Patents

Literature

109 results about "Continuous feedback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

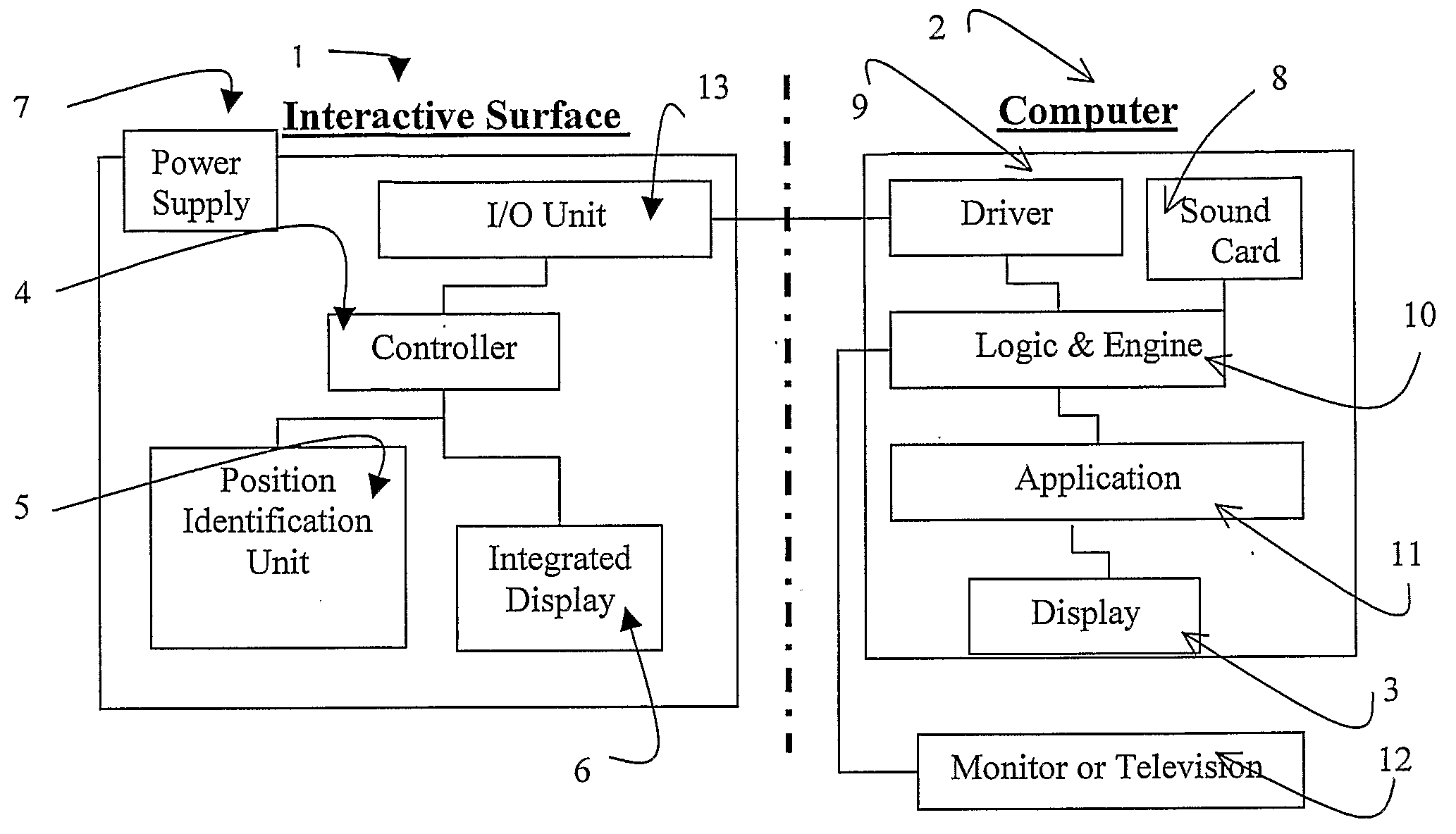

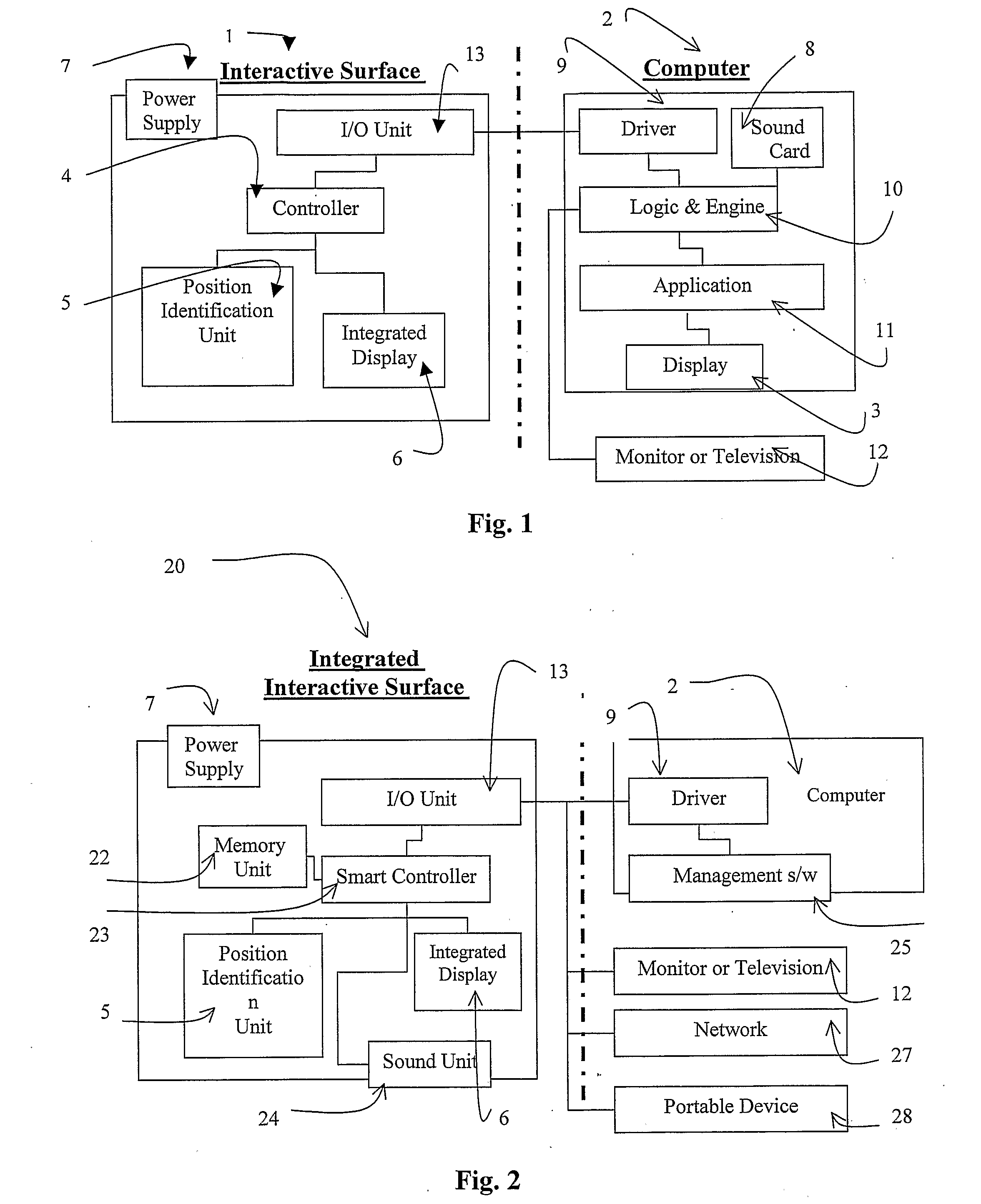

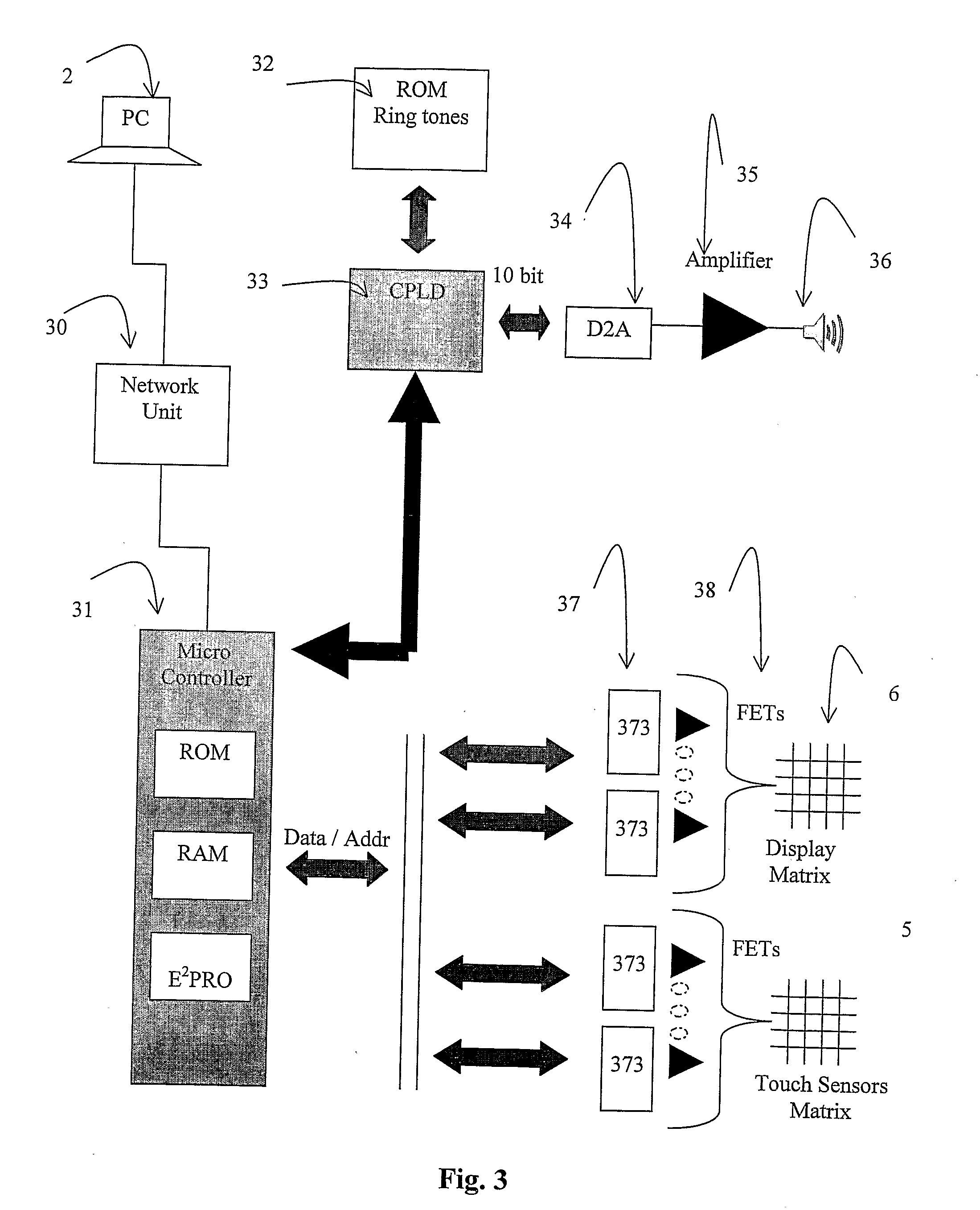

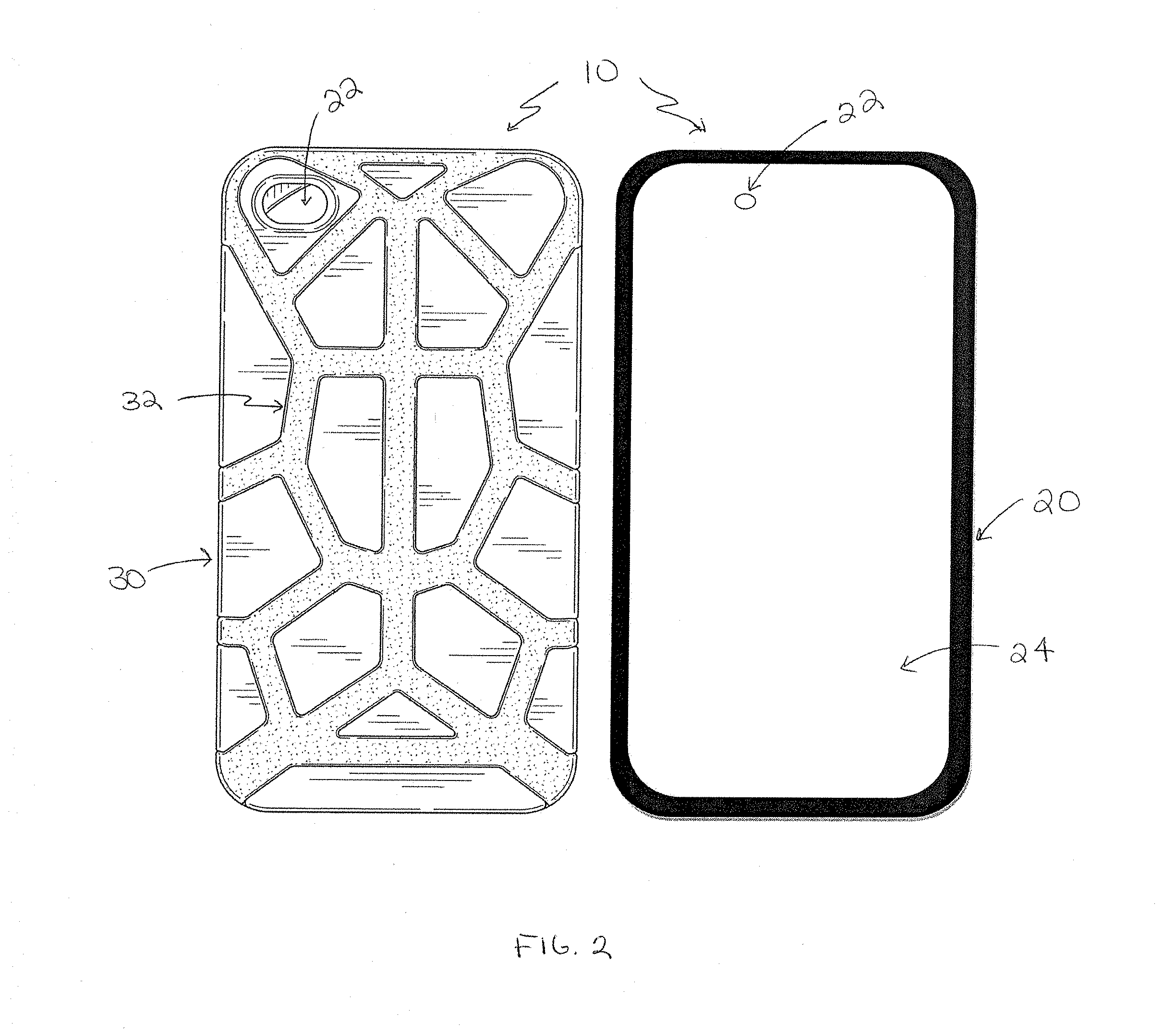

Interactive Surface and Display System

InactiveUS20080191864A1Heavy weightGood flexibilityAlarmsVideo gamesContinuous feedbackHuman–computer interaction

An interactive training system capable of generating continuous feedback for physical therapy and training applications based on capturing and analyzing the movement of a user on an interactive surface. The training system captures sophisticated input such as the entire areas in contact with the interactive surface, center of gravity, pressure distribution, velocity, acceleration, direction, orientation etc. The training system also captures and / or calculates and / or estimates the position of a body part while in the air, not touching the interactive surface, and also while sensor input is unavailable. The training system can also provide alerts for predefined events such as a fall or the beginning of a fall.

Owner:ZOOZ MEDICAL

System and Method For Gathering And Analyzing Biometric User Feedback For Use In Social Media And Advertising Applications

ActiveUS20130280682A1Add emotional intelligenceEfficient recommendationData processing applicationsDiagnostic recording/measuringSocial mediaContinuous feedback

A system and method for measuring biologically and behaviorally based responses to social media, locations, or experiences and providing instant and continuous feedback in response thereto. The system and method of the invention is capable of monitoring stress levels and well-being and may be implemented using a cloud-based infrastructure for remote monitoring.

Owner:NIELSEN CONSUMER LLC

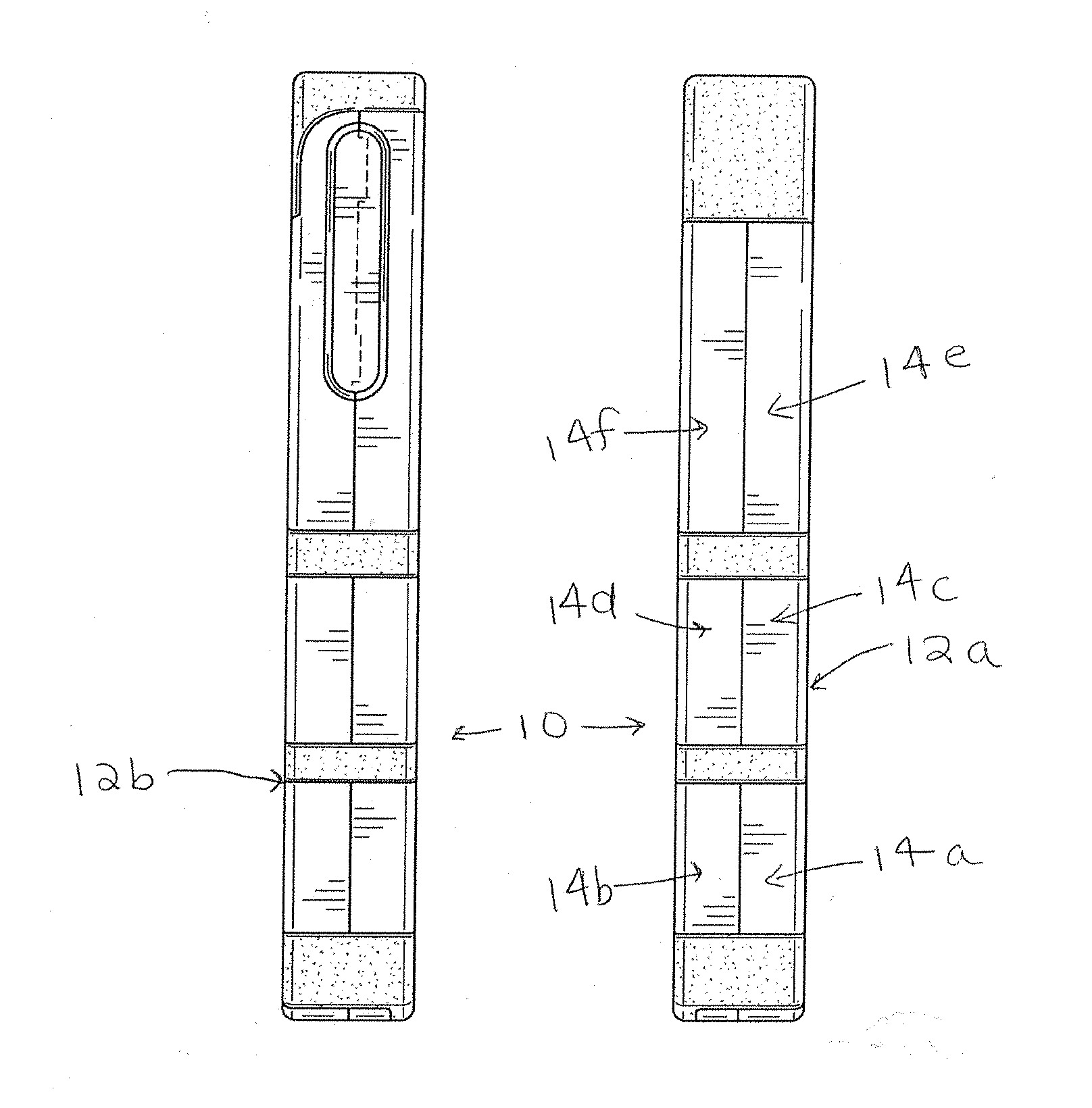

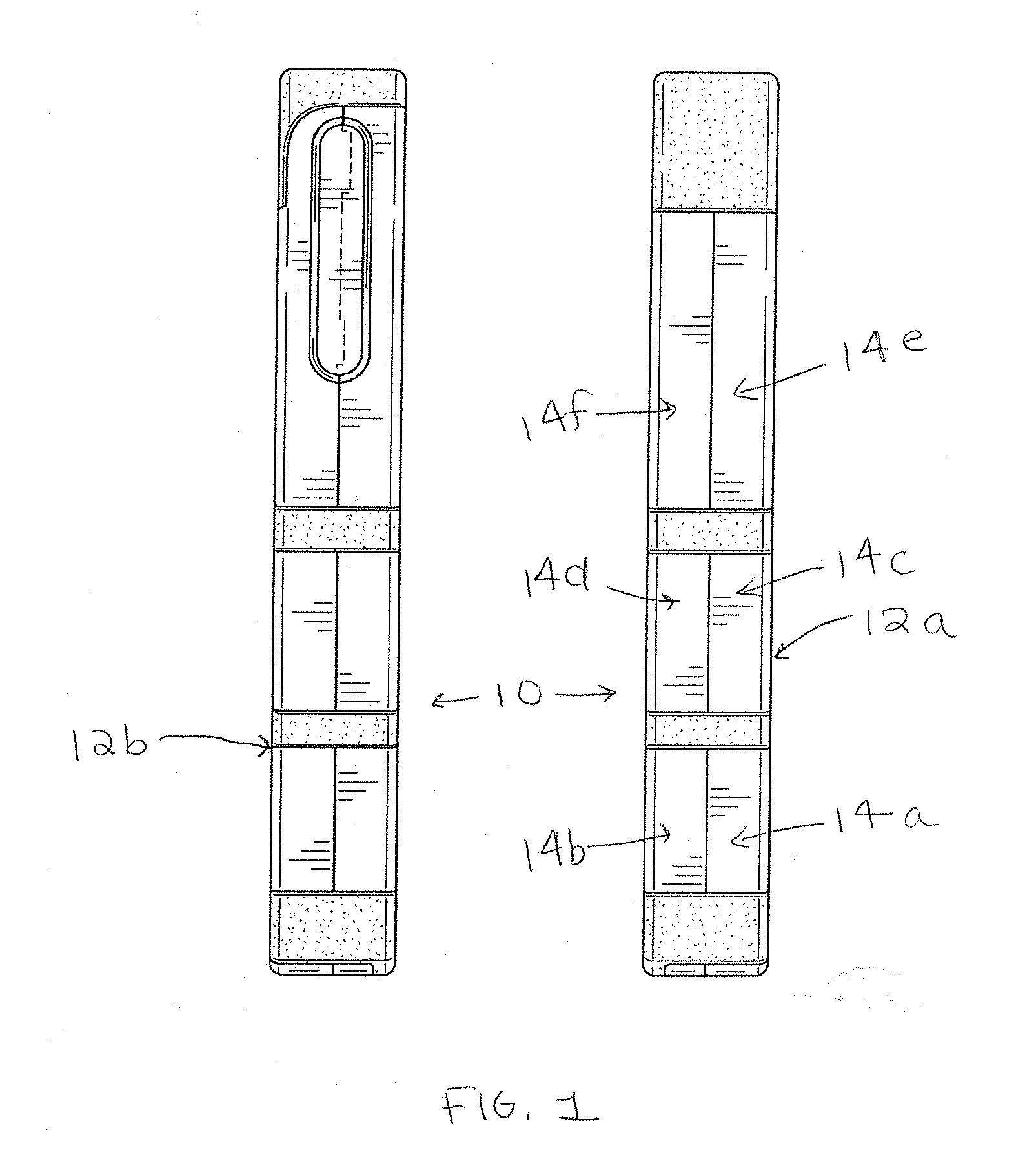

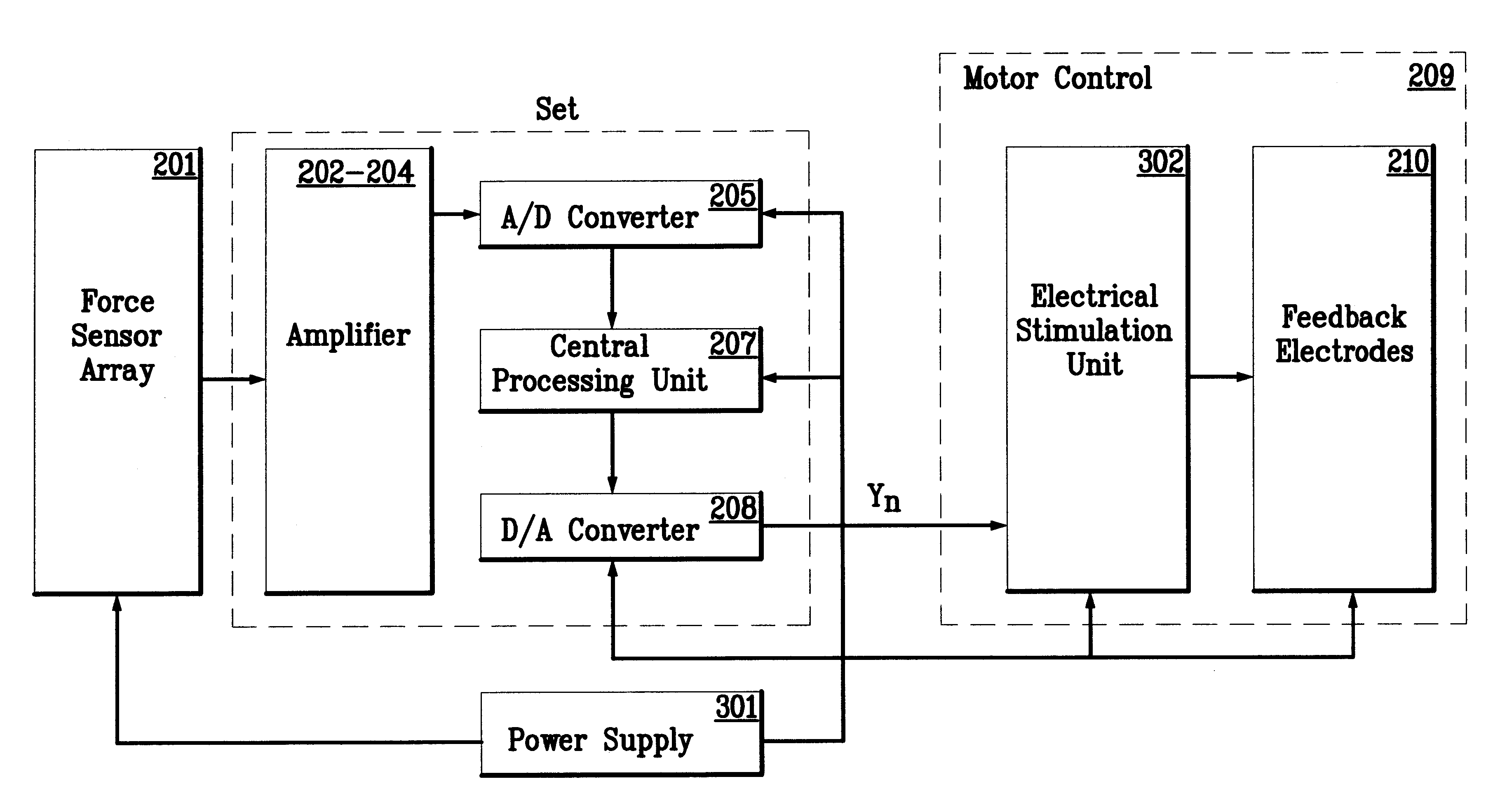

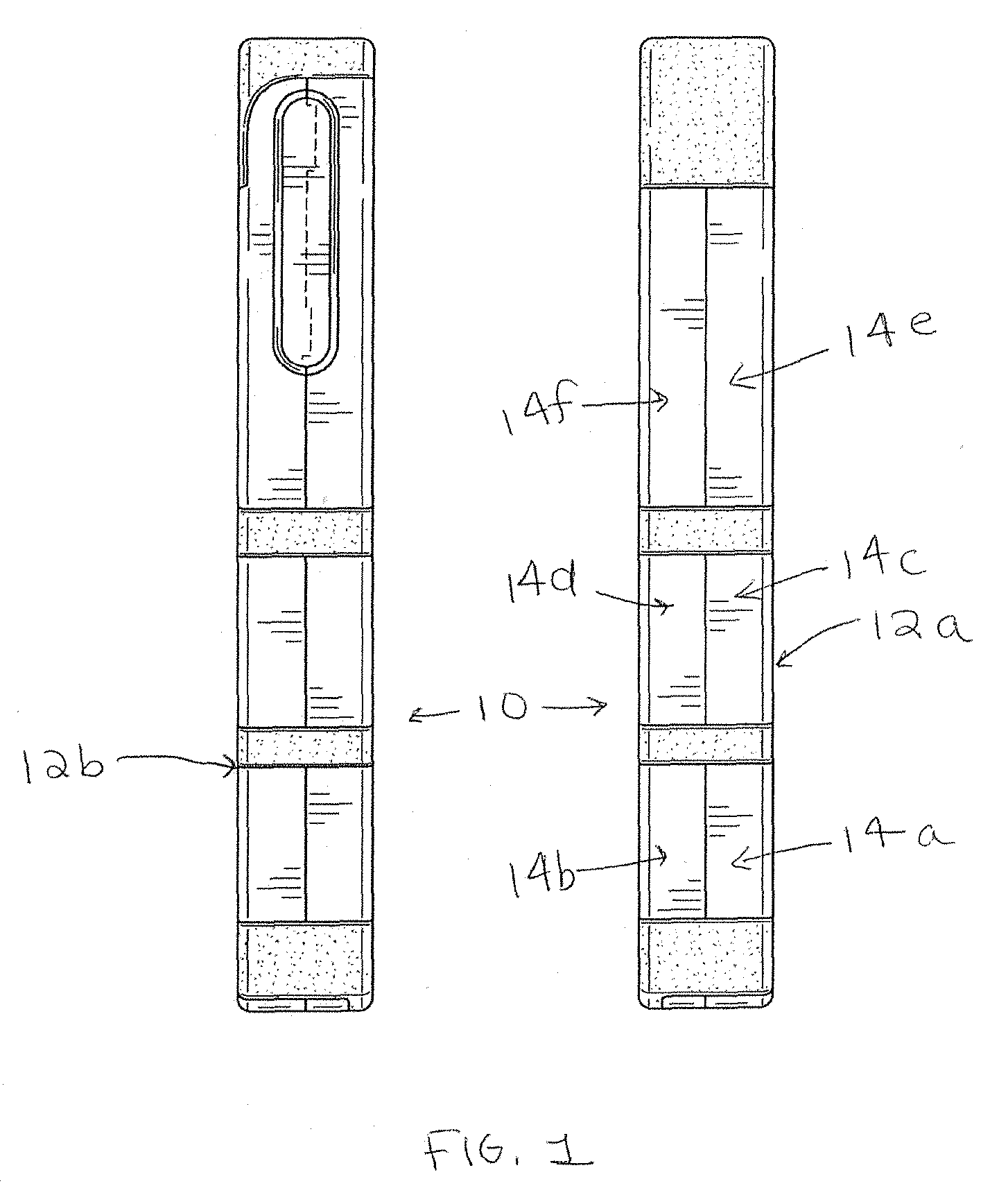

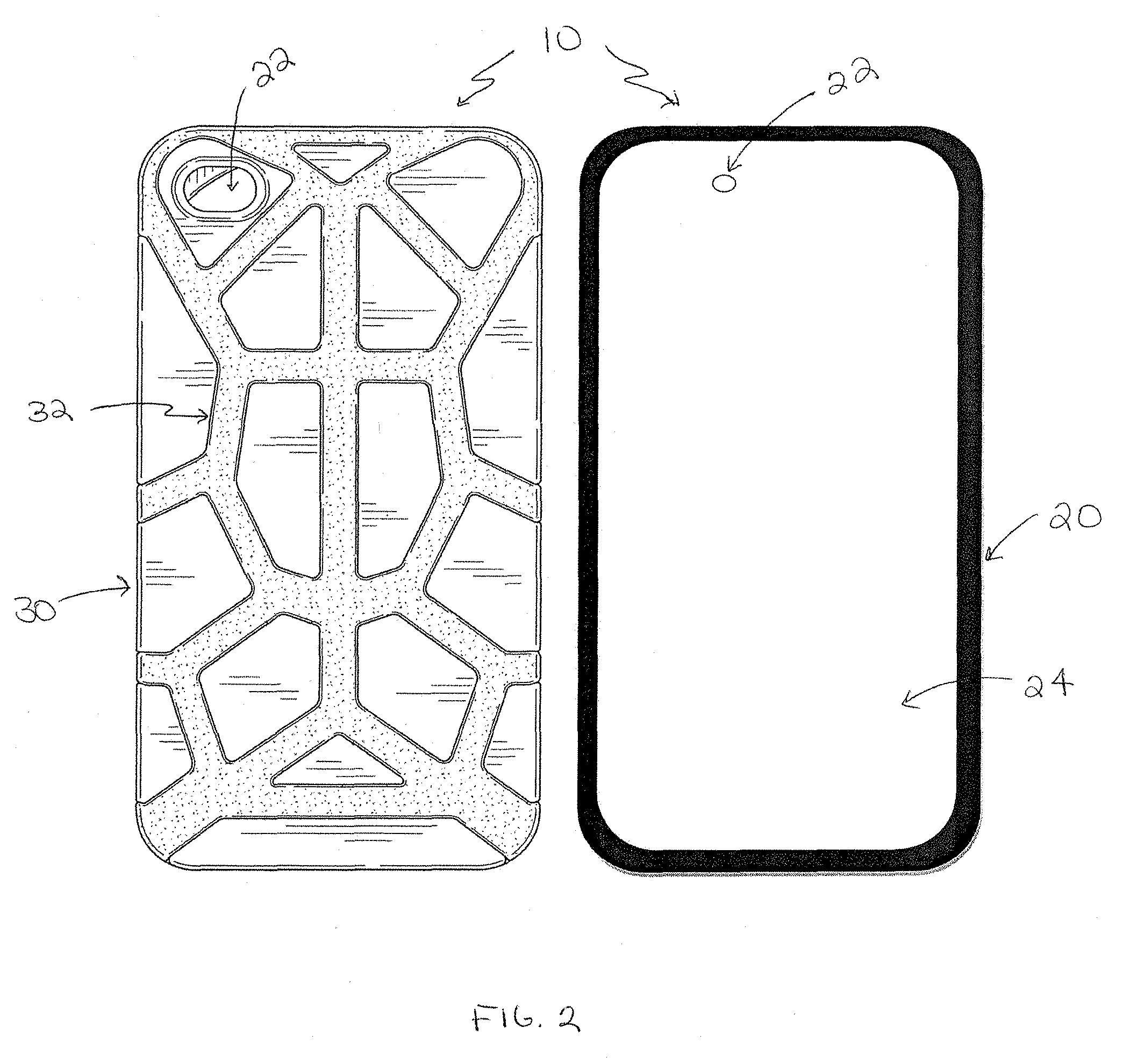

Adaptive weight bearing monitoring system for rehabilitation of injuries to the lower extremities

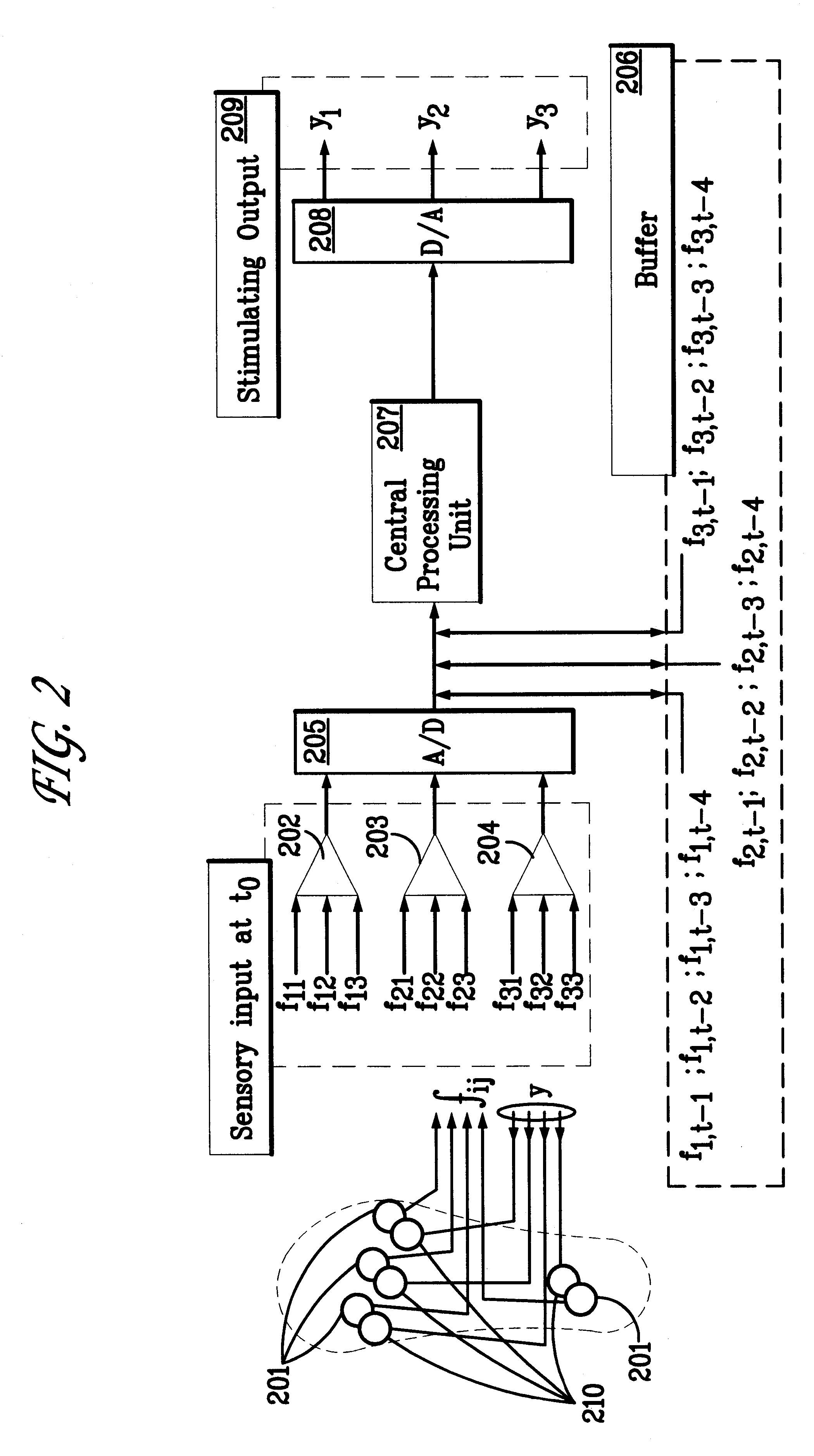

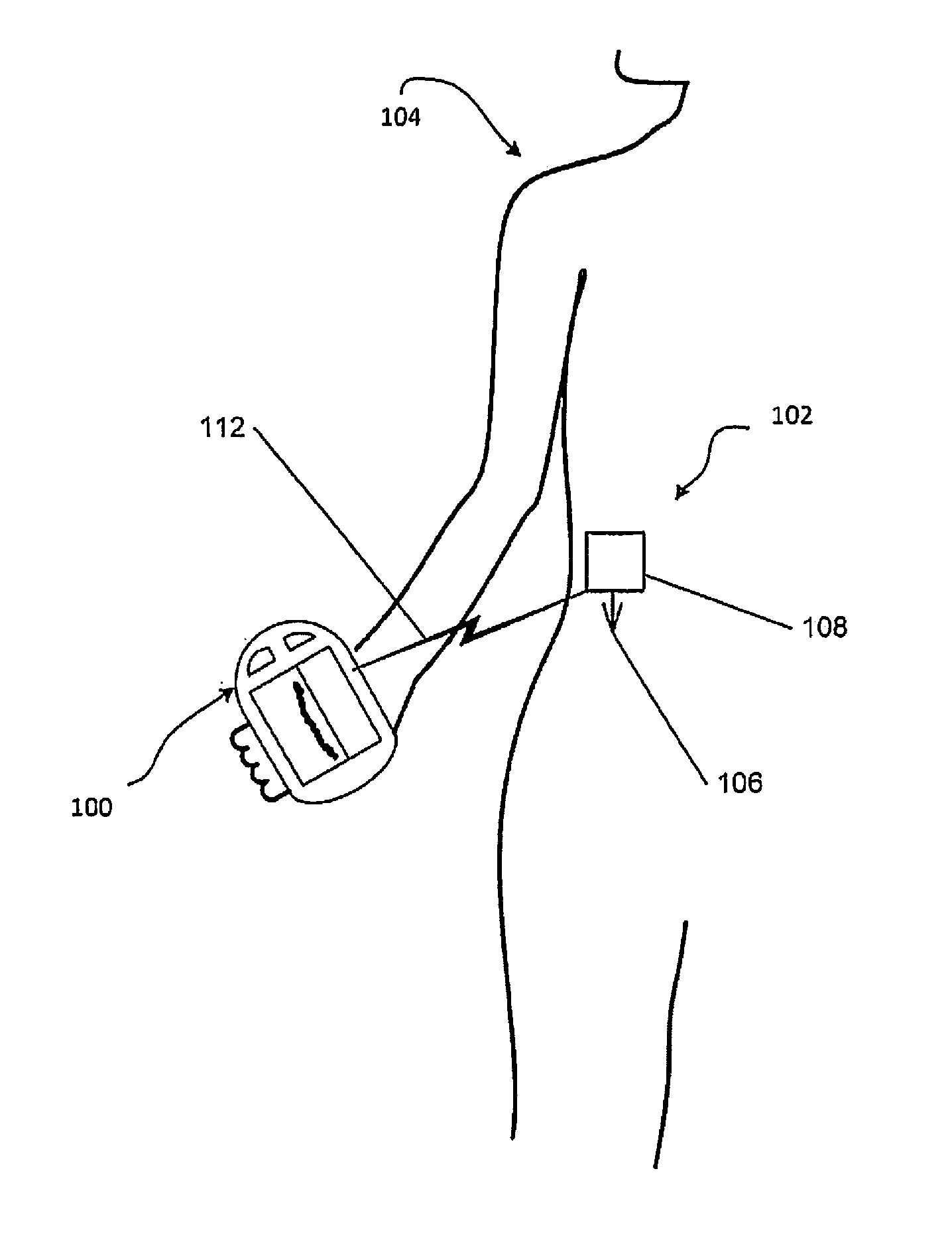

A portable, self-learning adaptive weight bearing monitoring system for personal use during rehabilitation of orthopedic patients with fractures of the lower extremities. The system includes a flexible insole which is worn inside the shoe. The insole includes pressure and / or force sensor that measure the GRF force applied at key bearing points under the foot or other portions of the patient's lower extremity. The sensors are, in turn, connected through an A / D converter to a CPU that is connected so as to drive a stimulator that delivers closed-loop sensory stimulation (electrical, mechanical, and / or audio) as feedback to encourage the patient to load the optimal target weight for the limb for which the weight bearing force is being measured. Accurate real-time monitoring of the weight bearing during physical rehabilitation is also provided, and, through the use of closed-loop sensory stimulation, the patient is given continuous feedback for improving rehabilitation.

