Patents

Literature

36results about How to "Increase efficiency and effectiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

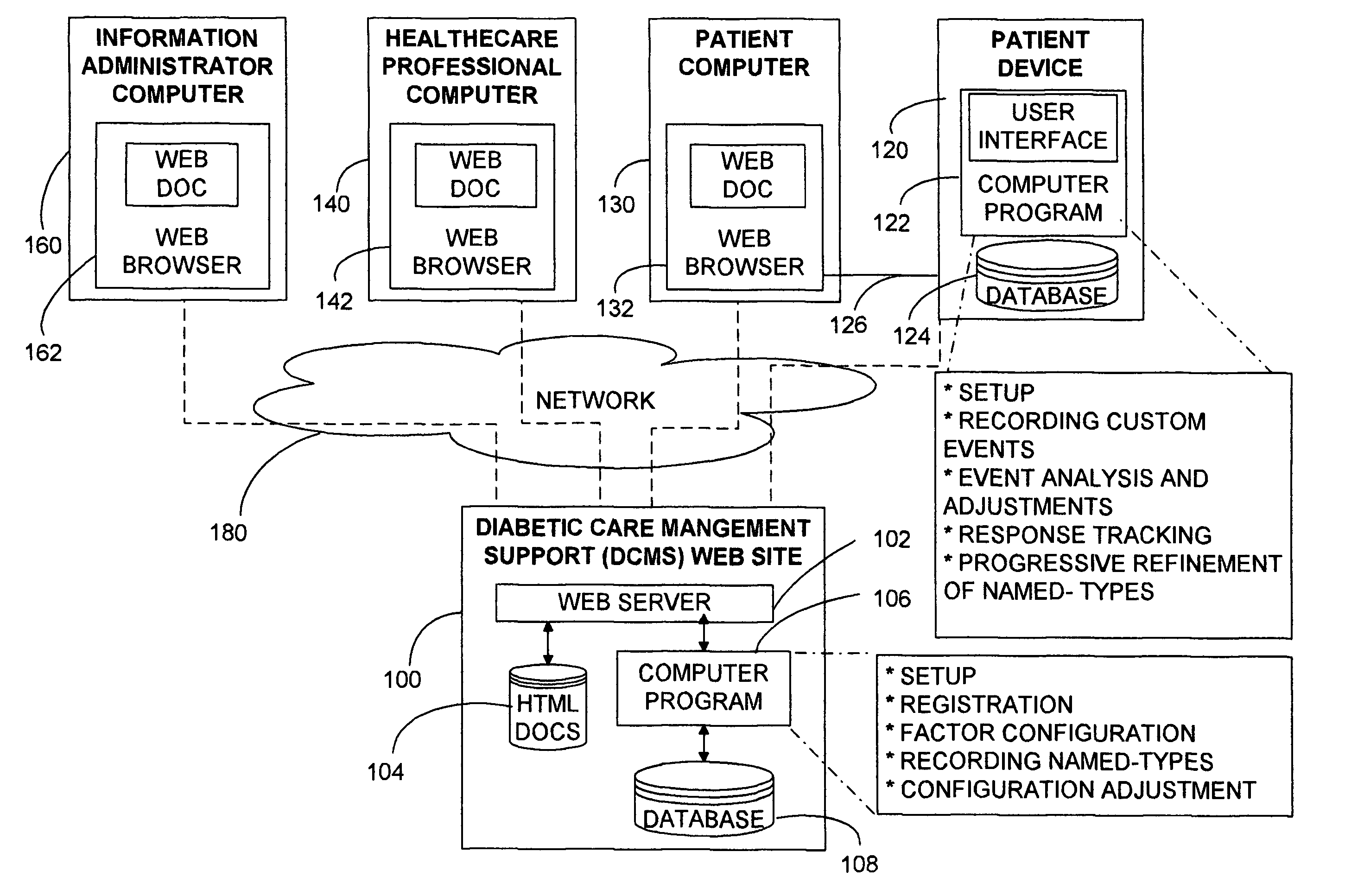

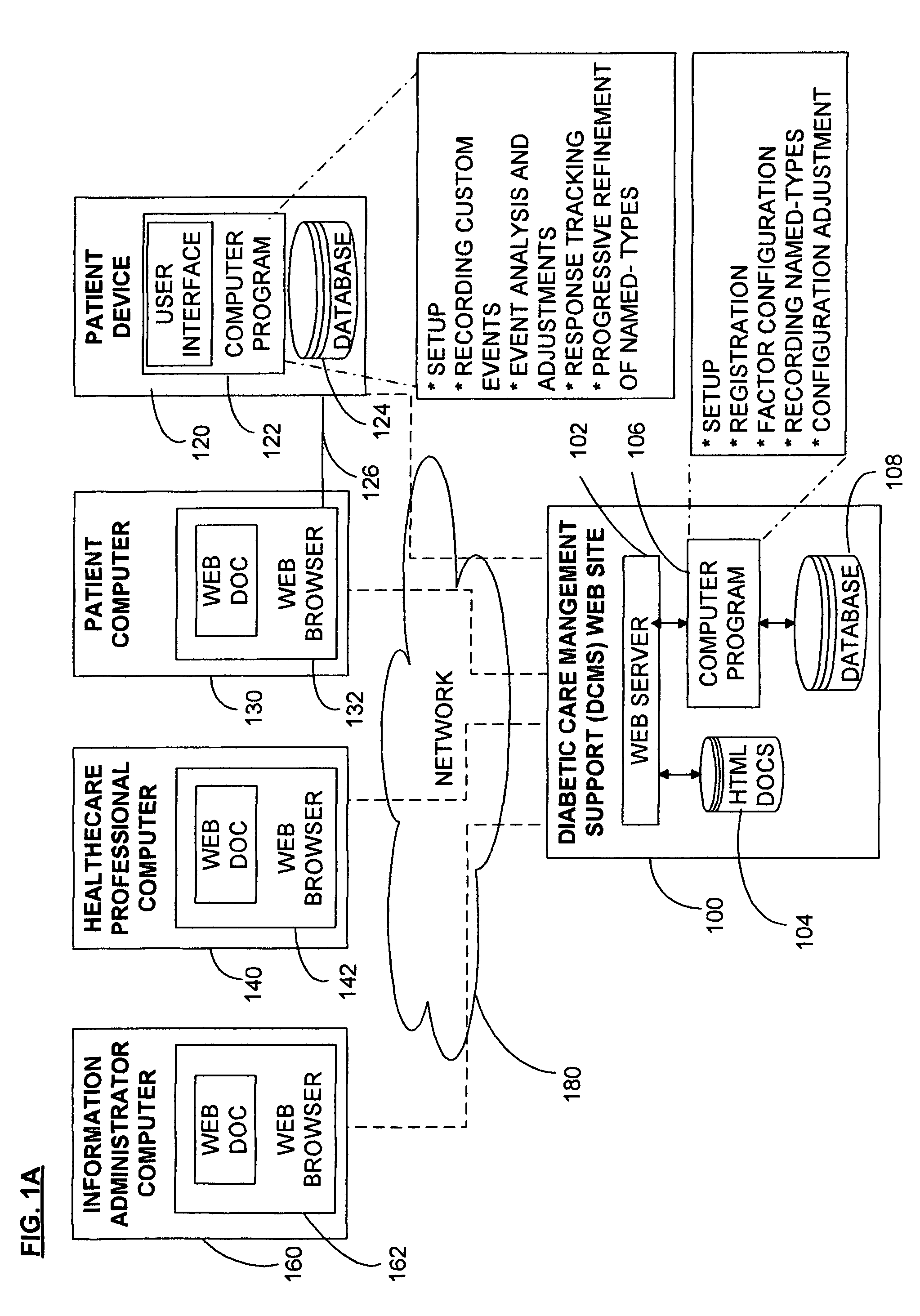

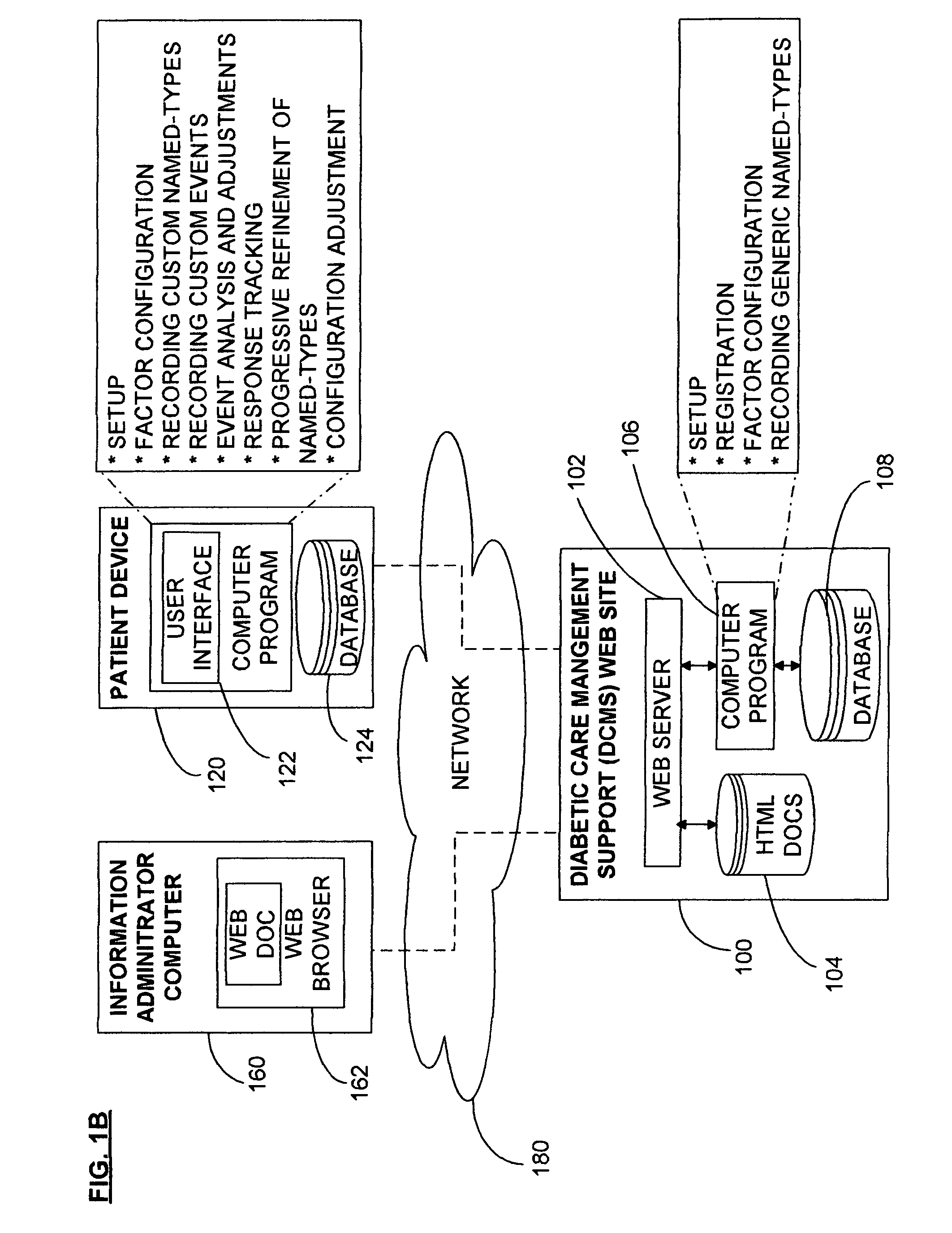

Method and apparatus for chronic care treatment control with custom named-type factors and user estimation error correction

ActiveUS8185412B1Improve patient wellConvenient treatmentData processing applicationsDrug and medicationsStress levelGlycemic

A method and apparatus to record and track patient's estimation of arbitrary factor types, to analyze response errors utilizing discrete measurements, to isolate errors in various factor types and their response correlations, to enable patient in refining factor mix to reduce estimated outcome variations, and to improve patient estimation with corrections using a continuous feedback system. The input factors for the treatment in case of a Diabetic patient may be food intake, medication, activity, stress level etc, while the treatment outcome or response may be blood glucose level that the patient needs to keep within specific limits. Present invention enables a chronic care patient, such as a Diabetic patient, to make better and informed decisions about their treatment, reduce input factor estimation errors, reduce outcome parameter variations, and improve the patient well being by better treatment control.

