Patents

Literature

32results about How to "Easy and inexpensive to construct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

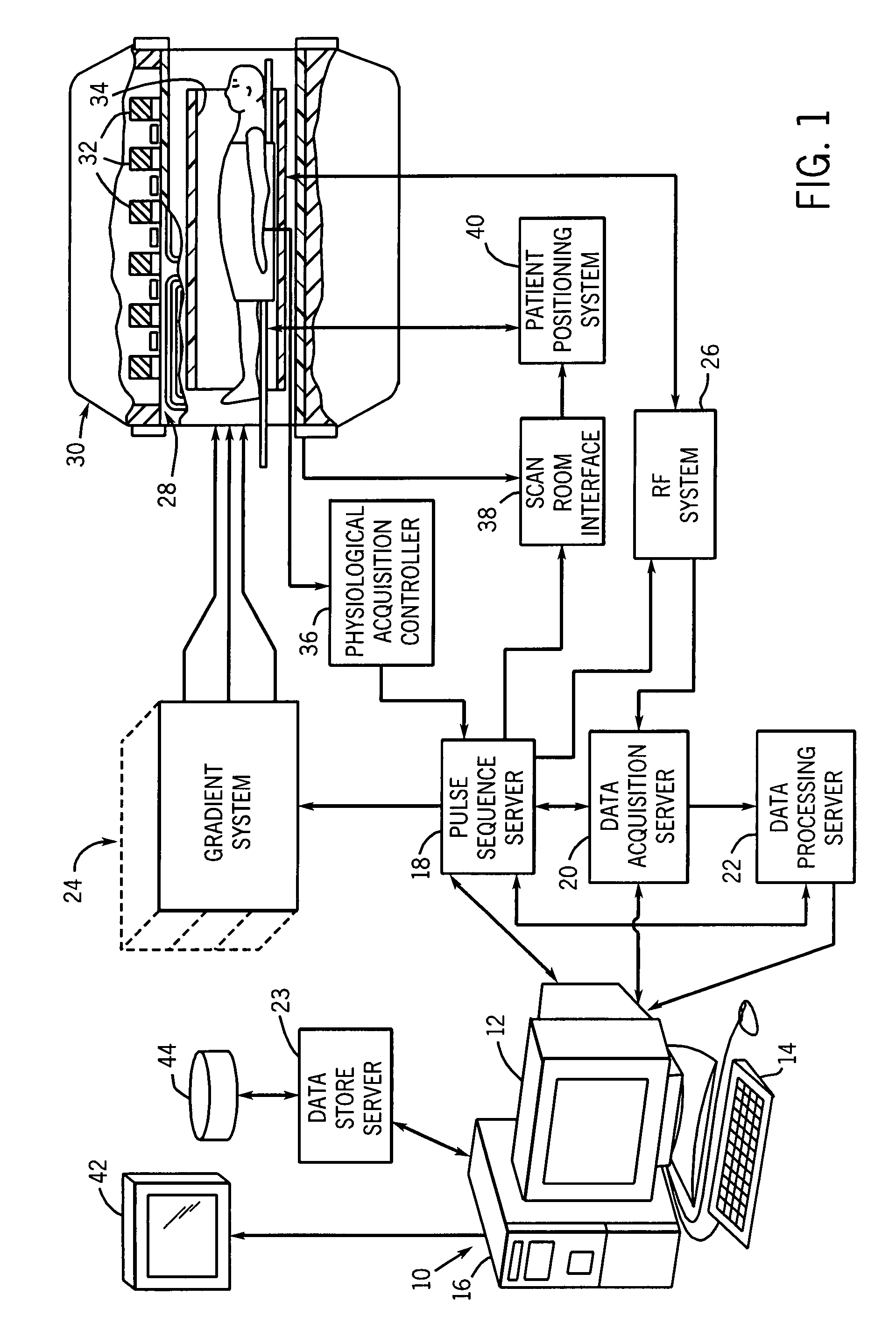

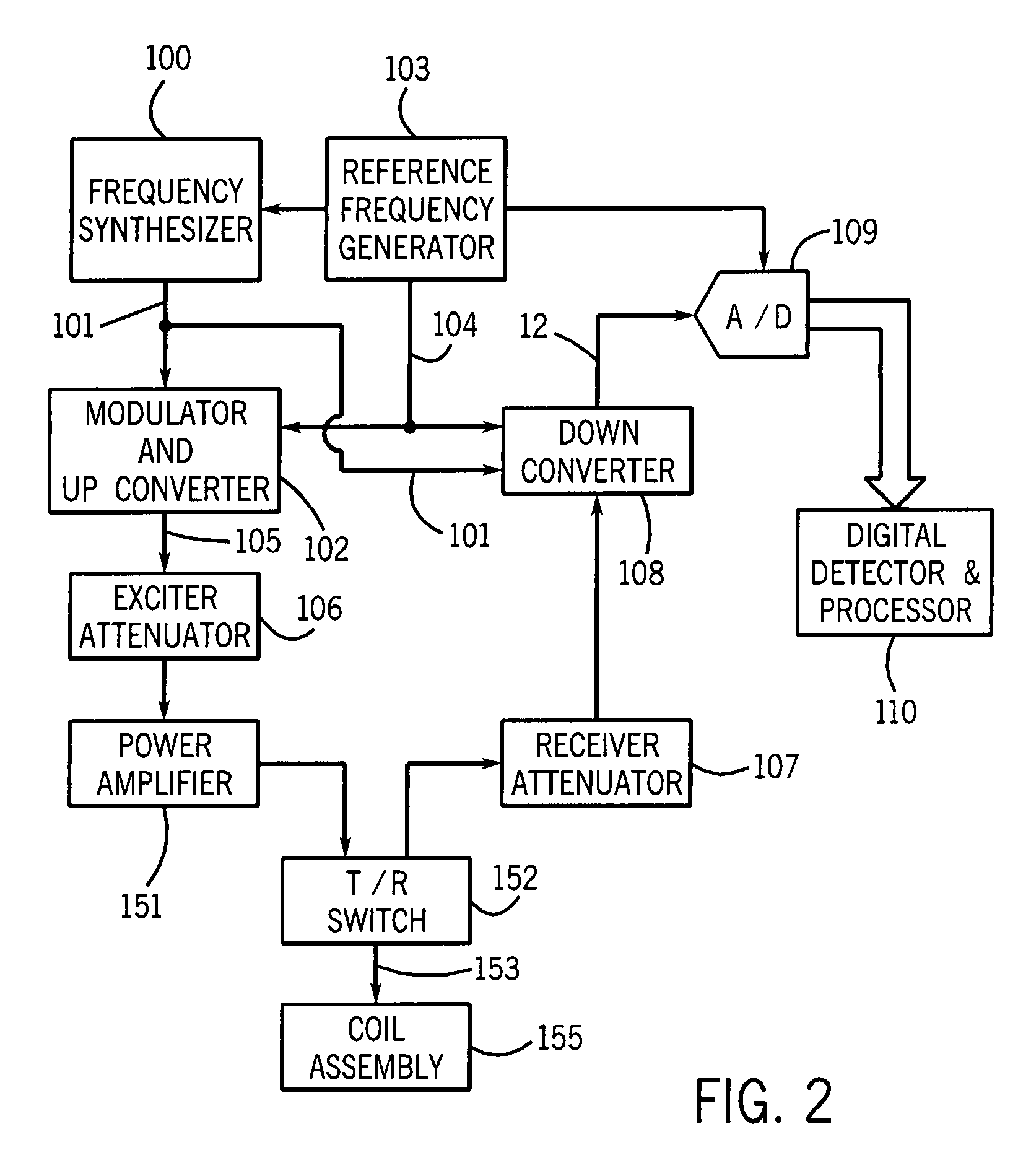

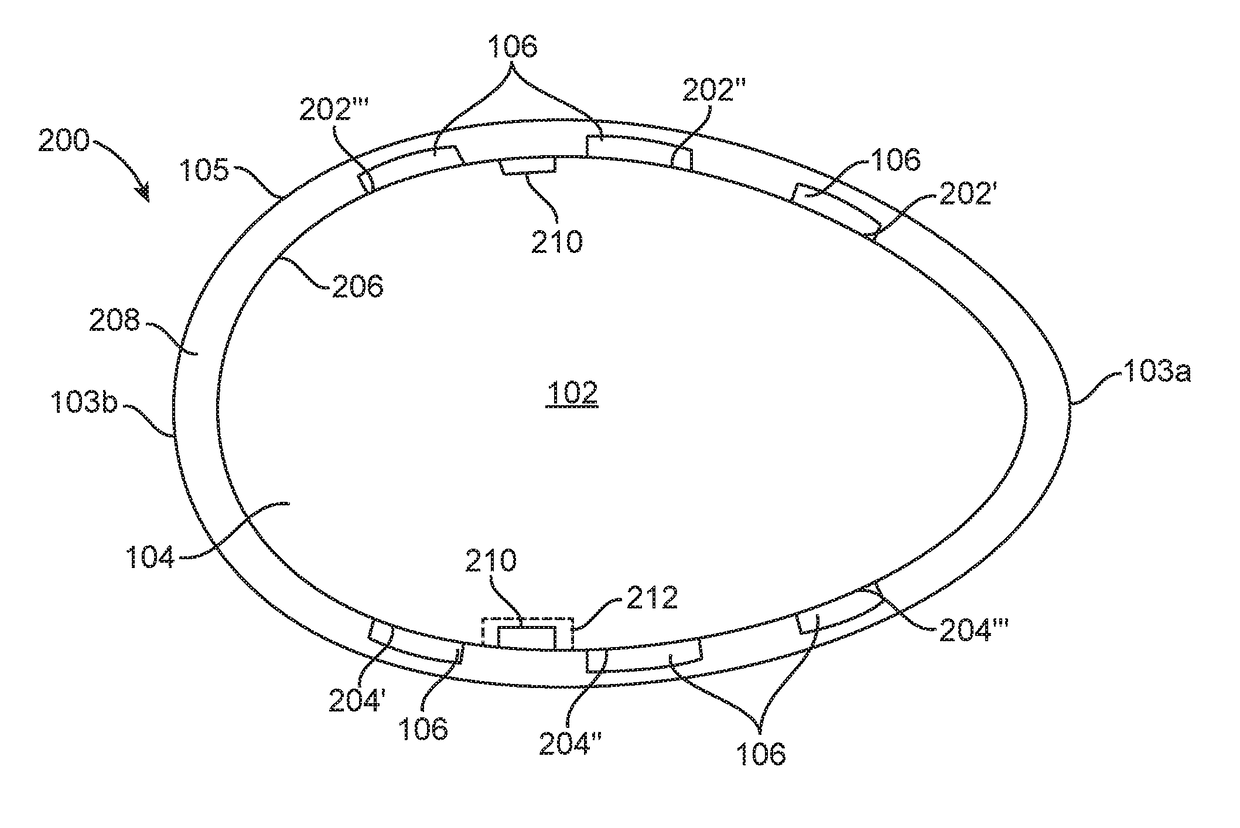

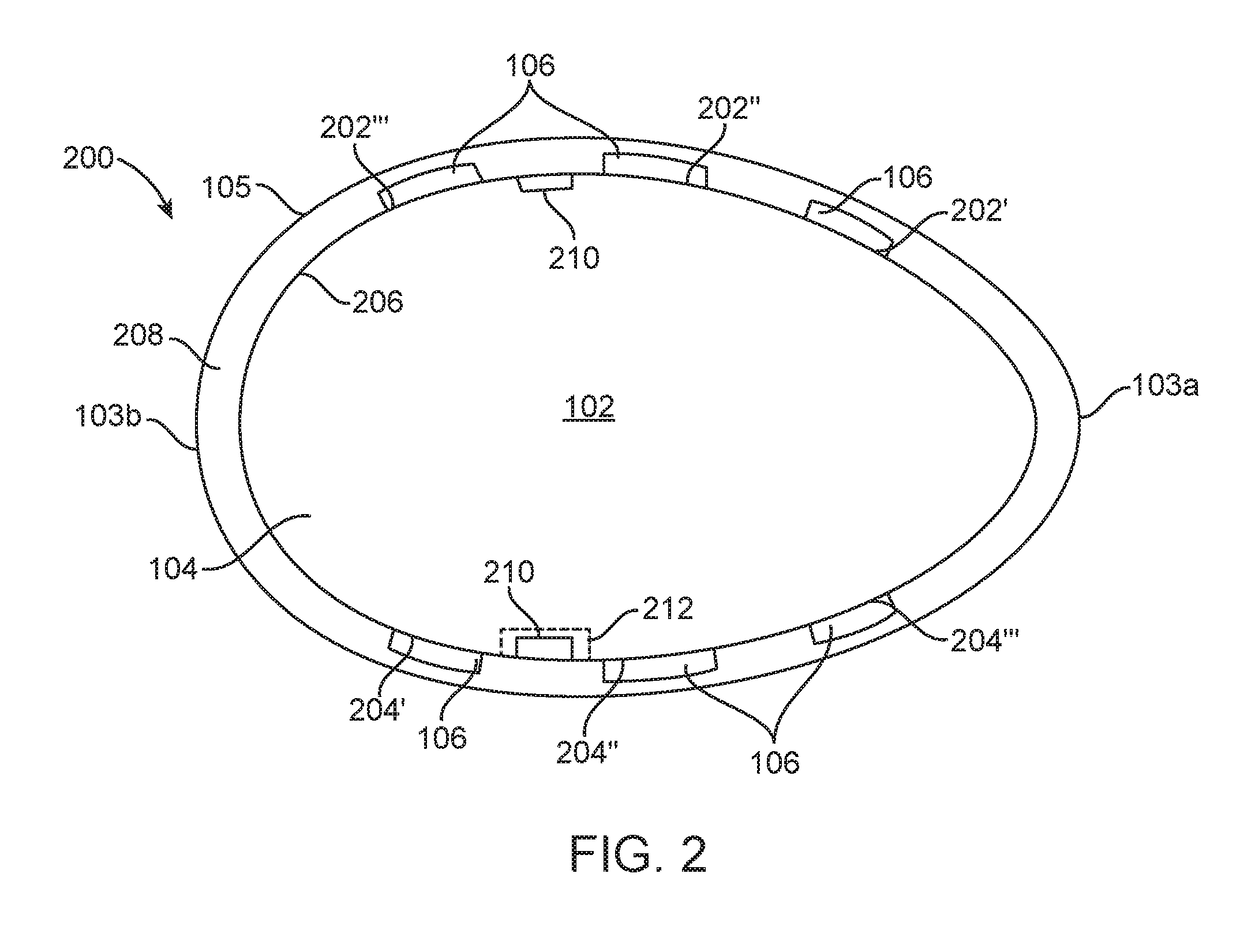

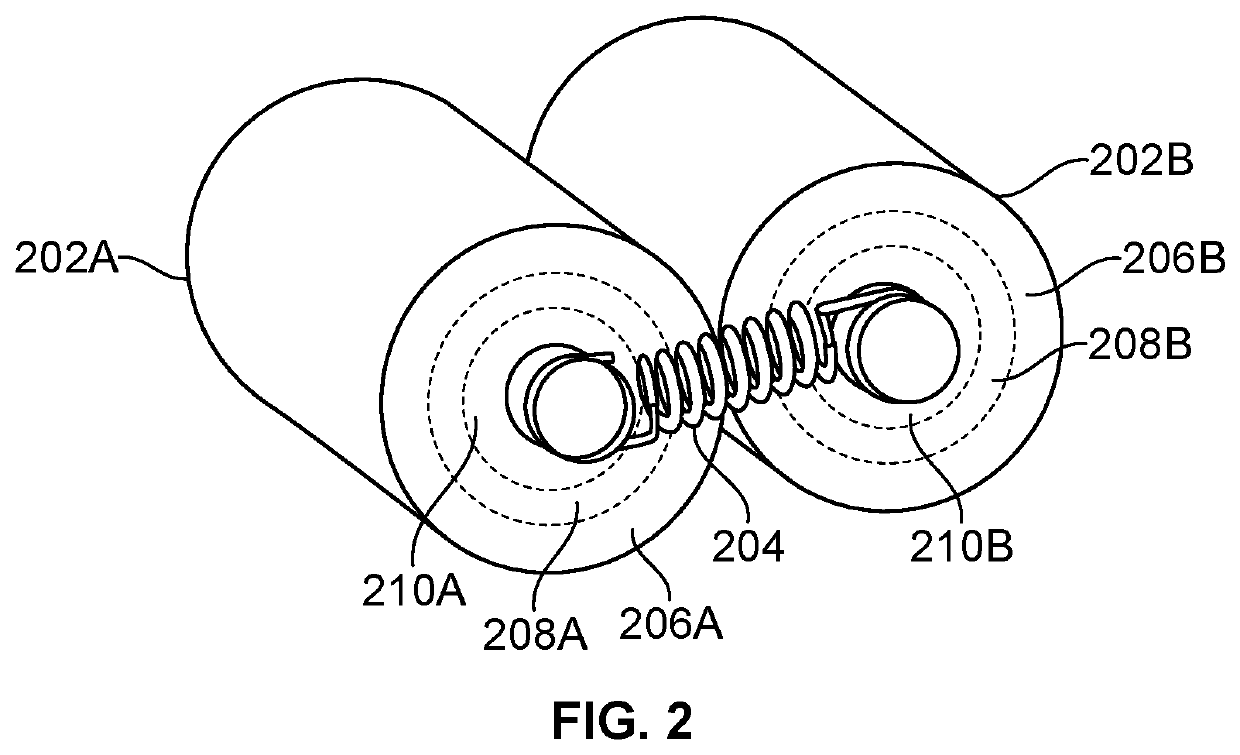

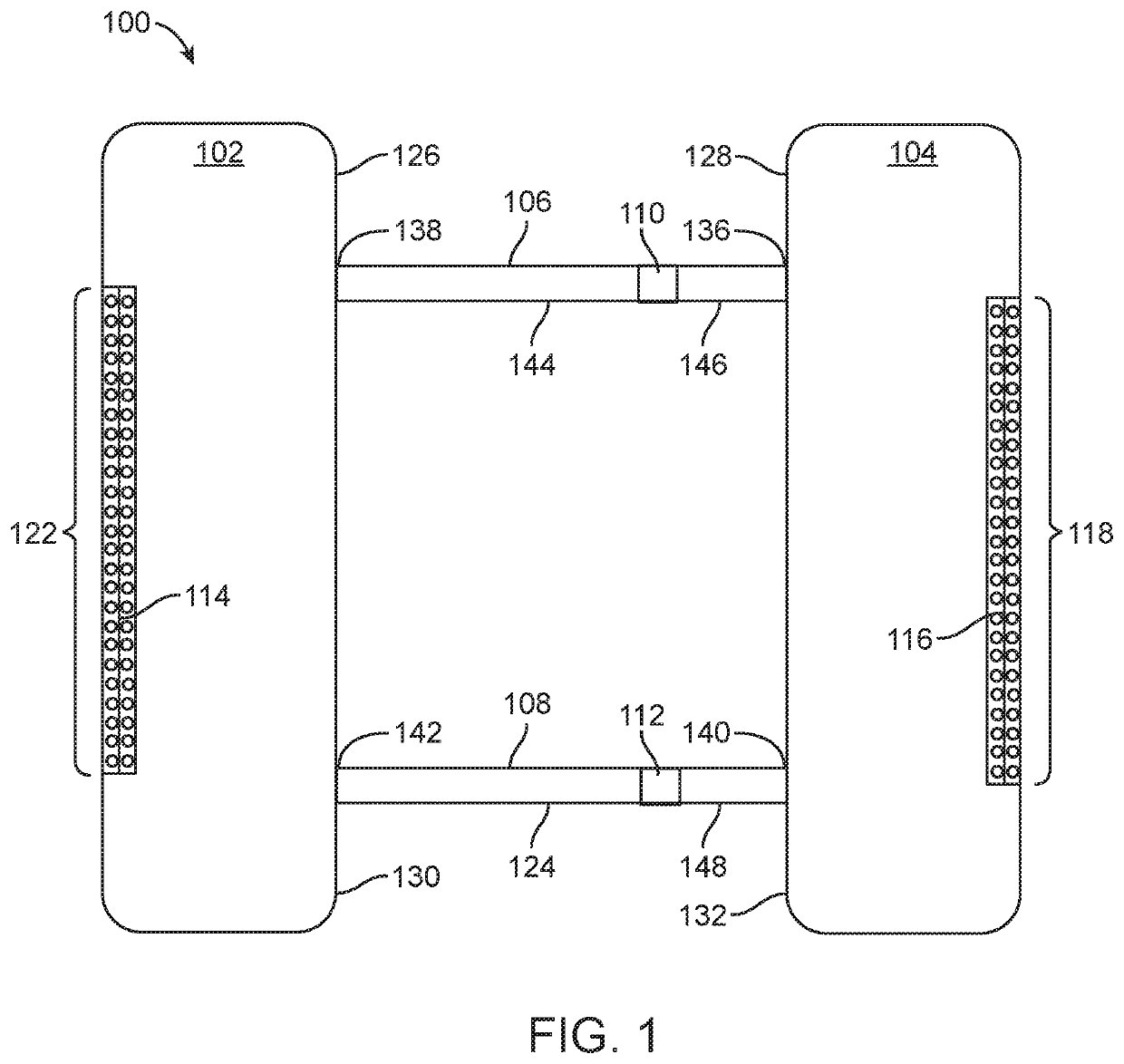

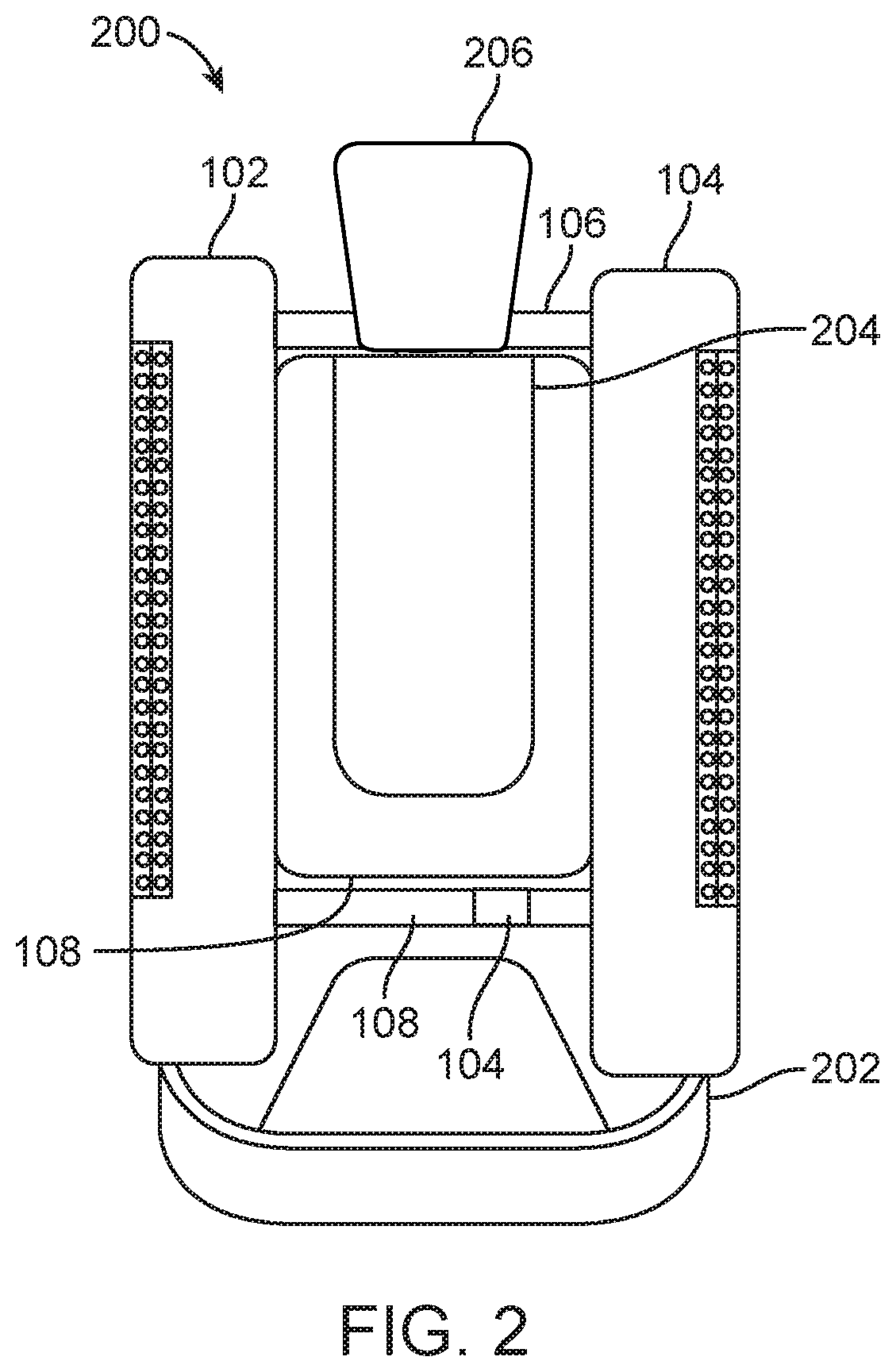

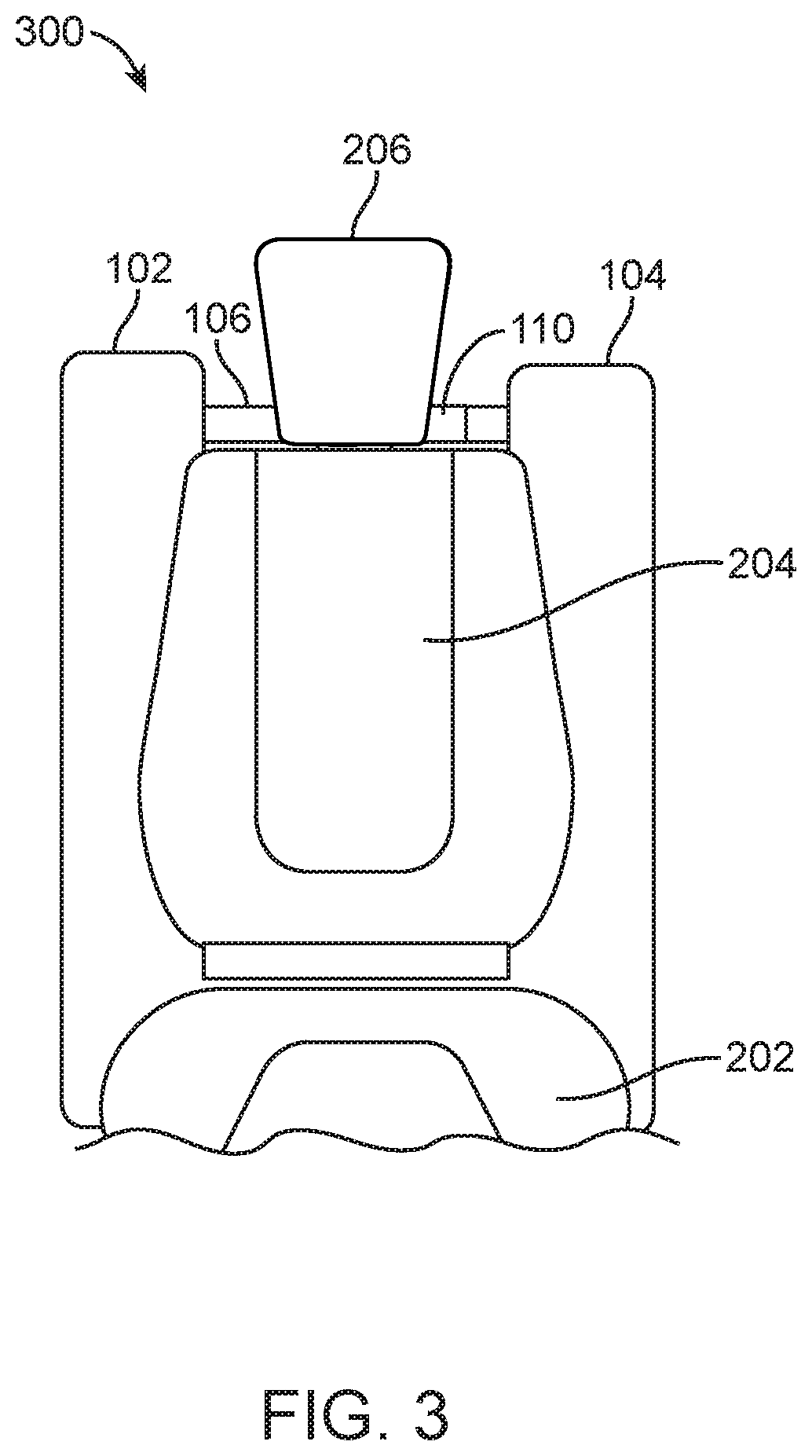

RF coil assembly for magnetic resonance imaging and spectroscopy systems

ActiveUS20070279061A1Easy to carryEasily and inexpensively constructedElectric/magnetic detectionMeasurements using magnetic resonanceDriver circuitTransformer

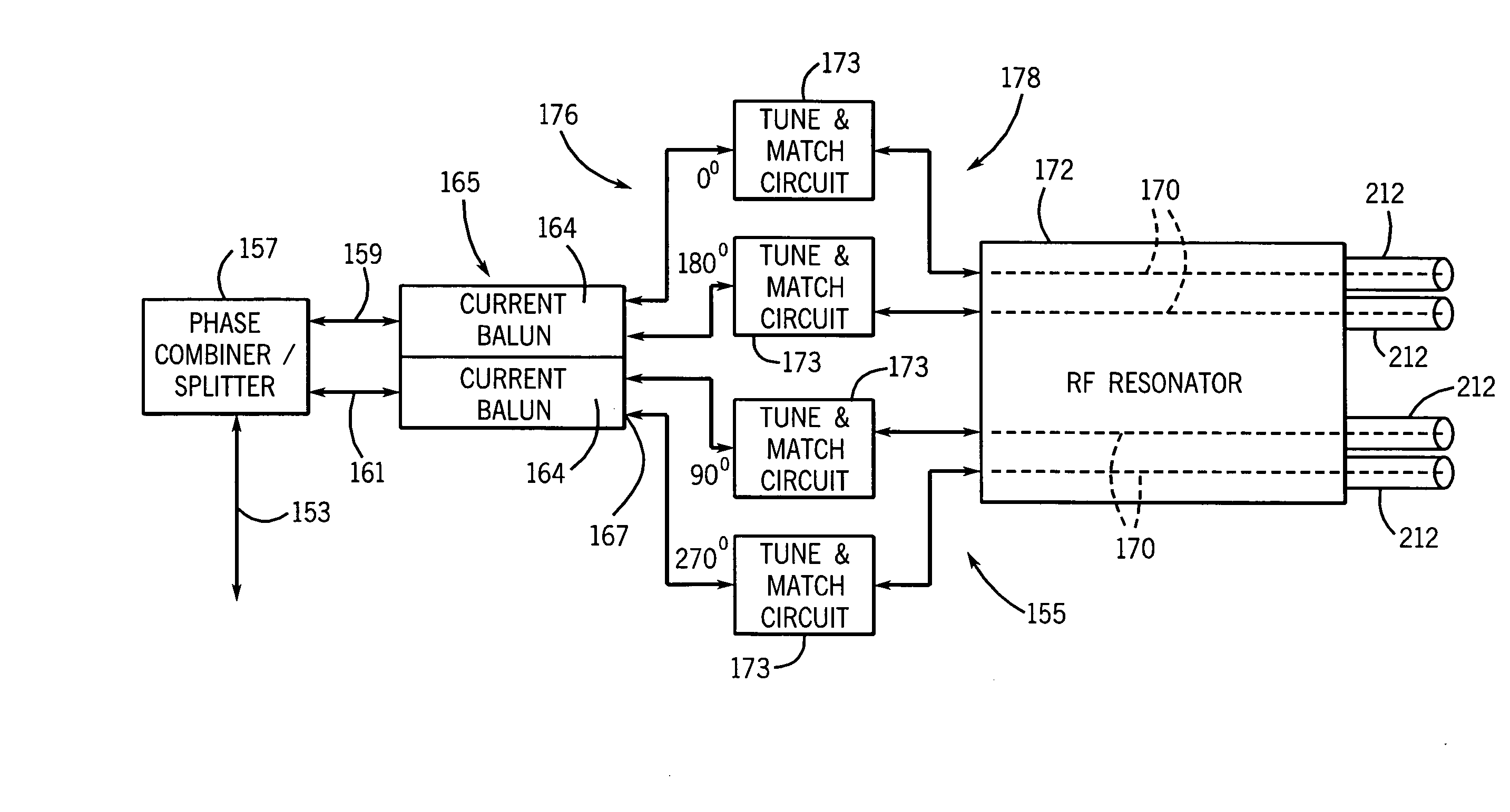

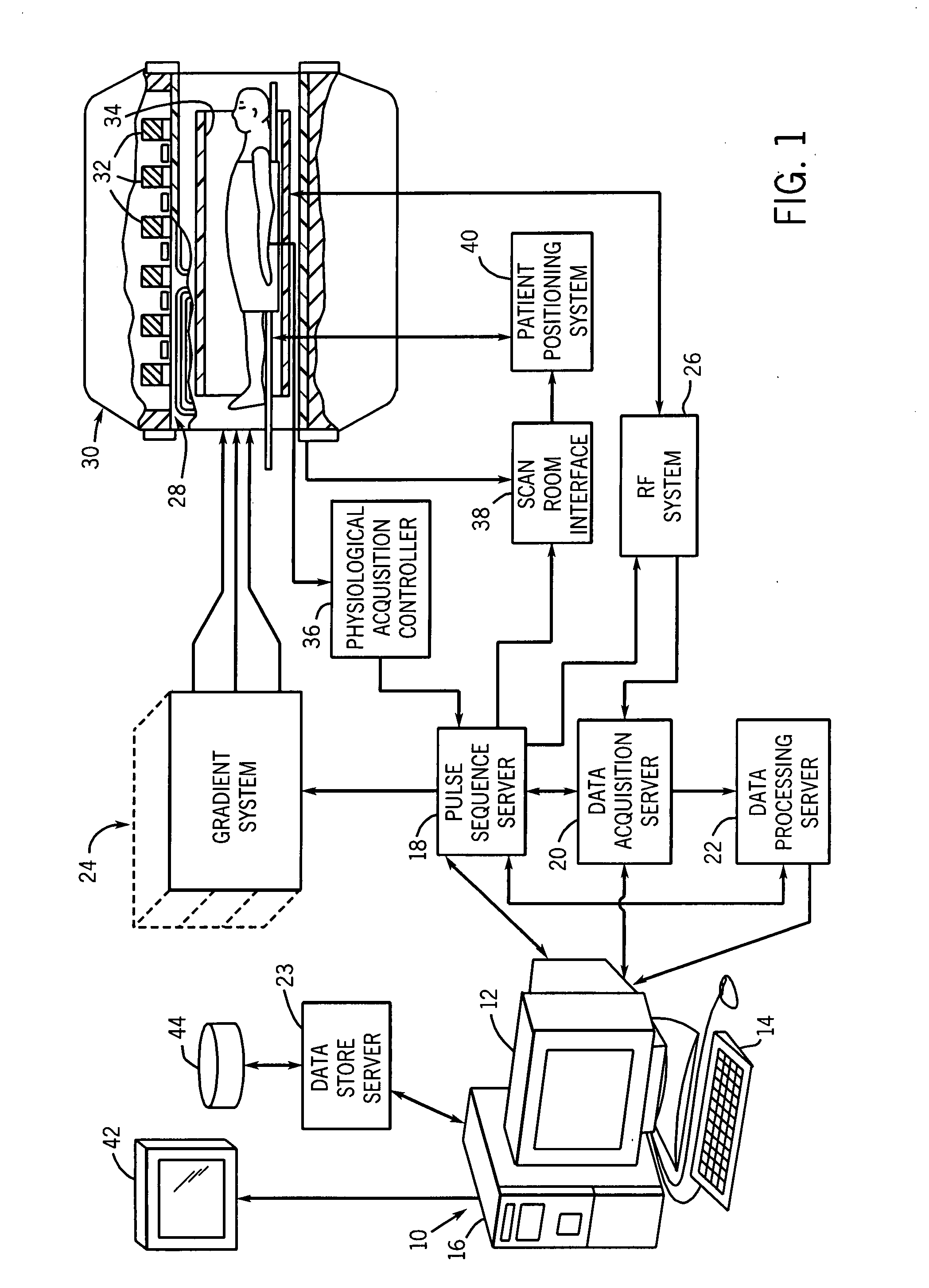

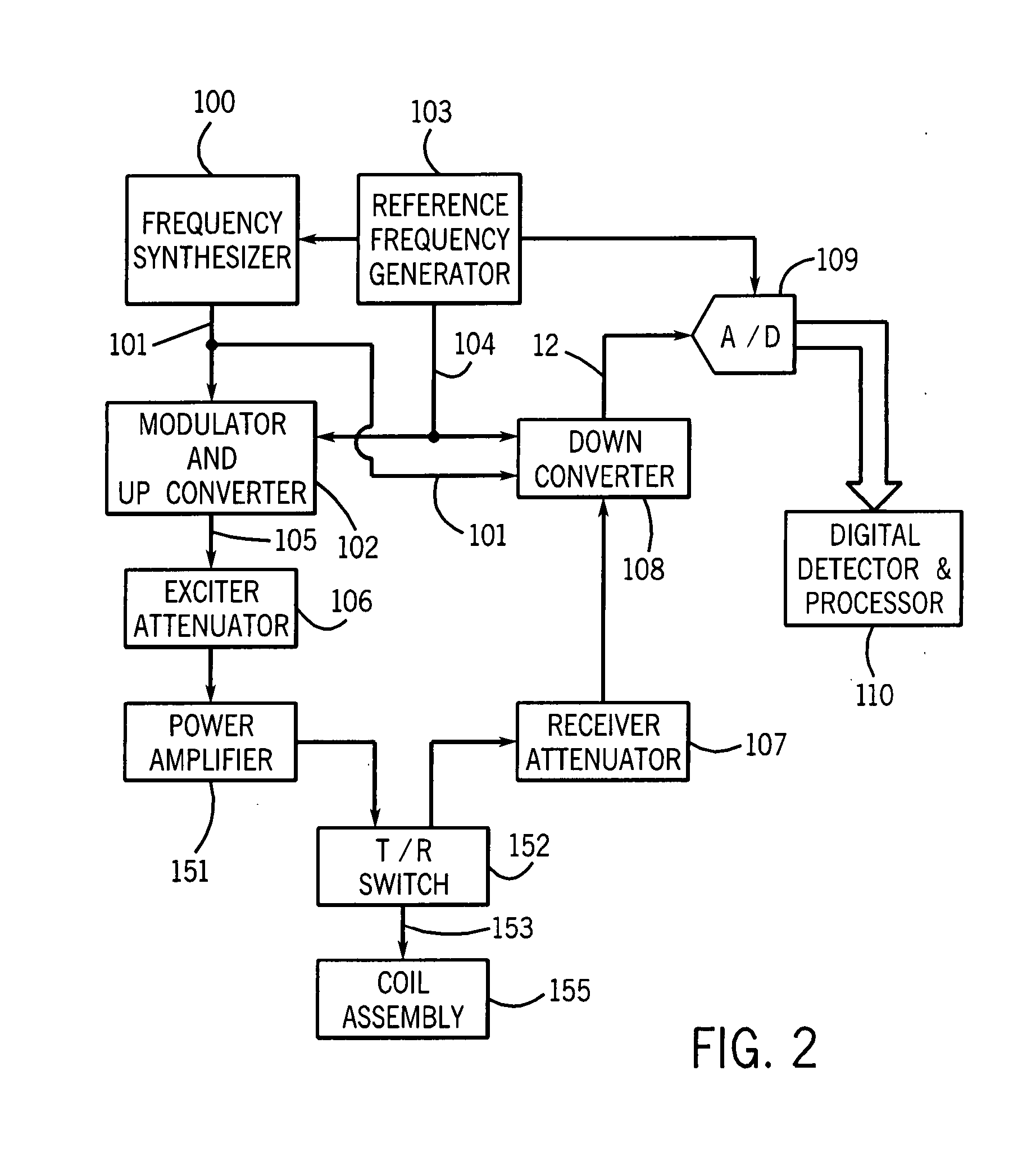

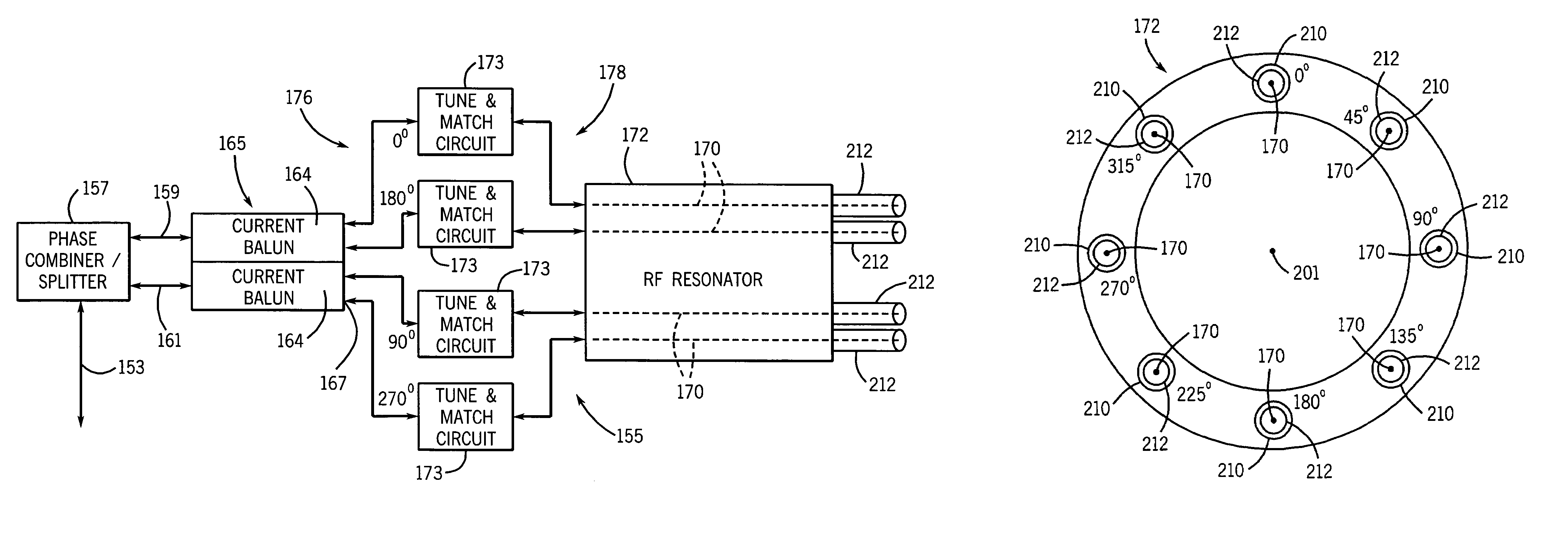

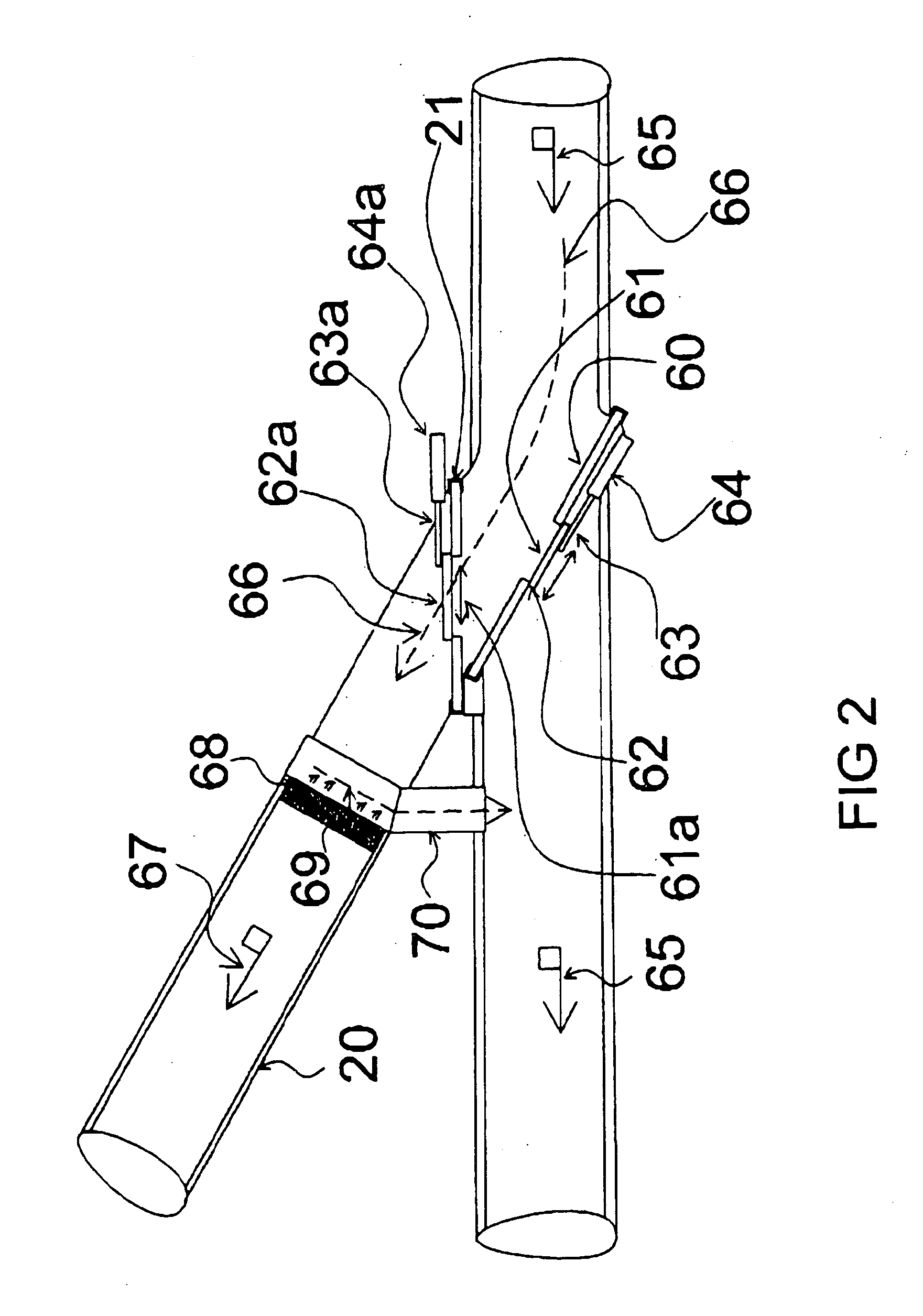

An RF coil assembly for an MRI system includes a resonator formed by a cylindrical shield and pairs of opposing conductive legs disposed symmetrically around a central axis and extending the axial length of the shield. Drive circuitry for each pair of opposing conductive legs includes a current balun that maintains substantially equal and opposite currents in the two conductive legs. Terminal susceptance elements are used to maintain maximum currents and minimum voltage at the midpoints of the conductive legs. Multinuclear measurements can be made simultaneously at different Larmor frequencies.

