Method for realizing continuous feedback control by duality of hot finishing outlet instruments

A technology of instrument detection and feedback control, used in rolling mill control devices, metal rolling, temperature control and other directions, can solve the problems of the inability to accurately control the width index of the coil strip, the shutdown of the rolling line for maintenance, and the impact on output, and to reduce the Scrap rate and safety accident rate, quality assurance, effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

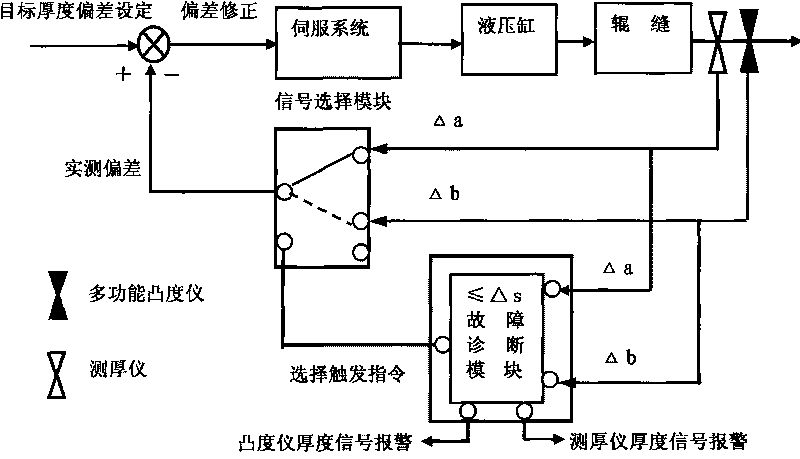

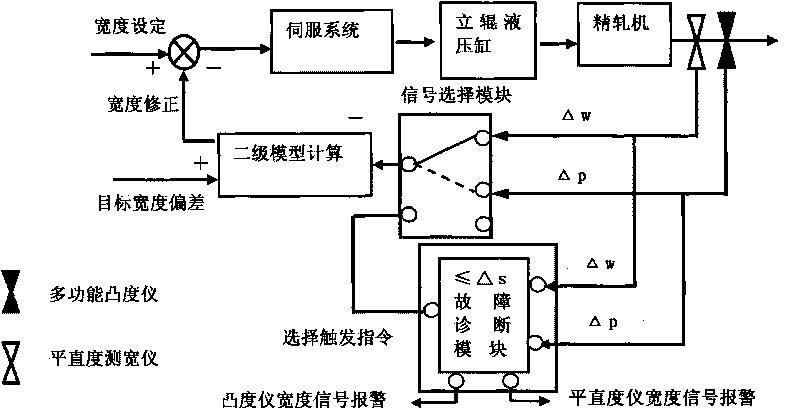

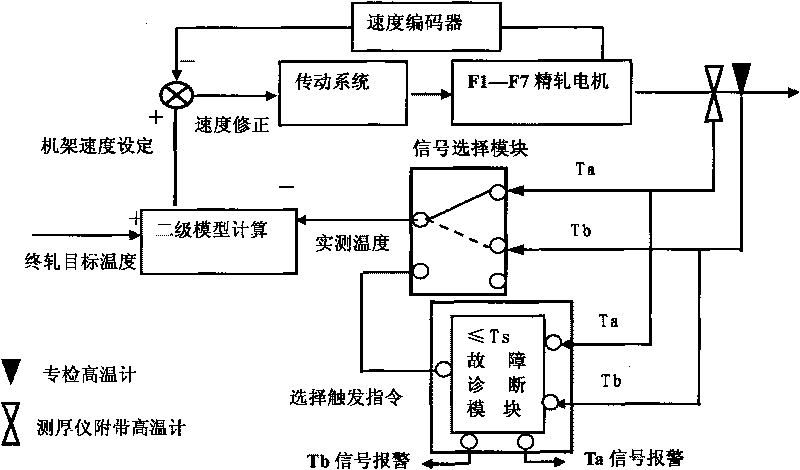

[0020] The method for realizing continuous feedback control by dual instrument detection at the exit of hot rolling and finishing rolling of the present invention is specifically: integrating the instrument for detecting production index parameters into the output roller table from the exit of the finishing mill to the coiler, wherein each production index parameter At least two instruments are used to detect at the same time. Each production index parameter is output in the same data output mode. For each production index parameter, the parameter measured by one of the instruments is used as the measured signal, and the signal measured by other instruments is used as the actual signal. Redundant signals, measured signals and redundant signals are all transmitted to the basic automation control computer TDC system and process control computer to form redundant output of test data for key quality indicators of finished products, mutual diagnosis and fast switching of redundant si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com