Owner:HARPALE MAHESH

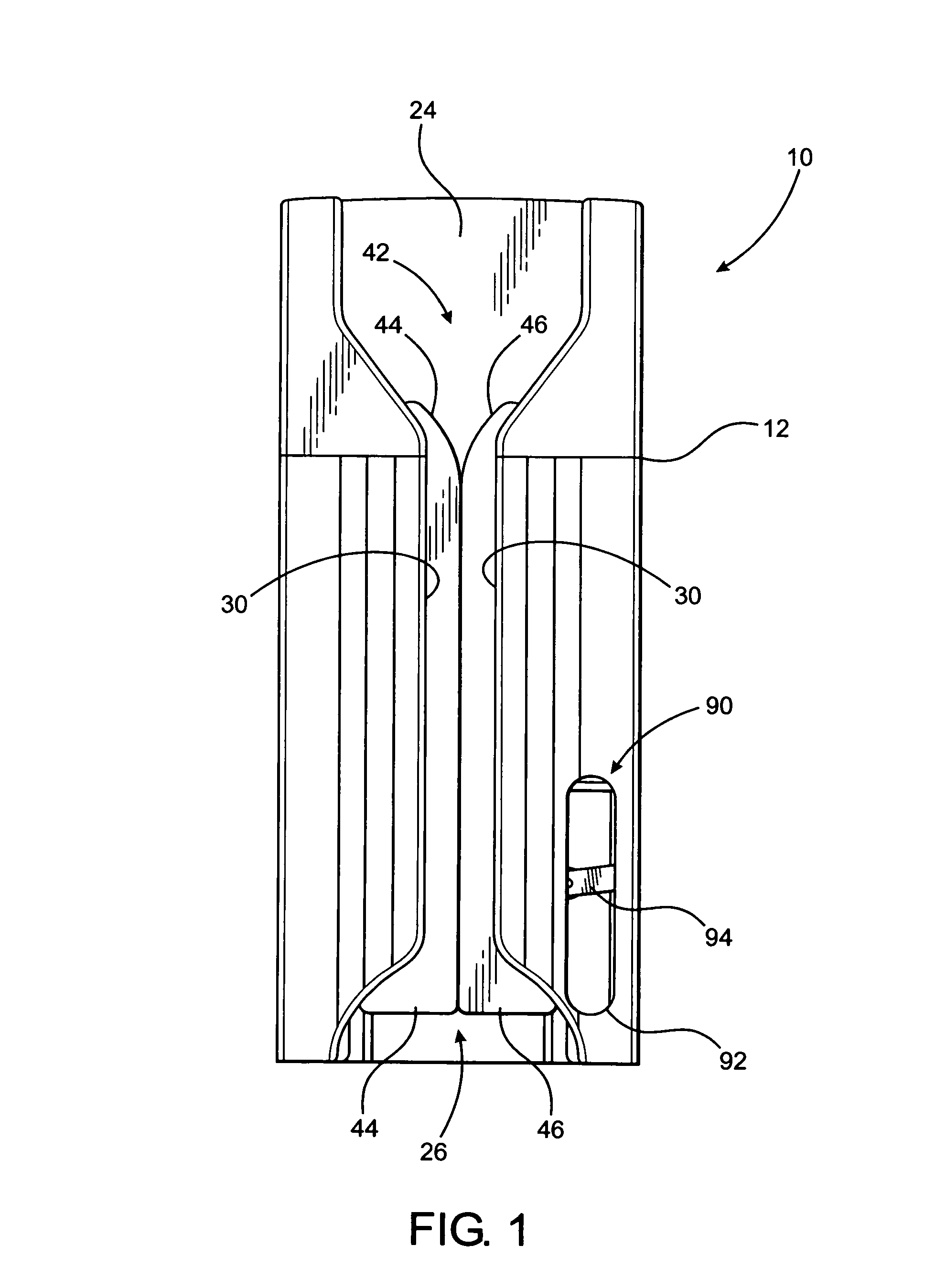

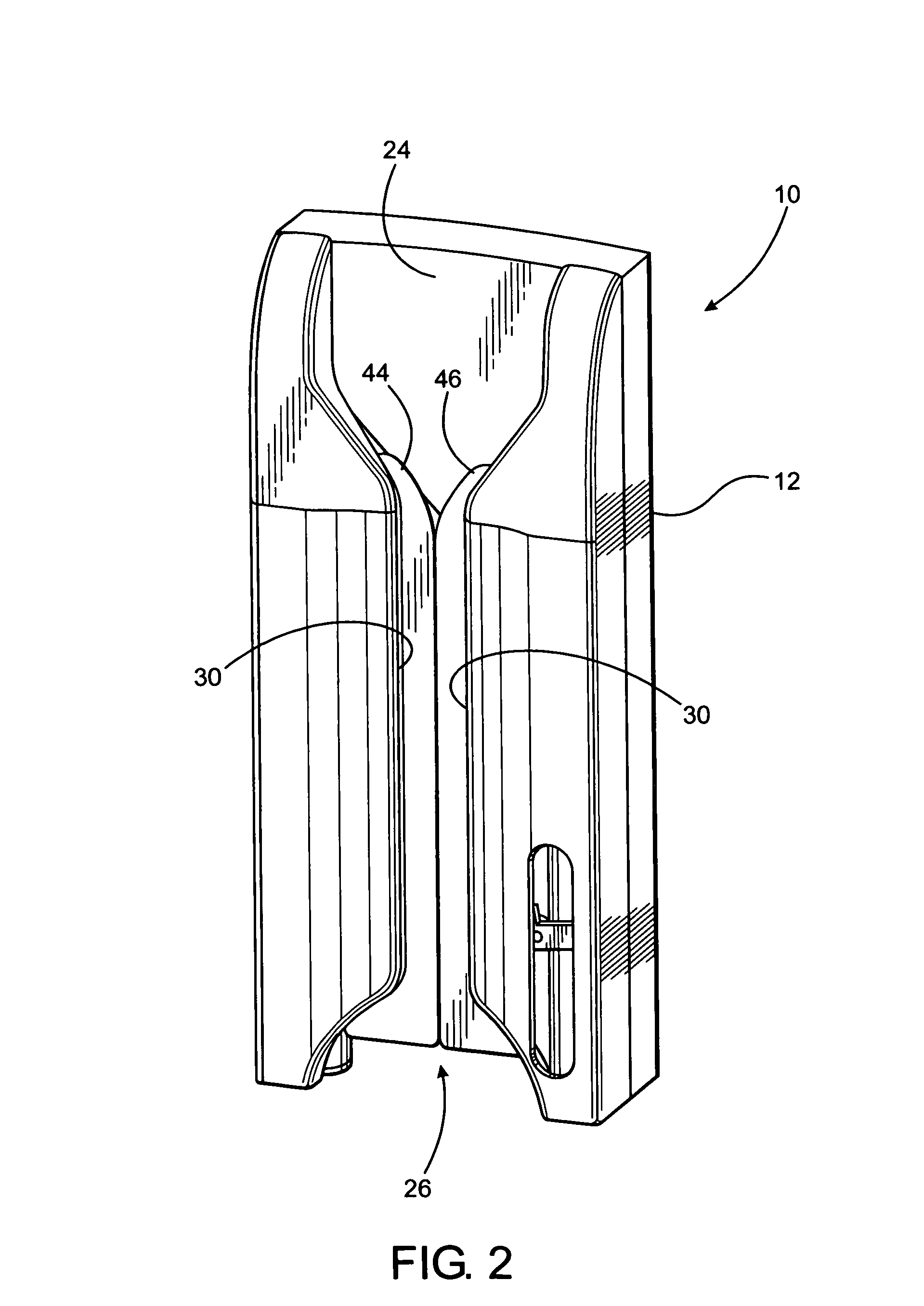

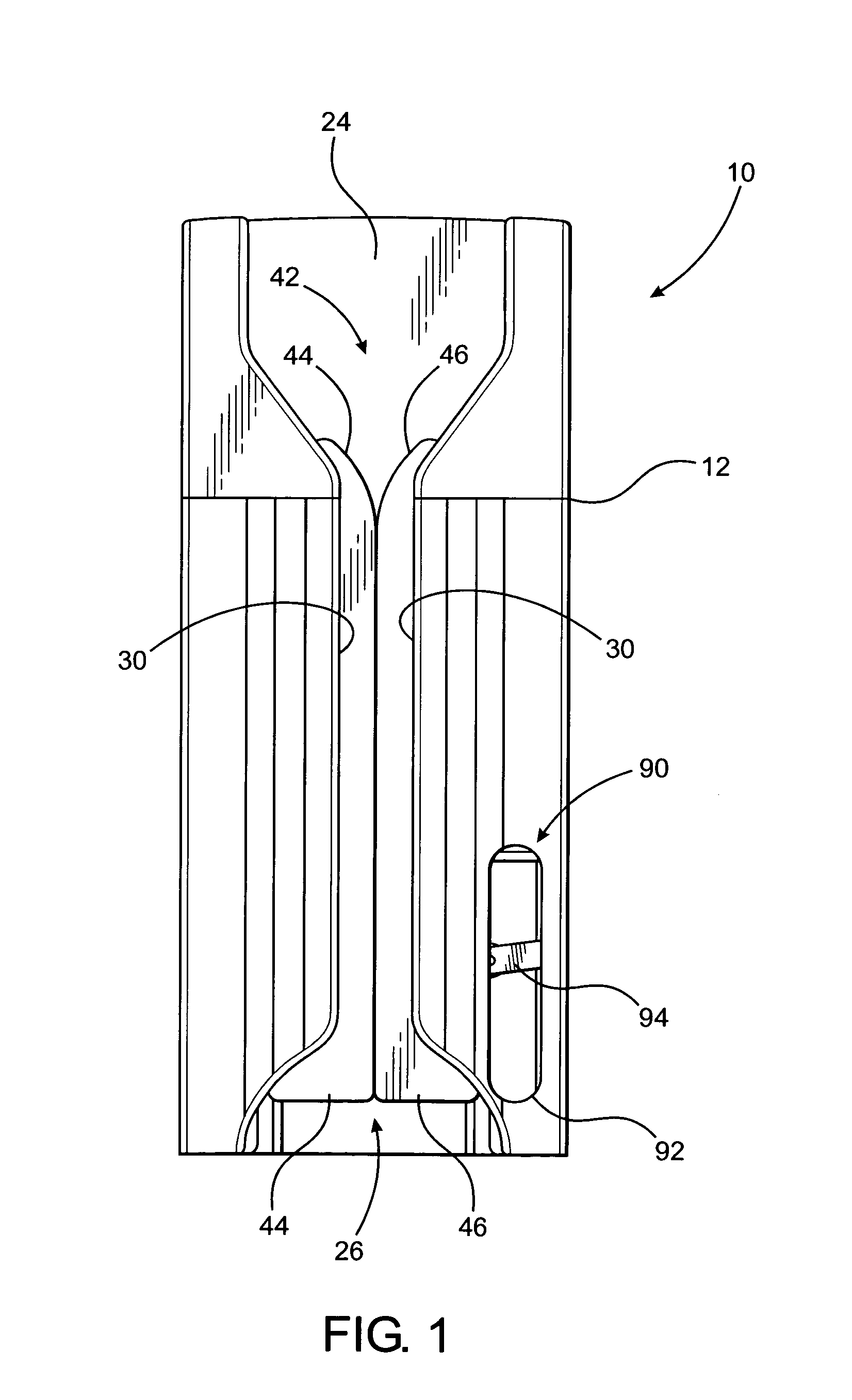

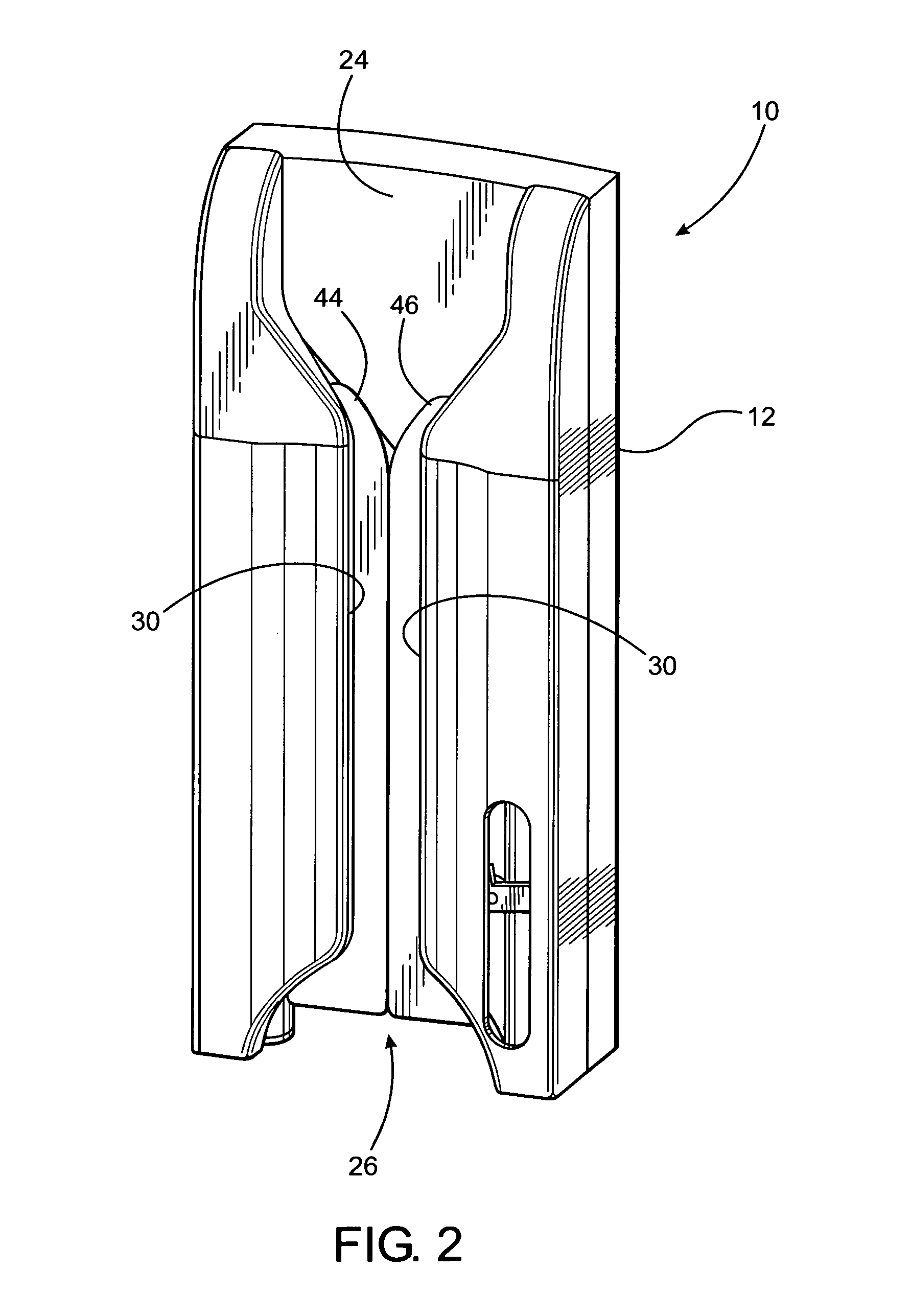

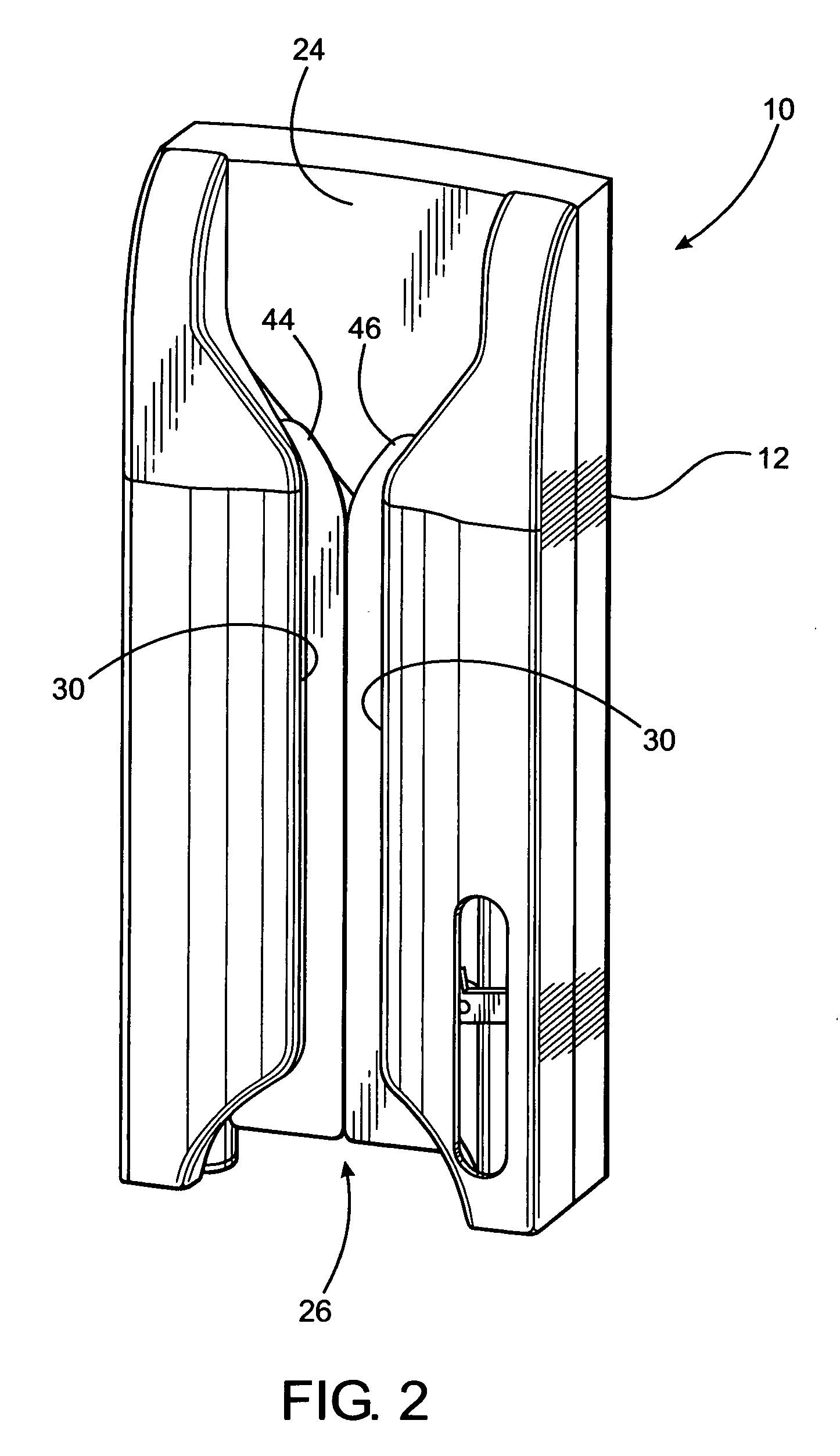

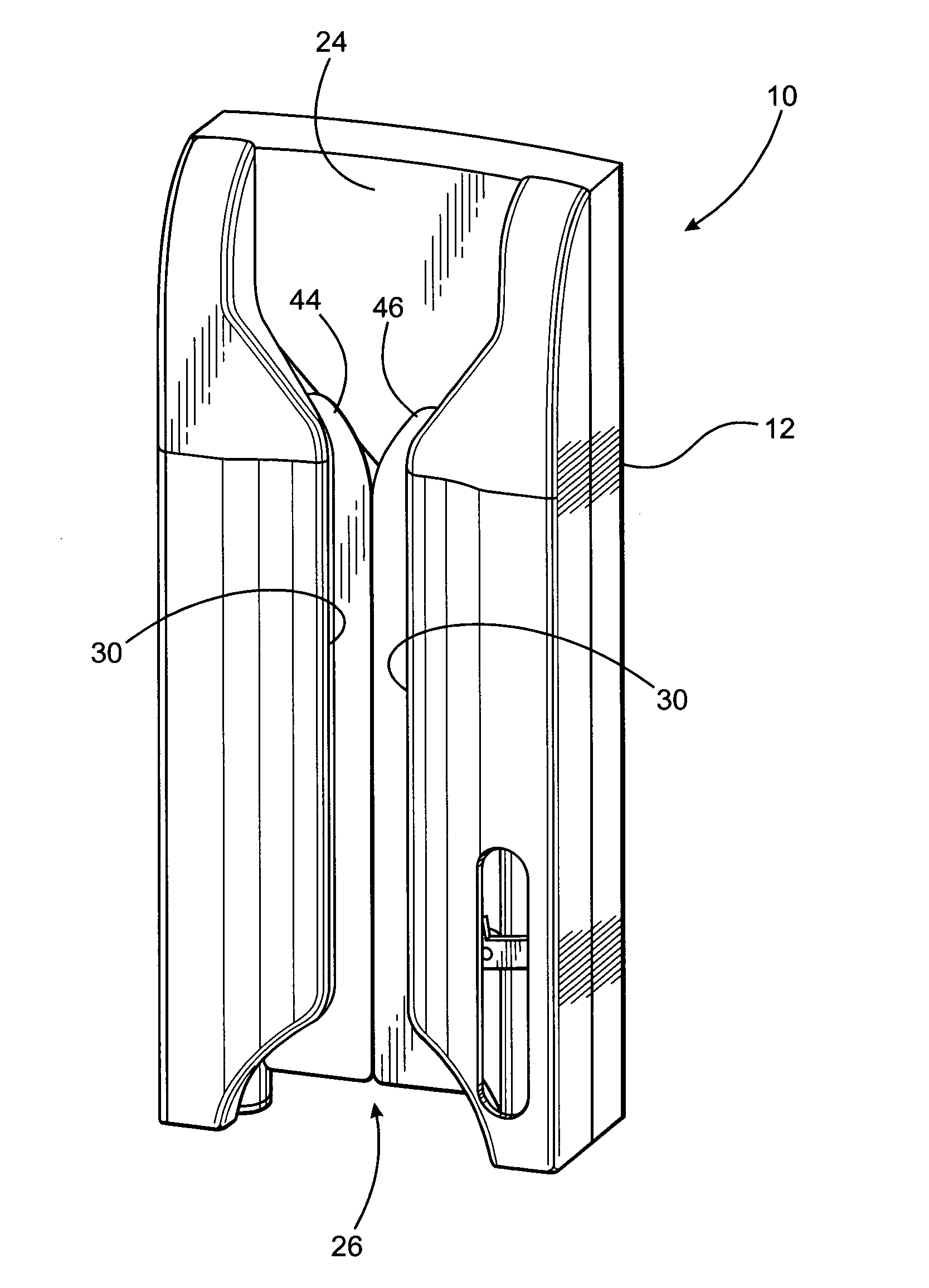

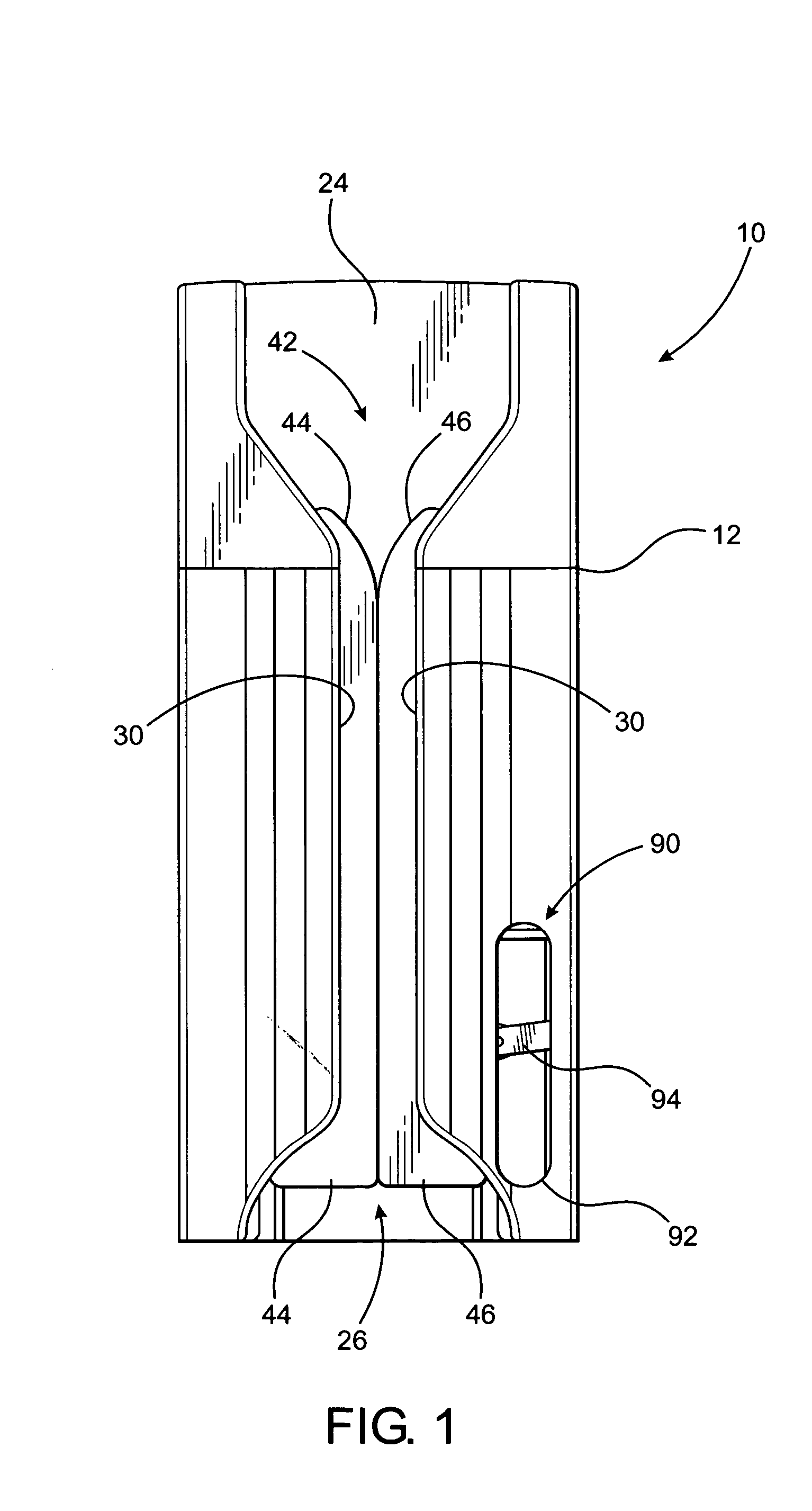

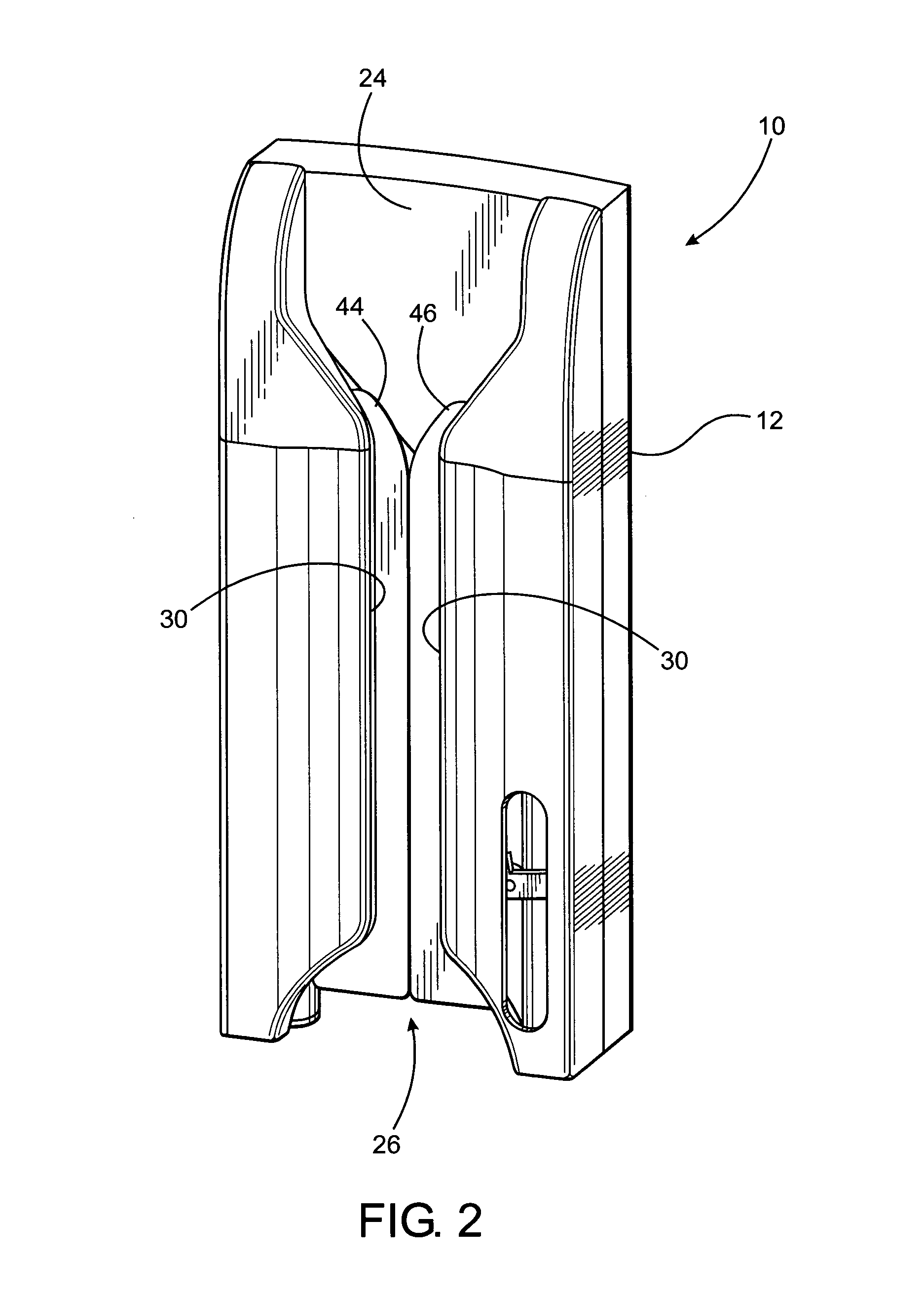

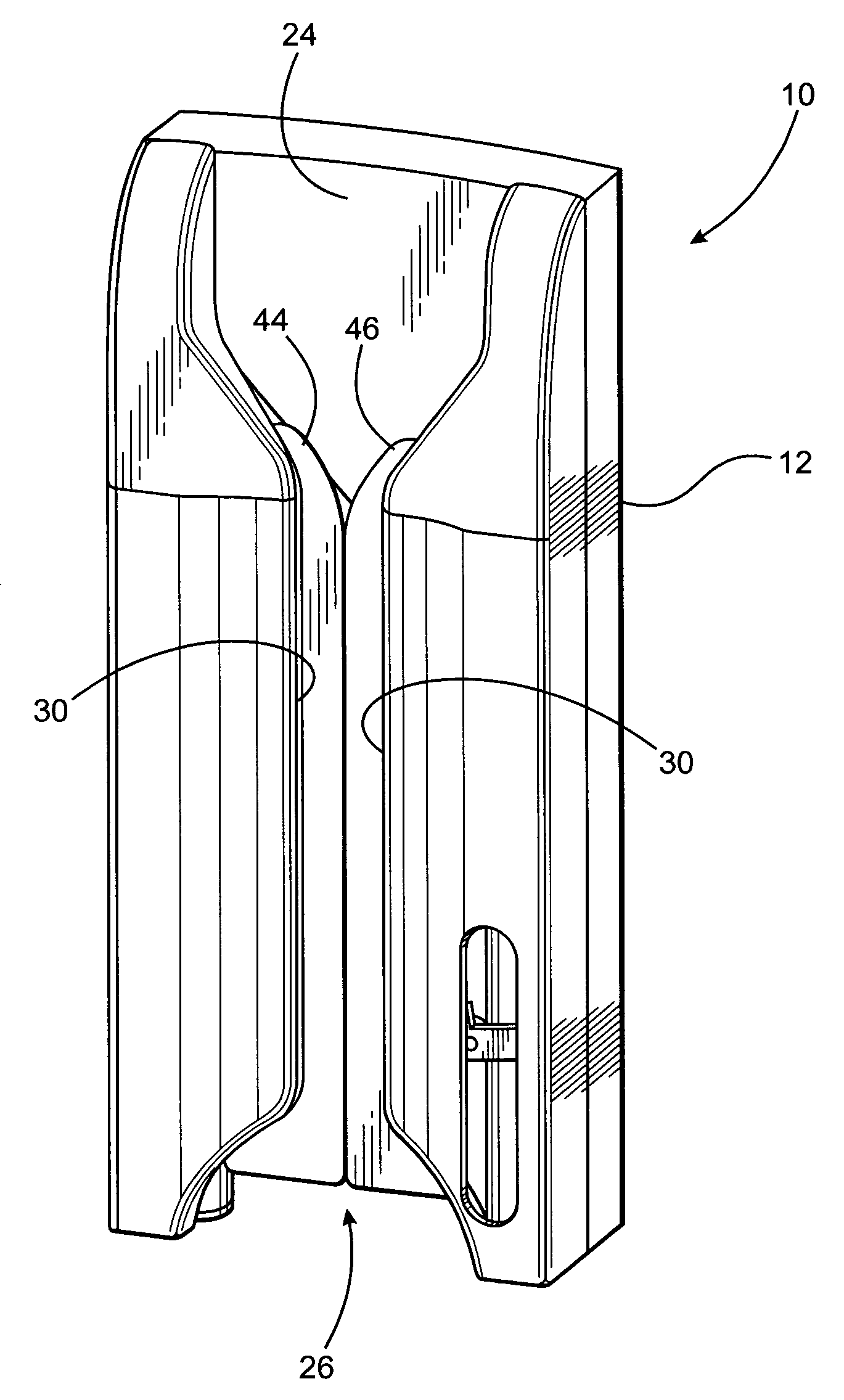

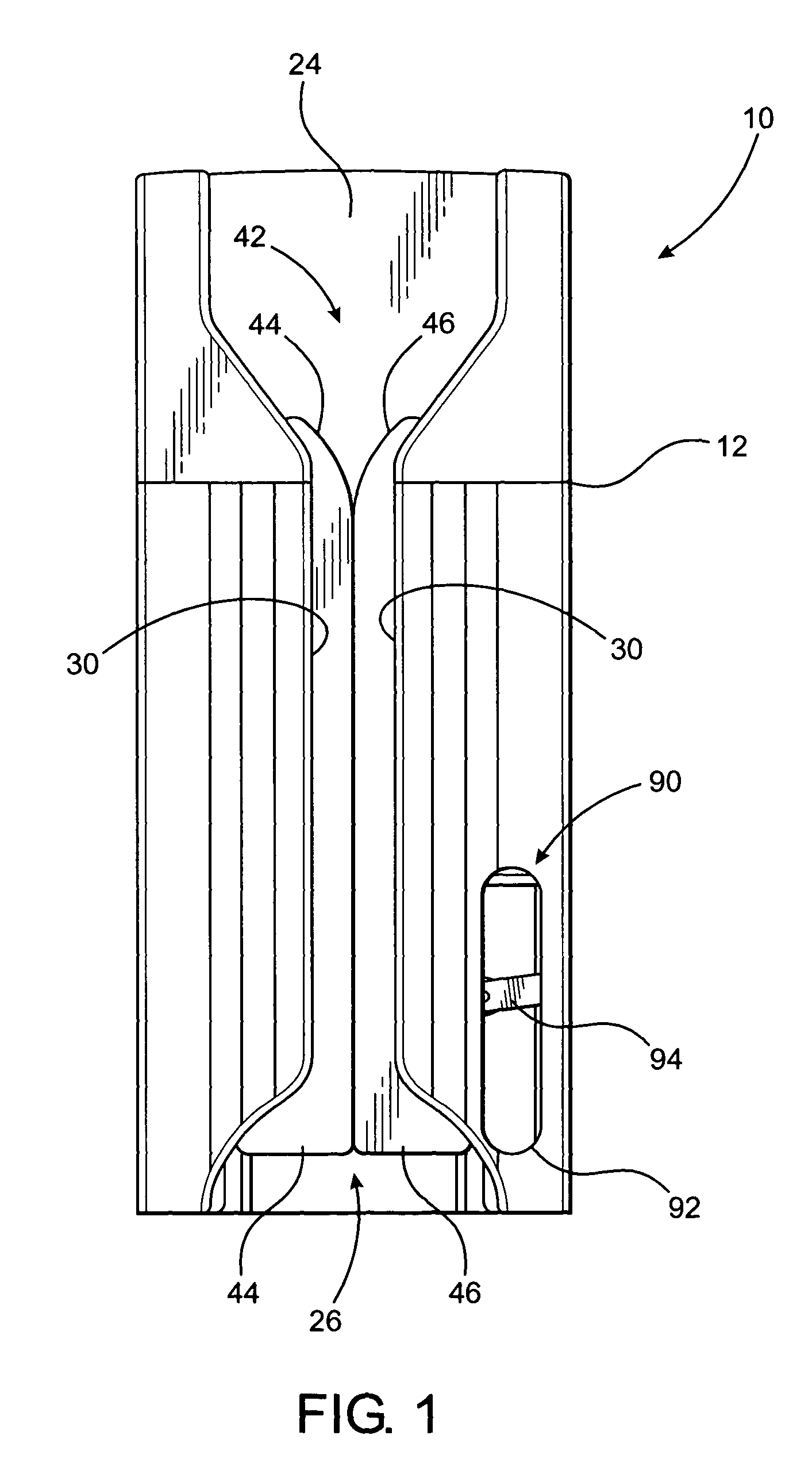

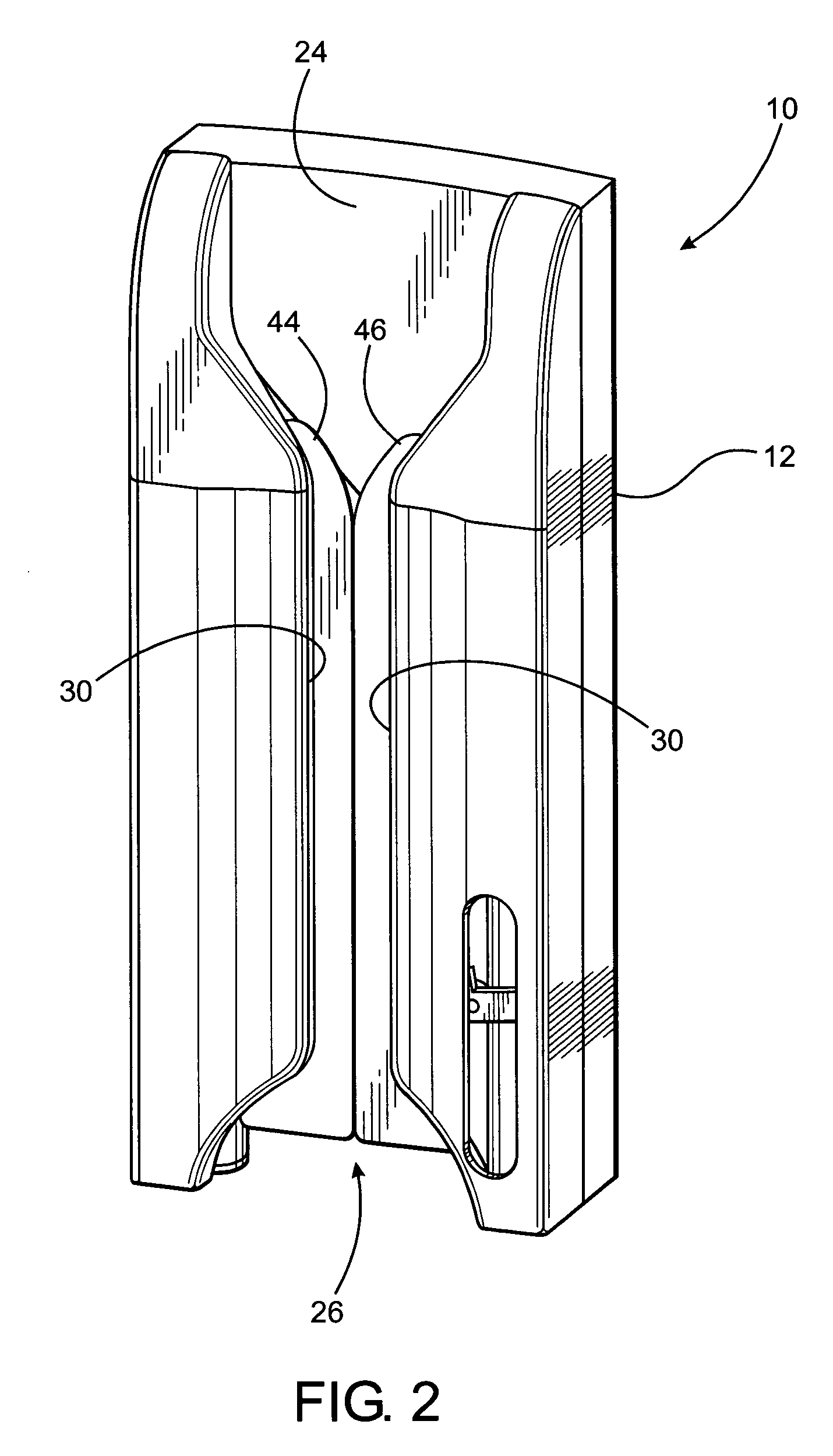

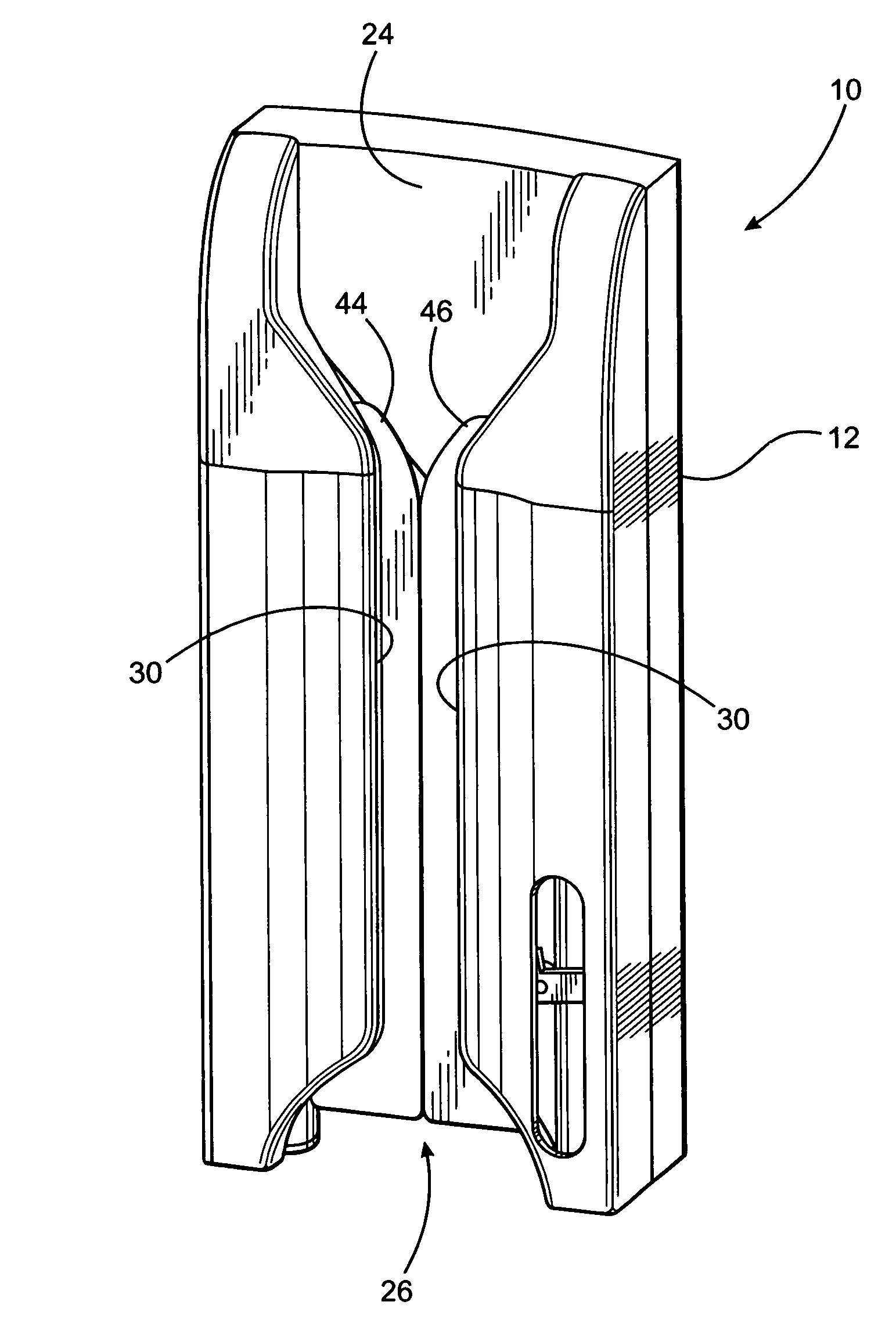

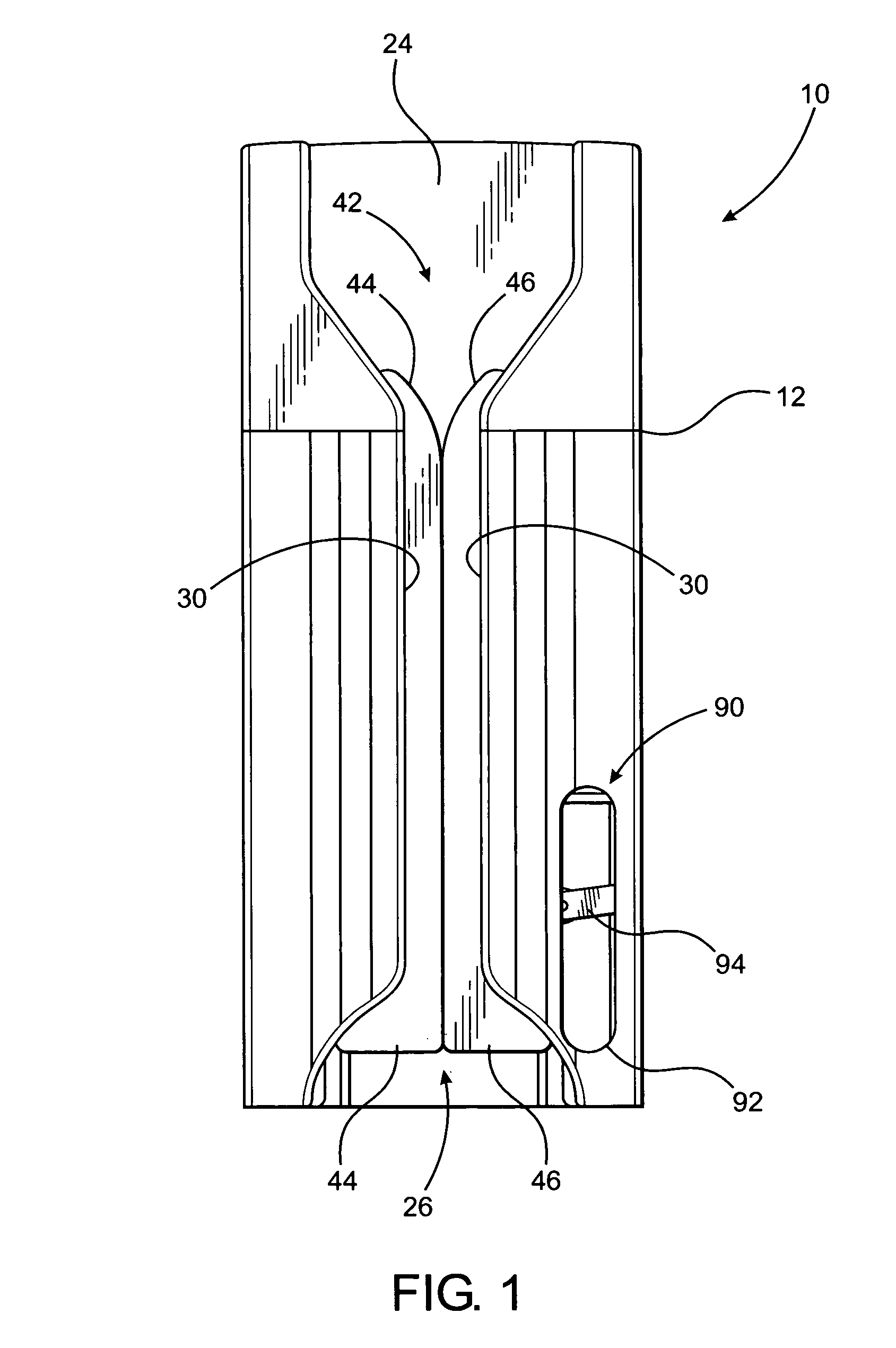

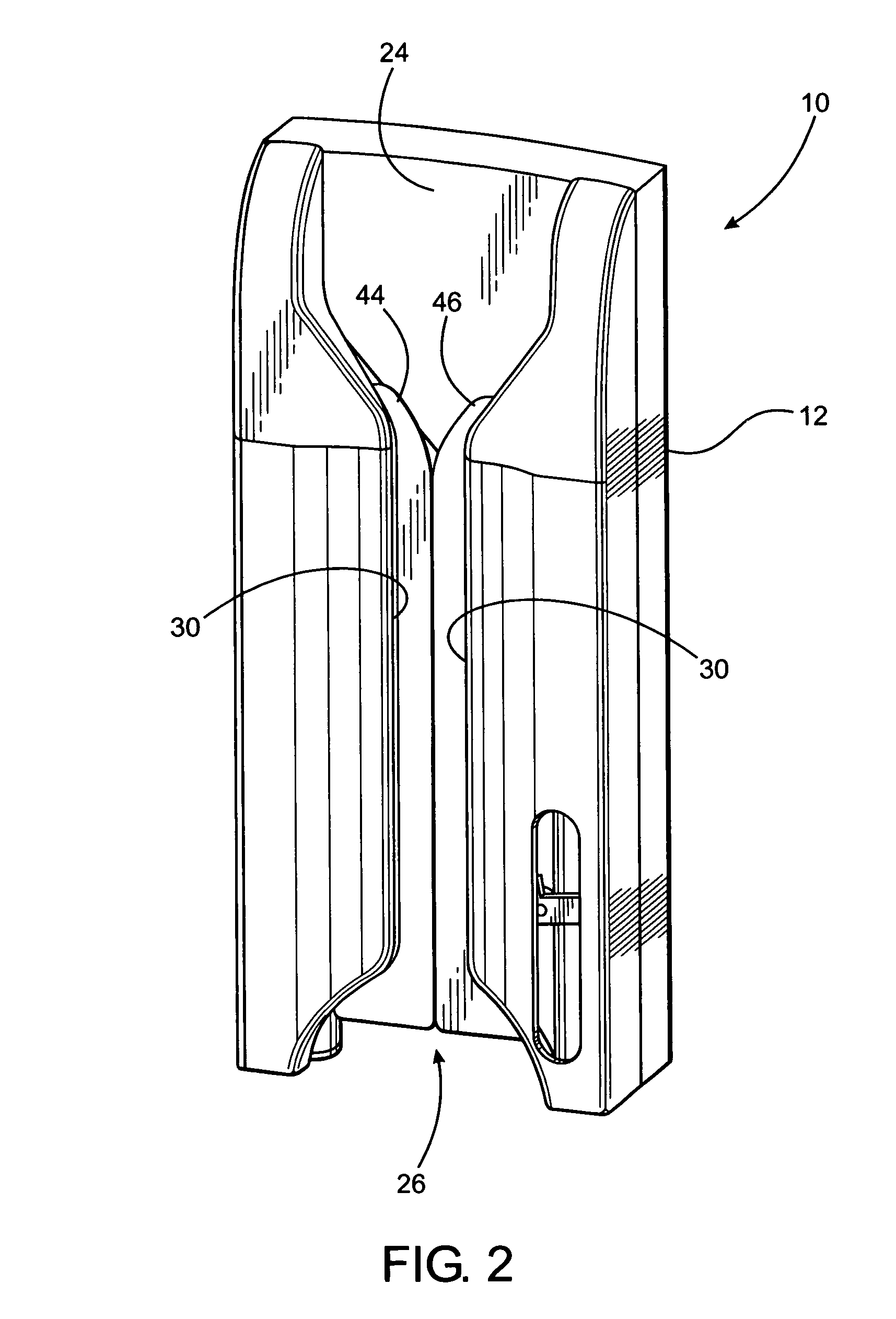

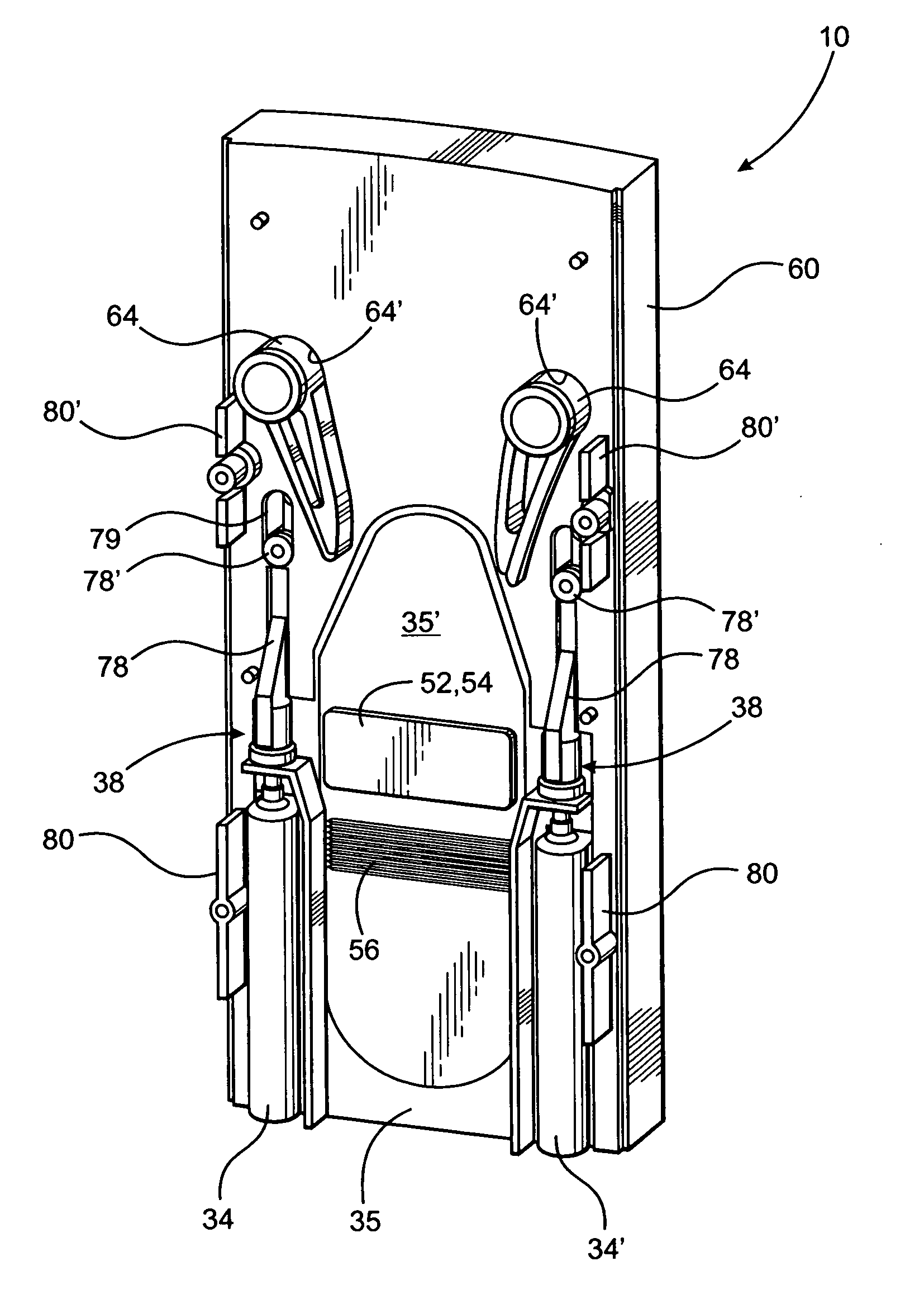

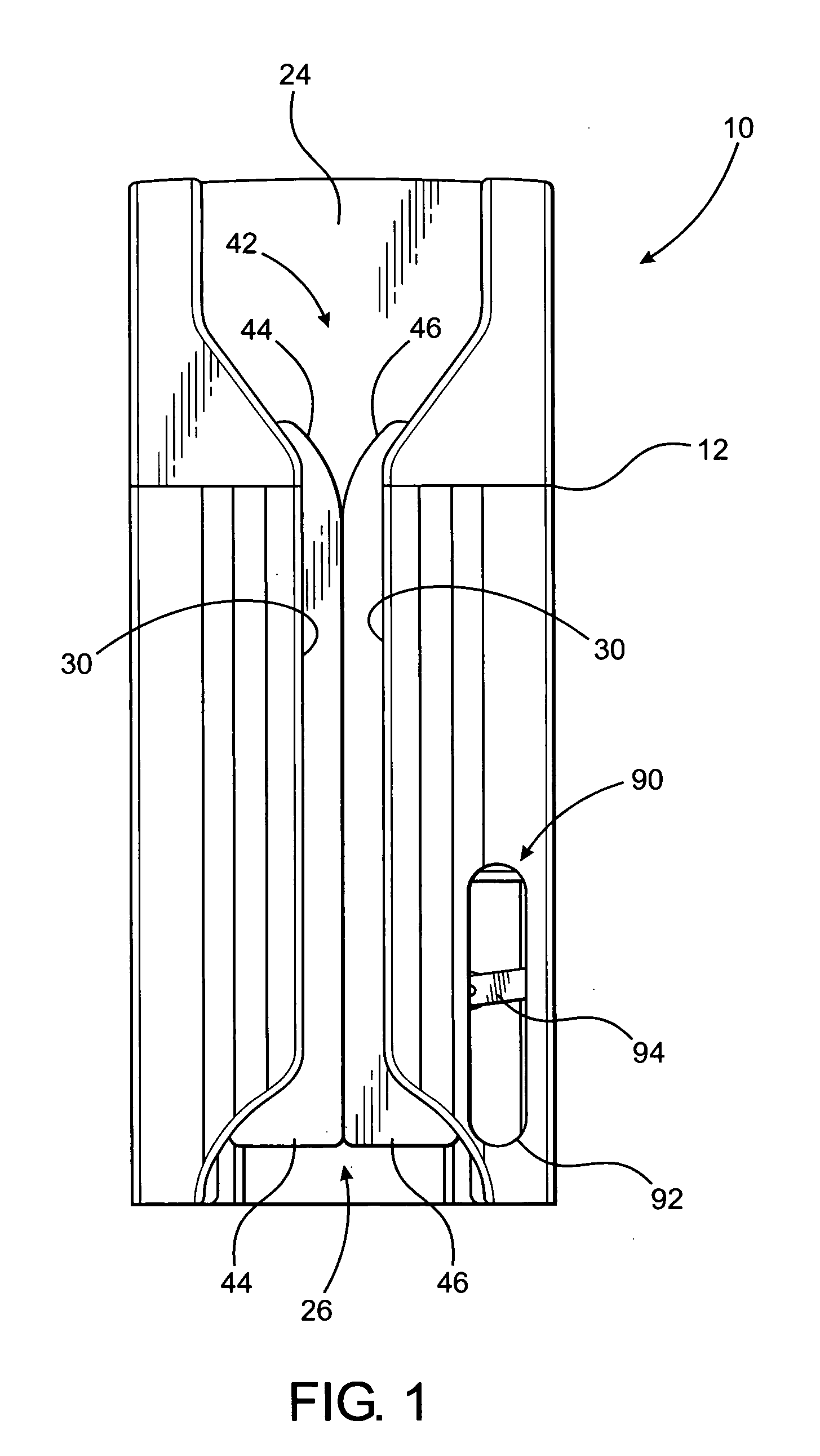

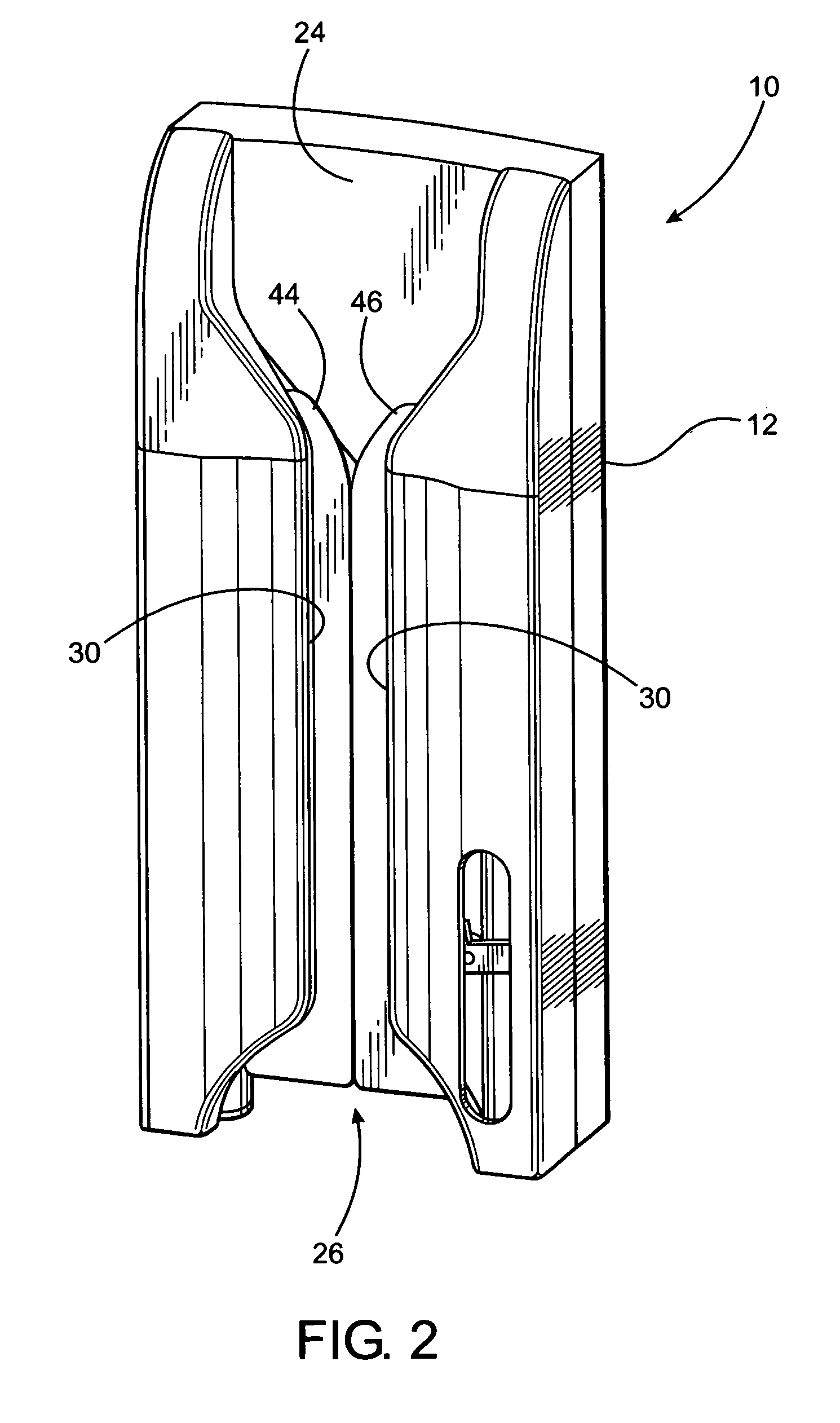

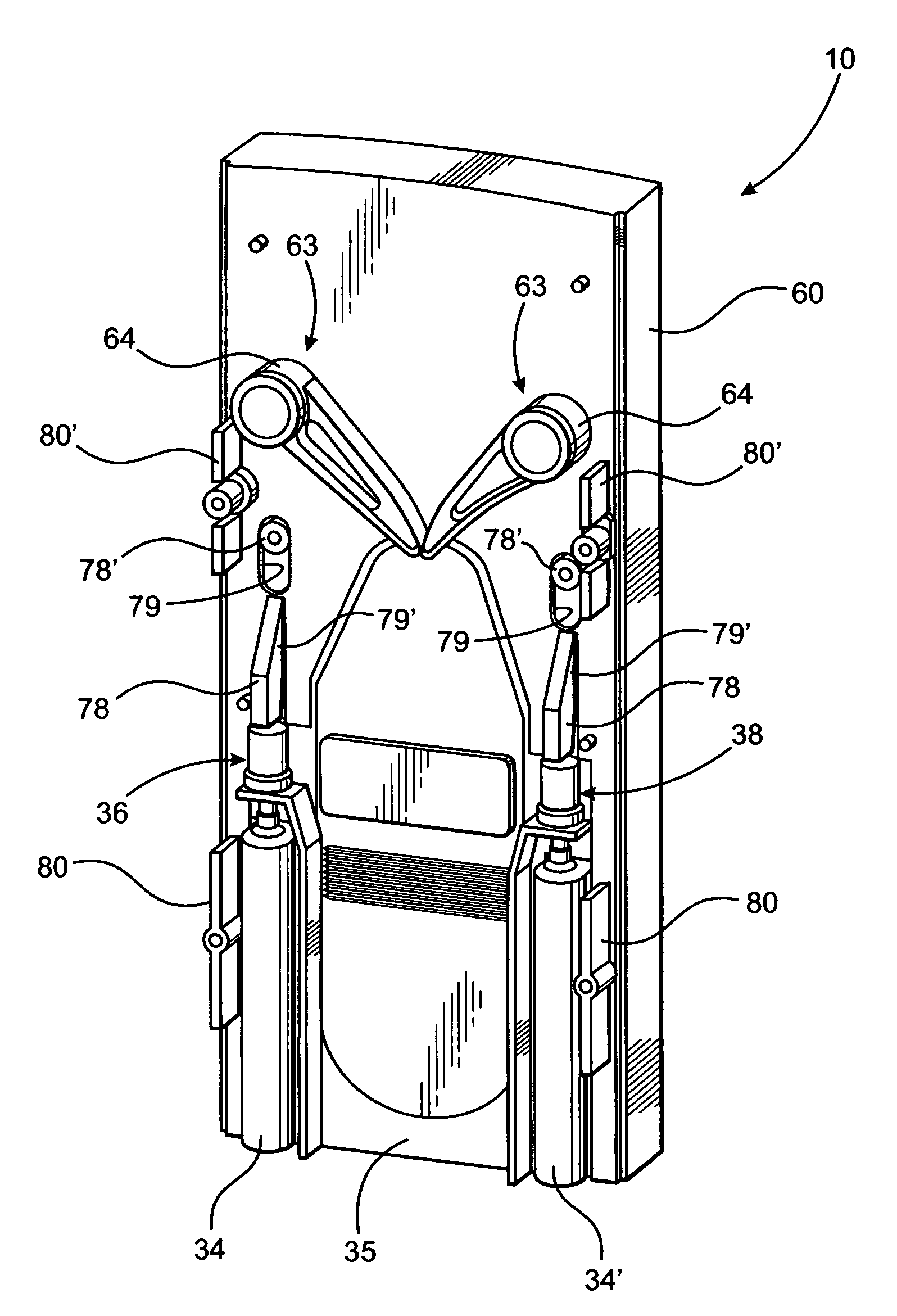

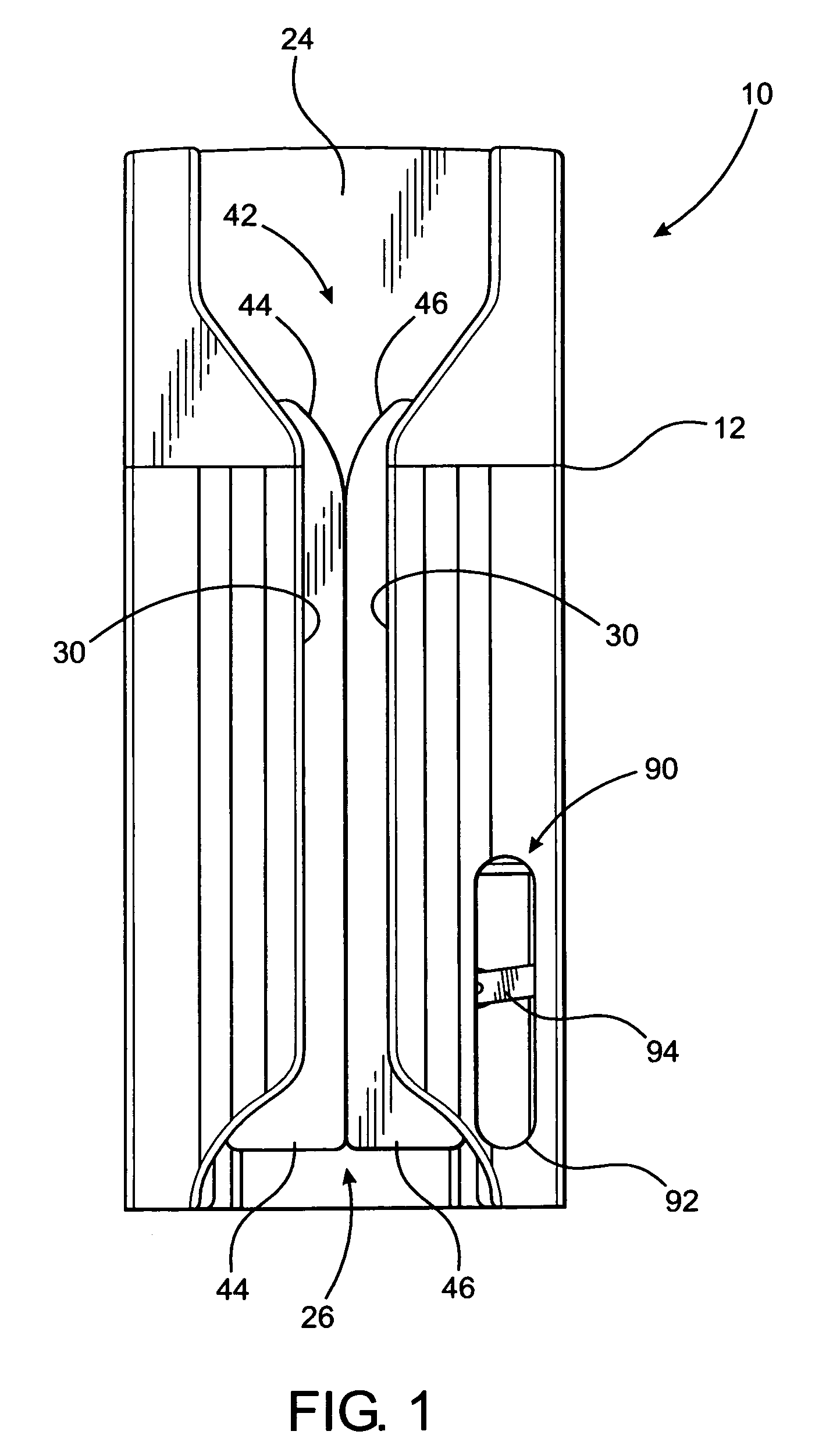

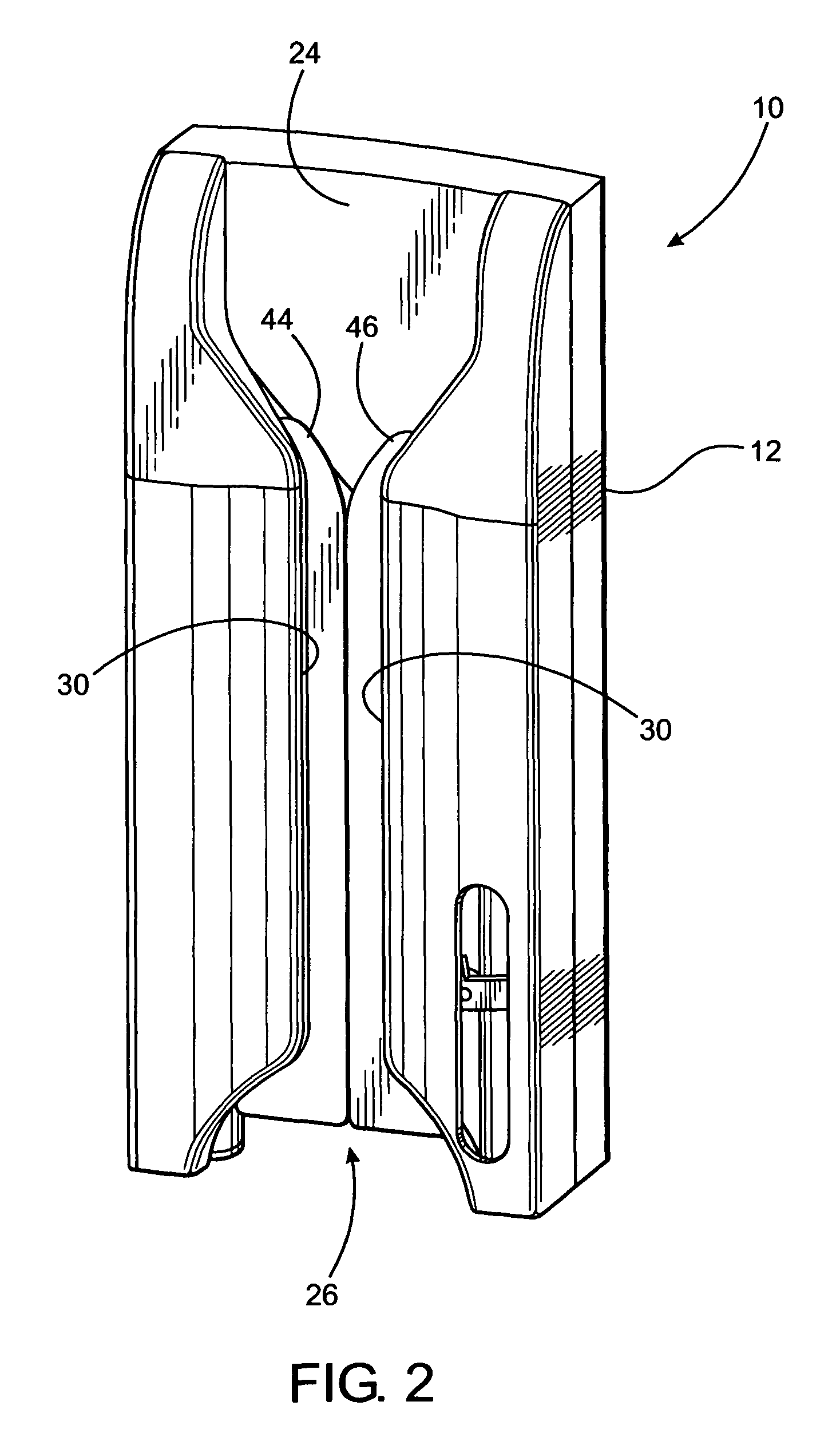

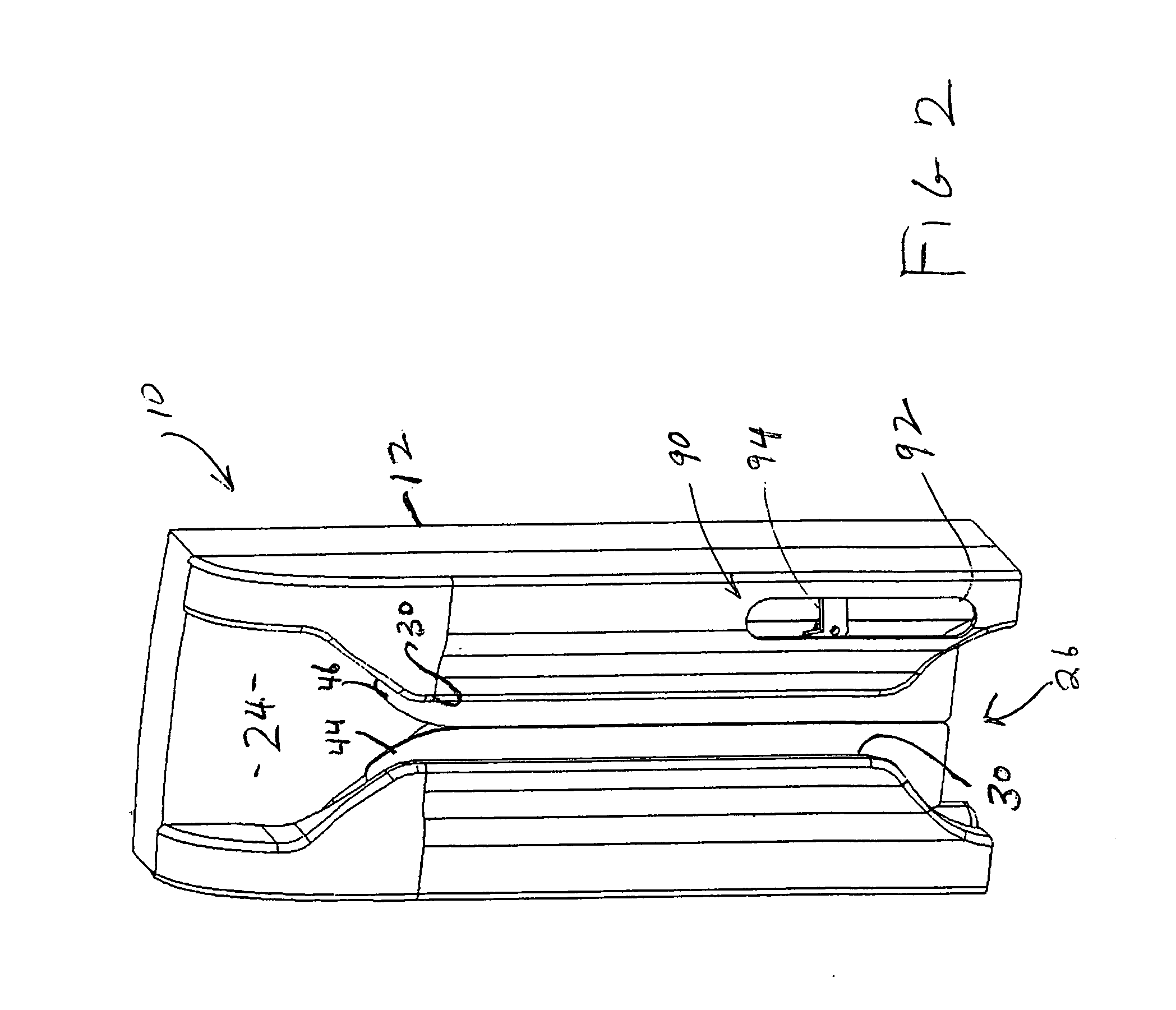

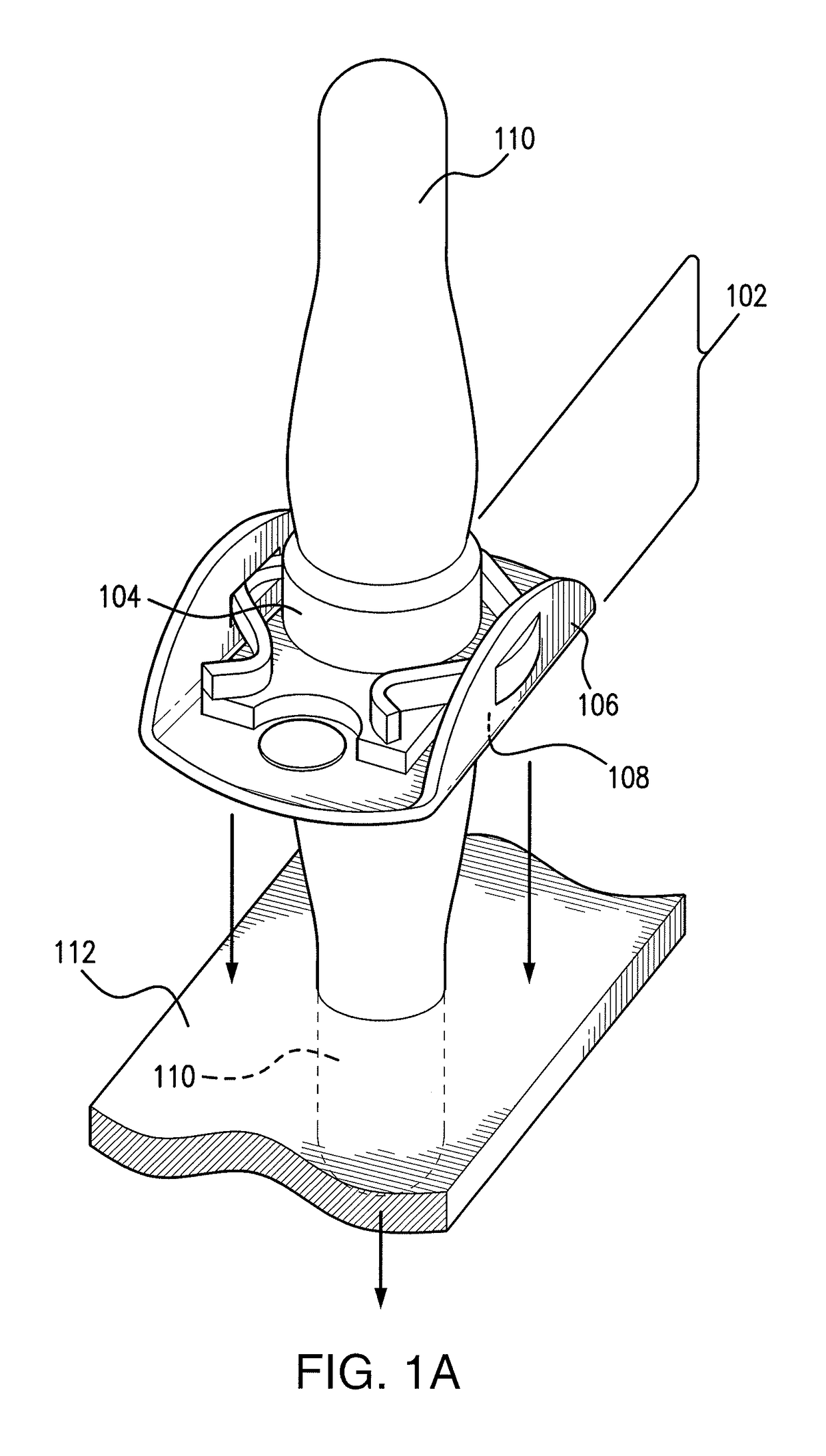

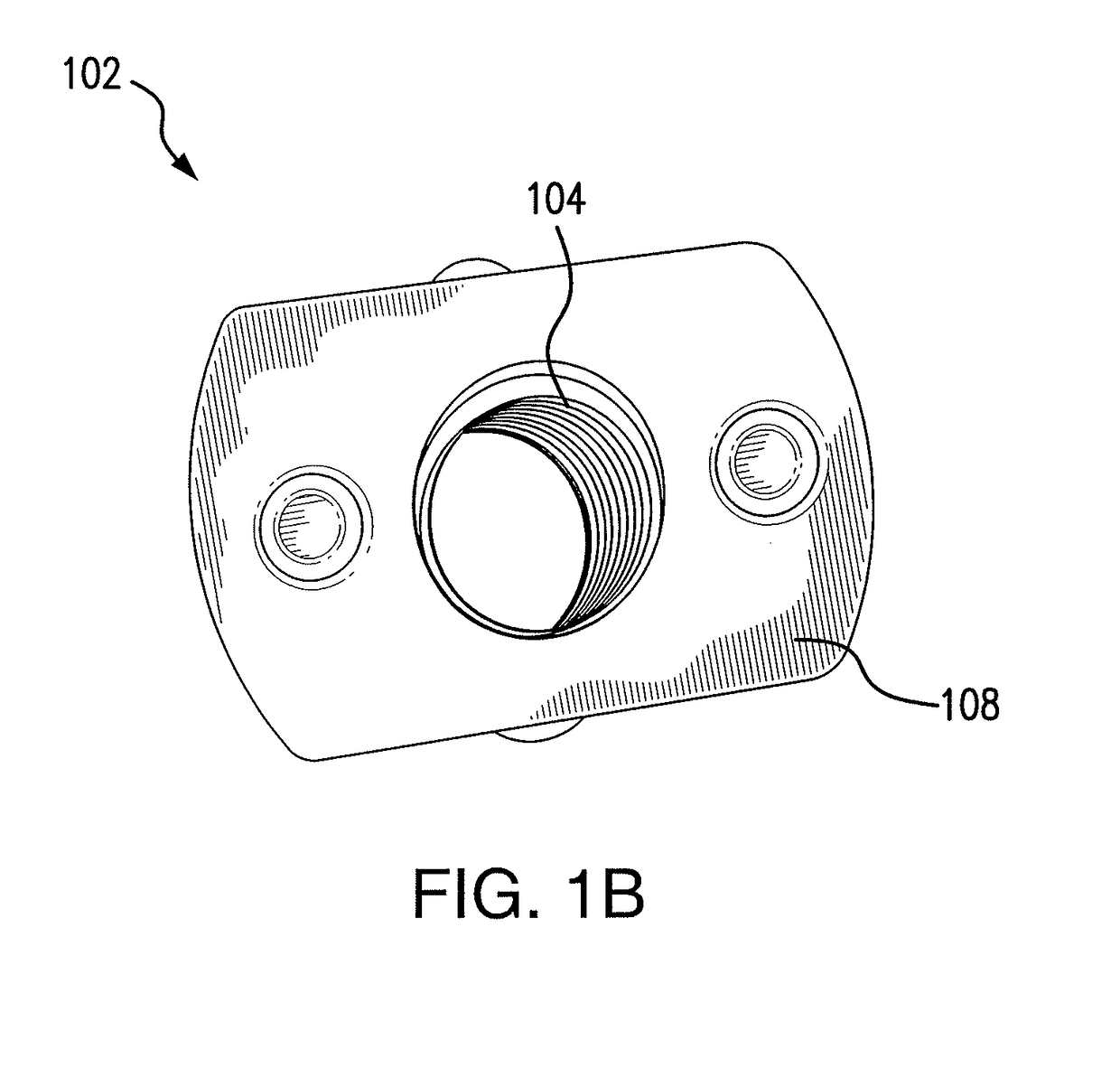

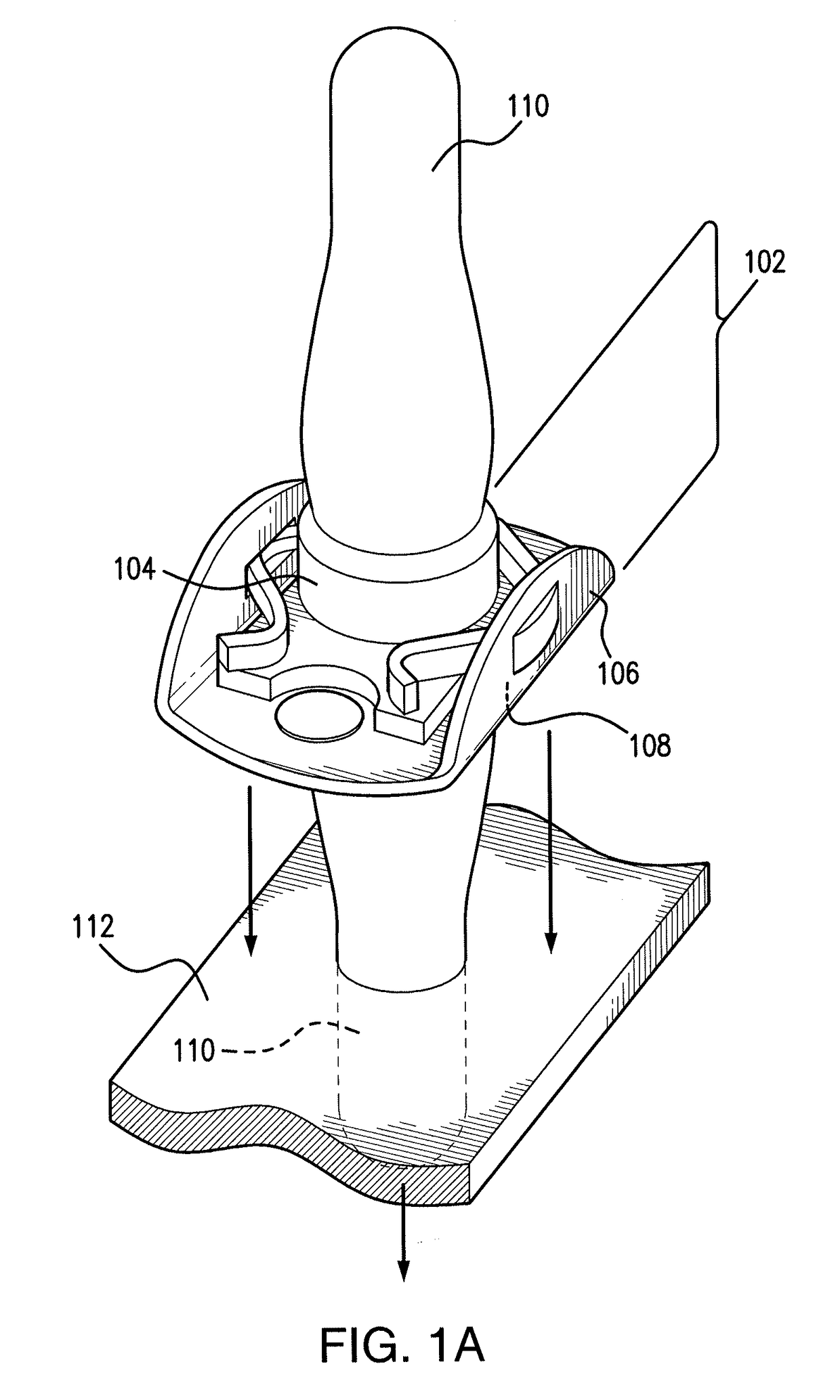

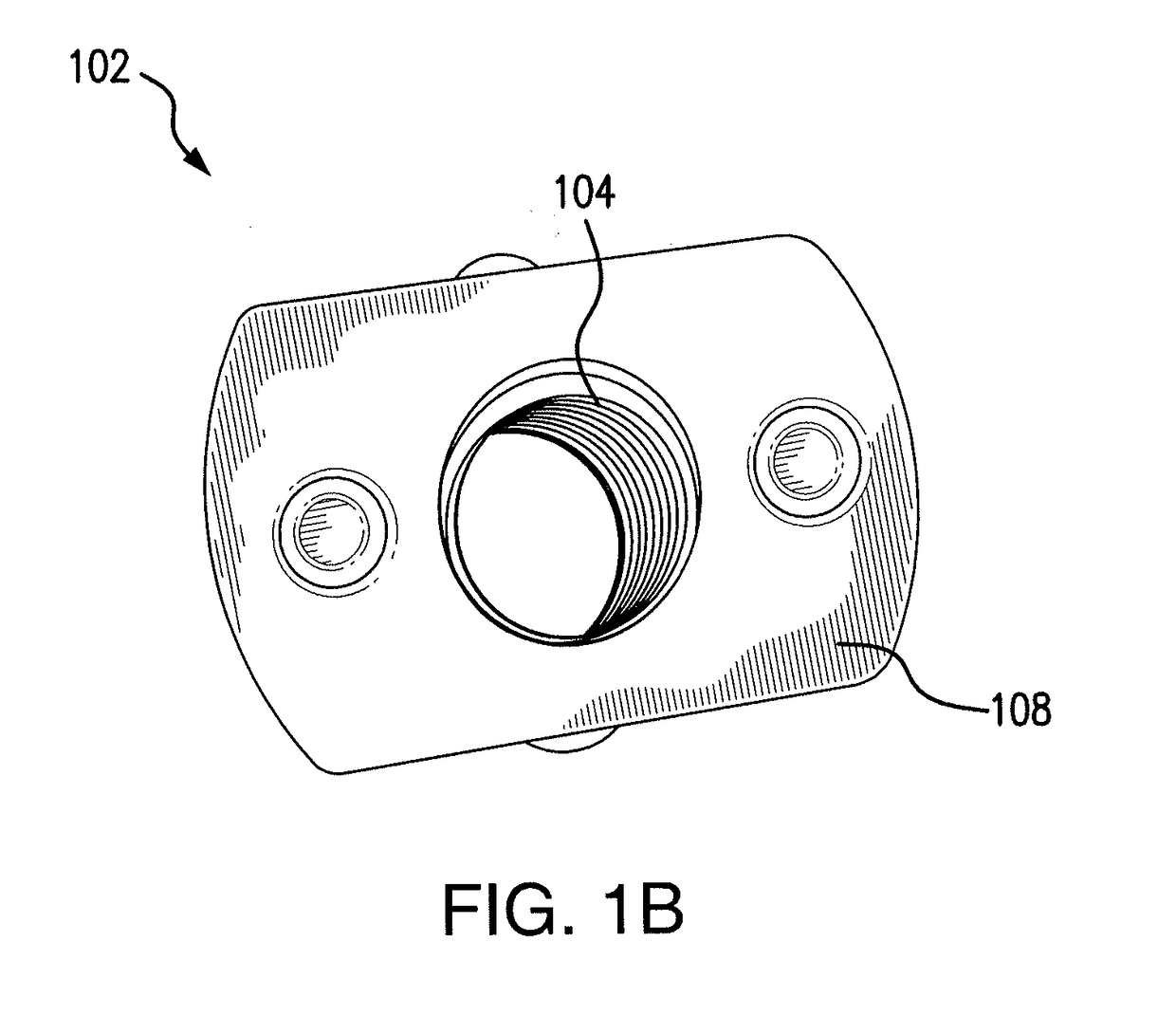

Stethoscope cleaning assembly

ActiveUS7503335B2Increase efficiency and effectivenessFacilitate passage of the headStethoscopeSurgeryAssembly structureStethoscope

Owner:SEEDLINGS LIFE SCI VENTURES

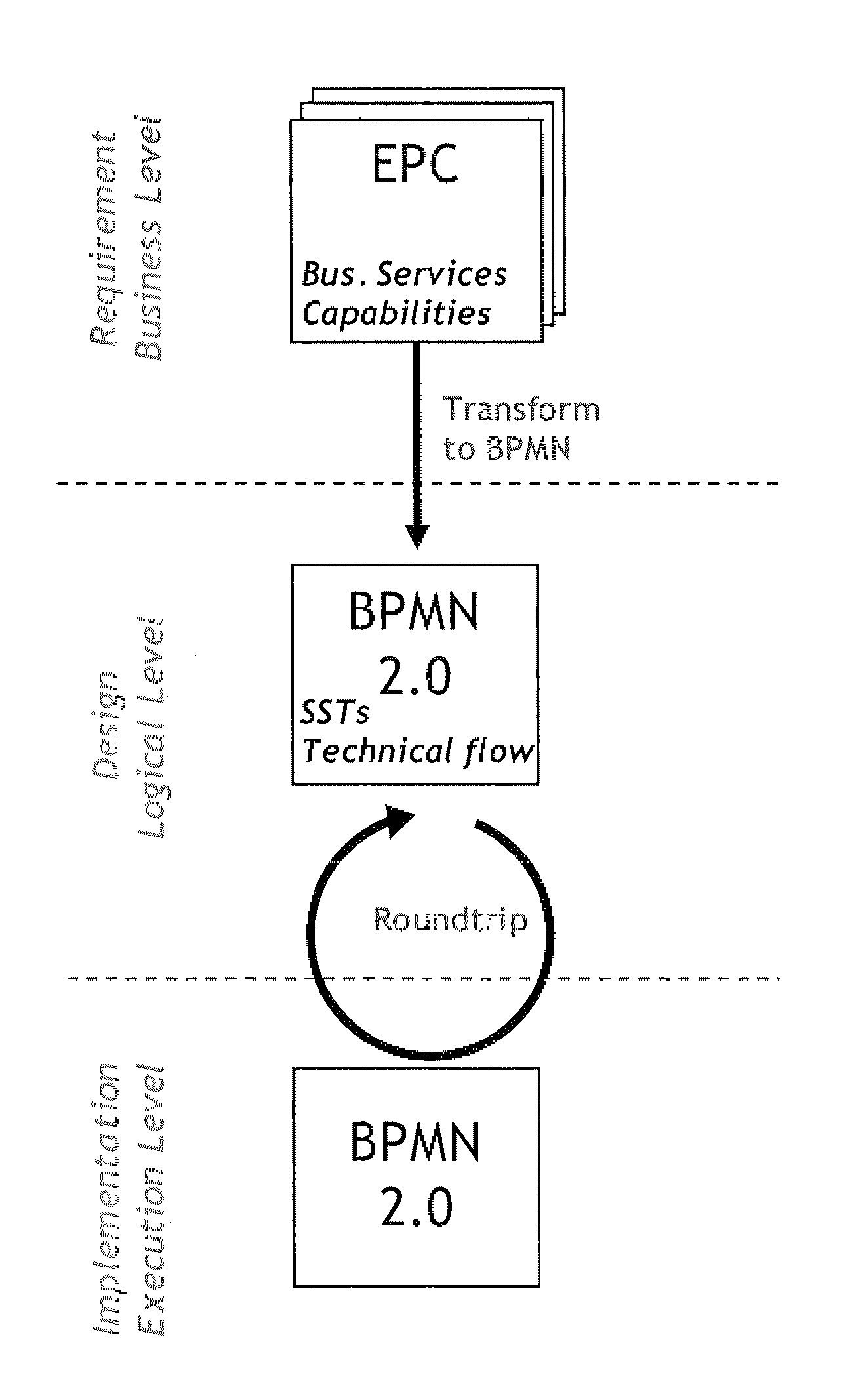

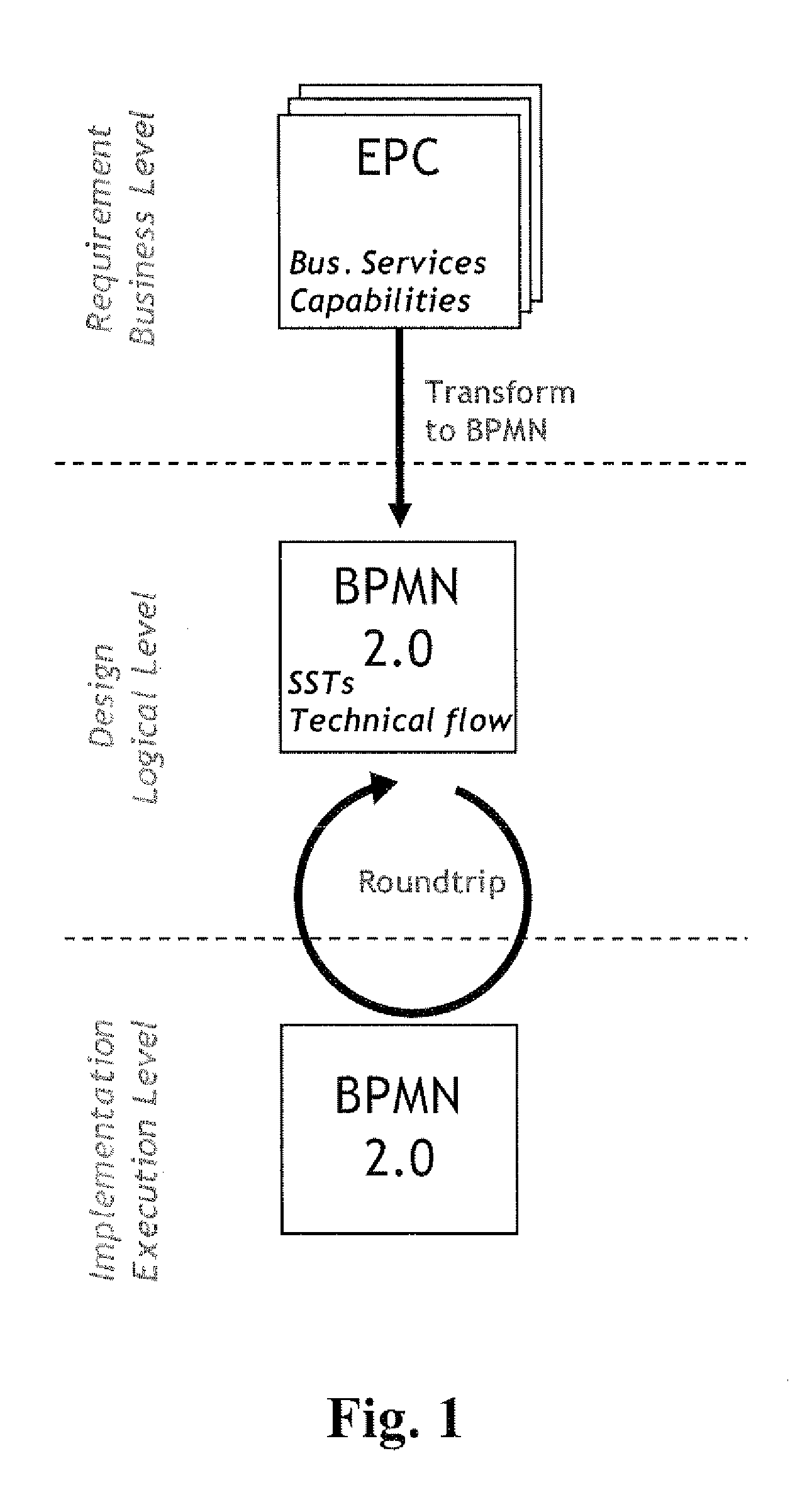

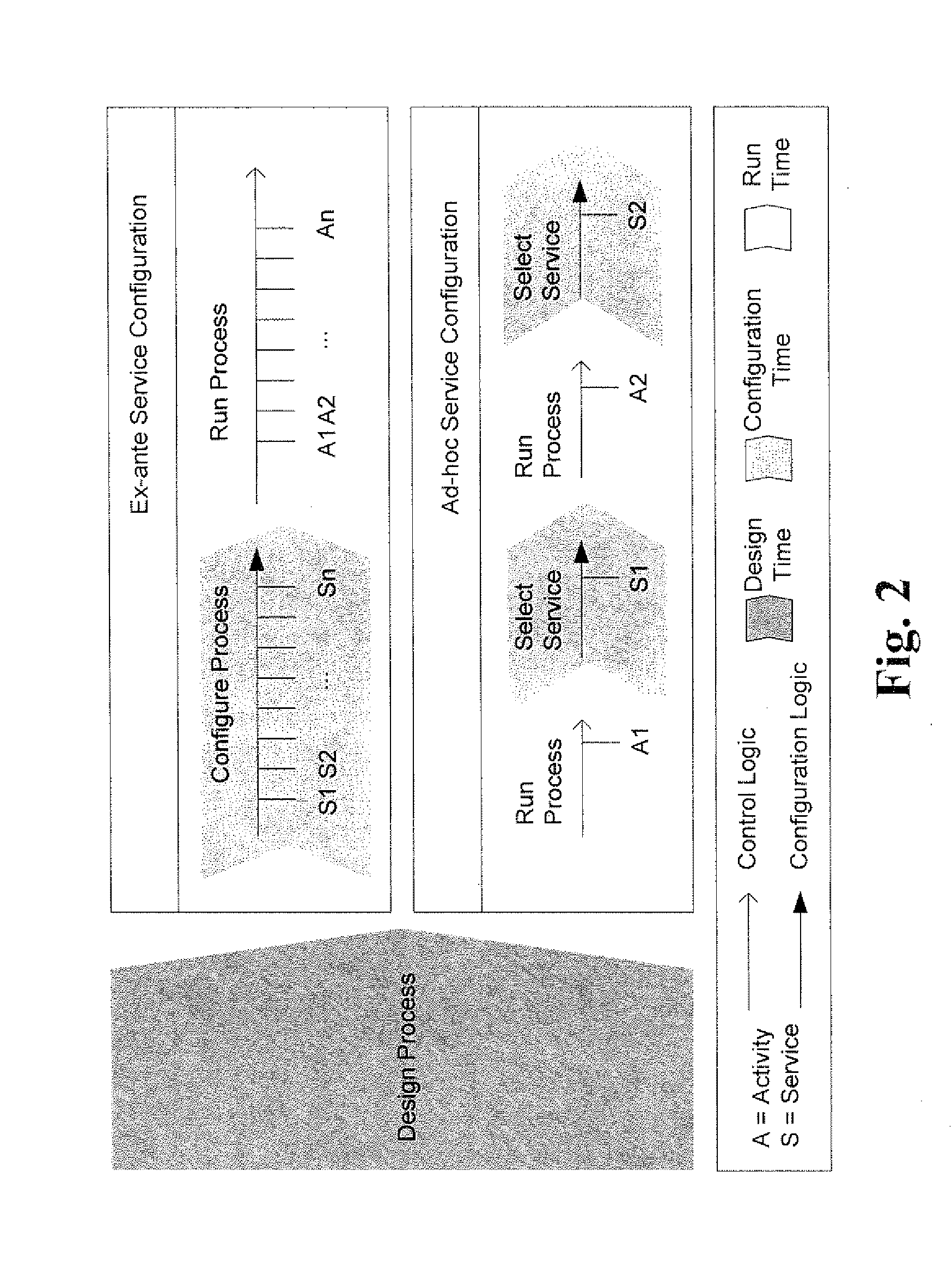