Owner:WISCONSIN ALUMNI RES FOUND

RF coil assembly for magnetic resonance imaging and spectroscopy systems

ActiveUS7714581B2Improve isolationEasy to carryMagnetic measurementsElectric/magnetic detectionSpectroscopyEngineering

An RF coil assembly for an MRI system includes a resonator formed by a cylindrical shield and pairs of opposing conductive legs disposed symmetrically around a central axis and extending the axial length of the shield. Drive circuitry for each pair of opposing conductive legs includes a current balun that maintains substantially equal and opposite currents in the two conductive legs. Terminal susceptance elements are used to maintain maximum currents and minimum voltage at the midpoints of the conductive legs. Multinuclear measurements can be made simultaneously at different Larmor frequencies.

Owner:WISCONSIN ALUMNI RES FOUND

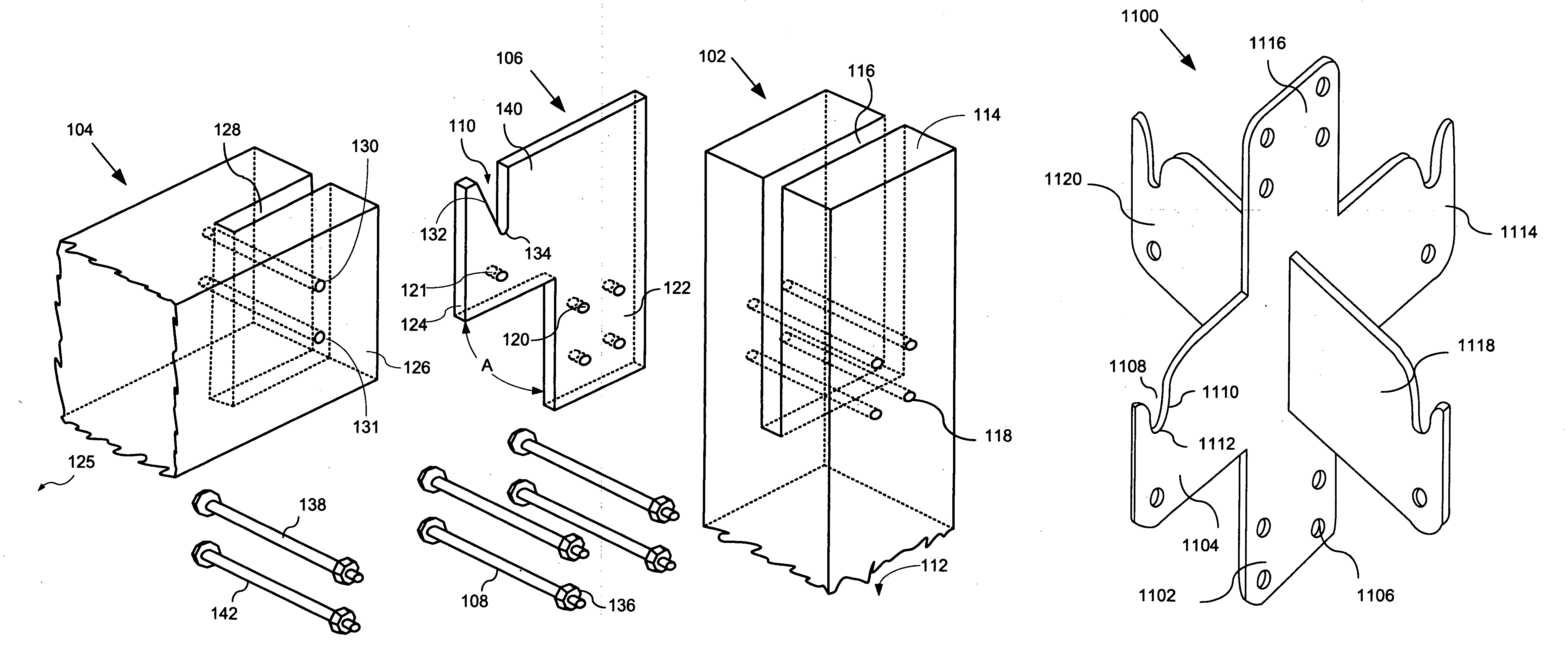

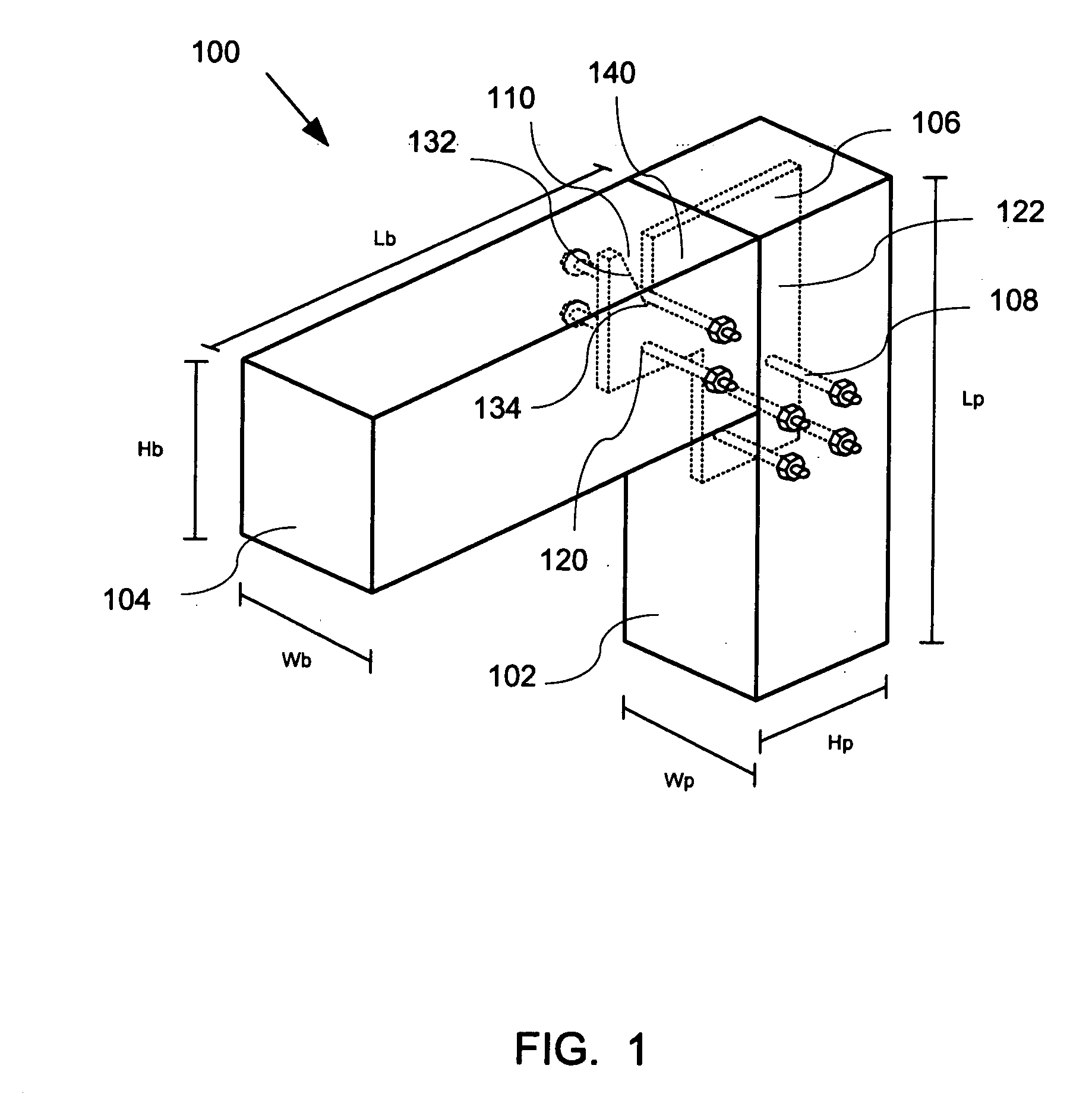

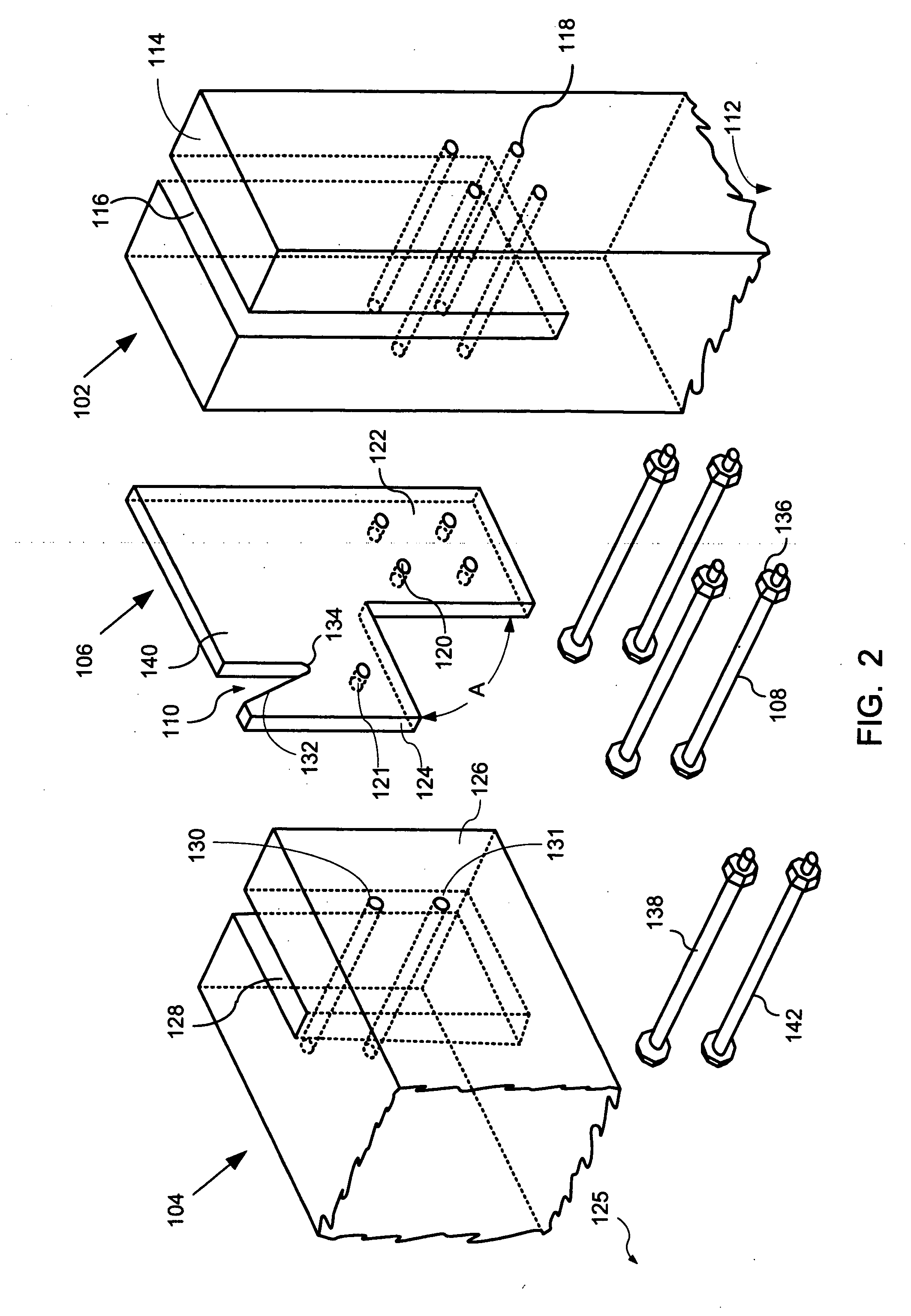

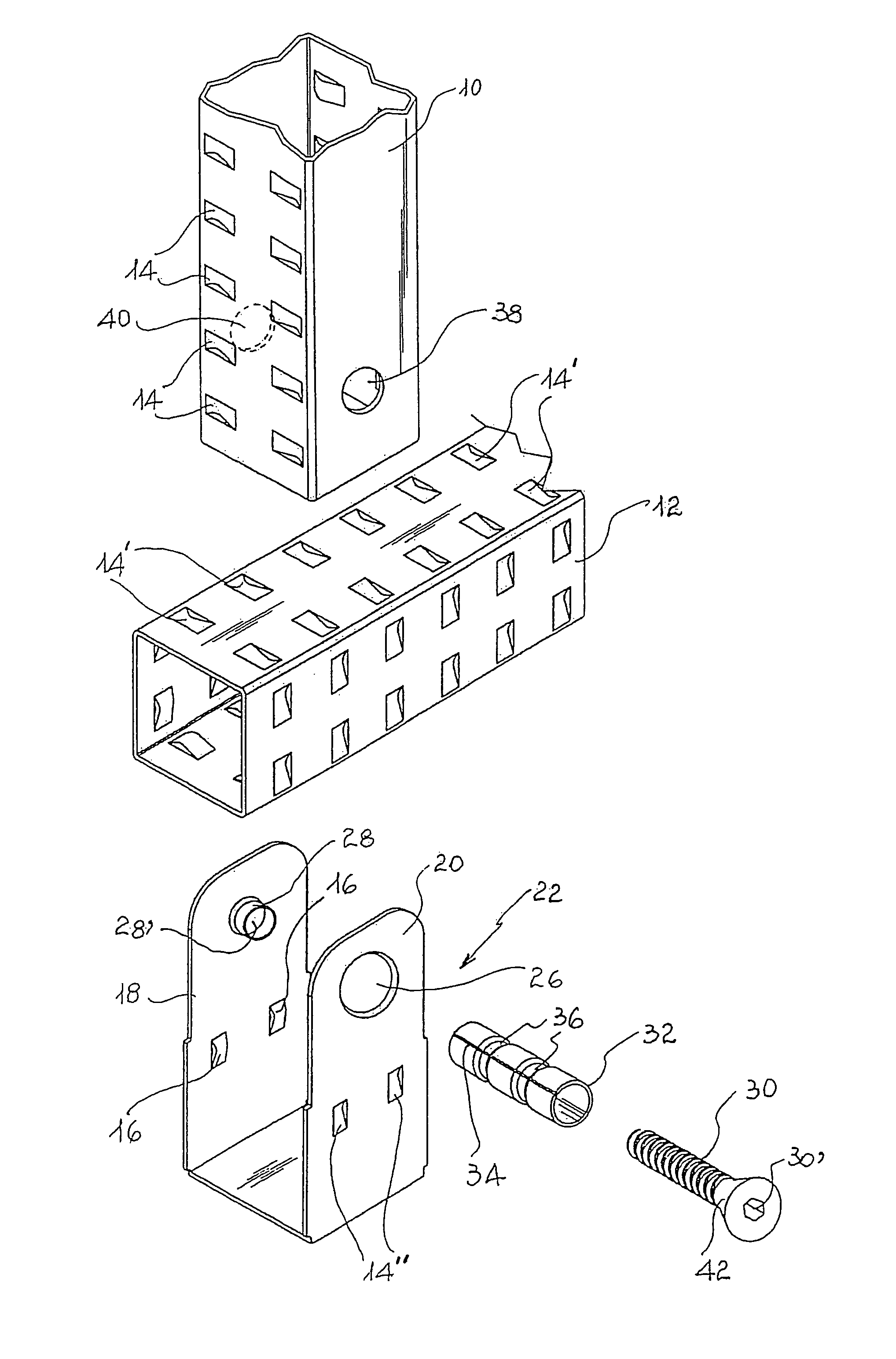

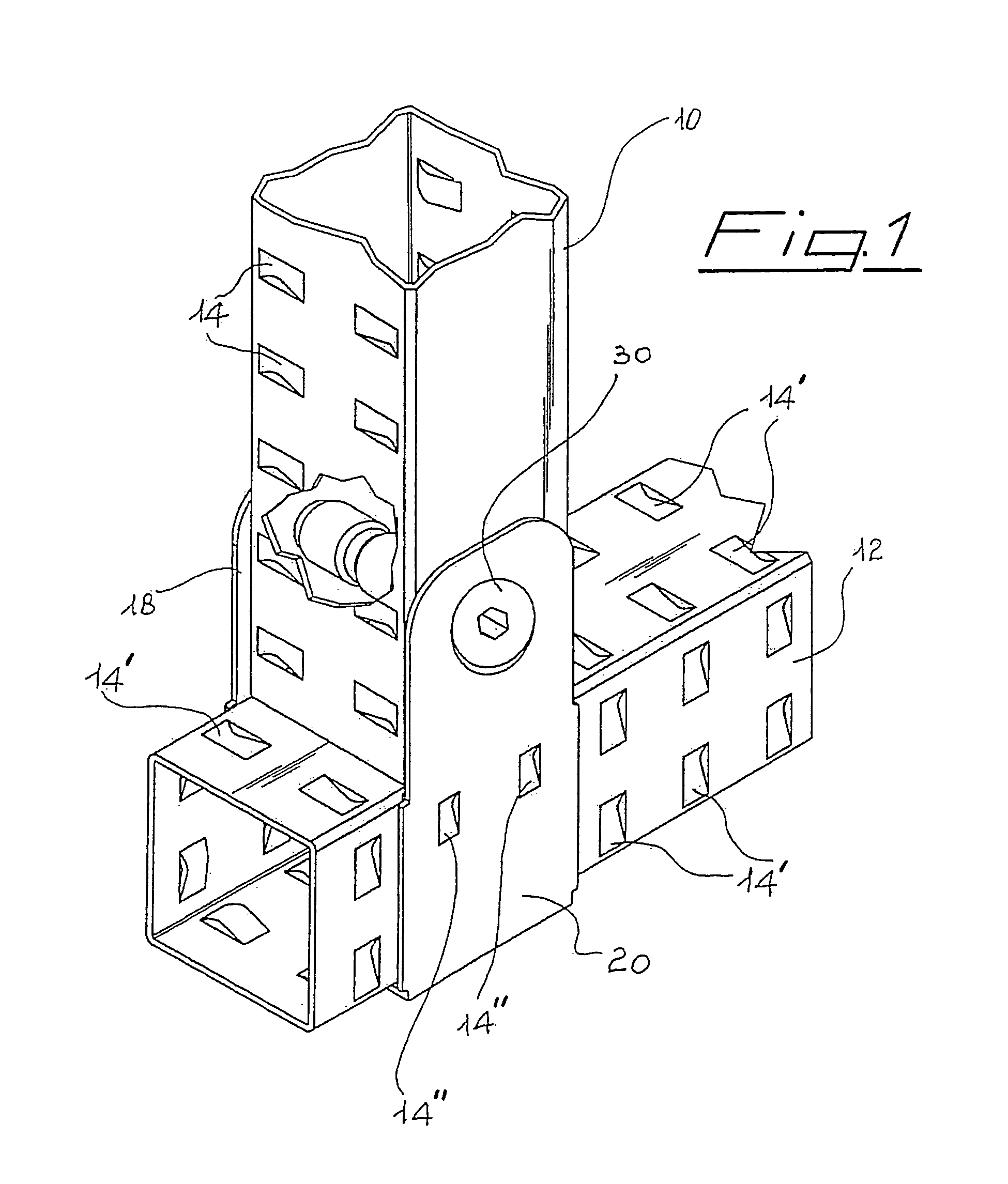

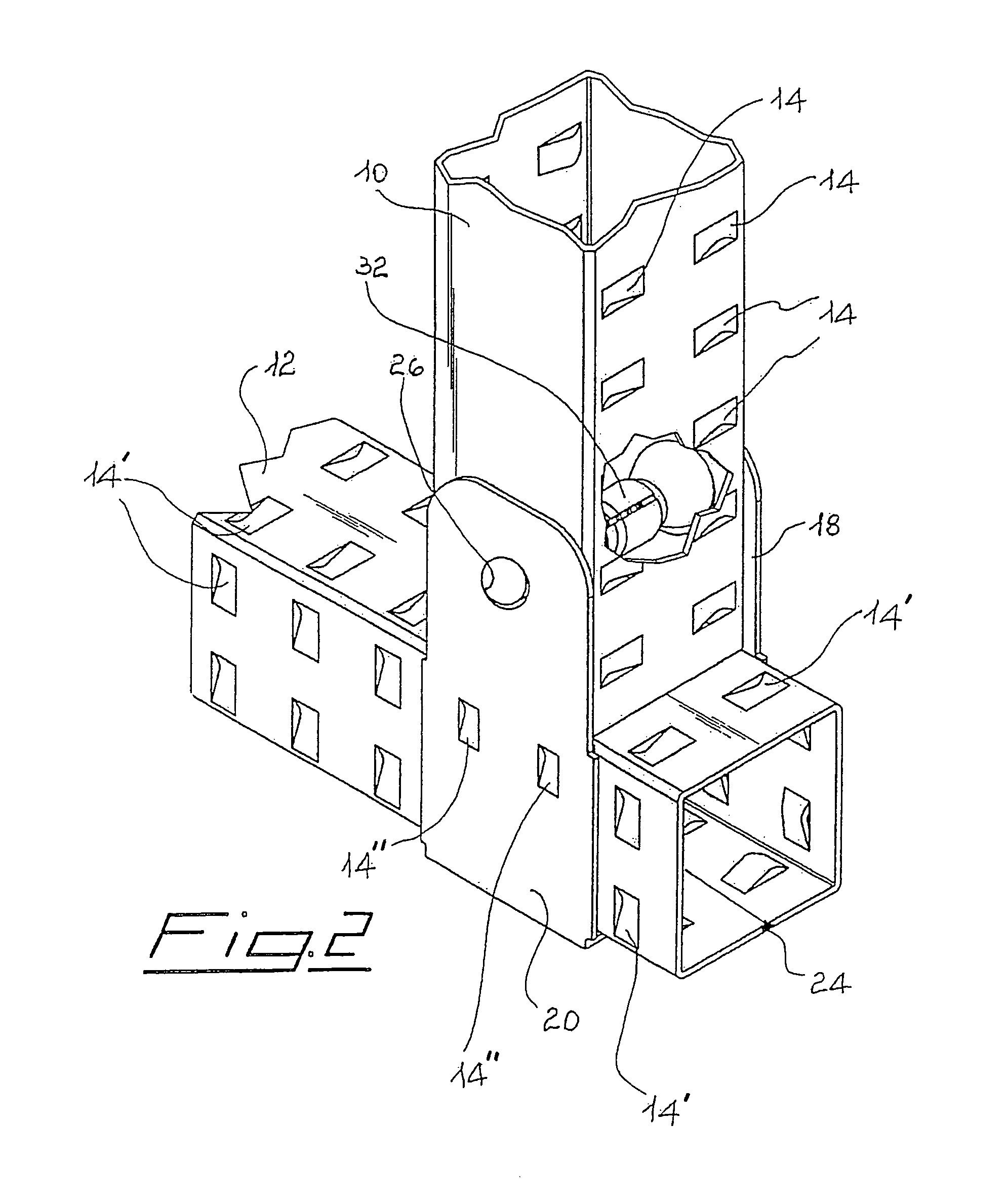

Construction framing system and method

InactiveUS20070186503A1Easy and inexpensive to constructShort amount of timeTowersBuilding reinforcementsFastenerEngineering

The framing fastener is made up of a configuration of plates used to attach any number of posts and beams to each other or to a base material. The framing fastener may include a substantially flat first plate with at least one hole extending there through and a substantially flat second plate with a hook formed at one edge thereof. The first and second plates are attached together such that the first and second plates are substantially coplanar or substantially perpendicular. The first plate of the framing fastener is attached to a post by means of one or more fastening rods. Then a beam is attached to the second plate of the framing fastener by means of one or more fastening rods, one of which rests in the hook.

Owner:ZEPHYR USA DEV

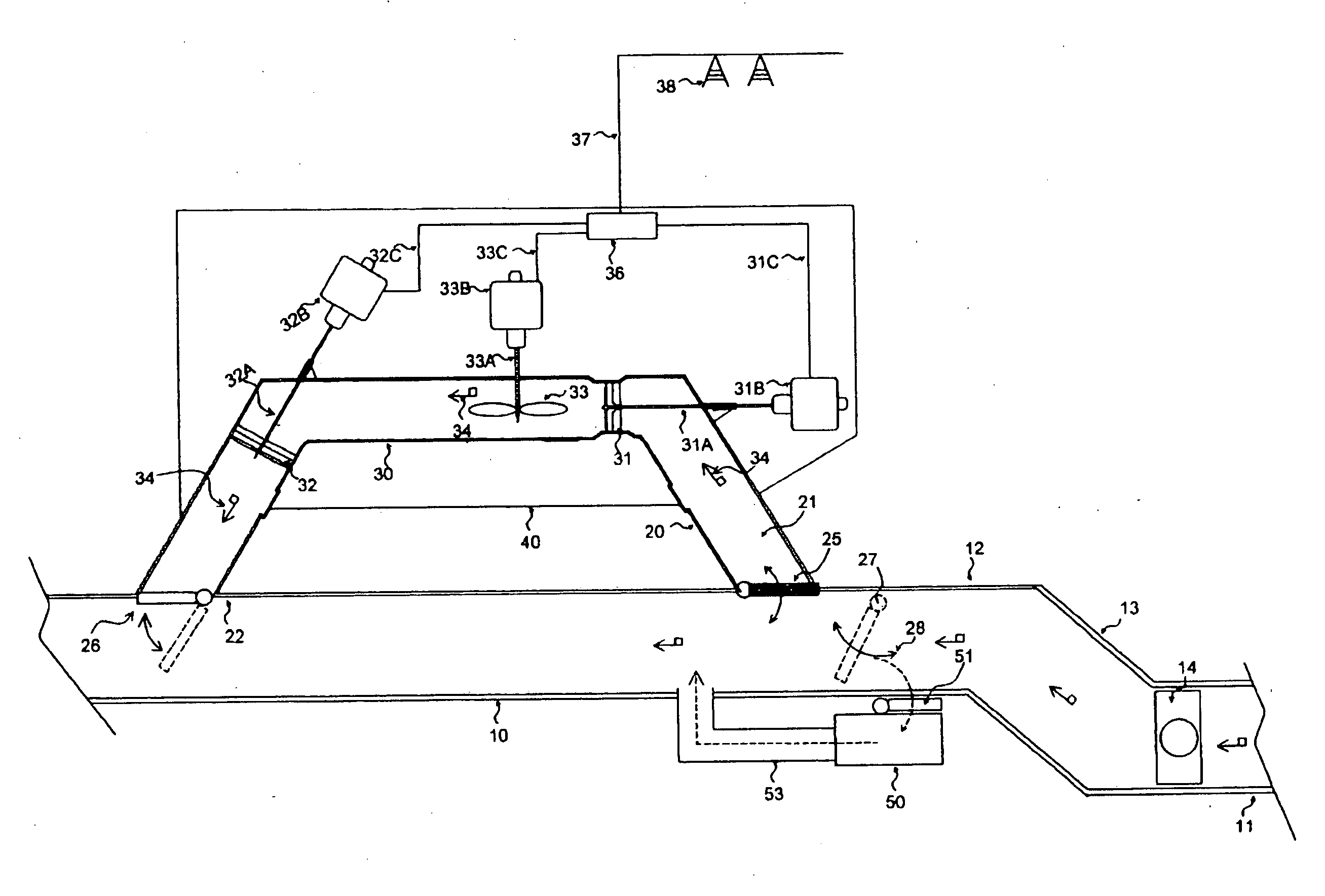

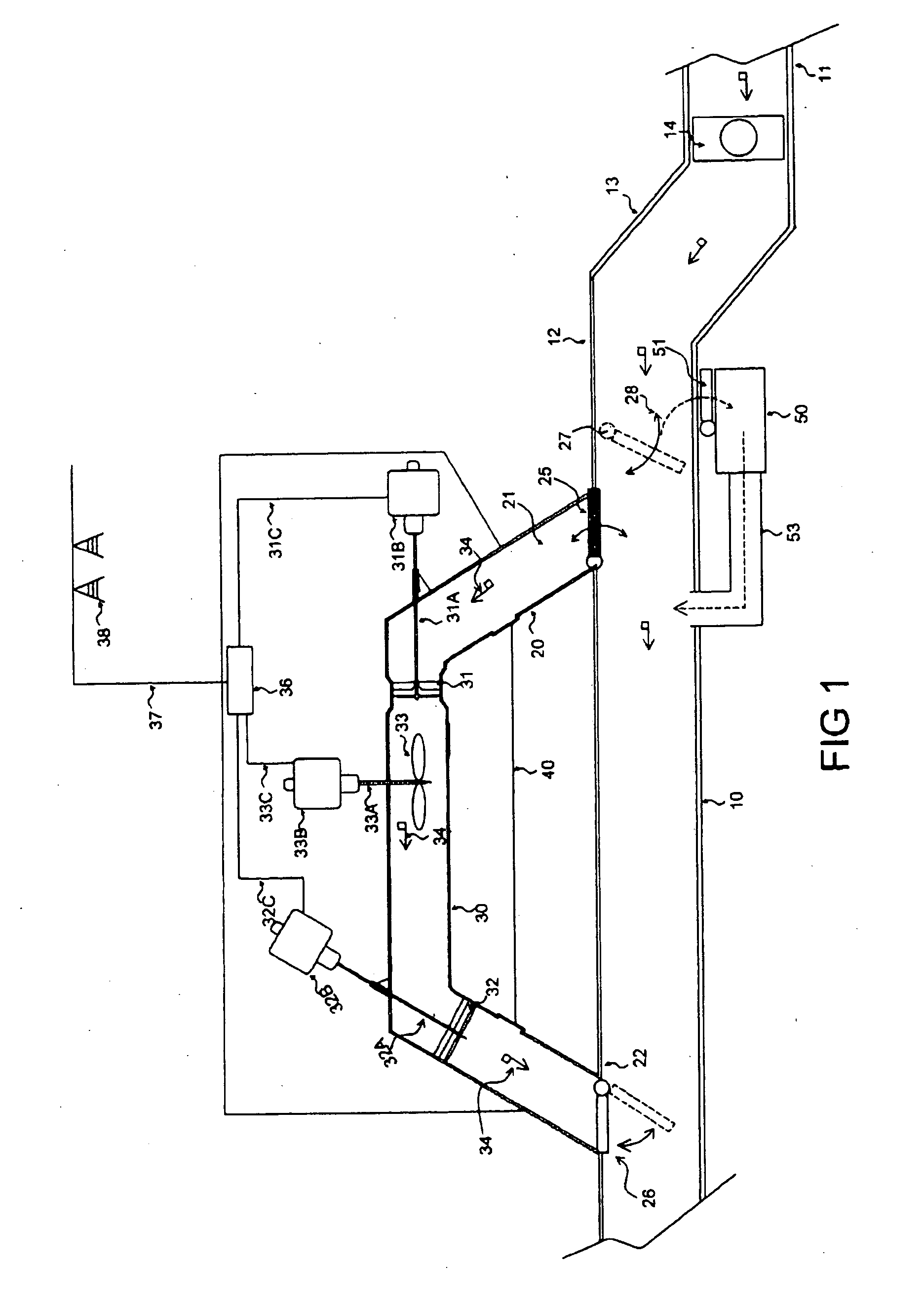

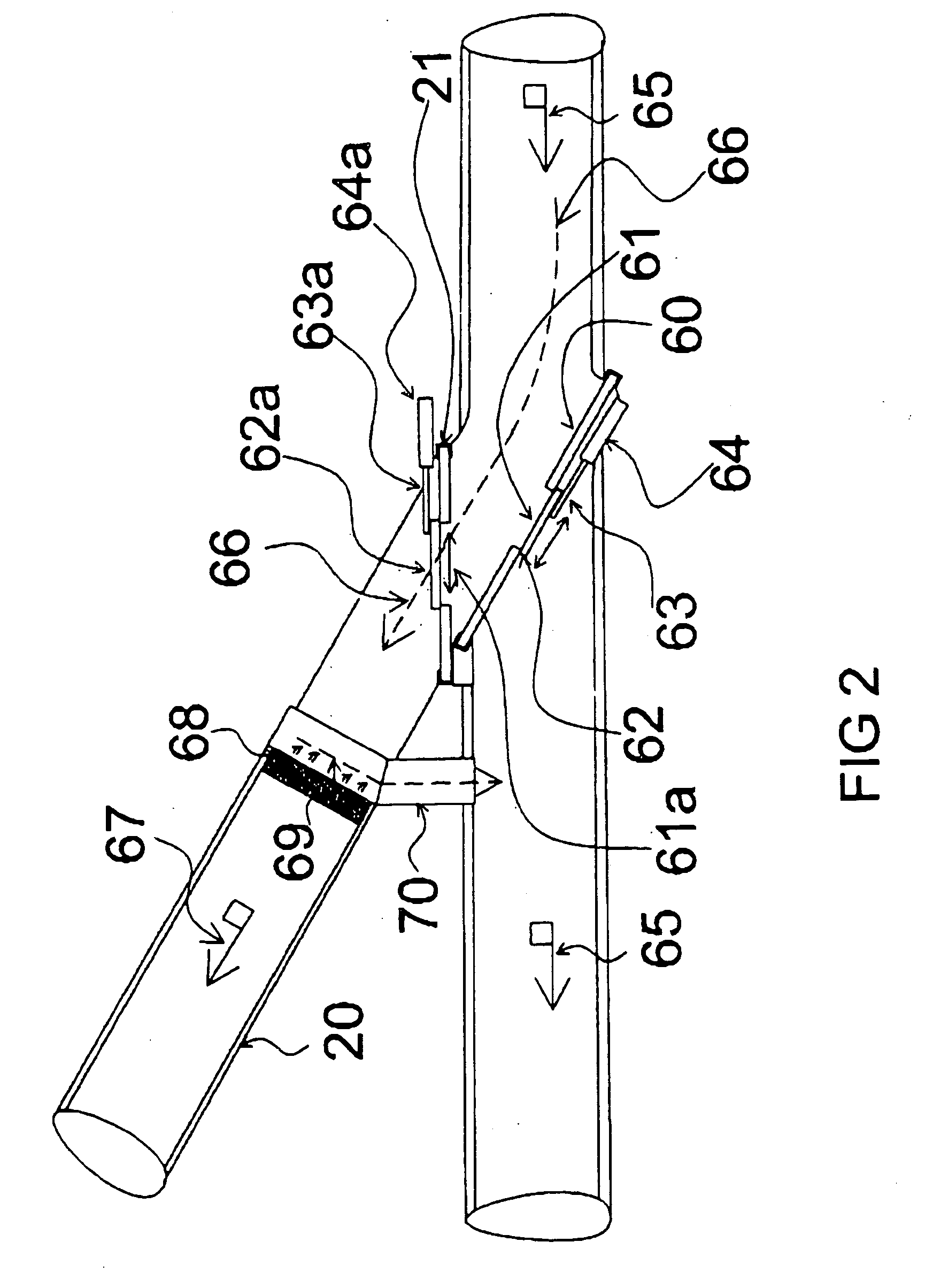

Waste water electrical power generating system

ActiveUS20070041790A1Without adversely impactingEasy and inexpensive to constructWater-power plantsSafety/regulatory devicesPipingSteel tube

An environmental protective electrical power generating system is formed by a penstock connected at its opposite ends to a large sewer for conveying waste water from feeder pipelines to a sanitary treatment station. Sewer waste water is propelled through the sewer line by pumping equipment which simultaneously pulverizes most large objects carried by the waste water. The waste water is diverted, through a control gate, into the penstock where it flows through and operates one or more water-operated turbines. The turbines are operatively connected to electrical power generators for producing electrical power and dispersing the power through an electrical power transmission system. Depending upon the size of the sewer pipes, the volume of liquid flowing there-through, and the turbine and generator equipment, electrical power is generated without affecting the environment or ecology and without the use of fossil fuels.