Owner:ANDANTE MEDICAL DEVICES

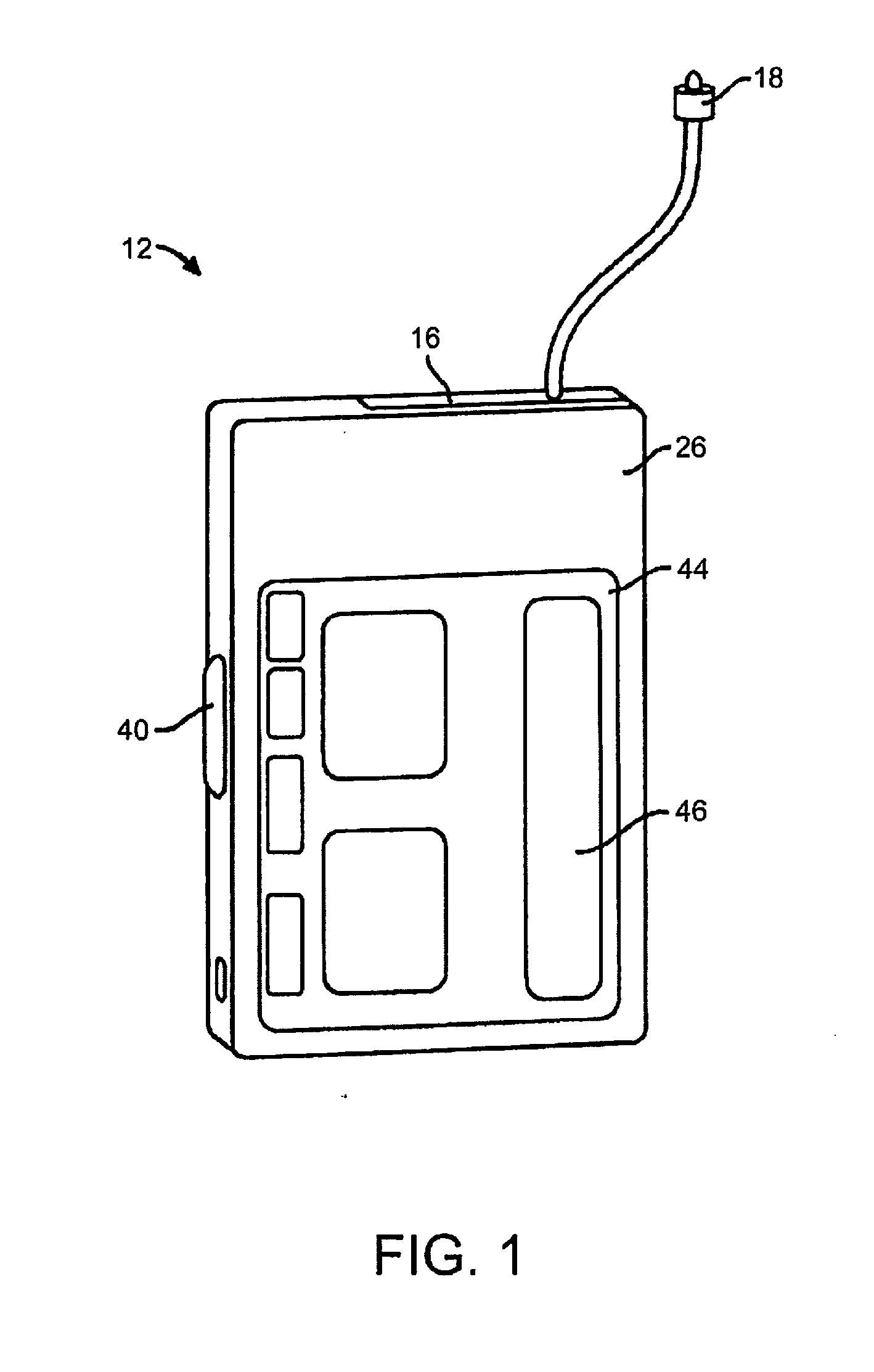

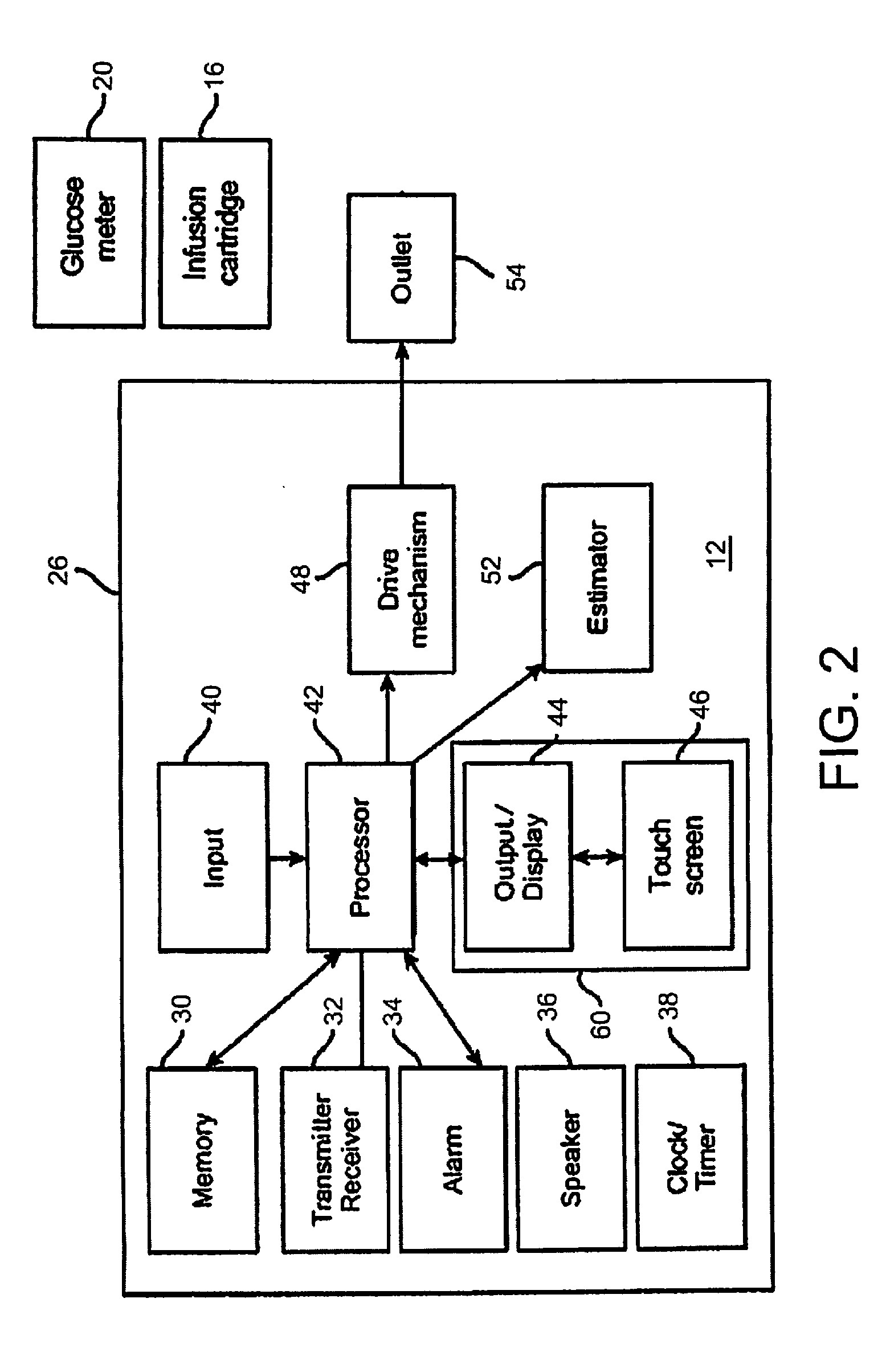

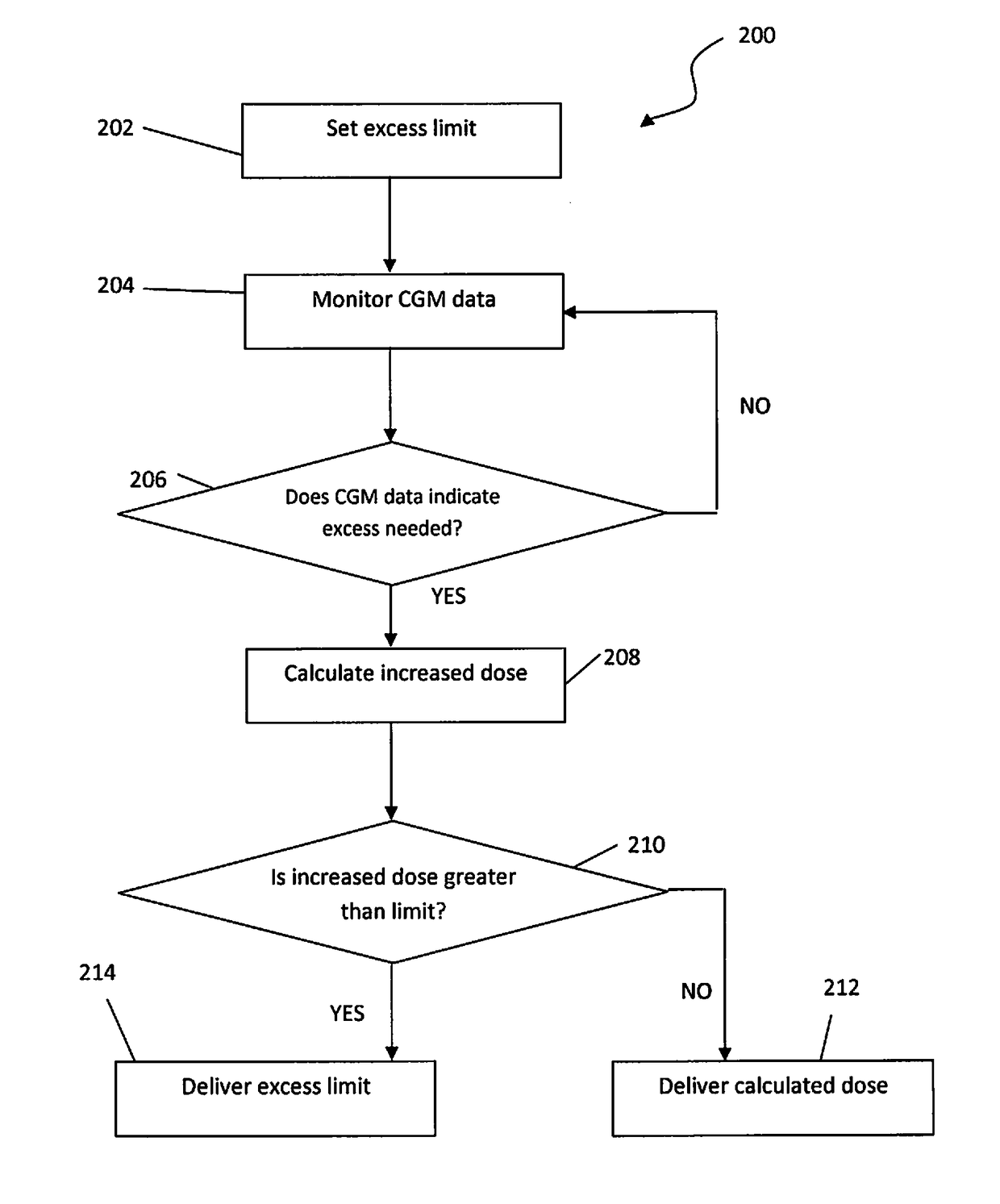

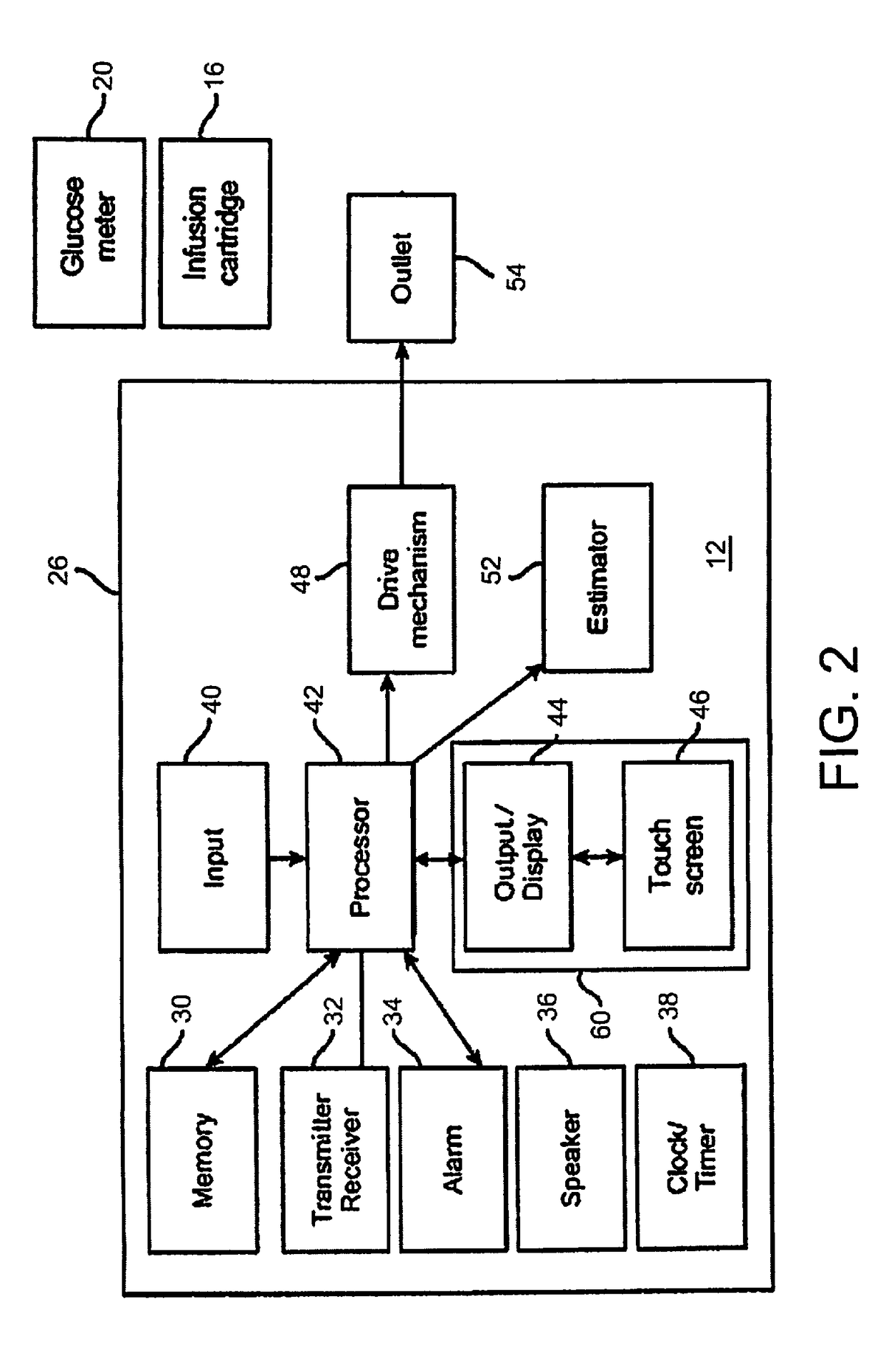

System and method for mitigating risk in automated medicament dosing

ActiveUS20150073337A1Reduce riskPrevent fallingMedical data miningDrug and medicationsContinuous feedbackCvd risk

A portable infusion pump can communicate with glucose monitor, such as a continuous glucose monitor (CGM), to receive continuous feedback relating to a user's blood glucose level during insulin or other medicament therapy and can automatically deliver insulin to a user when the CGM data indicates a need for additional insulin. Due to potential unreliability in the correlation of the CGM data to the user's actual blood glucose level, risk mitigation can be employed to limit the amount of extra insulin that can be delivered by the pump in response to the CGM data.

Owner:TANDEM DIABETES CARE INC

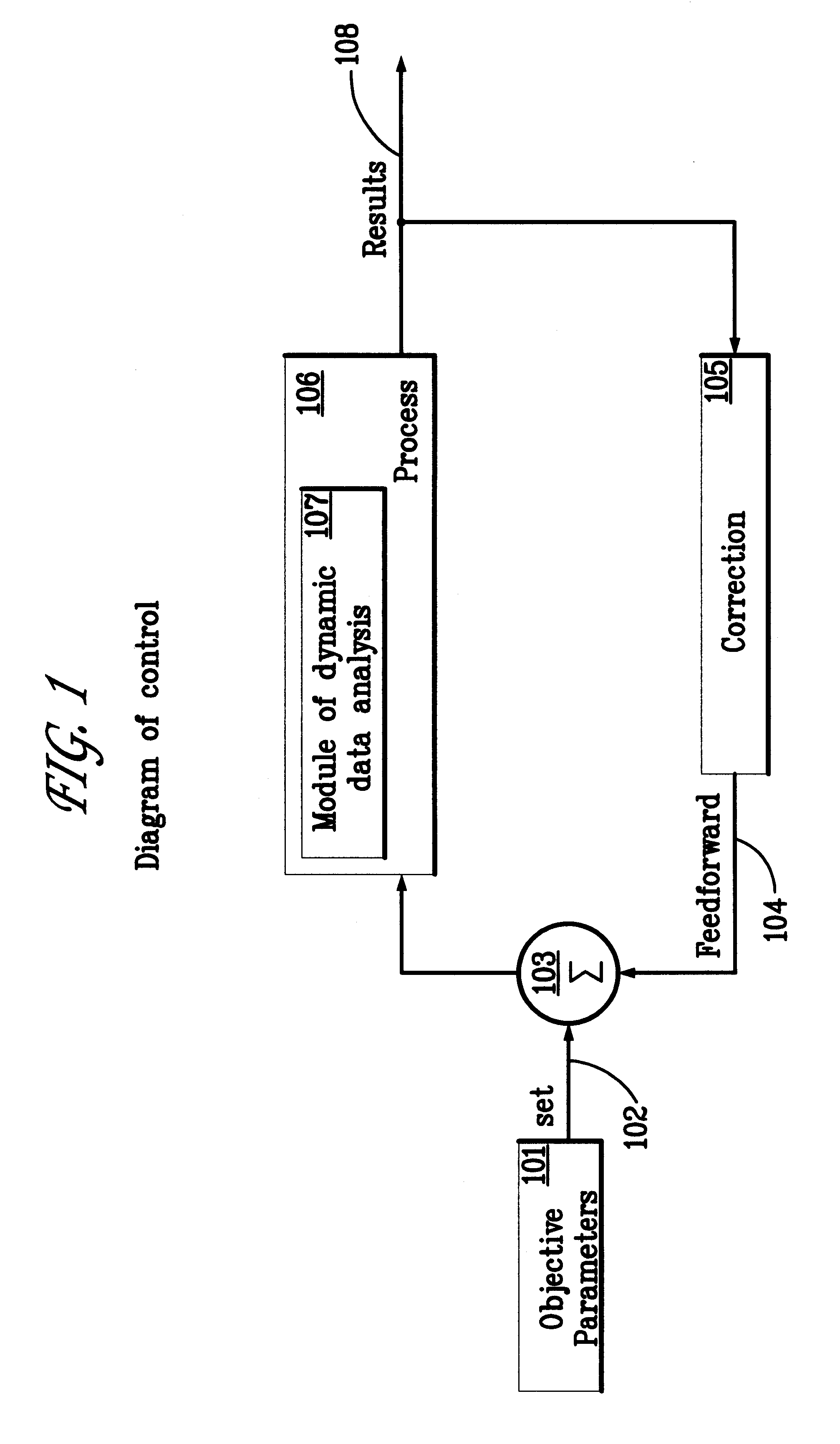

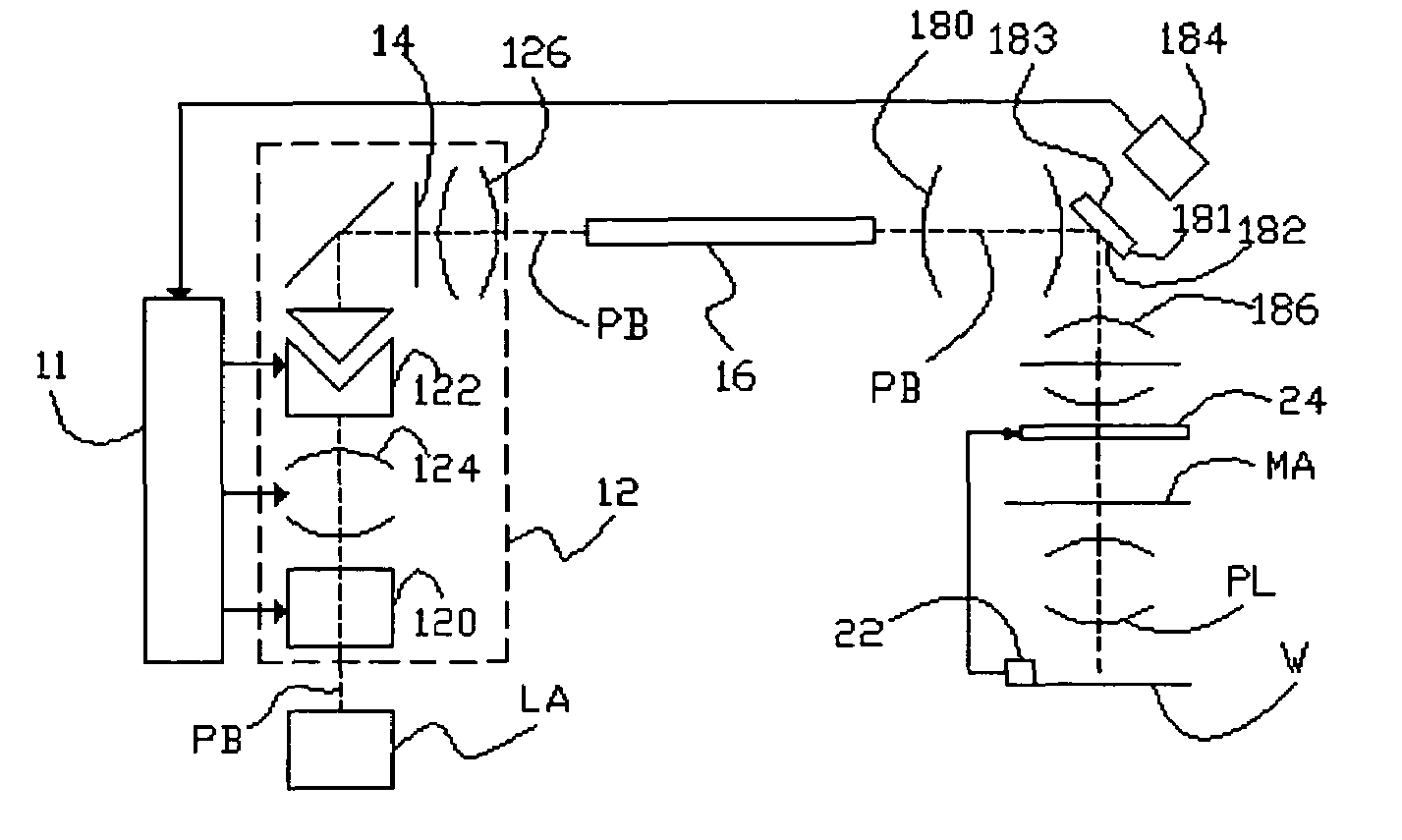

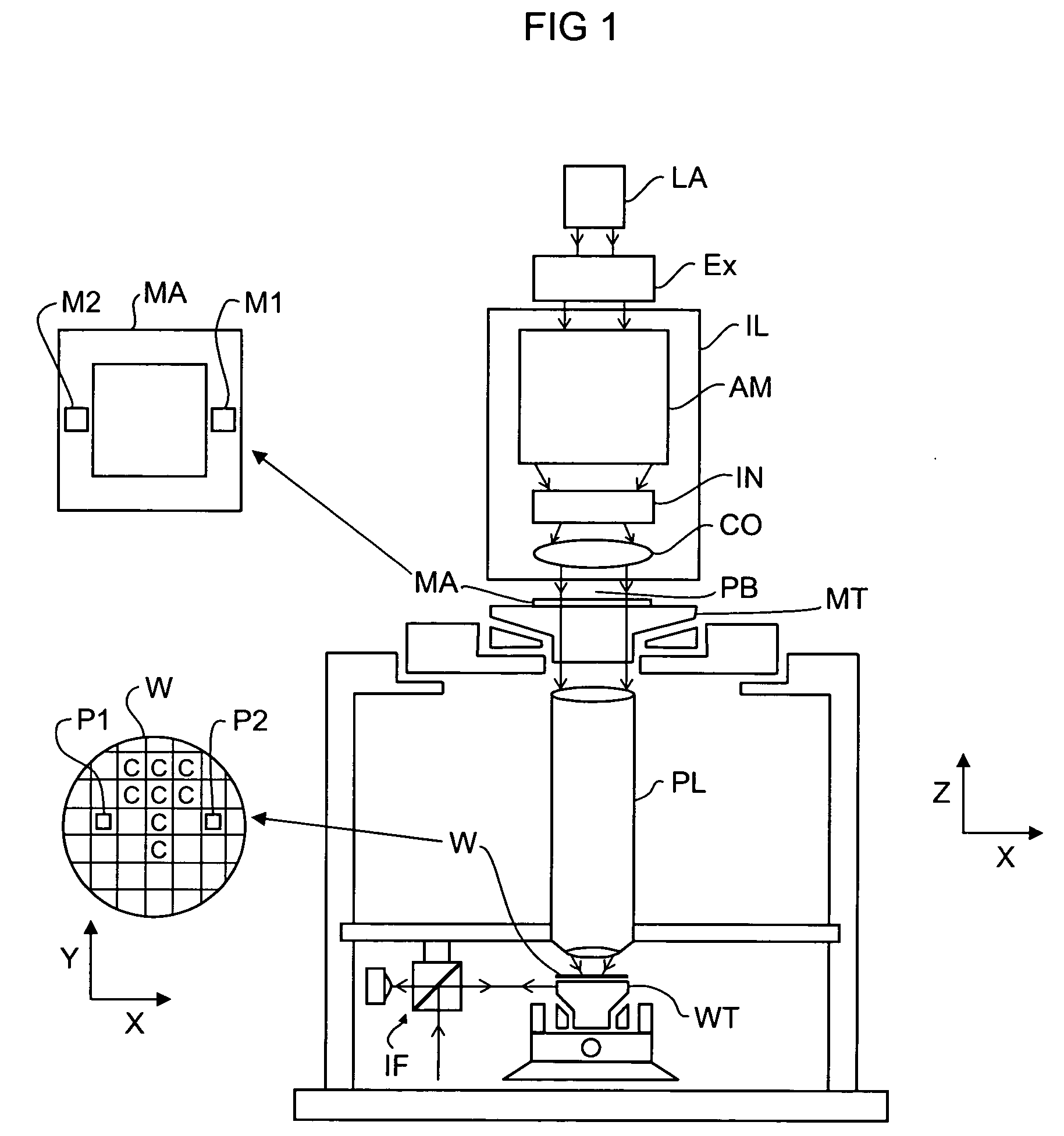

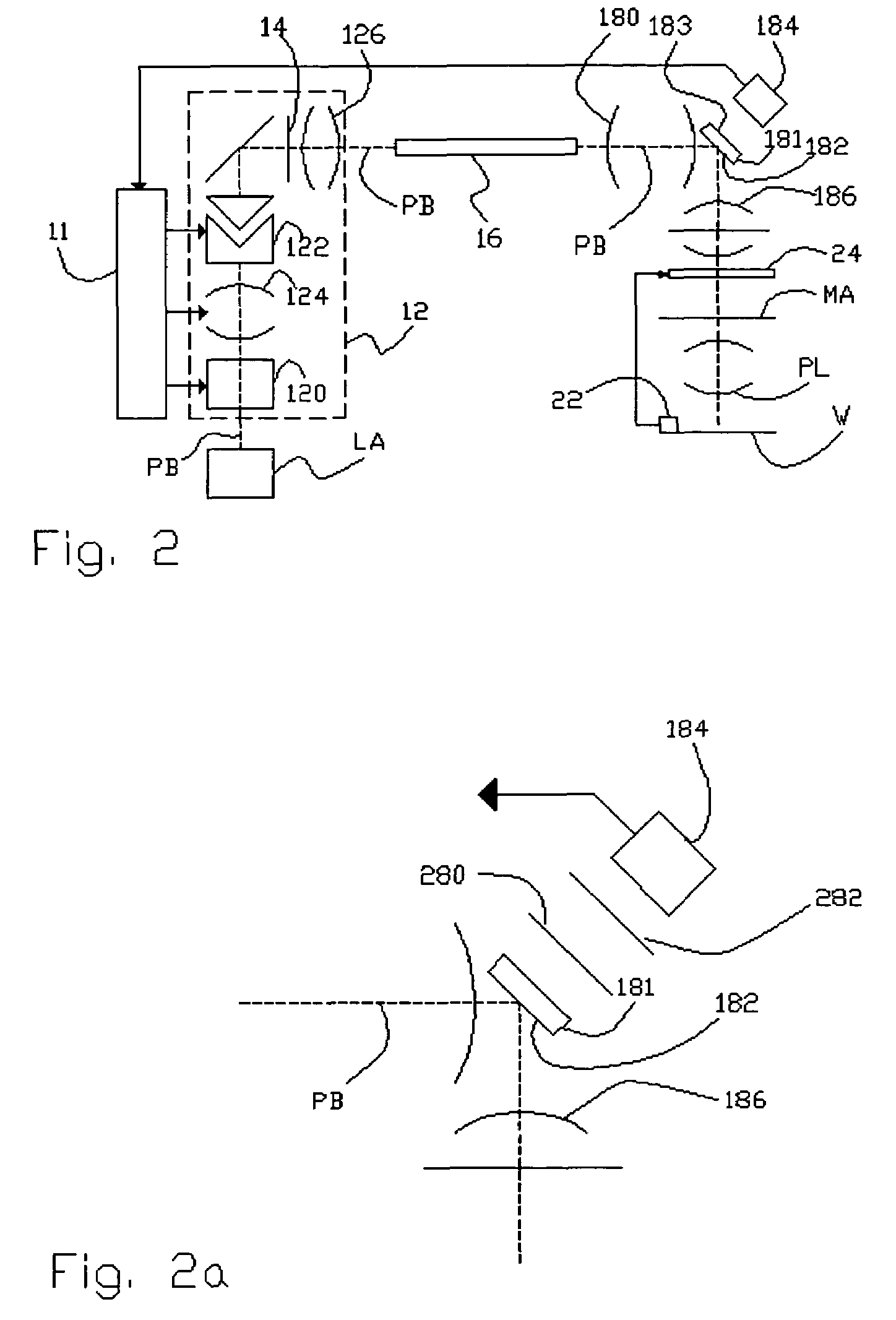

Lithographic apparatus and device manufacturing method

InactiveUS6958806B2Possible to obtainReduce controlSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusAngle dependenceBeam splitter

In a lithographic apparatus the angle dependence of the intensity distribution of a projection beam at a substrate is controlled. A beam splitter is located in the beam near a pupil plane. The beam splitter splits off an auxiliary beam, which is used to measure information about the spatial intensity distribution of the beam at the pupil plane. The measured position dependence in the auxiliary beam may be decontrolled using boundary conditions inherent to the illuminator to compensate for offset between the pupil plane and a detection element. The measured position dependence may be used to control parameters of an optical element that manipulates the position dependence in the pupil plane. An example of such an optical element is a matrix of elements that controllably steer the direction of parts of the beam. Thus a continuous feedback loop may be realized.

