Closed filter press

A filter press and closed technology, applied in the field of filter press for filtration equipment, can solve problems such as affecting economic benefits, leakage, deformation and leakage of filter plates, etc., to improve filtration efficiency, keep the environment clean, and compact and closed performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

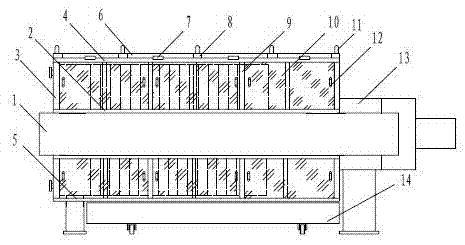

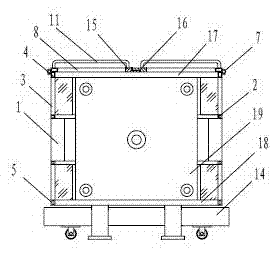

[0014] see figure 1 and figure 2 As shown, the present invention provides a closed filter press. The structure is based on the main beam 1 of the filter press. The filter press is an automatic pulling plate, and its components are all installed in the main beam. The main beam 1 is a box type seal. type, pulling plate and unloading cakes are all known technologies, and will not be described here. The fixed frame 2 is installed on the upper end of the main beam 1, the fixed frame 2 is welded to the column 3 and the support 9 to connect the upper frame 4, and the upper horizontal frame 17 is set to weld the upper frame 4 The upper frame body is formed by welding with the column 3. The material used to make the upper and lower frame body is a profiled square tube made of carbon structural steel or stainless steel. A fixed frame 2 is welded at the lower end of the main beam 1, and the fixed frame 2 is welded to the column 3 and the support. 9 Connect the lower frame 5, set the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com