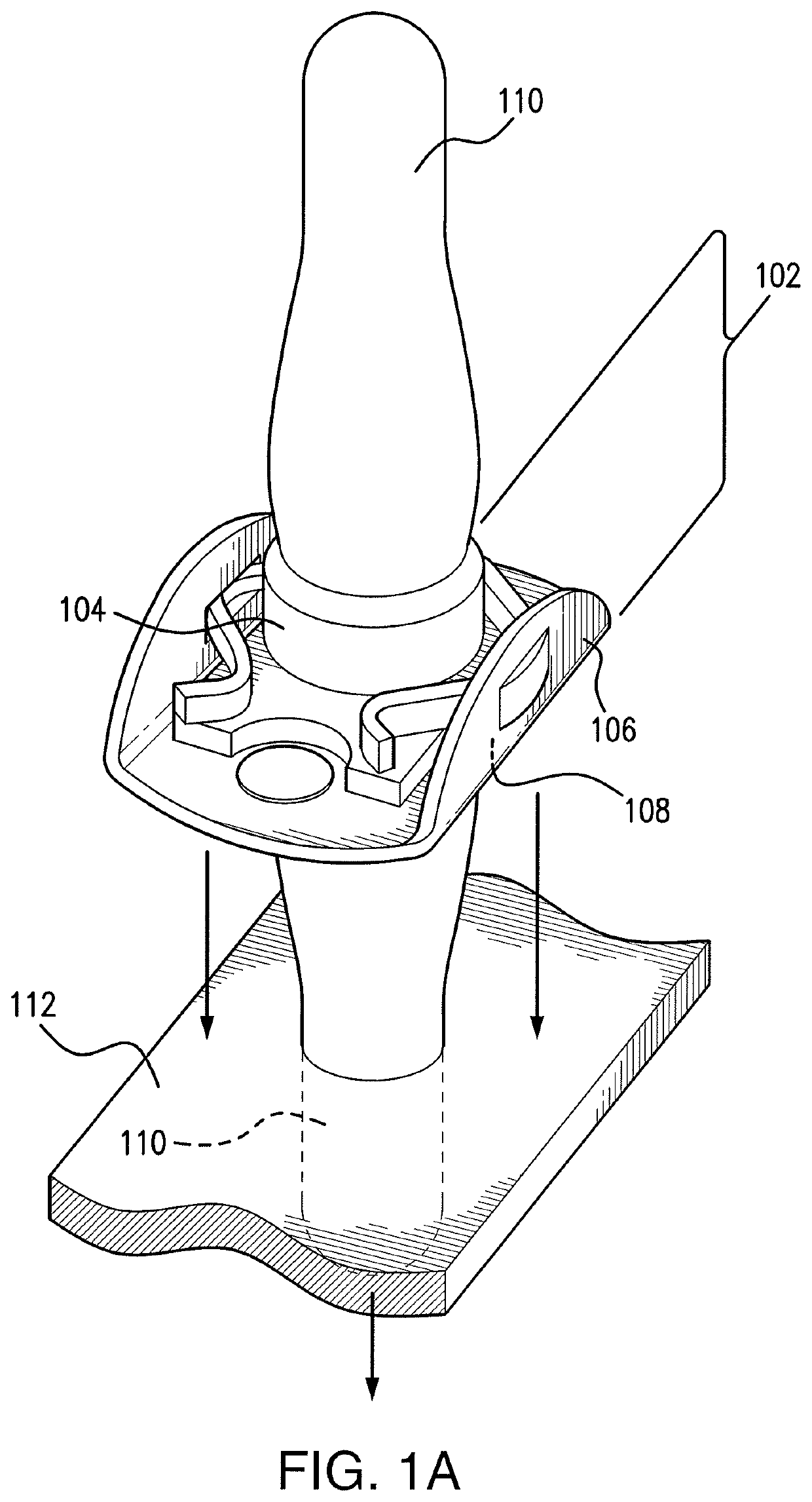

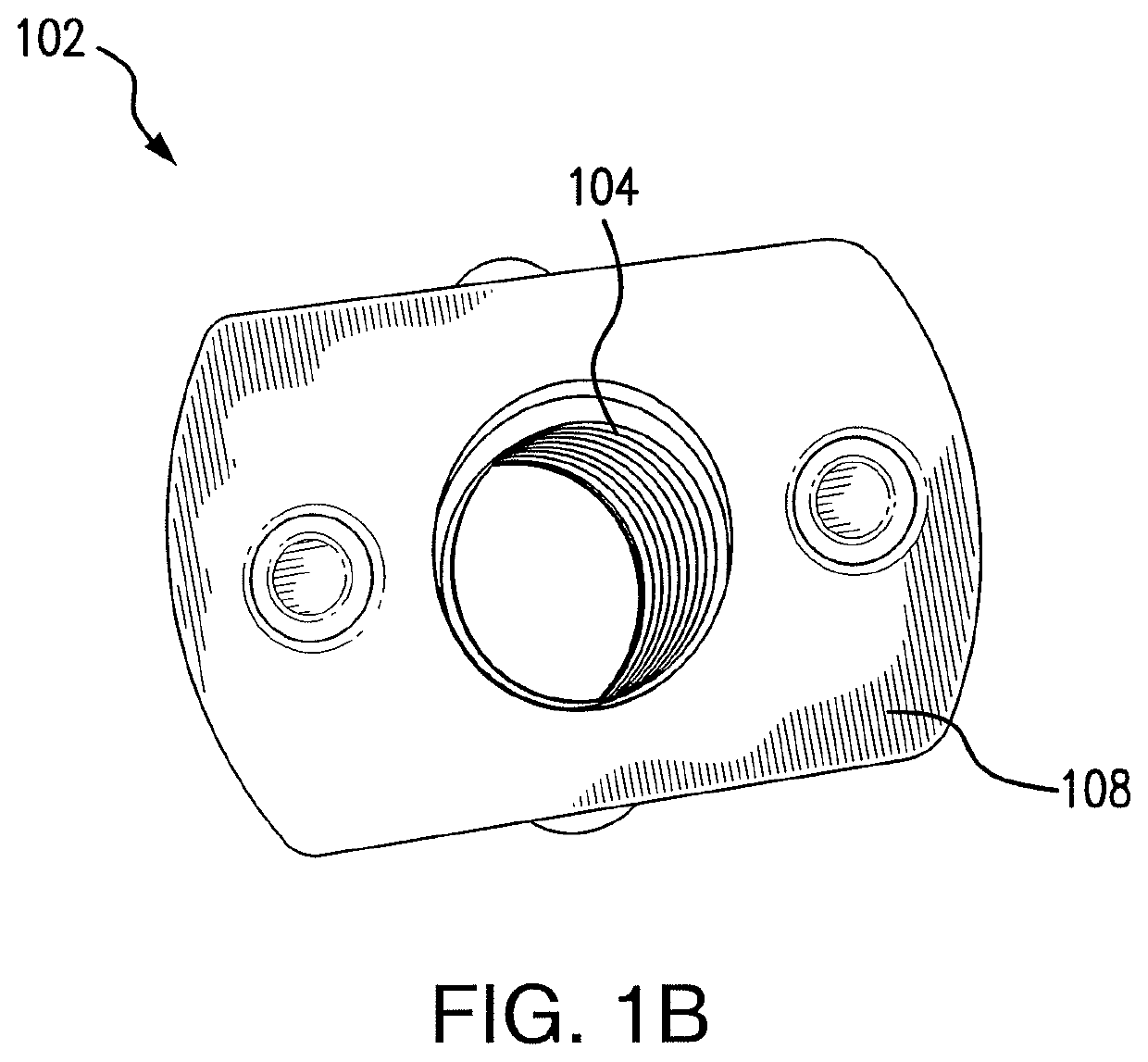

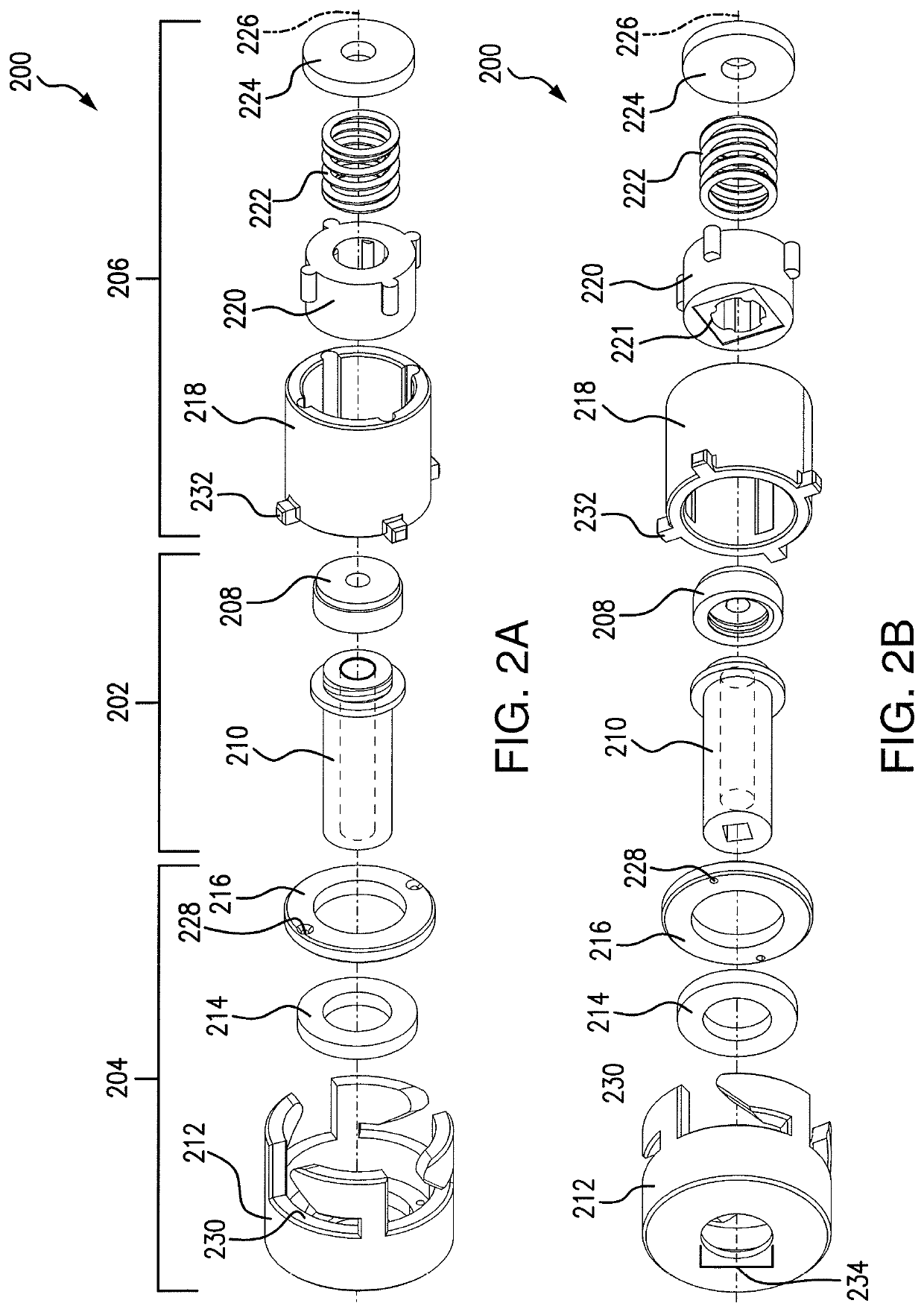

Nutplate Rotary Abrasion Tool

ActiveUS20180369873A1More secure attachmentIncrease efficiency and effectivenessPortable grinding machinesCleaning using toolsMechanical engineeringFaying surface

A system includes an abrasion component containing an abrasion pad configured to clean a faying surface of a nutplate and a shaft attached to the abrasion pad and configured to rotate the shaft and the abrasion pad during cleaning of the nutplate, which includes abrading the faying surface with the abrasion pad. The system further includes a base configured to attach to a pressure applicator, and the pressure applicator, which is configured to attach to the base, hold the nutplate such that the faying surface is capable of contacting the abrasion pad during the cleaning of the nutplate, and apply pressure to the nutplate such that the nutplate contacts the abrasion pad during the cleaning of the nutplate. Furthermore, the abrasion component is configured to rotate the abrasion pad within at least one of the base and the pressure applicator during the cleaning of the nutplate.