Owner:CRIPTONIC ENERGY SOLUTIONS

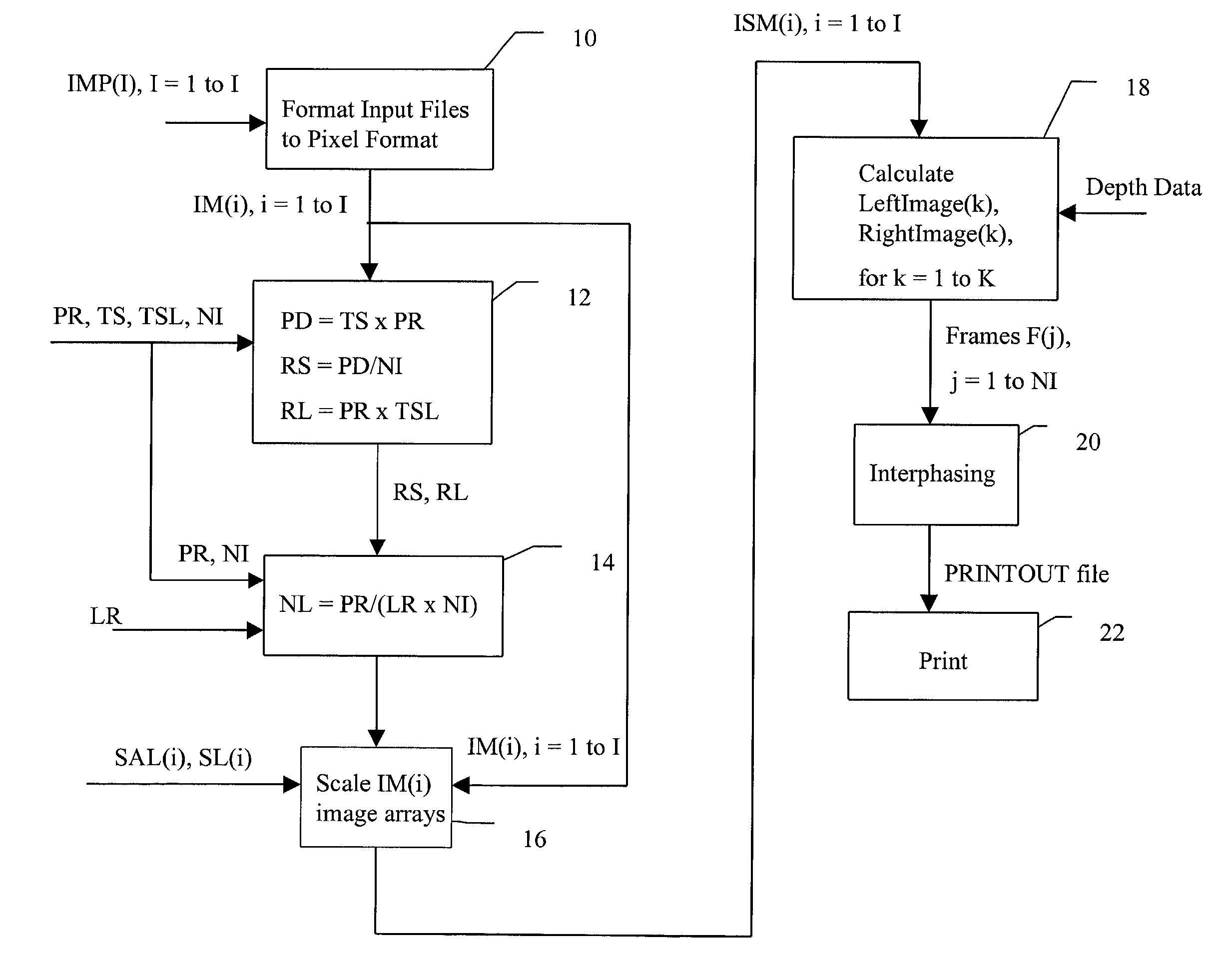

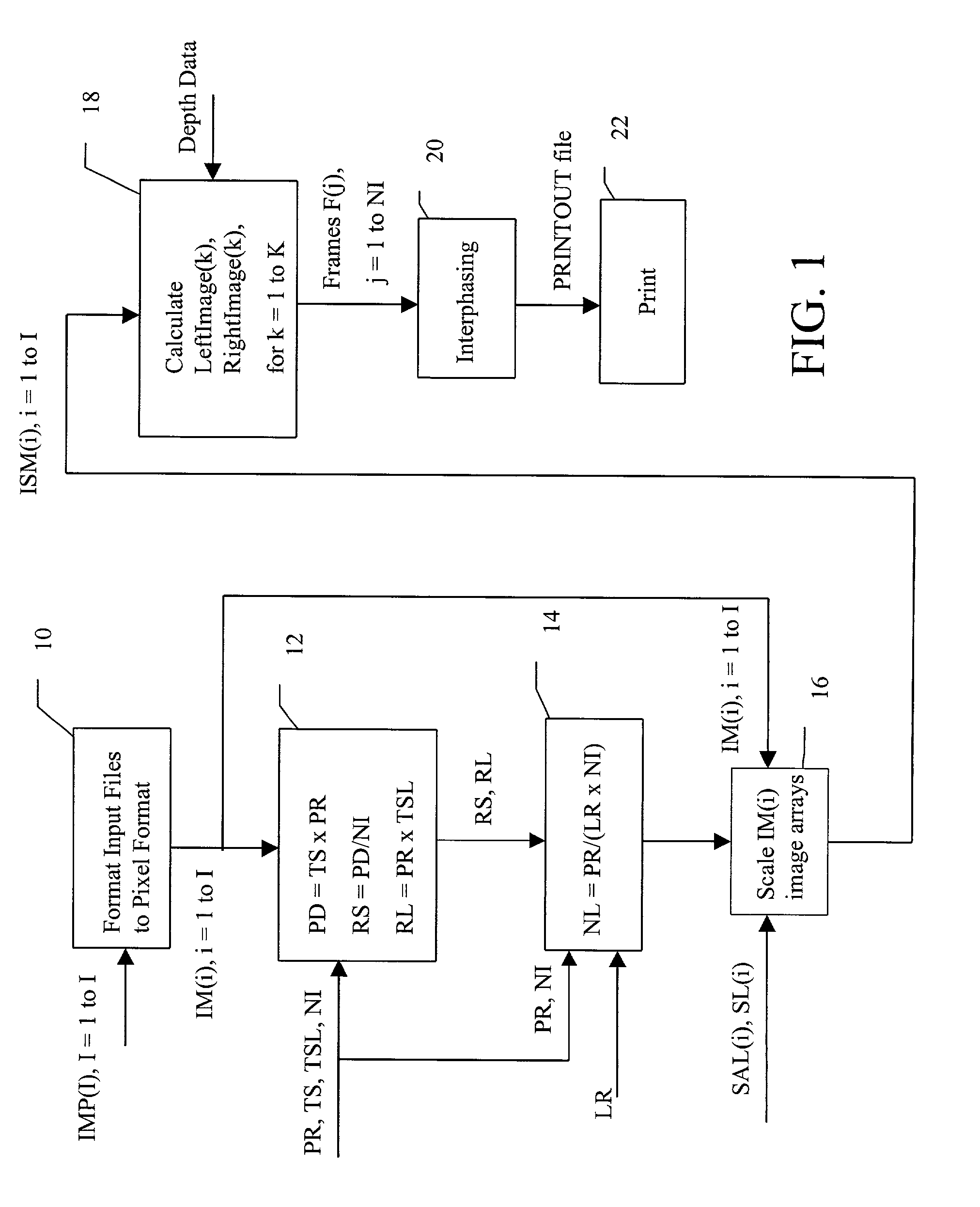

Method for scaling and interlacing multidimensional and motion images

ActiveUS7019865B2Easy and inexpensive to constructDigitally marking record carriersGeometric image transformationMultiple dimensionImage resolution

A plurality of input digital pixel images, having differing pixel array sizes, are scaled to a plurality of common pixel dimension input images based on a printer resolution value, a data characterizing dimensions of the printed image, and a final size value for at least one of the plurality of digital pixel images. A lenticule resolution data is received. A composite image file is formed of the plurality of scaled input digital pixel images, and at least one left-right image file pair is generated from the composite image file. The left-right image file pair are interlaced and printed on a printer associated with the printer resolution value.

Owner:ORASEE CORP

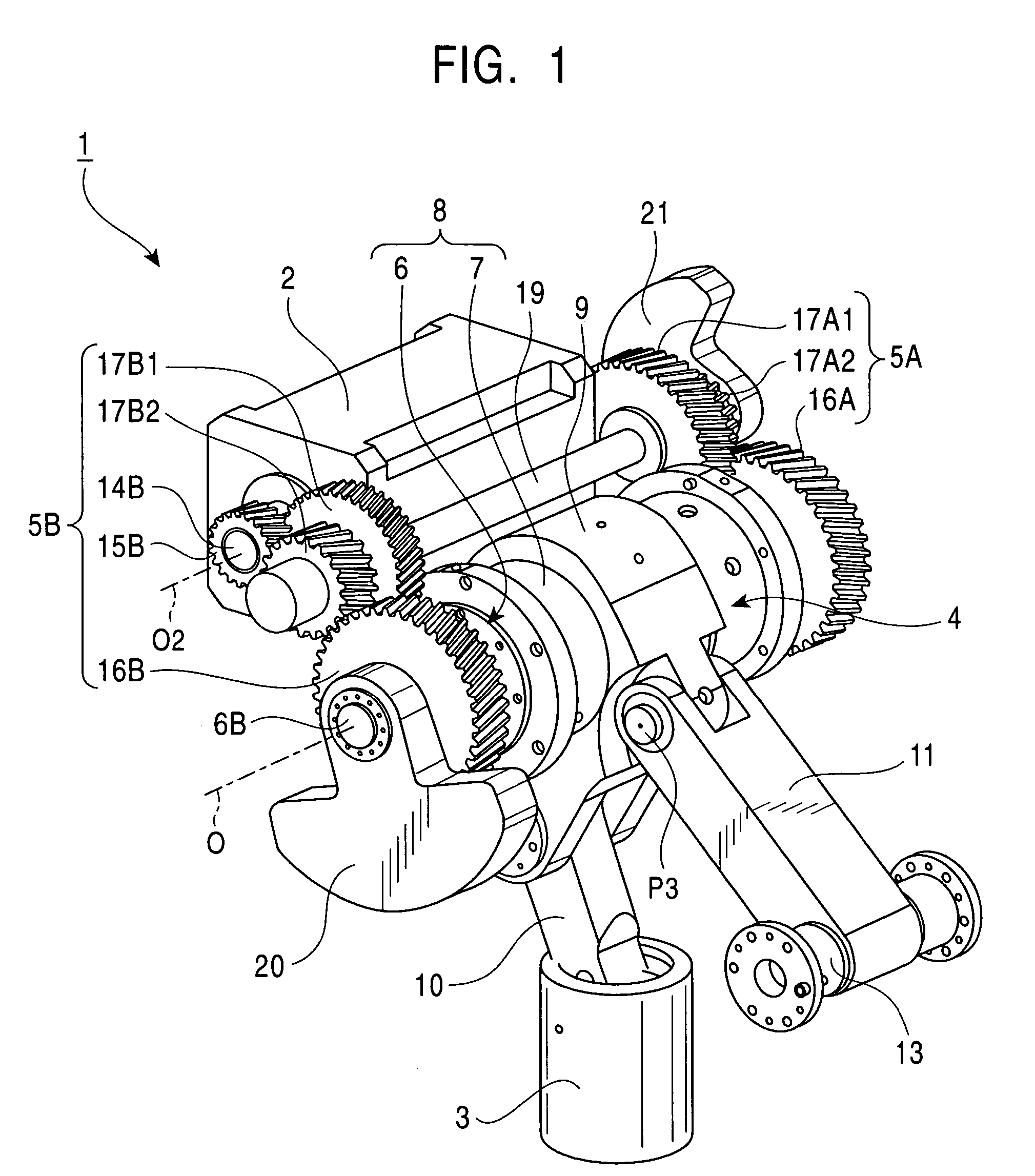

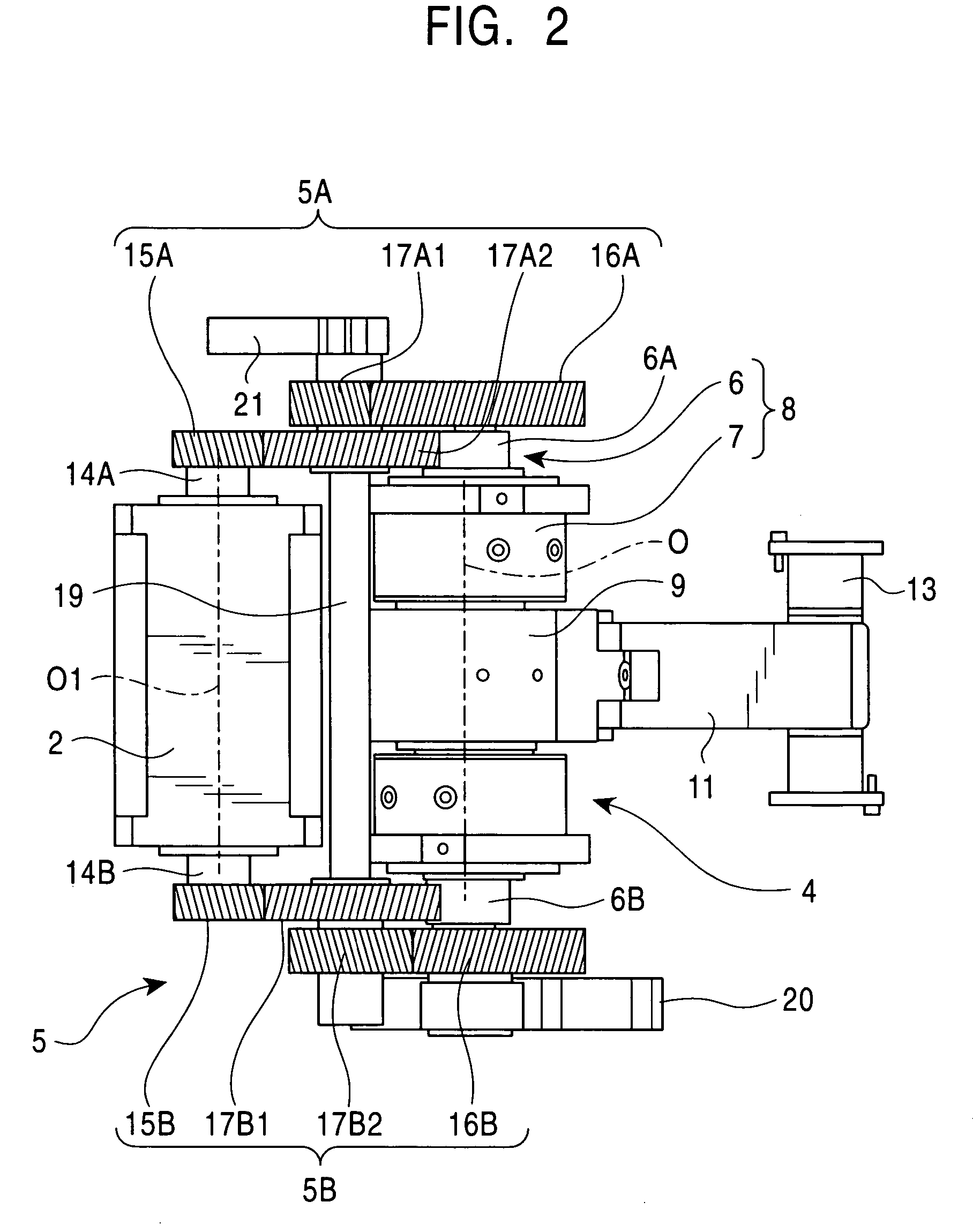

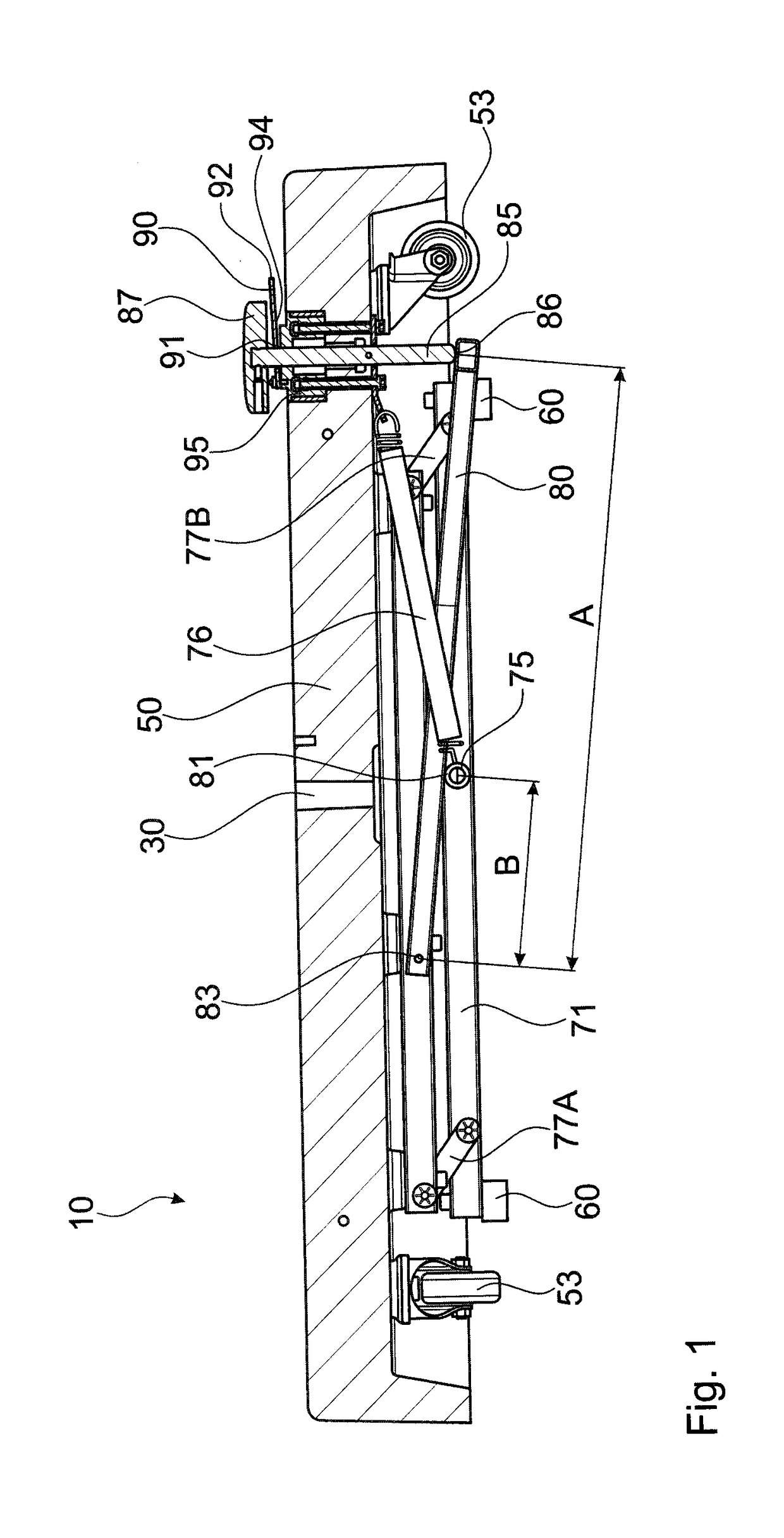

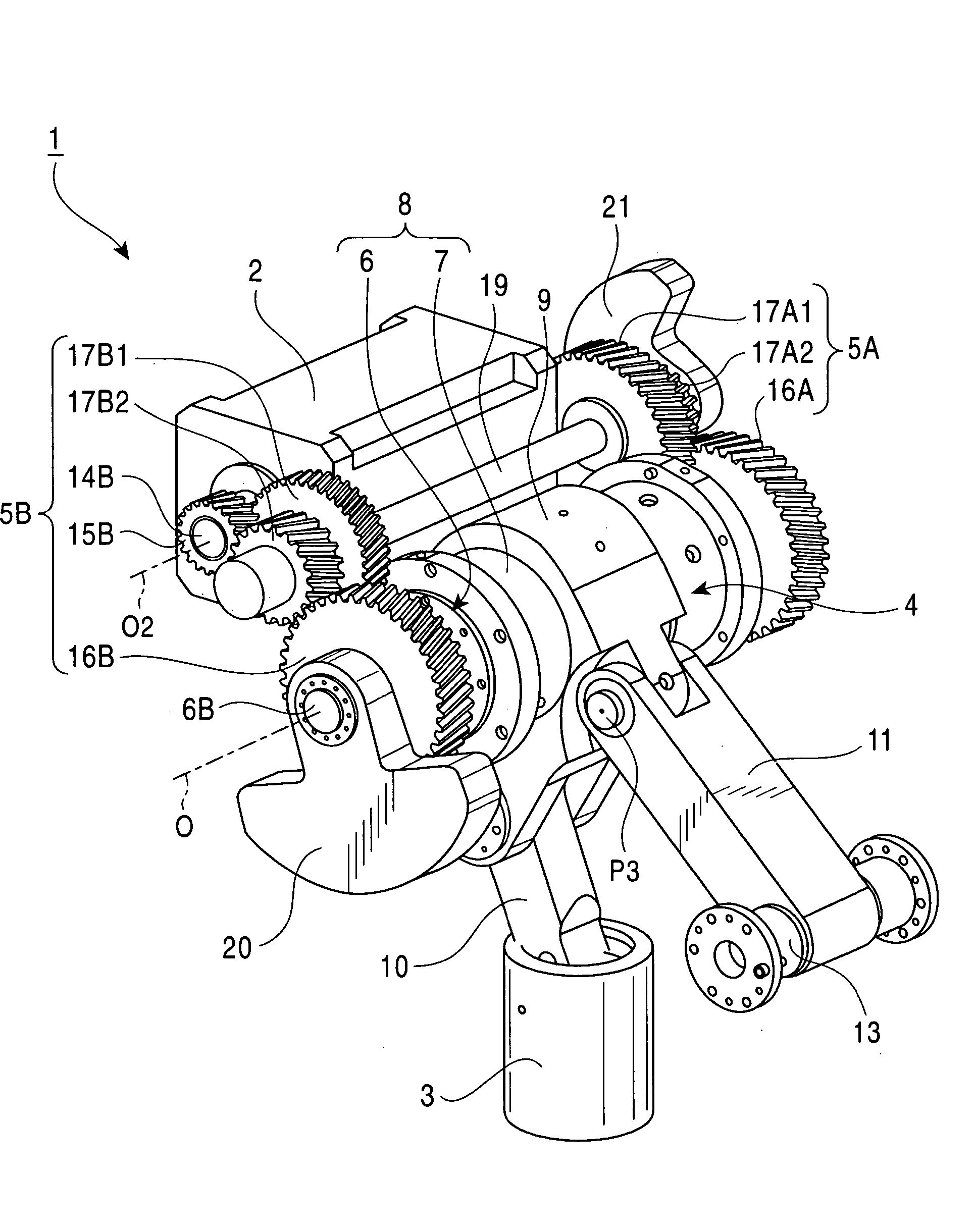

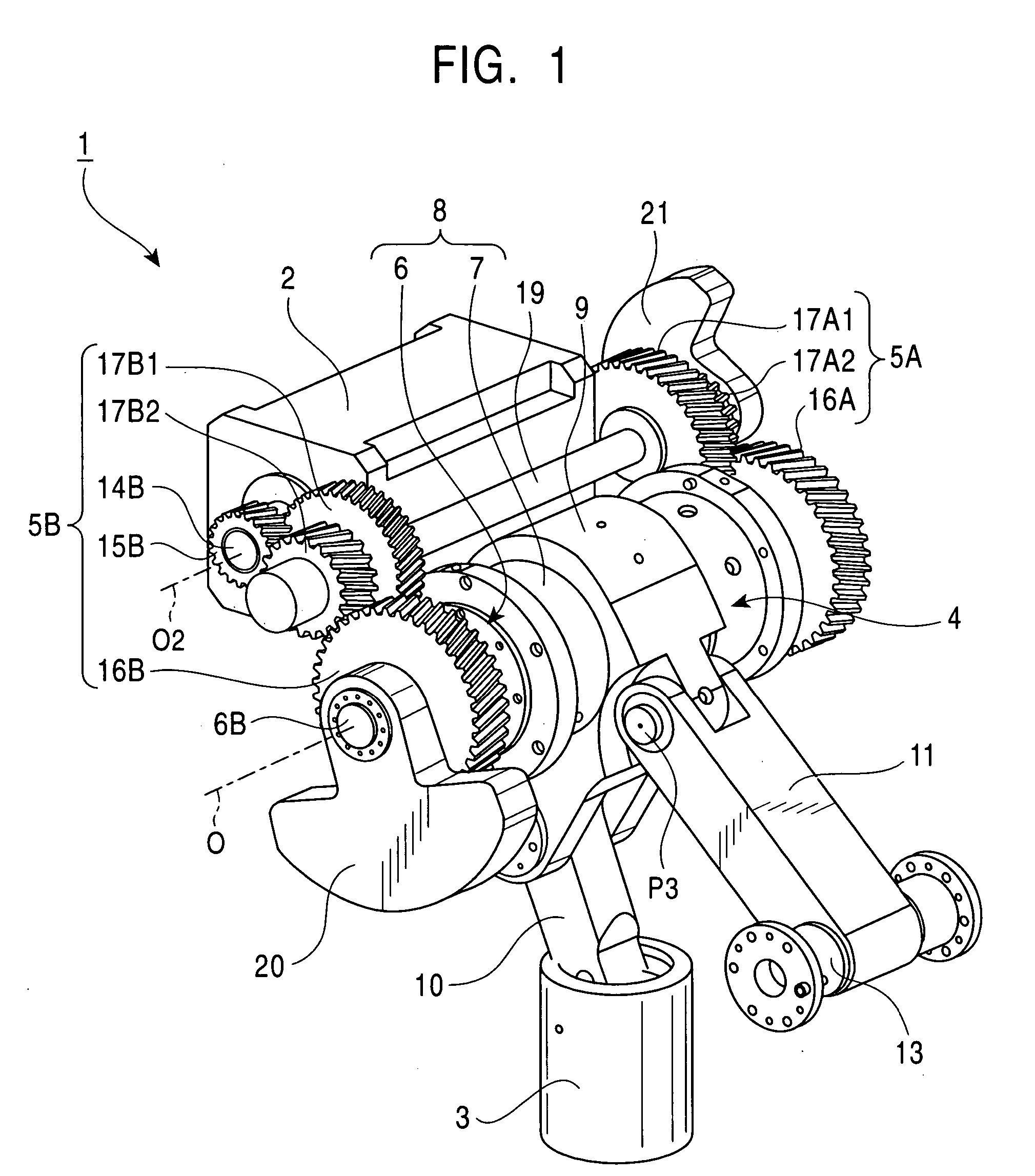

Punch Press

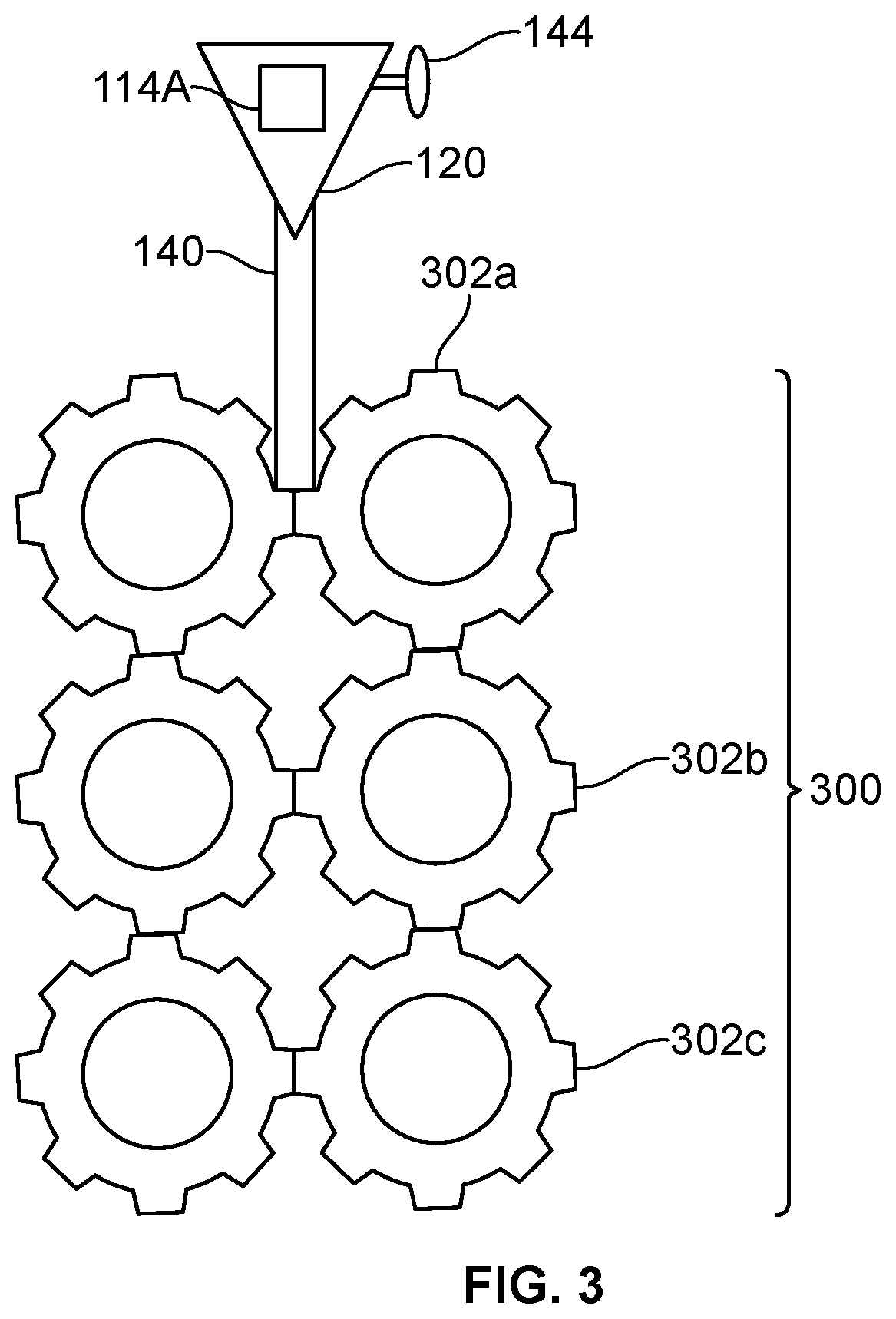

ActiveUS7234337B2Reduce vibrationReduce distortionForging press detailsForging press drivesPunch pressGear wheel

A punch press that provides an arrangement of a motor and a crank mechanism so that the motor does not project far from the side of a frame. The punch press includes a servo motor, a ram which drives a press tool, a crank mechanism which converts a rotating motion transmitted to a crank shaft into an elevating and lowering operation of the ram, and a drive transmitting mechanism which transmits rotation of the servo motor to the crank shaft while reducing rotation speed. The servo motor is next to the crank mechanism and its rotating axis is parallel to the axis of the crank shaft. The drive transmitting mechanism includes servo motor side gears joined to respective output shafts of the servo motor. The servo motor side gears respectively engage, directly or via intermediate gears, with crank side gears joined to the crank shaft.