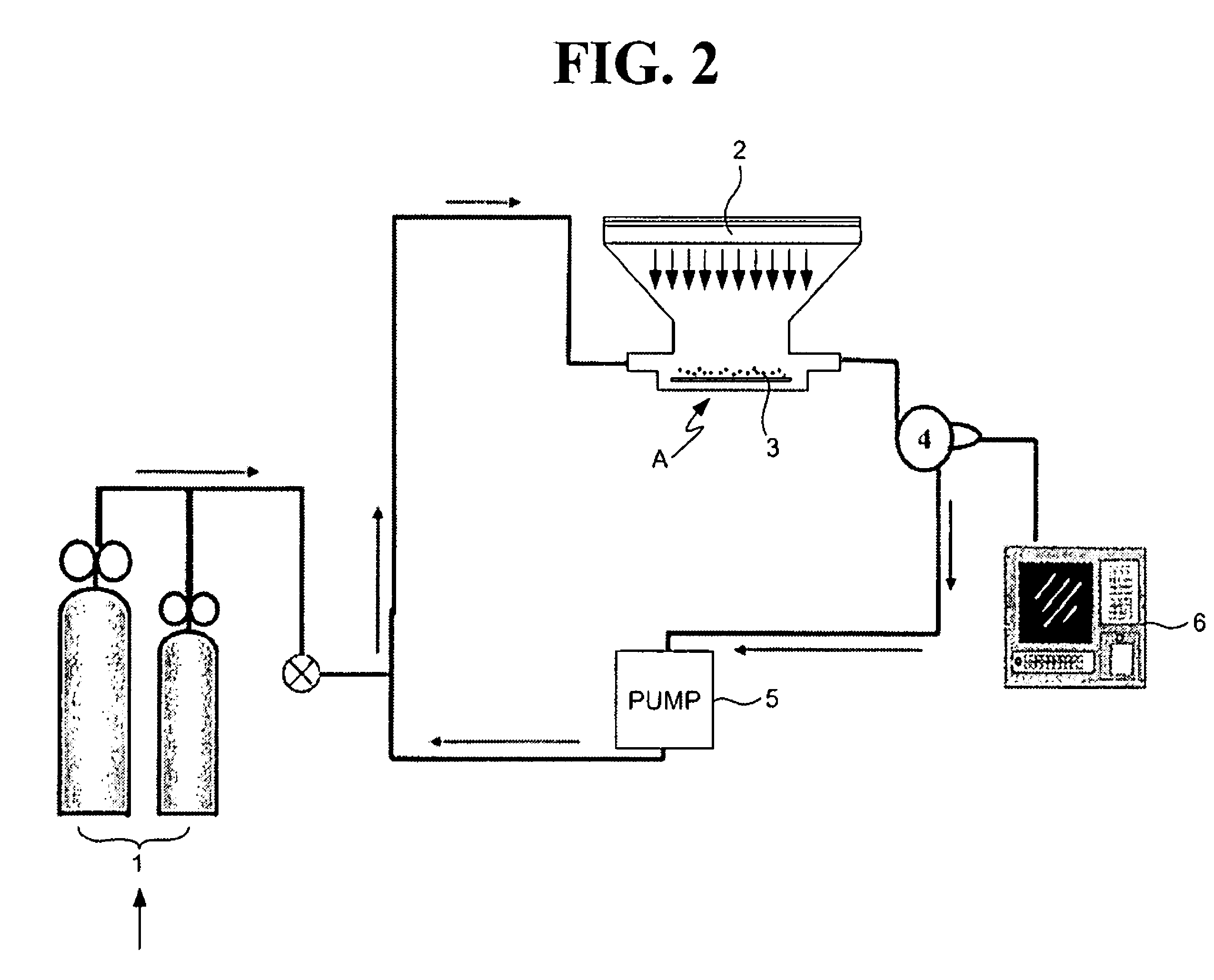

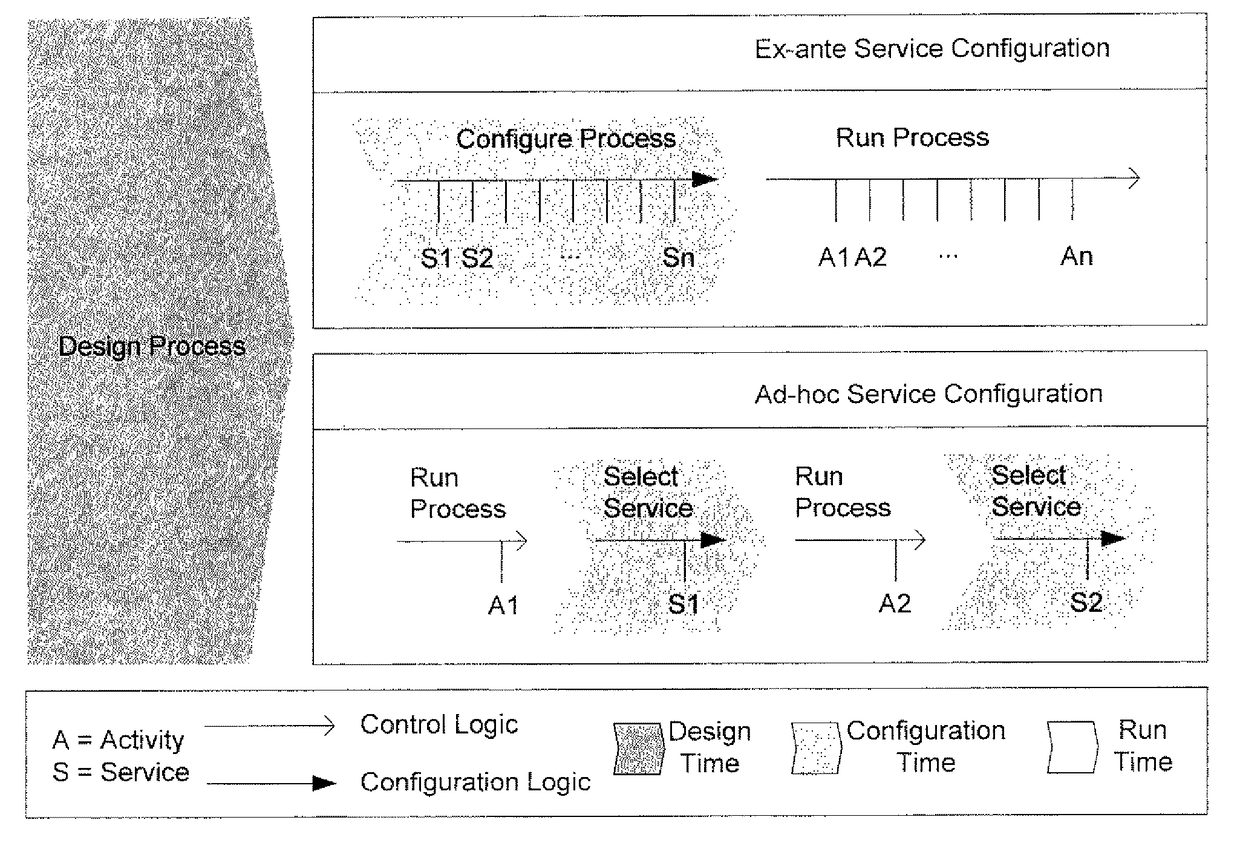

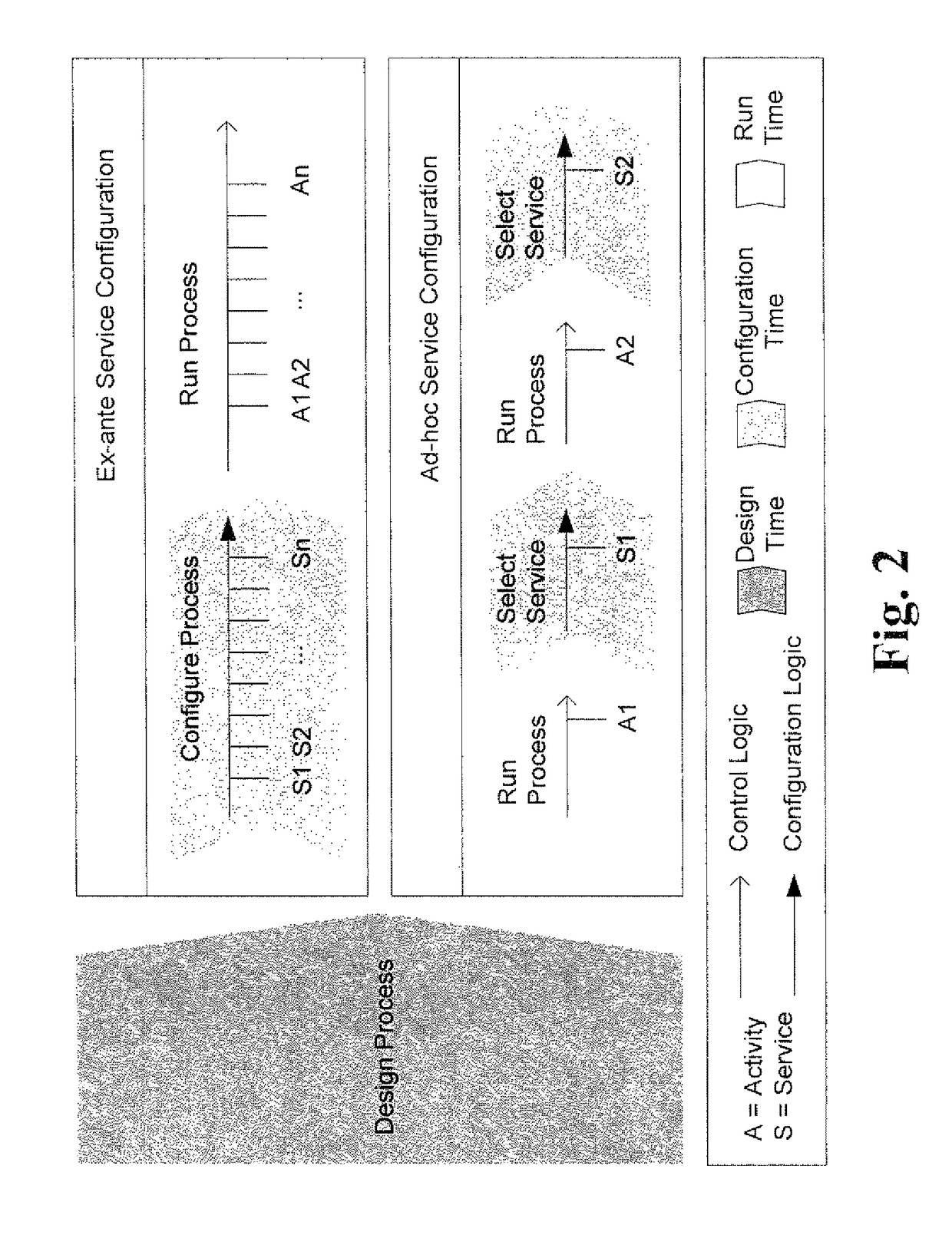

Service-oriented process configuration systems and/or methods

ActiveUS20120166246A1Increase efficiency and effectivenessReduce complexityDigital data processing detailsRequirement analysisProcess configurationLogical connective

Certain example embodiments described herein relate to techniques for matching business requirements with available services in service-oriented business process systems. An n-to-m relationship between process steps and services may be established. In certain example embodiments, both future design and dynamic runtime changes become possible by elaborating on possible resolution techniques before process execution and by identifying / resolving configurational dependencies. The addition of a service-oriented process configuration layer is made possible in certain example embodiments by enhancing the way that business processes are modeled visually or notationally, and through the implementation of a metamodel. The model linking process steps and services may be extended so as to support logical operators, rules or constraints for matching process steps and services, dependencies and relationships, etc. A meta model may be provided so as to provide support for evaluating or analyzing matches, sometimes automatically, at either or both of runtime and design time.