Owner:LOCKHEED MARTIN CORP

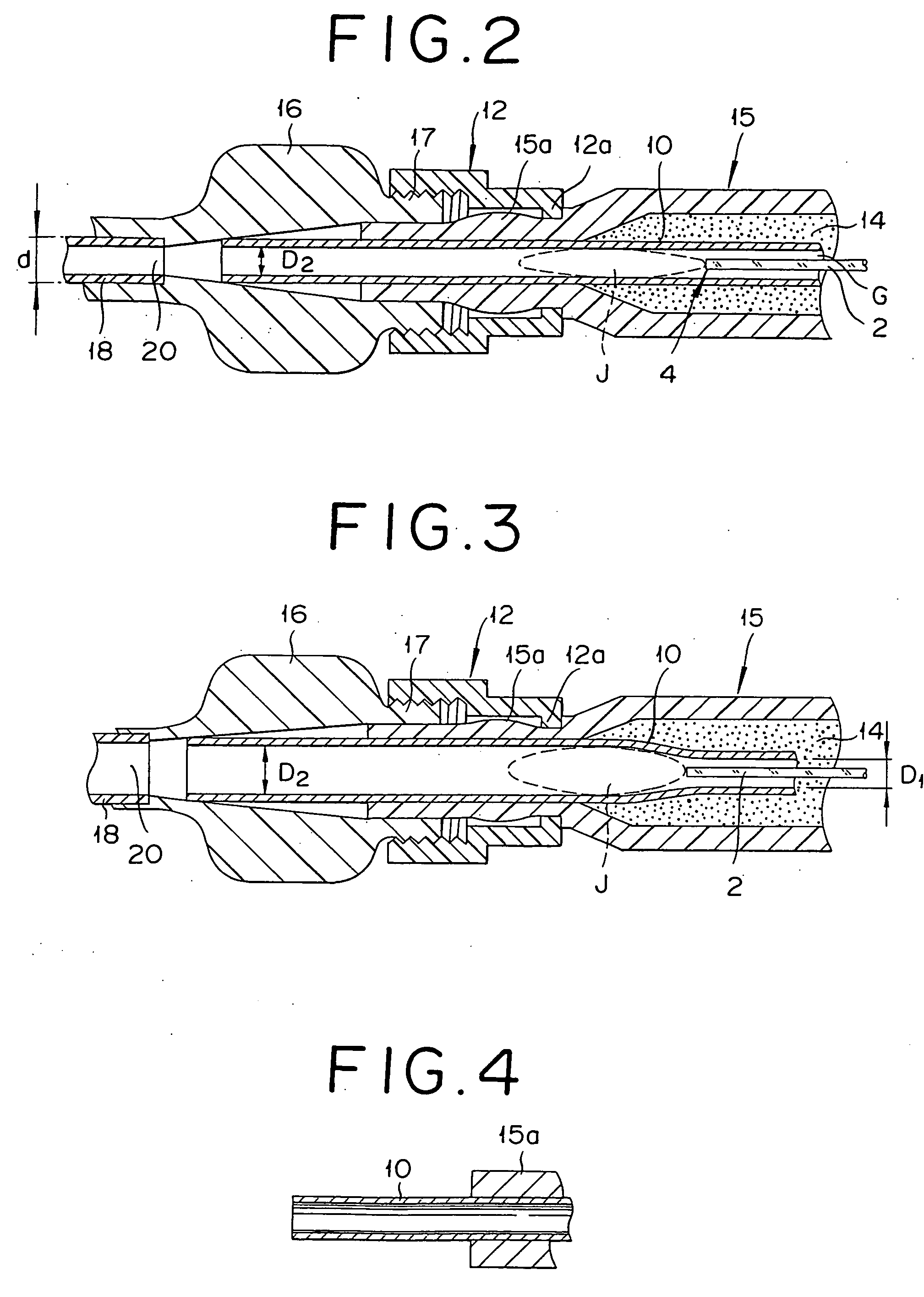

Multiple Nutplate Rotary Abrasion Tool

ActiveUS20180372143A1More secure attachmentImprove efficiencyNutsPortable grinding machinesBiomedical engineeringFaying surface

A system includes an abrasion assembly containing one or more abrasion pads configured to clean a faying surface of multiple nutplates, and a shaft attached to at least one of the abrasion pads and configured to rotate some or all of the abrasion pads during cleaning, wherein cleaning includes abrading the faying surfaces with the abrasion pads. The system also includes a base configured to attach to a pressure applicator, and a pressure applicator configured to attach to the base, hold the nutplates such that the faying surface of each nutplate is capable of contacting one of the abrasion pads, and apply pressure to the nutplates such that each of the nutplates contact one of the abrasion pads during the cleaning. Furthermore, the abrasion assembly is configured to rotate the abrasion pads within at least one of the base and the pressure applicator during cleaning.

Owner:LOCKHEED MARTIN CORP

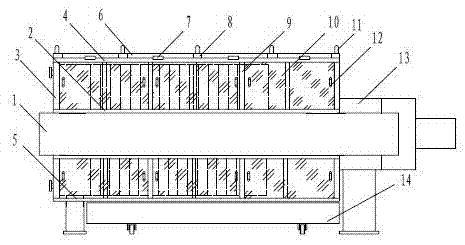

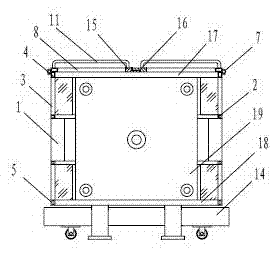

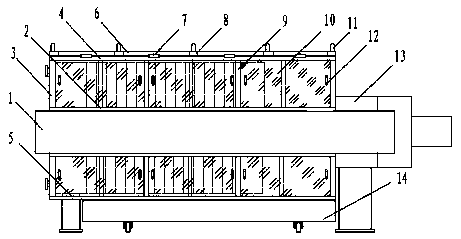

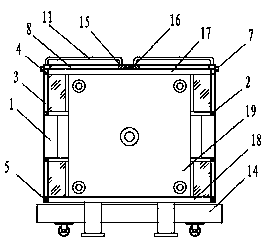

Closed filter press

The invention relates to a closed filter press. A main beam of the filter press is provided with an upper frame body and a lower frame body; a fixed frame is arranged and installed on the upper end of the main beam; the fixed frame is welded with columns, and used for supporting and connecting an upper side frame; an upper transverse frame is arranged and welded with the upper frame body composed of the upper side frame and columns; the lower end of the main beam is welded with a fixed frame, and the fixed frame is welded with the columns and used for supporting and connecting a lower side frame; a lower transverse frame is arranged and welded with the lower frame body composed of the lower side frame and columns; both sides of the frame bodies are connected with a thrust plate and a base; a groove is installed in the frame bodies; a sealing plate is arranged and installed in the groove; the lower end of the lower frame body is provided with a material receiving tray; the upper end of the upper frame body is provided with a door side frame, and a door inner frame is welded with a transverse rib plate to constitute door-leaf upper covers; the upper end of the transverse rib plate is welded with a plate grip; and a sealing plate is installed in the door-leaf upper covers. According to the structure, the filter plate-filter cloth overall filter system is closed in the frame bodies, the leaked or ejected material is collected in the frame under control, and the sealing plate is made of an organic glass material which is transparent, and thus, can be used for observing the filtering conditions. The closed filter press has the advantages of compact structure and favorable closeness.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

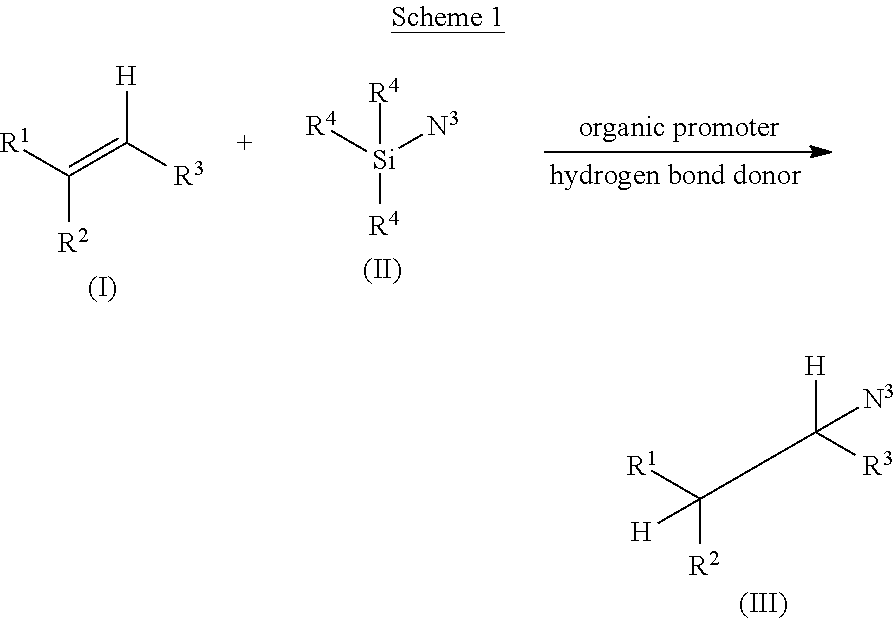

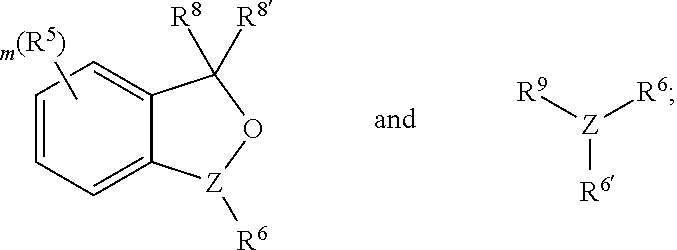

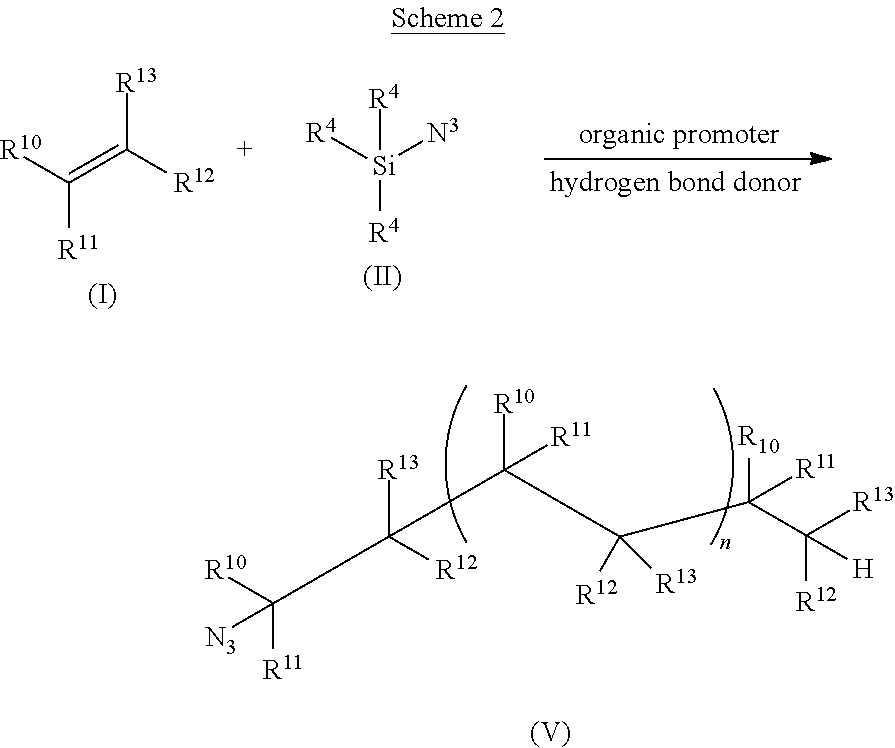

Environmentally-friendly hydroazidation of olefins

ActiveUS20210284601A1Operator safetyEasy to handleGroup 4/14 element organic compoundsBiochemical engineeringAlkene