Owner:MURATA MASCH LTD

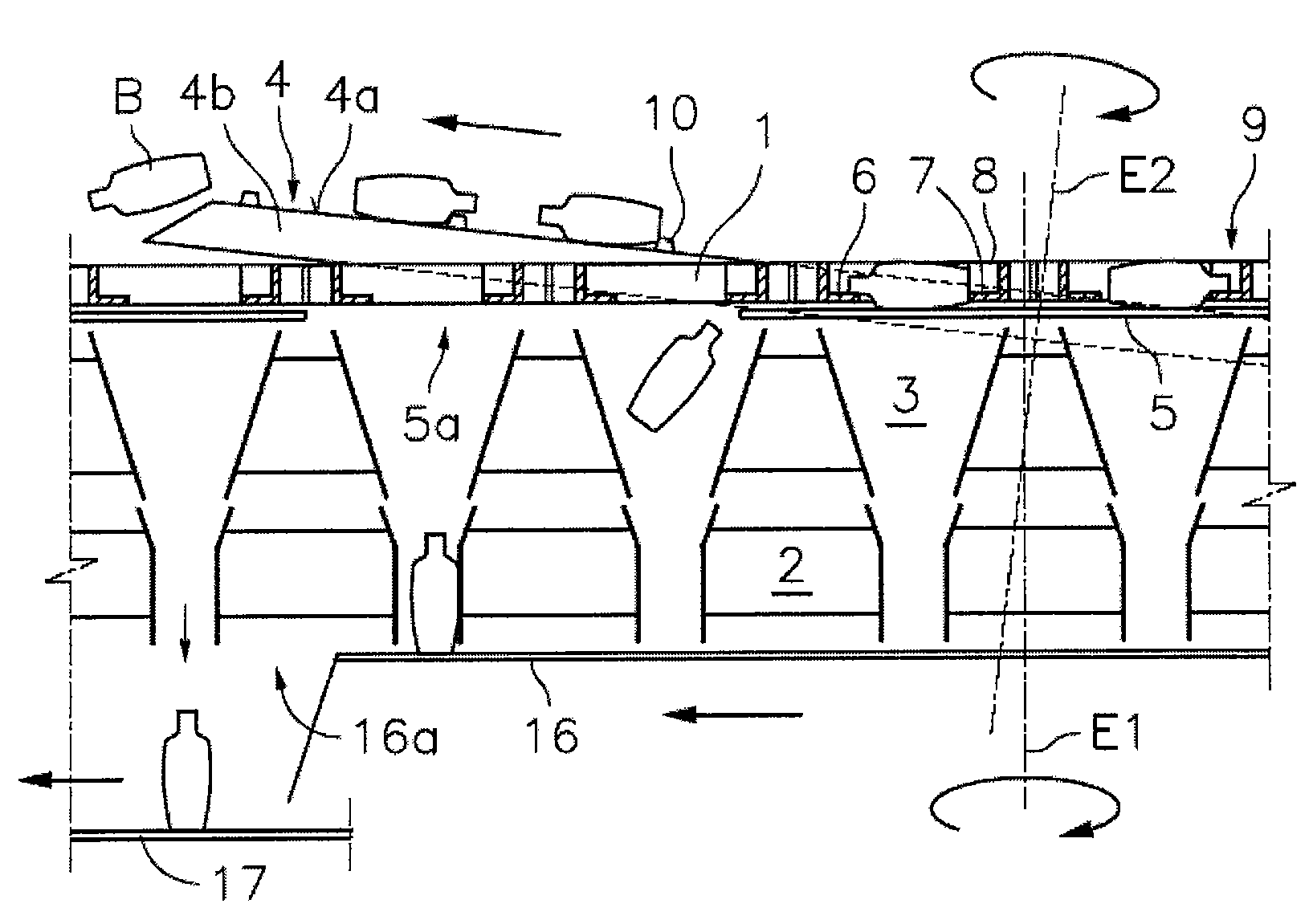

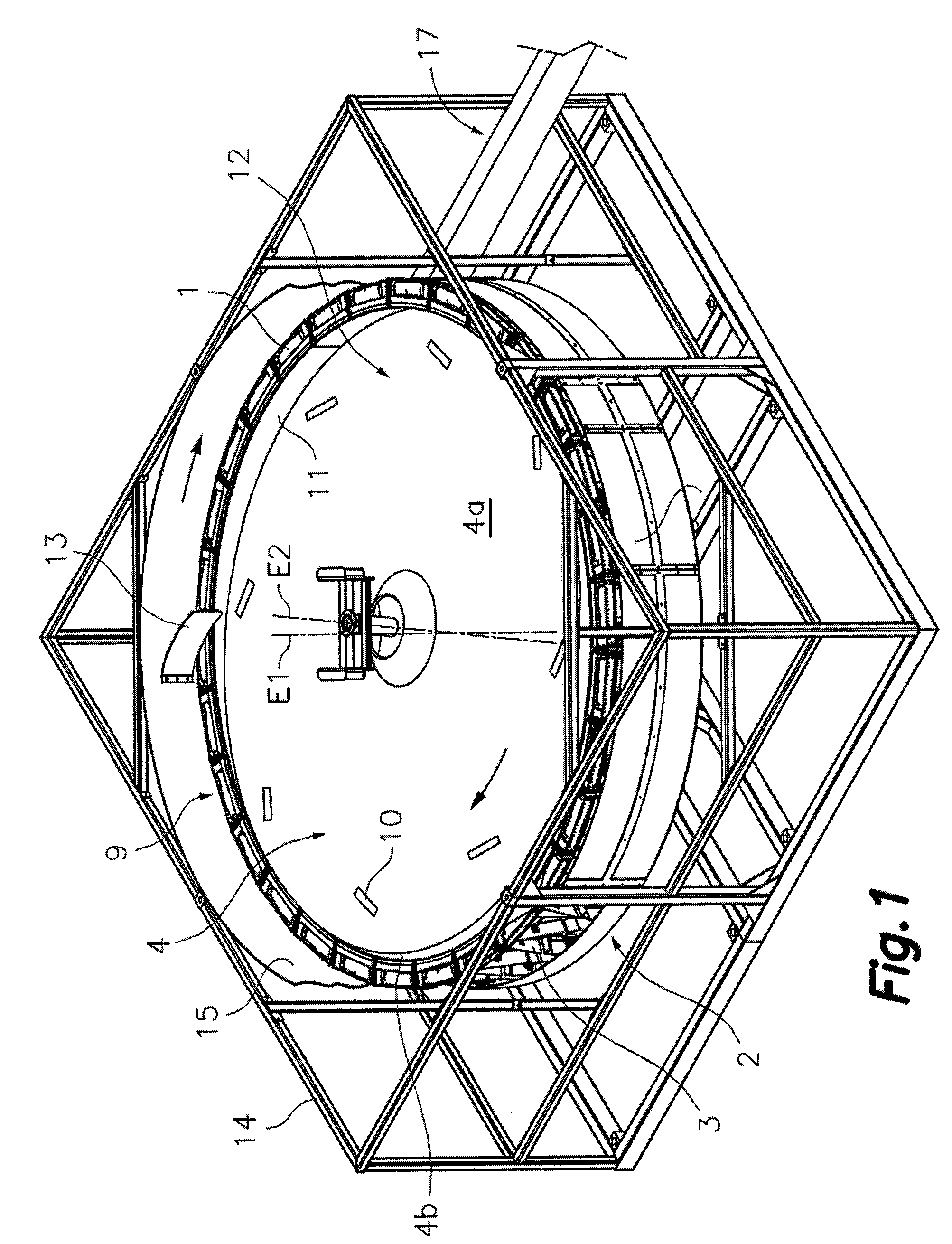

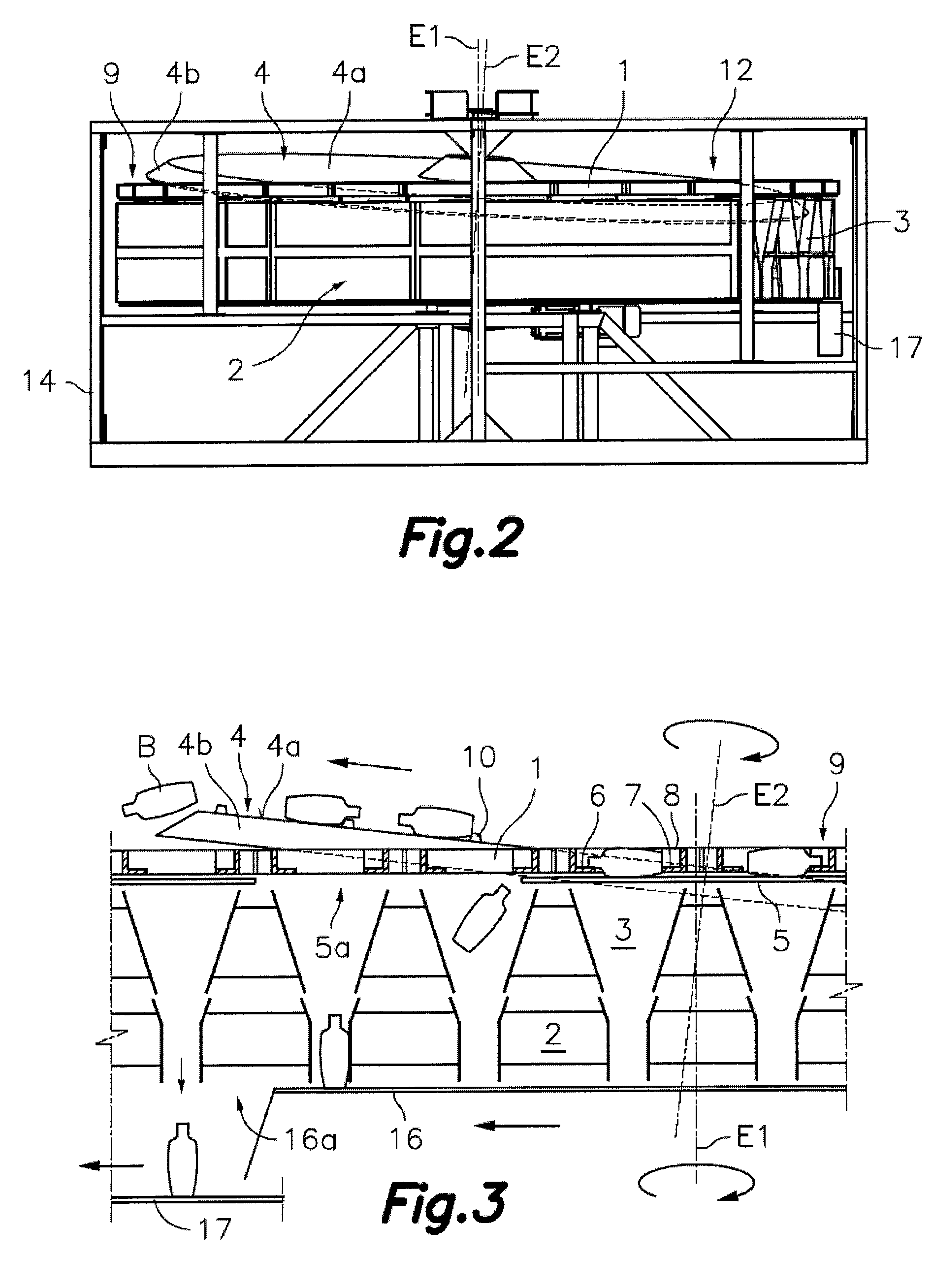

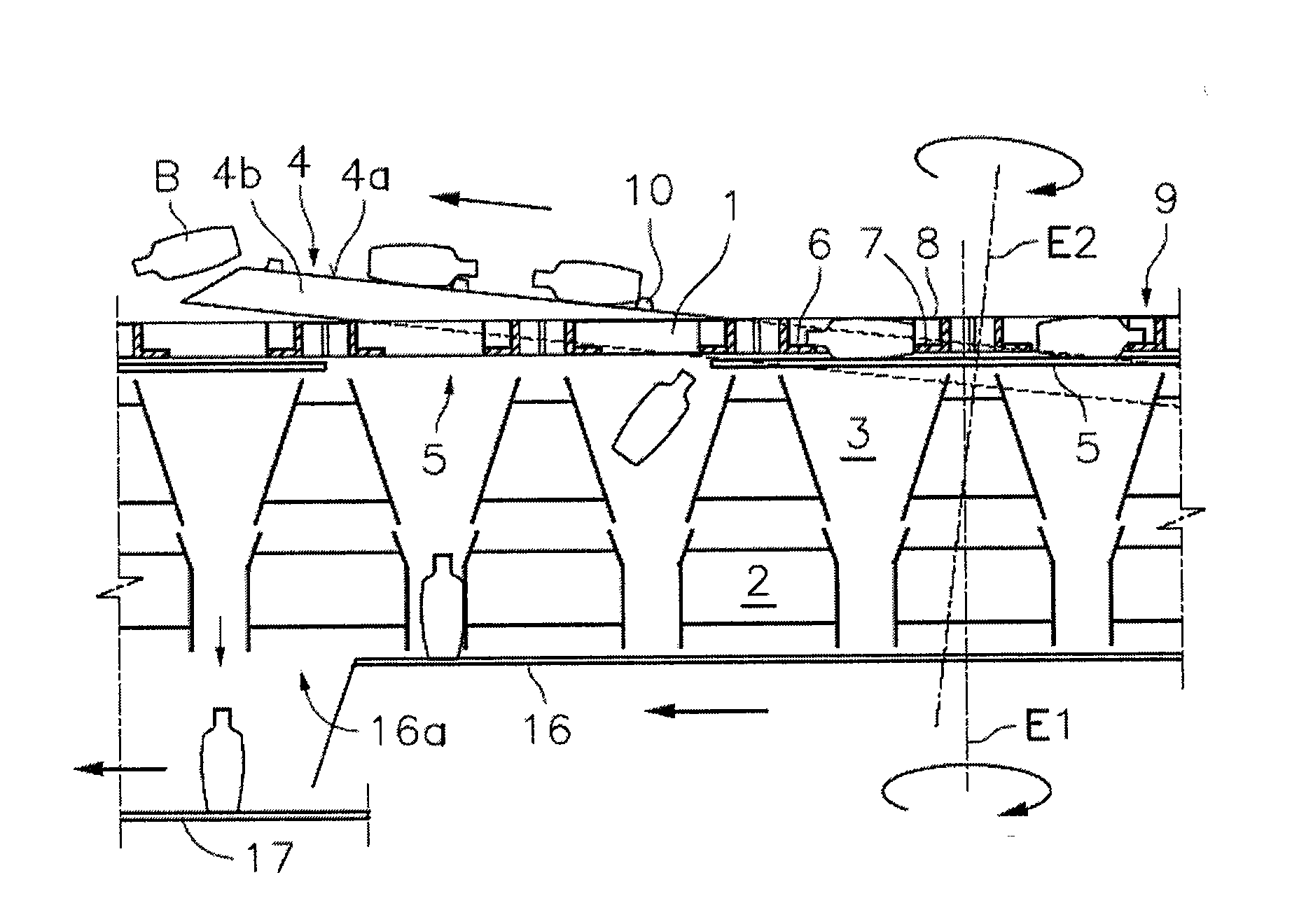

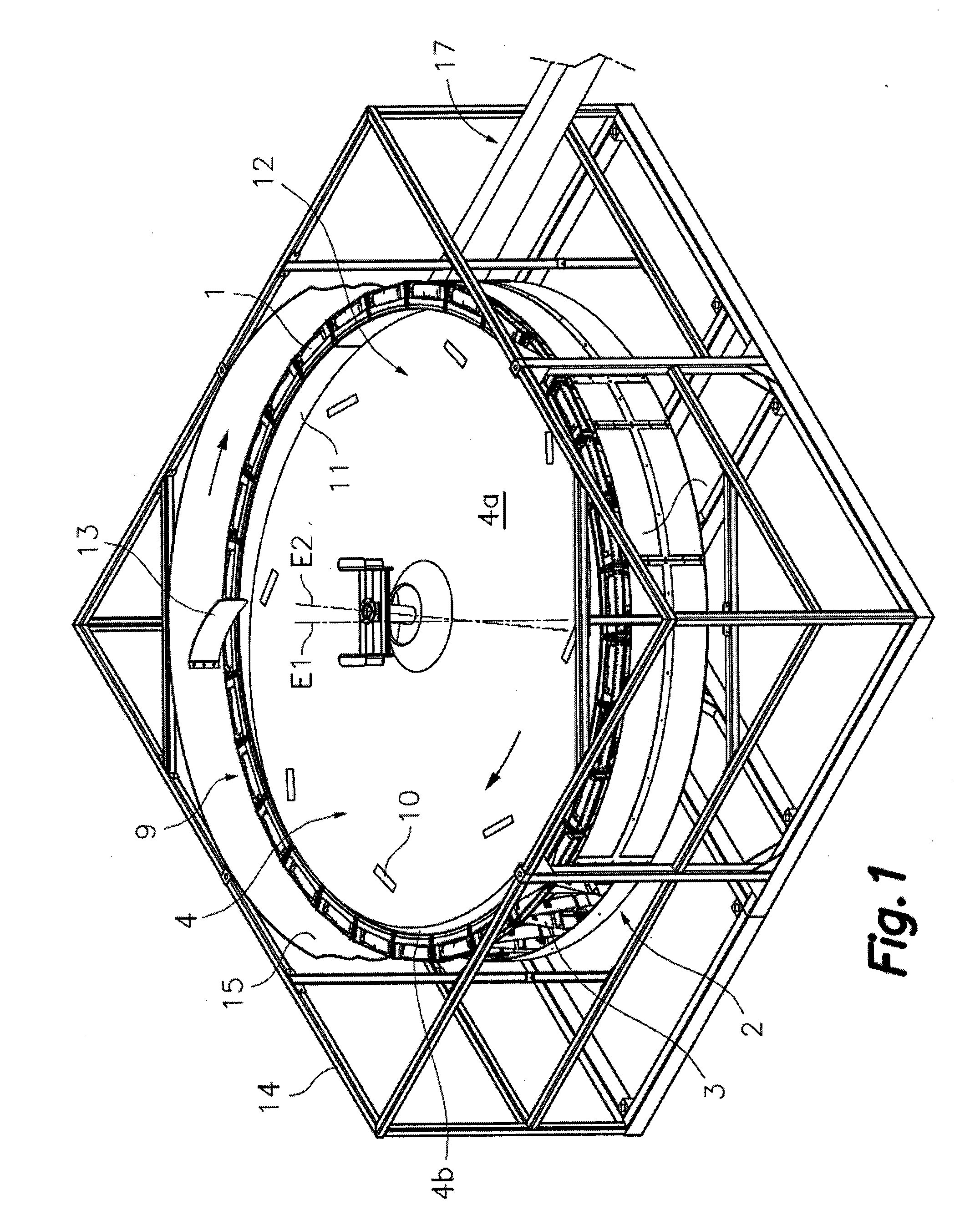

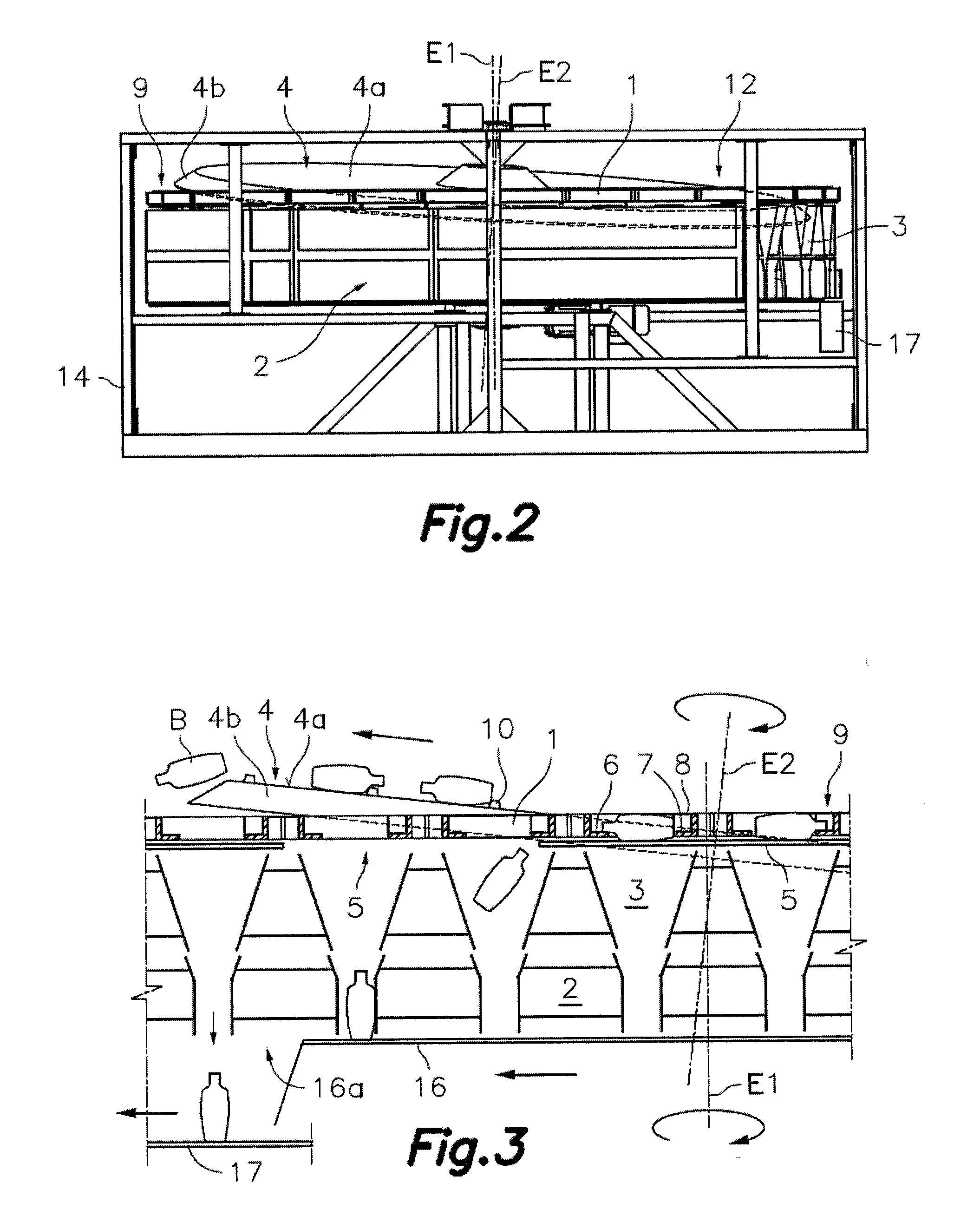

Machine for orienting and aligning articles

InactiveUS7950517B2Easy and inexpensive to constructMedium productivity ratesConveyor partsRotary conveyorsEngineeringSupport plane

A rotary structure carries cavities with an upper inlet for receiving articles and an open bottom for dropping articles distributed along a closed circuit, and funnel-shaped conduits, each of which is located below a respective cavity to receive an article therefrom, a support plane for temporarily supporting the articles in the cavities and dropping them into the corresponding conduits in a site of the closed circuit, and support elements in each cavity to cooperate with parts of the article when the latter falls in order to confer to it a predetermined orientation inside the conduit. The cavities have their inlets in a perimetric ring surrounding a receptacle for the accumulation of the articles on a bottom formed by a rotating disk the peripheral edge of which reaches, upon rotating, a level above the perimetric ring.

Owner:MARTI SALA JAIME +1

Machine for orienting and aligning articles

InactiveUS20090283384A1Easy and inexpensive to constructMedium productivity ratesConveyor partsRotary conveyorsEngineeringFunnel shape

A rotary structure carries cavities with an upper inlet for receiving articles and an open bottom for dropping articles distributed along a closed circuit, and funnel-shaped conduits, each of which is located below a respective cavity to receive an article therefrom, means for temporarily supporting the articles in the cavities and dropping them into the corresponding conduits in a site of the closed circuit, and support elements in each cavity to cooperate with parts of the article when the latter falls in order to confer to it a predetermined orientation inside the conduit. The cavities have their inlets in a perimetric ring surrounding a receptacle for the accumulation of the articles on a bottom formed by a rotating disk the peripheral edge of which reaches, upon rotating, a level above the perimetric ring.

Owner:MARTI SALA JAIME +1

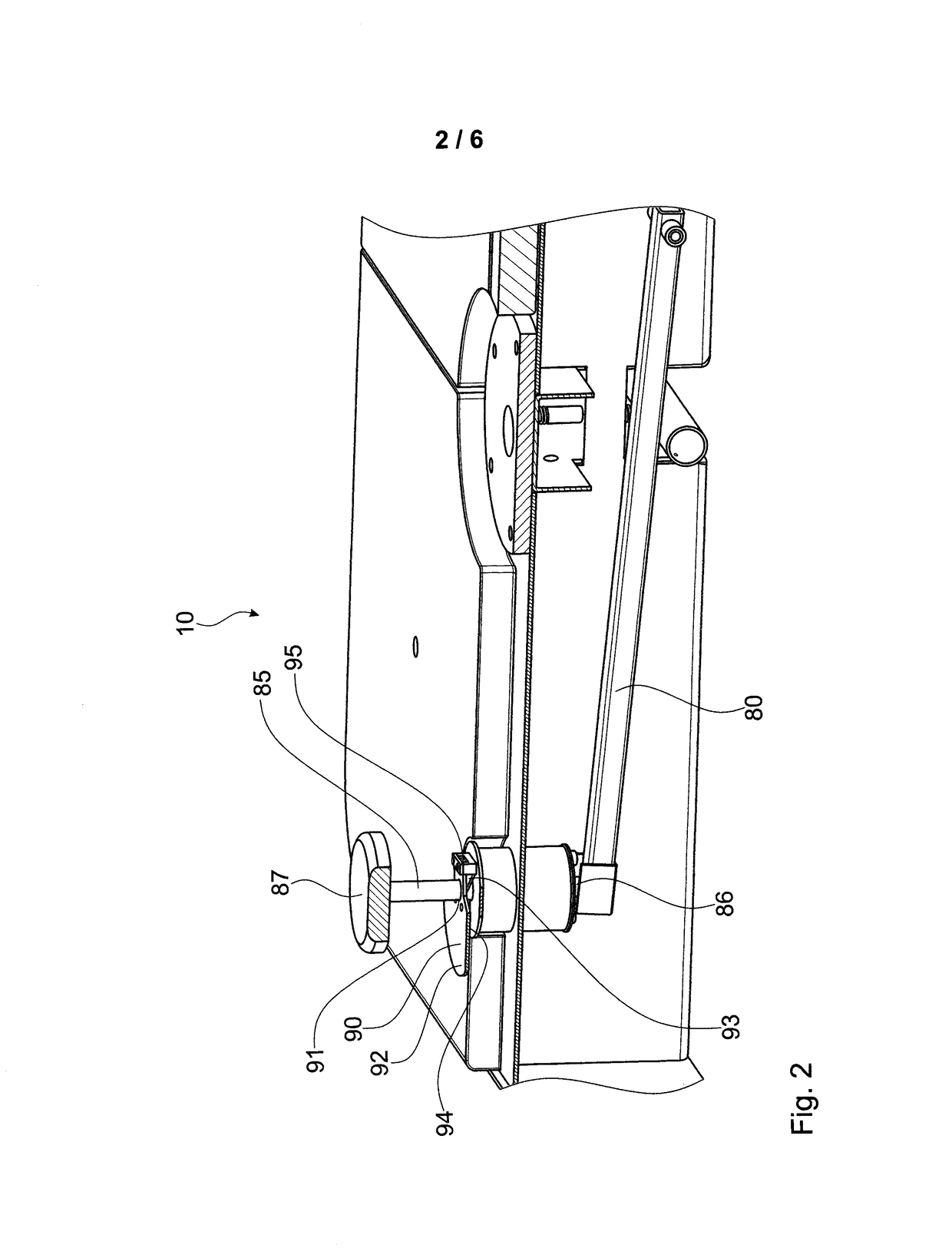

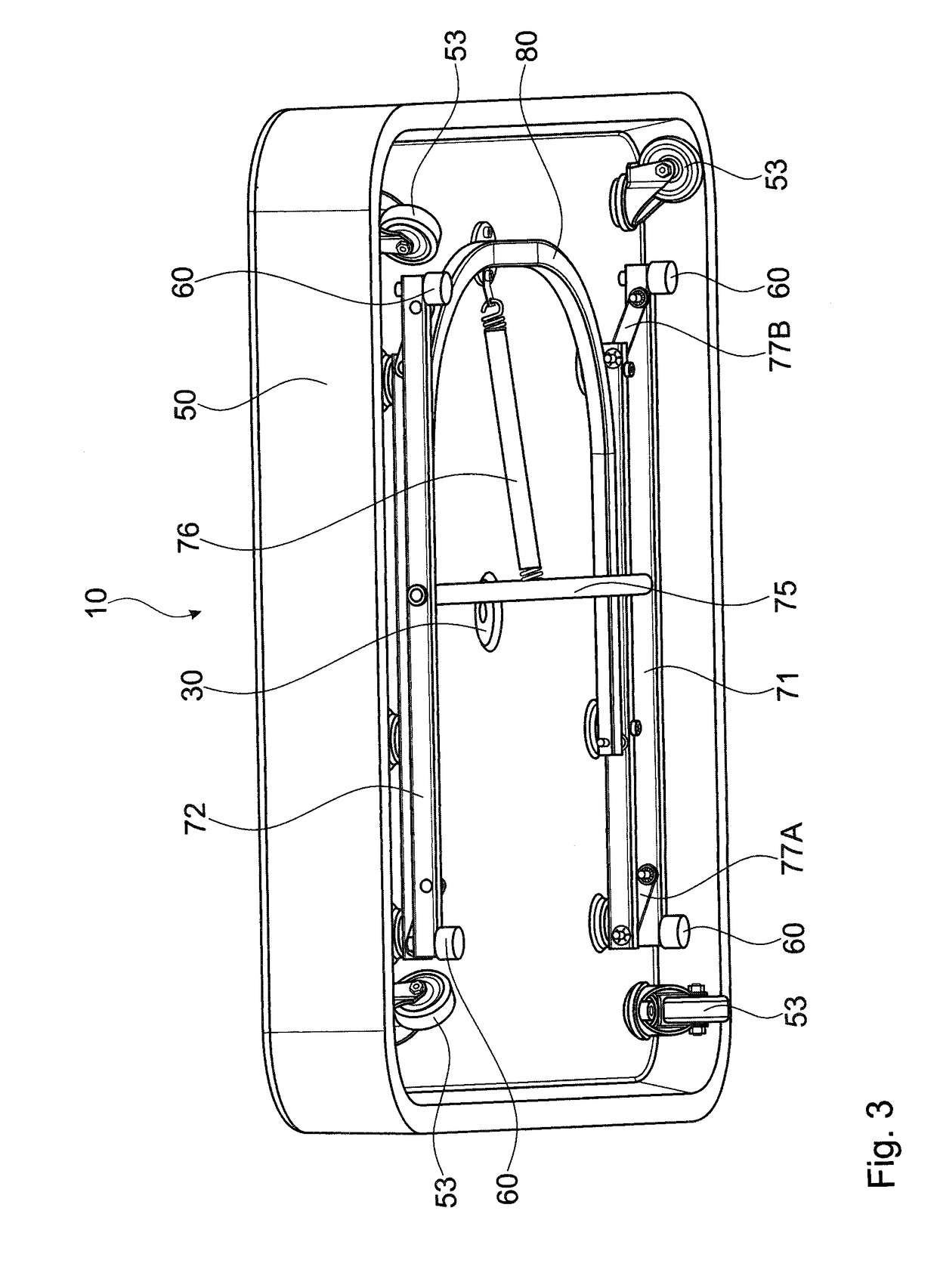

Stand Base with Rollers

ActiveUS20190063103A1Easily and safely establishedEasily and safely and releasedBraking element arrangementsUmbrellasDisplay boardDisplay device

A movable standing base for parasols, display boards, flagpoles and the like comprises a weight part having, firmly attached at the bottom side thereof, at least three, preferably four steering rollers, and it further comprises attachment elements for a parasol, for a display board, for a flagpole or for any other objects to be set up, and a plurality of preferably four lowerable blocking feet. In order to improve ease of handling without loss of stability, the blocking feet are connected to each other in the edge region of the weight part by two bridge girders arranged opposite to each other and a middle yoke and are anchored to the weight part in a substantially parallelogram shaped lowerable manner by two pivot levers. A tensioning lever is disposed resting on the middle yoke, and a pressure element leads to a blocking pedal at the upper side of the standing base.

Owner:GLATZ AG

Waste Water Electrical Power Generating System

InactiveUS20080031691A1Without adversely impactingEasy and inexpensive to constructWater-power plantsSafety/regulatory devicesElectric power transmissionPenstock

Owner:CRIPPS JEFFREY L

Modular furniture system

InactiveUS7798076B1Easy and inexpensive to constructImprove artTablesSectional furnitureModularityEngineering

A modular furniture system that includes a base cabinet having a drawer used for storage and able to be opened and closed; a plurality of shelf members; means for support the plurality of shelf members in at least one stacked array over said base cabinet; and a plurality of modular leg members that are interengageable by screwing together and that are adapted for placement in said drawer.

Owner:ROUND & ROUND

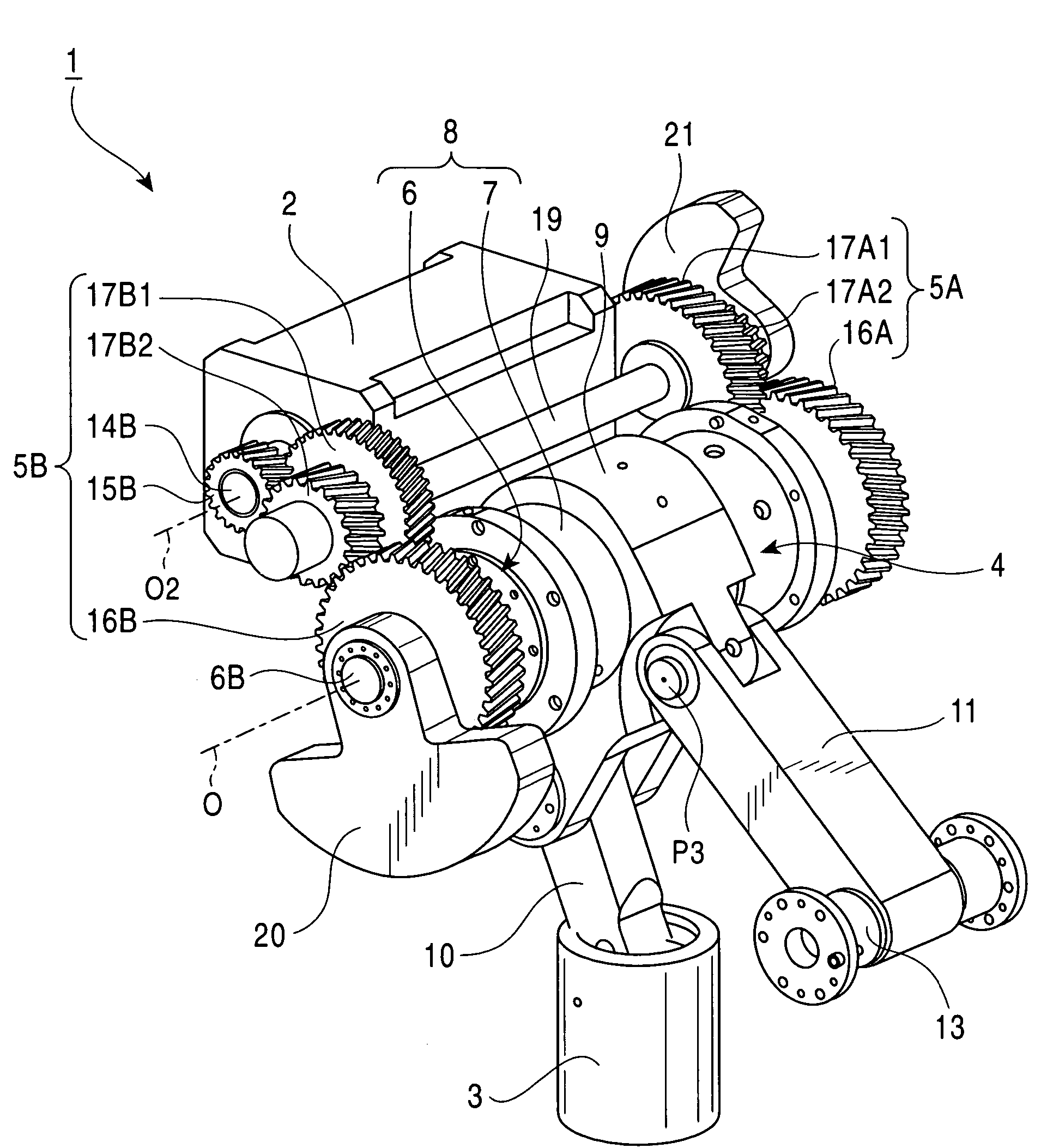

Punch press

ActiveUS20050040775A1Reduce vibrationReduce distortionGas pressure propulsion mountingDynamo-electric converter controlPunch pressThermal expansion

The present invention provides a punch press that enables the arrangement length of a motor and a crank mechanism to be reduced so that the motor can be installed without being projected far from a side of a frame, the punch press avoiding biasing the motor, which may act as a heat source, to reduce the magnitude of deformation resulting from a difference in thermal expansion between the right and left sides of the frame. A punch press includes a servo motor 2, a ram 3 which drives a press tool, and a crank mechanism 4 which converts a rotating motion transmitted to a crank shaft 6 into an elevating and lowering operation of the ram 3. The punch press is provided with a drive transmitting mechanism 5 which transmits rotation of the servo motor 2 to the crank shaft 6 while reducing a rotation speed. The servo motor 2 is placed by the side of the crank mechanism 4 so that its rotating axis 01 is parallel to the axis 0 of the crank shaft 6. The drive transmitting mechanism 5 is composed of a gear mechanism in which servo motor side gears 15A, 15B joined to respective output shafts 14A, 14B of the servo motor 2 engage, directly or via intermediate gears 17A1 to 17B2, with crank side gears 16A, 16B, respectively, joined to the crank shaft 6.

Owner:MURATA MASCH LTD

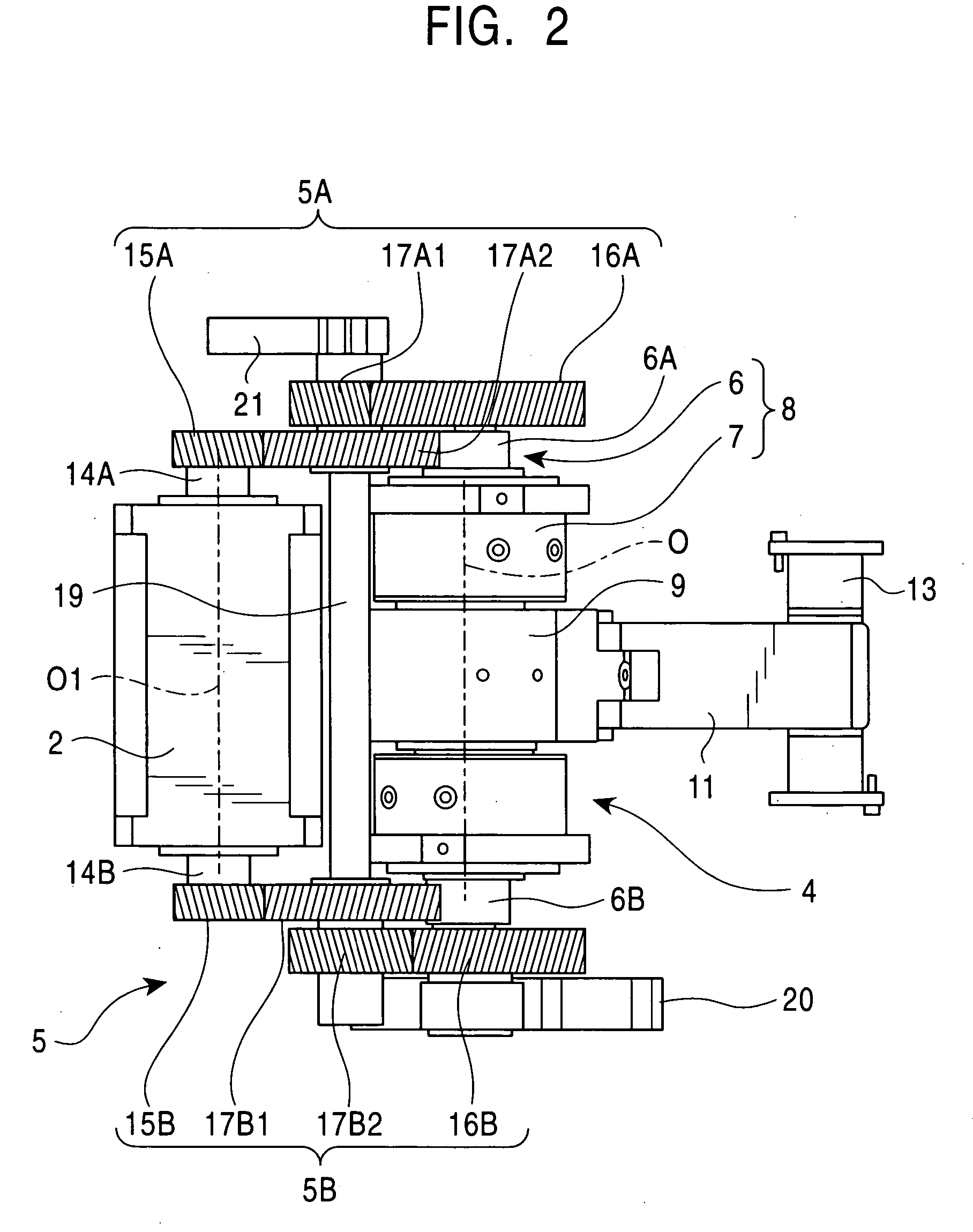

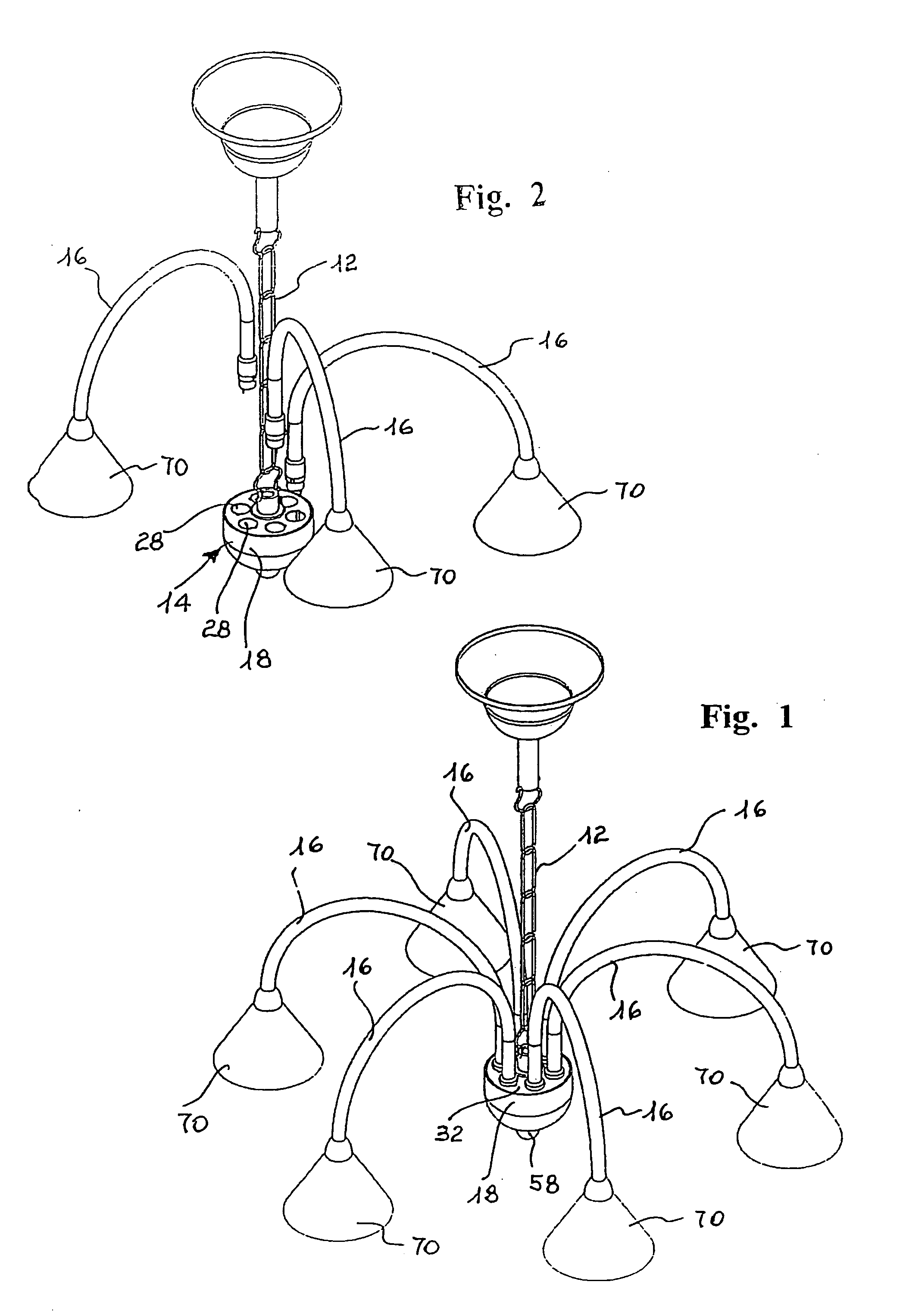

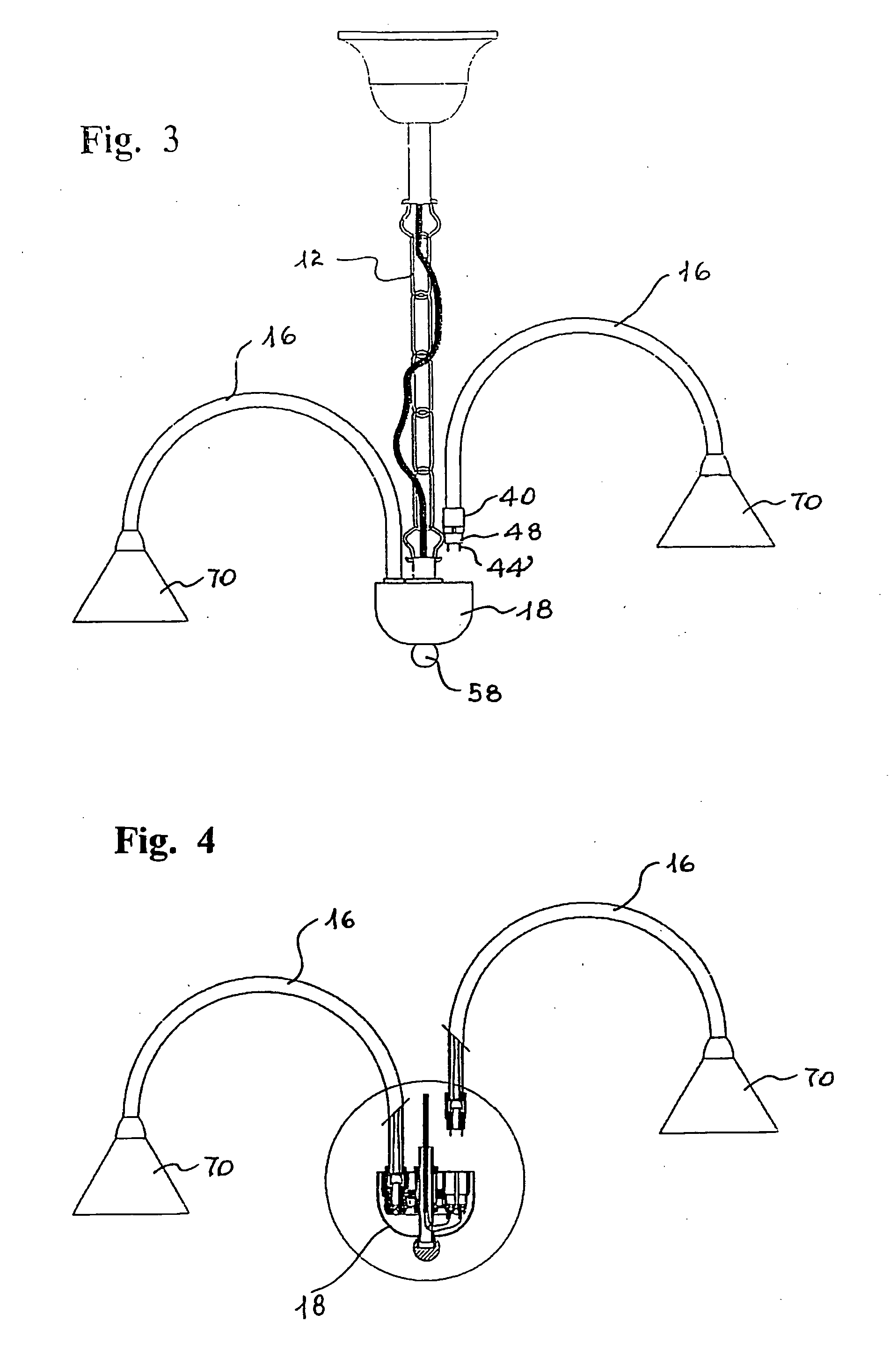

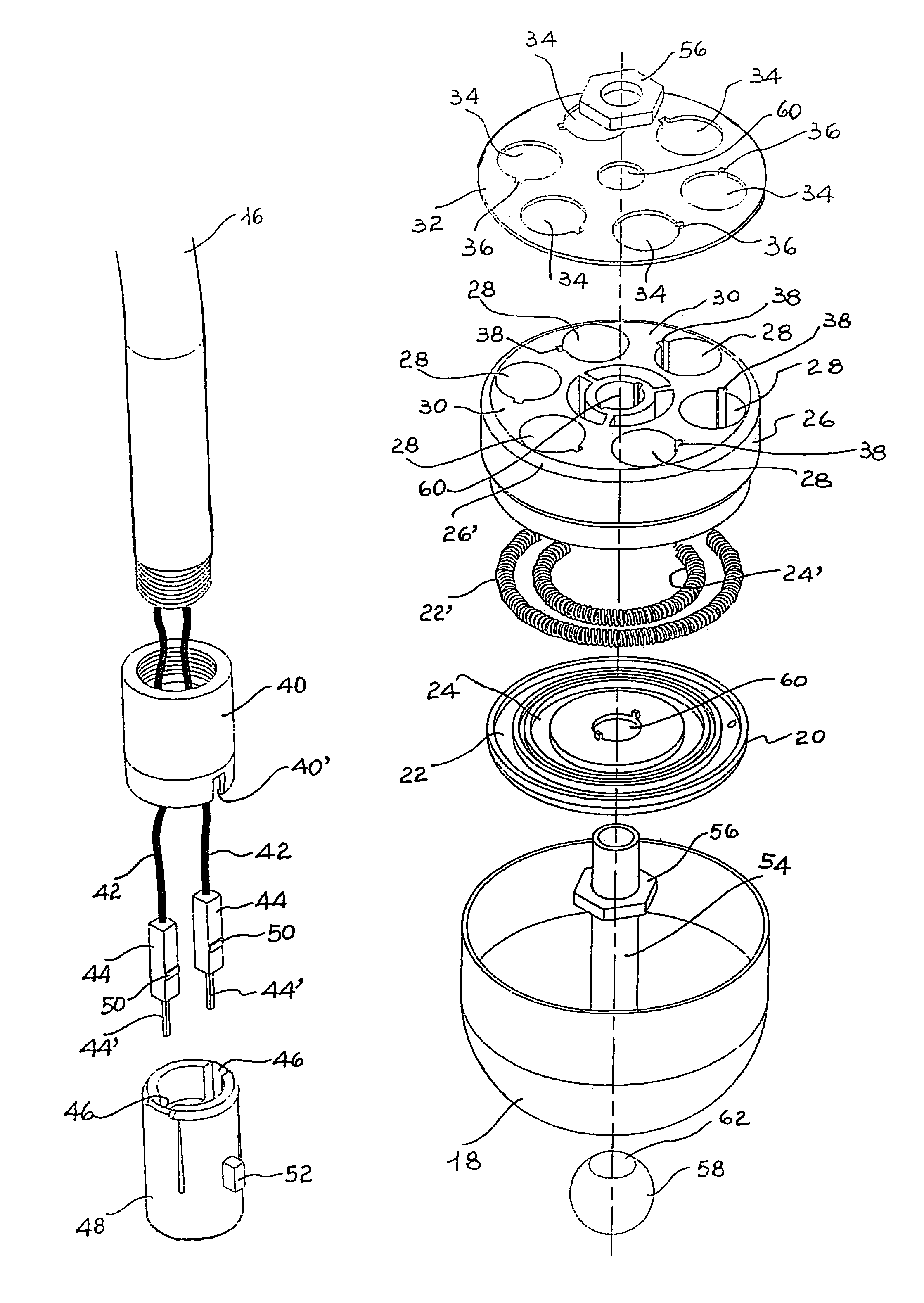

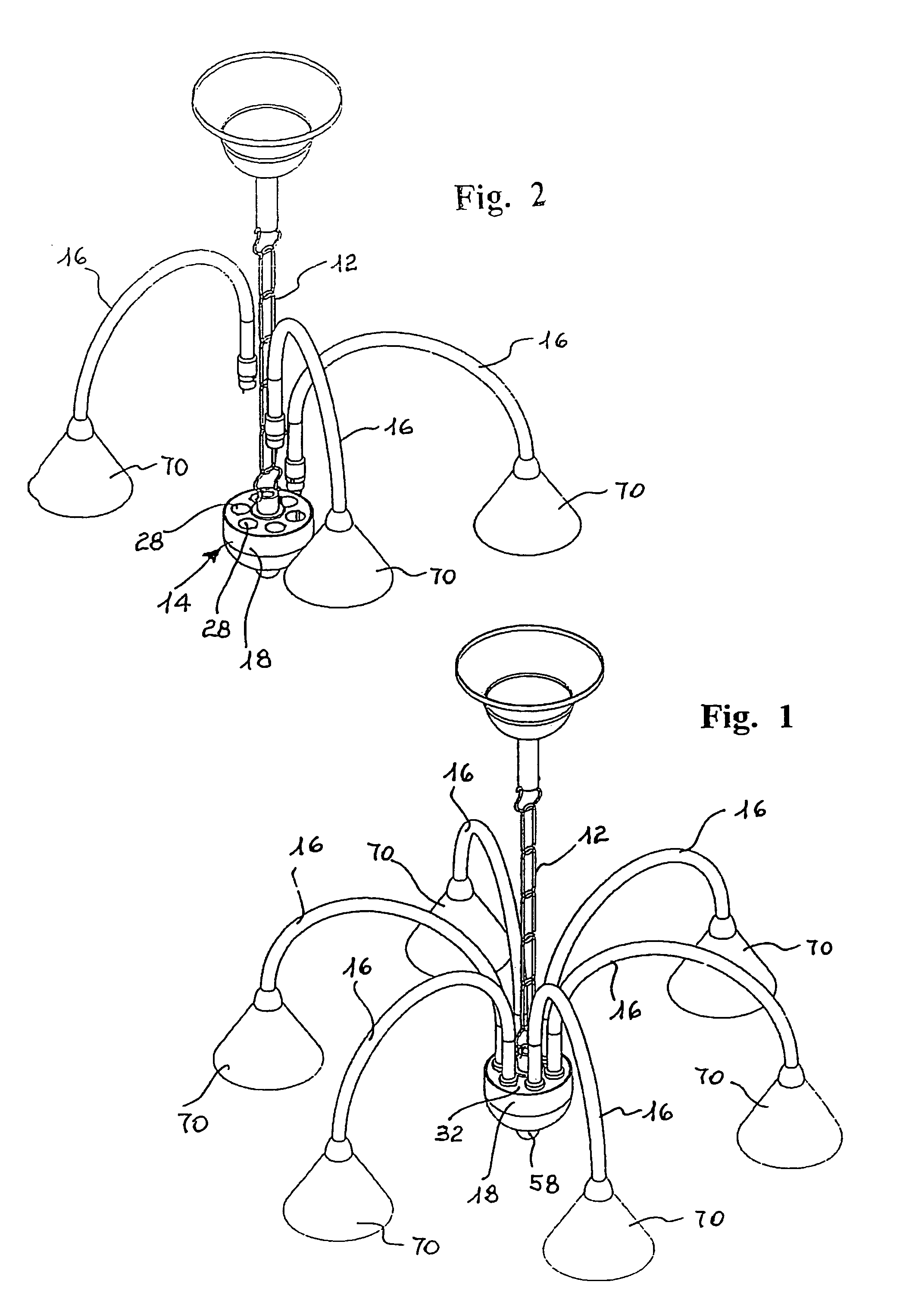

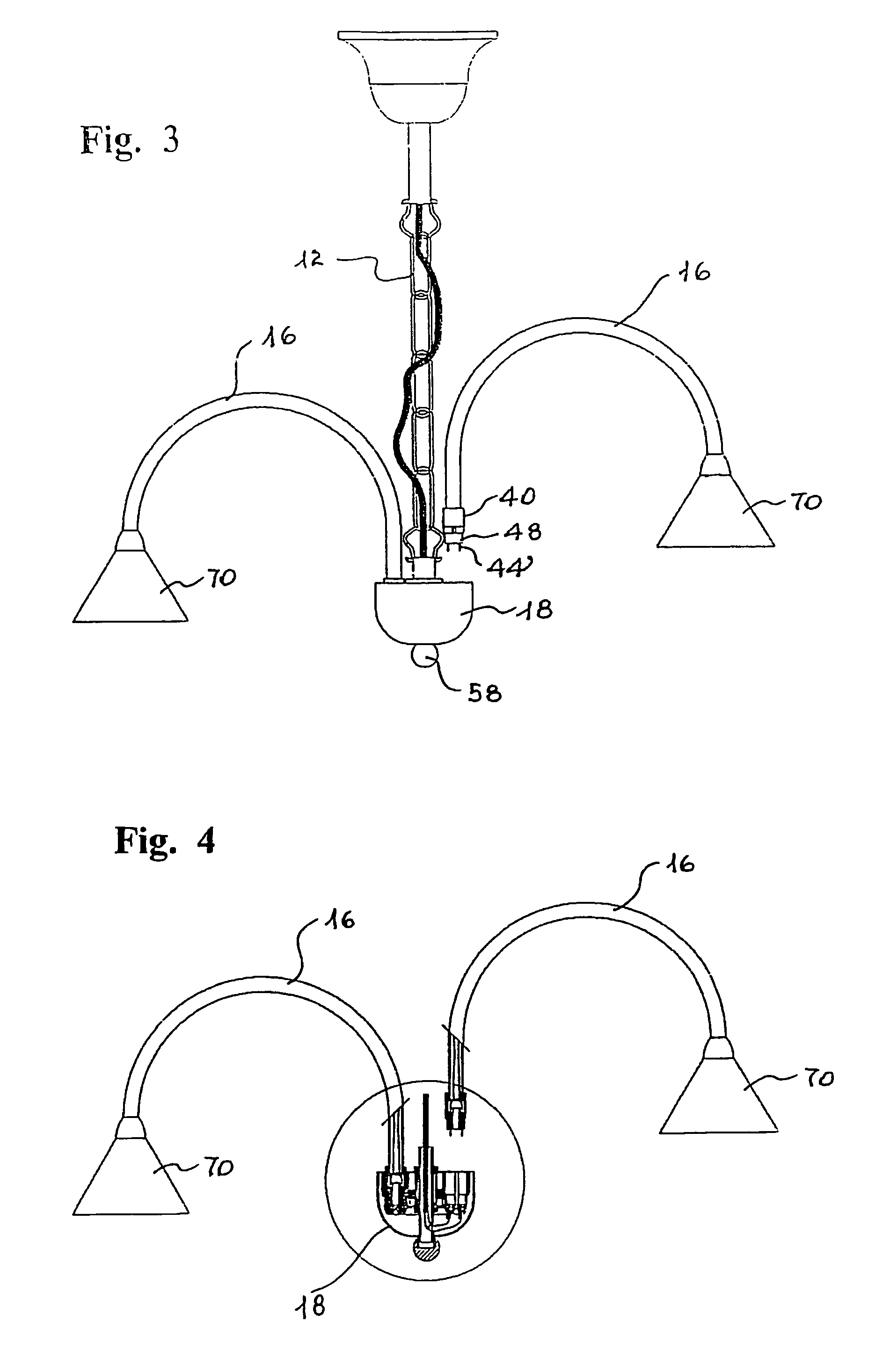

Modular lighting fixture with improved device for connecting the arms to the respective support

InactiveUS20110199775A1Reduced dimensionEasy to packLighting support devicesElectric circuit arrangementsElectrical conductorLight fixture

A modular lighting fixture (10) is provided with a plurality of arms (16) branching off a central support (14) wherein they are inserted pressure-wise starting from the respective bottom ends. The central support comprises a containment body (18) wherein a plate (20) is arranged, with concentric seats (22,24) for as many spiral electrical conductors (22′, 24′) surmounted by a cylindrical plate (26) of insulating material wherein a plurality of through seats (28) with circular plan or wells is peripherally obtained, starting from a plane (30), wherein the bottom ends of arms (16) are inserted, provided with the electrical cables (42) for powering a lighting body connected to the opposite top end of the same arms. The bottom end of the arms is made integral to a sleeve (40) provided, along the base perimeter, with a vertical notch (40′) intended for coupling with a projection (52) protruding from the outer side surface of a cylindrical body (48), whereon the sleeve is fitted pressure-wise.