Owner:SOFTWARE AG

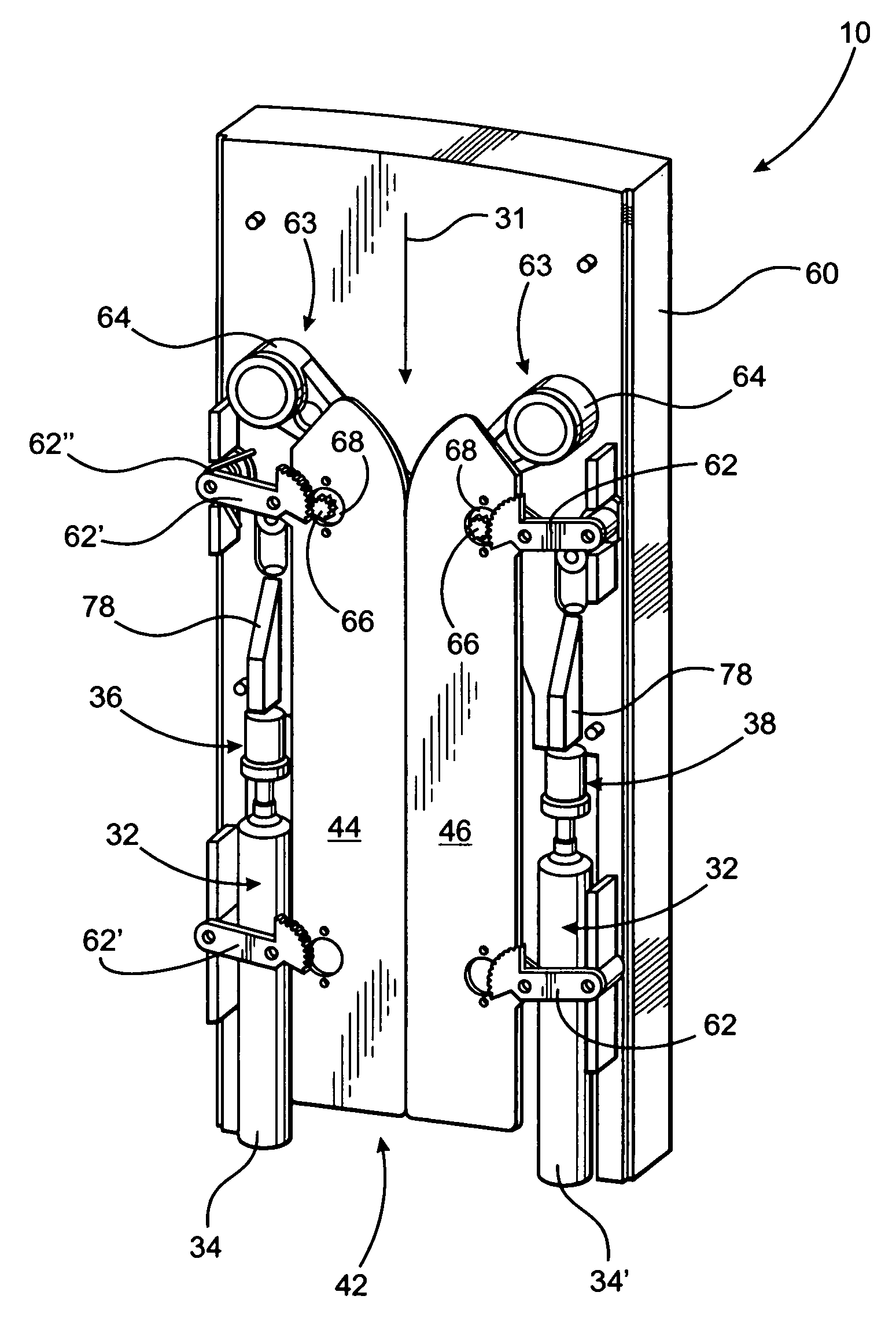

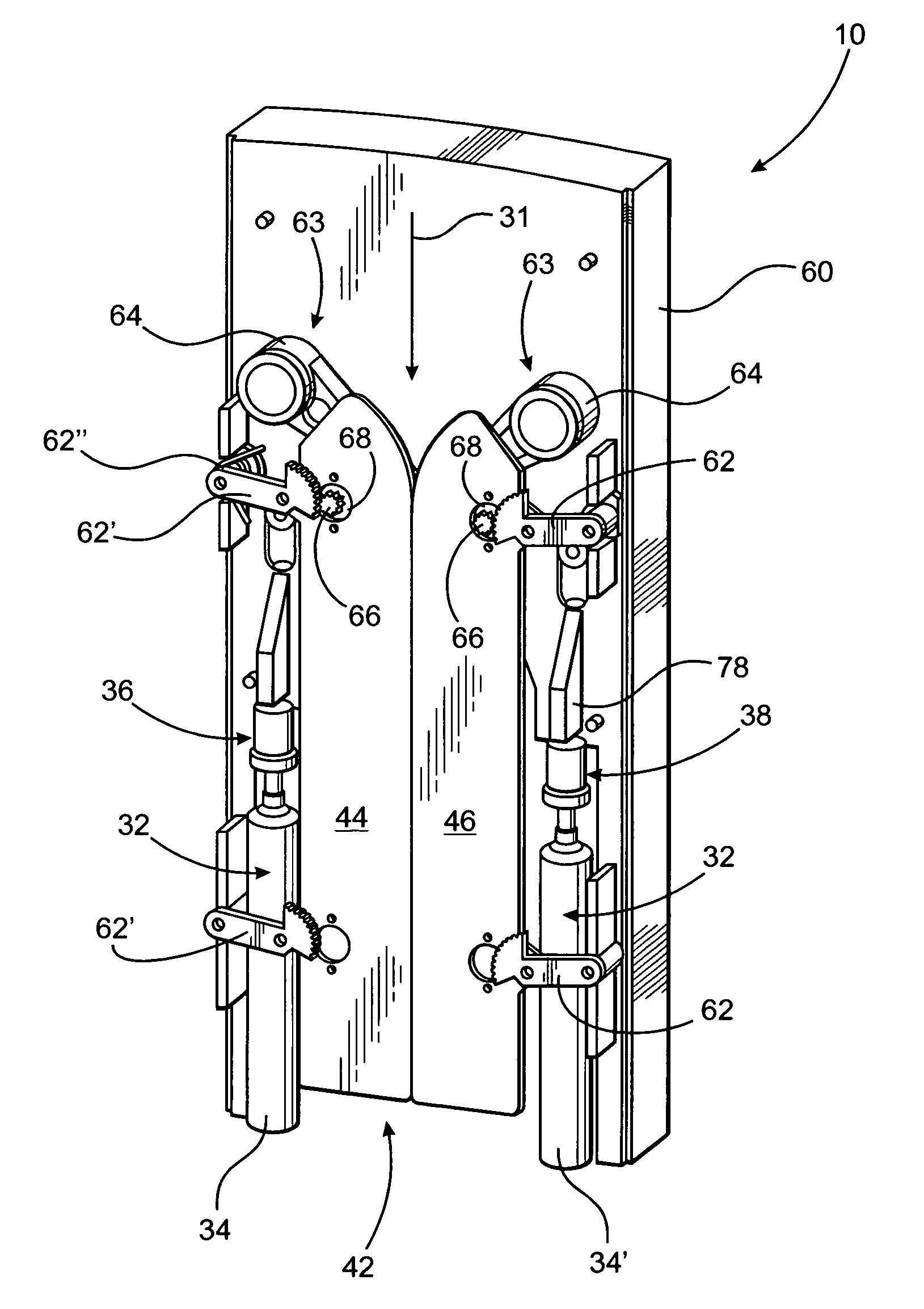

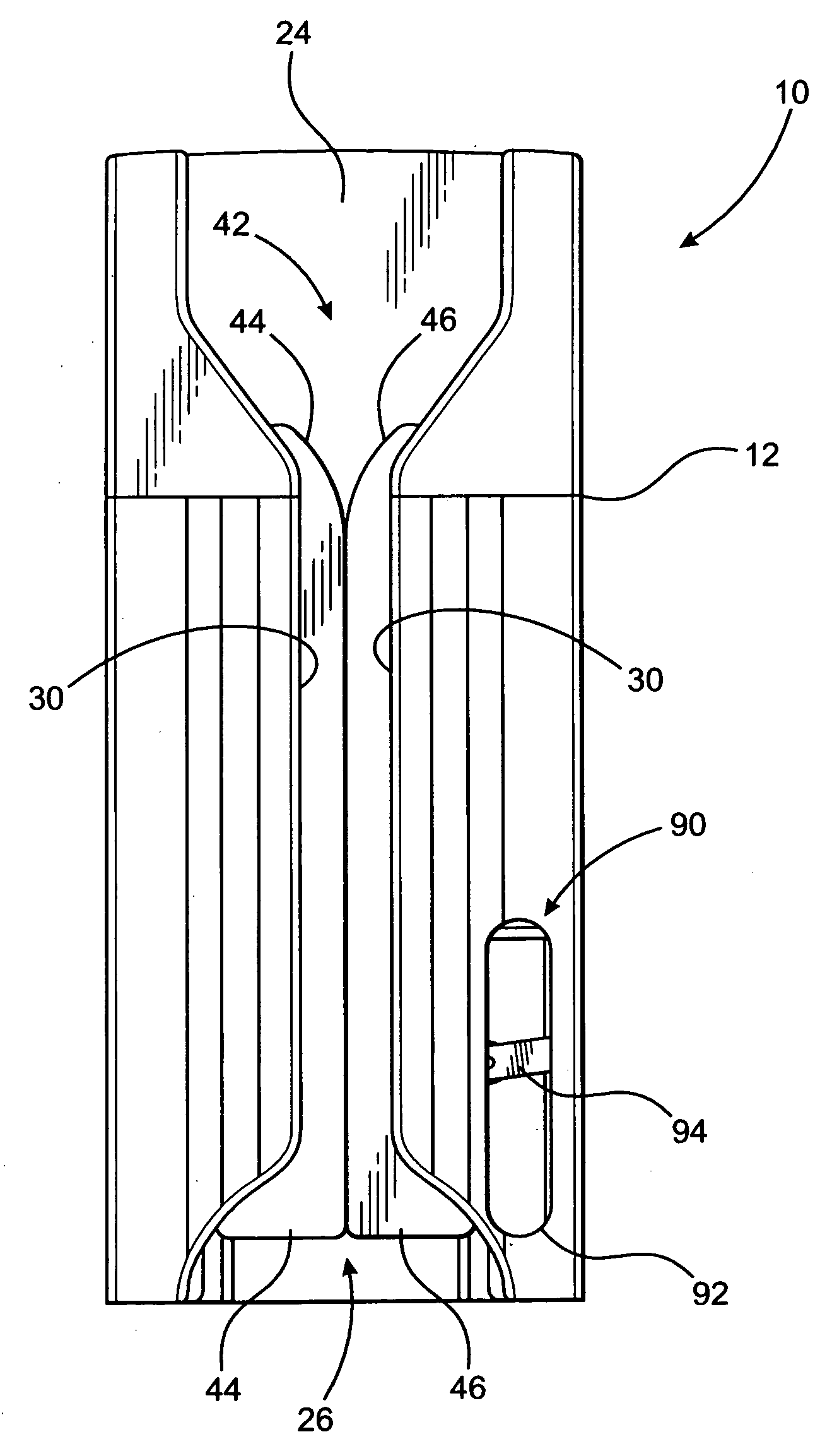

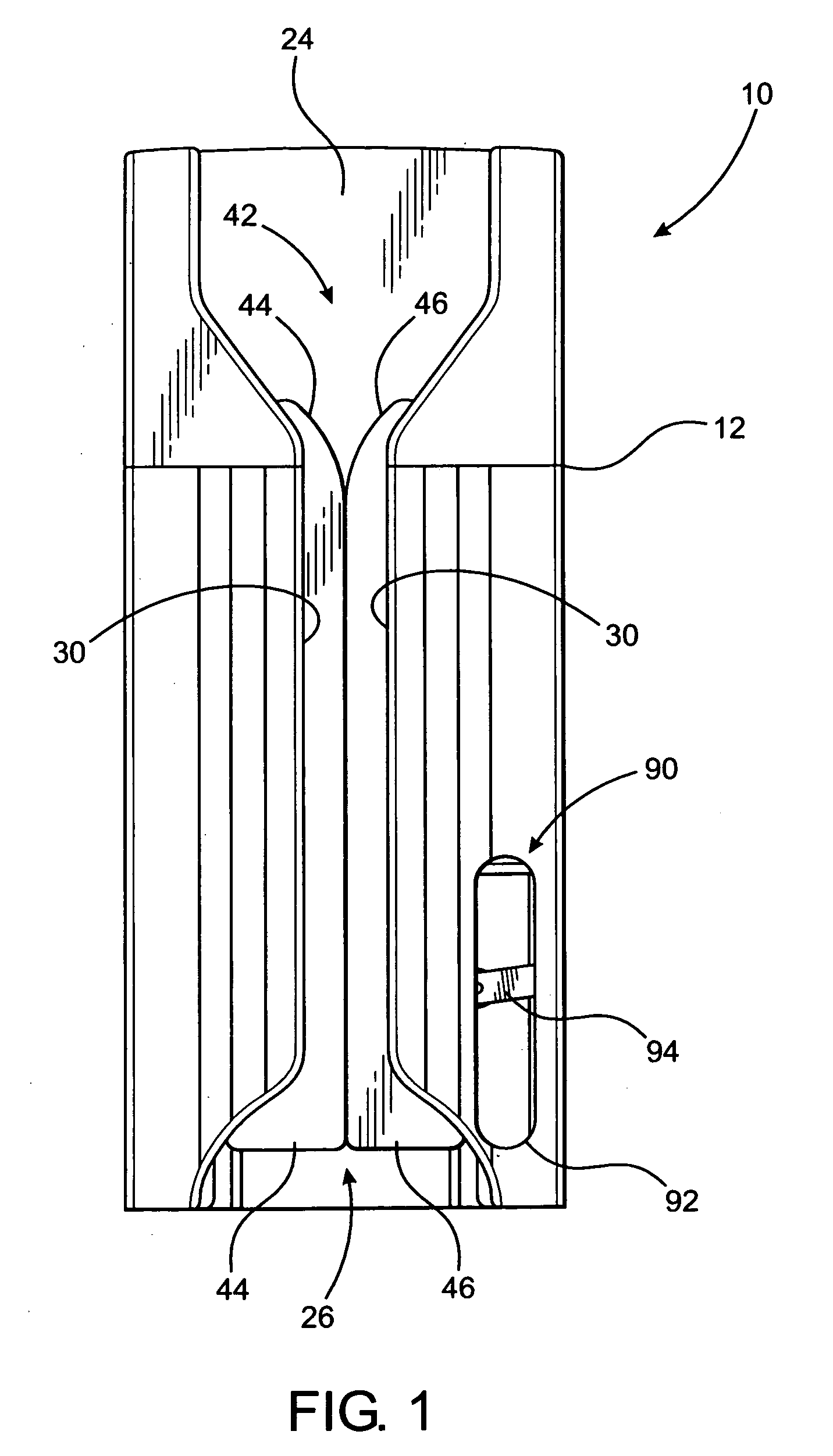

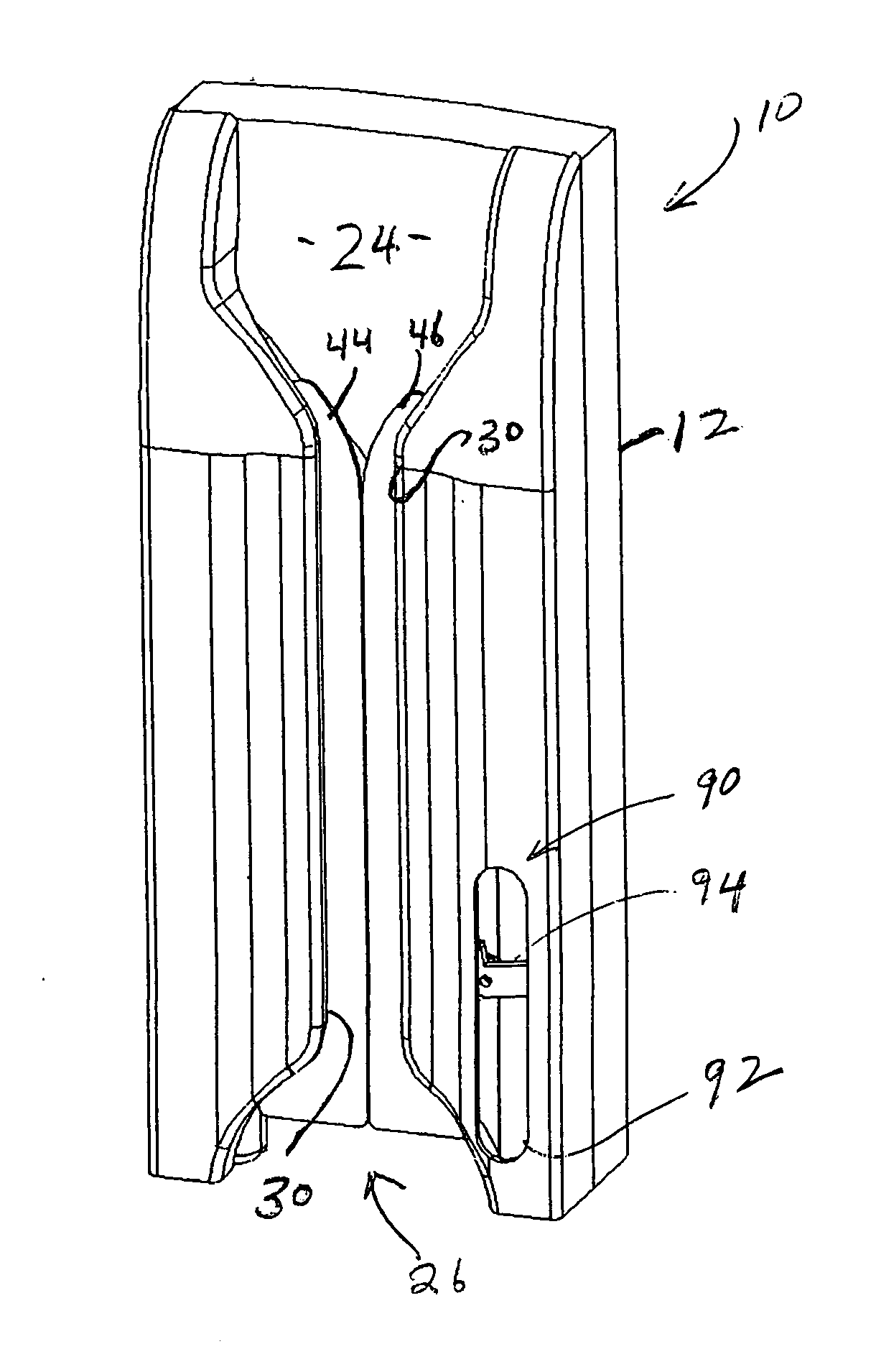

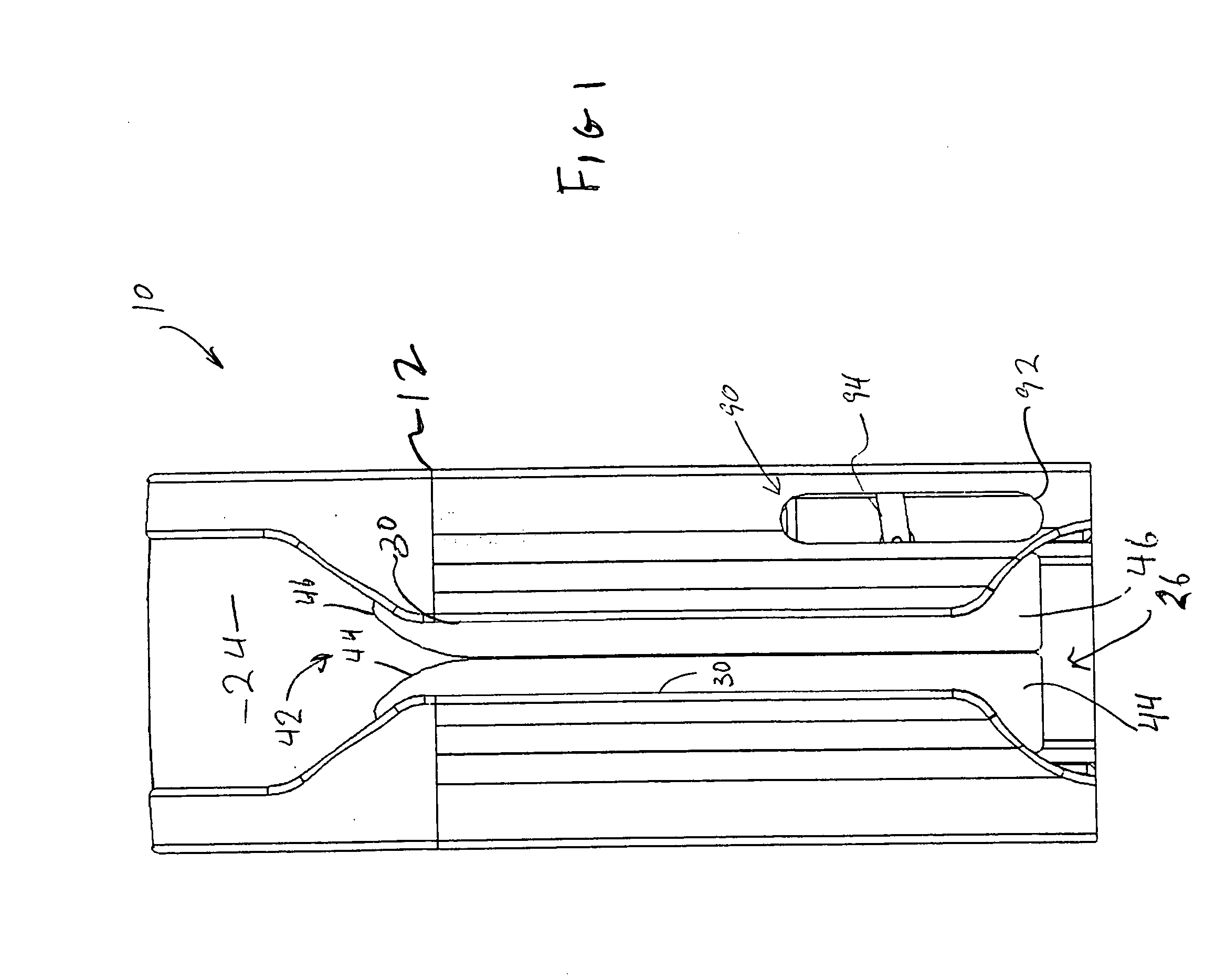

Stethoscope cleaning assembly

ActiveUS7406973B1Increase efficiency and effectivenessFacilitate passage of the headSurgeryHollow article cleaningEngineeringAssembly structure

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid is associated with a dispensing assembly which is cooperatively disposed relative to an activating assembly. The activating assembly is manually operated due to moveable engagement with the head portion as it travels along the path of travel. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispensing assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from.

Owner:SEEDLINGS LIFE SCI VENTURES

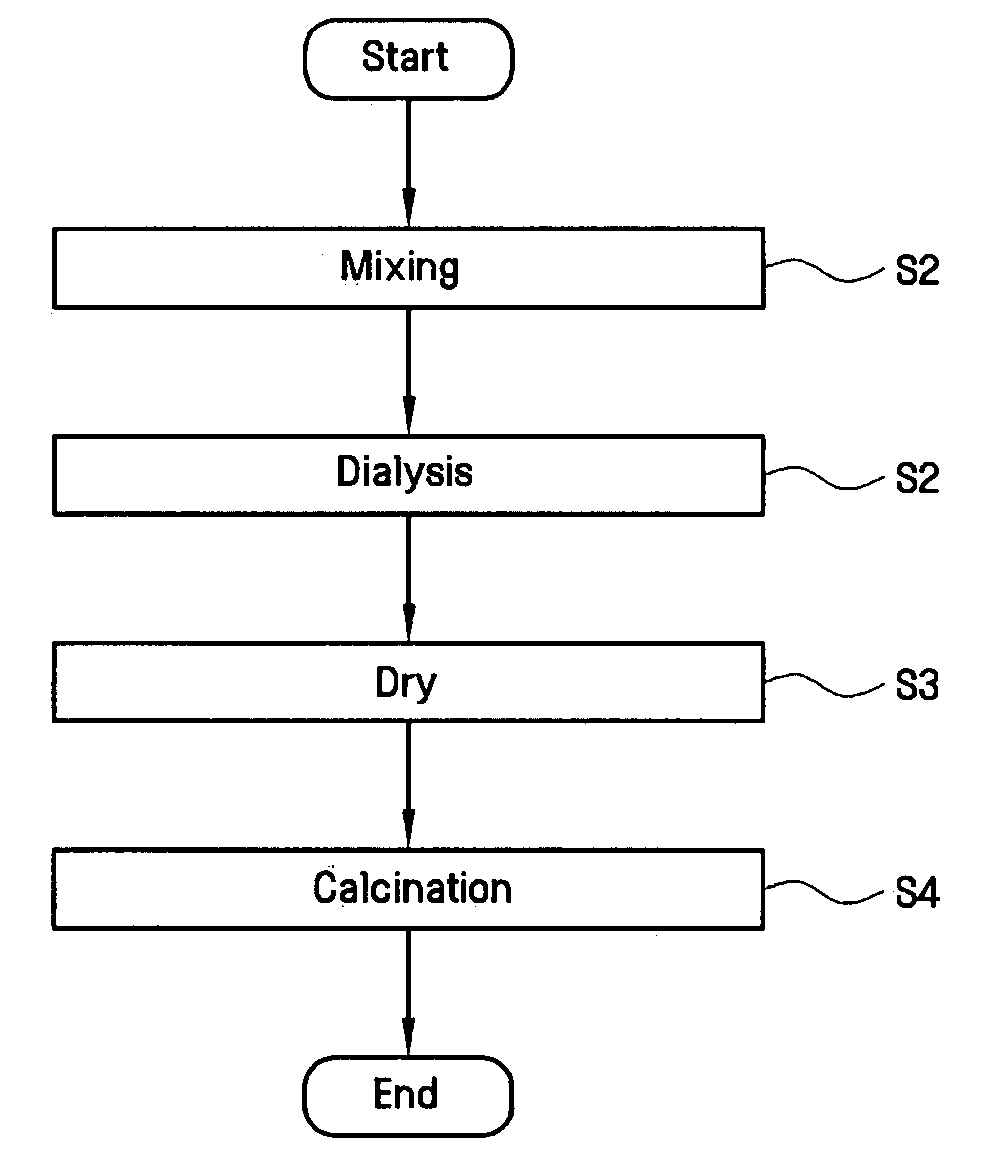

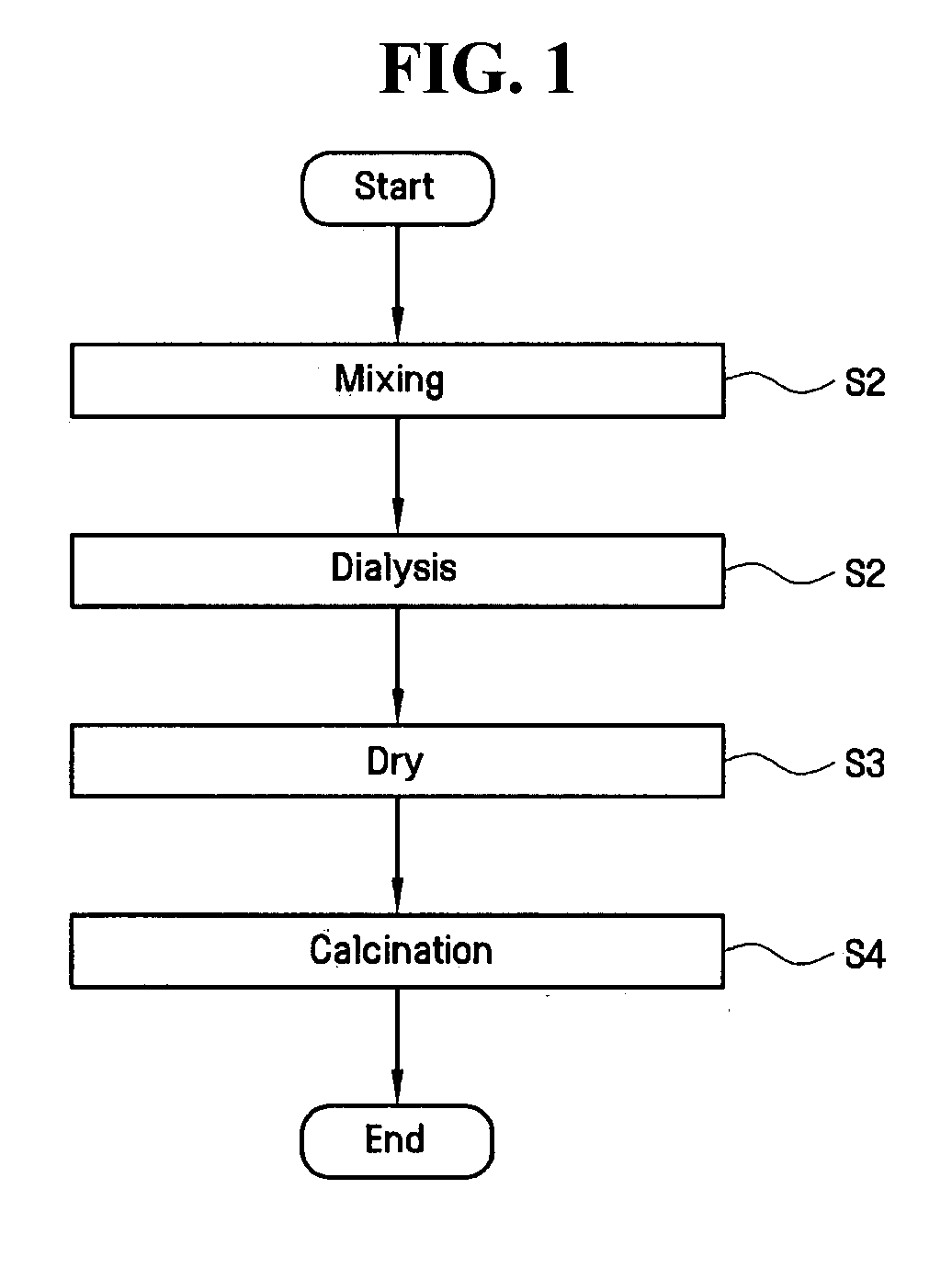

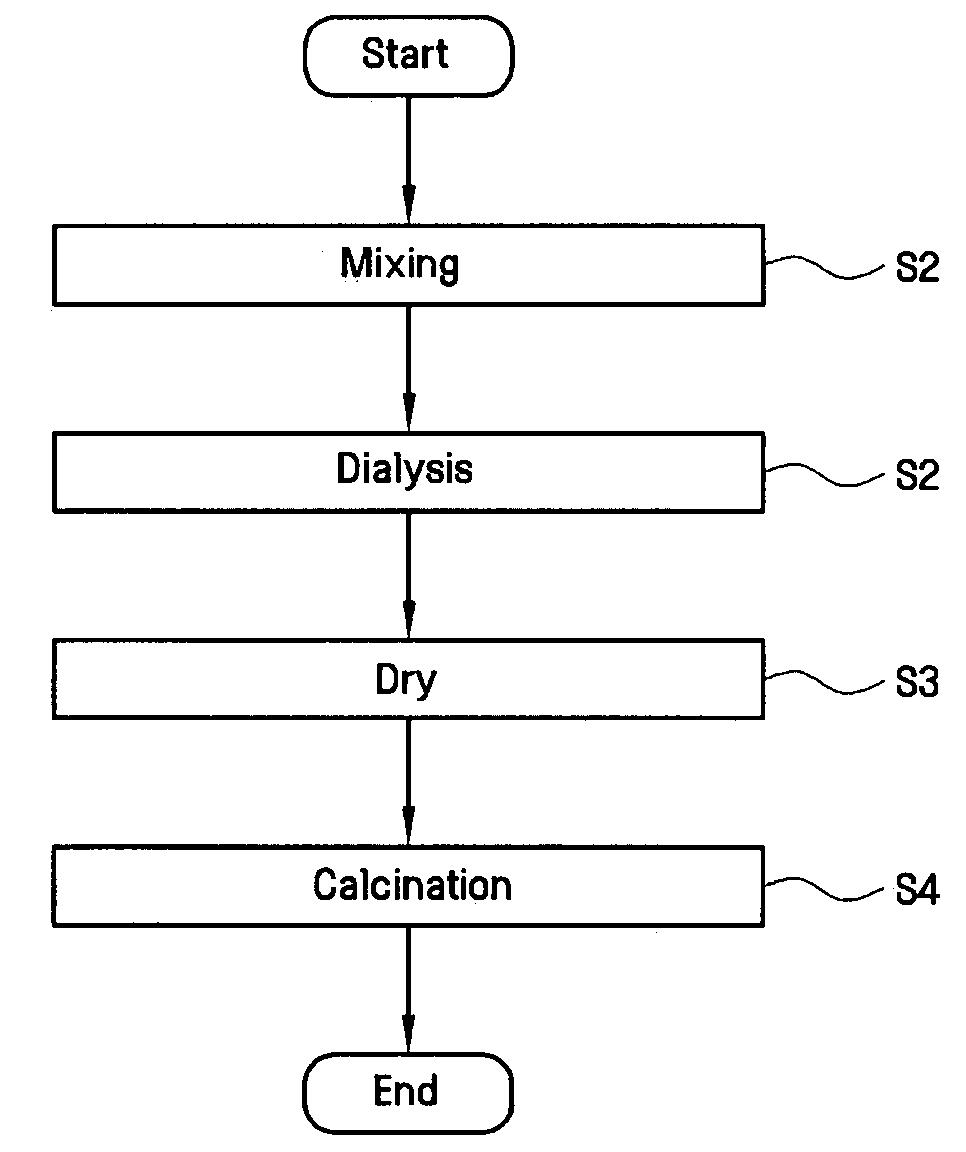

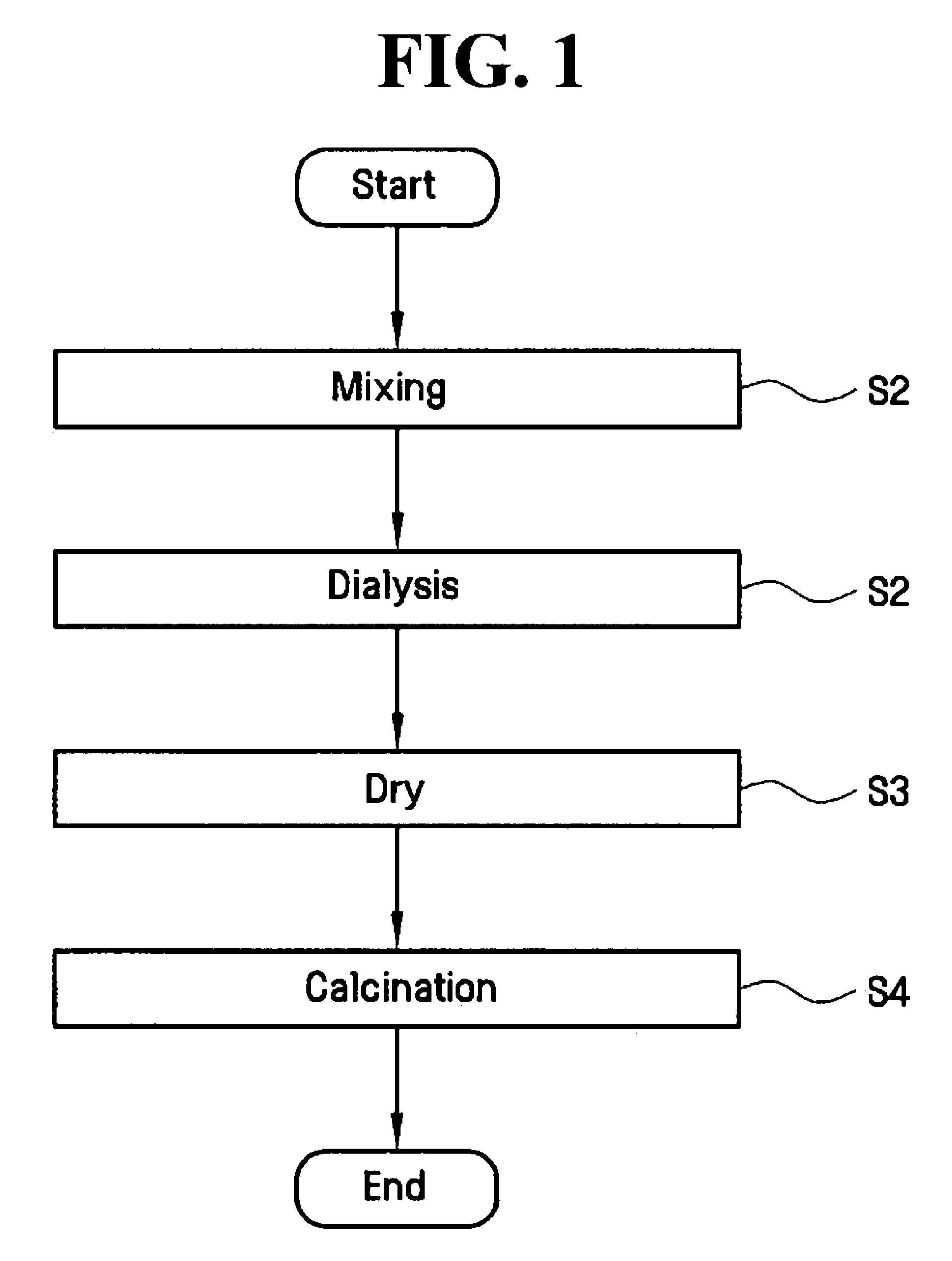

Photocatalyst materials having semiconductor characteristics and methods for manufacturing and using the same

InactiveUS20070193875A1Strong oxidation abilityRapidly and effectively oxidizingSemiconductor/solid-state device manufacturingDialysisPhysical chemistryAir treatment

New types of photocatalyst materials are disclosed together with methods for preparing and using these materials, as well as air treatment systems incorporating such materials. The photocatalyst materials of this invention consist essentially of very small particles of a first-metal oxide, the first-metal being a metal that exhibits photo-induced semiconductor properties, having ions of a second-metal dispersed throughout its lattice structure, the second-metal being selected from the group of dopant metals. Such photocatalyst materials are prepared by the steps of mixing first-metal and second-metal precursors, removing nonessential ions from the mixture, drying the resulting product, and calcinating the dried product to produce the completed photocatalyst material.