Owner:GEORGIA STATE UNIV RES FOUND INC

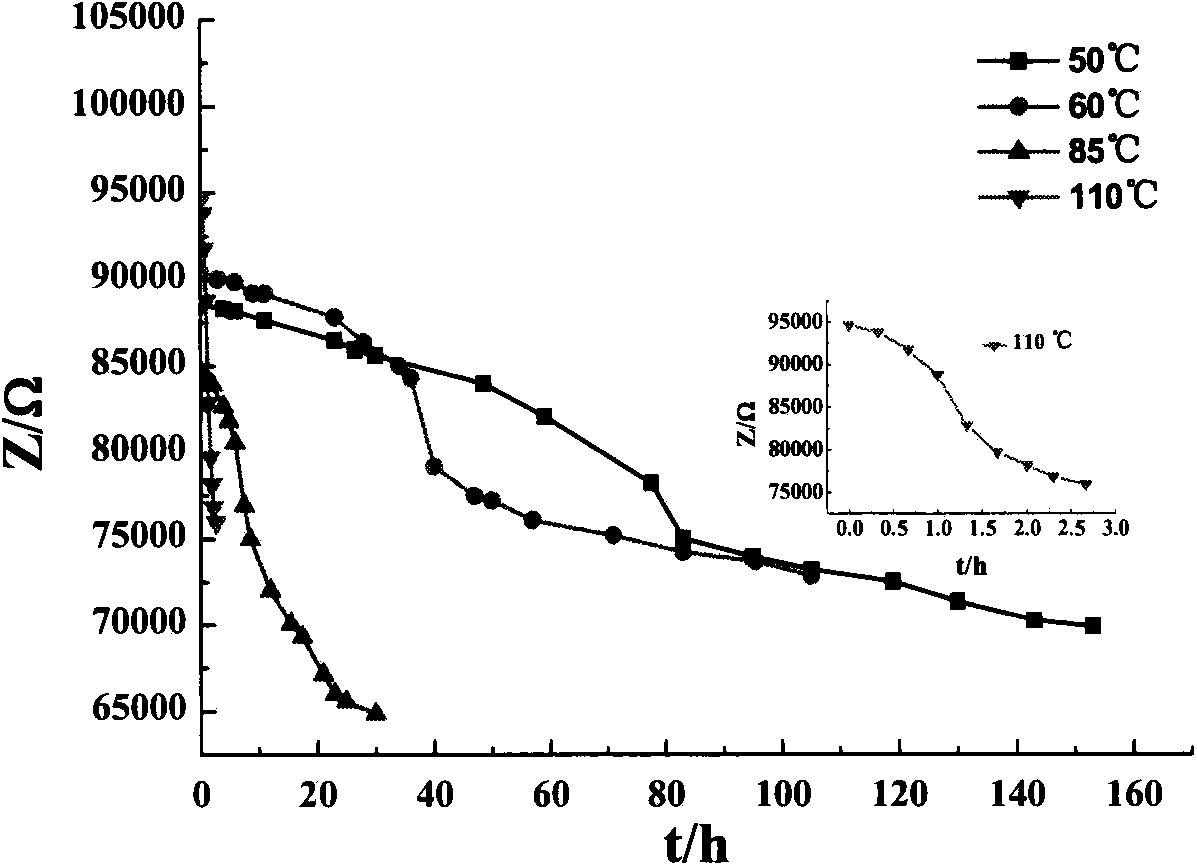

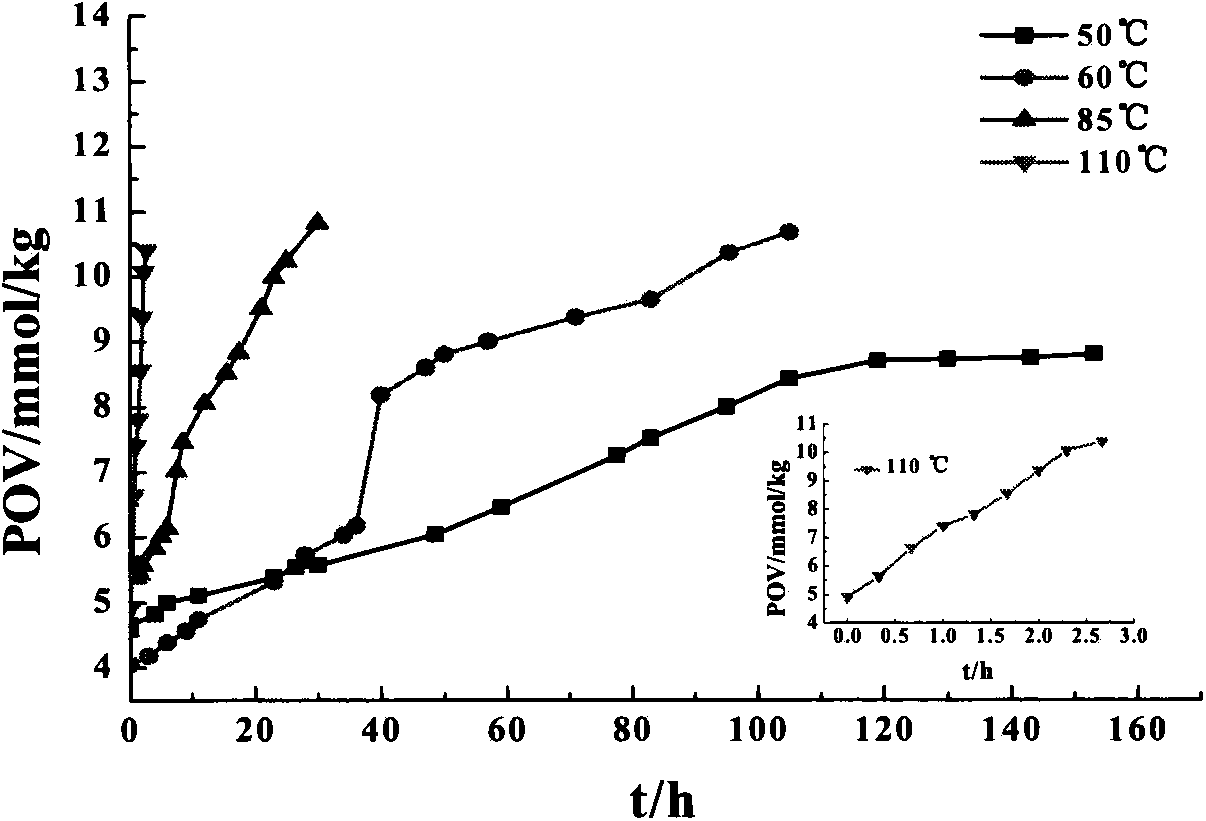

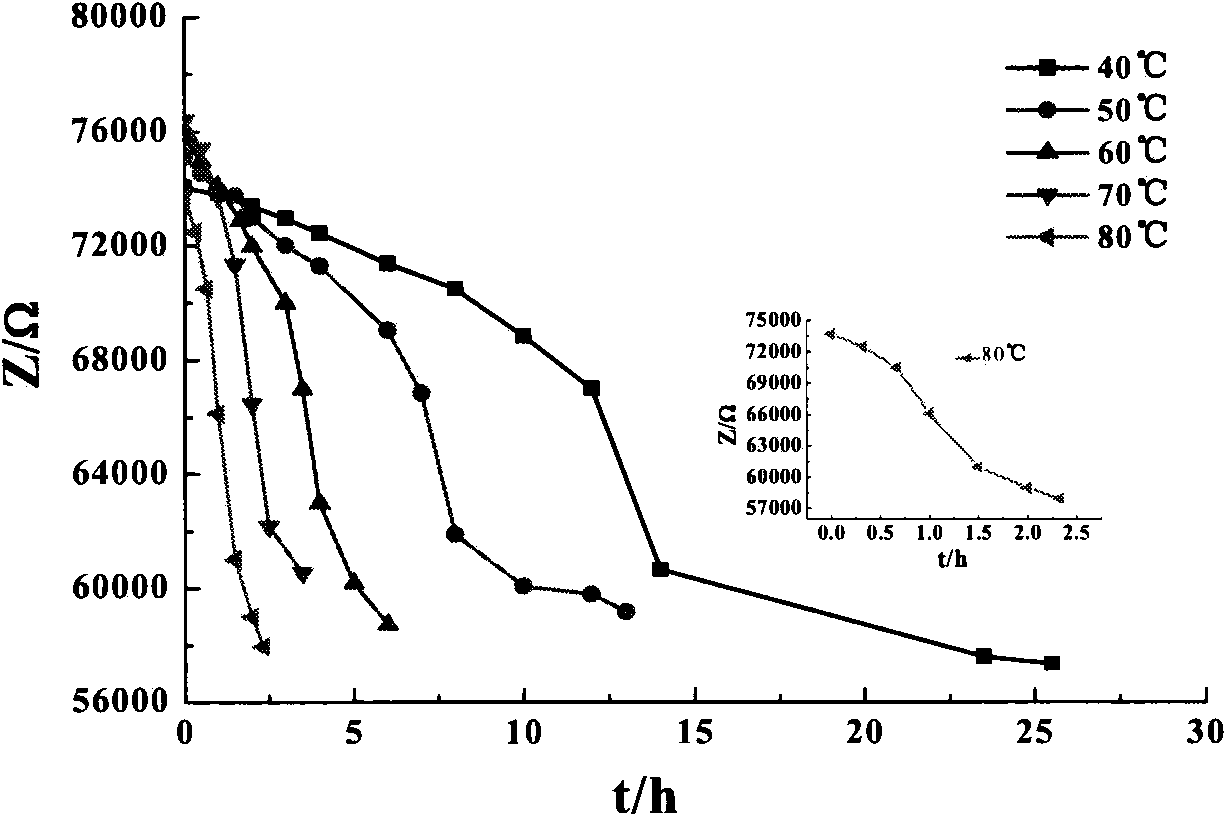

A method of predicting the shelf life of fats and oils

ActiveCN104713921BQuick forecastForecasting is simple and accurateMaterial electrochemical variablesSupporting electrolyteDisturbance voltage

The invention relates to a method for predicting the grease shelf life. The method comprises the following steps: diluting grease to be detected by a supporting electrolyte solution, adding the diluted solution into an electrolysis tank, assembling a three-electrode system, wherein in the system the work electrode is a glass-carbon electrode, the counter electrode is a platinum sheet electrode, and the reference electrode is a calomel electrode; adjusting the disturbance voltage and frequency, measuring and recording the alternating current (AC) impedance spectrum; calculating the resistance value of the solution through the equivalent circuit of the impedance spectrum; and rapidly predicting the grease shelf life through an established prediction model of grease shelf life.

Owner:河南福美生物科技有限公司

A closed filter press

A closed filter press, the upper and lower frames are arranged on the main beam of the filter press, the fixed frame is installed on the upper end of the main beam, the fixed frame is welded with columns and supports to connect the upper frame, and the upper horizontal frame is welded with the upper frame and columns to form the upper frame The fixed frame is welded at the lower end of the main girder. The fixed frame is welded to the column and the support to connect the lower frame, and the lower horizontal frame is set to weld the lower frame and the column to form the lower frame body. The groove is installed, and the sealing plate is installed in the groove. The lower end of the lower frame body is provided with a material receiving tray, and the upper end of the upper frame body is provided with a door frame and a door inner frame welded with a transverse rib plate to form a door leaf type upper cover. There is a sealing plate installed in the door-shaped upper cover. This structure seals the filter plate and the filter cloth as a whole filter system in the frame body. Material leakage or spraying is controlled and collected in the frame. The sealing plate is made of plexiglass material with transparent observation and filtration. The structure is compact and the sealing performance is good.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

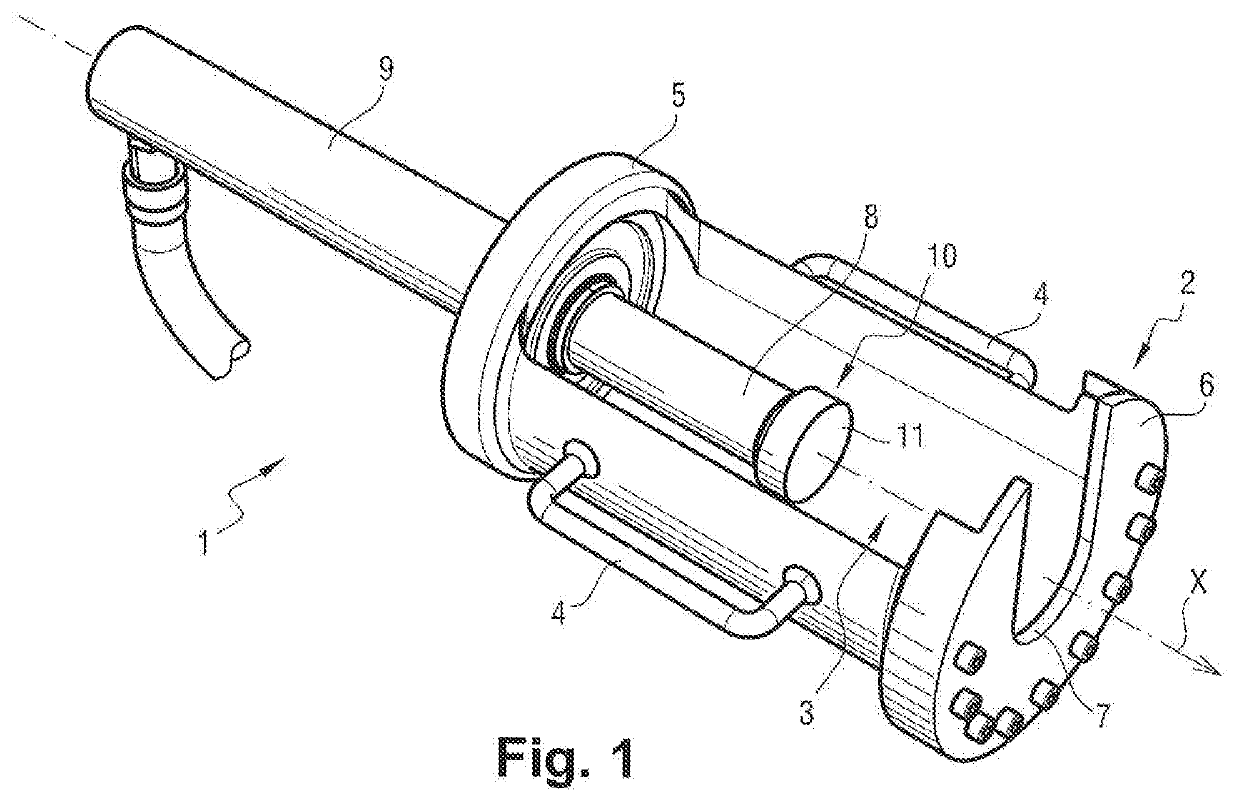

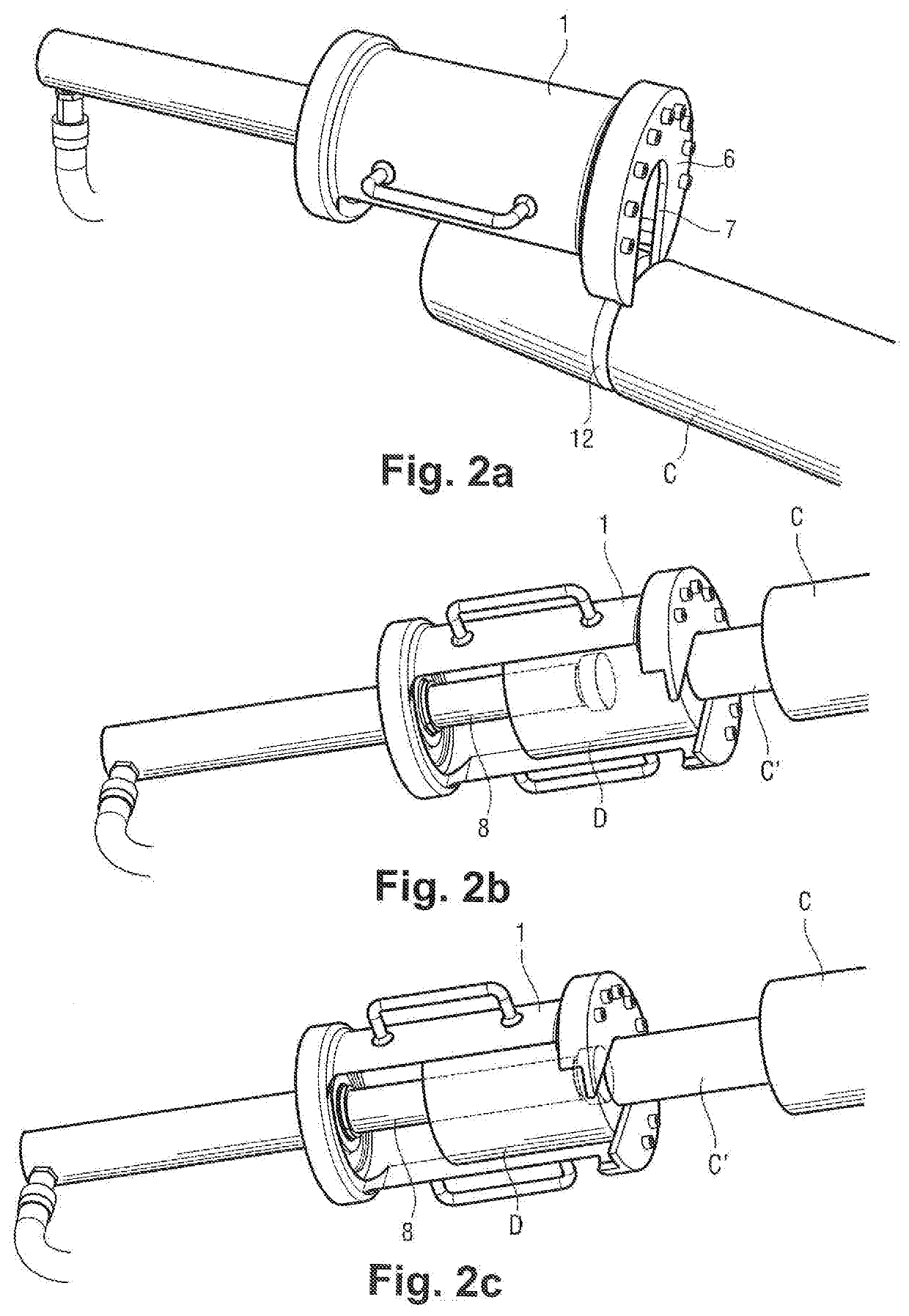

Cable stripping device

ActiveUS11451002B2Simple and quick to useOperator safetyLine/current collector detailsApparatus for removing/armouring cablesControl theoryElectric cables