Owner:ASML NETHERLANDS BV

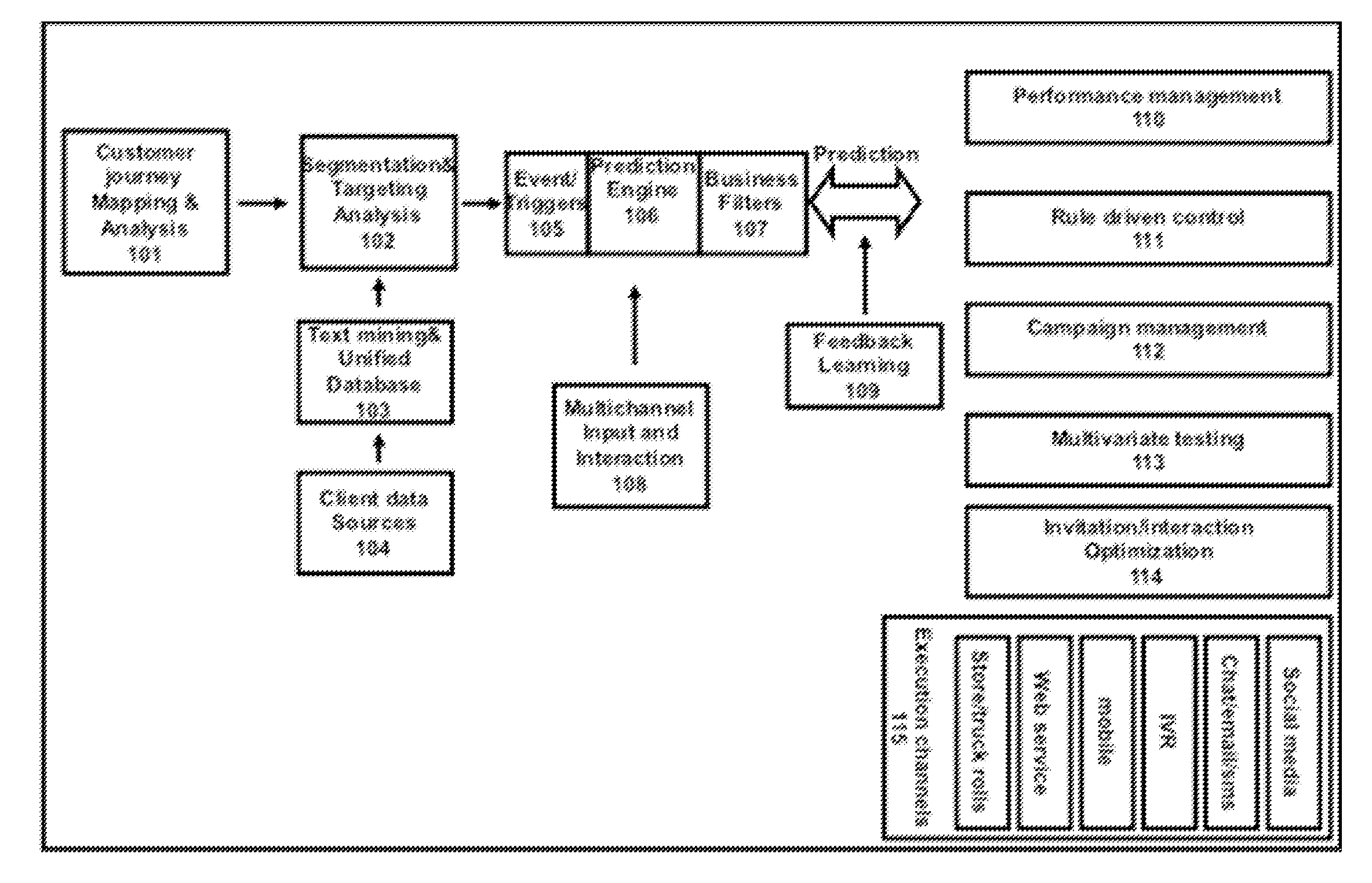

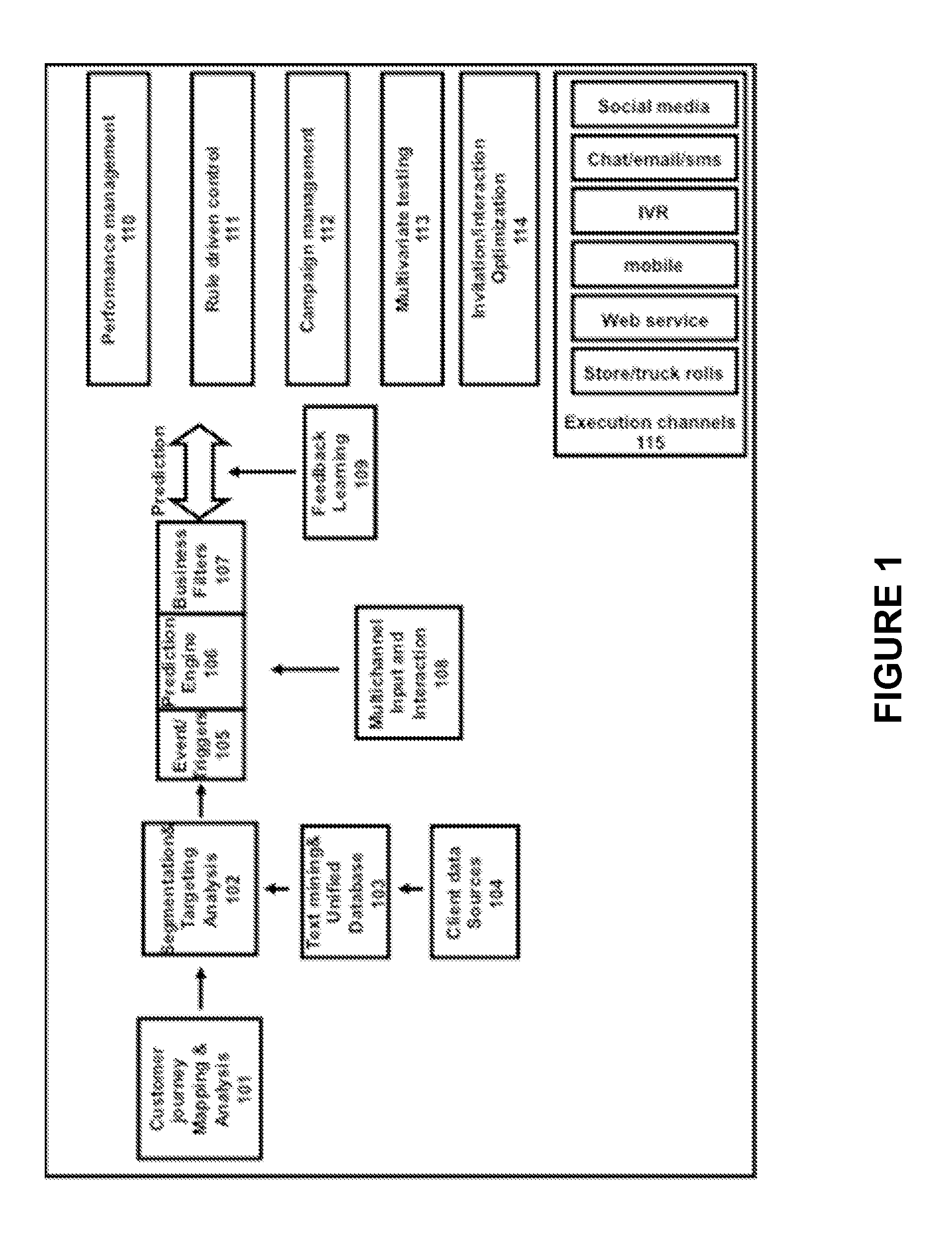

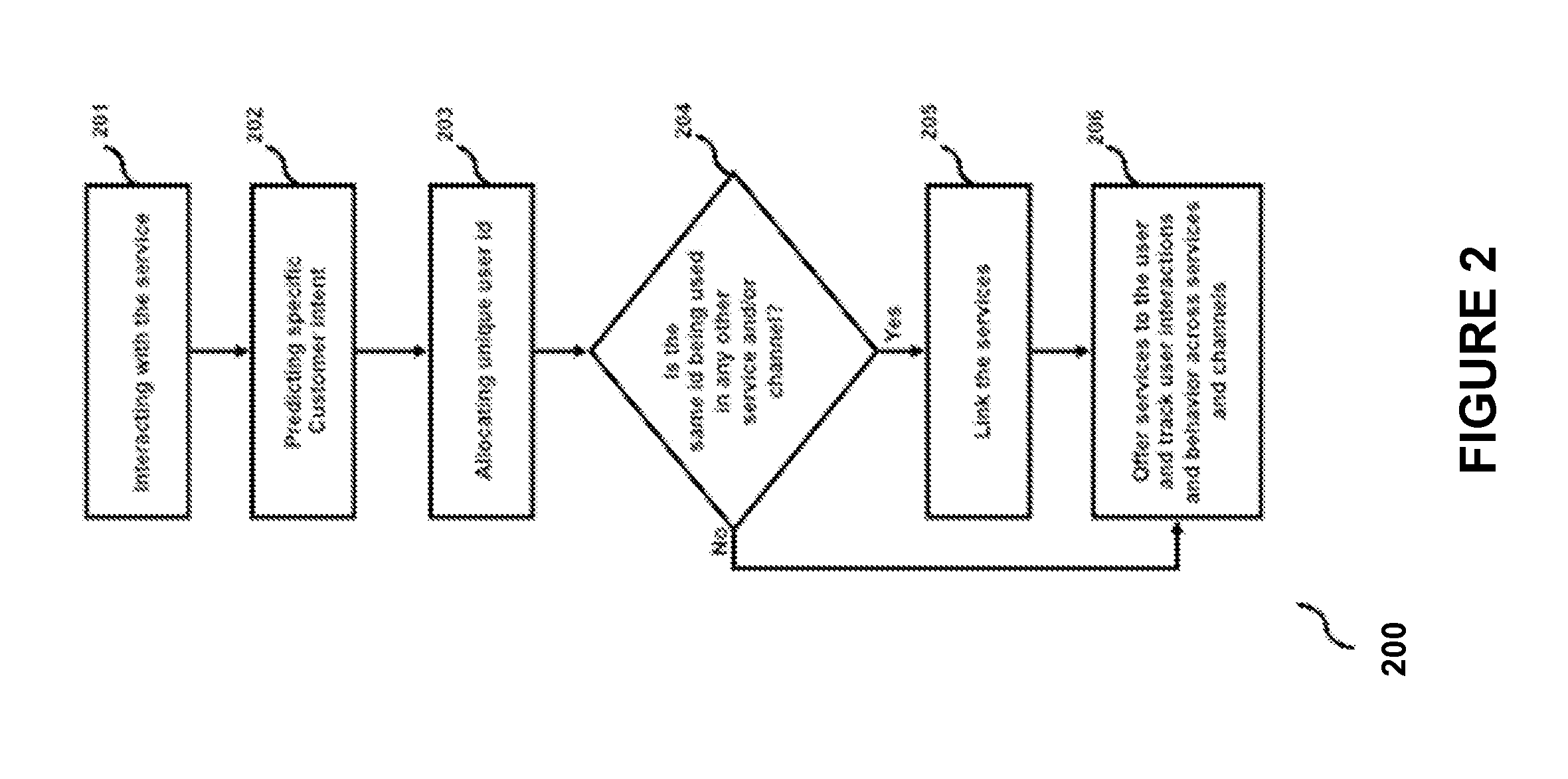

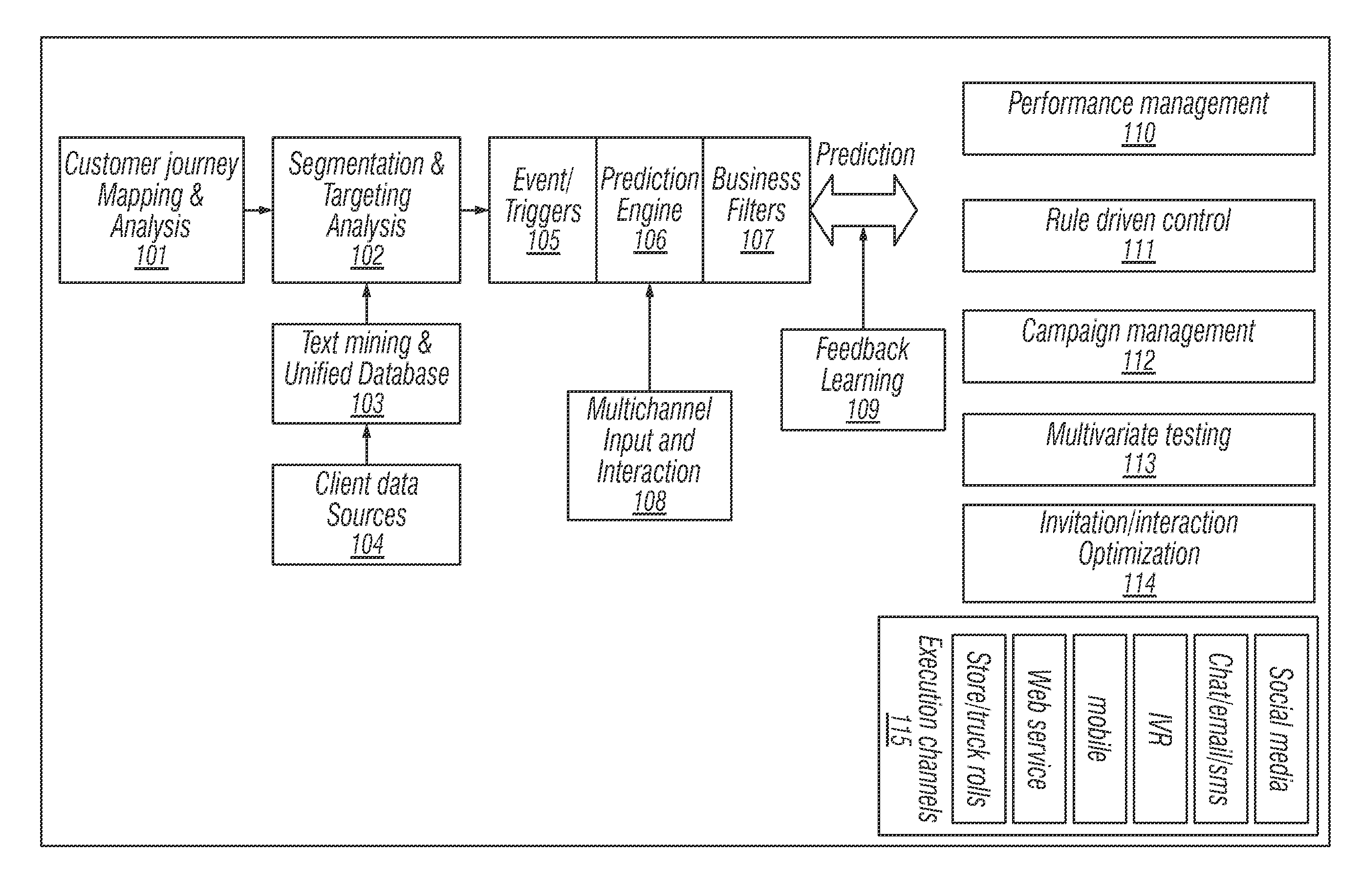

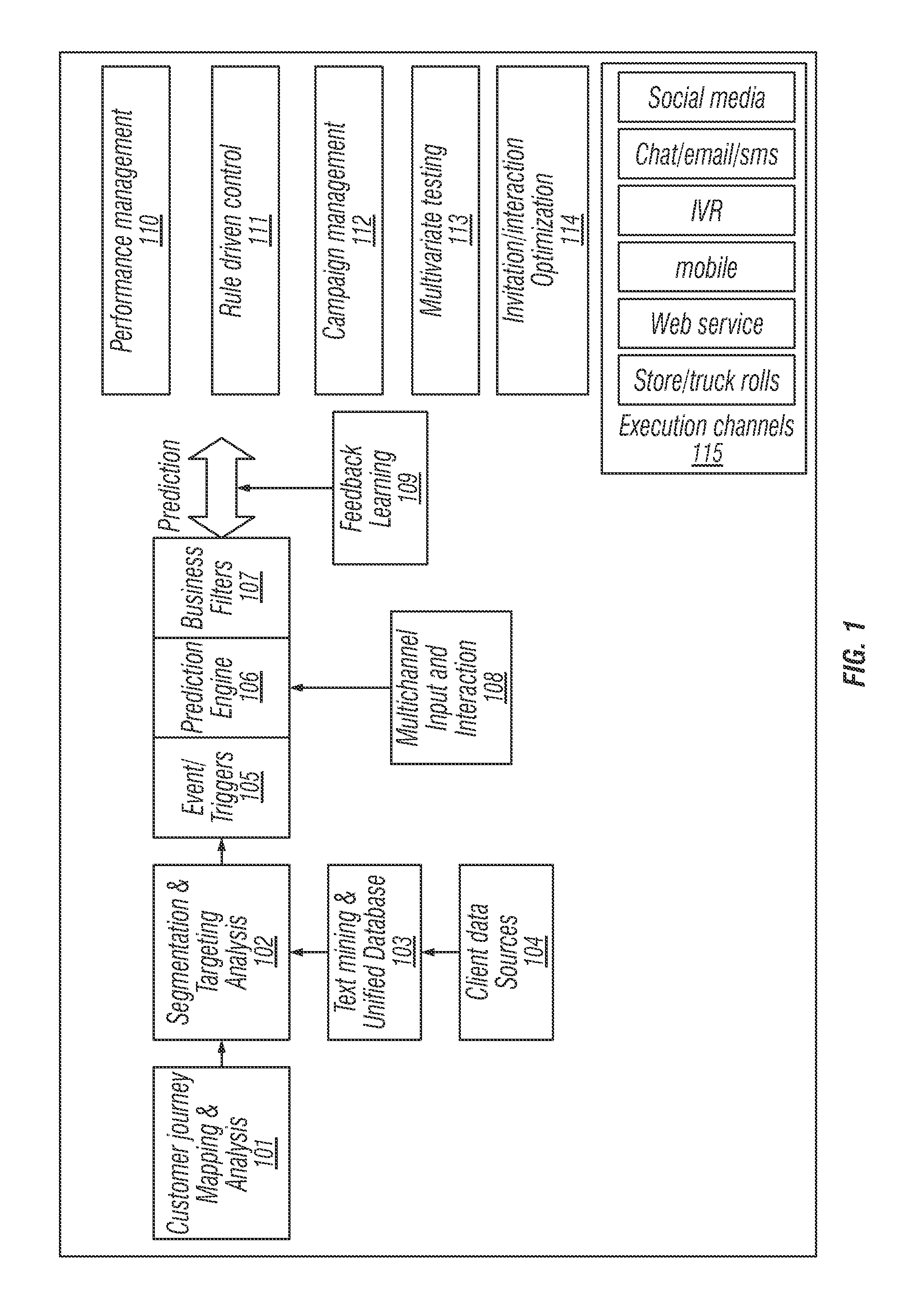

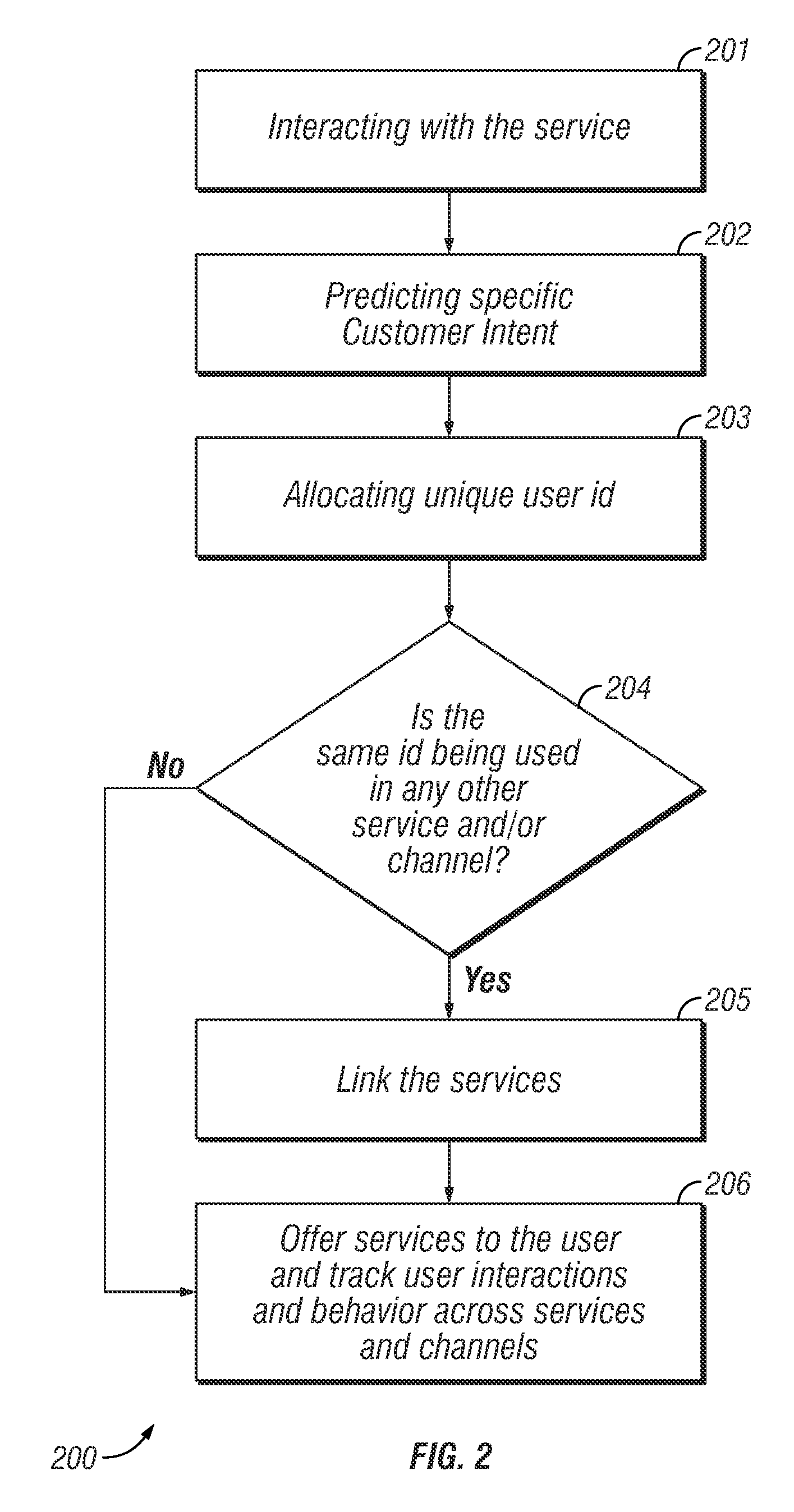

Customer journey prediction and resolution

Customer journey prediction and resolution is accomplished via a predictive model in which each user is mapped onto all available user journey information corresponding to a specific business. The predictive model is analyzed to understand the characteristics, preferences, and lowest effort resolution for the user related to the services that are subscribed to by the user. The predictive model is analyzed to predict the service or collection of services for each user. Embodiments interact with, provide and receive information from, and react to and / or deliver action to the customer across channels and across services. All customer and system behavior, data, and action is tracked and coordinated and leveraged for continuous feedback and performance improvement.

Owner:24 7 AI INC

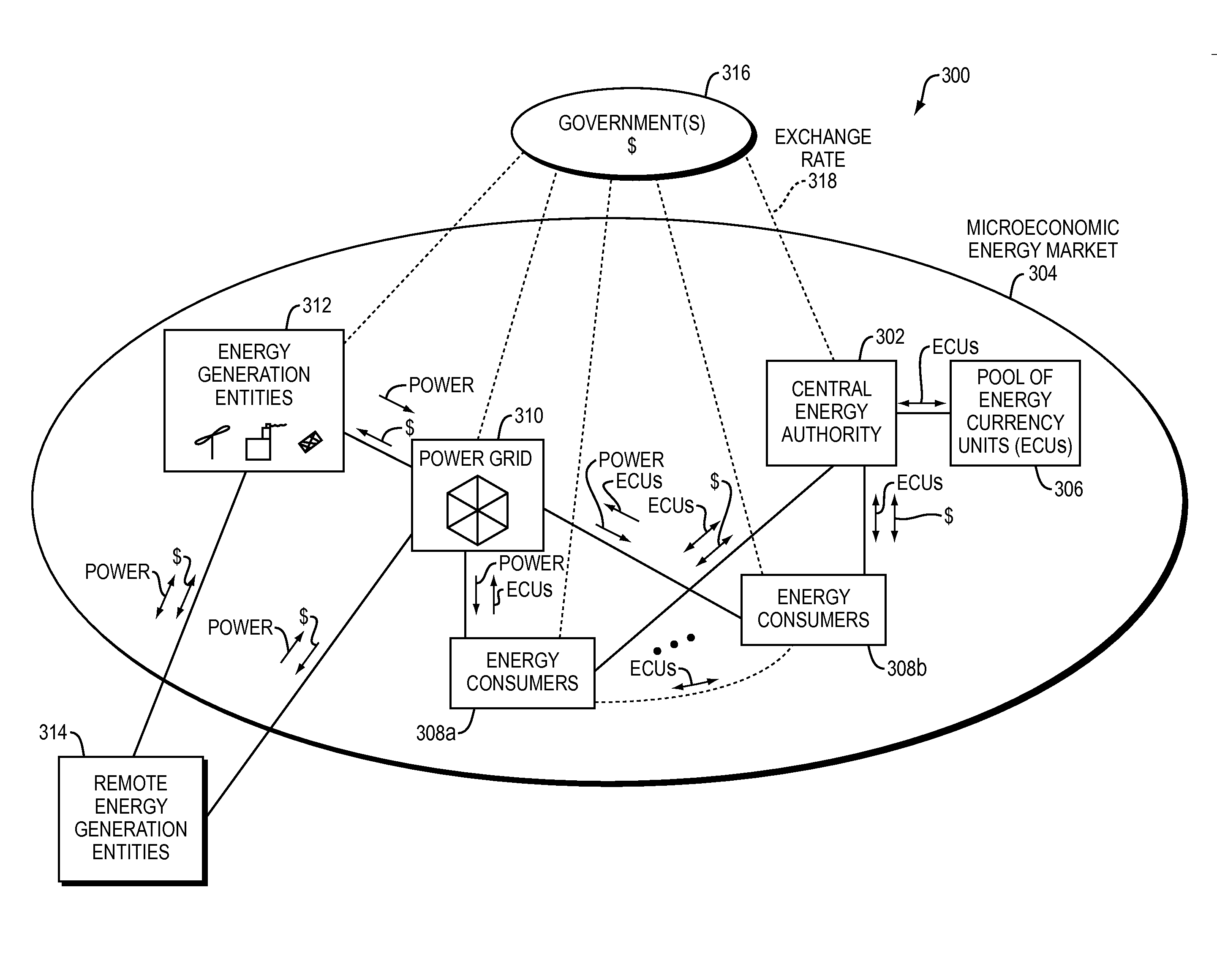

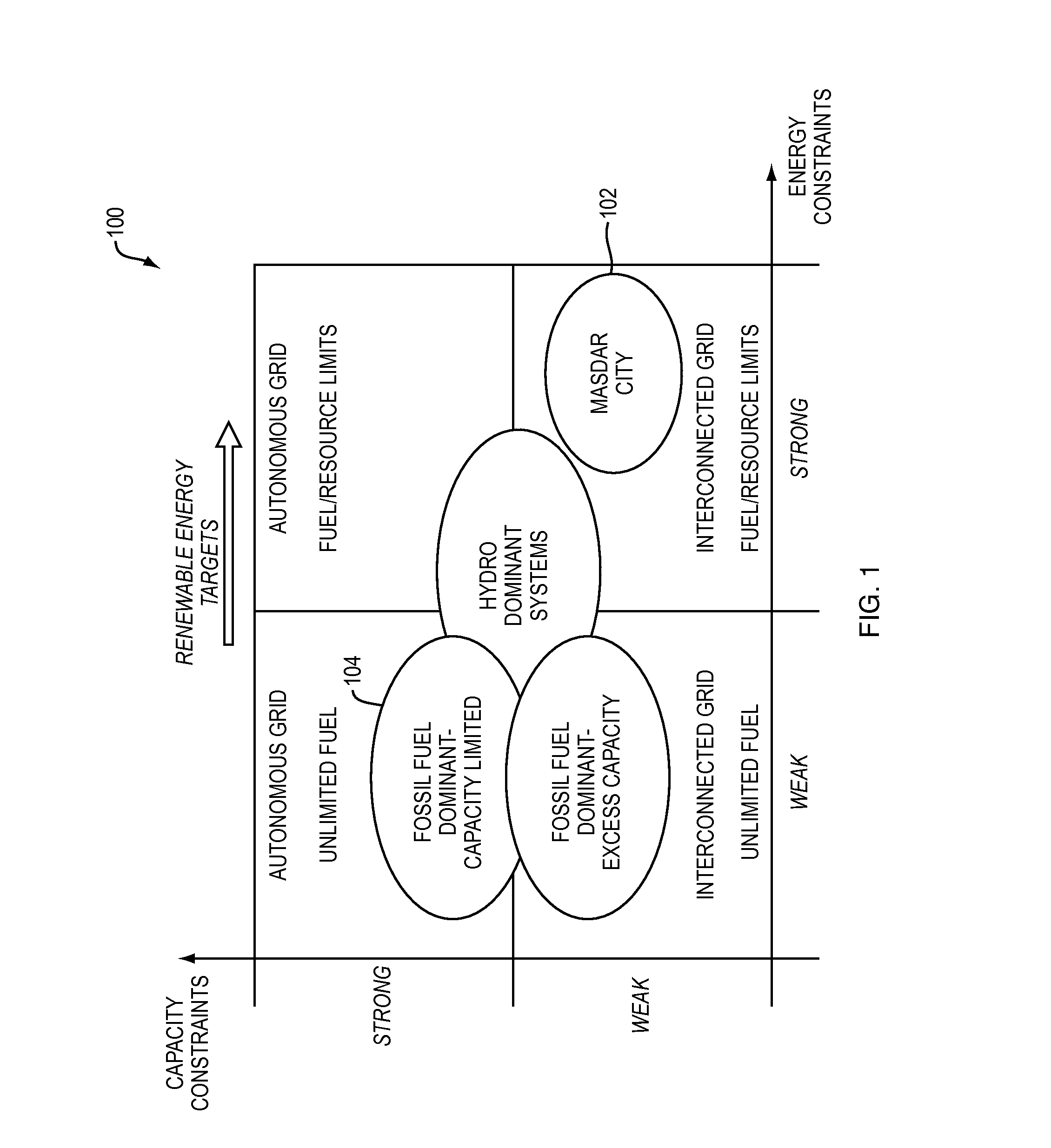

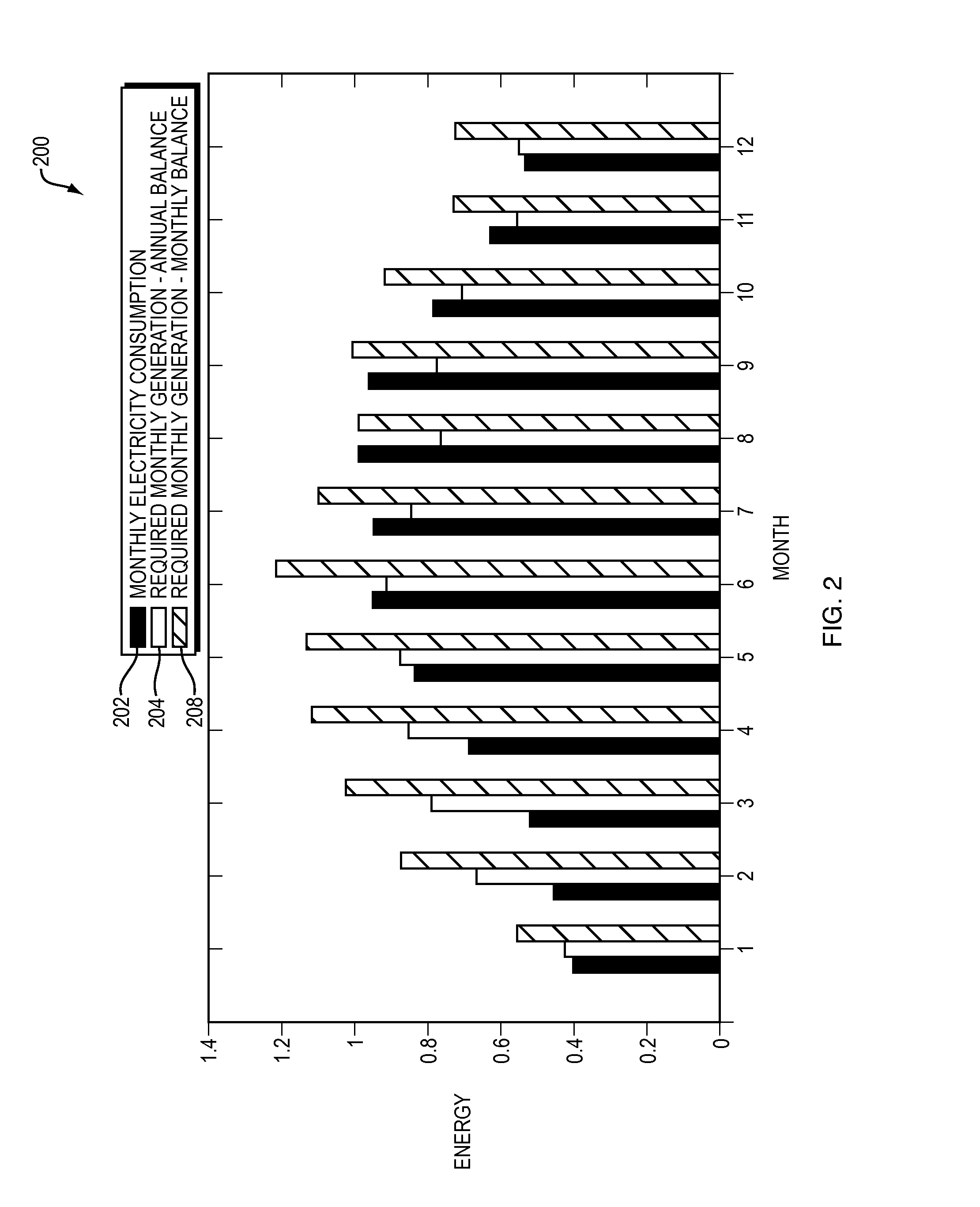

Hybrid Energy Market and Currency System for Total Energy Management

InactiveUS20130332327A1Simple and flexiblePermit auditingFinanceContinuous feedbackProcess engineering

A hybrid energy market and currency systems is provided to manage energy consumption in an energy market comprising a community of users. Energy currency units may be issued to users and an exchange rate between the energy currency units and a monetary currency unit may be set, providing a variable price for energy. Energy currency units may have a defined validity period, at the end of which the energy currency unit is automatically converted to monetary currency units. Users consume energy currency units through use of energy consumptive services, such as domestic consumption of electricity and hot water, and through use of transportation. Prices for energy may be set by comparing the cumulative actual and desired demand. By providing a continuous feedback mechanism, some embodiments of methods disclosed herein may raise an energy conscience—an awareness of when the community needs the help of its citizens to meet its ambitious sustainability goals.

Owner:MASDAR INST OF SCI & TECH

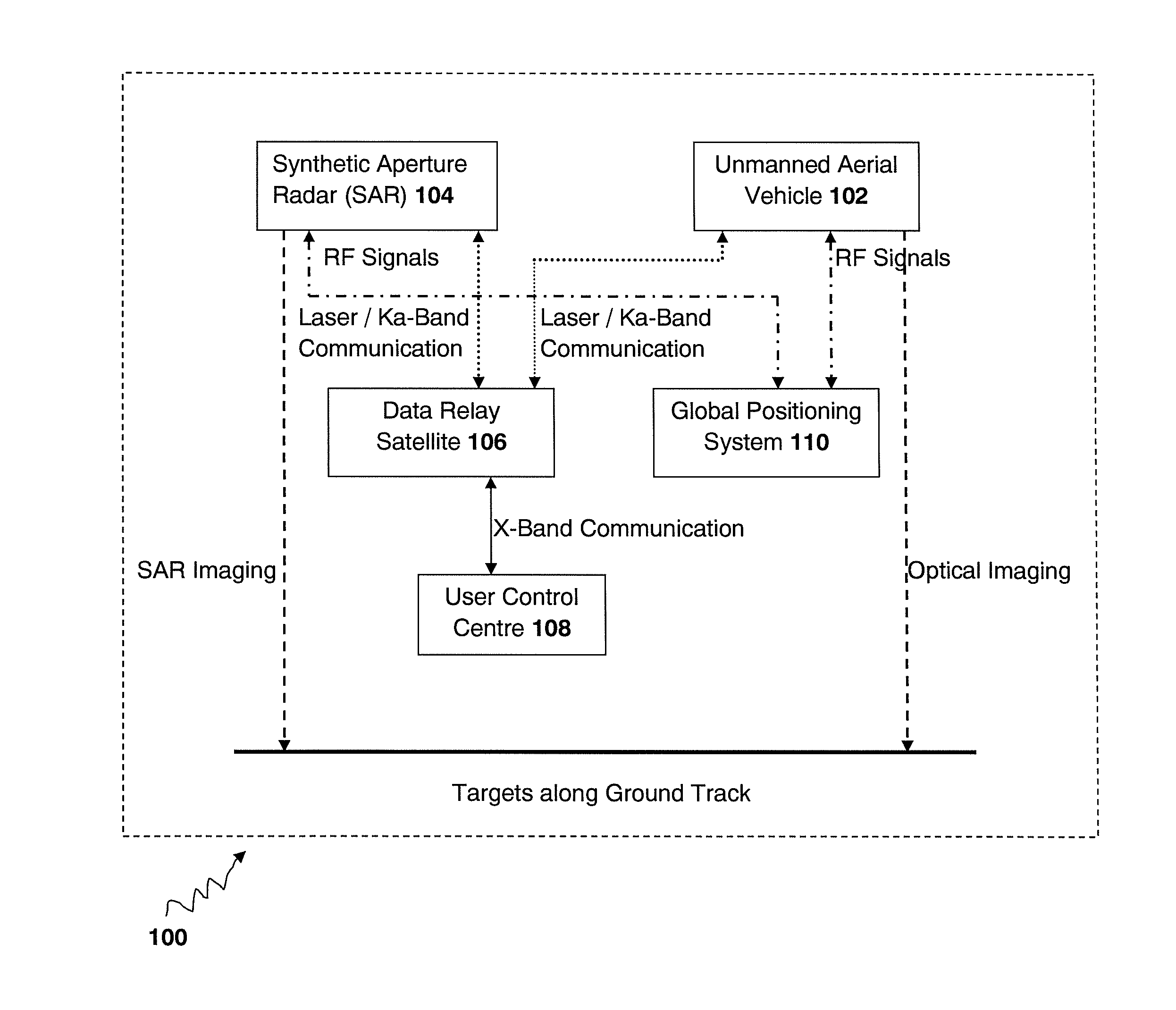

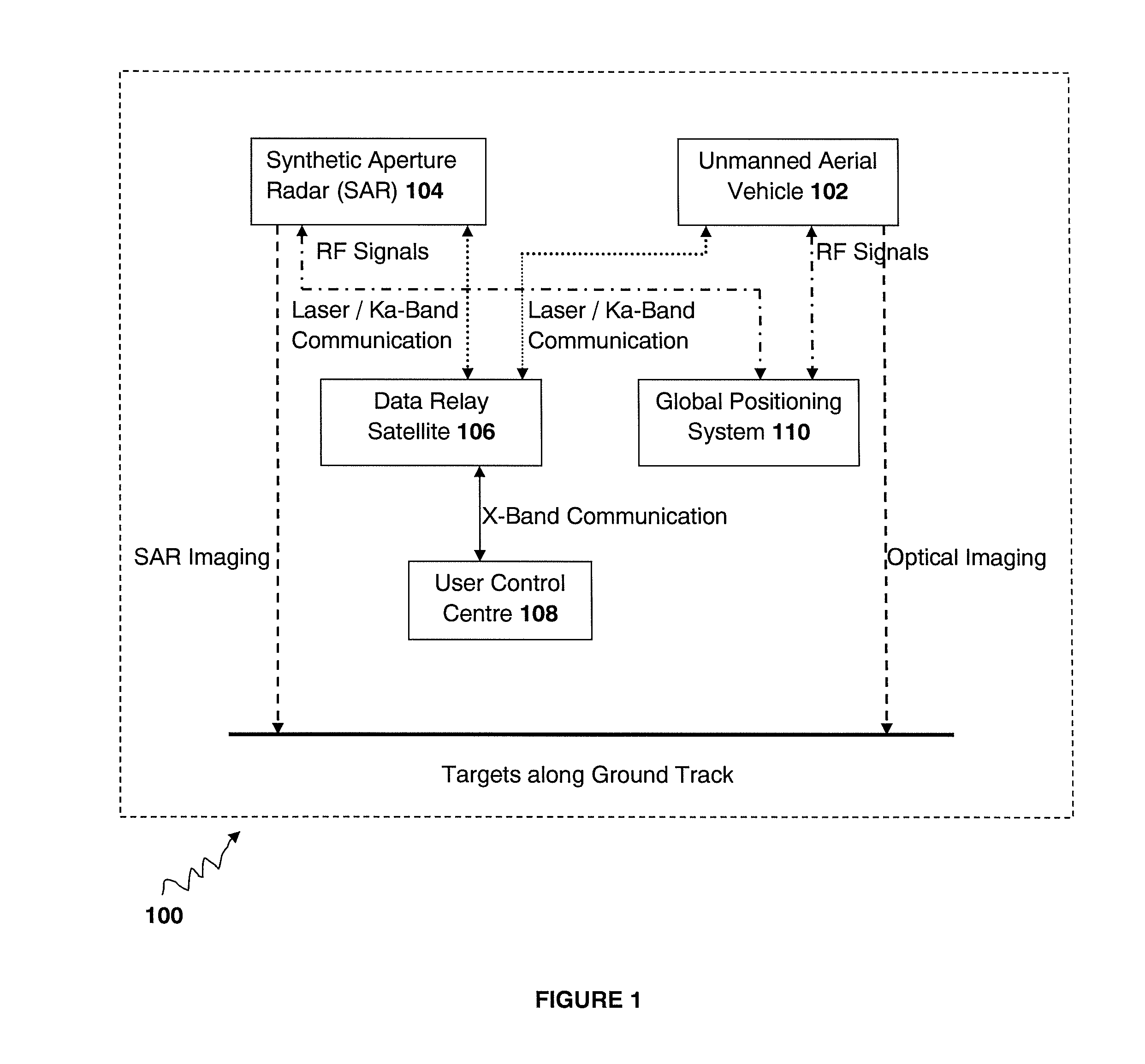

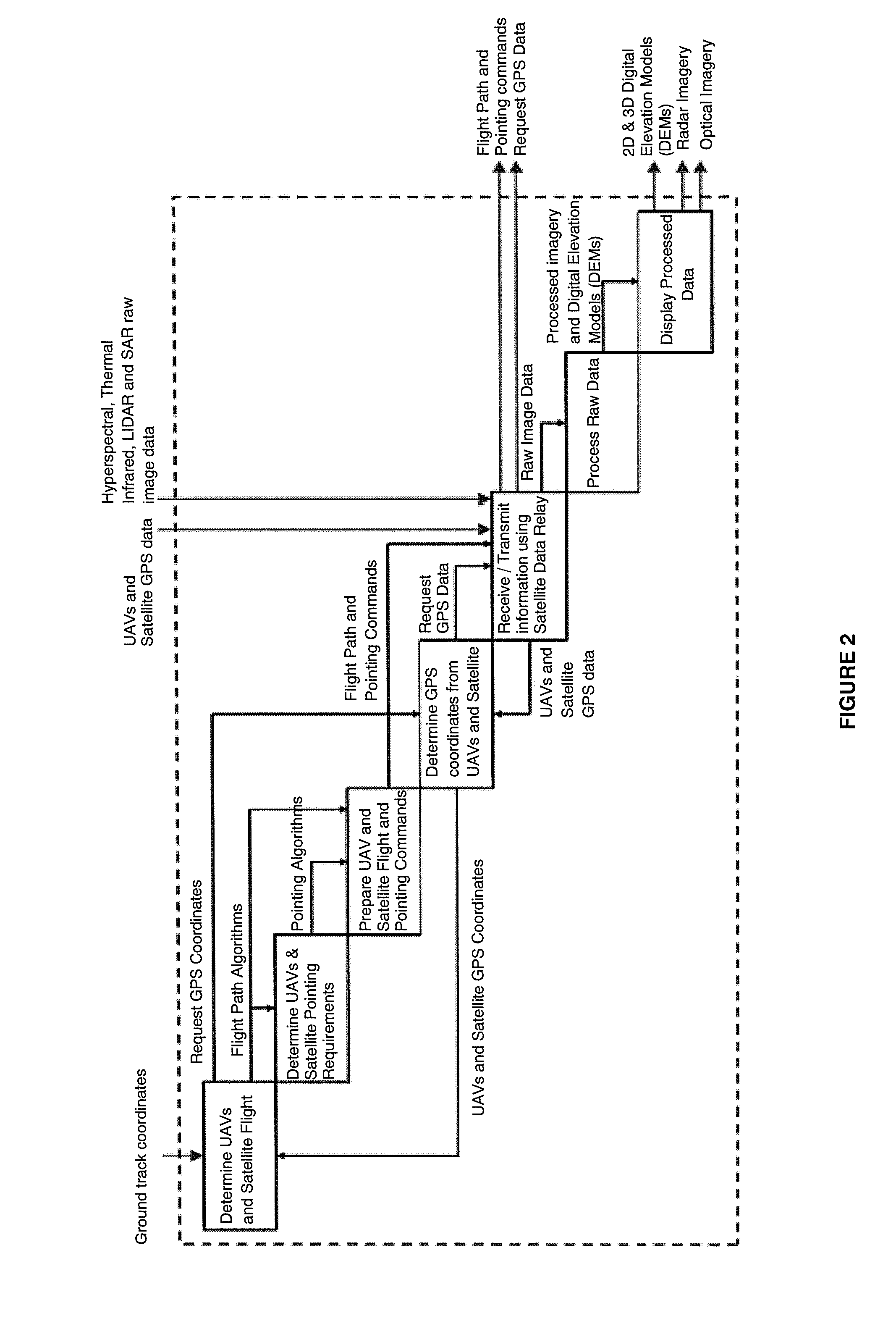

System for mapping and tracking ground targets

ActiveUS20150204974A1Easy to controlEfficient and cost-effectiveElectromagnetic wave reradiationRadio wave reradiation/reflectionContinuous feedbackOn board