Owner:SAMSUNG ELECTRONICS CO LTD

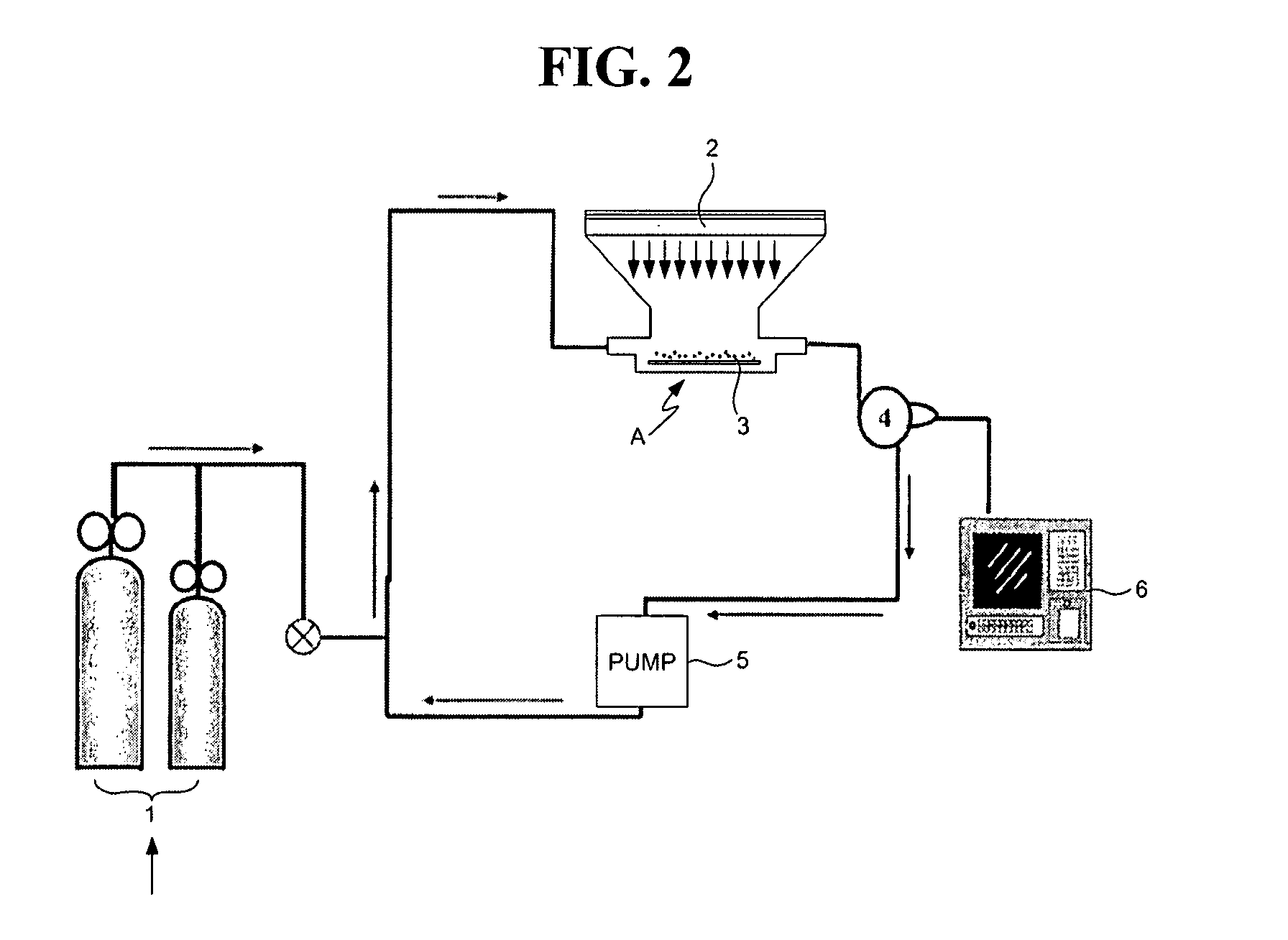

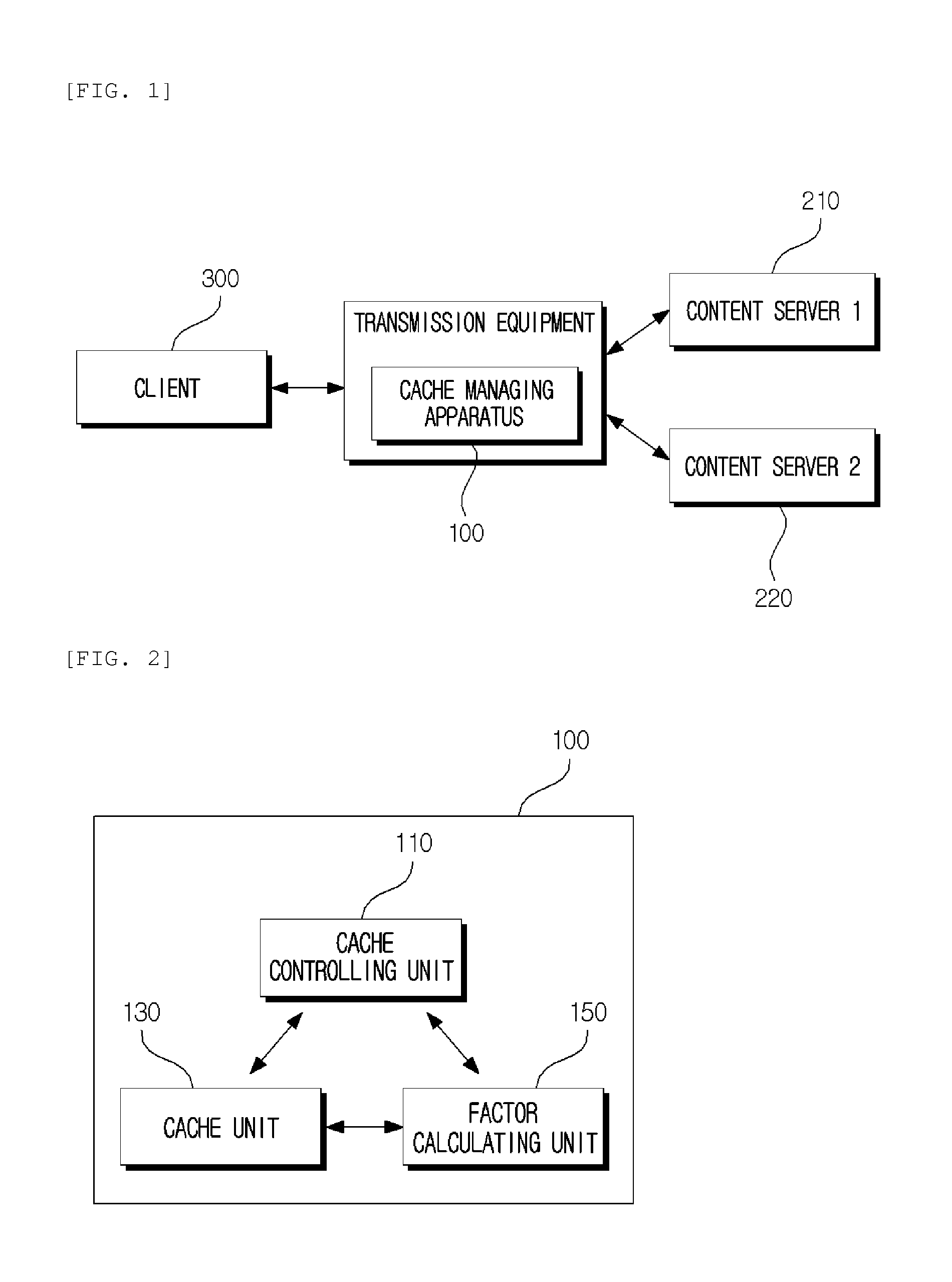

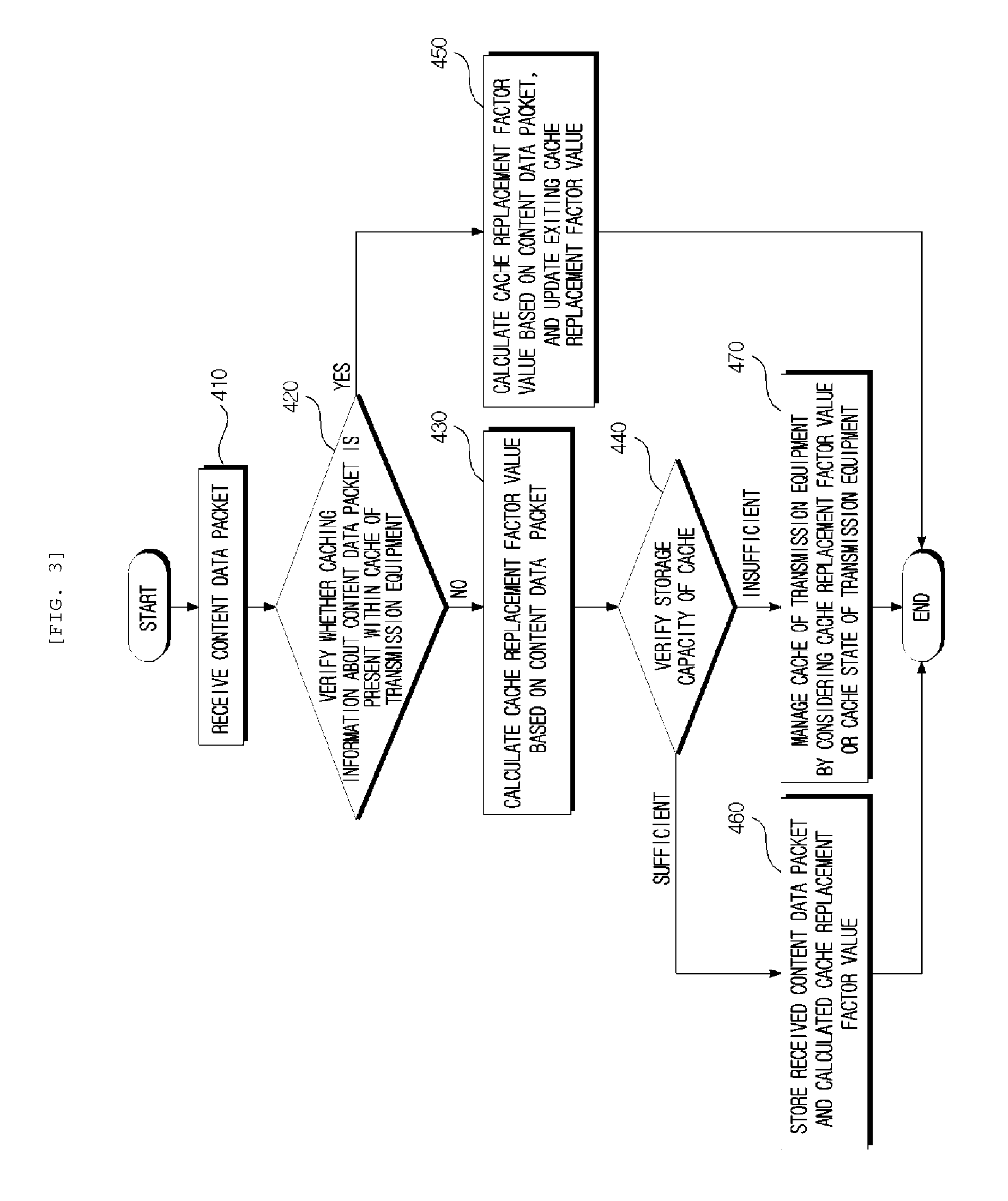

Apparatus and method for managing contents cache considering network cost

InactiveUS20130215756A1Reduce networking costsLow costError preventionTransmission systemsData packComputer science

Provided is a content cache managing method and apparatus, and more particularly, a method and an apparatus for managing a content cache by considering network cost in a network. A content cache managing method of transmission equipment that forwards a content data packet may include calculating a cache replacement factor value by using network cost that is incurred in a network path from the transmission equipment to an original content server storing original content data, based on the content data packet that the content data packet is received from neighboring transmission equipment, and managing a cache in the transmission equipment based on the calculated cache replacement factor value or a state of cache in the transmission equipment to store the content data packet.

Owner:ELECTRONICS & TELECOMM RES INST

Stethoscope cleaning assembly

ActiveUS20090144918A1Easy to replaceEasy maintenanceLiquid surface applicatorsLiquid processingAssembly structureStethoscope

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid is associated with a dispenser assembly which is cooperatively disposed relative to an activating assembly. The activating assembly is manually operated due to moveable engagement with the head portion as it travels along the path of travel. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispenser assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from.

Owner:SEEDLINGS LIFE SCI VENTURES

Stethoscope cleaning assembly

ActiveUS20100116841A1Avoids serious contamination riskOvercome disadvantagesSmall article dispensingStethoscopeSTETHOSCOPE HEADProtective barrier

An assembly structured to restrict contamination of individuals from association with the heads of stethoscope comprising a housing including a path of travel along which the head portion passes. Different embodiments include the dispensing of cleaning fluid or the delivery of protective barriers onto predetermined portions of the stethoscope heads, while passing along the path of travel. A dispenser assembly and a cooperatively disposed activating assembly are manually operated by moveable, driving engagement with the head portion passing through the housing. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by a head passing along the path of travel. Differently structured dispenser assemblies function to either deliver the cleaning fluid or individually dispense the barriers onto different heads, so as to either facilitate the cleaning or protective covering of exposed surfaces of the stethoscope heads, dependent on the embodiment utilized.

Owner:SEEDLINGS LIFE SCI VENTURES

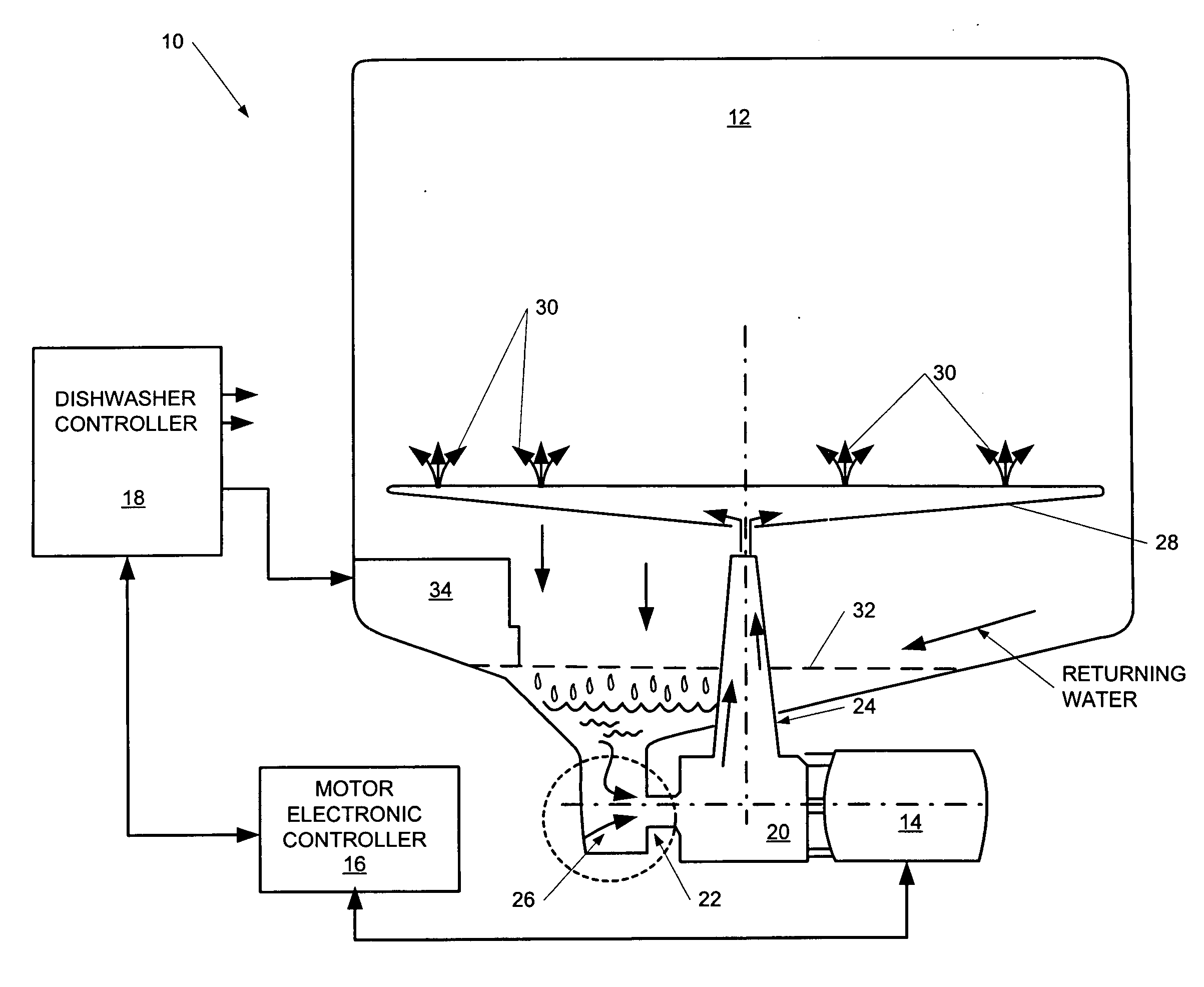

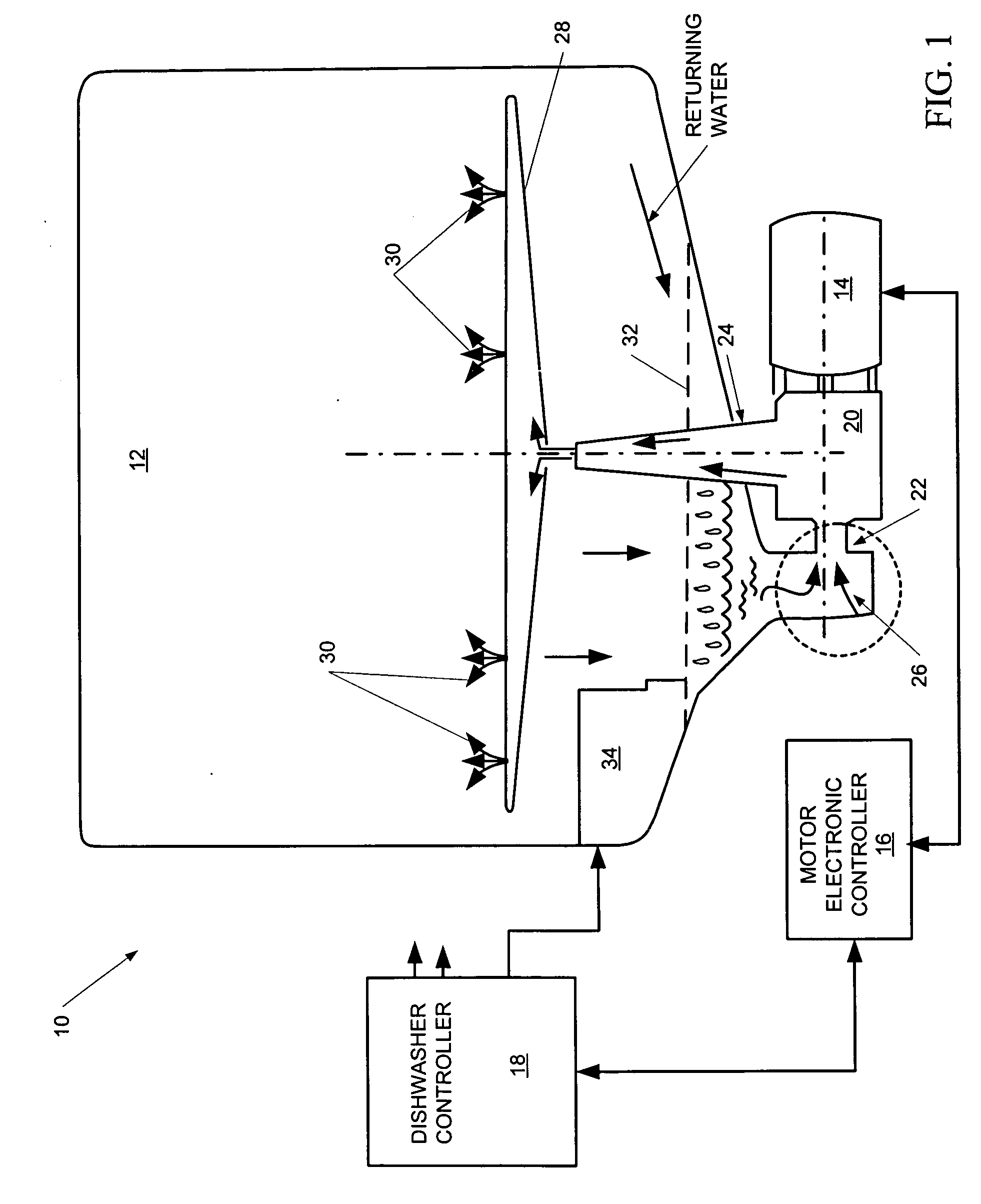

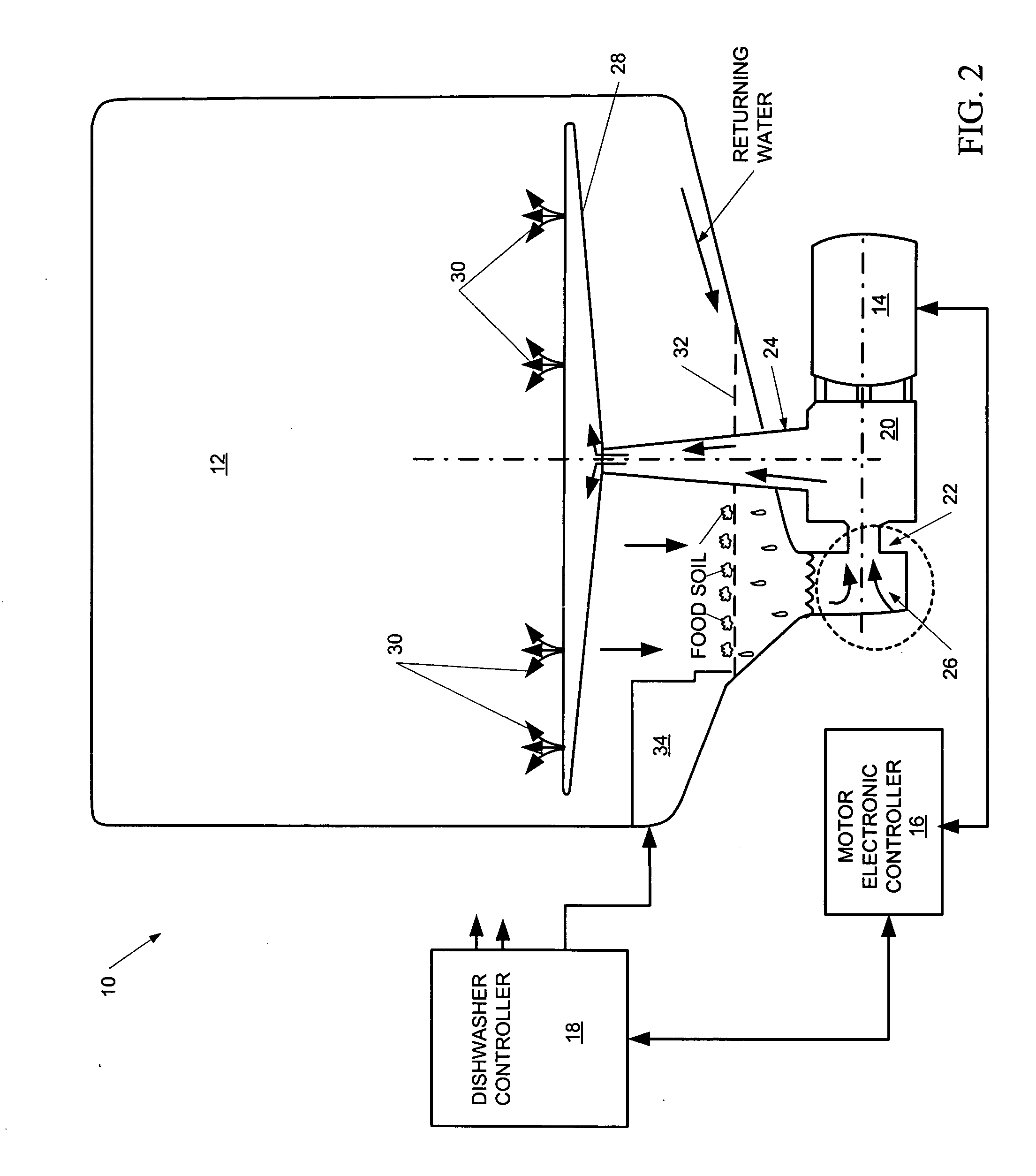

Dishwasher incorporating a pump prime sensing system for managing a filtration system

InactiveUS20060237048A1Improve efficiencyImprove effectivenessAutomatic washing/rinsing machine detectionHollow article cleaningFiltrationControl theory

A pump priming sensing system for managing a filtration system is provided. The sensing system is capable of monitoring the state of the motor that operates the pump in a dishwasher to determine if the pump is receiving enough water to operate at a normal torque level. A filter is provided above the pump inlet to the pump. When a mixture of water and air is received through the pump inlet, the torque level falls. The motor transmits this decrease in torque level to a controller, which activates a filter cleaning system to clean the filter of soil / food / debris loosed from the dishes being cleaned in the dishwasher. Once the filter has been cleaned, normal operation of the dishwasher is resumed with the pump operating at a normal torque level.

Owner:VIKING RANGE

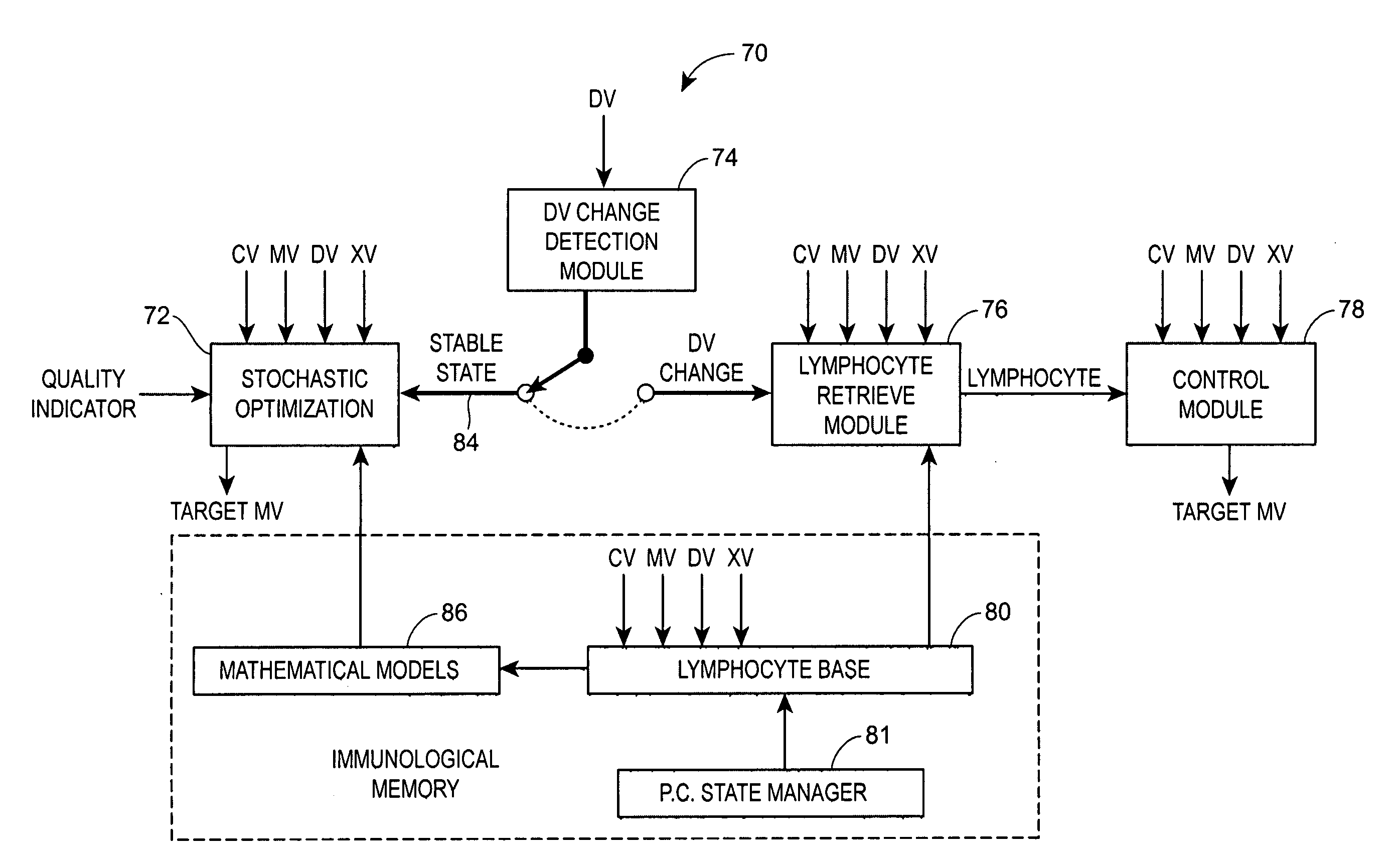

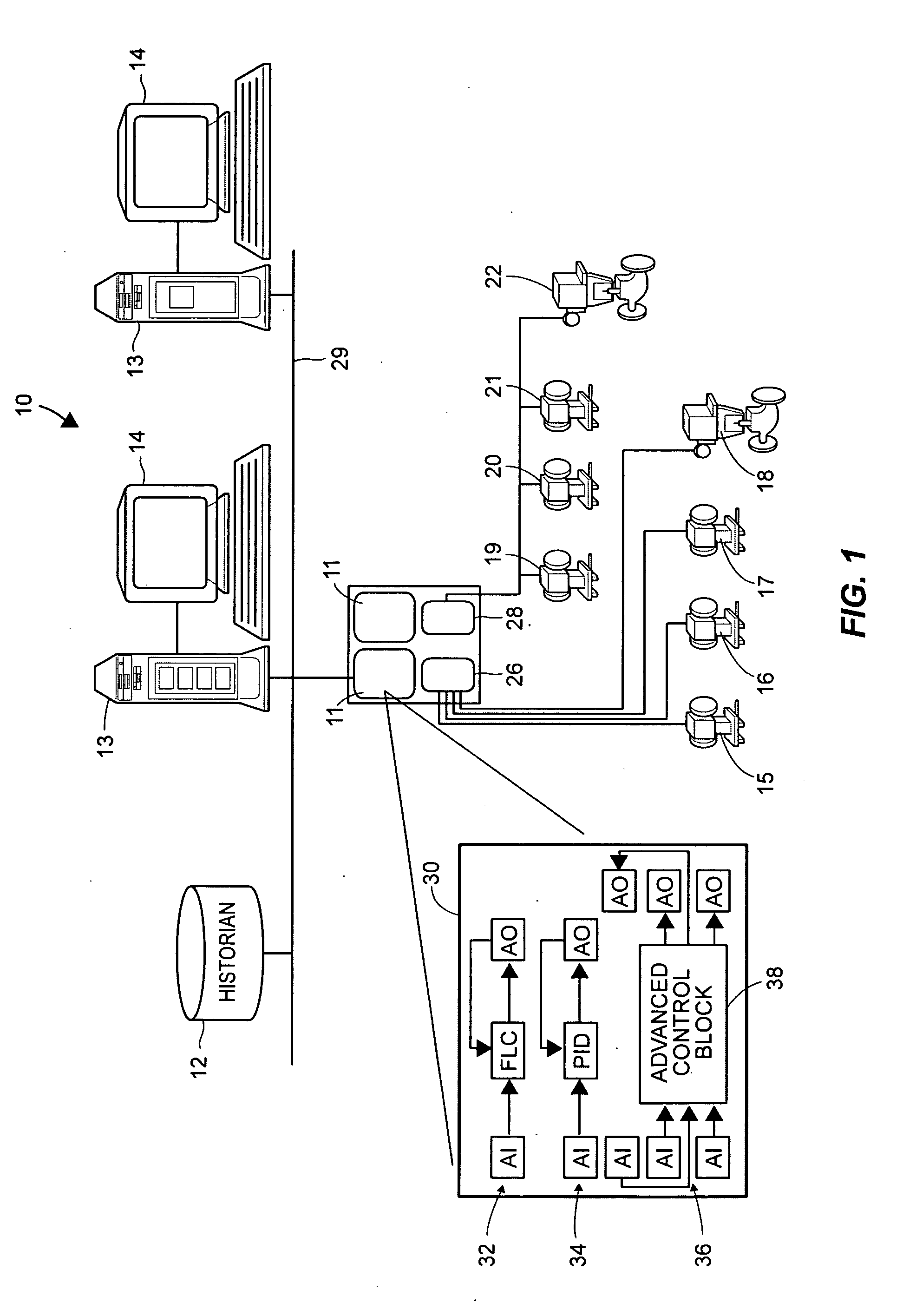

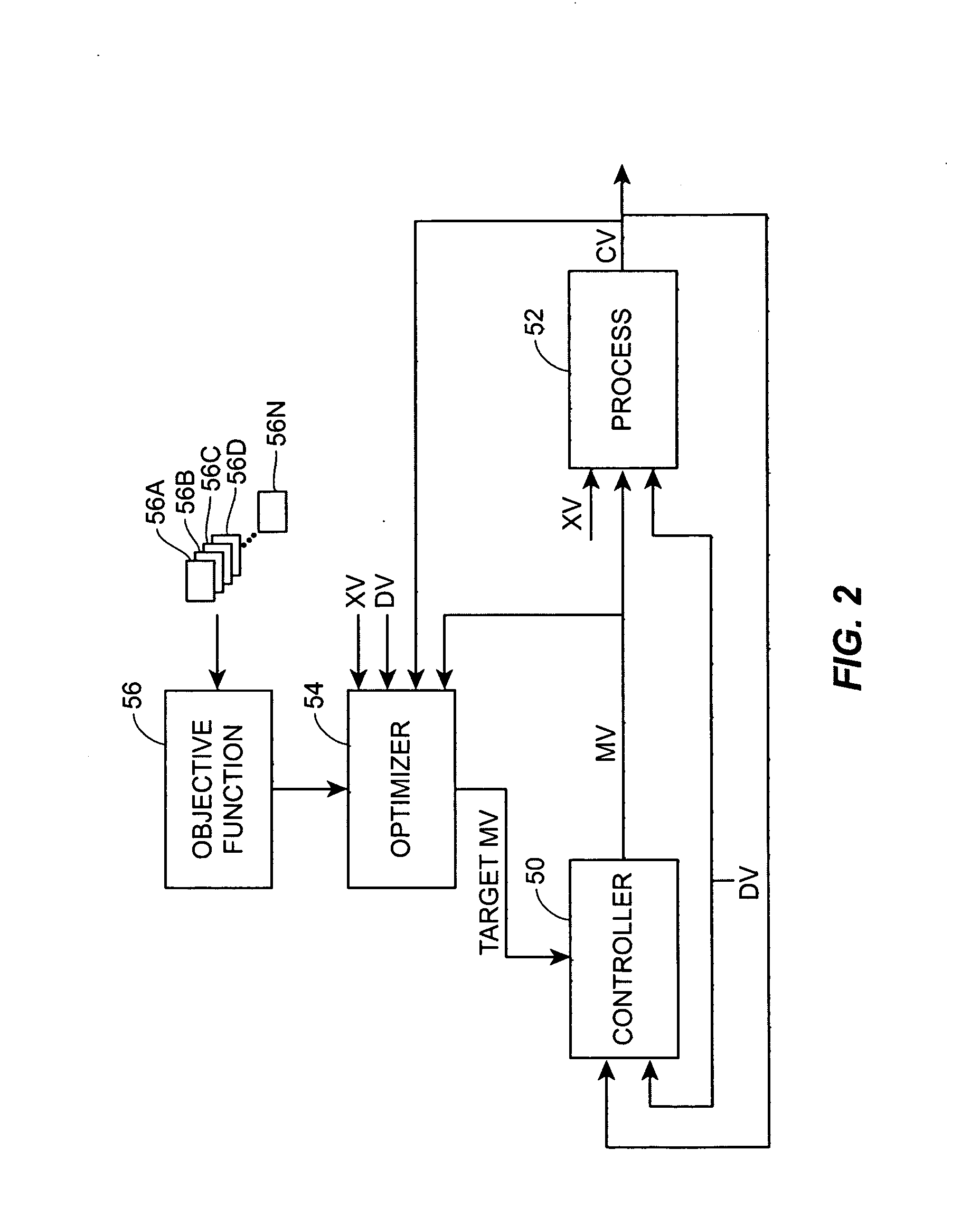

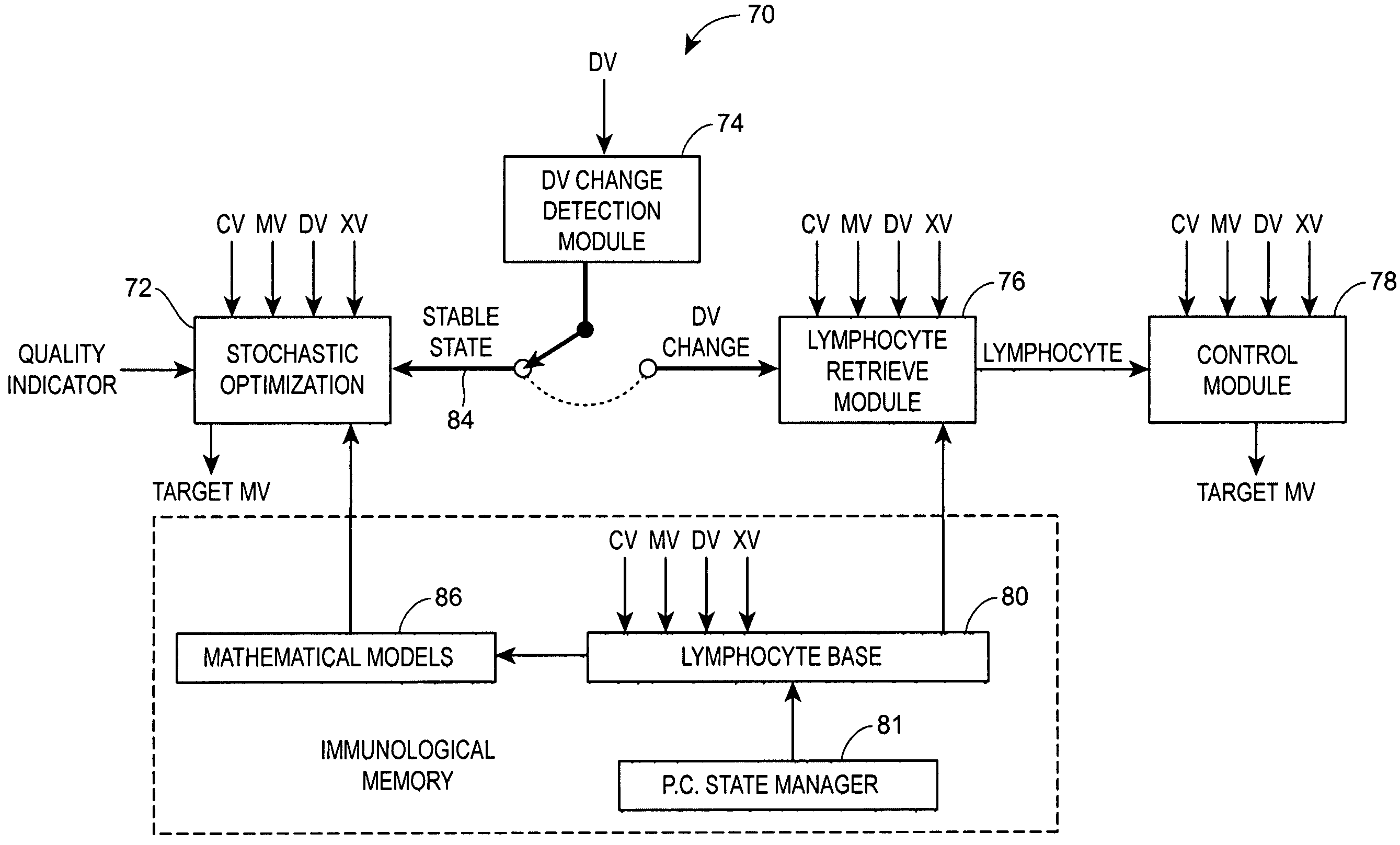

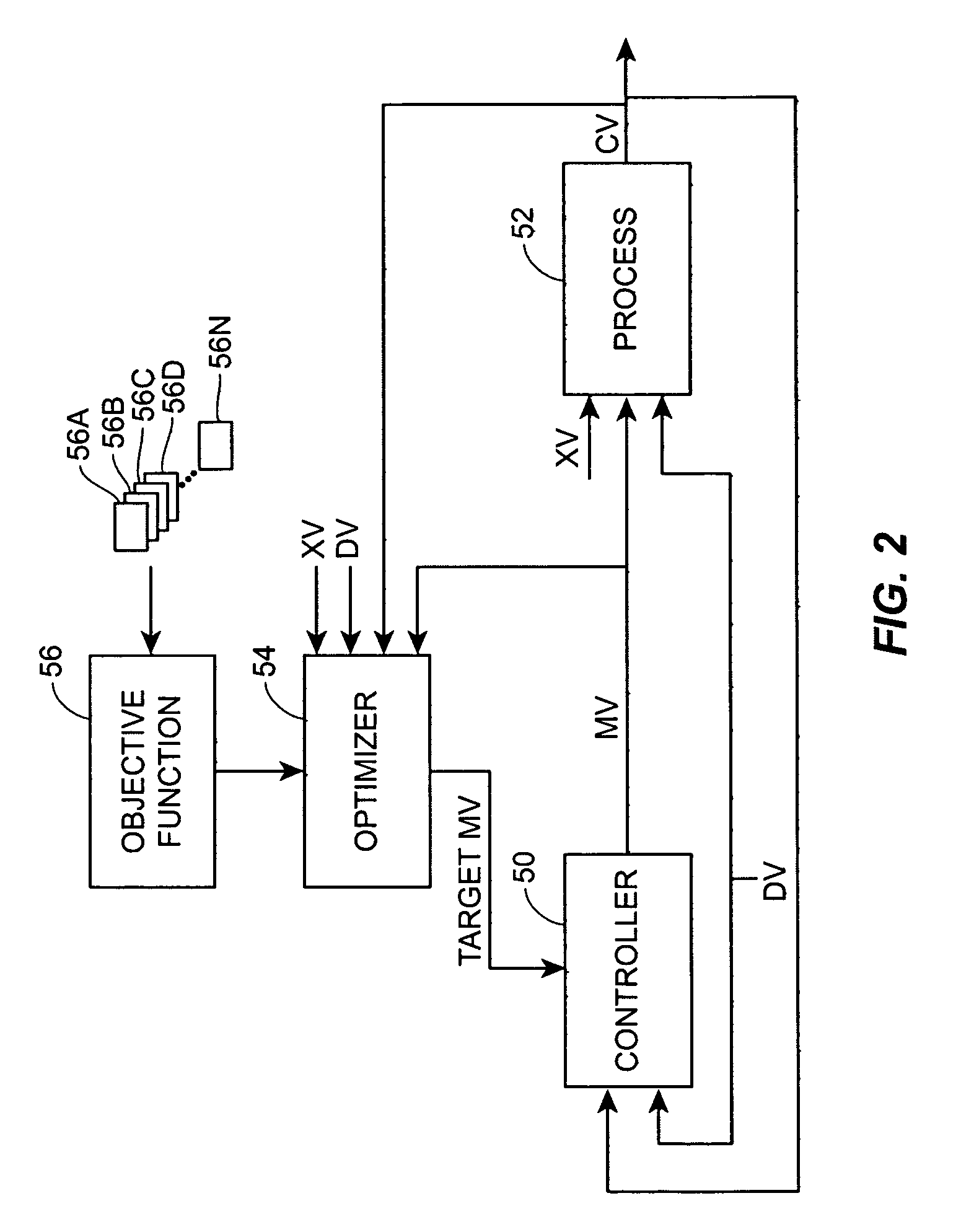

Process control and optimization technique using immunological concepts

ActiveUS20080125881A1Improve efficiencyImprove effectivenessAC motor controlField or armature current controlBiological immune systemEngineering

An integrated optimization and control technique performs process control and optimization using stochastic optimization similar to the manner in which biological immune systems work, and thus without the use of historical process models that must be created prior to placing the control and optimization routine in operation within a plant. In particular, an integrated optimization and control technique collects various indications of process control states during the on-line operation of the process, and stores these process control states within a memory. During steady-state operation of the process, the integrated optimization and control technique attempts to optimize the process operation by developing a series of sets of process control inputs to be provided to the process, wherein the series of process control inputs may be developed from the stored process control states using an objective function that defines a particular optimality criteria to be used in optimizing the operation of the process. Moreover, the integrated optimization and control technique may respond to a significant change in the current process state by determining a new set of process control inputs to be provide to the process based on one or more of the stored process control states. In this case, the optimization and control technique compares the disturbance inputs of the current process control operating condition, after one or more of these disturbance inputs experiences a significant change, to the disturbance inputs of at least some of the stored process control states to determine the one or more of the stored process control states that is / are closest to the new process operating condition. The integrated optimization and control technique then develops the new set of control inputs to be delivered to the process based on the control inputs associated with the one or more stored process control states determined to be closest to the new process operating condition.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

Assembly for delivering protective barriers onto stethoscope heads

ActiveUS7942597B2Increase efficiency and effectivenessFacilitate passage of the headSurgeryStethoscopeSTETHOSCOPE HEADEngineering

An assembly structured to restrict contamination of individuals from association with the heads of stethoscope comprising a housing including a path of travel along which the head portion passes. Different embodiments include the dispensing of cleaning fluid or the delivery of protective barriers onto predetermined portions of the stethoscope heads, while passing along the path of travel. A dispenser assembly and a cooperatively disposed activating assembly are manually operated by moveable, driving engagement with the head portion passing through the housing. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by a head passing along the path of travel. Differently structured dispenser assemblies function to either deliver the cleaning fluid or individually dispense the barriers onto different heads, so as to either facilitate the cleaning or protective covering of exposed surfaces of the stethoscope heads, dependent on the embodiment utilized.