Owner:SILEC CABLE

Multiple nutplate rotary abrasion tool

ActiveUS11149778B2More secure attachmentIncrease efficiency and effectivenessNutsPortable grinding machinesEngineeringMechanical engineering

A system includes an abrasion assembly containing one or more abrasion pads configured to clean a faying surface of multiple nutplates, and a shaft attached to at least one of the abrasion pads and configured to rotate some or all of the abrasion pads during cleaning, wherein cleaning includes abrading the faying surfaces with the abrasion pads. The system also includes a base configured to attach to a pressure applicator, and a pressure applicator configured to attach to the base, hold the nutplates such that the faying surface of each nutplate is capable of contacting one of the abrasion pads, and apply pressure to the nutplates such that each of the nutplates contact one of the abrasion pads during the cleaning. Furthermore, the abrasion assembly is configured to rotate the abrasion pads within at least one of the base and the pressure applicator during cleaning.

Owner:LOCKHEED MARTIN CORP

Variable frequency rapid electric iron

InactiveCN1935436BImprove thermal efficiencyHigh and low thermal efficiencySoldering ironTemperature controlTransformer

The present invention relates to a variable frequency quick electric soldering iron which need not be preheated or be heat-insalated, and can quickly heat to the 360 deg.C for milting soldering tin from room temperature within 2-6 Sec. and can be quickly cooled to room temperature when it is not used. It is characterized by that said invention adopts integrated circuit chip or semiconductor to make frequency change and temperature regulation, and adopts Curie point magnetic torque lattice physical temperature control sensing technique and amorphous nano alloy high-frequency transformer so as to change the traditional 50H2 electric soldering table into the invented electric soldering iron which can be worked under the 1000 H2 to 1200KH2 frequency.

Owner:徐小羚

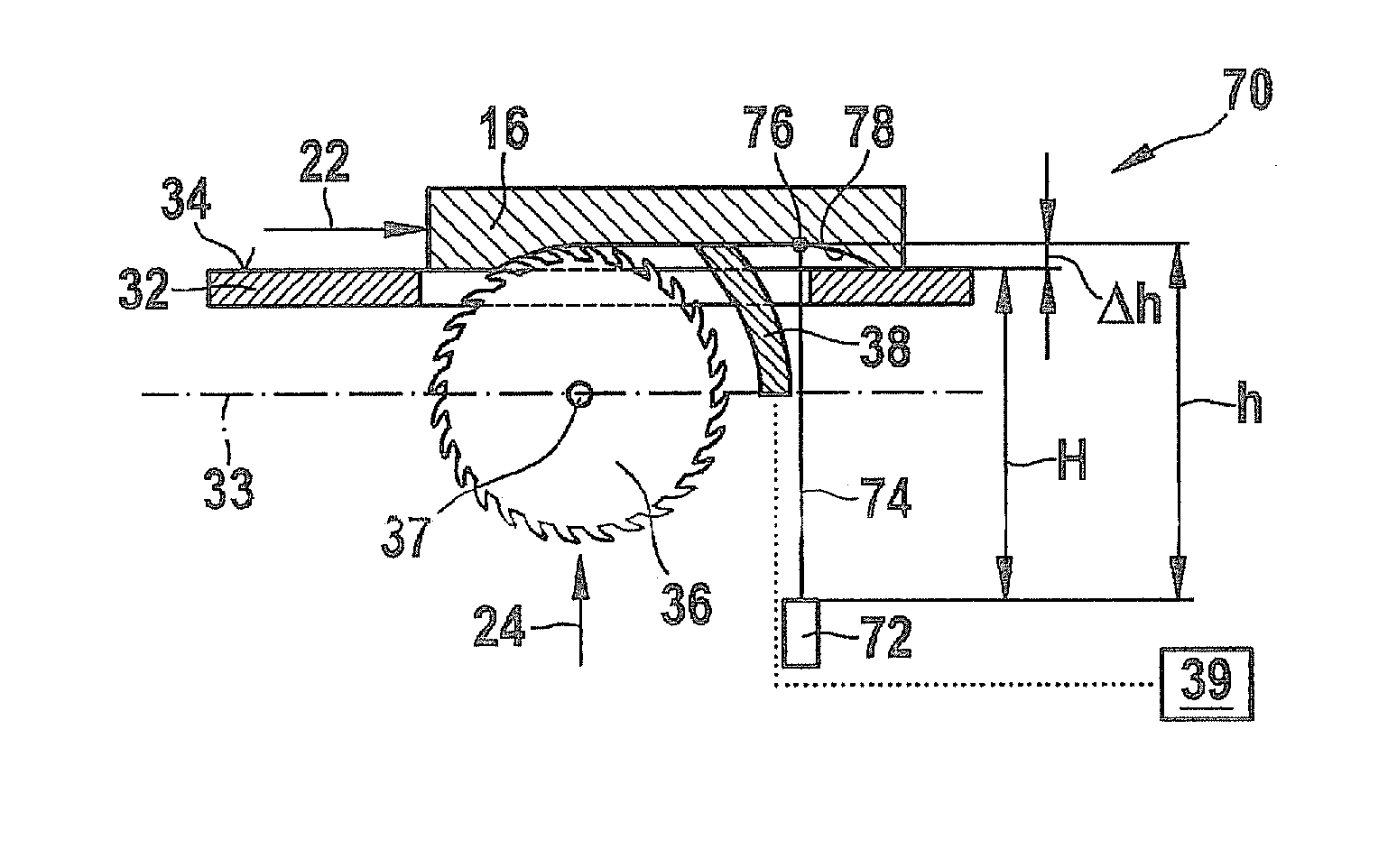

Circular saw

InactiveUS9027449B2Low costShorten the timeMetal sawing devicesGang saw millsRotational axisClassical mechanics

A circular saw including a saw blade (36) which may be rotatingly driven about a rotational axis, and at least one first splitting wedge is described. The circular saw is configured so that the first splitting wedge is movable relative to the rotational axis of the saw blade.