A system for autonomously mapping and tracking of ground targets at a location of interest has been disclosed. The system comprises at least one user control center in operative communication with one or more data relay satellites in Geostationary Equatorial Orbit (GEO), the data relay satellites in operative communication with one or more UAVs and / or SAR satellites with on-board different imaging sensors to obtain various types of imagery data from the ground targets. The data relay satellites target specific constant communication with the user control center and the UAVs and SAR satellites for continuous feedback and control. Moreover, the system process all raw data obtained from the UAVs and SAR satellites to produce 2D and 3D Digital Elevation Models (DEMs) and high resolution images, which are displayed on the user control center and / or selected mobile handheld devices.

Owner:PILLAY VENKATESHWARA

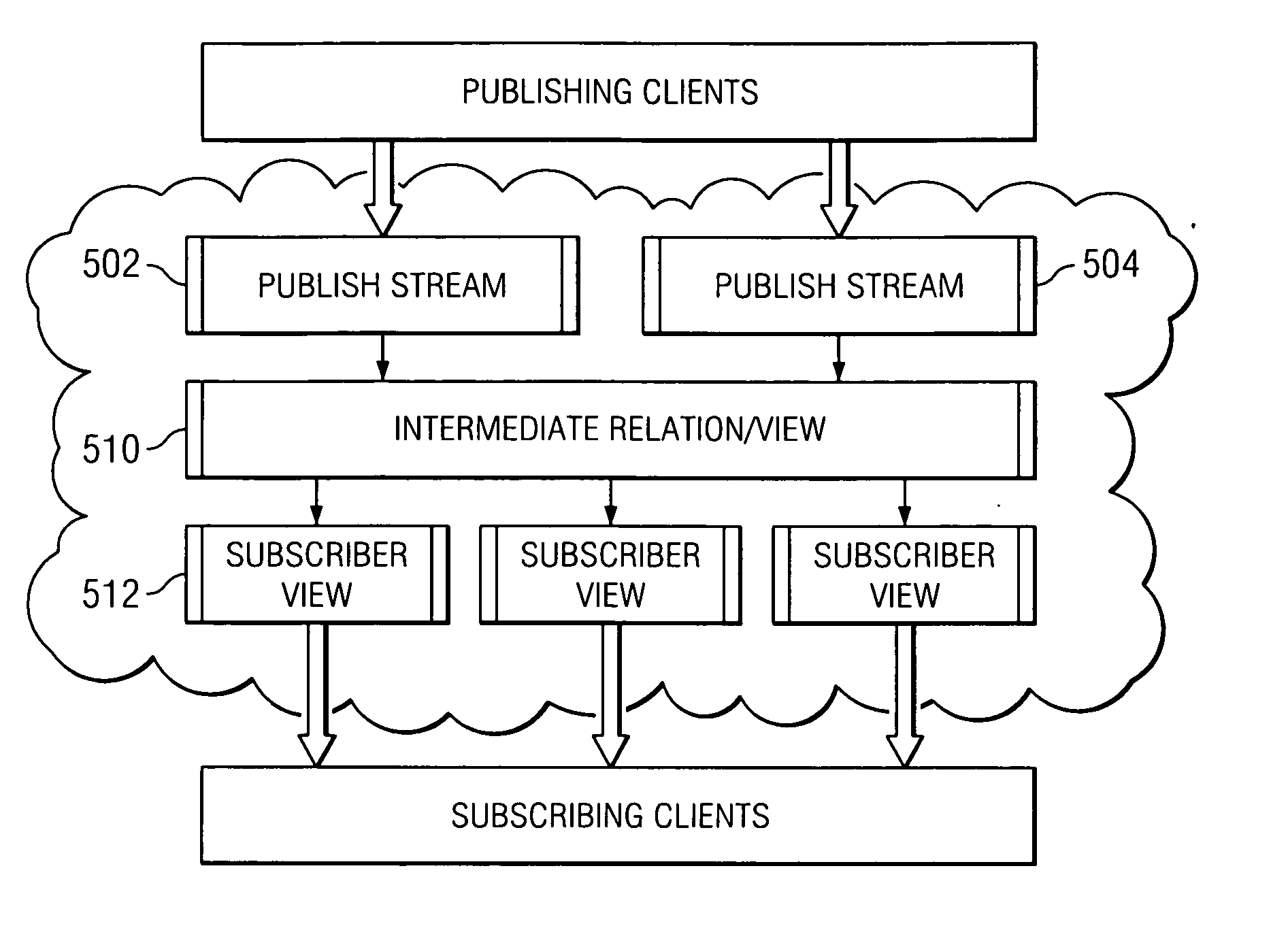

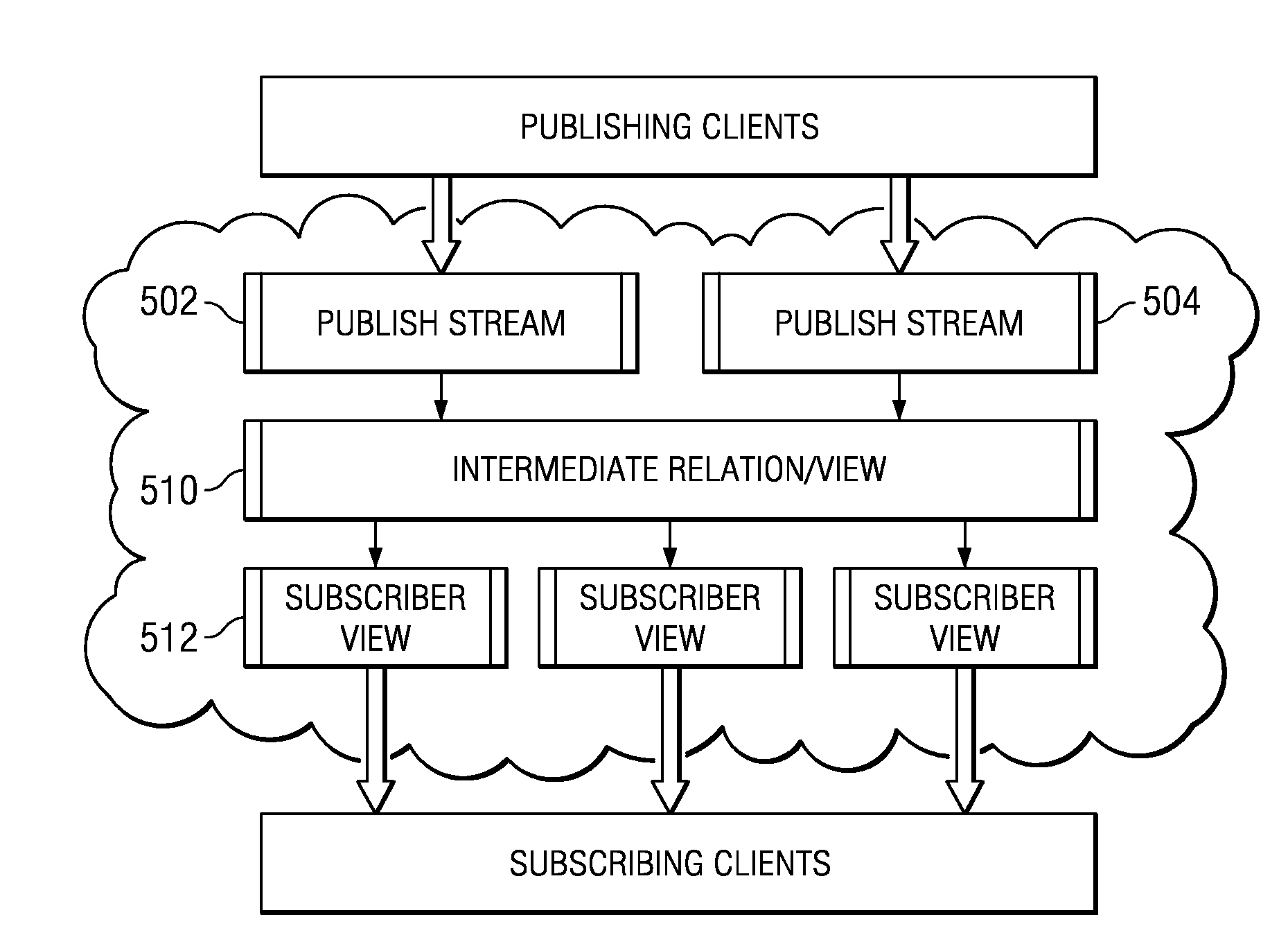

Continuous feedback-controlled deployment of message transforms in a distributed messaging system

InactiveUS20050251556A1Solution has disadvantageImprove system performanceMultiple digital computer combinationsTransmissionContinuous feedbackClient-side

The present invention solves the disadvantages of the prior art and provides a distributed messaging system supporting stateful subscriptions. A stateful publish-subscribe system extends the functionality of the content-based approach to include more general state-valued expressions. A plurality of broker machines is provided to deliver messages sent by publishing clients toward subscribing clients based upon the contents of the messages and stateful transformations requested by the subscribing clients. Subscription specifications are analyzed by a compiler and converted into a collection of message transforms and views. A deployment service component deploys tasks to optimize system performance. A monitoring services component detects a possible need to reconfigure. A performance optimization service component computes new assignment of transforms. A continuous deployment service implements a redeployment protocol that installs changes to transform placement while the existing publish-subscribe system continues to operate.

Owner:IBM CORP

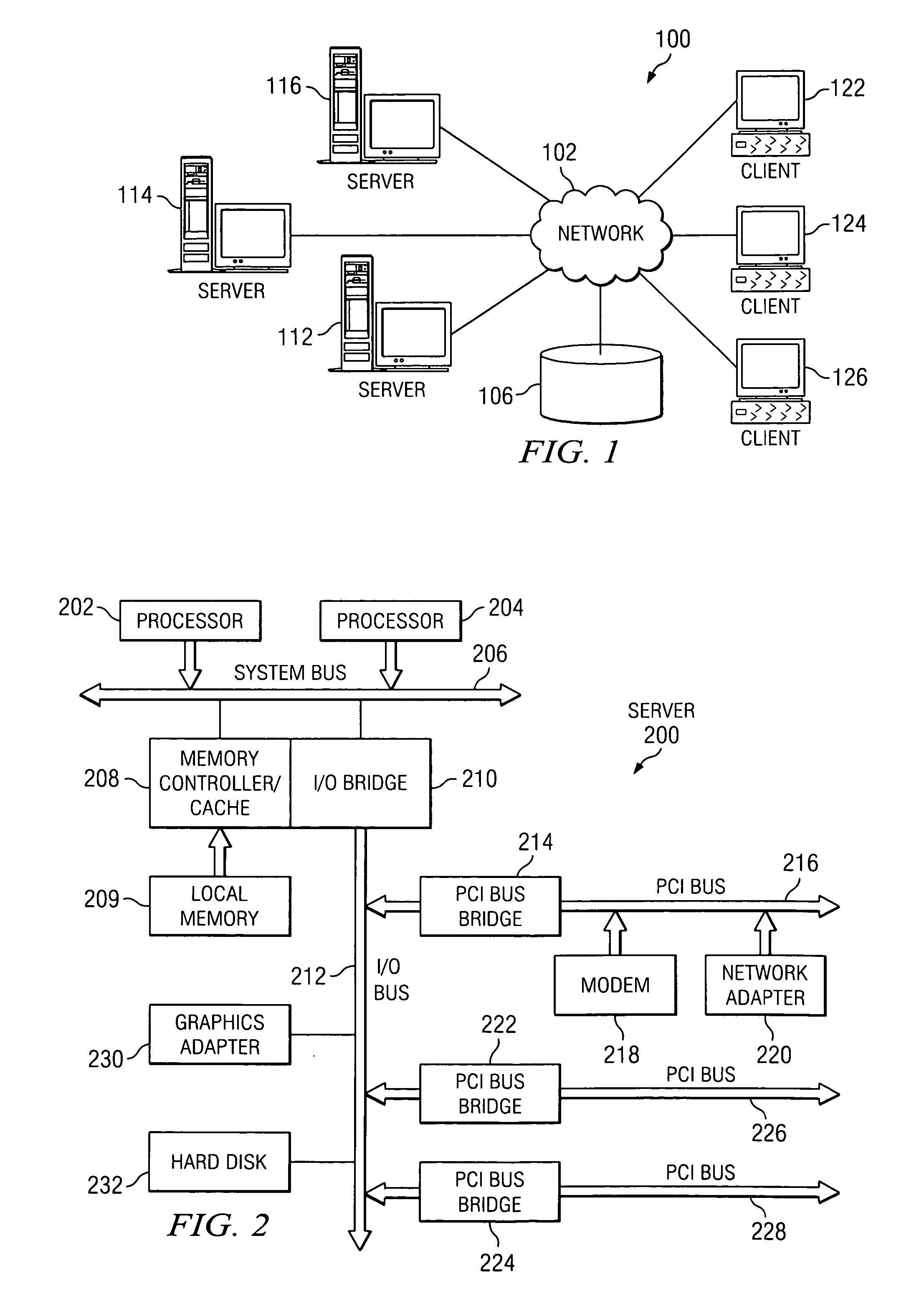

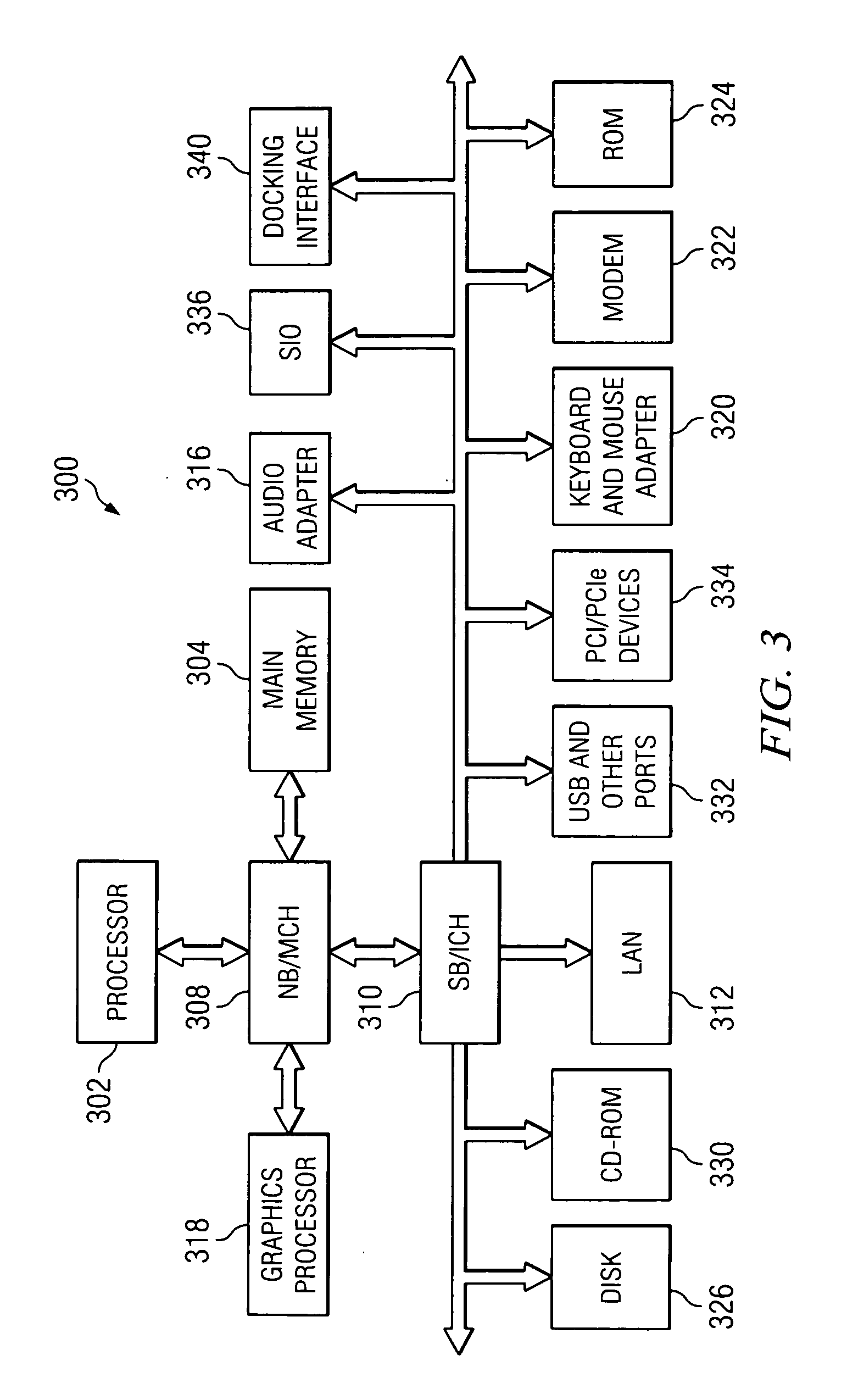

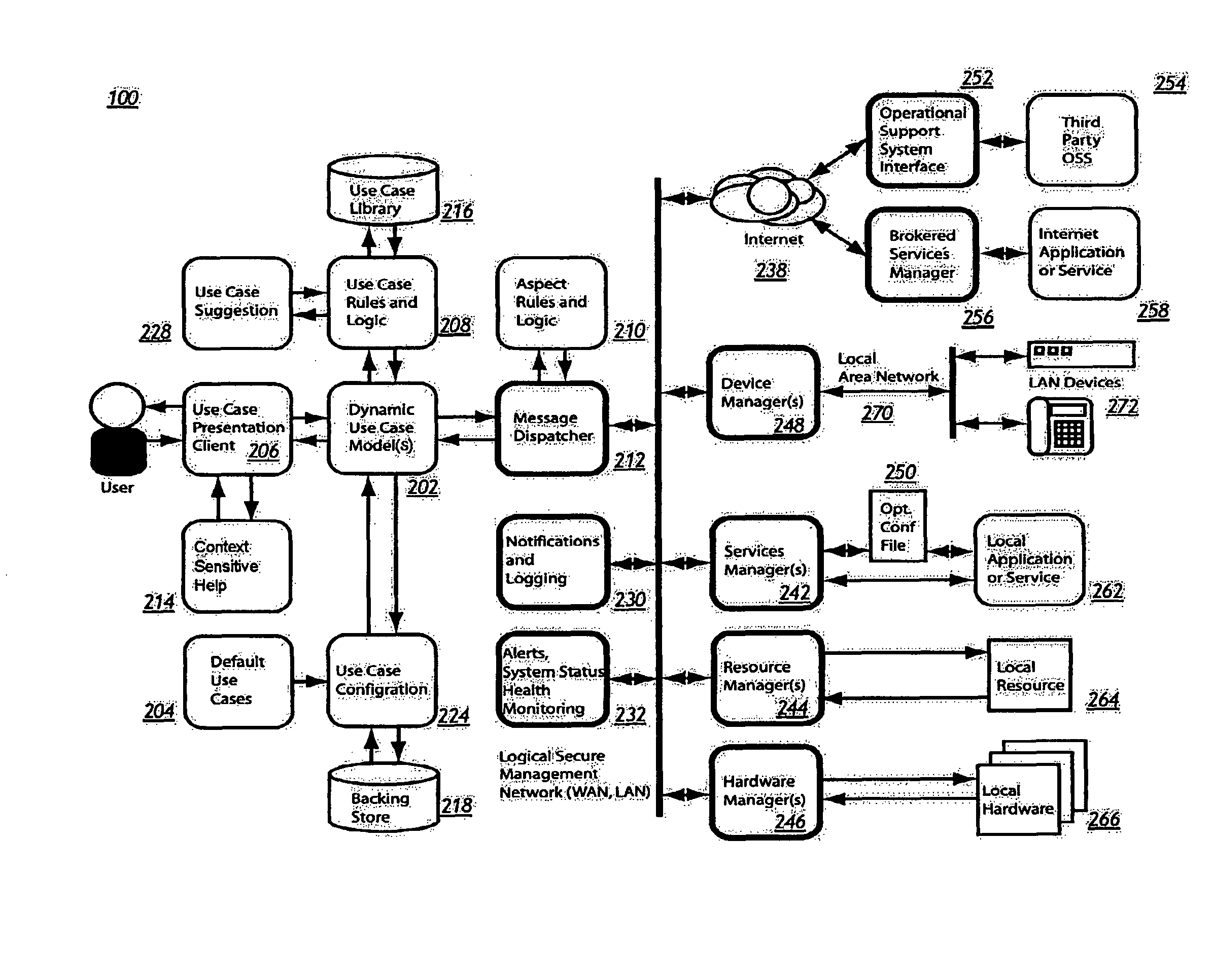

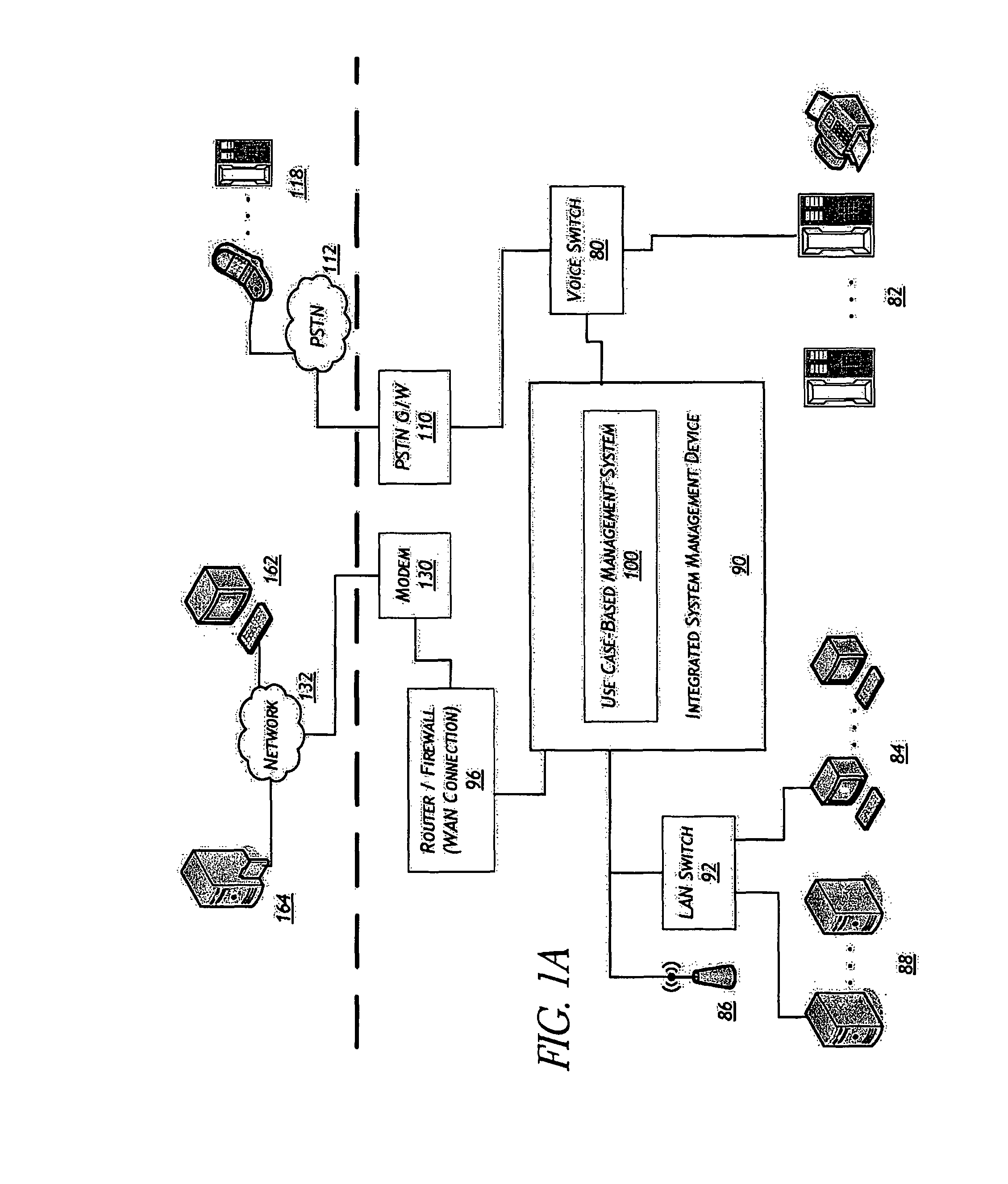

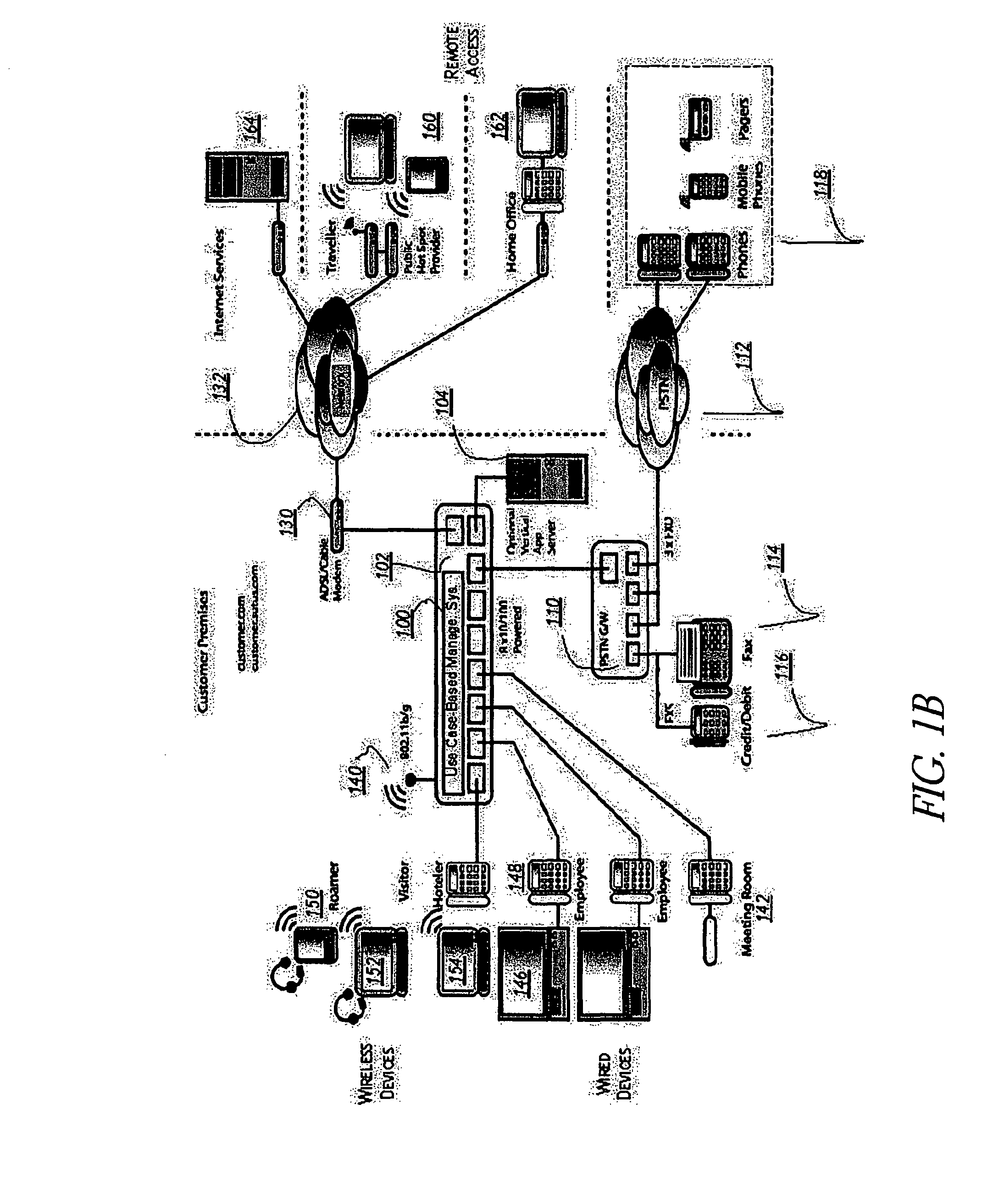

Systems and methods for managing integrated systems with use cases

InactiveUS7886048B1Low specialized trainingGreat physicalSpeech analysisMultiple digital computer combinationsContinuous feedbackManagement system

Embodiments of the use case-based management system enable non-technical users to manage complex integrated systems based on familiar languages and workflows, and thus reduce the costs of installing and managing these integrated systems. The dynamic use cases respond to the users' input as well as the continuous feedback of system status and health. Based on these input and feedback, the use case-based management system then subscribes to and authorizes services, manages services and resources, and configures and provisions services, resources, and devices.