Owner:SEEDLINGS LIFE SCI VENTURES

Stethoscope cleaning assembly

ActiveUS8057117B2Increase efficiency and effectivenessFacilitate passage of the headWriting implementsStethoscopePathogenic bacteriaAssembly structure

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid associated with a dispenser assembly is cooperatively disposed relative to an activating assembly. The activating assembly is operated in moveable engagement with the head portion, and activates the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispenser assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from. At least one disinfectant agent is dispersed within or comprises a portion of the housing and is formulated to be destructively effective against pathogenic bacteria, such as in the spore form, which is generally not affected by the cleaning fluid.

Owner:SEEDLINGS LIFE SCI VENTURES

Stethoscope cleaning assembly

ActiveUS20100116300A1Easy to replaceEasy maintenanceStethoscopeWriting implementsEngineeringPathogenic bacteria

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid is associated with a dispenser assembly which is cooperatively disposed relative to an activating assembly. The activating assembly is manually operated due to moveable engagement with the head portion as it travels along the path of travel. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispenser assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from. At least one disinfectant agent is dispersed within or comprises a portion of said housing and is formulated to be destructively effective against pathogenic bacteria which is generally not affected by the cleaning fluid.

Owner:SEEDLINGS LIFE SCI VENTURES

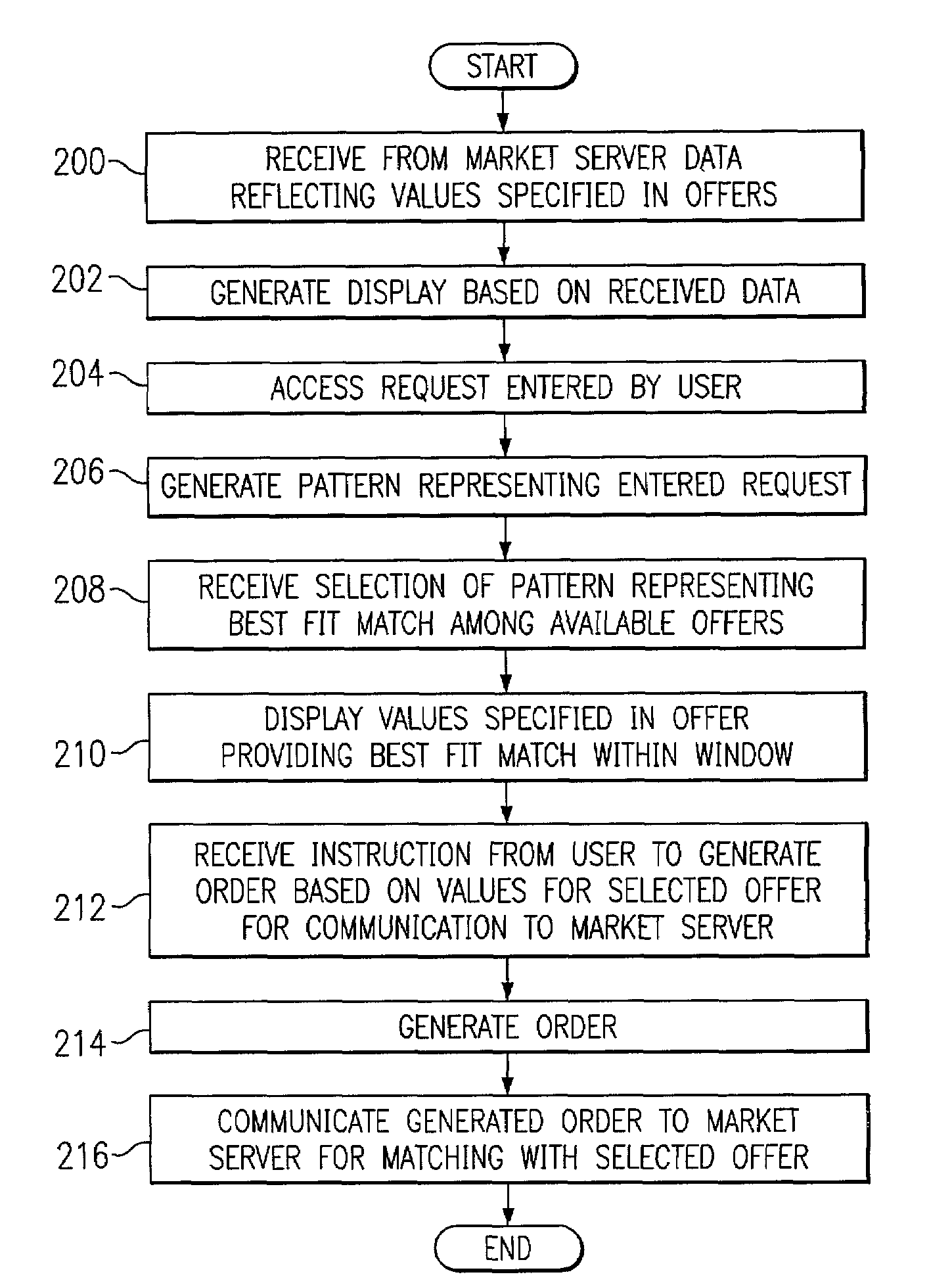

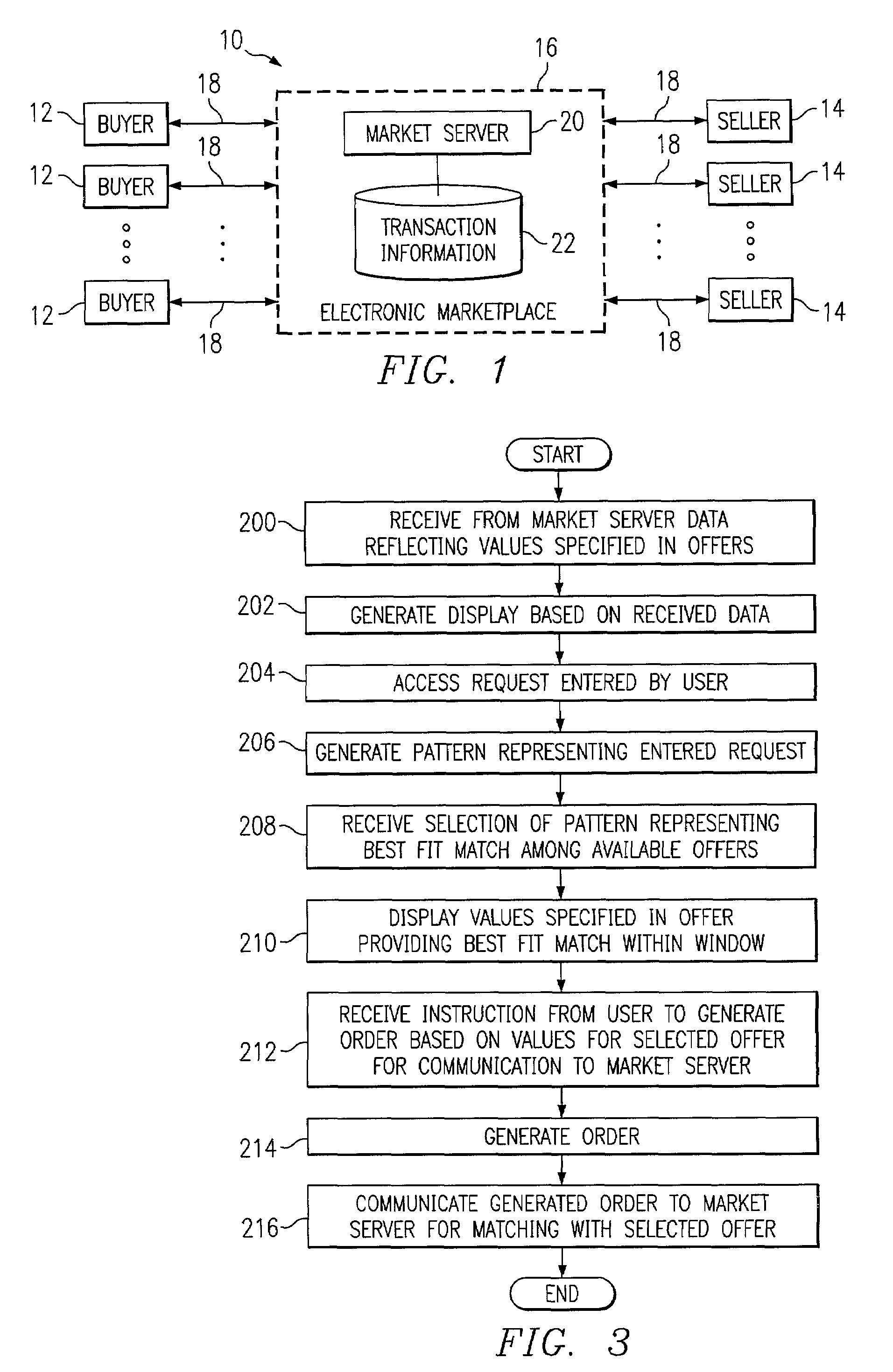

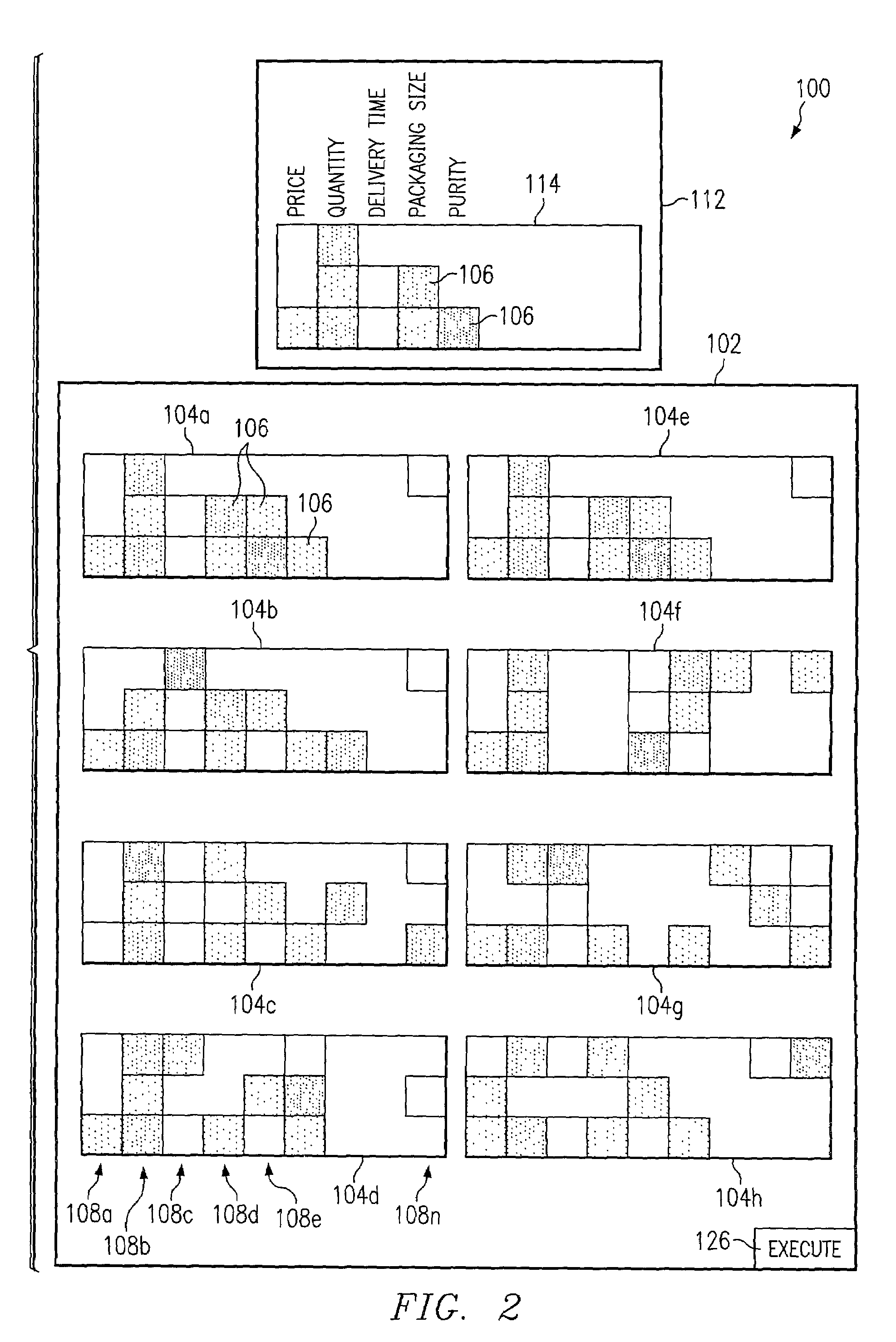

Providing visualization of market offers using patterns of geometric display elements

InactiveUS7702562B1Data be reduced eliminatedDisadvantages can be reduced eliminatedFinanceCommerceData science

A method of providing visualization of market offers includes receiving offer data for multiple offers, the offer data reflecting values specified in the offers for multiple offer variables. The method further includes generating a display of the offer data. The display includes multiple patterns, each pattern representing a particular offer and including multiple bars. Each bar within the pattern represents a particular offer variable and includes a set of one or more geometric display elements that by virtue of their appearance collectively encode, according to a predefined encoding scheme, a value for the offer variable corresponding to the bar.

Owner:BLUE YONDER GRP INC

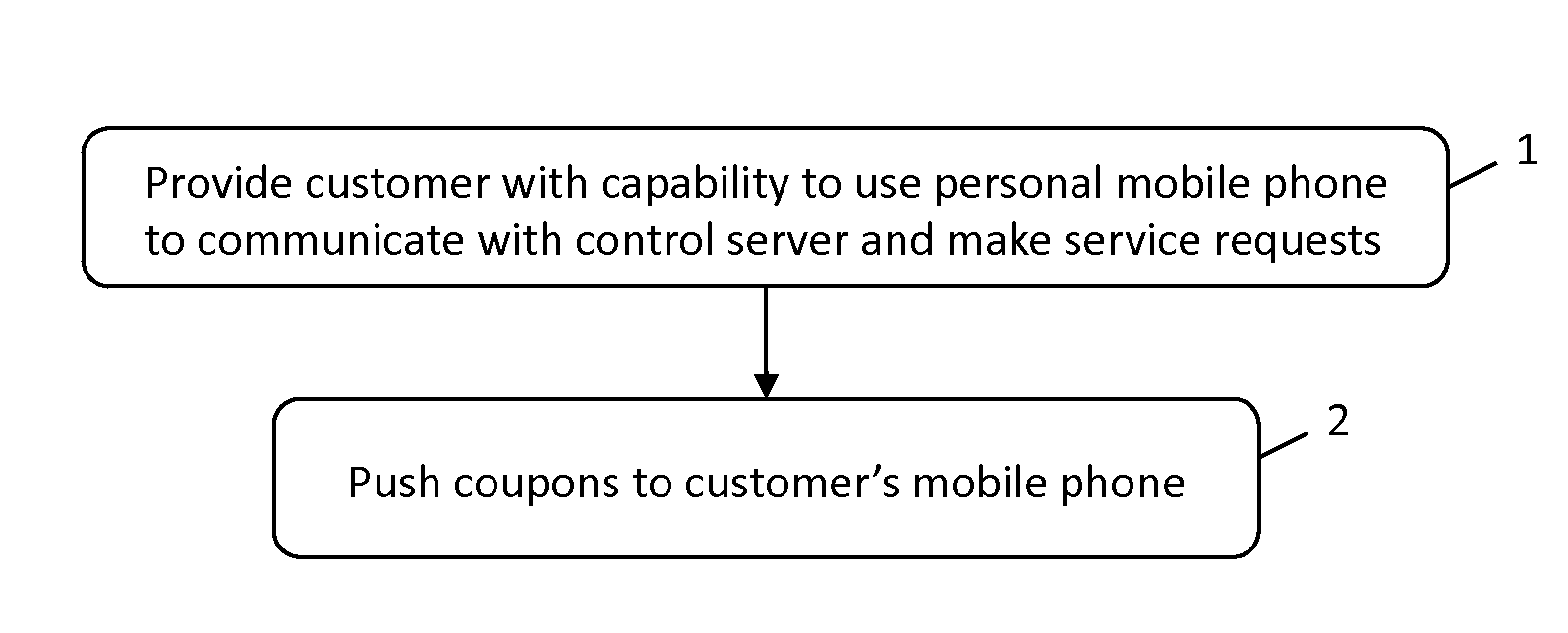

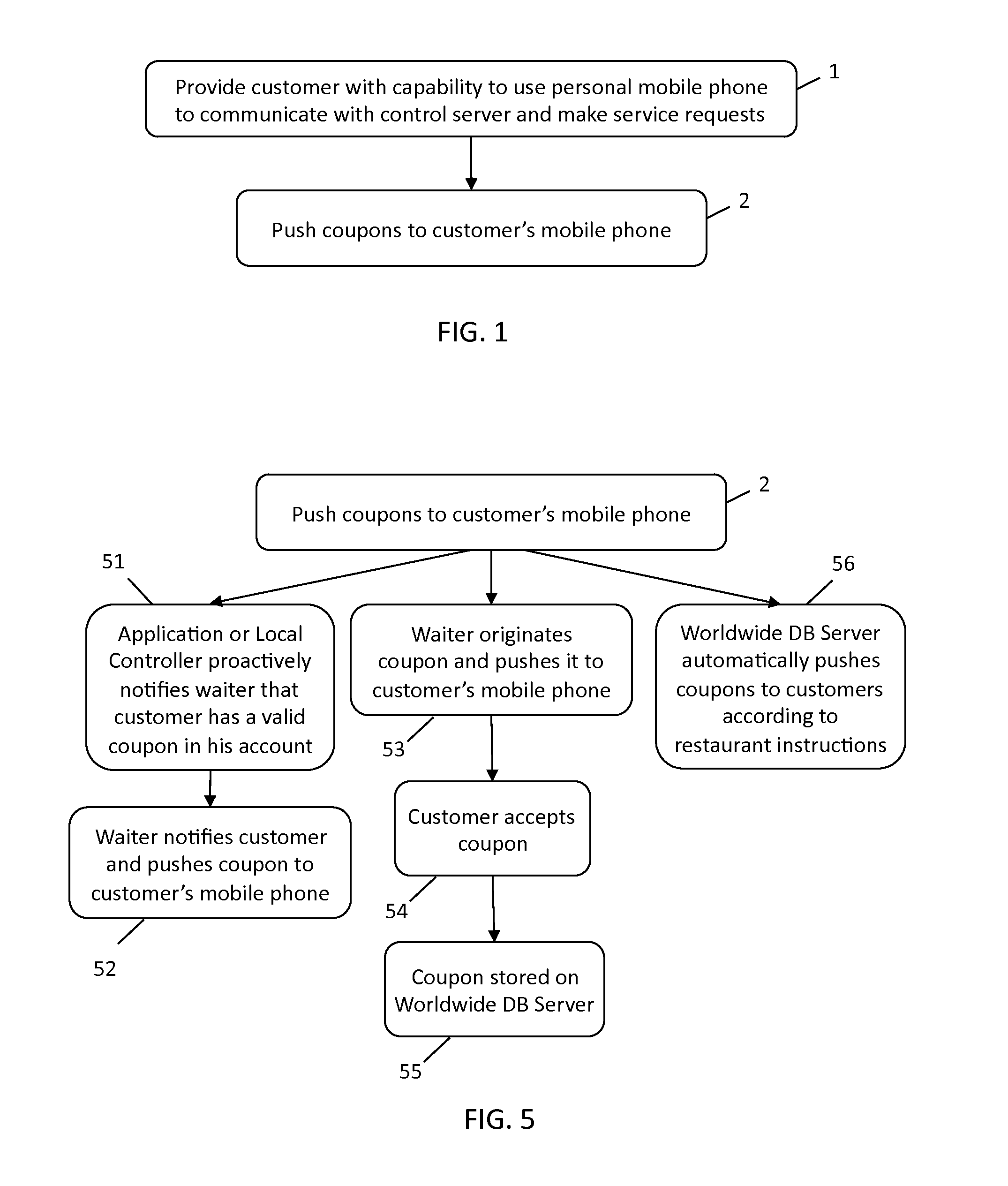

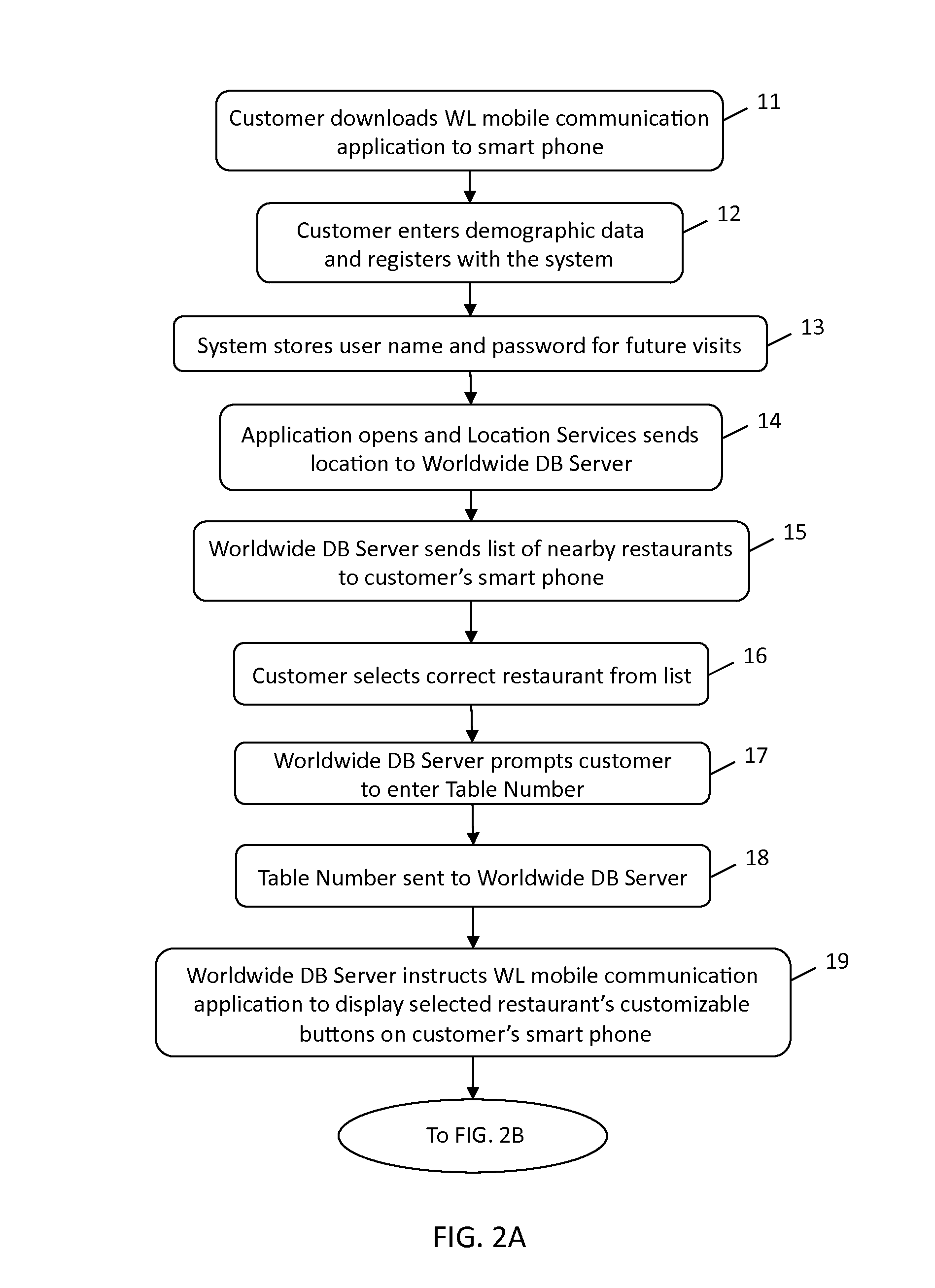

Mobile Communication and Coupon-Pushing System and Method

InactiveUS20140195327A1Improve efficiencyImprove effectivenessMarketingTelecommunications linkWaiters/waitresses

A system and method for providing discount coupons to a customer in a business establishment such as a restaurant. A control server associated with the business establishment is configured to communicate over a wireless communication link with a mobile telecomputing device, such as a smart phone, of the customer. The control server enables the customer to request services utilizing the customer's smart phone. The control server sends the discount coupons to the customer's mobile telecomputing device proactively or in response to customer or waiter requests.

Owner:TEZHQ

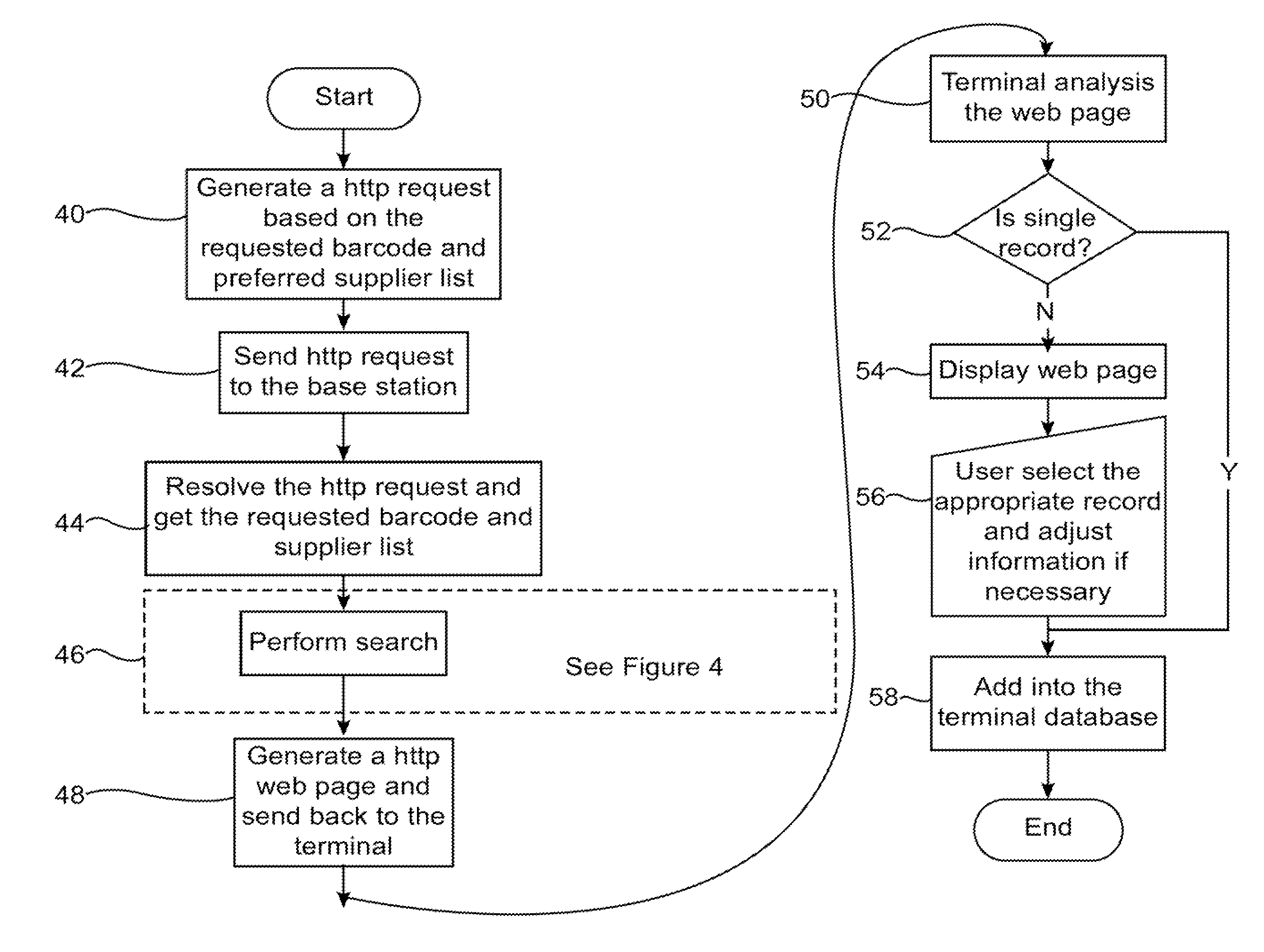

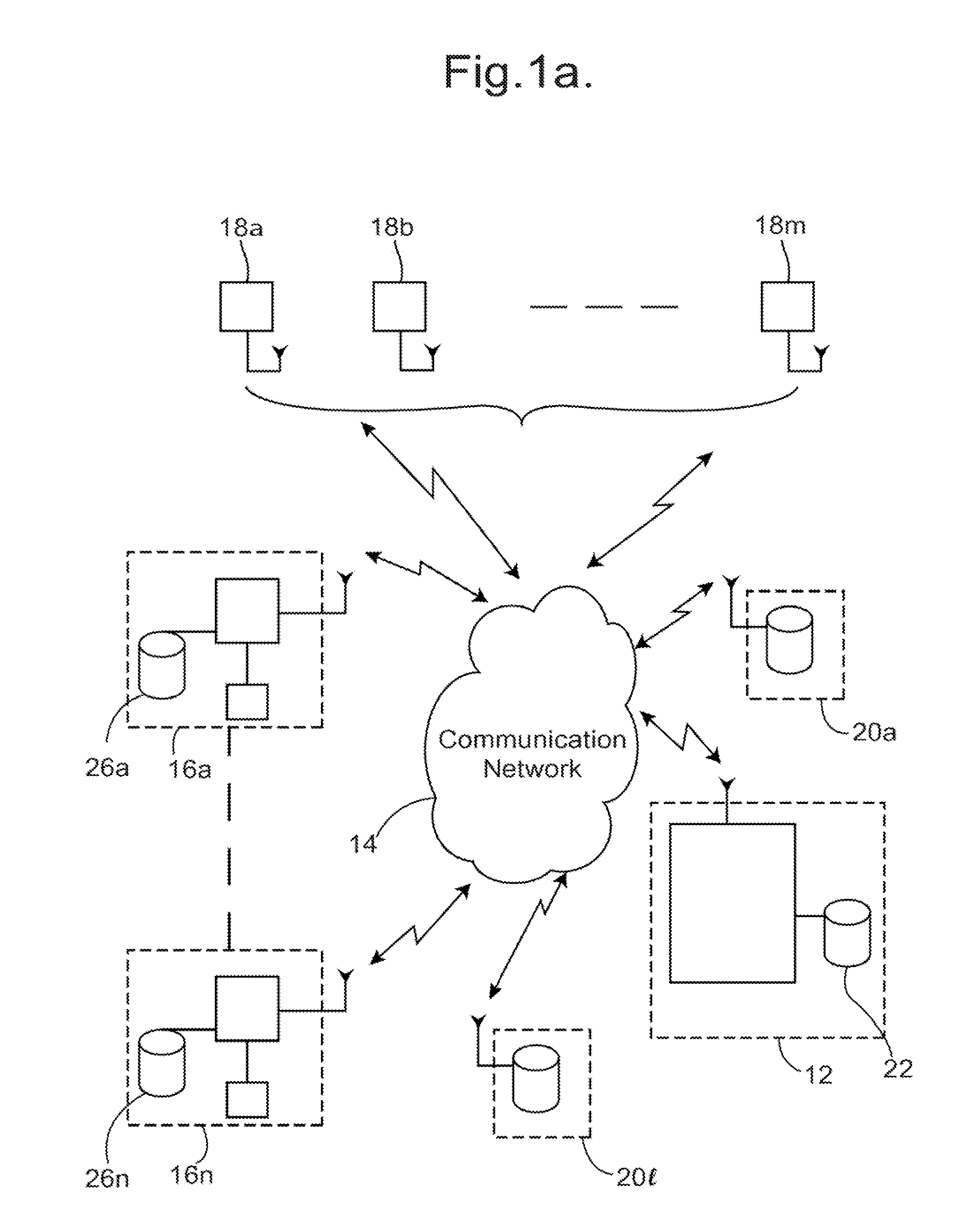

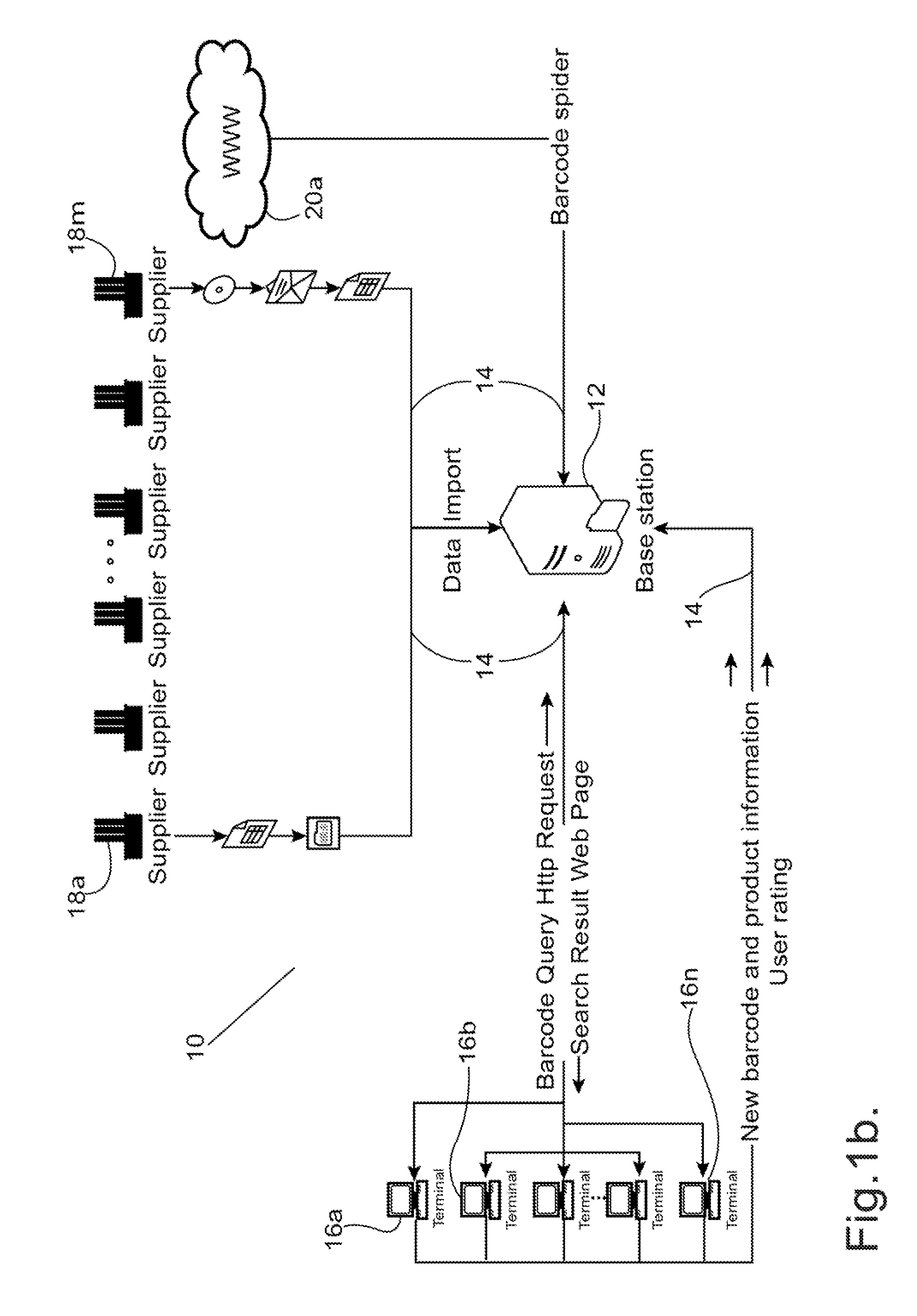

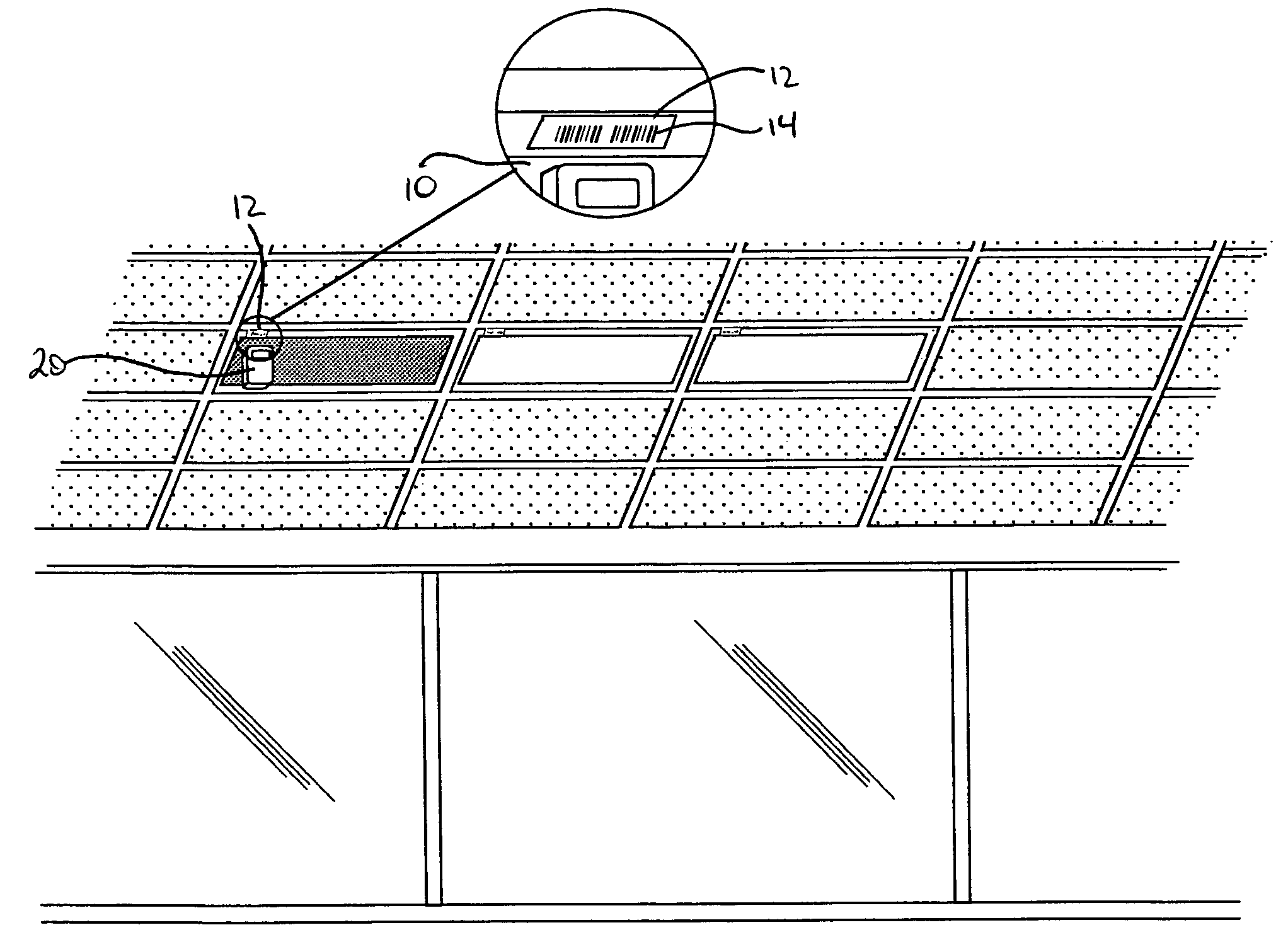

Barcode information distribution system

InactiveUS20120061460A1Increase efficiency and effectivenessIncrease accuracyDatabase updatingData acquisition and loggingDistribution systemBarcode

A system (10) for distributing barcode information. The system (10) includes a plurality of terminal systems (16a to 16n) in communication with a database system (12). The database system (12) includes a database (22) of item information related to a plurality of item identifiers representative of barcode information. At least one of the terminal systems (16a) requests barcode information from the database system (12). The request including an item identifier representative of a barcode, and in response, the database system (12) transmits barcode information associated with the requested item identifier to the at least one terminal system (16a).

Owner:INTELLIGENT RETAIL

Stethoscope cleaning assembly

ActiveUS7866908B2Increase efficiency and effectivenessFacilitate passage of the headPhotosensitive materialsStethoscopeAssembly structureStethoscope

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid is associated with a dispenser assembly which is cooperatively disposed relative to an activating assembly. The activating assembly is manually operated due to moveable engagement with the head portion as it travels along the path of travel. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispenser assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from.