Owner:VOLTOLINA FRANCESCO

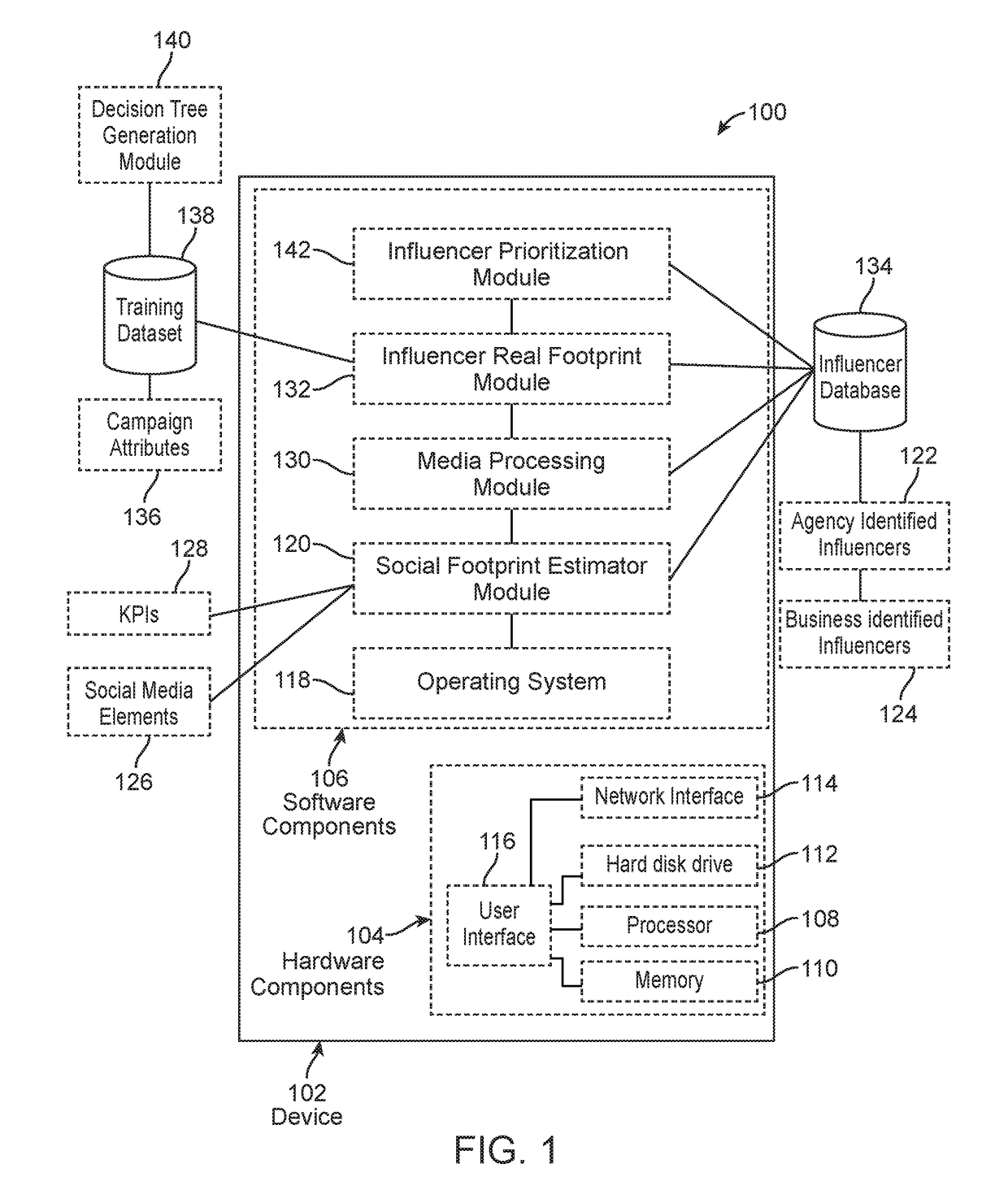

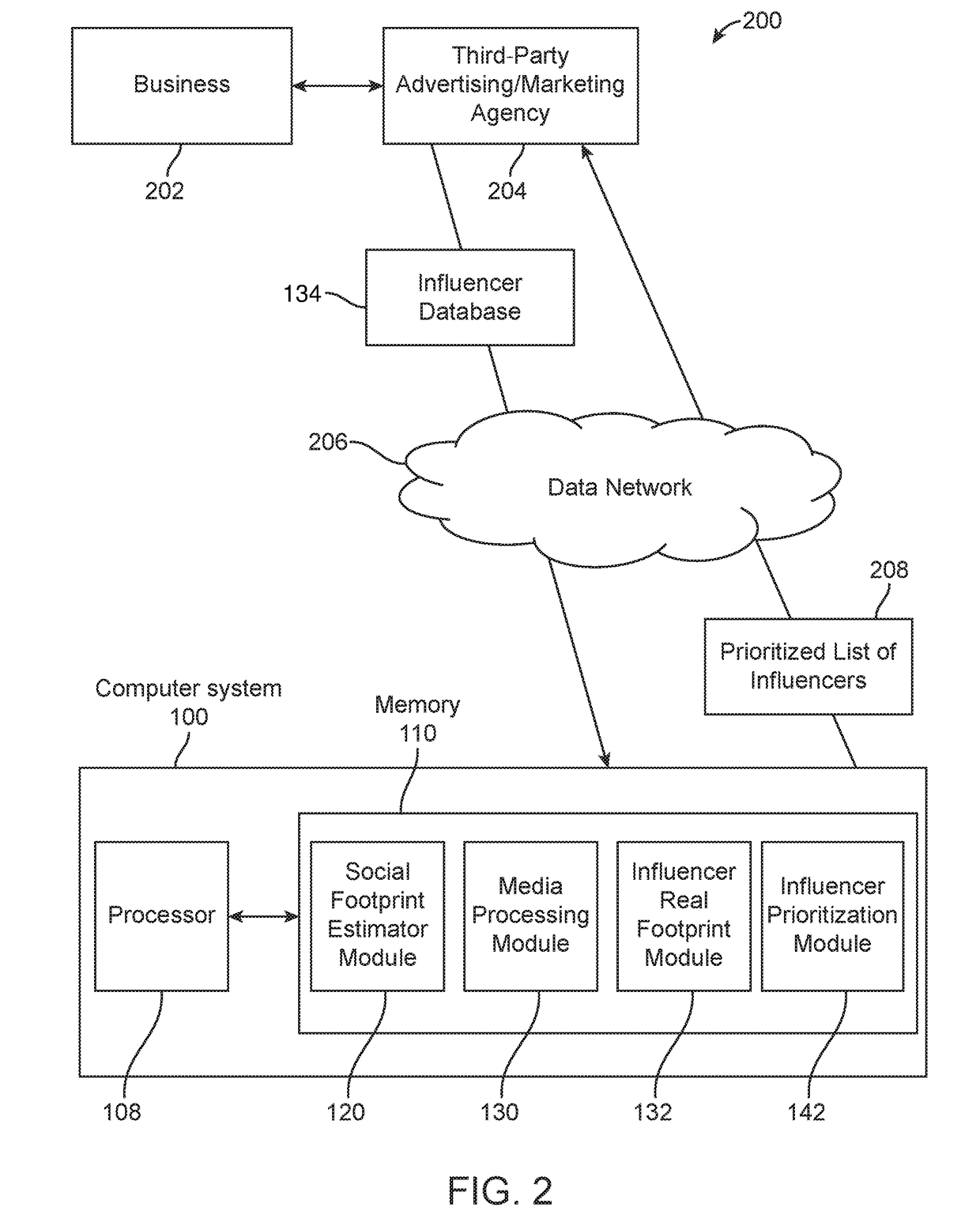

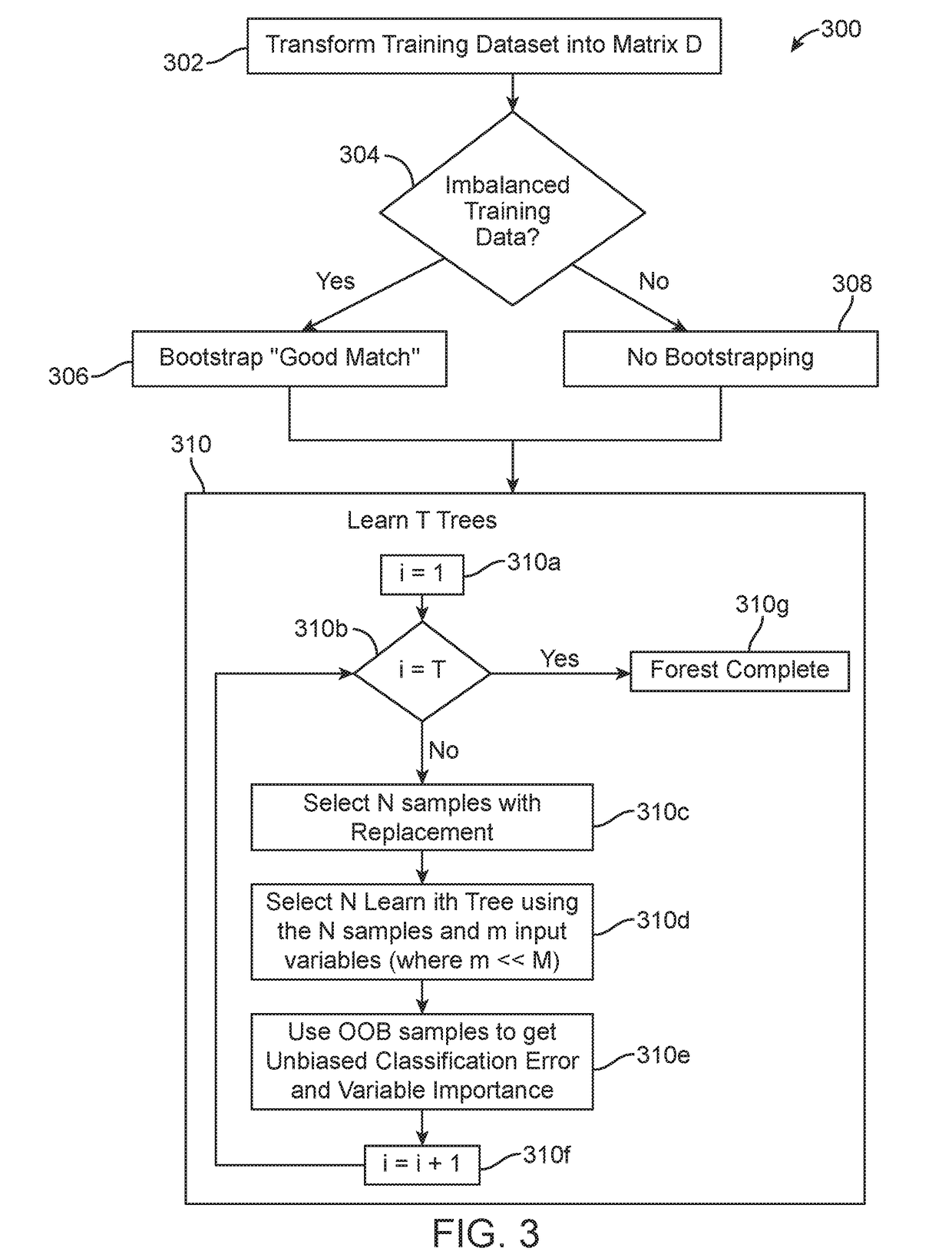

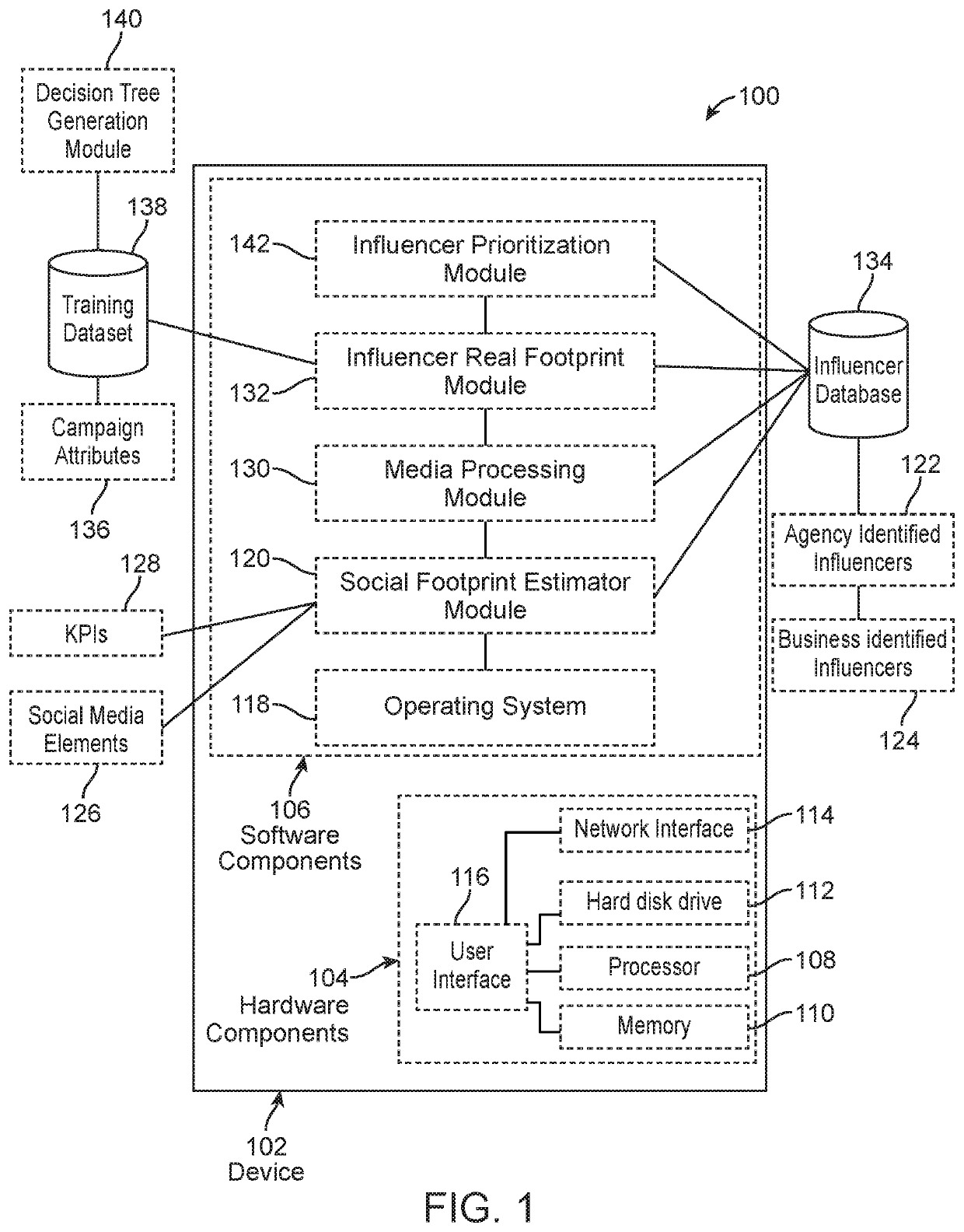

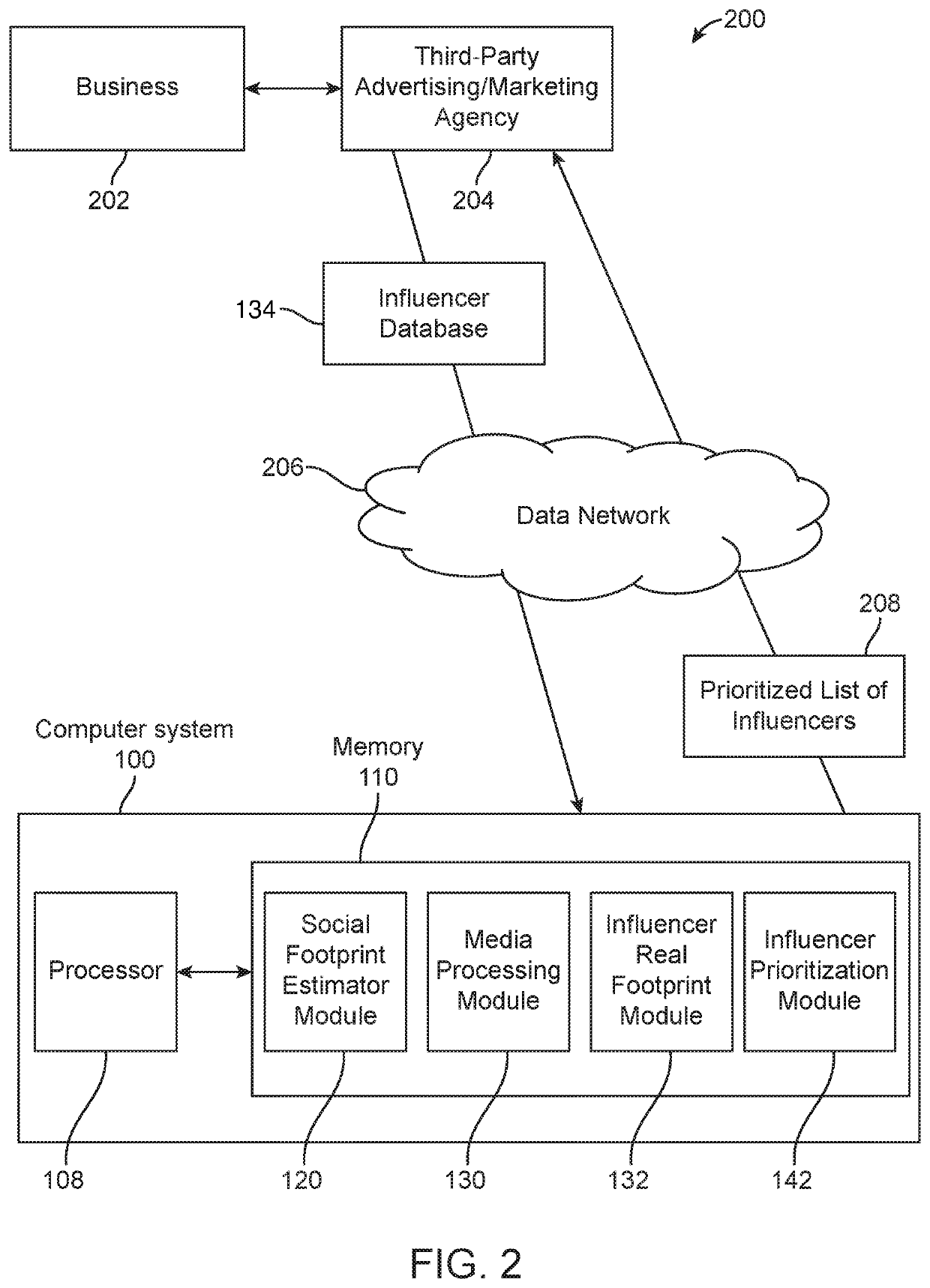

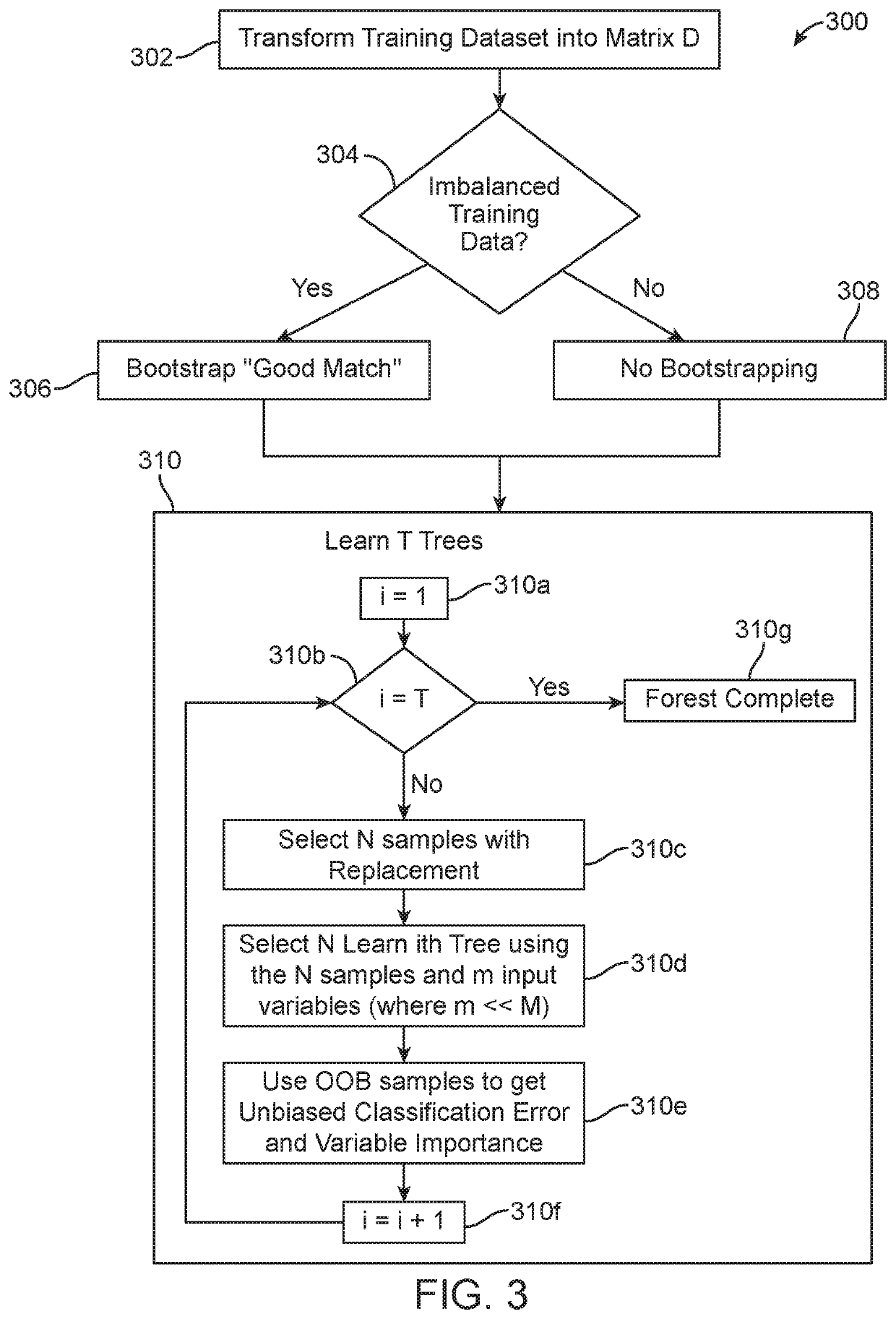

System and method for evaluating the true reach of social media influencers

ActiveUS20190012746A1Increase efficiency and effectivenessEasy and inexpensive to constructEnsemble learningBiological modelsData setSocial media

A non-transitory computer readable storage media having computer-executable instructions, when executed by a processor, performs a method for evaluating a reach of a social media influencer. The methods provides for receiving a plurality of influencers at a server, wherein a data set is associated with each of the plurality of influencers; parsing the data set into quantitative data readable by a machine learning algorithm at the server; receiving, inputting, or both, a type of product or service at the server; classifying the type of product or service into at least one class of goods or services; training a node using the machine learning algorithm using the date set an input; and executing the machine learning algorithm to determine a score of each influencer for each class of goods or services. Systems for evaluating the reach of a social media influencer as it relates to advertisers and content is also disclosed herein.