Owner:SUTUS

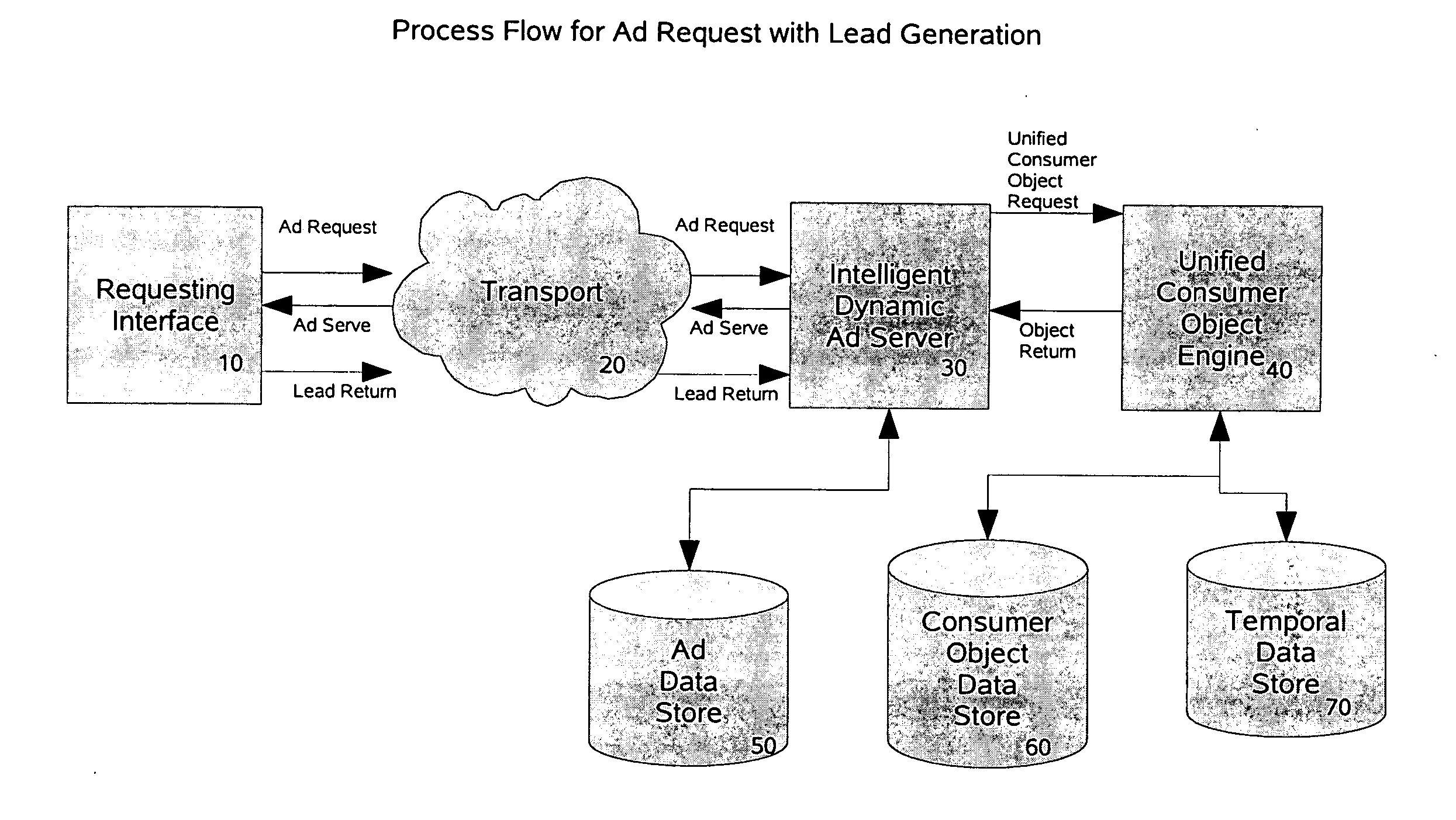

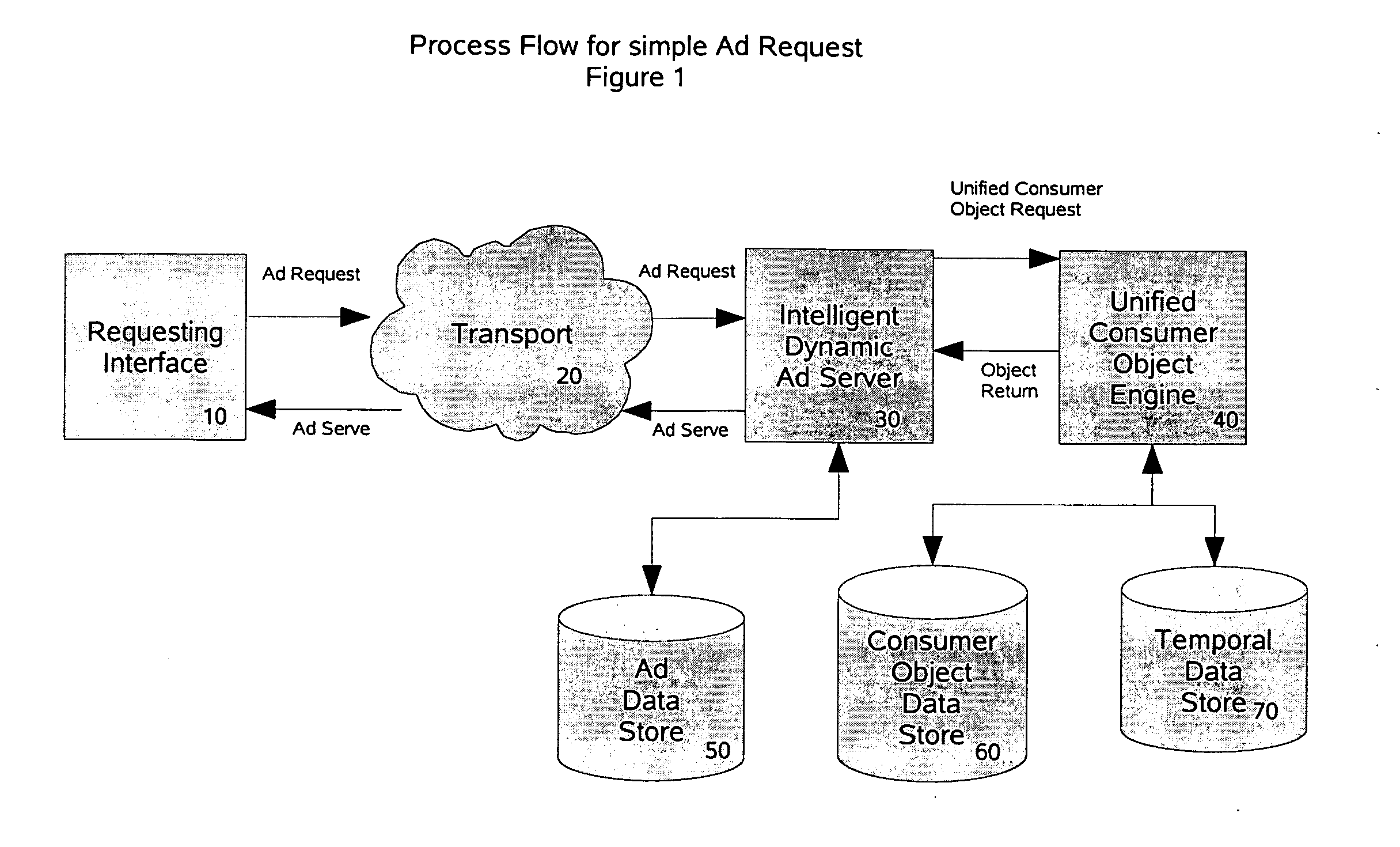

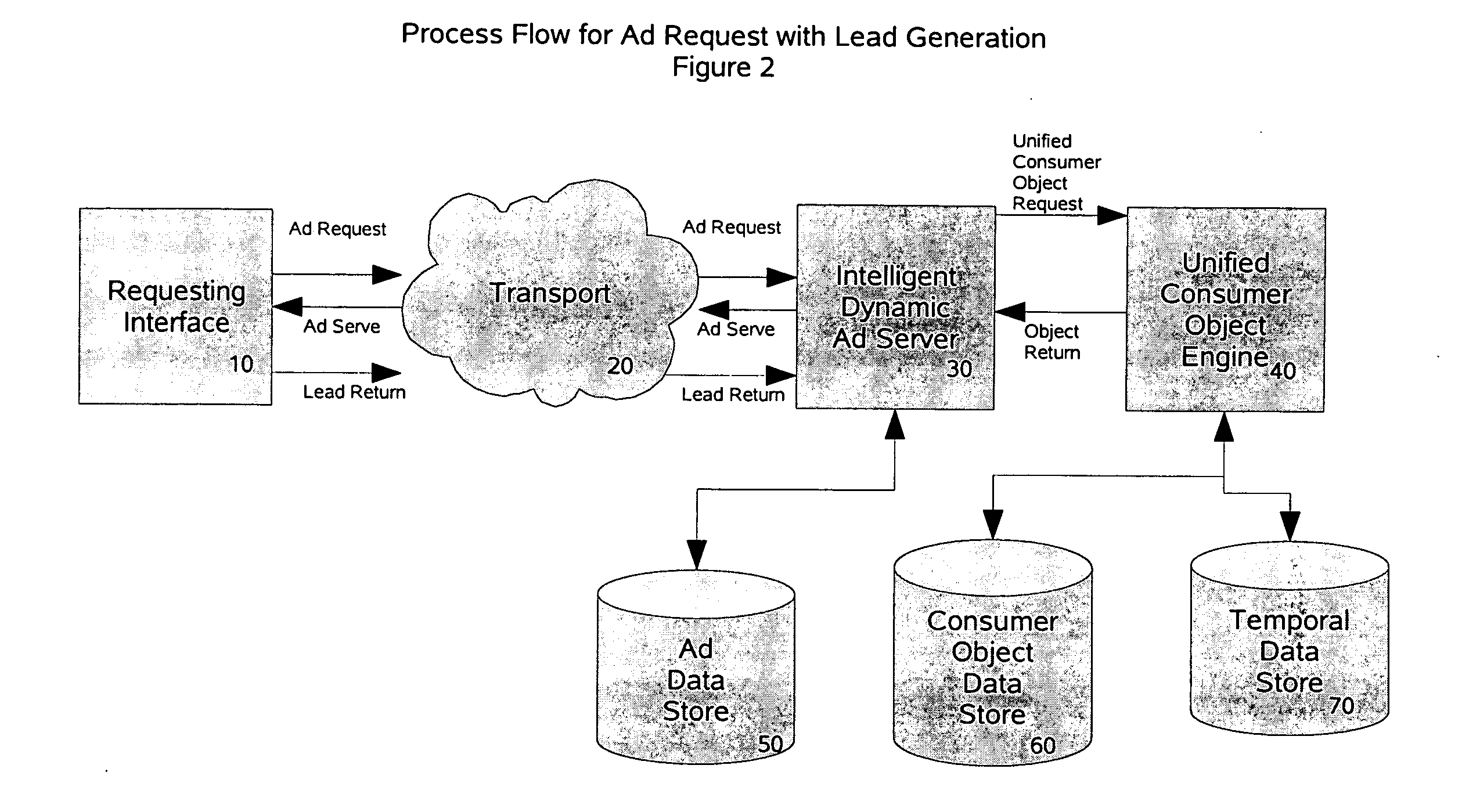

Exchange and interactive ad server system and method

InactiveUS20070022009A1Deepen profilePositive reinforcementAdvertisementsContinuous feedbackWorld Wide Web

The exchange & interactive ad server system and method allow an advertiser to bid or directly purchase publisher inventory across both interactive and traditional media networks. Furthermore, the system further allows the automation and optimization of advert, publisher networks, and consumer rewards via a continuous feedback loop of consumer interactions, consumer data, and analysis of behavioral algorithms.

Owner:DATAAPP

Customer journey prediction and resolution

Customer journey prediction and resolution is accomplished via a predictive model in which each user is mapped onto all available user journey information corresponding to a specific business. The predictive model is analyzed to understand the characteristics, preferences, and lowest effort resolution for the user related to the services that are subscribed to by the user. The predictive model is analyzed to predict the service or collection of services for each user. Embodiments interact with, provide and receive information from, and react to and / or deliver action to the customer across channels and across services. All customer and system behavior, data, and action is tracked and coordinated and leveraged for continuous feedback and performance improvement.

Owner:24 7 AI INC

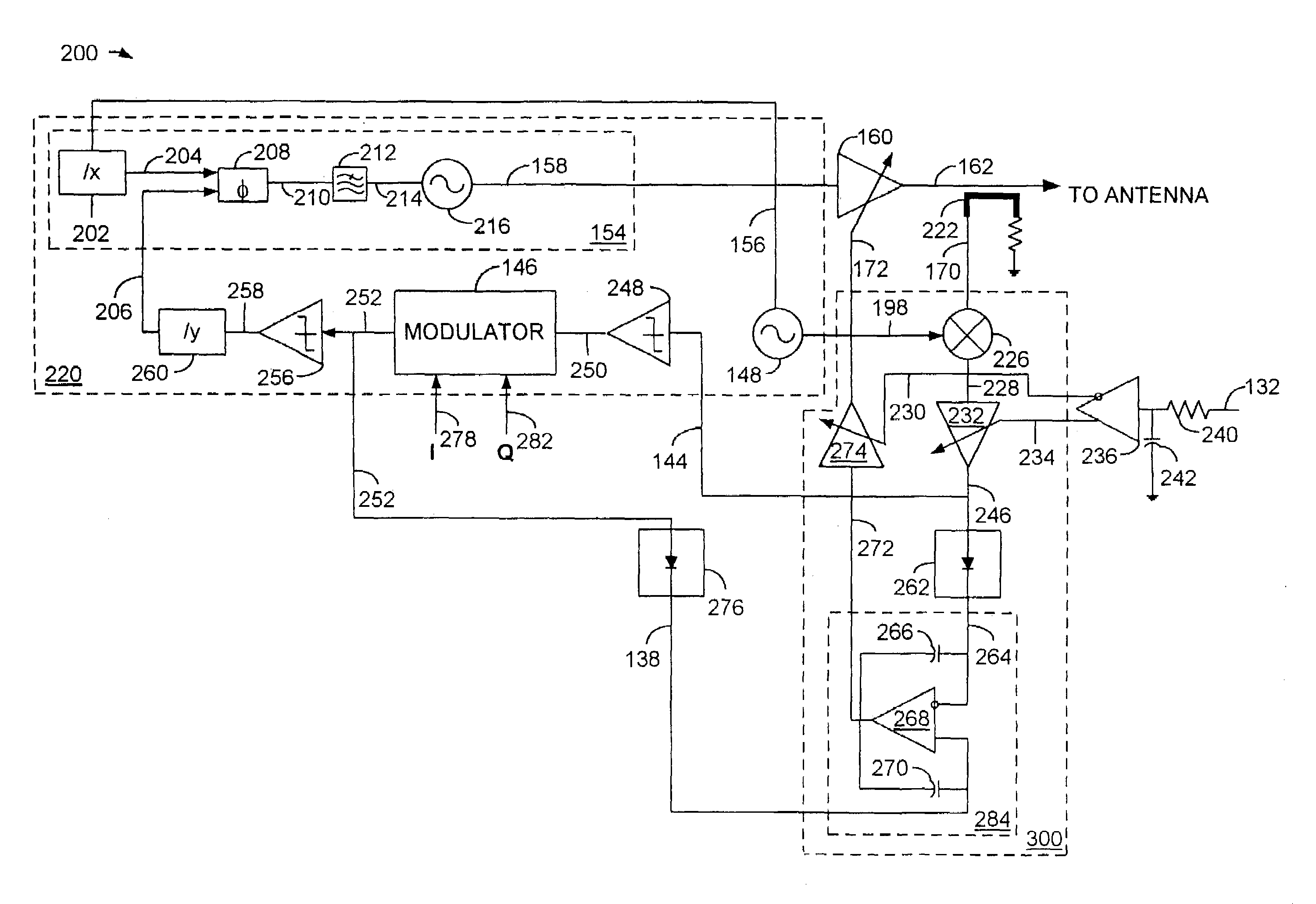

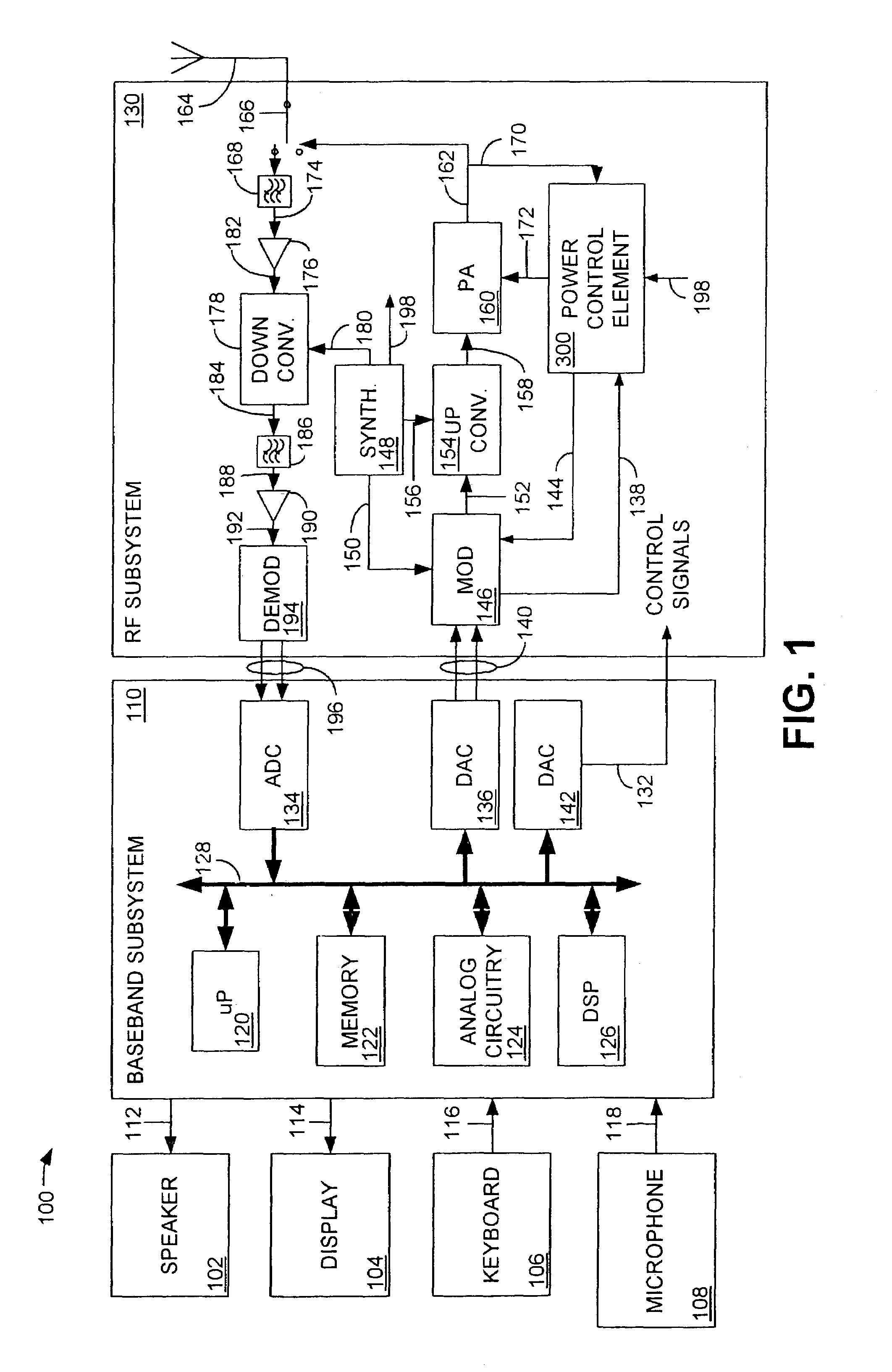

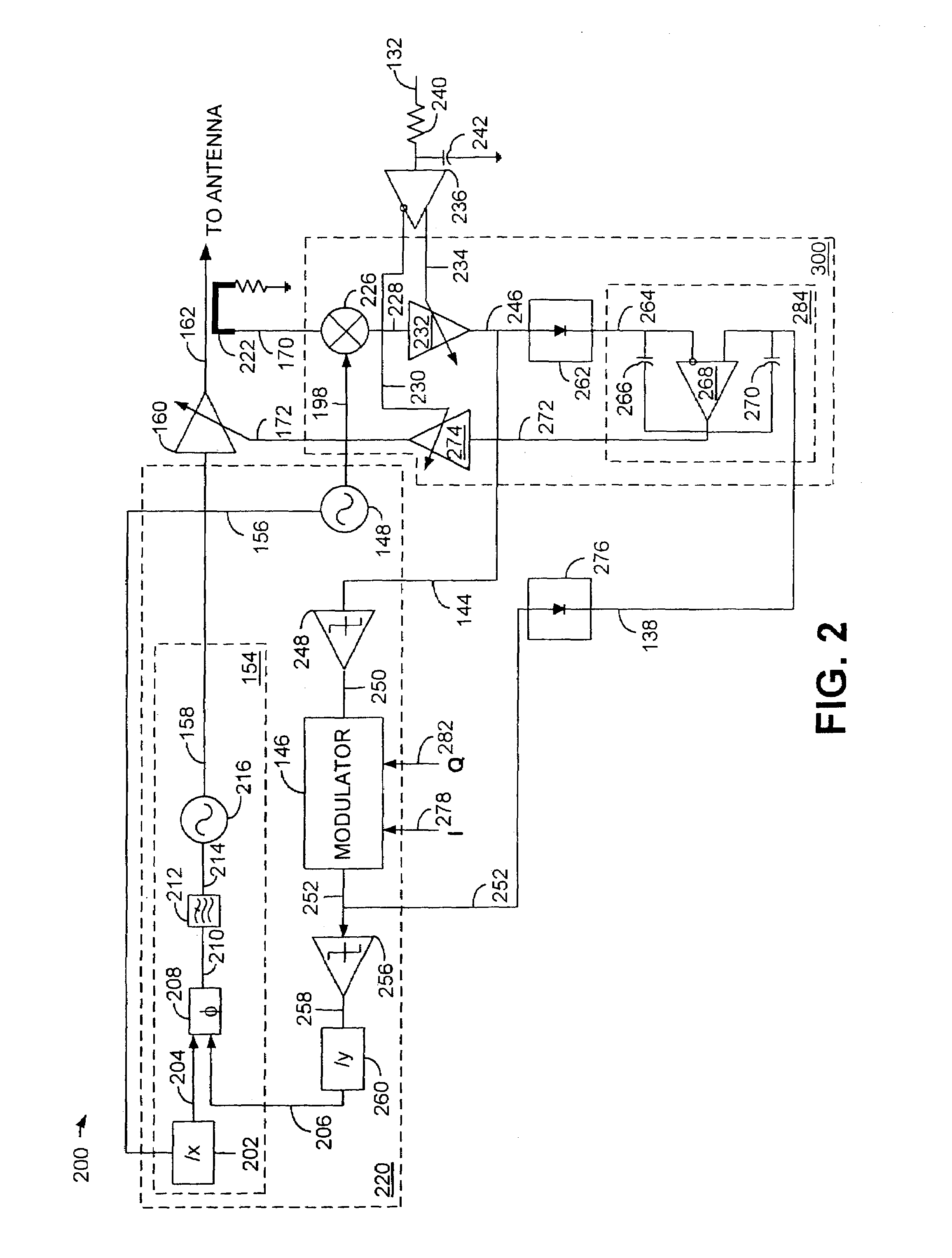

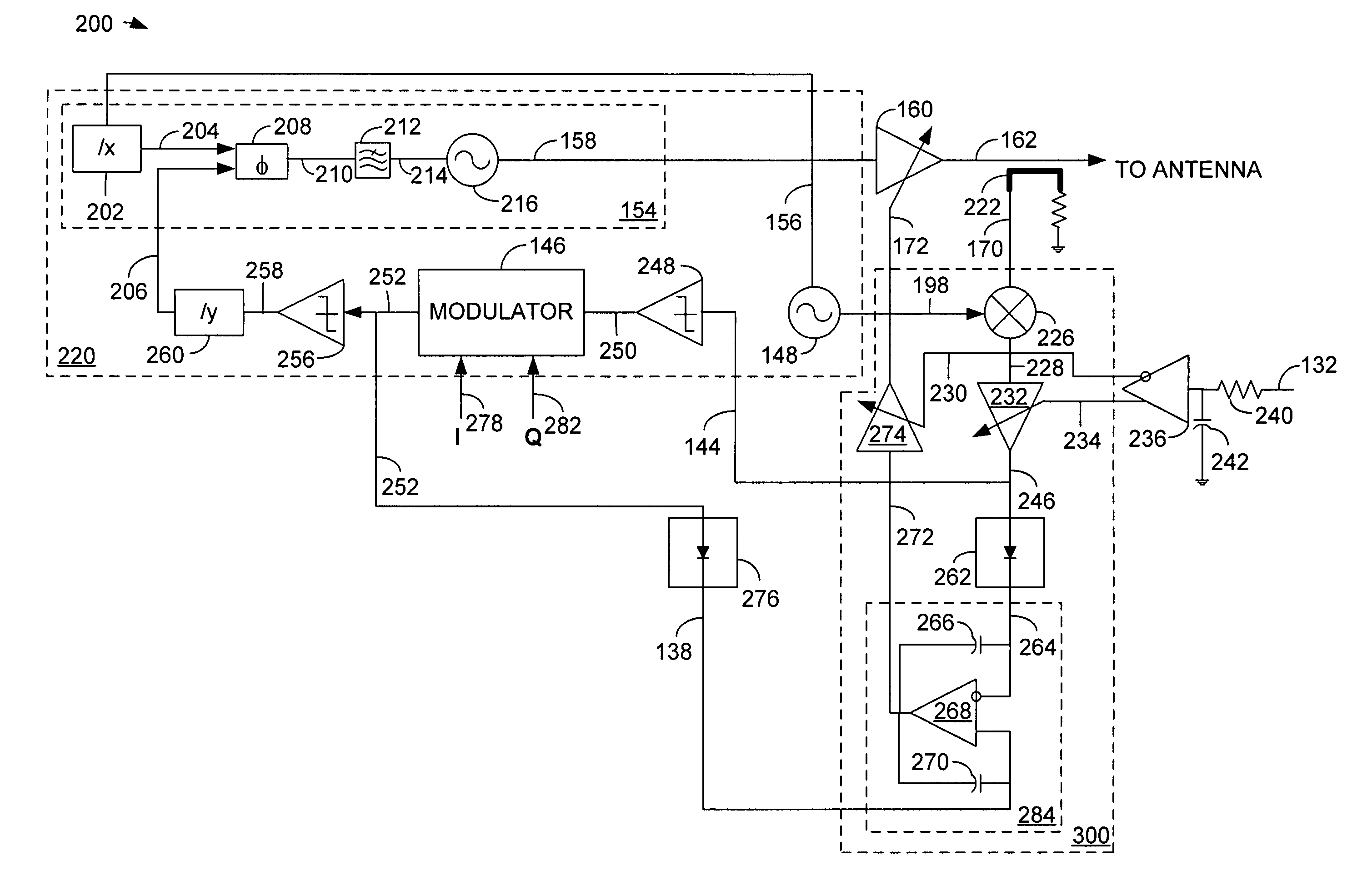

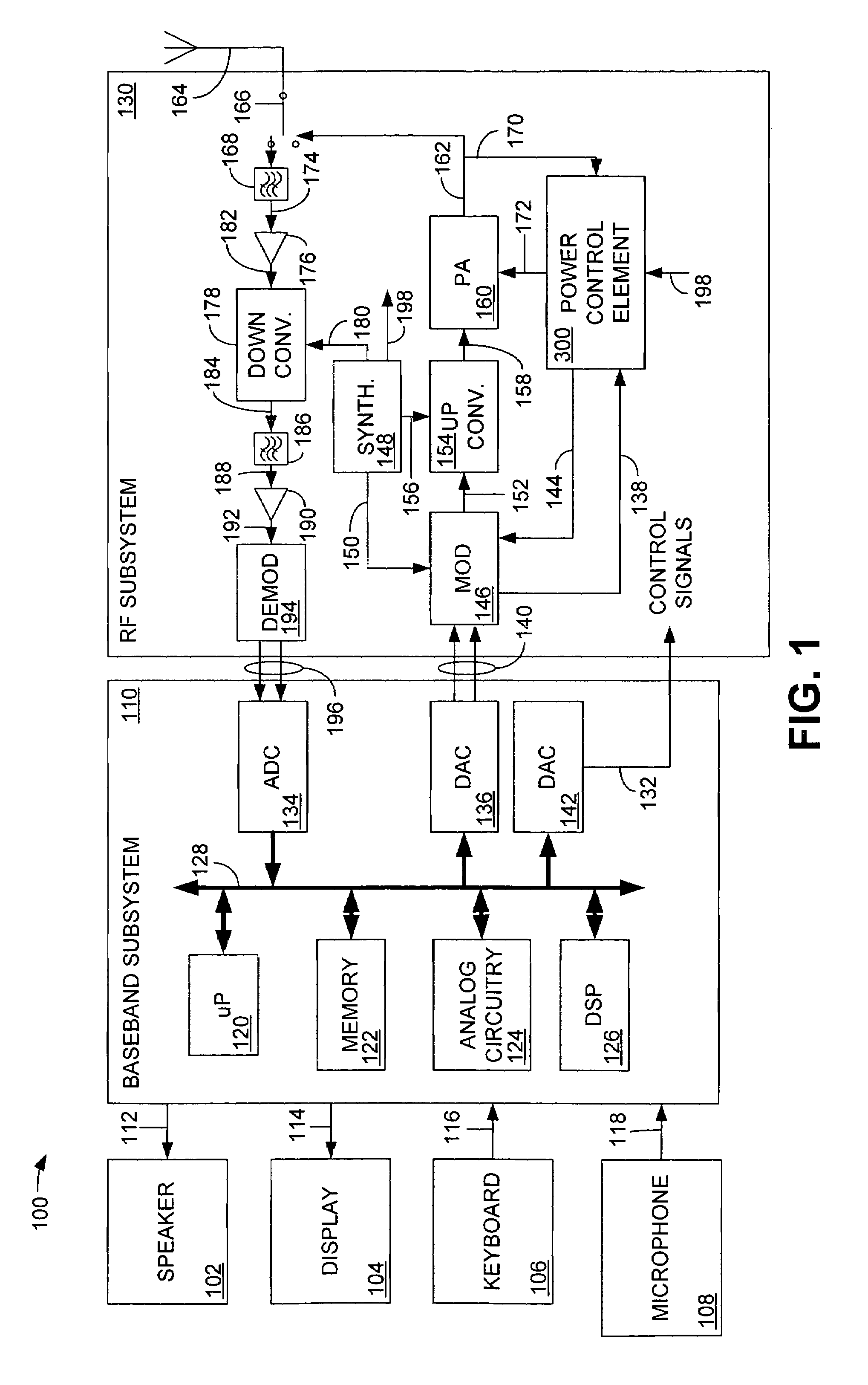

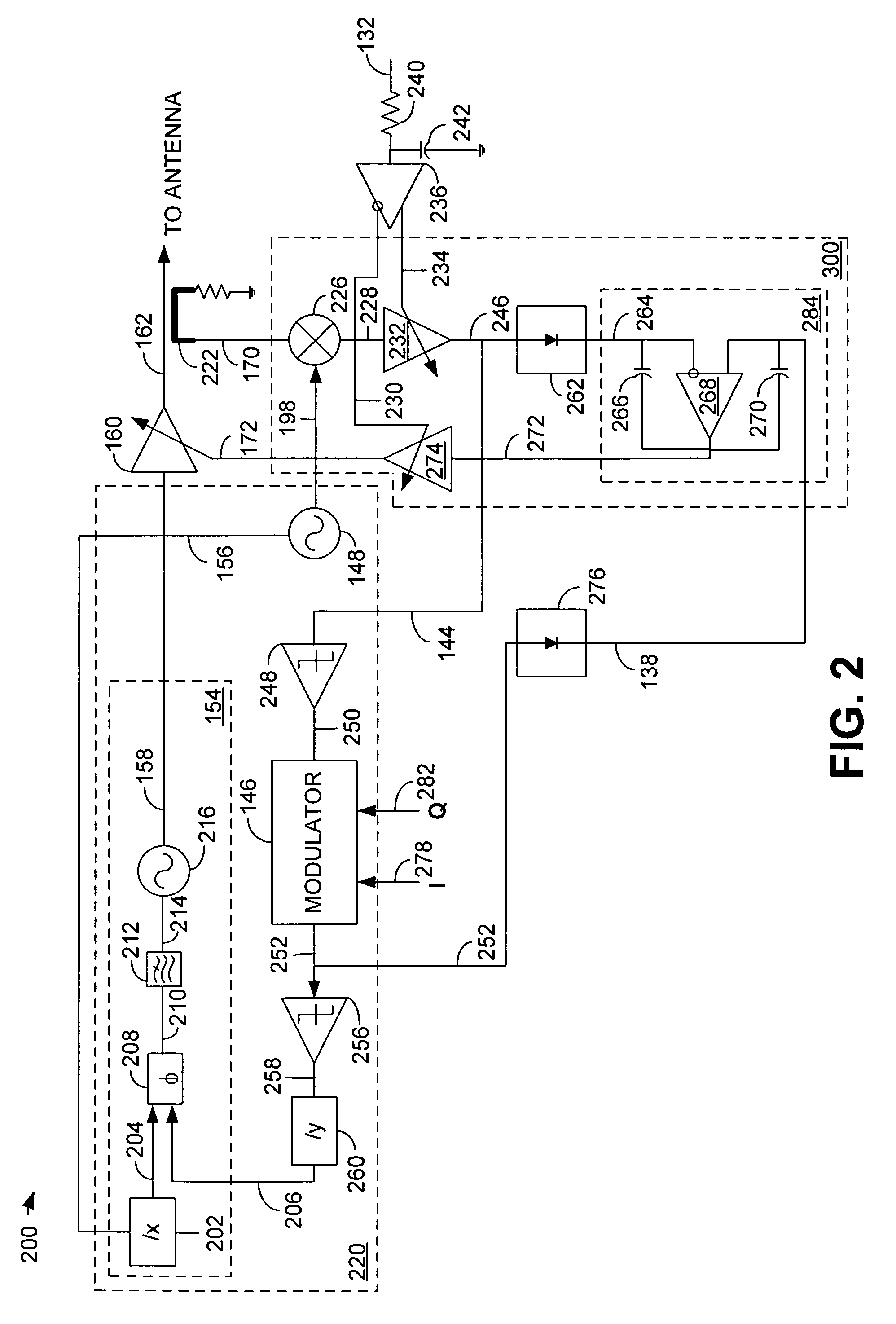

Continuous closed-loop power control system including modulation injection in a wireless transceiver power amplifier

InactiveUS7099636B2Allow useEliminate needPower managementResonant long antennasWireless transceiverAudio power amplifier

A single continuous closed-loop power control feedback system provides seamless power control for a power amplifier and also enables an AM signal to be injected into the power amplifier through the power amplifiers' control port. The AM signal is developed by an I / Q modulator and supplied to a comparator located in the power control loop. By using leakage from the power amplifier as feedback to a phase locked loop during initial power amplifier power ramp-up, the single continuous closed-loop power control system provides continuous feedback to the phase locked loop during the entire power amplification ramp-up period and eliminates the need for multiple feedback loops.

Owner:XUESHAN TECH INC

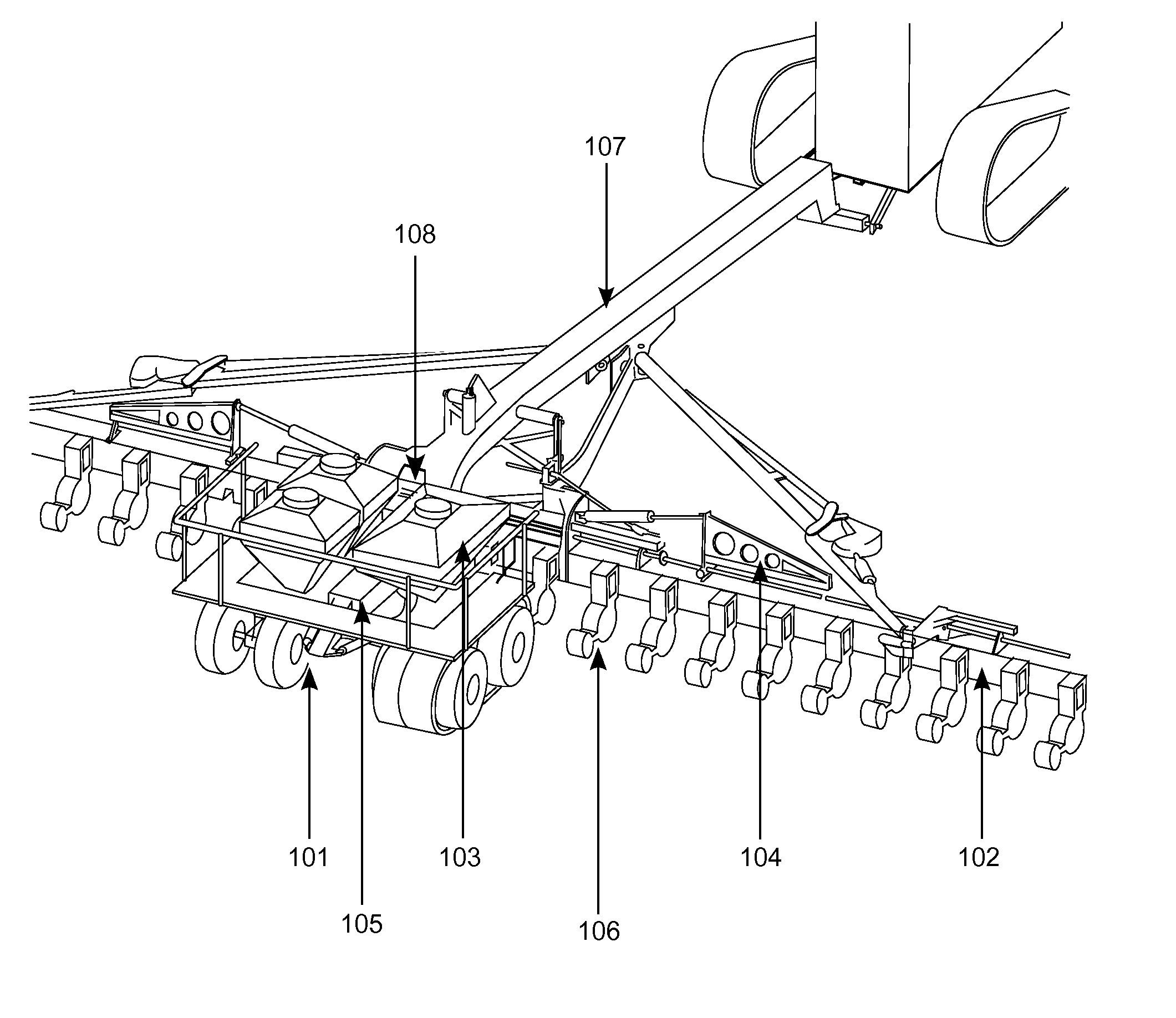

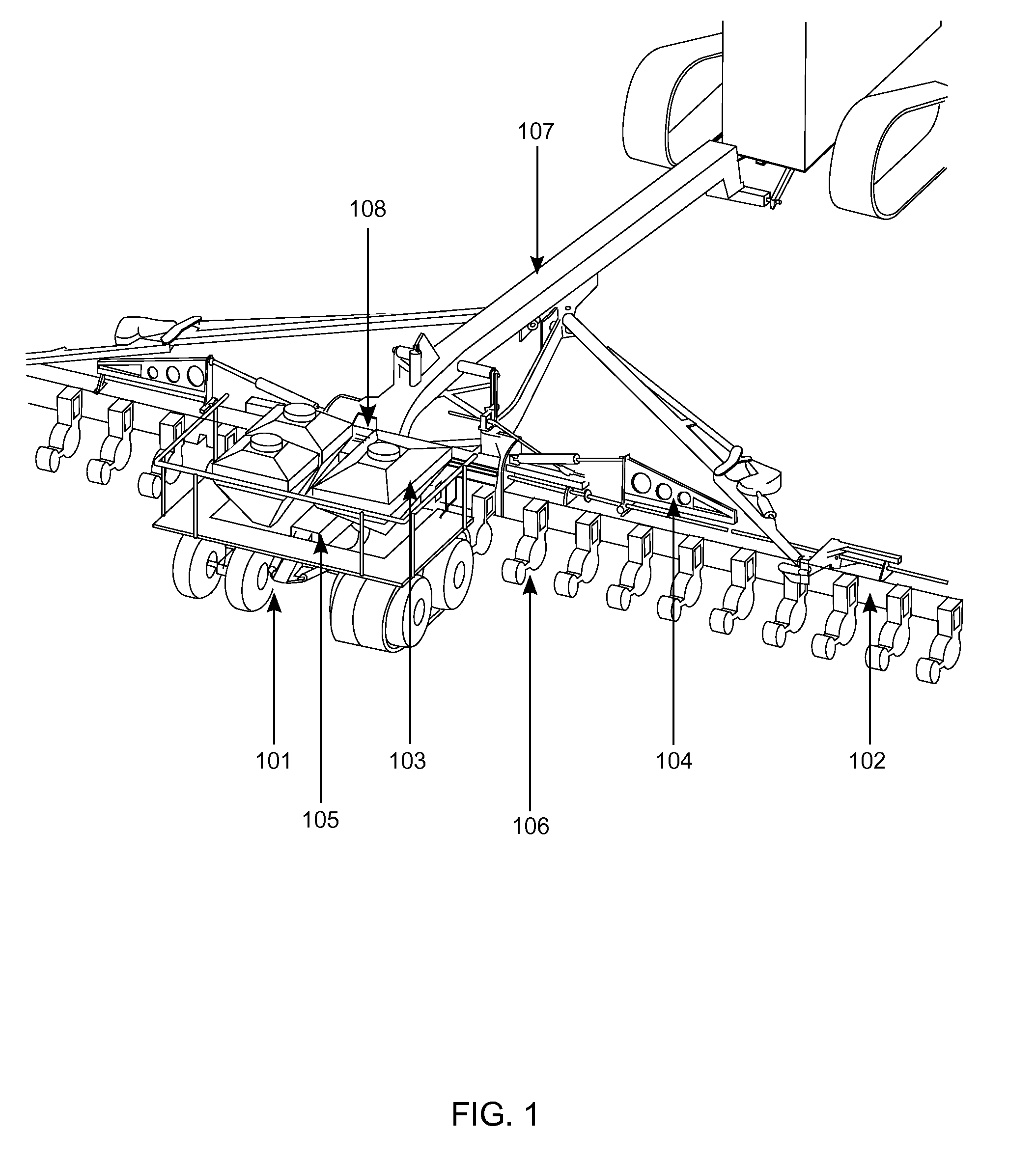

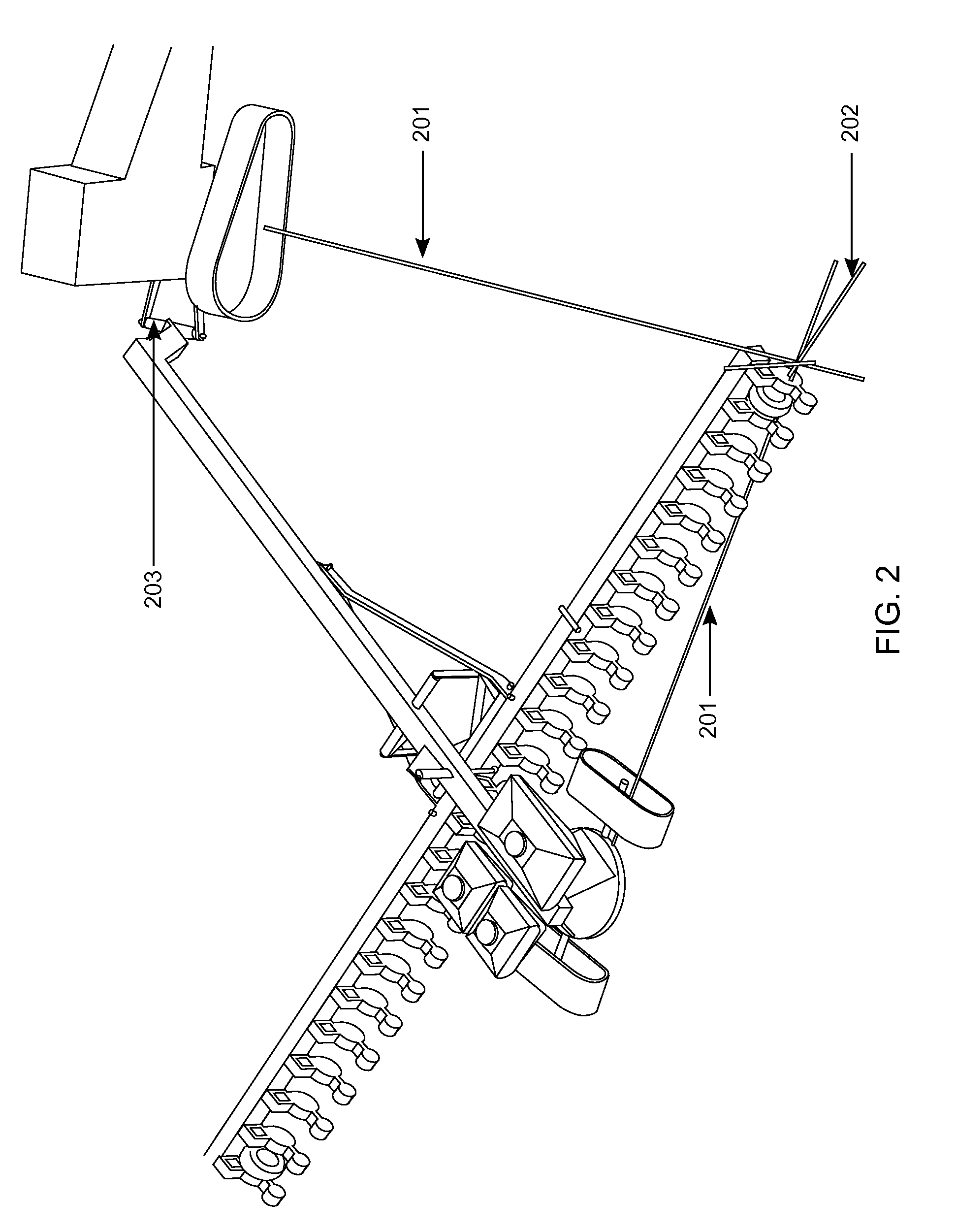

Row-producing system for agricultural crops

An integrated system for row-producing in agriculture fields comprises several implements each having an elevated central frame, an undercarriage assembly with a rear active steering system and the undercarriage assembly is rear located and being behind the structures of toolbar and row units. The rear active steering system controlled by a GPS system comprises a steer angle sensor and a closed loop continuous feedback system, with the purpose of keeping a precise lateral location. This integrated system also comprises an active toolbar height controlling system. When needed, the undercarriage assembly can be disconnected from the implement. This integrated system functions to reduce compactions in the field and ensure lateral accuracy of the implement movement. The integrated system works as a strip tiller, and as a planter.