Owner:SEEDLINGS LIFE SCI VENTURES

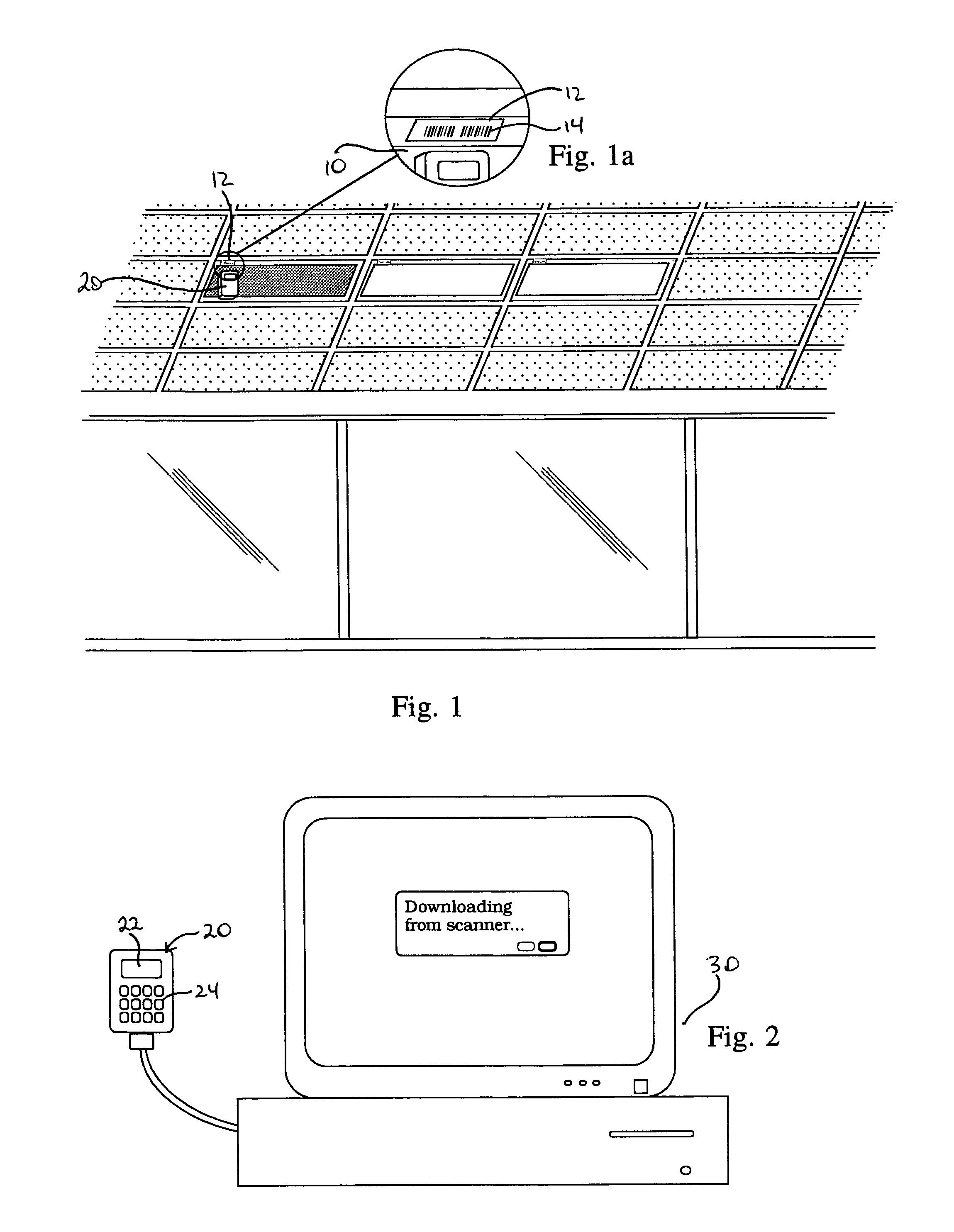

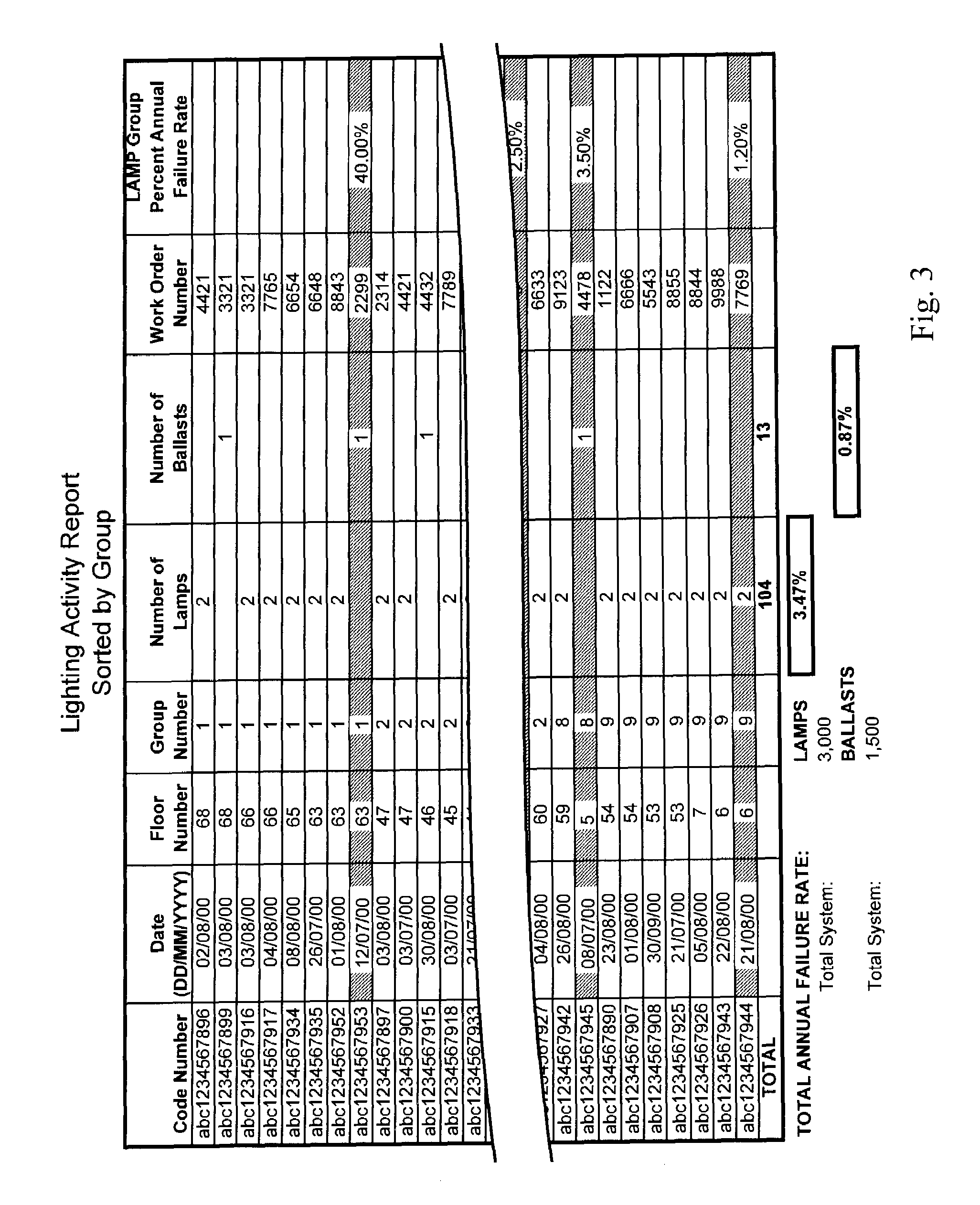

Light fixture management system

InactiveUS7503478B2Simple taskIncrease efficiency and effectivenessRegistering/indicating working of machinesSubscribers indirect connectionIdentifying problemsManagement system

A light fixture management system and method is provided for tracking one or more of the location, history and operating characteristics of light fixtures in a structure or a group of structures and surrounding premises. Each fixture is assigned indicia such as an identifier transmitted by a RFID transponder, information regarding which is stored in a database in association with fixture details. Fixtures requiring repair or maintenance are identified and the identifier is received by a portable reader. A user may optionally enter into the reader any observable problem. Received and entered information is downloaded into a computer, which generates a repair route for identified fixtures based on their locations and identified problems. Reports may be generated with other desired information such as the location of the circuit breaker associated with each fixture. The task of tracking light fixtures is thus simplified and efficiency and effectiveness of repair personnel increased.

Owner:JEFFERY R CLARK

Stethoscope cleaning assembly

An assembly structured to clean the head portion of a stethoscope comprising a housing including a path of travel along which the head portion passes during cleaning. A supply of cleaning fluid is associated with a dispensing assembly which is cooperatively disposed relative to an activating assembly. The activating assembly is manually operated due to moveable engagement with the head portion as it travels along the path of travel. The activating assembly is thereby operatively positioned to activate the dispenser assembly when engaged by the head portion as it passes along the path of travel. The dispensing assembly delivers the cleaning fluid to an applicator assembly which distributes the cleaning fluid to the head portion and facilitates the cleaning thereof and removal of excess cleaning fluid there from.

Owner:SEEDLINGS LIFE SCI VENTURES

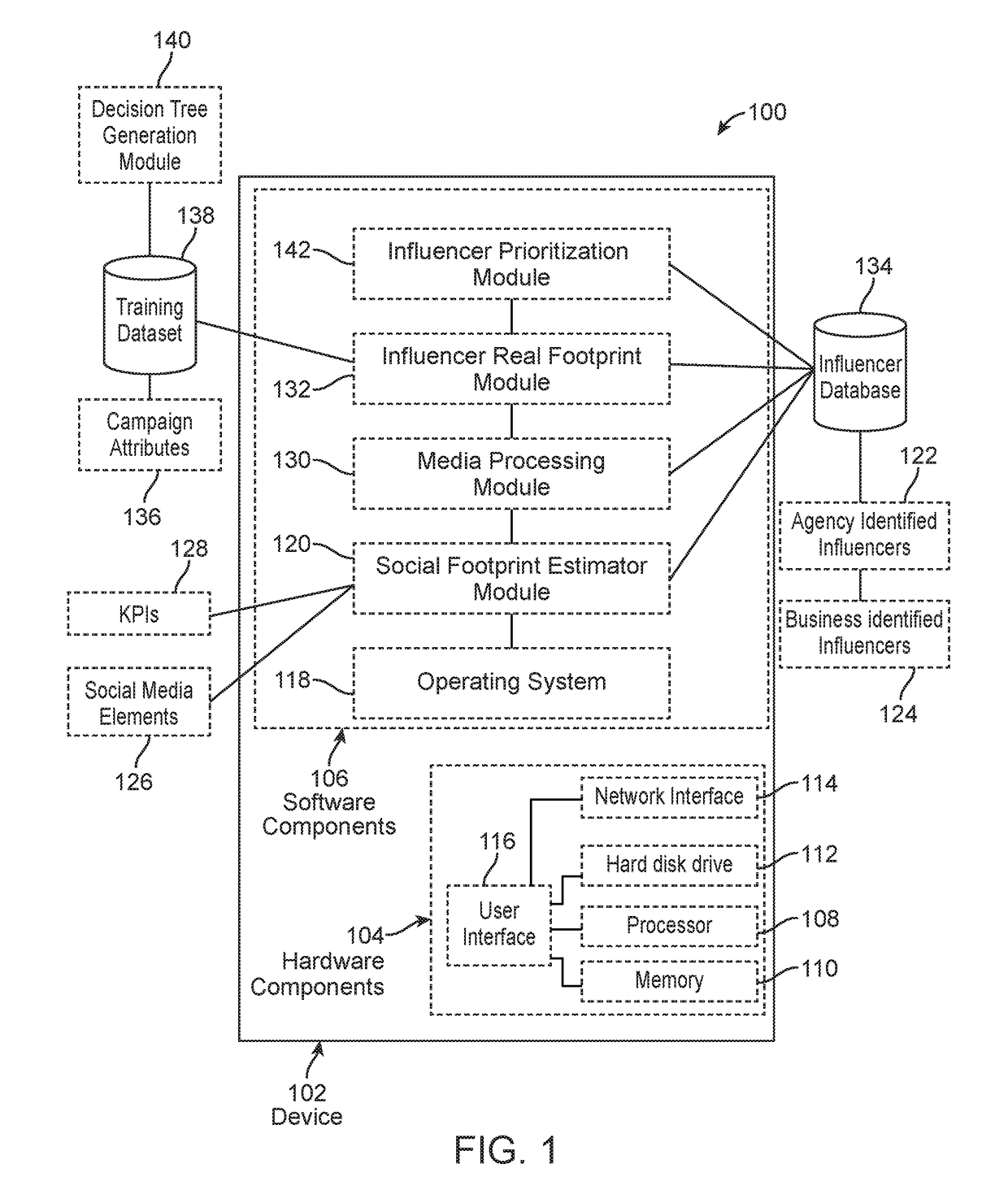

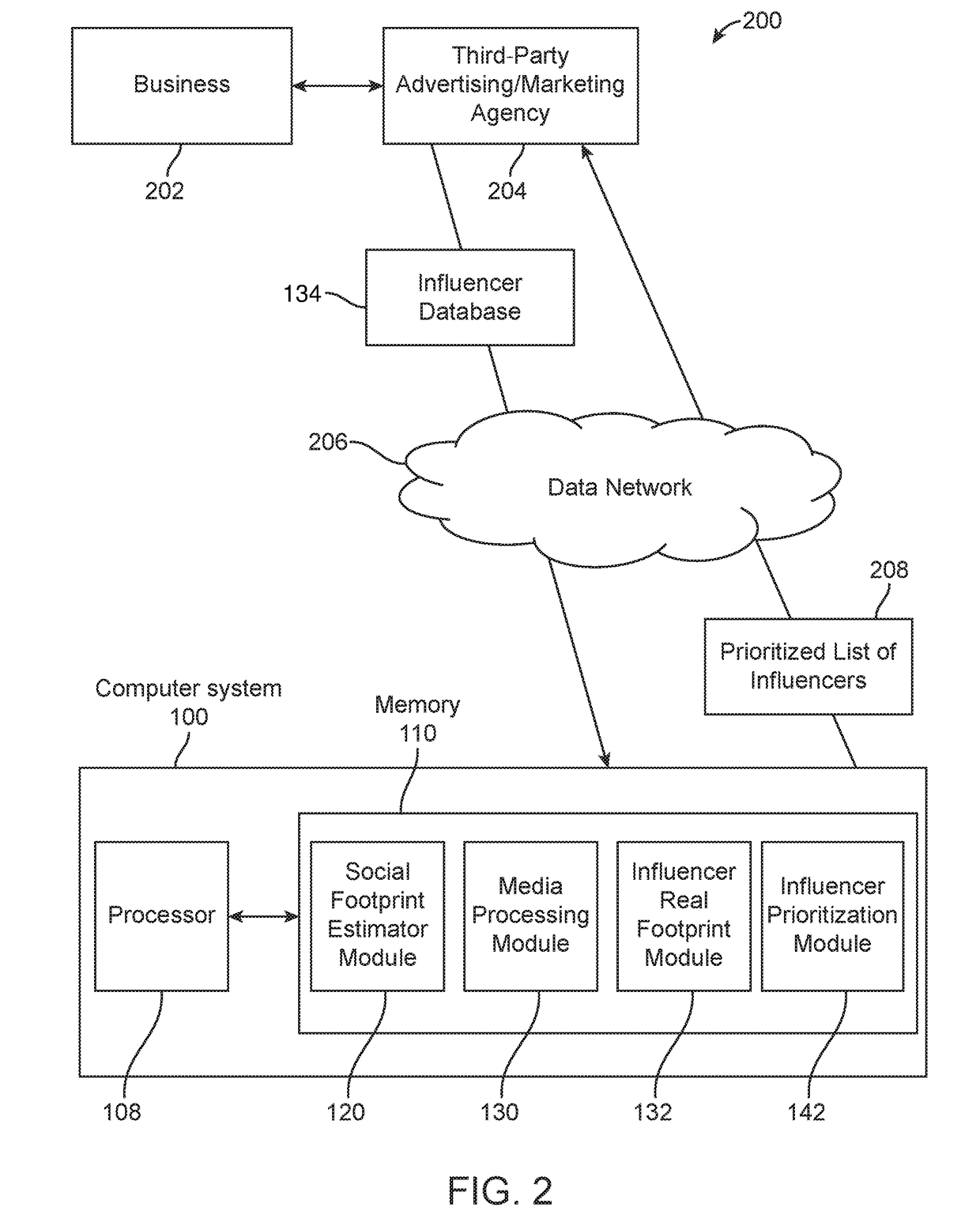

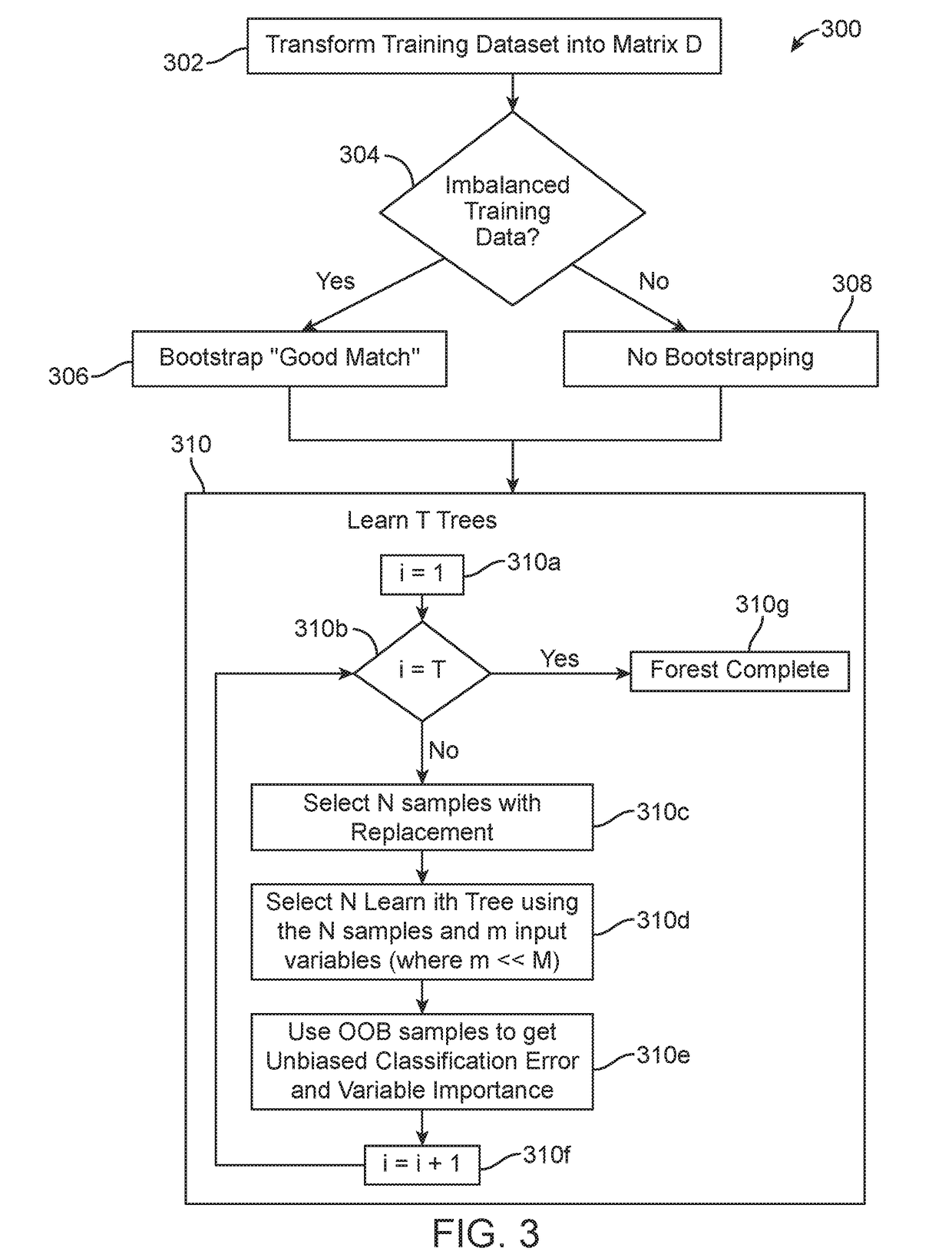

System and method for evaluating the true reach of social media influencers

ActiveUS20190012746A1Increase efficiency and effectivenessEasy and inexpensive to constructEnsemble learningBiological modelsData setSocial media

A non-transitory computer readable storage media having computer-executable instructions, when executed by a processor, performs a method for evaluating a reach of a social media influencer. The methods provides for receiving a plurality of influencers at a server, wherein a data set is associated with each of the plurality of influencers; parsing the data set into quantitative data readable by a machine learning algorithm at the server; receiving, inputting, or both, a type of product or service at the server; classifying the type of product or service into at least one class of goods or services; training a node using the machine learning algorithm using the date set an input; and executing the machine learning algorithm to determine a score of each influencer for each class of goods or services. Systems for evaluating the reach of a social media influencer as it relates to advertisers and content is also disclosed herein.

Owner:MSM HLDG PTE

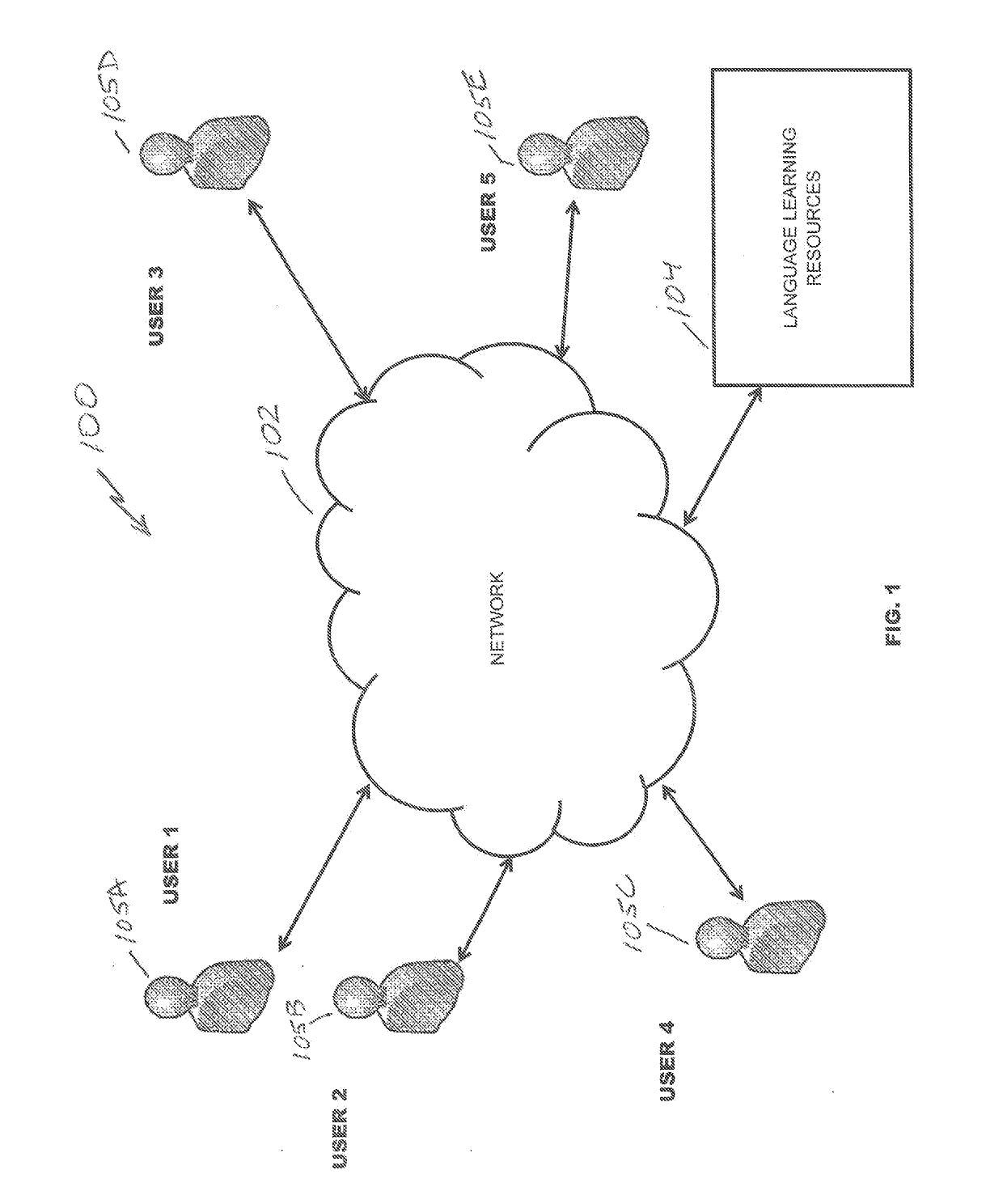

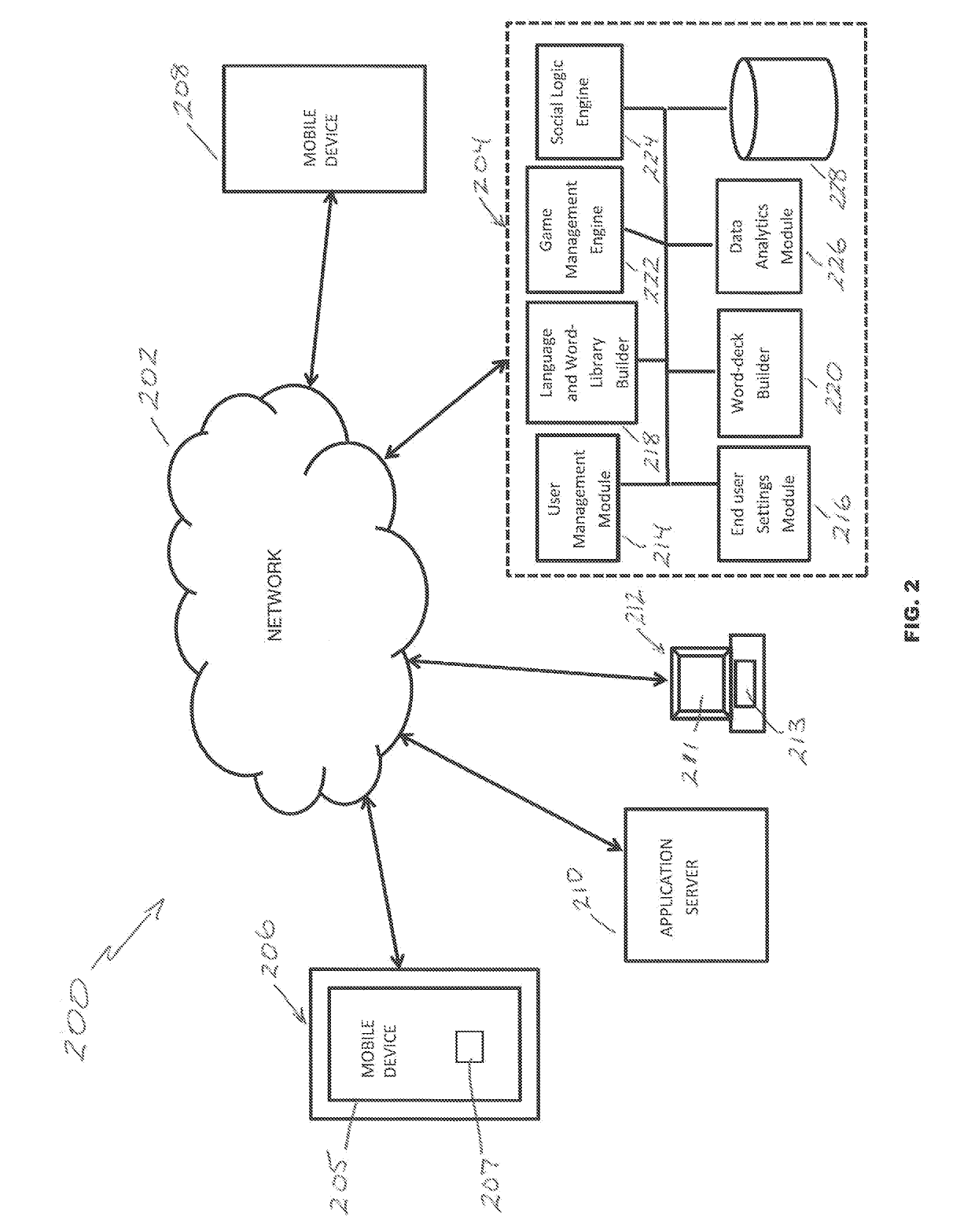

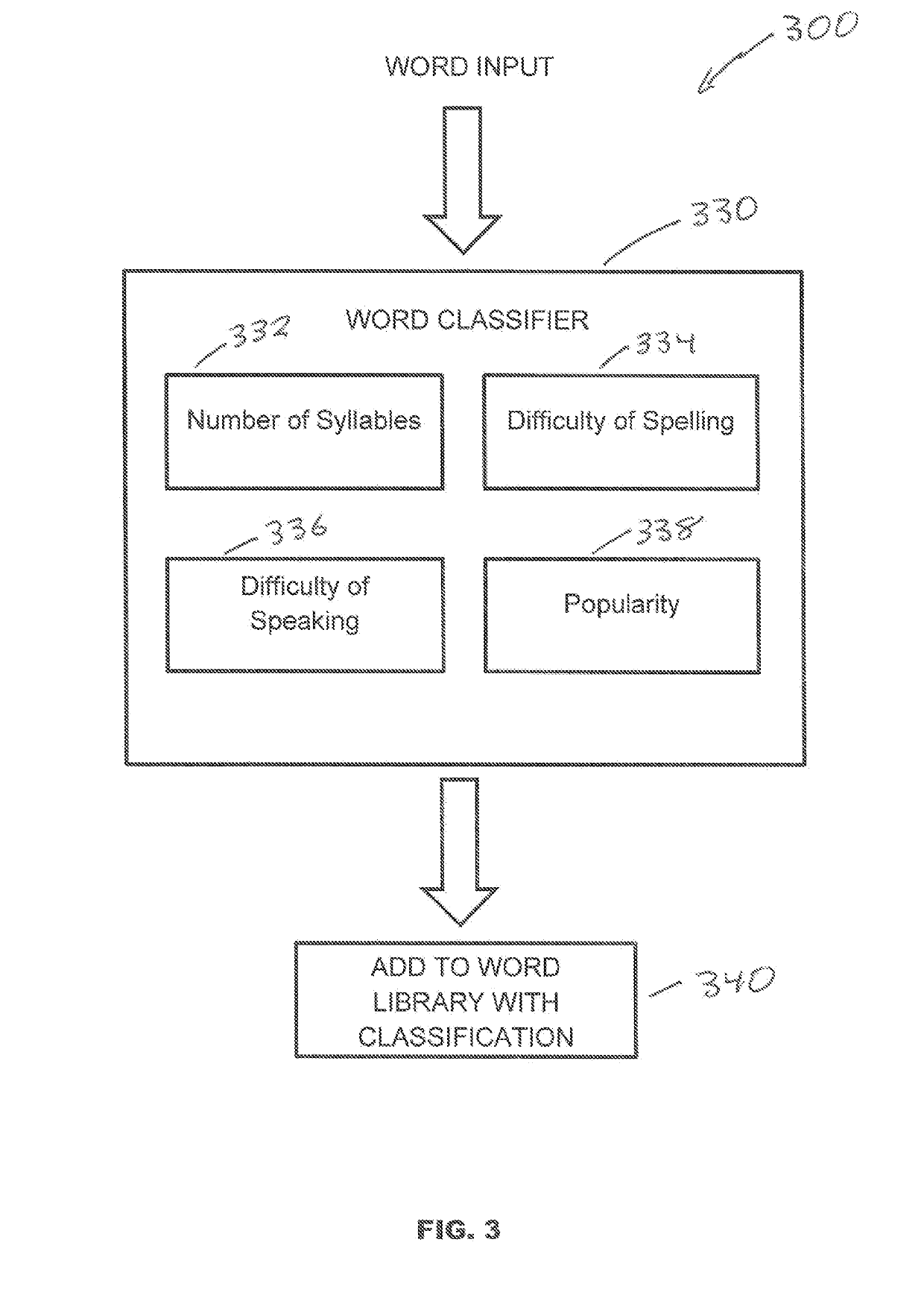

System and Method for Language Learning

ActiveUS20190122578A1Increase efficiency and effectivenessImproves student achievementNatural language data processingElectrical appliancesSpeech soundVerbal learning

A method for peer-to-peer learning of a common language by a plurality of students. A first student selected from the plurality of students acts as a speaker in the common language with a second student selected from the plurality of students acting as a speller. A word-deck is generated for use by the student-group. The word-deck includes a plurality of words that are selected because they are related to another word, respectively, found in the common language based on a phonetic similarity between the respective words. The first student is provided with a word selected from the plurality of words included in the word-deck where the word has a correct spelling. An audio output is provided to the second student where the audio output includes the word as spoken by the first student. An entry includes a spelling of the word as spelled by the second student following a receipt of the audio output. If the spelling of the word matches the correct spelling of the word, a score for the student-group is improved.

Owner:ZOUNDSLIKE LLC

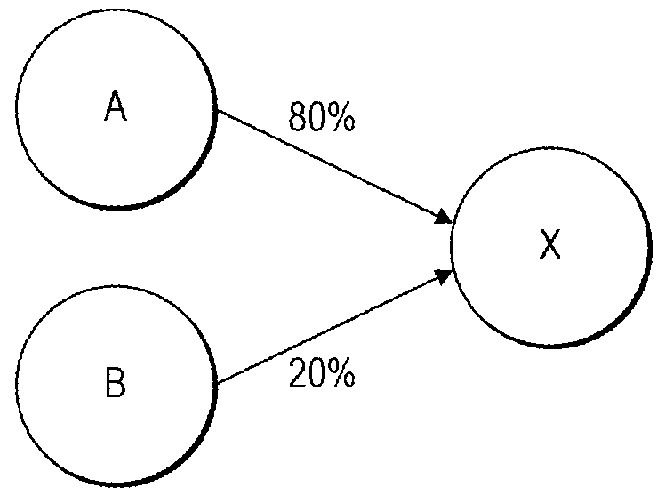

Projecting project outcome

InactiveUS20120179991A1Improve robustnessImprove adaptabilityForecastingResourcesGraphicsGraphical user interface

Apparatus has at least one processor and at least one memory having computer-readable code stored thereon which when executed controls the at least one processor to perform a method comprising: providing a graphical user interface (GUI); allowing a user to define, through the GUI, a project at least in terms of plural initiative components, plural outcome components, and interrelationships between the initiative components and the outcome components; allowing the user to define, through the GUI, two or more quality components for each initiative component, each quality component comprising a performance level and resource costs associated with achieving the performance level; allowing the user to define, through the GUI, plural parameters associated with the project, the parameters including performance levels and resource costs for each of at least two quality components; allowing the user to allocate, through the GUI, resources to each of the initiative components; providing a projected measure of project outcome based on the allocated resources; allowing the user to alter, through the GUI, the resources allocated to the initiative components; and providing revised projected measure of project outcome based on the altered resource allocations.

Owner:BRM FUSION

Process control and optimization technique using immunological concepts

ActiveUS7856280B2Increase efficiency and effectivenessAccurately reflectAC motor controlField or armature current controlBiological immune systemProcess engineering

An integrated optimization and control technique performs process control and optimization using stochastic optimization similar to that used in biological immune systems during on-line operation of a process, the technique collects and stores indications of process control states. During steady-state operation, the technique optimizes process operation by developing sets of process control inputs from stored process control states using an objective function that defines an optimality criterion. Moreover, after one or more disturbance inputs experiences a significant change, the technique responds by comparing the changed disturbance inputs to the disturbance inputs of at least some of the stored process control states to determine the stored process control states that are closest to the new process operating condition. The technique then develops a new set of control inputs based on the control inputs associated with the stored process control states determined to be closest to the new process operating condition.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

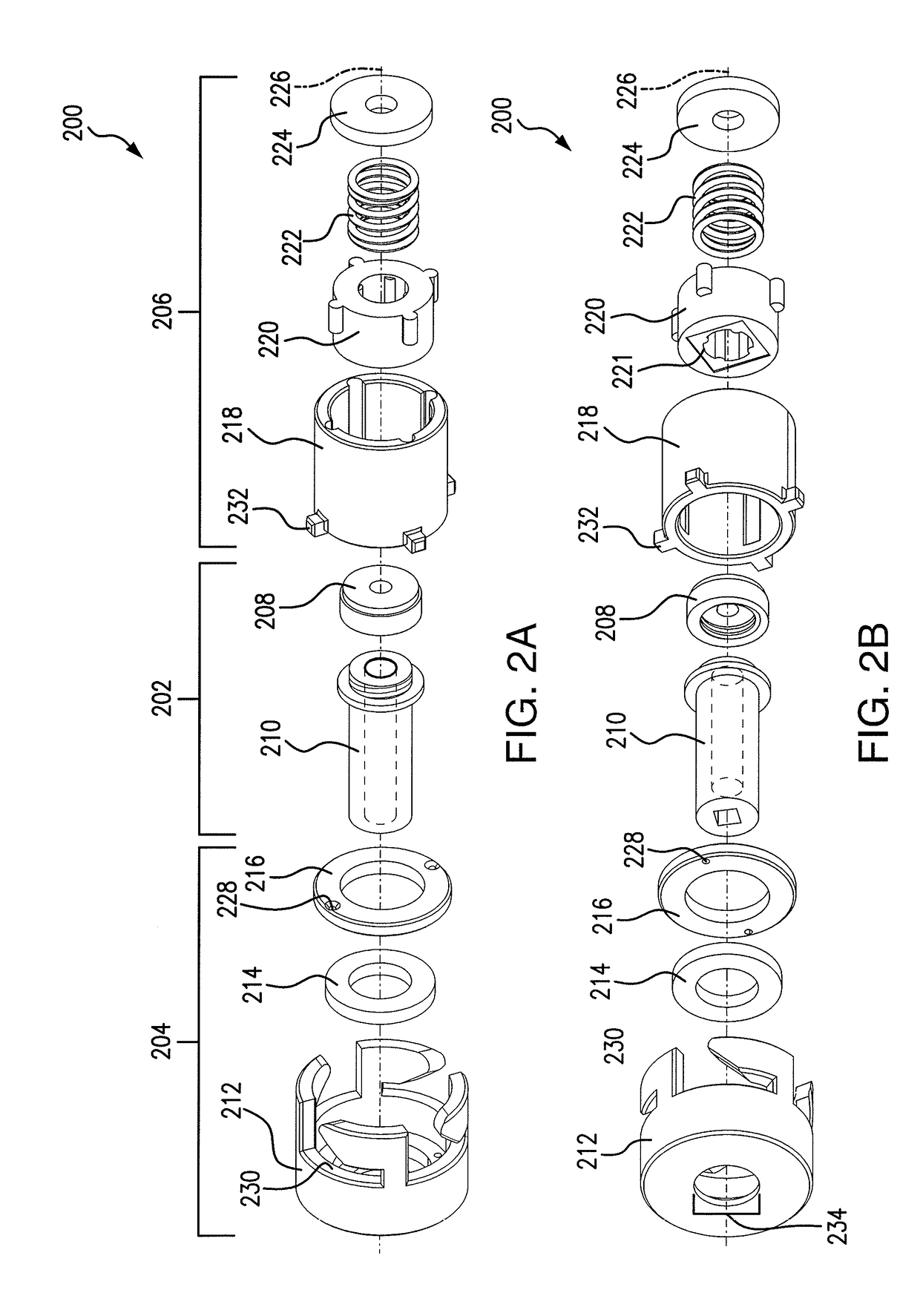

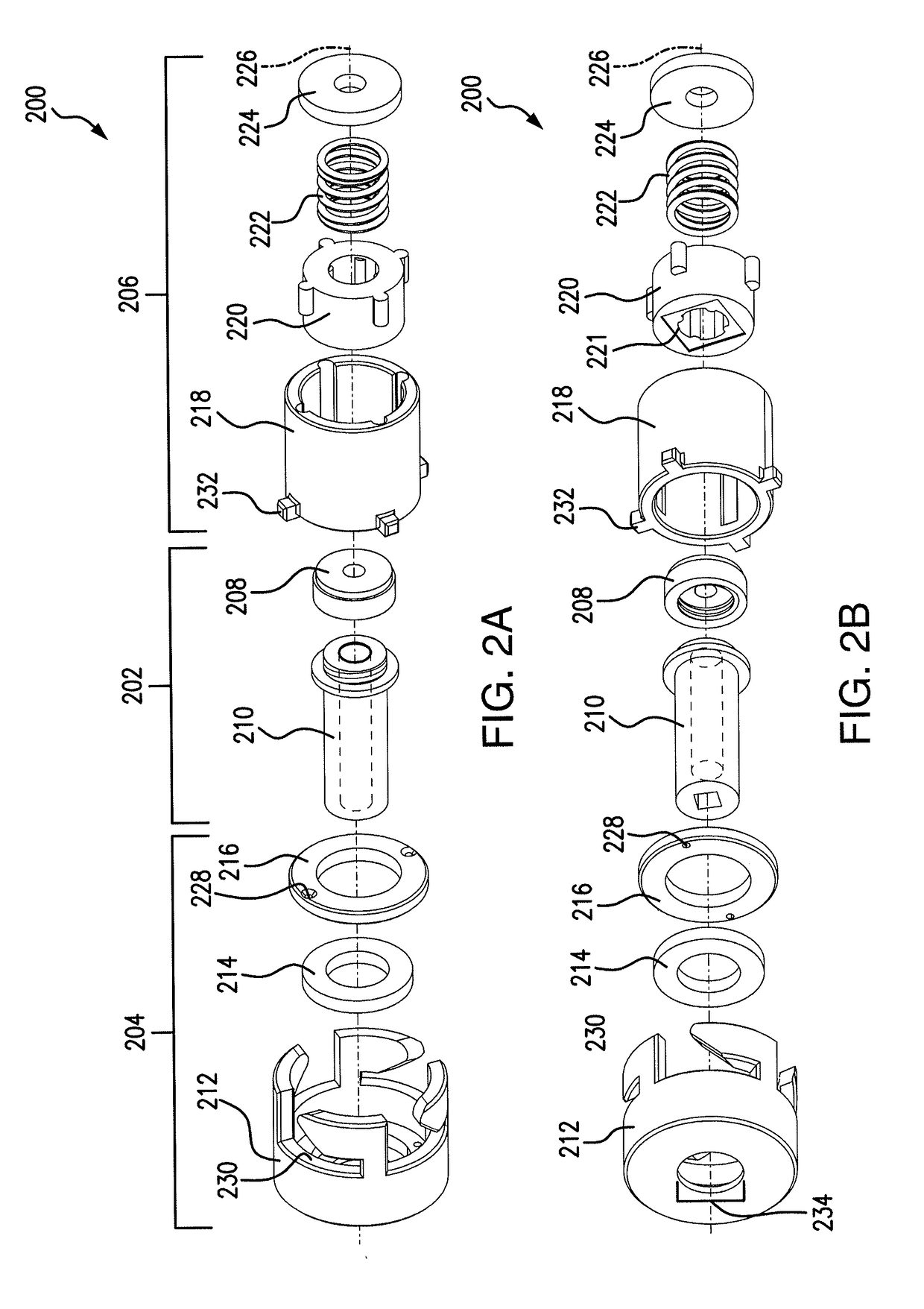

Nutplate Rotary Abrasion Tool

ActiveUS20180369873A1More secure attachmentIncrease efficiency and effectivenessPortable grinding machinesCleaning using toolsMechanical engineeringFaying surface

A system includes an abrasion component containing an abrasion pad configured to clean a faying surface of a nutplate and a shaft attached to the abrasion pad and configured to rotate the shaft and the abrasion pad during cleaning of the nutplate, which includes abrading the faying surface with the abrasion pad. The system further includes a base configured to attach to a pressure applicator, and the pressure applicator, which is configured to attach to the base, hold the nutplate such that the faying surface is capable of contacting the abrasion pad during the cleaning of the nutplate, and apply pressure to the nutplate such that the nutplate contacts the abrasion pad during the cleaning of the nutplate. Furthermore, the abrasion component is configured to rotate the abrasion pad within at least one of the base and the pressure applicator during the cleaning of the nutplate.