Owner:MSM HLDG PTE

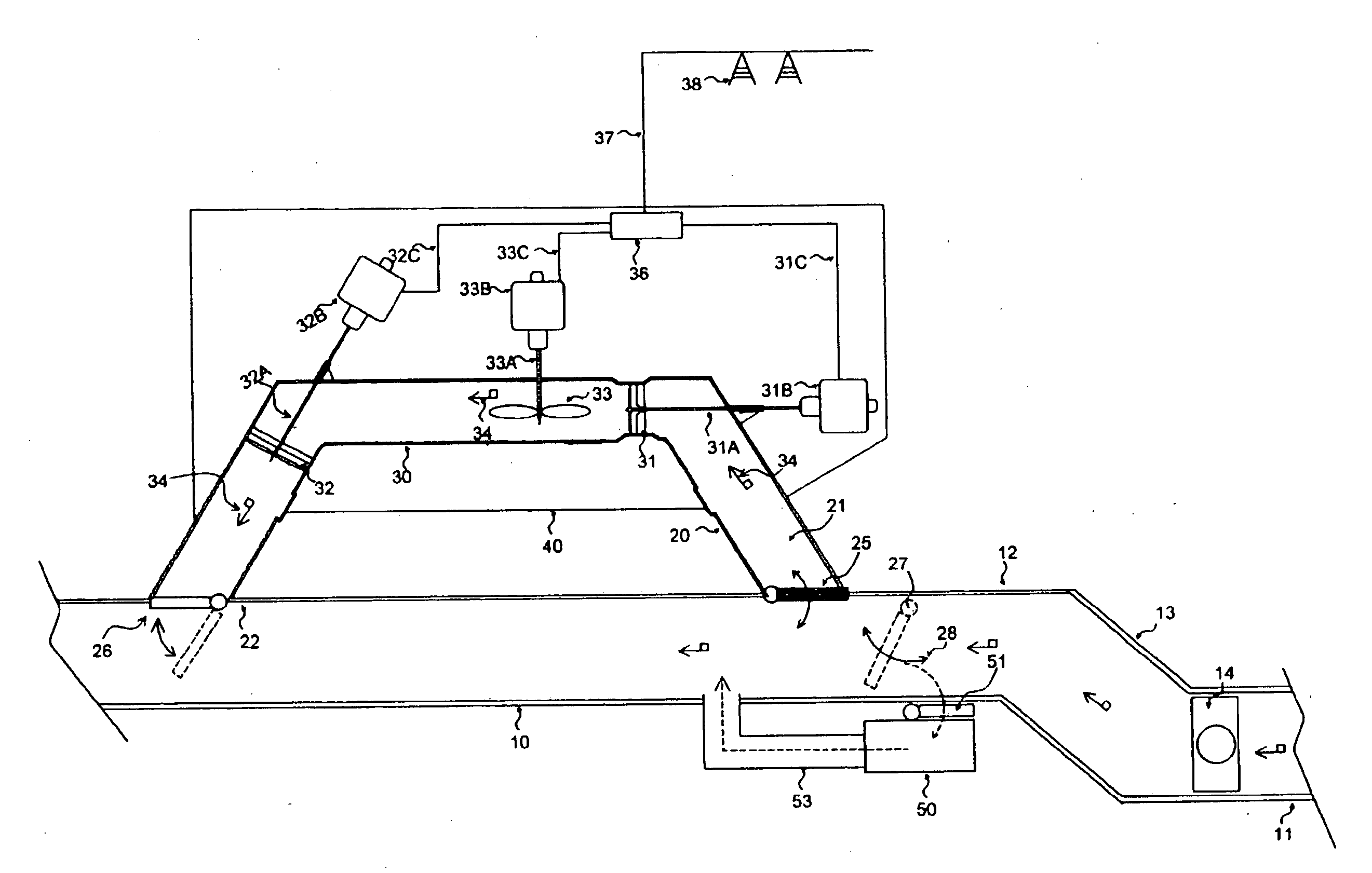

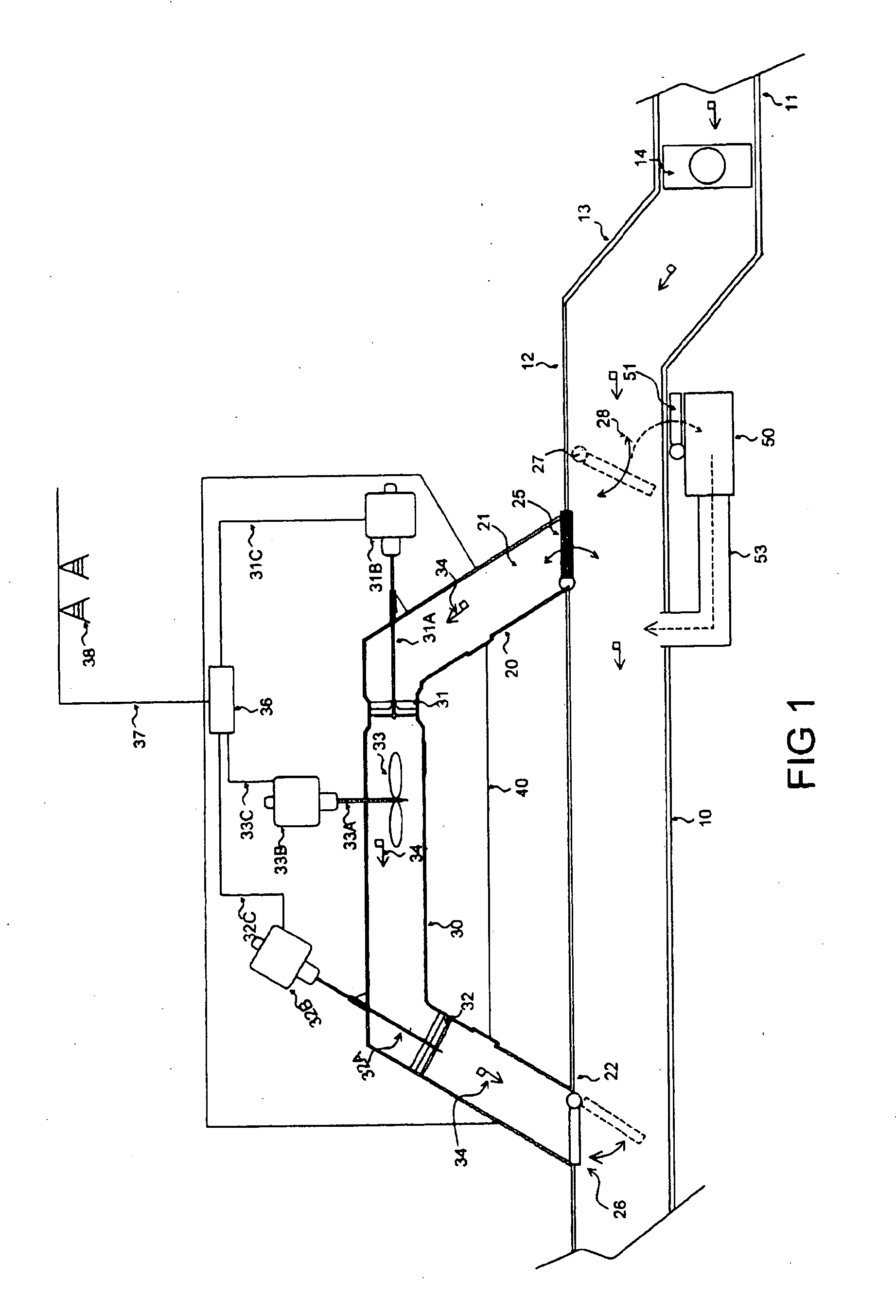

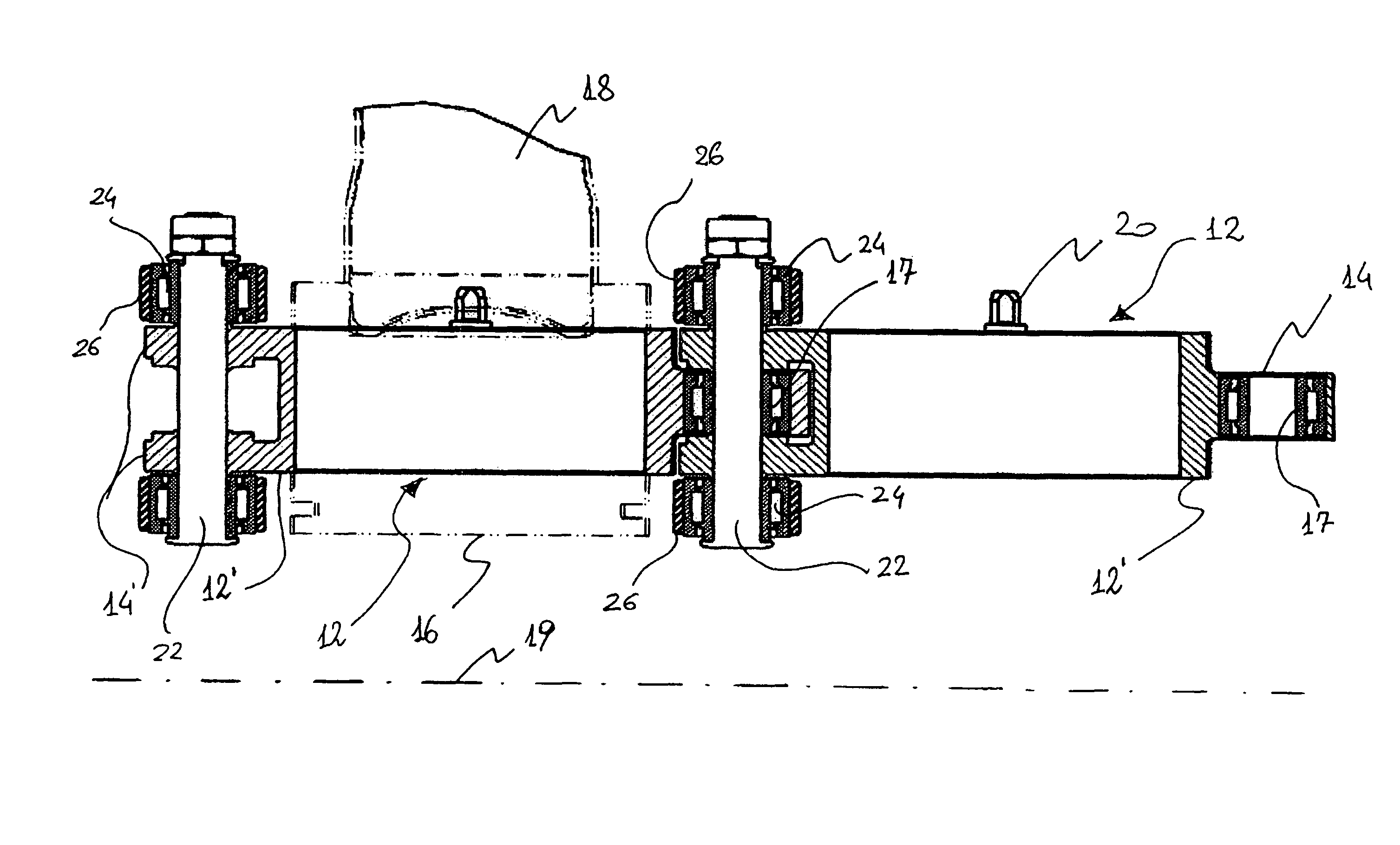

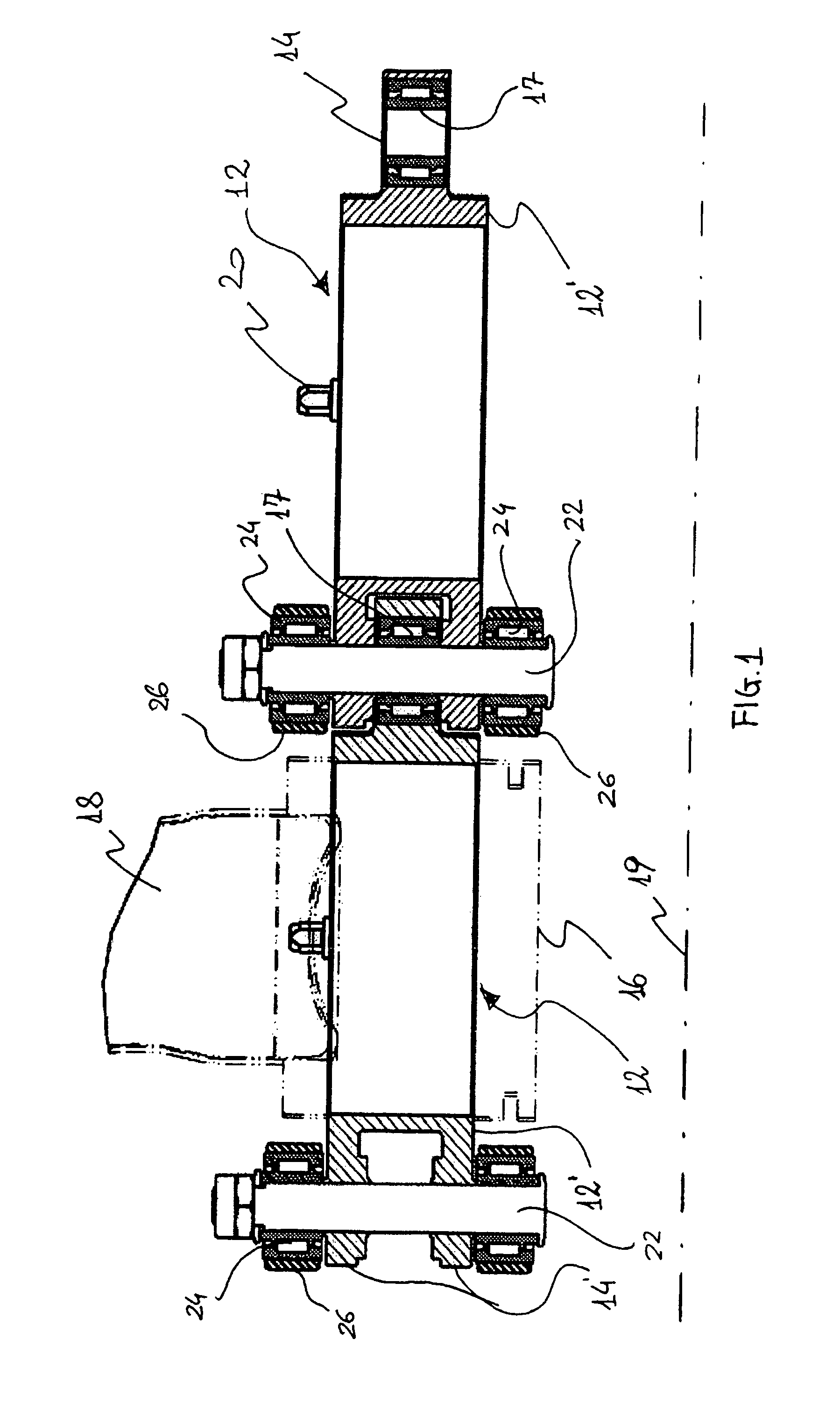

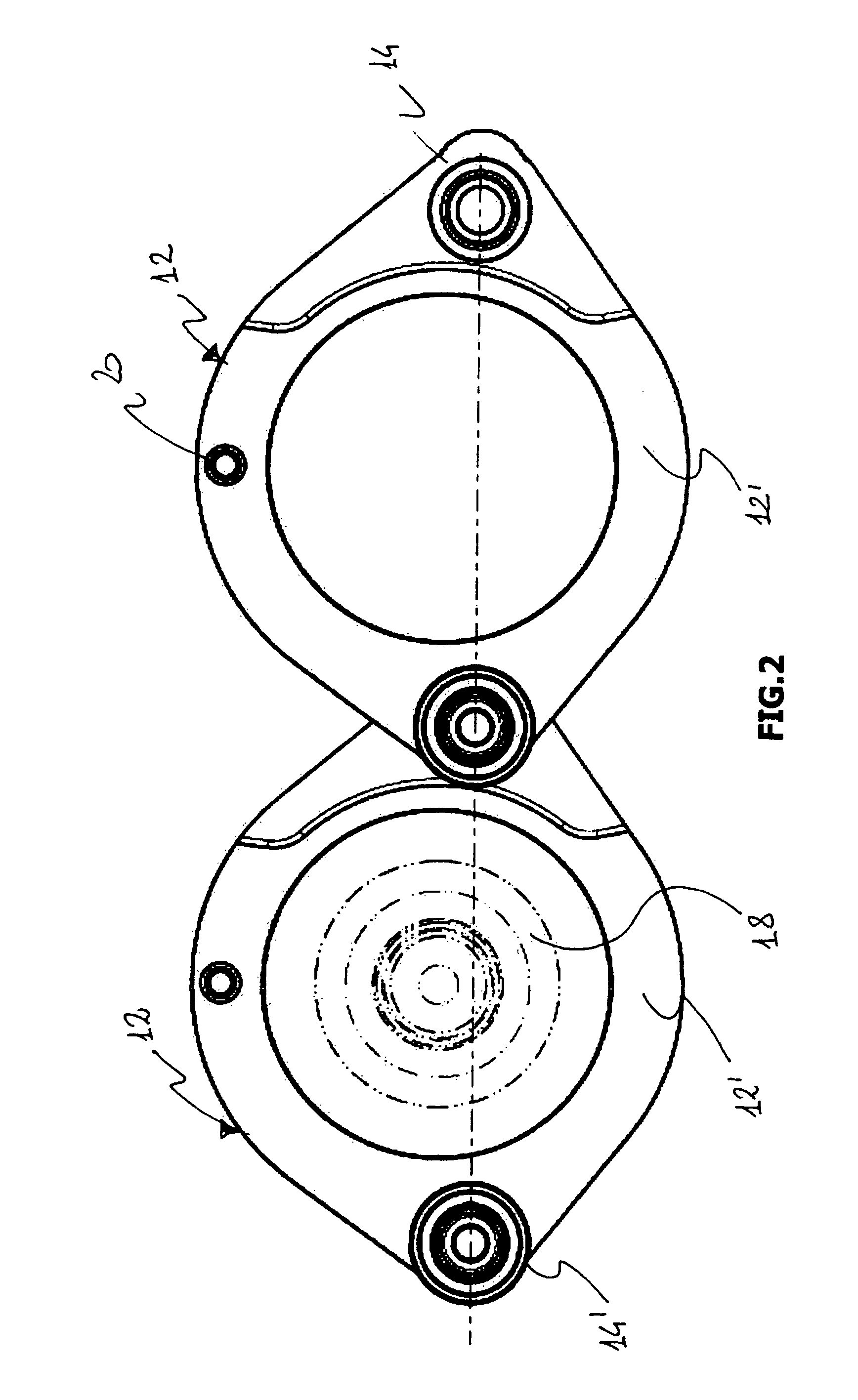

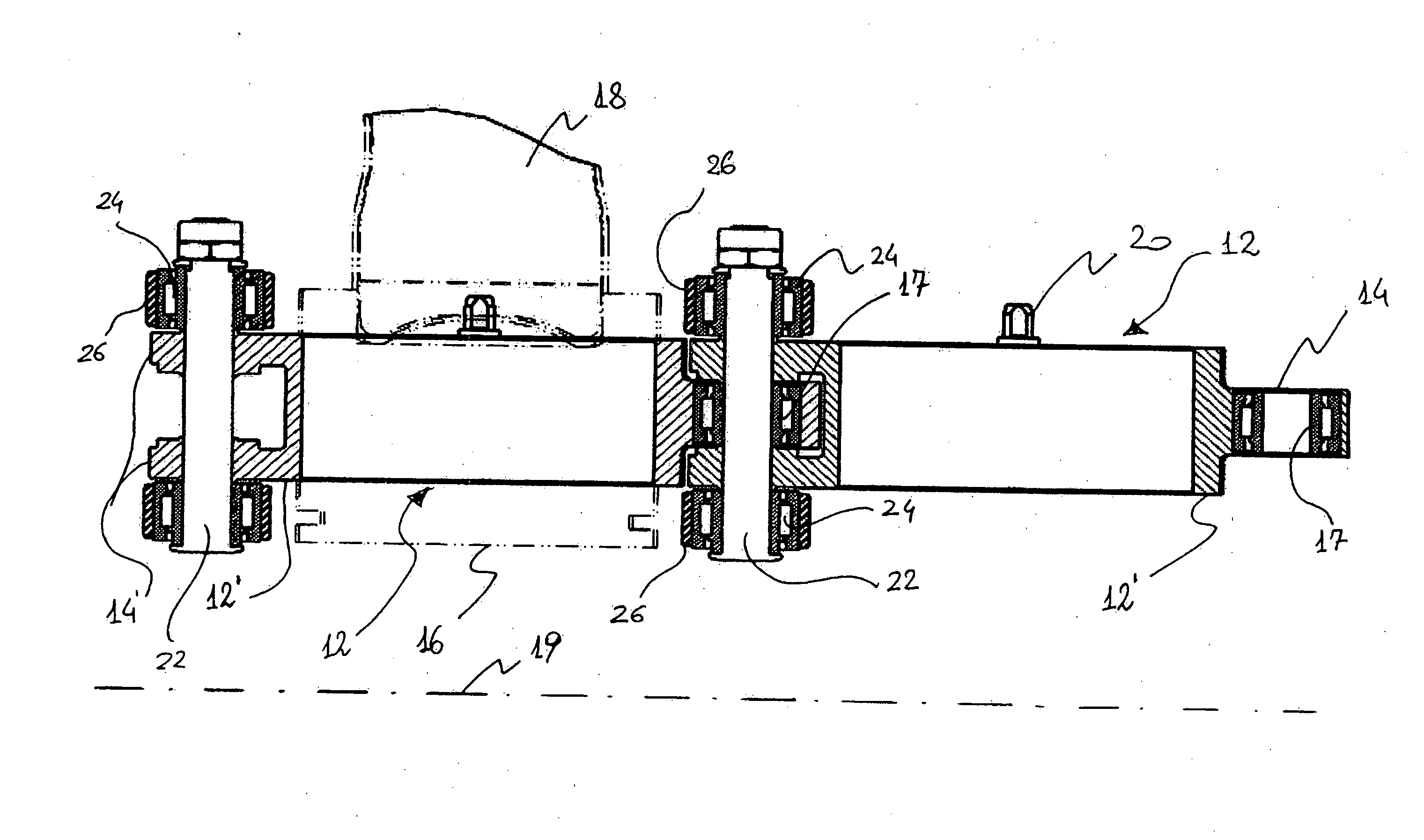

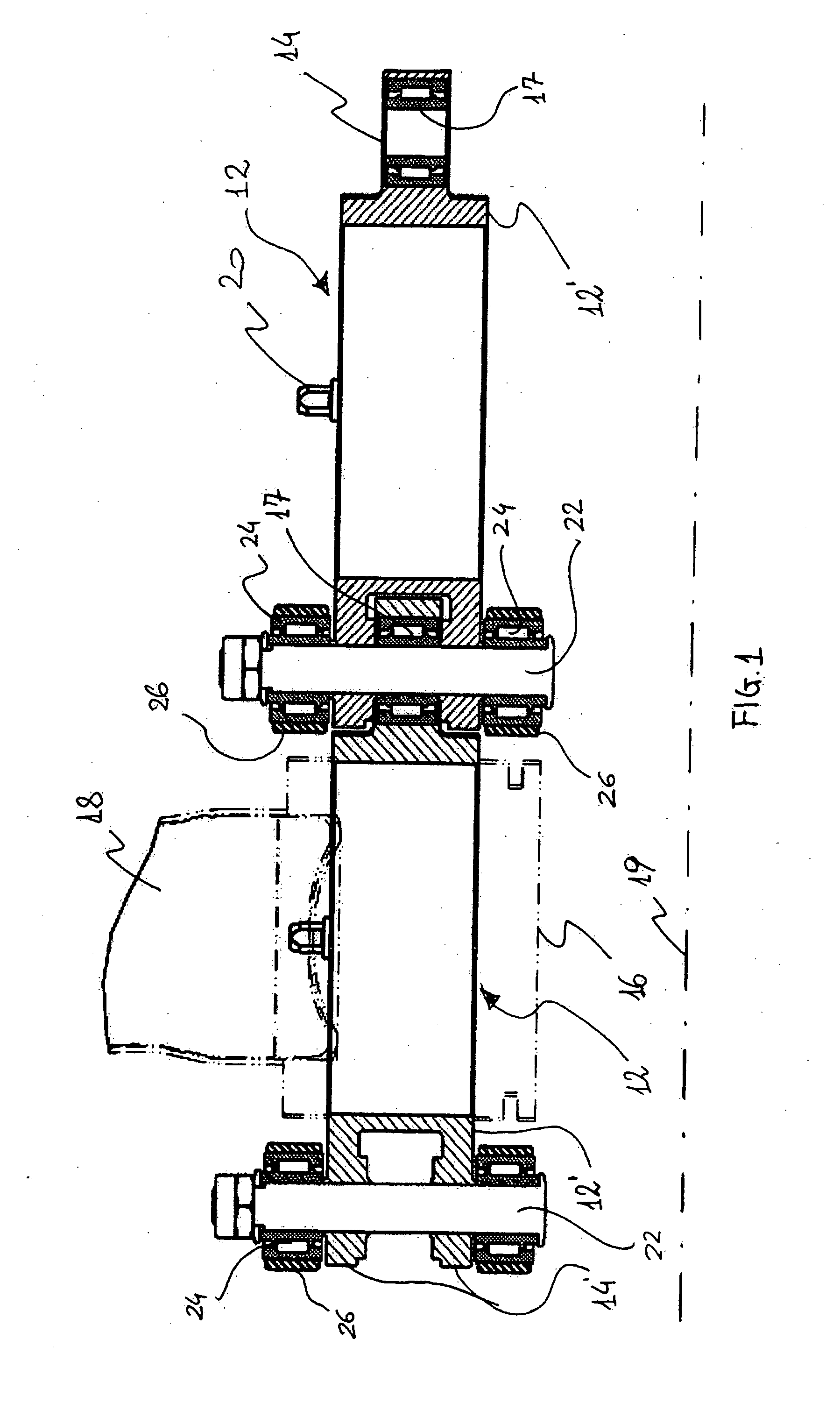

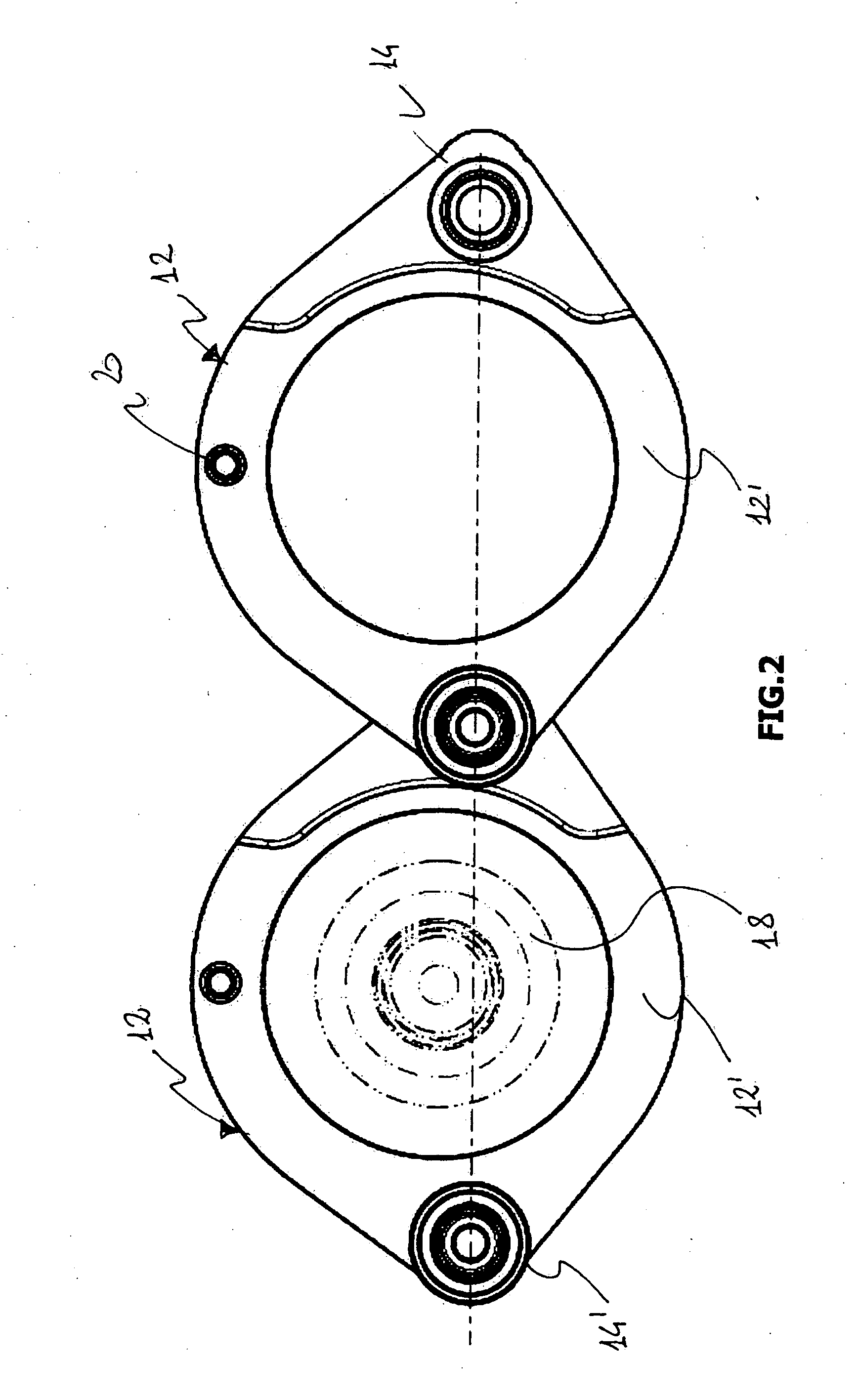

Apparatus for working on metal containers

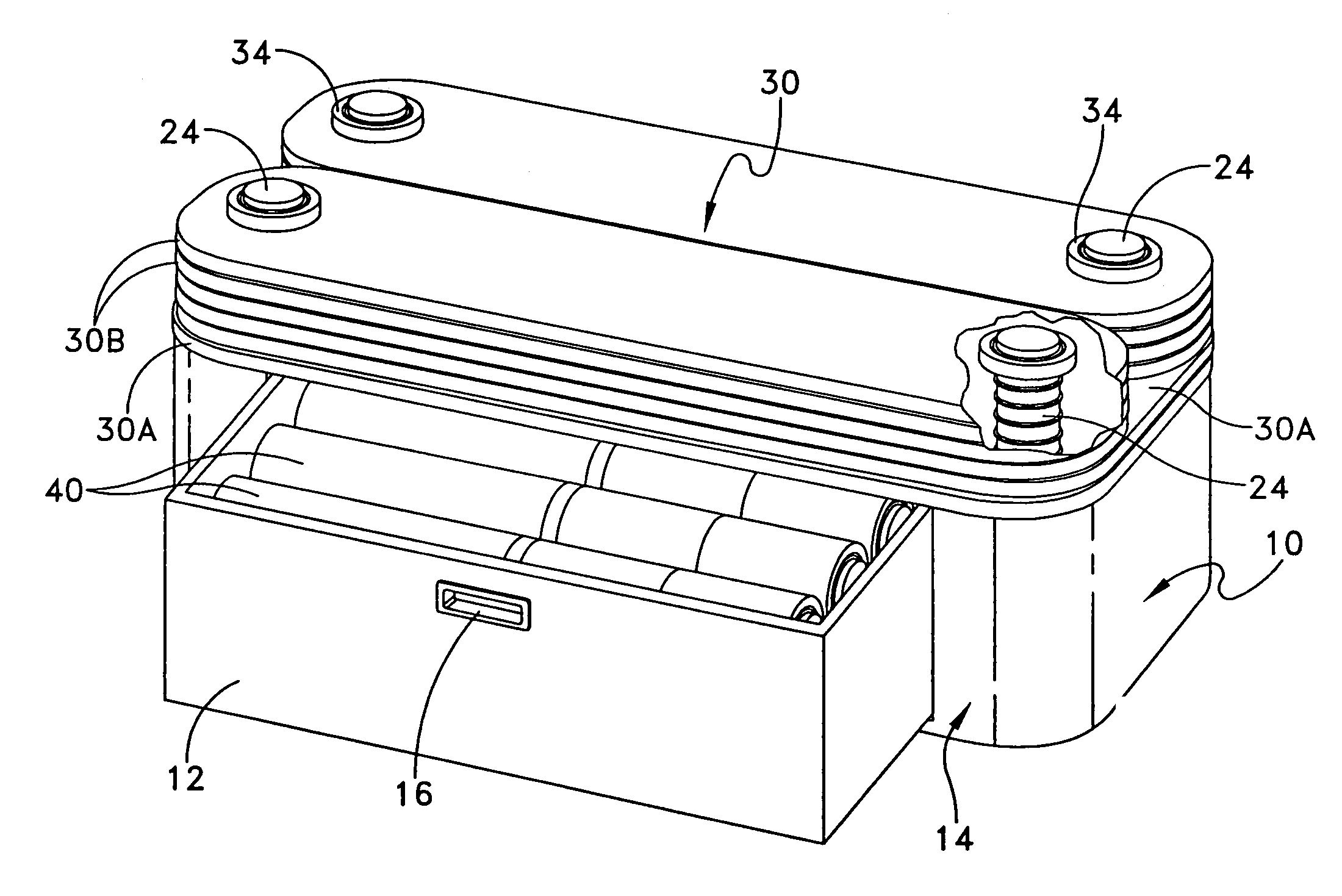

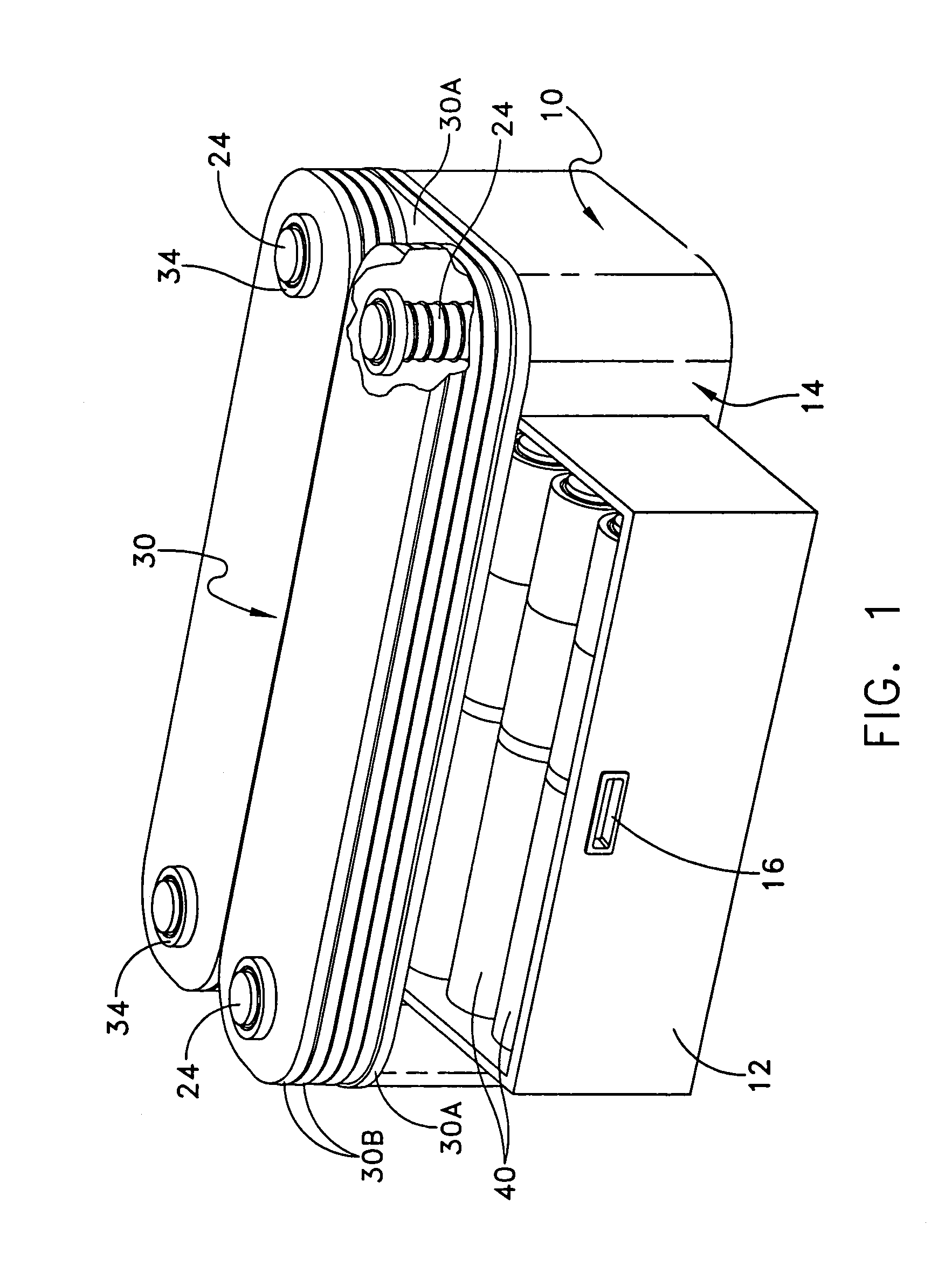

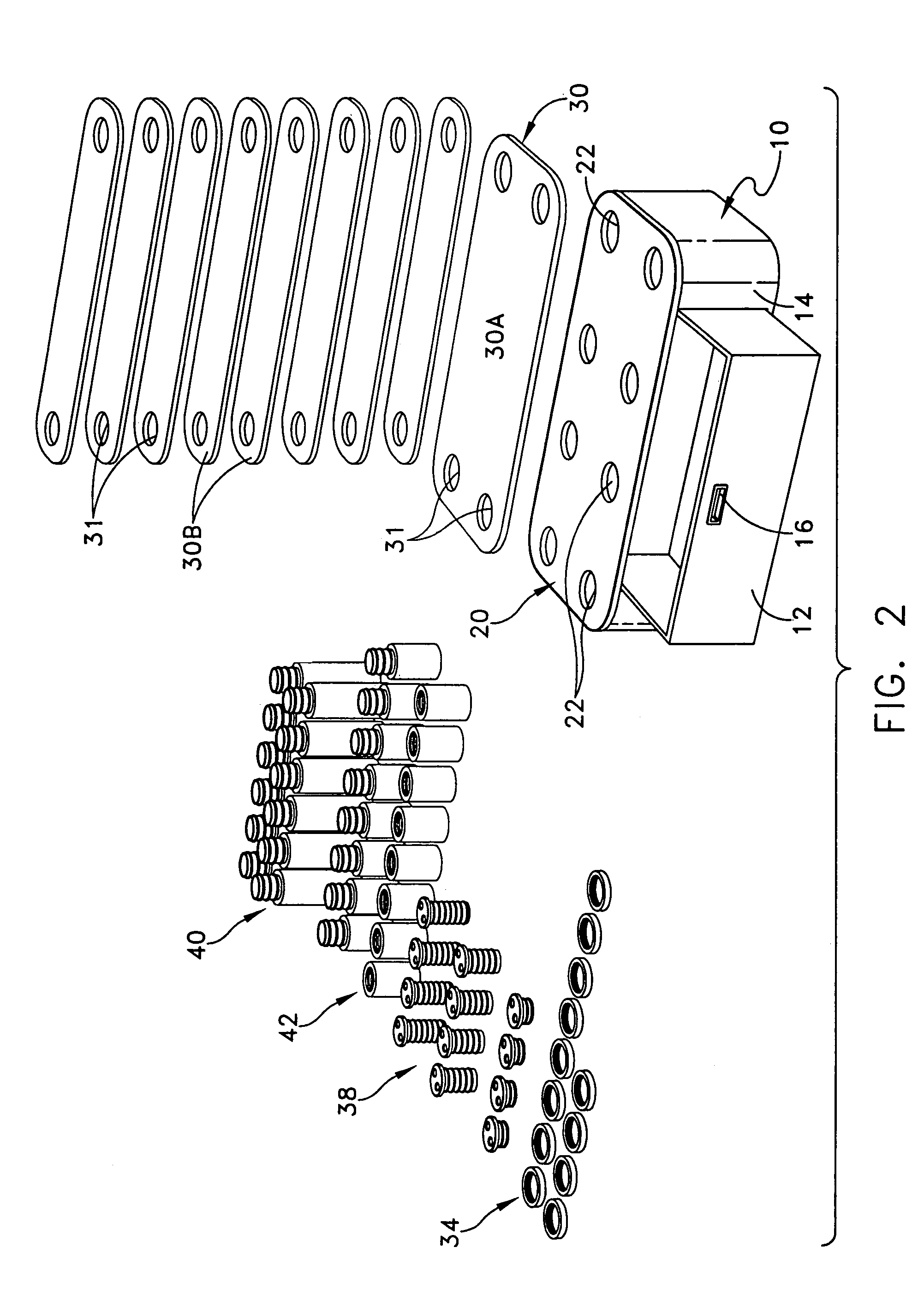

InactiveUS8066115B2Increase speedHigh phase displacementCharge manipulationConveyor partsEngineeringMetal

An apparatus (10) for working on metal containers, especially suitable for high speed machines and intended for performing a sequence of operations on the metal containers themselves including a chain composed of a plurality of elements (12) linked in a succession and cooperating in simultaneous transporting and processing of metal containers.

Owner:MALL HERLAN SCHWEIZ AG

Modular lighting fixture with improved device for connecting the arms to the respective support

InactiveUS8272769B2Easily packaged and transported and storedReduced dimensionLighting support devicesElectric circuit arrangementsElectrical conductorEngineering

Owner:VOLTOLINA FRANCESCO

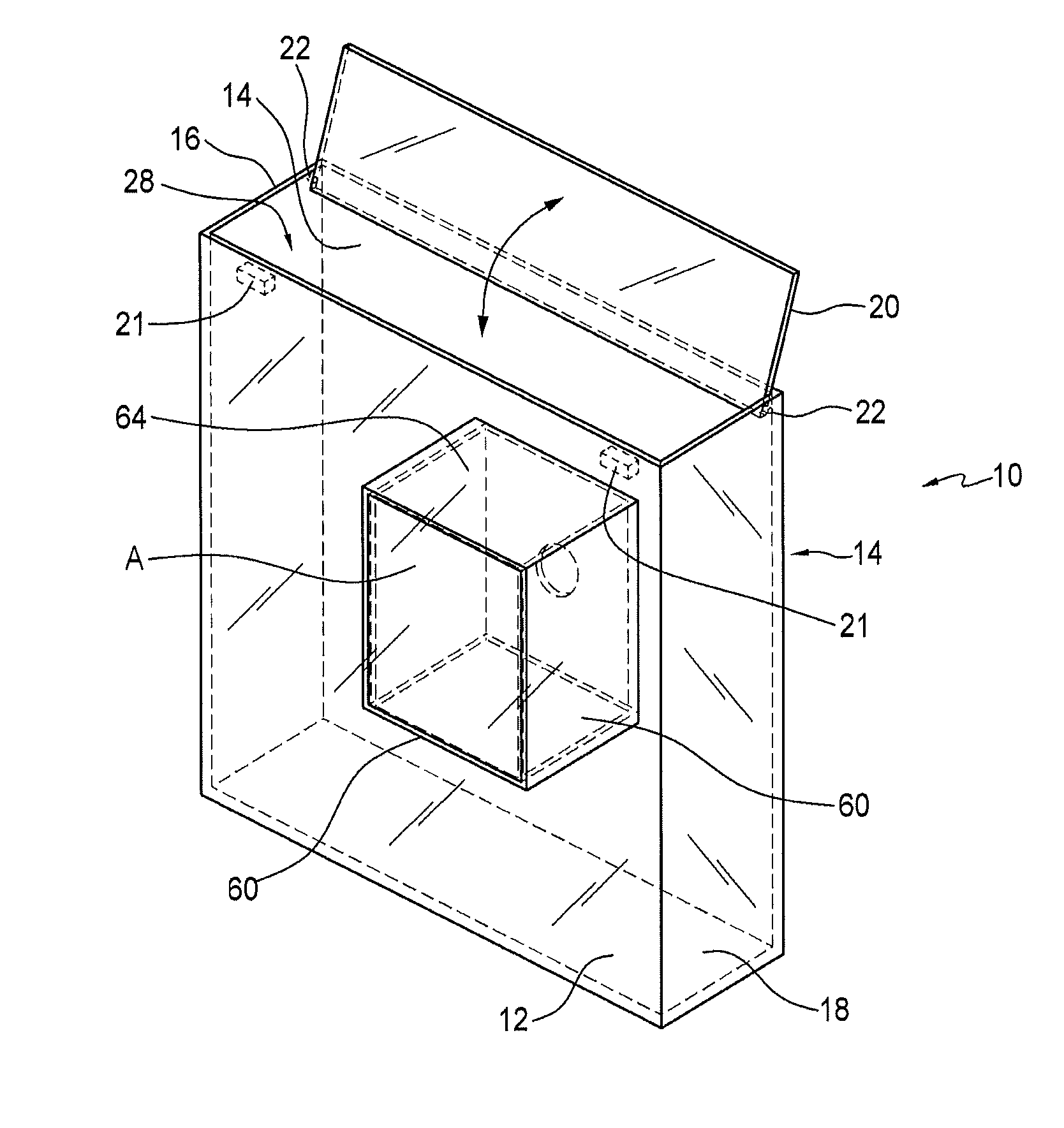

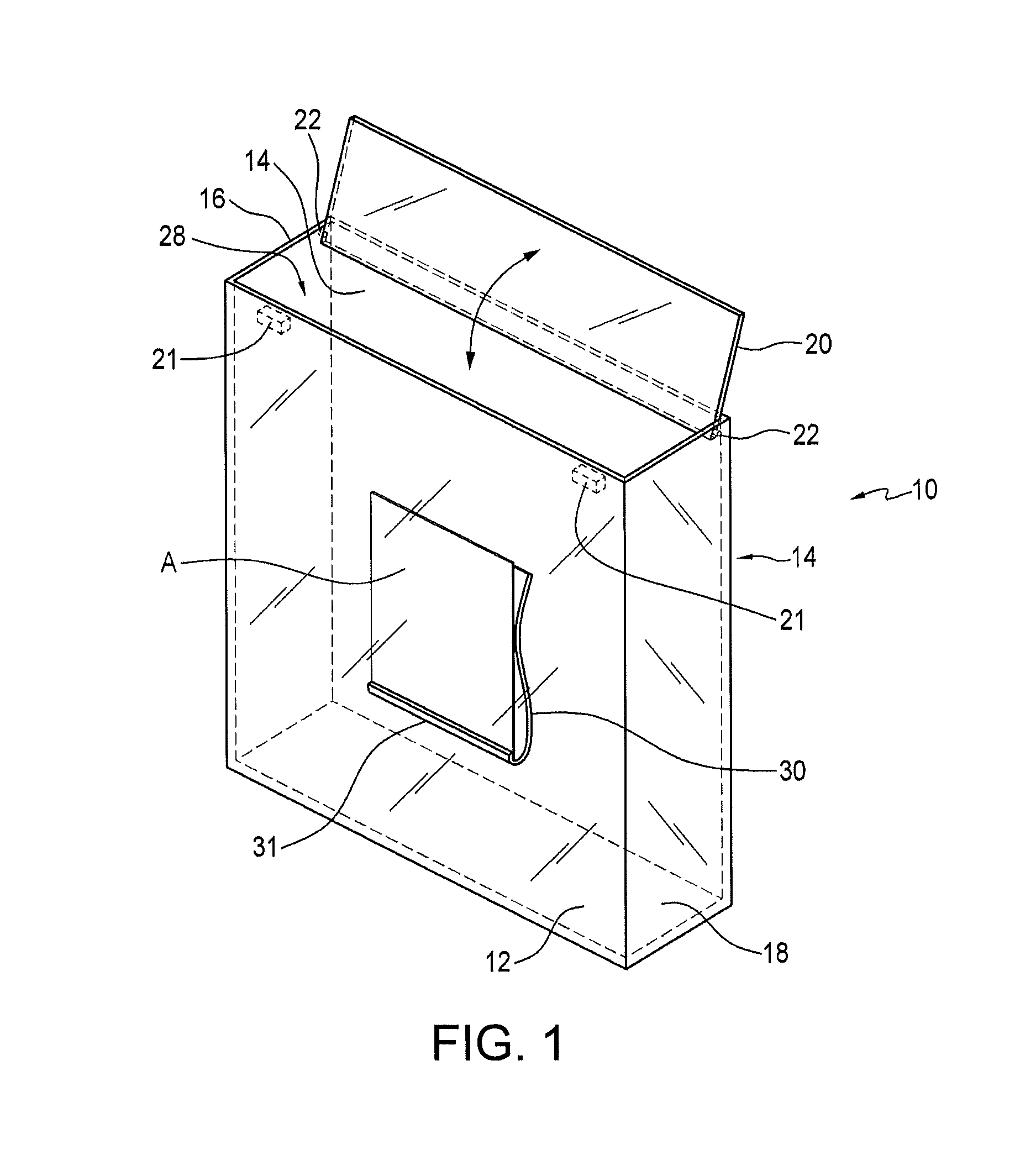

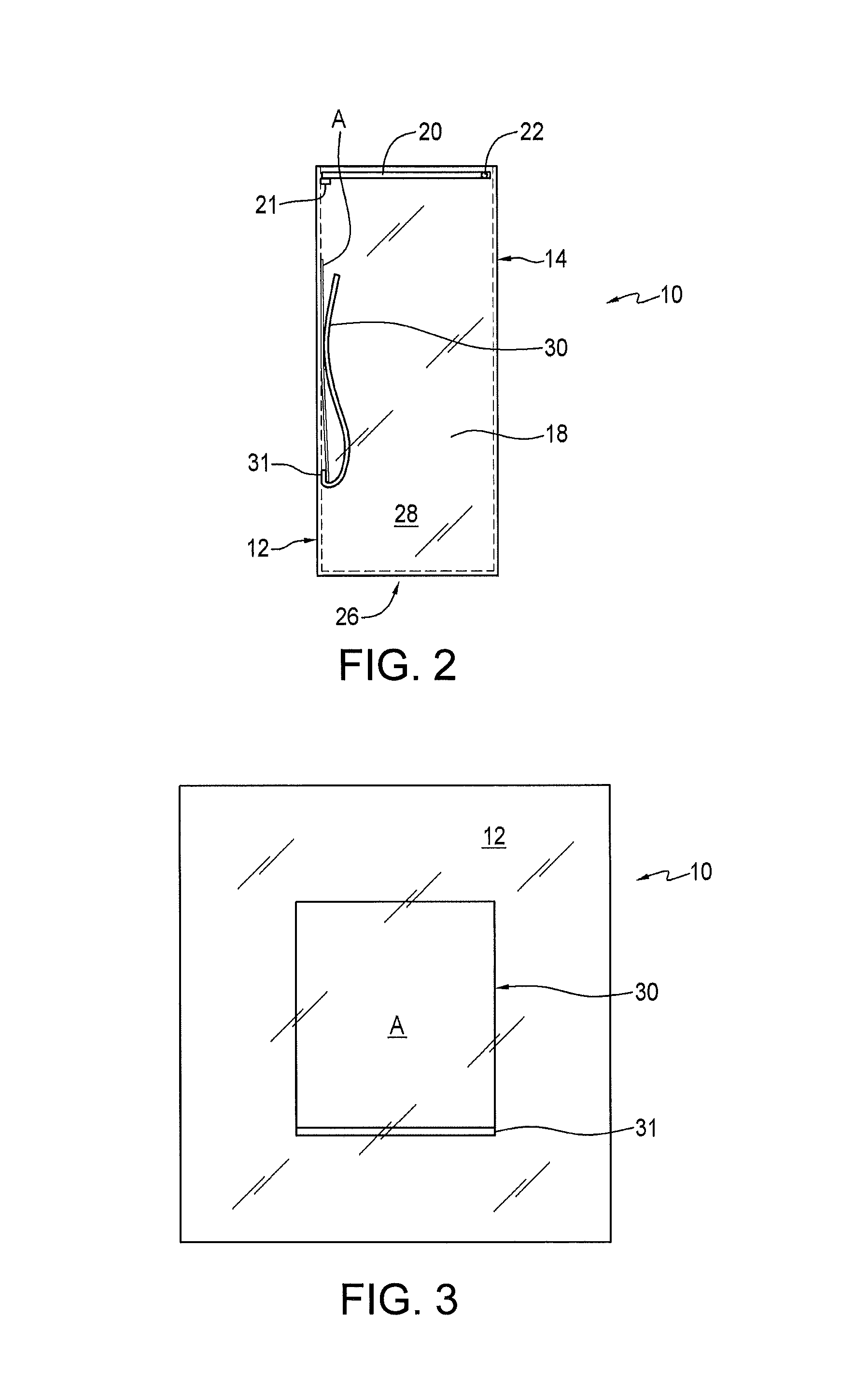

Display frame

InactiveUS8875430B2Easy and inexpensive to constructPermits displayEnvelopes/bags making machineryPicture framesEngineeringSurface plate

Owner:LEBOFF LYNN ELIZABETH

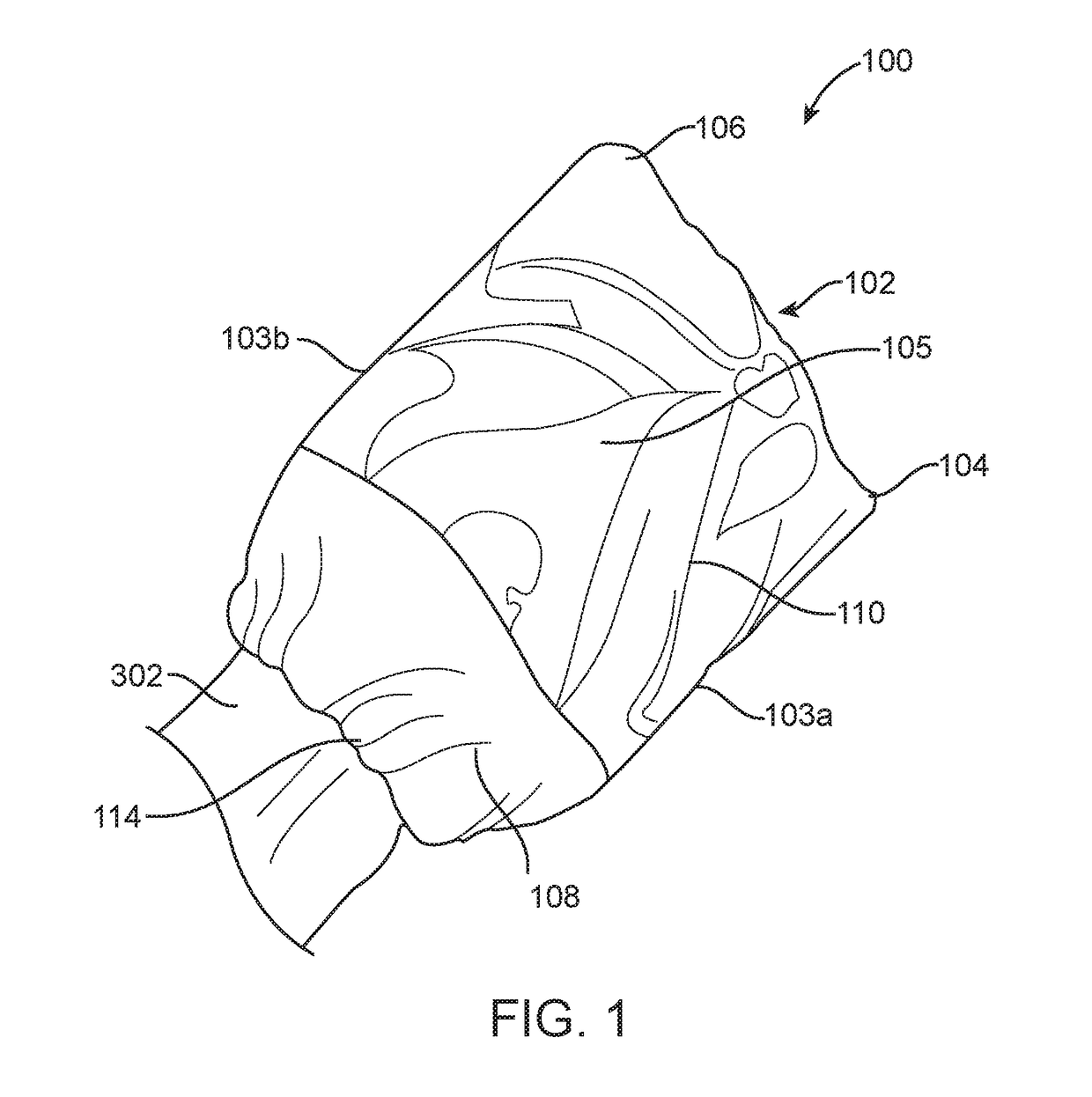

Hand warmer with a sealable end

ActiveUS10010121B2Ample warmthEasy and inexpensive to constructGarment special featuresProtective garmentPull forceEngineering

A hand warmer is disclosed herein. The hand warmer has a central pocket defined by a cylindrical housing and a sealing member proximate an anterior end of the housing, wherein the sealing member is configured switch positions from a closed position to an open position with an application of a pulling or pushing force by the user in a direction parallel an arm of the user. A method of warming a user's hands is also provided.