Owner:ROBERT BOSCH GMBH

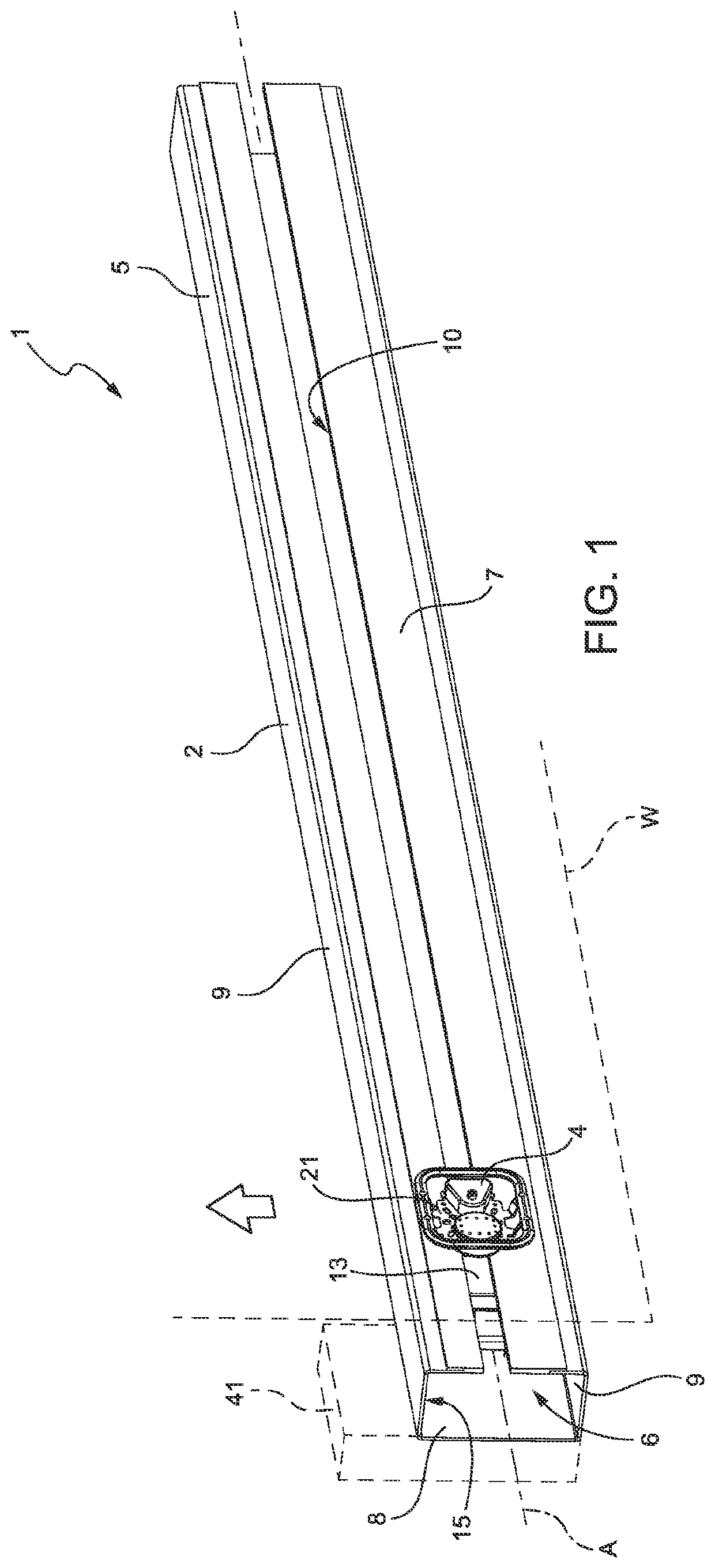

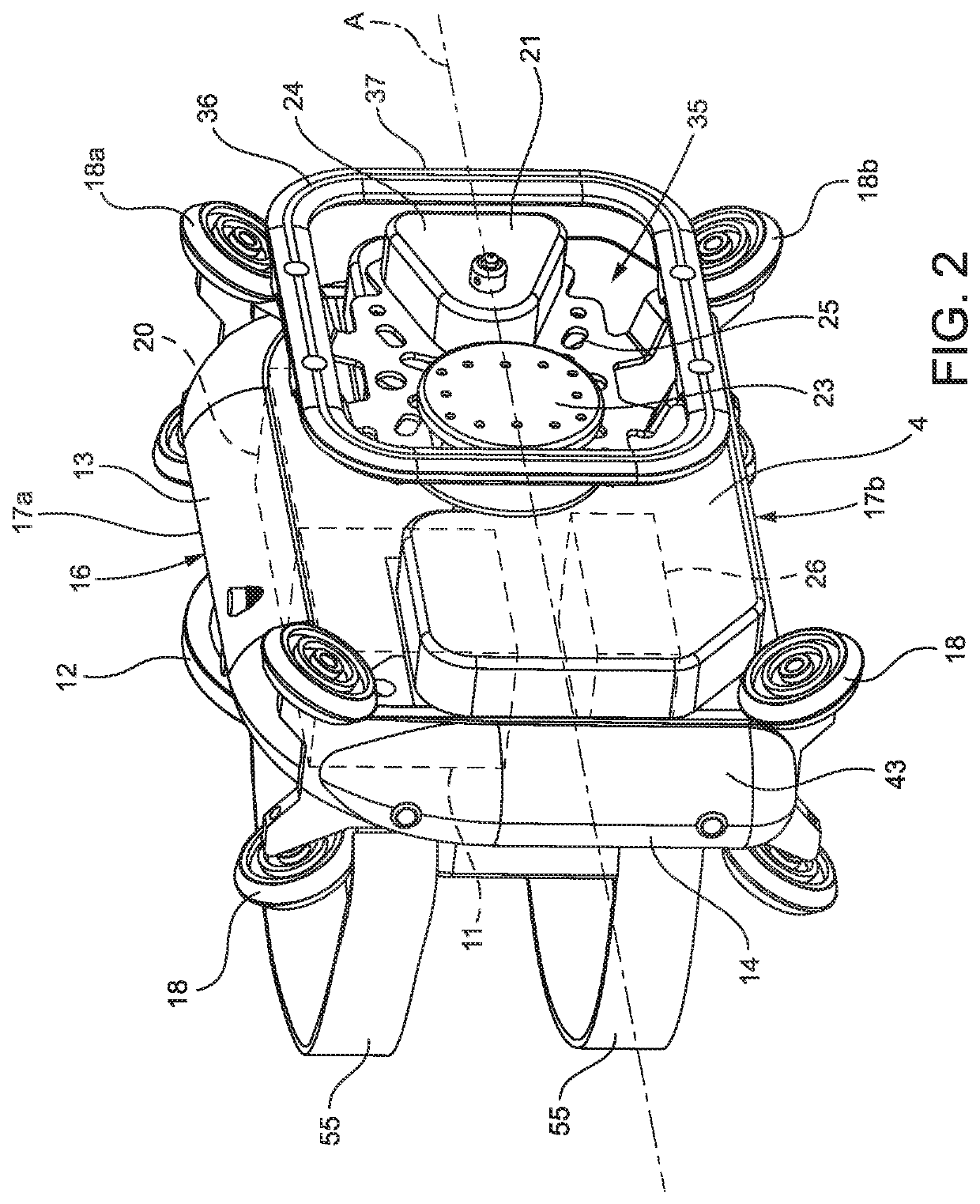

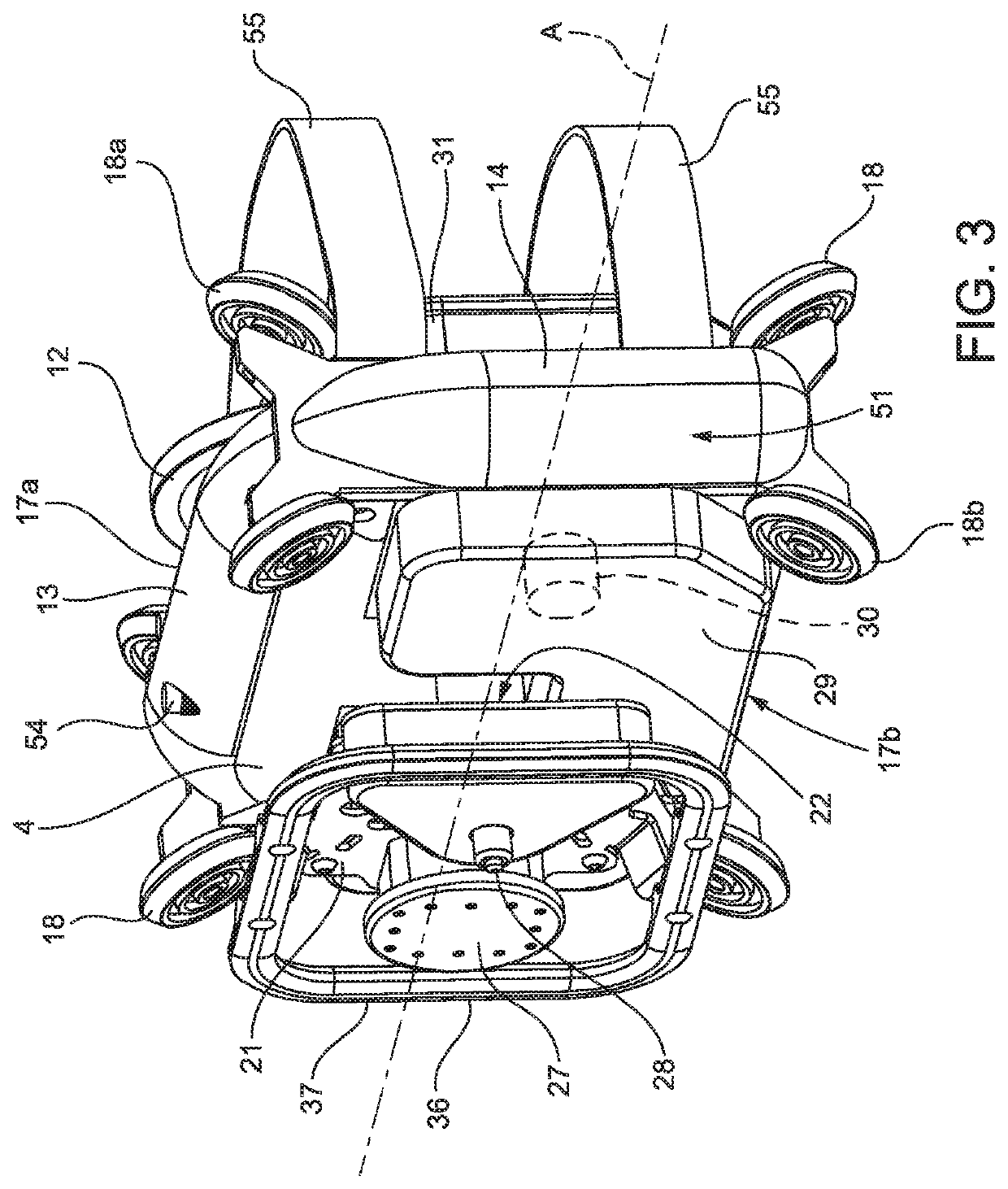

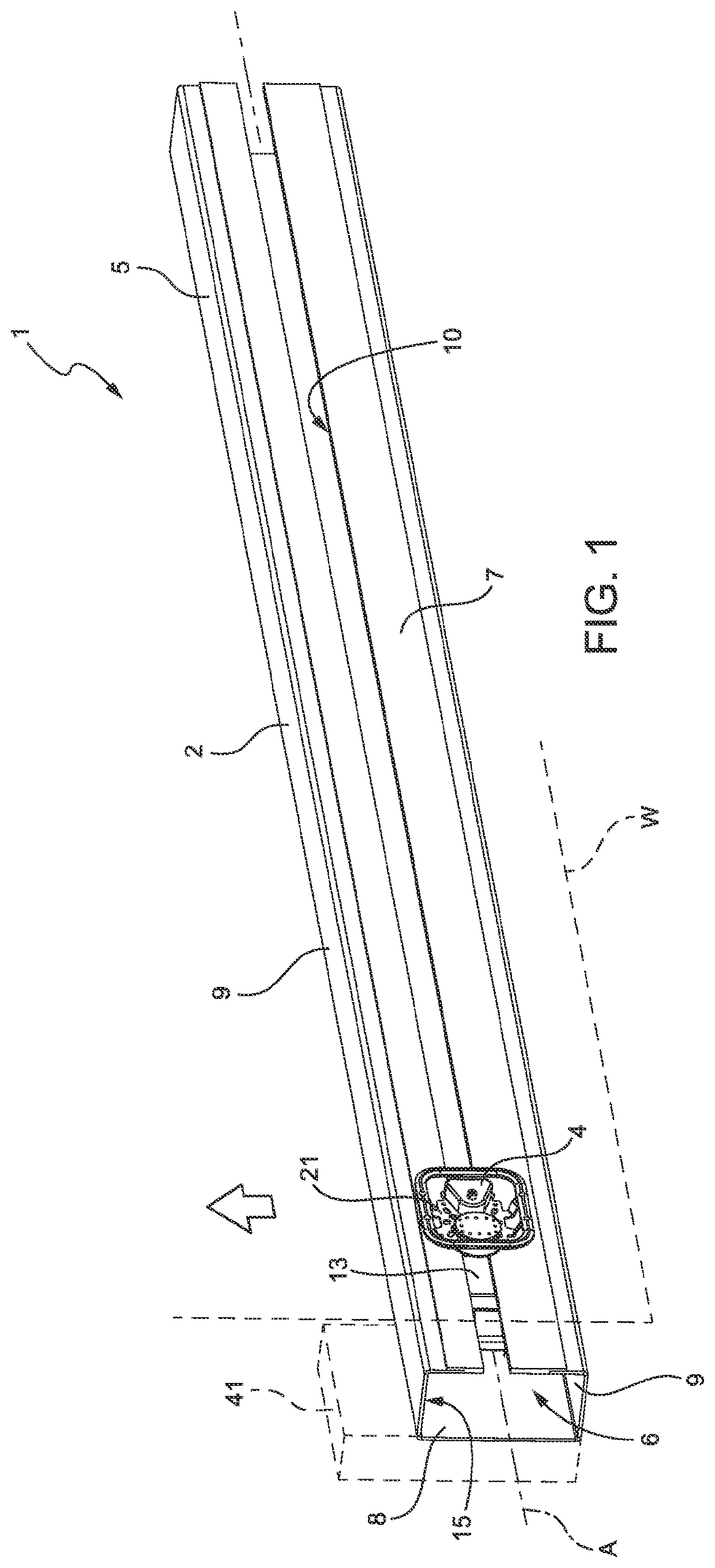

Monitoring system for monitoring the conditions of a band circulating in a papermaking machine

ActiveUS20200141060A1Simple and inexpensive to produceOperator safetyMoisture content investigation using microwavesPaper-making machinesControl engineeringMonitoring system

A monitoring system for monitoring the conditions of a band circulating in a paper-making machine, comprises a guide extending substantially along an axis; and a monitoring apparatus movable along the guide and comprising at least one measuring device configured to measure at least one parameter indicative of the conditions of the band; the apparatus is a self-propelled motorized apparatus, provided with a motor and at least one driving member operated by the motor and which engages at least one corresponding surface of the guide to move the apparatus along the guide.

Owner:GIUSEPPE CRISTINI

Nutplate rotary abrasion tool

ActiveUS11148175B2More secure attachmentIncrease efficiency and effectivenessPortable grinding machinesCleaning using toolsRotational axisEngineering

A system includes an abrasion component containing an abrasion pad configured to clean a faying surface of a nutplate and a shaft attached to the abrasion pad and configured to rotate the shaft and the abrasion pad during cleaning of the nutplate, which includes abrading the faying surface with the abrasion pad. The system further includes a base configured to attach to a pressure applicator, and the pressure applicator, which is configured to attach to the base, hold the nutplate such that the faying surface is capable of contacting the abrasion pad during the cleaning of the nutplate, and apply pressure to the nutplate such that the nutplate contacts the abrasion pad during the cleaning of the nutplate. Furthermore, the abrasion component is configured to rotate the abrasion pad within at least one of the base and the pressure applicator during the cleaning of the nutplate.