Owner:SATZLER RONALD L +1

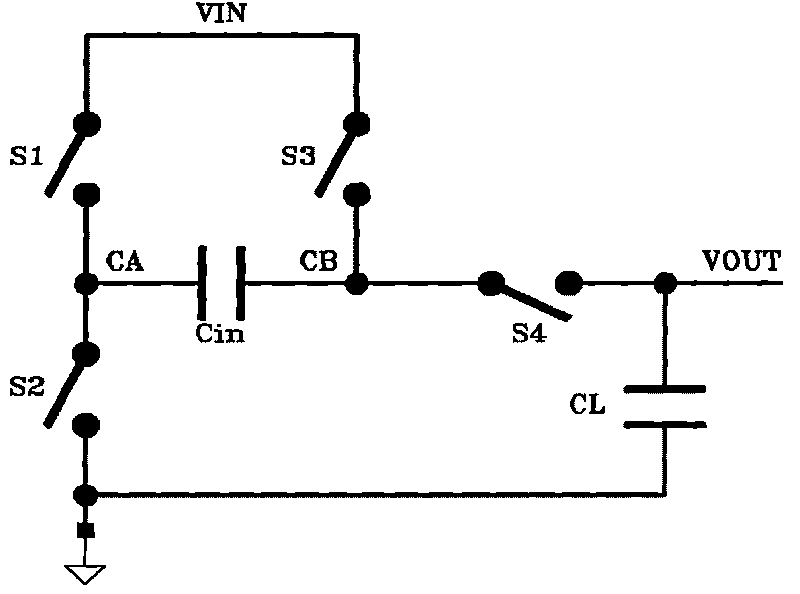

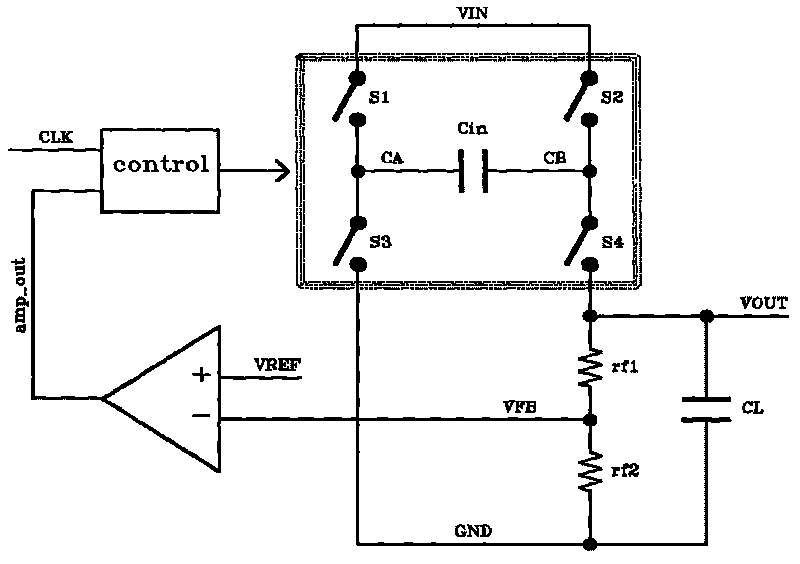

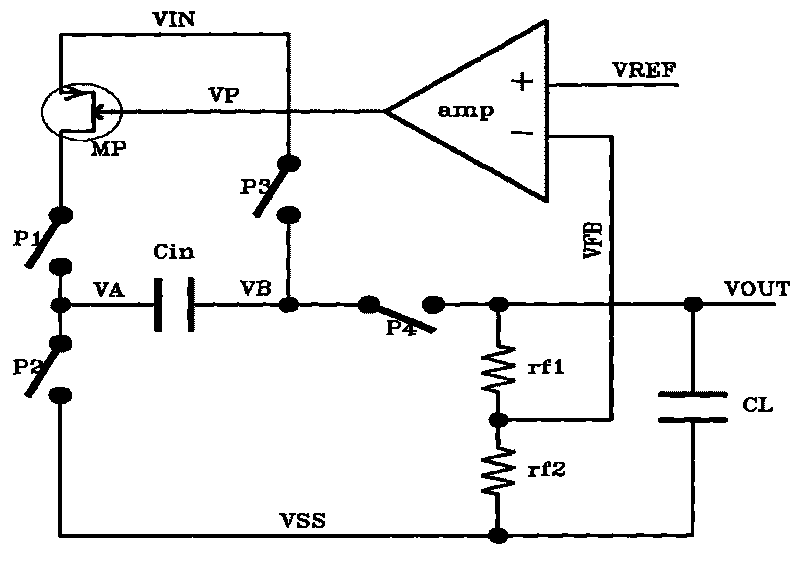

Low ripple wave boosting type charge pump

InactiveCN101694961ASmall rippleApparatus without intermediate ac conversionAudio power amplifierContinuous feedback

The invention discloses a low ripple wave boosting type charge pump which comprises a single-capacitor voltage doubling circuit, wherein a continuous feedback circuit is arranged between the output voltage and the input voltage of the single-capacitor voltage doubling circuit; the continuous feedback circuit comprises an output voltage sampling branch circuit, an operation amplifier and an adjusting pipe which are sequentially connected; the detecting voltage and the reference voltage of the output voltage sampling branch circuit are respectively connected to both input ends of the operation amplifier, the output end of the operation amplifier is connected to the input end of the adjusting pipe, and a feedback mechanism of the continuous feedback circuit finally stabilizes the output voltage to a preset value. The continuous feedback mechanism comprising the output voltage sampling branch circuit, the operation amplifier and an active adjusting pipe is added; on one hand, when the factor of input voltage or temperature, and the like is changed, the stability of the output voltage is maintained by feedback; on the other hand, a ripple wave of the output voltage does not comprise the unideal factor of offset voltage, and the like due to the continuity of the feedback, thereby having a lower ripple wave.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