Owner:LOCKHEED MARTIN CORP

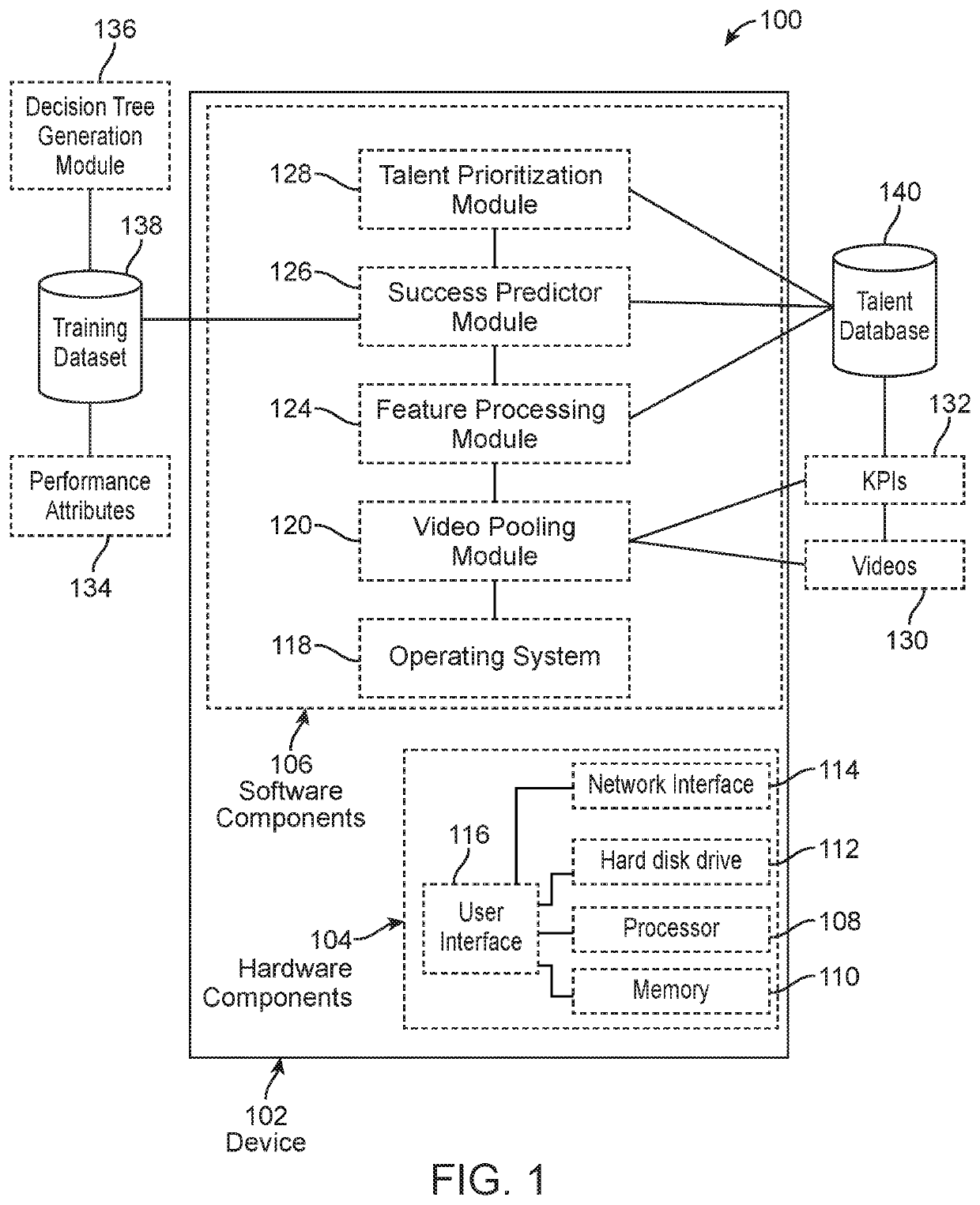

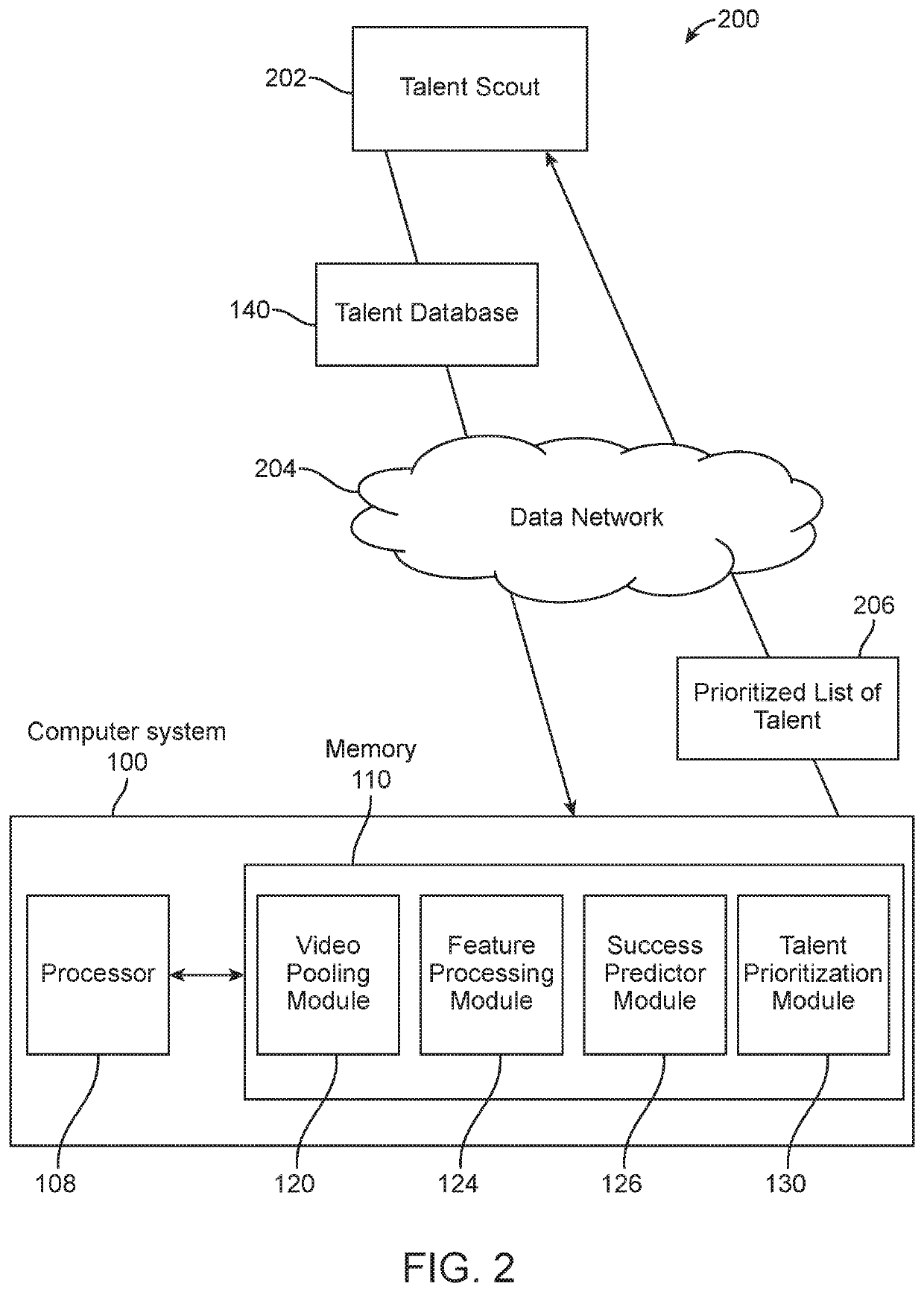

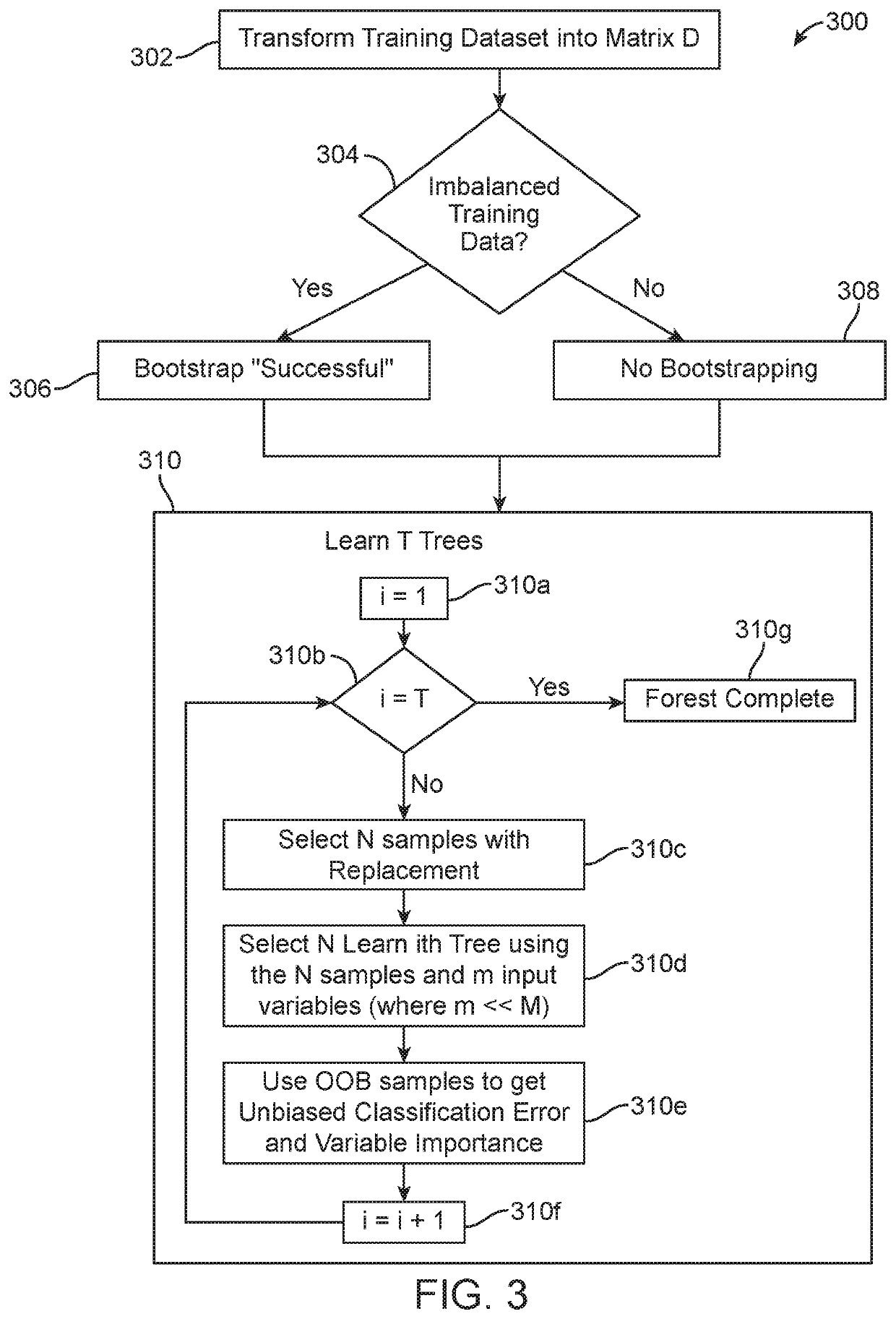

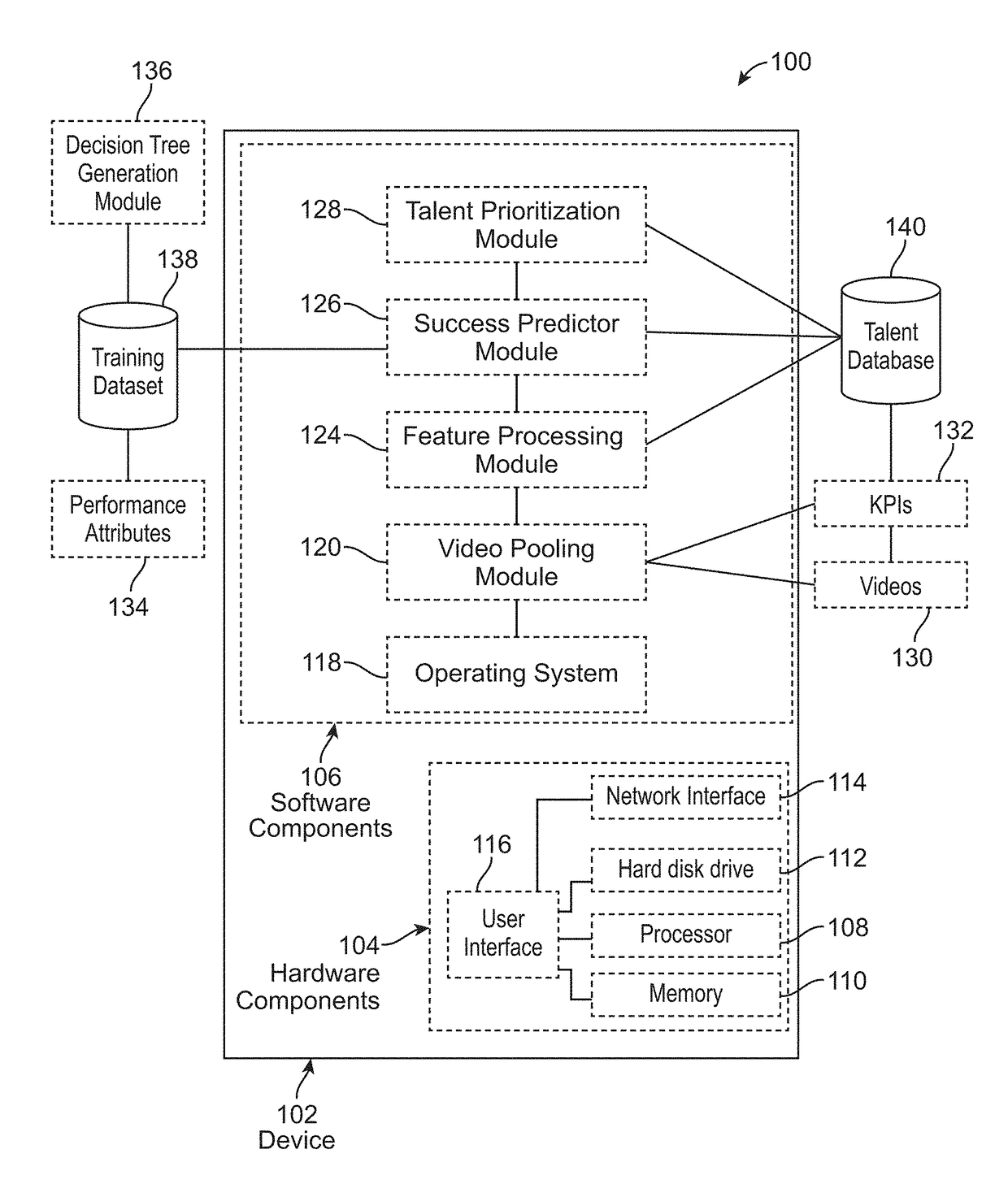

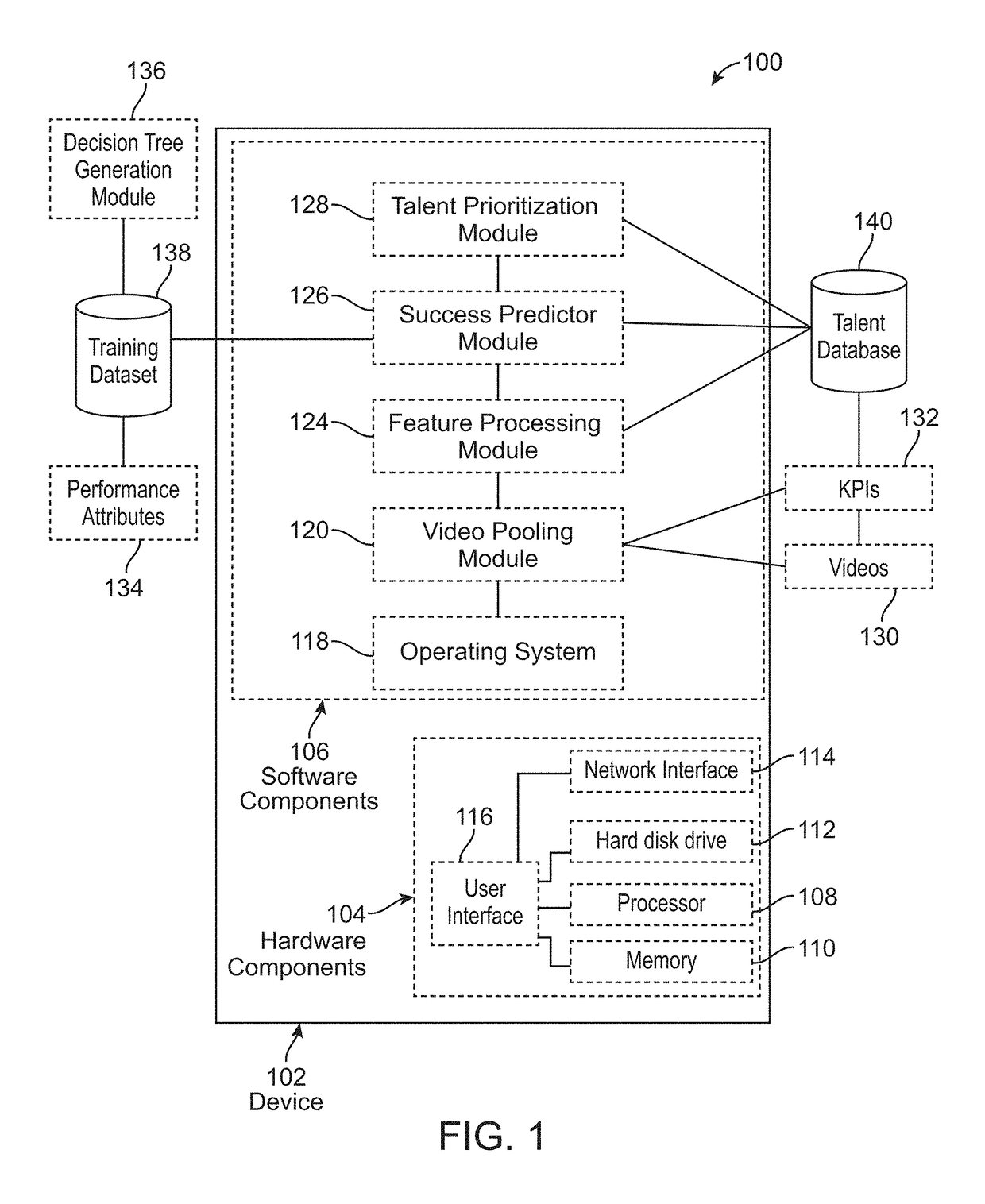

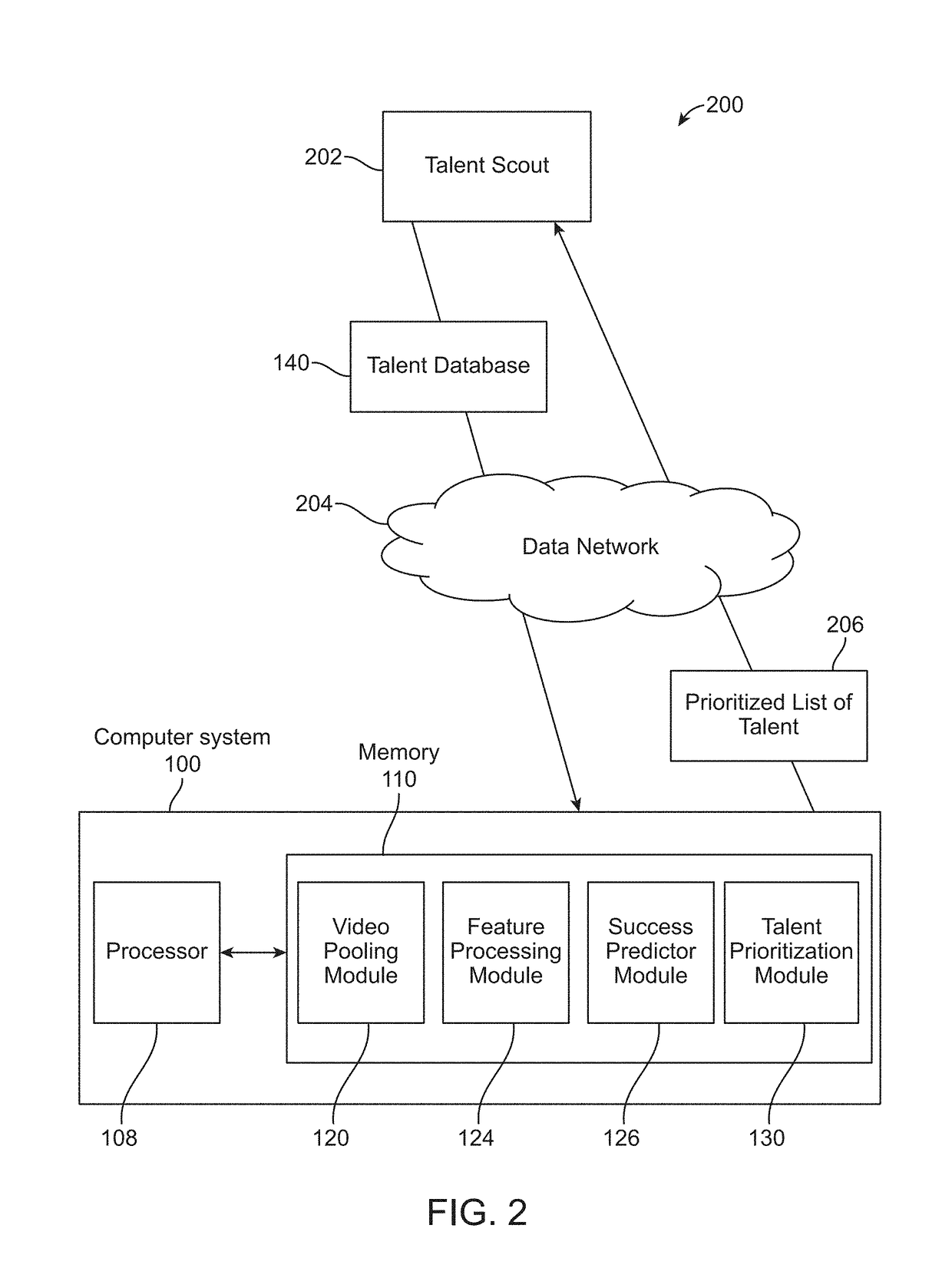

System and method for analyzing media for talent discovery

ActiveUS20200327477A1Improve efficiencyImprove effectivenessOrganic active ingredientsVoting apparatusData setMediaFLO

A method for analyzing media to evaluate talent of a subject portrayed in the media is provided. The steps describe receiving a plurality of the media at a server, the media being performance based media; transforming the media into at least a data set corresponding to at least a characteristic of the media at the server, wherein the server is in communication with a node; identifying features in the data set that correspond to a probability of success of the subject in the media; receiving subjective opinion polling data from a plurality of participants as to whether the subject in the media has talent; training the node via machine learning algorithm to identify, using the identified features in the data set and the subjective opinion polling data provided, whether the subject is likely to have talent; and executing the machine learning algorithm to output a score relating to the talent of the subject in the media. A system for discovering talent is also provided herein.

Owner:MSM CORP INT LTD

System and method for analyzing media for talent discovery

ActiveUS20180189709A1Improve efficiencyImprove effectivenessOrganic active ingredientsVoting apparatusNODALData set

A method for analyzing media to evaluate talent of a subject portrayed in the media is provided. The steps describe receiving a plurality of the media at a server, the media being performance based media; transforming the media into at least a data set corresponding to at least a characteristic of the media at the server, wherein the server is in communication with a node; identifying features in the data set that correspond to a probability of success of the subject in the media; receiving subjective opinion polling data from a plurality of participants as to whether the subject in the media has talent; training the node via machine learning algorithm to identify, using the identified features in the data set and the subjective opinion polling data provided, whether the subject is likely to have talent; and executing the machine learning algorithm to output a score relating to the talent of the subject in the media. A system for discovering talent is also provided herein.

Owner:MSM CORP INT LTD

Photocatalyst materials having semiconductor characteristics and methods for manufacturing and using the same

InactiveUS7846864B2Increase efficiency and effectivenessIncrease trappingSemiconductor/solid-state device manufacturingDialysisPhysical chemistryAir treatment

New types of photocatalyst materials are disclosed together with methods for preparing and using these materials, as well as air treatment systems incorporating such materials. The photocatalyst materials of this invention consist essentially of very small particles of a first-metal oxide, the first-metal being a metal that exhibits photo-induced semiconductor properties, having ions of a second-metal dispersed throughout its lattice structure, the second-metal being selected from the group of dopant metals. Such photocatalyst materials are prepared by the steps of mixing first-metal and second-metal precursors, removing nonessential ions from the mixture, drying the resulting product, and calcinating the dried product to produce the completed photocatalyst material.

Owner:SAMSUNG ELECTRONICS CO LTD

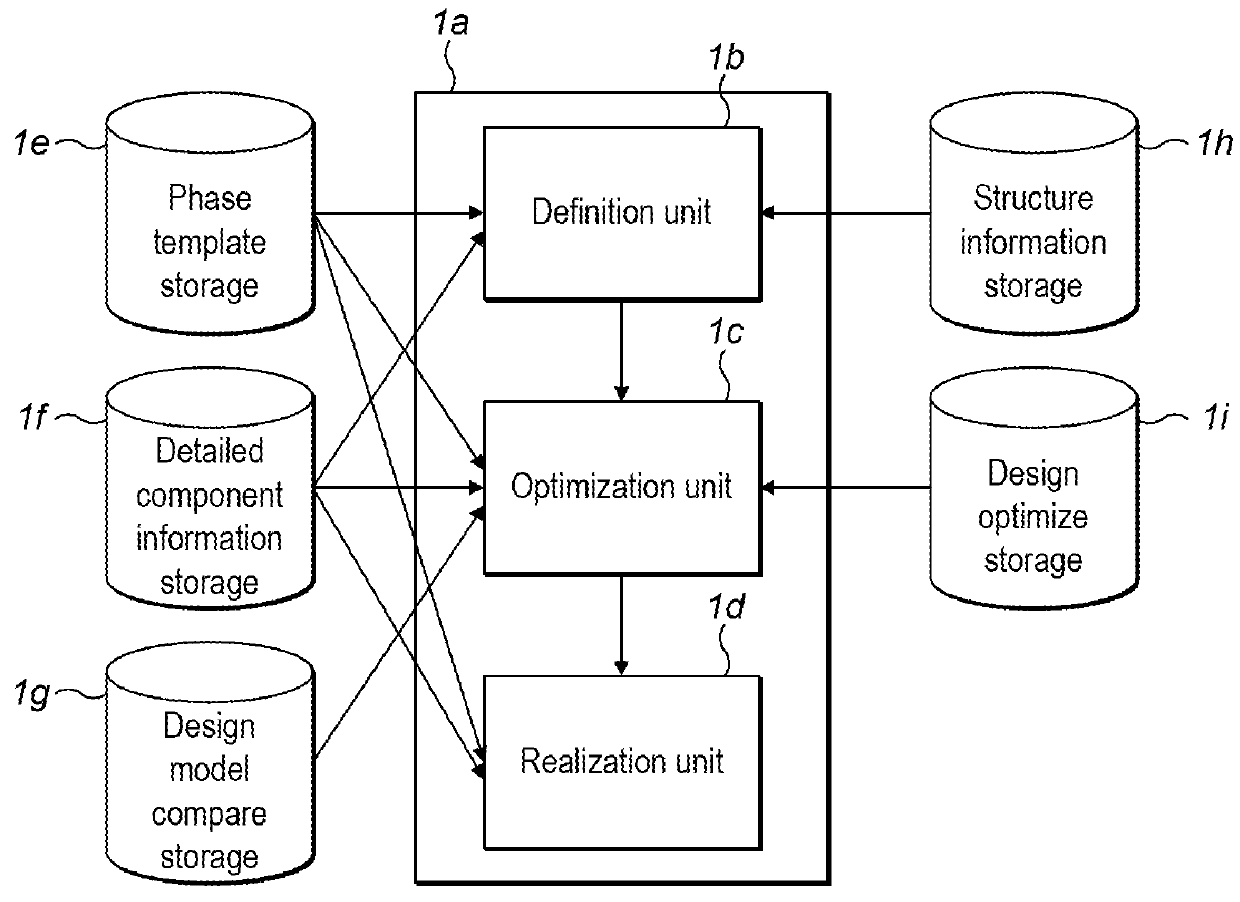

Service-oriented process configuration systems and/or methods

ActiveUS9858043B2Increase efficiency and effectivenessReduce complexityDigital data processing detailsResourcesService-orientationProcess configuration

Certain example embodiments described herein relate to techniques for matching business requirements with available services in service-oriented business process systems. An n-to-m relationship between process steps and services may be established. In certain example embodiments, both future design and dynamic runtime changes become possible by elaborating on possible resolution techniques before process execution and by identifying / resolving configurational dependencies. The addition of a service-oriented process configuration layer is made possible in certain example embodiments by enhancing the way that business processes are modeled visually or notationally, and through the implementation of a metamodel. The model linking process steps and services may be extended so as to support logical operators, rules or constraints for matching process steps and services, dependencies and relationships, etc. A meta model may be provided so as to provide support for evaluating or analyzing matches, sometimes automatically, at either or both of runtime and design time.

Owner:SOFTWARE AG

Multiple Nutplate Rotary Abrasion Tool

ActiveUS20180372143A1More secure attachmentImprove efficiencyNutsPortable grinding machinesBiomedical engineeringFaying surface

A system includes an abrasion assembly containing one or more abrasion pads configured to clean a faying surface of multiple nutplates, and a shaft attached to at least one of the abrasion pads and configured to rotate some or all of the abrasion pads during cleaning, wherein cleaning includes abrading the faying surfaces with the abrasion pads. The system also includes a base configured to attach to a pressure applicator, and a pressure applicator configured to attach to the base, hold the nutplates such that the faying surface of each nutplate is capable of contacting one of the abrasion pads, and apply pressure to the nutplates such that each of the nutplates contact one of the abrasion pads during the cleaning. Furthermore, the abrasion assembly is configured to rotate the abrasion pads within at least one of the base and the pressure applicator during cleaning.

Owner:LOCKHEED MARTIN CORP

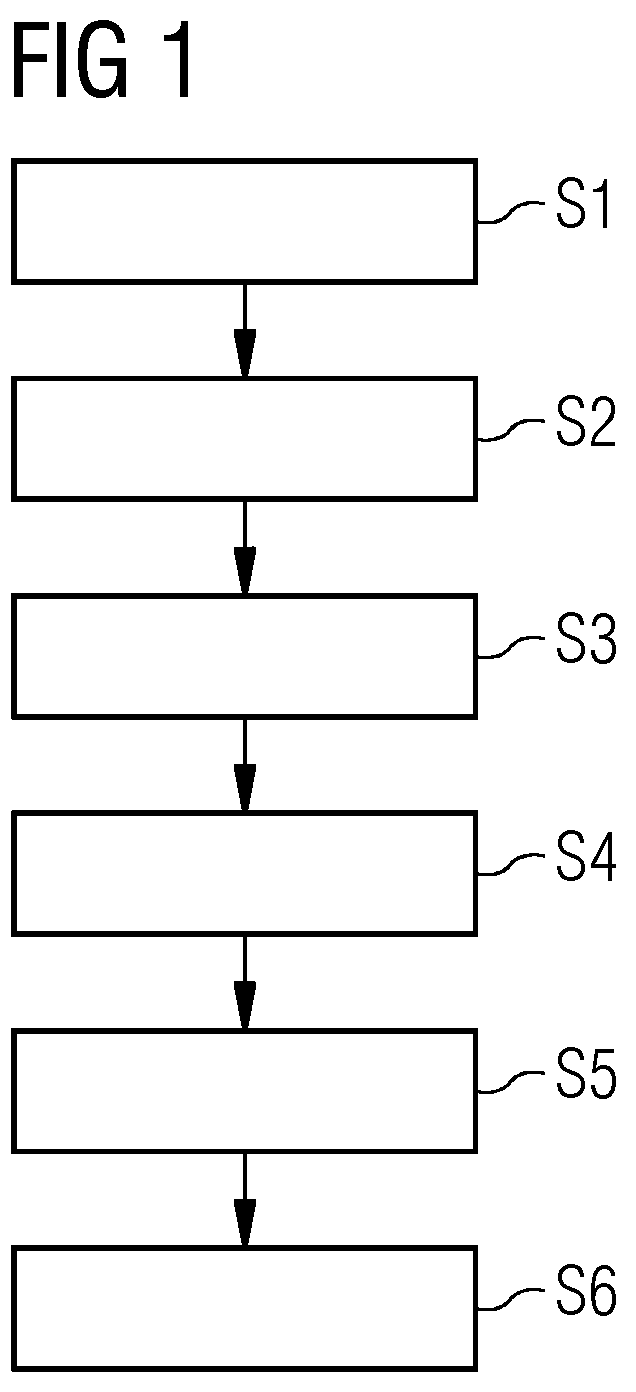

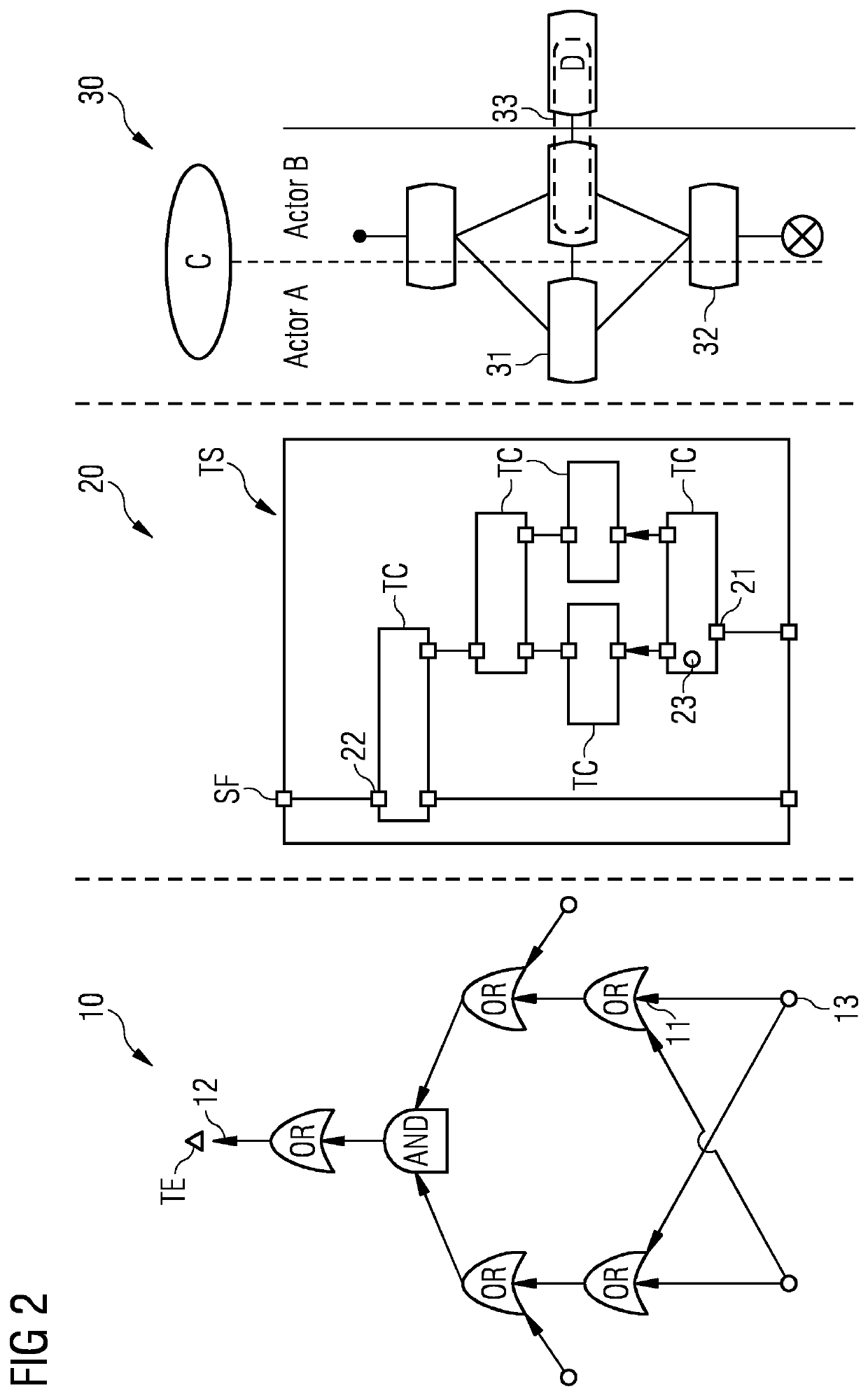

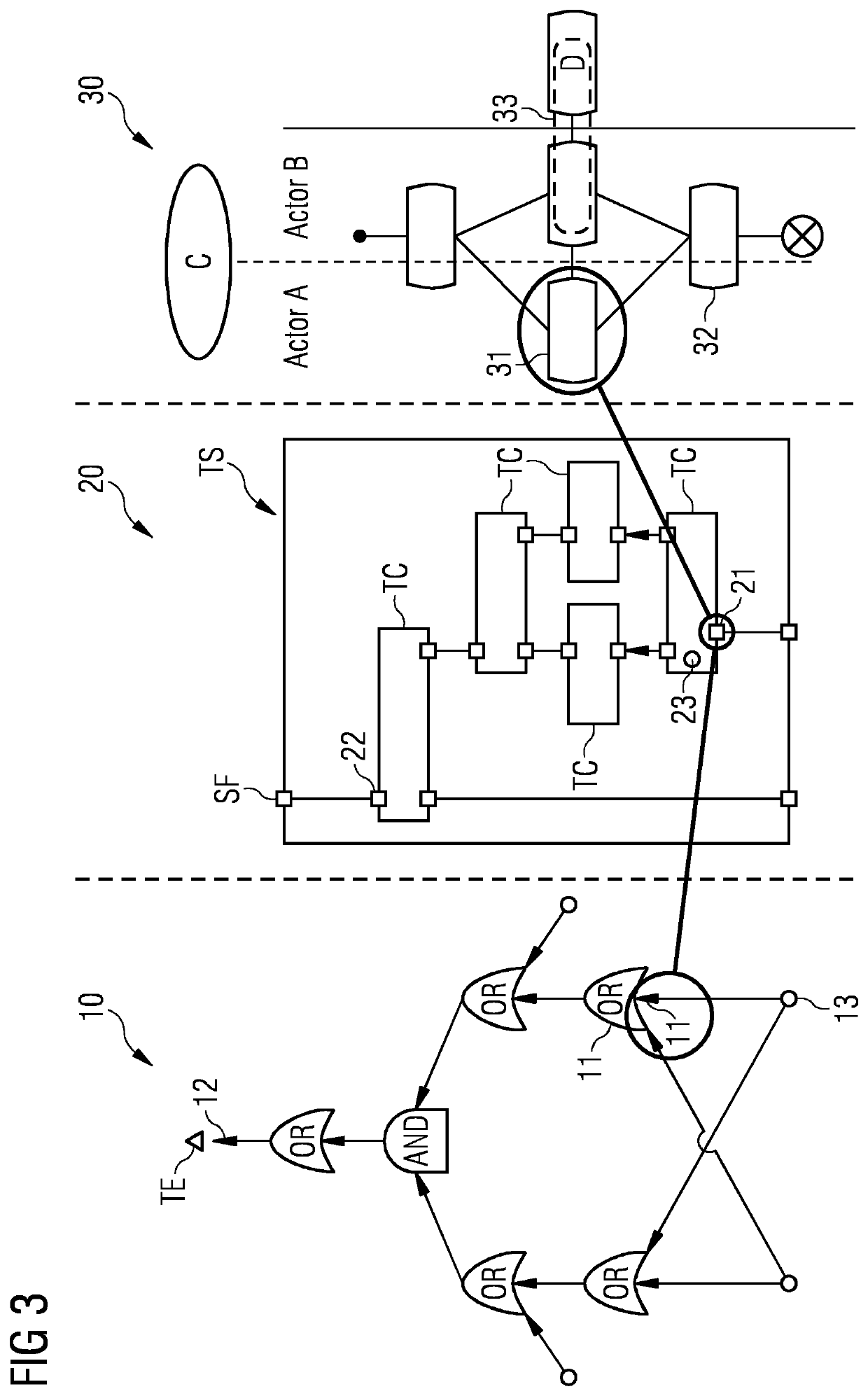

Computer-implemented method and computerized device for testing a technical system

PendingUS20220067239A1Increase efficiency and effectivenessImprove test efficiencyTesting/monitoring control systemsElectrical testingSpecific testReliability engineering

The computer-implemented method for testing a technical system having a plurality of technical components includes: providing a safety model modeling a safety relevant functionality of the technical system, providing a test model including test cases for testing the technical system, linking elements of the safety model with elements of the test model for enabling a tracing between the test cases of the test model and the safety-relevant functionality of the safety model, generating test parameters for at least one certain test case of the test cases and / or a new test case for the test model using the safety model linked to the test model, and testing the technical system using the certain test case and / or the new test case. Further, a computer program product, a computerized device and an arrangement having a technical system and a computerized device are provided.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com