Owner:LOCKHEED MARTIN CORP

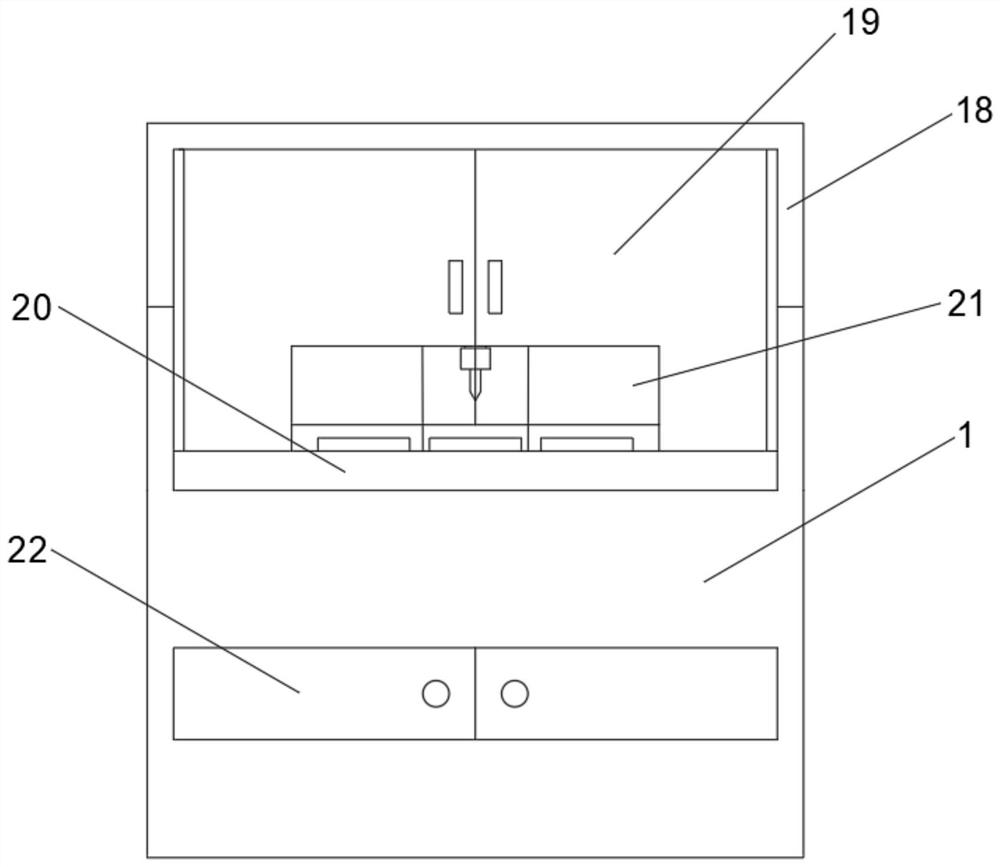

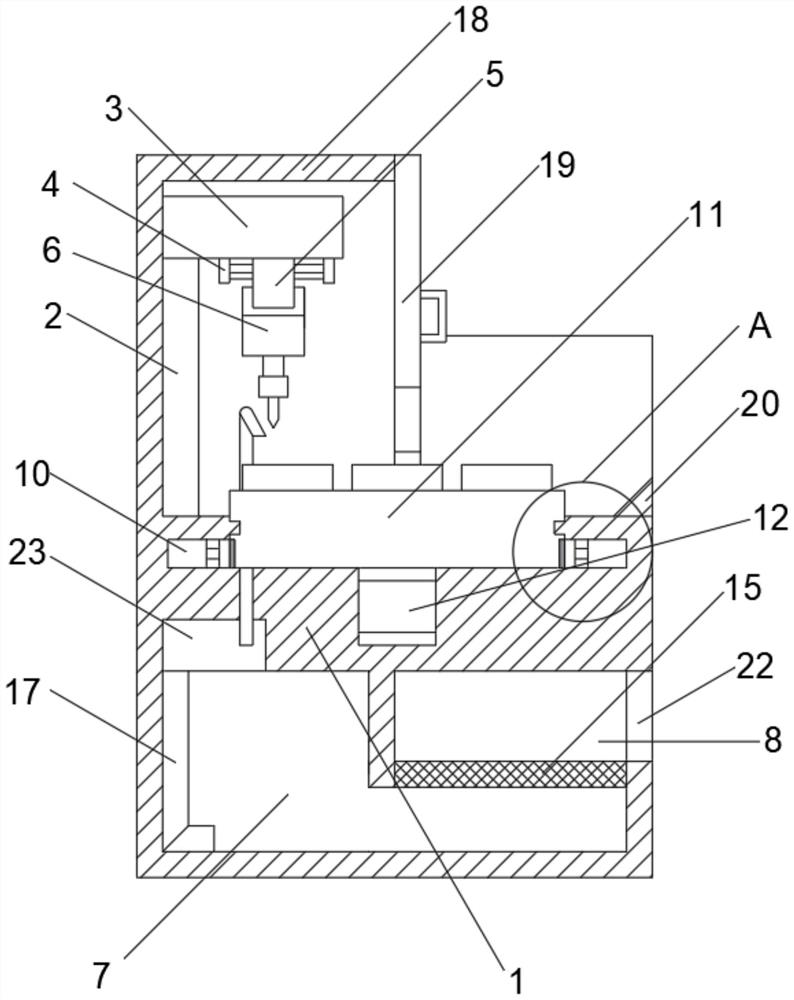

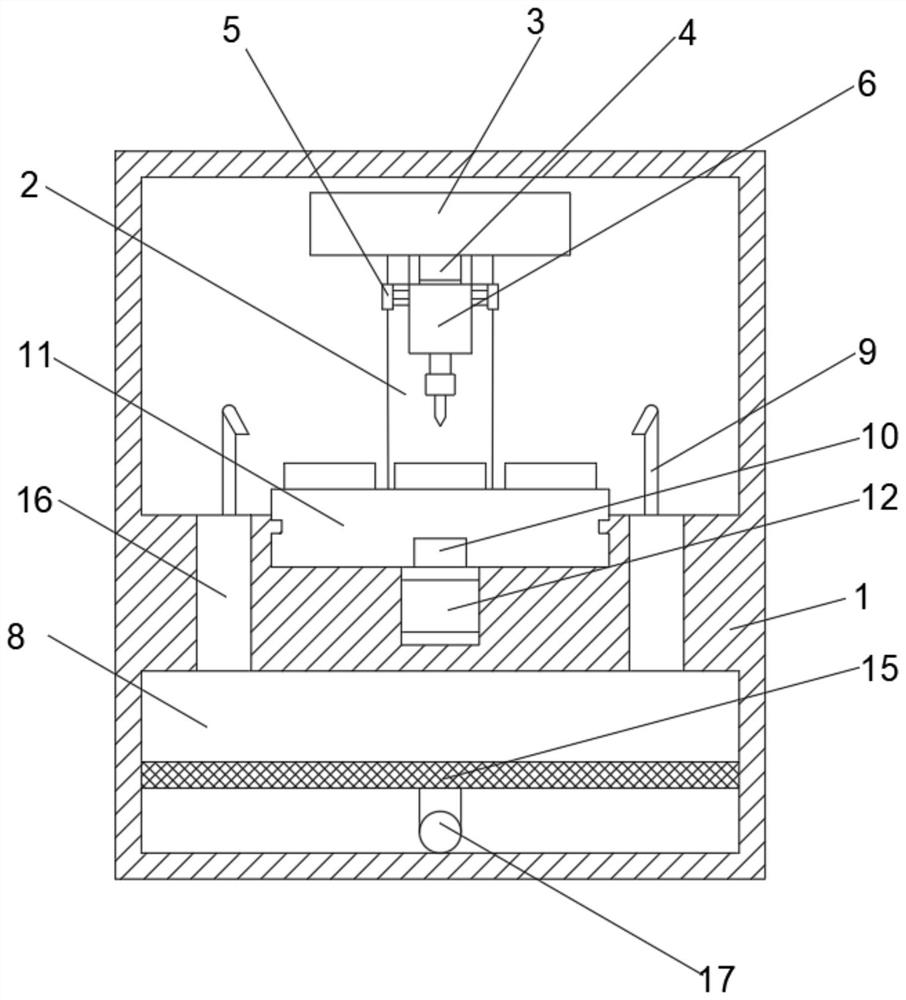

Bench drilling machine for machining wind power generation metal parts

InactiveCN114055212ASolution to short lifeImprove processing efficiencyLarge fixed membersPositioning apparatusStructural engineeringMachining time

The invention discloses a bench drilling machine for machining wind power generation metal parts. The bench drilling machine comprises a drilling machine body and a working element installed above the drilling machine body. The working element comprises a lifting assembly, a fixing plate, a front-back moving assembly, a left-right moving assembly and a drilling assembly which are installed on the drilling machine body, the fixing plate is installed at the upper end of the lifting assembly, the front-back moving assembly is installed below the fixing plate, the left-right moving assembly is installed on the front-back moving assembly, and the drilling assembly is installed on the left-right moving assembly. The service life of a drill bit is longer through the arranged cooling assembly, the machining efficiency of the drilling machine is higher through the arrangement of a rotating disc, continuous work can be conducted, the machining time is saved, an operator is safer during operation through the arrangement of a protection door, accidents are not prone to occurring, the front-back and left-right positions of the drill bit assembly can be adjusted, the hole is positioned by adjusting the position of the drill bit, and operation is more convenient.

Owner:深圳市鹏瑞精密钣金制品有限公司

A Transformer Core V-Rush Operation Method

ActiveCN103887057BReduce mistakesReduce noiseInductances/transformers/magnets manufacturePunchingTransformer

The invention discloses a V-type punching operation method of a transformer core, and relates to the technical field of V punching of the transformer core. A punching platform, a V-type punching die, backers and an iron yoke piece are included, the two backers are arranged on the punching platform, the V-type punching die is fixed to a V-type punching machine, and the iron yoke piece is matched with the backers. The V-type punching operation method of the transformer core comprises the steps that A, the two backers are arranged on the punching platform; B, the V-type punching die is fixed to the V-type punching machine; C, the lower edge of an upper iron yoke or the upper edge of a lower iron yoke of the iron yoke piece is taken as a base level to lean against the backers; D, finally, the iron yoke piece is attached to the punching platform to be moved towards the V-type punching die, and the iron yoke piece is punched to be formed through the V-type punching die. The noise, the temperature rising and no-load losses of a transformer are reduced, an operator feels safe, and the production efficiency is improved.

Owner:NANTONG LONGXIANG ELECTRICAL APPLIANCE EQUIP

Machine and method for removing beads from tires at the end of life

ActiveUS10081120B2Operator safetyEffectively and reliably pullPlastic recyclingTyresCommand and controlMechanical engineering

Machine for extracting a cord made of metal material from a sidewall of a tire, being part of the sidewall and defining a support structure of said tire, including: a frame; support means for the tire configured to support said tire resting on one sidewall in a loading zone; a hook for extracting said cord from the sidewall of the tire; means for manipulating said hook, configured to manipulate the hook with respect to the frame in an extraction direction between a position for engagement with said tire in the loading zone and a position for disengagement from said tire and extraction of said cord; a command and control unit to command said means for manipulating the hook,:an element able to move with respect to the frame to detach the cord from the hook when the hook is in position for disengagement;and means for manipulating the movable element, to manipulate the movable element from a first position to a second position to carry out releasing of the cord from the hook.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

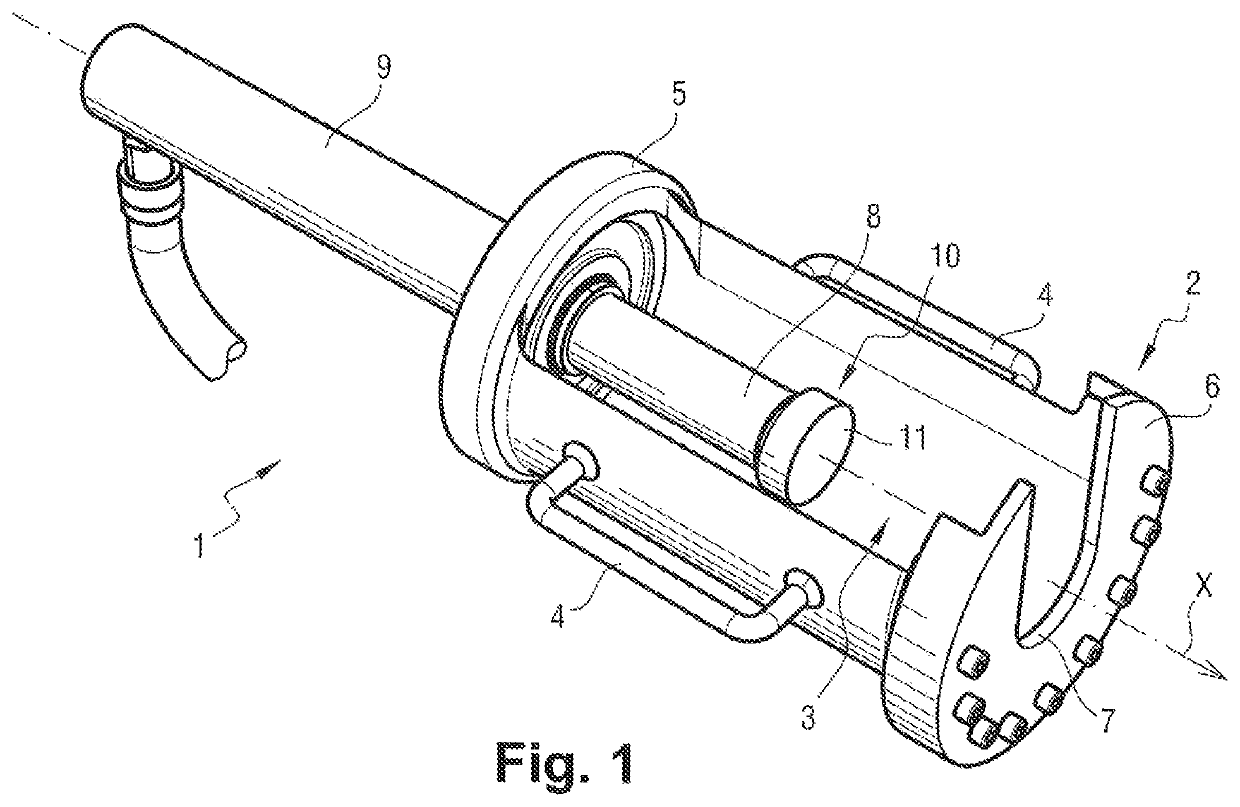

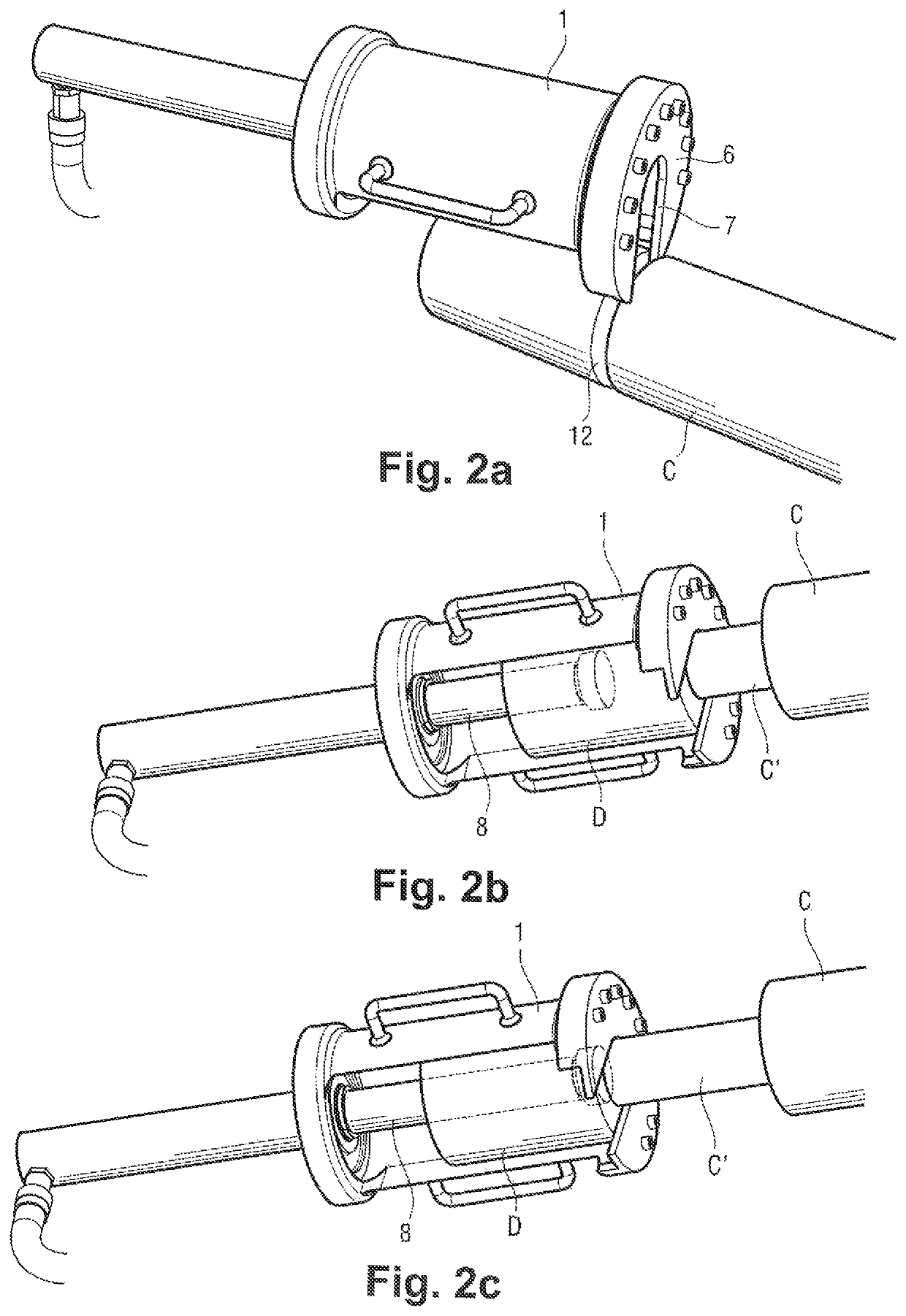

Cable Stripping Device

ActiveUS20220140560A1Easy to handleSimple and quick to useLine/current collector detailsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention concerns a cable stripping device, the device comprising at least:—an extraction chamber (2) of which a distal end is closed by a flange (7) comprising a groove (7), —a pusher (8) movably mounted in the extraction chamber between a rest position in which the pusher extends at a proximal end of the chamber and a deployed position, the pusher being intended to push on the cable in order to press it against the groove of the flange.