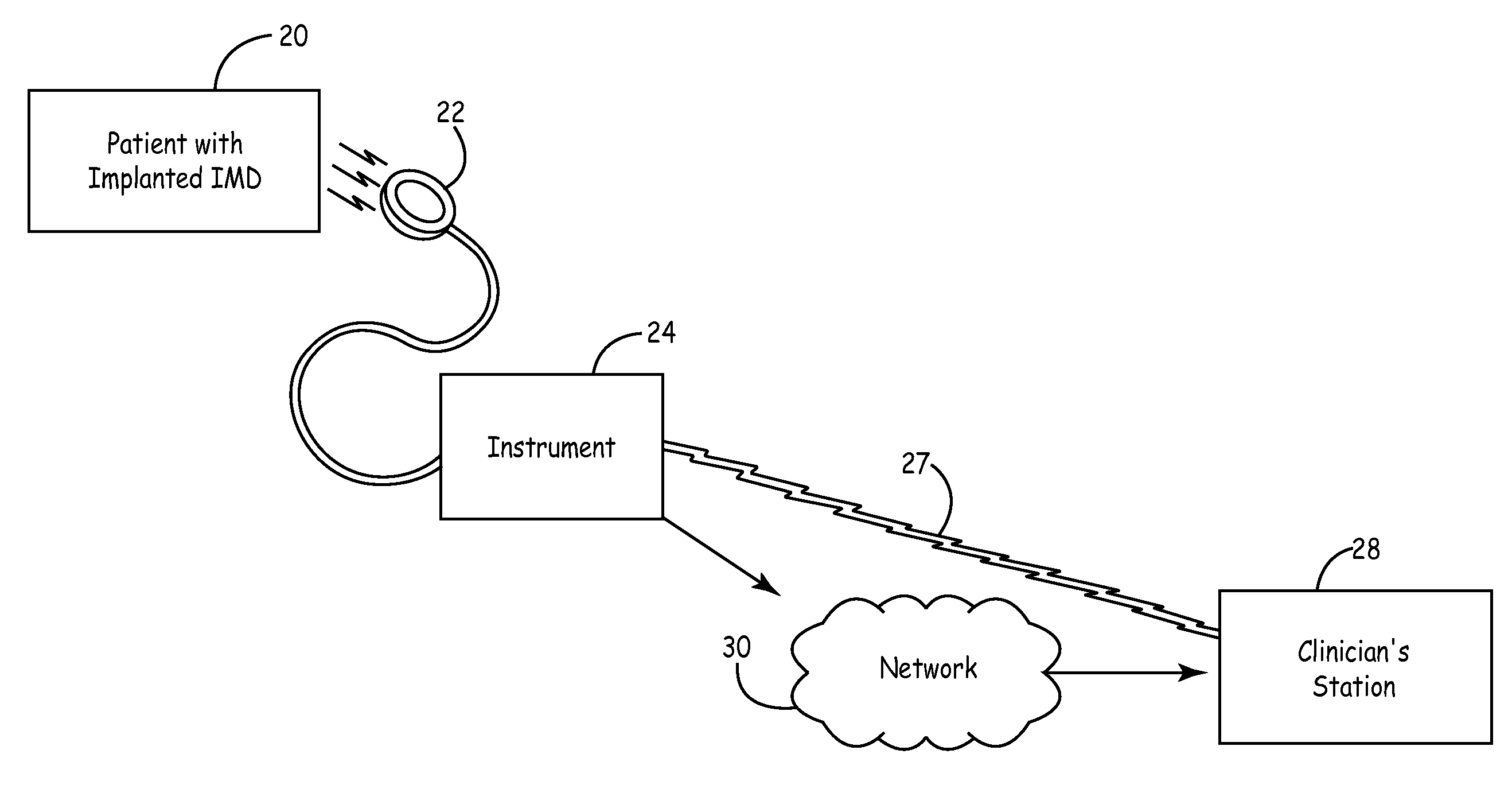

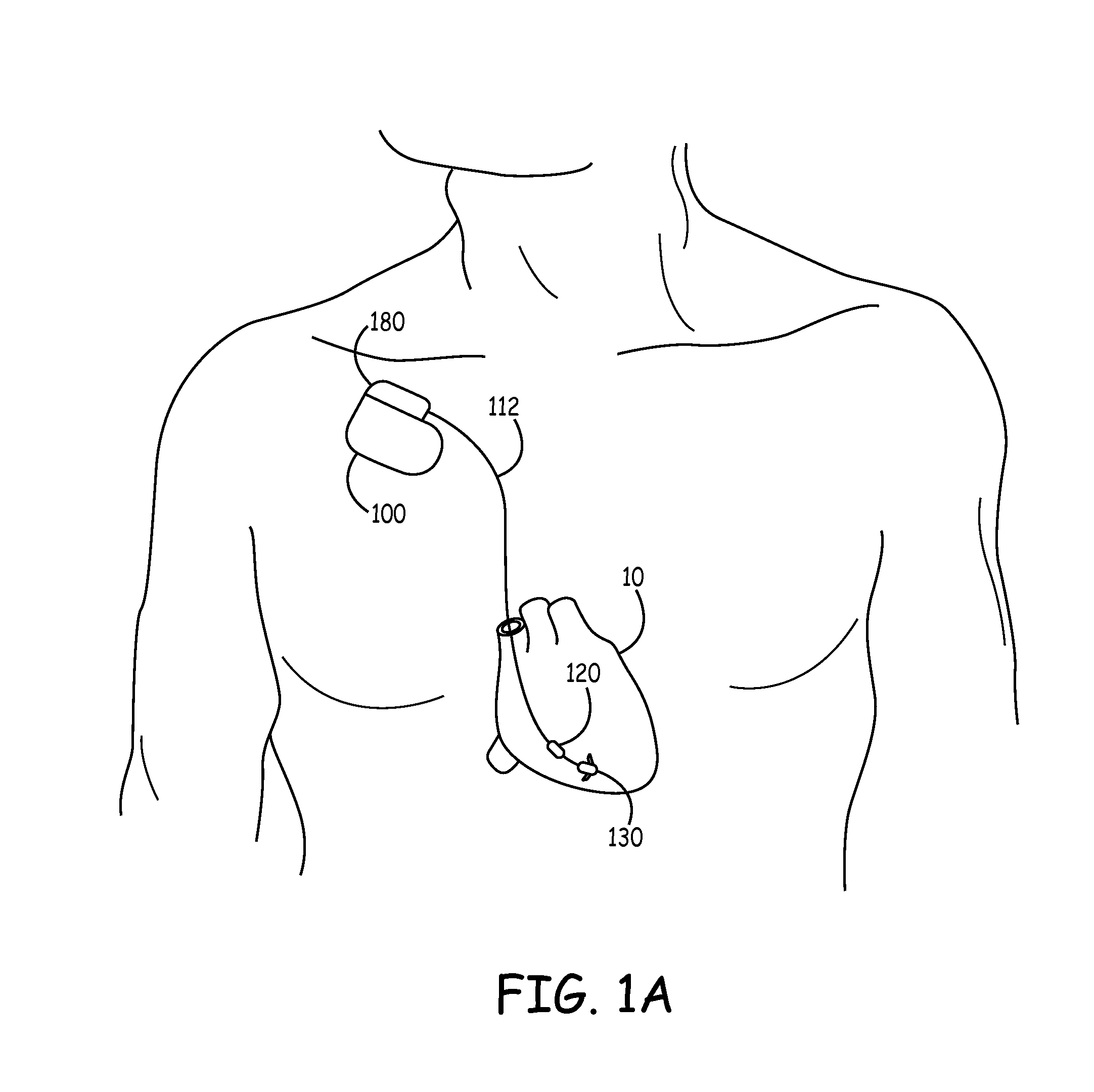

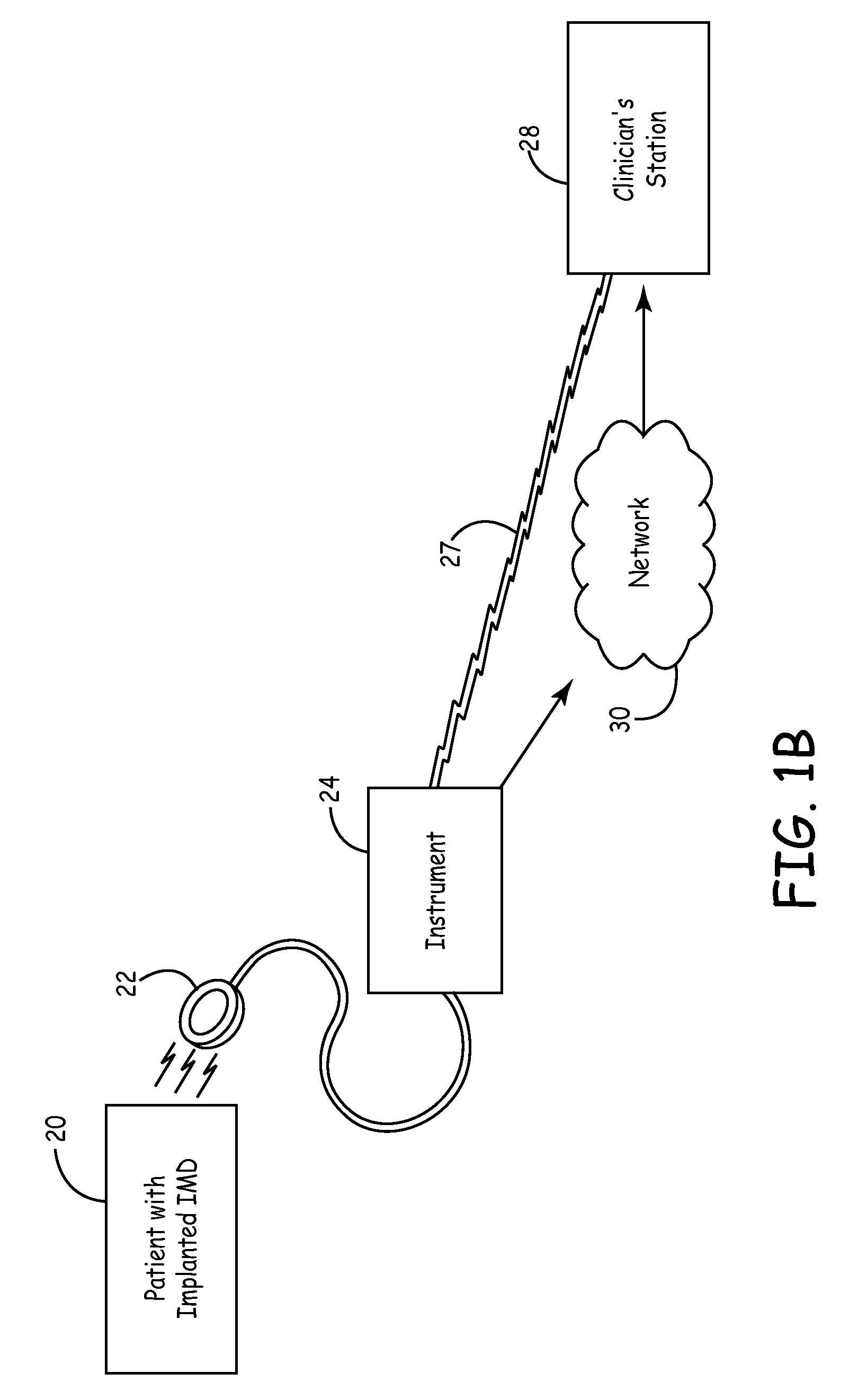

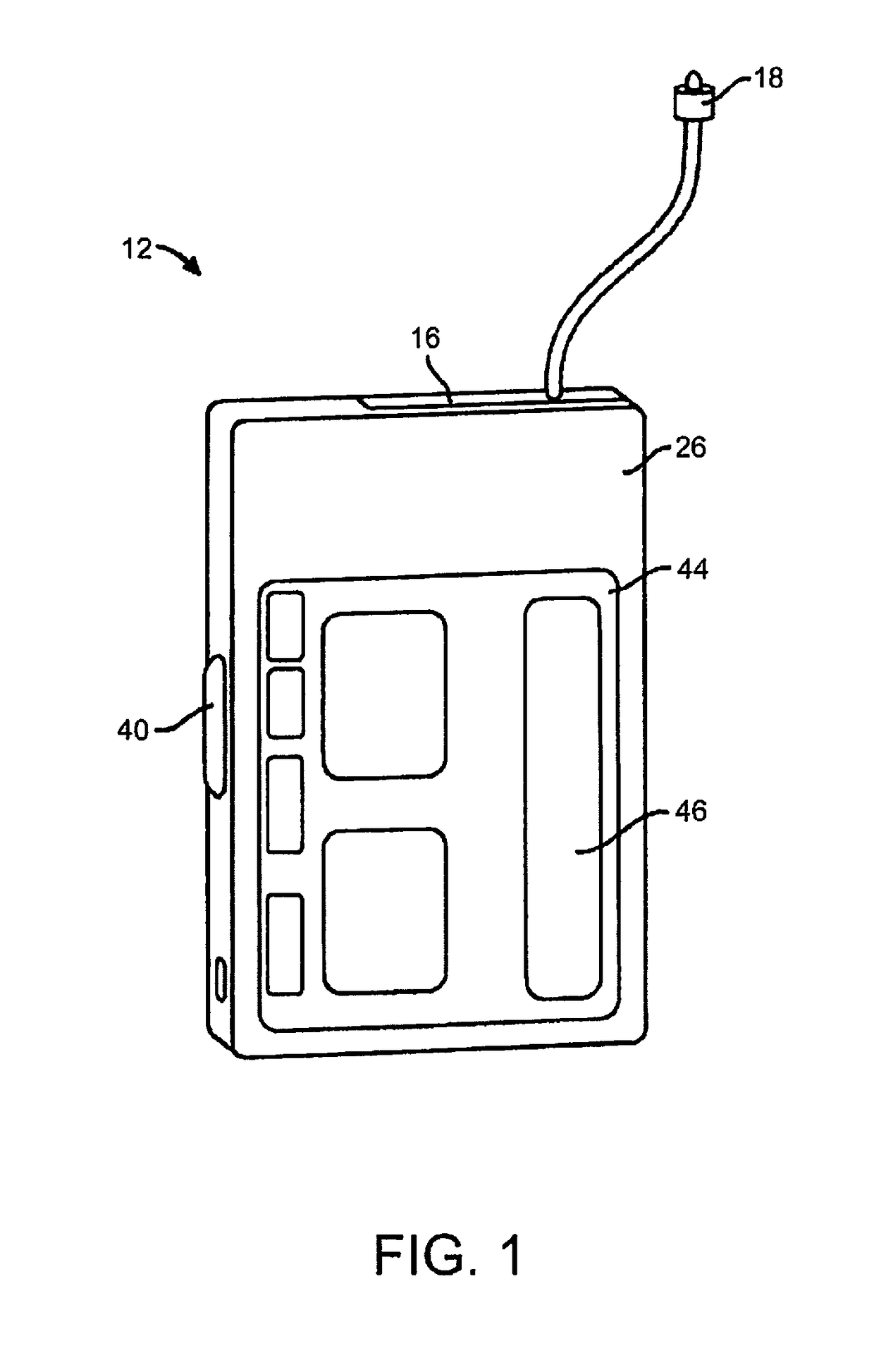

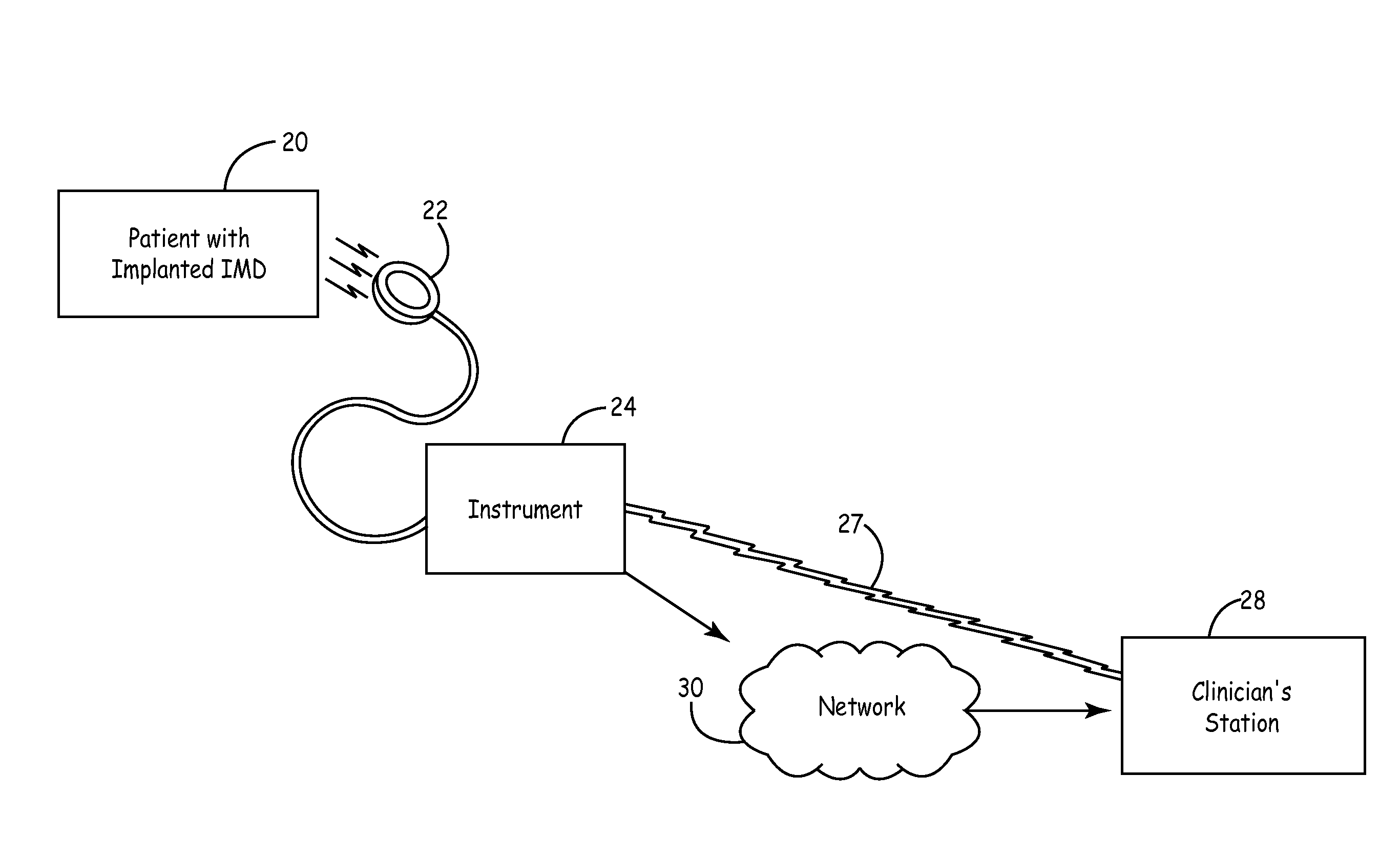

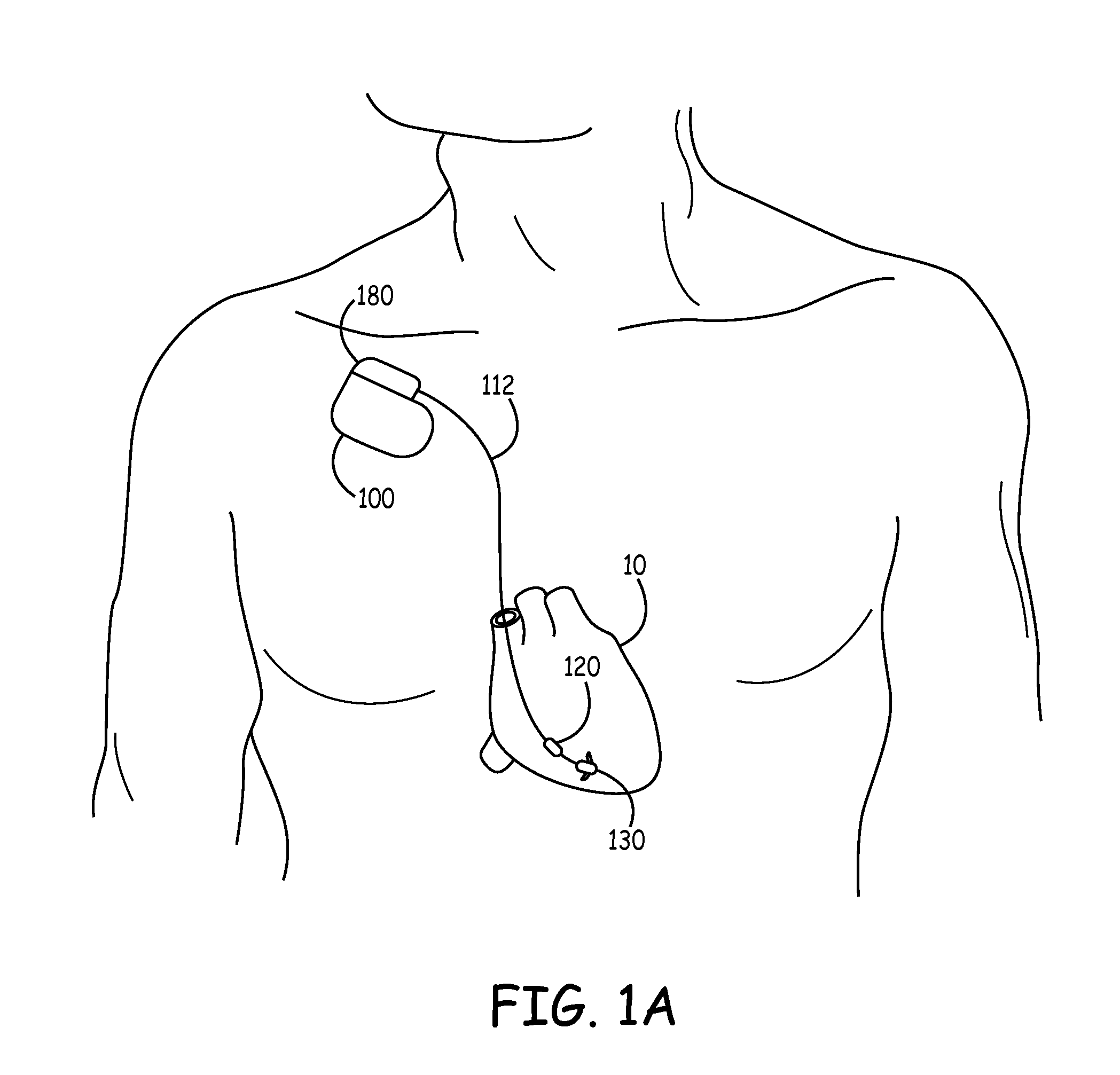

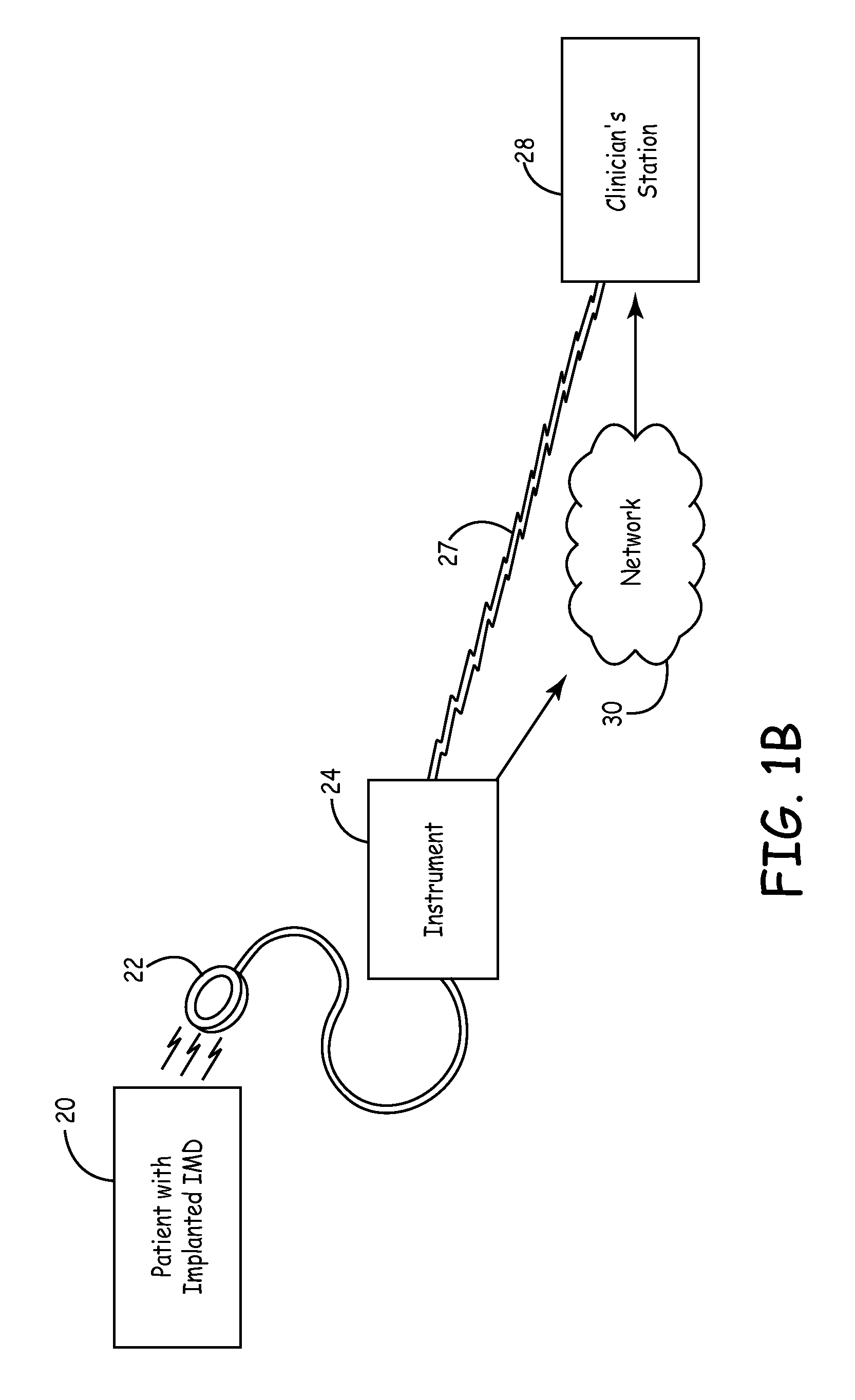

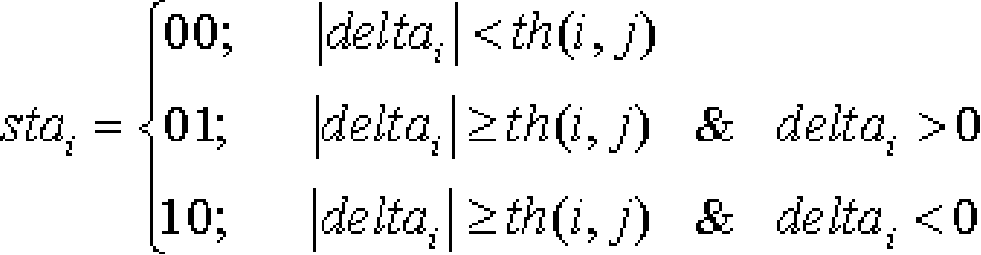

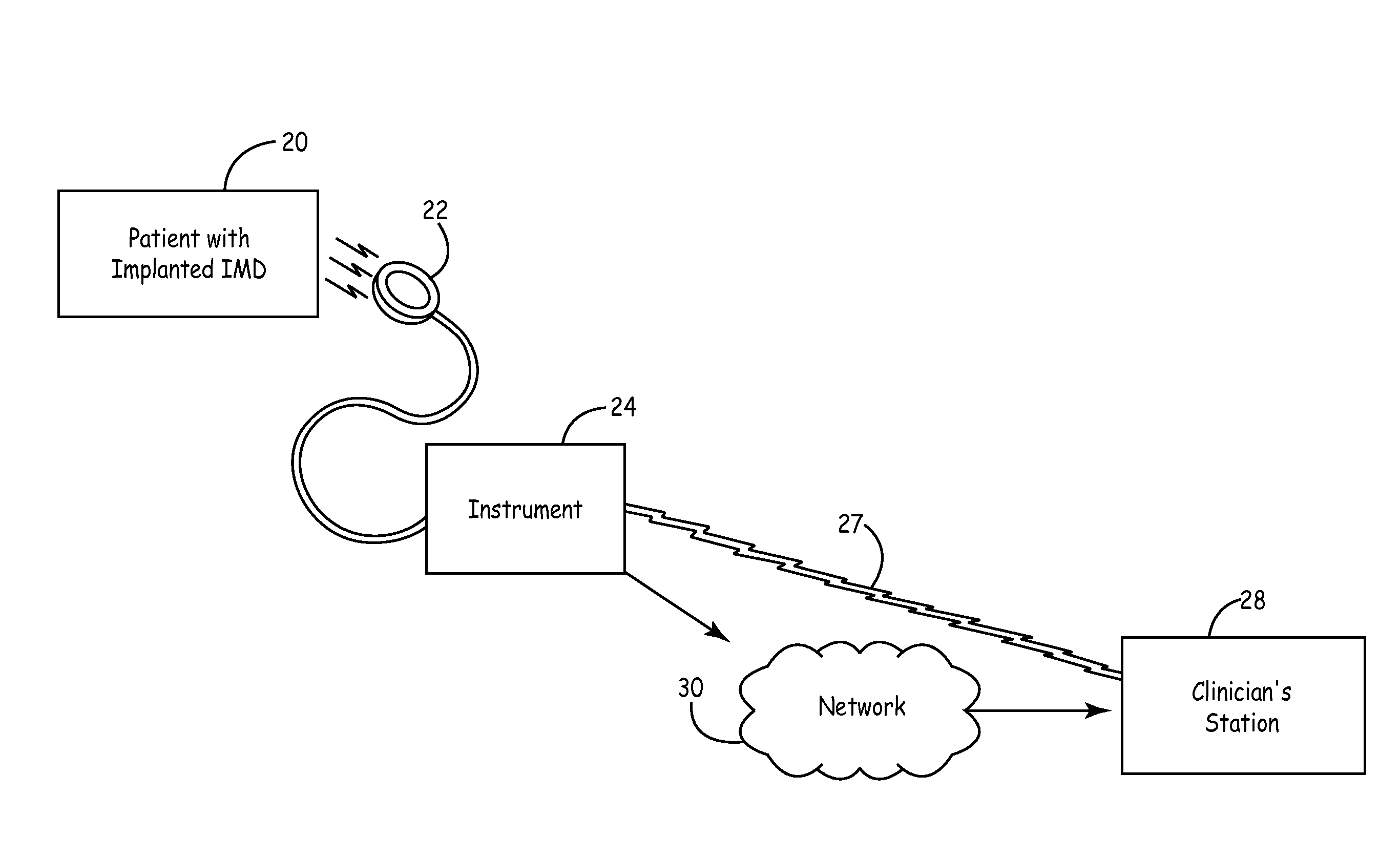

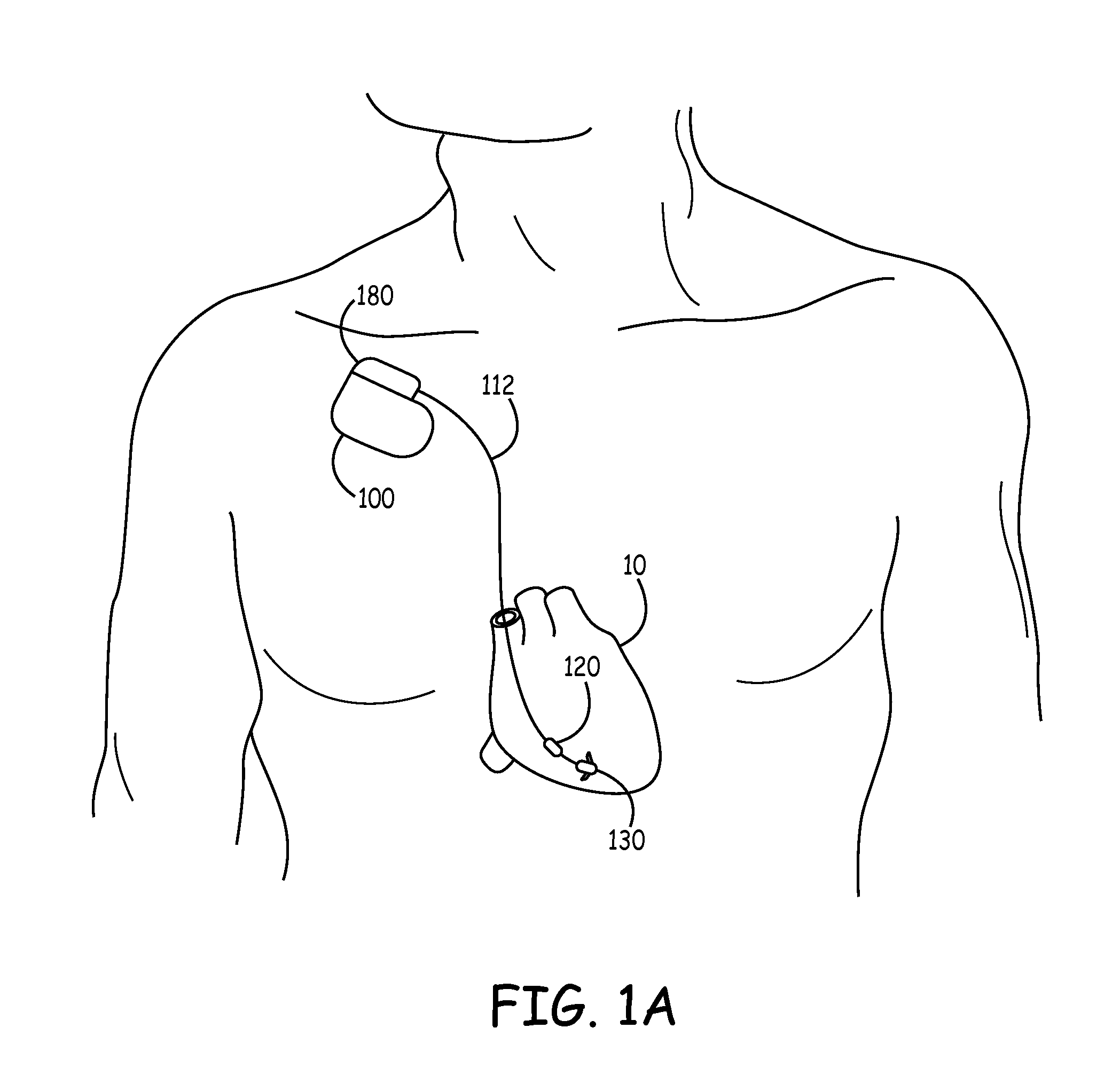

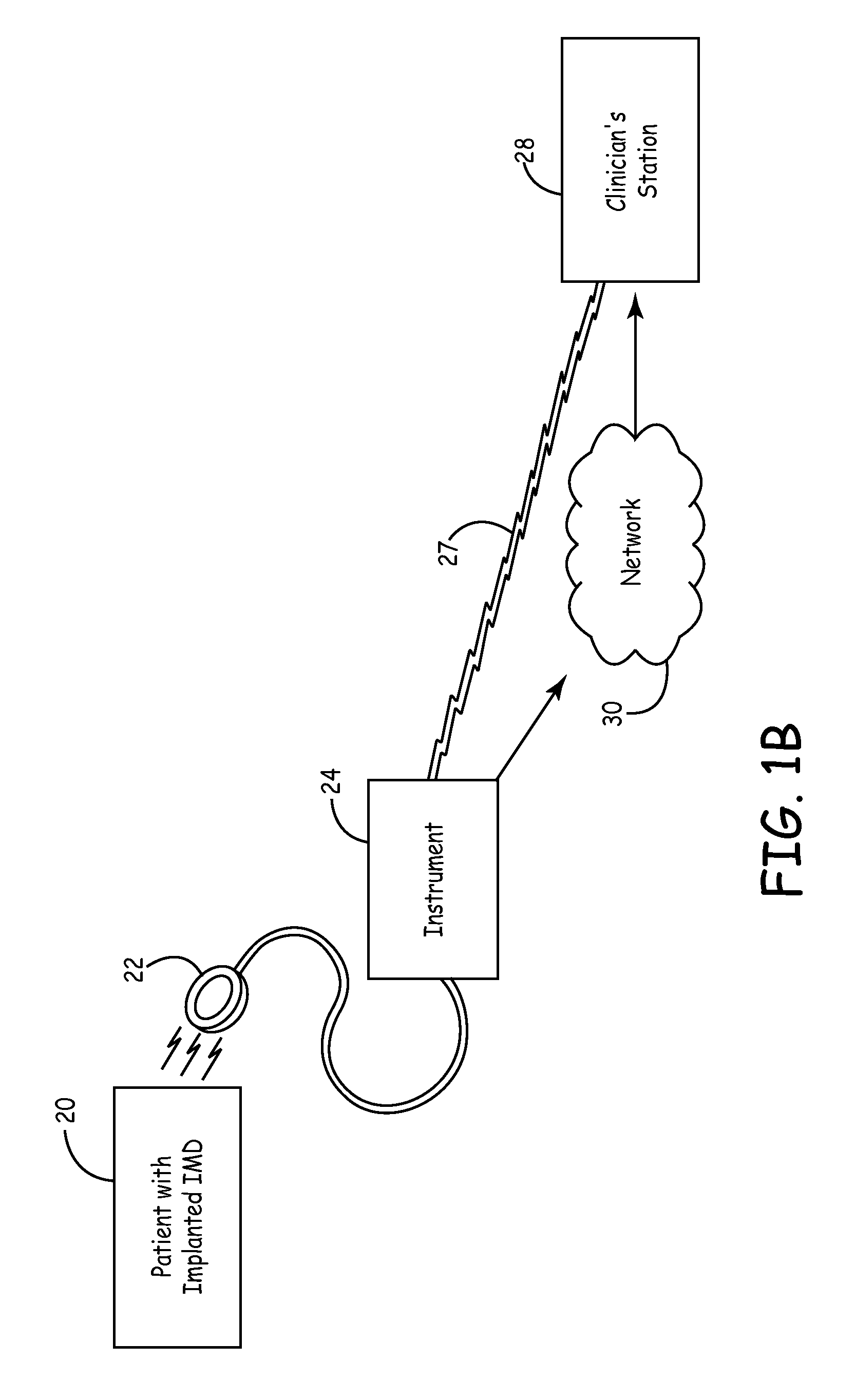

Heart failure monitor quicklook summary for patient management systems

ActiveUS7831301B2Long-term monitoringEmphasize highElectrotherapyCatheterThird partyPatient management

Continuous remote monitoring of patients based on data obtained from an implantable hemodynamic monitor provides an interactive patient management system. Using network systems, patients are remotely monitored to continuously diagnose and treat heart-failure conditions. A screen displayable summary provides continuous feedback and information to physicians, patients and authorized third parties. The quick look summary includes various sites and presentation tailored to match the patients' and physicians' needs. The quick look summary further includes intelligent features that understand and retain the user's interests, preferences and use patterns. Patients, physicians and other caregivers are seamlessly connected to monitor and serve the chronic needs of heart-failure patients in a reliable and economic manner.

Owner:MEDTRONIC INC

Continuous closed-loop power control system including modulation injection in a wireless transceiver power amplifier

InactiveUS7218951B2Eliminate needPower managementResonant long antennasWireless transceiverAudio power amplifier

A single continuous closed-loop power control feedback system provides seamless power control for a power amplifier and also enables an AM signal to be injected into the power amplifier through the power amplifiers' control port. The AM signal is developed by an I / Q modulator and supplied to a comparator located in the power control loop. By using leakage from the power amplifier as feedback to a phase locked loop during initial power amplifier power ramp-up, the single continuous closed-loop power control system provides continuous feedback to the phase locked loop during the entire power amplification ramp-up period and eliminates the need for multiple feedback loops.

Owner:XUESHAN TECH INC

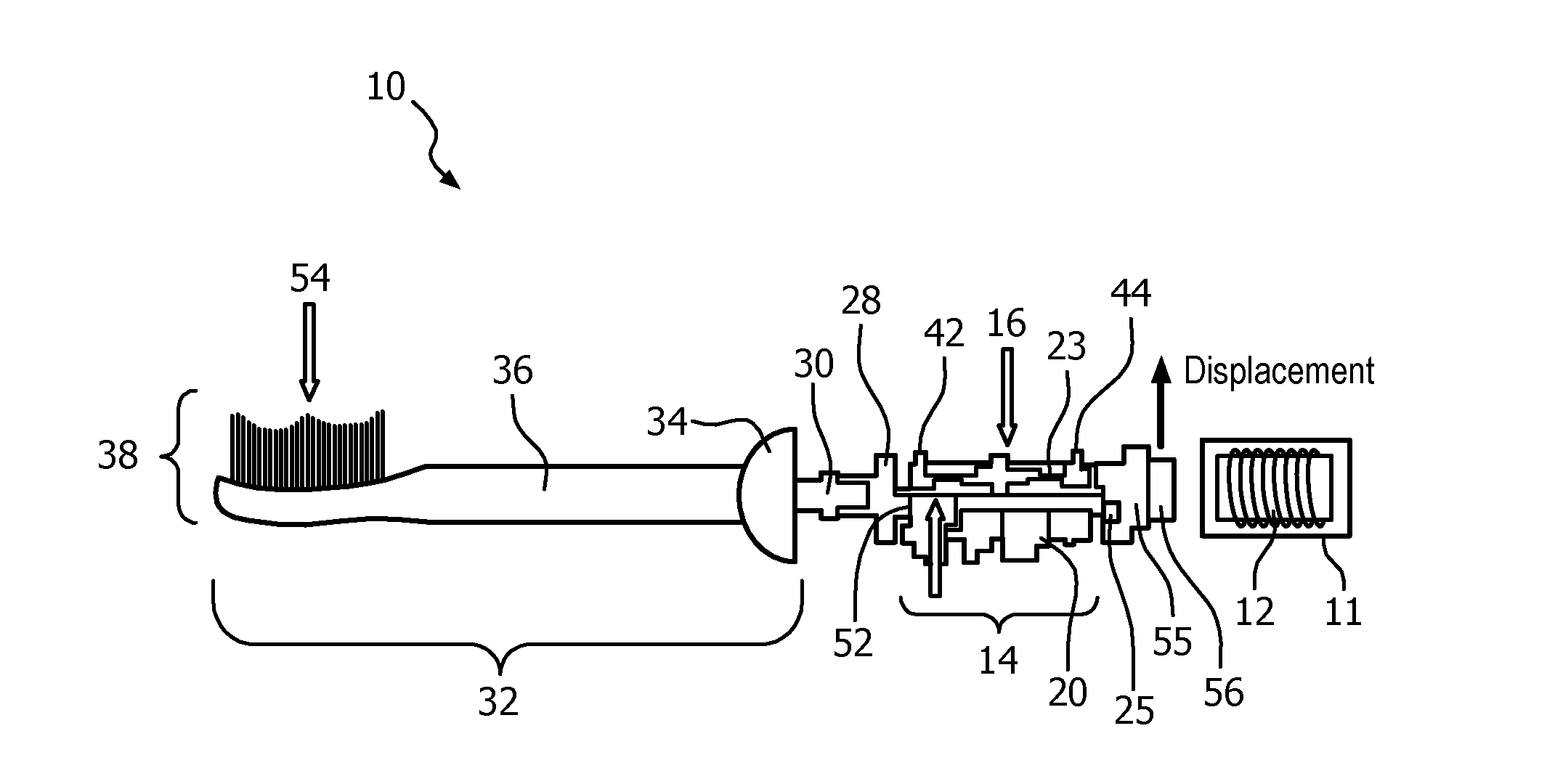

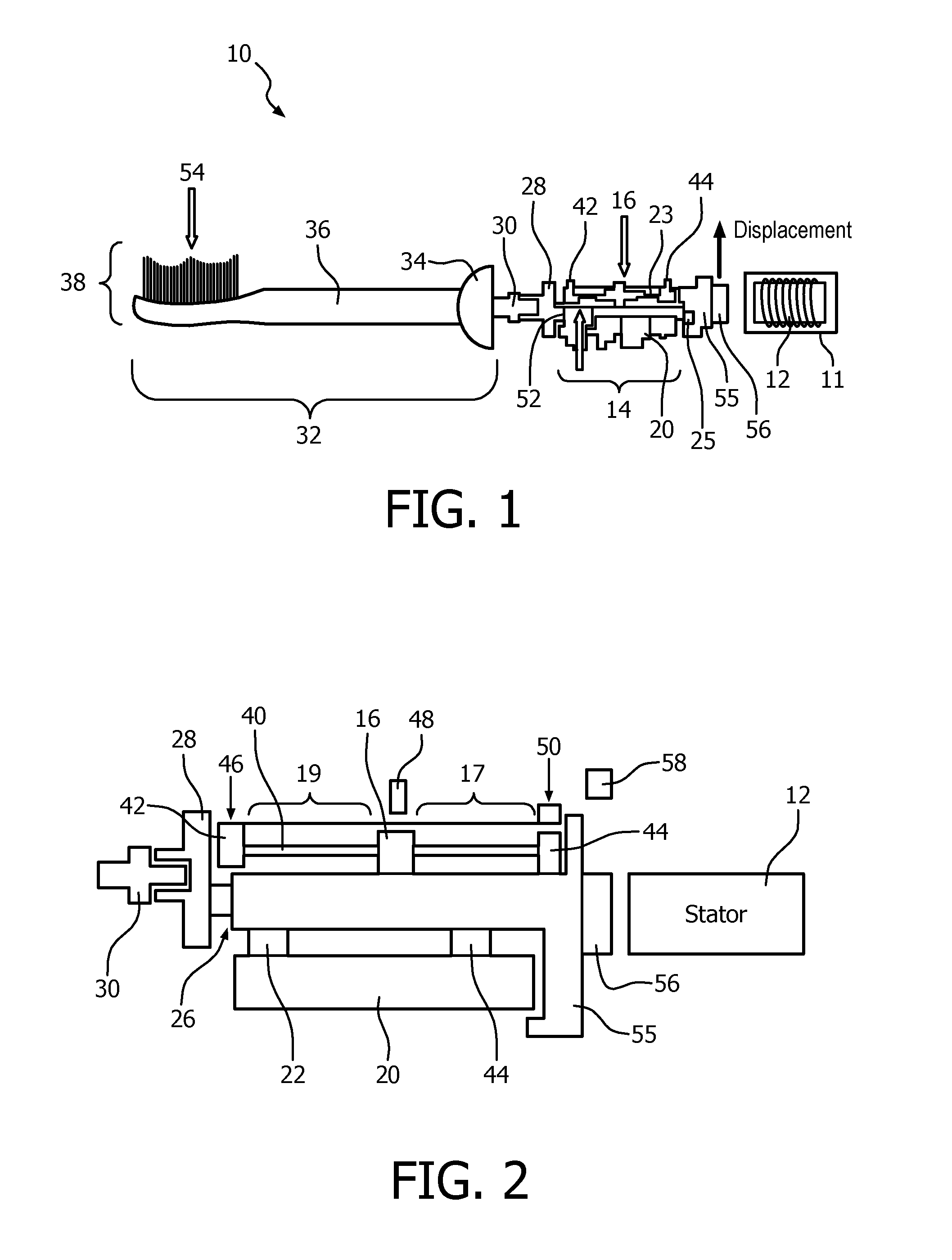

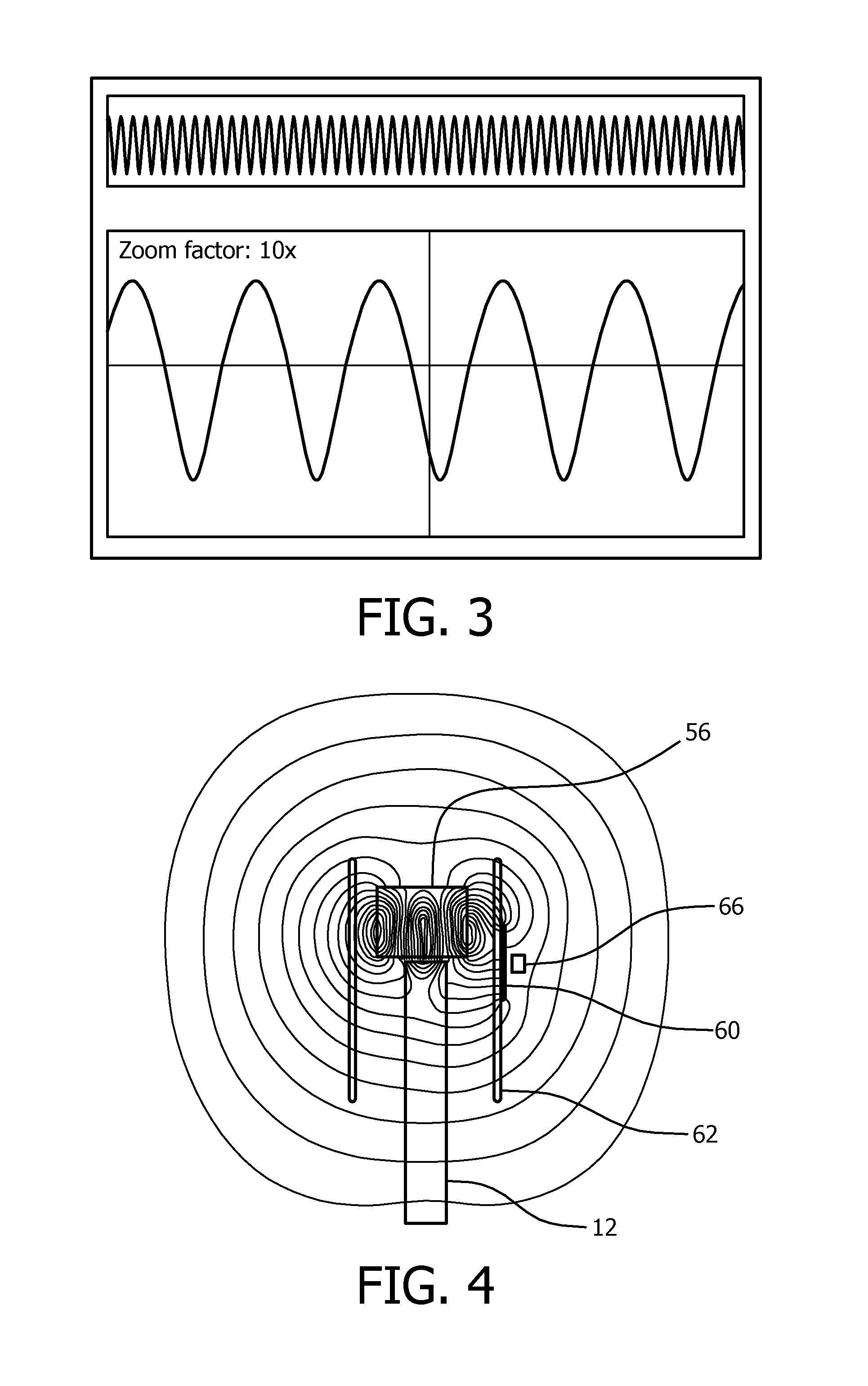

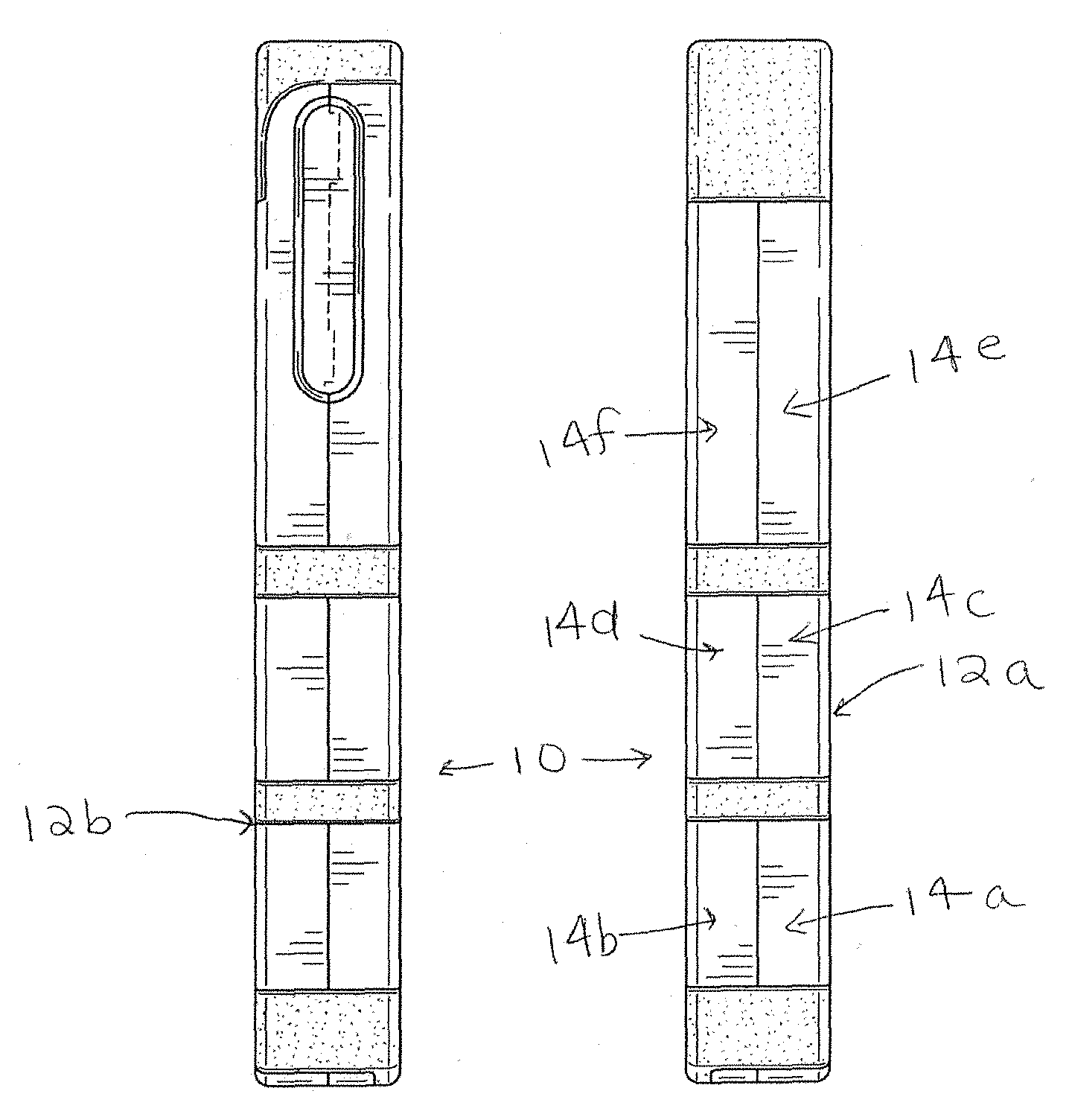

Force sensor providing continuous feedback for a resonant drive toothbrush using a hall sensor

The power toothbrush includes a brushhead arm (36) and a brush element (38) at a distal end thereof. A V-spring assembly (14) converts the movement of a power drive assembly in a back-and-forth movement. A mounting member (55) at the rear end of the V-spring assembly provides a base for a magnet (56). The back end of the V-spring assembly is displaced in accordance with pressure applied to the brush member. A Hall effect sensor (58) is mounted within the changing magnetic field produced by the magnet as the rear end of the V-spring assembly is displaced due to pressure on the brushhead. A processor (65) is responsive to the output from the Hall sensor and provides an indication when the pressure exceeds a threshold value.

Owner:KONINKLJIJKE PHILIPS NV

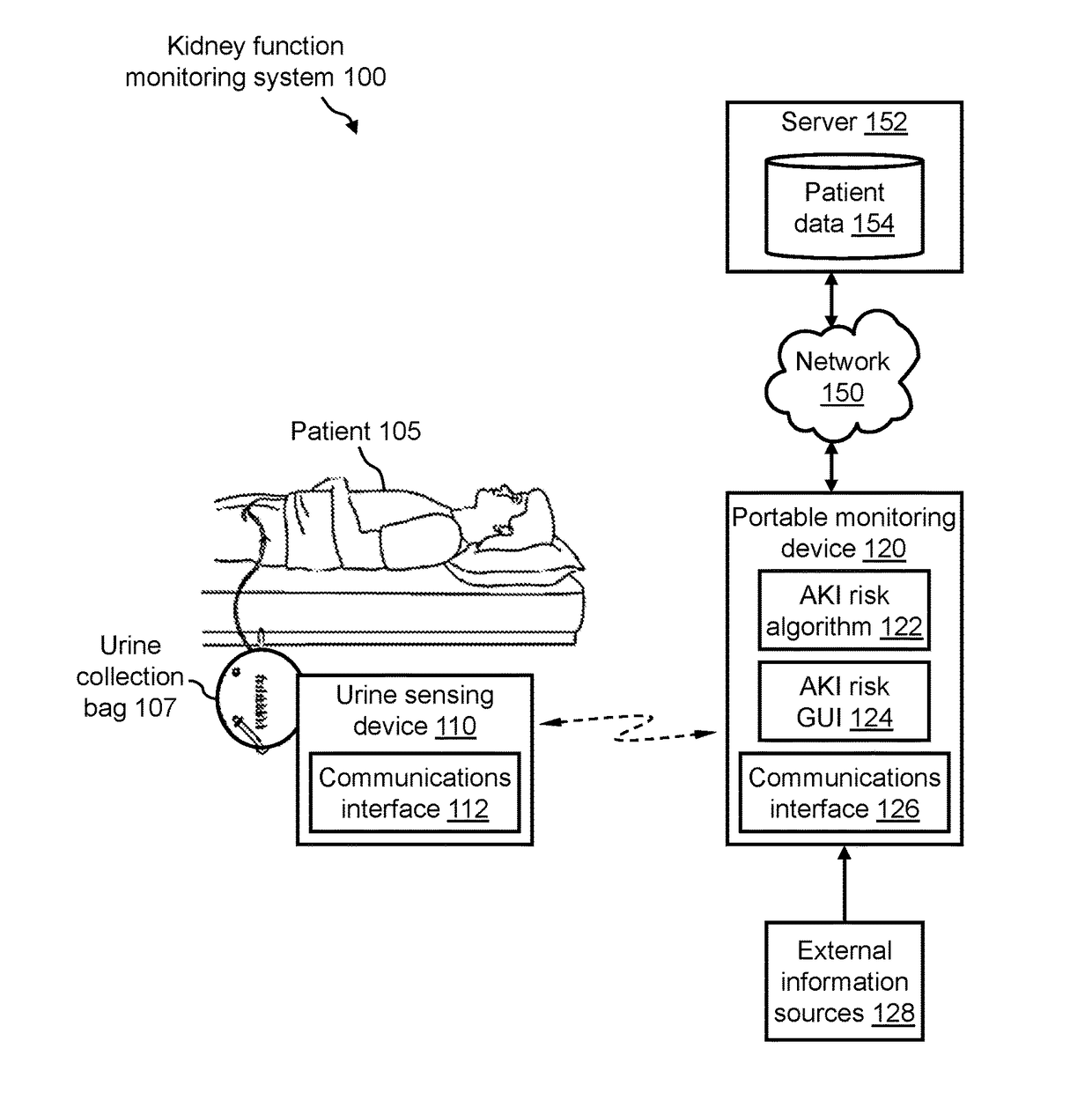

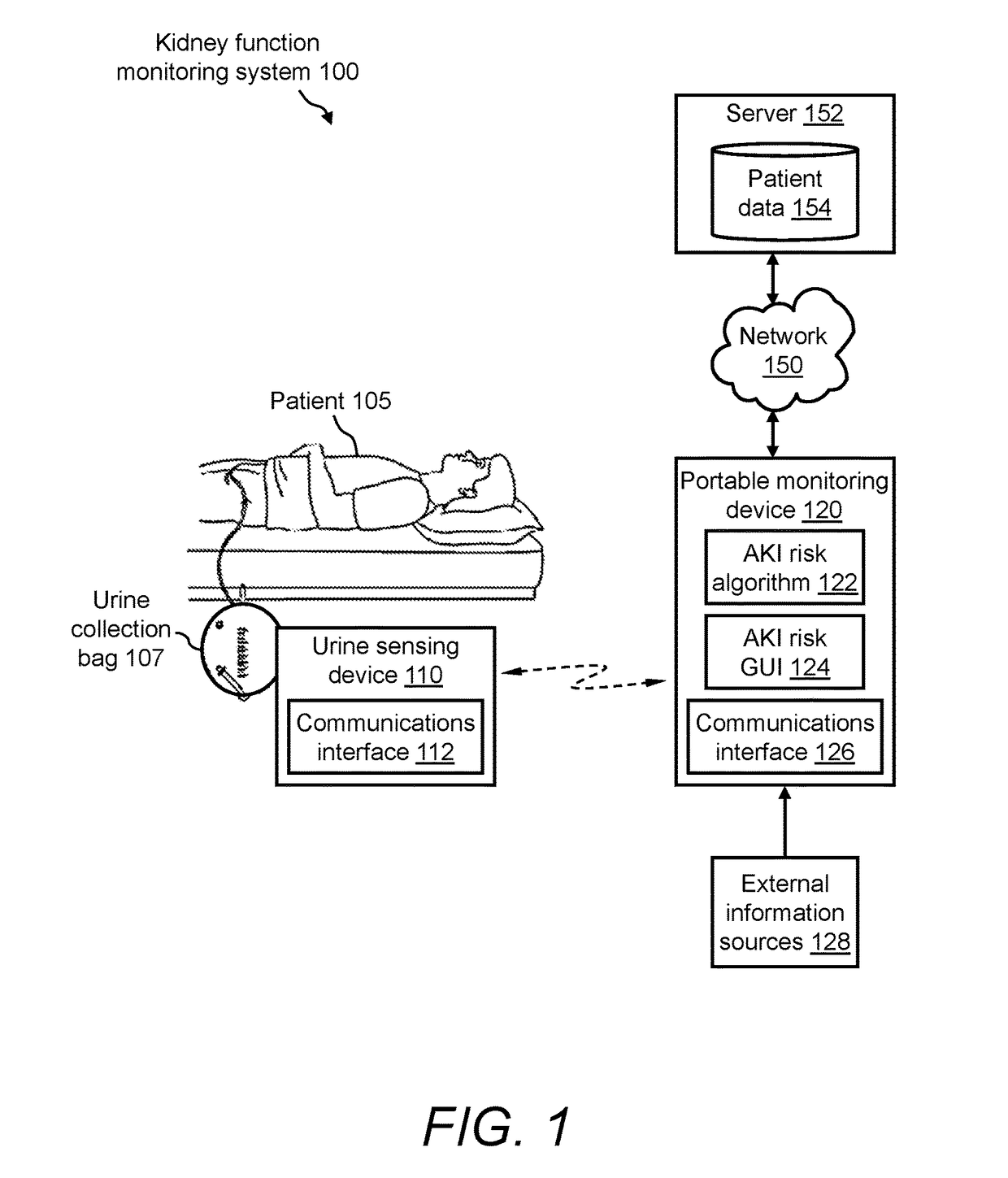

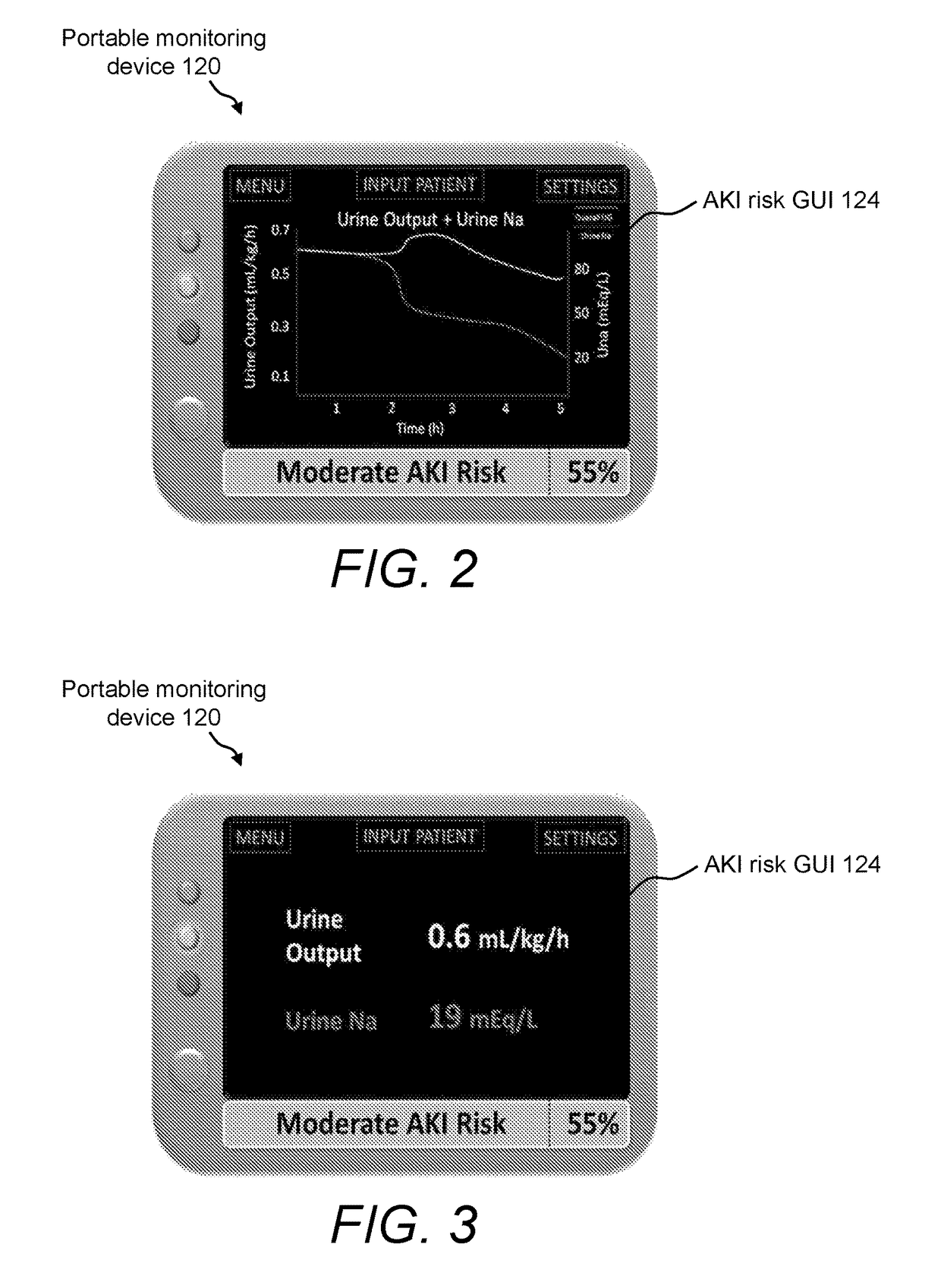

System and urine sensing devices for and method of monitoring kidney function

A system and urine sensing devices for and method of monitoring kidney function is disclosed, wherein acute kidney injury (AKI). Namely, a kidney function monitoring system provides a portable urine monitor system that can provide real-time and continuous feedback about urine output and / or level of at least one urinary component (e.g., sodium). The kidney function monitoring system further comprises at least one urine sensing device, wherein the urine sensing device comprises a digital weight scale, a stand onto which a urine collection vessel can be positioned, and an interface between the digital weight scale and the stand that transfers the force of the stand and contents of the urine collection vessel to the digital weight scale. Further, the portable monitoring device comprises an adaptive and modular self-learning algorithm for the real-time assessment of AKI risk.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

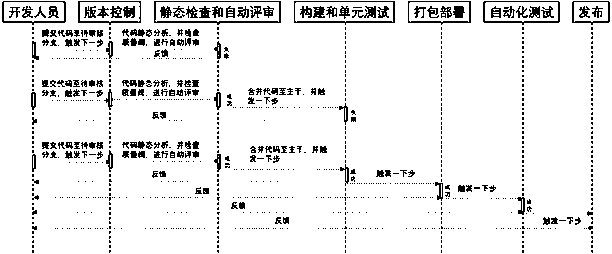

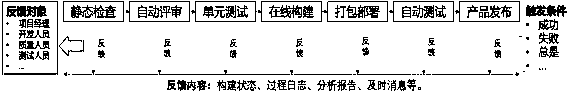

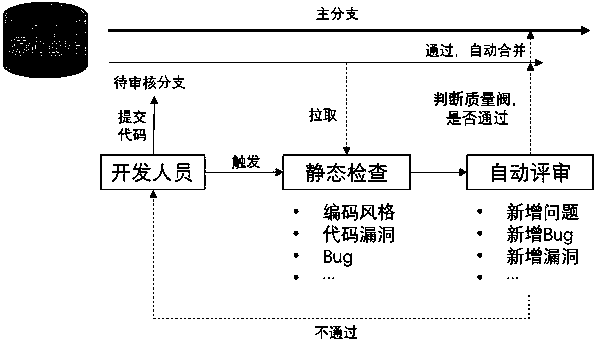

An automatic software system quality inspection and rapid iteration method

InactiveCN109684215AImplement QAFast iterationSoftware testing/debuggingSoftware systemContinuous feedback

The invention discloses an automatic software system quality inspection and rapid iteration method which comprises the following steps: firstly, a developer submits a code to a branch to be audited, and when a monitoring server detects that the branch has code change, a static analysis task is triggered to carry out code automatic review; After the code passes the review, the automatic branches are merged to the trunk and unit testing and online compiling tasks are triggered; When the unit test and the online compiling have no problem, packaging and deploying are carried out, and meanwhile anautomatic system software test is started; And finally, the tested software product is published. According to the method, the automation level of software research and development is improved; The complexity of manual review is reduced; An automatic test framework of multiple languages is established, the manual participation cost is reduced, and manpower resources are saved; A continuous feedback mechanism of each stage of software system research and development is established, problems occur, feedback is conducted in time, and engineering software quality control is achieved.