Owner:KUMPREY WILLIAM T +1

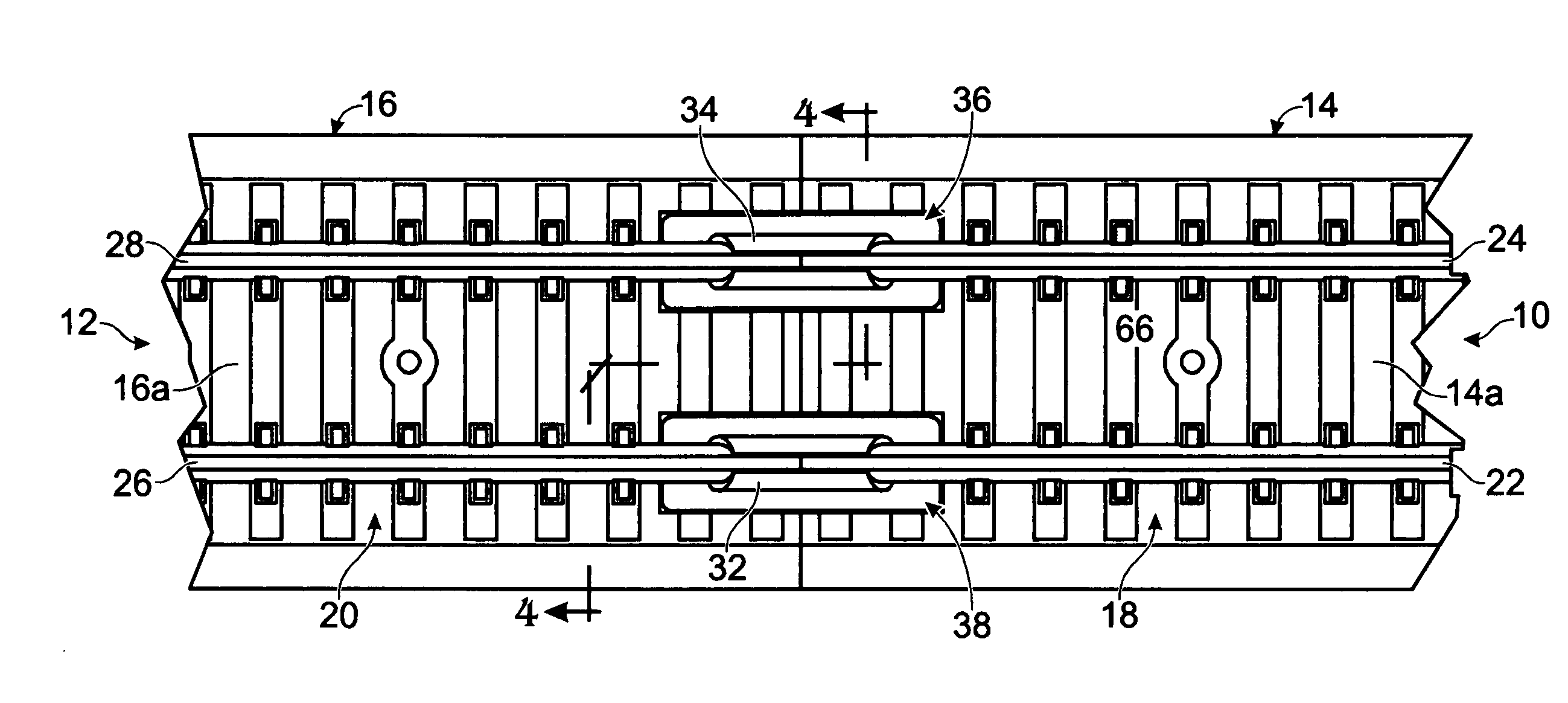

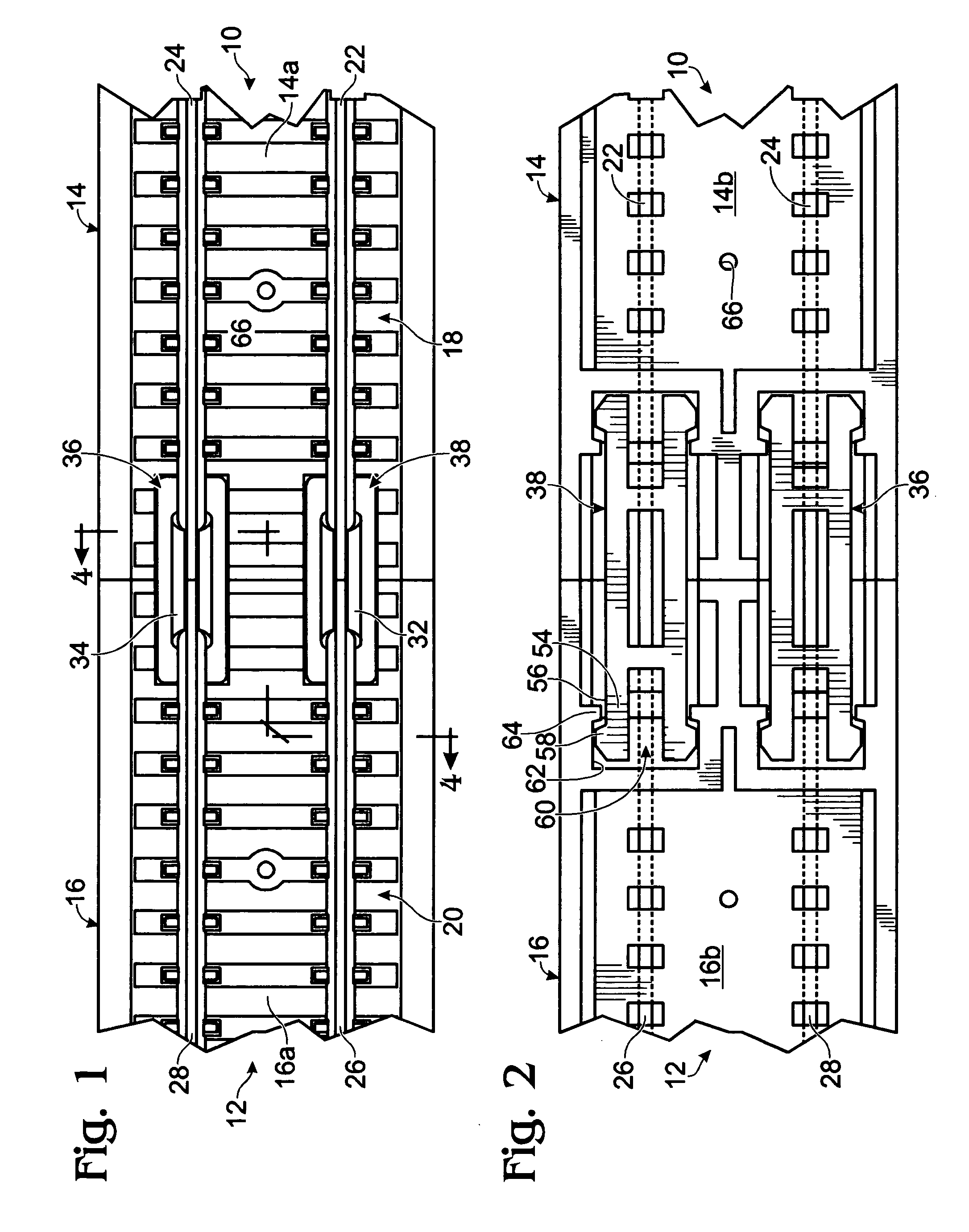

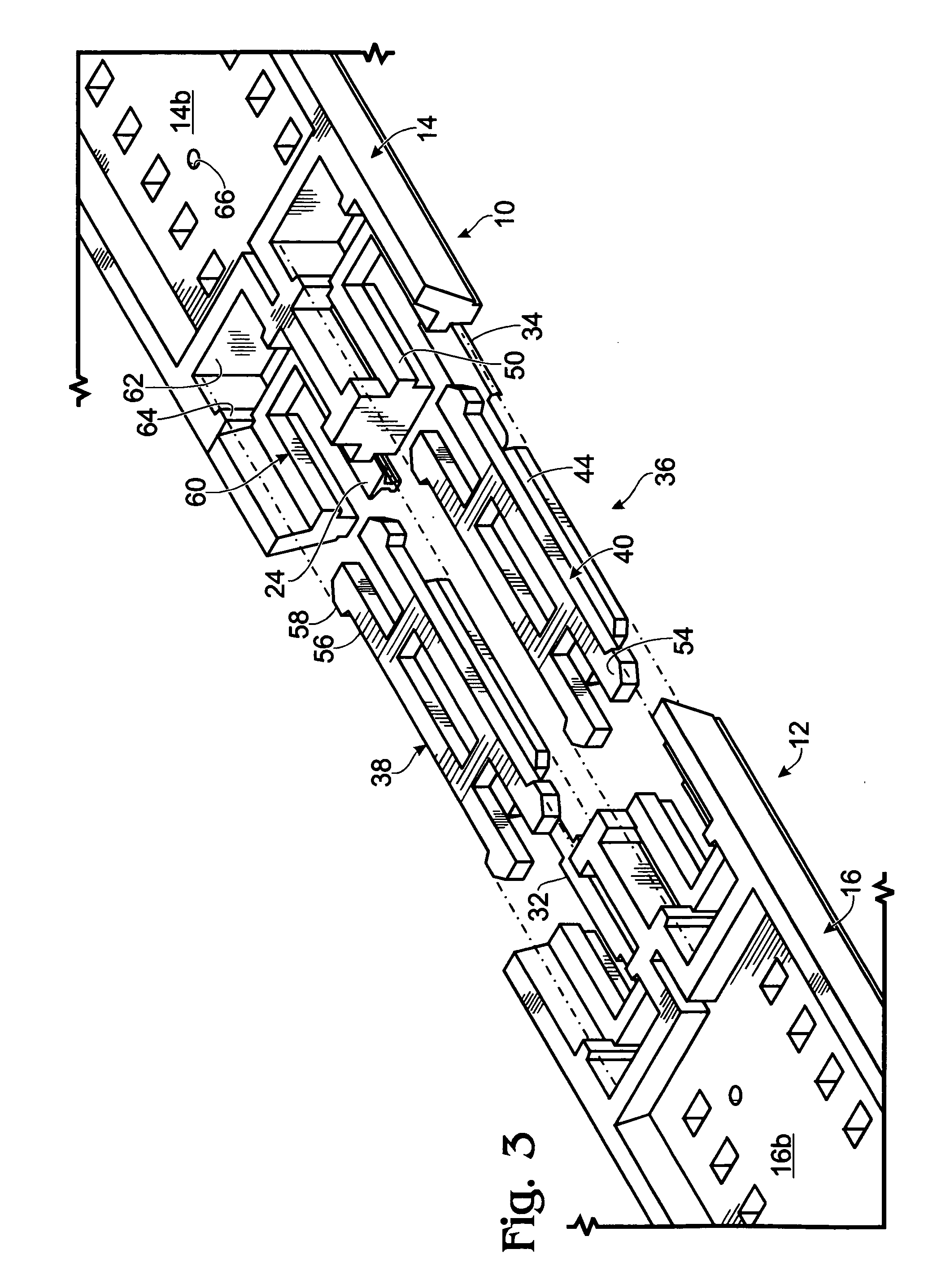

Combined track-railbed joining apparatus

InactiveUS20070131788A1Protection from damageEasy and inexpensive to constructMovable tracksModel railwaysMechanical engineeringEngineering

A joining apparatus is provided for a model railroad track, wherein the model railroad track includes a pair of combined track-railbed sections, with each end thereof configured for abutting an end of another combined track-railbed section, including a tie array disposed on an upper portion of each railbed and a pair of spaced apart rails fixed thereto, wherein the rails are electrically and physically joined to a rail on an abutted rail by a rail connector. Each combined track-railbed section includes a joining element retainer located adjacent each end of the section, underlying the railbed adjacent an end of each rail fixed to the railbed. A joining element is removably retainable in each joining element retainer for providing horizontal, vertical and longitudinal alignment between abutted combined track railbed sections.

Owner:MICRO TRAINS LINE

Device for the forced locking of two elements oriented orthogonally to one another

ActiveUS8444341B2Easy and inexpensive to constructStable and accurateSecuring devicesBuilding constructionsMechanical engineeringQuadrilateral

Owner:METALSISTEM

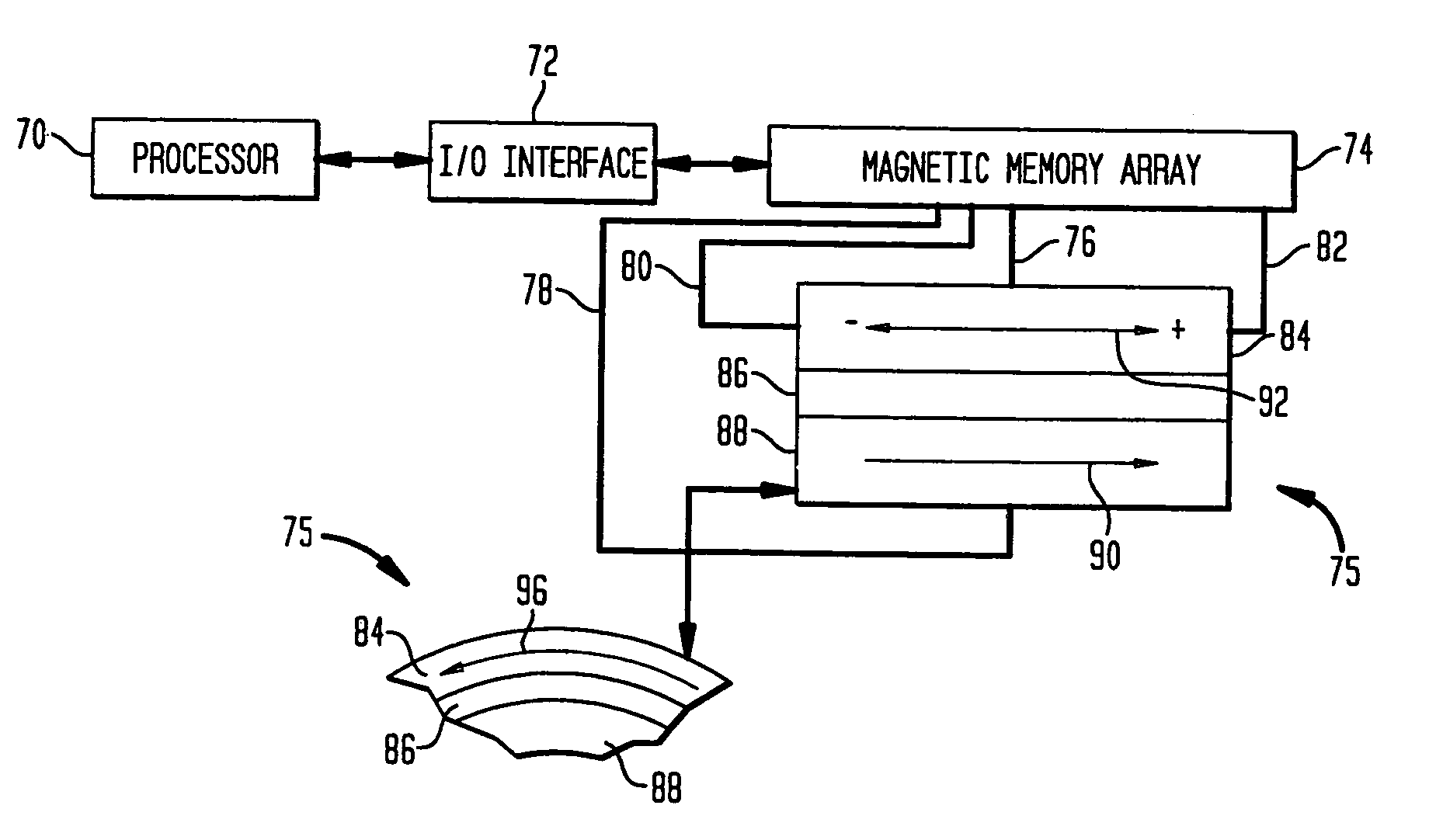

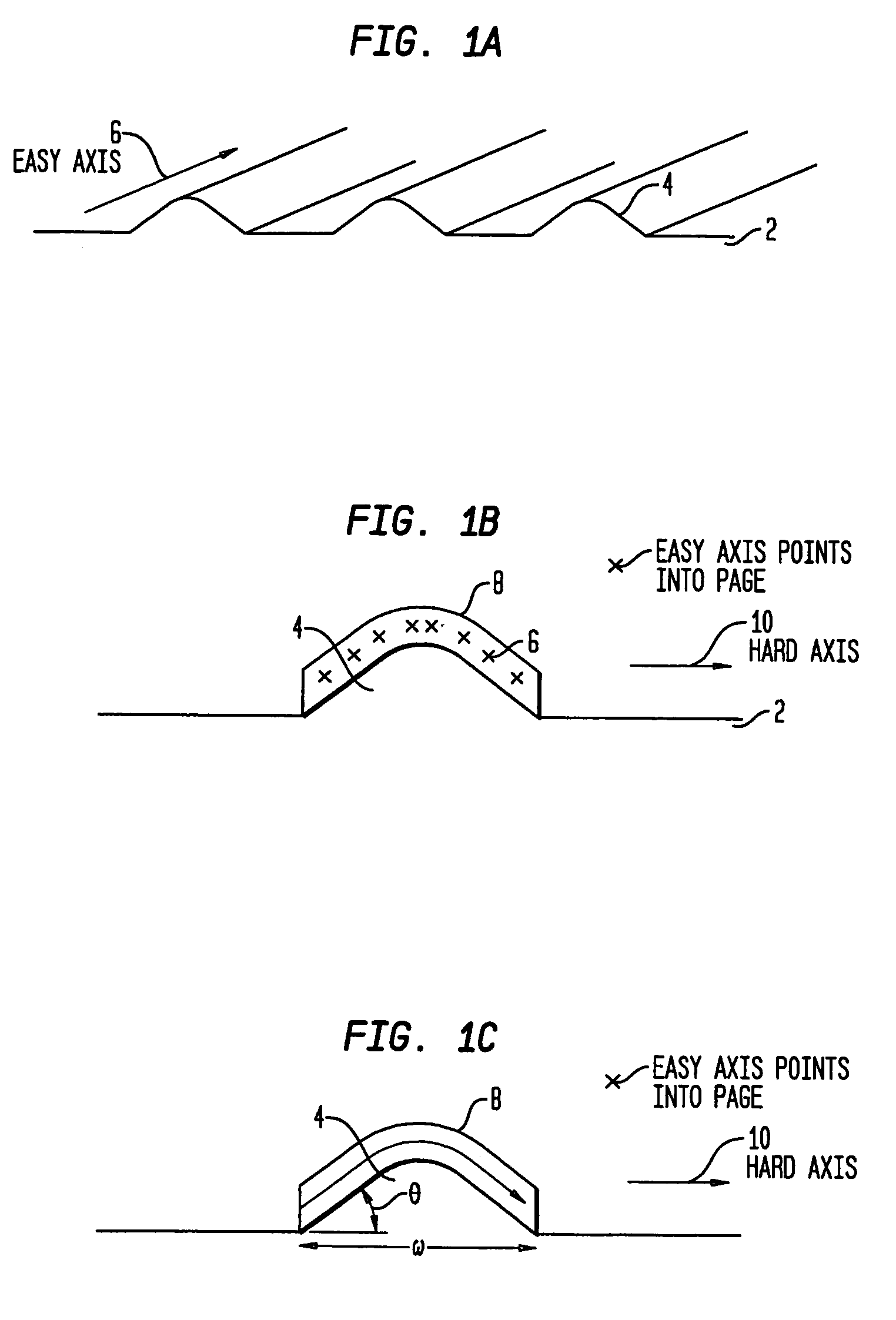

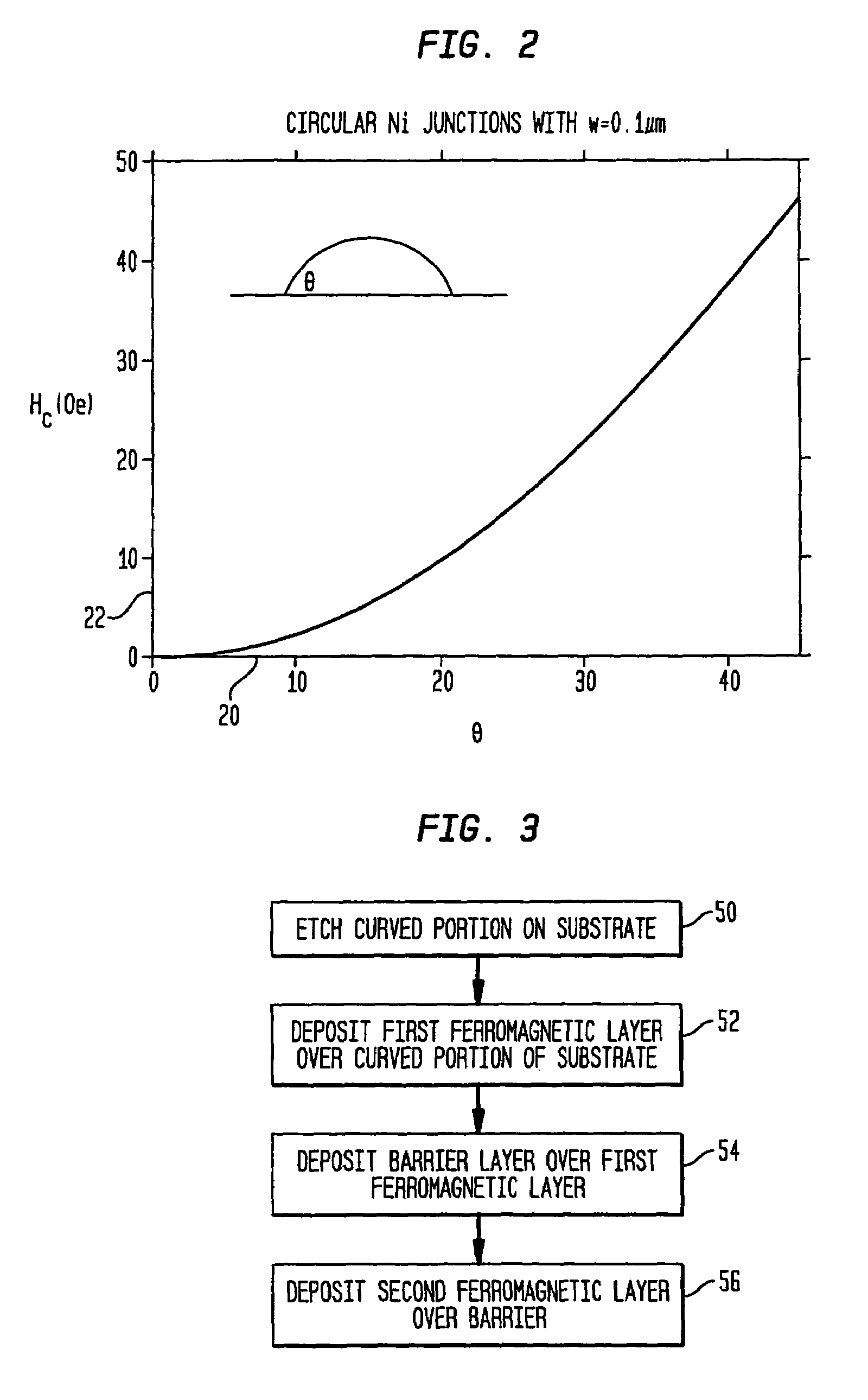

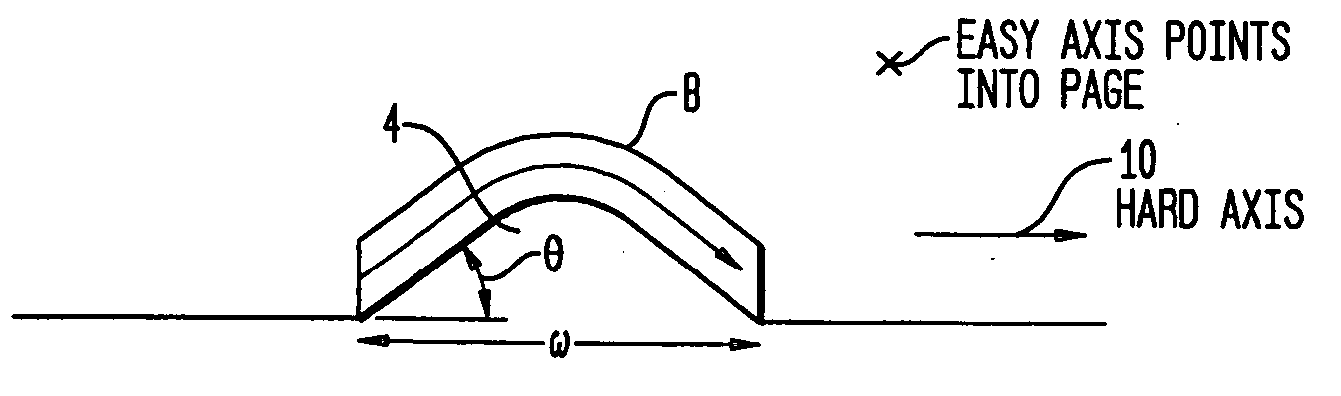

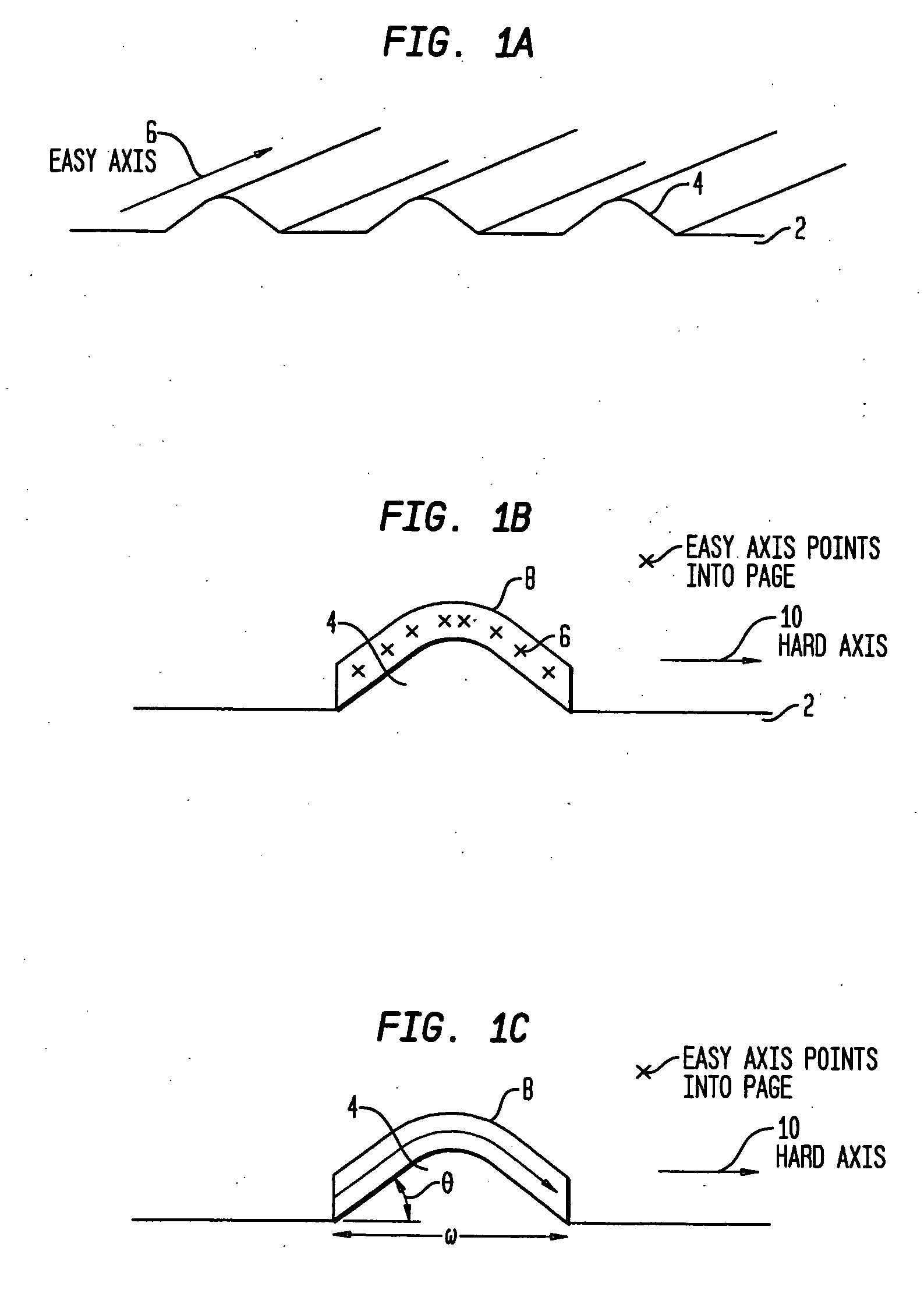

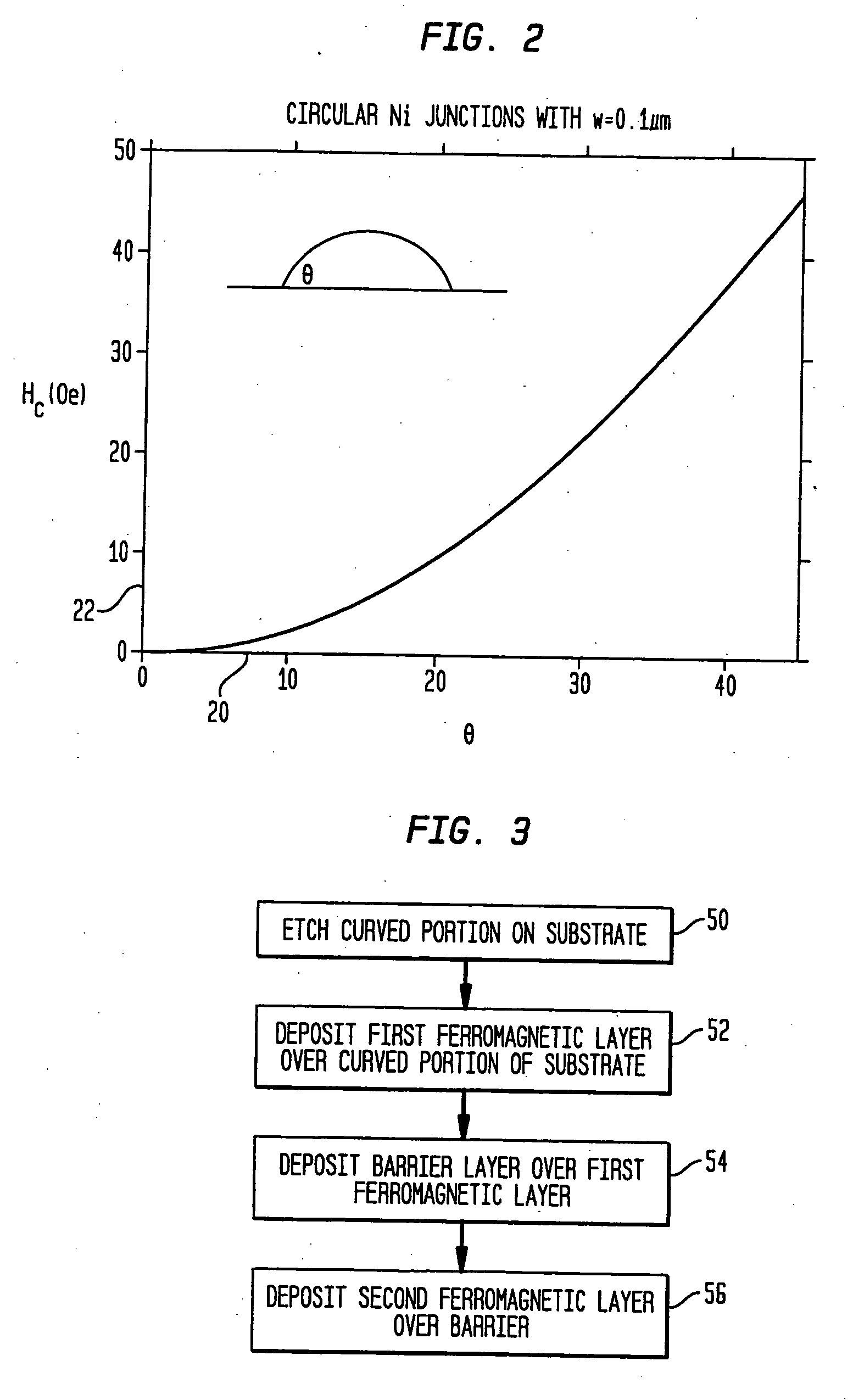

Curvature anisotropy in magnetic bits for a magnetic random access memory

InactiveUS7205163B2Easy and inexpensive to constructLower the volumeNanomagnetismMagnetic-field-controlled resistorsMagnetic anisotropyStatic random-access memory

A magnetic memory cell that uses a curved magnetic region to create magnetic anisotropy is provided by the present invention. The magnetic memory cell is created from a free magnetic layer, a barrier layer and a reference magnetic layer. The magnetic layers are constructed such that they have portions that are curved with respect to a first axis and straight with respect to a second perpendicular axis. These curved portions result in a magnetic memory cell that has an easy axis that is parallel to the first axis and a hard axis that is perpendicular to the easy axis. In addition, the resulting magnetic memory cell's coercivity is independent of it's thickness. Thus, the magnetic memory cell is well adapted to being scaled down without increasing the likelihood of thermally induced errors.

Owner:INT BUSINESS MASCH CORP

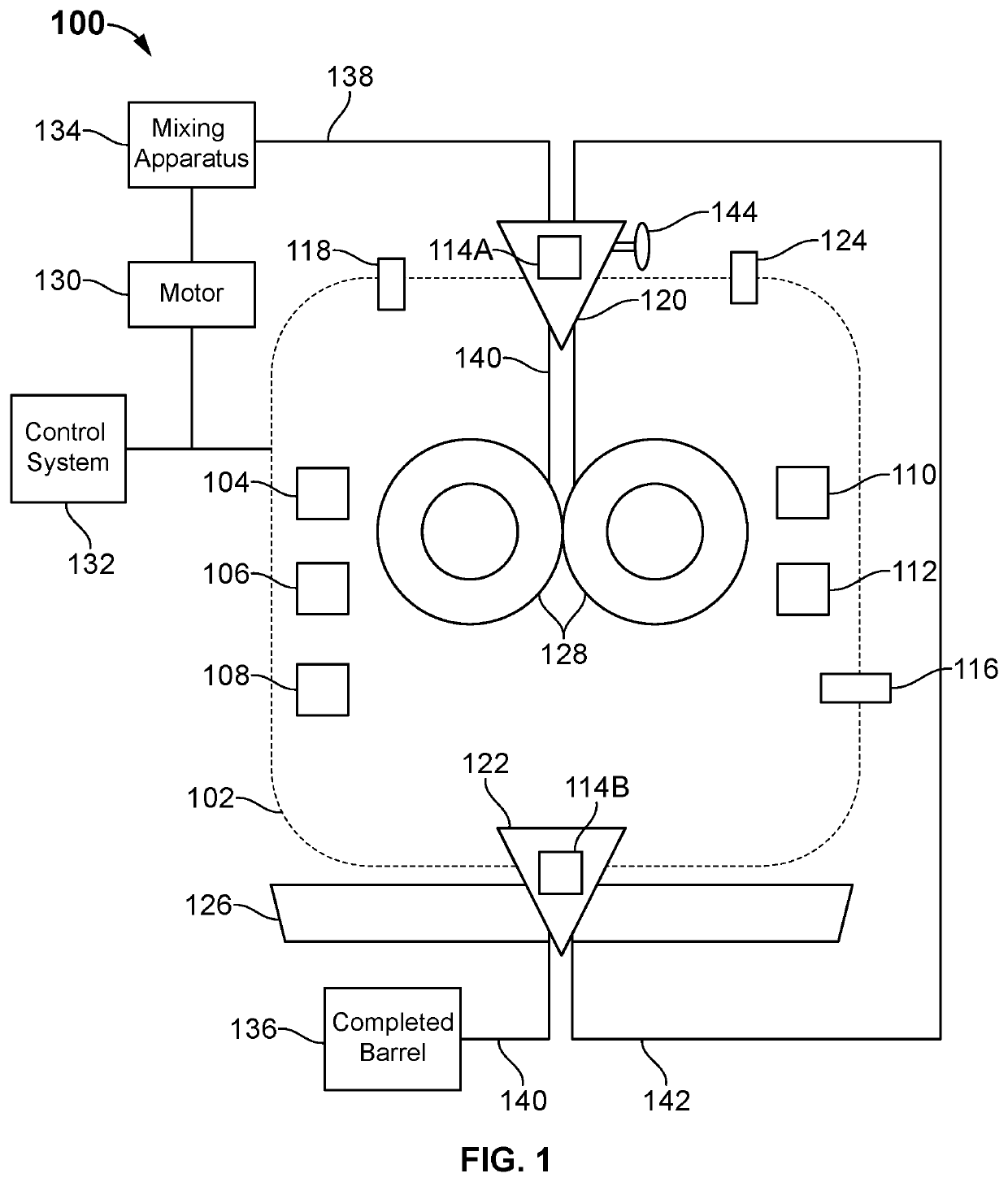

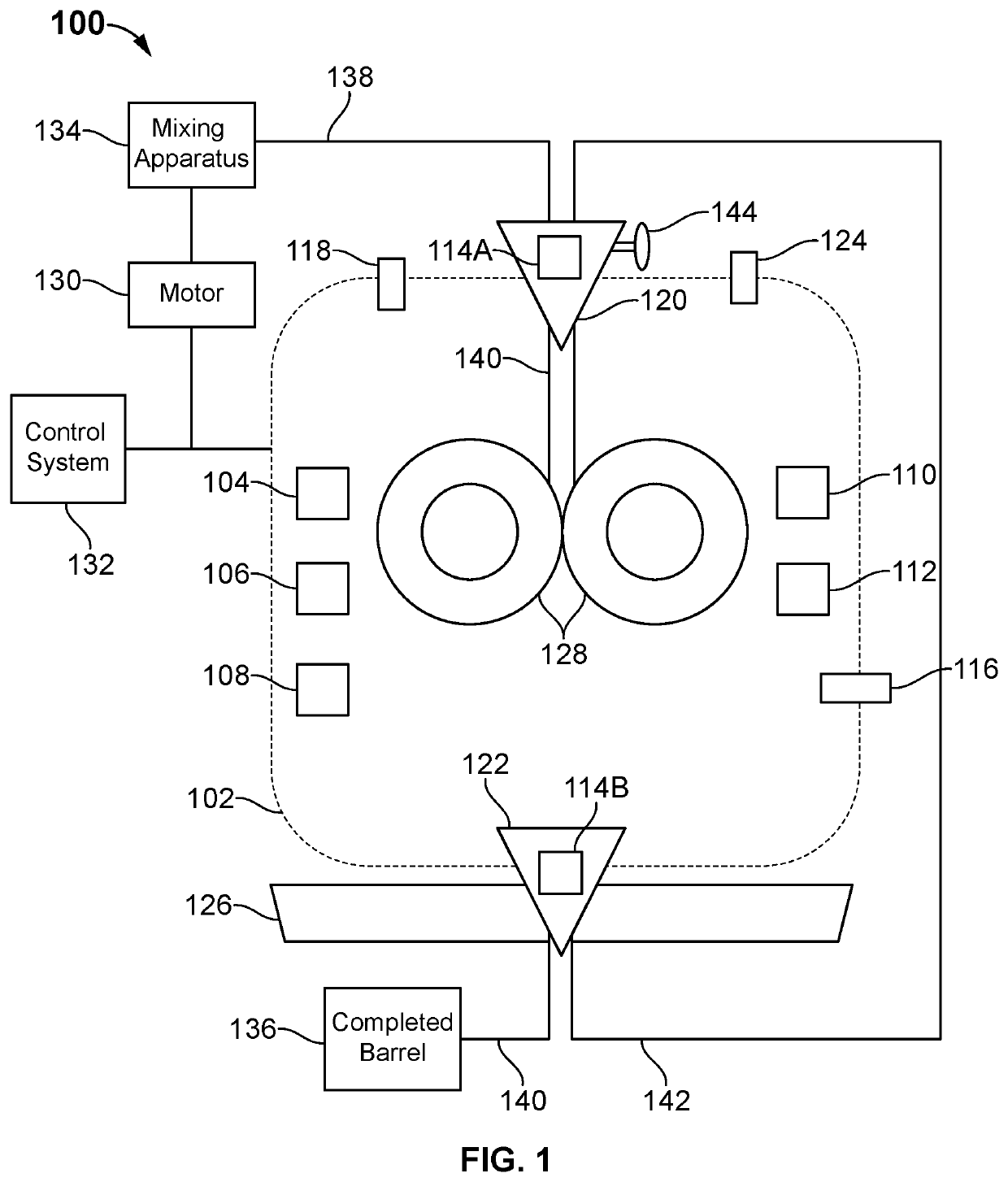

System to convert cellulosic materials into sugar and method of using the same

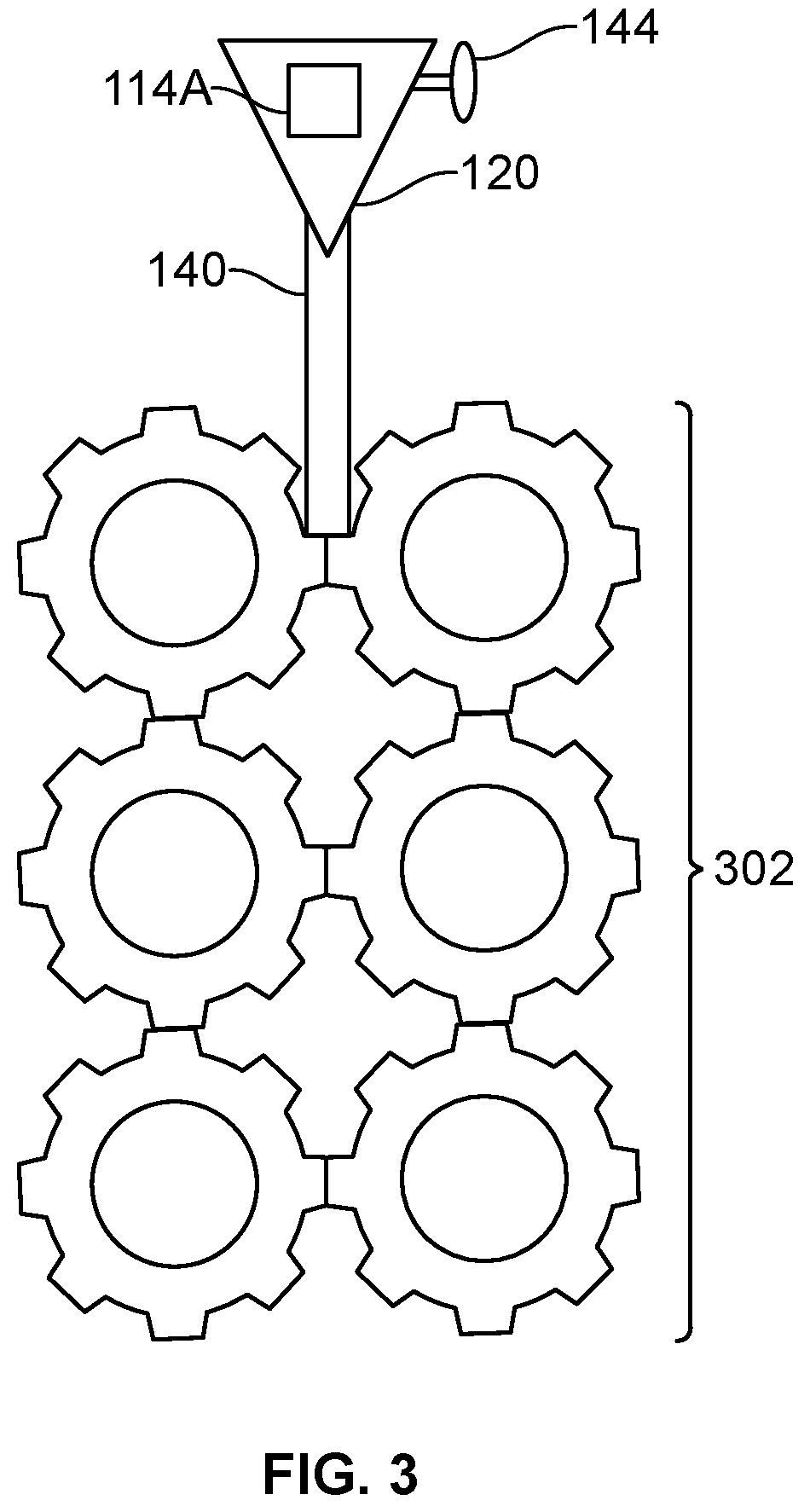

ActiveUS20210001301A1Optimized sugar outputOutput maximizationProcess control/regulationBiofuelsCellulosePtru catalyst

A device for converting cellulose to sugar comprises a reactor chamber with a plurality of control components, and a control assembly. The control assembly is operatively connected to the reactor chamber, a chive assembly and control components to transmit and receive interoperability signals. The device has an inlet hopper with a detector, a crusher, an outlet hopper, a sensor assembly, a steam inlet, and a carbon dioxide inlet. The inlet hopper is configured to receive and analyze proportion data of matters in a feedstock and catalyst mixture via the detector. The crusher receives and grinds the mixture from the inlet hopper to induce chemical reaction for producing sugar. The outlet hopper is configured to determine a proportion data of matter in the grinded mixture. The control assembly is configured to determine adjustments need to be performed on the components and chive assembly to optimize the sugar production.