Owner:SILEC CABLE

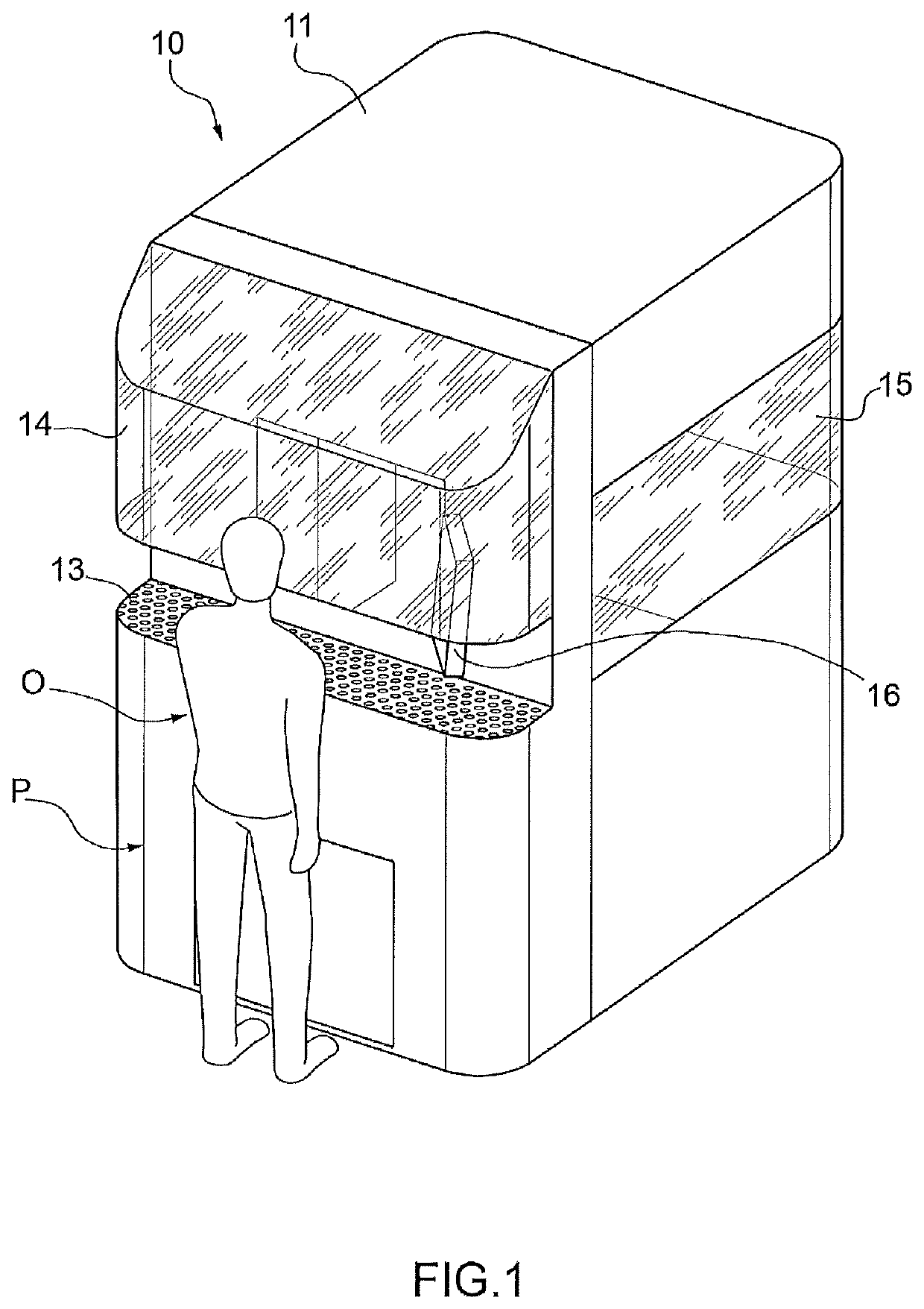

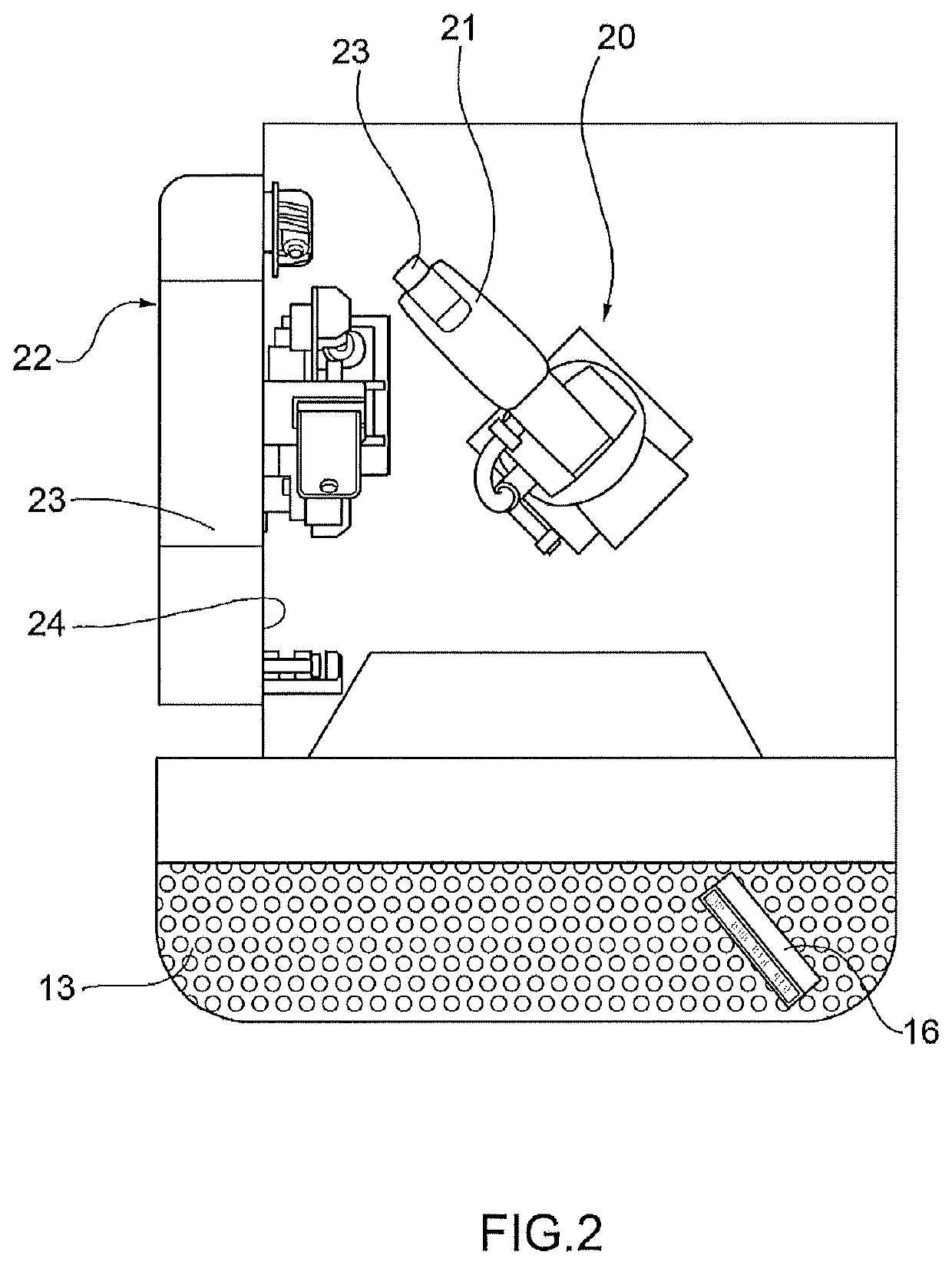

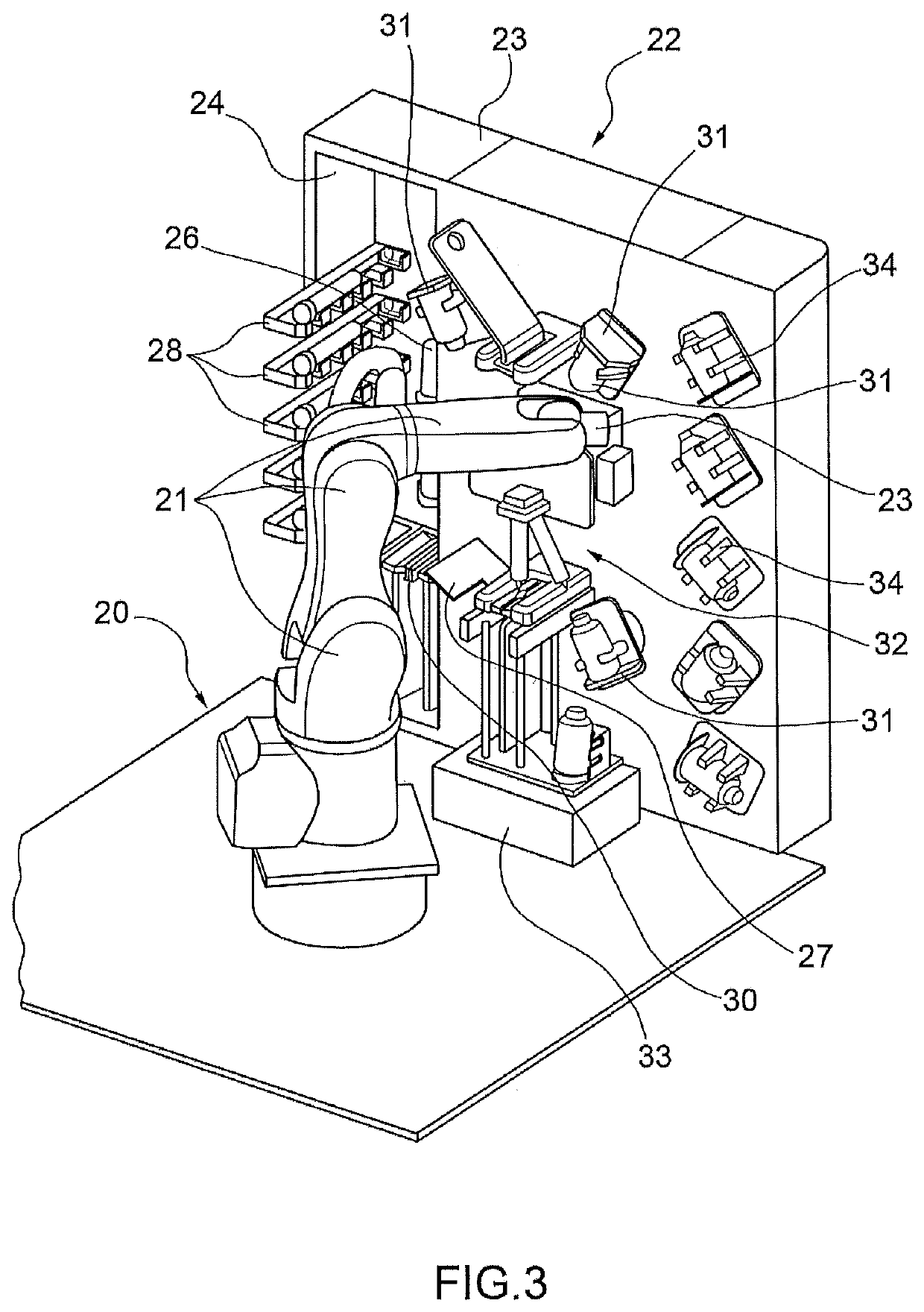

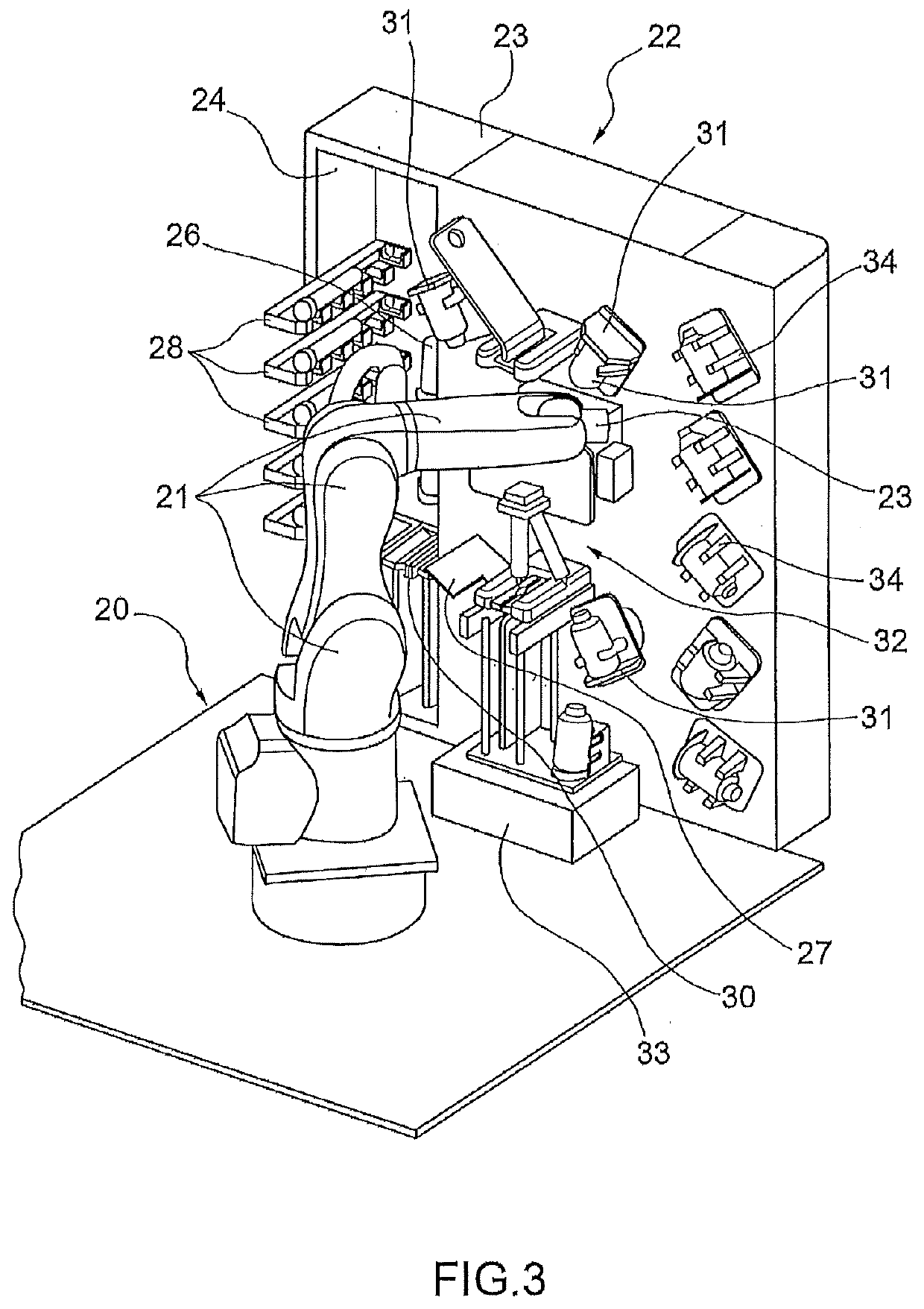

Machine and process for preparing intravenous medicaments

ActiveUS11142355B2Easy to useEasy to cleanPharmaceutical containersPharmaceutical product form changeWorking environmentIntravenous drug

Owner:SWISSLOG ITAL

Monitoring system for monitoring the conditions of a band circulating in a papermaking machine

ActiveUS10961661B2Simple and inexpensive to produceOperator safetyMoisture content investigation using microwavesPaper-making machinesControl engineeringMonitoring system

A monitoring system for monitoring the conditions of a band circulating in a paper-making machine, comprises a guide extending substantially along an axis; and a monitoring apparatus movable along the guide and comprising at least one measuring device configured to measure at least one parameter indicative of the conditions of the band; the apparatus is a self-propelled motorized apparatus, provided with a motor and at least one driving member operated by the motor and which engages at least one corresponding surface of the guide to move the apparatus along the guide.

Owner:GIUSEPPE CRISTINI

Machine and process for preparing intravenous medicaments

ActiveUS20220041309A1Easy to useEasy to cleanPharmaceutical containersPharmaceutical product form changeWorking environmentIntravenous drug

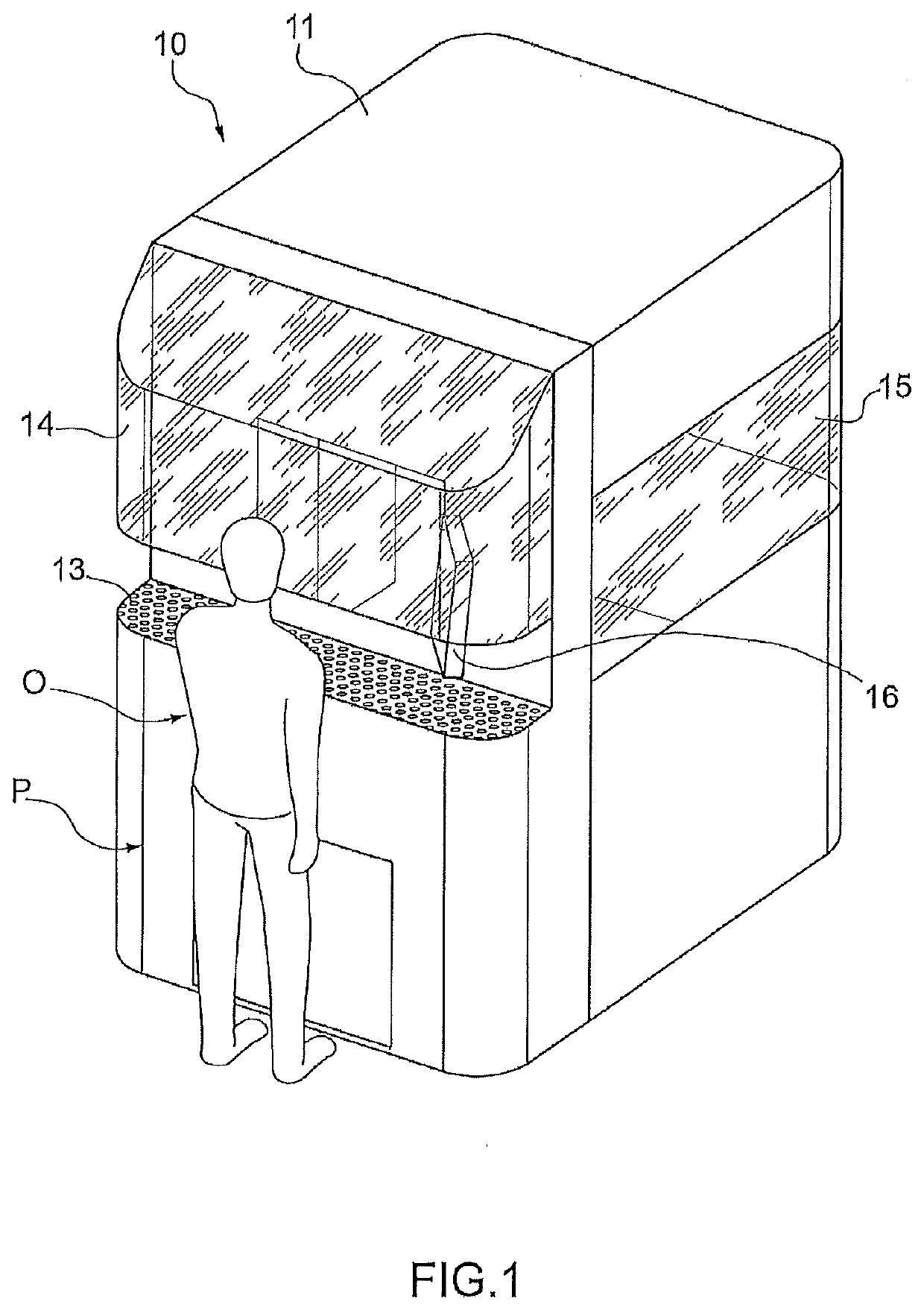

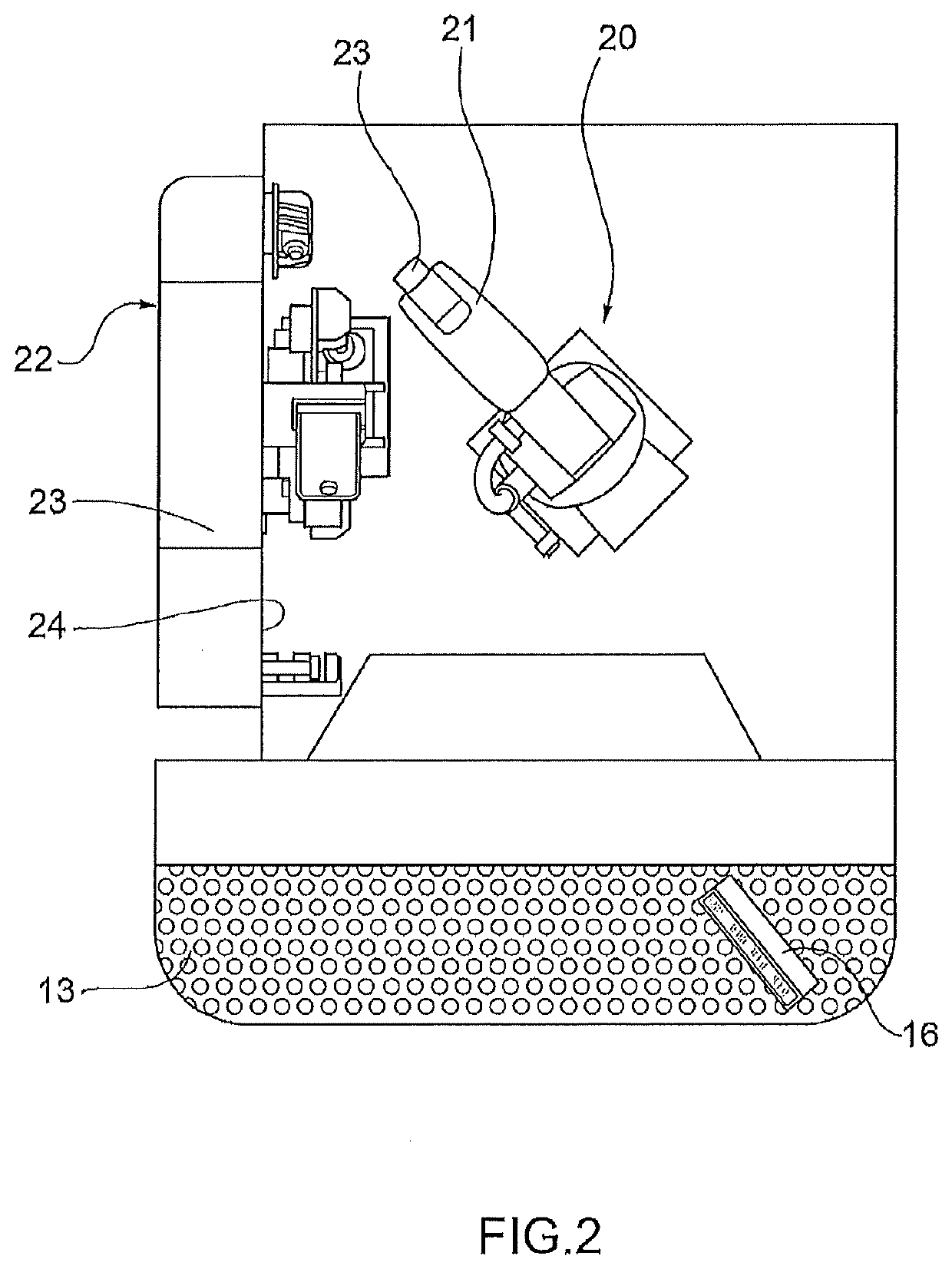