Owner:中国科学院电子学研究所苏州研究院

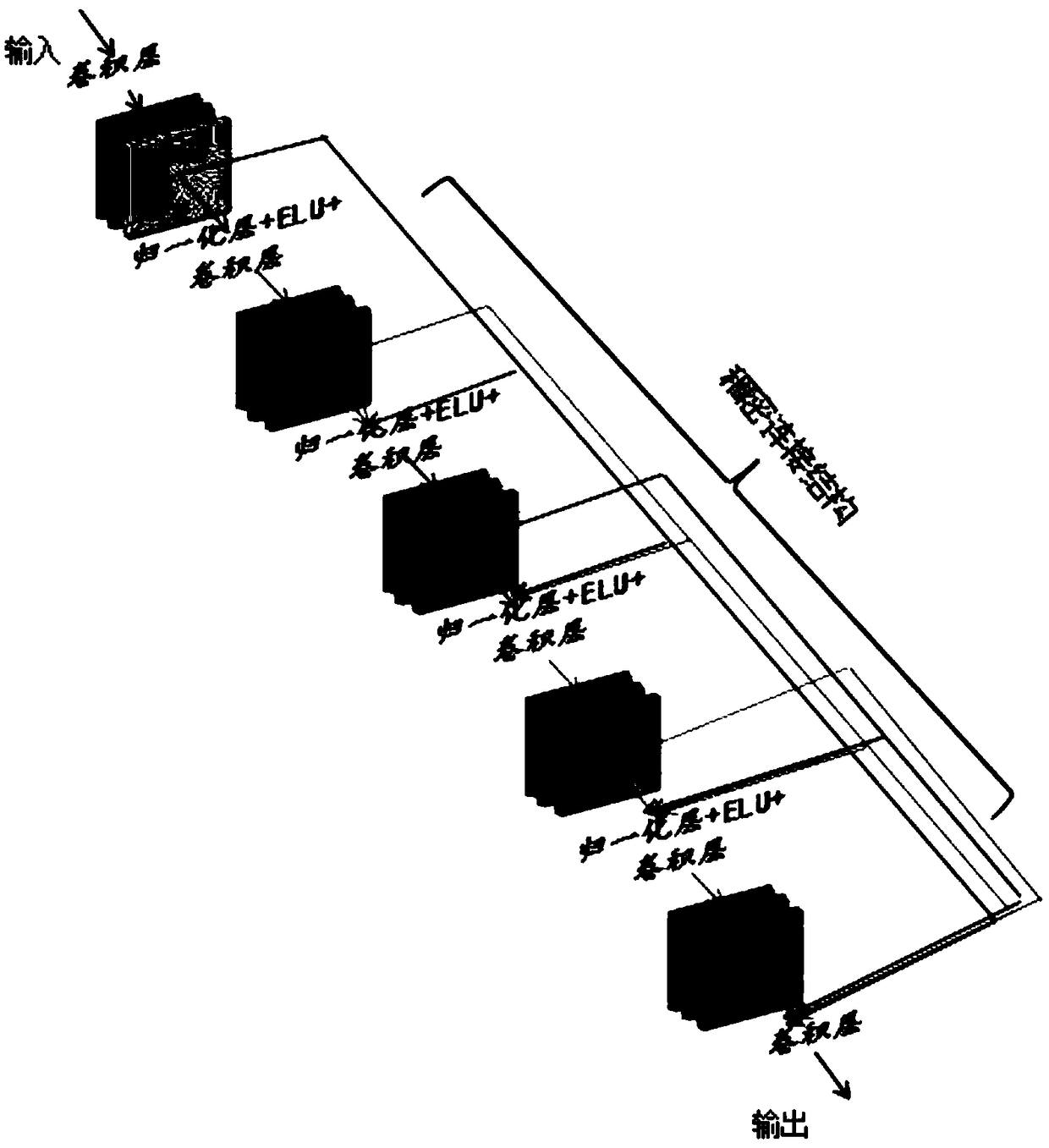

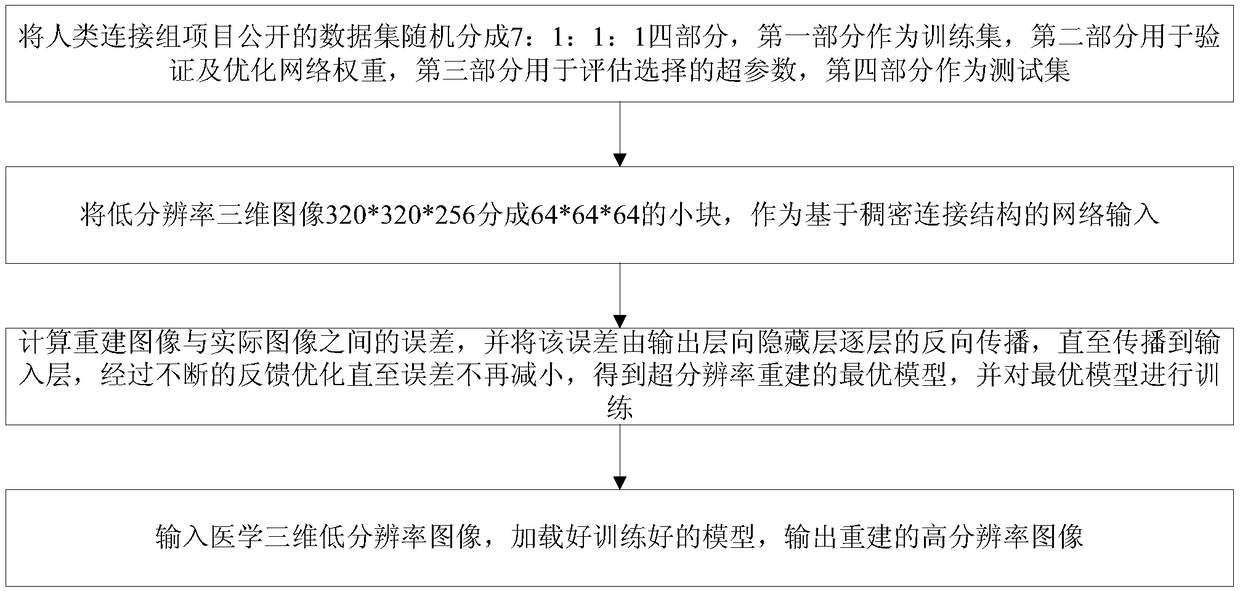

3D medical image super-resolution reconstruction method based based on dense convolution neural network

PendingCN109360152ALose weightBackpropagation worksGeometric image transformationImage generationHidden layerData set

The invention discloses a 3D medical image super-resolution reconstruction method based on a dense convolution neural network, which includes: randomly dividing the data set disclosed by human connection group project into four parts, wherein the first part is used as training set, the second part is used for verifying and optimizing network weight, the third part is used for evaluating selected super-parameters, and the fourth part is used as test set; dividing a low-resolution three-dimensional image 320*320*256 into small blocks of 64*64*64 as network input based on a dense connection structure; The error between the reconstructed image and the actual image is calculated, and the error is propagated backward from the output layer to the hidden layer until it is propagated to the input layer. After continuous feedback optimization until the error is no longer reduced, the optimal model of super-resolution reconstruction is obtained, and the optimal model is trained. The medical three-dimensional low-resolution image is input, the trained model is loaded, and the reconstructed high-resolution image is output.

Owner:TIANJIN UNIV

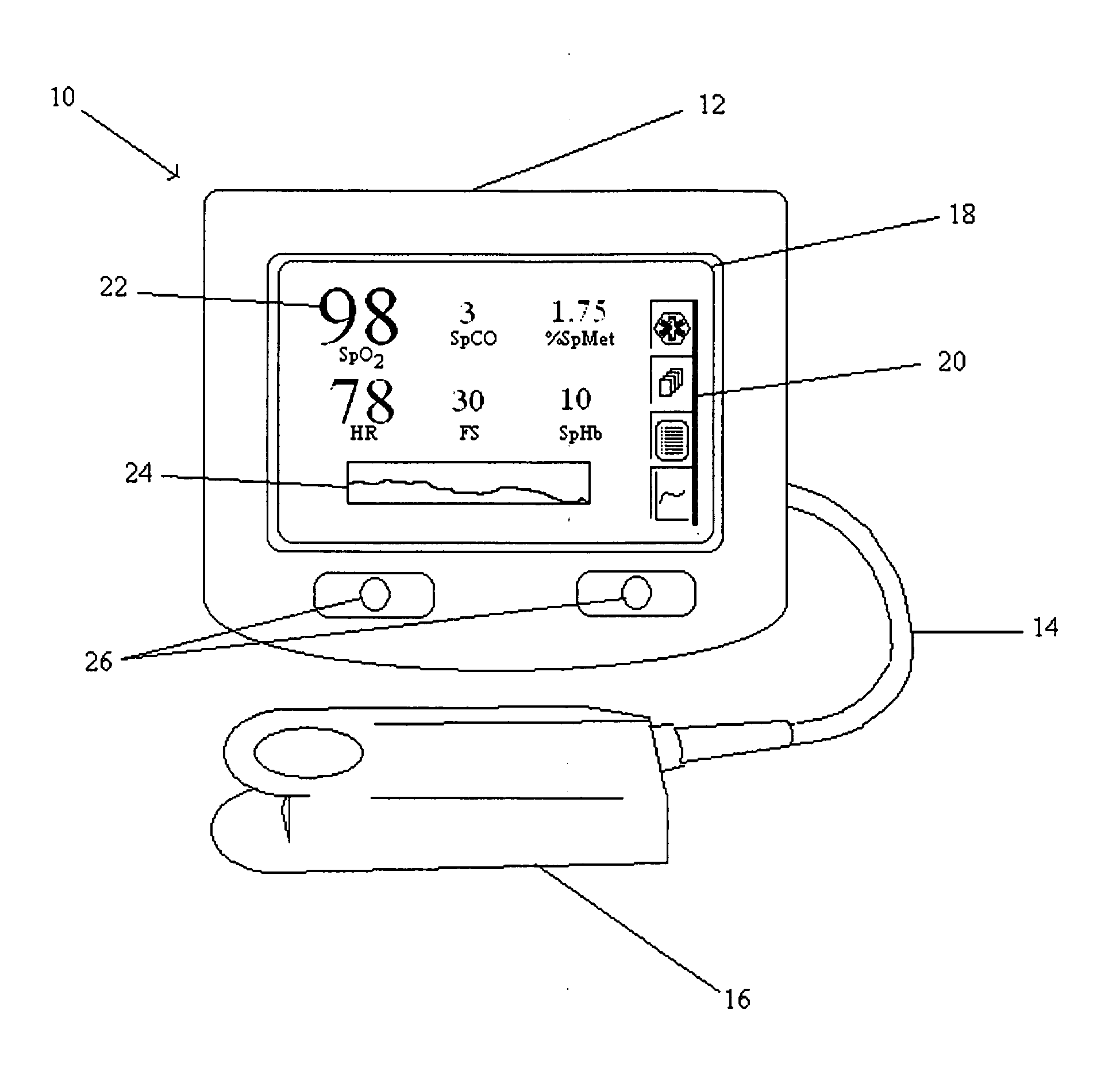

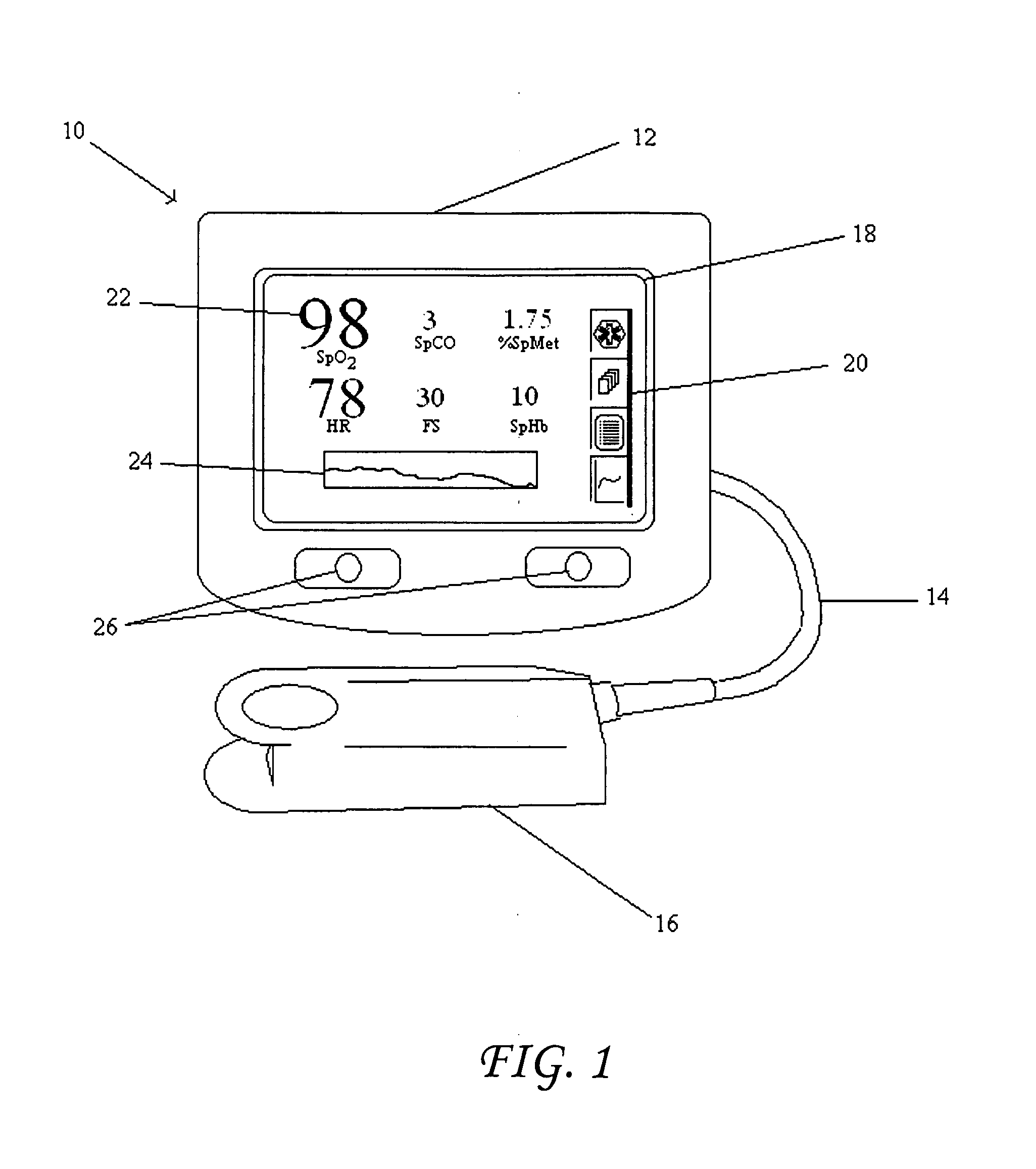

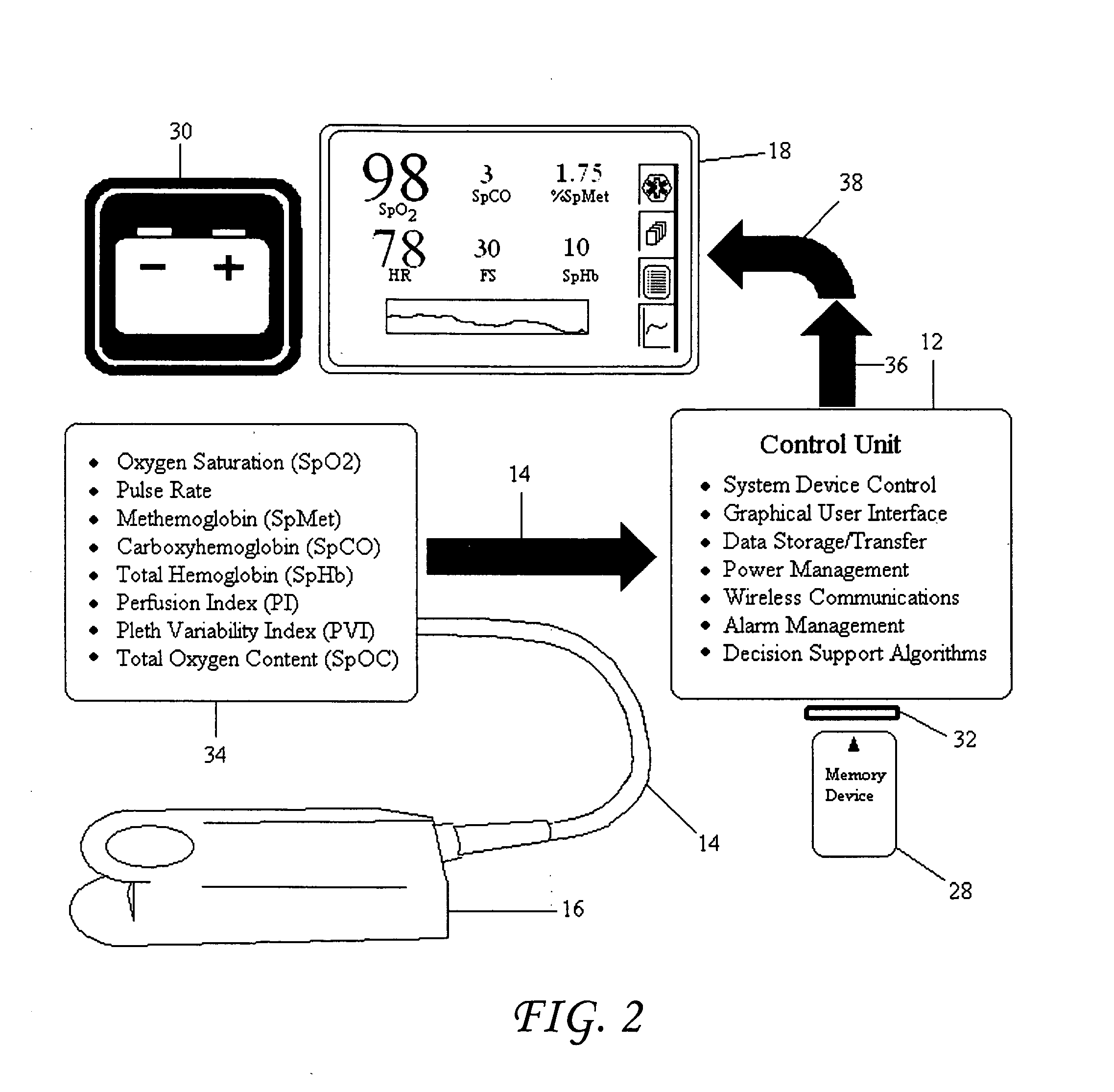

Decision support method for casualty treatment using vital sign combinations

InactiveUS20110201905A1Continuous monitoringConfirm and improve uponDiagnostic recording/measuringSensorsTreatment demandWhole blood product

A device and control software and system capable of accepting patient vital sign readings from an oximeter and applying a predetermined decision algorithm that incorporates unique combinations of vital signs and will allow the care giver to continuously monitor and have continuous feedback regarding certain patient vital functions, body trauma status, and immediate treatment needs, such as the patient's likelihood of the onset of shock and the advisability of introducing blood or blood products to the patient.

Owner:OFFICE OF THE GOVERNOR

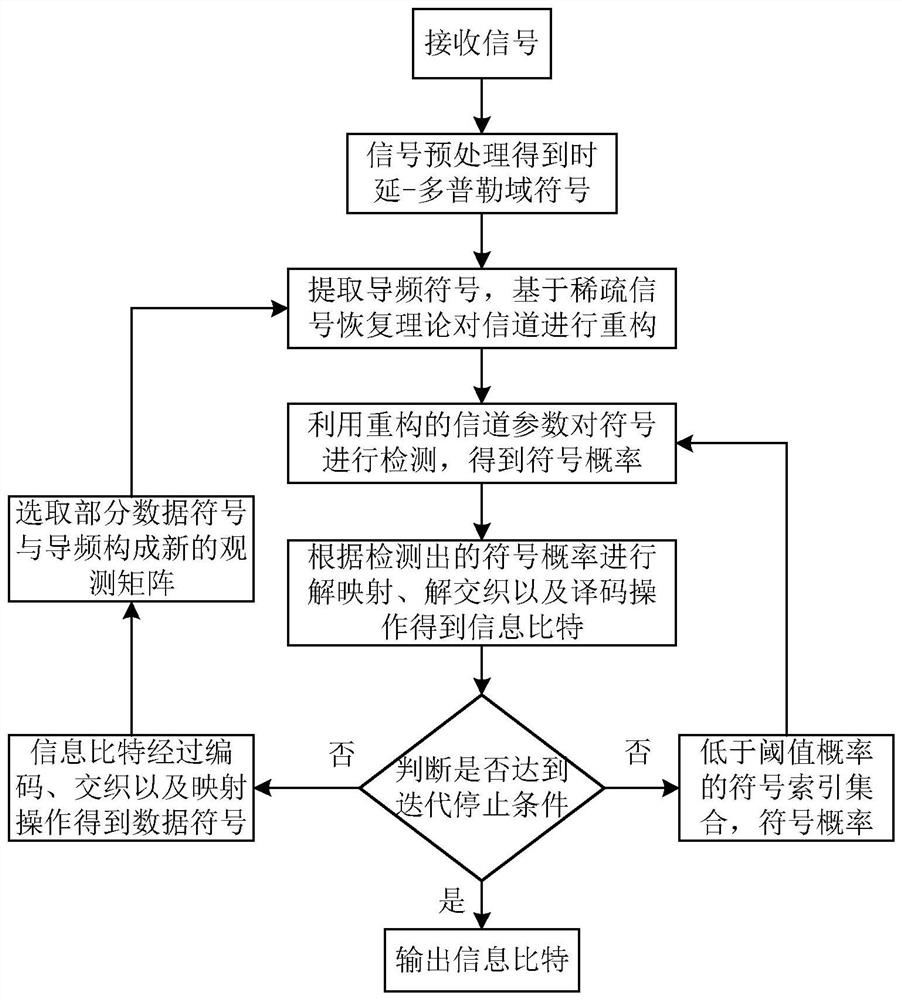

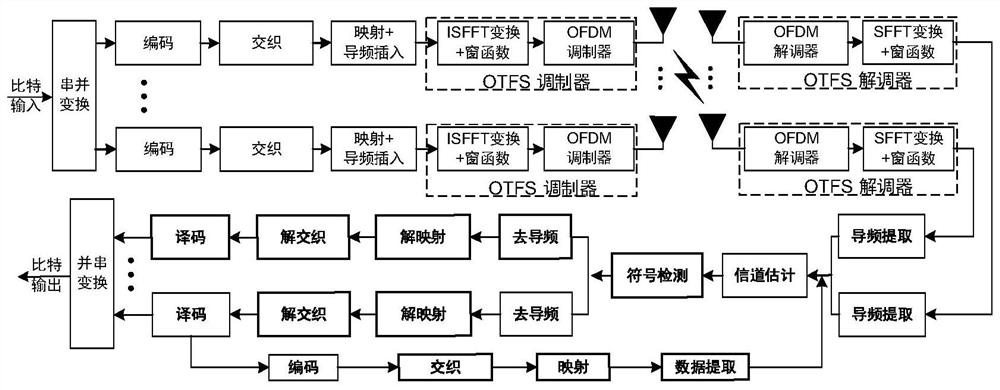

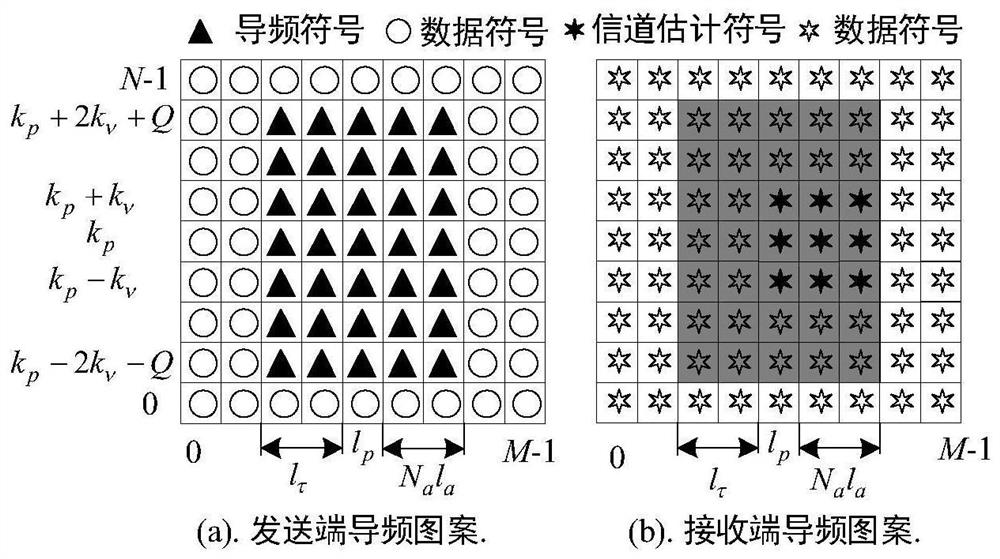

Channel estimation and symbol detection method based on orthogonal time-frequency-space joint

ActiveCN113395221AImprove performanceChannel estimationHigh level techniquesMulti inputChannel parameter

The invention discloses a channel estimation and symbol detection method based on orthogonal time-frequency-space joint, and the method comprises the following steps: 1, pilot symbol placement: building a mathematical model according to the relation between the input and output of an MIMO-OTFS system, and converting a channel estimation problem into a sparse signal reconstruction problem through the analysis of the mathematical model; 2, channel estimation: at a receiving end, pre-processing the signal to obtain a time delay-Doppler domain symbol; 3, symbol detection: at a receiving end, performing symbol detection according to the channel parameters obtained in the channel estimation step; 4, iterative feedback. The method has the advantages that the joint channel estimation and symbol detection method under the multi-input multi-output orthogonal time-frequency-space system is provided on the basis of the idea of iterative joint, the system performance can be improved through continuous feedback iteration, the symbol index set with the probability lower than the threshold value is detected again, and combined iterative detection of signal detection and channel estimation is formed to improve the system performance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

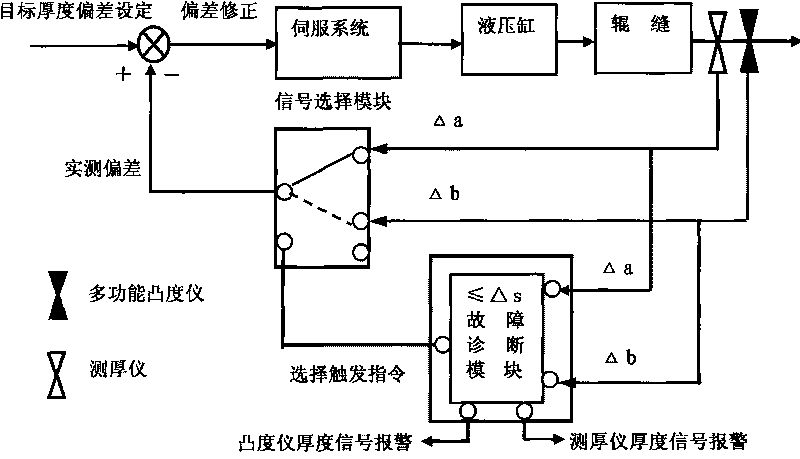

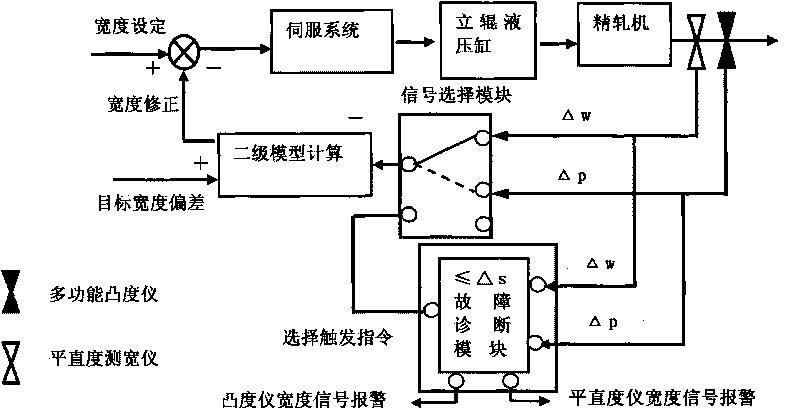

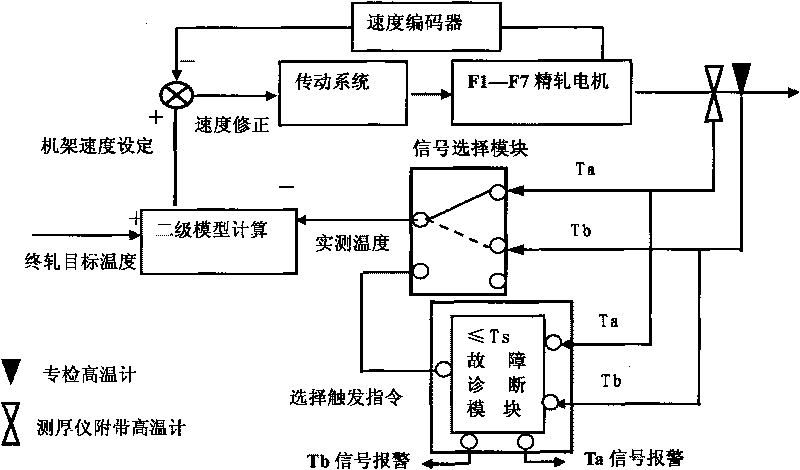

Method for realizing continuous feedback control by duality of hot finishing outlet instruments

InactiveCN101693257ATo meet the full load fast-paced high-quality rolling requirementsThe quantity configuration is reasonable and not complicatedTemperature control deviceMetal rolling stand detailsProduction lineAssurance quality

The invention discloses a method for realizing continuous feedback control by duality of hot finishing outlet instruments, which particularly includes steps that instruments used for detecting production target parameters are integrated into a hot continuous rolling production line, wherein each production target parameter is detected by at least two instruments simultaneously and utilizes identical data output modes to output, a parameter detected by one instrument of each production target parameter is utilized as a measured signal while a signal detected by the other instrument of each production target parameter is utilized as a redundant signal, the measured signal and the redundant signal are transmitted to a control system to form functions of redundantly outputting finished product key quality target detection data, mutually diagnosing the redundant signal basically and automatically and fast switching, thereby realizing closed loop control of instrument detected information continuous participating feedback, effectively guaranteeing four basic quality indexes of finished steel strips, and increasing operating rate of a rolling mill. The method plays a strong guarantee for increasing yield, guaranteeing quality and reducing waste steel rate and safety accident rate.

Owner:TANGSHAN GUOFENG IRON & STEEL

System and method for gathering and analyzing biometric user feedback for use in social media and advertising applications

ActiveUS9569986B2Add emotional intelligenceEfficient recommendationData processing applicationsDiagnostic recording/measuringSocial mediaCloud base

A system and method for measuring biologically and behaviorally based responses to social media, locations, or experiences and providing instant and continuous feedback in response thereto. The system and method of the invention is capable of monitoring stress levels and well-being and may be implemented using a cloud-based infrastructure for remote monitoring.

Owner:NIELSEN CONSUMER LLC

System and method for mitigating risk in automated medicament dosing

ActiveUS9867937B2Reduce riskPrevent fallingMedical data miningDrug and medicationsContinuous feedbackGlucose polymers

A portable infusion pump can communicate with glucose monitor, such as a continuous glucose monitor (CGM), to receive continuous feedback relating to a user's blood glucose level during insulin or other medicament therapy and can automatically deliver insulin to a user when the CGM data indicates a need for additional insulin. Due to potential unreliability in the correlation of the CGM data to the user's actual blood glucose level, risk mitigation can be employed to limit the amount of extra insulin that can be delivered by the pump in response to the CGM data.

Owner:TANDEM DIABETES CARE INC

Heart failure monitor quicklook summary for patient management systems

InactiveUS20110301445A9Effective evaluationLong-term monitoringElectrotherapyEvaluation of blood vesselsCaregiver personThird party

Continuous remote monitoring of patients based on data obtained from an implantable hemodynamic monitor provides an interactive patient management system. Using network systems, patients are remotely monitored to continuously diagnose and treat heart-failure conditions. A screen displayable summary provides continuous feedback and information to physicians, patients and authorized third parties. The quick look summary includes various sites and presentation tailored to match the patients' and physicians' needs. The quick look summary further includes intelligent features that understand and retain the user's interests, preferences and use patterns. Patients, physicians and other caregivers are seamlessly connected to monitor and serve the chronic needs of heart-failure patients in a reliable and economic manner.

Owner:MEDTRONIC INC

Continuous feedback-controlled deployment of message transforms in a distributed messaging system

InactiveUS20080244025A1Multiple digital computer combinationsTransmissionContinuous feedbackClient-side

The present invention solves the disadvantages of the prior art and provides a distributed messaging system supporting stateful subscriptions. A stateful publish-subscribe system extends the functionality of the content-based approach to include more general state-valued expressions. A plurality of broker machines is provided to deliver messages sent by publishing clients toward subscribing clients based upon the contents of the messages and stateful transformations requested by the subscribing clients. Subscription specifications are analyzed by a compiler and converted into a collection of message transforms and views. A deployment service component deploys tasks to optimize system performance. A monitoring services component detects a possible need to reconfigure. A performance optimization service component computes new assignment of transforms. A continuous deployment service implements a redeployment protocol that installs changes to transform placement while the existing publish-subscribe system continues to operate.

Owner:IBM CORP

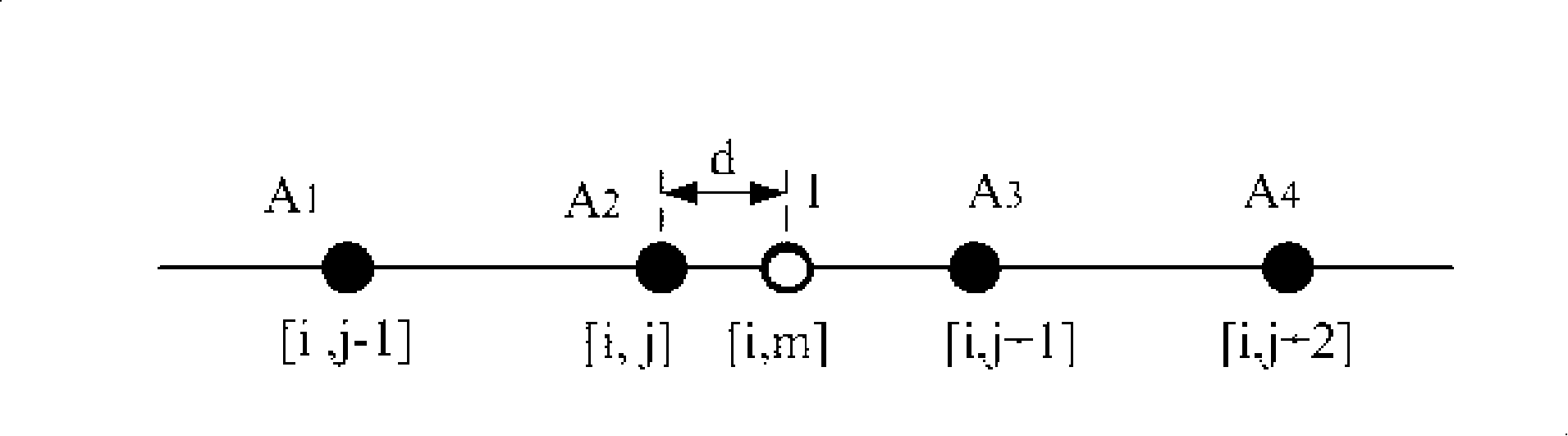

Interpolation method based on cubic spline function

InactiveCN101226630AGuaranteed smoothnessImprove edge sharpnessImage enhancementGeometric image transformationLocation statusContinuous feedback

The invention relates to an image scaling method of margin self-adapting treatment, in particular to cubic spline interpolation algorithm. The technique problem needed to be resolved by the invention is to provide a self-adapting interpolation method based on cubic spline function with smooth image and clear outline after being interpolated. The technical scheme comprises detecting the position of interpolation points first and employing different treatment methods to interpolate to the interpolation points located at different positions. The invention adds edge sharpness, and simultaneously effectively eliminates problems that continuous feedbacks pixels on the bilateral sides of the image edge interfering with each other cause virtual images on bilateral sides of the edge in original cubic spline interpolation algorithm on the basis of guaranteeing image gliding property. Simultaneously, the invention employs the same operational formula to calculate all interpolation points, which enables the invention to be simple to realize, and is equal to the complexity of realizing common cubic spline function interpolation algorithm.

Owner:SICHUAN PANOVASIC TECH

Heart Failure Monitor Quicklook Summary for Patient Management Systems

InactiveUS20110021897A1Effective evaluationLong-term monitoringElectrotherapyEvaluation of blood vesselsThird partyCaregiver person

Continuous remote monitoring of patients based on data obtained from an implantable hemodynamic monitor provides an interactive patient management system. Using network systems, patients are remotely monitored to continuously diagnose and treat heart-failure conditions. A screen displayable summary provides continuous feedback and information to physicians, patients and authorized third parties. The quick look summary includes various sites and presentation tailored to match the patients' and physicians' needs. The quick look summary further includes intelligent features that understand and retain the user's interests, preferences and use patterns. Patients, physicians and other caregivers are seamlessly connected to monitor and serve the chronic needs of heart-failure patients in a reliable and economic manner.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com