Owner:ALLIANCE BIOENERGY PLUS INC DBA BLUE BIOFUELS +1

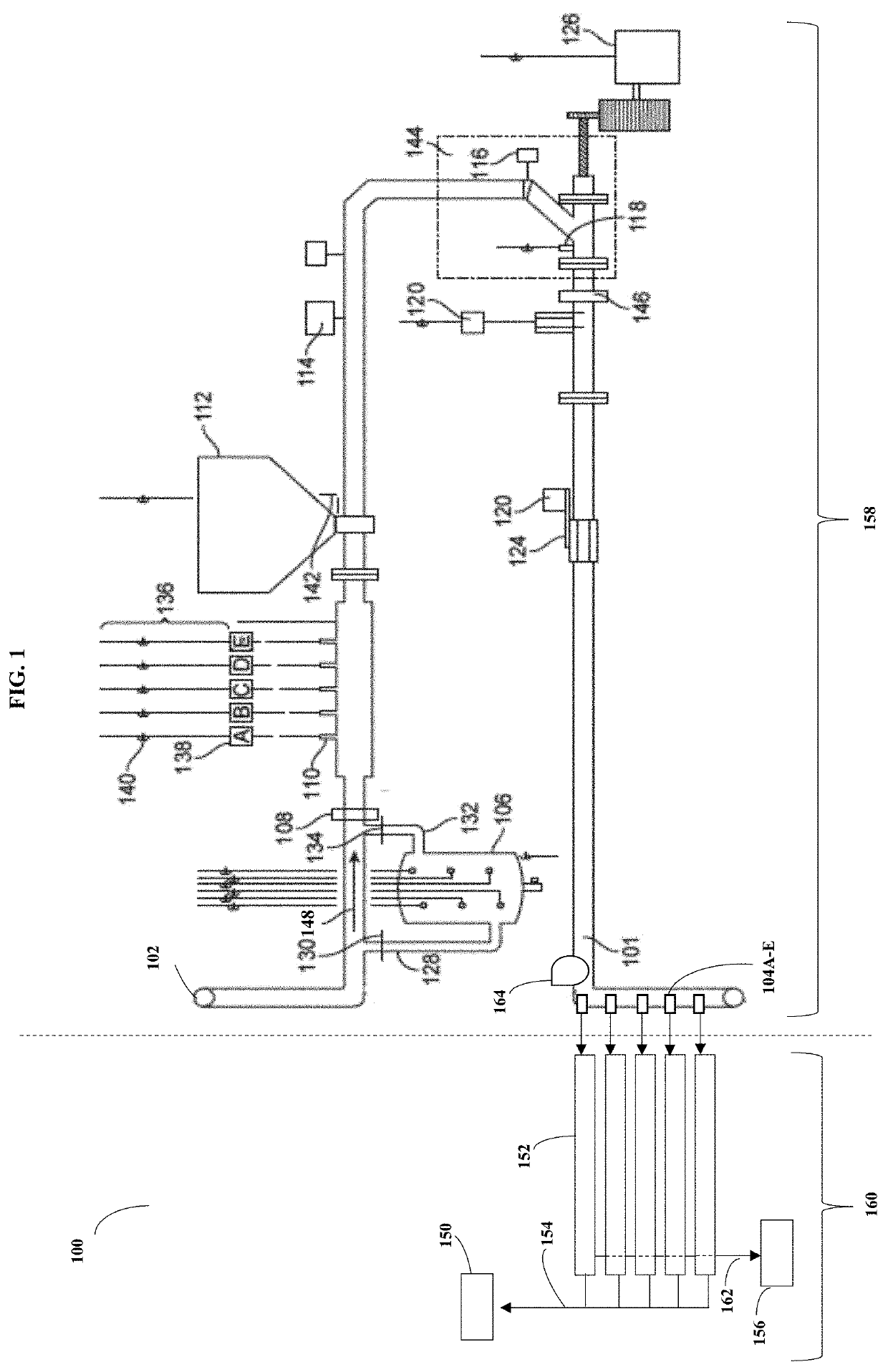

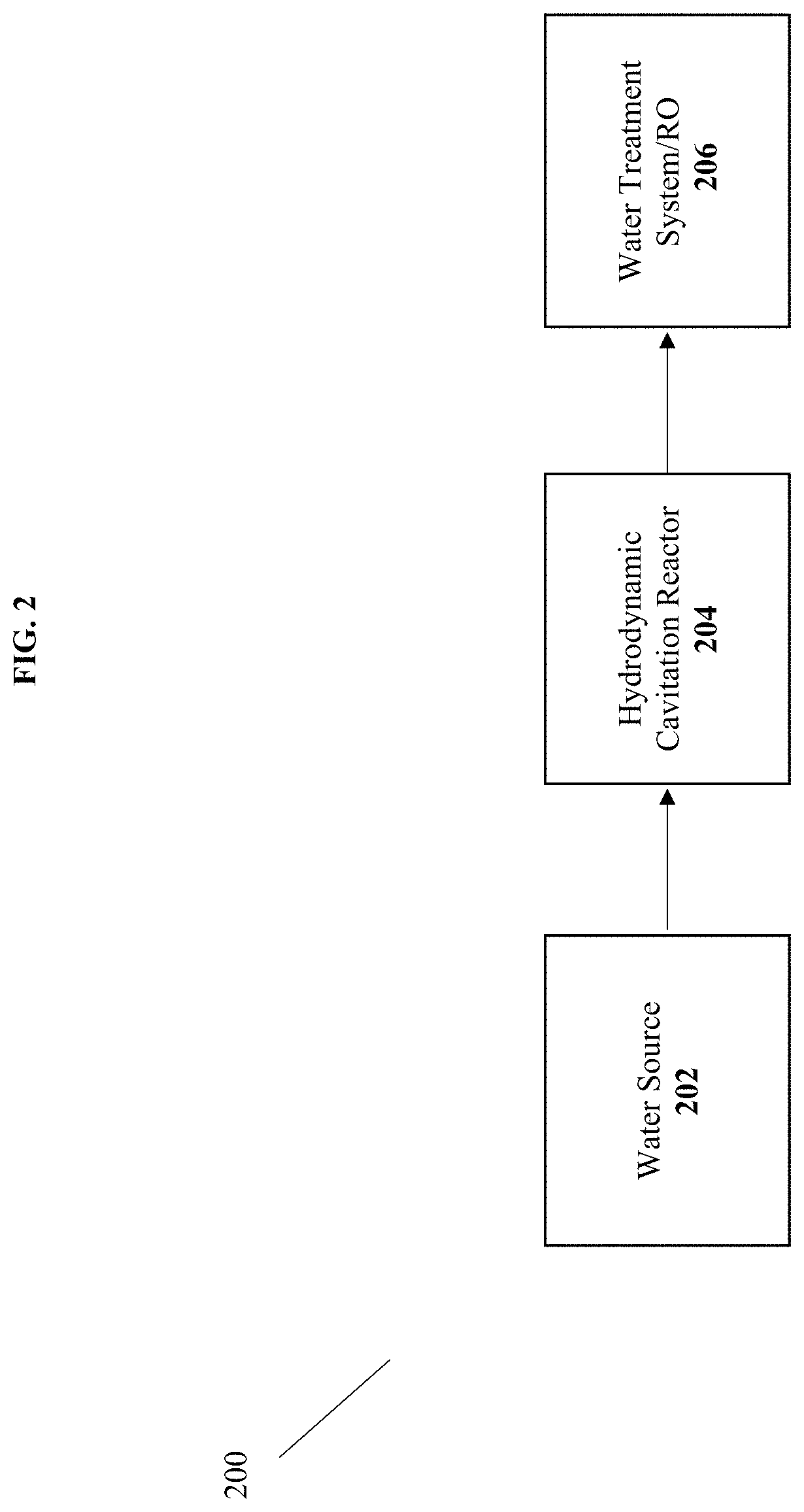

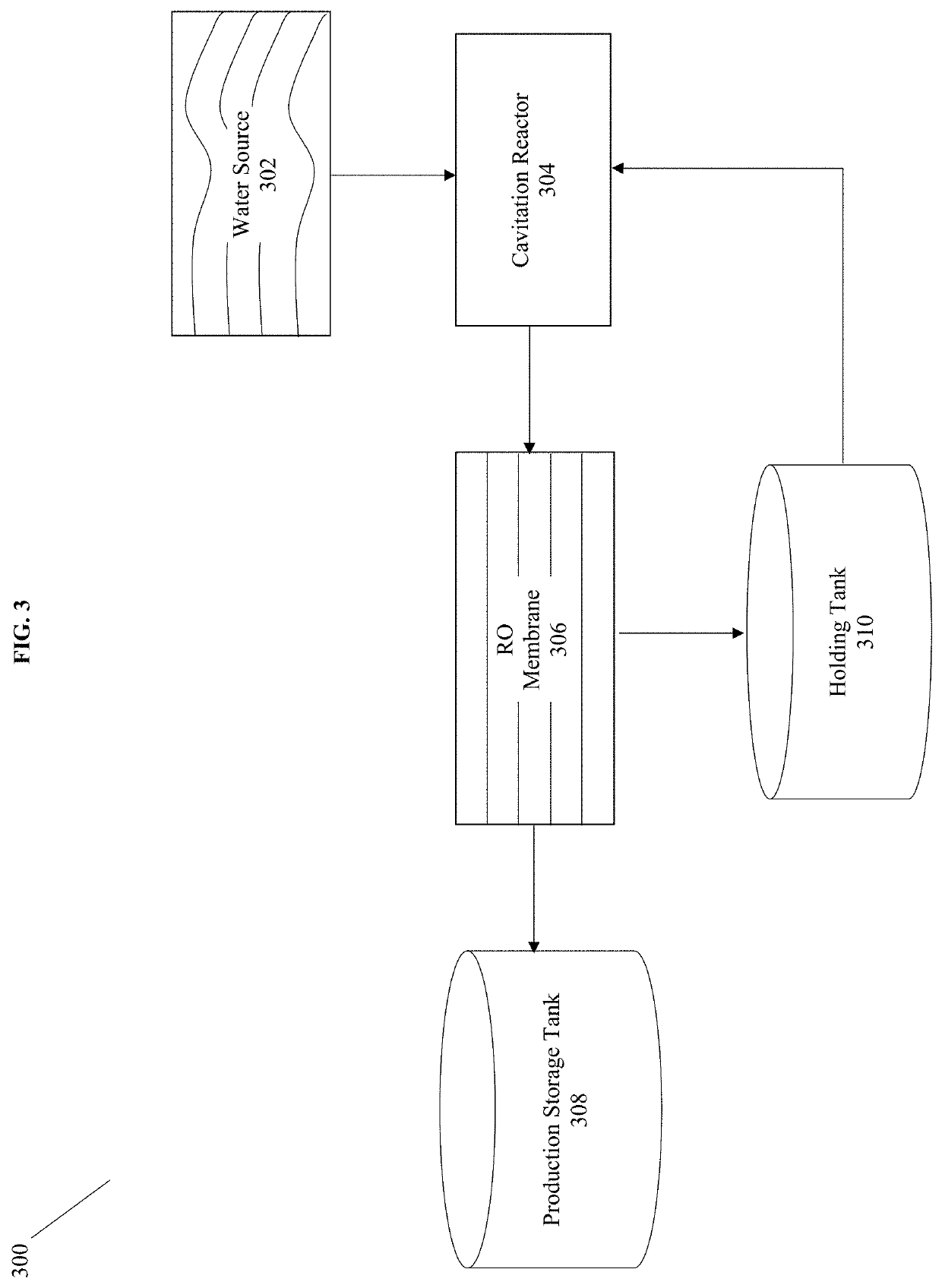

System and method for preventing membrane fouling in reverse osmosis purification systems utilizing hydrodynamic cavitation

InactiveUS20190344221A1Easy and inexpensive to constructMembranesWater treatment parameter controlSolid componentCavitation

The present disclosure provides a method for preventing membrane fouling in a fluid treatment system having at least one membrane. The method describes hydrodynamically cavitating a fluid flow prior to injecting it into the fluid treatment system and through the at least one membrane, wherein after undergoing hydrodynamic cavitation in the cavitation reactor, solid components in the fluid change their (i) molecular structure, (ii) a charge, or both, such that the components repulse each other and disperse around an edge of the membrane to prevent fouling. A system for preventing membrane fouling in a fluid treatment system having at least one membrane is also provided.

Owner:SMITH MICHAEL

Apparatus for working on metal containers

InactiveUS20100252396A1Increase speedHigh phase displacementMetal sawing devicesFeeding devicesEngineeringMetal

An apparatus (10) for working on metal containers, especially suitable for high speed machines and intended for performing a sequence of operations on the metal containers themselves including a chain composed of a plurality of elements (12) linked in a succession and cooperating in simultaneous transporting and processing of metal containers.

Owner:MALL HERLAN SCHWEIZ AG

System to convert cellulosic materials into sugar and method of using the same

ActiveUS10994255B2Optimized sugar outputOutput maximizationProcess control/regulationBiofuelsCellulosePtru catalyst

A device for converting cellulose to sugar comprises a reactor chamber with a plurality of control components, and a control assembly. The control assembly is operatively connected to the reactor chamber, a drive assembly and control components to transmit and receive interoperability signals. The device has an inlet hopper with a detector, a crusher, an outlet hopper, a sensor assembly, a steam inlet, and a carbon dioxide inlet. The inlet hopper is configured to receive and analyze proportion data of matters in a feedstock and catalyst mixture via the detector. The crusher receives and grinds the mixture from the inlet hopper to induce chemical reaction for producing sugar. The outlet hopper is configured to determine a proportion data of matter in the grinded mixture. The control assembly is configured to determine adjustments need to be performed on the components and drive assembly to optimize the sugar production.

Owner:ALLIANCE BIOENERGY PLUS INC DBA BLUE BIOFUELS +1

Curvature anisotropy in magnetic bits for a magnetic random access memory

InactiveUS20050088905A1Easy and inexpensive to constructLower the volumeNanomagnetismMagnetic-field-controlled resistorsNuclear magnetic resonanceMagnetic layer

A magnetic memory cell that uses a curved magnetic region to create magnetic anisotropy is provided by the present invention. The magnetic memory cell is created from a free magnetic layer, a barrier layer and a reference magnetic layer. The magnetic layers are constructed such that they have portions that are curved with respect to a first axis and straight with respect to a second perpendicular axis. These curved portions result in a magnetic memory cell that has an easy axis that is parallel to the first axis and a hard axis that is perpendicular to the easy axis. In addition, the resulting magnetic memory cell's coercivity is independent of it's thickness. Thus, the magnetic memory cell is well adapted to being scaled down without increasing the likelihood of thermally induced errors.

Owner:IBM CORP

Portable support device and method of using the same

ActiveUS20200281360A1Efficient use ofReduce the possibilityPillowsVehicle seatsPhysical medicine and rehabilitationPhysical therapy

A support device configured to overlay a seating assembly and configured to support the torso, neck, and head of a user is provided. The support device has a first elongated bolster cushion configured to support a first thoracic side of the user, a second elongated bolster cushion configured to support a second thoracic side of the user, a first adjustable strap coupled to a upper portion of the first elongated bolster cushion and an upper portion of the second elongated bolster cushion such that the strap connects each of the first and second elongated bolster cushions on their respective lower portions, a second adjustable strap coupled to a lower portion of the first elongated bolster cushion and a lower portion of the second elongated bolster cushion such that the strap connects each of the first and second elongated bolster cushions on their respective lower portions, wherein when the first adjustable strap is tightened the upper portions of the first and second elongated bolsters move towards each other such that the first and second elongated bolsters for a tapered shape with respect to the other to support the user's thoracic sides, neck, head of the user or any combination thereof.

Owner:HAMPARSOMIAN SAKO

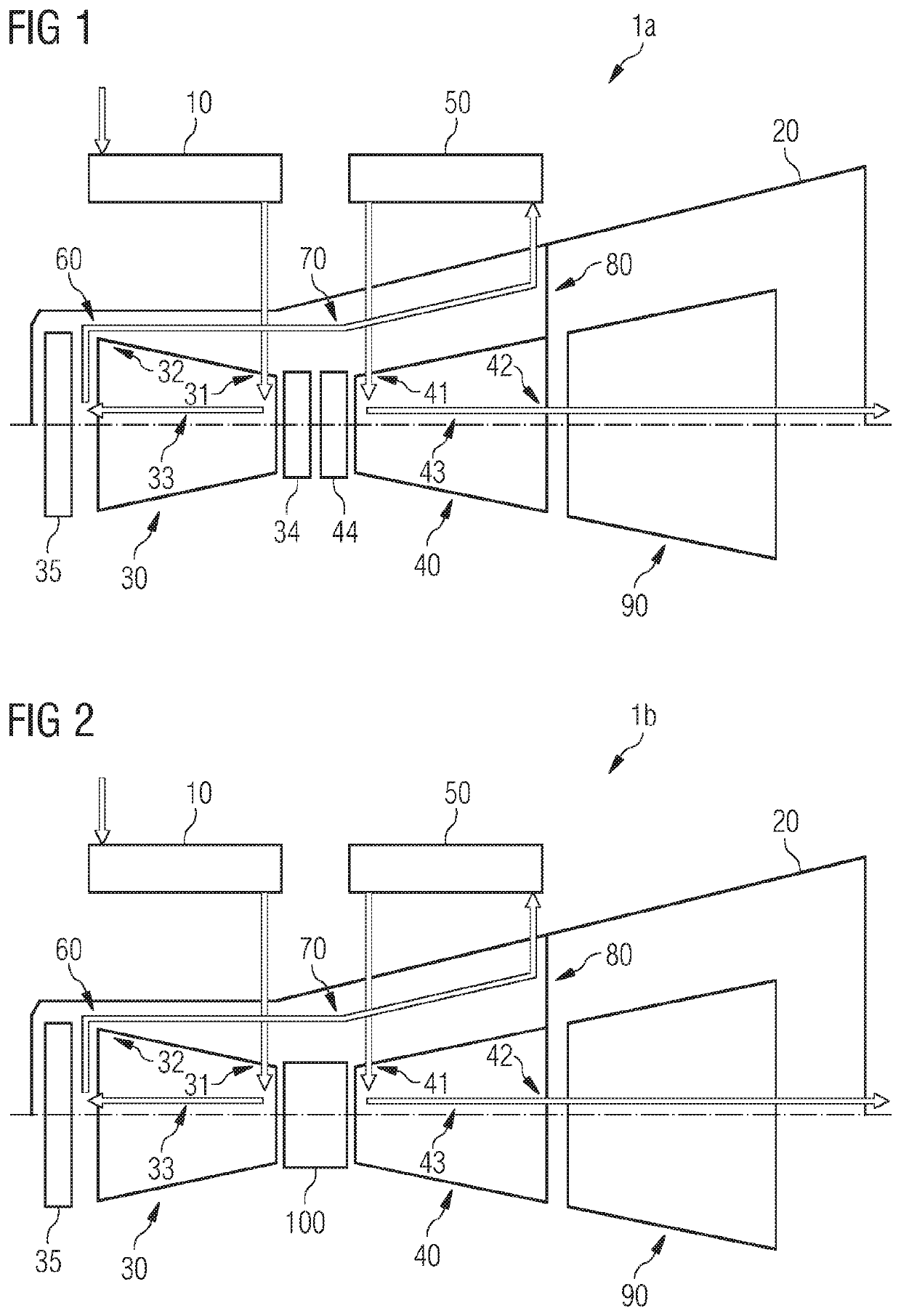

Steam turbine and method for operating same

ActiveUS11352910B2Easy and inexpensive to constructSimple and space-savingEngine fuctionsEngine componentsProcess engineeringSuperheater

A steam turbine, having a steam turbine outer housing; a high-pressure inner housing having first process steam inlet and outlet sections for conducting process steam therethrough from the inlet to the outlet section in a first process steam expansion direction; a low-pressure inner housing having second process steam inlet and outlet sections for conducting process steam therethrough from the second process steam inlet section to the second process steam outlet section in a second process steam expansion direction; and an intermediate superheater, which is arranged downstream of the high-pressure inner housing and upstream of the low-pressure inner housing, wherein the high-pressure and low-pressure inner housings are arranged within the steam turbine outer housing and the high-pressure and the low-pressure inner housings are arranged in such a way that the first steam inlet section of the high-pressure inner housing faces the second steam inlet section of the low-pressure inner housing.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

System and method for evaluating the true reach of social media influencers

ActiveUS11238544B2Increase efficiency and effectivenessEasy and inexpensive to constructEnsemble learningNeural architecturesSocial mediaData set

A non-transitory computer readable storage media having computer-executable instructions, when executed by a processor, performs a method for evaluating a reach of a social media influencer. The methods provides for receiving a plurality of influencers at a server, wherein a data set is associated with each of the plurality of influencers; parsing the data set into quantitative data readable by a machine learning algorithm at the server; receiving, inputting, or both, a type of product or service at the server; classifying the type of product or service into at least one class of goods or services; training a node using the machine learning algorithm using the date set an input; and executing the machine learning algorithm to determine a score of each influencer for each class of goods or services. Systems for evaluating the reach of a social media influencer as it relates to advertisers and content is also disclosed herein.

Owner:MSM HLDG PTE

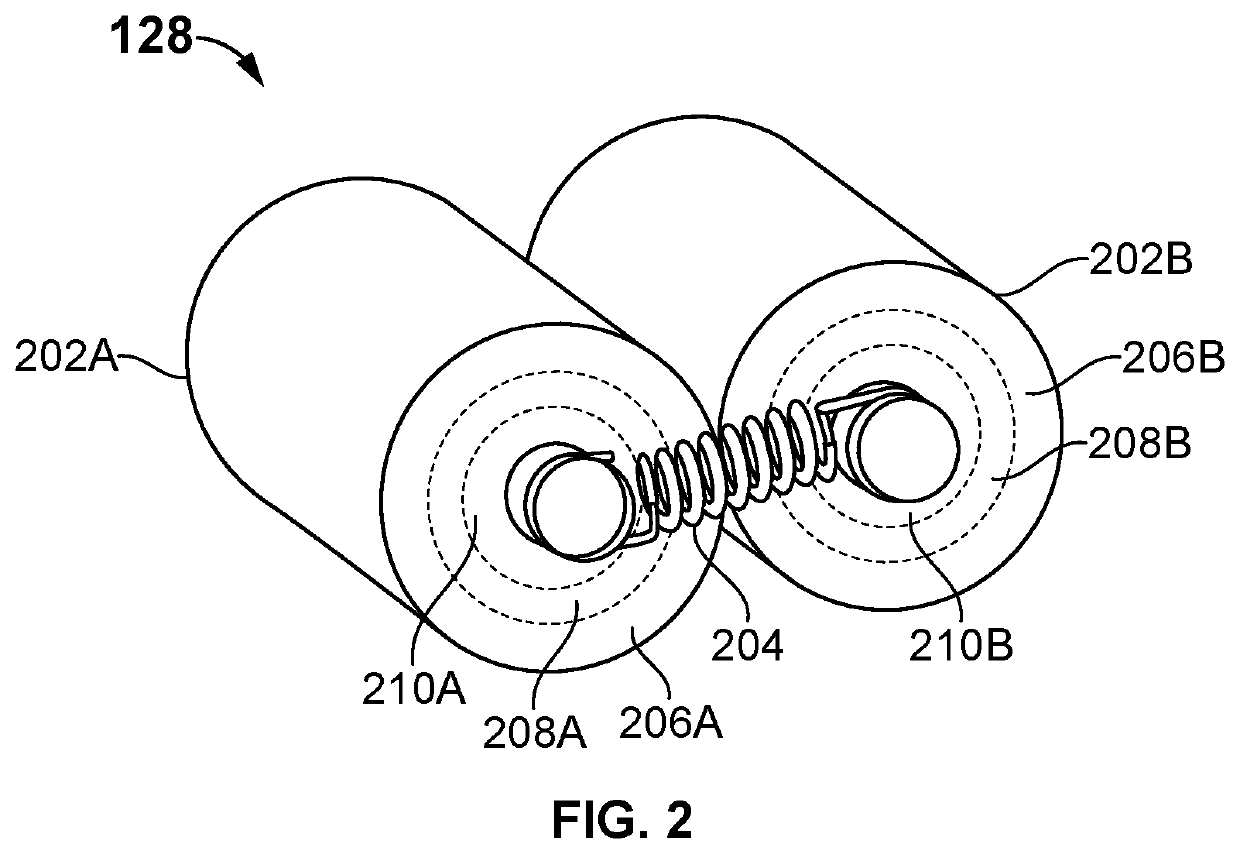

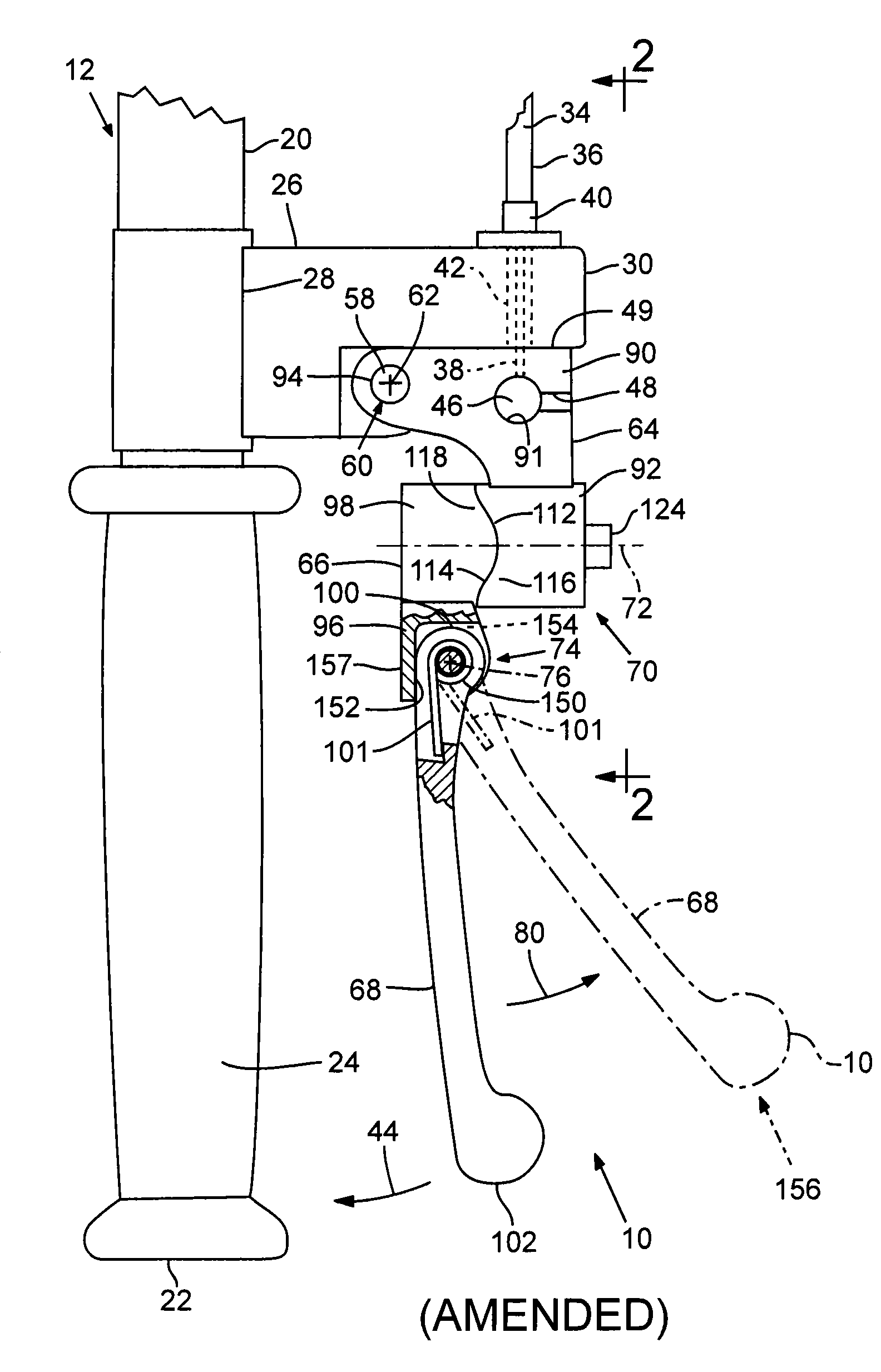

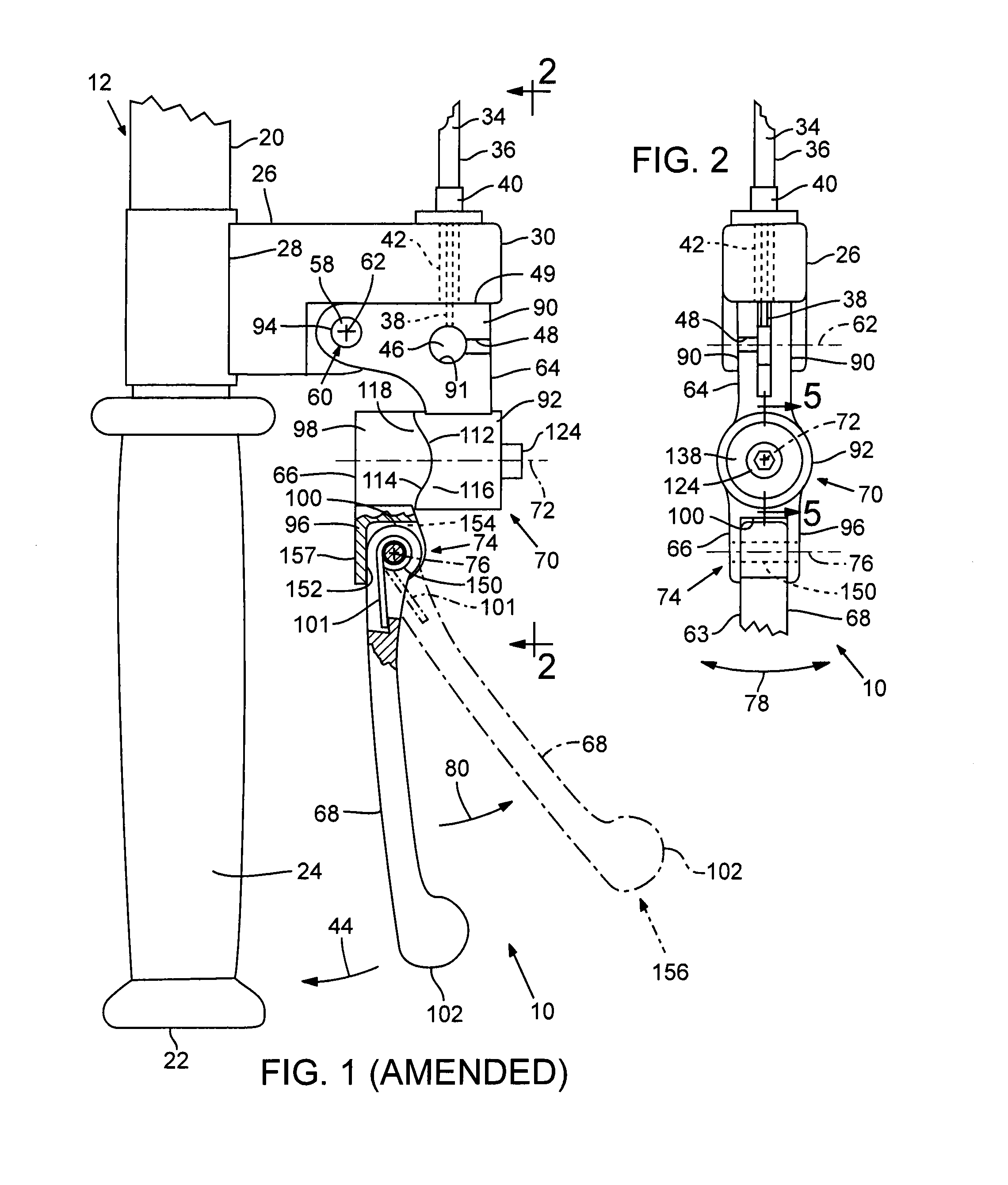

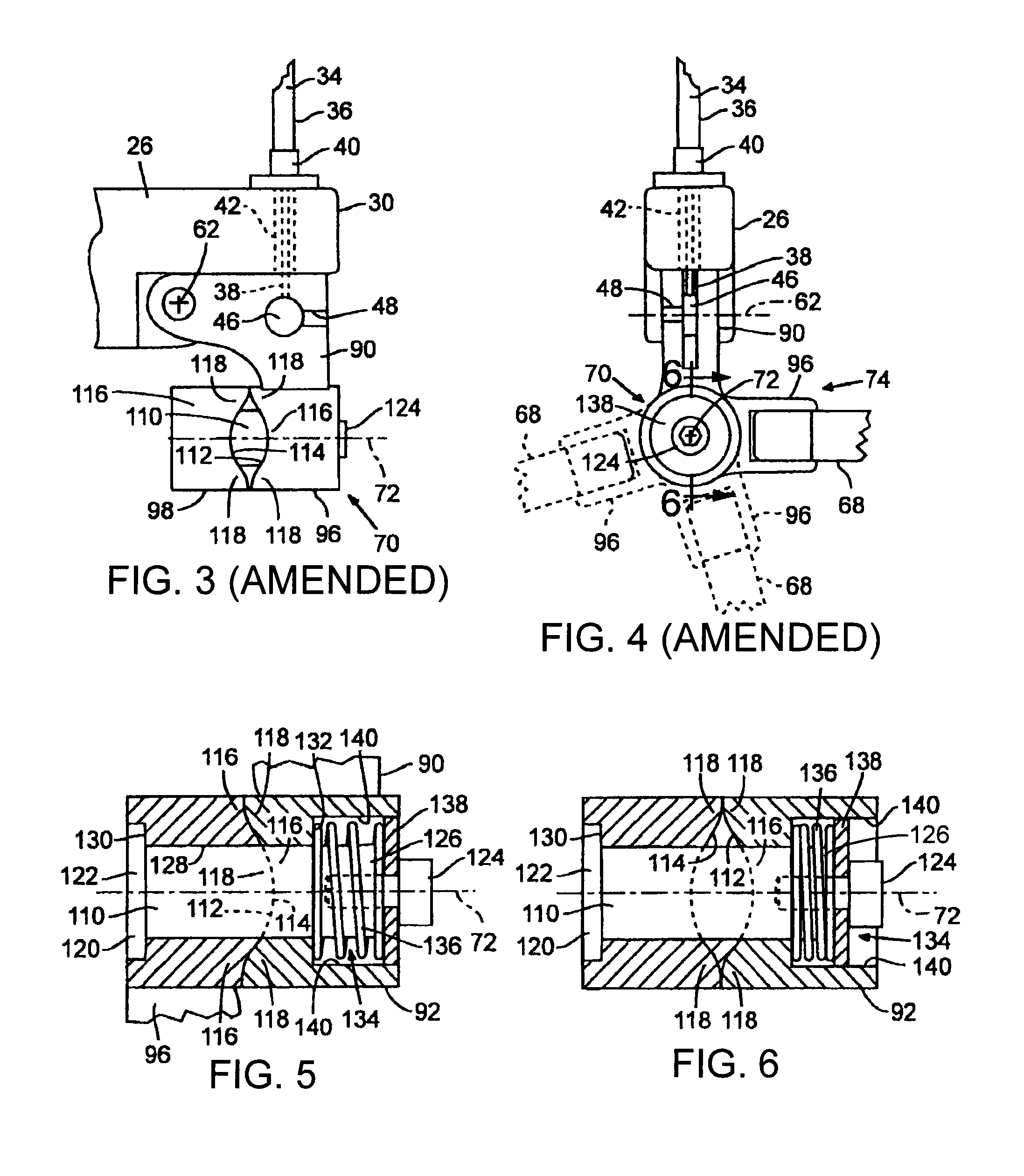

Collapsible control lever

InactiveUSRE44839E1Low costEasy maintenanceCycle control systemsShaft for linear movementRotational axisUser assistance

A collapsible control lever for use with a control system having levers including a conventional cable control lever system such as those found on motorcycles and bicycles. The lever has three independent axes of rotation about which sections of the lever rotate during impact to deflect the impact force. However, the lever remains rigid in the direction of the applied control force when in its operational position during normal operation. The lever restores itself to its operational position following impact with minimal user assistance. The lever may be sized and shaped to be easily retrofit into existing known pivot bases, and at least one of the pivots may include an improved swivel pivot that is sealed from mud and other debris in its operational configuration. The improved swivel pivot has a first and second generally cylindrical frame portion that rotate about a pivot pin with each frame portion having a sliding surface with a smoothly alternating concave and convex-shaped sliding surface. The two surfaces are in intermeshed alignient when the lever is in its operational configuration. The two surfaces slide out of intermeshed alignment during impact. A coil spring received within the frame portions urges the two frame portions toward each other and the misaligned concave and convex surfaces urge the frame portions to rotate to restore the sliding surfaces into intermeshed alignment following an impact.

Owner:VINCE WARREN LEVERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com