A machine for preparing intravenous medicaments including an enclosing structure having a plurality of lateral walls arranged to define a closed internal working environment. An access station affords selective access to the closed internal working environment. One lateral wall is an equipped wall on which there are defined a plurality of stations for objects used in the preparation of intravenous medicaments. The stations on the equipped wall include temporary receiving or parking stations for the objects and operating stations for carrying out operations on the objects. A handling robot is programmed to transfer the objects from any station to any other station. The machine includes a metering module with one or more container support groups, a syringe support / metering member group, and a weighing group for weighing objects used in the preparation of intravenous medicaments.

Owner:SWISSLOG ITAL

System and method for the diagnosis, evaluation and prediction of leakages in different hydraulic circuits, quickly and safely for the operator

ActiveUS10525961B2Operator safetyMeasurement of fluid loss/gain rateBraking action transmissionCouplingHydraulic circuit

Transportable system for the diagnosis, evaluation and prediction of leakages in hydraulic circuits of low pressure between 0 to 7 bar and of high pressure from 0 to 170 bar, quickly and safely for the operator is provided having a first independent circuit of high pressure and low flow and a second independent circuit of low pressure and high flow wherein the first independent circuit comprises: a first pressure subsystem, which delivers pressure to a first 4 / 3 valve with ports A, B, P and T, which is actuated by first solenoids, to deliver pressure to a first coupling A or to a first coupling B, in fluid communication with the ports A and B of the first 4 / 3 valve respectively a computer arranged to control the pressure of each pressure subsystem and associated method.

Owner:SOC RAMIREZ E HIJO LTDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com